L.B. White Premier 350, TS350, Premier 350 DF, TS350DF Owner's Manual And Instructions

Attention

This heater has been tested and

evaluated by the CSA Group in

accordance with the requirements

of Standard ANSI Z83.7•CSA 2.14

and is listed and approved as a

ductable direct gas-fi red forced-air

construction heater with

application for the temporary

heating of buildings under

construction, alteration, or repair.

Additionally, this heater has been

application reviewed and approved

by the CSA Group for U.S.and

Canadian Tent Heating

Applications with temporary human

occupancy. CHECK WITH YOUR

LOCAL FIRE SAFETY

AUTHORITY, YOUR LOCAL FUEL

GAS SUPPLIER, OR THE L.B.

WHITE COMPANY IF YOU HAVE

QUESTIONS REGARDING

APPLICATIONS.

www.lbwhite.com

SCAN THIS

with your smartphone or

visit http://goo.gl/5j21G

to view maintenance

videos for L.B.White heaters.*

WORLD PROVIDER - INNOVATIVE HEATING SOLUTIONS

411 Mason Street, Onalaska, WI 54650 • 800-345-7200 • 608-783-5691 • 608-783-6115 (fax) • www.lbwhite.com

Congratulations!

You have purchased the fi nest circulating heater available.

Your new L.B. White heater incorporates the benefi ts from the

most experienced manufacturer of heating products using stateof-the-art technology.

We, at L.B. White, thank you for your confi dence in our products

and welcome any suggestions or comments you may have...

contact us at 1-800-345-7200, or email us at

customerservice@lbwhite.com.

LP Vapor Withdrawal or Dual Fuel

Premier

Ductable Heaters

TS350

TS350DF

350,000 Btuh / 102.6 kW

350,000 Btuh / 102.6 kW

Owner’s Manual and Instructions

View this manual online at www.lbwhite.com

* Requires an app like QR Droid

for Android or for iPhone

SEE ASSEMBLY

INSTRUCTIONS

INSIDE

Please refer to important

elevation information on

inside cover.

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

2

TABLE OF CONTENTS

WARNING

Standard products are manufactured to operate at optimum effi ciency at elevations

between 0 and 2000 ft. (0-610 m) above sea level.

If operated at higher elevations the product will not function correctly and may

function in an unsafe nature.

Products providing proper operation for alternate elevations may be available.

If you require a high elevation product, did not specify when ordering, and/or the

box this unit came in does not have an alternate altitude designation sticker please

contact technical support.

Heater Specifi cations ............................................................................................................... 4

General Information ................................................................................................................. 5

Safety Precautions .................................................................................................................. 6

Installation Instructions

General .................................................................................................................................... 9

Gas Supply Sizing ................................................................................................................... 11

Connecting Hose to Heater ..................................................................................................... 12

Connecting Regulator to Gas Supply ...................................................................................... 12

Thermostat .............................................................................................................................. 13

Installation of Heater ................................................................................................................ 14

Inside Structure ................................................................................................................. 14

Outside Structure (Using air distribution accessories) ...................................................... 14

A. Duct Kit ......................................................................................................................... 14

B. End Diffuser .................................................................................................................. 14

C. Infl atable Duct Kit ......................................................................................................... 15

Start-Up Instructions ................................................................................................................ 16

Shut-Down Instructions ........................................................................................................... 17

Gas Selector Valve (Premier 350 DF Heaters Only) ............................................................... 17

Cleaning Instructions ............................................................................................................... 18

Maintenance Instructions ......................................................................................................... 19

Service Instructions

General .................................................................................................................................... 20

Belt Replacement .................................................................................................................... 20

Fan and Motor Pulleys ............................................................................................................. 21

Drive Component Troubleshooting .......................................................................................... 22

Fan Motor ................................................................................................................................ 23

Air Proving Switch ................................................................................................................... 23

Ignition Control ........................................................................................................................ 24

Relay ....................................................................................................................................... 24

Transformer ............................................................................................................................. 24

Igniter Assembly ...................................................................................................................... 25

Manual Reset High Limit Switches .......................................................................................... 26

Fan Wheel, Bearings, and Shaft .............................................................................................. 27

Burner Orifi ce and Gas Control Valve ..................................................................................... 27

Gas Pressure Checks .............................................................................................................. 28

Troubleshooting Information .................................................................................................... 30

Electrical Connection and Ladder Diagram Premier 350 DF ................................................... 37

Premier 350 Propane Gas .................................. 38

Heater Component Function ................................................................................................... 39

Parts Identifi cation Parts Schematic ........................................................................................ 40

Parts List .................................................................................................................................. 41

Warranty Policy, Replacement Parts and Service ................................................................... 44

Premier Ductable Heaters

Owner’s Manual • Premier 350

3

WARNING

FIRE, BURN, INHALATION, AND

EXPLOSION HAZARD

■ KEEP SOLID COMBUSTIBLES A SAFE DISTANCE AWAY FROM THE HEATER.

■ SOLID COMBUSTIBLES INCLUDE WOOD,

PAPER, OR PLASTIC PRODUCTS, BUILDING

MATERIALS AND DUST.

■ DO NOT USE THE HEATER IN SPACES WHICH

CONTAIN OR MAY CONTAIN VOLATILE OR

AIRBORNE COMBUSTIBLES.

■ VOLATILE OR AIRBORNE COMBUSTIBLES

INCLUDE GASOLINE, SOLVENTS, PAINT

THINNER, DUST PARTICLES OR UNKNOWN

CHEMICALS.

■ FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN A FIRE OR EXPLOSION.

■ FIRE OR EXPLOSIONS CAN LEAD TO

PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open fl ame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other fl am-

mable vapors and liquids in the vicinity of this

or any other appliance.

GENERAL HAZARD WARNING

■ FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS PROVIDED WITH

THIS HEATER CAN RESULT IN:

— DEATH

— SERIOUS BODILY INJURY OR BURNS

— PROPERTY DAMAGE OR LOSS FROM FIRE OR EXPLOSION

— ASPHYXIATION DUE TO LACK OF ADEQUATE AIR SUPPLY OR CARBON MONOXIDE

POISONING

— ELECTRICAL SHOCK

■ READ THIS OWNER’S MANUAL BEFORE INSTALLING OR USING THIS PRODUCT.

■ ONLY PERSONS WHO CAN READ, UNDERSTAND, AND FOLLOW THE INSTRUCTIONS

SHOULD USE OR SERVICE THIS HEATER.

■ SAVE THIS OWNER’S MANUAL FOR FUTURE USE AND REFERENCE.

■ OWNER’S MANUALS AND REPLACEMENT LABELS ARE AVAILABLE AT NO CHARGE. SEE

WEBSITE, OR FOR ASSISTANCE, CONTACT L.B. WHITE AT 1-800-345-7200.

WARNING

■ PROPER GAS SUPPLY PRESSURE MUST BE PROVIDED TO THE INLET OF THE HEATER.

■ REFER TO DATA PLATE FOR PROPER GAS SUPPLY PRESSURE.

■ GAS PRESSURE IN EXCESS OF THE MAXIMUM INLET PRESSURE SPECIFIED AT THE

HEATER INLET CAN CAUSE FIRES OR EXPLOSIONS.

■ FIRES OR EXPLOSIONS CAN LEAD TO SERIOUS INJURY, DEATH, OR BUILDING

DAMAGE.

■ GAS PRESSURE BELOW THE MINIMUM INLET PRESSURE SPECIFIED AT THE HEATER INLET

MAY CAUSE IMPROPER COMBUSTION.

■ IMPROPER COMBUSTION CAN LEAD TO ASPHYXIATION OR CARBON MONOXIDE POISONING AND THEREFORE SERIOUS INJURY OR DEATH.

WARNING

FIRE AND EXPLOSION HAZARD

■ NOT FOR HOME OR RECREATIONAL VEHICLE USE.

■ INSTALLATION OF THIS HEATER IN A HOME OR RECREATIONAL VEHICLE MAY RESULT IN A

FIRE OR EXPLOSION.

■ FIRE OR EXPLOSIONS CAN CAUSE PROPERTY DAMAGE OR LOSS OF LIFE.

WARNING

CALIFORNIA RESIDENTS:

When operating, this heater produces

chemicals, including Carbon Monoxide,

known to the State of California to cause birth

defects and other reproductive harm.

For more information,

go to www.P65Warnings.ca.gov

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

4

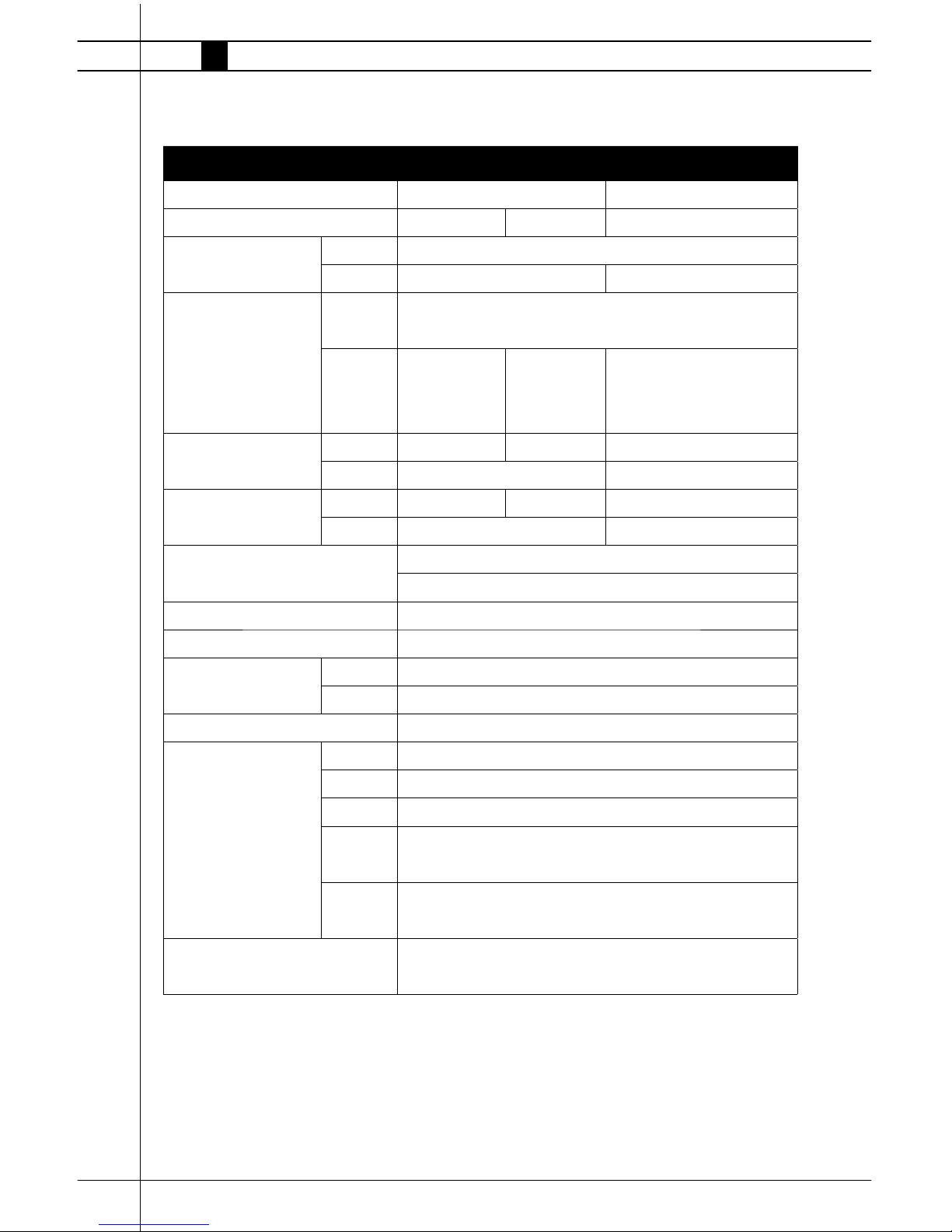

Specifications

Description Model

TS350DF TS350

Fuel Type Propane Gas Natural Gas Propane Gas

Maximum Input (Btuh/kW) MAX 350,000 / 102.6

MIN N/A 175,000 / 51.3

Inlet Gas Supply Pressure

Acceptable at the Inlet of

the Heater for Purpose of

INput Adjustment (Inches

W.C./kPa)

MAX 13.5 / 3.36

MIN 11.0 / 2.74 7.0 / 1.74 11.0 / 2.74

Burner Manifold Pressure

(Inches W.C/kPa)

MAX 5.2 / 1.30 5.3 / 1.32 8.0 / 2.0

MIN N/A 2.0 / .49

Fuel Consumption Per

Hour

MAX 16.2 lbs. / 7.34 kg 350 cu.ft./9.9m³ 16.2 lbs./7.34 kg

MIN N/A 8.12 lbs/3.54 kg

Motor Characteristics Ball Bearing

1 H.P. / 745.7 Watts / 1,725 RPM

Blower Speed 915 RPM

Electrical Supply (Volts/Hz/Phase) 115 / 60 / 1

Amp Draw Starting 35.0

Continuous 11.0

Dimensions L x W x H (Inches/cm) 48 x 22.25 x 32.75 / 122 x 56.5 x 83.2

Minimum Safe Distances

from Nearest Combustible

Material (Feet / Meters)

Top 1 / 0.3

Sides 1 / 0.3

Back 1 / 0.3

Blower

Outlet

6 /1.83

Gas

Supply

Propane - U.S.: 6, Canada: 3.05 - Natural Gas - N/A

Minimum Ambient Temperature

Can be Used

-20°F / -29°C

Premier Ductable Heaters

Owner’s Manual • Premier 350

5

This Owner’s Manual includes accessories commonly

used on this heater. These accessories must be

ordered seperately.

When calling for technical service assistance, or for

other specifi c information, always have model

number, confi guration number and serial number

available. This information is contained on the

dataplate.

This manual will instruct you in the operation and care

of your unit. Have your installer review this manual

with you so that you fully understand the heater and

how it functions.

Contact your local L.B. White distributor or the

L.B. White Co., Inc. for assistance, or if you have

any questions about the use of the equipment or its

application.

The L.B. White Co., Inc. has a policy of continuous

product improvement. It reserves the right to change

specifi cations and design without notice.

General Information

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

6

Propane gas and natural gas have man-made odorants added specifi cally for detection of fuel gas leaks.

If a gas leak occurs, you should be able to smell

the fuel gas . THAT’S YOUR SIGNAL TO GO INTO

IMMEDIATE ACTION!

■ Do not take any action that could ignite the fuel

gas. Do not operate any electrical switches. Do not

pull any power supply or extension cords. Do not

light matches or any other source of fl ame. Do not

use your telephone.

■ Get everyone out of the building and away from the

area immediately.

■ Close all fuel supply valves.

■ Propane gas is heavier than air and may settle in

low areas. When you have reason to suspect a

propane leak, keep out of all low areas.

■ Use your neighbor’s phone and call your fuel gassupplier and your fi re department. Do not re-enter

the building or area.

■ Stay out of the building and away from the area

until declared safe by the fi refi ghters and your fuel

gas supplier.

■ FINALLY, let the fuel gas service person and the

fi refi ghters check for escaped gas. Have them

air out the building and area before you return.

Properly trained service people must repair the

leak, check for further leakages, and then relight

the heater for you.

■ Some people cannot smell well. Some people

cannot smell the odor of the man-made chemical added to propane or natural gas. You must

determine if you can smell the odorant in these

fuel gases.

■ Learn to recognize the odor of propane gas and

natural gas. Local propane gas dealers and your

local natural gas supplier (utility) will be more than

happy to give you a “scratch and sniff” pamphlet.

Use it to become familiar with the fuel gas odor.

■ Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your

sensitivity to that particular odor.

■ The odorant in propane gas and natural gas is colorless and the intensity of its odor can fade under

some circumstances.

■ If there is an underground leak, the movement of

gas through the soil can fi lter the odorant.

■ Propane gas odor may differ in intensity at different

levels. Since propane gas is heavier than air, there

may be more odor at lower levels.

■ Always be sensitive to the slightest gas odor. If you

continue to detect any gas odor, no matter how

small, treat it as a serious leak. Immediately go into

action as discussed previously.

Fuel Gas Odor

Safety Precautions

Odor Fading - No

Odor Detected

WARNING

Asphyxiation Hazard

■ Do not use this heater for heating human living quarters, garages, workshops, or other such

confi ned spaces.

■ Do not use in unventilated areas.

■ The fl ow of combustion and ventilation air must not be obstructed.

■ Proper ventilation air must be provided to support the combustion air requirements of the heater

being used.

■ Lack of proper ventilation air will lead to improper combustion.

■ Improper combustion can lead to carbon monoxide poisoning leading to serious injury or death.

Symptoms of carbon monoxide poisoning can include headaches, dizziness and diffi culty in

breathing.

■ Proper ventilation air for combustion must be provided in accordance with OSHA 29 CFR

1926.154, Temporary Heating Devices, ANSI A10.10, Safety Requirements for Temporary and

Portable Space Heating Devices, or the Natural Gas and Propane Installation Code, CAN/CSA

B149.1 as appropriate.

Premier Ductable Heaters

Owner’s Manual • Premier 350

7

2. All installations and applications of L.B. White

heaters must meet all relevant local, state and

national codes. Included are L.P. gas, natural gas,

electrical, and safety codes. Your local fuel gas

supplier, a local licensed electrician, the local fi re

department or similar government agencies, or

your insurance agent can help you determine code

requirements.

Refer to the following:

U.S. Installations:

-- ANSI/NFPA 58, latest edition, Standard for Storage

and Handling of Liquefi ed Petroleum Gas and/or

-- ANSI Z223.1/NFPA 54, National Fuel Gas Code

-- ANSI/NFPA 70, National Electrical Code.

Canadian Installations:

-- CSA B149.1 Natural Gas and Propane Gas Instal-

lation Code.

-- CSA C22.1 Part 1 Standard Canadian Electrical

Code, and CSA C22.2 No.3, Electrical Features of

Fuel Burning Equipment.

3. We cannot anticipate every use which maybe

made of our heaters. Other standards govern the

use of fuel gases and heat producing products

in specifi c applications. Your local authority can

advise you about these. Check with the local

fi re safety authority if you have questions about

applications.

4. Do not wash the interior of the heater. Use only

compressed air, a soft brush or dry cloth to clean

the interior of the heater and it’s components.

5. For safety, this heater is equipped with manual

reset high limit switches, an air-proving switch

and a redundant gas control valve. Never operate

the heater with any safety device that has been

bypassed. Do not operate this heater unless all of

these features are fully functioning.

6. Do not locate fuel gas containers or fuel supply

hoses within 20 ft./6.10 meters of the blower outlet

of the heater.

7. Do not block air intakes or discharge outlets of the

heater. Doing so may cause improper combustion or damage to heater components leading to

property damage.

■ Propane gas has a distinctive odor. Learn to

recognize these odors. (Reference Fuel Gas Odor

and Odor Fading sections above).

■ If you have not been properly trained in repair and

service

■ Even if you are not properly trained in the service

and repair of the heater, ALWAYS be consciously

aware of the odors of propane gas and natural gas.

A periodic sniff test around the heater or at the

heater’s joints; i.e. hose, connections, etc., is a good

safety practice under any conditions. If you smell

even a small amount of gas, CONTACT YOUR FUEL

GAS SUPPLIER IMMEDIATELY. DO NOT WAIT!

1. Do not attempt to install, repair, or service this

heater or the gas supply line unless you have

continuing expert training and knowledge of gas

heaters.

QUALIFICATIONS FOR SERVICING AND

INSTALLATION:

a. To be a qualifi ed gas heater service person, you

must have suffi cient training and experience to

handle all aspects of gas-fi red heater installation,

service and repair. This includes the task of installation, troubleshooting, replacement of defective

parts and testing of the heater. You must be able

to place the heater into a continuing safe and

normal operating condition. You must completely

familiarize yourself with each model heater by

reading and complying with the safety instructions,

labels, Owner’s Manual, etc., that is provided with

each heater.

b. To be a qualifi ed gas installation person, you must

have suffi cient training and experience to handle

all aspects of installing, repairing and altering gas

lines, including selecting and installing the proper

equipment, and selecting proper pipe and tank size

to be used. This must be done in accordance with

all local, state and national codes as well as the

manufacturer’s requirements.

c. In the Commonwealth of Massachusetts, this

product must be installed by a gas fi tter licensed in

the Commonwealth of Massachusetts.

Attention - Critical

Points to Remember!

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

8

8. The hose assembly shall be visually inspected on

a daily basis after heater relocation and when the

heater is in use. If it is evident there is excessive

abrasion or wear, or if the hose is cut, it must be

replaced prior to the heater being put into operation. The hose assembly shall be protected from

building materials, and contact with hot surfaces

during use. The replacement hose assembly

shall be that specifi ed by the manufacturer. See

parts list.

9. Premier 350DF heaters are equipped with a gas

selector valve. The selector valve must be properly positioned for the gas supplied to the heater.

Further information on this feature is provided on

page 17 of this manual.

10. Check for gas leaks and proper function upon

heater installation, when relocating, and after

servicing. Refer to leak check instructions within

installation section of this manual.

11. This heater shall be inspected for proper opera-

tion by a qualifi ed service person before each

use and at least annually.

12. Always turn off the gas supply to the heater if the

heater is not going to be used in the heating of

the work space.

13. This heater is equipped with a three-prong

(grounding) plug for your protection against

shock hazard and must be plugged directly into

a properly grounded three-prong receptacle.

Failure to use a properly grounded receptacle

can result in electrical shock, personal injury, or

death.

14. If gas fl ow is interrupted and fl ame goes out, do

not relight the heater until you are sure that all

gas that may have accummulated has cleared

away. In any event, do not relight the heater for

at least 5 minutes.

15. The heater requires a minimum 500 gallon/1892

litre propane tank for proper gas supply pressure

and operation. A larger tank may be required

depending upon operating conditions at the site.

16. When the heater is to be stored indoors, the

connection between the propane gas supply

cylinder(s) and the heater must be disconnected

and the cylinder(s) removed form the heater and

stored in accordance with the Standard for the

Storage and Handling of Liquifi ed Petroleum

Gases, ANSI/NFPA 58 or Standard CSA B149.1

Natural Gas and Propane Installation Code as

appropriate.

17. Propane gas supply containers have left handed

threads. Always use the appropriate wrench

to make a connection to tighten or loosen the

pigtail connector’s P.O.L. fi tting at the container’s

gas supply valve.

Premier Ductable Heaters

Owner’s Manual • Premier 350

9

building materials (tar, concrete, plaster, etc.)

which can affect safe operation and could result

in property damage or injury.

5. Heaters used in the vicinity of combustible

tarpaulins, canvas, plastics, wind barriers,

or similar coverings shall be located at least

10 ft./3.05 meters from the coverings. The

coverings shall be securely fastened to prevent

ignition or upsetting of the heater due to wind

action on the covering or other material.

6. Check all connections for gas leaks using approved gas leak detectors. Gas leak testing is

performed as follows:

-- Check all pipe connections, hose connections,

fi ttings and adapters upstream of the gas control

with approved gas leak detectors.

-- In the event a gas leak is detected, check the

components involved for cleanliness and proper

application of pipe compound before further

tightening.

-- Furthermore, tighten the gas connections as

necessary to stop the leak.

-- After all connections are checked and any leaks

are stopped, turn on the main burner.

-- Stand clear while the main burner ignites to

prevent injury caused from hidden leaks that

could cause fl ashback.

-- With the main burner in operation, check all

connections, hose connections, fi ttings and joints

as well as the gas control valve inlet and outlet

connections with approved gas leak detectors.

General Installation Instructions

WARNING

Burn Hazard

Can cause property damage, severe injury or death.

1. To avoid dangerous accumulation of fuel gas, turn

off gas supply at the appliance service valve before

starting installation, and perform gas leak test after

completion of installation.

2. Do not force the gas control knob. Use only your

hand to turn the gas control knob. Never use any

tools. If the knob will not operate by hand, the

control should be replaced by a qualifi ed service

technician. Force or attempted repair may result in

fi re or explosion.

1. Read all safety precautions and follow L. B. White

recommendations when installing this heater. If

during the installation or relocating of heater, you

suspect that a part is damaged or defective, call a

qualifi ed service agency for repair or replacement.

2. Make sure the heater is level (use a level) and

properly positioned before use. Observe and obey

all minimum safe distances of the heater to the

nearest combustible materials. Safe distances are

given on the heater dataplate and on page 4 of this

manual.

3. This heater may be installed either indoors or outdoors. For outdoor installations, only the following

air distribution devices may be used:

-- 18 in./43.7 cm Dia. x 12 ft./3.66 m Duct: Part

#22835

-- End Diffuser: Part #23189

DO NOT USE ANY OTHER LENGTH OF DUCTWORK OR FIELD FABRICATED DUCT, TARPS,

STOVE PIPE, ETC. ON THIS HEATER.

■ When using the ducting, ensure that bends in duct

are kept to a minimum. A maximum of two 90º

bends is allowed.

■ Reducing the number of bends will ensure that the

warm air exiting the heater fl ows freely, thereby

preventing overheating. If there are excessive

bends, the high limit switches may open.

4. The heater’s gas pressure regulator (with pressure

relief valve) must be protected from adverse

weather conditions (rain, ice, snow) as well as from

WARNING

Fire and Explosion Hazard

■ Do not use open fl ame (matches, torches,

candles, etc.) in checking for gas leaks.

■ Use only approved leak detectors.

■ Failure to follow this warning can lead to fi res

or explosions.

■ Fires or explosions can lead to property damage, personal injury or loss of life.

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

10

-- If a leak is detected, check the components

involved for cleanliness in the thread areas and

proper application of pipe compound before

further tightening.

-- Tighten the gas connection as necessary to stop

the leak.

-- If necessary, replace the parts or components

involved if the leak cannot be stopped.

-- Ensure all gas leaks have been identifi ed and

repaired before proceeding.

7. A qualifi ed service agency must check for proper

operating gas pressure upon installation of the

heater.

8. Light according to instructions on heater or within

owner’s manual.

9. Make sure the heater has the proper gas

regulator for the application. A regulator must be

connected to the gas supply so that gas pressure

at the inlet to the gas valve is regulated within the

range specifi ed on the dataplate at all times.

Premier 350DF heaters: The regulator supplied with the heater is suitable for use with propane

gas or natural gas.

Premier 350 Propane Gas heaters: The

regulator supplied with these heaters is designed for

use specifi cally for the fuel being used.

Contact your gas supplier, or the L.B. White Co., Inc.

if you have any questions.

10. This heater is confi gured for use for L.P. gas va-

por withdrawal. Do not use the heater in an L.P.

gas liquid withdrawal system or application. If

you are in doubt, contact the L.B. White Co., Inc.

11. The heater must be installed so as not to inter-

fere with or obstruct normal exits, emergency

exits, doors and walkways.

12. Railing, fencing or suitable substitute materials

must be used to keep the heating equipment

from any people using and visiting the structure.

13. The heater shall be located so that rain, ice, or

snow drainage from the structure does not affect

equipment operation. If the heater is mounted

outside, it must be mounted above any pooled or

standing water. If the unit is to be located on

the ground, a surrounding trench is recommended to drain any rain, ice or snow away

from the unit.

14. The ground and surrounding terrain must be

cleared of any combustible vegetation and

other combustible materials when the heater

is utilized outside.

15. Eventually, like all electrical/mechanical

devices, the thermostat can fail. Thermostat failure may result in an underheating

condition. The thermostat should be tested

to make sure it turns the heater on and off

within a temperature differential of ±3°F

(±1.5 °C).

16. Take time to understand how to operate and

maintain the heater by using this Owner’s

Manual. Make sure you know how to shut

off the gas supply to the building and also to

the individual heater. Contact your fuel gas

supplier if you have any questions.

17. Any defects found in performing any of the

service or maintenance procedures must

be eliminated and defective parts replaced

immediately. The heater must be retested by

properly qualifi ed service personnel before

placing the heater back into use.

Premier Ductable Heaters

Owner’s Manual • Premier 350

11

The vaporization of propane is affected by several

factors: the surface area of the container, the liquid

level of propane, temperature surrounding the

container, and the relative humidity. All of these

factors are specifi c to a site. Therefore, a degree of

experience and judgement is required to select the

proper propane supply.

Although experience is the best guide, the following recommendations can be used as a starting

point. The table is based on experience in northern

climates where cold weather and high humidity are

prevalent in the winter. If more or less favorable

conditions prevail at a specifi c site, adjustments can

be made on the basis of experience.

If more than one gas supply container is used per

heater, the containers must be manifolded together

to allow vapor withdrawal simultaneously from

multiple containers. Manifold system shall be in accordance with NFPA 58 or CSA B149.1.

Gas Supply Sizing

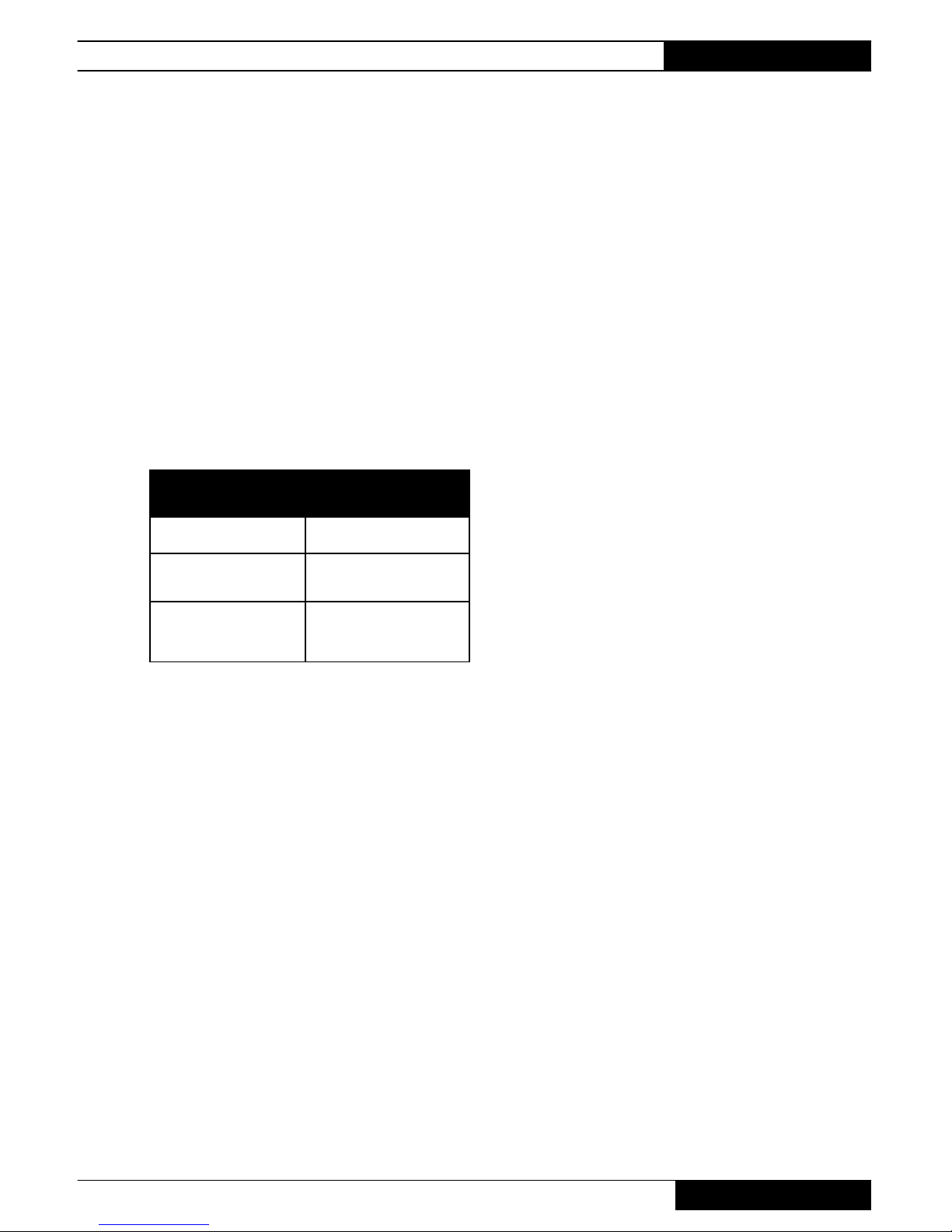

Recommended Gas Supply

TANK SIZE HEATERS / TANK

500 gall. / 1892 litre 1

1000 gall. / 3784 litre 2

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

12

1. Thread swivel onto connector at gas inlet of heater.

See Fig. 1. Tighten securely.

2. The hose may be coiled up and hung on the hose

hanger, with the regulator stored within the regulator

storage bracket.

FIG. 1

Connecting Regulator to

Gas Supply

WHEN USING PROPANE GAS:

1. Lift the tank’s cover.

2. Assemble the gas componets as shown, depending

on heater type. Tighten connections securely. See

Fig. 2 for Premier 350DF heaters, and Fig. 3 for

Standard Premier 350 LP heaters.

FIG. 2

Connecting Hose to

Heater

SWIVEL

PREMIER 350 DUAL FUEL CONNECTIONS

3/4 X 1/4 Bushing Tank Valve

POL

Pigtail Connector

1/4 in.

NPT

FIG. 3

3. Form the connector to ensure the regulator will be

supported by the tank, and the tank valve cover will

protect the regulator from weather conditions.

4. Thread connector’s POL fi tting counter-clockwise

into the tank valve. Tighten securely. See Fig. 2 or

Fig. 3.

5. Open the tank valve.

6. Check all connections with an approved leak detector. Close the tank’s cover.

7. When storing or transporting the heater, ensure the

connector’s fi tting is protected from damage and

dirt entry.

WHEN USING NATURAL GAS:

--- The regulator only should be used if the gas supply

pressure to the heater is above the maximum inlet

pressure stated on the heater’s dataplate.

--- Connect the regulator as supplied with the heater

to the natural gas supply line, using the appropriate connections. (DO NOT USE THE POL/PIGTAIL

FOR NATURAL GAS INSTALLATIONS)

--- Gas supply pressure to the regulator

must be a minimum of 2 PSI/13.7 kPa.

--- The regulator supplied with Premier

350 DF heater is also for use with

natural gas.

STANDARD PREMIER 350 LP CONNECTIONS

1/4 In. NPT

Pigtail Connector

POL Fitting

Tank Valve

Premier Ductable Heaters

Owner’s Manual • Premier 350

13

Thermostat

The remote thermostat that ships with this heater is

factory wired into the control circuit.

Premier 350 DF heaters:

The thermostat is a single stage design. When

there is a call for heat from the thermostat, the

thermostat cycles the heater to full heat output.

Premier 350 Propane Gas heaters:

The thermostat is a two stage device and is

designed to cover a broad range of heating

requirements.

The two stage thermostat allows the heater to fi ll

an application where a single high heat rate is

undesirable. The two stage thermostat will allow the

heater to operate and cycle at a low heat condition

when the heating load is less severe, or it will cycle

to highest heat as demand is increased.

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

14

CLAMP

DUCT ADAPTER

TABS

DIFFUSER

Installation of Heater

Inside of Structure

FIG. 4

Outside of Structure

(Air distribution accessories not supplied with heater)

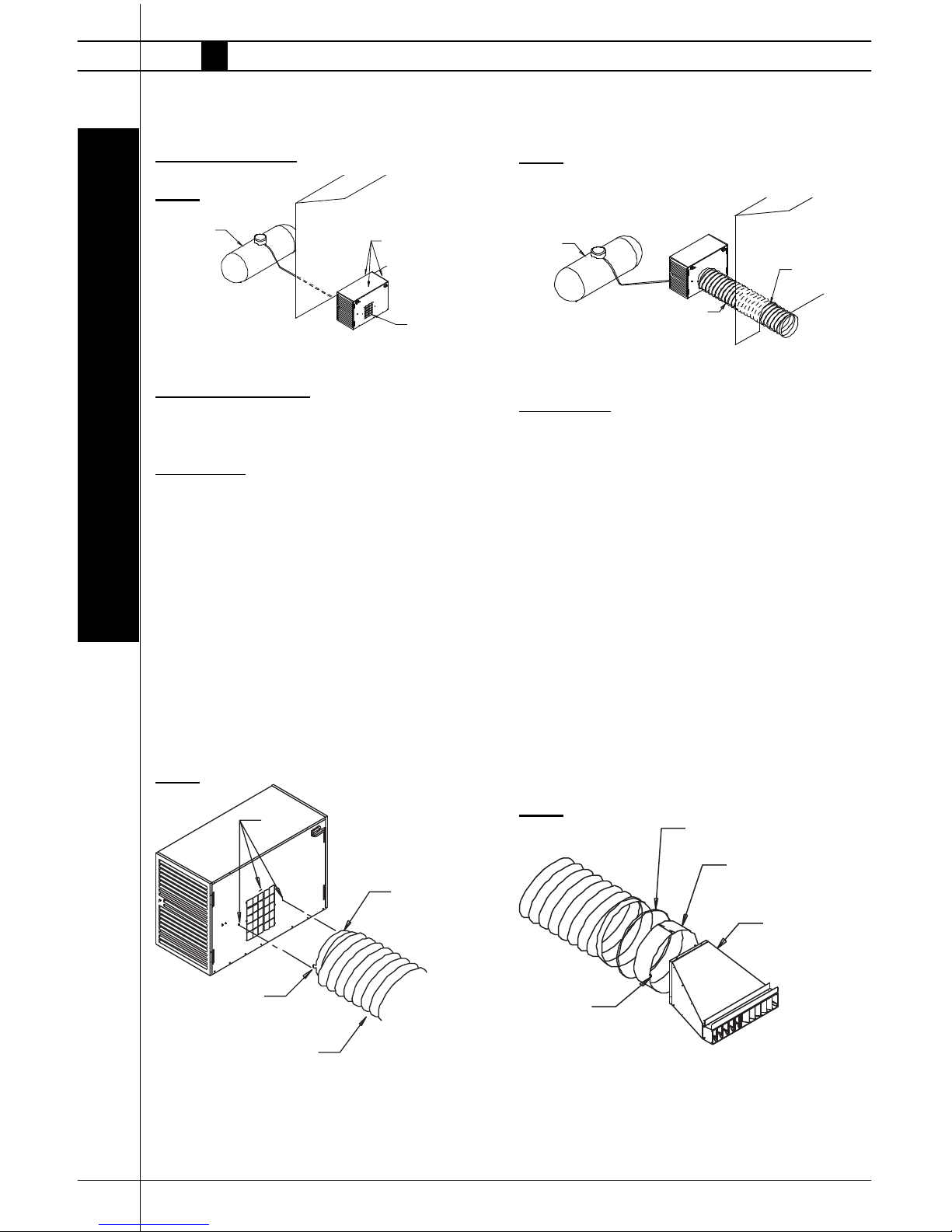

A. Flex Duct Kit

Part Number: 22835 (18 in. x 12 ft. / 46 cm x 3.65 m)

1. Extend duct kit to 12 feet/3.6 meter length.

2. Mount duct to blower outlet of heater by inserting tabs

on duct adapter into vertical and horizontal slots located

at top and sides of blower outlet. See Fig. 5. Push down

on duct adapter to secure adapter into slots. See below

for typical installation of heater located at exterior.

When using 12 ft. / 3.65m fl ex ducts, the maximum

number of fl ex ducts to use per heater is 3. See Fig. 6

for typical installation.

FIG. 5

SLOTS

DUCT ADAPTER

WITH TABS

TA B

DUCT KIT

SIDE WALL

500 GALLON (1892 litre)

GAS SUPPLY

(MINIMUM)

MINIMUM SAFE DISTANCE FROM

GAS SUPOPLY TO HEATER MUST

CONFORM TO LOCAL CODES

DISTANCE FROM HEATER TO SIDE WALL MUST

COMPLY WITH LOCAL CODES, AND BE ACCORDING

TO MANUFACTURER'S REQUIREMENTS

MINIMUM SAFE DISTANCE FROM

BLOWER OUTLET TO COMBUSTIBLES

IS 6 FEET (1.83m)

MINIMUM SAFE DISTANCE FROM

TOP, SIDES, AND BACK OF HEATER

TO COMBUSTIBLES IS 1 FOOT (0.3m)

INSTALLATION INSTRUCTIONS

FIG. 6

MINIMUM SAFE DISTANCE FROM GAS

SUPPLY TO HEATER MUST CONFORM

TO LOCAL CODES

DISTANCE FROM HEATER TO SIDE WALL MUST

COMPLY WITH LOCAL CODES, AND BE ACCORDING

TO MANUFACTURER'S REQUIREMENTS

TENT DRAPED OVER DUCT

DUCT KIT

500 GALLON

(1892 LITRE)

GAS SUPPLY

(MINIMUM)

SIDE WALL

TENT DRAPED

OVER DUCT

B. End Diffuser

Part Number: 23189

1. Loosen screw on duct clamp so clamp is easily

positioned over ribs at end of fl exible duct.

2. Slide duct adapter into duct end. Duct adapter tabs

must be facing away from duct and are located at 3,

9 and 12 o’clock positions. See Fig. 7.

3. Tighten screw clamp so adapter is held securelywithin duct.

4. Insert tabs of adapter into slots on air diffuser back.

5. Push down on adapter so tabs are seated fi rmly to

air diffuser.

6. Locate diffuser under side wall. See Fig. 8.

FIG. 7

Premier Ductable Heaters

Owner’s Manual • Premier 350

15

TENT DRAPED OVER DIFFUSER

TENT SIDE WALL

TENT DRAPED

WITHIN DIFFUSER

CHANNEL

OPTIONAL AIR DIFFUSER

FIG. 8

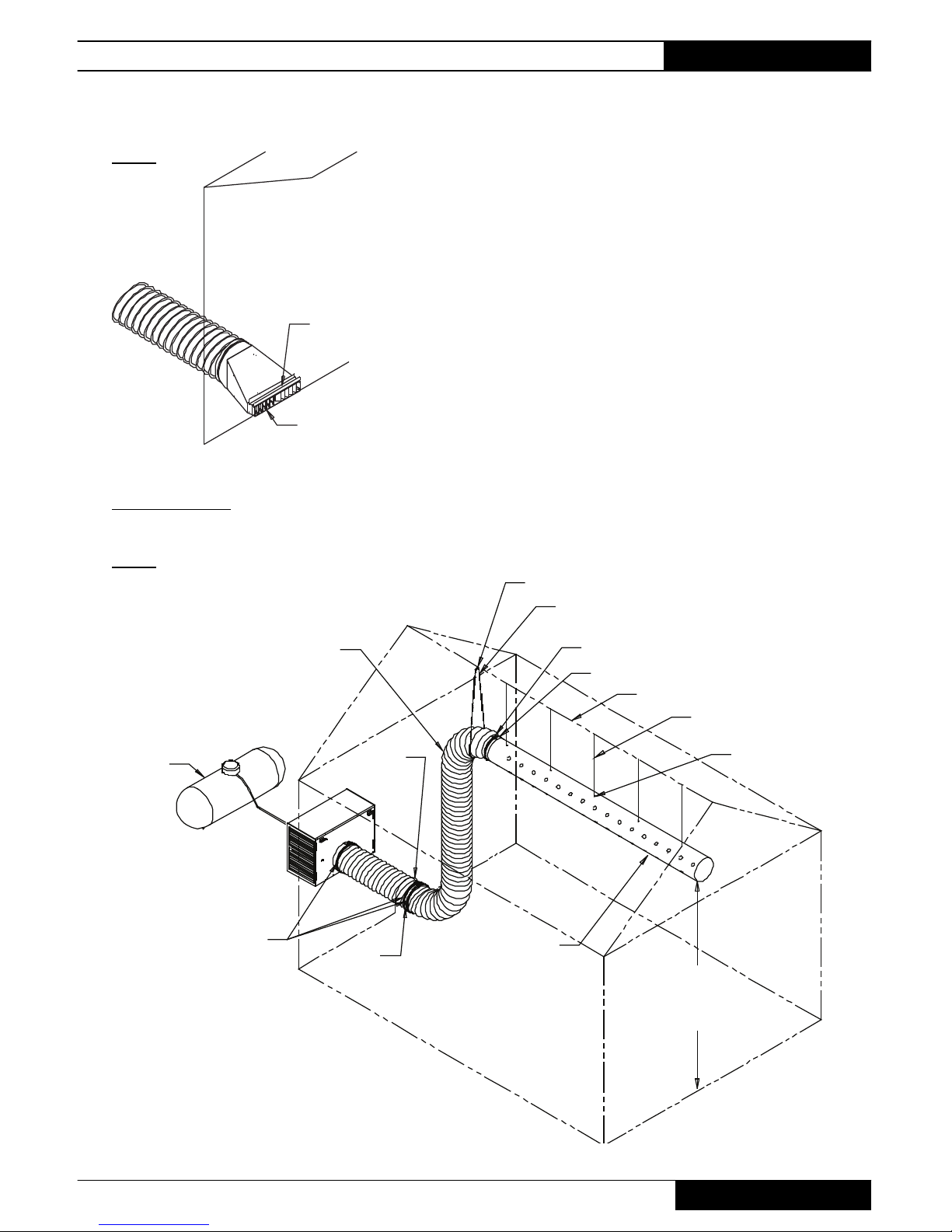

C. Infl atable Ducting

Use only 2 fl ex ducts when also using infl atable duct.

FIG. 9

500 GALLON

(1892 LITRE)

GAS SUPPLY

(MINIMUM)

TO ALLOW PROPER AIR DISTRIBUTION

FLEXT DUCT MUST NOT HAVE MORE THAN

TWO 90 DEGREE BENDS

CLEARANCE OF HEATER TO

TENT WALL MUST CONFORM

TO LOCAL CODES

CLAMP

MATERIAL

DRAPED

OVER DUCT

DUCT RING

INFLATABLE DUCT,

100 FT. (130.5m)

DISCHARGE HOLES

POINTED DOWNWARD

(OPTIONAL ACCY 23053)

8 FEET (12.44m)

CLEARANCE

TO GROUND

TYPICAL

CHAIN LOOPED AROUND DUCT

DUCT RING

ROOF SUPPORT

WIRE OR CABLE

(SUPPLIED BY CUSTOMER)

HANGING CLAMP

S-HOOK

CLAMP

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

16

Start-Up Instructions

For initial start-up after heater installation, follow

steps 1-5. For normal start-up, set the thermostat

above room temperature.

1. Connect electrical cord to an approved electrical

outlet.

2. Set thermostat to desired room temperature.

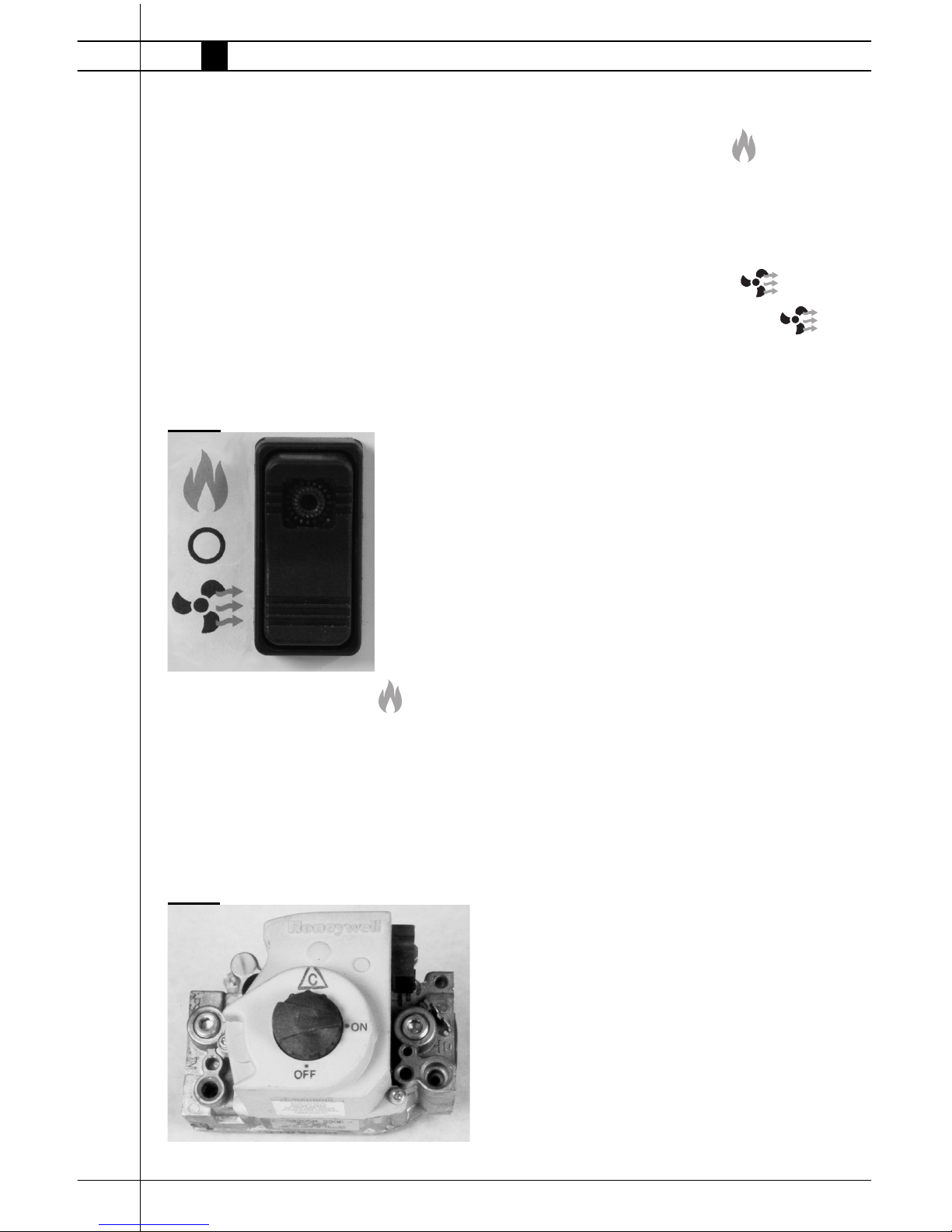

3. A selector switch is located on the back of the

heater. This switch allows you to either heat or

ventilate (no heat). See Fig. 10 for selector switch

positions.

FIG. 10

A. Heating Mode Operation

a. Open all manual fuel supply valves. Check for

gas leaks using an approved leak detector.

Regardless of model purchased , the gas control

valve in the heater has a manual shut-off feature

incorporated into the valve assembly. Ensure the

indicator is turned to the on position. See Fig 11,

Premier 35DF valve shown.

FIG. 11

b. Position the selector switch to heat.

See Fig. 10. A red light within the switch will come

on. The fan motor will start, the igniter will spark

and ignition will occur. The thermostat will cycle

the heater on or off based upon temperature

setting.

B. Ventilation Mode Operation

When the selector switch is positioned to vent,

the red light will NOT be on. The fan motor will start,

but the igniter will not spark, nor will ignition occur.

This feature is used only when air circulation is

required. The heater will not cycle on its thermostat

setting. To discontinue the ventilation feature, position the switch to off or heat.

C. Off O

Position the switch to midpoint. O

ATTENTION

■ It is normal for air to be trapped in gas hose on

new installations. The heater may attempt more

than one trial for ignition before air is fi nally

purged from line and ignition takes place.

4. The direct spark ignition (DSI) control board

within this heater is self-diagnostic. The board

works in conjunction with a light emitting diode

(L.E.D.) built into the selector switch. The L.E.D.

will fl ash a specifi c continuous fl ash pattern de-

pending on a problem that occurs. Match specifi c

fl ash pattern given by L.E.D. to troubleshooting

label applied to inside of burner cap access panel

of the heater. The troubleshooting label identifi es the causes of the problem as it relates to

specifi c fl ash pattern and remedies to correct the

problem. See also “Troubleshooting Data” within

this Owner’s Manual.

5. Gas Control Valve

Premier 350 DF Heaters:

The gas control is a single stage design. When the

valve opens, it delivers full heat output.

Premier 350 Propane

Gas Heaters:

The gas control valve is a step opening design.

When a call for heat occurs, the valve will open to

a rate equal to half its total heat output. Depend-

Premier Ductable Heaters

Owner’s Manual • Premier 350

17

ing upon temperature requirements and thermostat

setting, the valve will then either remain at low heat rate

before the thermostat is satisfi ed, or the valve will open

completely to its total capacity.

5. Do not exceed input rating stamped on nameplate or

manufacturer’s recommended burner orifi ce pressure

for size orifi ce(s) used. Make certain that the primary

air supply to main burner is open and free of dust, dirt

and debris for complete, proper combustion.

Shut-Down Instructions

If the heater is to be shut down for cleaning, maintenance, or repair, follow steps 1-5. Otherwise, set the

thermostat to below room temperature for standard

shut-down. Do not shut the heater off by

the selector switch. Doing so will remove

power to the heater, preventing cooling of

heat chamber. The burner end high limit

switch will trip.

1. Close the gas supply valve.

2. Allow the heater to burn off any fuel gas remaining in

the gas supply line.

3. Set the thermostat below room temperature. When

the thermostat cycles the burner off, the

fan motor will continue to run for 1 minute, allowing the heat chamber to cool.

After 1 minute, the fan motor will shut off.

4. Position selector switch to off O

5. Disconnect the heater from its gas and electrical

supplies.

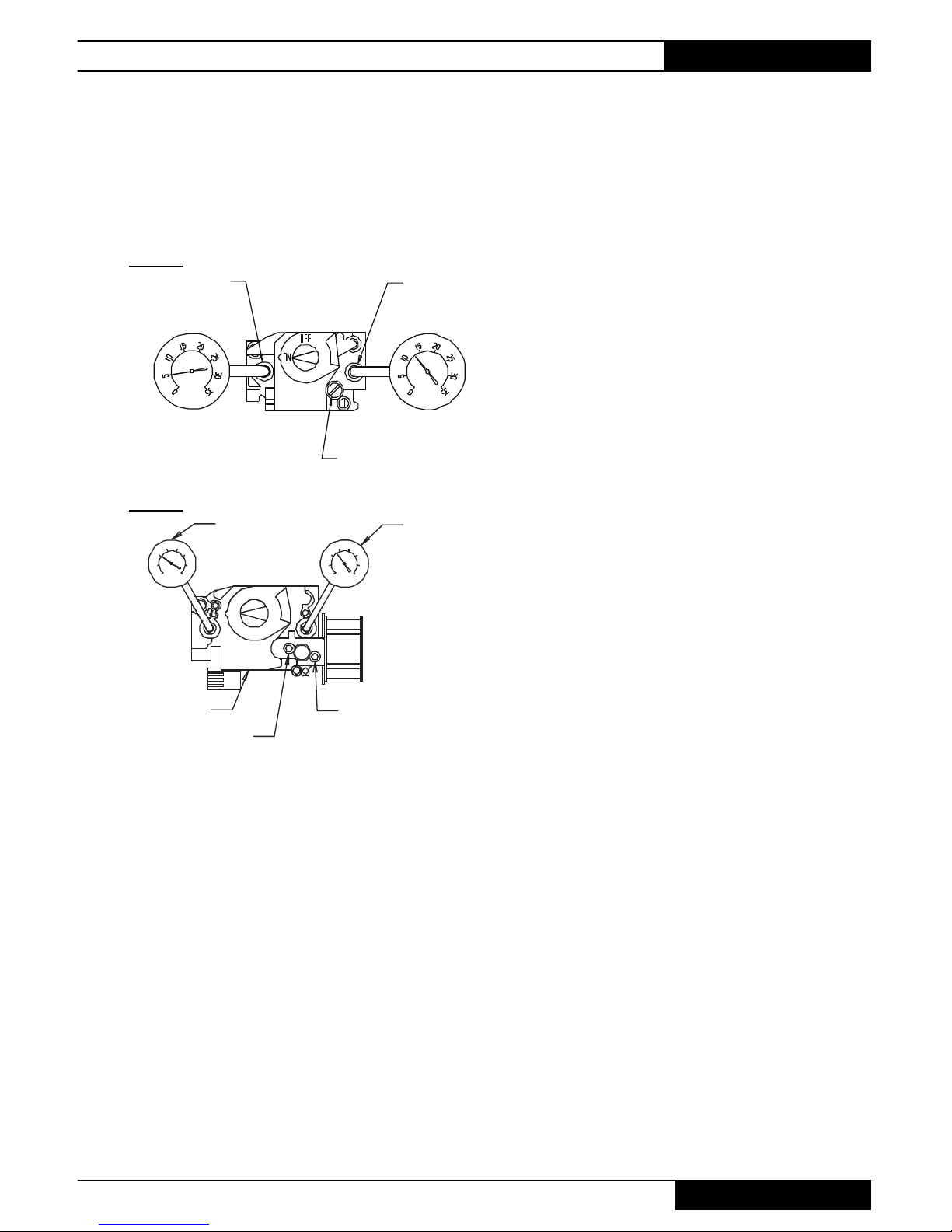

Gas Selector Valve

Premier 350 DF Only

1. This feature allows the heater to operate on either pro-

pane or natural gas without changing out the burner

orifi ce. The gas selector valve is located between

the gas control valve and the burner. Gas selection

is made by repositioning the valve’s handle. THIS IS

NOT A MANUAL GAS SHUT OFF VALVE.

2. Refer to Figs. 12 and 13. The valve handle must be

properly positioned for the specifi c gas being used,

otherwise the unit will overheat or underheat.

FIG. 12

FIG. 13

3. The handle must be fully set at 90 degrees to gas

fl ow (propane gas) or parallel to gas fl ow (natural

gas) for proper operation. Do not operate the

heater with the valve handle set between either

postion, otherwise improper operation will occur.

4. The valve’s handle can be locked to prevent

improper positioning. Use the holes provided on

the valve’s body and handle. See Fig. 14.

FIG. 14

Handle position

propane gas

Handle position

natural gas

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

18

Cleaning Instructions

WARNING

Fire, Burn, and Explosion Hazard

■ This heater contains electrical and mechanical

components in the gas management, safety

and airfl ow systems.

■ Such components may become inoperative or

fail due to dust, dirt, wear, aging, or the corrosive atmosphere of an animal confi nement

building.

■ Periodic cleaning and inspection as well as

proper maintenance are essential to avoid

serious injury or property damage.

1. Before cleaning, shut off all gas supply valves

and disconnect the electrical supply.

2. The heater should have dirt or dust removed

periodically:

a. Before each use give the heater a general

cleaning using compressed air or a soft

brush or dry rag on its case and internal

components. At this time, dust off the motor

case to prevent the motor from over-heating.

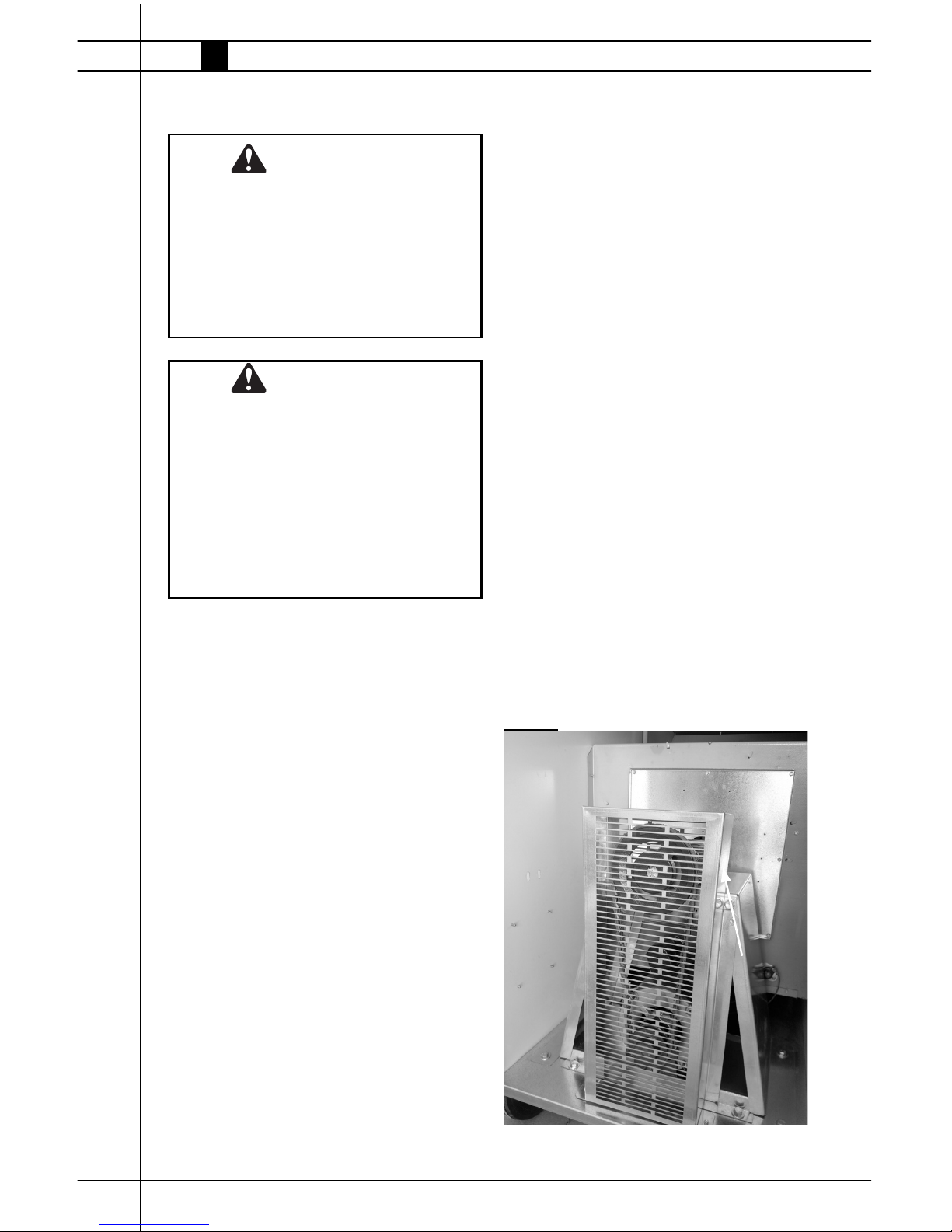

b. At least once a year, give the heater a thor-

ough cleaning. At this time, remove the fan

and motor assembly and brush or blow off

the fan blade assembly. Additionally, make

sure the burner air inlet venturi ports and

the casting are free of dust accumulation.

WARNING

Do not use a pressure washer, water, or liquid

cleaning solution on any gas controls. Use of a

pressure washer, water, or liquid cleaning solution on the control components can cause severe

personal injury or property damage due to water

and/or liquids:

■ In electrical components, and wires causing

electrical shock or equipment failure.

■ On gas control valves causing corrosion which

can result in gas leaks and fi re or explosion

from the leak.

Clean all components of the heater with

pressurized air, a dry brush, or a dry cloth.

Premier Ductable Heaters

Owner’s Manual • Premier 350

19

Maintenance Instructions

BEFORE EACH USE:

■ Check the area surrounding the heater to

ensure it is clear and free of combustible materials, gasoline, and other fl ammable vapors

and liquids.

■ Have your gas supplier check all gas connections for leaks or restrictions in gas lines.

■ Inspect the regulator vent to make sure the

regulator vent is not blocked. Debris, insects,

insect nests, snow, or ice on a regulator can

block vents and cause excess pressure at the

heater.

■ Check all wiring associated terminals and electrical components within the heater for corrosion, frayed or cut insulation, tight connections,

etc. Repair or replace as necessary.

■ Check the hose assembly after heater

installation, relocation and when the heater

is in use. If it is evident there is excessive

abrasion or wear, or if the hose is cut, it must

be replaced prior to the heater being put back

into operation

■ Check the heater’s fan drive belt. Make sure

the belt is not cracked. If so, replace it. Additionally, ensure the belt is not slipping, that belt

tension is proper, and sheaves are properly

aligned and not worn.

■ Review all heater markings (i.e. wiring diagram, warnings, start-up, shut-down, troubleshooting, etc.) at the time of maintenance

for legibility. Make sure none are cut, torn, or

otherwise damaged. Any damaged markings

must be replaced immediately by contacting

the L.B. White Co., Inc. Data plate, startup

and shut-down instructions and warnings are

available at no cost.

MONTHLY

■ Lubricate the bearings once a month. Use

NLGI grade 2 mineral oil lithium or lithium base

grease.

ANNUALLY:

■ Clean and check the igniter for cracks. Replace

if necessary.

■ Regulators can wear out and function improperly.

Have your gas supplier check the date codes

on all regulators installed and check delivery

pressures to the heater to make sure that the

regulator is reliable.

■ Test both manual reset high limit heat switches

to ensure proper operation. (See Testing instructions for same in this owner’s manual.)

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

20

Service Instructions

1. Close the fuel supply valve to the heater and

disconnect the electrical supply before servicing

unless necessary for your service procedure.

2. Clean the heater’s orifi ce with compressed air or

a soft, dry rag. Do not use fi les, drills, broaches,

etc. to clean the orifi ce hole. Doing so will enlarge

the hole, causing combustion or ignition problems.

Replace the orifi ce if it cannot be cleaned properly.

3. The high limit switches, heat/vent switch and thermostat can be tested by disconnecting the leads at

the component and jumpering the leads together.

-- Reconnect the electrical supply and open fuel

supply valves.

-- If the heater lights, the component is defective and

must be replaced.

-- Do not leave the jumper on or operate the heater if

the part is defective. Replace the part immediately.

-- An alternate method for checking the components

is to perform a continuity check..

4. The air proving switch must not be jumpered. If

jumpered, the ignition control will not allow heater

operation. Test the air proving switch for continuity.

If defective, replace the switch

WARNING

Burn Hazard

■ Heater surfaces are hot for a period of time after

the heater has been shut down.

■ Allow the heater to cool before performing

service, maintenance, or cleaning.

■ Failure to follow this warning will result in burns

causing injury.

WARNING

Fire and Explosion Hazard

■ Do not disassemble or attempt to repair any

heater components or gas train components

such as gas valves, or gas hoses.

■ All component parts must be replaced if defects

are found.

■ Failure to follow this warning will result in fi re or

explosions, causing property damage, injury, or

death.

5. Open the respective case panel for access to

burner or fan related components.

6. For reassembly, reverse the respective service

procedure. Ensure gas connections are tightened

securely.

7. After servicing, start the heater to ensure proper

operation and check for gas leaks.

8. If pulley or fan keys are lost during service, replacements are made by using 3/16 in. (4.7 mm.)

square x 1 in. (2.54 cm) bar stock. Otherwise,

order Part #22955.

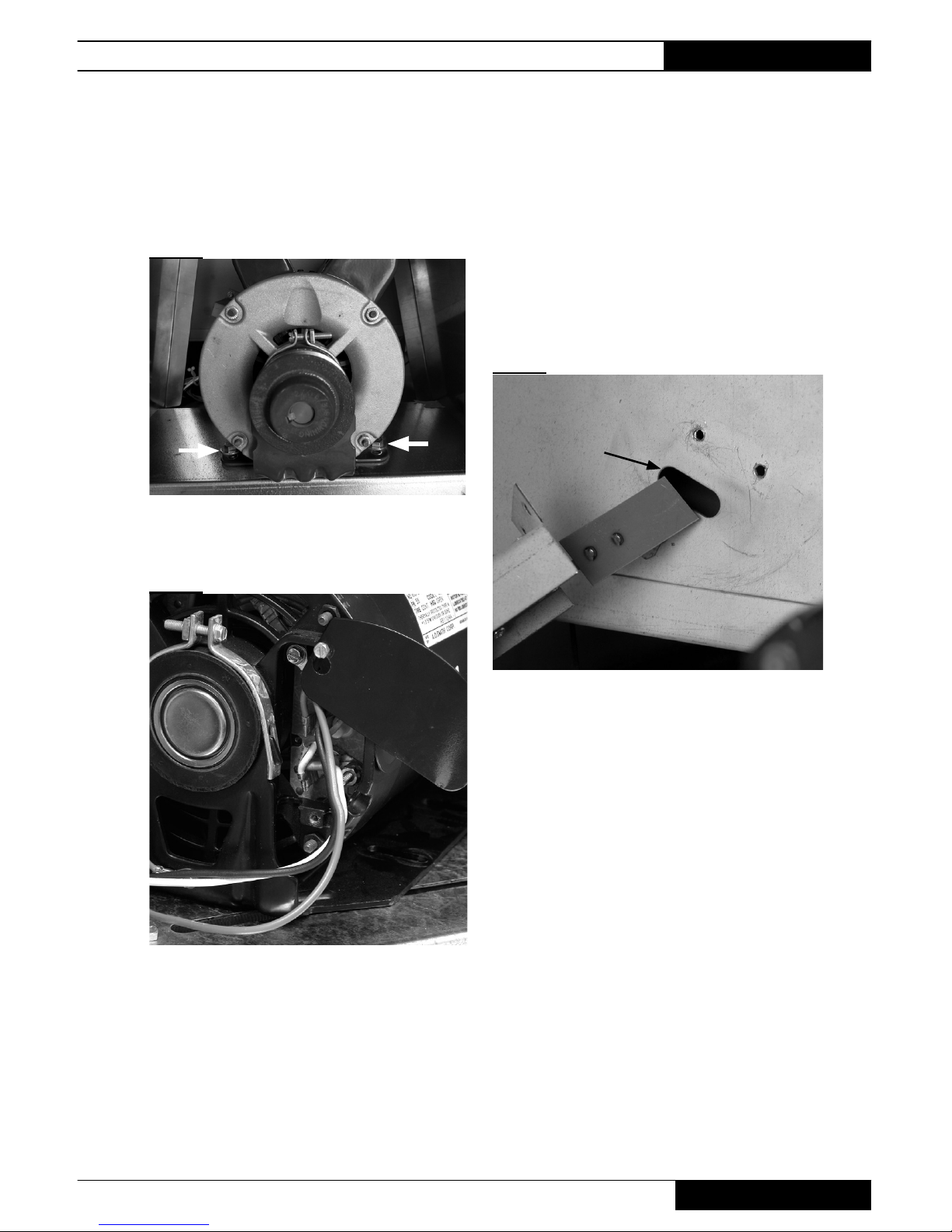

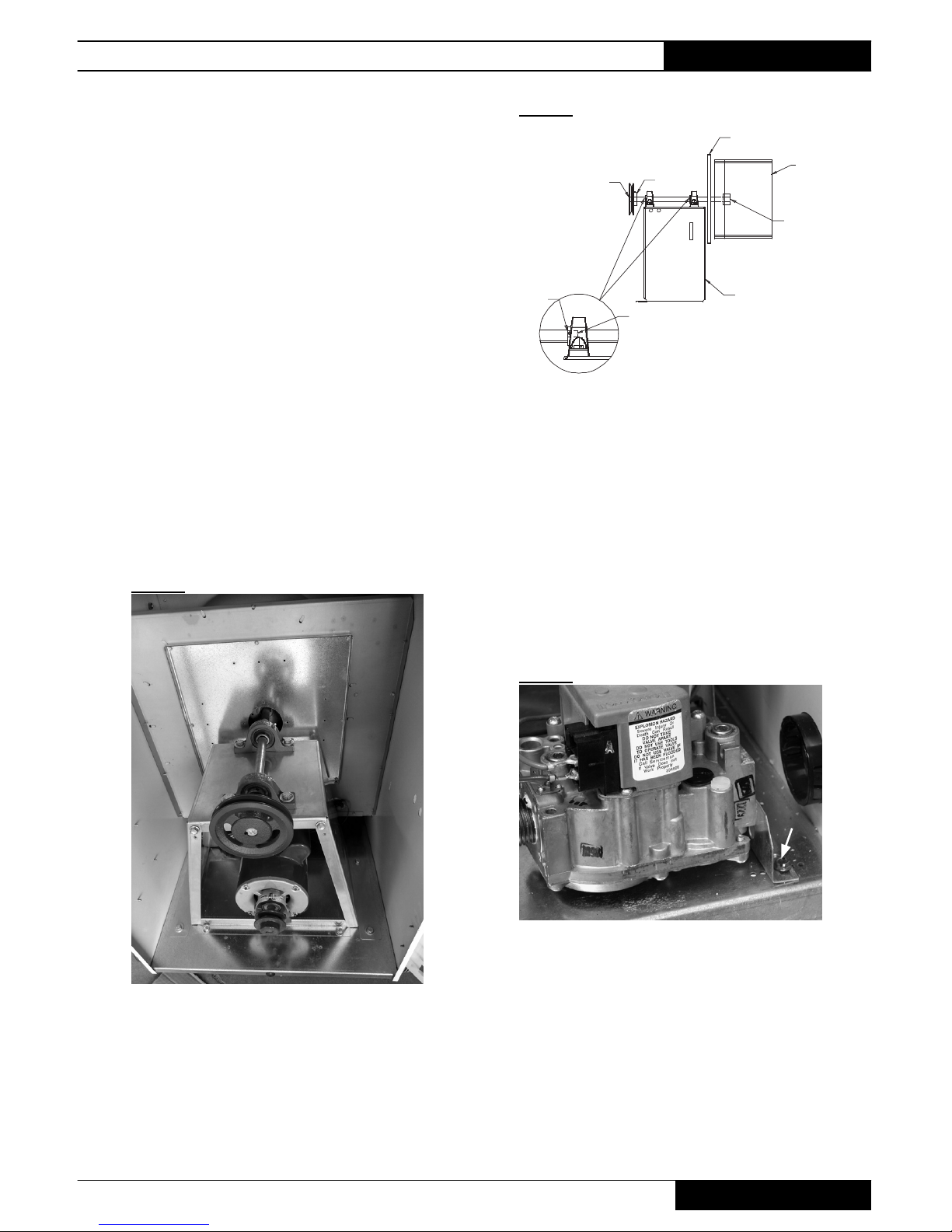

Belt Replacement

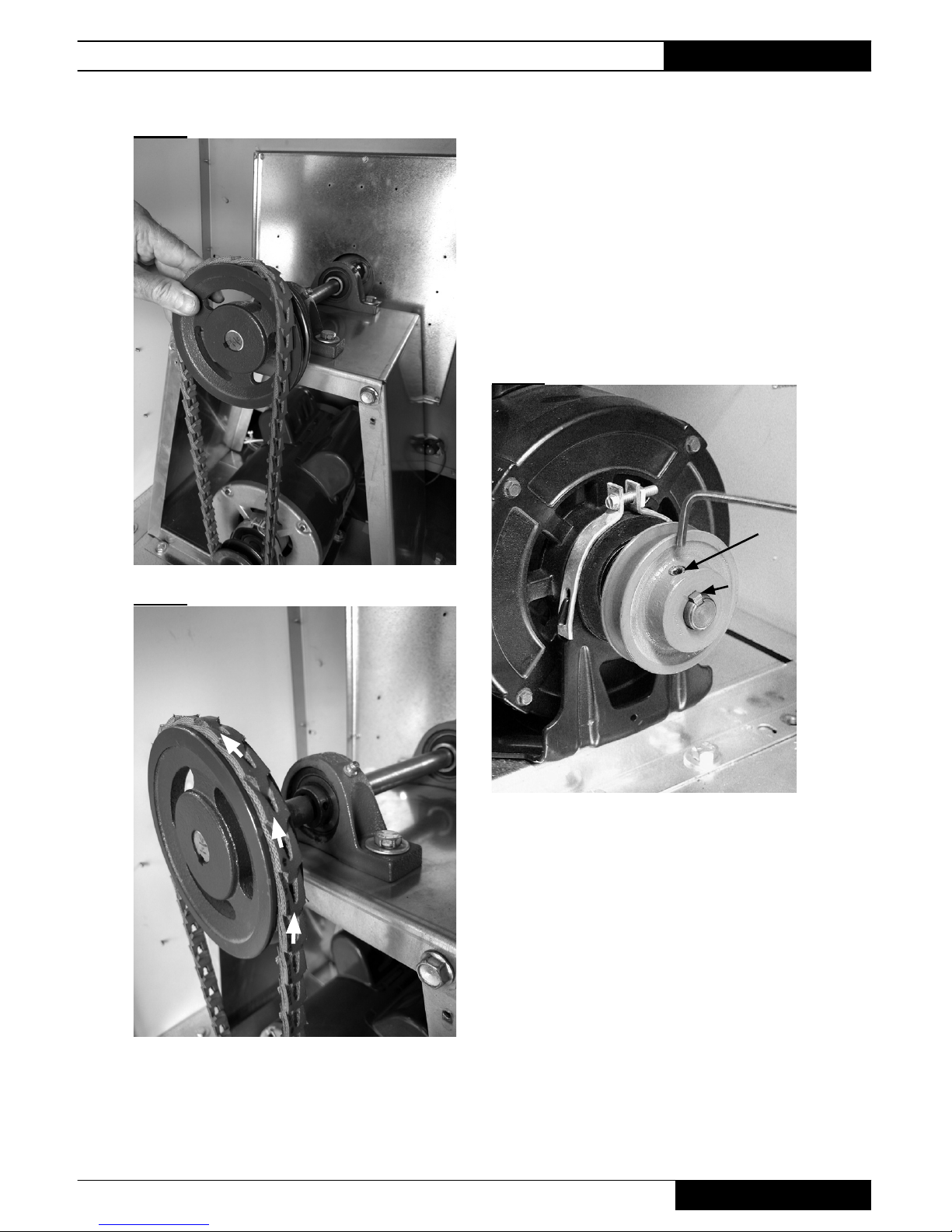

1. Remove the belt guard from the heater.

See Fig. 15.

2. Rotate the fan pulley CW while carefully lifting the

belt so it clears the fan pulley groove. See Fig.16.

3. Check the fan and motor pulleys for dirt. Clean

the pulleys if needed.

4. When reinstalling the belt, ensure the arrows are

directed CCW. See Fig. 17.

FIG. 15

Premier Ductable Heaters

Owner’s Manual • Premier 350

21

Fan and Motor Pulley

1. Remove belt guard from heater.

2. Remove belt from pulleys. See Belt Replacement.

3. Loosen set screw on fan and motor pulleys with a

9/64 in. allen wrench. See Fig. 18.

4. Remove pulleys and keys from fan shaft and motor.

FIG. 18

Set screw

Shaft key

FIG. 16

FIG. 17

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

22

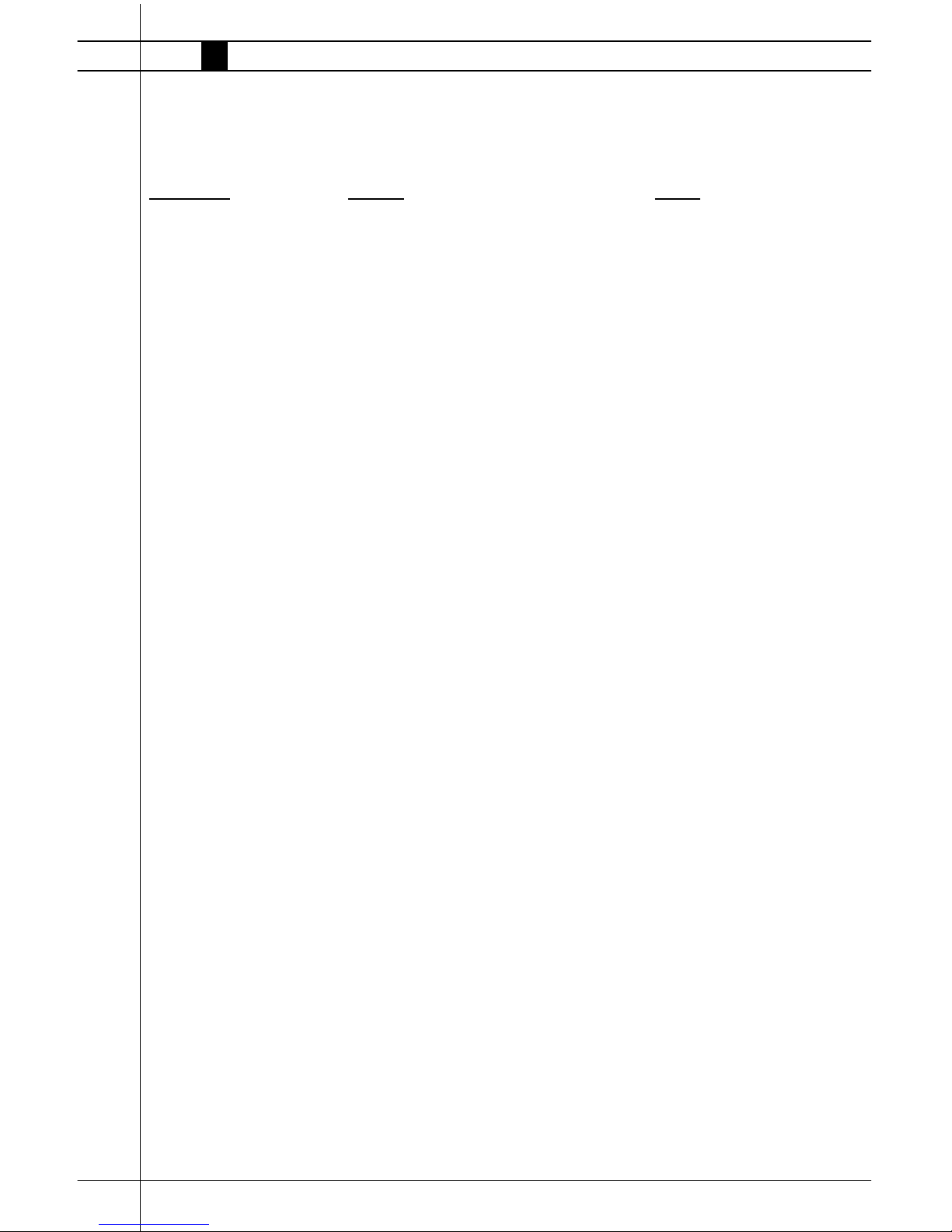

Fan Drive Components Troubleshooting

Refer to the following table to identify basic problems, causes and cures associated with V-Belt drive systems.

PROBLEM CAUSE CURE

Belt Slips Pulleys worn (Belts bottoming out in grooves) Replace pulleys

Oil or grease on belt Clean pulleys or belt.

Belt Breaks Improper belt installation Belt pried over pulleys

using sharp or pointed

tools. Install new belt

properly.

Belt Jumps Pulley Drive misaligned Check and realign

Grooves

Dirt entering pulley Remove belt, clean the

pulleys

Belt hitting belt guard Realign guard (check

for loose or missing

guard screws)

Belt Cracking Dirt or grease on belt or aged belt Remove dirt or

replace belt.

Belt Wearing Rapidly Belt hitting belt guard Realign guard (check

for loose or missing

guard screws)

Worn pulleys Replace pulley

Dirt in pulleys Remove dirt

Premier Ductable Heaters

Owner’s Manual • Premier 350

23

Fan Motor

1. Remove the belt guard.

2. Remove the fan belt.

3. Remove the four bolts and washers from the motor

mount fl anges. See Fig.19.

FIG. 19

4. Open the electrical access panel on the motor and

disconnect the motor wiring. See Fig. 20.

FIG. 20

5. Remove the motor pulley from the motor shaft.

• When reinstalling the motor, ensure the motor

pully is fl ush to the shaft end of the motor.

Air Proving Switch

1. The air proving switch is located on the the side panel

of the fan housing, adjacent to the fan motor, inside the

louvered door end of the heater.

2. Remove the screws that secure the switch bracket to

the fan housing panel and turn switch assembly so the

paddle on the switch arm can be pulled through oblong

hole on side of fan housing. See Fig. 21.

3. Disconnect the leads from the air proving switch.

FIG. 21

If the air proving switch contacts are closed on a call for

heat before the fan motor starts, or do not close after the

fan motor starts, the igniter will not spark nor will the gas

valve open.

Oblong Hole

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

24

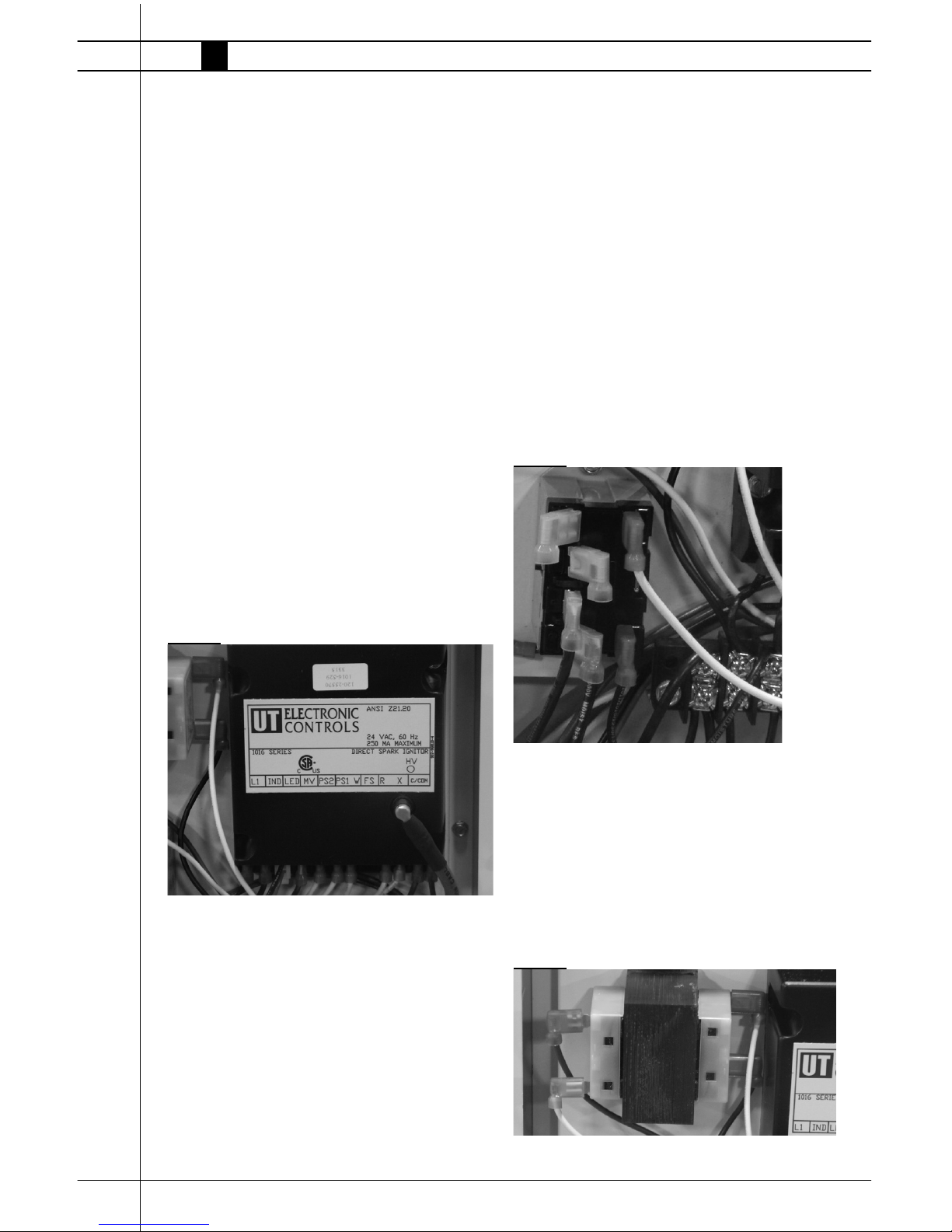

Ignition Control

The control sends and receives voltages to operate or

verify operation of components. Refer to the following

and Fig. 22 to understand the ignition control’s terminal

designators if doing voltage checks on the control.

L1: Main power supply voltage to control.

IND: Main power supply voltage from control to motor.

LED: Wire connection to red light of selector switch.

MV: 24 VAC from ignition control through both high

limit switches to gas control valve.

PS2: 24 VAC return from air proving switch back to

ignition control.

PS1: 24 VAC from ignition control to air proving switch.

W: 24 VAC return from thermostat to ignition control

FS: No terminal.

R: 24 VAC from ignition controller to thermostat.

X: 24 VAC from transformer to ignition controller

(without 24 VAC the contoller will not function.

C/COM: Earth ground for transformer and ignition

control.

Also refer to “Operation Sequence” within this manual

as needed to understand operation of the ignition

control during a call for heat.

FIG. 22

Relay

The relay is responsible for supply of power to the motor. Numbers adjacent to its male terminals for

reference of voltage received and supplied for troubleshooting. Refer to Fig. 23 and the following table for

connection of wiring and voltage checks.

Terminal Function

2 Not used.

4 Not used.

6 115 VAC from relay to start fan motor

8 115 volts to relay from power supply

0 Neutral for relay

1 115 VAC from ignition controller

(IND) to relay for coil closure

If the relay is receiving 115 volts at terminal 8 from

the the power supply, along with 115 volts from

the ignition control at terminal 1, but voltage is not

supplied to the motor from terminal 6, the relay is

defective.

FIG. 23

Transformer

The transformer reduces main power supply voltage

FIG. 24 to 24 VAC for operation of the the ignition

control.

Without 24 VAC from the transformer, the ignition

control will not function, nor will the heater operate.

FIG. 24

0

2

4

6

8

1

Premier Ductable Heaters

Owner’s Manual • Premier 350

25

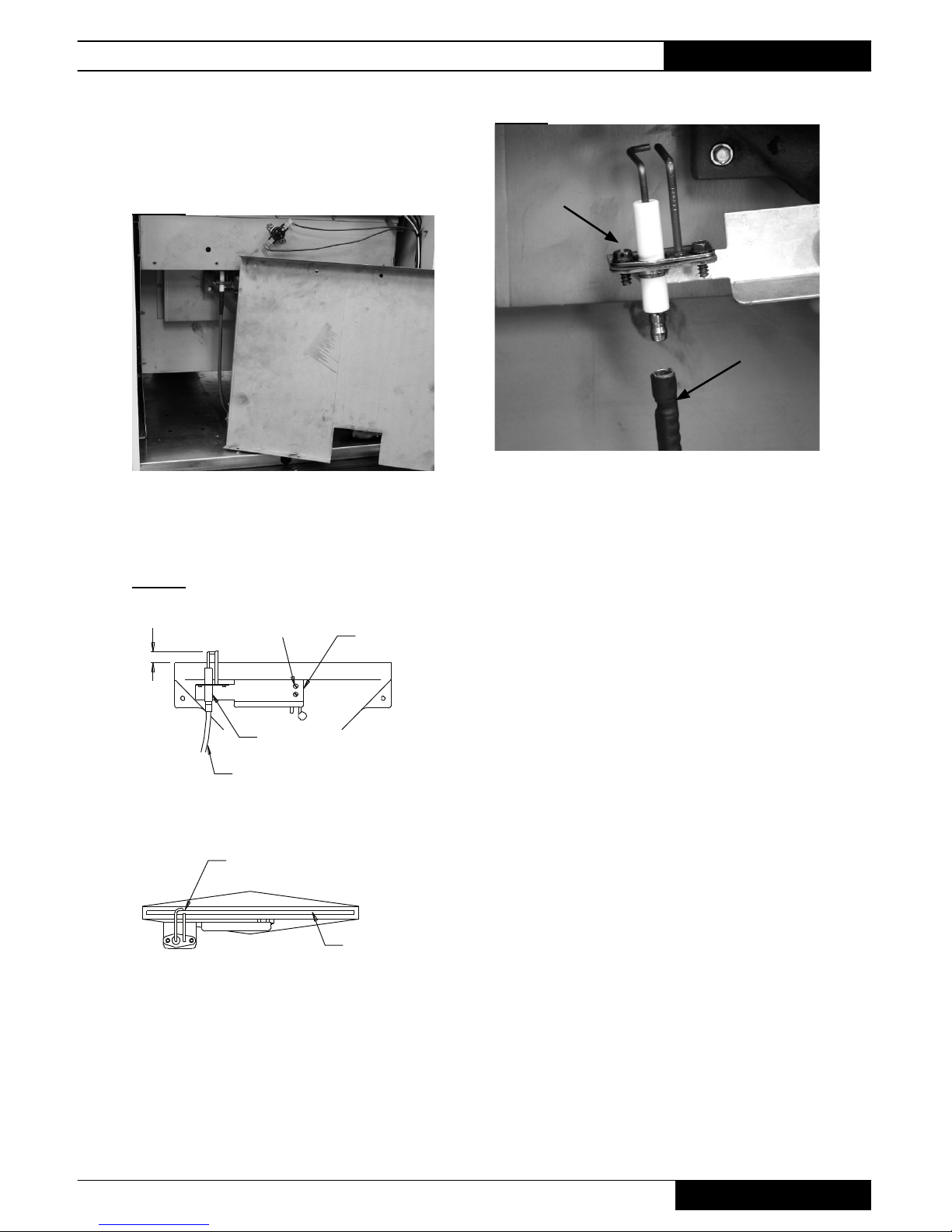

Igniter Assembly

1. Remove burner access panel. See Fig. 25.

FIG. 25

2. The igniter assembly is located at the top of the burner

casting. Remove the two screws securing the mounting

bracket to the burner. See Fig. 26.

FIG. 26

3. Disconnect high voltage ignition lead. Remove the

screws. See Fig. 27.

3/16 IN (4mm) IGNITOR BOTTOM

TO BURNER TOP

SCREWS

MOUNTING

BRACKET

IGNITOR/SENSOR

IGNITOR CABLE

ELECTRODE GAP IS 1/8 IN

AND CENTERED OVER BURNER PORT

BURNER

PORT

FIG. 27

The igniter and ground rod should be cleaned during

routine maintenance to maintain proper ignition.

-- Use steel wool or emery cloth.

-- Rub briskly to remove buildup of dust, dirt,

and oxide.

■ Check the igniter’s ceramic base for cracks.

-- Replace the igniter if cracks are found.

Screws

FRONT VIEW

TOP VIEW

Ignition Lead

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

26

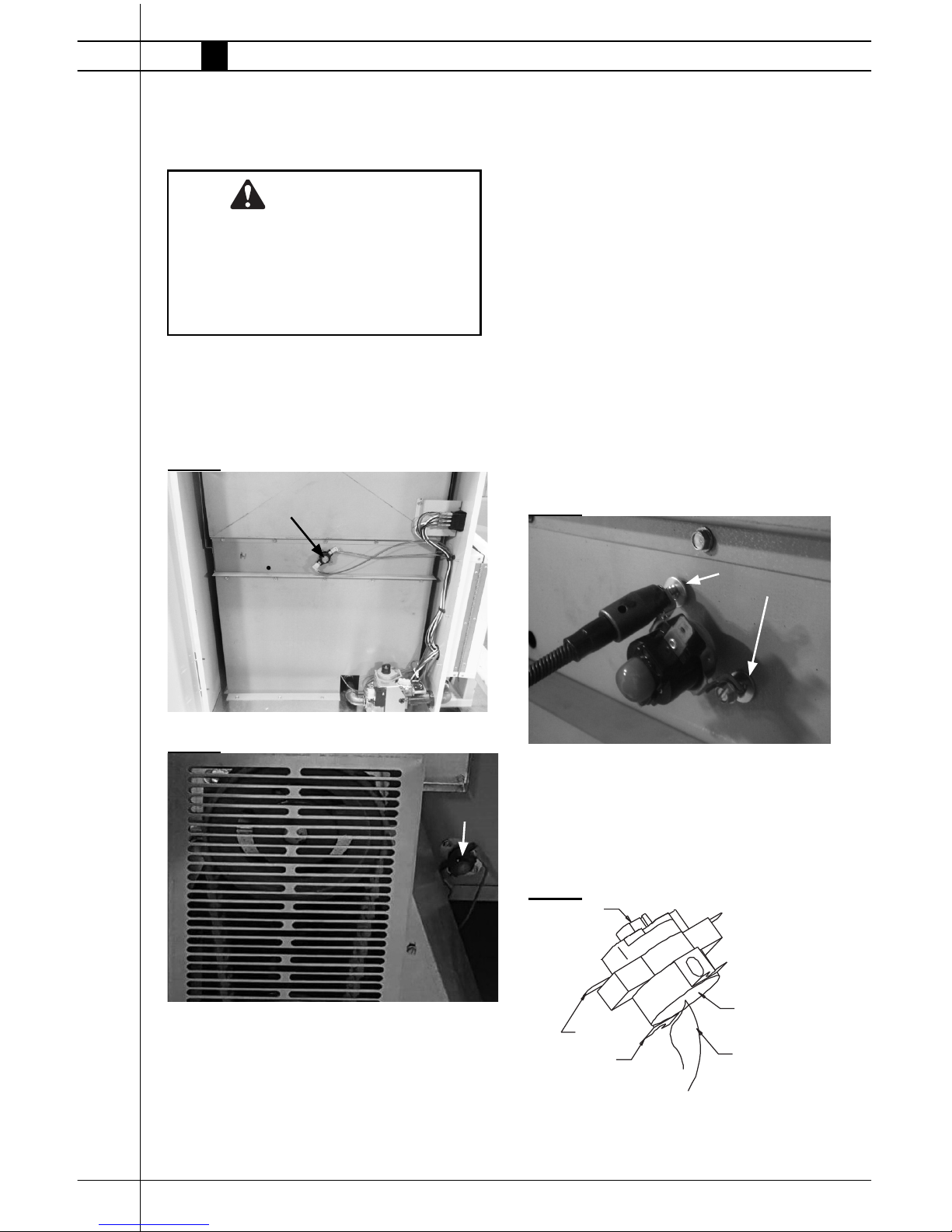

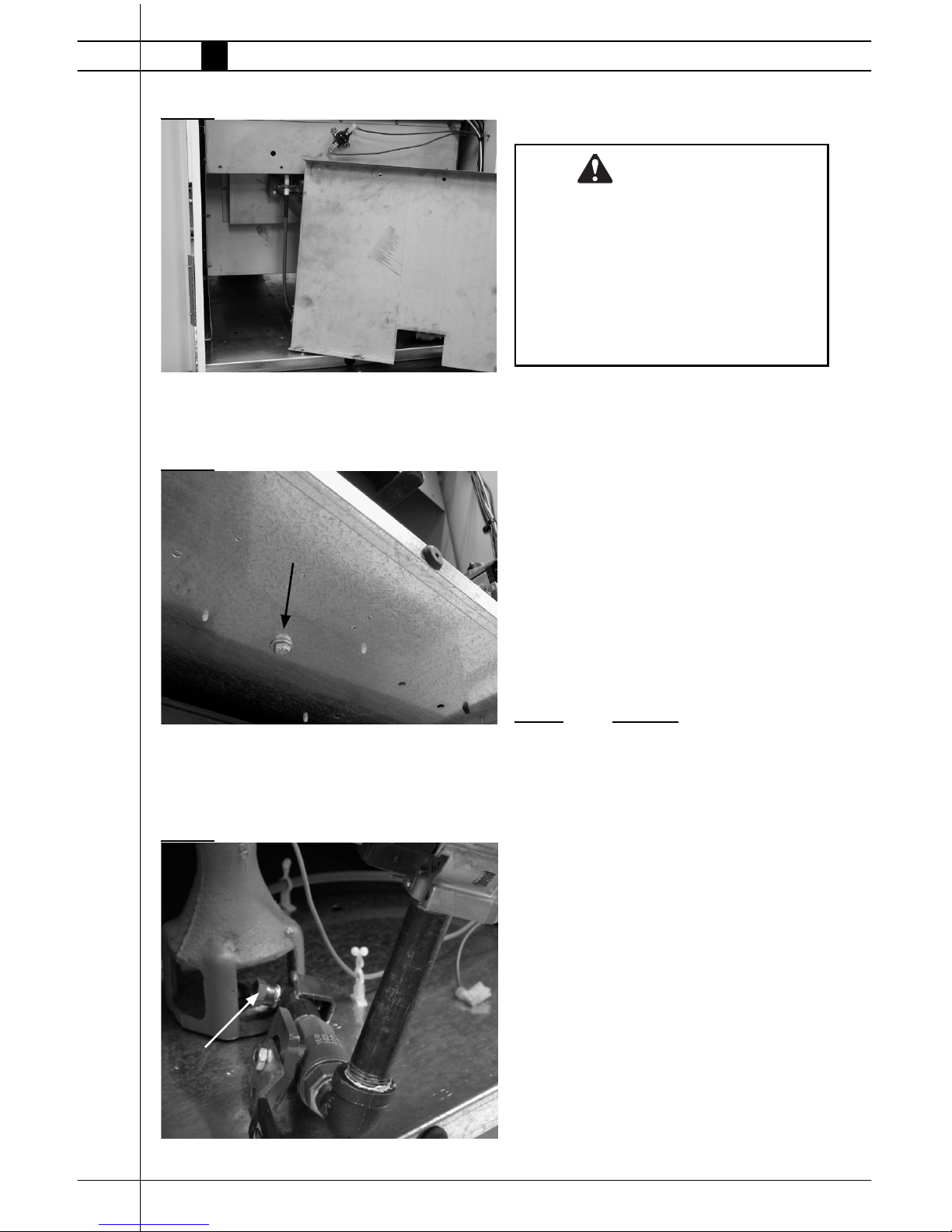

Manual Reset High Limit

Switches

This heater has two high limit switches. One is located at

the burner end of the heater on the heat chamber. See

Fig. 28. The other is located on the fan housing behind

the fan motor. See Fig. 29.

FIG. 28

FIG. 29

Their purpose is to safely shut the heater down if the

heater should overheat.

Burner end limit: Protects the burner and associated wiring from overheating caused by excessive gas

pressure.

WARNING

Burn Hazard

■ Do not operate the heater with the high limit

switch bypassed.

■ Operating the heater bypassed high limit switch

may lead to overheating, possibly resulting in a

fi re, with subsequent damage to the heater or

property damage.

Burner End Limit

Motor end limit: Protects from overheating if

the duct is kinked or restricted, or if the air inlet is

blocked.

The switches are wired in series and will disconnect power to the gas control valve if either senses

an overheat condition.

Both high limit switches should be tested a minimum of once per year when the heater is given a

thorough cleaning.

1. Remove the high limit switches from the heater.

Also remove the red cap from both switches.

The burner end limit switch has a washer located

between each leg of the limit switch and the

heat chamber. The washers act as spacers and

prevent the switch from tripping prematurely.

Both must be reinstalled after conducting this

test. See Fig. 30.

FIG. 30

2. Holding a switch by one of its mounting legs,

apply a small fl ame only to the sensing portion

on the back of the switch.See Fig. 31. Be careful

not to melt the plastic housing of the switch

when conducting this test.

FIG. 31

RESET BUTTON

SENSING

SURFACE

TERMINAL

FLAME

MOUNTING

LEG

3. Within a minute, you should hear the contacts of

the switch have opening.

Washers

(#8 - 3/16 ID x

7/16 OD x .041

Thickness)

Premier Ductable Heaters

Owner’s Manual • Premier 350

27

4. Allow the switch to cool for about a minute before fi rmly

pressing its reset button. Put the red cap back on the

switch.

5. Check for electrical continuity across the switch termi-

nals to make sure the contacts have closed.

Fan Wheel, Bearings

and Shaft

1. Remove the following:

a. Belt guard and belt.

b. Bolts and washers securing the bearing platform at

the heater’s base.

c. Screws securing the fan panel to the fan housing.

2. Slide the complete assembly from the heater.

3. Replace the components as needed

4. When reinstalling, ensure fan shaft is fl ush with fan hub

and fan pulley. See Fig. 33.

FIG. 32

FIG. 33

Burner Orifice and Gas

Control Valve

1. Remove hose and pipe nipple from control

valve inlet.

2. Open burner end door.

3. Remove screws from gas control bracket and

disconnect control valve’s electrical wiring. See

Fig. 34.

FIG. 34

4. Remove burner access panel. See Fig. 35.

PULLEY HUB

SHAFT PULLEY FLUSH

WITH SHAFT END

BEARING RACE FLUSH

WITH FRONT EDGE

OF SHAFT FLAT.

SET SCREWS TIGHTENED

TO FLATS.

SHAFT FLAT

MAIN SUPPORT

FAN HUB

FLUSH WITH

SHAFT END

FAN WHEE

L

FAN PANEL FLANGES

TOWARD PULLEY

Screws

Fan Panel

Bearing

Platform

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

28

FIG. 35

5. Remove burner retaining bolt from under base at gas

control end of heater. See Fig. 36.

FIG. 36

6. Lift and pivot the gas train assembly so orifi ce is

exposed. See Fig. 37, Dual Fuel shown. Replace control

valve or orifi ce if needed.

FIG. 37

Bolt

Orifi ce

WARNING

Burn Hazard

■ Do not disassemble the gas control valve.

■ Do not attempt to replace any components of the

gas control valve.

■ The gas control valve must be replaced if any

physical damage occurs to the control valve

assembly.

■ Failure to follow this warning will result in fi re

or explosions, leading to injury or death to

humans, and property damage.

ATTENTION

■ The following explains a typical procedure to be

followed in checking gas pressures.

■ The gas pressures will vary depending upon fuel

type.

■ Consult the dataplate on the heater or page 4 in

this manual for specifi c pressures to be used in

conjunction with this procedure.

■ Gas pressure measured at the inlet to the gas valve

is Inlet Pressure and gas pressure measured at the

outlet of the gas valve is Burner Manifold Pressure.

MATERIALS REQUIRED

Quantity Description

2 Gas pressure gauges capable of

reading up to 35 in.W.C./8.7 kPa.

(Available from L.B.White Company

if desired)

A. Preparation

1. Disconnect the heater from the electrical supply

and close the fuel supply valve to the heater.

2. Open the case access panel at burner end of

heater.

3. Brush or blow off any dust or dirt in the vicinity of

the gas control valve.

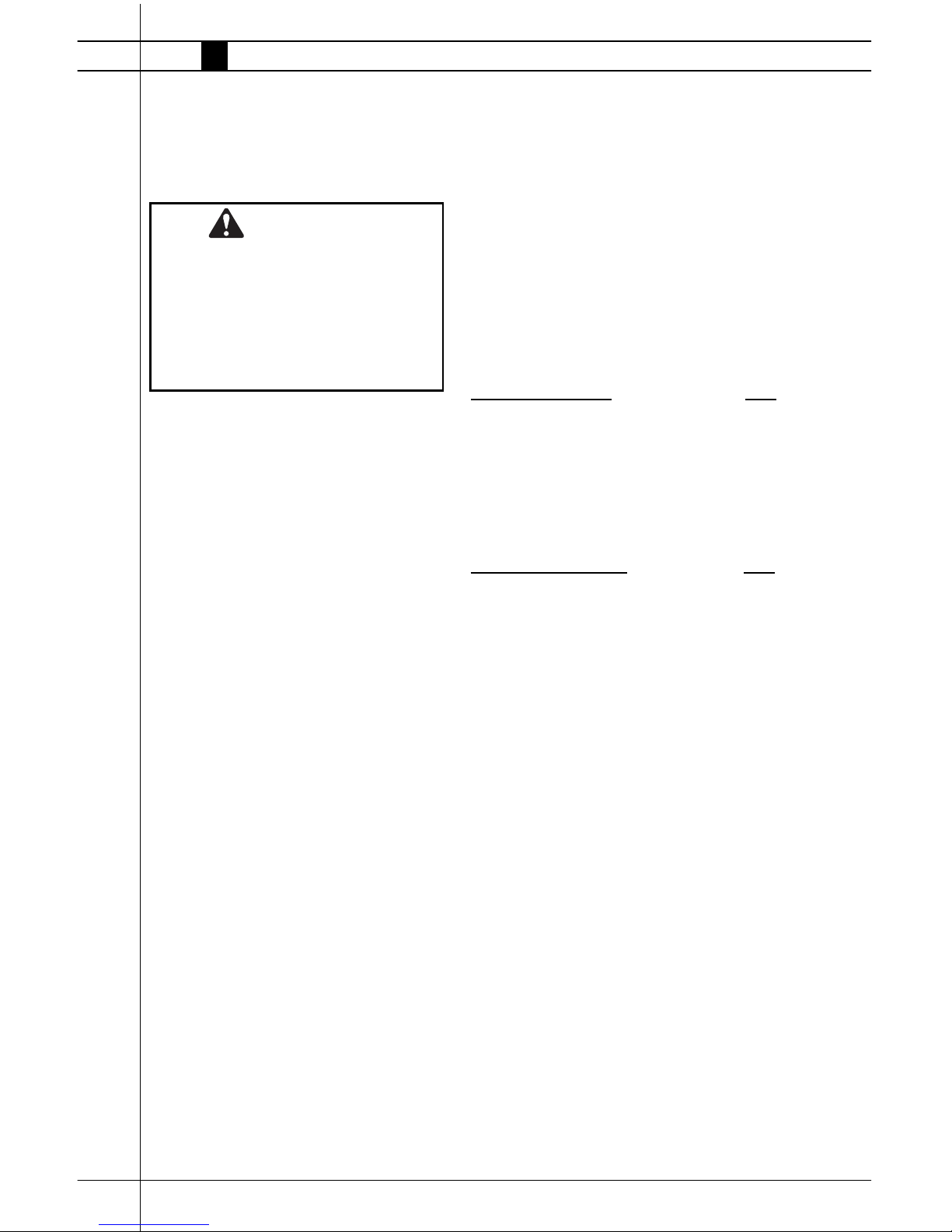

B. Gauge Installation

1. Locate the gas control pressure taps. See Fig.

38 for single stage valve, or Fig. 39 for two stage

valve. Remove the pressure tap plugs using a 3/16

in. allen key.

Gas Pressure Checks

Premier Ductable Heaters

Owner’s Manual • Premier 350

29

2. Securely connect pressure gauges at these points.

3. Open the fuel supply valves to the heater and reconnect the heater electrical supply.

4. Start the heater

FIG. 38

OUTLET PRESSURE TAP

INLET PRESSURE TYPE

INTERNAL PRESSURE REGULATOR

GAUGE AT VALVE INLET

GAUGE AT VALVE OUTLET

FIG. 39

OUTLET

GAUGE

INLET

GAUGE

GAS CONTROL

LOW HEAT

HIGH HEAT

OFF

ON

LO

HI

0

5

10

15

20

25

30

35

0

5

10

15

20

25

30

35

C. Reading Pressures

1. With the heater operating, the pressure gauges should

read the pressures specifi ed on the dataplate.

2. Do the readings at the inlet and outlet pressure gauges

agree with that specifi ed on the dataplate? If so, then

no further checking or adjustment is required. Proceed

to section D.

3. If the inlet pressures do not agree with that specifi ed

on the dataplate, then the regulator controlling gas

pressure to the heater requires adjustment.

4. If the inlet pressure is correct but the burner manifold

pressure does not agree with that specifi ed on the

dataplate, then the gas control valve’s internal pressure

regulator needs adjustment:

Premier 350DF Heater:

-- Remove the regulator cap on the control valve.

-- Using a standard screwdriver turn the adjusting

screw clockwise (to increase pressure) or counterclockwise

(to decrease pressure) until the burner manifold

pressure is set.

-- Install regulator cap.

-- Proceed to COMPLETION.

Premier 350 Propane Gas Heater

-- Turn the thermostat down to its lowest setting.

-- Remove the cap from the high and low heat adjusting screws at the two stage pressure regulator on

the gas control valve.

-- Slowly turn up the thermostat until a pressure is read

no greater than 2.0 in.W.C./.49 kPa at the outlet

pressure gauge.

-- If less than these pressures is observed, the low

heat setting at the regulator on the gas control will

require adjusting.

-- Turn clockwise to increase, or counterclockwise to

decrease pressure.

-- Turn the thermostat completely up.

-- You should see the gas pressure increase from 2.0

in. W.C./ .49 kPa at low heat to 8.0 in.W.C./2.0 kPa

high heat.

-- If less or greater than these pressure are observed

the high heat setting must be adjusted clockwise or

counterclockwise accordingly until proper pressure

is achieved.

D. Completion

1. Once the proper inlet and burner manifold pressures

have been confi rmed and/or properly set, close the

fuel supply valve to the heater and allow the heater

to burn off any gas remaining in the gas supply line.

2. Disconnect the heater from its electrical supply and

close fuel supply valve.

3. Remove the gauges.

4. Install pressure tap plugs.

5. Open fuel supply valve and reconnect electrical

supply to heater. Start the heater and check for gas

leaks.

6. Set thermostat to desired temperature.

SINGLE STAGE

TWO STAGE

Premier Ductable Heaters

www.lbwhite.com

Owner’s Manual • Premier 350

30

Troubleshooting Guide

READ THIS ENTIRE SECTION

BEFORE BEGINNING TO

TROUBLESHOOT PROBLEMS.

The following troubleshooting guide provides

systematic procedures for isolating equipment

problems. This guide is intended for use by a

QUALIFIED GAS HEATER SERVICE PERSON.

DO NOT ATTEMPT TO SERVICE THESE HEATERS UNLESS YOU HAVE BEEN PROPERLY

TRAINED.

TEST EQUIPMENT REQUIRED

The following pieces of test equipment will be

required to troubleshoot this system with minimal

time and effort.

• Digital Multimeter - for measuring AC

voltage and resistance.

• Low Pressure Gauge - for checking inlet

and outlet pressures at the gas control valve

against dataplate rating.

■ Visually inspect equipment for apparent

damage.

■ Checking all wiring for loose connections and

worn

Refer to the system operation sequence in this

section to gain an understanding as to how the

equipment operates during a call for heat. Understanding the sequence of operation of the ignition

module and related components is esential as it

will relate directly to problem solving provided by

the fl ow charts.

The ignition control module is self-diagnostic. The

red light, located within the selector switch, will

fl ash a specifi c light pattern depending upon the

problem which is diagnosed. To effectively use

the fl ow charts, you must fi rst identify what the problem

is by the light pattern of the L.E.D. (light emitting diode)

diagnostic light. If the light is fl ashing, the fl ash pattern

will be followed by a pause and then a repeat of the

fl ash pattern until the problem is corrected. Refer to

the tables below to identify what page to refer to when

troubleshooting any problems.

The L.E.D. light will only be on when the selector switch

is positioned to HEAT and the thermostat is set above

room temperature. The light will not be on when the

selector switch is positioned to VENT.

Heating Mode Problems Page

L.E.D. light is not on ........................................... 32

L.E.D. diagnostic light is fl ashing:

A. One Time........................................................ 33

B. Two Times ...................................................... 34

C. Three Times ................................................... 35

D. Four Times ..................................................... 35

E. Five Times ...................................................... 35

Ventilation Mode Problems Page

A. Motor Does Not Run ...................................... 36

B. Motor “Hums,” Does Not Run ......................... 36

C. Motor Runs with Low Air Output .................... 36

Components should be replaced only after each step

has been completed and replacement is suggested in

the fl ow chart. Refer to the Servicing sections as neces-

sary to obtain information on disassembly and replacement procedures of the component once the problem is

identifi ed by the fl ow chart.

DIRECT IGNITION OPERATION

SEQUENCE:

-- Selector switch is set to heat.

-- Line voltage is sent to ignition control and to

transformer.

-- Transformer reduces line voltage to 24 volts which is

sent to thermostat.

-- The thermostat calls for heat.

-- The thermostat sends 24 volts to ignition control.

-- Red light is illuminated

-- Ignition control module performs self safety check.

-- Internal components are tested.

-- Air proving circuit is checked.

-- Ignition control module begins ignition trial sequence.

-- Ignition control module sends 24 volts to air proving

switch.

-- Ignition control sends line voltage to motor relay

-- Motor relay closes and fan motor starts.

-- Air proving switch closes and 24 volts are returned to

the ignition control module.

WARNING

■ This heater can start at any time.

■ Troubleshooting this system may require

operating the unit with line voltage present and

gas on. Use extreme caution when working on

the heater.

■ Failure to follow this warning may result in

property damage, personal injury or death.

Loading...

Loading...