Page 1

ENJOY YOUR BOOKS

PLEASE VISIT OUR STORE FOR EVEN MORE GREAT

STUFF!

COPYRIGHT NOTICE

ALL MATERIALS INCLUDING CD/DVD AND PDF

FILES ARE COPYRIGHTED

VON

WALTHOUR PRODUCTIONS AND MAY NOT BE

REPROD UCED, COPIE D OR RESOLD UNDER ANY

CIRCUMSTANCES. YOU MAY HOWEVER MAKE A

COPY FOR YOUR OWN PERSONAL BACKUP.

MATERIALS ARE FOR PERSONAL USE ONLY.

IF YOU PURCHASED THIS FROM ANYWHERE BUT

FROM US PLEASE NOTIFY US IMMEDIATELY SO

THAT WE MAY CHECK IF YOU PURCHASED FROM

AN AUTHORIZED RESELLER SO WE CAN LET YOU

KNOW IF YOU NEED TO RETURN FOR FULL REFUND

FROM AN UNAUTHORIZED SELLER.

THANKS AGAIN AND PLEASE TAKE THE TIME TO

VISIT OUR STORE.

ATTE NTION! EVERYTHING ON S ALE NOW!!

Page 2

Page 3

WARNING!

THE SERVICING INSTRUCTIONS CONTAINED IN THIS MANUAL

ARE FOR USE BY QUALIFIED PERSONNEL ONLY. TO AVOID

ELECTRIC SHOCK, DO NOT PERFORM ANY SERVICING

OTHER THAN THAT CONTAINED IN THE OPERATING

INSTRUCTIONS UNLESS YOU ARE QUALIFIED TO DO SO.

Page 4

TABLE OF CONTENTS (Continued)

3-4 CALIBRATION OUTPUT ADJUSTMENT ...................................................................................................... 30

3-5 A TIMEBASE ALIGNMENT ........................................................................................................................... 30

3-5-1 Slow Sweep Time ................................................................................................................................. 30

3-5-2 Sweep Length .......................................................................................................................................30

3-5-3 Fast Sweep Time .................................................................................................................................. 30

3-5-4 Sweep Start Point .................................................................................................................................30

3-5-5

Timebase Accuracy Check .................................................................................................................... 30

3-6 A TIMEBASE X10 MAGNIFIER ADJUSTMENT ........................................................................................... 30

3-6-1 Magnifier Positioning ........................................................................................................................... 30

3-6-2 Magnifier Speed Accuracy ....................................................................................................................30

3-7 B TIMEBASE ALIGNMENT ........................................................................................................................... 30

3-7-1 Slow Sweep Time ................................................................................................................................. 30

3-7-2 Length Adjustment ...............................................................................................................................31

3-7-3 Sweep Start Point .................................................................................................................................31

3-7-4 Fast Sweep Time .................................................................................................................................. 31

3-7-5 Timebase Accuracy Check ....................................................................................................................31

3-7-6 Start Points Alignment ..........................................................................................................................31

3-8 VERTICAL AMPLIFIERS ...............................................................................................................................31

3-8-1 DC Balance Adjustment ........................................................................................................................31

3-8-2 Attenuator Step Balance ........................................................................................................................30

3-8-3 X1 AC Gain Compensation ................................................................................................................... 31

3-8-4 X10 AC Gain Compensation ................................................................................................................. 31

3-8-5 Gain Calibration ................................................................................................................................... 31

3-8-6 CH-2 Invert Balance Adjustment ........................................................................................................... 32

3-8-7 CH-1/CH-2 Input Capacitance Adjustment ............................................................................................32

3-8-8 CH-1/CH-2 Input Attenuator Compensation ..........................................................................................32

3-8-9 CH-3 Direct Input Capacitance Adjustment ...........................................................................................32

3-8-10 CH-3 Attenuator Compensation .......................................................................................................... 32

3-8-11 CH-3 Attenuator Input Capacitance Adjustment ...................................................................................32

3-8-12 CH-3 Gain Adjustment ....................................................................................................................... 32

3-8-13 CH-1 Output Level Adjustment ........................................................................................................... 32

3-8-14 CH-1/CH-2 HF Pulse Response Alignment .......................................................................................... 32

3-8-15 CH-1/CH-2 Frequency Response Check .............................................................................................. 33

3-8-16 CH-1 Output Pulse Response .............................................................................................................. 33

3-8-17 CH-1/CH-2 X10 Magnifier Bandwidth Check .....................................................................................33

3-8-18 Vertical Position Control Centering ..................................................................................................... 33

3-8-19 ADD Balance Adjustment ................................................................................................................... 33

3-9 TRIGGER CIRCUITRY ADJUSTMENTS .......................................................................................................33

3-9-1 Trigger Balance and Centering Alignments ........................................................................................... 33

3-9-2 Trigger Balance Adjustments for Multitrace Modes ...............................................................................33

3-9-3 Preset Trigger Adjustment .................................................................................................................... 34

3-9-4 CH-3 Pulse Response Adjustment .........................................................................................................34

3-9-5 Internal Trigger-Pulse Response Adjustment ......................................................................................... 34

3-10 X-Y MODE ADJUSTMENTS .................................................................................................................. 34

3-10-1 Gain Adjustment .................................................................................................................................... 34

3-10-2 Balance Adjustment ...............................................................................................................................34

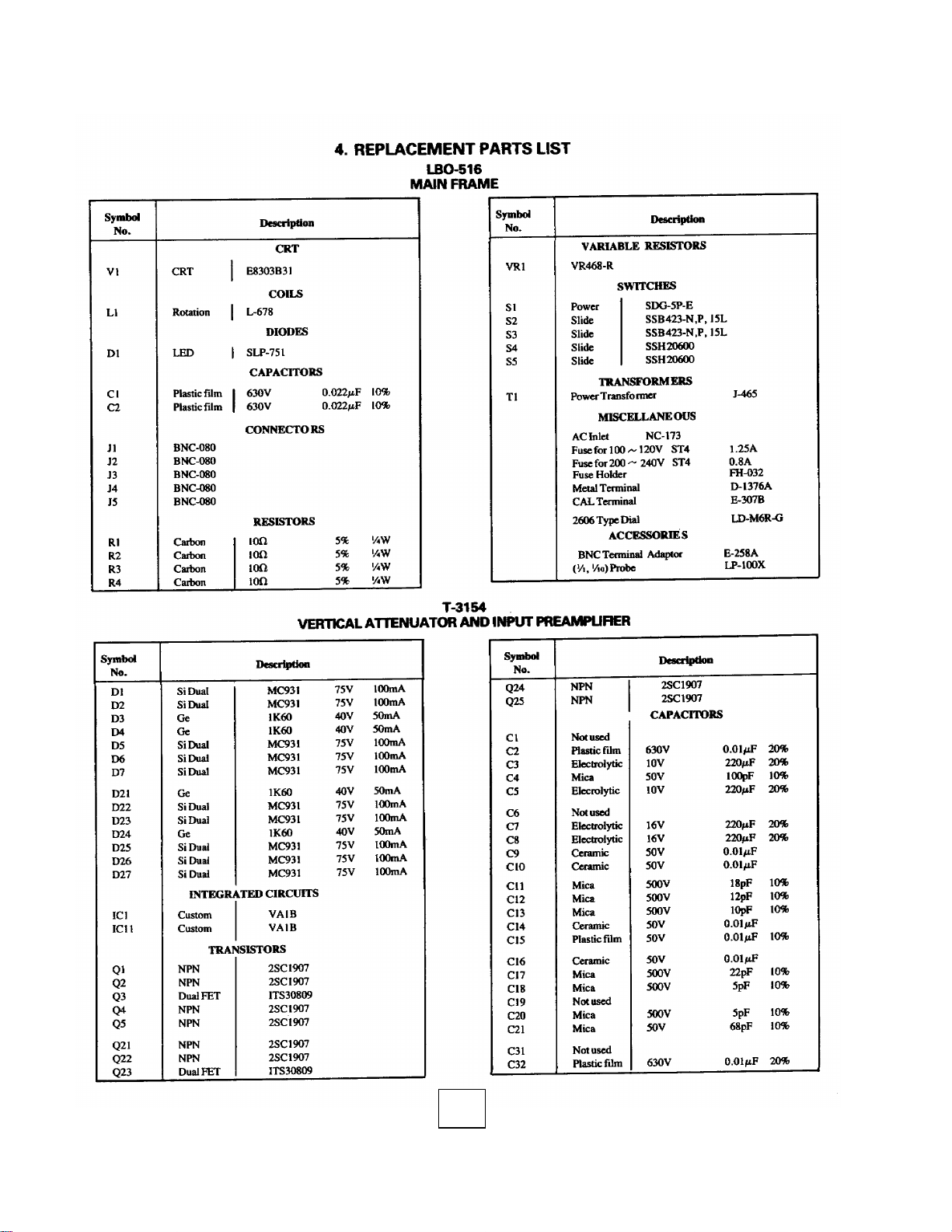

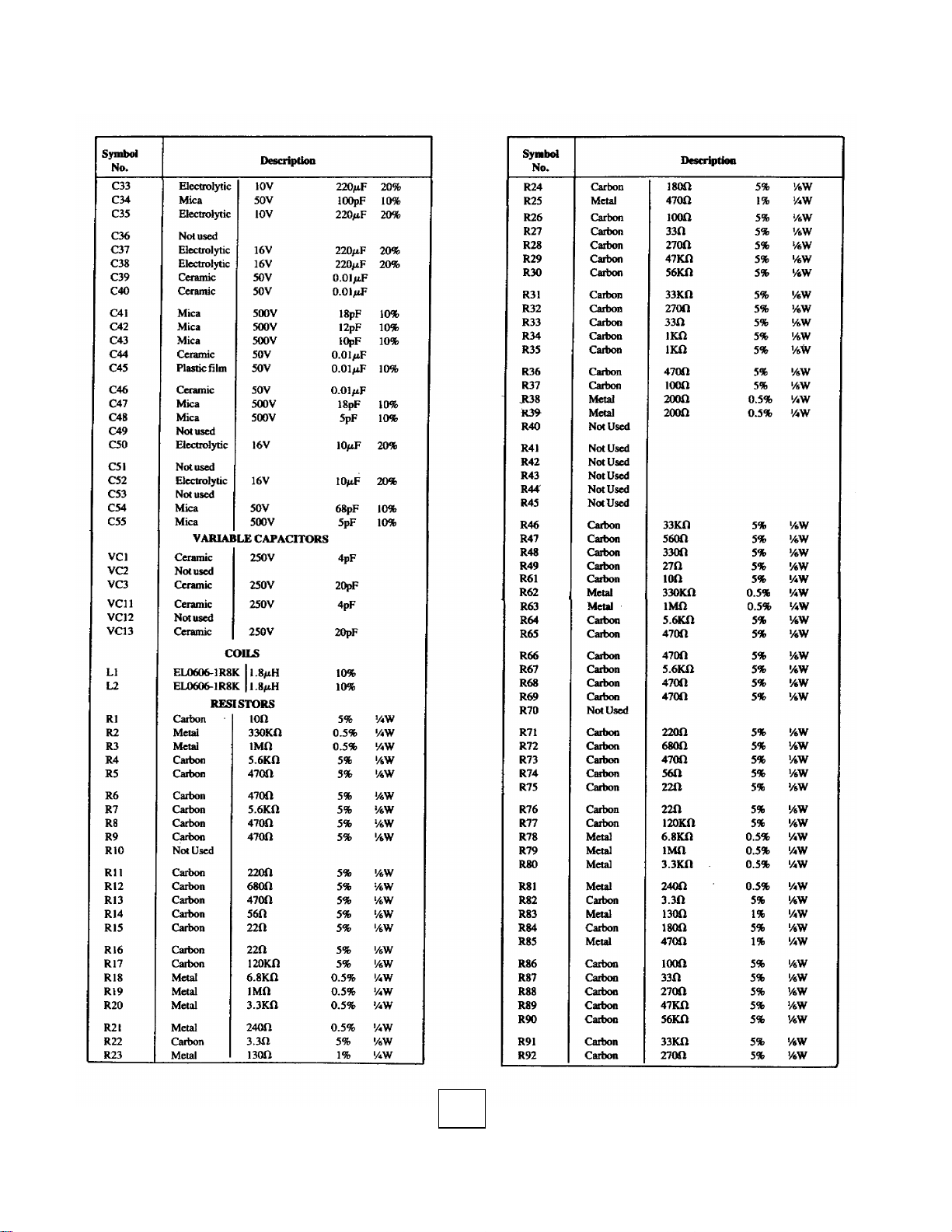

4. REPLACEMENT PARTS LIST 37

5. BLOCK DIAGRAM, SCHEMATICS AND P.C. BOARDS 51

Page 5

3. MAINTENANCE AND CALIBRATION

3-0.

The following test equipment is required to perform the

calibration/maintenance procedures described in this section.

The performance specifications given are the minimum

necessary to accurately calibrate the oscilloscope.

Description Minimum Specifications

1. Digital Voltmeter DC Voltage Range: 0-200 VDC

Accuracy: +0.5%

2. High Voltage DC Voltage Range: 0-2000 VDC

Voltmeter Accuracy: -+ 1%

3. Frequency Counter Frequency Range: 100 Hz -

200 MHz

Overall Accuracy: +0.001%

4. Time Mark Generator Marker Outputs: 2nS - 0.5 S with

calibrated

Accuracy: -+0.1%

5. Sine Wave Generator Frequency Range: lkHz - 200 kHz

Output Level: 15 mV - 5 Vp.p

Accuracy: -+.3 dB, 1 MHz - 200

MHz as frequency is changed

6. Test Oscilloscope 100 MHz Bandwidth

7. Square Wave Frequency: 1 kHz - 100kHz, -+1%

Generator Output Level: I mV - 1.0 Vp-p,

-+1%

Rise Time: 3 nS

8. Amplitude Calibrator Output: 1 kHz square wave

Frequency Accuracy: -+0.25%

Output Level: 2 mV - 20 Vp-p

9. Capacitance Meter Range: 0-50 pF

Accuracy: --- 1%

3-1. INITIAL SETUP CONDITIONS

POWER switch ......................…………Pushed in

A INTEN control ............................... Centered*

B INTEN control ................................ Centered*

ILLUM control .................................. Clockwise

FOCUS control .................................. Centered*

AC/GND/DC switches ....................... DC

VOLTS/DIV switches ........................ 20mV

VARIABLE controls .......................... Clockwise

X10 MAG switches ………………… Pushed in

Vertical POSITION controls ......…… Centered*.

PULL QUAD control ...............… Pushed in

PULL TRIPLE control ...............… Pushed in

V MODE switches ...................... … CH-1

CH-2 INV switch ....................... …… Out

DLY TIME MULT control .........…… Counterclockwise.

COUPLING switch ...................…… AC

SOURCE switch ......................……….CH-1

LEVEL control ........................………. 0

HOLDOFF control ..................... Detented counter

A/B TRACE SEP control .............. Centered

SLOPE switch ........................... Out

HORIZ DISPLAY switches. .......... A

START switch .......................... Out

SWEEP MODE switches .............. AUTO

+

5% offset adjust

clockwise and

pulled out

29

A TIME/DIV switch .................... .5 mS

B TIME/DIV switch .................... .1 mS

A VARIABLE control ................. Clockwise

Horizontal POSITION control ........ Centered*

* Adjusted afterwards for best viewing

Allow 30 minutes warmup before making any adjustments. Remove the top and bottom covers to gain access to test

points and internal adjustments.

3-2 POWER SUPPLY CHECK AND ADJUSTMENT

3-2-1 -8 Volt Adjustment

Connect a digital voltmeter's positive lead to the scope

chassis (GND), and the voltmeter's negative lead to TP-5 located on PCB T-3153. Adjust VR-1 for -8.0 V.

3-2-2 Power Supply Check

Check the voltages listed below by moving the

voltmeter's negative lead to chassis ground, and applying the

positive lead, in turn, to each of the associated test points on

PCB T-3153.

Nominal

Test Point Voltage Tolerance

TP-I +100 +98 VDC 'to 102VDC

TP-2 + 50 49 51

TP-3 + 12 11.75 12.25

TP-4 + 8 7.85 8.15

TP-6 + 5 4.8 5.2

TP-7 + 19 17.5 20.5

3-2-3 High-Voltage Adjustment

Turn off the unit under test. Connect the positive lead of a

HV voltmeter to chassis ground, and its negative lead to TP-8.

Turn the scope on and allow a 2 minute warmup. Adjust VR-2

on PCB T-3162 for a reading of - 1950 volts. Connect an X10

probe to the test oscilloscope and hold its tip close to the face

of the CRT under test. The high-voltage ripple displayed on

the test oscilloscope should be less than 0.1Vp-p.

3-3. CRT CONTROL ADJUSTMENTS

Make sure the controls are set according to the initial

setup conditions in Paragraph 3-1 before starting the following

adjustments.

3-3-1 Intensity Range Adjustment

Center the CH- 1 trace on the CRT with the vertical

POSITION control. Set the A INTEN control knob mark to an

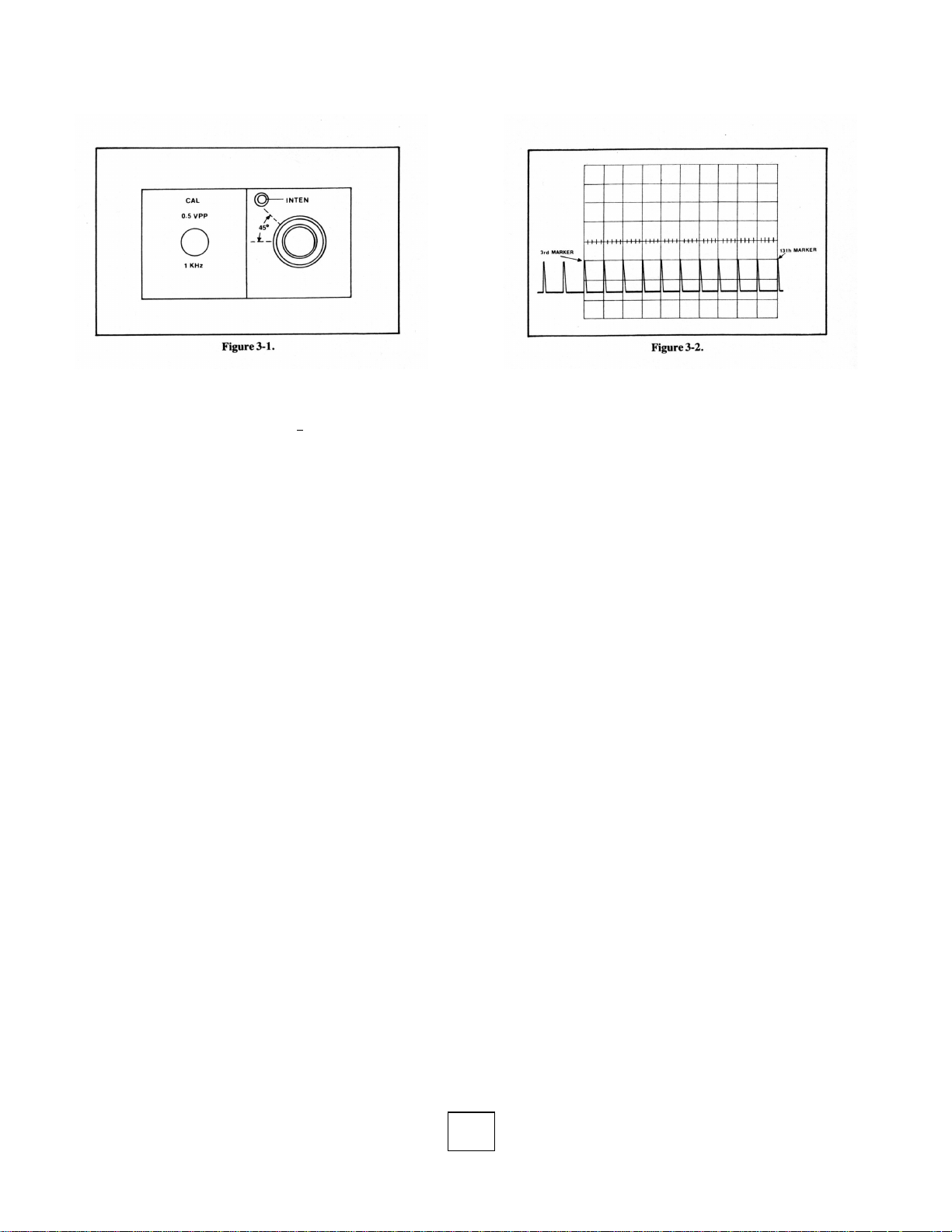

approximate 45° angle as shown in Figure 3-1. Adjust VR-I on

PCB T-3162 until the trace becomes just barely visible.

3-3-2 Astigmatism Adjustment

Connect a sine wave generator to the CH-1 input connector. Set generator frequency and output to produce five or six

sine waves. Set output level and POSITION controls for a

centered display 6 cm high. (Peaks of the sine waves just

touching the graticule lines I cm above and below the bottom

and topmost graticule lines.) Adjust A INTENS and FOCUS

for a medium-bright, sharp display. Adjust VR- 1 on PCB T3157 for optimum overall sharpness.

.

.

Page 6

3-4. CALIBRATION OUTPUT ADJUSTMENT

Connect the test oscilloscope to the CAL connector on the

fron panel of the LBO-516. Adjust VR-1 on PCB T-3287 for a

CAL output level of 0.5 Vp-p +-1%.

square wave should be 45-55%.

Connect the CAL output to a frequency counter; the frequency should be 1000 Hz + - 10%.

3-5. A TIMEBASE ALIGNMENT

3.5-1 Slow Sweep Time

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1). Adjust the time-mark generator for an

output of .5 mS and connect it to the CH-1 input connector.

Using the horizontal POSITION control, align the first mark

with the leftmost vertical graticule line. Adjust VR-22 on PCB

T-3158 to align each subsequent mark with a major vertical

graticule line.

3.5-2 Sweep Length

With the same conditions as in the previous paragraph,

adjust the horizontal POSITION control to align the third mark

with the leftmost vertical graticule line. (See Figure 3-2.)

Adjust VR-1 on PCB T-3158 so the 13th mark is fully displayed on the CRT screen.

3.5-3 Fast Sweep Time

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1). Set the A TIME/DIV switch to 0.5 PS.

Set the time-mark generator to 0.5/.PS and connect it to the

CH- 1 input connector. Using the horizontal POSITION

control, align the first mark with the leftmost vertical graticule

line. (See Figure 3-2.) Adjust VC-22 on PCB T-3158 to align

each subsequent mark with a major vertical graticule line.

3.5-4 Sweep Start Point

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1). Set the A TIME/DIV switch to 0.1 mS.

With the horizontal POSITION control, adjust the trace

startpoint to the first minor division (0,2 major division).

Change the A T1ME/DIV switch to 50/aS and adjust VC-1 on

PCB T-3158 so the sweep starts at the leftmost vertical

graticule line.

3.5-5 Timebase Accuracy Check

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1). Set the A TIME/DIV switch to 0.5 S. Set

The duty cycle of the

the time-mark generator to 0.5 S and connect it to the CH- 1

input connector. Align the first mark with the left-most vertical

graticule line. Adjust the generator so that each subsequent

mark is aligned with a major vertical graticule line. Repeat for

each A TIME/DIV switch setting from.2 S to 0.2PS, verifying

that the timebase accuracy is within +-2% at each sweep

speed.

3-6. A TIMEBASE X10 MAGNIFIER ADJUSTMENT

3-6-1 Magnifier Positioning

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1.) Set the CH-1 AC/GND/DC switch to

GND, and press the INTEN BY B pushbutton. Set the B

TIME/DIV switch to .5 mS. Adjust the horizontal POSITION

control to start the A trace on the leftmost vertical graticule

line. Adjust the DLY TIME MULT control to start the B

(intensified) trace at the center vertical graticule line. Center

the horizontal POSITION control knob. Pull the timebase X10

MAG switch. Adjust VR-33 on PCB T-3158 so that the B

sweep starts on the center graticule line. Afterward, push in the

X 10 MAG switch knob, and adjust VR-34 on PCB T-3158 so

that the B sweep starts on the center graticule line. Repeat

these two adjustments (VR-33 and VR-34) until the B trace

starts on the center graticule line in both positions of the XI0

MAG switch.

3-6-2 Magnifier Speed Accuracy

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1). Connect a time-mark generator set for. 5

mS output to the CH-1 input connector. Set the A TIME/DIV

switch and horizontal POSITION control so every third mark

is aligned with a major vertical graticule line. Pull the X10

MAG knob, then adjust VR-35 on PCB T-3158 so a mark is

aligned with the first, center, and last major vertical graticule

line.

3-7. B TIMEBASE ALIGNMENT

3-7-1 Slow Sweep Time

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1.) Set the CH-1 VOLTS/DIV switch to. 1

V. Connect a time-mark generator set for .5 mS to the CH-1

input connector. Set the DLY TIME MULT control to 2.50,

and press the B HORIZ DISPLAY pushbutton. Adjust the

DLY TIME MULT control to align the nearest mark with the

30

Page 7

leftmost vertical graticule line. Adjust VR-21 on PCB T-3158

to align each of the subsequent marks with a major vertical

graticule line.

3-7-2 Length Adjustment

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1.) Connect a time-mark generator set for 0.5

mS to the CH- 1 input connector. Using the horizontal POSITION control, align the third mark with the leftmost vertical

graticule line, and adjust VR-11 on PCB T-3158 so that the

13th mark is fully displayed on the CRT screen.

3-7-3 Sweep StartPoint

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1.) Press the B HORIZ DISPLAY

pushbutton. Using the horizontal POSITION control, adjust

the trace start point to a little less than the first minor division

on the center horizontal graticule line (0.15 major division).

Change the B TIME/DIV switch to 50 PS, then adjust VC- 11

on PCB T-3158 so the sweep starts at the leftmost vertical

graticule line.

3-7-4 Fast Sweep Time

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1.) Set the A TIME/DIV switch to PS, and

the B TIME/DIV switch to 0.5PS. Press the B HORIZ DISPLAY pushbutton. Connect a time-mark generator set for

0.5PS output to the CH-1 input connector. With the horizontal

POSITION control, align the first mark with the leftmost

vertical graticule line. Adjust VC-21 on PCB T-3158 to align

each of the subsequent marks with the other vertical graticule

lines.

3-7-5 Timebase Accuracy Check

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1.) Set the A and B TIME/DIV switches to

50 mS, and press the B HORIZ DISPLAY pushbutton.

Connect a time-mark generator set for 50 mS output to the

CH- 1 input connector. Align the first mark with the leftmost

vertical graticule line. Adjust the generator so each subsequent

mark is aligned with a major vertical graticule line. Repeat the

above for each TIME/DIV setting from 20 mS to .02PS, verifying that the timebase accuracy is within +-2% at each sweep

speed.

3-7-6 Start Points Alignment

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1). Set the CH- 1 AC/GND/DC switch to

GND, and the B TIME/DIV switch to 5PS. Press the INTEN

BY B HORIZ DISPLAY pushbutton, and adjust the A and B

INTEN controls for a noticeable difference between the A and

B traces. Using the horizontal POSITION control, make the A

trace start at the leftmost vertical graticule line. Check that the

DLY TIME MULT control is set at 0.2 (fully CCW), then

adjust VR-13 on PCB T-3158 so that the B trace starts at the

minor

first

VR-12 on PC T-3158 to make the B trace start at the rightmost vertical graticule line. Repeat both of these adjustments

until the B trace starts at the proper points.

3-8. VERTICAL AMPLIFIERS

vertical graticule line.

Turn the DLY TIME MULT control to 10.0 and adjust

3-8-1 DC Balance Adjustment

Retain the oscilloscope to the initial setup conditions.

(See Paragraph 3-1). Set the CH-1 and CH-2 VOLTS/DB/

switches to 5 reV, the CH-I and CH-2 AC/GND/DC switches

to GND, and center the trace vertically with the vertical

POSITION control. Then, pull the CH-I X10 MAG switch

knob, and adjust VR-5 on PCB T-3154 to recent

Repeat the above by turning the X10 MAG switch on and off,

and readjusting the vertical POSITION control and VR-5 for

minimum shift.

Press the CH-2 V MODE pushbutton, and repeat the

above procedure for CH-2. VR-15 on PCB T-3154 is the CH-2

adjustment.

3-8-2 Attenuator Step Balance

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1). Set the CH-I and CH-2 VOLTS/DIV

switches to 10 mV, and the AC/GND/DC switches to GND.

Center the trace vertically using the CH-I vertical POSITION

control. Change the CH-1 VOLTS/DIV switch to 5 mV, and

adjust VR4 on PCB T-3154 to recenter the trace. Repeat the

above until there is very little shift in the trace when switching

between I0 mV and 5 mV positions of the VOLTS/DIV

switch.

Press the CH-2 V MODE pushbutton, and repeat the

above procedure for CH-2. VR-14 on PCB T-3154 is the CH-2

adjustment.

3-8-3 X1 AC Gain Compensation

Return the oscilloscope to the initial setup conditions.

(See Paragraph 3-1). Set the CH-1 and CH-2 VOLTS/DIV

switches to 5 mV, the A TIME/DIV switch to .2 mS, and press

the ALT V MODE pushbutton.

Connect a square-wave generator to the CH-1 and CH-2

input connectors. Adjust the generator frequency to I000 Hz,

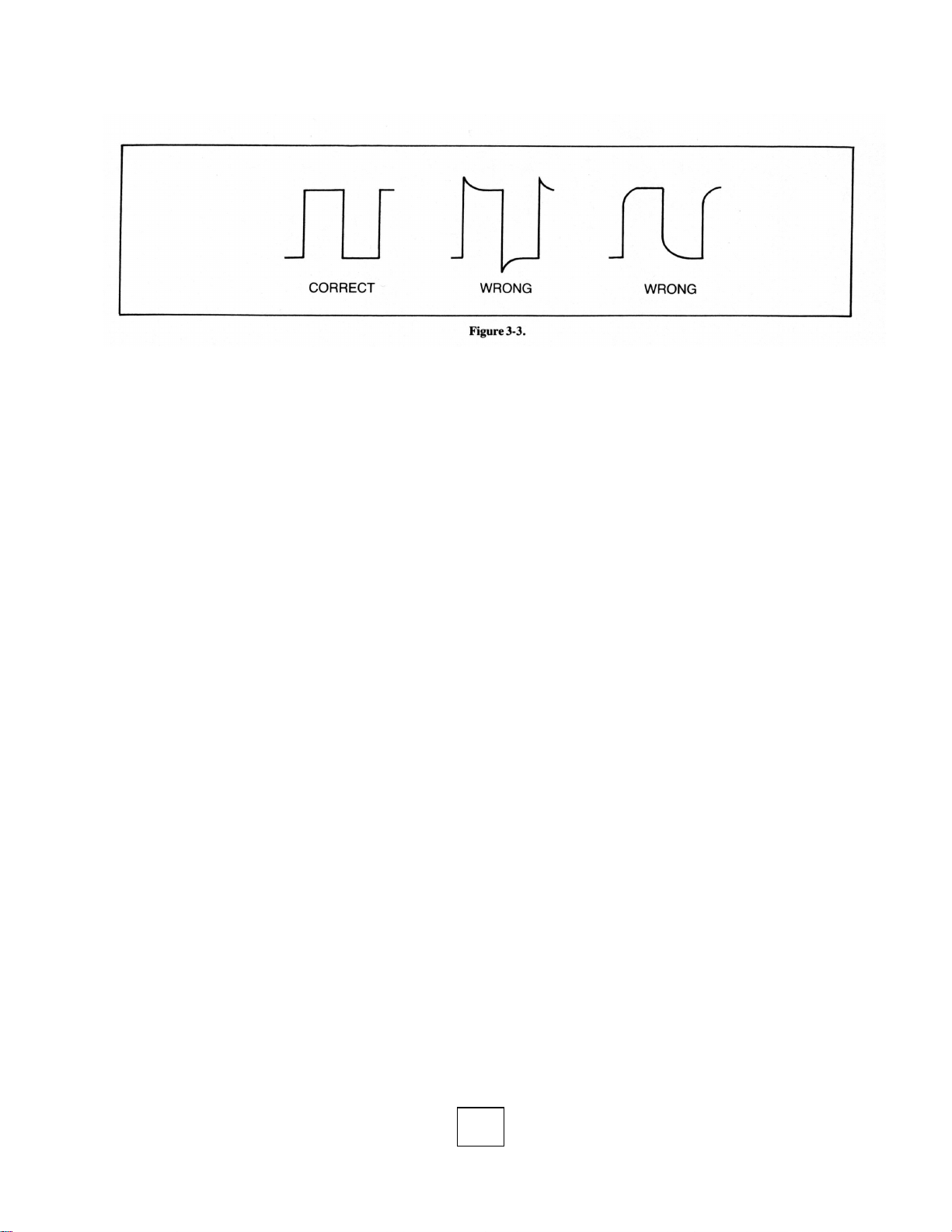

and its output level to 25 mVp-p.Adjust VR- 1 on PCB T-3154

for a correct square-wave display, per Figure 3-3. After

channel 1 is compensated, adjust VR-11 on PCB T-3154 for a

correct channel 2 display.

3-8-4 X10 AC Gain Compensation

With conditions set as in Paragraph 3-8-3, turn both

VOLTS/DB/switches to 20 mV and pull both vertical X10

MAG control knobs. Set the square-wave generator output to

10 mVp-p.

Adjust VR-2 on PCB T-3154 for a correct square-wave

display, per Figure 3-3. After channel 1 is compensated, adjust

VR-12 on PCB T-3154 for a correct CH-2 display.

3-8-5 Gain Calibration

With conditions set as in Paragraph 3-8-4, turn both

VOLTS/DIV switches to 5 mV, and remove the square wave

generator.

Connect an amplitude calibrator whose output is set for

25 mVp-p to the CH-1 and CH-2 input connectors. Adjust VR21 on PCB T-3155 for a CH-1 vertical deflection of~ major

divisions. Adjust VR-23 on PCB T-3155 for a CH-2 vertical

deflection of 5 major divisions.

er

the trace.

31

Page 8

3-8-6 CH-2 INV Balance Adjustment

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Press the CH-2 V MODE switch, and set the

CH-2 AC/GND/DC switch to GND.

Center the trace vertically using the CH-2 vertical POSITION control. Press the CH-2 INV switch, and note the amount

that the trace shifts from the centered position. Using VR-11 on

PCB T-3155, move the trace half the distance it shifted, back

towards the center of the CRT screen. Release the CH-2 INV

switch, and recenter the trace with the CH-2 vertical POSITION

control. Repeat the above adjustments as the CH-2 INV switch

is operated, until there is no trace shift from one position to the

other.

3-8-7 CH-1/CH-2 Input Capacitance Adjustment

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1). Set the VOLTS/DIV switches to 5mV.

Connect a capacitance meter to the CH-1 input connector

and adjust VC-1 (Ci-1) on PCB T-3154 for 30 pF. Reset the

VOLTS/DIV switch to 20 mV and adjust 1/2 Ci for 30 pF. Reset

the VOLTS/DIV switch to 50 mV and adjust 1/5 Ci for 30 pF.

Reset the VOLTS/DIV switch to .1 V and adjust l/l0 Ci for 30

pF. Reset the VOLTS/DIV switch to 1 V and adjust 1/100 Ci for

30 pF.

Press the CH-2 V MODE pushbutton, and repeat the above

adjustments on VC-11 for channel 2.

3-8-8 CH-1/CH-2 Input Attenuator Compensation

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1). Connect a square-wave generator to the CH-1

input connector. Set the generator controls for 100 mV output at

1000 Hz.

Adjust CH-1 1/2Cc on PCB T-3154 for a correctly compensated

square-wave. (See Figure 3-3.) Reset the CH-1 VOLTS/DIV

switch to 50 mV, and the generator output level for 250 mVp-p.

Adjust CH-1 1/5Cc on PCB T-3154 for a correctly compensated

square wave. Reset the CH-1 VOLTS/ DIV switch to .1 V, and

the generator output level to .5 V. Adjust CH-1 1/10Cc on PCB

T-3154 for a correctly compensated square-wave. Reset the CH1 VOLTS/DIV switch to 1 V, and the generator output level to 5

Vp-p. Adjust CH-1 1/100Cc for a correctly compensated squarewave.

Press the CH-2 V MODE switch, and repeat the above procedure for CH-2, using the CH-2 1/2Cc, 1/5Cc, 1/10Cc. and

1/100Cc adjustment trimmers.

3-8-9 CH-3 Direct Input Capacitance Adjustment

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Press the ALT V MODE pushbutton, pull the

PULL TRIPLE control knob, set the SOURCE switch to .2

V/DIV, and the COUPLING switch to DC.

Connect a capacitance meter to the CH-3 input connector.

Adjust VC-5 (C IN) on PCB T-3153 for a 30 pF indication.

3-8-10 CH-3 Attenuator Compensation

With conditions set as in Paragraph 3-8-9, reset the

SOURCE switch to 2 V/DIV. Connect a square-wave generator

to the CH-3 input connector. Set the generator controls for 10

Vp.p output at 1000 Hz.

Adjust VC-3 (CC) on PCB T-3153 for a correctly

compensated square- wave, per Figure 3-3.

3-8-11 CH-3 Attenuator Input Capacitance Adjustment

With conditions set as in Paragraph 3-8-10, remove the

square-wave generator and connect a capacitance meter to the

CH-3 input connector. Adjust VC-3 (C-l) for 30pF meter

indication.

3-8-12 CH-3 Gain Adjustment

With conditions set as in Paragraph 3-8-11, remove the

capacitance meter and connect an amplitude calibrator to the

CH-3 input connector. Set the calibrator controls for 1 Vp-p

output at 1000 Hz. Adjust VR-26 on PCB T-3155 for 5 major

divisions of vertical deflection on the CRT screen.

3-8-13 CH-1 Output Level Adjustment

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Connect the CH-1 OUTPUT connector to a test

oscilloscope having a 50-ohm feedthrough termination on its

input. Set the test oscilloscope's input attenuator at 20 mV/div.

Connect an amplitude calibrator adjusted for an output level of

100 mVp-p at 1000 Hz to.the CH-1 input connector of the LBO-

516.Adjust the CH-1 VARIABLE control for 4 major divisions

of vertical deflection on the LBO-516, then adjust VR- 1 on

PCB T-3155 for 4 divisions of vertical deflection on the test

oscilloscope.

Set the CH-1 AC/GND/DC switch to GND, and the CH-1

VARIABLE control to CAL'D. Make sure the test oscilloscope

is DC coupled and its ground reference is known. Adjust VR-2

on PCB T-3155 for a 0 VDC output as indicated on the test

oscilloscope.

3-8-14 CH-I/CH-2 HF Pulse Response Adjustment

Return the oscilloscope to the initial setup conditions. (See

32

Page 9

Paragraph 3-1.) Set the CH-1 VOLTS/DIV switch to 5 mV, the

A TIME/DIV switch to 2/aS, the B TIME/DIV switch to .2 PS,

and press the INTEN BY B HORIZ DISPLAY pushbutton.

Connect a square-wave generator to the CH-1 input conneetor, and set the generator for 25 mVp-p output at 100 kHz.

Adjust the DLY TIME MULT control so the B (intensified)

trace is positioned over a leading edge of the displayed square

wave. Press the B HORIZ DISPLAY pushbutton, and adjust

VC-21 on PCB T-3155 and VC-1, VR-1, VC-2, VR-2, and VC3 on PCB T-3156 for minimum observed overshoot and ringing.

This can be checked by setting the CH-1 VOLTS/ DIV switch to

20 mV and pulling the CH-1 X10 MAG knob.

Cheek that the overshoot and ringing is less than 3% at all

positions of the CH-1 VOLTS/DIV switch. In each case the

generator output level should be adjusted for 5 major divisions

of vertical deflection.

Repeat the above procedure for CH-2. The corresponding

adjustment parts for CH-2 are VC-11 and VC- 12 on PCB T3155, and VC-13 on PCB T-3154.

3-8-15 CH-1/CH-2 Frequency Response Check

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Make sure the X10 MAG switches are pushed

in. Set the VOLTS/DIV controls to 5 mV, and the A TIME/DIV

switch to 2PS.

Connect a sine-wave generator to the CH-1 input connector, making sure the feedthrough termination appropriate for the

generator is attached to the CH- 1 input connector. Adjust the

generator for an output level of 40 mVp-p at 1 MHz; monitor the

frequency with a frequency counter.

Increase the frequency until the display indicates 5.6 major

divisions of vertical amplitude. This is the -3 dB point. The

counter should indicate a frequency of over 100 MHz. Repeat

the applicable adjustments in Paragraph 3-8-14 if it does not.

Move the generator to the CH-2 input connector, and press

the CH-2 V MODE pushbutton. Set the SOURCE switch at CH2, and repeat the above procedure for channel 2.

3-8-16 CH-1 Output Pulse Response

With conditions set as in Paragraph 3-8-13, set the CH-1

VOLTS/DIV switch of LBO-516 and that of the test oscilloscope to 5 mV/div.

Connect a square-wave generator adjusted for an output

frequency of I00 kHz to the CH-1 input connector. Adjust the

generator output level for 4 divisions of vertical deflection on

the test oscilloscope. Then, adjust VC- 1 and VC-2 on PCB T3155, and VC-3 on PCB T-3154 for less than 7% overshoot at

the leading and trailing edges of the waveform displayed on the

test oscilloscope.

3-8-17 CIt-1 & CH-2 Xl0 Magnifier Bandwidth Check

Return the oscilloscope to the initial setup conditions.(See

Paragraph 3-1.) Set the A TIME/DIV switch to 2PS, and pull the

CH-1 and CH-2 X10 MAG switch knobs.

Connect a sine-wave generator to the CH-1 input connector, and adjust it for 8 divisions deflection at 1 MHz. Monitor

the generator frequency with a frequency counter. Increase the

generator frequency until the displayed amplitude decreases to

5.6 divisions. This is the -3 dB point. The counter should

indicate a frequency of over 5 MHz.

Move the generator to the CH-2 input Connector, and press

the CH-2 V MODE pushbutton. Set the SOURCE switch at CH2, and repeat the above procedure for CH-2.

3-8-18 Vertical POSITION Control Centering

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Press the ALT V MODE pushbutton, and pull

the PULL TRIPLE control knob. Make sure the CH-1, CH-2,

and CH-3 vertical POSITION control knobs are set with their

index marks pointing straight up.

Adjust VR-22 on PCB T-3155 to position the CH-1 trace

on the center horizontal graticule line. Adjust VR-24 on PCB T3155 to position the CH-2 trace on the center horizontal

graticule line. Adjust VR-25 to position the CH-3 trace on the

center horizontal graticule line.

3-8-19 ADD Balance Adjustment

With conditions set as in Paragraph 3-8-18, push in the

ADD V MODE pushbutton. Adjust VR-27 on PCB T-3155 to

position the trace on the center horizontal graticule line.

3-9 TRIGGER CIRCUITRY ADJUSTMENTS

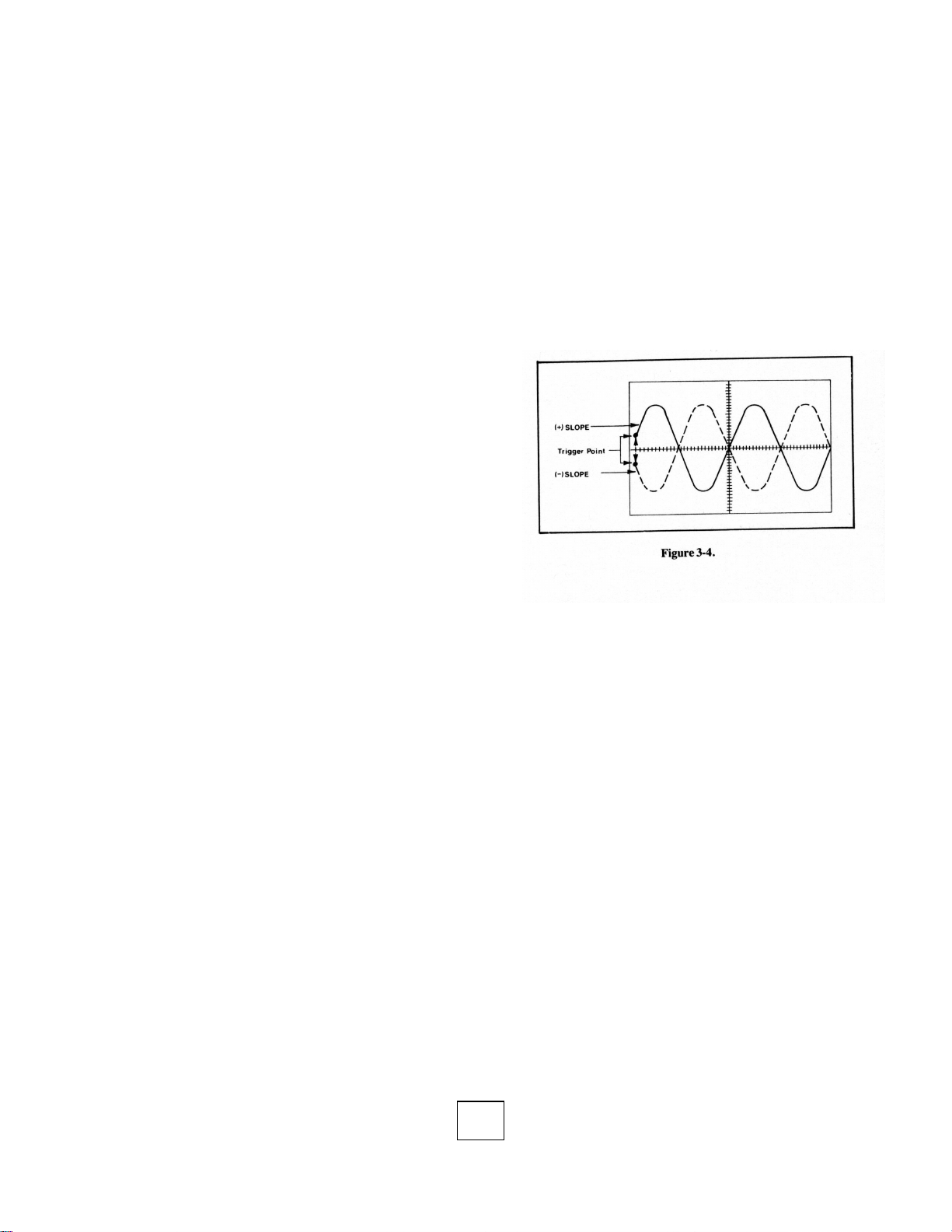

3-9-1 Trigger Balance and Centering Adjustments

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Set the CH-1 AC/GND/DC switch to AC, the

COUPLING switch to DC, and the A TIME/DIV switch to .2

mS.

Connect a sine-wave generator set for 1.2 Vp-p output at

1000 Hz to the CH-1 input connector. Make sure the LEVEL

control is centered (index mark up), and center the displayed

sine wave by means of the CH-1 vertical POSITION control so

the waveform extends from 3 major divisions above to 3 major

divisions below the center horizontal graticule line. Adjust the

horizontal POSITION control so the sweep starts on the first

vertical graticule line. Adjust VR-21 on PCB T-3153 for

symmetrical trigger points (above and below the center

horizontal graticule line) when the SLOPE switch is changed

from + to -. (See Figure 3-4.)

Adjust VR-32 on PCB T-3153 until the trigger point of the

displayed sine wave starts on the center horizontal graticule line

when the SLOPE switch is changed from + to -.

Reduce the output of the generator so the displayed sine

wave's p-p amplitude is only 0.4 (2 minor) divisions. Then fine

adjust VR-I and VR-12 on PCB T-3153 for a stable display in

each position of the SLOPE switch.

3-9-2 Trigger Balance Adjustments for Multitrace Modes

Return the oscilloscope to the initial setup conditions (See

Paragraph 3-1.) Set the AC/GND/DC switches to GND, press

the ALT V MODE pushbutton, pull the PULL TRIPLE control

knob, and set the SOURCE switch to CH-2.

Turn the CH-1 vertical POSITION control fully counterclockwise, and center the CH-3 trace with the CH-3 vertical

POSITION control. Change the COUPLING switch to DC and

adjust VR-22 on PCB T-3153 to recenter the trace.

Set the SOURCE switch to .2 V/DIV and adjust VR-23 on

PCB T-3153 to recenter the trace. Reset the AC/GND/DC

switches to AC and recenter the trace if necessary.

Restore the COUPLING switch to AC and recenter the

trace with VR-31 on PCB T-3153.

33

Page 10

3-9-3 PRESET Trigger Adjustment

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Connect a sine-wave generator to the CH-1

input connector. Adjust the generator output for 2 minor divisions of vertical deflection at I000 Hz. Pull the HOLDOFF

control for PRESET trigger. Adjust VR-2 on PCB T-3159 until

the waveform is triggered and the TRIG'D lamp lights.

3-9-4 CH-3 Pulse Response Adjustment

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Press the ALT V MODE pushbutton, pull the

PULL TRIPLE control knob, set the COUPLING switch to DC,

and the SOURCE switch to.2 V/DIV. Center the CH-3 trace.

Connect a square-wave generator to the CH-3 input connector. Set the generator for 1 Vp-p output level at 100 kHZ.

Adjust VC-6 on PCB T-3153 and VC-23 on PCB T-3155 to

reduce overshoot and ringing to below 10%. Check the frequency response of CH-3 in the same manner as was done in

Paragraph 3-8-15.

3-9-5 Interred Trigger-Pulse Response Adjustment

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Set the VOLTS/DIV switches to 5 mV, the

COUPLING switch to DC, and press the ALT V MODE

pushbutton.

Connect a square-wave generator set for 25 mVp-p output

at I00 kHz to the CH-1 input connector. Adjust VC-I on PCB T3153 to minimize overshoot and ringing. Total overshoot and

ringing should be less than 10%.

Repeat the above procedure for channel 2, adjusting VC-2

on PCB T-3153.

3-10. X-Y MODE ADJUSTMENTS

3-10-1 Gain Adjustment

Return the oscilloscope to the initial setup conditions. (See

Paragraph 3-1.) Press the X-Y pushbutton.

Connect a square-wave generator set for 100mVp-p output

at 1000 Hz to the CH-1 (X IN) connector. Adjust VR-31 on

PCB T-3158 for 5 major divisions of separation between the two

dots displayed on the CRT screen. (Note: the position of the dots

will change when adjusting VR-31; this is normal.)

3-10-2 Balance Adjustment

With conditions set as in Paragraph 3-10-1, set both AC/

GND/DC switches to GND. Check that the horizontal POSITION and X FINE control knobs are set with their index marks

up, then adjust VR-32 on PCB T-3158 to center the dot

horizontally on the CRT screen.

34

Page 11

35 36 37 38 39

40 41 42 43

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

44

Page 21

45

Page 22

46 47 48 49 50

Page 23

Page 24

Page 25

Page 26

Page 27

51

Page 28

52

Page 29

53

Page 30

54

Page 31

55

Page 32

56

57

Page 33

Page 34

58 59 60 61

Page 35

Page 36

Page 37

Page 38

62

Page 39

63 64 65

Page 40

Page 41

Page 42

66

67 68 69

Page 43

Page 44

Page 45

Page 46

70

71

Page 47

Page 48

72 73

Page 49

Page 50

74

Page 51

ENJOY YOUR BOOKS

PLEASE VISIT OUR STORE FOR EVEN MORE GREAT

STUFF!

COPYRIGHT NOTICE

ALL MATERIALS INCLUDING CD/DVD AND PDF

FILES ARE COPYRIGHTED

VON

WALTHOUR PRODUCTIONS AND MAY NOT BE

REPRODUCED, COPIED OR RESOLD UNDER ANY

CIRCUMSTANCES. YOU MAY HOWEVER MAKE A

COPY FOR YOUR OWN PERSONAL BACKUP.

MATERIALS ARE FOR PERSONAL USE ONLY.

IF YOU PURCHASED THIS FROM A NYWHERE BUT

FROM US PLEASE NOTIFY US IMMEDIATELY SO

THAT WE MAY CHECK IF YOU PURCHASED FROM

AN AUTHORIZED RESELLER SO WE CAN LET YOU

KNOW IF YOU NEED TO RETURN FOR FULL REFUND

FROM AN UNAUTHORIZED SELLER.

THANKS AGAIN AND PLEASE TAKE THE TIME TO

VISIT OUR STORE.

ATTENTION! EVERYTHING ON SALE NOW!!

THIS PAGE COPYRIGHT VON WALTHOUR PRODUCTIONS

Loading...

Loading...