Page 1

PANEL–TYPE TRANSIENT VOLTAGE SURGE SUPPRESSORS

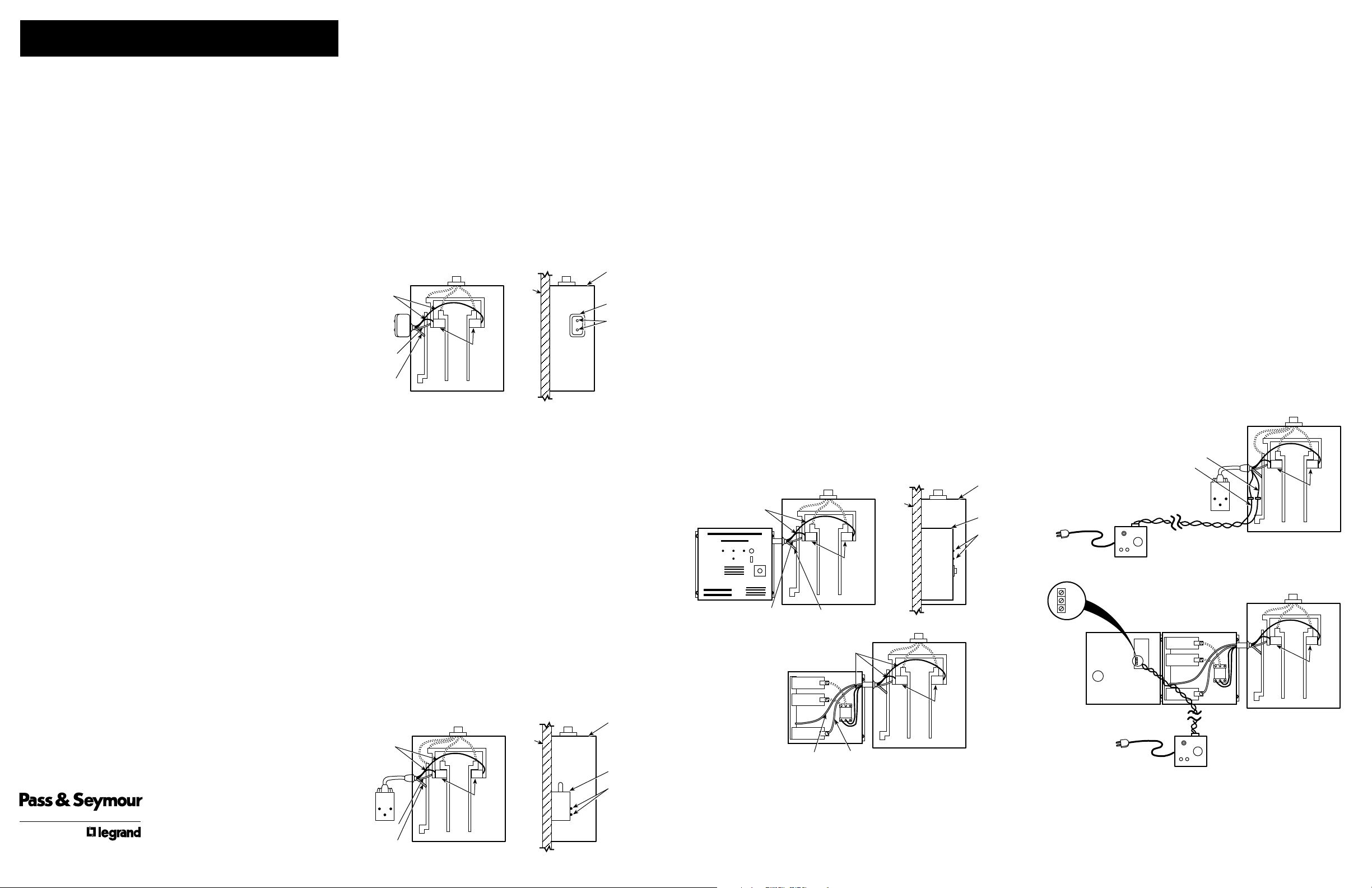

Required Connections

(Cat No. 1224-SH Shown

with Front Panel

Removed)

WALL

TVSS

LED

INDICATORS

SERVICE

CABINET

HOT

(BLACK)

NEUTRAL

(WHITE)

GROUND

(GREEN)

GROUND

LINE

HOT

(BLACK)

NEUTRAL GROUND

GROUND

LINE

NEUTRAL

NEUTRAL

CIRCUIT

BREAKER

CIRCUIT

BREAKER

HOT

(BLACK)

TVSS

NEUTRAL

(WHITE)

GROUND

(GREEN)

GROUND

NEUTRAL

LINE

WALL

TVSS

LED

INDICATORS

SERVICE

CABINET OR

SUB-PANEL

CIRCUIT

BREAKER

WALL

TVSS

LED

INDICATORS

SERVICE

CABINET

HOT

(BLACK)

NEUTRAL

(WHITE)

GROUND

(GREEN)

GROUND

LINE

NEUTRAL

CIRCUIT

BREAKER

M SUFFIX DEVICES

H SUFFIX DEVICES

GROUND

LINE

Connect to “NO” and “C” contacts on terminal

block located on board on inside of front cover.

NO

C

NC

NO

C

NC

RSKIT

YELLOW

ORANGE

GROUND

LINE

RSKIT

CIRCUIT

BREAKER

CIRCUIT

BREAKER

INSTALLATION & OPERATING INSTRUCTIONS

DESCRIPTION

Knock-out mounted and cabinet type hard-wired Transient Voltage Surge

Suppressors for use at main panel or sub-panel locations.

APPLICATION

Protects electronic equipment from damaging voltage transients. These high

energy impulses are caused by electrical disturbances conducted through

utility powerlines or internal sources such as adjacent equipment switching on

the same branch circuit or service panel feed. These impulses can result in

catastrophic damage to connected electronic equipment. More likely is less

obvious damage in the form of information errors and erratic operation, which

eventually lead to permanent damage.

Pass & Seymour’s panel mount Transient Voltage Surge Suppressors, when

installed at the main service entrance or sub-panel locations, will help limit

transient voltage disturbances to a level tolerable to the connected equipment.

Supplementary protection is also recommended in the form of receptacle or

portable cord connect/direct plug-in devices and can be provided by Pass

& Seymour. Please contact Pass & Seymour for additional device or Catalog

Number information.

STANDARDS

Light duty units are UL1449 and OWHX Listed (1224-SL). Medium duty units

are UL1449 and CUL Listed (1224-SM, 1220-TWM, 2748-TWM, 240-TDM).

Heavy duty units are UL1449, UL1283, CUL and CSA Listed (1224-SH,

1220-TWH, 2748-TWH, 240-TDH, 480-TDH).

LIMITED FIVE YEAR WARRANTY

Pass & Seymour will remedy any defect in workmanship or material in Pass &

Seymour products which may develop under proper and normal use within five

(5) years from date of purchase by a consumer:

(1) by repair or replacement, or, at Pass & Seymour’s option, (2) by

return of an amount equal to consumer’s purchase price. Such remedy is

IN LIEU OF ANY AND ALL EXPRESSED OR IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Such remedy by Pass & Seymour does not include or cover cost of labor for removal or

reinstallation of the product. ALL OTHER FURTHER ELEMENTS OF DAMAGE

(INCIDENTAL OR CONSEQUENTIAL DAMAGES) FOR BREACH OF ANY AND

ALL EXPRESSED OR IMPLIED WARRANTIES INCLUDING WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE

EXCLUDED HEREBY. (Some states do not allow disclaimer or exclusion or

limitation of incidental or consequential damages, so the above disclaimers

and limitation or exclusion may not apply to you.) ANY IMPLIED WARRANTIES

INCLUDING WHERE REQUIRED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE SHALL BE LIMITED TO THE FIVE

YEAR PERIOD SET FORTH ABOVE. (Some states do not allow limitations on

how long an implied warranty lasts, so the above limitation may not apply to

you.)

To insure safety, all repair to Pass & Seymour products must be made by Pass &

Seymour, or under its specific direction. Procedure to obtain performance of any

warranty obligation is as follows: (1) Contact Pass & Seymour, Syracuse, New

York 13221, for instructions concerning return or repair, (2) return the product

to Pass & Seymour, postage paid, with your name and address and a written

description of the installation or use of the Pass & Seymour product, and the

observed defects or failure to operate, or other claimed basis for dissatisfaction.

This warranty gives you specific legal rights and you may also have other rights

which vary from state to state.

P.O. Box 4822 Syracuse, NY 13221 (800) 223-4185

Part No. 340412 Printed in U.S.A.

ALL DEVICES SHOULD BE INSTALLED BY A LICENSED

ELECTRICIAN. ALL WIRING MUST COMPLY WITH THE NATIONAL

ELECTRICAL CODE AND ANY APPLICABLE LOCAL CODES.

CATALOG NUMBER 1224-SL

1. Insure that all power is removed before beginning installation.

2. Mount the surge suppressor through a knockout on the service panel. The

unit should be positioned for a minimum of wire length between itself and the

input power terminals of the service panel. Remove nut from threaded nipple

of surge suppressor, place nipple through knockout and reapply nut.

3. Connect black wires to line buss bars through a circuit breaker rated 30

amperes or less, capable of delivering not more than 42,000 amperes of RMS

symmetrical current. Circuit breakers should be located as close as possible

to the input power terminals of the service panel.

4. Connect the white wire to the neutral bar and the green wire to the ground

bar. Keep wires as short as possible. Avoid bending the wires at sharp angles.

5. Apply power. The surge suppressor is protecting when the two green lights

are illuminated. If green lights do not come on, remove power and check

all connections to the unit. If lights still do not come on, contact Pass &

Seymour/Legrand at 800-223-4185.

6. Periodically monitor the status of the green lights. Loss of protection is indicated by a green light (or lights) turning off. There are no user serviceable

parts, contact Pass & Seymour/Legrand for replacement.

CATALOG NUMBERS 1224-SM, 1220-TWM, 2748-TWM, 240-TDM

1. Insure that all power is removed before beginning installation.

2. Mount the surge suppressor as close as possible to the service panel. The

unit should be positioned for a minimum of wire length between itself and the

input power terminals of the service panel.

3. Remove the fitting from the conduit provided and cut the conduit so that it will

fit between the TVSS and the knockout selected on the service panel. Feed all

wires through the conduit into the panel and tighten all fittings.

4. Connect black wires to the line 1 and 2 or phase A, B, and C buss bars through

circuit breakers rated 20 amperes or less, capable of delivering not more

than 65,000 amperes of RMS symmetrical current. Circuit breakers should be

located as close as possible to the input power terminals of the service panel.

For Catalog Number 240-TDM, insure that the black wire marked “Phase B”

is connected to the high leg, failure to do so will result in damage to the surge

suppressor.

5. Connect the white wire to the neutral bar and the green wire to the ground

bar. Keep wires as short as possible. Avoid bending the wires at sharp angles.

6. If not using remote supervisor circuit (RSKIT), cut and dress the blue, orange,

and yellow wires into the conduit. If utilizing the RSKIT, see the directions for

connection under Catalog Number RSKIT.

7. Apply power. The surge suppressor is protecting when the green lights are

illuminated and the red light is off. If green lights do not come on, remove

power and check all connections to the unit. If lights still do not come on,

contact Pass & Seymour/Legrand at 800-223-4185.

8. Periodically monitor the status of the green and red indicators. Loss of protection is indicated if a green light or lights turn off, or if the red light turns on.

Loss of protection is also indicated by activation of an audio alarm. There are

no user serviceable parts, contact Pass & Seymour/Legrand for replacement.

CATALOG NUMBERS 1224-SH, 1220-TWH, 2748-TWH, 240-TDH, 480-TDH

1. Insure that all power is removed before beginning installation.

2. Install the side mounting flanges to the holes provided in the side of the

surge suppressor (hardware included), so that the mounting holes are against

the wall.

3. Determine where the surge suppressor is to be mounted, allowing for minimum lengths of wire between itself and the input power terminals of the service panel. Punch or cut proper size hole in the side of the surge suppressor

closest to the knockout to be utilized in the service panel. Mount surge suppressor and connect to service panel via conduit.

4. Connect black wires (line or phase) to the screw terminals connections of the

rotary disconnect switch through circuit breakers capable of delivering not more

than 200,000 amperes of RMS symmetrical current. Circuit breakers should be

located as close as possible to the input power terminals of the service panel.

Run 1/0-14 AWG wire from the service panel through the conduit into the surge

suppressor. It is recommended that green colored wire be used for ground, white

colored wire for neutral, and black colored wires for line or phase connections.

5. Connect black wires (line or phase) to the screw terminal connections of

the rotary disconnect switch. Connections should be made to the terminals

opposite those with wires connected to the line or phase modules. Connect

the green (ground) wire to the screw terminal marked “Transient Ground.”

Connect the white (neutral) wire to the screw terminal marked “N.” Keep

all wires as short as possible. Avoid bending the wires at sharp angles. To

obtain the UL1449 surge voltage rating marked on the device, wiring must

enter the device as shown in the accompanying diagram. Utilizing any other

wiring location will yield different suppression levels.

6. If utilizing the remote supervisor circuit RSKIT, see the directions under

Catalog Number RSKIT.

7. Apply power. The surge suppressor is protecting when the green lights are

illuminated and the red light is off. If the green lights do not come on, check

to make sure the rotary disconnect switch on the front panel is in the “on”

position. If it is, remove power to the surge suppressor and the service panel

and check all connections. If lights still do not come on, contact Pass &

Seymour/Legrand at 800-223-4185.

8. Set the front panel alarm enable/disable switch to the desired location.

9. Periodically monitor the status of the green and red indicators. Loss of

protection is indicated if a green light or lights turn off and the red light turns

on. Loss of protection is also indicated by an audio alarm if the front panel

switch is set to the enable position.

10. The protection modules in these units are replaceable, contact Pass &

Seymour/Legrand for replacement numbers.

CATALOG NUMBER MFKIT

NOTE: This catalog number is for use only with Pass & Seymour/Legrand

Catalog Numbers 1224-SM, 1220-TWM, 2748-TWM, and 240-TDM. It should

be used when flush mounting of these catalog numbers is desired.

1. After determining where the surge suppressor is to be mounted, mount the

surge suppressor (mounting hardware not included) such that it will protrude

from the flush mount wall from 1/8" to 3/8".

2. Cut a hole in the flush mount wall. Rough opening should be 4.5" wide by

8.0" high, and the hole should be placed so that the surge suppressor is at

the bottom of this opening (insures access to conduit fitting).

3. Place flush trim over unit and secure to wall (mounting hardware not included).

CATALOG NUMBER RSKIT

NOTE: This device can be used with all M and H suffix devices.

1. Insure that all power is removed before beginning installation.

2. Locate RSKIT in convenient location, up to a maximum of 500 feet from the

surge suppressor to be monitored.

3. Connect wires to RCA type male connector (not supplied). Allowable wire

gauge is 12-26 AWG. Plug connector into jack marked “Fault Input.”

4. Run wires to surge suppressor. Wires can be twisted during length of run

between RSKIT and surge suppressor.

5. For M suffix devices, connect to yellow and orange wires. For H suffix

devices, connect wires to terminal block on inside of unit, marked “NO” and

“C.” Wires may be brought in through conduit used to connect unit to service

panel or through their own punched or cut hole.

6. Apply power to surge suppressor and RSKIT, which may be plugged into any

120VAC receptacle. Device is operational if green indicator is lit. H suffix units

may be tested by pressing the test switch on the surge suppressor, this will

cause the red indicator to light, the green indicator to go off, and the alarm to

energize if alarm disable switch is set to enable.

7. Recommended wire size for relay terminal block is 18 AWG.

14-22 AWG may be used.

TORQUE: GREEN Terminal blocks: 3.5 in/lbs.

GRAY Terminal blocks: 4.5 in/lbs.

Page 2

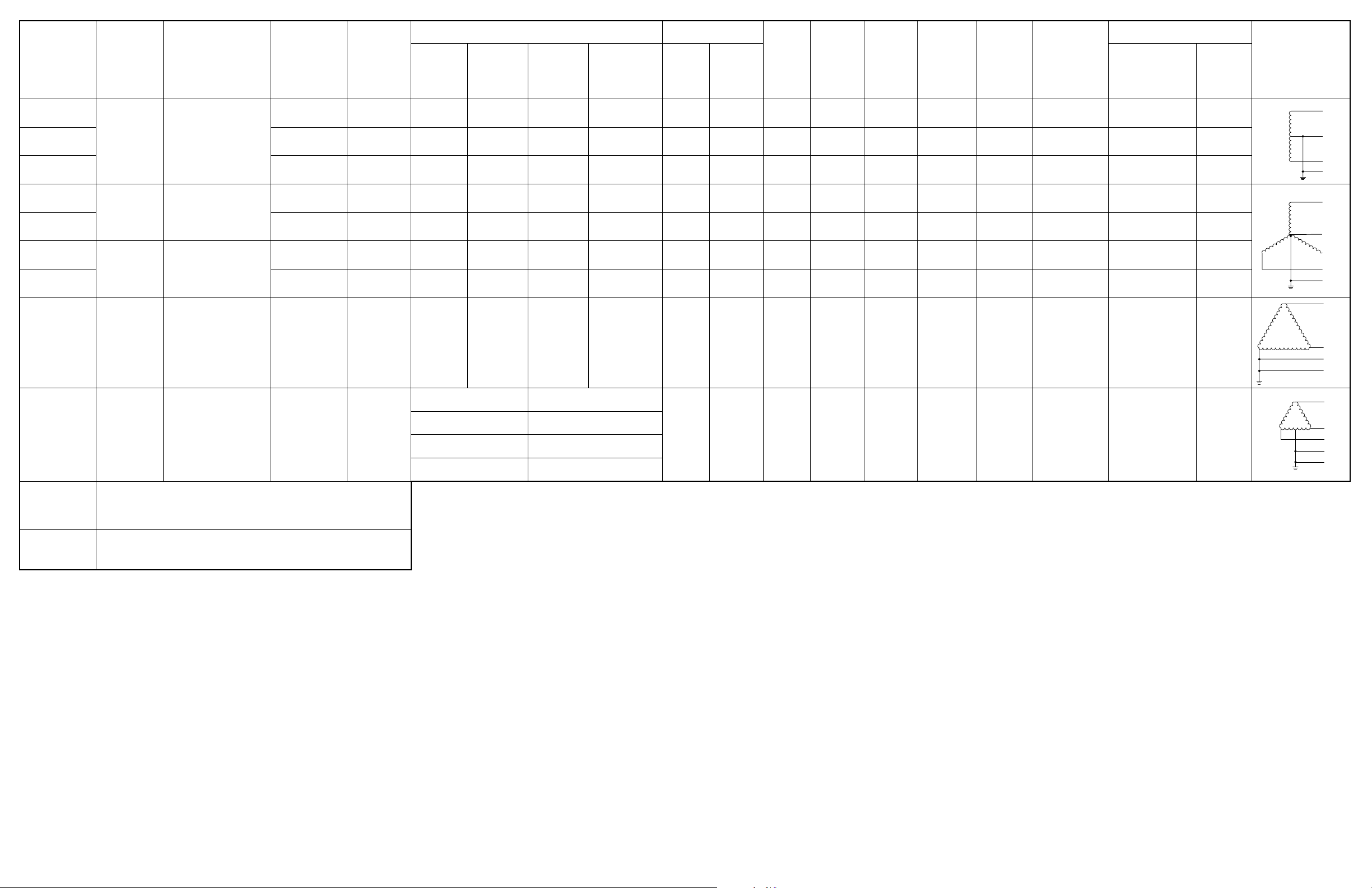

Catalog

L1

L2

A

B

C

G

N

G

L1

L2

A

N

B

C

G

A

B

C

G

B

C

A

N

G

N

G

A

B

C

G

A

B

C

G

B

C

A

N

G

Number

Nominal

Voltage

System

Application

Max Surge

Capability

Available

Interrupt

Current

UL 1449 Suppressed Voltage Ratings (Vpk) Visual Indicators

Line to

Neutral

Line to

Ground

Line to

Line

Neutral to

Ground

Red Green Type Gauge

Audio

Alarm

Alarm

Disable

Switch

Test

Switch

Form C

Contact

EMI/RFI

Filtering

Rotary

Disconnect

Connection Means

Transformer

Configurations

1224-SL

1224-SM 100KA 65kAIC 400 800 800 400 1 2 X X X Wire 12

120VAC

Single Phase, 3W

plus Ground

40KA 42kAIC 400 N/A 700 N/A 0 2 X Wire 10

1224-SH 200KA 200kAIC 400 400 700 400 1 1 X X X X X X Screw Terminal 1/0 – 14

1220-TWM

1220-TWH 200KA 200kAIC 400 400 700 400 1 1 X X X X X X Screw Terminal 1/0 – 14

2748-TWM

2748-TWH 200KA 200kAIC 700 700 1500 700 1 1 X X X X X X Screw Terminal 1/0 – 14

120/

208VAC

277/

480VAC

Three Phase, Wye,

4W plus Ground

Three Phase, Wye,

4W plus Ground

100KA 65kAIC 400 800 800 400 1 3 X X X Wire 12

100KA 65kAIC 800 1500 1500 800 1 3 X X X Wire 12

Three Phase,

480-TDH 480VAC

Delta, 3W plus

200KA 200kAIC N/A 1500 1500 N/A 1 1 X X X X X X Screw Terminal 1/0 – 14

Ground

A-N,C-N: 400 B-N: 800

240-TDM

120/

240VAC

Three Phase,

Delta, High Leg,

4W plus Ground

100KA 65kAIC

A-G,C-G: 800 B-G: 1500

1 3 X X X Wire 12

N-G: 400 A-B: 1500

A-C: 800 B-C: 1500

Operates from 120VAC. Interfaces with any of the above

RSKIT

surge suppressors available with the

“Form C Contact” option.

MFKIT

Allows for flush mounting of Catalog Numbers 1224-SM,

1220-TWM, 2748-TWM, 240-TDM.

Nominal Voltage – this is the nominal line to neutral or line to line voltage

that the surge suppressor is intended to be connected to. Failure to match

surge suppressors to nominal system source voltages can permanently

damage the device or provide inadequate surge suppression.

System Application – the electrical transformer source configuration the

surge suppressor was designed to be connected to.

Maximum Surge Capability – the maximum surge current the device can

withstand non-repetitively without a change in measured limiting (clamping)

voltage of more than plus or minus 10%. This number is also a reflection

of the number of lower current pulses the device can withstand without a

change in measured limiting voltage. The higher this number is the more

lower current transients the device can withstand.

Available Interrupt Current (AIC) – the highest current at rated voltage

that a device is intended to interrupt under standard test conditions.

(NEMA Surge Protection Institute)

UL1449 Suppressed Voltage Rating – Underwriters Laboratories Standard

1449, “Transient Voltage Surge Suppressors,” contains a section that mandates the measurement of let-through (clamping) voltage under a certain

repeatable transient condition, for each mode in which surge suppression

is claimed. This allows for comparison among various manufacturers of

let-through voltage in a way that is meaningful to the end user.

Visual Indicators – provides a method for determining the status of the

surge suppression components. When all surge suppression components

are operational, the green lights will be lit and the red light (if provided) will

be off. Loss of surge suppression in any mode will cause a green light or

lights to go out and the red light to come on. Periodic monitoring of these

status indicators is necessary to insure prompt replacement of surge

suppression in case of failure.

Audio Alarm – provides supplementary indication of failed surge suppression components. The alarm will sound whenever surge protection is lost.

Alarm Disable Switch – this switch has two positions. The “enable”

position allows the alarm to sound upon loss of surge protection. The

“disable” position turns the alarm off if protection has been lost, or inhibits

the alarm from sounding if this position has been selected prior to failure of

surge suppression components.

Test Switch – allows for operational testing of the red indicator light and the

audio alarm. Pressing this switch will turn the red light on and energize the

audio alarm if alarm disable switch is set to enable.

Form C Contact – provides a normally open, normally closed, and common

set of contacts for use with RSKIT, or for other user defined functions. The

relay that controls these contacts is energized when all surge suppression

components are functional. It will deenergize upon loss of protection.

EMI/RFI Filtering – provides for a degree of protection against conducted

radio frequency and electromagnetic noise present on electrical power

distribution wiring. Attenuation levels up to 40db are possible between

frequencies of 100KHz and 30MHz.

Rotary Disconnect – allows for removal of electrical power in the event that

servicing is required.

Connection Means – required type of electrical connection to the surge

suppressor. If the connection requirement is for screw terminal, the allowable wire gauges are shown.

Transformer Congurations – pictorial representation of the transformer

configuration the surge suppressor is intended to be connected to.

Loading...

Loading...