Page 1

V1.01.000

2015-09-23

Page 2

LAUNCH X-831M Wheel Aligner Installation and Parts Manual

Trademark Information

LAUNCH is a registered trademark of LAUNCH TECH.

CO., LTD. (LAUNCH for short) in China and other

countries. All other LAUNCH trademarks, service marks,

domain names, logos and company names referred to in

this manual are either trademarks, registered

trademarks, service marks, domain names, logos and

company names of or otherwise the property of

LAUNCH or its affiliates. In other countries where any of

the LAUNCH trademarks, service marks, domain names,

logos and company names are not registered, LAUNCH

claims other rights associated with unregistered

trademarks, service marks, domain names, logos, and

company names. Other products or company names

referred to in this manual may be trademarks of their

respective owners. You may not use any trademarks,

service marks, domain names, logos, or company

names of LAUNCH or any third party without permission

from the owner of the applicable trademarks, service

marks, domain names, logos, or company names. You

may contact LAUNCH at http://www.cnlaunch.com, or

write to LAUNCH Industrial Park, North of Wuhe Rd.,

Banxuegang, Longgang, Shenzhen, Guangdong, P. R.

China, to request written permission to use Materials on

this manual for purposes or for all other questions

relating to this manual.

General Notice

Other product names used herein are for identification

purposes only and may be trademarks of their

respective owners. LAUNCH disclaims any and all rights

in those marks.

Copyright Information

Copyright © 2015 by LAUNCH TECH. CO., LTD. All

rights reserved. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted

in any form or by any means of electronic, mechanical,

photocopying and recording or otherwise without the

prior written permission of LAUNCH. The information

contained herein is designed only for the use of this unit.

LAUNCH is not responsible for any use of this

information as applied to other units.

Neither LAUNCH nor its affiliates shall be liable to the

purchaser of this unit or third parties for damages,

losses, costs, or expenses incurred by purchaser or third

parties as a result of accident, misuse, or abuse of this

unit or unauthorized modifications, repairs or alterations

to this unit or failure to strictly comply with LAUNCH

operating and maintenance instructions.

LAUNCH shall not be liable for any damages or

problems arising from the use of any options or any

consumable products other than those designated as

Original LAUNCH Products or LAUNCH Approved

Products by LAUNCH.

i

Page 3

LAUNCH X-831M Wheel Aligner Installation and Parts Manual

Precautions

Please read the User’s Manual and the Installation

and Parts Manual carefully before operating

X-831M Wheel Aligner.

Only the qualified technician can operate the

Wheel Aligner.

The operator must have knowledge of computer

application and basic theory of wheel alignment.

The power voltage of X-831M wheel aligner is of

AC220V±10% 50±1Hz / AC110V±10% 60±1Hz(It

can be customized according to the requirements

of customer). The 3-terminal socket must be used,

and the earth terminal must be well grounded. If

the power voltage is not stable, please purchase

and use AC voltage stabilizer.

Before installing the wheel aligner, the lift should

be installed at first according to the requirements.

Regularly check the lift for fastening and leveling,

ensuring the test accuracy and personnel safety;

Take away the roadblocks around the lift to prevent

influencing operation.

Don’t install X-831M on a vibrated object or an

oblique surface. Avoid direct sunlight and moisture.

Turn off the power after operation. Check all bolts

and parts after maintenance, and tighten the

slackened bolts and parts in turn for safety.

Since computer visual technology is used in

recognizing the targets mounted on the wheels

through the camera with high resolution, it is

necessary to keep X-831M wheel aligner away

from the outside infrared rays (e.g. sun-lights) from

directly lighting to the targets and reflecting to the

cameras. It is also necessary to avoid blocking the

light way from the targets to the cameras for a long

time during the instrument is working.

The targets of X-831M wheel aligner are the key

components for testing. Do not damage their

structures when using and storing. Keep the

surface of target clean. Please use the soft cloth

dipped with an appropriate amount of the neutral

detergent or the absolute alcohol to wipe the

surface of target lightly if there are some smuts on

it.

When using and storing, please pay much

attention to prevent water from entering into the

targets.

The wires inside the post and the lateral beam are

connected compactly. Don’t move them after first

installation.

The precision position calibration has been

performed for the cameras after first installation,

the user can not move or wobble the post or lateral

beam during or after using it.

Without approval of the supplier, please do not

disassemble the post and the lateral beam in order

to avoid damaging the components, influencing the

test accuracy and increasing the costs and

difficulties of maintenance and repair. For the

damage caused by unauthorized disassembling

will not be covered by the Warranty.

The fastening method should be selected correctly

and flexibly according to the actual conditions of

the rim, the turning force should be equal when

fastening, after fastening, please check the wheel

clamp again.

The force should be equal when using each knob,

please don’t fasten it too tight in order to avoid

damaging the locking mechanism or other parts.

After using, please cut off all power supply timely.

The cameras of X-831M wheel aligner are the key

optical components for testing. Do not impact them

when using, keep the surface of the camera lens

clean. Please use the lens paper to wipe the

surface of the camera lens lightly if there are some

smuts on it.

ii

Page 4

LAUNCH X-831M Wheel Aligner Installation and Parts Manual

Table of Contents

General Information ..................................................... 1

Brief Installation Introduction ..................................... 1

Precautions before Installation .................................. 1

Installation Tools ........................................................ 1

Power Supply Requirement ....................................... 1

Unpacking ..................................................................... 2

Post/Beam Box .......................................................... 2

Accessory Carton ...................................................... 2

Cabinet Carton ........................................................... 2

Main Component Structure and Parts List ................ 3

Complete Set Structure and Components List........... 3

Structures of Main Components ................................ 4

Post assembly ....................................................... 4

Lateral beam assembly ......................................... 6

Front target assembly ............................................ 7

Rear target assembly ............................................ 8

Components Structure ................................................ 9

Overall Structure ........................................................ 9

Post Assembly ........................................................... 9

Cameras and Lateral Beam Assembly....................... 9

Cabinet ...................................................................... 9

Targets and Wheel Clamps ........................................ 9

Turntables and Transition Bridges ............................. 9

Installation and Adjustment ...................................... 11

Install X-831M Wheel Aligner ................................... 11

Check One by One if the Spot Meets the

Requirements according to Spot Inspection Item

Table before Installation ...................................... 11

Confirm the Installation Position .......................... 11

Install Post Assembly and Lateral Beam Assembly

............................................................................ 11

Adjust the Computer Host ........................................ 12

Calibration for Installation ........................................ 12

Camera Calibration ............................................. 14

Target Calibration ................................................ 15

Precautions and Solutions ........................................ 17

Common Problems and solutions in Installation ...... 17

Precautions .............................................................. 17

Spot Inspection Item Table before Installation ........ 18

iii

Page 5

LAUNCH X-831M Wheel Aligner Installation and Parts Manual

Iron hammer, > 2kg;

General Information

Special caution: All the operations mentioned in this

manual should be performed by the qualified

technical personnel trained by Launch for X-831M

Wheel Aligner!

Cable drilling tool, Φ16 drilling bits;

Monkey wrench, medium size, 20cm;

Lineation chalk;

Hexagon ring spanner, M4—M6;

Cross screw driver, medium size;

Installation sets (including installation bolts, etc.).

Power Supply Requirement

Brief Installation Introduction

This installation manual is only suitable for the

installation of X-831M wheel aligner (post type)

manufactured by Launch, this type of wheel aligner

mainly includes two installation components: the post

assembly and the lateral assembly. For easy use and

measurement, the following four factors should be taken

into consideration during installation:

Horizontal distance from the center of the turntable

on the lift to the post;

Installation height of camera;

Distance between left and right camera;

Camera installation inclination degrees.

The operator must have knowledge of computer

application and basic theory of wheel alignment.

The post height of the wheel aligner is 2653mm, and the

working height of the lift is between 0~1800mm. Correct

installation is very important to the alignment

performance and the types of the vehicle that can be

aligned, please do read this manual carefully.

X-831M wheel aligner is a precise computer system that

needs AC220V±10% 50±1Hz / AC110V±10% 60±1Hz

power supply. Good ground helps to protect the

equipments and persons. If power supply cable needs to

be lengthened, its load must not be less than 220V 8A.

So in order to protect electronic products such as

X-831M Wheel Aligner, it is advisable to use AC power

supply voltage stabilizer.

Note:

Installation engineer must confirm that power

supply satisfies the above-mentioned requirements

before switching the wheel aligner on.

Precautions before Installation

Spot Inspection Item Table before Installation must be

provided by business personnel before installation. It is

convenient for installation engineer to learn beforehand

if the spot satisfies the use requirements of the wheel

aligner and then select suitable installation position.

Working flow:

If there is no Spot Inspection Item Table before

Installation, please fill out another kind of the table.

Every measurement must be marked correctly

(very important) and confirmed by technical service

personnel.

Solve the problems met in the process of filling out

the table first and then perform the installation

operation.

During installation, please abide by the advice and

requirements of this manual strictly. Please contact

the technical support engineers for help if

necessary. To install the wheel aligner together with

lift, mark out the spot according to the Spot

Inspection Item Table before Installation, install and

adjust the lift first and then install the wheel aligner.

Installation Tools

Tools needed in X-831M wheel aligner installation are:

5m tapeline, accuracy: 1mm;

1

Page 6

LAUNCH X-831M Wheel Aligner Installation and Parts Manual General Information

Unpacking

X-831M wheel aligner is packed in three separated

boxes: a post/beam wooden box, an accessory carton

and a cabinet carton.

Post/Beam Box

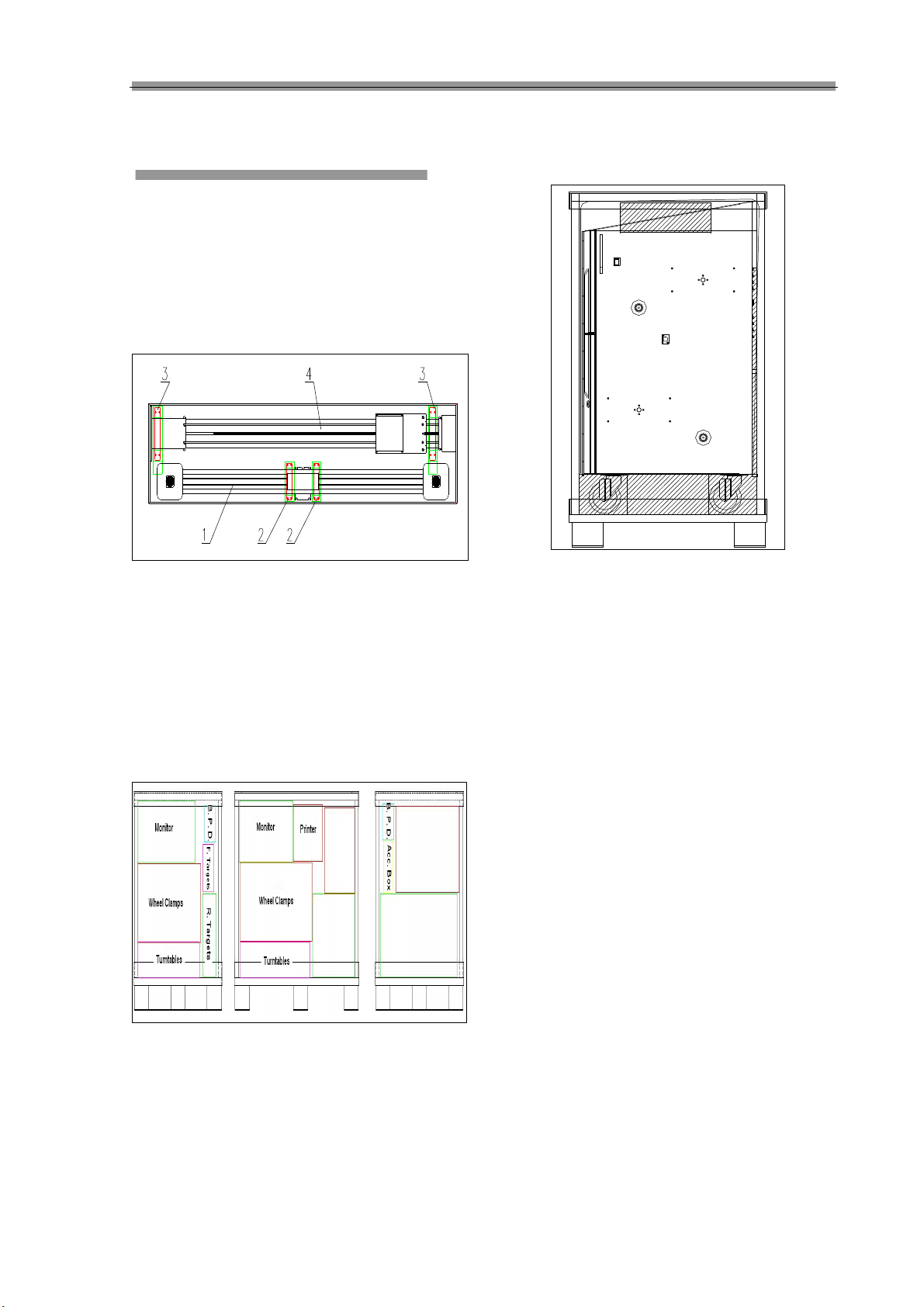

For unpacking of the post/beam box, please take Fig.2.1

as reference. The post assembly and the lateral beam

assembly are contained in this wooden box.

Fig. 2.1

1. Lateral beam; 2. Lateral beam fastening iron

sheets; 3. Post fastening iron sheets; 4. Post

Accessory Carton

Two front targets, two rear targets, two mechanical

turntables, printer, four wheel clamps, four wheel clamp

hanging brackets, monitor, brake pedal depressor and

steering wheel holder, etc. are packed in one package

box as shown in Fig. 2.2.

Fig. 2.2

Cabinet Carton

For cabinet box, please take Fig. 2.3 as reference. The

communication cables and the computer host are inside

the cabinet. The User’s Manual and Installation and

Parts Manual are contained in cabinet drawer.

Fig.2.3

2

Page 7

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Parts List

ERP Code

04

05

Monitor

Cabinet

Main Component Structure and Parts List

Complete Set Structure and Components List

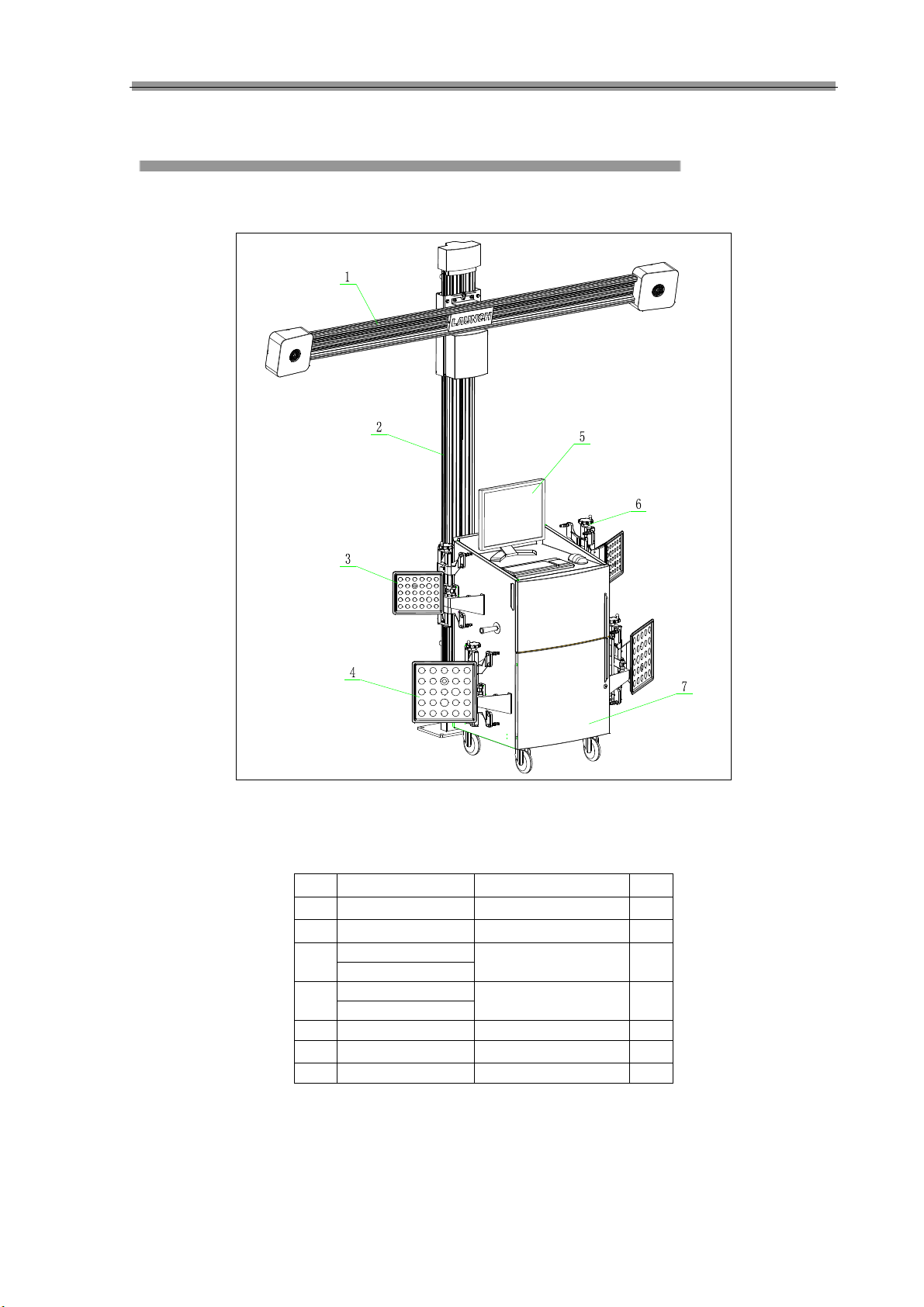

Fig.3.1

Components List (Note: Take the parking list as the criterion)

No.

206010597

01

206010599

02

206010590 (FL)

03

206010591 (FR)

206010592 (RL)

206010593 (RR)

108020021

103250250

06

07 206010598

Lateral beam assembly

Post assembly

Front target assembly

Rear target assembly

Wheel clamp

Part Name Qty

1

1

2

2

1

4

1

3

Page 8

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Parts List

Structures of Main Components

Post assembly

Fig. 3.2

4

Page 9

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Parts List

No. ERP Code

Part

/Component

Qty. No. ERP Code

Part

/Component

Qty.

Post base plate

Stud,

GB/T901

-

1988

,

Cover shape nut,

Plain washer,

Half round head square

Spring washer,

Electric motor cover

Hexagon nut,

Inner hexagon column

Position

-

limited block

Plain washer,

Position

-

limited rolling

Hexagon nut,

Pull rope

Zinc alloy bearin

g with

Stud,

GB/T901

-

1988

,

Inner hexagon column

Hexagon lock nut,

Spring washer,

Inner hexagon column

Plain washer,

Gear

Electric motor bracket

Speed reducing motor

Pulley bracket

Gear rack

Pulley

Aluminum post

Post top cover

Inner hexagon column

Parts and components list of post assembly:

P01 103209008

P02

P03

P04 103209007

P05

P06

P07

P08 103070029

P09

P10

P11

P12 103209006

P13 103209009

P14 103209014

P15 103209010

Name

GB/T923-1988, M8

neck bolt, GB/T12-1988,

MN8*15

head screw,

GB/T70.1-2000, M5*15

GB/T95-2000, 5

GB/T6170-2002, M5

base, KFL08

head screw,

GB/T70.1-2000, M8*15

GB/T93-1987, 8

GB/T95-2000, 8

1 P16

8 P17

8 P18

1 P19

3 P20 104011559

2 P21 104011558

2 P22 101060029

1 P23

4 P24

4 P25

12 P26 103209011

1 P27 102990275

1 P28 103209012

2 P29 103230287

1 P30

Name

2

M10*60

4

GB/T95-2000, 10

4

GB/T93-1987, 10

4

GB/T6170-2002, M10

4

4

wheel

1

4

M8*90

8

GB/T889.1-2000,M8

21

head screw,

GB/T70.1-2000, M4*10

1

1

1

1

1

head screw,

GB/T70.1-2000, M10*25

5

Page 10

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Parts List

No. ERP Code

Part

/Component

Name

Qty.

Camera cover

Aluminum lateral beam

Front decoration plate

Decoration support plate

Cross recessed countersunk head screws,

GB/T819.1

-

2000, M4*10

Aluminum alloy support plate

Camera assembly

Outer casing cover plate

Seal bar

Lateral beam bracket

Half round head square neck bolt,

GB/T12

-

1988, M8*15

Cover shape nut,

GB/T923

-

1988, M8

Inner hex

agon column head screw,

GB/T70.1

-

2000, M4*10

Lateral beam assembly

Parts and components list of lateral beam assembly:

B01 103209016

B02 103230288

B03 103209018

B04 103209019

B05

B06 101050117

B07 08990014

B08 103209017

B09 104011560

B10 103209015

B11

B12

B13

Fig.3.3

2

1

1

1

2

2

2

2

4

1

18

18

4

6

Page 11

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Parts List

No. ERP Code

Part

/Component

Name

Qty.

Target label

Front

target casing

Hexagon plane end set screws,

GB/T77

-

2000, M5*12

Target pin shaft

Plain washer,

GB/T95

-

2002, 14

Standard spring washer,

GB/T93

-

1987, 14

Hexagon nut,

GB/T6170

-

2000, M14

Front

target pan

Front target assembly

Parts and components list of front target assembly:

F01 107022380

F02 104011261

F03 103010266

F04 103203283

F05 103040021

F06 103040200

F07 103030140

F08 101050118

Fig. 3.4

1

1

1

1

1

1

1

1

7

Page 12

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Parts List

No. ERP Code

Part

/Component

Name

Qty.

Target label

Rear target

casing

Hexagon plane end set screws,

GB/T77

-

2000, M5*12

Target pin shaft

Plain washer,

GB/T95

-

2002, 14

Standard spring washer,

GB/T93

-

1987, 14

Hexagon nut,

GB/T6170

-

2000,

M14

Rear target pan

Rear target assembly

Parts and components list of rear target assembly:

F01 107022380

F02 104011262

F03 103010266

F04 103203283

F05 103040021

F06 103040200

F07 103030140

F08 101050119

Fig. 3.5

1

1

1

1

1

1

1

1

8

Page 13

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Components Structure

keyboard drawer. Printer is on the drawer in the middle

Components Structure

Overall Structure

The X-831M wheel aligner mainly consists of computer

host, monitor, lateral beam assembly, post assembly,

cabinet, front targets, rear targets, wheel clamps, wheel

clamp ties, turntables, steering wheel holder and brake

pedal depressor etc.

of the cabinet. The computer host is in the lower

compartment of the cabinet.

The power supply assembly includes power lead, power

socket, switch, and switch power. The power switch is at

the sideboard of cabinet. The power lead is at the rear of

the lower compartment inside the cabinet. The power

socket is at the spacer board and near to the sideboard.

The switch power supply is also on the backboard of the

cabinet.

Post Assembly

X-831M wheel aligner post assembly mainly consists of

Aluminum post, post base, electric motor bracket and

pulley bracket, etc.

Cameras and Lateral Beam

Assembly

X-831M wheel aligner includes 2 high definition cameras,

which respectively capture the images from the 4 targets

attached on the vehicle wheels. The cameras are

mounted inside the lateral beam, one on left side and

another on right side. The accurate adjustment for

camera has been performed during first installation, so it

is not necessary for user to adjust it when using the

instrument.

The lateral beam assembly of X-831M wheel aligner

mainly consists of two sets of camera assemblies, one

switch power supply, one main control board and its

signal/power cables.

Note: During or after using, ensure to prevent the

post/lateral beam from swaying, otherwise the

position of camera will be changed, influencing the

accuracy of test result.

Cabinet

The cabinet assembly of X-831M wheel aligner is an

operation control platform. It consists of cabinet,

computer group, interface circuit, power supply

assembly, etc., as shown in Fig.4.1.

Targets and Wheel Clamps

X-831M wheel aligner totally has 4 target-clamp

assemblies, which are key components for whole test

system, and are the objects monitored by cameras.

There are some bull-eye signs on the targets as shown

in Fig. 4.2.

Fig. 4.2

Whether the wheel clamps are fastened correctly or not

has the great relations with the test result. Turn the

adjusting knob to adjust the span between wheel claws

until it is proper, and then attach the clamp to the wheel

rim. Adjust the knob to make the wheel clamp fixed on

wheel rim tightly. Use the wheel clamp tie to bind the

wheel clamp and the wheel rim together.

The installation of wheel clamp is crucial to the test

result. The claws should be in even contact with the

wheel rim without touching the lead weight.

Avoid hitting during operation. Otherwise, distortion may

be caused and the test result may be influenced.

Turntables and Transition

Bridges

Fig.4.1

The computer group includes computer, monitor,

keyboard, mouse, and printer. The monitor is on the top

platform of the cabinet. Mouse and keyboard are on the

X-831M wheel aligner has two mechanical turntables

(standard configuration, see Fig. 4.3):

Fig 4.3

9

Page 14

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Components Structure

The turntables are placed at the front wheel positions of

the vehicle on the lift.

Use the lock pin to lock the turntable before driving the

vehicle on. Pull out the lock pin after the vehicle is

stopped and the front wheels are at the centers of the

turntables.

While testing, try your best to keep the vehicle front

wheels at the centers of the turntables.

Each turntable is equipped with a transition bridge,

which is placed between the turntable and lift, to ensure

the wheel on the turntable move reposefully.

10

Page 15

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Installation and Adjustment

1. Confirm the lift height

Installation and

Adjustment

Professional technical personnel are responsible for the

installation and calibration of X-831M Wheel Aligner.

Users need not to do these but to provide installation

conditions as follows: X-831M wheel aligner is a type of

three dimensions infrared image wheel aligner, and it

should be used indoors without strong infrared light

irradiating directly. So it is best to be installed indoors.

Install X-831M Wheel Aligner

Check One by One if the Spot Meets the

Requirements according to Spot Inspection

Item Table before Installation

Confirm that the lift has been installed and adjusted well

before installing X-831M Wheel Aligner. Generally

speaking, the spot which meets the installation

requirements for the lift, also can meet the requirements

for the ground where the X-831M wheel aligner is

installed. If not, in some special cases, it is required to

lay a new foundation for X-831M wheel aligner in

designated place (poured with more than 200# concrete,

800mmx800mmx400mm); keep the installation plane of

the foundation flush to the ground level where the lift is

installed, and keep the level degree of the installation

plane within 3mm; after the whole foundation is poured

well, appropriate maintenance work should be

performed, and it can be used after completely

concreted and dried.

The present working height of the lift is of the height

between ground and turntable upper end surface

center.

2. Confirm the post installation center line

Obtain two center points by measuring front and

rear widths between two lift runway rails. Connect

these two points to confirm the center line of the lift,

lengthen the line in the direction of post.

3. Confirm the post base line B

Confirm line B according to the positions of two

turntables. Make sure that this base line is parallel

to turntable center line and vertical to lift center line.

The distance between line B and the turntable

center line is 1900~2800mm.

4. Place the post on the ground vertically and drill on

the ground by cable drilling tool according to the

installation holes on the post pedestals and then

install the anchor bolts. During installation make

sure that the post is vertical to the ground and the

lateral beam is in level status.

Install Post Assembly and Lateral Beam

Assembly

Caution:As shown in Fig.5.2, do remember to install

screw M10*25 in order to fasten the counterweight

rod during shipping, and do remember to remove

the screw M10*25 before equipment first installation,

otherwise the equipment will not run normally!

Confirm the Installation Position

The position relationship of post and lift is as shown in

Fig.5.1.

Fig 5.1

Screw M10*25

Fig.5.2

1. Lay the post near the installation place as shown in

Fig.5.3.

Fig.5.3

11

Page 16

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Installation and Adjustment

up down

M

ain

board

Data cables

Power

cables

Data

inter

faces

Power

interfac

es

Power

cable

from cabinet

Data cable

from cabinet

2. Remove the electric motor cover as shown in

Fig.5.3.

3. Adjust the electric motor bracket assembly to the

middle of the post. The specific operation

procedures are as follows:

a. Switch on the cabinet power supply;

b. Connect the mainboard power cable from the

cabinet to the power supply interface at the lower

end of the mainboard as shown in Fig.5.4.

power supply

interface

Fig.5.4

c. Use the key “down” (as shown in Fig.5.5) to

control the electric motor bracket assembly moving

to the middle position of the post.

6. Connect the two power cables and the two USB

data cables from the lateral beam to the interfaces

at the upper end of the mainboard. Connect the

mainboard power cable and the USB data cable

from the cabinet to the power supply interface and

USB data interface at the lower end of the

mainboard as shown in Fig.5.7.

Fig.5.7

7. After the power cables and data cables are all

connected well, please reset the electric motor

cover and fasten it with the four screws.

Fig.5.5

4. Stand the post and fasten it on the ground.

5. Start installing the lateral beam as shown in Fig.5.6.

Remove the four M8*15 screws on the electric

motor bracket; Install the lateral beam on the

middle position of the post.

Screw M8*15

Fig.5.6

Caution: It is required to use inner hexagon

spanner when performing the installation

operation.

Adjust the Computer Host

1. Adjust the computer host before operating X-831M

Wheel Aligner.

2. Connect the main power cable to the power socket

(220V AC), press down the indicator switch to

power the main unit.

3. Press down the power supply switch to start the

computer. The system will automatically enter the

software operating system.

4. Press down the power supply switch of the printer.

Print the test page to see if it is normal.

5. The adjustment for the computer host is successful

if all the above steps are normal. Exit X-831M

wheel aligner software operating system and the

computer will automatically shut down.

Calibration for Installation

Note: Under normal circumstances, please do not

perform the calibrating operations. The “front left,

rear left, front right, rear right” mentioned in this

manual refers the orientation when the driver faces

to the cameras.

12

Page 17

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Installation and Adjustment

Fig 5.8 Installation calibration diagram

13

Page 18

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Installation and Adjustment

down the spring snap, and then click [OK] icon. The next

Camera Calibration

interface is as shown in Fig.5.12.

Click the [Camera Calibration] icon, the system will enter the

interface as shown in Fig.5.9.

Fig.5.9

Enter the password (Note: the password is provided by

LAUNCH), and click [OK] button, the interface is as shown

in Fig.5.10.

Fig.5.10

According to the prompts on the interface, put the calibration

frame on the right-side slide board of the lift. Click [OK] icon,

the next interface is as shown in Fig.5.11.

Fig.5.12

According the prompts on the interface, unlock the spring

snap, and simultaneously put the calibration frame on the

left and right turntables. Click [OK] icon, the next interface is

as shown in Fig.5.13.

Fig.5.13

According to the prompts on the interface, move the

calibration frame back by 600mm, and then click [OK] icon,

the next interface is as shown in Fig.5.14.

Fig.5.11

According to the prompts on the interface, please press

Fig.5.14

According to the prompts on the interface, once more, move

14

Page 19

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Installation and Adjustment

the calibration frame back by another 600mm, and then click

[OK] icon, the next interface is as shown in Fig.5.15.

Fig.5.15

According to the prompts on the interface, move the

calibration frame back by 1200mm to the turntables, and

click [OK] icon, the next interface is as shown in Fig.5.16

Fig.5.16

According to the prompts on the interface, put the calibration

frame on the left-side slide board of the lift, and then click

[OK] button to confirm, the next interface is as shown in

Fig.5.17.

spring snap, and then click [OK] button to confirm, the whole

calibration process is finished. Click [RETURN] button, you

can exit from the system.

Note:

It is not necessary to perform the calibrating operation

during equipment first installation. Generally speaking,

only in following two cases is the calibrating operation

performed:

1. The camera is adjusted or moved;

2. The target is changed.

Please do not perform the calibrating operation in

normal test operation process.

Target Calibration

After the camera recalibration, it is required to perform the

target calibration operation, in order to reduce the errors

caused by the target itself, and the system will automatically

create the corresponding calibration files and save them.

The target calibration procedures are as follows:

Turn the steering wheel to keep the front wheels straight

forward, and then hold the steering wheel with the steering

wheel holder. Remove the brake pedal depressor, and then

put up the vehicle body with the lift, keep the wheels hanged

in the air and can be turned freely.

Install the four wheel clamps and targets respectively, and

then adjust each target be inclined forward 10 degrees

around.

Select [System Management]-[Target Calibration] in the

main interface, after entering correct password, please click

“Start TID calibration” button to start calibration, as shown in

Fig.5.18.

Fig.5.17

According to the prompts on the interface, press down the

Fig.5.18

According to the prompts on the screen, start FL target

calibration operation. Adjust FL target 10 degrees forward,

after that, please click [Start TID calibration] button. The

interface is as shown in Fig.5.19.

15

Page 20

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Installation and Adjustment

Fig.5.19

According to the prompts on the screen, turn the FL wheel

by -25~ -16 degrees, i.e. turn it forward. After finished, the

system will automatically perform the next step. The

interface is as shown in Fig.5.20.

Fig.5.20

According to the prompts on the screen, turn the FL wheel

by 56~65 degrees, i.e. turn it backward. After finished, the

system will automatically perform the next step. The

interface is as shown in Fig.5.21.

Fig.5.22

According to the prompts on the screen, finish the

calibration operations for FR, RR and RL wheels

respectively. The interface is as shown in Fig.5.23.

Fig.5.23

Put the vehicle body down on the ground, wobble the

vehicle body in order to keep the wheels touch the ground

surface firmly. The target calibration operation is finished.

Click [Return] button to exit the system and then login again.

Cautions

1. Avoid the targets be blocked during calibration as

far as possible.

2. Please pay attention to the target calibration

sequence (FL, FR, RR and RL).

3. If target is turned forward, the turn angle is of

negative angle; if turned backward, positive angle;

before starting calibration, the default position of target

is of 0 degree. As far as possible, keep the target be

inclined forward 10 degrees around.

Fig.5.21

According to the prompts on the screen, turn the FL wheel

by -25~ -16 degrees, i.e. turn it forward. After that, the

interface is as shown in Fig.5.22.

16

Page 21

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Installation and Adjustment

Precautions and Solutions

Common Problems and solutions

in Installation

The screen displays the prompt of “Illegal user” when

you run the software, how to handle it?

At first examine if the soft dog is installed properly or in poor

contact. Then check if the serial number and user’s

password provided are correct. If necessary, contact the

technical service section of our company for verification.

The screen displays no image when you run the

software and select “Target Monitoring”, how to handle

it?

First check if cable connection of video camera and

illumination is right and the illuminating lamp is lightened.

Secondly, check the light path. Sway a target near the

camera lens and observe if there is an image appears.

Precautions

Calibration for installation is the base of X-831M

Wheel Aligner, so every step of operations must be

performed very careful. Otherwise, test precision and

equipment usage will be affected.

After calibration for installation, the post/lateral beam

and cameras are not permitted to move and adjust.

Keep targets clean.

The filter of camera is a special optical device, so it

must be kept clean and cleaned with soft lens tissue

when dirty. Avoid crushing the filter and moving the

camera.

17

Page 22

LAUNCH X-831M Wheel Aligner Installation and Parts Manual Appendix

Inspection Item

Installation

Actual

Measurement

Evaluation

Post installation height (

vertical distance from ground

2653mm Height of positioning platform (vertical distance from

AH=

0~1800mm

Post base distance (

horizontal

distance from

AB=1900~280

0mm Height

difference

between the front and the rear of

<5mm Power supply Requirement

AC220

or

110V 8A

Spot Inspection Item Table before Installation

For X-831M Wheel Aligner

to post top)

ground to turntable top )

turntable center to post installation base)

positioning platform

Requirement

Value

Comments

18

Loading...

Loading...