Leer Walk-In Operator’s Manual

An Employee Owned Company

206 Leer Street

New Lisbon, WI 53950

WALK-IN COOLER AND FREEZER

INFORMATION, INSTALLATION

AND

MAINTENANCE MANUAL

IF ADDITIONAL INFORMATION IS NEEDED PLEASE CONTACT YOUR LOCAL

REPRESENTATIVE OR CONTACT LEER WALK-IN ENGINEERING OR SALES DEPARTMENT

1-888-766-5337.

TOOLS AND SUPPLIES GENERALLY REQUIRED

SOME OF THE TOOLS LISTED BELOW MAY BE REQUIRED FOR SPECIFIC TYPES OF

INSTALLATIONS DEPENDING ON IF THE WALK-IN IS SUPPLIED WITH A FLOOR, VINYL SCREED

OR FLAT BOTTOM SIDEWALLS. IF YOU ARE UNSURE OR HAVE ANY QUESTIONS, CONTACT

LEER’S WALK-IN ENGINEERING OR SALES DEPARTMENT.

* TAPE MEASURE * 4’ LEVEL * CHALK LINE * MITER SAW

* SCREWDRIVERS * SHIMS * LAG ANCHORS OR SUITABLE FASTENERS

* HAMMER * RAM SET GUN * POWER DRILL

- NSF LISTED SILICONE SEALANT AND CAM-LOCK WRENCH ARE PROVIDED -

NOTICE: CONCRETE AND TILE WORKERS

The sheet metal facings inside this Walk-In may be susceptible to staining or oxidation due to

excessive moisture created by hydration of concrete type materials. Also note that extra care must be

taken when using muriatic acid or other harsh cleaning materials on the inside or outside of this WalkIn. It is extremely important that the Walk-In door is left open and properly ventilated while the

concrete is curing.

Rev-9 2012 Part # 1070024

TABLE OF CONTENTS

• SHIPMENT INFORMATION & JOB SITE PREPARATION ………………………….……3

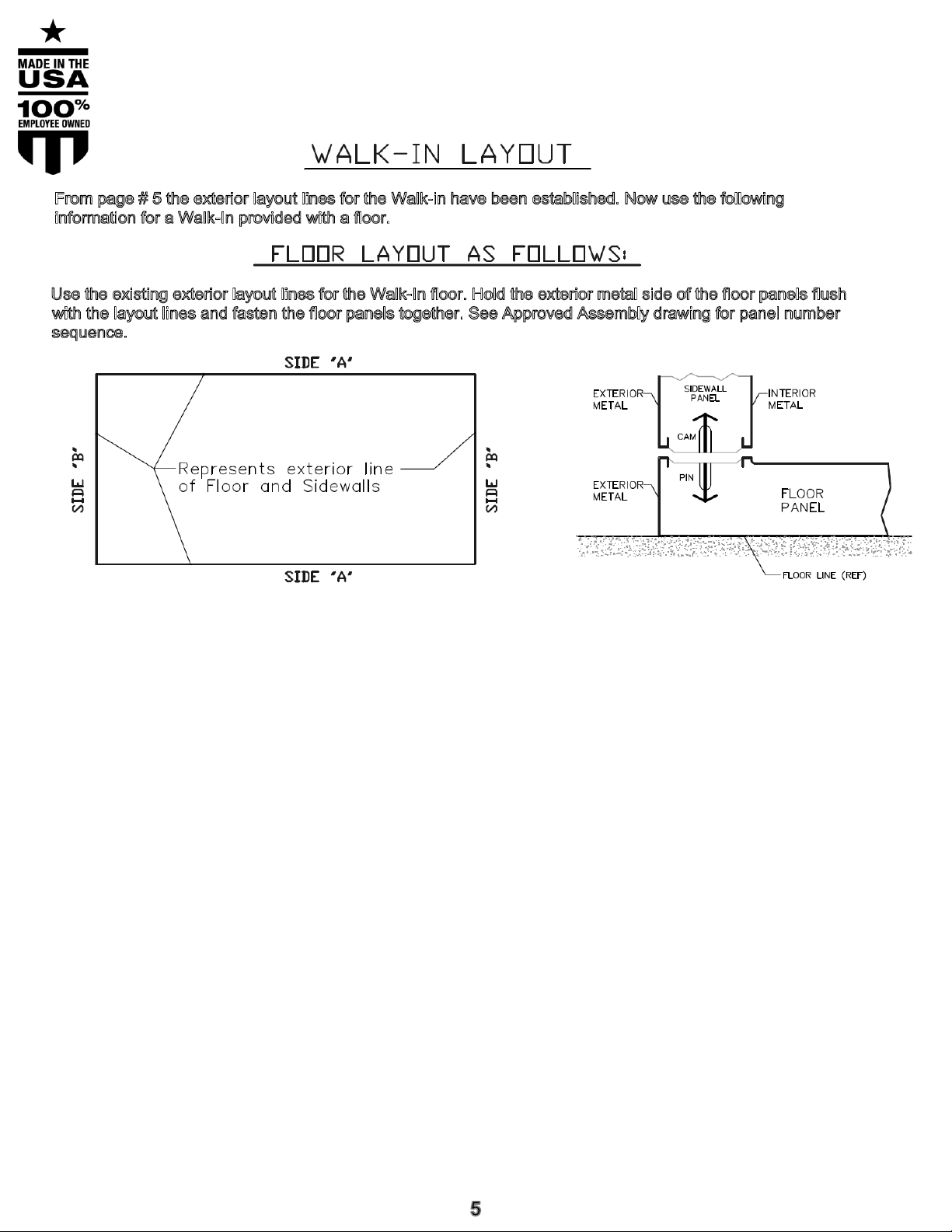

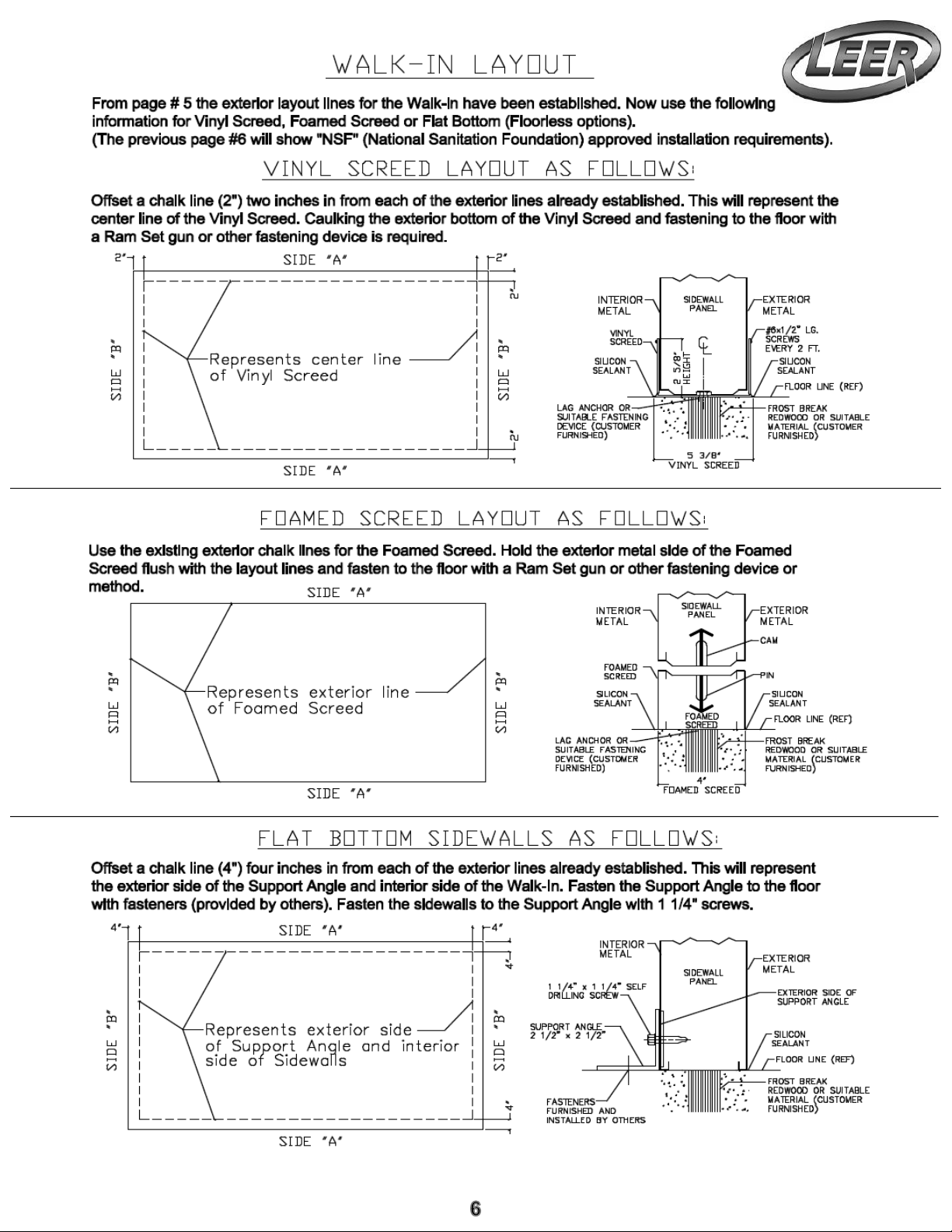

• JOB SITE, WALK-IN LAYOUT (Marking Walk-in Outlines) ……………………….…....4-6

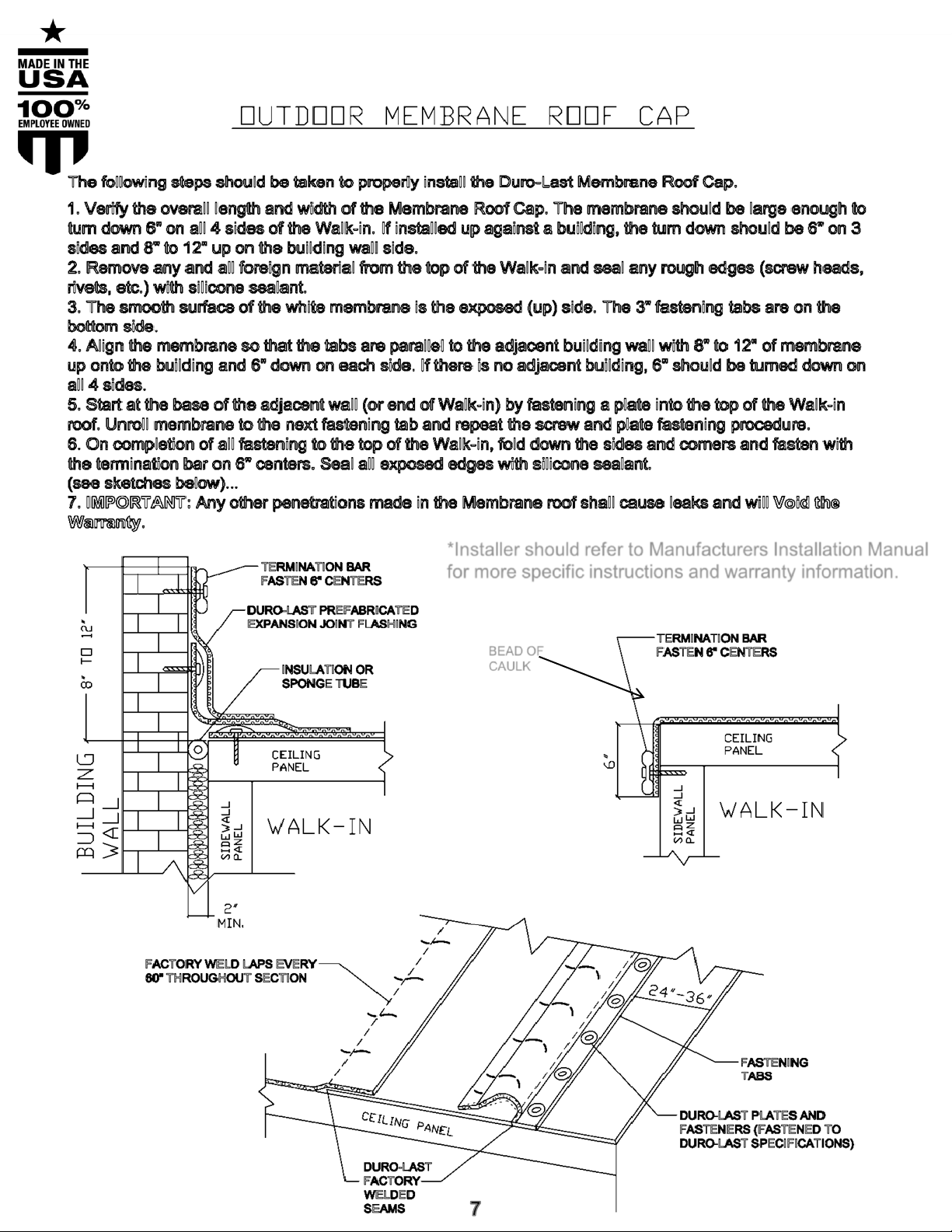

• OUTDOOR MEMBRANE ROOF CAP (Reference Drawing) ……………………….…....7

• FLOOR SCREED & THRESHOLD (Reference Drawing) ………………………….......8-9

• FLOORLESS Z-ANGLE (Reference Drawing) …………………………………….….10-11

• SKID STRIPES ………………………………………………………………………………12

• PANEL & CAM LOCK INFORMATION (How to Lock Panels) ……………………….…13

• WALK-IN ASSEMBLY (Reference Drawing) ……………………………………………...14

• CEILING SUPPORTS (Options) ………………………………………………………...…15

• REFRIGERATION (Reference Drawing) ……………………………………………….…16

• ELECTRICAL (Reference Drawing) ……………………………………………………….17

• GENERAL MAINTENANCE (Thermometer Calibration)………………………….….18-19

• DOOR GASKET/WIPER/HEAT WIRE INSTALLATION………………………………20-23

• PRODUCT WARRANTY INFORMATION …………………………………….……..…....24

USE THESE SAFETY TIPS

To avoid injury while assembling the Walk-In, Leer recommends protective eye gear, hard hat,

gloves and steel toe foot wear.

Prevent back injuries. Walk-In panels are heavy and care should be taken using ergonomic

lifting and handling methods.

Any electrical work should be done by a licensed electrician.

Any refrigeration work should be done by licensed refrigeration company.

Never work alone. Always have another person helping or observing in case of an emergency.

Follow installation instruction pages. The information is designed to assist the correct method

of walk-in assembly.

If unsure about something, contact your local representative or Leer Walk-In engineering or

sales department at 1-888-766-5337.

Rev-9 2012

GENERAL SHIPMENT INFORMATION

This Walk-In has been thoroughly inspected, packing list checked and carefully packaged

before shipment. Any damages, whether obvious or hidden, must be reported to the freight

carrier immediately. Damages not reported could void all freight claims. If the damage is

obvious, write the words “received damaged” on the freight bill and have the driver sign the

freight bill. Leave the item “as is” and notify the freight carrier local office and ask for an

immediate inspection of the item. After receiving carrier inspection and damage report, notify

Leer about action required to correct the problem. Please provide purchase order number,

Leer serial and invoice number to assist claim process.

The packing list should be checked to be sure there are no shortages. Once the freight bill has

been signed and accepted, there is no recovery from the freight carrier or Leer. If there are

any questions regarding the shipment, please contact Leer immediately. It is consignee

responsibility to follow these instructions or the carrier will not honor any claims for damage or

shortage.

Notice: If the Walk-In will not or cannot be installed when received, panels should be stored

on a flat surface in a clean, dry, temperature maintained location. Keep panels covered to

prevent moisture or condensation from entering stacked panels. Avoid placing heavy objects

on panels and shade panels with protective film from direct sunlight. Carefully remove film

cover after panel assembly.

JOB SITE INSPECTION AND PREPARATION

A clean and clear area with access for getting the walk-in into the site is the first step for site

preparation. The installer must determine the best and safest way to get the panels to the

installation site without damage or bodily injury.

Check overhead for anything that could cause a safety hazard (electrical wires, utility lines, air

ducting) or any other obstructions. It should be confirmed that there is enough overhead

clearance to install the Walk-In. A minimum of 2” is recommended clearance between existing

walls and walk-in panels to allow for any irregularities and ventilation.

A level floor is most important for proper installation of the walk-in even if the walk-in is

supplied with a floor. The high point of the floor must be determined and shims

(customer provided) must be used as required to assure the walk-in floor or screeds

are level. IMPORTANT: If the floor is not level, wall panels will not be plumb and self-

closing door may not close as designed.

Make sure the correct electrical voltage and circuit breakers are available for the walk-in

electrical components and refrigeration system. The voltage and breaker sizes must match the

components or serious damage can occur to the equipment or injury to the installer. Improper

voltage or wiring will not be covered by Leer’s warranty.

Rev-9 2012

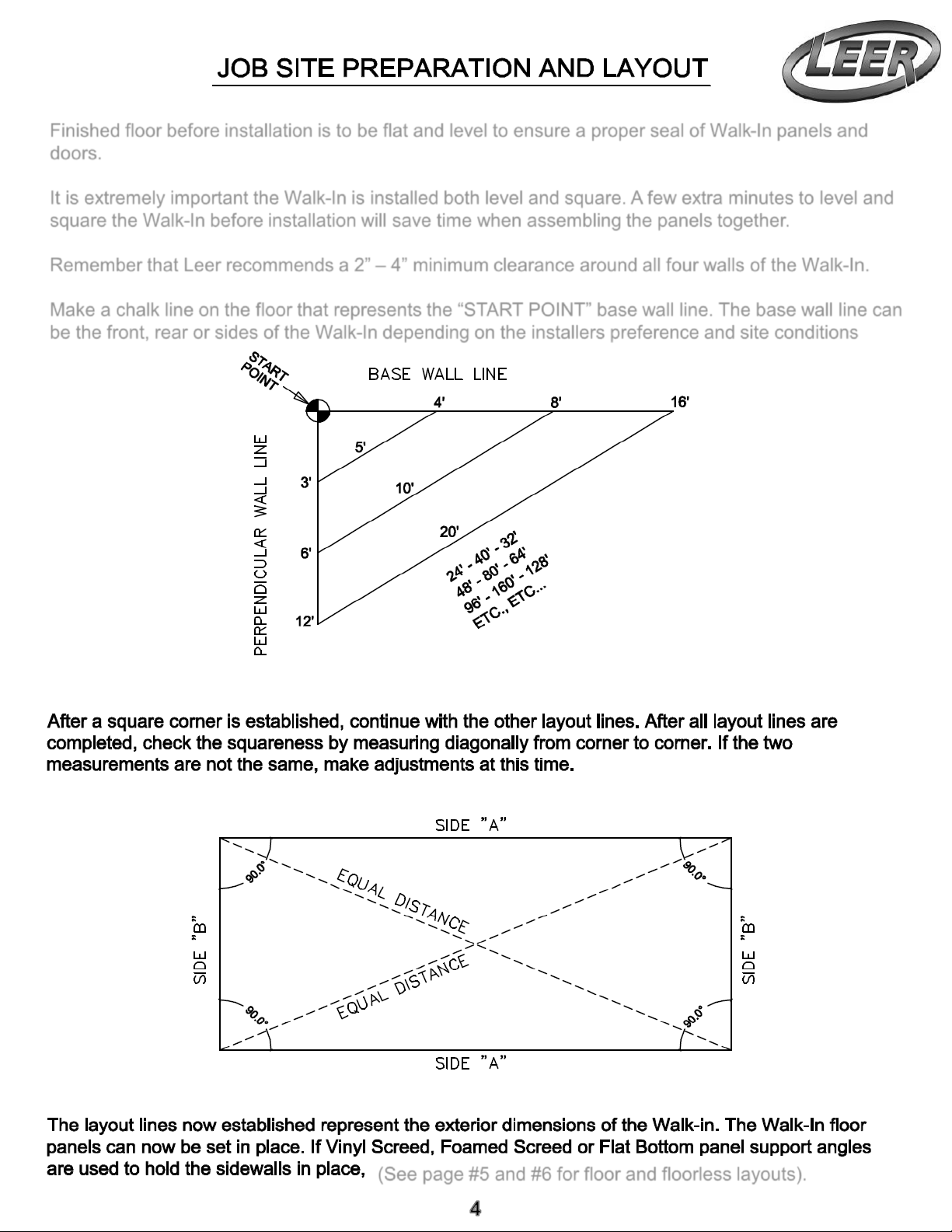

Finished floor before installation is to be flat and level to ensure a proper seal of Walk-In panels and

doors.

It is extremely important the Walk-In is installed both level and square. A few extra minutes to level and

square the Walk-In before installation will save time when assembling the panels together.

Remember that Leer recommends a 2” – 4” minimum clearance around all four walls of the Walk-In.

Make a chalk line on the floor that represents the “START POINT” base wall line. The base wall line can

be the front, rear or sides of the Walk-In depending on the installers preference and site conditions

(See page #5 and #6 for floor and floorless layouts).

Rev-9 2012

Rev-9 2012

Rev-9 2012

*Installer should refer to Manufacturers Installation Manual

for more specific instructions and warranty information.

BEAD OF

CAULK

Rev-9 2012

Loading...

Loading...