Page 1

Page 2

LAUNCH X-631/X-631+ Wheel Aligner

General Notice

Trademark Information

LAUNCH is a registered trademark of LAUNCH

TECH. CO., LTD. (short for LAUNCH) in China and

other countries. All other LAUNCH trademarks,

service marks, domain names, logos, and company

names referred to in this manual are either

trademarks, registered trademarks, service marks,

domain names, logos, company names of or are

otherwise the property of LAUNCH or its affiliates. In

countries where any of the LAUNCH trademarks,

service marks, domain names, logos and company

names are not registered, LAUNCH claims other

rights associated with unregistered trademarks,

service marks, domain names, logos, and company

names. Other products or company names referred to

in this manual may be trademarks of their respective

owners. You may not use any trademarks, service

marks, domain names, logos, or company names of

LAUNCH or any third party without permission from

the owner of the applicable trademarks, service

marks, domain names, logos, or company names.

You may contact LAUNCH by visiting Launch at

http://www.cnlaunch.com

Industrial Park, North of Wuhe Rd., Banxuegang,

Longgang, Shenzhen, Guangdong, P. R. China, to

request written permission to use Materials on this

manual for purposes or for all other questions relating

to this manual.

, or writing to Launch

Other product names used herein are for

identification purposes only and may be trademarks

of their respective owners. LAUNCH disclaims any

and all rights in those marks.

Copyright Information

Copyright © 2010 by Launch Tech Co., Ltd. All rights

reserved. No part of this publication may be

reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise,

without the prior written permission of LAUNCH. The

information contained herein is designed only for the

use of this unit. LAUNCH is not responsible for any

use of this information as applied to other units.

Neither LAUNCH nor its affiliates shall be liable to the

purchaser of this unit or third parties for damages,

losses, costs, or expenses incurred by purchaser or

third parties as a result of: accident, misuse, or abuse

of this unit, or unauthorized modifications, repairs, or

alterations to this unit, or failure to strictly comply with

LAUNCH operating and maintenance instructions.

LAUNCH shall not be liable for any damages or

problems arising from the use of any options or any

consumable products other than those designated as

Original LAUNCH Products or LAUNCH Approved

Products by LAUNCH.

i

Page 3

LAUNCH X-631/X-631+ Wheel Aligner

of measurement.

Precautions

z Please read the User’s Manual and the

Installation and Parts Manual carefully before

operating X-631/X-631+.

z Only the qualified technician can operate the

Wheel Aligner.

z The operator must have knowledge of computer

application and basic theory of wheel alignment.

z The power voltage of X-631/X-631+ is

AC230V±10% 50±1Hz / AC110V±10% 60±1Hz

˄AC220V±10% 60±1Hz for South Korea. It can

be customized according to the requirements of

customer˅. The power outlet must be a 3PIN

socket and its earth pin must be well

grounded. Otherwise, the equipment will be

damaged! If the power voltage is not stable,

please purchase and use AC voltage stabilizer.

z X-631/X-631+ is operated with image sensing. Do

not stop the light beam between sensors. Avoid

reflection light of the ground and direct light to the

probe rod while testing.

z Charge the probe rod for 4 hours if it is not

operated for over 30 days. Turn off the power of

the probe rod before charging it.

z The probe rods are precision parts of the wheel

aligner. Do not plug or unplug the connecting

cable when the power is turned on. Otherwise,

the built-in sensor may be damaged. Special care

should be taken during installation and operation

to prevent the casing from being distorted and

the internal parts from being damaged.

z Install the lift according to specifications before

installing X-631/X-631+, for it is necessary to lift

the vehicle when adjusting vehicle wheels. The

vehicle may need lift for two times for

compensation of rim run-out. Check the lift

regularly for fixedness and levelness to ensure

personal safety and correct measurement.

Remove the obstacles around the lift for

convenient operation.

z Don’t place X-631/X-631+ on a vibrated object or

an oblique surface. Avoid direct sunlight and

moisture.

z Avoid splashing water on the surface of

X-631/X-631+, for it may cause permanent

damage to the system.

z The wires inside the cabinet and the probe rod

sensors are connected compactly. Any

disconnection may cause damage to the sensor.

Damage due to unauthorized disconnection is not

covered by warranty.

z The battery for the probe rod is the consumable

goods. After finishing its span life, the user should

change it in his own charge.

z Maintain X-631/X-631+ periodically for accuracy

z Turn off the power after operation. Check all bolts

and parts after maintenance, and tighten the

slackened bolts and parts in turn for safety.

z Check the packing list before installing. Do not

hesitate to contact LAUNCH or LAUNCH

distributors for any questions.

General Safety Instructions

Safety equipment may not be removed

and/or disabled.

Any work on the electrical installation may

only be performed by electricians.

The wheel alignment system may not be

operated in explosion-prone surroundings.

The operator must provide appropriate fire

protection measures at the measuring platform. In

particular, any flammable or self-combusting items

(such as cloths soaked in solvents or oil) and fluids, or

foreign items and other ignition sources, should not be

stored in the tool trolley.

Warning symbol tags used:

Legend: Pull the power plug before

opening the housing!

Obligation by the operator to be

considerate and avoid negligent acts:

The equipment was designed and constructed with

consideration to required harmonized standards, as

well as additional technical specifications. It therefore

corresponds with the current state of technology and

provides the maximum standard in safety during the

operation.

The machine safety, however, can only be

implemented during the operation, if all of the

required steps have been taken. The operator of the

machine has the obligation to plan these actions and

check their compliance.

The operator must specifically verify that:

• The machine is only used according to

specifications.

• The machine is only operated in perfect operational

condition and that the safety equipment is routinely

ii

Page 4

LAUNCH X-631/X-631+ Wheel Aligner

inspected as to their operational condition.

• The necessary personal safety equipment for

operating, maintenance and repair personnel is

available and being worn.

• The operating instructions are always in a legible

condition and are completely available at the

machine location.

• The machine is only operated, maintained and

repaired by qualified and authorized personnel.

• This personnel is instructed routinely in all pertaining

questions of work safety and environmental

protection, and knows the operating instructions,

especially the safety instructions contained therein.

• All safety and warning labels attached to the

machine are not removed and are legible.

Concrete safety instructions

and applied symbols

Concrete safety instructions are provided in the

following operating instructions which will point out

any unavoidable remaining risks during the machine

operation. These remaining risks contain hazards for:

Persons

Product and machine

The environment

Symbols used in the operating instructions should

draw attention to the safety signs!

This symbol points out that specifically

personal injury risks may be anticipated (Mortal

danger, risk of injuries).

completely read!

Basic safety measures during normal

operations:

The machine may only be operated by trained and

authorized personnel who know the operating

instructions and are capable of working with them!

Prior to switching the machine on, check and verify

that:

Only authorized personnel are located within the

working range of the machine.

No one can be injured when the machine is activated!

Check the machine for visible damages prior to use

and verify that it is only operated in perfect condition!

Report any problems immediately to the supervisor!

Prior to each operating start, check and verify that all

safety equipment operates perfectly!

Basic safety measures during service

and maintenance:

Adhere to the inspection and maintenance intervals

specified in the operating instructions!

Block access to the work area of the machine

to unauthorized personnel prior to performing

maintenance or repairs! Attach or set up a warning

sign that points out maintenance or repair work!

Pull the power plug prior to any maintenance

or repair work or switch off the main switch for the

power supply and secure with a lock, if the power

supply is installed.

The key to this lock must be in the hands of the

person that is completing the maintenance or repair

work! Only use perfect load suspension and lifting

equipment when replacing heavy machine parts!

This symbol signifies that especially

hazards for the machine, material and the

environment may be encountered.

The most important objective of the safety signs

exists in the prevention of personal injuries.

If the warning triangle with the wording “danger” is on

a safety notice, hazards for the machine, material and

the environment are not excluded.

If the warning triangle with the wording “caution” is on

a safety reference, personal injuries are not

anticipated.

The applied symbol cannot replace the text of the

safety reference. The text must therefore always be

Properly dispose of environmentally

hazardous lubricants, coolants or cleaning agents!

Working on the electrical equipment:

Repairs on electrical equipment of the

machine may only be performed by trained

iii

Page 5

LAUNCH X-631/X-631+ Wheel Aligner

electricians!

Electrical equipment must be routinely inspected!

Re-attach any loose connections!

Immediately replace damaged lines/cables!

Always keep housings of electrical equipment closed!

Access is only permitted for authorized personnel

with key/tools!

Never spray the housing of electrical equipment with

a hose when cleaning!

Pay attention to rechargeable battery

references and disposal regulations:

Lithium Rechargeable batteries:

• Do not throw into fire

• Only charge in the chargers provided in the delivery

• Protect from water sprays

• Do not open or short-circuit electrical contacts

• Do not use if the housing has been damaged or if

the electrical contacts have been damaged

Observe environmental regulations:

The legal regulations for waste prevention and

proper recycling/disposal must be adhered to for all

operations on and with the machine.

Especially during installation, repair and maintenance

operations, water-polluting materials, such as:

Lubricants and oils - hydraulic oils - coolants.

Solvent-containing cleaning liquids may not pollute

the ground or reach the sewage system!!

These materials must be stored, transported,

collected and disposed of in suitable containers!

iv

Page 6

LAUNCH X-631/X-631+ Wheel Aligner

Ta ble of Contents

Introduction .................................................................1-1

Definition.................................................................1-1

When Is Wheel Alignment Required.......................1-1

Main Vehicle Alignment Parameter.........................1-1

Toe-in and Toe-out..............................................1-1

Kingpin Inclination (SAI).....................................1-1

Caster.................................................................1-2

Thrust angle .......................................................1-2

Wheelbase Difference........................................1-2

Track Width Difference.......................................1-3

Functions................................................................1-3

Features .................................................................1-3

Specifications .........................................................1-4

Requirements on Surroundings..............................1-4

Working Principle....................................................1-4

Structures....................................................................2-1

Overall Structure.....................................................2-1

Wheel Aligner Main Unit .........................................2-1

Probe Rods.............................................................2-1

Wheel Clamps ........................................................2-3

Wheel Clamp Hanging Bracket...............................2-3

Turntables...............................................................2-3

Steering Wheel Holder ...........................................2-3

Brake Pedal Depressor...........................................2-4

Calibrating Frame and its Converter Connector

(Optional)................................................................2-4

Basic Operation Procedures .......................................3-1

Get Vehicle Information ..........................................3-1

Wheel Alignment Checking.....................................3-1

Adjustment..............................................................3-1

Test-drive................................................................3-1

Operation Instructions.................................................4-1

Preparation.............................................................4-1

Operation procedures.............................................4-1

Standard Measurement ..........................................4-1

Quick Measurement .............................................4-10

Additional Measurement....................................... 4-11

System Measurement........................................... 4-11

Print ......................................................................4-22

3D Interface / 2D Interface....................................4-23

Help ......................................................................4-23

Exit........................................................................4-23

New Functions of X-631+ Wheel Aligner..............4-23

Maintenance ...............................................................5-1

Computer................................................................5-1

Wheel Clamp and Probe Rod.................................5-1

Printer.....................................................................5-1

v

Page 7

LAUNCH X-631/ X-631+ Wheel Aligner Introduction

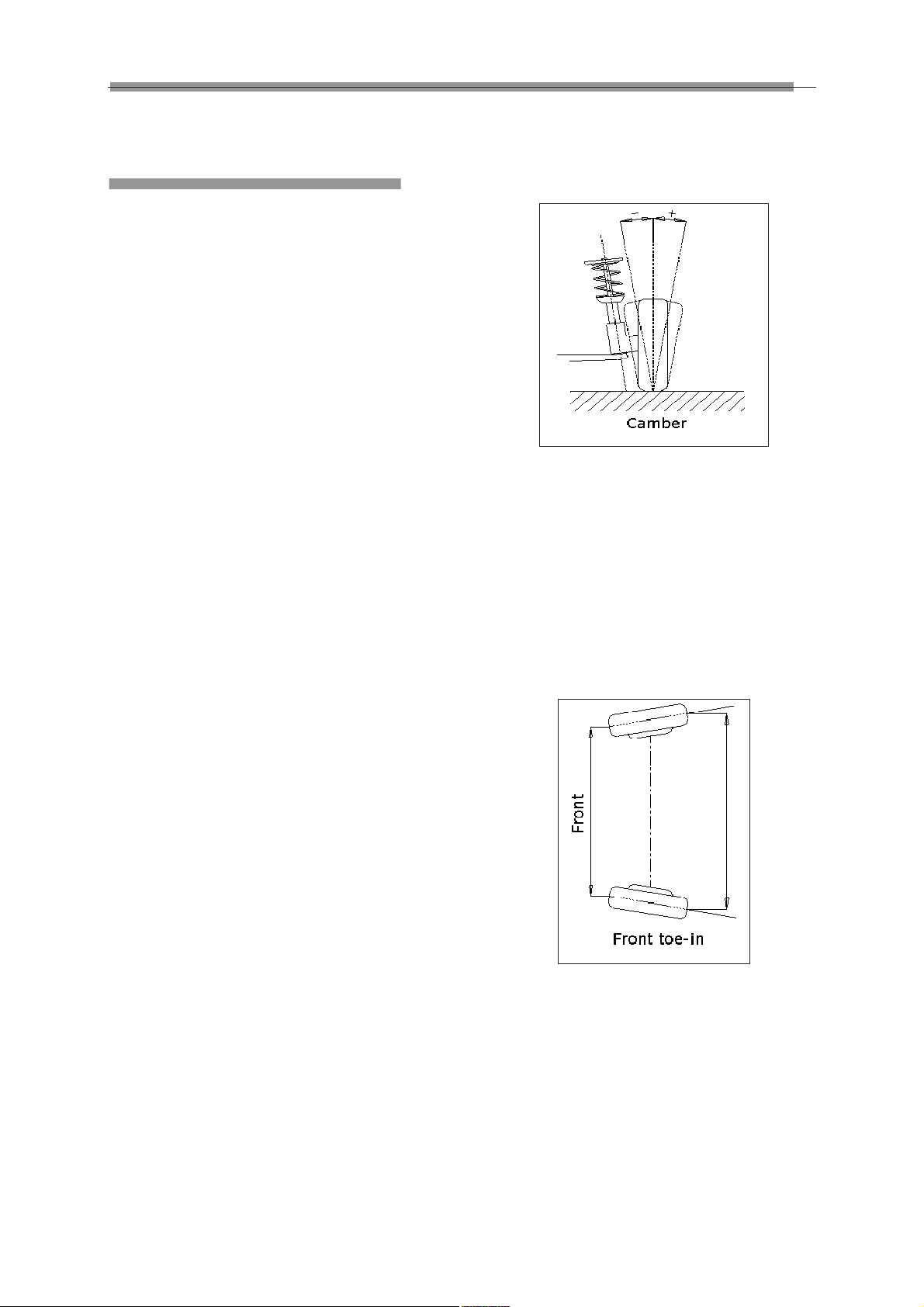

If the road wheel leans outwards from the vertical, it

Introduction

Thank you for using X-631/X-631+ wheel aligner

manufactured by Launch Tech Co., Ltd.

has positive camber and when leaning inwards from

the vertical - negative camber, looking from the front

or rear of the vehicle. See Fig.1.1.

Definition

X-631/X-631+ CCD wheel aligner adopts the charge

coupled device (CCD) with high resolution, the

clinometer with high precision and the accurate optics

imaging system.

X-631/X-631+ is a device designed to measure the

wheel alignment parameters and compare them with

the specifications provided by vehicle manufacturer. It

also gives instructions to the user for performing

corresponding adjustments so as to get the best

steering performance and reduce tire wear.

The wheel aligner compares the measured results

with the original data of vehicle manufacturer and

gives instruction to the user for adjustment, so its

databank should contain enough information.

X-631/X-631+ Wheel Aligner contains wheel

alignment databank of over 10,000 vehicle types all

over the world. User can also add new vehicle wheel

alignment data in the databank when necessary.

When Is Wheel Alignment

Required

Fig.1.1

Camber is measured in degrees.

Toe-in and Toe-out

The toe setting is the amount by which the front or

rear wheels point inwards or outwards at the front of

the wheel in relation to each other (see Fig.1.2).

When the wheels point inwards they are said to toe-in.

Toe-in figures are given a positive value. Conversely

when the wheels point outwards they are toe-out and

the figures are shown as a negative value.

z The driver has to firmly hold the steering wheel

to maintain a straight-ahead driving.

z Abnormal wear of tires occurs, such as single

side wear, concave-convexity wear and

featheriness wear.

z Too heavy or too light steering, or shaking at

high-speed driving.

z When the tire(s), steering knuckle or shock

absorber are replaced.

z When the vehicle is impacted.

z When the vehicle has covered the first 3000km

or 10000km.

Main Vehicle Alignment

Parameter

The wheel alignment mainly consists of camber,

toe-in, kingpin inclination, caster, etc. They are

designed mainly to improve the steering performance

and driving stability of the vehicle, and reduce tire

wear.

Camber

Camber is the leaning of the wheel inwards or

outwards from the vertical.

Fig.1.2

The purpose of correct toe is to ensure that the

wheels run parallel when the vehicle is driving. An

incorrect toe setting may affect the stability and

controllability of the vehicle.

Kingpin Inclination (Steering Axle

Inclination SAI)

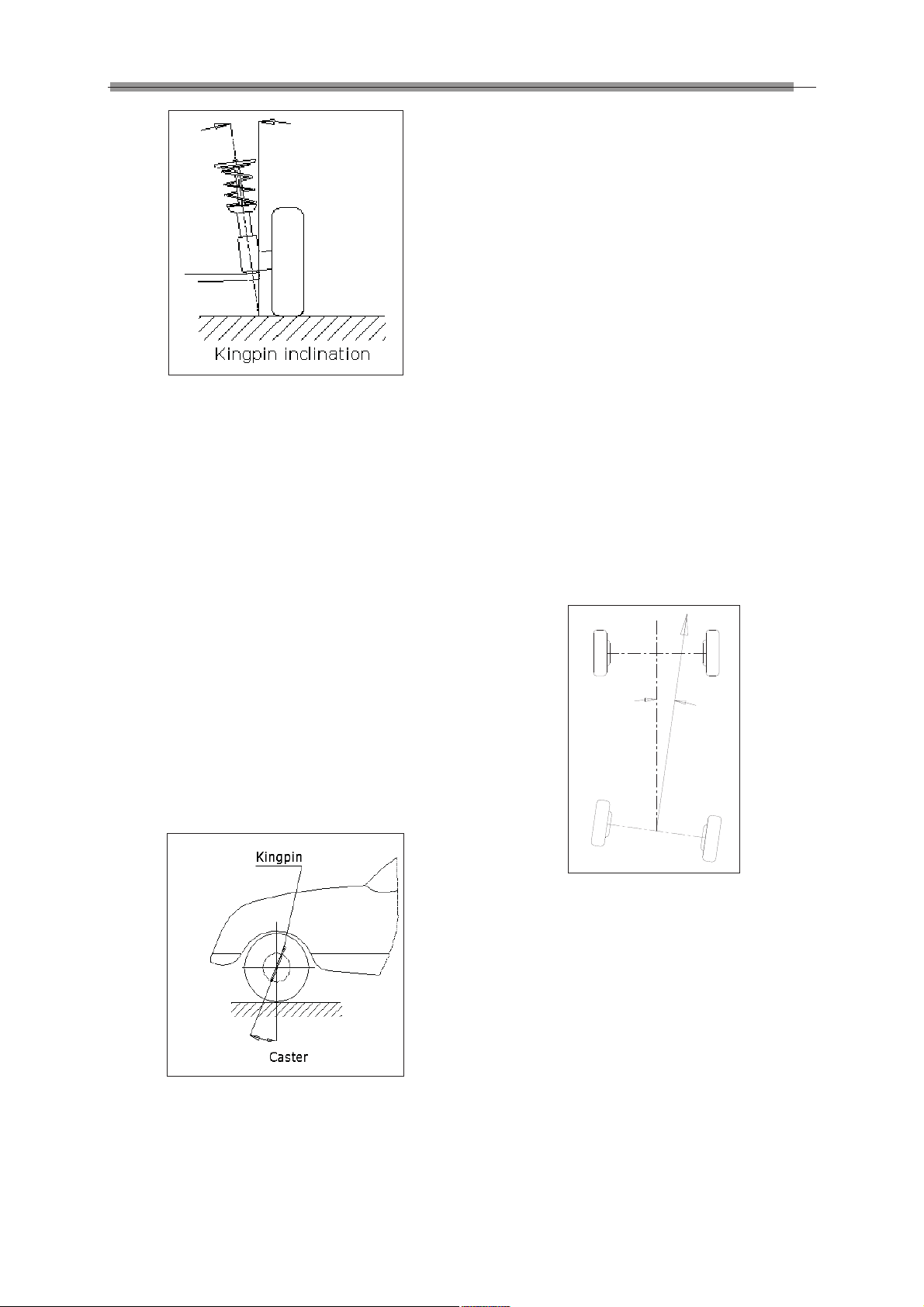

Kingpin Inclination (KPI or SAI) is the angle of

inclination of the king pin towards the centre-line of

the vehicle from the vertical (see Fig.1.3).

1-1

Page 8

LAUNCH X-631/ X-631+ Wheel Aligner Introduction

steering. To increase the tendency of the steering to

self-centre, the steering will normally be designed

with positive caster.

Thrust angle

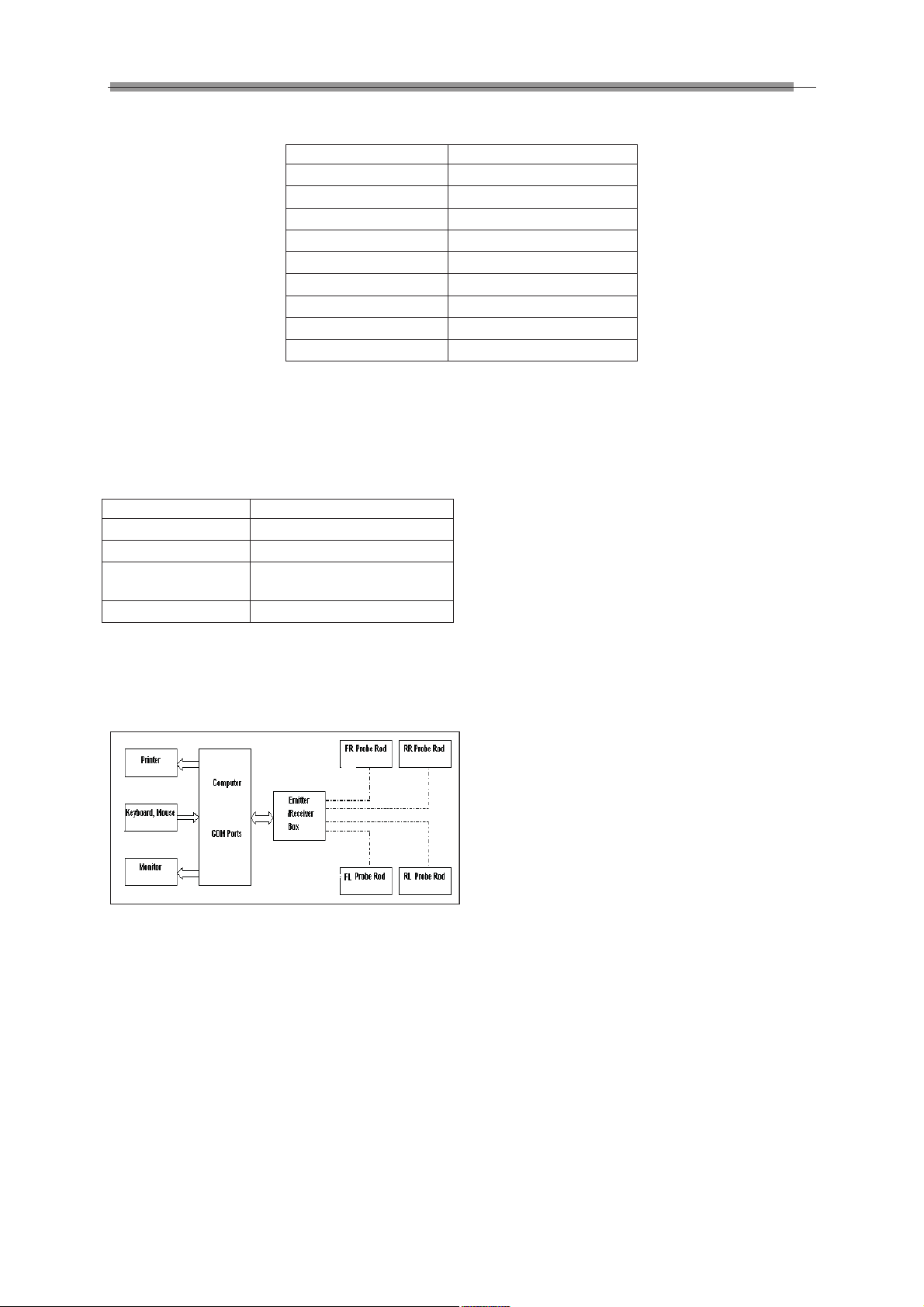

The thrust angle is defined according to the driven

mode of vehicle.

z Rear wheel driven: the thrust angle equals half of

the toe-in difference between the two rear wheels.

As shown in Fig.1.5.

z Front wheel driven: the thrust angle equals half

of the toe-in difference between the two front

wheels.

Fig.1.3

Correct Kingpin Inclination can equalize the loads

applied on bearings so that the life of bearings can be

prolonged and the controllability of steering is

improved.

Without the inclination, the controllability of the

steering may be affected; further more, the vehicle

weight and the ground counterforce may cause

significant stress in the axle and finally damage the

axle.

z Four-wheel driven: the thrust angle equals half of

the toe-in difference between the two front

wheels plus half of the toe-in difference between

the two rear wheels.

The thrust angle is defined as positive when the

thrust line is towards left and negative when the line

is towards right.

If the thrust angle is not zero, the vehicle will have the

side-moving trend. In this case, adjust the front toe-in

of the drive wheels first, and then adjust the toe-in of

driven wheels.

Correct inclination of king pin is also helpful for the

vehicle to restore its straight-ahead position after

steering.

Kingpin Inclination is determined when the vehicle

suspension is designed. It is not service adjustable.

Caster

Caster is the tilting of the kingpin either forwards or

backwards from vertical, as viewed from side of the

vehicle. See Fig.1.4

Fig.1.4

When the king pin is tilted backwards from the vertical,

caster is positive. When the king pin is tilted forwards,

caster is negative.

Caster angle influences the directional stability of the

Fig.1.5

Wheelbase Difference

Wheelbase difference is defined as the angle

between the joint line of the centre of two rear wheels

and that of the front wheels. It is positive when

distance between the centre of the right wheels is

large than that of left wheels; and negative otherwise.

If the tread is available from the vehicle specifications,

then the wheelbase difference can be also expressed

by angle. See Fig. 1.6

1-2

Page 9

LAUNCH X-631/ X-631+ Wheel Aligner Introduction

function.

z The probe rods provide LCD display function.

z Electronic level function.

z Black box self-diagnosis function.

z Front and rear probe rods interchangeable.

z Special test for Mercedes-Benz and BMW

vehicles.

Features

z Infrared 8-beam and 16-sensor loop

measurement, accurate and stable.

Fig. 1.6

Track Width Difference

Track width difference is defined as the angle

between the joint line of the ground-contact point of

left wheels and that of the right wheels. It is positive

when distance between the centre of the rear wheels

is large than that of front wheels; and negative

otherwise. If the wheelbases are available from the

vehicle specifications, then the tread difference can

be also expressed by angle. See Fig. 1.7.

Fig. 1.7

Functions

z Complete test: The X-631/X-631+ Wheel Aligner

can be used to measure the most wheel

alignment parameters, such as front wheel

toe-in, front wheel camber, caster, Kingpin

inclination, rear wheel toe-in, rear wheel camber,

thrust angle, wheelbase difference, tread

difference, axle offset, front wheel setback and

rear wheel setback, etc.

z Complete databank: wheel alignment data of

over 10,000 vehicle models is stored in the

system. User can also add new data to the

databank.

z Kingpin and camber adjustment real time

display function.

z HELP information for vehicle adjustment.

z Language operating prompt function.

z Emergency power supply and in-time charging

z Newly developed CCD signal processing

technology, nearly uninfluenced by the strong

sunlight.

z Complete system upgrading function.

z Unique voice prompt function and visualized

animation, very easy to understand.

z Trustworthy operating system to give more

convenient and safe operations.

z Keyboard quick switch operation.

z Both special version and common version are

provided for user to select.

z Both normal version and demonstration version

are provided to make user’s training more

convenient and quick.

z Large capacity (4000mAh) Lithium battery with

low power consumption and dormancy mode of

design.

z Camber, toe-in, battery electricity quantity,

charging status and electronic level, etc. can be

real-time displayed by LCD.

z In-block type of casting Aluminum alloy probe

rods can strongly guarantee the stability and the

test precision of the product.

1-3

Page 10

LAUNCH X-631/ X-631+ Wheel Aligner Introduction

Specifications

Item Range

Front total toe-in f40嘙

Front toe-in f20嘙

Front camber f8.0嘙

Caster f20嘙

Kingpin inclination f20嘙

Rear total toe-in f40嘙

Rear toe-in f20嘙

Rear camber f8.0嘙

Thrust angle f5.0嘙

Notes:

1. The above measurement ranges can be confirmed only when the user follows the specified operation

procedures.

Requirements on Surroundings

Item Specification

Ambient temperature -10~+50ć

Relative humidity İ85%

Exterior magnetic

field strength

Lifter gradient İ1e

İ400A/m

Working Principle

The working framework of X-631and X-631+ Wheel

Aligner is as shown in Fig.1.8.

Fig.1.8

1-4

Page 11

LAUNCH X-631/X-631+ Wheel Aligner Structures

top platform of the cabinet. Mouse and keyboard are

Structures

on the keyboard drawer. Printer is on the drawer in

the middle of the cabinet. The

the lower compartment of the cabinet.

computer host is in

Overall Structure

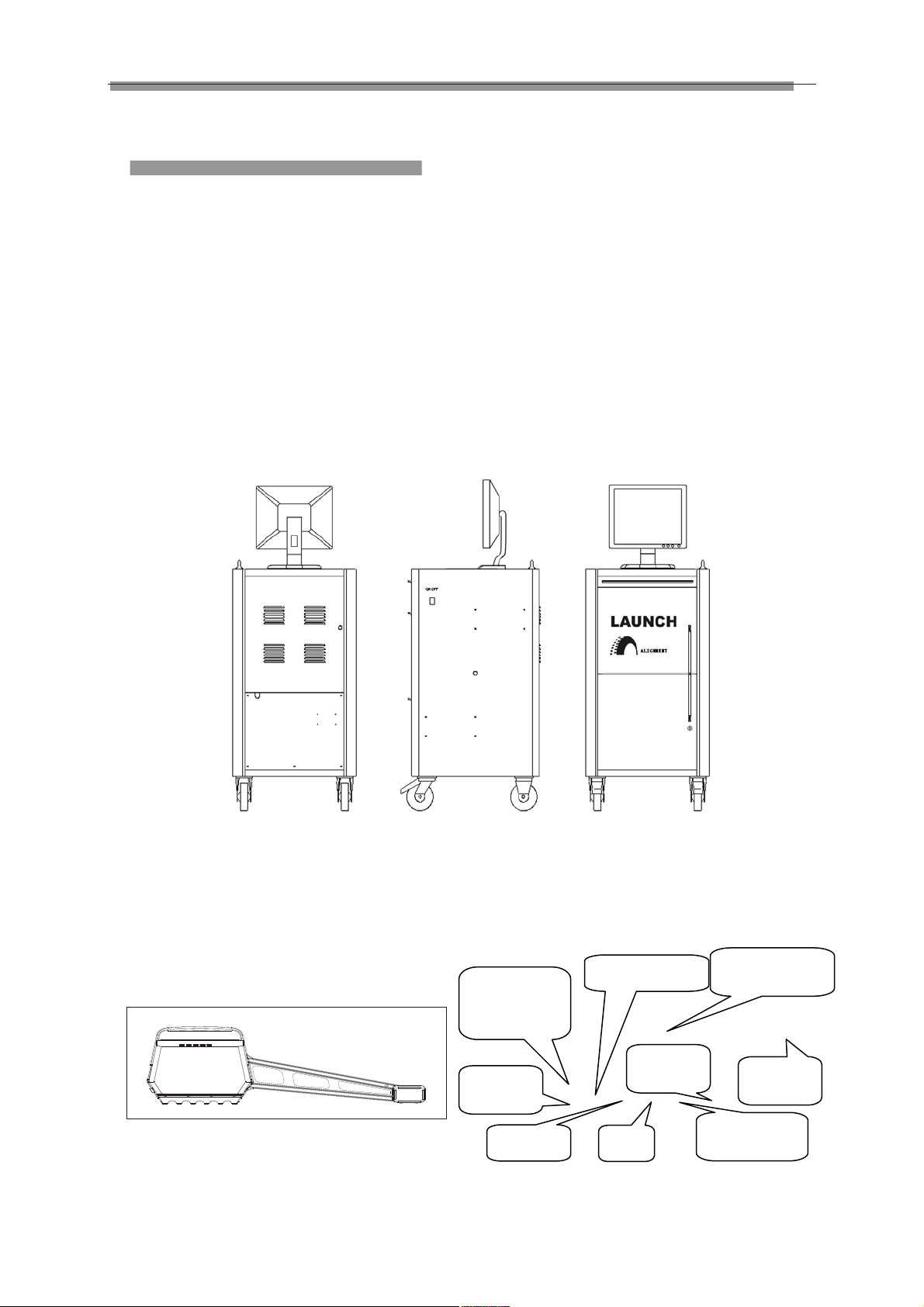

X-631/X-631+ Wheel Aligner mainly consists of the

wheel aligner main unit, probe rods, wheel clamps,

turntables (optional), steering wheel holder, and brake

pedal depressor, etc.

Wheel Aligner Main Unit

The main unit is an operation control platform. It

consists of cabinet, computer group, interface circuit,

power supply assembly, etc., as shown in Fig.2.1.

The computer group includes computer, monitor,

keyboard, mouse, and printer. The monitor is on the

The interface circuit includes the RF main emitter box.

The main emitter box is placed in the cabinet.

The power supply assembly includes power lead,

power socket, switch, and switch power. The power

switch is at the sideboard of cabinet. The power lead

is at the rear of the lower compartment inside the

cabinet. The power socket is at the spacer board and

near to the sideboard. The switch power supply is

also on the backboard of the cabinet.

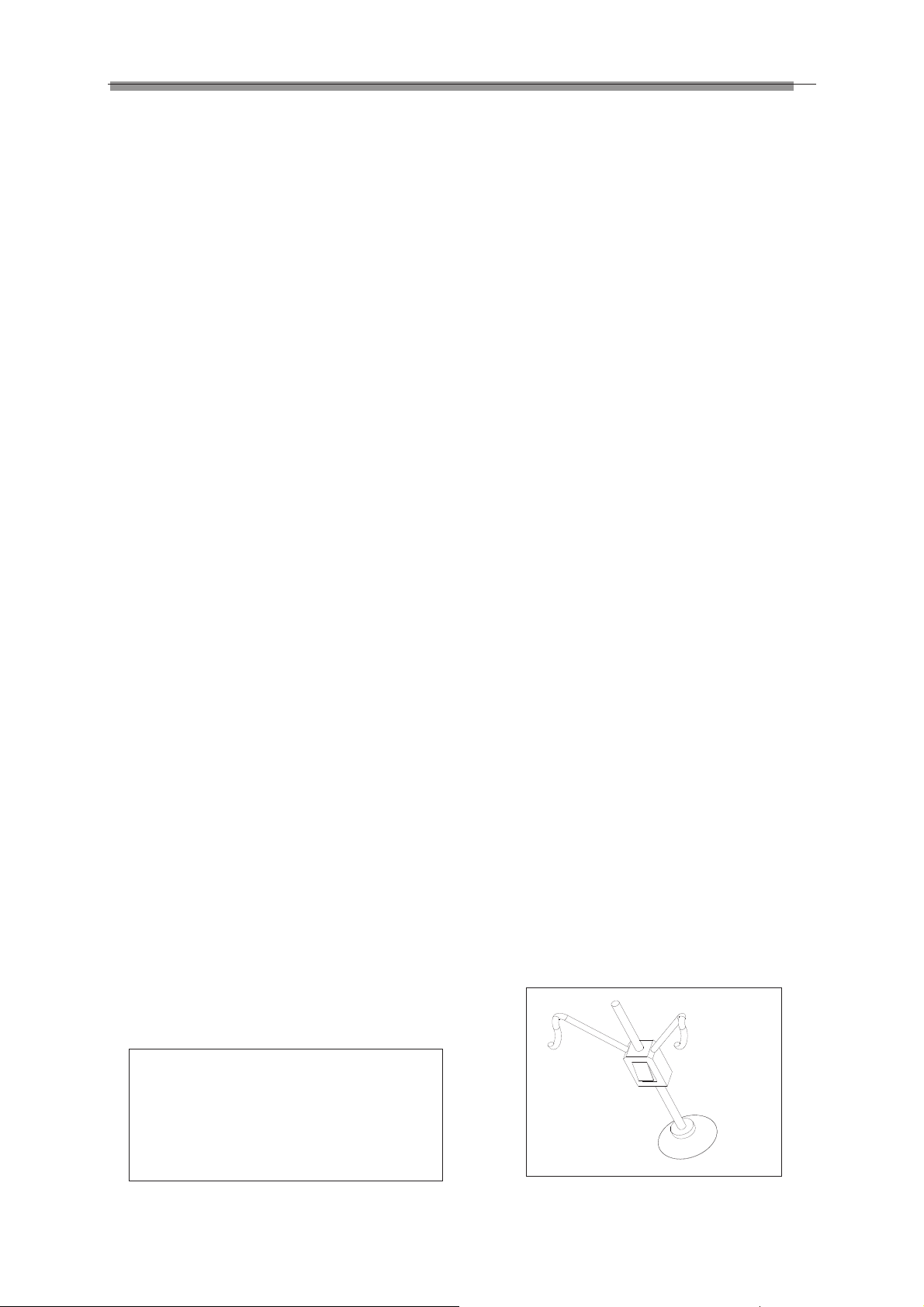

Probe Rods

X-631/X-631+ is equipped with four probe rods. They

are FL, RL, FR and RR probe rods, as shown in

Fig.2.2. The front probe rods and the rear probe rods

can be across interchanged each other. If one of the

probe rods is changed, it is only necessary to

calibrate the changed probe rod, and the other three

probe rods needn’t be re-calibrated.

Fig.2.2 probe rod

Each probe rod is equipped with a CCD sensor at

end, and a blue-teeth emitter/receiver at the middle.

The CCD sensor picks-up the light pot coordinate and

Fig.2.1

transmit them to the computer through the blue-teeth

emitter. The computer processes the received

coordinate data signal.

There is a button/LCD panel in the middle of each

probe rod as shown in Fig.2.3.

Run-out

compensation

indicator

Power

indicator

2-1

Previous

LCD Rear Light

Power

Switch

Next

Fig.2.3

LCD Display

area

Level

bubble

Run-out

compensation

Page 12

LAUNCH X-631/X-631+ Wheel Aligner Structures

Ģ

LCD display area has six functions: take the X-631 as

an example.

[Display start interface]: “Welcome to use X-631” is

displayed on LCD as shown in Fig.2.4.

Fig.2.4

[Display charging status]: “Battery Charging” is

displayed on LCD as shown in Fig.2.5. It indicates

that the battery is being charged.

Fig.2.5

“Charge Finished!” is displayed on LCD as shown in

Fig.2.6. It indicates that the battery charging is

finished.

Fig.2.6

Notes: When the characters of “>>>” are

displayed on LCD, it indicates that the probe rod

is being charged

When “=D-”is displayed, it

indicates that the charging is finished, and the

cables are connected, the probe rod is powered

by the power supply from outside.

[Display electric level]: “level” is displayed on LCD. It

indicates that the level position adjustment is being

performed, and the black float mark indicates the

position of the bubble level as shown in Fig.2.7.

[Display for run-out compensation]: To display the

current compensation status of the probe rod: 0

indicates the run-out compensation operation should

be started for the current probe rod. The interface is

as shown in Fig.2.9.

Fig.2.9

90,180, 270 and 360 indicates respectively the

corresponding angles by which the tire should be

rotated. The interface is as shown in Fig.2.10.

Fig.2.10

After finishing the compensation operation for the

probe rod, the level status of the probe rod will be

displayed on LCD, and the run-out compensation

indicator on the control panel of the probe rod will turn

green. The interface is as shown in Fig.2.11.

Fig.2.11

[Display probe rod measurement]: Real-time display

Camber (C), Toe-in (T) and Battery electricity quantity

(B) as shown in Fig.2.12.

Fig.2.7

The probe rod is level when the black float mark turns

to “OK” as shown in Fig.2.8.

Fig.2.8

Fig.2.12

[Display probe rod status]: Display the position of

probe rod and the electricity quantity of battery as

shown in Fig.2.13.

Fig.2.13

2-2

Page 13

LAUNCH X-631/X-631+ Wheel Aligner Structures

[Display Standby status]: “Stand By…” is displayed

on LCD. It indicates that the probe rod is in standby

mode for saving electricity. The standby mode can be

switched to normal working mode as shown in

Fig.2.14.

Fig.2.14

Button area includes 5 buttons:

[Backlight]: Key to switch on/off the backlight of LCD.

[Next]: To perform the test according to the default

sequence (Select Vehicle Model Run-out

Compensation Kingpin Measurement Rear

Axle Measurement Front Axle Measurement

Print Report Form ) of the system.

[Previous]: To return to the previous operating

procedure during test.

[Run-out compensation]: It is the special key-press for

run-out compensation operation.

[Power switch]: Switch on/off the battery power

supply of the probe rod.

There is a 9V power supply socket on the side wall of

the probe rod box. It is used for charging the battery

of the probe rod. When the electricity quantity of the

battery is full, the charging circuit will automatically

stop charging.

Caution! Make sure to turn off the power of the

probe rod before charging it. The probe rod is a

precision component; please handle it with care

to ensure measuring accuracy.

Wheel Clamps

X-631/X-631+ has 4 wheel clamps (see Fig.2.15).

Turn the adjusting knob to adjust the span between

wheel claws, and then attach the clamp to the wheel

rim. Adjust the knob to make the wheel clamp fixed

on wheel rim tightly. Use the wheel clamp tie to bind

the wheel clamp and the wheel rim together.

The installation of wheel clamp is crucial to the test

result. The claws should be in even contact with the

wheel rim without touching the lead weight.

Avoid hitting during operation. Otherwise, distortion

may be caused and the test result may be influenced.

Wheel Clamp Hanging Bracket

X-631/X-631+ wheel aligner is equipped with 4 wheel

clamp hanging brackets as shown in Fig.2.16.

Fig.2.16

After unpacking, it is necessary to install these 4

hanging brackets on left and right side wall of the

cabinet.

Turntables

X-631/X-631+ has two mechanical turntables

(standard configuration, see Fig.2.17).

Fig.2.17 mechanical turntables

When testing, the turntables should be placed at the

front wheel position of vehicle on the lift.

Use the lock pin to lock the turntable before driving

the vehicle on. Pull out the lock pin after the vehicle is

stopped and the front wheels are at the center of the

turntables.

While testing, try your best to keep the vehicle front

wheel at the center of the turntable.

Steering Wheel Holder

X-631/X-631+ has a steering wheel holder as shown

in Fig.2.18. Use the steering wheel holder to lock the

steering wheel according to the tips on the screen.

Fig.2.15

Fig.2.18 Steering wheel holder

2-3

Page 14

LAUNCH X-631/X-631+ Wheel Aligner Structures

Brake Pedal Depressor

X-631/X-631+ has a brake pedal depressor is as

shown in Fig.2.19. It is used to hold the brake pedal

down.

Fig.2.19 Brake pedal depressor

Calibrating Frame and its

Converter Connector (Optional)

They are mainly used to calibrate the probe rod

system of X-631/X-631+ wheel aligner.

Fig.2.20 Calibrating frame and its converter connector

2-4

Page 15

LAUNCH X-631/X-631+ Wheel Aligner Basic Operation Procedures

Basic Operation

Procedures

Get Vehicle Information

Ask the owner for vehicle drivability problems,

symptoms, and wheel alignment history, and find out

vehicle information such as make, model and year,

etc.

Check each chassis part carefully, include dust cover,

bearing, rock arm, tripod-ball, shock absorber, tie rod

ball and steering mechanism, for any loose or wear.

Then check to see if the tire pressure, tire treads of

the left and right wheels are alike.

Wheel Alignment Checking

Perform the wheel alignment checking after the initial

condition is known.

Adjustment

If the measuring values do not accord with the

specifications given in the databank, the wheel

alignment should be adjusted.

Test-drive

After finishing the wheel alignment, test the vehicle to

see if the abnormal conditions are eliminated.

Re-adjust the wheel alignment if necessary.

3-1

Page 16

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

Operation procedures

Operation Instructions

Preparation

I. Drive the vehicle onto the lift or over the pit, so

that the front wheels are centered to the

turntables; Apply hand brake to ensure safety. To

prevent the turntable from turning, lock the

turntables with the lock pins before driving the

vehicle; release the lock pins after the vehicle is

well-positioned.

II. Ask the owner for vehicle drivability problems and

symptoms, wheel alignment history, and find out

vehicle information such as make, model and

year, etc.

III. Check each chassis part carefully, include dust

cover, bearing, rock arm, tripod-ball, shock

absorber, tie rod ball and steering mechanism,

for any loose or wear. Then check to see if the

tire pressure and treads of the left and right

wheels are alike.

IV. Install the wheel clamps on the four wheels in

turn and turn the knobs to lock the wheel clamps.

The claws of the wheel clamp should be fixed on

the external or internal edge of the rim according

to the practical condition. Ensure equal depth for

each claw and avoid attaching it on the distorted

area.

V. Install the probe rods on the pin

wheel clamps as shown in Fig.4.1.

bushes of

Turn on the power switch, start the computer and

enter the main interface of the measurement program.

The screen displays the main function menu. There

are 8 functions available in the main menu: [Standard

Measurement], [Quick Measurement], [Additional

Measurement], [System Management], [Print], [2D

Interface/3D Interface], [Help], and [Exit]. See Fig.4.2

Fig.4.2

Standard Measurement

Click [Standard Measurement] in the interface as

shown in Fig.4.2. The screen system will enter the

standard measurement interface.

Select Vehicle Model

Before alignment, the standard data of the vehicle

model must be selected first. The interface is as

shown in Fig.4.3:

Navigation column

Fig.4.1

VI. Level the probe rod by adjusting the bubble in the

level gauge to the center position.

VII. Plug the power cable of the Wheel Aligner into a

standard power outlet of 3PIN. Switch on the

power supply of the cabinet and start the

computer.

VIII. Place the steering wheel holder on the driver seat;

and press the handle to lock the steering wheel.

IX. Put the brake pedal depressor between the brake

pedal and the driver seat to keep the brake

applied.

Tire parameter

Commonly used data list

Help

Quick search

Selected from

standard data

Fig.4.3

[Next]: To perform the test according to the default

sequence (Select vehicle model

compensation

Rear axle measurement ė Front axle

measurement

4-1

ė Kingpin measurement ė

ėPrint report form ) of the system.

ė Run-out

Next

Page 17

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

[Navigation column]: To enter into the item you want

to test in spite of the default sequence.

[Commonly used data list]: The vehicle model in the

list can be directly selected to perform the next-step

operation. It is blank when firstly used. Only the

vehicle model data must be added into this list from

the standard database, can the list be used (See

[System Management] - [Commonly used data

management]).

[Selected from standard data]: If there is no the

vehicle model you want, you can directly search for

the vehicle model you want from the standard

database, and directly perform the next-step

operation

the commonly used data list

˄This vehicle model is no longer saved in

˅. If you want to add this

you can click

data provided by the system into this form. If you

want to add user-defined data, you need to add it

from Standard Data Management interface of

System Management. The unit of Wheelbase,

Front wheelbase and Rear wheelbase is mm.

Special Measurement:

For different data of vehicle model, some special

measurement methods and operating procedures will

occur:

1. Aiming at some vehicle model of Benz, the

system provides the operations for measuring

the standard data with gradient meter. When the

data selected is of Benz vehicle, the system will

pop up a dialogue box as shown in Fig.4.4.

button to add the standard

vehicle model into the commonly used data list, it

needs to be added from the interface of [System

Management] - [Standard Data Management]).

[Quick search]: The input box for quick search aiming

at the vehicle model is provided at the bottom of the

interface. Please input the first letter of the vehicle

model to perform the searching operation.

[Tire parameter]: When the unit of toe-in is used in

mm or In (The unit of toe-in can be set in [System

Management] – [System setting]), the diameter of the

present tire must be input.

The interface for vehicle level measurement is

displayed in Fig.4.5.

Fig.4.4

[Low chassis measurement setting]: When test the

vehicle with the low chassis, please use this setting to

perform the measurement for the intelligent positiondropping of the probe rod's end part, in order to solve

the problem of blocking the sensors when testing the

vehicle with the low chassis. This setting can be

automatically reset when re-selecting the vehicle

Vehicle

adjustment

Help

model or exiting the test system. Caution: After the

probe rod's position dropped, the level adjustment

should take the electronic level as the standard.

[Help]: To provide the description of operating method

and note.

Operating procedures:

Select the corresponding vehicle model item in

[Commonly used data list], then click [Next].

Note:

1. When the toe of the system uses linear measure,

it is required to enter the vehicle tire diameter at

the right bottom corner on this interface,

otherwise the system cannot enter the next

operating procedure

2. The form currently provided is the same form

with Commonly Used Data Management in the

Use gradient meter—the special measurement

instrument (optional) to get the level values of four

wheels, which are displayed in the editing boxes. Also,

the operator can take the level value scopes

displayed on the top of the editing boxes as the

reference, and manually input the corresponding level

values of four wheels.

[Vehicle Adjustment Help]: It provides the using

method of the gradient meter for Benz vehicle, the

operator can perform the vehicle test and adjustment

with the reference of the operating methods in Help

Fig.4.5

System Management interface, in the same way,

4-2

Page 18

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

interface as shown in Fig.4.6.

Fig.4.6

Operating procedures:

According to the prompts on the interface of [Vehicle

adjustment Help], please perform the level

measurement for four suspensions by the way of

using the gradient meter, and then connect the

gradient meter to the computer host, the system will

confirm the standard data of current vehicle model

according to each level value measurement by the

gradient meter.

2. When some special vehicle models (such as

BMW 3 series) are selected, the screen will pop

up an interface of [Vehicle Counterweight] as

shown in Fig.4.7.

Fig.4.8

Operating methods:

According to the prompts on the picture at the bottom of

the interface, measure left, right, front and rear ride

height values respectively to see if they are within the

standard range or not. If the height measurement

value(s) is (are) not within the standard range, please

check the vehicle status, and adjust the corresponding

components to keep 4 Height Measurement Values

within the standard range. Click [NEXT] after finished.

4. When some special vehicle models (such as

RENAULT MEGANE

Ċ) are selected, the screen

will pop up an interface of [Dependent

Suspension Measurement] as shown in Fig.4.9.

This interface provides an operating platform for

dependent suspension measurement system, in

order to confirm the standard data according to

the current status of the vehicle body.

Fig.4.7

According to the requirements on the interface, put

the sandbags with appropriate weight on the vehicle

seats or in the baggage case, and fill the oil tank

according to the requirement. Please click [NEXT]

button to perform the next operation after finishing the

previous procedures.

3. When some special vehicle models (such as

BMW 3 series) are selected, the screen will pop

up an interface of [Height Measurement] as

shown in Fig.4.8. This interface provides an

operating platform for ride height measurement

system, in order to check if the ride height meets

the design requirements of OEM.

Fig.4.9

Operating methods:

According to the prompts on the picture at the bottom

of the interface, measure left, right, front and rear ride

height values respectively, and input them into the

corresponding inputting boxes. Click [NEXT] after

finished.

Caution:

1). Testing conditions for ride height measurement

z Specified tire pressure

z Good and even tread pattern

z Specified wheel bearing clearance

4-3

Page 19

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

p

z Specified rim and tire

z The brake pedal depressor is installed

z Counterweight the whole vehicle

according to the normal driving

conditions. Adjust the seats to the

middle positions and fill the gasoline

tank full.

2). If the measured values are beyond the tolerance

range, it indicates that the vehicle is faulty, and the

faults must be eliminated before performing the ride

height measurement.

3). For the vehicle with air shock absorbers, please

pull out the security device of the air feeding

equipment to prevent the vehicle from being

adjusted up and down.

4). The sandbags and height measurement meter are

not delivered with the instrument, users should

prepare them by themselves.

Run-out Compensation

This function is to reduce the error caused by the

distortion of the wheel rim and tire. It is advisable to

select this function to ensure measuring accuracy.

The interface is as shown in Fig.4.10.

The icon for the level status

robe rod

of

Previous

Fig.4.10

[Icon for the level status of probe rod]: To indicate the

level status of the present probe rod. Green indicates

the probe rod is level and red indicates not level.

[Previous]: To return to the previous operating

procedure.

Operating procedures:

1. Keep the vehicle wheels on straight-ahead

positions, fix the steering wheel with the steering

wheel holder, remove the brake pedal depressor

to keep the wheels can be freely rotated.

2. Install four wheel clamps and probe rods, and

then adjust each probe rod level respectively.

3. According to the prompts on the screen, start the

run-out compensation operation for LF wheel.

Adjust LF probe rod level, and click [NEXT] after

finished.

4. According to the prompts on the screen, turn LF

wheel by 180°. Adjust LF probe rod level, and

click [NEXT] after finished.

5. According to the prompts on the screen, turn LF

wheel by 360°. Adjust LF probe rod level, and

click [NEXT] after finished.

6. According to the prompts on the screen, perform

the run-out compensation operation for RF, RR

and LR wheel respectively.

7. Put down the vehicle body, keep the four wheels

on the ground. Shake the vehicle body, keep four

wheels cling to the ground, the run-out

compensation operation is finished (The

interface displays the values of run-out

compensation).

Caution:

1. Before performing run-out compensation

operation, be sure to fix the steering wheel

according to the requirements, in order to avoid

the wheels' swing to left or right when performing

run-out compensation operation, causing the

inaccurate run-out compensation.

2. You are required to swing the vehicle tires when

performing the run-out compensation operation.

Keep each probe rod to be at rest comparatively

and level (if some probe rod is not level during

operating, the system cannot perform the next

operation until the probe rod is adjusted level).

3. If the left wheels and right wheels of some

vehicles are linked (i.e. when left wheel rotates,

the right wheel rotates, too), and you want to

perform run-out compensation operation, you

must hold the right (left) wheel when you rotate

the left (right) wheel, and you should notice that

force from you hands must be balanced (in order

to avoid wheel's swing to left and right and

causing inaccurate run-out compensation).

Meanwhile you should check if the probe rods

are level or not. If not, it is necessary to adjust

the probe rods level by the way of rotating the

wheels. You should note that the probe rods

mustn't be adjusted level by the way of loosing

them.

4. If the second-time lift can put up the front and

rear axles at the same time, the front and rear

axles should be put up at the same time when

performing the run-out compensation operations;

if the second-time lift can only put up one axle at

a time, please put up the front axle individually

when performing the front wheel run-out

compensation operations, and put up the rear

axle individually when performing the rear wheel

run-out compensation operations.

5. Three types of run-out compensation operation

modes (90°, 180° and rolling run-out

compensation) can be set on the interface of

[System Management]-[System Setting].

180°run-out compensation mode is a standard

one. It is with high accuracy, and cross reference

between front and rear probe rod is necessary

4-4

Page 20

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

j

for the measurement under this mode; the

accuracy of 90°run-out compensation mode is

comparatively lower, but each probe rod can

finish run-out compensation operation

independently under this mode, needless to take

other probe rod as reference. This run-out

compensation operation mode can be selected in

the case of CCD sensor cannot work normally

caused by second-time lift or other factors; it is

not required to lift up the vehicle during rolling

run-out compensation operation. Only

vehicle-pushing is required to accomplish the

run-out compensation operation. Among the

three kinds of run-out compensation modes

mentioned above, the accuracy of rolling run-out

compensation is lowest.

Vehicle-pushing Run-out Compensation

Vehicle-pushing run-out compensation is mainly used

for getting the inherent parameters of the four wheels

before the normal measurement, so as to ensure the

measurement more accurate. You do not always

perform this operation. If the measurement is

accurate, the user can directly skip this step, and start

from Caster Swing measurement. The interface is as

shown in Fig.4.11:

Fig.4.11

Operating procedures:

1. Turn the steering wheel to make the front wheels

on straight-ahead position. Hold the steering

wheel with the steering wheel holder, and then

remove the brake pedal depressor;

2. Respectively install four wheel clamps and probe

rods, and then adjust each probe rod level;

3. Release all four probe rods respectively, and

push the vehicle back by 45°, and then adjust all

probe rods level. Please click [NEXT] after

finished;

4. Push the vehicle back to the original position,

and then adjust all probe rods level. Please click

[NEXT] after finished.

Caster Swing

Kingpin measurement is aimed at the front wheels,

which includes kingpin inclination and caster. Correct

Kingpin Inclination can equalize the loads applied on

bearings so that the life of bearings can be prolonged

and the controllability of steering is improved. The

existence of kingpin inclination can make the

intersection point of steering axes and road surface

be in front of the adherent point between tire and the

ground, which can make use of the resistance from

the road surface to the tire to keep the vehicle driven

straight-ahead. The interface is as shown in Fig.4.12.

Fig.4.12

Operating procedures:

1. Adjust the steering wheel to straight-ahead status,

i.e. when the toe-in of FL wheel is equal to the

toe-in of RF wheel, the small round ball on the

operating interface will move to middle position

and turn green from red. At this moment you can

adjust all probe rods level.

2. Turn the steering wheel left or right, after arriving

at the desired position, the small ball turns green

again from red. It indicates that the acquisition for

this side is finished.

3. Center the steering wheel, and turn it in reverse

direction, after arriving at the desired position, the

newly created small ball turns green again from

red, and the acquisition is finished.

After test finished, please center the steering

wheel. The system will automatically return to the

next page to check the measurement result. The

interface is as shown in Fig.4.13.

Fig.4.13

[Measurement for Max. steering angle]: According to the

prompts on the screen, read the data of Max. steering

indicated by mechanical turntables for FL and

angles

HELP for vehicle

ustment

ad

Detailed data

4-5

Page 21

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

FR wheels, and input them into the corresponding data

boxes respectively, and then click [Return]. The interface

is as shown in Fig.4.14.

Fig.4.14

[HELP for vehicle adjustment]: Click this button, the

screen will pop up an interface of [HELP for vehicle

adjustment], the different kingpin adjusting methods for

various vehicle models have been enumerated in this

interface for vehicle adjustment, the operator can

perform the kingpin adjustment operation according to

the operating methods in the HELP interface. The

interface is as shown in Fig.4.15

Fig.4.15

[Detailed data]: This interface provides the result outputs

for whole testing operations, which includes the

measured values of each parameter for front and rear

wheels. The interface is as shown in Fig.4.16.

in Fig.4.17.

Language format

Fig.4.17

Caution:

1. Before perform kingpin measurement, please

install brake pedal depressor and lock the hand

brake first, in order to ensure the vehicle wheels

cannot move; remove the steering wheel holder

finally.

2. The steering angle for [Kingpin Steering

Operation] can be set on the interface of [System

Setting]. The standard kingpin measurement is

the measurement of 20-degree-steering. But in

some special cases, 10-degree-steering

measurement can be selected when the steering

angle cannot be up to 20 degrees.

3. The measured values are displayed with different

colors on each measurement interface.

z Green, it indicates that the measured values

are within the standard specifications.

z Red, it indicates that the measured values

are beyond the standard specifications.

z Blue, it indicates that this measured

parameter has not the standard

specification.

Rear axle measurement

This interface can provide the real-time result related to

rear axle measurement, the operator can compare the

measurement result with the reference data while

adjusting the vehicle, until the vehicle is adjusted to the

best status. The interface is as shown in Fig.4.18.

Fig.4.16

[Figure format]: Figure format data display mode is

newly added in the system. Click [Word Format] button

to switch it between Traditional Data Format and

newly-added Figure Format. The interface is as shown

4-6

Double click

HELP for vehicle adjustment

Put up the vehicle body

Fig.4.18

Page 22

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

[Double click]: Double click (with left key of the mouse)

on the data display forms for camber and toe-in of RL

and RR wheels, the corresponding displayed data will

be enlarged. The interface is as shown in Fig.4.19.

Fig.4.21

Fig.4.19

[Additional Measurement]: This interface provides an

operating platform for special measurement, which can

measure and display left lateral offset, right lateral offset,

axle offset, front setback, rear setback, track width

difference and wheelbase difference, etc. The interface

is as shown in Fig.4.20.

Note: The system provides the dynamic measurement

and display for these special values, but the

measurement result will not be saved in the database.

[HELP for vehicle adjustment]: Click this button, the

screen will pop up an interface of [HELP for vehicle

adjustment], the different toe-in and camber adjusting

methods for various vehicle models have been

enumerated in this interface for vehicle adjustment, the

operator can perform the toe-in and camber adjustment

operation according to the operating methods in the

HELP interface. The interface is as shown in Fig.4.22.

Fig.4.20

Click

pushbutton to select the parameters of

standard vehicle model. If the parameter values of

wheelbase and front/rear track width are contained in

the standard database, each angle value displayed on

the screen will automatically be converted into length

value with the unit of mm. The interface is as shown in

Fig.4.21.

Fig.4.22

[Lift up the vehicle body]: Sometimes it is required to lift

the vehicle body up in order to be convenient to adjust

front/rear camber and caster.

When the vehicle wheels are lifted up, the inclinometers

will move, and the corresponding measured values will

change, too. In this case, please use Lifting Adjustment

function. Click

button, and then lift up the vehicle

body according to the prompts on the screen. The

software will automatically compensate the offset of

inclinometer in order to realize accurate adjustment.

4-7

Page 23

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

j

on the data display forms for camber and toe-in of LR

and RR wheels, the corresponding displayed data will

be enlarged.

[Additional measurement]: This interface provides an

operating platform for special measurement, which can

measure and display left lateral offset, right lateral

offset, axle offset, front setback, rear setback, track

width difference and wheelbase difference, etc.

[Toe-in adjustment for the front wheel steering]: Click

to perform toe-in adjustment for front wheel

Fig.4.23

Attention: After adjustment, please remember to click

button, and then put down the vehicle body

according to the prompts on the screen. If the lift is not

put down, it will be limited to select the other interfaces

(except for [Front axle measurement] interface) as

shown in Fig.4.24.

Fig.4.24

Front axle measurement

This interface can provide the real-time result related to

front axle measurement, the operator can compare the

measurement result with the reference data while

adjusting the vehicle, until the vehicle is adjusted to the

best status. The interface is as shown in Fig.4.25.

Double click

HELP for vehicle

ustment

ad

Lift up vehicle body

steering, and click

to center the steering wheel

(Note: When using two probe rods to perform the

measurement operation, only total toe-in is displayed,

and individual toe-in is not displayed).

[HELP for vehicle adjustment]: Click this button, the

screen will pop up an interface of [HELP for vehicle

adjustment], the different adjusting methods for various

vehicle models have been enumerated in this interface

for vehicle adjustment, the operator can perform the

vehicle adjustment operation according to the

operating methods in the HELP interface.

[Lift up vehicle body]: Sometimes it is required to lift the

vehicle body up in order to be convenient to adjust

front/rear camber and caster. When the vehicle wheels

are lifted up, the inclinometers will move, and the

corresponding measured values will change, too. In

this case, please use Lifting Adjustment function. Click

button, and then lift up the vehicle body

according to the prompts on the screen. The software

will automatically compensate the offset of inclinometer

in order to realize accurate adjustment.

Attention: After adjustment, please remember to click

button, and then put down the vehicle body

according to the prompts on the screen

[Toe-in curve change] provides the special

measurement methods relative to some vehicle models

of VOLKSWAGE and AUDI, etc. First, the operator

must adjust the toe-in curve changes of these kinds of

vehicles to the standard range, and then Front Axle

Measurement can be performed normally. When

[Toe-in Curve Change] is activated, please click the

icon of

, the screen will display the interface as

shown in Fig.4.26.

Additional measurement

Toe-in curve change

Fig.4.25

[Double click]: Double click (with left key of the mouse)

4-8

Page 24

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

5. Put down the vehicle to position B1. Adjust the

vehicle front toe-in to the allowed scope according

to the standard specifications. The interface is as

shown in Fig.4.29:

Fig.4.26

Operating Methods:

1. Click [Toe-in Curve Change] on the interface of

[Front Axle Measurement] to enter Toe-in Curve

Change interface as shown in Fig.4.24.

2. According to the prompts on the screen, please

select the appropriate vehicle adjustment tools by

the way of referring to the vehicle adjustment

HELP information for the front toe-in curve change

regulator. Please perform the next operation

procedure after finished.

3. The vehicle is now in put-down status (position B1).

Adjust the vehicle front toe-in to the allowed scope

according to the standard specifications (see

Fig.4.25). Put up the vehicle with the special tools

equipped according to the prompts on the screen.

Click [NEXT] button, the screen will display the

interface as shown in Fig.4.27.

Fig.4.29

6. Put down the vehicle, and then click

button to return to the interface of [Front Axle

Measurement].

Attention: After adjustment, please remember to click

button, and then put down the vehicle body

according to the prompts on the screen. If the lift is not

put down, it will be limited to select the other interfaces

(except for [Rear axle measurement] interface) as

shown in Fig.4.30.

Fig.4.27

4. Put up the vehicle (to position B2) according to the

requirements of the manufacturer. The screen

display the interface as shown in Fig.4.28:

Fig.4.28

Fig.4.30

Print Report

Print Report can print and save the alignment data of

the vehicle under test. The interface is as shown in

Fig.4.31.

4-9

Page 25

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

Client information

Fault cause

Vehicle license plate number

Save

Print

Fig.4.31

[Vehicle license plate number]: The license plate

number of the vehicle under test.

[Client information]: The corresponding information for

the owner of the vehicle under test, including [Client

name], [Contact], [Telephone] and [Address]. The client

information cannot be directly entered in this interface

with the keyboard. Icon

behind [Client name] must

be clicked to enter the interface of [Client Management],

and then the corresponding [Client information] can be

selected. If information of this client is not available in

[Client Management], it must be added first before

selection (Please refer to [Configuration] – [Client

management]).

[Vehicle information]: The corresponding information of

the vehicle under test, including [Mileage],

[Manufacturer], [Model], [Start year] and [End year].

The vehicle information cannot be directly entered in

this interface with the keyboard. If the vehicle model

has been selected in [Measurement] – [Select vehicle

model], the corresponding information of the vehicle

model selected will be displayed in this interface. If not,

no any information is displayed in this interface.

[Operator]: Name of the operator who is operating

the instrument now. The corresponding [Operator] can

be selected only after the [Operator] column of

[Information for service station] is added (Please refer

to [System management] – [User information]).

[Fault cause]: The symptoms of the vehicle under test.

There are 5 options: [Tire wear], [Pull], [Steering wheel

is not centered], [Steering wheel swings] and [Others].

[Save]: To save the alignment data of the vehicle under

test ([Vehicle plate number] and [Client name] must be

entered, and [Fault cause] must be selected first before

saving).

[Print]: To print the alignment data of the vehicle under

test in the format of form or image (Please refer to

[System management] – [Report setting] for the format

setting of the report form).

Caution: The report form print function provided by this

interface only aims at the individual information report

form for the test at this time; the report form print

function provided by the main interface aims at all the

information report forms saved and done before.

Quick Measurement

Select [Quick measurement] icon on the main menu,

the system will enter the [Quick measurement]

interface. This interface provides an operating platform

for quick measurement, which can test and display

toe-in and camber of front and rear wheels at the same

time. The interface is as shown in the following figure:

Figure format

Select Vehicle Model

Print report

Fig.4.32

[Select Vehicle Model]: You can select the parameters of

standard vehicle models to be convenient for vehicle

adjustment (Please refer to [Standard

Measurement]-[Select Vehicle Model]);

[Print Report]: To provide the functions for saving and

printing the test data (Please refer to [Standard

Measurement]-[Print Report]).

[Figure Format]: It is the data display interface which can

be switched to Figure Format. The fig-format data

display interface provides the display for thrust angle.

The interface is as shown in Fig.4.33.

Fig.4.33

Note:

4-10

Page 26

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

1. This interface provides only the functions of the test

and adjustment for front and rear toe-in and camber.

For other functions, please select them on the

interface of [Standard Measurement].

2. The default unit for toe-in on this interface is

centigrade. Only the vehicle model data is selected,

can the display unit for toe-in be in accordance with

the toe-in unit set on the interface of System

Management]-[System Setting].

3. Only the vehicle model data is selected, can the

measured values be saved in the interface of [Print

Report].

Special Note: During [Caster Swing], [Rear Axle

Measurement], [Front Axle Measurement] and [Quick

Measurement], if the sensor is blocked, it is

necessary to perform the settings for low-chassis

vehicle. The interface is as shown in Fig.4.34.

[Select Vehicle Model]: Click this button to select the

parameters of standard vehicle model. If the parameter

values of wheelbase and front/rear track width are

contained in the standard database, each angle value

displayed on the screen will automatically be converted

into length value with the unit of mm.

Caution:

The system provides the dynamic measurement and

display for these special values, but the measurement

result will not be saved in the database.

System Measurement

On the main menu, please click the icon of [System

Measurement] to enter the measurement interface as

shown in Fig.4.36.

4.34

This setting can be automatically reset when

re-selecting the vehicle model or exiting the test system.

Caution: After the probe rod's position dropped, the level

adjustment should take the electronic level as the

standard.

Additional Measurement

This interface provides an operating platform for

special measurement, which can measure and display

left lateral offset, right lateral offset, axle offset, front

setback, rear setback, track width difference and

wheelbase difference, etc. The interface is as shown in

Fig.4.35.

Select Vehicle Model

Fig.4.36

User information

<>

The information of maintenance station is mainly used

to record the contact method of the maintenance

station and the information of the maintenance

technician. This kind of information can be imported to

report forms, which can make the information of

maintenance station be displayed on the report form

printed out, and is convenient for your data

management and tracing operation. The interface is as

shown in Fig.4.37.

Fig.4.35

Fig.4.37

[Setting]: After entering this interface, the information

box will be displayed with French gray back-ground, in

4-11

Page 27

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

this state the system only provides view function.

Click

button to perform information editing

operation.

After entering the information, please click

button,

the system will automatically save the information and

return to the previous interface.

Note: If there are multi-operators for performing wheel

alignment, the input method of recording or saving the

operators' names is using "#" to separate every

operator's name. For instance,

Tom#John#Paul#Steven#.

Client management:

Client information is very important in our daily routine,

so we must manage and maintain these data very well,

which can ensure us to solve the problem in time and

improve our service quality. The interface is as shown

in Fig.4.38.

[Delete]: Delete the items selected in client information

data form. When performing Delete operation, please

note that Delete operation will delete all the

corresponding information (including previous testing

information) of client. Ensure that you do want to delete

the information before performing Delete operation.

[Print]: Print client information data form.

The input box for Quick search aiming at the vehicle

model provided at the bottom of the interface

OEM Specs

This interface provides the parameter information

(These parameter information has been set before the

vehicles leave factory) for the vehicles with various

models. The database contains the information of

various kinds of vehicles manufactured by many

manufacturers all over the world, and the contents in

database can be updated in time via system upgrade.

In addition, this interface provides the function of

adding the user-defined data. The operator can add by

him-self (or her-self) all the vehicle model information

which the standard database does not has. This

system is fit more for the service data application.

The interface is as shown in Fig.4.40.

Fig.4.38

[Quick search]: Directly input the first letter of the

customer name in the text box, the system will

automatically perform the search operation.

[Add]: Click this button, and then add the client

information in the pop-up window for detailed

information of the client. The interface is as shown in

Fig.4.39.

Fig.4.39

[Modify]: Select the items required to modify, and then

click this button, modifying the client information in the

popped-up window for the detailed information of client.

Quick search for model

Modify

Newly added

Delete

Fig.4.40

[Search for model]: To provide the function of Quick

search for vehicle model. Directly input the first letter of

the model name of the vehicle under test in the text

box, the system will automatically perform the search

operation.

[Newly added]: To add the vehicle models which are

not included in the standard database. Click this button,

you can add the user-defined information in the

popped-up window (as shown in the following figure)

for the detailed information of the user-defined data.

After confirming, you can save the information into the

data list.

4-12

Page 28

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

A

and display effect of software system. The interface is

as shown in Fig.4.43.

Fig.4.41

[Modify]: This function is only applied to modifying the

user-defined information in the list. It cannot modify the

information imported from the standard data.

[Delete]: This function is only applied to deleting the

user-defined information in the list. It cannot delete the

information imported from the standard data.

Operating procedures:

Directly click manufacturer to select corresponding

vehicle model, in order to give the operator a

convenient view for the standard data of the vehicle

model.

Frequent Model

In order to speed up the information search, the system

provides the commonly used data management

function which can individually add the vehicle

information in the standard data into the commonly

used data. The interface is as shown in Fig.4.42.

dded from the standard data

Delete

Fig.4.42

[Added from the standard data]: Click this button, the

standard data window will be activated. Select the

required vehicle model from the standard data list. After

confirming, the information can be added from the

standard data to the commonly used data list.

[Delete]: Delete the items selected from the commonly

used data.

System Setting

System setting function is used to adjust the function

Fig.4.43

[Basic setting]: With this function the system can be

switched between Normal Version and Demo Version,

and between Special Version and Common Version.

[Normal version]: is the version directly applied in

actual testing operation; [Demo version]: this version

can, in stand-alone status, simulate the testing process

without external hardware equipments, it hasn't testing

ability, only used to demonstrate the testing process;

[Common version]: this version provides all-around

HELP information and operating demo animation to

fully help the testing personnel who contacts this

system for the first time; [Special version]: for

experienced operator, too much HELP information will,

on the contrary, become encumbrance, so this

version provides the necessary HELP information only

to make the operator be working with more high

efficiency.

[Normal mode]: It is a default mode, and used in the

case of no direct sunlight or strong ground reflection

light.

[Strong light mode]: It is used when there is direct

sunlight or strong ground reflection light.

[Setting for run-out compensation]: the system provides

three types of run-out compensation: 1) 180-degree

compensation (turning for 2 times) 2) 90-degree

compensation (turning for 4 times) 3) Rolling run-out

compensation.

[Setting for kingpin steering operation]: the system

provides two types of kingpin measurement: 1)

Steering wheel turns by 20 degrees; 2) Steering wheel

turns by 10 degrees.

[Probe rod calibration setting]: you can select all CCD

sensors or end CCD sensor to calibrate

[Probe rod setting]: When one pair of front probe rods

or rear probe rods is faulty, you can use the normal pair

of probe rods to finish the part of the test items. For

example, all four probe rods are used in normal case.

When front probe rods are faulty, you can select “Use

rear probe rods” to tell the system only to use rear

probe rods to perform the test.

4-13

Page 29

LAUNCH X-631/X-631+ Wheel Aligner Operation Instructions

[Unit setting]: Used to set the displayed unit system of

system data, two types of unit systems can be selected:

percentage degree system and degree/minute system.

[Unit setting for toe-in]: Aiming to the particularity of the

unit for toe-in, the system adds the units of mm and

inch.