Page 1

Page 2

WARNING!

THE SERVICING INSTRUCTIONS CONTAINED IN THIS MANUAL ARE FOR

USE BY QUALIFIED PERSONNEL ONLY. TO AVOID ELECTRIC SHOCK, DO

NOT PERFORM ANY SERVICING OTHER THAN THAT CONTAINED IN THE

OPERATING INSTRUCTIONS UNLESS YOU ARE QUALIFIED TO DO SO.

Page 3

LBO-516 100 MHz

DELAYED TIME BASE OSCIILOSCOPE

TABLE OF CONTENTS

1. GENERALINFORMATION

1-1 INTRODUCTION ................................................................................................................................1

1-2 SPECIFICATIONS ..........…..................................................................................................................................1

2. OPERATING INSTRUCTIONS

2-1 FUNCTION OF CONTROLS, CONNECTORS, AND INDICATORS .......................................................... 3

2-1-1 Display Block ........................................................................................................................................... 3

2-1-2 Vertical Amplifier Block ........................................................................................................................... 4

2-1-3 Sweep and Trigger Blocks ......................................................................................................................... 5

2-1-4 Miscellaneous ........................................................................................................................................... 7

2-2 INITIAL OPERATION ................................................................................................................................ 7

2-2-1 Power Connections and Adjustments ......................................................................................................... 7

2-2-2 Installation ................................................................................................................................................ 8

2-2-3 Preliminary Control Settings and Adjustments ........................................................................................... 8

2-3 BASIC OPERATING PROCEDURES ......................................................................................................... 9

2-3-1 Signal Connections ................................................................................................................................... 9

2-3-2 Single-trace Operation ..............................................................................................................................11

2-3-3 Triggering Alternatives ............................................................................................................................11

2-3-4 Probe Compensation ................................................................................................................................14

2-3-5 Dual-trace Operation ................................................................................................................................15

2-3-6 Additive and Differential Operation ..........................................................................................................16

2-3-7 Triple-trace Operation ..............................................................................................................................17

2-3-8 Four-trace Operation ................................................................................................................................17

2-3-9 Delayed Timebase Operation ....................................................................................................................18

2-3-10 Single-shot Operation .............................................................................................................................20

2-3-11 X-Y Operation .......................................................................................................................................20

2-3-12 Intensity Modulation ..............................................................................................................................20

2-4 MEASUREMENT APPLICATIONS ...........................................................................................................21

2-4-1 Amplitude Measurements .........................................................................................................................21

2-4-2 Differential Measurement Techniques .......................................................................................................22

2-4-3 Time Interval Measurements ....................................................................................................................23

2-4-4 Phase Difference Measurements ...............................................................................................................24

2-4-5 Distortion Comparison .............................................................................................................................26

2-4-6 Frequency Measurements .........................................................................................................................27

2-4-7 Risetime Measurements ............................................................................................................................27

2-4-8 -3dB Bandwidth Measurement ..................................................................................................................28

........................................................................................................................................1

..................................................................................................................................3

Page 4

1. GENERAL INFORMATION

1-1. INTRODUCTION

The LBO-516, shown in Figure 1-1, is a 100 MHz oscilloscope

with all of the features normally found on a lab-grade scope: highfidelity pulse response, stable operation, dual timebase with

calibrated sweep delay, flexible triggering facilities, and a bright

CRT display with illuminated internal graticule. Moreover, it also has

a very unusual feature found on few scopes in any price class: it can

simultaneously display up to eight traces from three different input

signals! In addition to the two vertical-input channels and their difference signal, the signal used to externally trigger the main timebase

can also appear on the CRT display. The alternate sweep mode,

which allows the main and delayed timebases to simultaneously

sweep the CRT, effectively doubles this four-trace display to an

eight-trace display.

The comprehensive triggering facilities of the LBO-516 include

several features that ease the problem of triggering on complex

signals: a variety of frequency-selective coupling filters, a trigger

holdoff-control, and a trigger pickoff that alternates between the two

vertical channels.

1-2. SPECIFICATIONS

Specifications for the model LBO-516 oscilloscope are given in

Table 1-1.

Table 1-1

SPECIFICATIONS

Vertical Amplifiers (Ch. 1 & 2)

Bandwidth (-3 dB)

DC coupled DC - 100 MHz

AC coupled 10 Hz - 100 MHz

Rise Time 3.5 KS

Deflection Coefficients

Accuracy 5 mV/div to 5 V/div in 10 calibrated

steps, 1-2-5 sequence. Continuously

variable between steps. XI0

magnification adds 0.5, 1, and 2

mV/div steps for frequencies below 5

MHz

Input Impedance -+3%; -+5% with Xl0magniflca-tion

1 megohm +-2%, 25 pF +-3 pF

Maximum Input Voltage 400 V (DC plus AC peak)

1

Page 5

Signal Delay Leading edge displayed.

Leading edge displayed. CH-1 only, CH-2 only,

CH-1 & CH-2 displayed alternately,

CH-1 & CH-2 chopped (at 250

kHz rate),

CH-1 & CH-2 added, CH-1 &

CH-2 subtracted,

CH-1 & CH-2 & CH-3 displayed

alternately,

CH-1 & CH-2 & CH-3 chopped,

CH-1 & CH-2 & CH-3 & CH-1

+ CH-2 alternated,

CH-1 & CH-2 & CH-3 & CH-1

+ CH-2 chopped,

CH-1 & CH-2 & CH-3 & CH-1

- CH-2 alternated,

CH-1 & CH-2 & CH-3 & CH-1

- CH-2 chopped.

Common Mode Rejection 20dB at 20MHz

CH- 1 Output 25 mV/div into 50 ohms

Horizontal Amplifier (X-Y Mode)

Bandwidth (- 3 dB)

DC coupled DC - 3 MHz

AC coupled 10Hz - 3MHz

Rise Time 120 KS

Phase Shift <3° at 100 kHz

Deflection Coefficients 0.5 mV/div to 5 V/div in 13 calibrated

steps, 1-2-5 sequence, continuously

variable between steps

Accuracy +-3% for 5 mV/div to 5 V/div,

+-5% for 0.5 mV/div to 2 mV/div

Input Impedance 1 megohm -+2%, 25 pF +-3 pF

Maximum Input Voltage 400 V (DC plus AC peak)

Time-Base Generators

Display Modes Main timebase (TB) only,

Main TB intensified by delayed

TB,

Delayed timebase,

Main TB alternated with

delayed TB.

Main (A) Time Base 0.02 KS/div to 0.5 S/div in 23

calibrated steps, 1-2-5 sequence.

Continuously variable between steps.

Delayed (B) Time Base 0.2 PS/div to 50 mS/div in 20

calibrated steps, 1-2-5 sequence.

Magnifier XI0 deflection increase at any TB

setting extends sweep speeds of main

and delayed TB's to 2 KS/div.

Accuracy +- 3% unmagnified

+- 5% magnified

Delay Time Continuously variable multiplier with

1000 divisions.

Delayed TB Jitter 1/20,000

Trigger Circuits

Sources CH-l, CH-2, Alternate, Line, External

Modes Auto, Normal, Single-shot

Coupling AC, DC, HF reject, TV vertical, TV

horizontal

Slope + orHoldoff Normal, Variable (to greater than

one sweep), B ends A

Sensitivity

Internal Trigger DC – 10 MHz: 0.4div

External Trigger DC - 10MHz: 100mV

External Trigger Amplifier (Ch. 3)

Bandwidth (-3 dB)

DC coupled DC - 100 MHz

AC coupled 10Hz- l00 MHz

Rise Time 3.5 KS

Deflection Coefficients 0.2 V/div and 2 V/div

Accuracy +-3%

Input Impedance 1 megohm +-2%, 30 pF

Maximum Input Voltage 400 V (DC plus AC peak)

Z-Axis Modulation

Level for Blanking Standard TTL high (+ 2 to + 5V)

Coupling DC

Maximum Input Voltage 50 Vp-p

Input Impedance 10k:

Bandwidth DC-5 MHz

Calibrator

Output Voltage 500 m Vp-p--+ 2%, positive-going,

Frequency 1 kHz nominal

Waveform Fast-rise rectangular wave

CRT Display

Phosphor P31 (P39 optional)

Accelerating Potential 20 kV/2kV

Graticule Internal 1 cm square divisions, 8 div

Graticule Illumination Continuously variable

Trace Adjustments on Rotation, focus, intensity,

Front Panel B intensity

Other Features

"Out-of-Calibration"

Indicator

Other Indicators Main timebase triggered

Power Requirements

Line Voltage 100/120/200 VAC 220/240 VAC

Line Frequency 50-60 Hz

Power Consumption 55W

Physical & Environmental Data

Case Size (WxHxD) 12.3 x 5.8 x 16 inches

305 x 145 x 400 mm

Overall Size (WxHxD), 13.75 x 7.25 x 18.5 inches

handle folded back 350 x 185 x 470 mm

10 - 100 MHz: 1.5 divs

10 - 100 MHz: 400mV

ground referenced

high, 10 div wide.

Central axis subdivided into 0.2 cm

graduations.

Main timebase

Single-shot ready

Power on

2

Page 6

S

1

2

3 4 5 6 7 8 9

Weight 20.9 lbs, 9.5 kg

Ambient Operating 0-40°C (32-104°F) maximum

Temperature 15-35°C (60-95°F) for guaranteed

specs

Vibration Tolerance 2 mmp-p displacement at 12-33 Hz

and 33-35 Hz

Shock Tolerance 30g

Accessories

Supplied Instruction Manual

Two (2) LP- 100X probes

Two (2) BNC-to-post adaptors

Optional LP-2017 Probe Pouch

LC-2016 Protective Front Cover

LR-2402 Rack Mount Adaptor

LH-2015 Hood

Specifications for the model LP-100X scope probe are given in

Table 1-2.

2. OPERATING INSTRUCTION

This section contains the information needed to operate the

LBO-516 and utilize it in a variety of basic and advanced

measurement procedures. Included are the identification and function

of controls, connectors, and indicators, initial startup procedures,

basic operating routines, and selected measurement applications.

2-1. FUNCTION OF CONTROLS, CONNECTORS, AND

INDICATORS

Before turning on

controls, connectors, indicators, and other features described in this

section. The descriptions given below are keyed to the items called

out in Figures 2-1 to 2-4.

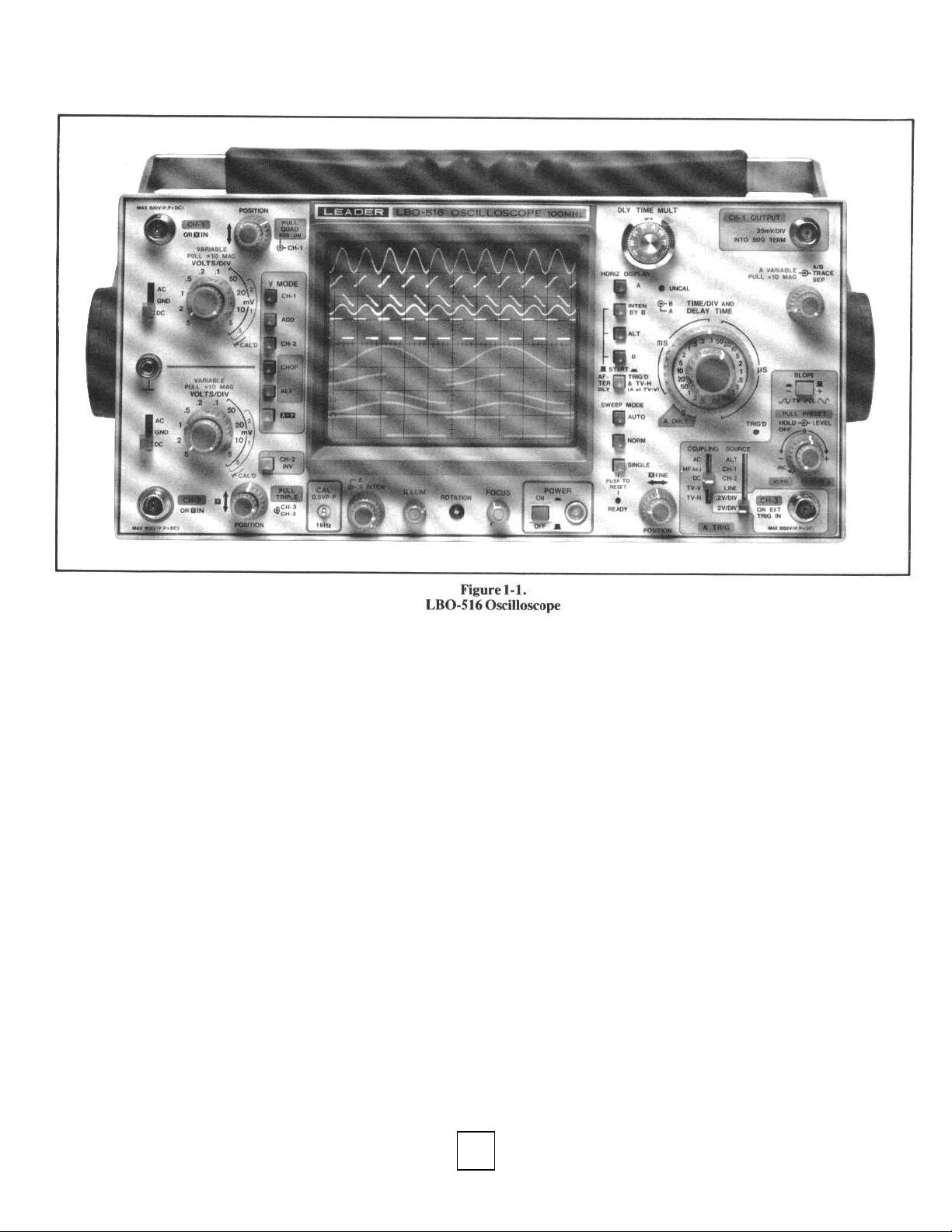

2-1-1 Display Block

Refer to Figure 2-1 for reference (1) to (9).

POWER switch Push in to turn instrument power on

POWER lamp Lamp lights when power is on

A INTEN control To adjust the overall brightness of the

B INTEN control Provides adjustment of CRT brightness

FOCUS control To attain maximum trace sharpness.

ROTATION control Provides screwdriver adjustment of

this instrument, familiarize yourself with the

and off

CRT display. Clockwise rotation

increases brightness

during INTEN BY B interval and B

timebase sweeps

Astigmatism is automatically adjusted.

horizontal trace alignment with regard

to the CRT graticule lines

Table 1-2

Attenuation Ratio 10:1 +-2% and 1:1, switch

selectable

Input Impedance

10X attenuation 10 megohms, 12 pF +

1X attenuation Scope input Z plus < 150 pF

Rise Time (10X atten.) 3.5 KS nominal

Overshoot & Ringing <10%

(10X atten.)

Bandwidth

10X attenuation DC- 100MHz

1X attenuation DC - 6 MHz

Maximum Input Voltage 600 V (DC plus AC peak)

Ambient Operating

Temperature

Maximum - 10 to + 55°C

For guaranteed

Specifications +5 to +35°C

Ambient Humidity

Maximum 40 to 90%

For guaranteed

Specifications 45 to 85%

CRT Display device having 1 cm square

ILLUM control To adjust graticule illumination.

Clockwise rotation increases

brightness

CAL connector Provides fast-rise waveform of precise

LP-100X SPECIFICATIONS

10%

graticule lines inscribed on the inner

CRT surface for parallax-free

measurements. Blue filter provides

good contrast and pleasing display.

amplitude for probe adjustment and

vertical amplifier calibration.

3

Page 7

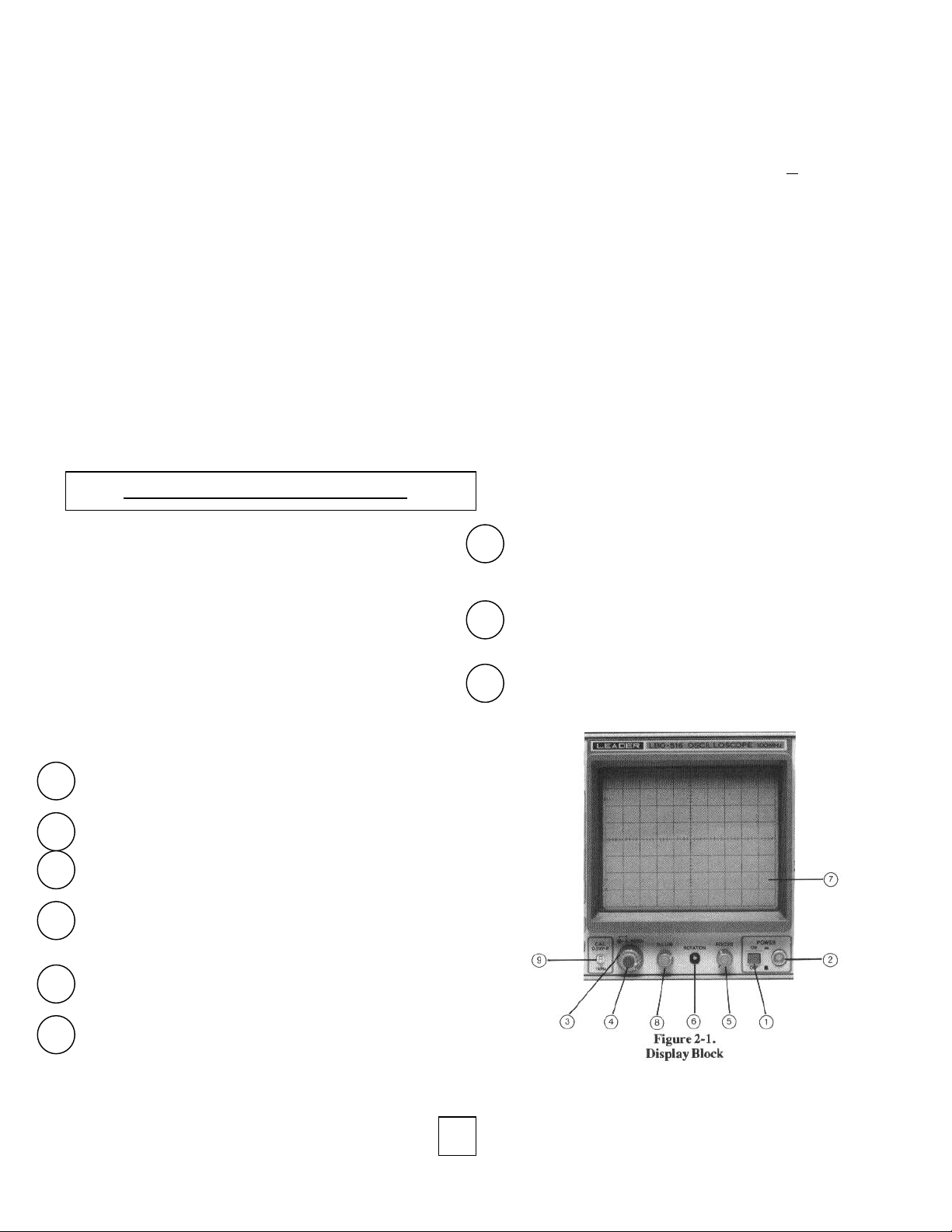

2-1-2 Vertical Amplifier Block

10

11 23 22 12

13 14

15

16 17 18 19 20 21

Refer to Figure 2-2 for references (10) to (12) and (14) to (23).

Refer to Figure 2-3 for reference (13).

VOLTS/DIV switches To select the calibrated deflection

factor of the input signals fed to the

vertical amplifier.

VARIABLEcontrols Provide continuously variable

adjustment of deflection factor between

steps of the VOLTS/DIV switches.

Calibrations are accurate only when the

VARIABLE controls are detented in

PULL X 10 MAG Pulling these out will increase the

(on VARIABLE sensitivity of the associated vertical

controls) amplifiers by ten times at reduced

Ground Connector Provides convenient point to attach

CH-1 OUTPUT Provides scaled output of the channel 1

Connector signal suitable for driving a frequency

CH- 1 or X-IN For applying an input signal to vertical

connector amplifier channel 1, or the X-axis

CH-2 or Y-IN For applying an input signal to vertical

connector amplifier 2, or the Y-axis (vertical)

AC/GND/DC To select the method of coupling the

switches input signals to the vertical amplifiers.

Channel 1 Vertical For vertically positioning trace 1 on the

POSITION control CRT screen. Clockwise rotation moves

Channel 2 Vertical or For vertically positioning trace 2 on the

Y POSITION control CRT screen. Clockwise rotation moves

CH-2 INV switch Push in to invert the polarity of the

X-Y switch Push in to select X-Y operation.

V MODE switches To select the vertical amplifier display

their fully clockwise positions.

bandwidth.

separate ground lead to oscilloscope.

counter or other instrument.

(horizontal) amplifier during X-Y

operation.

amplifier during X-Y operation.

AC position connects a capacitor

between the input connector and its

associated amplifier circuitry to block

any DC component in the input signal.

GND position connects the amplifier

input to ground instead of the input

connector, so a ground reference can be

established. DC position connects the

amplifier inputs directly to the

associated input connector, thereby

passing alt signal components on to the

amplifiers.

the trace up. Inoperative during X-Y

operation.

the trace up. Adjusts the Y-axis of the

trace during X-Y operation.

Channel 2 signal.

CH-1

mode.

the input signal of channel 1 on the

CRT when pressed

push-button displays only

Figure 2-2

Vertical Amplifier Block

CH-2

push-button displays only the input signal

of channel 2 on the CRT when pressed.

ALT

push-button displays the input signals of

both channels 1 and 2 (or more) on the CRT

when pressed. The CRT beam is switched

between channels at the end of each sweep to

achieve this multi-channel display.

CHOP

push-button displays the input signals of

both channels 1 and 2 (or more) on the CRT

when pressed. The CRT beam is switched

between channels at a 250 kHz rate during the

horizontal sweep to achieve this multi-channel

display.

ADD

push-button displays a single trace that is

the algebraic sum of the input signals of channels

1 and 2 when pressed.

PULL TRIPLE control When pulled, displays traces for CH-1,

CH-2, and CH-3 (trigger), providing

ALT or CHOP push-button is also

pressed. Rotating this control also

vertically positions the CH-3 trace on

the CRT screen. This control is not

operative if any single-trace display

mode is selected.

PULL QUAD control When pulled, displays traces for CH-l,

CH-2, CH-3 (trigger), and algebraic

sum of CH-1 and CH-2 signals,

providing ALT of CHOP pushbutton is

also pressed. This control is not

operative if any single-trace display

mode is selected.

4

Page 8

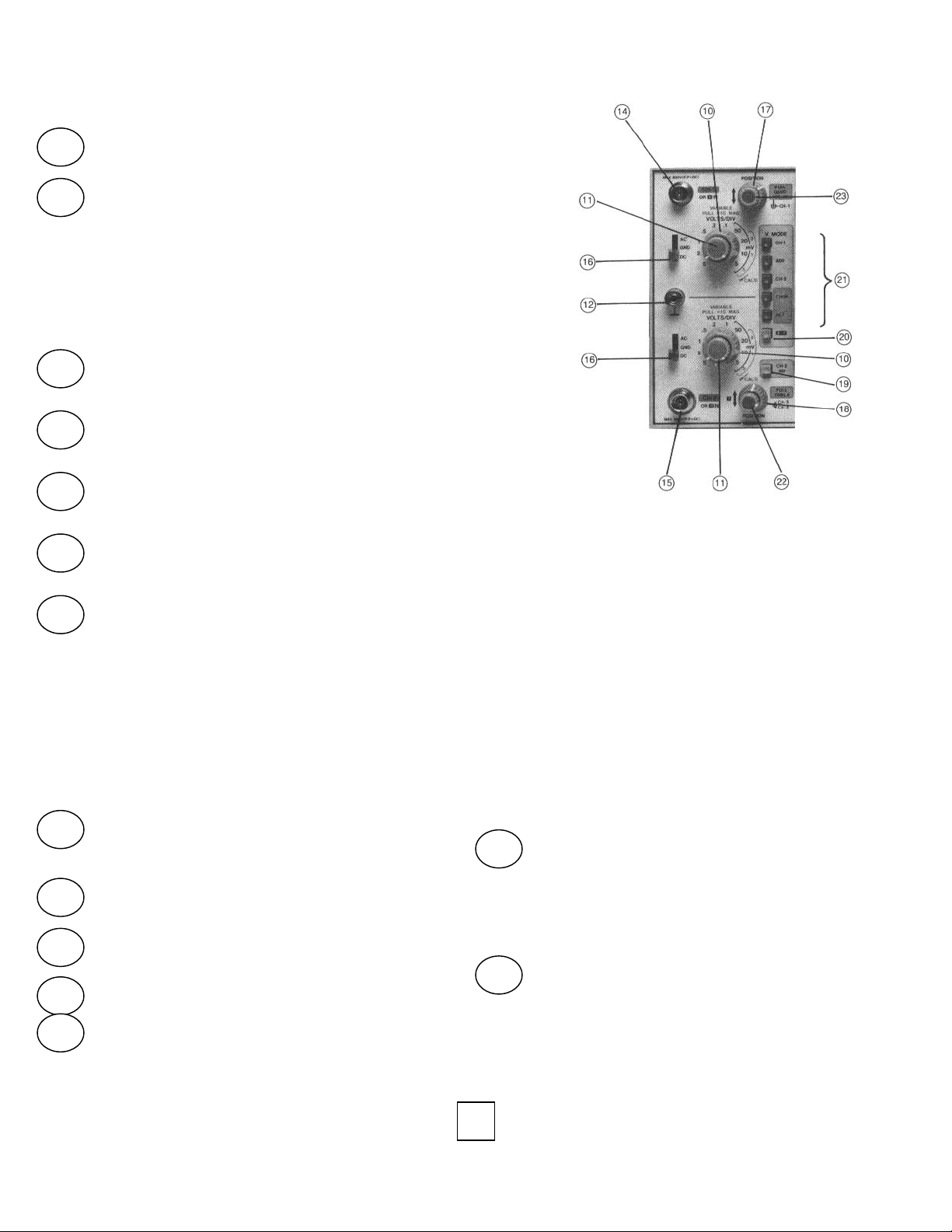

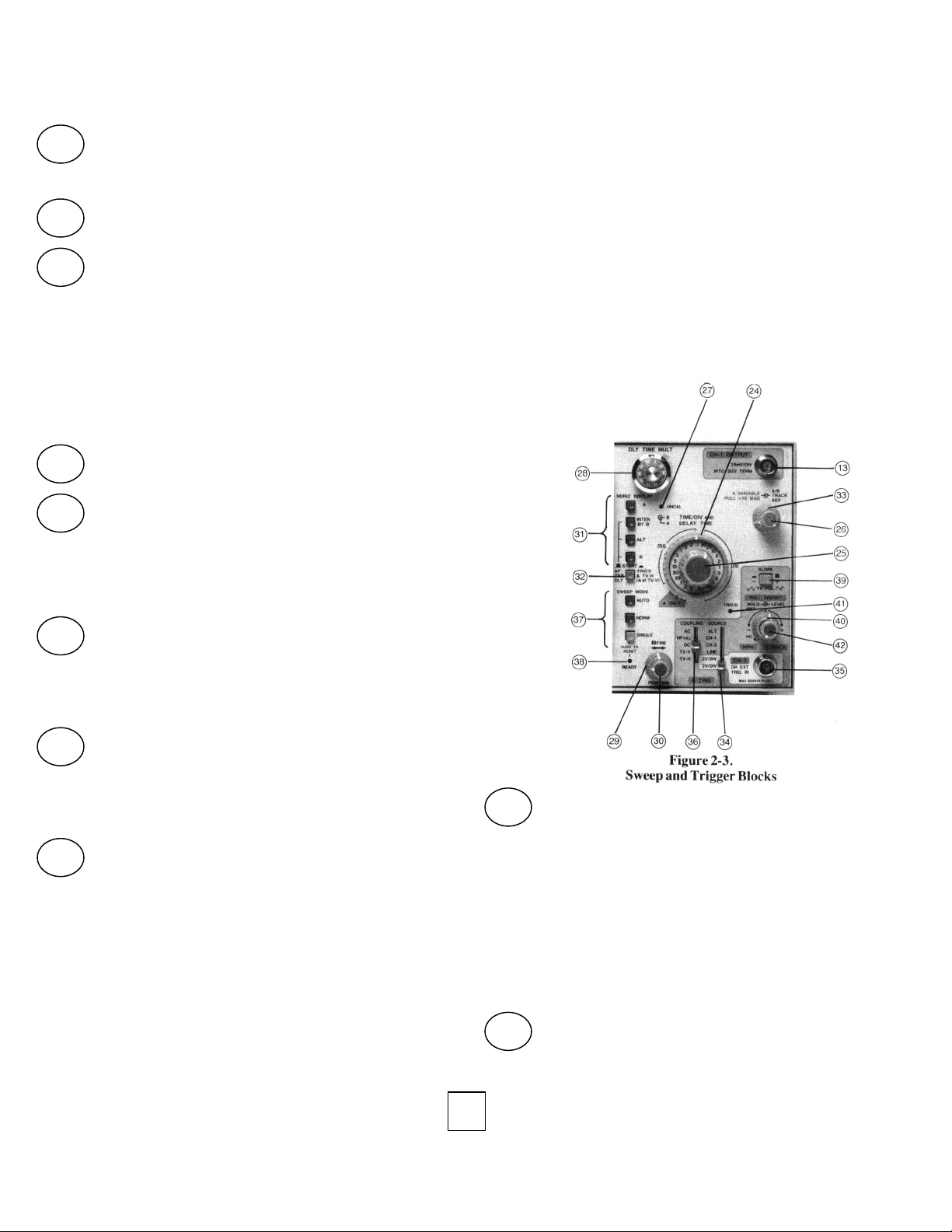

2-1-3 Sweep and Trigger

24 32 25 26 27 28 29 30 31 33

Refer to Figure 2-3 for reference (24) to (42).

ATIME/DIV and To select either the calibrated

DELAY TIME sweep of the main (A) time-base

switch or the delay time range for delayed sweep operation.

B TIME/DIV switch To select the calibrated sweep rate of

A VARIABLE/ Provides continuously variable

PULL X 10 MAG adjustment of sweep rate between steps

Control of the TIME/DIV switches. TIME/DIV

UNCAL lamp Indicates when the VARIABLE control

DLY TIME MULT To determine the exact starting point

control within the A time base delay range at

Horizontal POSITION To adjust the horizontal position of the

control traces displayed on the CRT.

X FINE Position To adjust the horizontal position of the

control CRT traces as described above, but has

HORIZ DISPLAY To select the sweep mode.

Switches

Blocks

the delayed (B) time base.

calibrations are accurate only when the

A VARIABLE control is detented in its

fully clockwise position. Pulling the

control out expands the horizontal

deflection by 10 times for X-Y

operation. The effective time-base

sweep rate is also increased by 10

times, making 2 nS per division the

highest sweep rate available.

is not detented as described above.

which the B timebase will begin

sweeping. The absolute delay time is

equal to the sweep time rate (A

TIME/DIV) multiplied by the DLY

TIME MULT.

Clockwise rotation moves the trace(s)

to the right. During X-Y operation, this

control must be used for X-axis

positioning.

less effect per degree of rotation. This

facilitates precise positioning when Xl0

magnification is used.

A push-button sweeps the CRT at the

main (A) timebase rate when pressed.

INTEN BY B push-button sweeps the

CRT at the main (A) time-base rate

when pressed, and the delayed (B)

time-base intensifies a section of the

trace(s). The location of the intensified

section is determined by the DLY

TIME

MULT control, and under some

circumstances also by the START

switch (32).

B push-button sweeps the CRT at the

rate selected by the B TIMEY DIV

switch, after a delay determined by the

A TIME/DIV switch and DLY TIME

MULT control.

The trace displayed over the full CRT

graticule width corresponds to the

intensified section of trace displayed

during INTEN BY B operation.

ALT push-button alternately sweeps

the CRT at the main (A) time-base and

delayed (B) time-base rates when

pressed. This results in twice as many

traces displayed on the CRT as are displayed during any of the sweep modes

described above.

START switch When pressed in (TRIG'D position),

causes the B sweep to be triggered by

the first trigger pulse occurring after the

delay time set by the DLY TIME

MULT control. In this position, the

delay time is adjustable only in whole

increments of the time between trigger

pulses.

When released (AFTER DELAY

position), causes the B sweep to start

immediately after the delay time set by

the DLY TIME MULT control. In this

position, the delay time is adjustable

with infinite resolution.

A/B TRACE SEP Permits adjustments of the distance

control between corresponding A and B traces

when the ALT sweep mode is selected.

5

Page 9

SOURCE switch To select the signal used for A or B

34 36 37 35

36

38 39 40

time-base triggering.

CH-1 position selects the channel 1

signal for triggering. CH-2 position

selects the channel 2 signal for

triggering.

ALT position selects the triggering

mode that allows a stable display of

two asynchronous signals on the CRT.

Must be used in conjunction with the

ALT vertical mode.

LINE position (A only) selects a trigger

signal derived from the AC power line,

permitting the scope to display

stabilized line-related components of a

signal even though they may be very

small compared to other signal

components.

0.2 V/DIV position selects the full

signal applied to the EXT TRIG IN

connector.

2 V/DIV position selects an attenuated

sample of the signal applied to the EXT

TRIG IN connector.

CH-3 or EXT TRIG For applying an external signal to the

IN connector oscilloscope for triggering the A

timebase and/or displaying the channel

3 trace.

COUPLING switch To select the frequency characteristics

of the coupling to the trigger circuits.

DC position selects direct trigger

coupling so all components of the

trigger signal are applied to the trigger

circuit.

AC position inserts a large capacitor in

the trigger-coupling chain to remove

any DC components from the trigger

signal. AC signals below 10 Hz are also

attenuated, as is the case in all of the

trigger coupling modes listed below.

HF-REJ position inserts a filter in the

trigger-coupling chain that removes

signal components higher in frequency

than 35 kHz.

TV-V (A only) position inserts a

shaping filter (TV sync separator)

whose low-frequency output (vertical

sync pulses) is used for triggering. This

trigger mode will also pass and

differentiate waveforms in the 1-100

Hz range.

TV-H position inserts a shaping filter

(TV sync separator) whose highfrequency output (horizontal sync

pulses) is used for triggering. This

trigger mode will also pass and

differentiate waveforms in the 2-500

kHz range.

When triggered B sweep is selected as

the horizontal-display mode, and the

COUPLING switch is set to any

position other than TV-V, the A- and

B- time base trigger signals are

identical. However, when the

COUPLING switch is set to TV-V

during triggered B sweep, the TV-V

shaping filter is inserted only in the Atime base trigger signal. The trigger

signal fed to the B time base will be

shaped by the TV-H filter.

SWEEP MODE To select the triggering mode. AUTO

switches push-button allows sweep to flee-run

and display a base-line in the absence

of signal when pressed. Automatically

switches to triggered sweep mode when

signal of 20 Hz or higher is present and

other trigger controls are properly set.

NORM push-button produces sweep

only when signal is present and other

triggering controls are properly set. No

trace is visible if any trigger

requirement is missing.

SINGLE pushbutton disables recurrent

sweep operation when pressed. The

sweep generator can then be manually

reset before each sweep by depressing

this switch again. No trace is visible

before or after sweep occurs.

READY lamp Indicates when sweep generator is

armed for single-sweep operation.

Lamp is extinguished at start of sweep.

SLOPE switch Push-button selects the positive or

negative slope of the trigger signal for

initiating sweep. +position n causes

triggering on the positive-going edge or

slope of the trigger signal. - .position

causes triggering on the negative-going

edge or slope of the trigger signal.

LEVEL control Selects the amplitude level at which the

sweep is triggered. When rotated

clockwise (+ direction), the trigger

point moves towards the positive peak

of the trigger signal. When rotated

counterclockwise (- direction), the

trigger point moves towards the

negative peak of the trigger signal.

Pulling the HOLDOFF knob

(concentric to the LEVEL control)

selects PRESET level, a trigger point

near the zero-crossing point of the

trigger waveform.

6

Page 10

TRIG'D lamp Indicates when the sweep generator is

41 42 46 47 48 43 44 45

being triggered.

HOLDOFF control Allows triggering on certain complex

signals by changing the hold-off (dead)

time of the main (A) sweep. This

avoids triggering on intermediate

trigger points within the repetition

cycle of the desired display. NORM is

a detented position at full CCW

rotation that is used for ordinary

signals.

B ENDS A is a detented position at full

clockwise rotation that increases the A

timebase repetition rate to the

maximum to improve the apparent

brightness of "short" duration (lowduty cycle) pulses in the delayed mode.

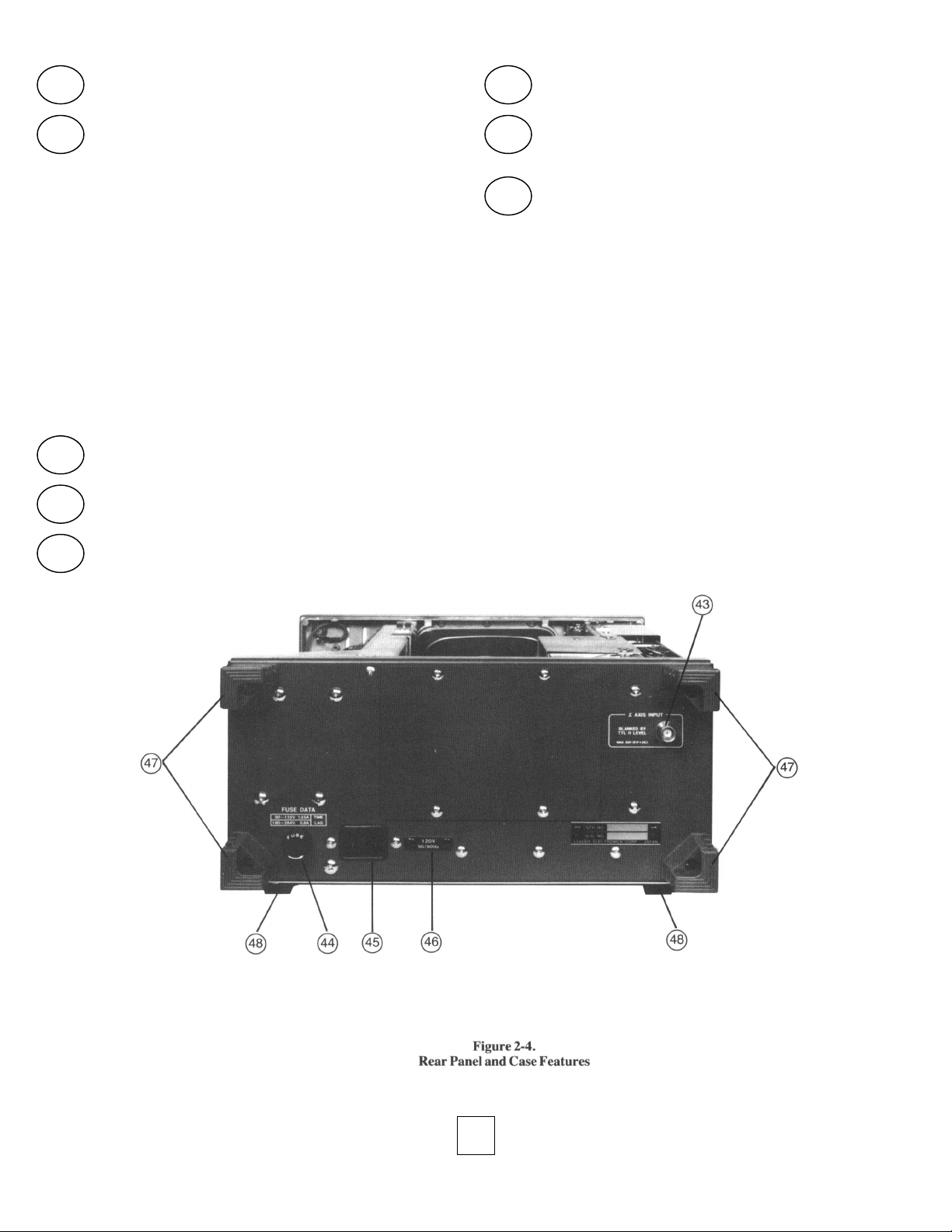

2-1-4 Miscellaneous

Refer to Figure 2-4 for references (43) to (48).

Z AXIS INPUT For applying signal to intensity

Connector modulate the CRT.

FUSE Receptacle permits quick fuse re-

placement without opening case

Power Connector Permits removal or replacement of AC

power cord.

Voltage Label Indicates the voltage of the oscil-

loscope's primary wiring.

Cord Caddy Provides a quick method of securing

the power cord, and supports the

oscilloscope for vertical operation.

Feet Supports the oscilloscope for shelf

mounting.

2-2. INITIAL OPERATION

Before the instrument is operated for the first time, perform the

following procedures in the order listed to ensure satisfaction and

prevent damage to the instrument.

2-2-1 Power Connections and Adjustments

The instrument is normally shipped wired for a 120-volt power

source but can be adapted to operate from power sources with - 10%

of the rated values given in Table 2-1. Operation with a voltage less

that t0% of the rated value may result in improper performance of the

instrument and a voltage more than 10% in excess of the rated value

may damage the power supply circuitry.

To check or alter the power-transformer wiring, proceed as

follows:

1. Disconnect the power cord from the Power Connector (45).

2. Remove the 14 Phillips-head screws around the periphery of the

top and bottom covers.

3. Remove the covers and carefully turn the LBO-516 upside

down.

7

Page 11

4. Compare the wiring of the power transformer to that shown in

Figure 2-5. If you want to adapt the instrument to operate from a

different voltage, determine the correct wiring diagram from

Table 2-1.

5. Unsolder any connections not appropriate to the desired

connection, and install the new wiring.

6. Change the fuse (if necessary) to the value indicated in Table 21 for the selected voltage range. In all cases the fuse must be the

delayed-action ("SLO-BLOW') type.

Table 2-1

POWER TRANSFORMER PRIMARY WIRING

Nominal

Voltage

100V

120V

200 V

220 V

240 V

2-2-2 Installation

The LBO-516 will operate in either a horizontal or vertical

position, so it is highly suited to field or laboratory work. It can

therefore be positioned on a bench top, riser shelf, or even the floor.

Voltage

Range

90-110V

110-130 V

180-220 V

200-240 V

215-265 V

Rating Wiring

Diagram

1.25 A

1.25 A

0.80 A

0.80 A

0.80 A

B

C

D

E

F

For bench-top mounting, it is advantageous to have the front of

the instrument tilted upward for straight-on viewing. Press in the two

Handle-position Locks and simultaneously rotate the Handle so it

points below the case, then release the locks.

If the instrument is placed on a riser shelf above the work bench,

rotate the Handle above the instrument and as far towards the back as

possible. It is not necessary to lock it in this position.

If lack of working space requires that the instrument be placed

on the floor, stand the LBO-516 on end. The Cord Caddy (47) will

act as legs to support the instrument. Rotate the Handle just enough

back for clear access to the front-panel controls.

The LBO-516 is designed to operate over a temperature range of

0°C to +40°C (32°F to 104°F) and a humidity range of 10 to 90%.

Operation in a more severe environment may shorten the life of the

instrument.

Operation in a powerful magnetic field may distort the

waveform or tilt the trace. This is most likely to occur if the

instrument is operated close to equipment having large motors or

power transformers.

2-2-3 Preliminary Control Settings and Adjustments

1. Set the following controls as indicated:

AC/GND/DC switches (16) ........... AC

8

Page 12

VOLTS/DIV switches (10) ............. 2V

VARIABLE VOLTS/DIV controls (11) Fully CW, and

pushed in

V MODE switches (21) ................ ALT

Vertical POSITION controls (17 & 18) Index up

A INTEN control (3) ................... Index up

FOCUS control (5) ..................... Index up

ILLUM control (8) ...................... Fully CCW

CH-2 INV switch (19) ................. Out

PULL TRIPLE control (22) ........... Pushed in

PULL QUAD control (23) ............. Pushed in

HORIZ DISPLAY switches (31) ..... A

B TIME/DIV switch (25) .............. Any Ps

A TIME/DIV switch (24) .............. .2 mS

A VARIABLE control (26)

Horizontal POSITION control (29) .. Index up

SOURCE switch (34) .................. CH-1

COUPLING switch (36) ............... AC

SWEEP MODE switches (37) ....... AUTO.

HOLDOFF control (42) ................ Fully CCW, and

2. Plug the power cord into a convenient AC receptacle and press

in the POWER switch (1). Shortly, two traces should appear. If

the traces appear extremely bright, turn the A INTEN control (3)

counterclockwise. Otherwise, let the instrument warm up for a

few minutes.

CAUTION:

in the CRT. However, if the CRT is left with an extremely

bright dot or trace for a very long time, the fluorescent

screen may be damaged. Therefore, if a measurement

requires high brightness, be certain to turn down the

INTEN control immediately afterward. Also, get in the

habit of turning the brightness way down if the scope is left

unattended for any period of time.

3. Turn the A INTEN control (3) to adjust the brightness to the

desired amount.

4. Turn the FOCUS control (5) for a sharp trace.

5. Turn the CH-1 vertical POSITION control (17) to move the CH1 trace two divisions down from the top of the graticule grid.

Turn the CH-2 vertical POSITION control (18) to move the CH2 trace two divisions up from the bottom of the graticule grid.

6. See if the traces are precisely parallel with the graticule lines. If

they are not, adjust the ROTATION control (6) with a small

screwdriver.

7. Turn the horizontal POSITION control (29) to align the left edge

of the traces with the left-most graticule line.

8. Connect the CH- 1 (14) and CH-2 (15) input connectors to the

CAL connector (9). The TRIG'D lamp (41) should light and two

rectangular waveforms appear on the CRT screen.

9. Carefully examine the waveform, particularly at the corners,

while adjusting the FOCUS control to assure sharpest focus.

10. Disconnect the vertical inputs from the calibrator.

...........

A burn-resistant fluorescent material is used

Fully CW, and

pushed in

pulled out

2-3 BASIC OPERATING PROCEDURES

The following paragraphs in this section describe how to operate

the LBO-516, beginning with the most elementary operating modes,

and progressing to the less frequently-used and/or complex modes.

2-3-1 Signal Connections

There are three methods of connecting an oscilloscope to the

signal you wish to observe. They are: a simple wire lead, coaxial

cable, and scope probes.

A simple lead wire may be sufficient when the signal level is

high and the source impedance low (such as TTL circuitry), but is not

often used. Unshielded wire picks up hum and noise; this distorts the

observed signal when the signal level is low. Also, there is the

problem of making secure mechanical connection to the input

connectors. A binding post-to-BNC adapter is advisable in this case.

Coaxial cable is the most common method of connecting an

oscilloscope to signal sources and equipment having output

connectors. The outer conductor of the cable shields the central signal

conductor from hum and noise pickup. These cables are usually fitted

with BNC connectors on each end, and specialized cables and

adaptors are readily available for mating with other kinds of

connectors.

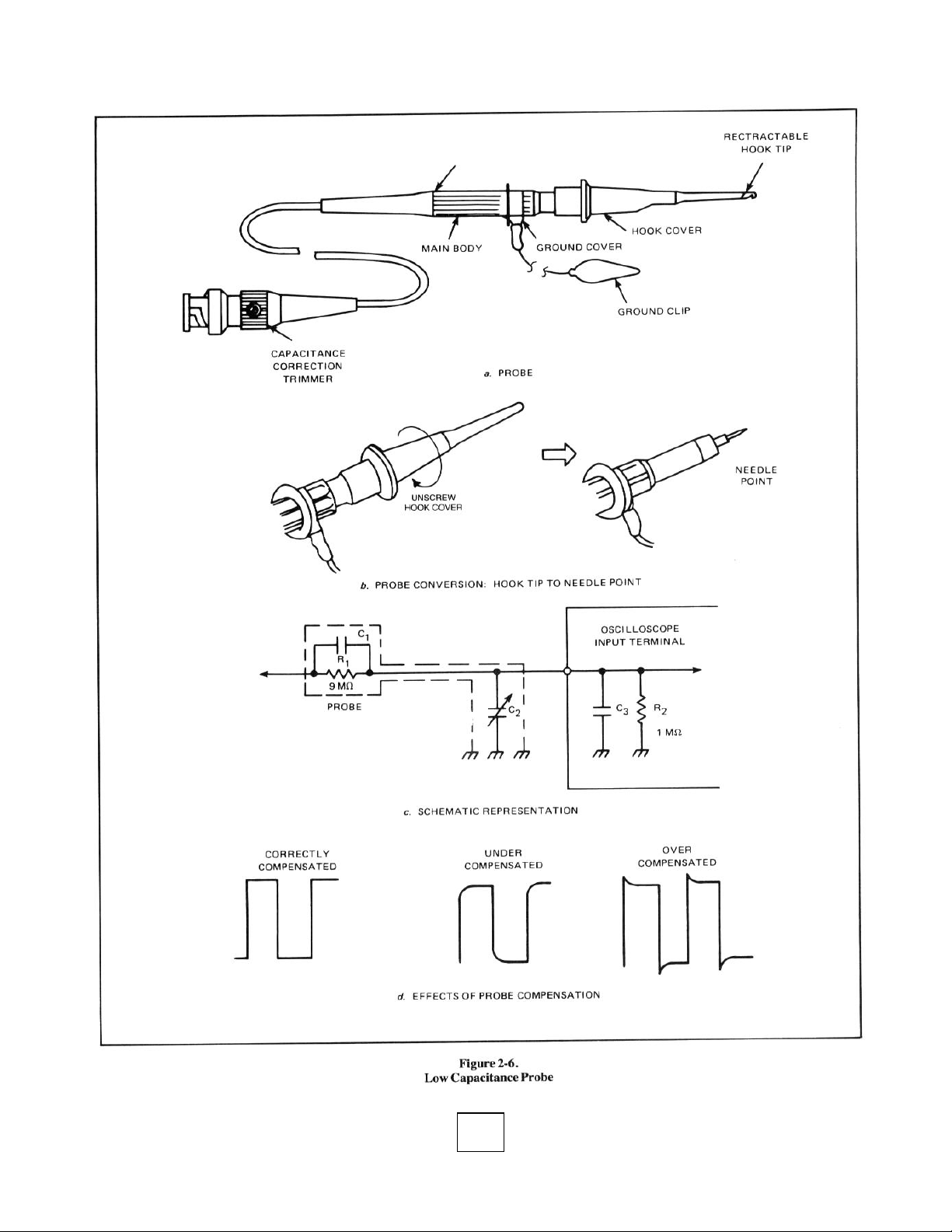

Scope probes are the most common method of connecting the

oscilloscope to circuitry. These probes are available with 1X

attenuation (direct connection), 10X and 100X attenuation. The 10X

attenuator probe increases the effective input impedance of the

probe/scope combination to 10 megohms shunted by a few

picofarads. The 100X probe increases the effective input impedance

of the probe/scope combination to anywhere from 10 to 100

megohms shunted by a few picofarads, depending upon probe model.

The reduction in input capacitance is the most important reason for

using attenuator probes at high frequencies, where capacitance is the

major factor in loading down a circuit and distorting the signal.

Despite their high input impedance, attenuator probes do not

pick up appreciable hum or noise. As was the case with coaxial cable,

the outer conductor of the probe cable shields the central signal

conductor. Scope probes, of any attenuation, are also quite

convenient from a mechanical standpoint. Nearly all quality probes

have a spring-loaded hook end that quickly and securely holds the

probe to wiring and component leads (see Figure 2-6). This hook can

be removed to expose a needlepoint, excellent for use on the foil side

of a pc board, or for quickly moving from one point to another.

To determine if a direct connection with shielded cable is

permissible, you must know the source impedance of the circuit you

are connecting to, the highest frequencies involved, and the

capacitance of the cable. If any of these factors are unknown, use a

10X low-capacitance probe.

An alternative connection method at high frequencies is

terminated coaxial cable. A feed-thru terminator having an

impedance equal to that of the signal-source impedance, is connected

to the input connector of the oscilloscope. A coaxial cable of

matching characteristic impedance connects the signal source to the

terminator. This technique allows using cables of nearly any practical

length without signal loss.

9

10

Page 13

Page 14

If a low-resistance ground connection between oscilloscope

and circuit is not established, enormous amounts of hum will

appear in the displayed signal. Generally, the outer conductor

of shielded cable provides the ground connection. If you are

using plain lead wire, be certain to first connect a ground

wire between the LBO-516 Ground connector (12) and the

chassis or ground bus of the circuit under observation.

WARNING:

chassis (via the 3-prong power cord). Be certain the

device to which you connect the scope is transformer

operated. Do NOT connect the LBO-516 or any other

test equipment to "AC/ DC", "hot chassis", or

"transformerless" devices. Similarly, do NOT connect

the LBO-516 directly to the AC power line or any

circuitry connected directly to the power line. Damage

to the instrument and severe injury to the operator may

result from failure to heed this warning.

2-3-2 Single-trace Operation

Single trace operation with single timebase and internal

triggering is the most elementary operating mode of the

LBO-516. Use this mode when you want to observe only a

single signal, and not be disturbed by other traces on the

CRT. Since the LBO-516 is fundamentally a two-channel instrument, you have a choice for your single channel. Channel

1 has an output terminal; use channel 1 if you also want to

measure frequency with a counter while observing the

waveform. Channel 2 has a polarity-inverting switch. While

this adds flexibility, it is not ordinarily used in single-trace

operation.

The LBO-516 is set up for single-trace operation as follows:

1. Set the following controls as indicated. Any controls not

mentioned here or in the following steps can be

neglected. Note that the trigger source selected (CH-1 or

CH-2 SOURCE) must match the single channel selected

(CH-1 or CH-2 V MODE).

VARIABLE VOLTS/DIV Fully CW,

controls (11) and pushed in

AC/GND/DC switches (16) .......... AC

V MODE switches (21) ............... CH- 1 or CH-2*

CH-2 INV switch (19) .................. Out

A INTEN control (3) ................... APS**

FOCUS control (5) ..................... APS**

POWER switch (1) ..................... In

HORIZ DISPLAY switches (31) ..... A

B TIME/DIV switch (25) .............. 0.5/KS

A VARIABLE control (26) ............ Fully CW, and

SOURCE switch (34) .................. CH- 1 or CH-2*

COUPLING switch (36) ............... AC

SWEEP MODE switches (37) ........ AUTO

HOLDOFF control (42) ................ Pulled out

Horizontal POSITION control (29) ..APS**

*These selections must match.

**As previously set.

2. Use the corresponding vertical POSITION control (17)

or (18) to set the trace near mid screen.

The LBO-516 has an earth-grounded

pushed in

PRESET level

3. Connect the signal to be observed to the corresponding

input connector (14) or (15), and adjust the

corresponding VOLTS/DIV switch (10) so the

displayed signal is totally on screen.

CAUTION:

4. Set the A TIME/DIV switch (24) so the desired number

of cycles of signal are displayed. For some

measurements just 2 or 3 cycles are best; for other

measurements 50-100 cycles (appears like a solid band)

works best.

5. If the signal you wish to observe is so weak that even

the 5 mV position of the VOLTS/DIV switch cannot

produce sufficient trace height for triggering or a usable

display, pull the VARIABLE (X10 MAG) control (11)

outwards. This produces 1 mV/div sensitivity when the

VOLTS/DIV switch is set to 10 mV, and .5 mW/div

when it is set to 5 mV.

6. If the signal you wish to observe is so high in frequency

that even the .02/KS position of the A TIME/DIV switch

results in too many cycles displayed, pull the A VARIABLE (X10 MAG) control (28) outwards. This

increases the effective sweep speed by a factor of 10, so

.02 KS/div becomes 2KS/div, .1/KS becomes .01 KS/div,

etc. The 2KS/div sweep speed achievable by

magnification is fast enough to display a single cycle of

a 50 MHz signal across the CRT face!

7. If the signal you wish to observe is either DC or low

enough in frequency that AC coupling attenuates or

distorts the signal, flip the AC/GND/DC switch (16) to

DC.

CAUTION:

2-3-3 Triggering Alternatives

Triggering is often the most difficult operation to

perform on an oscilloscope because of the many options

available and the exacting requirements of certain signals. By

using PRESET trigger level and the AUTO sweep mode,

error-free triggering is obtainable from the LBO-516. These

were the trigger options selected for the single-trace

operating procedure described in paragraph 2-3-2, and the

multi-trace and dual-time base operating modes described in

the following section. They will in fact work well with most

signals. However, for complex or otherwise difficult signals,

the LBO-516 operator may choose from an extensive

selection of trigger options. These are categorized as triggersource options, coupling options, sweep mode, and

triggerpoint selection.

Sweep Mode Selection. Normally, the CRT beam is not

swept horizontally across the face of the CRT until a sample

of the signal being observed, or another signal harmonically

related to it, triggers the timebase. This is the situation when

NORM SWEEP MODE (37) is selected. However, this trigger mode is inconvenient because no baseline appears on the

CRT screen in the absence of an input signal, or if the trigger

controls are improperly set. Since an absence of a trace can

also be due to an improperly set vertical position control or

VOLTS/DIV switch, much time can be wasted determining

the cause. The AUTO sweep mode solves this problem by

causing the timebase to automatically free run when not

triggered. This yields a single horizontal line with no signal,

greater than 400 V (DC + AC peak).

If the observed waveform is low-level

AC, make certain it is not riding on a highamplitude DC voltage.

Do not apply a signal

11

Page 15

and a vertically-deflected but non-synchronized display when

vertical signal is present but the trigger controls improperly

set. This immediately indicates what is wrong. The only

problems with AUTO operation are that signals below 20 Hz

cannot, and complex signals of any frequency may · not,

reliably trigger the timebase. Therefore, the usual practice is

to leave the AUTO pushbutton pushed in, but press NORM if

any signal (particularly one below 20 Hz) fails to produce a

stable display.

The third sweep mode, obtained by pressing the

SINGLE pushbutton, produces a nonrepetitive sweep. Its use

is described in

Trigger Source Options.

obtained from the signal applied to the vertical inputs, or

from a separate source of the same or a harmonically-related

frequency. The SOURCE switch (34) offers several choices.

The CH-1 and CH-2 positions offer a choice of which of

the two input channels the trigger signal is derived. The

choice of channels remains even if the trigger channel is not

displayed; the only requirements are that signal be applied to

the trigger-source channel and the associated VOLTS/DIV

switch be set to provide sufficient signal amplitude. The minimum trigger amplitude is around half a division below 10

MHz, and increases to 1 1/2 divisions at 100 MHz. For insurance, use at least a full division below 10 MHz, and two divisions above 10 MHz.

If both channels are displayed, and the two signals are

different but harmonically-related frequencies, trigger from

the low-frequency channel if possible. This will ensure that

traces are stable.

Select the ALT position when you want to display two

signals not harmonically related (720 Hz and 939 Hz, for

example). The ALT SOURCE position must be used in

conjunction with the ALT V MODE (21) pushbutton for this

type of dual-trace display.

The LINE position provides trigger signal at the local

power-line frequency. This is of great use when you wish to

observe a low-level ripple component imposed on a large DC

voltage, or within a mixture of other AC voltages. The linefrequency trigger will sync signal at any reasonable multiple

of the power-line frequency.

2-3-10 Single-shot Operation.

Trigger signal can be

The 0.2 V/DIV and 2 V/DIV positions both select

external trigger signal applied to the EXT TRIG IN

connector (35). Use 0.2 V/DIV position when the external

trigger amplitude is between 100 mV and 2000 mV peak-topeak. Use the 2 V/ DIV position when the signal amplitude is

between 2 V and 20 V peak-to-peak.

CAUTION:

V (DC + AC peak).

Using a trigger source not derived from the channel you

are watching has the advantage that changes in the amplitude

of the signal under observation will not cause the display to

lose sync, even if the amplitude of the observed signal falls

below a half graticule division. External trigger also has the

advantage that complex and/or noisy signals can be stably

displayed, providing the trigger signal is free of noise.

Trigger Coupling Options.

coupling options for the main (A) and delayed (B) timebases

increase the probability of stable triggering on difficult

signals, such as those containing several frequencies and/or

hum and noise.

The first two COUPLING positions (36) are frequencyselective filters that pass certain frequencies on to the trigger

circuitry and reject others. The AC position removes any DC

component in the trigger signal.

The HF-REJ position cuts off frequencies higher than

35 kHz, passing only signals in the 10 Hz to 35 kHz region.

Select this position if high-frequency noise (the CHOP

switching pulses for example) is mixed with a low-frequency

signal.

The DC position removes all filters from the trigger

chain, so everything in the trigger signal from DC to the

upper bandwidth limit of the oscilloscope is passed to the

trigger circuits. Select DC COUPLING if the trigger signal is

below 10 Hz, or may be expected to be below this frequency

at some time during a series of measurements.

The TV-V and TV-H positions insert a TV sync

separator into the trigger chain, so a clean trigger signal at

either the vertical or horizontal repetition rates can be

removed from a composite video signal. The TV-V position

is also effective in securing stable triggering at the low frequency (60 or 70 Hz) of an audio intermodulation distortion

Do not apply a signal greater than 400

The various trigger

12

Page 16

test signal. To trigger the scope at the vertical (field) rate,

select the TV-V position. To trigger the scope at the horizontal (line) rate, select the TV-H position. When either TV position is used, the SLOPE switch (39) must be matched to the

polarity of the video signal. Leave the SLOPE pushbutton out

(+ position) for positive-sync signals (Figure 2-7a), and push

it in (- position) for negative-sync video signals (Figure 2-7b).

timebase must be triggered at the exact same point on the re-

Trigger Point Selection

current waveform each time the timebase is swept. This is

sometimes difficult to achieve, so the LBO-516 has three

controls that enable the operator to achieve this condition.

They are the LEVEL control (40), the SLOPE switch (39),

and the HOLDOFF control (42).

. For a stable display, the

The SLOPE switch determines whether the sweep will begin

on a positive-going or negative-going slope of the trigger

signal (see Figure 2-8). In some cases, the choice of slope is

unimportant; in others, it is vitally important to attain a stable

and/or jitter-free display. Always select the steepest and most

stable slope or edge. For example, small changes in the

amplitude of the sawtooth shown in Figure 2.8a will cause

jitter if the timebase is triggered on the positive (ramp) slope,

but have no effect if triggering occurs on the negative slope (a

fast-fall edge). In the example shown in Figure 2-8b, both

leading and trailing edges are very steep (fast rise and fall

times). However, this particular pulse is the output of a

leading-edge triggered monostable, and has pulse-width jitter.

Triggering from the jittering trailing edge will cause the entire

trace to jitter, making observation diffi-

13

Page 17

cult. Triggering from the stable leading edge (+ slope) yields a

trace that has only the trailing-edge jitter of the original signal. If

you are ever in doubt, or have an unsatisfactory display, try both

slopes to find the best way.

The LEVEL control determines the point on the selected

slope at which the main (A) timebase or delayed (B) timebase will

be triggered. The effect of the LEVEL control on the displayed

trace is shown in Figure 2-9a. The +, 0, and - panel markings for

this control refer to the waveform's zero crossing and points more

positive (+) and more negative (-) than this. If the trigger slope is

very steep, as with square waves or digital pulses, there will be no

apparent change in the displayed trace until the LEVEL control is

rotated past the most positive or most negative trigger point,

whereupon the display will free run (AUTO sweep mode) or

disappear completely (NORM sweep mode). Try to trigger at the

mid point of slow-rise waveforms (such as sine and triangular

waveforms), since these are usually the cleanest spots on such

waveforms. As figure 2-9b shows, triggering on a noisy area will

cause instability in the display. Pulling the HOLDOFF control

outwards to the PRESET level position automatically triggers the

timebase near the zero-crossing point of the trigger signal.

The larger the amplitude of the trigger signal inputted to the

trigger circuits, the greater is the degree of rotation (control range)

over which the LEVEL control will maintain a stable display.

With internally-derived trigger, the actual trigger amplitude is

proportional to the number of graticule divisions occupied by the

trace. Therefore, the trigger point is more critical with small

signals than large. This is one reason why it is important to use as

much trace height as practical for the number of traces displayed.

The HOLDOFF control is used for special circumstances

only. It allows the operator to alter the mandatory "dead" time

between the end of one sweep and the start of the next (in

response to a trigger pulse). This prevents the triggering of

subsequent sweeps by the wrong trigger pulse in a complex

waveform. During normal operation, leave the HOLDOFF control

click-stopped at NORM. When viewing complex waveforms

containing multiple trigger points per repetition, rotate the

HOLDOFF control clockwise until the proper waveform is

secured, as shown in Figure 2-10. For example, the waveform

shown contains three pulses in each group capable of triggering

the timebase, but sweep must begin only on the first pulse in each

burst to obtain the proper display. In the lower display, the dead

time has been extended enough to make it impossible for last

pulse in the second burst to start the next sweep.

Rotate the HOLDOFF control fully clockwise to its B ENDS

A click-stopped position when using the delayed (B) timebase and

the difference between the A and B TIME/DIV setting is large (6

positions or more). The resulting brightness improvement is

greatest when the delay time between B and A timebases is short.

2-3-4 Probe Compensation

The LP- 100X probes furnished with the LBO-516 must be

adjusted to the input capacitance of the. channel(s) with which

they are used. If the probes are used only with vertical input

channels 1 and 2, this adjustment need be performed only when

the probes are first used, and the probes can be used

interchangeably between these channels without adjustment.

However, if an additional probe is purchased for the trigger input

channel (CH-3), mark it and compensate it separately, as the CH-3

input capacitance is somewhat different.

To compensate a probe for CH-1 or CH-2, proceed as follows:

1. Connect the probe to the CH-1 input connector (14) and the

CAL connector (9).

2. Set the CH- 1 VOLTS/DIV switch (10) to 20 mV, the CH- 1

AC/GND/DC switch (16) to DC, and the A TIME/DIV

switch (24) to .2 mS.

3. Press the CH-1 V MODE pushbutton (21) and A HORIZ

DISPLAY pushbutton (35), and select CH-1 SOURCE (34).

4. With a small screwdriver, adjust the capacitance-correction

trimmer (Figure 2-6a) for a correct-appearing square wave.

(Figure 2-6d).

14

Page 18

To compensate a probe for CH-3, proceed as follows:

1. Connect the probe to the CH-3 or EXT TRIG IN connector

(35) and a 1000 Hz signal source set for 8 Vp.p output

amplitude.

2. Set the A TIME/DIV switch to .2 mS, the SOURCE

switch to .2 V/DIV, and the COUPLING switch to DC.

3. Press the ALT V MODE pushbutton (21), the A HORIZ

DISPLAY pushbutton (35), and push in the HOLDOFF

control (42).

4. Pull the PULL TRIPLE control (22) and adjust it to position

the CH-3 trace at midscreen. Adjust the LEVEL control (40)

if needed.

5. With a small screwdriver, adjust the capacitance-correction

trimmer (Figure 2-6a) for a correct-appearing square wave.

(Figure 2-6d).

2-3-5 Dual Trace Operation

Dual-trace operation is the major operating mode of the

LBO-516, since full amplification and attenuation facilities are

provided for the two channels. As was the case with Single-trace

Operation, you have a choice here too, not of channel selection,

but of how to display the two channels.

The LBO-516 is set up for dual-trace operation as follows:

1. Set the following controls as indicated below. Any controls not

mentioned here or in the following steps can be neglected.

VARIABLE VOLTS/DIV controls (11) Fully CW, and

pushed in

AC/GND/DC switches (16) ......................... AC

CH-2 INV switch (19) ................................. Out

PULL TRIPLE control (22) ......................... In

PULL QUAD control (23) ........................... In

A INTEN control (3) ................................... APS*

FOCUS control (5) ...................................... APS*

POWER switch (1) ..................... In

HORIZ DISPLAY switches (31) ..... A

B TIME/DIV switch (25) .............. 0.5/PS

A VARIABLE control (26) ........... Fully CW, and

pushed in.

SOURCE switch (34) .................. CH-I or CH-2**

COUPLING switch (36) ............... AC

SWEEP MODE switches (37) ........ AUTO

HOLDOFF control (42) ............................... Pulled out

.................................................................... (PRESET level)

Horizontal POSITION control (29) .............. APS*

*As previously set.

**See Step 6.

15

Page 19

2. Press either ALT or CHOP V MODE pushbutton (21). Press

ALT for relatively high-frequency displays (A TIME/DIV

switch set at .2 mS or faster); press CHOP for relatively lowfrequency displays (A TIME/DIV switch set at .5 mS or

slower). If the CHOP pushbutton is pressed when fast sweep

speeds are used, the displayed traces will appear broken (as

in Figure 2-11) when signals are applied. If the ALT

pushbutton is pressed when slow sweep speeds are used, the

display will flicker excessively.

3. Use the vertical POSITION controls (17 and 18) to set the

CH-1 trace about two divisions down from the top graticule

line, and the CH-2 trace about two divisions up from the

bottom graticule line.

The LBO-516 is set up for dual-trace operation as follows:

4. Connect the signals to be observed to the CH-1 and CH-2 IN

connectors (14) and (15), and adjust the VOLTS/DIV

switches (10) so the displayed signals are totally on screen

and clear of each other.

CAUTION:

(DC + AC peak).

5. Set the A TIME/DIV switch (24) so the desired number of

cycles are displayed. Be certain the display mode (ALT or

CHOP) selected is consistent with this sweep speed (as per

Step 2).

6. If both channels are handling signals of the same frequency,

trigger from the channel having the steepest-slope waveform.

If the signals are different but harmonically-related

frequencies, trigger from the channel carrying the lowest

frequency. Also, bear in mind that if you disconnect the

signal to the channel serving as the trigger source, the entire

display will free run.

7. If the signals are different frequencies and not harmonically

related, select the ALT trigger SOURCE position (34) and

the ALT V MODE pushbutton (21) regardless of the A

TIME/DIV switch setting.

8. If the signal you wish to observe is so weak that even the 5

mV position of the VOLTS/DIV switch cannot produce

sufficient trace height for triggering a usable display, pull the

VARIABLE (XI0 MAG) control (11) outward. This

produces 1 mV/ div sensitivity when the VOLTS/DIV switch

is set to I0 mV, and .5 mV/div when it is set to 5 mV.

Do not apply signals greater than 400 V

9. If the signal you wish to observe is so high in frequency that

even the .02/aS position of the A TIME/DIV switch results in

too many cycles displayed. Pull the A VARIABLE (XI0

MAG) control (26) outward. This increases the effective

sweep by a factor of 10, so .02 PS/div becomes 2 KS/div,

0.1PS/div becomes .01 /PS/div, etc. The 2 KS/div sweep

speed achievable by magnification is fast enough to display a

single cycle of a 50 MHz signal across the CRT face.

10. If the signal you wish to observe is either DC or low enough

in frequency that AC coupling attenuates or distorts the

signal, flip the AC/GND/DC switch (16) to DC.

CAUTION:

low-level AC, make certain it is not riding

2-3-6 Additive and Differential Operation

Additive and differential operation are forms of two-channel

operation where two signals are combined to display one trace. In

additive operation, the resultant trace represents the algebraic sum

of the CH-1 and CH-2 signals. In differential operation, the

resultant trace represents the algebraic

CH-I and CH-2 signals.

To set up the LBO-516 for additive operation, proceed as

follows:

1. Set up the dual-trace operation per paragraph 2-3-5, Steps 1

to 6 and 8 to I0.

2. Make sure both VOLTS/DIV switches (I0) are set to the

same position; and the VARIABLE controls (11) are detented in their CAL'D position. If the signal levels are very

different, set both VOLTS/DIV switches to the position

producing a large on-screen display of the

signal.

3. Trigger from the channel having the biggest signal.

4. Press the ADD V MODE (21) pushbutton. The single trace

resulting is the algebraic sum of the CH- 1 and CH-2 signals.

Either or both of the vertical POSITION controls (17) and

(18) can he used to shift the resultant trace.

5. If the p-p amplitude of the resultant trace is very small, mm

both

Make sure both VOLTS/DIV controls are set to the same

position.

To set up the LBO-516 for differential operation, proceed as

follows:

1. Set up for dual-trace operation per paragraph 2-3-5,

2. Ensure that both VOLTS/DIV switches (10) are set to

3. Trigger from channel having the larger signal.

4. Press in the CH-2 INV pushbutton (19).

on a high-amplitude DC voltage.

NOTE: If the input signals are in-phase, the amplitude

of the resultant trace will be the arithmetic sum of the

individual traces (e.g., 4.2 div + 1.2 div = 5.4 div). If the

input signals are 180° out of phase, the amplitude of the

resultant trace will be the arithmetic difference of the

two traces (e.g., 4.2 div - 1.2 div = 3.0 div).

VOLTS/DIV switches to increase the display height.

Steps 1 to 6 and 8 to I0.

the same position. If the signal levels are very different,

temporarily set both VOLTS/DIV switches to the

position needed to produce a large on-screen display of

the highest-amplitude signal.

If the observed waveform is

difference

between the

higher amplitude

16

Page 20

5. Press the ADD V MODE pushbutton (21)· The single trace

resulting is the algebraic difference of the CH-1 and CH-2

signals. Either or both of the vertical POSITION controls

(17) and (18) can be used to shift the resultant trace.

NOTE: If the input signals are in-phase, the amplitude

of the resultant trace will be the arithmetic difference of

the individual traces (e.g., 4.2div - 1.2div = 3.0div). If

the input signals are 180° out of phase, the amplitude of

the resultant trace will be the arithmetic sum of the

individual traces (e.g., 4.2 div + 1.2 div = 5.4 div).

6. If the peak-to-peak amplitude of the resultant trace is very

small, mm both VOLTS/DIV switches to increase the display

height. Make sure both VOLTS/DIV controls are set to the

same position.

2-3-7 Triple-trace Operation

A very useful feature of the LBO-516 is that the timebase

trigger can be displayed on the CRT screen along with the two

vertical inputs. The trigger signal appears as the third trace,

permitting continuous trigger view and/or a third input channel.

Trigger Display.

trigger signal and two input channels, proceed as follows:

1. Set the following controls as indicated below. Any

controls not mentioned here or in the following steps can be neglected.

PULL TRIPLE control (22) ......................... Pulled out

CH-2 INV switch (19) ................................. Out

VARIABLE VOLTS/DIV Fully CW, and

controls (11) pushed in

AC/GND/DC switches (16) .......................... AC

PULL QUAD control (23) ........................... Pushed in

A INTEN control (3) ................................... APS*

FOCUS control (5) ...................................... APS*

POWER switch (1) ...................................... Pushed in

HORIZ DISPLAY switches (31) .................. A

B TIME/DIV switch (25) ............................. 05/PS

A VARIABLE control (26) ......................... Fully CW, and

.. ........ ........ ........ ........ ........ ........ ........ ........ .. pushed in

SOURCE switch (34)................................... CH-1 or

.. ........ ........ ........ ........ ........ ........ ........ ........ .. CH-2**

COUPLING switch (36) .............................. AC

SWEEP MODE switches (3'7) ..................... AUTO

HOLDOFF control (42) ............................... Pulled out

.. ........ ........ ........ ........ ........ ........ ........ ........ .. (PRESET level)

Horizontal POSITION control (29) .............. APS*

* As previously set.

** See Step 7.

2. Press the ALT or CHOP V MODE pushbutton (21). Press

ALT for relatively high-frequency displays (A TIME/DIV

switch set at .2 mS/div and faster); press CHOP for relatively

low-frequency displays (A TIME/DIV switch set at .5mS/div

and slower). If the CHOP pushbutton is pressed when fast

sweep speeds are used, the displayed traces will appear as

broken lines when signal is applied. Conversely, if the ALT

pushbutton is pressed when low sweep speeds are used, the

display will flicker excessively.

To continuously display the timebase

3. Use the vertical POSITION controls (17 and 18) to set the

CH- 1 trace near the 90% dotted graticule line, and the CH-2

trace on the center graticule line.

4. Use the PULL TRIPLE control (22) to set the third trace near

the 10% dotted graticule line.

5. Connect the signal to be observed to the CH-1 and CH-2 IN

connectors (14 and 15), and adjust the VOLTS/DIV switches

(10) so the displayed signals are totally on screen and clear

of each other.

6. Set the A TIME/DIV switch (24) so the desired number of

cycles is displayed. Be certain the display mode (ALT or

CHOP) selected is consistent with this switch setting (per

Step 2). If the signal you wish to observe is so high in fre-

quency that even the .02 PS position of the A TIME/DIV

switch results in too many cycles displayed, pull the A

VARIABLE (XI0 MAG) control (26). This increases the

effective sweep speed by a factor of 10, so .02 PS/div becomes 2 KS/div.

7. If CH-1 and CH-2 are both handling signals of the same

frequency, trigger from the channel haying the steepest

waveform. If the signals are different but harmonically-related frequencies, trigger from the channel carrying the

lowest frequency.

8. The third trace is the timebase trigger signal. With trigger

taken from either CH- 1 or CH-2, the trigger signal may appear to be the same as one of the vertical channels. However,

trigger COUPLING switch positions other than DC insert

frequency-selective networks into the CH-3 amplifier, so the

third trace may appear different at certain frequencies.

NOTE: If ALT trigger source is selected, the third trace

will resemble the CH-1 trace, not the composite trigger

channels, proceed as follows:

2-3-8 Four-trace Operation

displayed as the fourth trace in this mode of operation. To display

the CH-1 and CH-2 input signals, their algebraic sum, and the

signal triggering the timebase, proceed as follows:

17

signal.

Three Input Channels

1. Perform Steps 1 to 6 of the previous procedure.

2. Connect the third signal to be observed to the EXT

TRIG IN (CH-3) connector (35). If the three signals are

different but harmonically-related frequencies, apply the

lowest-frequency signal to this channel.

CAUTION: Do not apply a signal greater than 400 V

(DC + AC peak).

3. Set the SOURCE switch (34) to the 2 V/DIV position. If

the trace is less than one division high, external

amplification will be needed.

4. The third trace is the CH-3 input signal as well as the

timebase trigger, so do not use any trigger coupling

position other than AC or DC. The bandwidth-limiting

filters inserted at other positions of the COUPLING

switch (36) will distort the CRT display of the CH-3

input signal.

The algebraic sum of the CH-I and CH-2 input signals is

. To display three independent input

Page 21

1. Set the following controls as indicated. Any control not

mentioned here or in the following steps can be neglected.

PULL QUAD control (23) ........................... Pulled out

CH-2 INV switch (19) ................................. Out

VARIABLE VOLTS/DIV controls (11) Fully CW, and

pushed in

AC/GND/DC switches (16) ......................... AC

A INTEN control (3) ................................... APS*

FOCUS control (5) ...................................... APS*

POWER switch (1) ...................................... Pushed in

B TIME/DIV switch (25) .............. . 05P S

HORIZ DISPLAY switches (31) ..... A

A VARIABLE control (26) ........... Fully CW, and

pushed in

SOURCE switch (34) .................. CH-1 or CH-2**

COUPLING switch (36) ............... AC

SWEEP MODE switches (37) ........ AUTO

HOLDOFF control (42) ................ Pulled out

(PRESET level)

Horizontal POSITION control (29) .. APS*

* As previously set. ** See Step 6.

2. Press the ALT or CHOP V MODE pushbutton (21). Press

ALT for relatively high-frequency displays (A TIME/ DIV

switch set at .2 mS/div and faster); press CHOP for relatively

low-frequency displays (A TIME/DIV switch set at .5mS/div

and slower). If the CHOP pushbutton is pressed when fast

sweep speeds are used, the displayed traces will appear as

broken lines when signal is applied. Conversely, if the ALT

pushbutton is pressed when low sweep speeds are used, the

display will flicker excessively.

3. Use the vertical POSITION controls (17 and 18) to set the

CH-1 trace two graticule divisions from the bottom of the

CRT screen. This will set the sum trace (CH- 1 + CH-2) near

the center graticule line.

NOTE: The position of the sum trace is not separately

controllable.

4. Use the PULL TRIPLE control (22) to temporarily set the

CH-3 trace off screen.

5. Connect the signals to be observed to the CH-1 and CH-2 IN

connectors (14 and 15), and adjust the VOLTS/DIV switches

(10) so the displayed traces are totally on screen and well

clear of each other. Make sure both VOLTS/ DIV switches

are set to the same position, and their VARIABLE controls

(11) are detented in their CAL'D positions. If the signal

levels are very different, set both VOLTS/DIV switches to

the position suitable for the higher-level signal.

6. Set the trigger SOURCE switch (34) to match the channel

with the higher-amplitude signal.

7. Set the A TIME/DIV switch (24) so the desired number of

cycles is displayed. Be certain the display mode (ALT or

CHOP) selected is consistent with this switch setting (per

Step 2). If the signal you wish to observe is so high in

frequency that even the .02 p3 position of the A TIME/ DIV

switch results in too many cycles displayed, pull the A

VARIABLE (XI0 MAG) control (26). This increases the

effective sweep speed by a factor of I0, so .02PS/div

becomes 2 KS/div.

8. The CH-2 INV switch (19) can be pushed in to display the

difference signal between the CH-1 and CH-2 input signals

instead of their sum.

9. If your primary reason for selecting the four-trace display

mode is to view the sum or difference signal while simultaneously viewing the two signals from which it is derived,

leave the CH-3 trace off screen. If you need to see the timebase trigger trace as well, use the PULL TRIPLE control to

move the CH-3 trace to a relatively vacant spot on screen.

10. If the CH-3 trace is used as a third input channel, set the

trigger SOURCE switch to 0.2 V/DIV or 2 V/DIV, as befits

the input-signal amplitude. Since this trace is also the

timebase trigger signal, some positions of the trigger

COUPLING switch (36) will distort the trace because of the

limited-bandwidth filters they insert. Therefore, use either

the DC or AC COUPLING settings in this application.

2-3-9 Delayed-timebase Operation

The LBO-516 contains two timebases, arranged so one (the

A timebase) may provide a delay between a trigger event and the

beginning of sweep by the second (B) timebase. This allows any

selected portion of a waveform, or one pulse of a pulse train, to be

spread over the entire screen. Moreover, the CRT can be

alternately swept by the two timebases, so both the full waveform

and the selected portion appear across the full CRT screen width.

The aforementioned dual-timebase displays can be used with

any of the vertical display modes (single trace, dual trace, triple

trace, or quad). The procedure is the same regardless of the

number of traces displayed.

Basic Delayed Sweep

follows:

1. Set up the LBO-516 as directed for whatever vertical mode

you desire.

2. Make sure the START pushbutton (32) is out.

3. Press the INTEN BY B pushbutton (31). A section of the

trace(s) will intensify (brighten).

NOTE: The intensified portion will be quite small if there is

a large difference between the settings of the A and B

TIME/DIV switches. 4. Turn the B TIME/DIV control (25)

until the intensified portion of the trace widens to an amount

equal to the portion of the trace you wish to magnify (see

Figure 2-12b).

5. Turn the DLY TIME MULT control (28) to position the

intensification over the portion of the trace you wish to

magnify.

6. Press the B HORIZ DISPLAY pushbutton (31). That portion

of the trace intensified in Step 5 now appears spread over the

full width of the CRT screen. The trace now displayed is

being swept by the B timebase (Figure 2-12c).

7. If needed, additional enlargement is possible by palling the A

VARIABLE (X10 MAG) control (26) outward.

. For delayed sweep, proceed as

18

Page 22

B Intensity Adjustment.

relative to A trace brightness as the difference in A and B

TIME/DIV switch setting varies. The B INTEN control (4) allows

compensatory adjustment for the brightness difference. This

control can be rotated clockwise for increased brightness.

The B trace brightness varies

Alternate Sweep Mode.

main (A) and delayed (B) timebase traces for each vertical

channel used. The total number of traces is always doubled. Since

up to eight traces may appear in the alternate sweep mode, most

of the effort in this procedure involves adjusting trace amplitudes

and positions to get an understandable display.

To simultaneously display the A and B timebase traces,

proceed as follows:

1. Adjust the vertical VOLTS/DIV control(s) (10) so each trace

displayed does not exceed the number of divisions indicated

in Table 2-2. This is simply to insure that there is room for

all traces when switching to alternate sweep.

2. For the same reason, position the trace(s) so there is room

each

near

equal amplitude.

3. Display the B timebase as described in the preceding paragraph,

4. Press the ALT HORIZ DISPLAY pushbutton (31). The B

timebase trace(s) will now be displayed below its corresponding A timebase trace(s).

trace currently displayed for an additional trace of

Basic Delayed Sweep.

This sweep mode displays both

5. If necessary, adjust the A/B TRACE SEP control (33) so the

B timebase trace(s) do not overlap the A timebase traces.

Some adjustments with the vertical POSITION,

VOLTS/DIV, and A/B TRACE SEP controls may be necessary if the display is crowded (as in triple-trace and fourtrace operation).

NOTE:

Positioning eight traces can be difficult at first. The

suggested layout is to set the CH-1 baseline two graticule

divisions down from the top, and the CH-2 baseline two divisions up from the bottom. This puts the sum or difference

trace on the center graticule line. For positive-logic signals

(TTL, CMOS, etc.), set the CH-3 baseline on the bottom

graticule line, and later set the alternate B-sweep display

above

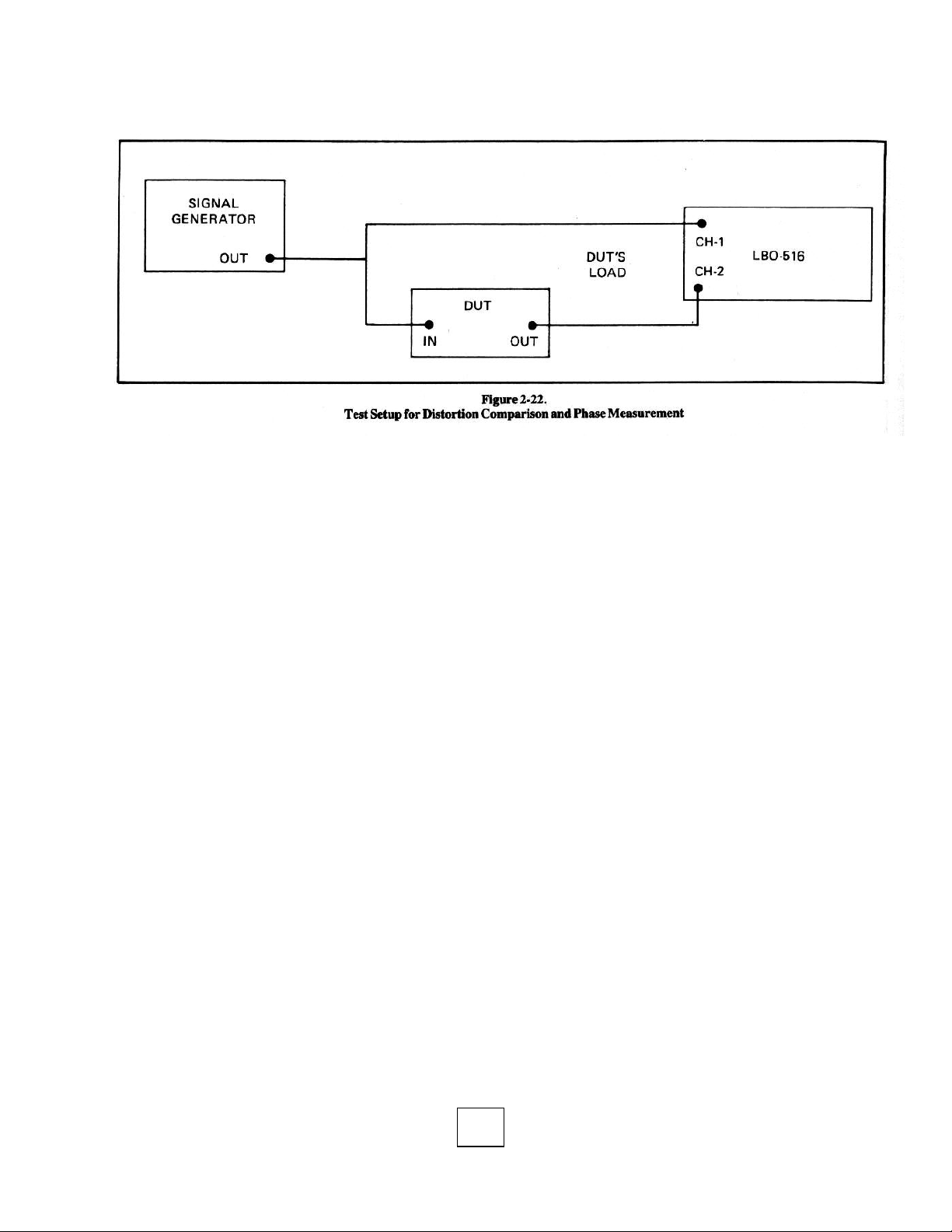

the A-sweep traces. For negative-logic signals (such