Page 1

,QVWUXFWLRQ0DQXDO

/H&UR\$3

$FWLYH'LIIHUHQWLDO3UREH

REVISION D — JANUARY 2000

Page 2

Warranty

LeCroy warrants this oscilloscope accessory for normal use and operation within

specifications for a period of three years from the date of shipment. Calibration after each 12

month interval is recommended to ensure performance to specification. Spare parts,

replacement parts and repairs are warranted for 90 days. The instrument’s firmware has

been thoroughly tested and thought to be functional, but is supplied without warranty of any

kind covering detailed performance.

In exercising its warranty, LeCroy will repair or, at its option, replace any assembly returned

within its warranty period to the Customer Service Department or an authorized service

center. However, this will be done only if the product is determined by LeCroy’s examination

to be defective because of workmanship or materials, and the defect is not caused by misuse,

neglect, accident, abnormal conditions of operation, or damage resulting from attempted

repair or modifications by a non-authorized service facility.

The customer will be responsible for the transportation and insurance charges for the return of

products to the service facility. LeCroy will return all products under warranty with

transportation prepaid.

This warranty replaces all other warranties, expressed or implied, including but not lim ited to

any implied warranty of merchantability, fitness, or adequacy for any particular purposes or

use. LeCroy shall not be liable for any special, incidental, or consequential damages, whether

in contract or otherwise.

Corporate Headquarters

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977-6499

Tel: (914) 578-6020, Fax: (914) 578-5985

Internet: www.lecroy.com

Copyright 2000, LeCroy Corporation. All rights reserved. Contents of this publication may not

be reproduced in any form without written permission of LeCroy Corporation.

LeCroy, Easywave, SMART Trigger, PowerMeasure, and ProBus are registered trademarks

of LeCroy Corporation.

AP034-OM-E Rev D 0100

Page 3

&RQWHQWV

Table of Contents

Overview

Description .................................................................................................................................. 1-1

Applications ................................................................................................................................. 1-1

Conventions used in this Manual ................................................................................................ 1-2

Safety Information

Operator Safety ........................................................................................................................... 2-1

Operation

Connecting the Probe to the Test Instrument ............................................................................. 3-1

Connecting the Probe to the Test Circuit ......................................................................................3-1

Probe Input Loading .................................................................................................................... 3-4

Grounding the Probe ................................................................................................................... 3-4

Selecting the Proper Range ........................................................................................................ 3-6

Operation with LeCroy Oscilloscopes ......................................................................................... 3-7

AP034 Use with the ADPPS Power Supply...................................................................................3-8

Adding Offset ............................................................................................................................ 3-10

Autobalance .............................................................................................................................. 3-11

Designing Test Fixtures for the AP033 Probe ........................................................................... 3-12

Reference Information

Differential Mode and Common Mode ........................................................................................ 4-1

Differential Mode Range and Common Mode Range...................................................................4-1

Common Mode Rejection Ratio ................................................................................................... 4-2

Care and Maintenance

Cleaning ...................................................................................................................................... 5-1

Calibration Interval ...................................................................................................................... 5-1

Service Strategy .......................................................................................................................... 5-1

Troubleshooting .......................................................................................................................... 5-1

Trace Off Scale................................................................................................................5-1

AP034-OM-E Rev D ISSUED: January 2000 LLL

Page 4

$3$FWLYH3UREH

Incorrect Frequency Response........................................................................................5-2

DC Errors.........................................................................................................................5-3

Poor Common Mode Rejection.......................................................................................5-3

Returning a Defective Probe ....................................................................................................... 5-4

Replacement Parts ...................................................................................................................... 5-5

Matching Procedure for ÷10 Plug-On External Attenuator .......................................................... 5-8

Equipment Required .....................................................................................................................5-8

Procedure......................................................................................................................................5-9

Performance Verification

Test Equipment Required .............................................................................................................6-1

Preliminary Procedure...................................................................................................................6-3

Procedure......................................................................................................................................6-3

Check Gain Accuracy.......................................................................................................6-4

Check High Frequency CMRR.........................................................................................6-5

Check Low Frequency CMRR..........................................................................................6-8

Performance Verification Test Record........................................................................................6-11

Adjustment Procedure

Introduction .................................................................................................................................. 7-1

Test Equipment Required .............................................................................................................7-2

Preliminary Procedure...................................................................................................................7-4

Procedure......................................................................................................................................7-7

Adjust Coarse DC Balance (R226) ..................................................................................7-7

Adjust Fine DC Balance (R304).......................................................................................7-8

Adjust Low Frequency CMRR (R7)..................................................................................7-9

Adjust Offset (R330) ......................................................................................................7-11

Adjust Gain (R322C)......................................................................................................7-13

Adjust Final Attenuator Compensation (C17) ................................................................7-14

Adjust Final Attenuator CMRR (C18A)...........................................................................7-15

Assemble Probe and Amplifier.......................................................................................7-16

Attenuator Matching and Final Check............................................................................7-17

LY ISSUED: January 2000 AP034-OM-E Rev D

Page 5

&RQWHQWV

Specifications

Nominal Characteristics .............................................................................................................. 8-1

Warranted Electrical Characteristics ........................................................................................... 8-2

Typical Electrical Characteristics ................................................................................................ 8-3

General Characteristics ............................................................................................................... 8-5

Compliance and Certifications .................................................................................................... 8-6

Operator Safety.............................................................................................................................8-6

Standard Accessories ................................................................................................................. 8-7

Optional Accessories .................................................................................................................. 8-7

Oscilloscope Software Compatibility ........................................................................................... 8-7

# # #

AP034-OM-E Rev D ISSUED: January 2000 Y

Page 6

BLANK PAGE

$3$FWLYH3UREH

YL ISSUED: January 2000 AP034-OM-E Rev D

Page 7

2YHUYLHZ

DESCRIPTION

2YHUYLHZ

The AP034 is a wide-band, active differential pr obe. The probe

features low noise, low input capacitance, high common mode

rejection, and Field Effect Tr ansistor (FET ) buffer ed inputs in the

probe head. The user-selectable offset gives the probe the

flexibility to measure a large range of signal types. Plug-on

attenuators and AC coupling accessories further extend the

application range. Included interconnect accessories allow

connection to surface mount and through-hole com ponents with

minimal signal degradation. The input receptacles in the probe

head are compatible with standard 0.025 in. (0.635 m m) square

pins, which provide a convenient, low-cost method of creating

device characterization test fixtures.

The probe is powered directly from a LeCroy oscilloscope

through the ProBus interface. T he ProBus interface also allows

local control of the probe through the os cilloscope user interface

and remote control through the inter face buses, (G PIB, RS-232).

The optional ADPPS power supply allows the AP034 to be used

with other instruments such as spectrum analyzers, network

analyzers, and oscilloscopes without ProBus interface.

APPLICATIONS

The AP034 Active Differential Probe is ideal for acquiring highspeed differential signals su ch as those found in disk drive read

channels, differential LAN, video, etc. The probe can be used

with spectrum analyzers to acquire signals in some RF systems

(for example, balanced IF mixers in hand-held cellular

telephones). The high impedance characteristics of both inputs

allow you to use the probe as an FET probe to make singleended measurements in digital systems without introducing a

ground loop, as a conventional FET probe would.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 8

CONVENTIONS USED IN THIS MANUAL

The following conventions may appear in this manual:

$3$FWLYH3UREH

Note

A Note contains general information relating to

the use of the product.

Caution

A Caution contains information that should to be

followed to avoid possible damage to the

instrument or the device under test.

WARNING

A Warning alerts you to potential injury to

yourself. Failing to adhere to the statement in a

WARNING message could result in bodily injury.

The following symbol may appear on the product:

This symbol refers you to additional information contained in this

manual. The corres ponding inform ation in the m anual is denoted

with the same symbol.

CAT I Overvoltage Installation Category per EN 61010-1

# # #

² ISSUED: January 2000 AP034-OM-E Rev D

!

Page 9

6DIHW\,QIRUPDWLRQ

OPERATOR SAFETY

The AP034 Active Differential Probe is intended to be used only

with instruments that are connected to earth ground thr ough the

input BNC connector. When you are using the probe with an

ADPPS Power Supply Adapter, make sure the adapter is

connected to a BNC connector that is grounded by the test

instrument before connecting the probe inputs to the test circuit.

Do not use the probe in wet or explosive atmos pheres. Remove

any contamination from the probe housing before connec ting the

probe inputs to any circuit. Make sure that the surface of the

probe head is completely dry before connecting the inputs.

Use of the probe, and/or the instrument it is connected to, in a

manner other than that specified may impair the protection

mechanisms.

Do not use the probe if any part is damaged. All maintenance

should be referred to qualified service personnel.

6DIHW\,QIRUPDWLRQ

# # #

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 10

BLANK PAGE

$3$FWLYH3UREH

² ISSUED: January 2000 AP034-OM-E Rev D

Page 11

2SHUDWLRQ

The input circuits in the AP034 Activ e Differ ential

Probe incorporate components that protect the

probe from damage resulting from electrostatic

discharge (ESD). Keep in mind that this is an

active probe, and it should be handled carefully

to avoid damage. When using the AP034 Active

Differential Probe, you are advised to take

precautions against potential instrument damage

due to ESD.

CONNECTING THE PROBE TO THE TEST INSTRUMENT

When you are using the AP034 Active Dif ferential Probe with a

LeCroy Oscilloscope equipped with ProBus, attach the probe

output connector to the oscilloscope input connector. The

oscilloscope will recognize the probe, set the oscilloscope input

termination to 50 DQG DFWLYDWH WKH SUREH FRQWURO IXQFWLRQV LQ

the user interface.

2SHUDWLRQ

Caution

To use the AP034 Active Differ ential Probe with instrumentation

not equipped with a ProBus interface, it is necessar y to use the

ADPPS Power Supply. Attach the ADPPS connector to the probe

output connector. The output connector of the ADPPS is a

standard male BNC that can be directly connected to another

instrument. If necessary, the output of the ADPPS can be

interconnected with a 50 FRD[LDOFDEOH7RPLQLPL]HWKHHIIHFWV

of skin loss, this cable should be 1 m or less in length. The

AP034 Active Differential Probe is des igned to drive a 50 ORDG

The gain will be uncalibrated if the output is not correctly

terminated. If you are using the probe with an instrument with a

high input impedance, place a 50 %1&LQOLQHWHUPLQDWRURQWKH

instrument input before attaching the ADPPS.

CONNECTING THE PROBE TO THE TEST CIRCUIT

At the probe tip, two inputs and a ground connection are

available for connecting the probe to a circuit under test. For

accurate measurem ents, both the + and – inputs m ust always be

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 12

$3$FWLYH3UREH

connected to the test circuit. The ground connection is optional.

Positive voltages applied to the + input relative to the – input will

deflect the oscilloscope trace toward the top of the screen.

To maintain the high performance capability of the probe in

measurement applic ations, user care in connecting the probe to

the test circuit. Increasing the parasitic capacitance or inductance

in the input paths may introduce a “ring,” or slow the rise time of

fast signals. To m inimize these effects, use the shortest length

possible when connecting the probe to the circuit under test.

Input leads that form a large loop area (even shielded coaxial

cables) will pick up any radiated magnetic field that passes

through the loop, and may induce noise in the probe inputs.

Because this signal will appear as a diffe rential mode signal, the

probe’s common mode rejection will not remove it. You can

greatly reduce this effect by using short interconnection leads,

and twisting them together to minimize the loop area.

High common mode rejection requires precise matching of the

relative gain or attenuation in the + and – input signal paths.

Mismatches in additional parasitic capacitance, inductance,

delay, and a source impedance differ ence between the + and –

signal paths will lower the common mode rejection ratio.

Therefore, it is desirable to us e the sam e length and type of wire

and connectors for both input connections . W hen possible, try to

connect the inputs to points in the circuit with approxim ately the

same source impedance.

If AC coupling is desired, install the AC coupling accessory on

the probe tip before connecting it to the test circuit. The low-

frequency cutoff (–3 dB point) of the AC coupler is approxim ately

16 Hz.

If the voltage in the test circuit exceeds the probe’s capability,

add the external ÷10 or ÷20 attenuator* to the probe tip. If both

the external attenuator and AC coupler are used, install the

attenuator on the probe tip first, then install the AC coupler on the

attenuator input.

* Note

The external attenuators are precisely adjusted

during manufacturing to match the

² ISSUED: January 2000 AP034-OM-E Rev D

Page 13

2SHUDWLRQ

characteristics of the input of the probe with

which they were shipped. The input

characteristics of the external attenuator itself do

not exactly match those of the probe. Therefore,

using the ÷10 and ÷20 attenuators at the same

time is not recommended. The scale factor

encoding system will not operate correctly with

both attenuators installed simultaneously.

The input characteristics of the AP034 1 GHz

Active Differential Probe are significantly

different than those of the AP033 500 MHz

Active Differential Probe. The external

attenuators are not interchangeable. The

external attenuators currently supplied with the

probes are labeled with the appropriate model

number. The attenuators supplied with model

AP033 probes prior to the introduction of the

AP034 did not include the model number on the

label. When using an external attenuator with the

AP034 Active Differential Probe, make sure it is

labeled “AP034.”

Interchanging non-compatible attenuators will

not damage the probes; however, the transient

response of the measured signals will be

significantly in error.

In addition to being compatible with the included lead set, the

probe input connectors will mate with standard 0.025 in.

(0.635 mm) square pins in any rotational orientation. To avoid

damaging the input connectors, do not attempt to insert

connectors or wire larger than 0.036 in. (0.91 m m) in diameter.

Avoid rotating square pins after they are inserted into the input

connectors.

The included accessories simplify the task of connecting the

probe to the test circuit:

• Use the small (0.5 mm) mini clips with the flexible

lead set when connecting to fine-pitch surface mount

IC leads.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 14

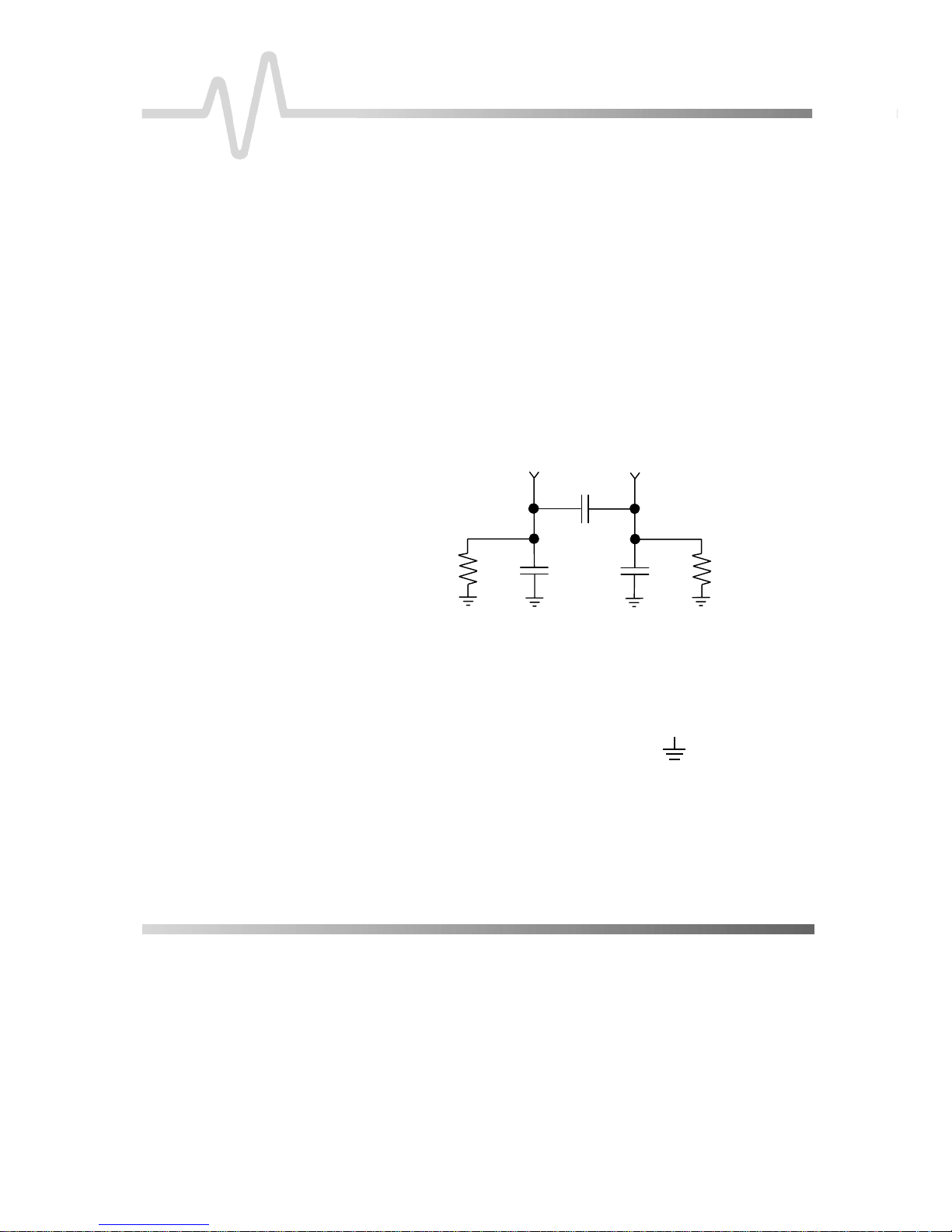

PROBE INPUT LOADING

$3$FWLYH3UREH

• The larger (0.8 mm) mini clips can be used to

connect to through-hole leaded components.

• The offset round pins can be used for hand-held

probing applications. Reposition the pins by rotating

them to obtain the required spacing.

Attaching any probe to a test circuit will add some loading. In

most applications, the high impedance of the AP034 Active

Differential Probe inputs im parts an insignificant load to the test

circuit. However at very high frequencies, the capacitive

reactance of the probe’s input capacitance may load the circuit

enough to affect meas urement accuracy. The equivalent model

of the probe input circuits is shown below:

GROUNDING THE PROBE

+

≈ 0.1 pF

1.5 pF

1 MΩ

Figure 1. AP034 Equivalent Input Model

The single lead along with one of the larger (0.8 mm) m ini clips

can be used to ground the probe to the test circuit. Insert the pin

end of the lead into the receptacle marked:

Note

Do not use the attenuator encoding receptacle

(unmarked socket near the – input) to ground the

probe. Connecting to the encoding receptacle

will not provide adequate grounding, and may

result in in correct scale factor indication.

-

1.5 pF

1 MΩ

² ISSUED: January 2000 AP034-OM-E Rev D

Page 15

2SHUDWLRQ

In most cases it is not necessary to ground the probe to the

circuit under test. However, if the test circuit is isolated from earth

ground, it is usually necessary to connect the probe ground to a

point in the circuit. Grounding test circuits that are referenc ed to

earth ground may improve the fidelity of high-frequency

components in the waveforms. The potential for improvement

with grounding will vary depending on the common mode source

impedance. However, connecting the probe ground to a circuit

that is referenced to earth ground c an create a ground loop that

may add noise to low-amplitude signals*. Rejection of highfrequency common mode signals is improved when the probe

head is ungrounded.

The best recomm endation for connecting or not connecting the

probe ground is to try both configurations and select the one that

performs the best.

Note

The AP034 Active Differential Probe transmits

the measured signal differentially through the

probe cable. This essentially eliminates signal

degradation from ground loop effects within the

probe. However, creating a ground loop may

introduce signal distortions in the test circuit

itself, or in any coaxial cable between the

ADPPS power supply and the test instrument.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 16

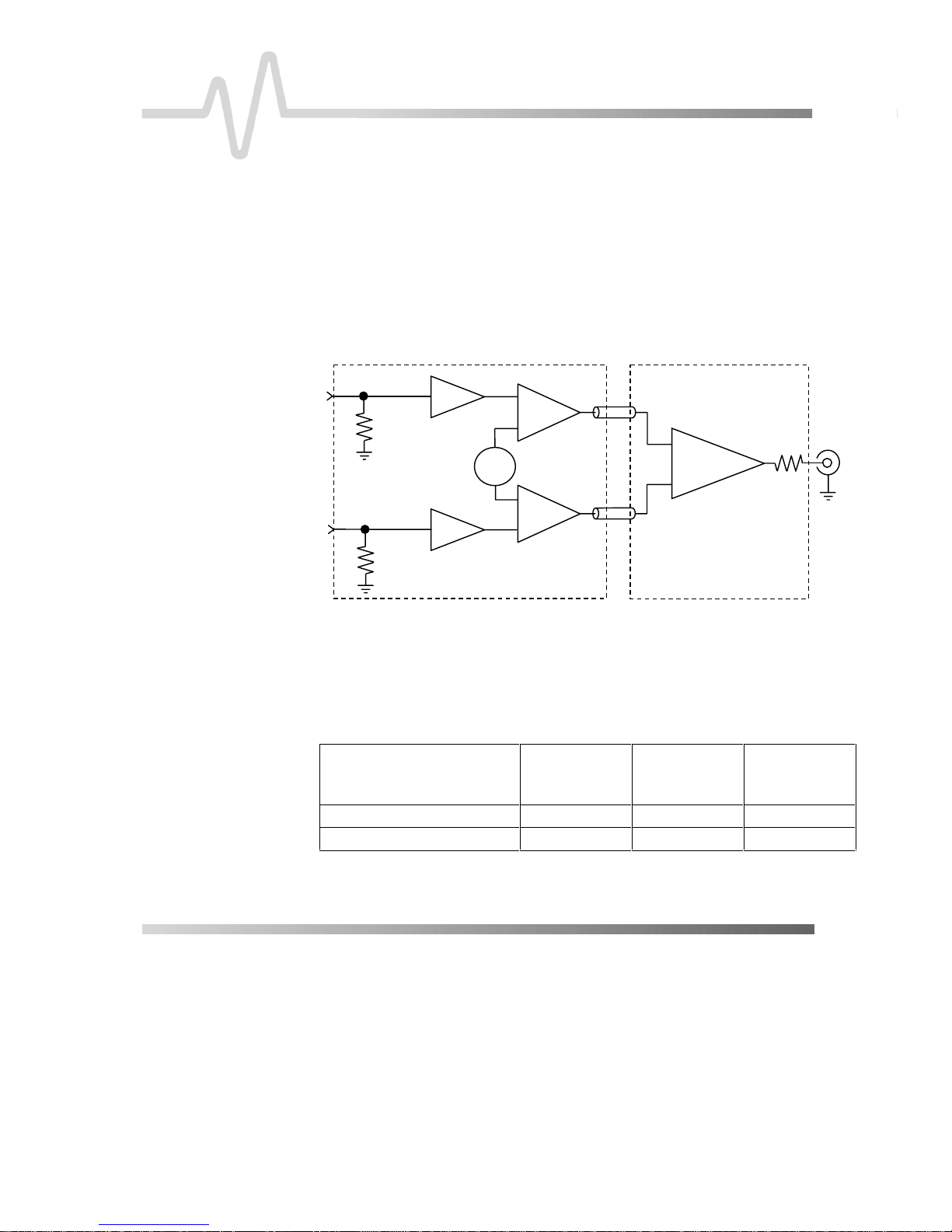

SELECTING THE PROPER RANGE

The AP034 Active Differential Probe has a fixed gain of X1

(unity). Use of the ÷10 or ÷20 external attenuators reduces the

amplitude of the input signal when it is necess ary to extend the

dynamic operating range of the probe. Attenuating the input

signal increases both the differential mode range and comm on

mode range of the probe.

Refer to the block diagram below.

$3$FWLYH3UREH

ControlProbe

+

1

-

1

By using the plug-on attenuator, you can extend the attenuation

range to ÷20. Do not use the ÷10 and ÷20 plug-on attenuators

simultaneously. The maxim um ranges are given in the f ollowing

table:

Table 1. AP034 Dynamic ranges and i nput capacitance at different attenuator

Common Mode Range

Differential Mode Range *

X1

Σ

+

V

Offs

Σ

X1

Figure 2. AP034 Block Diagram

settings

÷1

Attenuation

(Probe Only)

±16 V ±42 V ±42 V

±400 mV ±4 V ±8 V

*Offset moves the center point of this range.

Attenuation

+

-

÷10

X1

50

÷20

Attenuation

² ISSUED: January 2000 AP034-OM-E Rev D

Page 17

When us ing a differential probe or amplifier, be ca reful to avoid

exceeding the common mode range. Because the common

mode signal is rejected by the differential probe, and is not

displayed, changes in the amplitude of the common mode

component are not apparent to the user. Exceeding the c omm on

mode range may introduce distortion into the AP034 output.

Circuitry in the probe detects the presence of either attenuator,

and displays the effective gain of the probe on the probe front

panel.

OPERATION WITH LECROY OSCILLOSCOPES

When the AP034 probe is connected to a LeCroy oscilloscope

equipped with ProBus interface, the displayed scale fac tor will be

adjusted to account for the effective gain of the probe. The

channel O

FFSET knob will control the probe offset, rather than the

offset at the oscilloscope input. The probe contr ol menu can be

activated by pressing the COUPLING button while the channel to

which the probe is attached is selected.

2SHUDWLRQ

AP034-OM-E Rev D ISSUED: January 2000 ²

Figure 3. AP034 Probe Control Menu

Page 18

When the AP034 Active Differential Probe is first connected to

the oscilloscope, the following message will appear:

“WARNING: Probe offset buttons are locked.” This alerts you

that offset control m ust be m ade through the os cilloscope, rather

than through the buttons located on the probe. It does not

indicate a failure in the probe or oscilloscope.

Correct display of scale factor with the ÷20

attenuator installed and correct operation of

probe offset require that software version 8.1 or

higher be loaded. Refer to the manual section

“Oscilloscope Software Compatibility” for

additional information.

AP034 USE WITH THE ADPPS POWER SUPPLY

The optional ADPPS Power Supply allows the AP034 Active

Differential Probe to be used with instruments that are not

equipped with the ProBus interface. When used with the ADPPS,

the AP034 must be terminated into 50 ,I WKH WHVW LQVWUXPHQW

input impedance is not 50 LQVHUW D LQOLQH WHUPLQDWRU

between the ADPPS and the instrument input. If a coaxial

extension cable is used, the terminator should be located at the

instrument end of the cable. Note that the additional parasitic

losses of extension cables may reduce the usable bandwidth of

the system below the AP034 specification.

$3$FWLYH3UREH

Note:

To prevent signal distortion, it is necessary to keep the AP034

output less than 400 mV at all times.

With the ProBus interface (see note on following page), the

oscilloscope O

Without the ProBus, it is acceptable to use the oscilloscope to

position the waveform at high sensitivities , but it is a practic e that

can lead to erroneous measurements when the probe output

exceeds ±400 mV. Therefore, when the ADPPS is used, it is

preferable to use the AP034 offset function to perform all

waveform positioning.

The AP034 offset allows you to measure signals up to 2.0 V

(1.6 V of offset plus 400 mV of output signal). With accessory

plug-on attenuators, the effective offset is increased, and input

signals of 20 V (÷10) or 40 V (÷20) may be viewed. The peak

² ISSUED: January 2000 AP034-OM-E Rev D

FFSET control actually controls the AP034 offset.

Page 19

2SHUDWLRQ

signal that can be viewed at any equivalent scale factor is the

Input Differential Mode Range plus the off set used. See Adding

Offset on the following page.

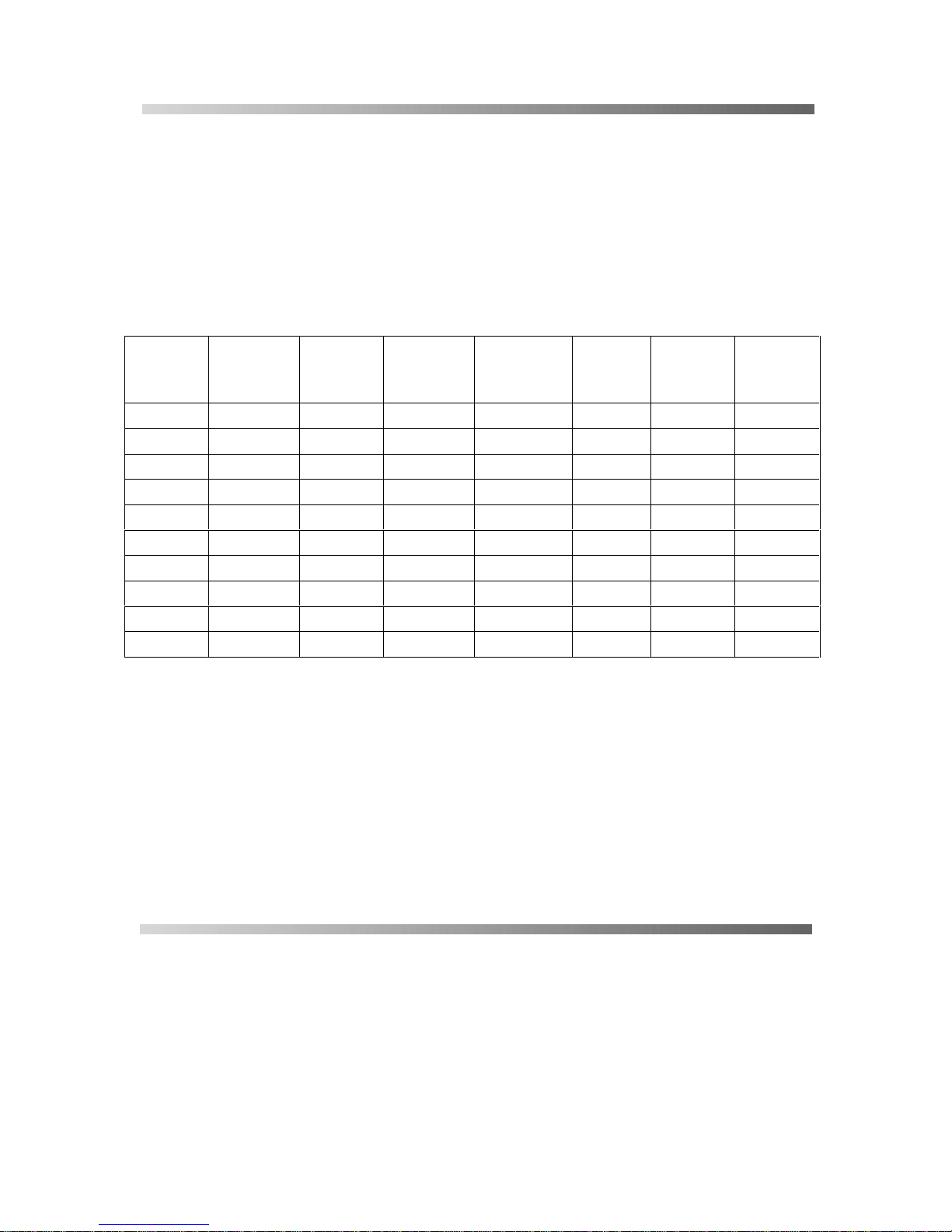

When using the AP034 with the ADPPS power supply on

oscilloscopes without ProBus interface, use the following table to

select the desired effec tive volts per division and determine the

offset available.

Equivalent

Scale

Oscilloscope

Scale Factor

Factor

2 mV/Div 2 mV/Div

5 mV/Div 5 mV/Div

10 mV/Div 10 mV/Div

20 mV/Div 20 mV/Div

50 mV/Div 50 mV/Div

100 mV/Div 100 mV/Div

200 mV/Div 20 mV/Div

500 mV/Div 50 mV/Div

1 V/Div 100 mV/Div

2 V/Div 100 mV/Div

Table 2. Recommended AP034 and Os cilloscope settings to obt ain desired

AP034

Attenuation

Common

Mode Range

÷1 ±16V ±8 mV

÷1 ±16 V ±20 mV

÷1 ±16 V ±40 mV

÷1 ±16 V ±80 mV

÷1 ±16 V ±200 mV

÷1 ±16 V ±400 mV

1

÷10

÷10

÷10

÷20

1

1

1

1

2

3

±42 V ±800 mV

±42 V ±2 V

±42 V ±4 V

±42 V ±8 V

Attenuation obtained using t he external ÷10 or ÷20 attenuator.

Input differential mode range displayed is limi ted by ±4 divisions of vertic al

scale on oscilloscope.

Limited by probe output and ±4 divisions of vertical scale on oscilloscope.

Oscilloscope OFFSET and POSITI ON must be set to zero.

equivalent Volts/Divi sion

Input

Differential

Mode Range

2

2

2

2

2

3

2

2

3

3

Maximum

Offset

Maximum

Observable

Signal with

Offset

±1.6 V ±1.608 V

±1.6 V ±1.620 V

±1.6 V ±1.640 V

±1.6 V ±1.680 V

±1.6 V ±1.800 V

±1.6 V ±2.0 V

±16 V ±16.8 V

±16 V ±18 V

±16 V ±20 V

±32 V ±40 V

Input Noise

(nV/√Hz),

Typical

35

35

35

35

35

35

350

350

350

700

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 20

ADDING OFFSET

$3$FWLYH3UREH

The AP034 Active Differential Probe has true differential offset

capability. This allows you to remove a DC bias voltage from the

differential input signal while maintaining DC coupling. By using

probe offset rather than the P

the full dynamic range of the probe remains centered around the

offset level.

OSITION control on the oscilloscope,

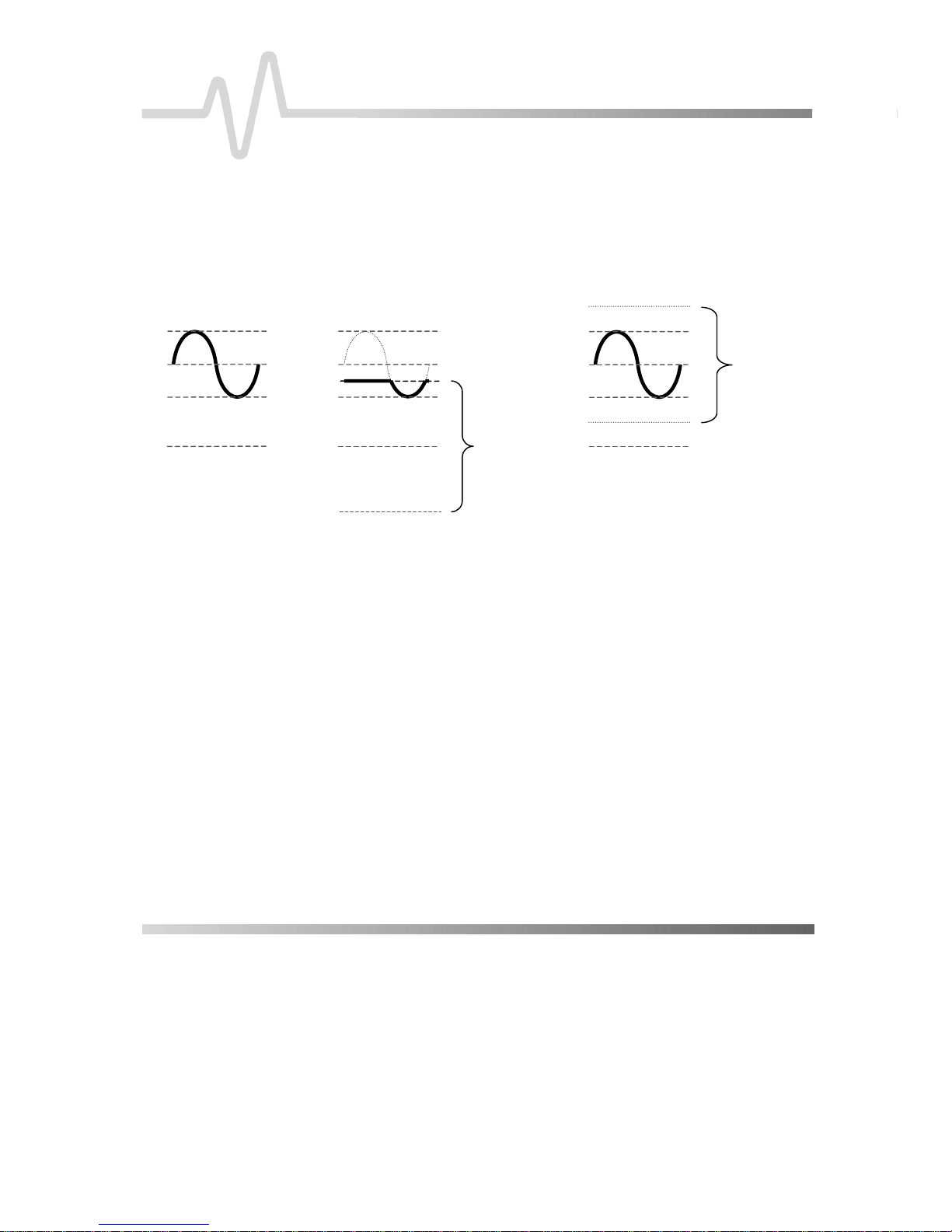

+700 mV

+500 mV

+300 mV

0 mV

Input Differential

Waveform

+700 mV

+500 mV

+400 mV

+300 mV

0 mV

-400 mV

Waveform “clipped”

+700 mV

±400 mV window

re-centered around

the probe offset.

with no offset

+500 mV

+300 mV

±400 mV

centered

at 0 V

Figure 4. Effect of Dif f erential Offset

0 mV

Offset used to re-center

the differential dynami c

range around +500 mV

When the AP034 Active Differential Probe is used with a LeCroy

oscilloscope equipped with ProBus interface, the probe offset

can be controlled with the channel O

FFSET knob.* The buttons on

the probe housing will be disabled.

When used with the ADPPS Power Supply on instruments that

lack ProBus support, of fset can be c ontrolled with the buttons on

the probe’s front panel. The offset can be returned to zero at any

time by briefly pressing both the Î and Ï O

same time. Pres sing both the Î and Ï O

FFSET buttons at the

FFSET buttons for more

than 2 seconds will initiate an Autobalance cycle.

² ISSUED: January 2000 AP034-OM-E Rev D

*Note

Probe offset is controlled with the channel

O

FFSET knob in oscilloscope software versions

8.1.0 or higher. The current offset value is

Page 21

AUTOBALANCE

2SHUDWLRQ

displayed above the graticule for a few seconds

after a change is made by turning the knob (refer

to Figure 3). In prior software versions, the

channel O

oscilloscope input rather than the probe offset.

When the AP034 Active Differential Probe is

used with LeCroy oscilloscopes with older

software versions, it is important that the channel

offset (controlled by the channel O

remain set to 0.0000 V. Moving the displayed

waveform with the channel offset rather than

probe offset will not re-center the dynamic

operating range of the probe. Offsetting the trace

with the oscilloscope channel offset introduces

the possibility of erroneous waveforms that result

from overloading the probe.

The AP034 Active Differential Probe incorporates an

Autobalance function to remove the DC offset from the output.

Autobalance must be invoked by you. When power is first

applied, the probe will return to the internal values resulting from

the last Autobalance cycle. For Autobalance to function properly,

all signals must be removed from the input.

FFSET knob adjusted the offset of the

FFSET knob)

After several minutes of warmup, or when the probe is exposed

to a large shift in ambient tem perature, s ome DC off set dr ift m ay

occur from thermal ef fects in the am plifier cir cuitry. To initiate an

Autobalance cycle, remove the probe from the test circuit and

select the AUTOBALANCE menu selection in the oscilloscope

“COUPLING” menu for the channel the probe is c onnected to. If

the probe is being used with the ADPPS power supply, remove

the input signal, then push and hold both O

FFSET buttons for two

seconds. The AP034 must be terminated into 50 IRUVXFFHVVIXO

Autobalance.

Upon successful completion of the Autobalanc e c ycle, all three of

the EFFECTIVE GAIN indicators will be briefly illuminated. If an

input signal is present during auto balance and the routine fails ,

the EFFECTIVE GAIN indicators will not illuminate. The probe

will then revert to the offset values resulting from the last

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 22

successful completion of the Autobalance cycle. In many

situations, this will be adequate to make routine measurements.

DESIGNING TEST FIXTURES FOR THE AP034 PROBE

Often it is desirable to connect the probe directly to userfabricated test fixtures, such as those used for semiconductor

characterization. To facilitate use with custom test fixtures, the

input receptacles used in the AP034 probe are compatible with

commercially available 0.025 in. (0.635 mm) square pins. The

receptacles do not require a specif ic rotational orientation for the

square pin. The dimensions listed below can be used as a layout

guide for a test fixture circuit board. T he recomm ended insertion

depth of the pins is 0.100 in. (2.5 mm) to 0.200 in. (5.0 mm).

Top View

Looking toward circuit board

$3$FWLYH3UREH

Side View

0.100”-

0.200”

0.110”

0.105”

0.170”

0.100”

Figure 5. Layout dimensions f or test fixtures

0.025” REF.

# # #

² ISSUED: January 2000 AP034-OM-E Rev D

Page 23

5HIHUHQFH,QIRUPDWLRQ

5HIHUHQFH,QIRUPDWLRQ

DIFFERENTIAL MODE AND COMMON MODE

Differential probes amplify the voltage difference that appears

between the + and – inputs. This voltage is referred to as the

Differential Mode or Normal Mode voltage. The voltage

component that is refer enced to earth ground, and is identic al on

both inputs, is rejected by the amplifier. This voltage is referred to

as the Common Mode voltage, because it is common to both

inputs. The common mode voltage can be expressed as:

V

VCM =

DIFFERENTIAL MODE RANGE AND COMMON MODE RANGE

The Differential Mode Range is the max imum signal that can be

applied between the + and – inputs without overloading the probe

amplifier, resulting in “clipping” or distortion of the waveform

measured by the oscilloscope.

+Input

+ V

2

-Input

The Common Mode Range is the max imum voltage with respect

to earth ground that can be applied to either input. Exceeding the

common mode range can result in unpredictable results.

Because the Common Mode s ignal is normally rejected, and is

not displayed on the oscilloscope, you need to be careful to avoid

accidentally exceeding the common mode range.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 24

$3$FWLYH3UREH

Common Mode Range

Maximum voltage from

either input to ground

Figure 6. Common Mode and Different i al Mode Range

COMMON MODE REJECTION RATIO

The ideal differential probe or diff erential amplifier would amplif y

only the differential mode voltage component and reject all of the

common m ode voltage component. Real differential probes and

amplifiers are not perfect, and a small portion of the common

mode voltage component does appear in the output. Common

Mode Rejection Ratio (CMRR) is the measure of how m uch the

probe or amplifier rejects the comm on m ode voltage com ponent.

CMRR is equal to the differential mode gain (or normal gain)

divided by the common mode gain. Com m on mode gain is equal

to the output voltage divided by the input voltage when both

inputs are driven by only the common mode signal. CMRR can

be expressed as a ratio (for exam ple, 10

(for example, 80 dB). Higher numbers indicate gr eater rejection

(better performance).

Differential Mode Range

Maximum voltage

between inputs

000:1) or implic itly in dB

The first-order term that determines the CMRR is the relative

gain matching between the + and – input paths. To obtain high

CMRR values, the input attenuators in a differential probe are

precisely matched to each other. The m atching includes the DC

attenuation as well as the capacitance that determines the AC

attenuation. As the frequency of the common m ode components

increases, the effects of stray parasitic capacitance and

inductance in determining the AC attenuation become more

pronounced. The CMRR becomes smaller as the frequency

increases. Hence, CMRR is usually specified as a plot versus

common mode frequency.

The common mode frequency in these plots is assumed to be

sinusoidal. In real life applications, the common mode signal is

² ISSUED: January 2000 AP034-OM-E Rev D

Page 25

5HIHUHQFH,QIRUPDWLRQ

seldom a pure sine wave. Signals with pulse wave shapes

contain frequency components much higher than the repetition

rate may suggest. As such, it is very difficult to predict actual

performance in the application for CMRR-versus-frequency

graphs. The practical application of these graphs is to compare

the relative common mode rejection performance between

different probes or amplifiers.

# # #

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 26

BLANK PAGE

$3$FWLYH3UREH

² ISSUED: January 2000 AP034-OM-E Rev D

Page 27

&DUHDQG0DLQWHQDQFH

CLEANING

!

The exterior of the probe and cable should be cleaned only using

a soft cloth moistened with water or isopropyl alcohol. Abrasive

agents, strong detergents, or other solvents may damage the

probe. Always ensure that the input receptacles are free of debris

before connecting accessories.

CALIBRATION INTERVAL

To guarantee accurate performanc e, you should have the probe

calibrated every 12 months. Avoid exposing the probe to extreme

mechanical shock and excessive bending of the cable because

these may alter the calibration.

SERVICE STRATEGY

The AP034 circuits utilize fine pitch surface m ount devices; it is,

therefore, impractical to attempt repair in the field. Defective

probes must be returned to a LeCr oy service f a cility for diagnos is

and exchange. A defective probe under warranty will be replaced

with a factory refurbished probe. A probe that is not under

warranty can be exchanged for a factory refurbished probe. A

modest fee is charged for this s ervice. The defec tive probe mus t

be returned in order to receive credit for the probe core.

&DUHDQG0DLQWHQDQFH

TROUBLESHOOTING

If the probe is not operating properly, the problem may be the

way in which it is used. Before assuming the probe is defective,

perform the following troubleshooting procedures.

A. Trace Off Scale

This is typically caused by improper offset setting, or by an input

signal that exceeds the probe differential or common mode

range. Perform the following:

1. Remove the input signal from the pr obe, retur n the of f s et to

zero, and Autobalance the probe. Does the trace return to

approximately the center of the graticule? If not, proceed to

step 7.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 28

$3$FWLYH3UREH

2. Set the oscilloscope calibrator to output a 100-m V, 1-kHz

square wave. Using the flex lead set, connect the probe +

input to the calibrator output signal, leave the – input open.

Set the oscilloscope to 50 mV/div and 500 µs/div. Is the

displayed waveform a 100-mV, 1-kHz square wave with the

correct polarity?

3. Repeat step 2 with the – input connected to the c alibrator

and the + input left open. In this case, the displayed

waveform should be inverted.

4. Connect both the + input and – input to the calibrator

output. Is the trace approximately a flat line near zero volts?

5. If steps 1 to 4 give the correct results, the problem is likely

a result of the input signal exceeding the differential or

common mode range.

6. Connect both the + input and – input to one of the two input

signals. If the trace is off sc ale, the input signal is probably

exceeding the common m ode range. Repeat with the other

input signal.

7. Is a ProBus Power Supply Overload error message

displayed? If so, remove all other ProBus ac cessories fr om

the oscilloscope. Is the message still displayed? If so,

remove the AP034. Is the message still displayed? If so,

the oscilloscope should be returned for service.

8. If, after removing the AP034, the Power Supply Overload

error message is not displayed, the problem m ay be either

the probe or the oscilloscope. Repeat the test with a

different ProBus acces sory. If the mess age does not return

with a different accessory, the AP034 m ay be def ective and

should be returned for service.

B. Incorrect Frequency Response

Possible causes are a defective probe or oscilloscope, poor

connections, or poor grounding. Try the following:

1. Verify that the BW limiting of the oscilloscope is off.

² ISSUED: January 2000 AP034-OM-E Rev D

Page 29

C. DC Errors

&DUHDQG0DLQWHQDQFH

2. Connect the probe to another oscilloscope. If the probe

now measures properly, the problem may be in the

oscilloscope.

3. If the probe behaves as if it is ac-coupled at high frequency,

check for an open input connection.

4. Poor frequency or transient response and AC gain errors

may result when one of the two input connections is open.

5. Excessive “ring” and other transient problems can result

from exces sive lead length. To test this, shorten the input

leads to less than 1 cm. If the transient response changes

significantly, the lead parasitics are the cause.

Incorrect DC gain requires recalibration or factory repair. This

can be determined by completing the gain checks in the

Performance Verification Procedure.

1. Extremely high source resistance will result in DC gain

errors. Check the probe accuracy with the oscilloscope

calibrator signal.

2. Verify that the probe is not being overdriven into clipping for

its current gain setting.

3. Exces sive offset can result from large changes in ambient

temperature. Remove the input s ignal from the probe and

repeat the Autobalance cycle. With the Of fset set to zero,

did the trace return to the center of the graticule?

D. Poor Common Mode Rejection

Use the 1-kHz calibrator signal from the oscilloscope to check

common mode rejection. With both the + input and – input

connected to the calibrator signal, a f lat line at zero volts should

be seen on the graticule.

1. Check the probe with the plug-on attenuator installed and

removed. If excessive com mon mode signal appears only

when the attenuator is present, the attenuator m ay need to

be rematched to the probe. Use the proc edure listed in this

section to match the attenuator.

2. If the common mode signal appears when the probe is

connected to the test circuit, but not when it is attached to

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 30

RETURNING A DEFECTIVE PROBE

The procedure for returning a defec tive probe to be exchanged,

is as follows:

Contact your local LeCroy sales representative to find out where

to return the product. All returned products should be identified

by model and serial number. You should describe the defect or

failure, and provide your name and contact num ber. In the case

of products returned to the factory, a Return Authorization

Number (RAN) should be used. T he RAN can be es tablished by

contacting your nearest LeCroy office, or the New York Customer

Care Center.

Return shipments should be made prepaid. LeCroy cannot

accept COD or Collect Return shipments. We recommend airfreighting. It is important that the RAN be clearly shown on the

outside of the shipping package for prompt redirection to the

appropriate LeCroy department.

$3$FWLYH3UREH

the calibrator, the problem may be caused by large

mismatches in the source impedance. T ry connecting both

inputs to one of the input signals in the test circuit, then the

other. If the comm on mode signal disappears, try probing

lower impedance points within the circuit.

1. Contact your local LeCroy sales or service representative to

obtain a Return Authorization Number.

2. Remove all accessories, including all removable cables,

from the probe.

3. Pack the probe in its case, surrounded by the original

packing material (or equivalent) and box.

4. Label the case with a tag containing:

• The RAN

• Name and address of owner

• Instrument model and serial number

• Description of the failure mode

5. Package the pr obe case in a cardboard shipping box with

adequate padding to avoid damage in transit.

² ISSUED: January 2000 AP034-OM-E Rev D

Page 31

REPLACEMENT PARTS

&DUHDQG0DLQWHQDQFH

6. Mark the outside of the box with the shipping address given

to you by the LeCroy representative; be sure to add the

following:

• ATTN: <RAN assigned by the LeCroy

representative>

• FRAGILE

7. Insure the item for the replacement cost of the probe.

8. Ship the package to the appropriate address.

The probe connection access ories, and other com mon parts c an

be ordered through the regional customer care centers. Ref er to

Figure 7 for LeCroy Part numbers. Defective probes can be

replaced on an exchange basis. The replacement exchange

probe will have been factory repaired, inspected and calibrated to

the same standards as a new product. In order to obtain an

exchange probe, you must return the defective probe. The

returned probe should be sent back to the regional customer

care center without any accessories, manual, or case.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 32

$3$FWLYH3UREH

10

3

2

1

4

5

7

6

9

8

11

12

13

14

Figure 7. Replceable Parts

² ISSUED: January 2000 AP034-OM-E Rev D

Page 33

&DUHDQG0DLQWHQDQFH

Reference LeCroy Part Number Description Rev Qty.

1 529-304-001 Plastic probe tip housing Top A 1

2 377-000-007 LeCroy AP034 Probe Tip Label A 1

3 529-304-003 Plastic probe tip housing End A 1

4 529-304-002 Plastic probe tip housing Bottom A 1

5 555-001-000 #2 Allen Screw, Black A 1

6 554-425-003 Screw, M 2.5x6, self tapping A 4

7 709-3XX-P53 ProBus End Cap A 1

8 70A-P03-303 Termination Box A 1

9 337-000-018 LeCroy Termination Box Label with

cutouts

10 416-090-004 Grey Switch Cap A 4

11 377-000-008 LeCroy Termination Box Rear

Label

12 PK033 Accessory Kit, AP033/34 without

AC Coupler and Attenuator

13 AP03X-FLEX-LEAD Flex Lead B 1

14 AP03X-OFFSET-PIN Offset Pin, package of 10 B --

A1

A1

A1

-- AP034-PROBE-FRU AP034 Probe only Exchange A --

-- AP034-DA10 Plug-On Attenuator, ÷10, AP034 A 1

-- AP034-DA20 Plug-On Attenuator, ÷20, AP034 A 1

-- AP03X-AC-COUPLER Plug-On AC Coupler,

B1

AP033/AP034

-- AP034-OM-E Instruction Manual, AP034, English D 1

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 34

$3$FWLYH3UREH

MATCHING PROCEDURE FOR ÷10 PLUG-ON EXTERNAL ATTENUATOR

The ÷10 and ÷20 Plug-on attenuators provided as standard

accessories with the AP034 are calibrated to match the specific

probe they are shipped with. Individual probes will have small

variations in parasitic capacitance within the input circuits. To

obtain maximum common mode rejection performance, the

attenuators are calibrated to match a specific probe during the

manufacturing process. In order to preserve the maximum

Common Mode Rejection, do not interchange external

attenuators between probes.

The Plug-on AC coupling adapter is not matched to a specific

probe and, therefore, does not need to be matched when

interchanged.

If the ÷10 or ÷20 Plug-on attenuators becom e accidentally mixed

between probes, you can use the procedure listed below to

restore the compensation m atc h. T his adj ustment does not affect

any of the parameters in the warranted specific ations. Ther efore,

the required test equipment does not need to be calibrated.

Note

The AP033 and AP034 Active Differential Probes have

÷

different input capacitance. The

supplied with model AP033 cannot be properly adjusted

for use with model AP034. Make sure that the attenuator

is marked “AP034” before attempting this procedure.

EQUIPMENT REQUIRED

Test Oscilloscope

The oscilloscope must support ProBus. Otherwise use a nonProBus oscilloscope and ADPPS power supply.

Signal Source

Low frequency square wave: frequency from 50 Hz to 5 kHz,

amplitude from 1 V to 10 V. The output waveform m ust have a

square corner and flat top with minimum overshoot suitable for

adjusting compensation. The generator should have trigger

output, or use a BNC Tee connector and separate BNC cable

² ISSUED: January 2000 AP034-OM-E Rev D

10 Plug-on attenuator

Page 35

Interconnect Cable

Tools

PROCEDURE

&DUHDQG0DLQWHQDQFH

from the output to provide the trigger signal for the test

oscilloscope.

This is for connecting the output of the signal source to the

probe. A BNC cable and a pair of small alligator clips or “lead

grabber” adapter (Pomona #3788) may be used.

0.025 in. (0.635 mm) Squar e Pins ( 3 r equired) . T he pins f r om the

header supplied in the probe accessory kit are suitable.

Flat bladed screwdriver, 0.040 in. (1 mm) wide

Adjustment Tool: 0.025 in. (0.635 mm) square head

Note

You can fabricate the Adjustment Tool by flattening the

end of a 0.025 in. (0.635 mm) square pin with a file.

Then, using heat from a soldering iron, insert the pin into

a short length of rigid plastic tubing to serve as a handle.

1. Attach the AP034 to the test oscilloscope. If the test

oscilloscope is not equipped with ProBus, use the ADPPS to

provide power for the AP034.

2. Attach the ÷10 or ÷20 Attenuator Adapter to the AP034 probe

tip.

3. Insert 0.025 in. (0.635 mm) square pins into the +, –, and

input connectors of the Plug-on Attenuator.

4. Attach the interconnect cable to the output of the signal

source.

5. Attach the Trigger Out signal from the signal source to the

External Trigger Input of the test oscilloscope. If the signal

source does not have a separate Trigger Out signal, use a

BNC Tee connector in the output. Run one cable to the

External Trigger Input of the test oscilloscope. Connect the

other to the probe inputs.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 36

$3$FWLYH3UREH

6. Using the alligator clips on the end of the interconnect cable,

connect the signal source ground to the square pin on the

Attenuator Adapter’s “–“ input. Attach the signal output to the

square pin on the Attenuator Adapter’s “+” input.

7. Turn on the test oscilloscope. The EFFECTIVE GAIN

indicator for ÷10 or ÷20 should be lit. (NOTE: If the X1

EFFECTIVE GAIN indicator is lit instead of the ÷10 or ÷20

indicator, make sure that the plug-on adapter installed on the

probe tip is the Attenuator, and not the AC Coupler.)

8. Set the test oscilloscope Volts/Div to 200 mV (for LeCroy

oscilloscopes with ProBus) or 20 mV/Div when using the

ADPPS with an oscilloscope without scale factor correction;

5 µs/Div; AUTO trigger mode; Trigger source: External. Set

the Bandwidth Limiting to 20–30 MHz and Average the

waveform 1:31 to reduce noise.

9. Turn on the signal source. Set the output frequency to

approximately 5 kHz. Set the output amplitude to

approximately 1 V for matching the ÷10 Attenuator Adapter,

or 2 V for matching the ÷20 Attenuator Adapter.

10. Adjust the test oscilloscope trigger level for a stable trace. If

necessary, use the probe offset to position the waveform to

show the square corner of the test signal. NOTE: Do not use

the oscilloscope offset or position controls to reposition the

trace. Many of the signal generators used for compensation

calibration only have square corners on one of the two edges

of the output waveform. (Rising or falling edge, but not both.)

Be sure to display the correct edge for this step.

11. Using the square adjustment tool, adjust the +LF Comp (See

Figure 8) to achieve the best square corner and flat top of the

displayed waveform. Note that the added capacitance of the

adjustment tool may change the compensation of the

waveform when it is inserted. The correct adjustment is

achieved when the best corner is displayed with the

adjustment tool removed.

² ISSUED: January 2000 AP034-OM-E Rev D

Page 37

&DUHDQG0DLQWHQDQFH

+LF Comp.

Adjust

–LF Comp.

Adjust

DC Atten.

Balance

Figure 8. Attenuator Adjustment Locations

12. Move the connections on the interconnect cable so the signal

generator ground is connected to the square pin inserted in

the ground connector of the Attenuator Adapter. Connect the

signal generator output to BOTH the + input and – input

square pins in the Attenuator Adapter.

13. Set the signal generator frequency to about 50 Hz, and the

output amplitude to about 10 V.

14. Set the test oscilloscope Volts/Div to 20 mV (for LeCroy

oscilloscopes with ProBus) or 2 mV/Div when using the

ADPPS with an oscilloscope without scale factor correction;

and set the time scale to 2 ms/Div. It may be necessary to

increase the averaging to 1:127 to remove noise.

15. The displayed waveform is the common mode response.

Using the adjustment screwdriver with the flat blade, adjust

the DC Atten. Balance (Figure 8) to minimize the amplitude

of the flat portions of the displayed waveform. This

adjustment only affects the flat portions of the square wave.

Do not be concerned with any overshoot at the transitions.

16. Reduce the Test Oscilloscope Averaging weighting to 1:31.

Return the Volts/Div to 200 mV (for LeCroy oscilloscopes

with ProBus) or 20 mV/Div when using the ADPPS with an

oscilloscope without scale factor correction, and the Time/Div

to 5 µs.

17. Return the signal source output frequency to approximately

5 kHz. Set the output amplitude to approximately 1 V for the

÷10 Attenuator Adapter, 2 V for the ÷20 Attenuator Adapter.

18. Using the 0.025 in. square adjustment tool, adjust the –LF

Comp (Figure 8) to minimize the amplitude of overshoot

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 38

$3$FWLYH3UREH

during the transition of the displayed waveform. It may not be

possible to completely eliminate the overshoot. As with the

+LF Comp adjustment, the added capacitance of the

adjustment tool may change the amplitude of the waveform

when it is inserted. The correct adjustment is achieved when

the overshoot is minimized with the adjustment tool removed.

# # #

² ISSUED: January 2000 AP034-OM-E Rev D

Page 39

3HUIRUPDQFH9HULILFDWLRQ

3HUIRUPDQFH9HULILFDWLRQ

This procedure can be used to verify the warranted

characteristics of the AP034 Active Differential Probe.

The recommended calibration interval for the model AP034

Active Differential Probe is one year. The complete perf ormance

verification procedure should be performed as the first step of

annual calibration. You can record test results on a photocopy of

the Test Record provided at the end of this section.

You can do the performance verification without removing the

instrument covers, exposing yourself to hazardous voltages.

Adjustment should only be attempted if a par am eter m easur ed in

the Performance Verification Procedure is outside of the

specified limits.

Adjustment should only be performed by qualified personnel.

TEST EQUIPMENT REQUIRED

Table 3 lists the test equipment and accessories (or their

equivalents) that are required to verify the performance of the

AP034 Active Differential Probe.

This procedure is designed to minim ize the number of calibr ated

test instruments required.

Only the parameters listed in boldface in the “Minimum

Requirements” column must be calibrated to the accuracy

indicated.

Because the input and output connector types may vary on

different brands and models of test instruments, additional

adapters or cables may be required.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 40

Description Minimum Requirements Test Equipment Examples

Wide Band Oscilloscope

TABLE 3. List of Required Equipment

1

Minimum 1 GHz bandwidth

2 mV to 5 V scale factors

ProBus interface equipped

2% vertical accuracy

$3$FWLYH3UREH

LeCroy LC584A

Digital Multimeter

DC: 0.1% accuracy

AC: 0.2% accuracy to measure

200 mV and 2 V rms @ 1 kHz

Agilent Technologies 34401A

Fluke 8842A-09

Keithley 2001

5½ digit resolution

Function Generator Sine Wave and Square Wave

output waveforms

LQWR0

20 V

p-p

70 Hz to 10 MHz frequency range

High Frequency Sine Wave

Generator

50 to 500 MHz and 50 kHz

Output adjustable from 300 mV to

2 V

p-p

Agilent Technologies 33120A

Stanford Research Model

DS340

Leader LAG-120B

Agilent Technologies 8648C

Terminator, in-line, BNC FRD[LDOWHUPLQDWLRQ Pomona 4119-50

Terminator, precision, BNC

Attenuator, BNC

BNC coaxial cable

±0.2%

÷10 (20 dB)

PDOHPDOH%1& LQ Pomona 5697-36

LeCroy TERM-CF01

Pomona 4108-20dB

(2 required)

Calibration Fixture ProBus Extension Cable LeCroy PROBUS-CF01

Calibration Fixture AP033/AP034 Calibration Fixture LeCroy AP03x-CF01

Banana Plug adapter BNC female-to-banana plug Pomona 1269

² ISSUED: January 2000 AP034-OM-E Rev D

Notes

1

If a LeCroy ProBus equipped oscilloscope is not available, you

may use an alternate oscilloscope that meets the other

minimum specifications listed, and the model ADPPS power

supply, to perform the adjustment procedure. The input

Page 41

PRELIMINARY PROCEDURE

3HUIRUPDQFH9HULILFDWLRQ

WHUPLQDWLRQ RI WKH RVFLOORVFRSH PXVW EH VHW WR DQG WKH

offset or position must remain at center screen.

1. Connect the AP034 Active Differential Probe to the

female end of the ProBus Extension Cable.

Connect the male end of the ProBus extension

cable to Channel 1 of the oscilloscope.

2. Turn the oscilloscope on and allow at least a 30minute warm-up time for the AP034 and test

equipment before performing the Verification

Procedure.

3. Tur n on the other test equipment and allow these

to warm up for the time per iod recommended by

the manufacturer.

4. While the instruments are reaching operating

temperature, make a photocopy of the

Performance Verification Test Record (located at

the end of this section), and fill in the necessary

information.

The warranted characteristics of the AP034 Active Differential

Probe are valid at any temperature within the Environmental

Characteristics listed in the Specif ications . However, som e of the

other test equipment used to verify the performance may have

environmental limitations required to m eet the accuracy needed

for the procedure. Make sure that the ambient conditions m eet

the requirements of all the test instruments used in this

procedure.

PROCEDURE

Note

Correct operation of the AP034 controls requires

oscilloscope software version 8.1.0 or higher.

The use of earlier versions is not recommended.

You can verify the software version in the test

oscilloscope by pressing the SHOW STATUS

button, then selecting the System menu option.

Contact your local LeCroy representative if the

software in your oscilloscope requires updating.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 42

A. Check Gain Accuracy

$3$FWLYH3UREH

1. From the oscilloscope display, select the channel that the

AP034 is connected to (channel 1), then select the

“Coupling” menu. Set the Coupling to DC 1 M Ω. (If the only

choice available is AC 1 MΩ, remove the Plug-on AC

Coupling adapter from the probe tip.)

2. If necess ary, set the probe offset to 0.000 V by rotating the

O

FFSET knob in the CHANNEL section of the oscilloscope.

3. Using a BNC f emale-to-female adapter, connec t one end of

a BNC cable to the probe end of the ProBus Extension

&DEOH &RQQHFW WKH 3UHFLVLRQ

end of the BNC cable.

4. Connect one end of a second BNC cable to the output of the

Function Generator. Attach the BNC-to-dual-male banana

plug adapter to the free end of the second BNC cable.

Connect the banana plugs to the Digital Multimeter (DMM).

5. Set the DMM to measure AC Volts.

6. Set the mode of the Function Generator to Sine W ave; the

frequency to approximately 1 kHz; and the output amplitude

to approximately 200 mV rms, as measured by the DMM.

7HUPLQDWRU WR WKH RWKHU

7. Record the m easured amplitude to 100 µV resolution in the

Test Record.

8. Unplug the output cable from the DMM. Remove the BNC- tobanana plug adapter from the end of the cable.

9. Autobalance the AP034 by pressing the AUTOBALANCE

menu button located in the “Coupling” menu.

10. Carefully align the four pins that correspond to the

Differential Drive No Termination portion of the AP03xCF01 Calibration Fixture with the input receptacles in the

AP034 probe head. Press the probe into the fixture to fully

engage the pins.

11. Connect the banana plugs of the precision ter minator to the

digital multimeter (DMM).

² ISSUED: January 2000 AP034-OM-E Rev D

Page 43

3HUIRUPDQFH9HULILFDWLRQ

12. Connect the free end of the output cable f rom the Function

Generator to the Differential Drive No Termination

connector of the AP033/AP034 Calibration Fixture.

13. After the DMM reading has stabilized, record the m easured

output amplitude to 100 µV resolution in the Test Record.

14. Divide the meas ured output voltage (recorded in step A-13)

by the sine wave generator output voltage (probe input

voltage) from step A-7. Subtract 1.0 from the ratio and

multiply the result by 100 to get the error in percent.

Error

15. Record the answer to two significant places (±x.xx%) on line

A-15 in the Test Record.

16. Verify that the X1 gain error is less than ±2%.

17. Disconnect both BNC cables from the test setup.

B. Check High Frequency Common Mode Rejection Ratio (CMRR)

1. Disconnect the ProBus Extension cable from the AP034 and

the oscilloscope. Reconnect the AP034 directly to the

Channel 1 input of the oscilloscope.

Common Mode Rejection Ratio (CMRR) is

defined as the Differential Mode Gain

divided by the Common Mode Gain

(normalized inverse of the Common Mode

response). At frequencies below

approximately 250 MHz, the bandwidthrelated attenuation in the AP034 Active

Differential Probe is so insignificant that

the Differential Mode Gain can be

assumed to be unity (1.0).

VoltageInput

Note

ageutput VoltMeasured O

−=

1001% ×

AP034-OM-E Rev D ISSUED: January 2000 ²

2. Care fully move the AP034 probe head from the Differential

Drive No Termination connector of the AP033/AP034

Calibration Fixture to the Common Mode Drive 50 ohm

Page 44

$3$FWLYH3UREH

Termination connector. Make sure that the probe is fully

engaged in the fixture.

3. Set the oscilloscope to display channel 1. In the oscilloscope

Channel 1 “COUPLING” menu, set Coupling to DC 1 MΩ,

and Global BWL to Off. Autobalance the AP034 by pressing

the AUTOBALANCE menu button twice. Set the

oscilloscope trigger mode to AUTO.

4. If necessary, center the trace with the Probe Off set (channel

FFSET knob).

O

5. Connec t a BNC cable from the output of the high frequency

sine wave generator to the Channel 2 input of the

oscilloscope.

6. Set the oscilloscope as follows:

Display Channel 2 only

Channel 2 VOLTS/DIV 0.5 V/div

Channel 2 Coupling DC 50Ω

Trigger on 2

Trigger coupling 2 HF

TIME/DIV 5 ns/div

Acquisition Mode NORMAL

7. Set the high-frequency sine wave generator frequency to

100 MHz, and the amplitude to approximately 2 V

. Set the

p-p

RF Output to ON.

8. Adjust the oscilloscope trigger level as needed for a stable

display.

9. Adj ust the output amplitude of the high frequency sine wave

generator for a display of exactly 4 divisions (2 V) peak-topeak. Turn off the RF Output.

10. Move the high frequency sine wave generator output cable

from the oscillos cope channel 2 input to the Common M ode

Drive 50 ohm Termination c onnector of the AP033/AP034

Calibration Fixture.

11. Set the high-frequency sine wave generator RF Output to

ON.

² ISSUED: January 2000 AP034-OM-E Rev D

Page 45

3HUIRUPDQFH9HULILFDWLRQ

12. Set the oscilloscope to display channel 1 only, set the trigger

source to channel 1, and set the channel 1 vertical scale

factor as needed to measure the amplitude of the displayed

waveform. Adjust the trigger level as neces sary for a stable

display. This is the common mode signal. Turn on Math

Channel A. Press MATH SETUP, then REDEFINE A. Set the

A Math type to Average, Avg Type to Continuous, with

1:15 weighting, of channel 1. Turn off the trace 1 display.

Note

The amplitude of the Common Mode

signal should be relatively small. If the

output waveform appears to be a 1 Volt

square wave, check that the Common

Mode Drive 50 ohm Termination

connector of the AP033/AP034 Calibration

Fixture is being used and not the

Differential Drive 50 ohm Termination

connector.

13. Measure the peak-to-peak output amplitude of the AP034.

Record the reading to two-digit resolution (xx mV) as

“Common Mode Signal at 100 MHz” in the Test Record.

14. Calculate the Common Mode Rejection Ratio (CMRR) at

100 MHz by dividing 2,000 mV by the measured Common

Mode Signal recorded in step B-14 (direct reciprocal of the

Common Mode Gain). Record the result to two-digit

resolution (xx:1) in the Test Record.

15. Verify that the CMRR at 100 MHz is greater than 18:1

(25 dB).

16. Turn off the high frequency sine wave generator RF output,

and disconnect the output cables.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 46

C. Check Low Frequency CMRR

$3$FWLYH3UREH

Note

Because greater amplitudes are required

to measure the higher CMRR

specifications at low frequencies, the

Function Generator will be used in place of

the high-frequency sine wave generator

for the low frequency CMRR test.

1. Carefully move the AP034 probe head from the Common

Mode Drive 50 ohm Termination connector of the

AP033/AP034 Calibration Fixture to the Common Mode

Drive No Termination connector. Mak e that sure the probe

is fully engaged in the fixture.

2. Set the oscilloscope to display channel 2, the channel 2 input

coupling to DC1 MΩ, the channel 2 vertical scale to

5 Volt/div, the horizontal scale to 5 ms/div, and the trigger

source to channel 2. Set BW limiting on channels 1 and 2 to

25 MHz.

3. Connect the BNC Tee adapter to the output connector of the

Function Generator. Connect a BNC cable f rom one end of

the BNC Tee adapter to channel 2 of the oscilloscope.

Connect a second BNC cable from the remaining end of the

BNC Tee adapter to the Common Mode Drive No

Termination input connector of the AP033/AP034

Calibration Fixture.

Caution

Make sure that the Common Mode Drive

No Termination connection is used.

Prolonged application of the power levels

used in the low frequency common mode

test may damage the termination

resistance in either 50 ohm Termination

input of the AP033/AP034 calibration

fixture.

² ISSUED: January 2000 AP034-OM-E Rev D

Page 47

3HUIRUPDQFH9HULILFDWLRQ

4. Set the sine wave generator frequency to 70 Hz, and the

output amplitude to 20 V

If necessary, adjust the trigger level for a stable display.

5. Set the oscilloscope to display channel 1, but leave the

trigger source set to channel 2. Set the vertical scale of

channel 1 to 2 mV/div. Create a math waveform on channel

A defined as the Average of channel 1. Set the average

factor as necessary to reduce noise. Incr ease the zoom to a

factor of four (0.5 mV/division). Turn off the waveform display

of all channels except the A Math waveform.

6. Increase the zoom of the A Math waveform as needed to

measure the peak-to-peak amplitude. This is the common

mode signal.

7. Record the displayed “Common Mode Signal at 70 Hz” to

two-digit resolution (x.xx mV) in the Test Record.

8. Calculate the Common Mode Rejection Ratio (CMRR) at

70 Hz by dividing 20

Mode Signal recorded in step C-7 (direct reciprocal of the

Common Mode Gain). Record the result to two-digit

resolution (xx

000:1) in the Test Record.

, (4 divisions on the oscilloscope).

p-p

000 mV by the measured Common

9. Verify that the “Comm on Mode Rejection Ratio at 70 Hz” is

greater than 10

000:1 (80 dB).

10. Change the output amplitude of the Function Generator to

approximately 8.0 V

, and the frequency to 1 MHz.

p-p

11. Set the oscilloscope to display channel 2 only. Change the

horizontal scale factor to 0.5 µs/div, and the channel 2

vertical scale to 2 V/div. Turn the BW L on channels 1 and 2

to 200 MHz.

12. Adjust oscilloscope trigger level as necessary for a stable

display. Adjust the Function Generator amplitude as needed

to maintain 8.0 V

as measured on channel 2.

p-p

13. Turn off the oscilloscope channel 2 display, turn on the

display of channel 1 and the A Math waveform (averaged

channel 1). Adjust the scale factor of channel 1 and the

Zoom of the A M ath waveform as necessary to accurately

measure the amplitude of the averaged signal.

AP034-OM-E Rev D ISSUED: January 2000 ²

Page 48

$3$FWLYH3UREH

14. Record the displayed “Common Mode Signal at 1 MHz” to

two-digit resolution in the Test Record.

15. Calculate the “Common Mode Rejection Ratio (CMRR) at

1 MHz” by dividing 8000 mV by the measured Common

Mode Signal recorded in step C-14. Record the result in the

Test Record.

16. Verify that the Common Mode Rejection Ratio at 1 MHz is

greater than 100:1 (40 dB).

17. Remove all cables and test fixtures from the AP034 probe.

This completes the Performance Verification of the AP034.

Complete and file the results recorded in the AP034 Performance

Verification Test Record, as required by your quality procedures.

Apply a suitable calibration label to the AP034 housing as

required.

# # #

² ISSUED: January 2000 AP034-OM-E Rev D

Page 49

3HUIRUPDQFH9HULILFDWLRQ

AP034 Performance Verification Test Record

This record can be used to record the results of measurements made during the performance

verification of the AP034 Active Differential Probe.

Photocopy this page and record the results on the copy. File the completed rec ord as required by

applicable internal quality procedures.

The section in the test record corresponds to the parameters tested in the performance

verification procedure. The numbers preceding the individual data records correspond to the steps

in the procedure that require the recording of data. Results to be recorded in the column labeled

“Test Result” are the actual specification limit check . The test limits are included in all of these

steps. Other measurements and the results of intermediate calculations that support the limit

check are to be recorded in the column labeled “Intermediate Results.”

Permission is granted to reproduce these pages for the purpose of recording test results.

Model: __________AP034_________

Serial Number: _________________________

Asset or Tracking Number: _________________________

Date: _________________________

Technician: _________________________

EQUIPMENT USED:

MODEL SERIAL

NUMBER

OSCILLOSCOPE

DIGITAL MULTIMETER

HF SINE WAVE GENERATOR

FUNCTION GENERATOR

1

The function generator provides st i mulus for making rel ative measurements . The output amplitude of t he generator is

measured with the DMM or oscilloscope in the procedure. Thus, the generator is not required to be calibrat ed.

AP034-OM-E Rev D ISSUED: January 2000 ²

1

CALIBRATION

DUE DATE

N/A

Page 50

$3$FWLYH3UREH

AP034 PERFORMANCE VERIFICATION TEST RECORD

Step Description Intermediate Data Test Result

Gain Accuracy

A-7 Sine Wave Generator Output Voltage ________________ mV

A-13 Probe Output Voltage ________________ mV

A-15 Gain Error (Test Limit 2%) _________________%

High Frequency Common Mode Rejection Ratio (CMRR)

B-13 Common Mode Signal at 100 MHz ________________ mV

B-15 CMRR at 100 MHz (Test Limit _________________:1

Low Frequency Common Mode Rejection Ratio

C-7 Common Mode Signal at 70 Hz ________________ mV

C-8 CMRR at 70 Hz (Test Limit

C-14 Common Mode Signal at 1 MHz ________________ mV

C-15 CMRR at 1 MHz (Test Limit _________________:1

Notes: _______________________________________________________________________

_____________________________________________________________________________