Page 1

|

|

g

g

I REMOTE CONTROL MANUAL

II

II

II

|

g

II

g

II

g

MODELS 9410/14/20/24/30/50

DUAL- AND QUAD-CHANNEL

DIGITAL OSCILLOSCOPES

I

li

g

a

Serial Number

May 1992

Page 2

g

I

i

n

ii

li

ii

li

LeCroy

Corporate Headquarters

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977-6499

Tel: (914) 425-2000, TWX: 710-577-2832

European Headquarters

2, rue Pr~-de-la-Fontaine

P.O. Box 341

1217 Meyrin 1/Geneva, Switzerland

Tel.: (022) 719 21 11, Telex: 419 058

Copyright~ May 1992, LeCroy. All rights reserved, information in this

publication supersedes all earlier versions. Specifications subject to change.

il

i

ii

g

li

i

II

g

II

L

Page 3

1

1

I TABLE OF CONTENTS

General Information

Initial Inspection

Warranty

Product Assistance

Maintenance Agreements

Document Discrepancies

Service Procedure

Return Procedure

2 About Remote Control

GPIB Implementation Standard

Program Messages

Commands and Queries

Local and Remote State

Program Message Form

Command/Query Form

Response Message Form

3 GPIB Operation

GPIB Structure

Interface Capabilities

Addressing

GPIB Signals

IEEE 488.1 Standard Messages

Programming GPIB Transfers

Programming Service Requests

Instrument Polls

Driving a Hard-copy Device

1

1

1

1

2

2

2

11

11

12

12

13

15

19

21

25

4 RS-232-C Operation

Introduction

RS-232-C Pin Assignments

RS-232-C Configuration

Commands Simulating GPIB Commands

29

29

30

33

Page 4

II

Table of Contents

System Commands

Organization

Command Summary

Command Execution

Command Notation

6

Waveform Structure

Introduction

Logical Data Blocks of a Waveform

Inspect? Command

Waveform? Command

Waveform Command

More Control of Waveform Queries

High-speed Waveform Transfer

Status Registers

Overview of Status and Service Request Reporting

Status Byte Register (STB)

Standard Event Status Register (ESR)

Standard Event Status Enable Register (ESE)

Service Request Enable Register (SRE)

Parallel Poll Enable Register (PRE)

Internal State Change Status Register (INR)

Internal State Change Enable Register (INE)

Command Error Status Register (CMR)

Device Dependent Error Status Register (DDR)

Execution Error Status Register (EXR)

User Request Status Register (URR)

35

35

37

37

179

179

180

182

187

188

188

191

193

194

195

195

195

195

196

196

196

196

196

|

|

|

Page 5

Appendix A

Table of Contents

Example 1: Use of the Interactive

GPIB Program ’IBIC’

Example 2: GPIB Program for IBM PC

(High-level Function Calls)

Example 3: GPIB Program for IBM PC

(Low-level Function Calls)

Appendix B

The Waveform Template

199

200

202

205

Page 6

Page 7

1

GENERAL INFORMATION

INITIAL INSPECTION

WARRANTY

It is recommended that the shipment be thoroughly inspected immediately upon delivery to the purchaser. All material in the

container should be checked against the enclosed Packing List.

LeCroy cannot accept responsibility for shortages in comparison

with the Packing List unless notified promptly. If the shipment is

damaged in any way, please contact the Customer Service Depart-

ment or local field office immediately.

LeCroy warrants its oscilloscope products to operate within specifications under normal use for a period of two years from the date of

shipment. Spares, replacement parts and repairs are warranted for

90 days. The instrument’s firmware is thoroughly tested and

thought to be functional, but is supplied "as is" with no warranty of

any kind covering detailed performance. Products not manufac-

tured by LeCroy are covered solely by the warranty of the original

equipment manufacturer.

In exercising this warranty, LeCroy will repair or, at its option,

replace any product returned to the Customer Service Department

or an authorized service facility within the warranty period, provided that the warrantor’s examination discloses that the product

is defective due to workmanship or materials and that the defect

has not been caused by misuse, neglect, accident or abnormal conditions or operation.

The purchaser is responsible for transportation and insurance

charges for the return of products to the servicing facility. LeCroy

will return all in-warranty products with transportation prepaid.

This warranty is in lieu of all other warranties, expressed or implied, including but not limited to any implied warranty of

merchantability, fitness, or adequacy for any particular purpose or

use. LeCroy shall not be liable for any special, incidental, or con-

sequential damages, whether in contract or otherwise.

PRODUCT ASSISTANCE

MAINTENANCE

AGREEMENTS

Answers to questions concerning installation, calibration, and use

of LeCroy equipment are available from the Customer Service

Department, 700 Chestnut Ridge Road, Chestnut Ridge, New

York 10977-6499, U.S.A., tel. (914)578-6061, and 2, rue

Pr6-de-la-Fontaine, 1217 Meyrin 1, Geneva, Switzerland, tel.

(41)22/719 21 11, or your local field engineering office.

LeCroy offers a selection of customer support services. Maintenance agreements provide extended warranty and allow the

customer to budget maintenance costs after the initial two year

warranty has expired. Other services such as installation, training,

enhancements and on-site repair are available through specific

Supplemental Support Agreements.

Page 8

General Information

DOCUMENTATION

DISCREPANCIES

SERVICE PROCEDURE

RETURN PROCEDURE

LeCroy is committed to providing state-of-the-art instrumenta-

tion and is continually refining and improving the performance of

its products. While physical modifications can be implemented

quite rapidly, the corrected documentation frequently requires

more time to produce. Consequently, this manual may not agree in

every detail with the accompanying product. There may be small

discrepancies in the values of components for the purposes of

pulse shape, timing, offset, etc., and, occasionally, minor logic

changes. Where any such inconsistencies exist, please be assured

that the unit is correct and incorporates the most up-to-date cir-

cuitry. In a similar way the firmware may undergo revision when

the instrument is serviced. Should this be the case, manual up-

dates will be made available as necessary.

Products requiring maintenance should be returned to the Cus-

tomer Service Department or authorized service facility. LeCroy

will repair or replace any product under warranty at no charge.

The purchaser is only responsible for transportation charges.

For all LeCroy products in need of repair after the warranty period, the customer must provide a Purchase Order Number before

repairs can be initiated. The customer will be billed for parts and

labor for the repair, as well as for shipping.

To determine your nearest authorized service facility, contact the

Customer Service Department or your field office. All products

returned for repair should be identified by the model and serial

numbers and include a description of the defect or failure, name

and phone number of the user, and, in the case of products returned to the factory, a Return Authorization Number (RAN).

The RAN may be obtained by contacting the Customer Service

Department in New York, tel. (914)578-6061, in Geneva, tel.

(41)22/719 21 11, or your nearest sales office.

Return shipments should be made prepaid. LeCroy will not accept

C.O.D. or Collect Return Shipments. Air-freight is generally recommended. Wherever possible, the original shipping carton

should be used. If a substitute carton is used, it should be rigid and

be packed such that the product is surrounded with a minimum of

four inches of excelsior or similar shock-absorbing material. In

addressing the shipment, it is important that the Return Authoriza-

tion Number be displayed on the outside of the container to ensure

its prompt routing to the proper department within LeCroy.

Page 9

2

ABOUT REMOTE CONTROL

Two modes of operation are available in the oscilloscope. The in-

strument may be operated either manually, by using the

front-panel controls, or remotely by means of an external control-

ler (which is usually a computer, but may be a simple terminal).

This Remote Control Manual describes how to control the oscillo-

scope in the remote mode. For explanations on how to manually

set front-panel controls, refer to the Operator’s Manual.

The oscilloscope is remotely controlled via either the GPIB (Gen-

eral Purpose Interface Bus) or the RS-232-C communication

ports. Whenever the rear-panel GPIB address switches are set be-

tween 0 and 30, control is via GPIB; when they are at 31 or above,

control is via RS-232-C. The instrument can be fully controlled in

remote mode. The only actions which cannot be performed re-

motely are switching on the instrument or setting the remote

address.

This section introduces the basic remote control concepts which

are common to both RS-232-C and GPIB. It also presents a brief

description of remote control messages.

Sections 3 and 4 explain how to send program messages over the

GPIB or the RS-232-C interfaces, respectively. Section 5 alphabetically lists all the remote control commands. Section 6 is a

detailed description and tutorial of the transfer and format of

waveforms, whereas Section 7 explains the use of status bytes for

error reporting. Appendix A shows some complete programming

examples. Appendix B contains a printout of a waveform tem-

plate.

GPIB IMPLEMENTATION

STANDARD

PROGRAM MESSAGES

1. ANSI/IEEE Std. 488.2-1987, "IEEE Standard Codes, Formats, Protocols, and Common Commands", The

Institute of Electrical and Electronics Engineers Inc., 345 East 47th Street, New York, NY 10017, USA.

The remote commands conform to the GPIB IEEE 488.2 stan-

1.

dard

IEEE 488.1 standard which dealt mainly with electrical and me-

chanical issues. The IEEE 488.2 recommendations have also

been adopted for RS-232-C communications whenever applica-

ble.

To remotely control the oscilloscope the controller must send pro-

gram messages which conform to precise format structures. The

instrument will execute all program messages which are in the cor-

rect form and ignore those where errors are detected.

This standard may be seen as an extension of the

Page 10

About Remote Control

Warning or error messages are normally not reported by the instrument, unless the controller explicitly examines the relevant status

register, or if the status enable registers have been set in such a way

that the controller can be interrupted when an error occurs. The

status registers are explained in Section 7.

During the development of the control program it is possible to

observe all remote control transactions, including error messages,

on an external monitor connected to the RS-232-C port. Refer to

the command "COMM_HELP" for further details.

COMMANDS

AND QUERIES

Program messages consist of one or several commands or queries.

A command directs the instrument to change its state, e.g. to

change its time base or vertical sensitivity. A query asks the instrument about its state. Very often, the same mnemonic is used for a

command and a query, the query being identified by a <?> after

the last character.

For example, to change the time base to 2 msec/div, the controller

should send the following command to the instrument

TIME DIV 2 MS

To ask the instrument about its time base, this query should be

sent

TIME DIV?

A query causes the instrument to send a response message. The

control program should read this message with a "read" instruc-

tion to the GPIB or RS-232-C interface of the controller. The

response message to the query above might be

TIME DIV 10 NS

m

The portion of the query preceding the question mark is repeated

as part of the response message. If desired, this text may be suppressed with the command "COMM_HEADER".

Depending on the state of the instrument and the computation to

be done, the controller may have to wait up to several seconds for

a response. Command interpretation does not have priority over

other oscilloscope activities. It is therefore judicious to set the controller IO timeout conditions to 3 or more seconds. In addition, it

must be remembered that an incorrect query message will not generate a response message.

4

Page 11

About Remote Control 2

LOCAL AND REMOTE

STATE

PROGRAM MESSAGE

FORM

As a rule, remote commands are only executed by the instrument

when it is in the REMOTE state, whereas queries are always executed. A few commands which don’t affect the state of the front

panel are also executed in LOCAL (refer to the beginning of Section 5 for a list of these commands). When the instrument is in

REMOTE, all front-panel controls are disabled, except the lefthand menu buttons, the intensity controls (which can be disabled

with the command "INTENSITY") and the LOCAL button

(which can be disabled by setting the instrument to LOCAL

LOCKOUT). For an explanation on how to set the instrument to

LOCAL, REMOTE or LOCAL LOCKOUT, refer to Section 3 for

GPIB and to Section 4 for RS-232-C.

An instrument is remotely controlled with program messages

which consist of one or several commands or queries, separated by

semicolons <;> and ended by a terminator:

<command/query>; .........

Upper and/or lower case characters can be used for program messages.

The instrument does not decode an incoming program message

before a terminator has been received (exception: if the program

message is longer than the 256 byte input buffer of the instrument,

the oscilloscope starts analyzing the message when the buffer is

full). The commands or queries are executed in the order in which

they are transmitted.

In GPIB mode, the following are valid terminators:

<NL> New-line character (i.e. the ASCII new-line

character, whose decimal value is 10).

<NL> <EOI> New-line character with a simultaneous <EOI>

signal.

<EOI> <EOI> signal together with the last character of

the program message.

Note: The <EOI> signal is a dedicated GPIB interface line which

can be set with a special call to the GPIB interface driver. Refer to

the GPIB interface manufacturer’s manual and support programs.

The <NL> <EOI> terminator is always used in response messages

sent by the instrument to the controller.

In RS-232-C, the terminator may be defined by the user with the

command "COMM_RS232". The default value is <CR>, i.e. the

ASCII carriage return character, the decimal value of which is 13.

;<command/query> <terminator>

Page 12

About Remote Control

|

|

Examples

COMMAND/QUERY

FORM

Example

GRID DUAL This program message consists of a

single command which instructs the

instrument to display a dual grid.

The terminator is not shown since it

is usually automatically added by

the interface driver routine which

writes to the GPIB (or RS-232).

BWL ON; DISPLAY OFF; DATE?

This program message consists of

two commands, followed by a

query. They instruct the instrument

to turn on the bandwidth limit, turn

off the display, and then ask for the

current date. Again, the terminator

is not shown.

The general form of a command or a query consists of a command

header <header> which is optionally followed by one or several

parameters <data> separated by commas:

<header>[?] <data> .....

The notation [?] shows that the question mark is optional (turning

the command into a query). The detailed listing of all commands

in Section 5 indicates which commands may also be queries.

There is a space between the header and the first parameter.

There are commas between parameters.

DATE 15,OCT,1989,13,21,16

<data>

This command instructs the oscillo-

scope to set its date and time to 15

OCT 1989, 13:21:16. The command header "DATE" indicates

the action, the 6 data values specify

it in detail.

|

|

|

|

I

1

I

|

|

|

1

Header

6

The header is the mnemonic form of the operation to be per-

formed by the oscilloscope. All command mnemonics are listed in

alphabetic order in Section 5.

The majority of the command/query headers have a long form for

optimum legibility and a short form for better transfer and decoding speed. The two forms are fully equivalent and can be used

interchangeably. For example, the following two commands for

switching to the automatic trigger mode are fully equivalent:

TRIG_MODE AUTO and TRMD AUTO

|

1

|

|

|

Page 13

About Remote Control 2

Some command/query mnemonics are imposed by the IEEE

488.2 standard. They are standardized so that different instruments present the same programming interface for similar

functions. All these mnemonics begin with an asterisk <*>, e.g.

the command "*RST" is the IEEE 488.2 imposed mnemonic for

resetting the instrument, whereas "*TST?" instructs the instrument to perform an internal self-test and to report the outcome.

Header path

Example

Some commands or queries apply to a sub-section of the oscilloscope, e.g. a single input channel or a trace on the display. In such

cases, the header must be preceded by a path name that indicates

the channel or trace to which the command applies. The header

path normally consists of a 2-letter path name followed by a colon

<:> which immediately precedes the command header.

Usually one of the waveform traces can be specified in the header

path (refer to the individual commands listed in Section 5 for details on which values apply to a given command header):

C1, C2

C3, C4

MC, MD

FE, FF Function E and F

EA, EB

EX, EX10 External trigger

CI:OFST -300 MV Set the offset of Channel 1 to

Header paths need only be specified once. Subsequent commands

whose header destination is not indicated are assumed to refer to

the last defined path. For example, the following commands are

identical:

C2:VDIV?; C2:OFST?

C2:VDIV?; OFST?

Channels 1 and 2

Channels 3 and 4 (in 4-channel instruments)

Memory C and D

Expand A and B

-300 mV

What is the vertical sensitivity and

the offset of channel 2?

Same as above, without repeating

the path.

Data

Whenever a command/query uses additional data values, they are

expressed in terms of ASCII characters. There is a single excep-

tion: the transfer of waveforms with the command/query

"WAVEFORM", where the waveform may be expressed as a sequence of binary data values. Refer to Section 6 for a detailed

explanation of the format of waveforms.

ASCII data can have the form of character, numeric, string or

block data.

Page 14

About Remote Control

|

|

Character data

Numeric Data

These are simple words or abbreviations for the indication of a

specific action.

BANDWIDTH LIMIT ON The data value "ON" indicates that

the bandwidth limit should be

turned on, rather than off.

In some commands, where as many as a dozen different parame-

ters can be specified, or where not all parameters apply at the same

time, the format requires pairs of data values. The first one names

the parameter to be modified and the second gives its value. Only

those parameter pairs to be changed need to be indicated.

HARDCOPY_SETUP DEV,HP7470A,PORT,GPIB,PSIZE,A4

Three pairs of parameters are specified. The first specifies the device

as the H7470A plotter (or compatible), the second indicates the

GPIB port and the third requests

the A4 format for paper size. While

the command "HARDCOPY SET-

UP" allows many more parameters,

they are either not relevant for plot-

ters or they are left unchanged.

The numeric data type is used to enter quantitative information.

Numbers can be entered as integers, as fractions or in exponential

representation.

EA:VPOS -5 Move the displayed trace of Expand A down-

wards by 5 divisions.

C2"OFST 3.56 Set the DC offset of Channel 2 to 3.56 V.

TDIV 5.0E-6 Adjust the time base to 5 issec/div.

Note: Numeric values may be followed by multipliers and units,

modifying the value of the numerical expression. The following

mnemonics are recognized:

|

|

|

|

|

|

|

|

|

II

|

II

II

II

|

|

Page 15

i

About Remote Control 2

I

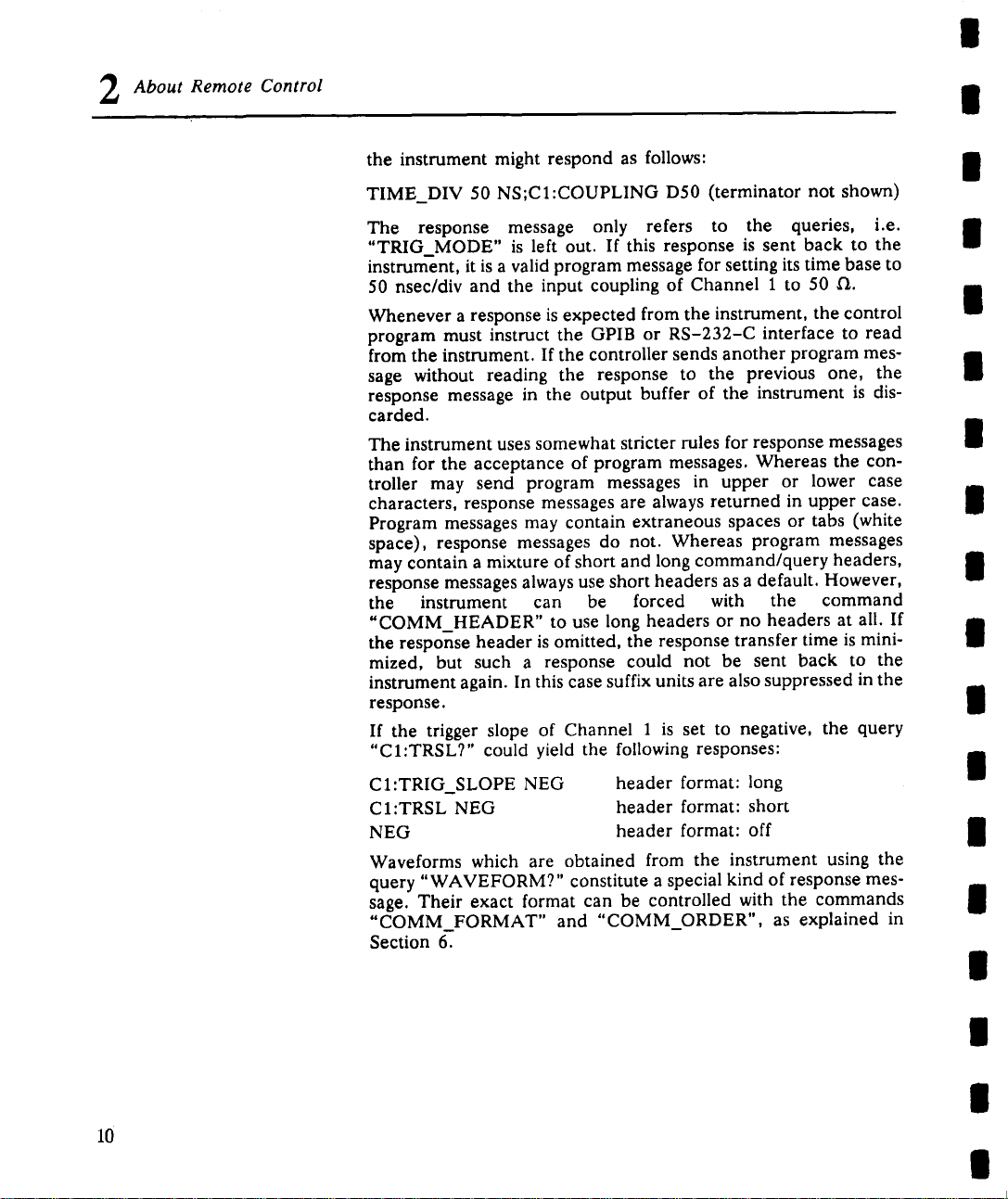

EX

l

l

I

T 1E 12 Tera- G 1E9 Giga-

MA 1E6 Mega- K 1E3 kilo-

M

N 1E-9 nano- PI 1E-12

F 1E-15 femto- A 1E-18 atto-

For example, there are many ways of setting the time base of the

instrument to 5 ~tsec/div:

TDIV 5E-6

1E18

1E-3 milli- U 1E-6 micro-

I

TDIV 5 US

l

TDIV 5000 NS

TDIV 5000E-3 US

String Data

This data type enables the transfer of a (long) string of characters

as a single parameter. String data are formed by simply enclosing

any sequence of ASCII characters between simple or double

quotes.

MESSAGE ’Connect probe to point J3’

The instrument displays this message in the Message field above

the grid.

Exa-

PE

Exponential notation, without any

suffix.

Suffix multiplier "U" for 1E-6,

with the (optional) suffix "S" for

seconds.

1E15

Peta-

pico-

Block Data

RESPONSE MESSAGE

FORM

These are binary data values coded in hexadecimal ASCII, i.e.

4-bit nibbles are translated into the digits 0,...9, A .... F and trans-

mitted as ASCII characters. They are only used for the transfer of

waveforms (command "WAVEFORM") and of the instrument

configuration (command "PANEL_SETUP")

The instrument sends a response message to the controller, as an

answer to a query. The format of such messages is the same as that

of program messages, i.e. individual responses in the format of

commands, separated by semicolons <;> and ended by a terminator. They can be sent back to the instrument in the form in which

they are received, and will be accepted as valid commands. In

GPIB response messages, the <NL> <EOI> terminator is always

used.

For example, if the controller sends the program message:

TIME_DIV? ;TRIG_MODE NORM;C 1 :COUPLING? (terminator

not shown)

Page 16

About Remote Control

|

|

the instrument might respond as follows:

TIME_DIV 50 NS;C 1:COUPLING D50 (terminator not shown)

The response message only refers to the queries, i.e.

"TRIG_MODE" is left out. If this response is sent back to the

instrument, it is a valid program message for setting its time base to

50 nsec/div and the input coupling of Channel 1 to 50 ~.

Whenever a response is expected from the instrument, the control

program must instruct the GPIB or RS-232-C interface to read

from the instrument. If the controller sends another program message without reading the response to the previous one, the

response message in the output buffer of the instrument is discarded.

The instrument uses somewhat stricter rules for response messages

than for the acceptance of program messages, Whereas the con-

troller may send program messages in upper or lower case

characters, response messages are always returned in upper case.

Program messages may contain extraneous spaces or tabs (white

space), response messages do not. Whereas program messages

may contain a mixture of short and long command/query headers,

response messages always use short headers as a default. However,

the instrument can be forced with the command

"COMM_HEADER" to use long headers or no headers at all. If

the response header is omitted, the response transfer time is mini-

mized, but such a response could not be sent back to the

instrument again. In this case suffix units are also suppressed in the

response.

If the trigger slope of Channel 1 is set to negative, the query

"CI:TRSL?" could yield the following responses:

CI:TRIG_SLOPE NEG

CI:TRSL NEG

NEG

Waveforms which are obtained from the instrument using the

query "WAVEFORM?" constitute a special kind of response mes-

sage. Their exact format can be controlled with the commands

"COMM FORMAT" and "COMM ORDER", as explained in

Section ~

header format: long

header format: short

header format: off

|

|

|

|

|

|

|

|

|

|

|

|

|

10

|

|

|

Page 17

|

GPIB OPERATION

I

3

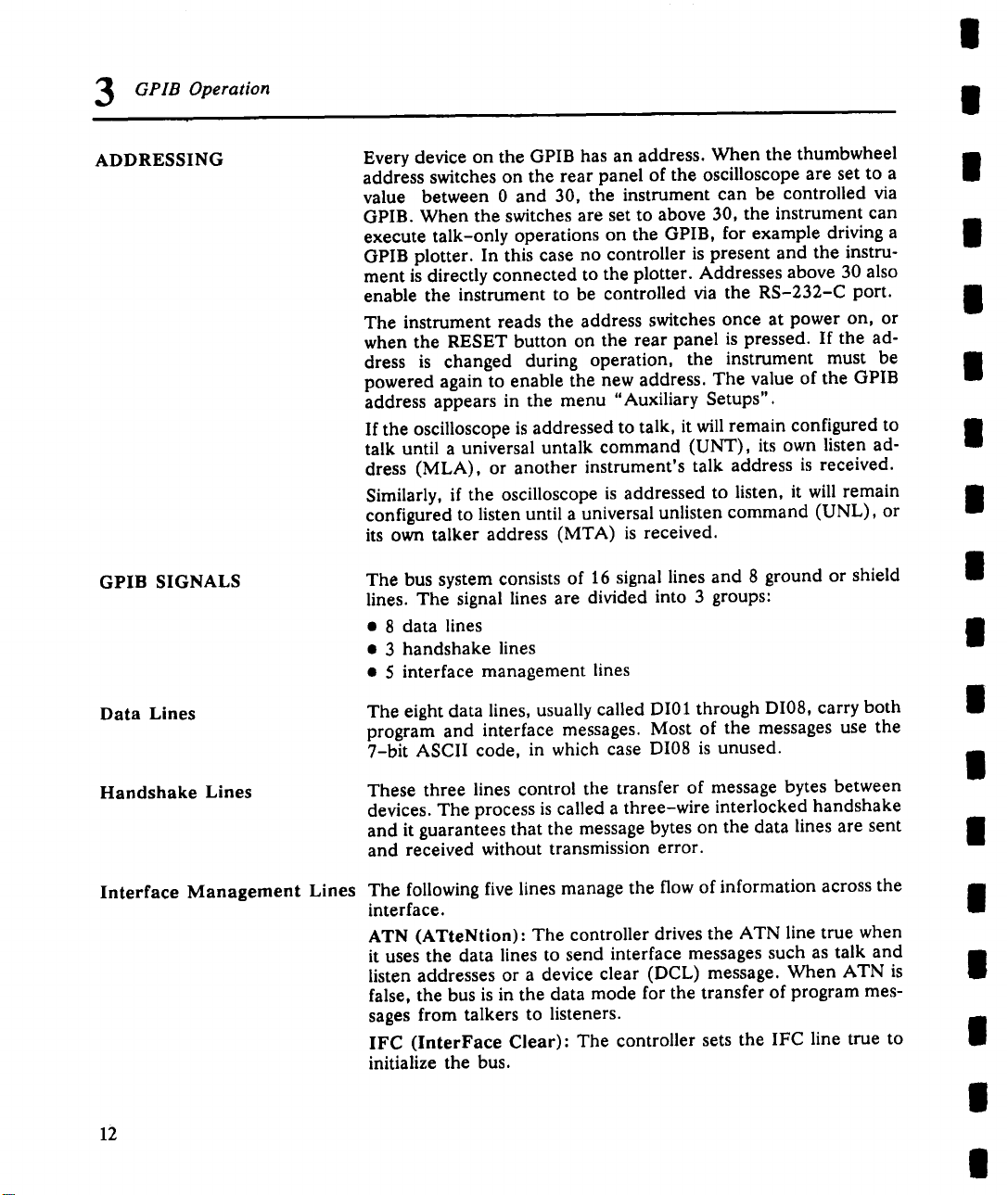

|

This section describes how to remotely control the oscilloscope via

the GPIB. Topics discussed include interface capabilities, addressing, standard bus commands, and polling schemes.

GPIB STRUCTURE

INTERFACE

CAPABILITIES The interface capabilities of the oscilloscope include the following

The GPIB is like an ordinary computer bus, except that it interconnects independent devices via a cable bus whereas a computer

has its circuit cards interconnected via a backplane bus. The GPIB

carries program messages and interface messages:

¯ Program messages, often called device-dependent messages,

contain programming instructions, measurement results, instrument status and waveform data. Their general form is

described in Section 2.

¯

Interface messages manage the bus itself. They perform functions such as initializing the bus, addressing and unaddressing

devices and setting remote and local modes.

Devices on the GPIB can be listeners, talkers, and/or controllers.

A talker sends program messages to one or more listeners. A controller manages the flow of information on the bus by sending

interface messages to the devices.

The oscilloscope can be a talker or a listener, but not a controller.

The host computer, however, must be able to act as a listener,

talker and controller. For details on how the controller configures

the GPIB for specific functions, refer to the GPIB interface manufacturer’s manual.

IEEE 488.1 definitions:

AH1

SH1

L4

T5

SR1

RL1

DC1

DT1

PP1

CO

E2

Complete Acceptor Handshake

Complete Source Handshake

Partial Listener Function

Complete Talker Function

Complete Service Request Function

Complete Remote/Local Function

Complete Device Clear Function

Complete Device Trigger

Parallel Polling: remote configurability

No Controller Functions

Tri-state Drivers

11

Page 18

GPIB Operation

|

|

ADDRESSING

GPIB SIGNALS

Every device on the GPIB has an address. When the thumbwheel

address switches on the rear panel of the oscilloscope are set to a

value between 0 and 30, the instrument can be controlled via

GPIB. When the switches are set to above 30, the instrument can

execute talk-only operations on the GPIB, for example driving a

GPIB plotter. In this case no controller is present and the instrument is directly connected to the plotter. Addresses above 30 also

enable the instrument to be controlled via the RS-232-C port.

The instrument reads the address switches once at power on, or

when the RESET button on the rear panel is pressed. If the address is changed during operation, the instrument must be

powered again to enable the new address. The value of the GPIB

address appears in the menu "Auxiliary Setups".

If the oscilloscope is addressed to talk, it will remain configured to

talk until a universal untalk command (UNT), its own listen ad-

dress (MLA), or another instrument’s talk address is received.

Similarly, if the oscilloscope is addressed to listen, it will remain

configured to listen until a universal unlisten command (UNL),

its own talker address (MTA) is received.

The bus system consists of 16 signal lines and 8 ground or shield

lines. The signal lines are divided into 3 groups:

¯

8 data lines

¯

3 handshake lines

¯

5 interface management lines

II

n

i

l

l

l

II

II

Data Lines

Handshake Lines

Interface Management Lines

12

The eight data lines, usually called DI01 through DI08, carry both

program and interface messages. Most of the messages use the

7-bit ASCII code, in which case DI08 is unused.

These three lines control the transfer of message bytes between

devices. The process is called a three-wire interlocked handshake

and it guarantees that the message bytes on the data lines are sent

and received without transmission error.

The following five lines manage the flow of information across the

interface.

ATN (ATteNtion): The controller drives the ATN line true when

it uses the data lines to send interface messages such as talk and

listen addresses or a device clear (DCL) message. When ATN

false, the bus is in the data mode for the transfer of program messages from talkers to listeners.

IFC (InterFace Clear): The controller sets the IFC line true

initialize the bus.

II

II

II

n

II

g

g

II

Page 19

n

|

|

GPIB Operation 3

REN (Remote ENable): The controller uses this line to place devices in remote or local program mode.

SRQ (Service ReQuest): Any device can drive the SRQ line true

to asynchronously request service from the controller. This is the

equivalent of a single interrupt line on a computer bus.

EOI (End Or Identify): This line has two purposes. The talker

uses it to mark the end of a message string. The controller uses it to

tell devices to identify their response in a parallel poll (discussed

later in this section).

I/O Buffers

IEEE 488.1

STANDARD MESSAGES

The instrument has a 256-byte input buffer and a 256-byte output

buffer. An incoming program message is not decoded before a

message terminator has been received. However, if the input buffer becomes full (because the program message is longer than the

buffer), the instrument starts analyzing the message. In this case

data transmission is temporarily halted, and the controller may

generate a timeout if the limit was set too low.

The IEEE 488.1 standard specifies not only the mechanical and

electrical aspects of the GPIB, but also the low-level transfer pro-

tocol, e.g. it defines how a controller addresses devices, turns

them into talkers or listeners, resets them or puts them in the remote state. Such interface messages are executed with the

interface management lines of the GPIB, usually with ATN true.

All of these messages (except GET) are executed immediately

upon reception and not in chronological order with normal com-

mands.

Note: In addition to the IEEE 488.1 interface message standards,

the IEEE 488.2 standard specifies some standardized program

messages, i.e. command headers. They are identified with a leading asterisk <*> and are listed among the commands in Section 5.

The command list in Section 5 does not contain any command for

clearing the input/output buffers or for setting the instrument to

the remote state. This is because such commands are already spe-

cified as IEEE 488.1 standard messages. Refer to the GPIB

interface manual of the host controller as well as to its support

programs which should contain special calls for the execution of

these messages.

The following describes those IEEE 488.1 standard messages

which go beyond mere reconfiguration of the bus and which have

an effect on the operation of the instrument.

Device Clear

In response to a universal Device CLear (DCL) or a Selected Device Clear message (SDC), the oscilloscope clears the input/output

13

Page 20

GPIB Operation

buffers, aborts the interpretation of the current command (if any)

and clears any pending commands. Status registers and status en-

able registers are not cleared. Although DCL has an immediate

effect it can take several seconds to execute this command if the

instrument is busy.

I

I

I

I

Group Execute Trigger

Remote ENable

Local LOckout

Go To Local

The Group Execute Trigger message (GET) causes the oscillo-

scope to arm the trigger system. It is functionally identical to the

"*TRG" command.

This interface message is executed when the controller holds the

Remote ENable control line (REN) true and configures the instrument as a listener. The REMOTE LED on the front panel lights up

to indicate that the instrument is set to the remote mode. All the

front-panel controls are disabled except the left-hand menu but-

tons, the intensity controls and the LOCAL button. The menu

indications on the left-hand side of the screen no longer appear

since menus cannot now be operated manually. Whenever the

controller returns the REN line to false, all instruments on the bus

return to LOCAL. Individual instruments can be returned to LO-

CAL with the Go To Local message (see below).

As a rule, remote commands are only executed when the instru-

ment is in the remote state, whereas queries are always executed.

Local front-panel control may be regained by pressing the LO-

CAL push button, unless the instrument was placed in the Local

LOckout (LLO) mode.

The Local LOckout command (LLO) causes the LOCAL button

on the front panel of the oscilloscope to be disabled. The LLO

command can be sent in local or remote mode but only becomes

effective once the instrument has been set to the remote mode.

The Go To Local message (GTL) causes the instrument to return

to the local mode. All front-panel controls become active and the

menus on the left-hand side of the screen reappear. Thereafter,

whenever the instrument is addressed as a listener it will be imme-

diately set to the remote state again.

Note that a GTL message does not clear the local lockout if it was

set. Thus, whenever the instrument returns to the remote state the

local lockout mode would immediately be effective again.

A command string should not be immediately followed by a GTL

message. Since GTL is executed at once, the instrument may already be returned to the local state before the commands in the

input buffer are interpreted. Therefore, the instrument may refuse

to execute them if they require the instrument to be in REMOTE.

I

I

I

I

I

I

I

I

I

I

I

I

14

I

I

Page 21

GPIB Operation 3

A safe way to ensure that all commands have been interpreted is to

append a query (e.g. "*STB?") to the command string and to wait

for the response before sending a GTL.

InterFace Clear

PROGRAMMING

GPIB TRANSFERS

Configuring the

GPIB Hardware

The InterFace Clear message (IFC) initializes the GPIB but has

effect on the operation of the oscilloscope.

To illustrate the GPIB programming concepts a number of examples written in BASICA are included in this section. It is assumed

that the controller is IBM-PC compatible, running under DOS,

and that it is equipped with a National Instruments2 GPIB inter-

face card. GPIB programming with other languages such as C or

Pascal is quite similar.

If you use another computer or another GPIB interface, refer to

the interface manual for installation procedures and subroutine

calls similar to those described here.

Check that the GPIB interface is properly installed in the comput-

er. If it is not, follow the installation instructions of the interface

manufacturer. In the case of the National Instruments interface, it

is possible to modify the base I/O address of the board, the DMA

channel number and the interrupt line setting using switches and

jumpers. In our program examples, they are assumed to be left in

their default positions.

Connect the oscilloscope to the computer with a GPIB interface

cable. Set the GPIB address on the rear of the instrument to the

required value. The program examples assume that it is set to 4.

Remember to power the instrument up after setting the GPIB ad-

dress.

Configuring the

GPIB Driver Software

National Instruments Corporation,

2.

The host computer needs an interface driver which handles the

transactions between the user’s programs and the interface board.

In the case of the National Instruments interface, the installation

procedure:

¯ copies the GPIB handler GPIB.COM into the boot directory.

¯ modifies the DOS system configuration file CONFIG.SYS to

declare the presence of the GPIB handler.

¯ creates a sub-directory GPIB-PC.

¯ installs in GPIB-PC a number of files and programs which are

useful for testing and reconfiguring the system, and for writing

user programs.

12109 Technology Boulevard, Austin, Texas 78727

15

Page 22

GPIB Operation

The following files in the sub-directory GPIB-PC are of particular

use:

IBIC. EXE allows interactive control of the GPIB via functions en-

tered at the keyboard. Use of this program is highly recommended

to anyone who is not familiar with GPIB programming or with the

oscilloscope’s remote commands. An example of the use of

IBIC.EXE is shown in Appendix A.

DECL.BAS is a declaration file that contains code to be included

at the beginning of any BASICA application program. Simple

application programs can be quickly written by appending the

user’s instructions to DECL.BAS and executing the complete file.

IBCONF.EXE is an interactive program which allows inspection

or modification of the current settings of the GPIB handler. To run

IBCONF.EXE, refer to the National Instruments user’s manual.

In the program examples in this section, it is assumed that the

National Instruments GPIB driver GPIB.COM is in its default

state, i.e. that the user has not modified it with IBCONF.EXE.

This means that the interface board can be referred to by the symbolic name ’GPIB0’ and that devices on the GPlB bus with

addresses between 1 and 16 can be called by the symbolic names

’DEVI’ to ’DEV16’.

Note: If you have a National Instruments PC2 interface card rather than PC2A, you must run IBCONF to declare the presence of

this card rather than the default PC2A.

|

|

l

|

II

I

l

II

II

II

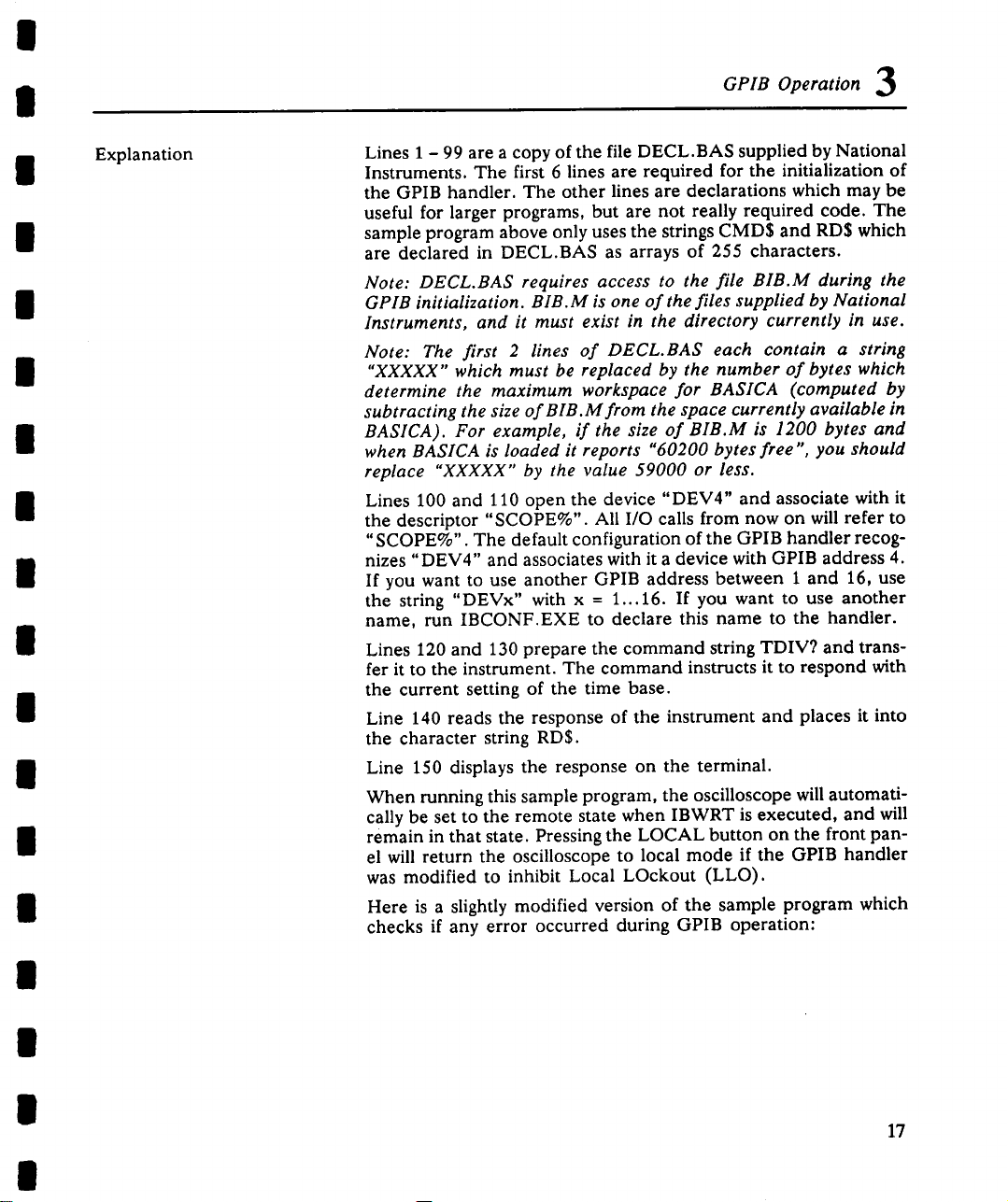

Simple Transfers

16

For a large number of remote control operations it is sufficient to

use just 3 different subroutines (IBFIND, IBRD and IBWRT) pro-

vided by National Instruments. The following complete program

reads the time-base setting of the oscilloscope and displays it on

the terminal:

1-99

100

110

120

130

140

150

160

<DECL.BAS>

DEV$="DEV4"

CALL IBFIND(DEV$,SCOPE%)

CMD$="TDIV?"

CALL IBWRT(SCOPE%,CMD$)

CALL IBRD(SCOPE%,RD$)

PRINT RD$

END

II

II

II

II

II

II

II

II

Page 23

GPIB Operation 3

Explanation

Lines 1 - 99 are a copy of the file DECL.BAS supplied by National

Instruments. The first 6 lines are required for the initialization of

the GPIB handler. The other lines are declarations which may be

useful for larger programs, but are not really required code. The

sample program above only uses the strings CMD$ and RD$ which

are declared in DECL.BAS as arrays of 255 characters.

Note: DECL.BAS requires access to the file BIB.M during the

GPIB initialization. BIB.M is one of the files supplied by National

Instruments, and it must exist in the directory currently in use.

Note: The first 2 lines of DECL.BAS each contain a string

"XXXXX" which must be replaced by the number of bytes which

determine the maximum workspace for BASICA (computed by

subtracting the size of BIB.M from the space currently available in

BASICA). For example, if the size of BIB.M is 1200 bytes and

when BASICA is loaded it reports "60200 bytes free ", you should

replace "XXXXX" by the value 59000 or less.

Lines 100 and 110 open the device "DEV4" and associate with it

the descriptor "SCOPE%". All I/O calls from now on will refer to

"SCOPE%". The default configuration of the GPIB handler recog-

"DEV4"

nizes

If you want to use another GPIB address between 1 and 16, use

the string "DEVx" with x = 1...16. If you want to use another

name, run IBCONF.EXE to declare this name to the handler.

Lines 120 and 130 prepare the command string TDIV? and trans-

fer it to the instrument. The command instructs it to respond with

the current setting of the time base.

Line 140 reads the response of the instrument and places it into

the character string RD$.

Line 150 displays the response on the terminal.

When running this sample program, the oscilloscope will automati-

cally be set to the remote state when IBWRT is executed, and will

remain in that state. Pressing the LOCAL button on the front pan-

el will return the oscilloscope to local mode if the GPIB handler

was modified to inhibit Local LOckout (LLO).

Here is a slightly modified version of the sample program which

checks if any error occurred during GPIB operation:

and associates with it a device with GPIB address 4.

17

Page 24

GPIB Operation

|

|

Some Additional

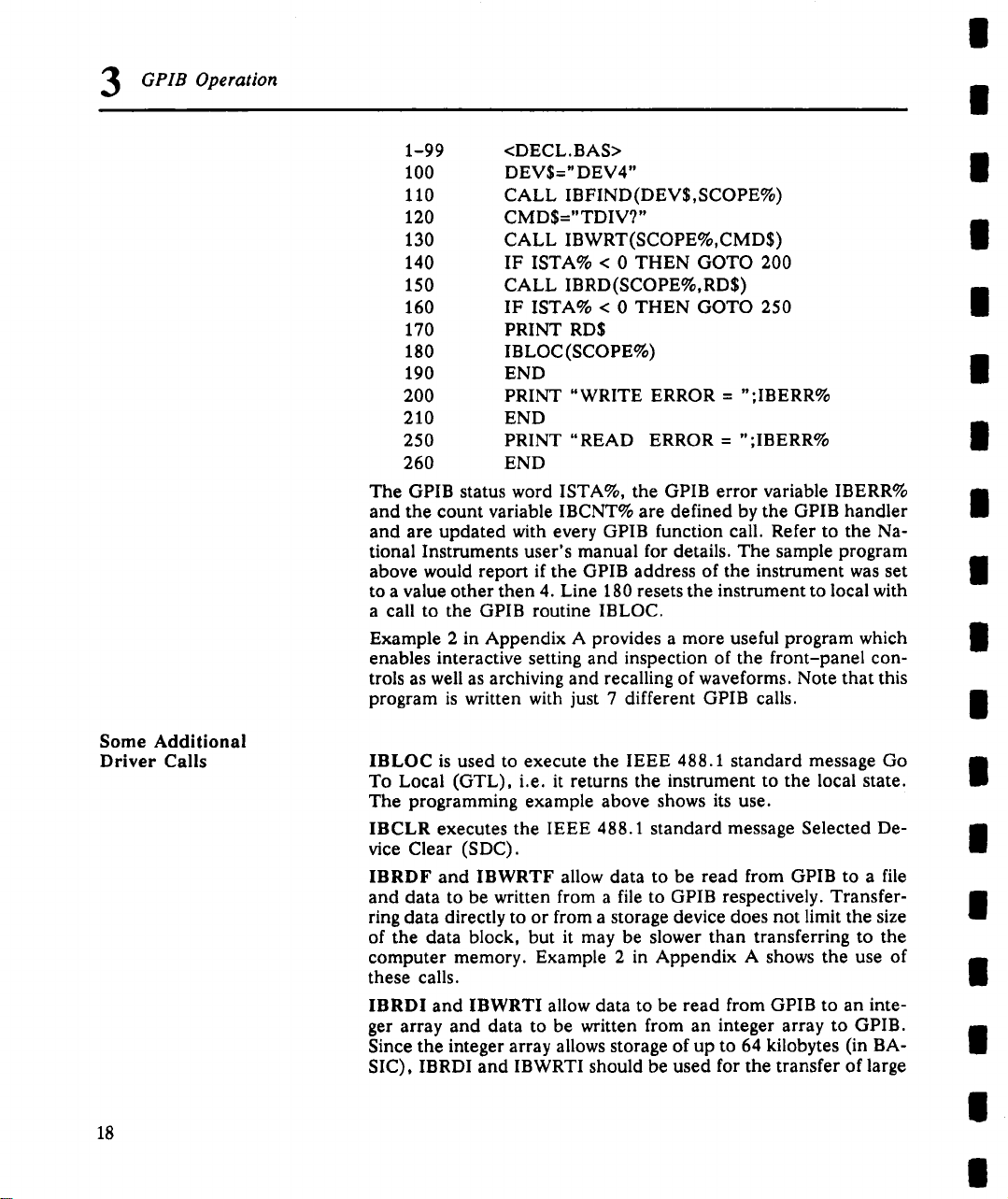

Driver Calls

1-99

100

110

120

130

140

150

160

170

180

190

200

210

25O

260

The GPIB status word ISTA%, the GPIB error variable IBERR%

and the count variable IBCNT% are defined by the GPIB handler

and are updated with every GPIB function call. Refer to the Na-

tional Instruments user’s manual for details. The sample program

above would report if the GPIB address of the instrument was set

to a value other then 4. Line 180 resets the instrument to local with

a call to the GPIB routine IBLOC.

Example 2 in Appendix A provides a more useful program which

enables interactive setting and inspection of the front-panel controis as well as archiving and recalling of waveforms. Note that this

program is written with just 7 different GPIB calls.

IBLOC is used to execute the IEEE 488.1 standard message Go

To Local (GTL), i.e. it returns the instrument to the local state.

The programming example above shows its use.

IBCLR executes the IEEE 488.1 standard message Selected De-

vice Clear (SDC).

IBRDF and IBWRTF allow data to be read from GPIB to a file

and data to be written from a file to GPIB respectively. Transferring data directly to or from a storage device does not limit the size

of the data block, but it may be slower than transferring to the

computer memory. Example 2 in Appendix A shows the use of

these calls.

IBRDI and IBWRTI allow data to be read from GPIB to an integer array and data to be written from an integer array to GPIB.

Since the integer array allows storage of up to 64 kilobytes (in BA-

SIC), IBRDI and IBWRTI should be used for the transfer of large

<DECL.BAS>

DEV$=" DEV4"

CALL IBFIND(DEV$,SCOPE%)

CMD$="TDIV?"

CALL IBWRT(SCOPE%,CMD$)

IF ISTA% < 0 THEN GOTO 200

CALL IBRD(SCOPE%,RD$)

IF ISTA% < 0 THEN GOTO 250

PRINT RD$

IBLOC(SCOPE%)

END

PRINT "WRITE ERROR = ";IBERR%

END

PRINT "READ ERROR = ";IBERR%

END

I

II

l

I

il

II

n

l

ii

m

ii

il

II

n

18

ti

II

Page 25

PROGRAMMING

SERVICE REQUESTS

GPIB Operation 3

data blocks to the computer memory, rather than IBRD or IBWRT

which are limited to 256 bytes by the BASIC string length. Note

that IBRDI and IBWRTI only exist for BASIC, since the function

calls IBRD and IBWRT for more modem programming languages,

such as C, are much less limited in the data block size.

IBTMO can be used to change the time-out value during program

execution. The default value of the GPIB driver is 10 seconds, e.g.

if the instrument does not respond to a IBRD call, IBRD will return

with an error after the specified time.

IBTRG executes the IEEE 488.1 standard message Group Execute Trigger (GET), which causes the oscilloscope to arm the

trigger system.

National Instruments supply a number of additional function calls.

In particular, it is possible to use the so-called board level calls

which allow a very detailed control of the GPIB. The use of such

calls is shown in Example 3 of Appendix A.

When an oscilloscope is used in a remote application, events often

occur asynchronously, i.e. at times that are unpredictable for the

host computer. The most common case is waiting for a trigger after

the instrument has been armed. The controller must wait until the

acquisition is finished before it can read the acquired waveform.

The simplest way of checking if a certain event has occurred is by

continuously or periodically reading the status bit associated with it

until the required transition is detected. Continuous status bit poll-

ing is described in more detail in the sub-section "Instrument

Polls". For a complete explanation of the status bytes refer to Section 7.

A potentially more efficient way of detecting events occurring in

the instrument is the use of the Service Request (SRQ). This GPIB

interrupt line can be used to interrupt program execution in the

controller. Therefore, the controller can execute other programs

while waiting for the instrument. Unfortunately, not all interface

manufacturers support the programming of interrupt service routines. In particular, National Instruments only supports the SRQ

bit within the ISTA% status word. This requires the user to continuously or periodically check this word, either explicitly or with the

function call IBWAIT. In the absence of real interrupt service routines the use of SRQ may not be very advantageous.

In the default state, after power-on, the Service ReQuest is disabled. The SRQ is enabled by setting the Service Request Enable

register with the command "*SRE" and specifying which event

should generate an SRQ. The oscilloscope will interrupt the con-

19

Page 26

GPIB Operation

3

troller as soon as the selected event(s) occur by asserting the SRQ

interface line. If several devices are connected to the GPIB, the

controller may have to identify which instrument caused the inter-

rupt by serial polling the various devices.

Note: The SRQ bit is latched until the controller reads the STatus

Byte Register (STB). The action of reading the STB with the com-

mand "*STB?" clears the register contents except the MAV bit

(bit 4) until a new event occurs. Service requesting may be dis-

abled by clearing the SRE register ("*SRE 0").

|

|

II

II

l

Example 1

Example 2

To assert SRQ in response to the events "new signal acquired"

or "return-to-local" (pressing the front-panel button LO-

CAL).

These events are tracked by the INR register which is reflected in

the SRE register as the INB summary bit in position 0. Since the bit

position 0 has the value 1, the command "*SRE 1" enables the

generation of SRQ whenever the INB summary bit is set.

In addition, the events of the INR register which may be summa-

rized in the INB bit must be specified. The event "new signal

acquired" corresponds to INE bit 0 (value 1) while the event "re-

turn-to-local" is assigned to INE bit 2 (value 4). The total sum

1+4=5. Thus the command "INE 5" is needed.

CMD$="INE 5;*SRE 1"

CALL IBWRT(SCOPE%,CMD$)

To assert SRQ when soft key 10 is pressed.

The event "soft key 10 pressed" is tracked by the URR register.

Since the URR register is not directly reflected in STB but only in

the ESR register (URR, bit position 6), the ESE enable register

must be set first with the command "*ESE 64" to allow the URQ

setting to be reported in STB. An SRQ request will now be gener-

ated provided that the ESB summary bit (bit position 5) in the SRE

enable register is set ("*SRE 32").

CMD$="*ESE 64;*SRE 32"

CALL IBWRT(SCOPE%,CMD$)

l

I

I

II

l

l

I!

n

II

2O

II

II

II

II

Page 27

GPIB Operation 3

INSTRUMENT POLLS

Continuous Poll

State transitions occurring within the instrument can be remotely

monitored by polling selected internal status registers. This subsection discusses a number of polling methods which may be used

to detect the occurrence of a given event.

1. Continuous poll

2. Serial poll

Parallel poll

3.

4. *IST poll

To emphasize the differences between these methods, the same

example will be presented in each case, i.e. determining if a new

acquisition has taken place. By far the simplest poll is the continuous poll. The other methods only make sense if interrupt service

routines (servicing the SRQ line) are supported or if multiple devices on GPIB must be monitored simultaneously.

In continuous polling a status register is continuously monitored

until a transition is observed. This is the most straightforward

method for detecting state changes but may be impracticable in

some situations, especially in multiple device configurations.

In the following example, the event "new signal acquired" is ob-

served by continuously polling the INternal state change Register

(INR) until the corresponding bit (in this case bit 0, i.e. value 1)

non-zero to indicate that a new waveform has been acquired.

Reading INR clears it at the same time so that there is no need for

an additional clearing action after a non-zero value has been detected. The command "CHDR OFF" instructs the instrument to

omit any command headers when responding to a query. This simplifies the decoding of the response. The instrument would

therefore send "1" rather than "INR 1".

CMD$="CHDR OFF"

CALL IBWRT(SCOPE%,CMD$)

MASK% = 1

LOOP% = 1

WHILE LOOP%

CMD$="INR?"

CALL IBWRT(SCOPE%,CMD$)

CALL IBRD(SCOPE%,RD$)

NEWSIG% = VAL(RD$) AND MASK%

IF NEWSIG% = MASK% THEN LOOP% = 0

WEND

’New Signal Bit has value 1

21

Page 28

GPIB Operation

3

|

|

Serial Poll

Serial polling takes place once the SRQ interrupt line has been

asserted. The controller examines which instrument has generated

the interrupt by inspecting the SRQ bit in the STB register of each

instrument. Because service request is based on an interrupt mech-

anism, serial polling offers a reasonable compromise in terms of

servicing speed in multiple device configurations.

In the following example, the command "INE 1" enables the

event "new signal acquired" to be reported in the INR to the INB

bit of the status byte STB. The command "*SRE 1" enables the

INB of the status byte to generate an SRQ whenever it is set. The

function call IBWAIT instructs the computer to wait until one of

three conditions occur: &Hg000 in the mask (MASK%) corresponds to a GPIB error, &H4000 to a time-out error and &H0800

to the detection of RQS (ReQuest for Service generated by the

SRQ bit).

Whenever IBWAIT detects RQS it automatically performs a serial

poll to find out which instrument generated the interrupt. It will

only exit if there was a time-out or if the instrument "SCOPE%"

generated SRQ. The additional function call IBRSP fetches the

value of the status byte which may be further interpreted. For this

example to function properly the value of ’Disable Auto Serial

Polling’ must be set ’off’ in the GPIB handler (use IBCONF.EXE

to check).

CMD$="*CLS; INE 1; *SRE 1"

CALL IBWRT(SCOPE%,CMD$)

MASK% = &HCg00

CALL IBWAIT(SCOPE%,MASK%)

IF (IBSTA% AND &HC000) <> 0 THEN PRINT "GPIB

Time-out Error" : STOP

CALL IBRSP(SCOPE%,SPR%)

PRINT "Status Byte = ", SPR%

Note: After the serial poll is completed, the RQS bit in the STB

status register is cleared. Note that the other STB register bits

remain set until they are cleared by means of a "* CLS" command

or the instrument is reset. If these bits are not cleared, they cannot

generate another interrupt.

Serial polling is only an advantage if there are several instruments

that may need attention. Board-level function calls can deal simul-

taneously with several instruments attached to the same interface

board. Refer to the National Instruments user’s manual.

II

II

I

II

II

l

II

l

l

l

II

II

II

22

I

II

|

Page 29

GPIB Operation 3

Parallel Poll Parallel polling is only an advantage if there are several instru-

ments that may need attention.

In parallel polling, the controller simultaneously reads the Individ-

ual STatus bit (IST) of all the instruments to determine which one

needs service. Since parallel polling allows up to eight different

instruments to be polled at the same time, parallel polling is the

fastest way to identify state changes of instruments supporting this

capability.

When a parallel poll is initiated, each instrument returns a status

bit via one of the DIO data lines. Devices may respond either individually using a separate DIO line or collectively on a single data

line. Data line assignments are made by the controller via a Parallel Poll Configure (PPC) sequence.

In the following example, the command "INE 1" enables the

event "new signal acquired" in the INR to be reported to the INB

bit of the status byte STB. The PaRallel poll Enable register (PRE)

determines which events will be summarized in the IST status bit.

The command "*PRE 1" enables the INB bit to set the IST bit

whenever it is set. Once parallel polling has been established, the

parallel poll status is examined until a change on data bus line

DI02 takes place.

Stage 1: Enable the INE and PRE registers, configure the con-

troller for parallel poll and instruct the oscilloscope to respond

on data line 2 (DI02)

CMDI$="?_@$"

CALL IBCMD(BRD0%,CMDI$)

CMD$="INE 1;*PRE 1"

CALL IBWRT(BRD0%,CMD$)

CMD4 $=CHR$ (&HS)+CHR$ (&H69)

CALL IBCMD(BRD0%,CMD4$)

23

Page 30

GPIB Operation

3

|

i

Stage 2: Parallel poll the instrument until DI02 is set

LOOP% = 1

WHILE LOOP%

CALL IBRPP(BRD0%,PPR%)

IF (PPR% AND &H2) = 2 THEN LOOP% =

WEND

Stage 3: Disable parallel polling (hex 15) and clear the parallel

poll register

CMD55=CHR$(&H15)

CALL IBCMD(BRD0%,CMD5$)

CALL IBCMD(BRD0%,CMDI$)

CMD$=" *PRE 0"

CALL IBWRT(BRD0%,CMD$)

Note 1: In the example above, board-level GPIB function calls

are used. It is assumed that the controller (board) and oscillo-

scope (device) are respectively located at addresses 0 and 4. The

listener and talker addresses for the controller and oscilloscope

are:

*IST Poll

Logic device

controller

oscilloscope

Note 2: The characters "?" and .... appearing in the command

strings stand for unlisten and untalkrespectively. They are used to

set the devices to a "known" state.

Note 3: To shorten the size of the program examples, device talk-

ing and listening initialization instructions have been grouped into

character chains. They are:

CMDI$ = "?_@$" ’Unlisten, Untalk, PC talker, DSO listener

Note 4: The remote message code for executing a parallel response

in binary form is 01101PPP where PPP specifies the data line.

Since data line 2 is selected, the identification code is 001 which

results in the code 01101001 (binary) or &H69 (hex). See Table

38 of the IEEE 488-1978 Standard for further details.

The state of the Individual STatus bit (IST) returned in parallel

polling can also be read by sending the "* IST?" query. To enable

this poll mode, the oscilloscope must be initialized as for parallel

polling by writing into the PRE register. Since *IST polling emulates parallel polling, this method is applicable in all instances

where parallel polling is not supported by the controller.

Listener address

32 (ASCII<space>)

32+4=36 (ASCII $)

Talker address

64 (ASCII @)

64+4=68 (ASCII D)

24

Page 31

GPIB Operation 3

In the following example, the command "INE 1" enables the

event "new signal acquired" in the INR to be reported to the INB

bit of the status byte STB. The command "*PRE 1" enables the

INB bit to set the IST bit whenever it is set. The command "CHDR

OFF" suppresses the command header in the response of the instrument, simplifying the interpretation. The status of the IST bit is

then continuously monitored until it is set by the instrument.

CMD$="CHDR OFF; INE 1; *PRE 1"

CALL IBWRT(SCOPE%,CMD$)

LOOP% = 1

WHILE LOOP%

CMD$=" * IST?"

CALL IBWRT(SCOPE%,CMD$)

CALL IBRD(SCOPE%,RD$)

IF VAL(RD$) = 1 THEN LOOP% =

WEND

DRIVING A HARD-COPY

DEVICE

Plotting/Printing without

a GPIB Controller

The oscilloscope can be interfaced to a wide range of plotters and

printers and be instructed to directly plot or print the screen con-

tents onto these devices. The devices supported by the unit are

listed with the command "HARDCOPY_SETUP" in Section 5.

When the hard-copy device is connected to the GPIB two different configurations should be considered depending on whether or

not a GPIB controller is available.

When only the oscilloscope and the hard-copy device are connected to the GPIB, the oscilloscope must be configured as

talker-only and the hard-copy device as listener-only to ensure

proper data transfer. The oscilloscope can be configured as a

talker-only by using the thumbwheel switch at the rear of the instrument to select an address larger than 30. The hard-copy

device manufacturer usually specifies an address which forces the

instrument into the listening mode.

¯

Select the oscilloscope’s address to be larger than 30.

¯ Switch on the oscilloscope.

¯ Configure the "Hardcopy" sub menu in the "Auxiliary Set-

ups" menu specifying "GPIB" as hard copy port.

¯

Put the hard-copy device in listener-only mode.

¯

Press the screen dump button on the front panel of the instrument.

25

Page 32

GPIB Operation

Plotting/Printing with

a GPIB Controller

1. Data read by controller

and sent to printer/plotter

If a controller is connected to the GPIB, data transfers must be

supervised by the controller. The oscilloscope must be set to an

address between 0 and 30 which differs from the controller’s and

the hard-copy device’s address. Different schemes can be used to

transfer the screen contents:

1. The controller reads the data into internal memory and then

sends them to the printer/plotter. This alternative can be

done with simple high-level GPIB function calls.

2. The oscilloscope sends data to both the controller and the

printer/plotter.

3. The controller goes into a standby state. The oscilloscope

becomes a talker and sends data directly to the printer/plotter.

The controller stores the full set of printer/plotter instructions and

sends them afterwards to the graphics device. This method is the

most straightforward way of transferring screen contents but it requires a large amount of buffer storage (110K for 4 traces).

CMD$ = "SCDP"

CALL IBWRT(SCOPE%,CMD$)

FILE$="PLOT.DAT"

CALL IBRDF(SCOPE%,FILE$)

CALL IBWRTF (PLOTTER%,FILE$)

|

|

n

i

i

I

i

m

I

I

l

2. Oscilloscope sends data to

controller and printer/plotter

26

The oscilloscope puts the printer/plotter instructions on to the bus.

The data is directly plotted out and saved in scratch memory in the

controller. The contents of the scratch file can be deleted later on.

Stage 1: Controller talker, oscilloscope listener. Issue the

screen dump command

CMDI$="?_@$": CALL IBCMD(BRD0%,CMDI$)

CMD$="SCDP": CALL IBWRT(BRD0%,CMD$)

Stage 2: Oscilloscope talker, controller and plotter listeners.

Plot data while storing data in scratch file SCRATCH.DAT

CMD2$="?_ D%": CALL IBCMD(BRD0%,CMD2$)

FILE$="SCRATCH.DAT": CALL IBRDF(BRD0%,FILE$)

n

il

n

n

ii

ii

ii

Page 33

GPIB Operation 3

3. Oscilloscope talks directly

to plotter/printer The controller goes into stand-by and resumes GPIB operations

once the data have been plotted, that is when an EOI is detected.

Stage 1: Controller talker, oscilloscope listener. Issue the

screen dump command

CMDI$="?_@$": CALL IBCMD(BRD0%,CMDI$)

CMD$="SCDP": CALL IBWRT(BRD0%,CMD$)

Stage 2: Oscilloscope talker, plotter listener. Put controller in

stand-by

CMD2$="?_D%": CALL IBCMD(BRD0%,CMD2$)

V%=l: CALL IBGTS(BRD0%,V%)

Note 1: In schemes 2 and 3, board-level GPIB function calls are

used. It is assumed that the controller (board), the oscilloscope

and the plotter are respectively located at addresses O, 4 and 5.

The listener and talker addresses for the controller, oscilloscope

and plotter are:

Logic device Listener address Talker address

controller 32 (ASCII<space>) 64 (ASCII @)

oscilloscope 32+4=36 (ASCII $) 64+4=68 (ASCII D)

hard-copy dev.

32+5=37 (ASCII %)

64+5=69 (ASCII E)

Note 2: The characters "?" and " " appearing in the command

strings stand for unlisten and untalk’respectively. They are used to

set the devices to a "known" state.

Note 3: To shorten the size of the program examples, device talk-

ing and listening initialization instructions have been grouped into

character chains. They are:

CMDI$ = "?_@$" ’Unlisten, Untalk, PC talker, DSO listener

CMD2$ = "? D" ’Unlisten, Untalk, PC listener, DSO talker

27

Page 34

i

i

n

II

i

n

I

m

II

l

i

II

I

n

I

II

II,

II

Page 35

4

RS-232-C OPERATION

I

INTRODUCTION

Notation

Example

RS-232-C

PIN ASSIGNMENTS

LeCroy oscilloscopes may be remotely controlled using a host, either a terminal or a computer, via the RS-232-C port. For this

purpose the oscilloscope must be set at an address higher than 30

using the thumbwheel switch at the rear of the instrument.

All the commands described in Section 5 are supported but wave-

form transfer is only possible in HEX mode. The default value

for COMM_FORMAT is set appropriately. The syntax of the response to WF? is identical to the GPIB case.

In this section some special RS-232-C commands are defined either for configuring the oscilloscope, or simulating GPIB 488.1

messages such as setting the oscilloscope into remote or local

modes.

Throughout this section, characters which cannot be printed in

ASCII will be represented by their mnemonics.

<LF>

<BS>

CTRL U

The remote RS-232-C pin assignments (indicated on the rear

panel) are as follows:

Pin #

2 T X D Transmitted data (from the oscilloscope).

3

4 RTS Request to send (from the oscilloscope).

5

20

is the ASCII line feed character whose decimal value is

10

is the ASCII backspace character whose decimal value

is 8

means that the control key and the U key are pressed

simultaneously.

Description

R × D Received data (to the oscilloscope).

If the software Xon/Xoff handshake is selected it is always TRUE.

Otherwise (hardware handshake) it is TRUE

when the oscilloscope is able to receive char-

acters and FALSE when the oscilloscope is

unable to receive characters.

CTS Clear to send (to the oscilloscope).

When true, the oscilloscope can transmit,

when false, transmission stops. It is used for

the oscilloscope output hardware handshake.

DTR Data terminal ready (from oscilloscope).

Always TRUE.

29

Page 36

RS-232-C Operation

RS-232-C

CONFIGURATION

1 GND Protective Ground.

7 SIG GND Signal Ground.

The RS-232-C port is configured in full duplex. This means that

the two sides (i.e. the controller and the oscilloscope) can both

send and receive messages at the same time. However, when the

oscilloscope receives a new command, it stops outputting.

Transmission of long messages to the oscilloscope should be done

while the oscilloscope is in a triggered mode with no acquisition

in progress. This is especially important when sending waveforms

or front-panel setups into the oscilloscope.

The behavior of the RS-232-C port may be set according to the

user’s needs. For this purpose, in addition to the basic setup on

the front-panel menu there are "immediate commands" as well

as a special command "COMM RS232". Immediate commands

consist of the ASCII ESCape character <ESC> (whose decimal

value is 27), followed by another character. Such commands are

interpreted as soon as the second character has been received.

Note: The RS-232-C baud rate, parity, character length and

number of stop bits are among the parameters that are saved or

recalled by the front-panel "SAVE" or "RECALL" button, or by

the remote commands "*SAV’, "*RCL" or "PANEL SETUP".

When recalling, care must be taken to ensure that these parame-

ters are set at the same value as the actual ones. Otherwise, the

host may no longer be able to communicate with the oscilloscope

and a manual reconfiguration would be necessary.

Echo of Received Characters

by the Oscilloscope

Handshake Control

30

The serial port may echo the received characters. Echo is useful if

the oscilloscope is attached to a terminal. Echoing can be turned

on or off by sending the two character sequence <ESC>] or

<ESC>[ respectively. Echoing is on by default.

Note: The host must not echo characters received from the oscilloscope.

When the oscilloscope input buffer becomes almost full, the instrument sends a handshake signal to the host telling it to stop

transmitting. When this buffer has enough room to receive more

characters another handshake signal will be sent. The handshake

signals are either the CTRL-S (or <XOFF>) and CTRL-Q

(<XON>) characters or a signal level on the RTS line (pin 4).

is selected by sending the two-character sequence <ESC>) for

XON/XOFF handshake - this is the default - or <ESC>( for RTS

handshake.

|

Page 37

|

RS-232-C Operation 4

The flow of characters coming from the oscilloscope may be controlled either by a signal level on the CTS line (pin 5) or by the

<XON>/<XOFF> pair of characters.

Editing Features

Message Terminators

Examples

When the oscilloscope is directly connected to a terminal, the following features will facilitate the correction of typing errors:

<BS> or <DELETE> Delete the last character.

CTRL U Delete the last line.

"Message terminators" are markers that indicate to the receiver

that a message has been completed.

On input to the oscilloscope, the Program Message Terminator

is one character which can be selected by the user. A good choice

would be a character that is never used for anything else. The

character is chosen using the command COMM_RS232 and the

keyword EI. The default Program Message Terminator is the

ASCII character <CR>, whose decimal value is 13.

The oscilloscope appends a Response Message Terminator to the

end of each of its responses. It is a string, like a computer prompt,

chosen by the user. This string must not be empty. The default

Response Message Terminator is "\n\r" which means

<LF><CR>.

COMM_RS232 EI,3

This command informs the oscilloscope that each message it

receives will be terminated with the ASCII character <ETX>

which corresponds to 3 in decimal.

(2) COMM_RS232 EO,"\r\nEND\r\n"

This command indicates to the oscilloscope that it must ap-

pend the string "\r\nEND\r\n" to each response.

After these settings, a host command will look like:

TDIV?<ETX>

The oscilloscope responds:

TDIV 1. S

END

Note: Having sent a COMM_RS232 command, the host must wait

for the oscilloscope to change its behavior before sending a com-

mand in the new mode. A safe way to do this is to include a query

on the line which contains the COMM_RS232 command and wait

until the response is received. For example,

COMM RS232 EI,3; *STB?

31

Page 38

RS-232-C Operation

SRQ Message

Example

Long Line Splitting

Each time the Master Summary Status (MSS) bit of the STatus

Byte (STB) is set, the SRQ message (a string of characters) is

to the host to indicate that the oscilloscope requests service. The

RS-232-C SRQ message has the same meaning as the GPIB SRQ

message. If the string is empty, no message will be sent. This is the

default setting. Note that no response message terminator is added

at the end of the SRQ message.

COMM_RS232 SRQ,"\r\n\nSRQ\r\n\a"

When the MSS bit is set, the oscilloscope will send

a <CR> followed by 2 <LF>s

SRQ

a <CR> followed by 1 <LF>

and the buzer will sound.

Line splitting is a feature provided for hosts that cannot accept

lines with more than a certain number of characters. The oscillo-

scope may be configured to split responses into many lines. This

feature is very useful for waveform or front-panel setup transfers

although it is applicable to all response messages. Two parameters

control this feature:

Line Separator: Off messages will not be

split into lines

<CR>,<LF> or <CR><LF> possible line termi-

nators.

the maximum number of characters in a line.Line length:

Example

Remarks

32

COMM_RS232 LS,LF,LL,40

The line separator is the ASCII character <LF>, the line is a maxi-

mum of 40 characters long (excluding the line separator).

If the oscilloscope receives the command PNSU?, it may answer:

PNSU #9000001496

A.AAA5555000655AA403000580019000000000001

000000000000000000000000000C1BO100580000

0000000000000000000000000000000000000000

Long commands sent to the oscilloscope may not be split into

lines. If a command sent to the oscilloscope is the response to a

previous query, the line split characters (<LF> and/or <CR>) must

be removed.

Page 39

COMMANDS SIMULATING

GPIB COMMANDS

<ESC>C or <ESC>c

Device clear command.

<ESC>R or <ESC>r

Set to remote command

(REN)

<ESC>L or <ESC>I

Set to local command

RS-232-C Operation 4

This also applies to line split characters inside strings sent to the

oscilloscope.

However, hex-ASCII data sent to the oscilloscope may contain

line split characters. If you wish to use line splitting, ensure that

neither the input message terminator characters nor the line split

characters occur in the data.

This command clears the input and output buffers. It has the same

meaning as the GPIB DCL or SDC interface messages.

This command puts the oscilloscope into the remote mode. Its

function is the same as GPIB asserting the REN line and setting the

oscilloscope to listener.

This command puts the oscilloscope into local mode. It clears local

lockout. It has the same function as GPIB setting the REN line to

false.

<ESC>F or <ESC>f

Set local lockout command

<ESC>T or <ESC>t

Trigger command (GET)

This command disables the front-panel "LOCAL" button either

immediately if the oscilloscope is already in the remote mode or

later when the oscilloscope is next set to remote control. This disabling of the front-panel "LOCAL" button is called "Local

Lockout" and can only be cancelled with the <ESC>L command.

<ESC>F has the same meaning as the GPIB LLO interface message.

This command rearms the oscilloscope while it is in "SINGLE" or

in "SEQUENCE" mode (valid only while the oscilloscope is in the

remote mode). It has the same meaning as the "*TRG" command, and also the same meaning as the GPIB GET interface

message.

33

Page 40

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Page 41

5

ISYSTEM COMMANDS

ORGANIZATION

COMMAND SUMMARY

This section of the manual lists all commands and queries recognized by the oscilloscope. For easy reference the listings are

arranged in alphabetical order. Each command starts on a new

page and the name (header) of the command is given in both the

long and short forms. Below each name (header) it is indicated

whether it denotes a command only, a command as well as a

query, or a query only. For those headers that may be used to

command an action, for example to modify a setup parameter, or

to obtain some information such as the current value of a setup

parameter, the query form is derived by appending a question

mark (?) immediately to the header without intervening spaces.

The description of each command starts with a short explanation

of the function performed by it, followed by a presentation of the

formal syntax. In the formal syntax the header appears in mixed

mode characters with the characters used to construct the short

form shown in upper case.