Page 1

LEAP FORWARD

Leapfrog 3D Printers

User Manual

Version 1.68

Page 2

Page 3

DEAR VALUED CUSTOMER,

Thank you for purchasing the Leapfrog Bolt 3D Printer. We strive to make our machines

as easy to use as possible, but printing 3D objects invites a lot of creativity. New

solutions and unknown problems often require the user to stretch the limits and

capabilities of their machines. This manual ensures that you will achieve the best results

with your printer.

Please take the time to read through this manual as it was designed to help you get

familiar with your new printer and get you on your way to creating great looking 3D

models.

Keep in mind also that we have an eager and experienced Technical Support Team

standing by to assist you with any questions you may have. If you are new to 3D printing,

sometimes it is better to ask before trying something you are unsure of. Our Support

Team works best through our ticketing system and regularly updated solution articles,

both found on our website under support.

We hope that you enjoy your new Bolt 3D printer, and look forward to providing

assistance in any way we can.

Sincerely,

Your Leapfrog Customer Support Team

CONTACT INFORMATION

General

info@lpfrg.com

+31 172 50 36 25

Support

support@lpfrg.com

+31 852 08 08 25

Sales

sales@lpfrg.com

+31 172 50 36 24

Page 4

4

1! USEFUL'INFORMATION' 6!

1.1! PURCHASE'INVOICE'AND'WARRANTY' 6!

1.2! SUPPORT'INFORMATION' 7!

1.3! WHAT'IS'IN'THE'BOX' 7!

1.4! UNBOXING'THE'PRINTER' 8!

1.5! ELECTRIC'POWER'CORD'COMPATIBILITY' 11!

2! ABOUT'THE'BOLT' 12!

2.1! BOLT'OVERVIEW' 12!

2.2! BOLT'SPECIFICATIONS' 13!

2.3! LEAPFROG'USER'INTERFACE'OVERVIEW' 15!

3! PRINTER'SETUP' 19!

3.1! SETTING'UP'ADMIN'AND'USER'ACCOUNTS' 20!

3.2! CONNECTING'THE'BOLT' 21!

3.3! AUTOMATIC'UPDATE'FUNCTION' 22!

3.4! CALIBRATE'PRINT'BED' 22!

3.5! LOADING/UNLOADING'FILAMENT' 23!

3.6! ADD'MATERIAL' 28!

3.7! ADHESIVE'MATERIAL' 28!

4! PRINTING' 29!

4.1! STARTING'PRINT'JOBS' 29!

4.2! FINISHING'PRINT'JOBS' 31!

4.3! USING'DIFFERENT'PRINTING'MODES' 32!

4.4! INFORMATION'AVAILABLE'ON'PRINT'JOBS' 33!

4.5! ACCESSING'AND'UPLOADING'PRINT'JOBS' 34!

5! CREATING'A'PRINTFILE' 35!

5.1! CREATR'POWERED'BY'MATERIALISE' 36!

5.2! PRINTER'SELECTION' 36!

5.3! IMPORT' 36!

5.4! TRANSFORM' 37!

5.5! SELECT'NOZZLE' 37!

5.6! PRINT' 38!

5.7! PREVIEW'AND'GENERATE'G-CODE' 39!

6! LEAPFROG'USER'INTERFACE' 40!

6.1! LEAPFROG'USER'INTERFACE'FEATURES' 40!

6.2! REMOTE'ACCESS' 40!

6.3! CONNECTION'THE'BOLT'USING'YOUR'NETWORK' 41!

6.4! USING'THE'WEBCAM' 42!

6.5! PURGE'NOZZLES' 42!

6.6! MATERIALS' 42!

7! PRINT'SETTINGS' 44!

Page 5

5

7.1! PRINT'SPEED'VS'PRINT'QUALITY' 44!

7.2! MATERIAL'PROFILES' 44!

7.3! PRINT'MODE' 44!

7.4! SLICING'STRATEGY' 45!

7.5! BUILD'STRATEGY' 45!

7.6! SUPPORT'STRATEGY' 45!

8! MAINTENANCE'&'TROUBLE'SHOOTING' 46!

8.1! INSTALLING'UPDATES' 46!

8.2! CLEANING'THE'PRINT'BED' 46!

8.3! CLEANING'THE'EXTRUDERS' 46!

8.4! REPLACING'THE'EXTRUDERS' 46!

8.5! LEVELLING'EXTRUDERS' 46!

8.6! CALIBRATE'PURGE'WIPERS' 47!

9! CONTACT'&'ADDITIONAL'SUPPORT' 48!

9.1! TECHNICAL'SUPPORT'INFORMATION' 48!

9.2! CREATR'SOFTWARE'ASSISTANCE' 49!

9.3! COMPANY'INFORMATION' 50!

Page 6

6

1 USEFUL INFORMATION

We would like to provide you with some useful information to prevent any problems

which may occur in the future.

1.1 PURCHASE INVOICE AND WARRANTY

We would like to kindly ask you at the beginning to make sure that you keep track of

your original purchasing invoice that Leapfrog or one of our distributors sends after

payment before the printer has been received. This invoice helps to verify the warranty

of the printer, and it allows us to match it with our records to confirm authenticity of

purchase. Please note that consumables are not within the standard warranty.

Without a copy of the printer’s original purchase invoice, the amount of support that

Leapfrog provides on technical issues may be considerably delayed and/or limited.

Therefore, it is highly recommended that you maintain this document and provide it in

any Technical Support Ticket that you may create in troubleshooting issues so that we

can provide you with the best support possible.

Page 7

7

1.2 SUPPORT INFORMATION

Keep in mind also that we have a Technical Support Team standing by to assist you with

any questions you may have. If you are new to 3D printing, do not hesitate to ask for

any support.

Our Support Team works best through our ticketing system and regularly updated

solution articles, both found on our website’s Support tab. This will direct you to

support.lpfrg.com. There are a lot of solutions already available so your solution might

already be there.

If your solution is not there, then creating a support ticket is the quickest means to get

help. By clicking new support ticket, you will create a personal communication channel

between you and our support team. They will help resolve your problem as fast and

efficient as possible.

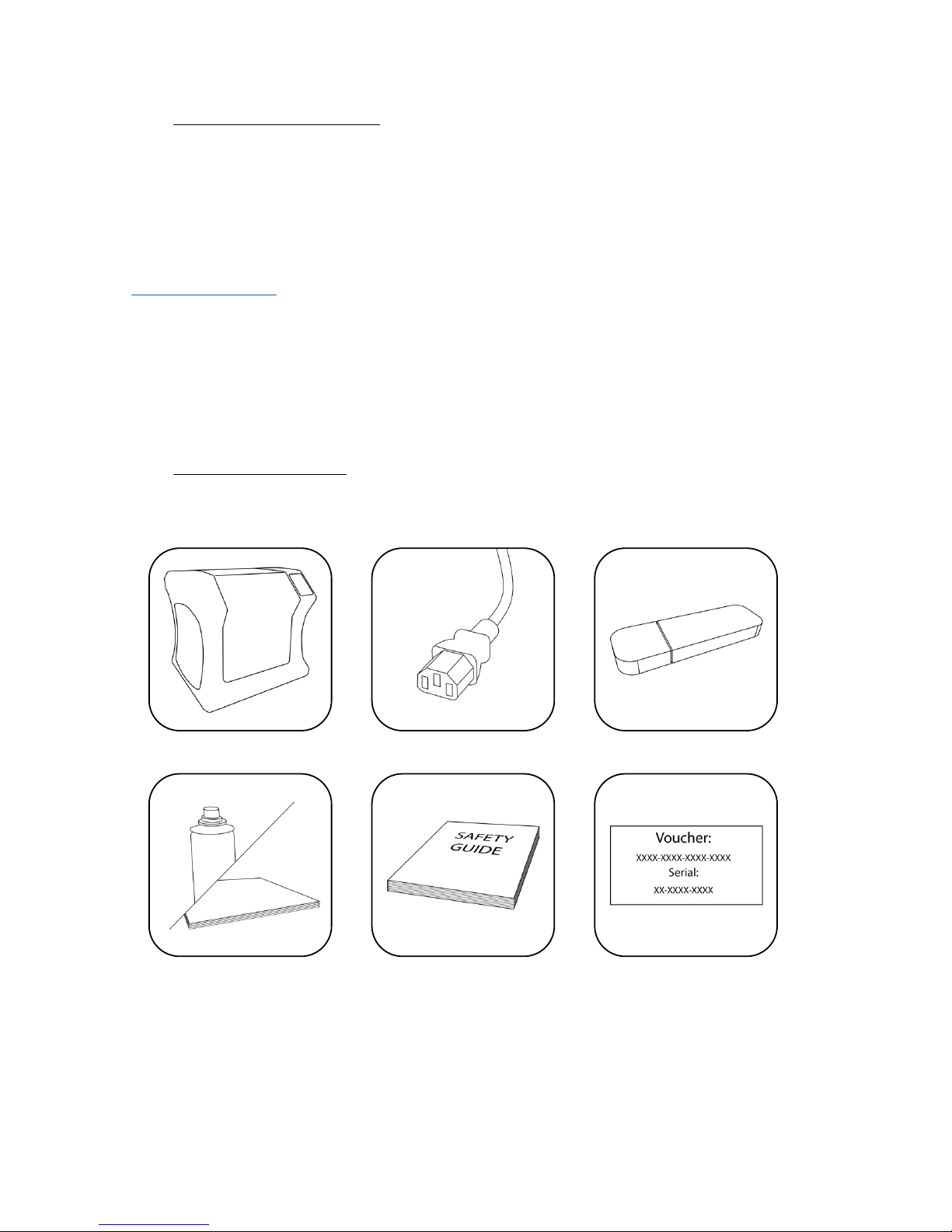

1.3 WHAT IS IN THE BOX

Bolt 3D Printer

Power cable

USB stick

Bed adherence

Safety guide

Creatr Software Voucher

Page 8

8

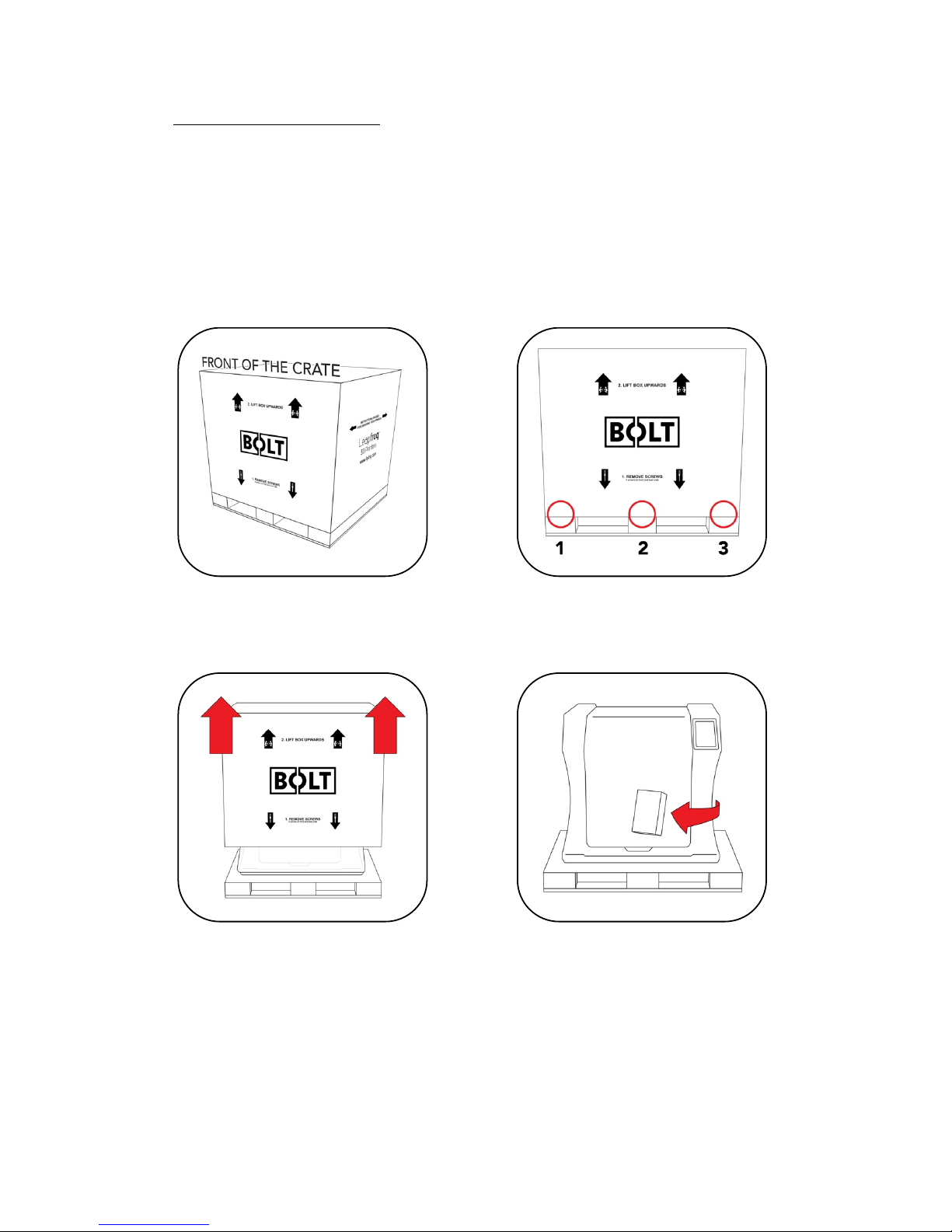

1.4 UNBOXING THE PRINTER

It is important to carefully unbox the printer according to the instructions in order not

to damage the printer. Never try to lift the printer by pulling it up on the print heads, X

or Y axis assemblies, or the print bed itself as this can throw off calibrations or possibly

even break part of the printer.

Place the box with the Box on the

ground.

3 screws can be found at the base of the

crate. Remove a total of 6 screws on the

front and the back of the crate.

Lift the top of the box upwards with two

persons.

Remove the box containing the power

cable and other accessories.

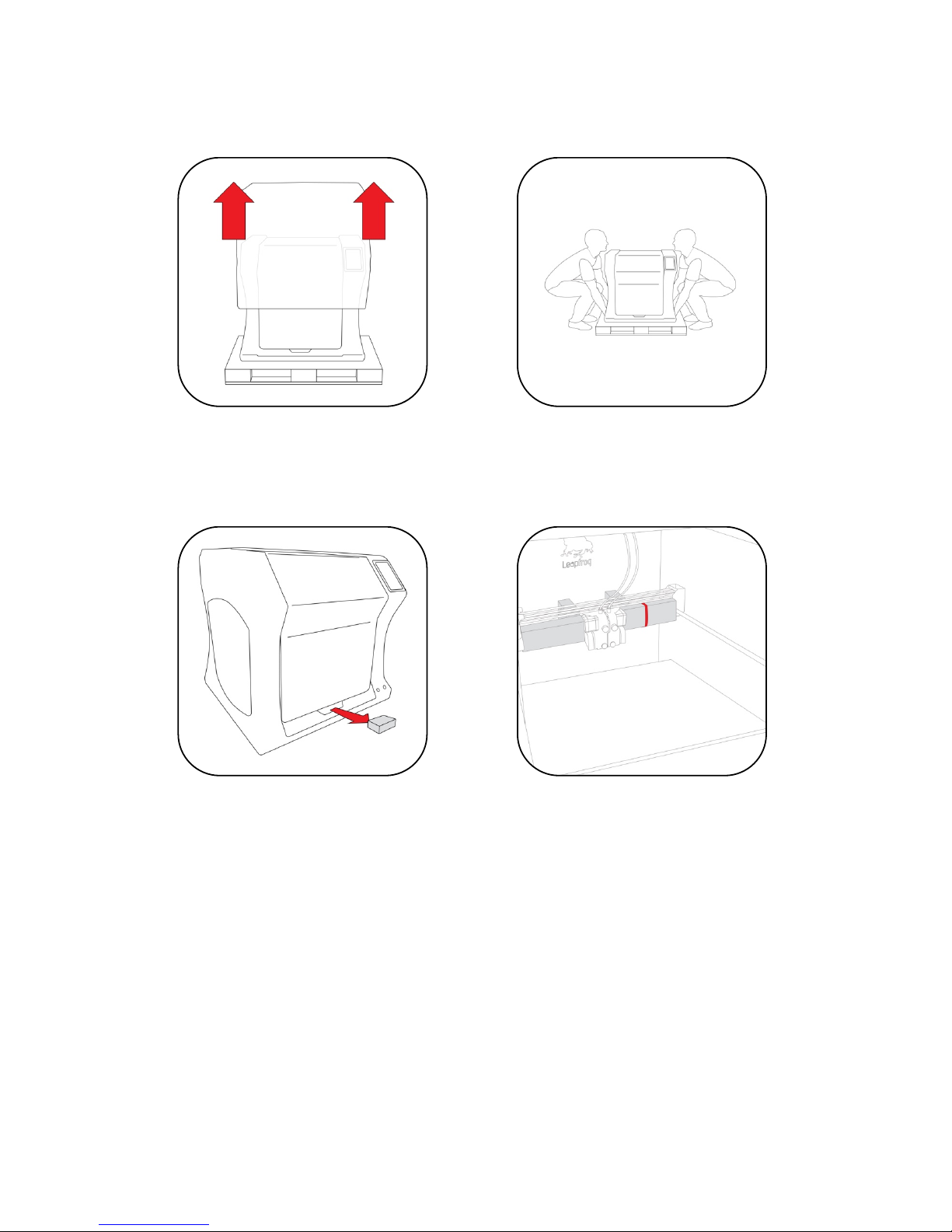

Page 9

9

Remove the cover protection on the

outside of the Bolt.

Place the Bolt securely on a table of

workbench.

Open the door and remove the piece of

foam between the Bolt and the door.

On the inside of the Bolt, cut the tie-

wrap found on the right side of the Print

heads.

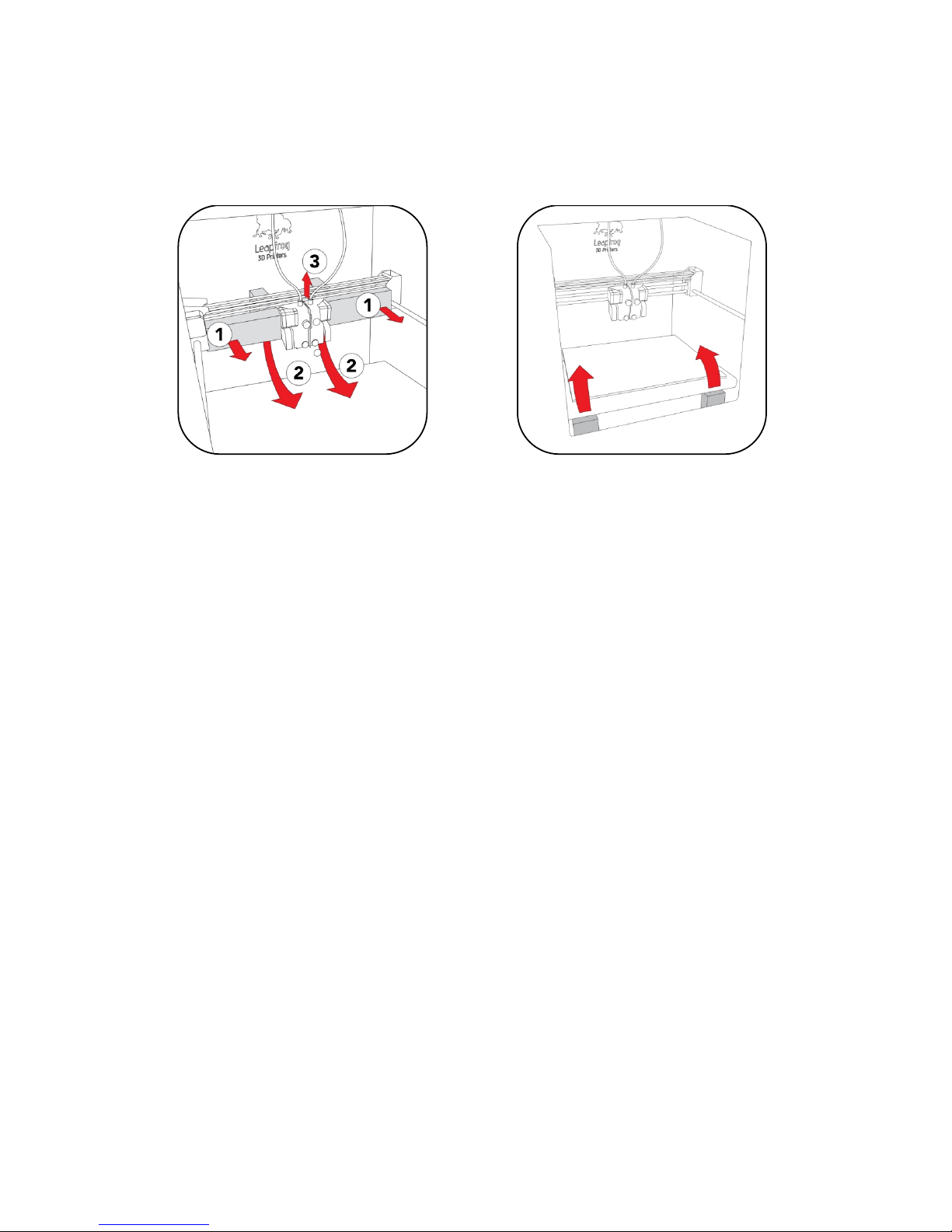

Page 10

10

Remove the 4 pieces of foam holding

the print heads in it is place. And

remove the piece of protection between

the two print heads.

Remove the two pieces of foam

underneath the front of the bed.

Get the power cable and plug this in the

back of the printer and plug the other

end in a grounded (!) wall outlet.

Remove any remaining foil, protecting

the exterior of the Bolt.

Page 11

11

1.5 ELECTRIC POWER CORD COMPATIBILITY

Please check the power cord that came with the printer to see if the plug matches the

electrical wall outlet that your country typically uses. The Bolt has a power supply unit

that is switched-mode capable – meaning it will automatically switch between allowed

voltage input between 100 volts and 230 volts. However, make sure that the correct

power chord has been supplied along with your printer.

If this is not the case, please go to our website and open a support ticket, attaching a

copy of the printer’s original purchasing invoice and a photo of the power cable that

came with the printer; our Technical Support Team will place an order for the correct

power cable as soon as possible.

Once you have confirmed that you have the correct power cord, please connect the

power cord to the back of the Bolt in the appropriate slot and plug the other end into

a grounded (!) wall outlet. Failing to make sure that you have a grounded wall outlet

can result in the printer possibly being damaged by an electric power surge. In addition

to using a grounded power outlet, it is also recommended to use a surge protector.

At this point, you can safely turn on the power switch on the back of your printer.

Page 12

12

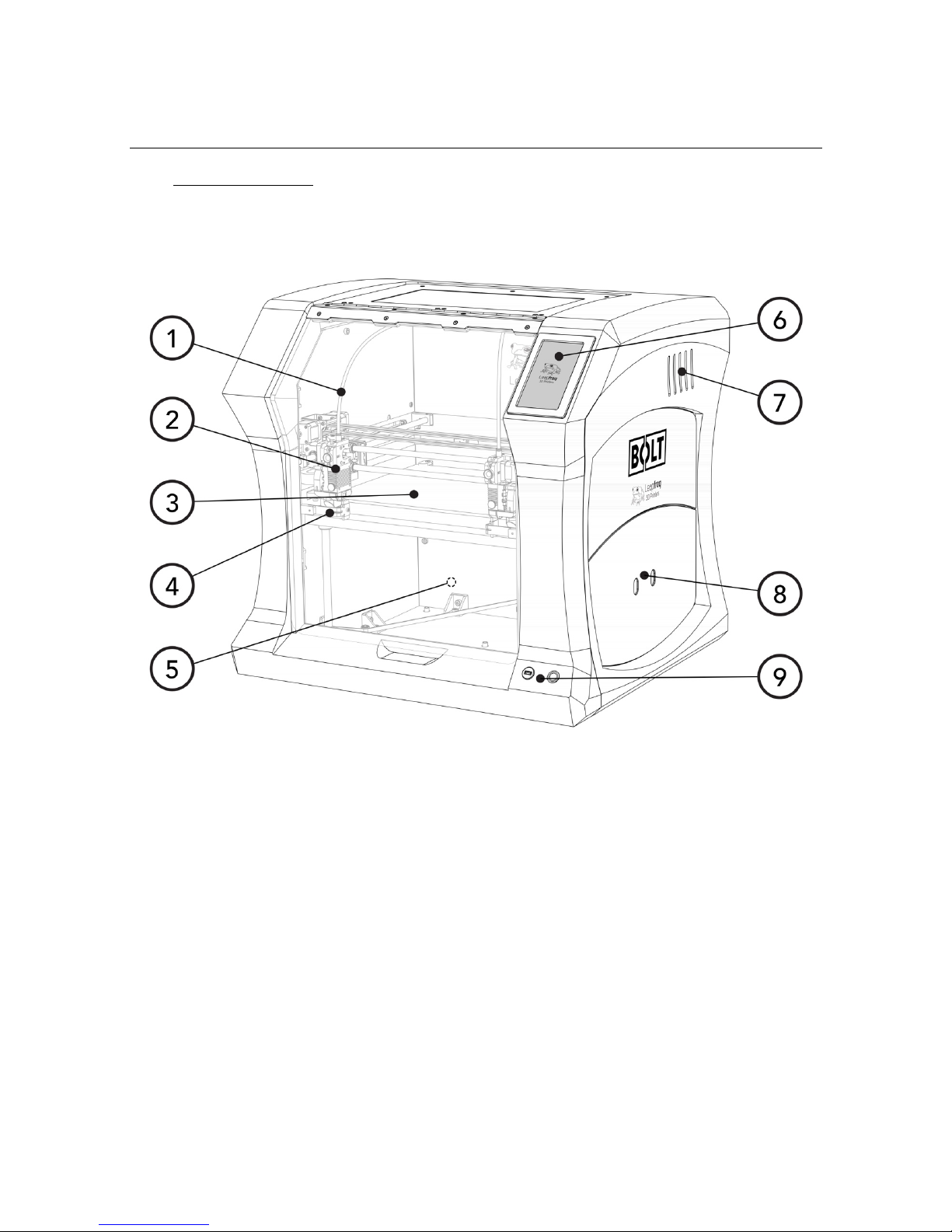

2 ABOUT THE BOLT

2.1 BOLT OVERVIEW

1. Filament guide tube

2. Print head (one of two)

3. Print bed

4. Nozzle wiper (one of two)

5. Power switch (on the back of the Bolt)

6. Touchscreen

7. Activated HEPA Carbon filter vent

8. Filament compartment

9. On/off button and USB port

Page 13

13

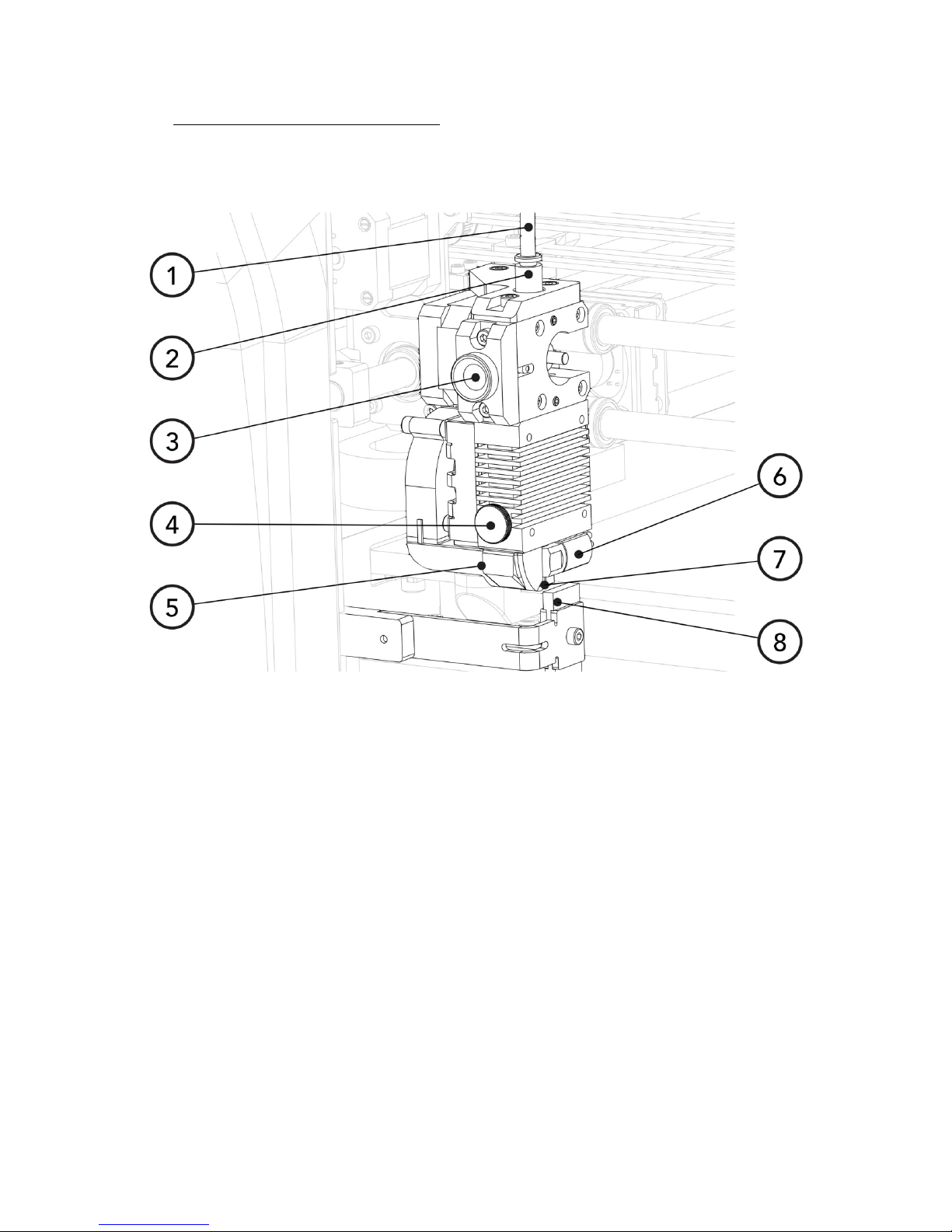

2.2 BOLT PRINTER HEAD OVERVIEW

1. Filament guide tube

2. Push-in coupling

3. Filament pinch wheel (used to control the grip on loaded filament)

4. Hot-end thumb screw (used to swap hot-ends tool-less)

5. Fan-duct

6. Hot-end (includes also nozzle)

7. Nozzle

8. Nozzle wipe

Page 14

14

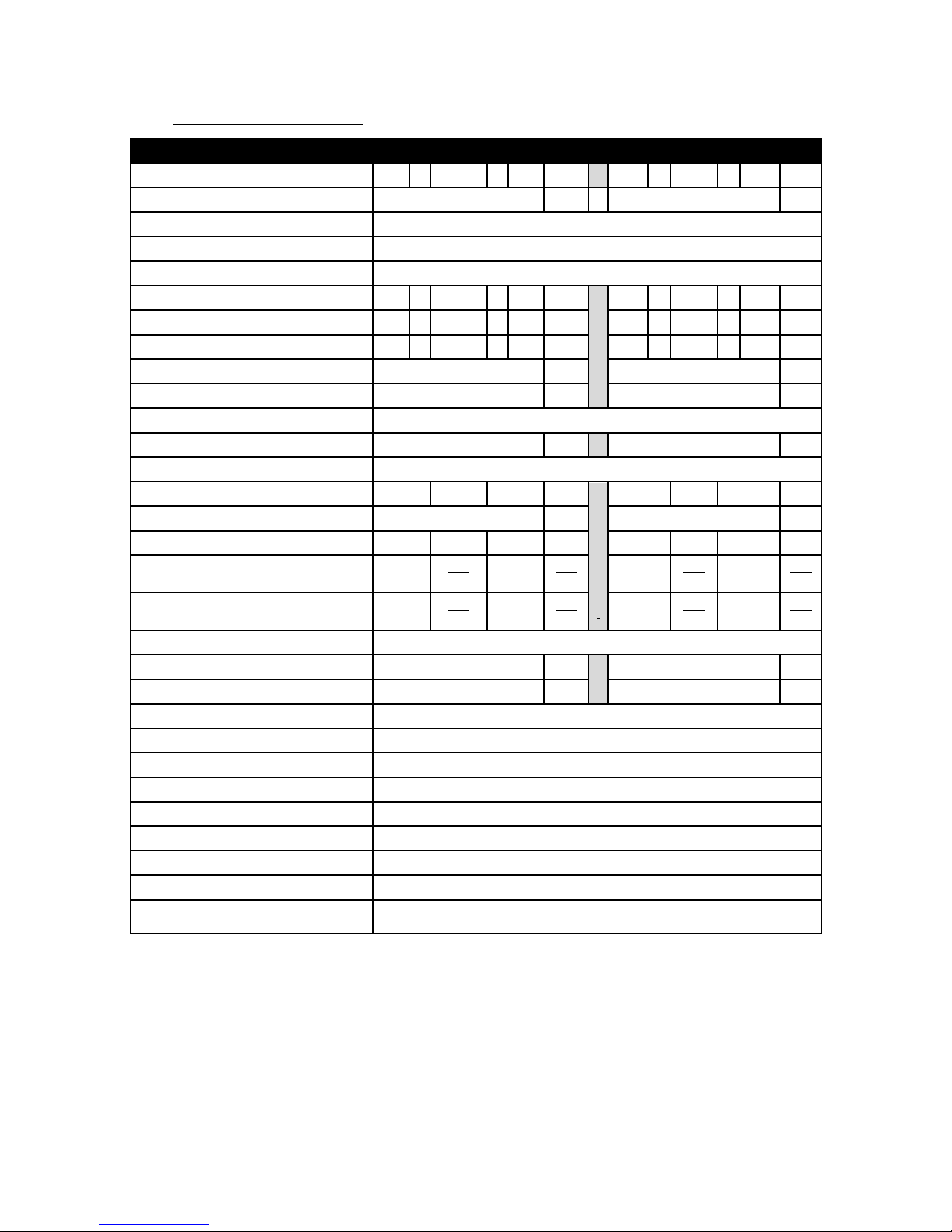

2.3 BOLT SPECIFICATIONS

Specification+

Metric+

++

Imperial+

Physical+dimensions+(DWH)+

723+x+831+

x+

801+

mm+++28.5+x+32.7+x+31.5+

inch+

Printer+weight+

61+

kg+

++

134+

lbs+

Input+voltage+range+

88-264VAC+

Input+frequency+

47+-+63+Hz+

Power+consumption+

600W+

Build+size+single+extruder+(DWH)+

320+x+330+

x+

205+

mm+++12.6+x+13.0+x+8.1+

inch+

Build+size+dual+extruder+(DWH)+

320+x+300+

x+

205+

mm+++12.6+x+11.8+x+8.1+

inch+

Build+size+replicator/mirror+mode+(DWH)+

320+x+164+

x+

205+

mm+++12.6+x+6.5+x+8.1+

inch+

Build+volume+

21.6+

L+

++

4.8+

gall.+

Heated+bed+max+temp+

90+

°C+

++

194+

°F+

Closed+chamber+

Yes+

Hot+end+Max+temp*+

360+

°C+

++

680+

°F+

Number+of+extruders+

2+

Extruder+size(s)+

0.35+++++

mm+++1.38E-02+++++

inch+

Filament+size+

1.75+

mm+++6.89E-02+

inch+

Layer+thickness+

0.05+

to+

0.35+

mm+++1.97E-03+

to+

1.38E-02+

inch+

Advised+printing+speed+(DW)+

6000+

mm+

min+

100+

mm+

s+

++

236+

inch+

min+

4+

inch+

s+

Max.+travel+speed+(DW)+

15000+

mm+

min+

250+

mm+

s+

++

591+

inch+

min+

10+

inch+

s+

Stepper+motors+

1.8°+Step+angle+with+1/32+micro+stepping+

Positioning+accuracy+(DW)+

0.008+

mm+++3.15E-04+

inch+

Positioning+accuracy+(H)+

0.010+

mm+++3.94E-04+

inch+

Body/frame+construction+

Aluminium+Framework+

Heated+bed+construction+

High+grade+glass+

Semi-automatic+print+bed+Z-levelling+

Yes+

Ethernet+connection+

Yes+

Wifi+connection+

Yes+

Internal+OS+

Linux+

USB+standalone+format+

.Gcode+format+

Printing+modes+

Single,+Dual+Material,+Replicator+mode,+Mirror+mode+

Open+ system+ print+ materials+ (*+

experimental)+

PLA,+ABS,+HIPS,+Flex,+Nylon,+Hybrid,+Woodfill,+PVA*,+Carbon*,+other*+

DWH:%Depth,%Width,%Height.%Coordinate%system%reference%Y,%X,%Z%

A%Low-temp%(max%250%degrees)%and%High-temp%hotend%(m a x%3 60 %degrees)%is%supplied%

Page 15

15

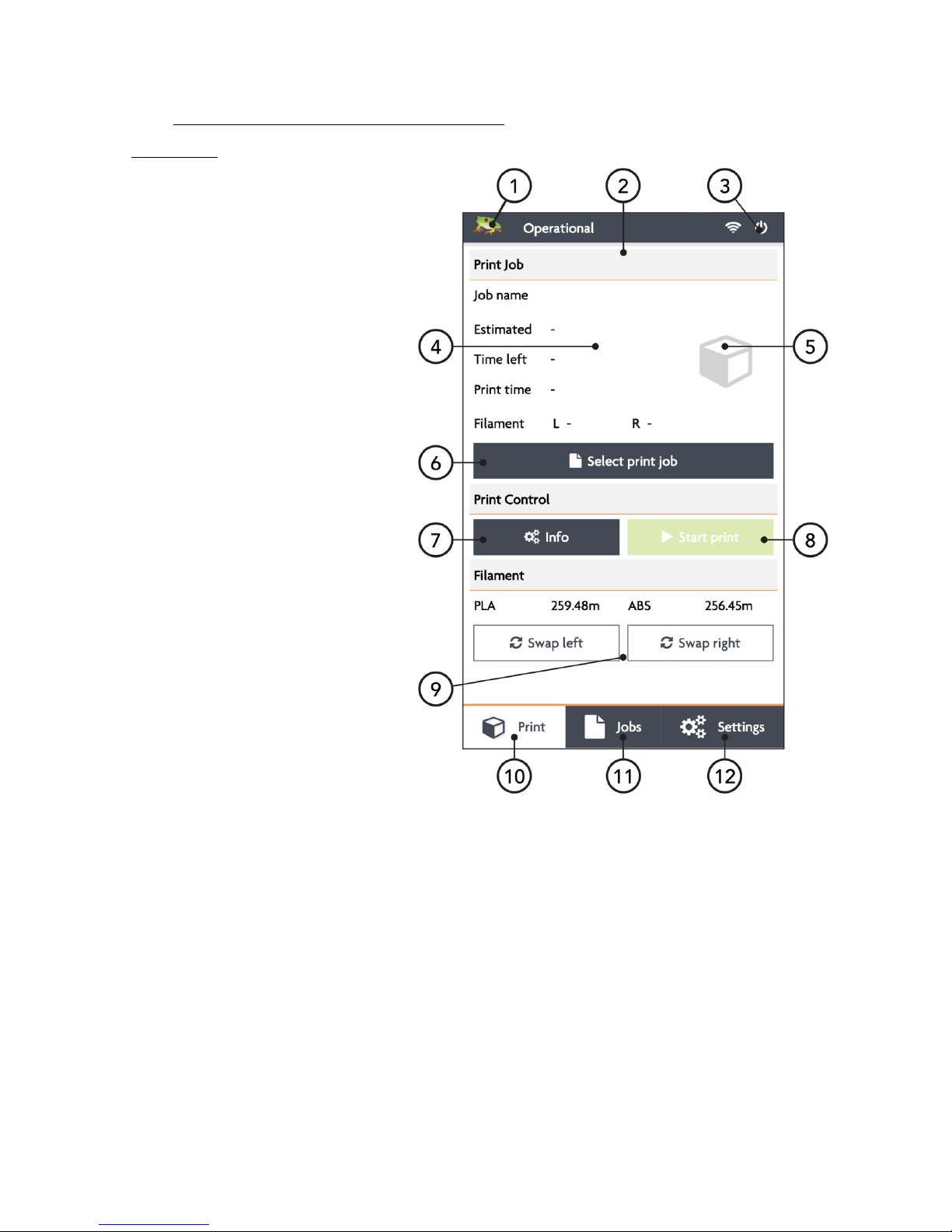

2.4 LEAPFROG USER INTERFACE OVERVIEW

PRINT TAB

1. Software refresh

2. Notifications area

3. Power power options

4. Shows information about

the selected print job.

5. Shows a preview of the

selected print job

6. Navigate to the Jobs tab to

select a print job

7. Shows the temperatures of

the nozzles and bed and

gives access to the built-in

webcam live view

8. Start a print job and select

the print mode

9. Loads the wizard to load or

unload filament for the left

and right extruder

10. Shows the current Print tab

11. Navigate to the Jobs tab

12. Navigate to the Settings tab

Page 16

16

JOBS TAB

13. Software refresh

14. Notifications area

15. Power power options

16. Local and USB storage

17. Search storage

18. Sort storage

19. Filename

20. Print selected file

21. Show information on file

22. Additional information on

file.

23. Delete or copy file to USB

or local storage

24. Shows that the file is not yet

printed

25. Shows that the file is

successfully printed

26. Shows that the file wasn’t

successfully printed

27. Navigate to the Print tab

28. Shows the current Jobs tab

29. Navigate to the Settings tab

Page 17

17

SETTINGS TAB

1. Software refresh

2. Notifications area

3. Power power options

4. General printer information

5. Navigate to maintenance

menu

6. Add, edit or remove

materials

7. Access built-in camera and

set/download created

timelapses

8. Add, edit or remove user

9. Connect to wireless

network and check IP

address.

10. Update the Bolt software

and firmware

11. Navigate to the Print tab

12. Navigate to the Jobs tab

13. Shows the current tab

Page 18

18

SETTINGS TAB

1. Moves both print heads to

the front of the Bolt for

head maintenance

2. Moves both prints heads to

the back of the printer for

bed maintenance

3. Change the amount of

filament on the loaded

spools

4. Calibrate both extruders in

reference to each other

5. Calibrate the print bed in

reference to the nozzles

6. Purge left/right extruder

7. Close maintenance menu

Page 19

19

3 PRINTER SETUP

Before you can start using the Bolt, some preparation is required. Also, be sure to read

Chapter 1.5: Electric Power Cord Compatibility.

The following chapters should be followed to make the Bolt operational and print

ready.

3.1 Setting up user accounts

3.2 Connecting the Bolt to the internet

3.3 Update the Bolt

3.4 Calibrate print bed

3.5 Load filament

3.6 Add materials (if necessary for 3.6)

3.7 Apply bed adhesive

You will be setting up admin and user accounts in order to control the amount of

privileges every user has on the Bolt

Connecting the to the internet and Wi-Fi is also highly recommended and fully use its

auto-updates and connectivity with your mobile phone and/or computer.

Calibrating the bed should be done at least once after transporting the Bolt. The wipers

will need to be check as well.

And finally filament should be loaded and the print bed should be prepared before

each print.

Page 20

20

3.1 SETTING UP ADMIN AND USER ACCOUNTS

As our 3D printers are being used in shared office environments, Leapfrog 3D Printers

has designed the Bolt Software to have User accounts. Remote control will only be

accessible to users with an account and those that do have access may be limited to

what they can do based on their account settings.

Setting up an Admin account is highly recommended before providing the Bolt’s IP

address to the users in your office environment.

NOTE Replacing a forgotten password for an Admin account will be very difficult to

do, so please write it down in a location that you will be able to recover it if need be

later on.

To add a user, select the Settings tab and tap on the

Users menu option. Add a admin user and be sure

to set the check-box on green, next to Admin.

In the picture you see that user admin has

administrative privileges and ‘john’ is an active user.

To the right you see a pencil icon for editing this

user account, a key for locking the account, and a trash can for deleting the user

account.

NORMAL USERS These users can only upload files but cannot start prints from a remote

device.

ACTIVE USERS These users can upload and print, but cannot change settings from a

remote device.

ADMIN USERS Admin users can also upload and print as well as change settings on the

printer from a remote device.

Page 21

21

To add a user, click the Add user button.

Use the touchscreen keyboard (by typing inside each

text field) to fill out the Username, Password, and

Repeat Password fields.

Make sure to indicate whether they will have

administrative privileges or not but switching the

slider on green or red.

Confirm to create the account, and Abort will cancel

the account creation.

3.2 CONNECTING THE BOLT

The Bolt can access the internet and your network by Ethernet or Wi-Fi.

To do so, you will need an internet service in your home/office that is set up on a router.

For a wired connection, simply connect the Bolt with your router using an Ethernet

cable.

For wireless you will also need to know the name and

password of the wireless network being transmitted

by that router so that your Bolt will be able to connect

to the correct network.

Once you have this information, go to Settings tab and

select the Wireless menu option. Your printer should

automatically scan for any wireless networks, but if the

network is not listed, select the Rescan button to have

it refresh the network list.

To connect, simply select the listed network that you

wish to connect to, type in the password and tab the

Connect button.

Once connected, you’ll see the network name, that it is communicating, the signal

strength and that it is locked by the Admin.

If you are currently connected to a network and wish to change networks, you will need

to first disconnect from the current one by selecting the Disconnect button.

Page 22

22

3.3 AUTOMATIC UPDATE FUNCTION

Because our Research & Design department is constantly trying to improve the quality

experience that our customers have with our 3D printers, they periodically provide new

updates that further improve the printer-user experience. For your convenience, these

updates are made available online and can be directly installed on the Bolt, with

minimal printer down-time.

To update your Bolt, go to Settings and press Update to Update to the latest version

available. Please ensure that you are connected to the internet to use this function.

3.4 CALIBRATE PRINT BED

The Bolt is a sensitive machine that moves and

extrudes on the micro-meter level, and exposure to

shipping and transportation can possibly cause the

bed level to lose calibration.

If the first layers don’t adhere to the printer bed, the

whole part can move while printing, resulting in a bad

print. The right distance between the bed and nozzle

prevents this from happening.

To level and calibrate the bed, go to Settings à

Maintenance à Calibrate bed.

Continue Calibration and the screen will show a top

view of the print bed with 4 squares in each corner and

a fifth one in the middle of the print bed. Each of these

squares represent a position on the print bed used for

calibration.

The recommended distance between bed and nozzle is around

0.15 mm or roughly the height of a sheet of paper.

Choose a corner position on the screen and find the knob

underneath the bed at the corresponding position. Turn this

knob clock-wise to raise the bed, and counter clock-wise to lower

the bed.

Page 23

23

Hold a piece of paper between the nozzle and print

bed and raise the bed until the paper is slightly

pinched between the bed and nozzle. Repeat this until

all four corner nozzles have the same distance from

the bed, checking the middle calibration position last.

3.5 LOADING/UNLOADING FILAMENT

Filament is the material what the Bolt uses to print. The

extruder on the right side is treated as the

default/main extruder. Our Creatr Software (powered

by Materialise) is also is set up that way.

We recommend Leapfrog MAXX filaments and preferably PLA for the initial loading

process and prints.

Filament will be loaded in the right side of the Bolt and guided via tubes to the

designated print head. The filament will be melted in the print head and printed to the

print bed.

In the following steps we will swap the Right filament. Swapping the Left filament will

follow the same process.

NOTE The print head assembly will perform some forceful movements during this

process. Please keep all body parts or objects clear when this movement occurs to

prevent injury or damage of the machine.

Page 24

24

NEEDED STEPS TO LOAD FILAMENT

1. Remove the filament guide tube from the coupling

2. Select Swap Left/Right in the print tab

3. Unload the current filament if necessary

4. Select the correct filament and set the estimated amount left on the spool

5. Feed the filament up to the drive gear

6. Feed the filament into the drive gear

7. ‘Load filament’ or ‘Load extra filament’ until the filament is gripped in the drive

gear

8. Re-connect the filament guide tube to the coupling if necessary

Page 25

25

STEP 1

Locate the orange push-in coupling on the right print

head, connecting the print head to the filament guide

tube. Remove the tube from the print head by pushing

the orange coupling down and pulling tube upwards

in the opposite direction. Let the tube disconnected

until the filament is loaded correctly.

NOTE Loading filament can also be done without

disconnecting the push-in coupling, but it is strongly

advised to use this method in order to ensure success

loading filament and know what is happening.

STEP 2

On the Bolt Software, select the

Print tab and choose the Swap Right

option for the right extruder.

It will ask you to confirm the unload

process; please do so.

NOTE The printer will first pre-heat the selected nozzle to help load and unload

filament. This is will extend the life of your nozzle blocks and will help prevent clogs.

STEP 3

You’ll then be prompted to physically unload and roll of the filament spool that was

previously loaded in the printer, if applicable. To do this, open de filament

compartment on the right side of the Bolt and remove the filament spool from the

filament compartment. The right extruder will then be empty and available to load the

replacement roll of filament.

Page 26

26

STEP 4

After unloading the previous roll of

filament (if applicable), the software will

ask which type of filament is loaded into

the extruder that you just unloaded.

Select the right material from the drop

menu. If the correct material isn’t listed,

select abort and add an additional

material. This can be done in the in the

Settings tab under Materials, as is

explained in the next chapter.

Select how much filament is on the spool.

This way, the Bolt knows whether or not

there will be sufficient filament to print the

selected print job and will notify you when

there will not be enough. Keep in mind

that this is as accurate as the user can

determine the amount of filament left on

the spool, so it will be an estimate.

STEP 5

Get the filament that needs to be loaded and un-package a roll of filament from the box

if needed.

NOTE Some filaments (like PVA and Nylon) have special properties that make them

susceptible to things like air moisture or sunlight. Please take extra care of these types

of filaments, making sure not to leave them in the printer or outside of their protective

packaging. PVA in particular should always be unloaded from the printer immediately

after use to help prevent clogging of the nozzle.

In order to help the filament feed through the machine, clip the end of the filament to

where it forms a point and then use your fingers to straighten the filament out. Being

wound around spool, the filament has a natural bend; straightening just the first few

centimetres out helps to prevent the filament from catching when it reaches a filament

tube coupling.

Page 27

27

Begin feeding the filament through the correct filament tube port

on the right side of the printer. For loading filament into the right

extruder, the right filament compartment must be used, for the

Left extruder, the left.

When feeding the filament to

the filament entry port, ensure

that the filament is rolled of

correctly of the filament spool. The filament should be

rolled from the bottom of the spool into the entry port.

If the filament is loaded incorrectly, then the loaded

filament can get damaged while printing and clog the

nozzles.

STEP 6

Feed the filament through the filament entry port;

keep feeding until you see the filament in the

translucent filament guiding tube reach all the way

print head filament drive gear. Make sure to that the

filament is fed past the end of the tube.

If you need help feeding the filament to the drive gear,

feel free to disconnect the translucent filament guiding

tube from the top of the print head and feed the

filament through the top down into the print head.

STEP 7

When the extruder is preheated, you will be prompted to confirm that you are ready to

load the filament. Press the Load button and the print head will begin feeding filament.

While the drive gear in the print head will start turning in order to feed filament, keep

feeding filament by hand and apply a little pressure in order for the drive gear to grip

the filament. Repeat this until the filament is gripped by the drive gear.

STEP 8

The filament will be correctly loaded if the nozzle extrudes filament by simply pressing

‘load more filament’ on the software. Re-connect the tube if necessary by pushing the

tube back in the pushing coupling.

Page 28

28

3.6 ADD MATERIAL

Materials in the Bolt software are used to pre-heat and

prepare the Bolt for loading and unloading filament.

The actual materials settings are set in the G-code of

the print file. Settings of changing temperatures for

print settings is done in the Creatr Software.

When a material isn’t available when loading filament,

it can be manually added. To see what materials are

available or to add an additional filament, go to the

Materials under the Settings tab.

A list of materials is visible under Materials and adding

a material can be done with +Add profile.

When adding a material, fill in a profile name and add

the correct temperatures to complete the material

profile. Press save the to keep, and start using the

profiles.

3.7 ADHESIVE MATERIAL

Many filament types require an adhesive material to be applied

to print bed in order to help the printed part to stick and hold to

the bed. Without it, most 3D printed parts would stick to the print

head and move around after the first few layers. Therefore, we

recommend almost always applying some sort of adhesive

material such as our print stickers or 3D Spray from Leapfrog

MAXX Essentials (for European countries only).

NOTE Failing to ensure that a print is sticking to the bed for at

least the first few layers could result in a large mass of filament

collecting on the tip of the nozzle and can severely damage the

printer. Though we don’t expect the print to be monitored from

beginning to end, we strongly advise to monitor the first critical layers of the print. Using

the built-in webcam enables the user to monitor the printing process remotely.

Page 29

29

4 PRINTING

The Bolt is capable of storing and 3D printing G-codes generated with Creatr powered

by Materialise.

The following will be covered in the next chapter

4.1 Starting Print jobs

4.2 Finishing Print jobs

4.3 Using different printing modes. Sync mode and Mirror mode

4.4 Information available on print jobs

4.5 Accessing and storing print jobs

4.1 STARTING PRINT JOBS

To make a 3D print, 3 things are required. Filament, a 3D file in G-code format and a

3D Printer. Creating a G-code from a STL is explained in the next chapter. To start your

first print, you can use the pre-installed file on the storage of the Bolt. Choose PLA as

filament for the Bolt example print.

NOTE When starting a print, it is strongly advised for the user to know that the filament

is loaded correctly, the bed is correctly calibrated and the print bed is supplied with

adhering material like 3D Spray or a print sticker. This is explained in the previous

chapter.

The following steps will be explained below.

1. Start-up the Bolt

2. Prepare the print bed

3. Select the print job

4. Select ‘Start print’.

5. Wait until the Bolt is heated up and starts printing its first layers.

STEP 1

Start up the Bolt and load filament in the Bolt as explained in the previous chapter.

Navigate on the Bolt software to the Print tab.

STEP 2

Prepare the print bed with necessary adhesive. This is explained in chapter 3.7.

Page 30

30

STEP 3

Press ‘Select print job’ to navigate to the internal storage of the Bolt. Here all prints on

the Bolt are located, as well as the linked USB storage device. Select the file you want

to print and navigate to the Print tab by pressing the ‘play’ button or ‘Print’ in the bottom

of the screen.

NOTE Trying to run a G-code file that was not designed for the Bolt and filament type

that you have loaded will result in a failed print, most likely a clogged extruder and can

damage the hardware of the Bolt. Ensure that you have used the latest and correct

settings in the Creatr Software from Leapfrog 3D Printers.

STEP 4

Press ‘Start print’, select the desired ‘printing mode’ (for the first sample print, we advise

‘normal’) and press Start Print.

STEP 5

The Bolt will start heating its extruders to the correct temperature. Afterwards it will

begin moving its head and start extruding filament on to the bed. The first couple of

layers is critical for a successful print.

For more advanced users; during the first layers, the bed height can still be adjusted

using the knobs underneath the bed.

NOTE If for any reason the result has holes, split layers, or failed, please contact

Leapfrog Technical Support via our ticketing system on support.lpfrg.com; please

upload a photo of the result along with a digital copy of your original purchasing invoice

so that we can provide you with a solution as fast as possible.

Page 31

31

4.2 FINISHING PRINT JOBS

After the needed amount of time, the Bolt will finish its Print job and will let the user

know that the Print job is finished.

The following steps can be followed to successfully remove the print and prepare the

Bolt for future print jobs.

1. Check if the print is done printing

2. Remove the print from the print bed

3. Clean the print bed.

STEP 1

A notification on the top of the Bolt software telling the user that de Print is finished.

Pressing the notification will remove it from the screen and the print can ben removed

from the Print bed. The notification will also be visible on another device if the user was

still logged into the printer.

STEP 2

Carefully remove the print from the print bed. The print might still be strongly adhered

to the print bed so apply gradually apply force if necessary. Applying, or spraying

regular water to the bed can help loosen the print from its bed. Waiting a couple of

minutes will let the water dissolve the 3D Spray, releasing the print from the print bed.

STEP 3

Clean the print bed of any debris and left over filament sticking to the print bed. A putty

knife or similar tool can be used. Take care when using a tool when cleaning a debris

from a print sticker, as it can damage the sticker. Window cleaner can be used to clean

the residue of 3D Spray.

Page 32

32

4.3 USING DIFFERENT PRINTING MODES

The Bolt is fitted with two separate heads which provides for new ways of printing. The

two heads can work at the same print job, extruding a single or dual material print, or

work simultaneously, both printing at the same time.

NOTE When the selected print is not yet fully

analysed, a Force print button will appear.

This will allow the user to print the print. Be

sure that the selected print is within the

bounds of the printing area.

NORMAL PRINTING MODE

Pro:

Dual material/Dual colour

Full bed range, larger objects

Con:

Normal production speed

In Normal printing mode, the Bolt can print single extrusion or dual extrusion prints and

the full print bed can be used in Normal printing mode.

Creating a single or dual extrusion print is set in the G-code and is done when creating

a G-code file.

Printing a single extruder print will need only the Right, or Left filament loaded. When

printing a dual extrusion print, both Right and Left filaments will have to be loaded.

SYNC MODE PRINTING

Pro:

Double production speed

Make a copy of the print

Used for multiples of 1 print

Con:

Single material/Dual colour

Page 33

33

Sync mode printing will use both print heads simultaneously for one single extruder

print, printed twice. The result is a copy of the selected G-code over the duration of one

print job. This means that printing with both heads simultaneously the Bolt prints twice

as fast!

In Sync mode, the print bed will be halved since the Bolt will have to print the same

object twice. Both extruders will be used so both the Left and Right filament should be

loaded.

Printing in sync mode will require a G-code file set on the correct (right) half of the print

bed. The Bolt will copy the G-code automatically to the other half of the print bed.

MIRROR MODE PRINTING

Pro:

Double production speed

Make a mirror copy of the print

Used for symmetrical prints

Con:

Single material/Dual colour

Printing a file in mirror mode will also use both print head simultaneously for on single

extruder print, printed twice. The difference with Sync mode printing is that the print

will be not be copied, but mirrored over the Z-axis. This can be useful when making

moulds or orb shaped objects.

In Mirror mode, the print bed will be halved since the Bolt will have to print an additional

mirrored copy of the selected print. Both extruders will be used so both the Left and

Right filament should be loaded.

Printing in sync mode will require a G-code file set on the correct (right) half of the print

bed. The Bolt will copy and mirror the G-code automatically to the other half of the print

bed.

4.4 INFORMATION AVAILABLE ON PRINT JOBS

The Bolt analyses any print job uploaded on the local storage of the Bolt. This

information will help you prepare you amount of filament en time, creating more insight

on the selected print job.

The Bolt will let the user know which nozzle is set in the G-code, as well as how much

filament will be needed. If the amount of filament left on the loaded filament spool is

less than needed, then the Bolt will disable the start print function, preventing the user

to start printing an incomplete print.

Page 34

34

It will also give you a rough preview of the selected print job as well as an estimation on

how much time it will take printing it.

4.5 ACCESSING AND UPLOADING PRINT JOBS

The Bolt is fitted with 32 GB which can be used for storage of G-codes for the Bolt. This

storage can be accessed on the Bolt or on your computer, phone or tablet using Wi-Fi.

The Bolt has a USB port as well.

Accessing the Storage can be done via the Jobs tab in the bottom of the screen. Here

you can access the local storage, USB storage and search for a print.

When plugging in a USB storage device, you will be prompted to browse the USB files.

You can also access the USB on the top of the Jobs tab. On the USB storage you can

navigate to the desired file and upload it to the Bolt.

Any file on the Bolt storage will be analysed. The Bolt will read the G-code for

information like which nozzle is used, how much filament will be needed and will

provide the user with a rough preview.

To upload prints to the Bolt using Wi-Fi, the Bolt has to be connected to the same

network as your computer. In the wireless menu, an IP address can be found. Place this

IP address into your browser as you would a website URL to access the Leapfrog User

Interface of the Bolt. Login to get the right privileges and upload files in the Jobs tab.

For more information on accessing the Bolt via your network, see to chapter 6.3.

Page 35

5 CREATING A PRINTFILE

The Bolt reads G-code. A G-code is a common used file type for production machines

and setting the right parameters for the Bolt is essential. The use of a different type of

settings of another machine can damage or crash the Bolt.

To create a G-code for the Bolt, a 3D model will be needed and imported in the Creatr

Software. A common used file type for digital 3D models is STL and this will be used to

import the 3D model into the Creatr Software.

NOTE Creating a 3D model is not explained in this tutorial. Free 3D model STL’s can

be found online, as well as free 3D modelling tools.

Creating a G-code from a STL means that the Creatr Software will slice the STL in

separate layer, in order for the Bolt to build the 3D model layer per layer. Another

commonly used word for a program like this is therefor a ‘slicer’. For more information

on 3D printing and slicing, go to courses.lpfrg.com and follow the free introduction

course.

Page 36

36

5.1 CREATR POWERED BY MATERIALISE

Install the Creatr Software on a computer which meets the minimum requirements and

create or download the desired STL file that you want to print. For more information on

the Creatr Software refer to the Creatr Software User Manual:

http://cloud.lpfrg.com/materialise/manuals/CREATR.pdf

And download the Creatr Software here:

http://www.lpfrg.com/materialise/download

NOTE Make sure you are using the latest version and profiles of the Creatr Software

for best results.

5.2 PRINTER SELECTION

Once Creatr Software opens, select the Bolt

from the Printer Selection tab at the top of

the program.

5.3 IMPORT

Click the Import tab button at the top. You’ll

be prompted to browse for the STL file that

you would like to print. Find the file’s

location, select the file, and click Open.

Your STL model will be imported to the build platform according how you have your

settings in the Options menu.

Page 37

5.4 TRANSFORM

Upon importing, the Transform tab will

automatically be selected. In the transform

tab you can adjust the imported model

using various options;

Move – This will let you move the selected object on the print bed.

Rotate – This will let you rotate the selected object.

Lay-flat – This will lay the selected plane of the object flat on the print bed.

Rescale – This can make the selected object bigger of smaller.

Duplicate – This allows you the duplicate the selected object multiple times.

Arrange the model keeping in mind in what printing mode the model will be printed.

In Normal printing mode, the print can be placed anywhere on the print bed.

SYNC AND MIRROR PRINTING MODE The print has to be placed on the Left half of the

print bed. The other half will be generated by the Bolt.

5.5 SELECT NOZZLE

Select the desired nozzle for the G-code. By default, the Right nozzle will be selected.

To switch nozzle, or allocate the desired nozzle to the desired part, toggle the Right and

Left indicator on the part information on the right top of the screen.

When using Sync or Mirror mode, the

single nozzle selection will be by-passed

and the nozzle selection won’t be used.

When printing dual material, the correct

filament needs to be loaded to the correct nozzle.

Page 38

38

5.6 PRINT

Select the Print tab. Creatr Software

has Categories of Profiles that need

to be set; one of them (Machine

Settings) is set automatically in the

Edit Profiles window. However, there

are variations of the other 4 types of

profiles, so you’ll need to select which of the variations you want to use under the Print

tab:

Material Profile – this profile

contains settings for the filament

material type that you plan to print

with.

Print mode – this determines what

Slicing Strategy – this profile

contains settings for layer

thickness.

Build Strategy – this profile

contains settings for the outside

contours of the print, the

upskins/downskins (top and

bottom printed layers), the infill,

and more.

Support Strategy – this profile contains settings for any additional printed material such

as a skirt, brim, raft, or generated support structure material.

The Edit profiles button allows you to change the settings of these profiles

NOTE For more detailed and in depth information, refer to the Creatr Software User

manual

http://www.lpfrg.com/materialise/download

Or contact our support: http://support.lpfrg.com/.

Page 39

5.7 PREVIEW AND GENERATE G-CODE

When you’re ready to ‘slice’ the model into a G-code, select the Generate G-CODE

button (found under the same Print tab near the bottom) and click Save. The software

will show a slicing completion percentage.

Note that there is a Cancel button if

you would like to change settings and

re-slice.

For now, we no longer need the

Creatr Software. However, printing

more complex parts often ask the user

to tweak and tune the settings to the shape of the part. This involves testing and

adjusting print settings in order to get the best result possible.

Page 40

40

6 LEAPFROG USER INTERFACE

The Bolt is equipped with software that will give the user control and information on

printing, storage and maintenance of the Bolt. For a quick overview of the Leapfrog

User Interface, see to chapter 2 of this manual. For more information on how to use the

software for printing, see to the chapter ‘Printing’.

6.1 LEAPFROG USER INTERFACE FEATURES

The software provides the user control over the Bolt when printing and keeping the

printer in good condition. In the settings tab the Bolt can be calibrated and set in certain

positions to help the user maintain and clean their Bolt.

The User Interface is accessible via other platforms like a phone, tablet and computer

and can update automatically. When connected to the Bolt with a remote device, the

user can download and upload files, stored on the Bolt. The built-in webcam can be

accessed as well and timelapses can be made and downloaded from the Bolt.

When uploading files, the Bolt will analyse the file to provide useful information as

printing time and needed filament. When the Bolt sees that the amount of filament

exceeds the amount filament left on the spool, it will tell the user.

6.2 REMOTE ACCESS

The Leapfrog User Interface can be controlled using the touchscreen on the machine,

or with another device equipped with network capability and a browser. This also

enables the user to use the webcam’s live view function.

Using the Bolt from the touchscreen will give the user full access to it’s functions and

capabilities. Accessing it remotely will restrict the user with certain functions depending

on the assigned privileges from the account. The different types of users are;

NORMAL USERS These users can only upload files but cannot start prints from a remote

device.

ACTIVE USERS These users can upload and print, but cannot change settings from a

remote device.

ADMIN USERS Admin users can also upload and print as well as change settings on the

printer from a remote device.

Page 41

6.3 CONNECTION THE BOLT USING YOUR NETWORK

Connecting to the Bolt via a remote device can be done using the following steps.

1. Connect the Bolt to your network

2. Find the IP address of your Bolt on your Bolt

3. Connect your device to the same network

4. Open the IP address in your preferred browser

5. Login with your user account

STEP 1

Connect the Bolt to the network using Ethernet or Wi-Fi. When using Ethernet, use a

Ethernet-cable to connect the Bolt directly to the router.

When using Wi-Fi, connect the Bolt to the Wi-Fi network using the Settings à Wireless

tab, as explained in the chapter ‘Printer Setup’.

STEP 2

Go to Settings on the Bolt and go to Wireless. If the Bolt

is connected correctly to the network, there will be a

number shown in the top right corner consisting of 6 to

8 numbers. In this example we will use the IP address

192.168.0.25.

This is the IP address your network as allocated to the

Bolt when it connected to the network and which will be

used to connect the remote device to the Bolt.

STEP 3

Go on your preferred device with network capabilities

and a browser and connect it to the same network as the

Bolt.

STEP 4

Open your preferred internet browser on the remote device and type in the IP address

you have found in the Wireless menu of the Bolt.

The browser should start up the Leapfrog User Interface of the Bolt on your device.

Page 42

42

STEP 5

In order to be able to print or change settings, the remote device should be logged in

to the admin or similar privileged user account.

To log in, click login in the top right corner of the screen and fill in the correct user name

and password.

6.4 USING THE WEBCAM

The Leapfrog User Interface can be used to access the

built-in webcam to view the current print job or create

a time lapse of your print.

There are two places where you can access the

webcam. On the print screen go to info, and click Live

stream to see a live stream of the built-in webcam.

To access the webcam, go to Settings à Webcam, to

open the webcam screen.

Here a current view of the webcam will be shown as a

picture, which can be refreshed. Livestream can also

be selected to view a live stream of the current print

job.

To create a time lapse, the Timelapse settings must be

enabled before starting a print job. Afterwards, the

timelapse can be found under ‘Finished timelapses’ were they can be saved or deleted

from the Bolt.

6.5 PURGE NOZZLES

This function can be used to purge the nozzles of excess or old filament. This can be

useful when cleaning the nozzles and keeping them in good condition.

6.6 MATERIALS

Under Settings àMaterials different types of materials and filament can be added,

edited and removed.

The Bolt pre-heats the nozzles before purging, cleaning and swapping filament.

Different filaments have different nozzle temperatures. Setting the temperature per

Page 43

type of material correctly helps prolong the life or your nozzles and will reduce the

possibility of clogged nozzles greatly.

Page 44

44

7 PRINT SETTINGS

Print settings are very important for successful prints. The print settings are tailored to

the type of material, part, use and quality the user wants.

A part consists of the outside and the inside, or skin and infill. How to print each part of

a total print can be changed, with the speed, amount of skins, amount of retraction and

many more. More information about print settings can be found in the Creatr Software

manual or on courses.lpfrg.com.

7.1 PRINT SPEED VS PRINT QUALITY

As is with regular paper printers, 3D printers also give the user the option to choose

between speed and quality. In general, this means that printing on slower speeds yields

better results in terms of quality and details.

7.2 MATERIAL PROFILES

Material profiles are settings for printing with a specific material. Choosing a profile will

tell the printer how to print the chosen material. This will heavily influence your print

quality and advanced users will adjust the settings per specific print.

7.3 PRINT MODE

Print mode specifies the kind of print your will print. There are 4 different print modes

each with their own use.

Part - Printing a part will print a regular print. This will be the setting most used

Support - This is generally used with dual extrusion. It can be useful to print the part

with one nozzle, and the support with the other like soluble support.

Contour - This will print a single wall shell, or contour, of the selected part in the Creatr

Software.

Infill - This is again generally used with dual extrusion. A part is made of its outside, or

the skin, and the inside, or the infill. The infill can influence the strength or weight of the

part by using more, or less infill.

Page 45

7.4 SLICING STRATEGY

Slicing strategy determines how thick each layer is of the print. Thicker layer will result

in faster print, but courses finishes and lower detail.

7.5 BUILD STRATEGY

The Build strategy determines the amount of up-skin and down-skin (top and bottom

layers) as well as the amount of contours and infill.

7.6 SUPPORT STRATEGY

Support is needed in 3D printing to prevent part of a print from falling down, also

known as overhang. Or is used for complex parts in combination with soluble support,

a material which can be dissolved after printing.

Brim – A brim is a layer, of multiple layer around the print, touching the outside of the

print. This can help stabilise delicate parts printed upwards of the print.

Raft – A raft is a layer underneath the print, which can be broken away, after printing.

This can help stabilise small footprints of the part to create a stronger foundation to

print on.

Standard – With standard, no support will be printed.

Support (same material) – Also known as break-away support. This support will be

printed in the same material and can be easily broken of the part after finished the print

job.

Support (solvable material) – This support can be dissolved after printing, using a

soluble material like Hips of PVA. This can be useful for complex past, where breaking

or removing the support can be hard to reach.

Page 46

46

8 MAINTENANCE & TROUBLE SHOOTING

When using a machine, maintenance has to be done to keep the Bolt in good condition,

of to ensure the Bolt is calibrated correctly. Whenever you encounter a problem, or the

printer isn’t functioning properly, don’t hesitate to contact our support on

support.lpfrg.com.

8.1 INSTALLING UPDATES

The Bolt can update automatically when connected to the internet. Be sure to check

regularly in the Settings tab if an update is available. The number of updates available

is indicated by the number shown in the red circle.

To update, go to Update in the Settings tab, and press refresh in the top right corner.

Then, press update to update the Bolt.

8.2 CLEANING THE PRINT BED

The print bed is normally provided of an adhesive layer, a sticker or 3D Spray, and

debris from the last print.

This Spray and debris can be removed using a detergent like window cleaner and a

putty knife. Scrape the filament debris away with a putty knife and clean the free

platform with a mild detergent. Be careful using a putty knife when removing any debris

from a print sticker as it can easily damage the print sticker.

8.3 CLEANING THE EXTRUDERS

In case of a clogged nozzle, heat up the clogged nozzle as if you were swapping

filament. Try to unload all filament from the extruder. Afterwards, wait until the extruder

is properly heated and re-load filament into the extruder.

8.4 REPLACING THE EXTRUDERS

When a nozzle is not working properly, replacing the hot-end can be a solution. To

replace the hot-end, unscrew the lower thumb screw on the front of the print head.

Disconnect the hot-end at the back of the nozzle block and replace the faulty hot-end

8.5 LEVELLING EXTRUDERS

Perform bed calibration and calibrate the bed on the four corners. Position the print

heads at the center position and get a sheet of paper, of a spacer of 0.150mm. Place

the spacer, or piece of paper, between the bed and nozzles. Unscrew the lower

Page 47

thumbscrews of both heads, loosening both hot-end and dropping them on the spacer.

Tighten both thumbscrews when both extruders are down on the spacer to level the

both extruders.

8.6 CALIBRATE PURGE WIPERS

NOTE The wiper height should be calibrated when the costumer receives their Bolt. If

you think that the wipers aren’t calibrated correctly, continue reading.

Before and after each layer, the Bolt will purge its nozzle

to remove any excess filament to prevent oozing and

leakage of filament on the printed part. The wiper

height should be gently touching the nozzles.

When the wipers are too low or too high, purging won’t

be effective, resulting in strings and oozing your printed

parts which need to be removed afterwards.

To adjust the height of the wipers, you can unscrew the

wiper from its holder. Then the wiper can be adjusted

by either widening the hole in which it is fastened or

cutting the top of the wiper to the correct height.

When the wiper is at the right height, fasten the screw

holding the wiper in place.

Page 48

48

9 CONTACT & ADDITIONAL SUPPORT

9.1 TECHNICAL SUPPORT INFORMATION

Obviously, there is a lot to 3D printing with the Bolt that we couldn’t include in our User

Manual. That doesn’t mean that the information isn’t available. We have already

mentioned that we provide an ever-growing knowledge database that we like to refer

to as ‘Solution Articles.’ If you’ve got a question or technical issue that we didn’t answer

in this manual, please feel free to go to:

http://support.lpfrg.com/support/home and start typing key words related to your

question/issue in the search field on that page. This search field will start generating a

list of articles usually before you’re even finished typing.

If you find that there isn’t an article related to your question/issue, we also have a

ticketing system that, once you set up an account (which is a free, and fast process),

you’ll be able to open new tickets direct to our support agents, who are eagerly

awaiting to assist you. In the ticketing system, up to 15MB of files can be sent per

message allowing Technical Support to send you links, photos, videos, test G-code files,

and more. You too could upload photos and videos of your technical issue to better

describe what is happening. Customers have praised our ticketing system in the past

as being fast, chat-like, and a quick method of resolving any questions or issues that

they had.

We also offer live messaging chat – when agents are available – that can be accessed

by logging into the ticket system.

Questions can also be answered over the phone. We advice you to create ticket

beforehand and have you ticket number nearby. Simply give us a call: +31852080825

between the hours of 7:00AM – 3:30PM CET, Monday through Friday. At the time of

writing this manual, we do not have a toll free phone number.

When leaving a message for a phone appointment, it is advised to have a ticket created

as well.

Page 49

9.2 CREATR SOFTWARE ASSISTANCE

You may also find that you need Technical Support for the Creatr Software (powered

by Materialise) program. Materialise (the company) has asked us to remind you that you

purchased the software though Leapfrog and are therefore our customers, not

Materialises customers. Therefore, please contact Leapfrog 3D Printers Technical

Support or Order Support (depending on your question) if you need help regarding

the software.

Page 50

50

9.3 COMPANY INFORMATION

ADDRESS

Leapfrog 3D Printers

H. Kamerlingh Onnesweg 10

PO BOX 252

2408 AW Alphen aan den Rijn

The Netherlands

ONLINE

Website: www.lpfrg.com

Courses: courses.lpfrg.com

Facebook: https://www.facebook.com/lpfrg

Twitter: https://twitter.com/Leapfrog_3D

Instagram: https://www.instagram.com/leapfrog_3d/

Youtube: youtube.com/c/Leapfrog3DPrintersBV

Website blog: http://www.lpfrg.com/en/blog

CONTACT

General

info@lpfrg.com

+31 172 50 36 25

Support

support@lpfrg.com

+31 852 08 08 25

Sales

sales@lpfrg.com

+31 172 50 36 24

COMPANY INFORMATION

Chamber of Commerce

The Hague: 28040550

VAT: NL006608565B01

BIC: RABONL2U

IBAN: NL19 RABO 0317 4454 05

Rabobank Walcheren/Noord Beveland

Account nr: 3174.45.405!

!

Loading...

Loading...