Page 1

LAUNCH X431 PAD Scopebox User’s Manual

Precaution on Operation

z The appliance is a sophisticated electronic device, never have it clashed

when in use.

z Main unit screen may flash at the moment of engine ignition, which is

normal.

z You may unplug the main unit if the program can not be actuated or

confused screen occurs. Plug again to continue the operation.

z Make sure the appliance is properly connected to the DLC to avoid

communication interruptions.

z During operation, keep the screen upward and leveled.

z Be careful when plugging and unplugging the main cable and diagnostic

connector. Tighten the screw before operation to avoid unexpected

disconnecting and/or damage to the port.

z Handle with care. Avoid collision. Unplug the power after operation.

z After the operation, the stylus shall be inserted into the slot on the main

unit, and put away the cable and connector, etc accessories to the box to

avoid the lost.

z Unplug the power cable by holding the connector, not the cable itself.

Page 2

LAUNCH X431 PAD Scopebox User’s Manual

Table of Contents

1 FOREWORD......................................................................................1

1.1

INTRODUCTIONS ...........................................................................1

1.2

PRODUCT FEATURES.....................................................................1

1.3

PRODUCT FUNCTION.....................................................................2

1.4

TECHNICAL PARAMETERS ..............................................................2

2 STRUCTURE AND ACCESSORIES ................................................. 3

2.1

SCOPEBOX STRUCTURE................................................................3

2.2

SCOPEBOX ACCESSORIES............................................................. 4

3 AUTOMOTIVE OSCILLOSCOPE......................................................6

3.1

CONNECTION................................................................................ 6

3.2

INITIAL INTERFACE INTRODUCTION.................................................6

3.3

OPERATIONS.................................................................................7

3.3.1 Channel selection and attributes

setting

..............................7

3.3.2 Trigger setting.......................................................................9

3.3.3 A

uto cal

i

bration...................................................................11

3.3.4 Display settings ................................................................. 12

3.3.5 Channel and cursor meas

ur

ement.................................... 12

3.3.6 File management...............................................................

13

3.3.7 View the softw

a

re version ................................................. 15

3.3.8 Exit the application............................................................

15

4 AUT OMOTIVE IGNITION WAVEFORM .......................................... 16

4.1

SECONDARY-DISTRIBUTOR IGNITION ANALYSIS............................. 16

4.2

SECONDARY-SIMULTANEOUS IGNITION ANALYSIS.......................... 19

4.3

SECONDARY-DIRECT IGNITION ANALYSIS...................................... 20

4.4

WA VEFORM ANAL YSIS MODE........................................................ 22

Page 3

LAUNCH X431 PAD Scopebox User’s Manual

1

1 Foreword

1.1 Introductions

X-431 PAD is a new generation of sophisticated and integrated automotive

diagnostic product with colorful screen and powerful functions developed by

LAUNCH, and Scopebox is an optional function box for X-431 PAD , including

automotive oscilloscope and automotive ignition waveform.

Automotive oscilloscope can make the auto repair technician quickly judged

the fault

s on automotive electronic equi

pment and wiring, and the oscilloscope

sweep speed is far greater than the signal frequency of such vehicles, usually

5-10 times of the measured signal. The automotive oscilloscope not only can

quickly capture the circuit signal, but also can slowly display the waveform to

observe and analyze. It can also record and store the tested signal waveform

which can be played back to observe for the fast signal, having great

convenience to failure analysis. Either high-speed signal (e.g.: injection nozzle,

intermittent fault signal) or the slow-speed signal (e.g. the throttle position

change and the oxygen sensor signal) can be observed through automotive

oscilloscope in an appropriate waveform.

The electronic signal can be compared and judged via measuring five

parameters index

es. The five parameters indexes are the amplitude (the

maximum voltage of signal), the frequency (the cy cle time of signal), the shape

(the appearance of signal), the pulse width (the duty cycle or the time range of

signal), and the array (the repetition characteristic of signal), which can be

tested, displayed, saved by the automotive oscilloscope. Via the waveform

analysis can further detect the circuit fault on sensors, actuators, circuits, and

electronic control units, etc.

1.2 Product features

z Rapidly capture the circuit signal.

z Display waveform slowly for observation and analysis.

z Record and store the tested signal waveform for playback and failure

analy

sis.

Page 4

LAUNCH X431 PAD Scopebox User’s Manual

2

z Detect, display and store all the electrical signal of five parameters,

namely amplitude, frequenc

y, shape, pulse width, and array.

1.3 Product function

Provides specialized automotive oscilloscope function and supports ignition

waveform analysis.

1.4 Technical parameters

Scopebox: 4 channels, highest sampling frequency 200MHZ, max storage

depth 64MSa, 8-bit resolution.

Page 5

LAUNCH X431 PAD Scopebox User’s Manual

2 Structure and Accessories

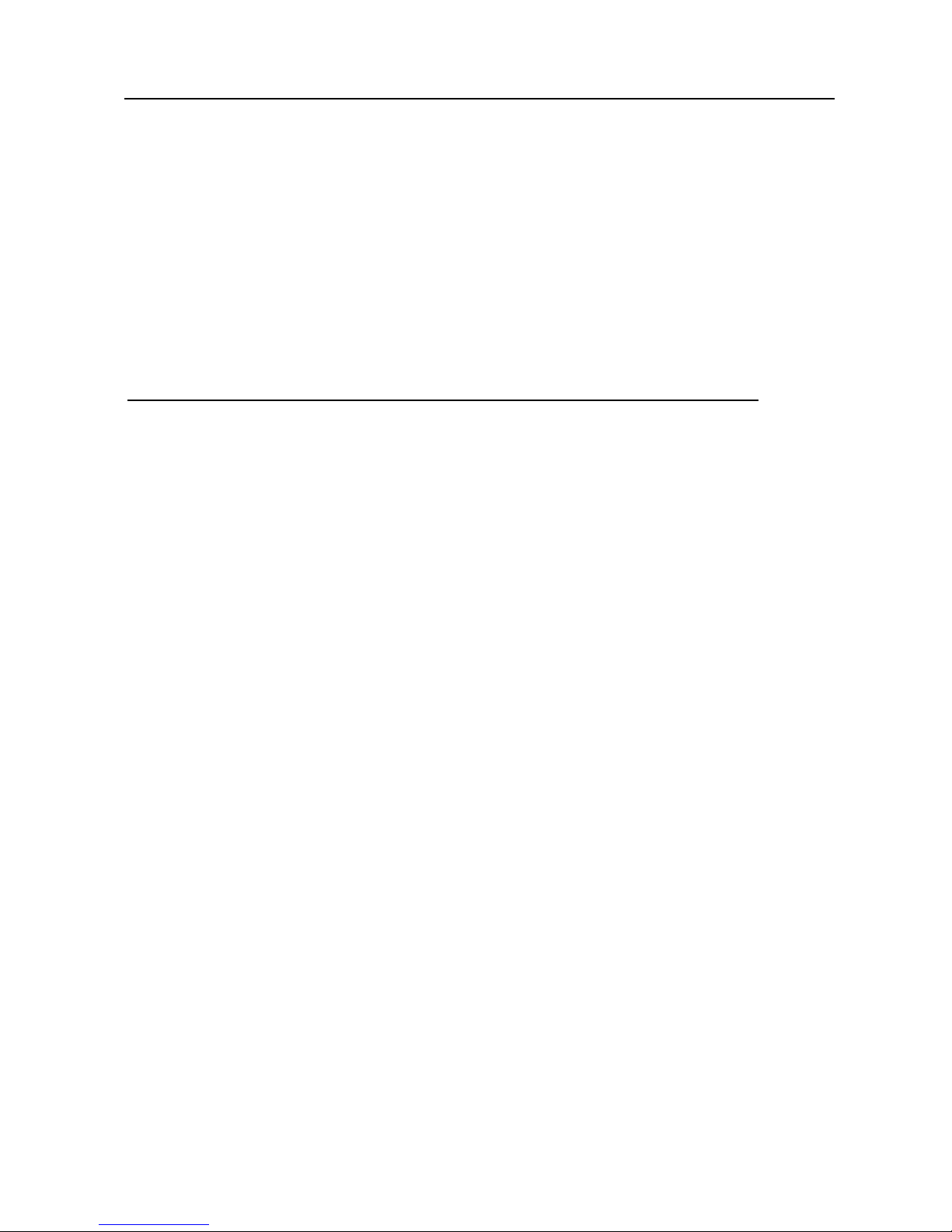

2.1 Scopebox structure

Fig 2-1 Scopebox Structure Diagram

Table 2-1 shows the ports and indicators for X-431 PAD Scopebox

No. Name Description

1 CH1 Channel 1

2 CH2 Channel 2

3 CH3 Channel 3

4 CH4 Channel 4

5 External trigger External trigger signal

6 Fixed signal

generator

Generate a square signal with fixed 1K frequency

3

Page 6

LAUNCH X431 PAD Scopebox User’s Manual

7 Power indicator Oscilloscope power indicator, which will be steady

red after the oscilloscope is powered on

8 Operating

indicator

The indicator will be steady green after the

oscilloscope operated.

9 Communication

indicator

After the data communication, the indicator will

blink (Green).

10 Power interface Connect to power supply via the power adapter.

11 B-shaped USB

interface

Connect main unit via USB connect line as

separated individual USB devices

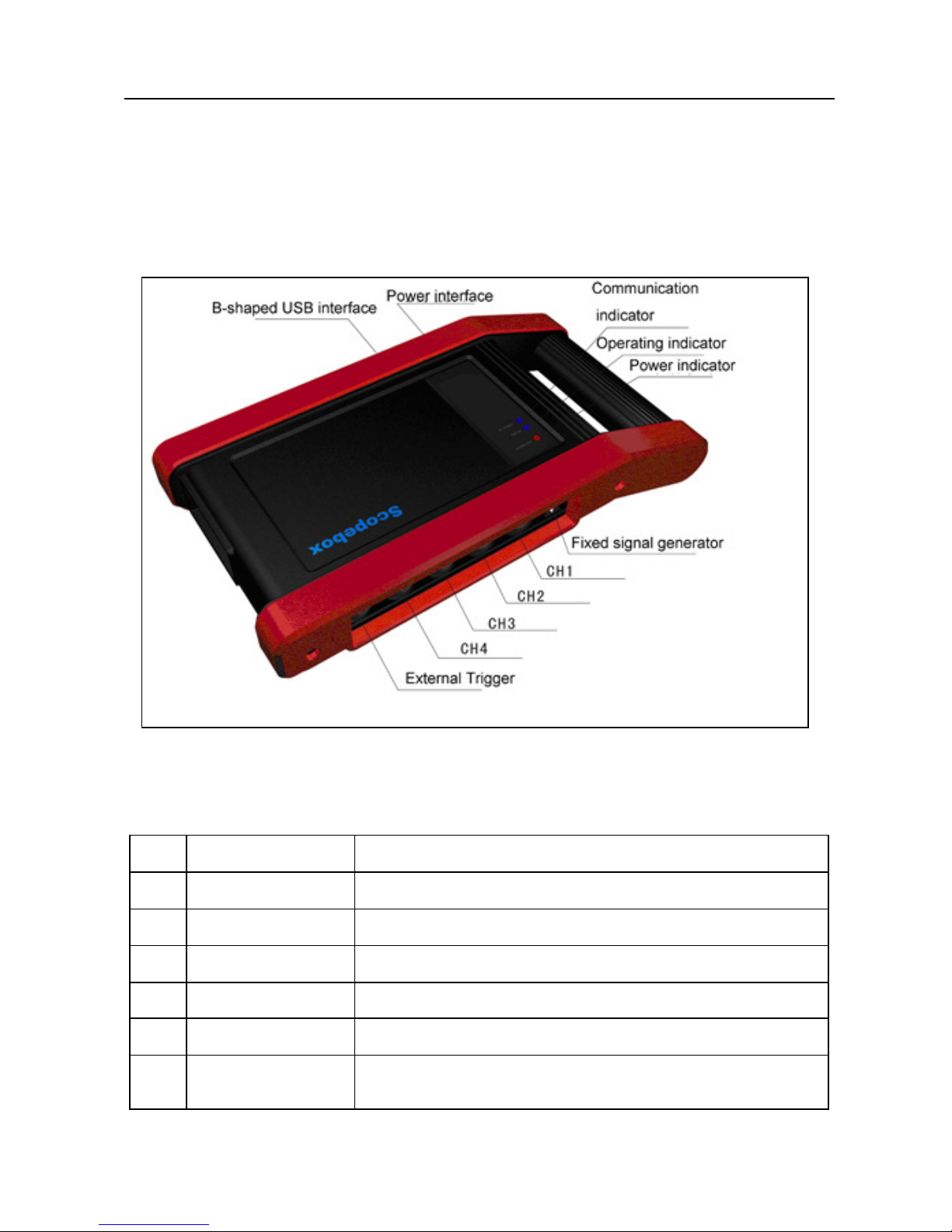

2.2 Scopebox accessories

Scopebox includes the secondary pickup cable for 4-channel oscilloscope,

crocodile clips for 4-channel oscilloscope, etc. See Table 2-2.

As the product configuration can be different, the accessories inc

luded with the

product may differ from the accessories listed on this manual. Please see the

packing list attached to the product for the detailed accessor ies.

Table 2-2 Accessory checklist

No. Name Picture

1 Secondary ignition pickup for

4-channel oscilloscope

2 Crocodile clips for 4-channel

Oscilloscope

3 Direct ignition extension cord

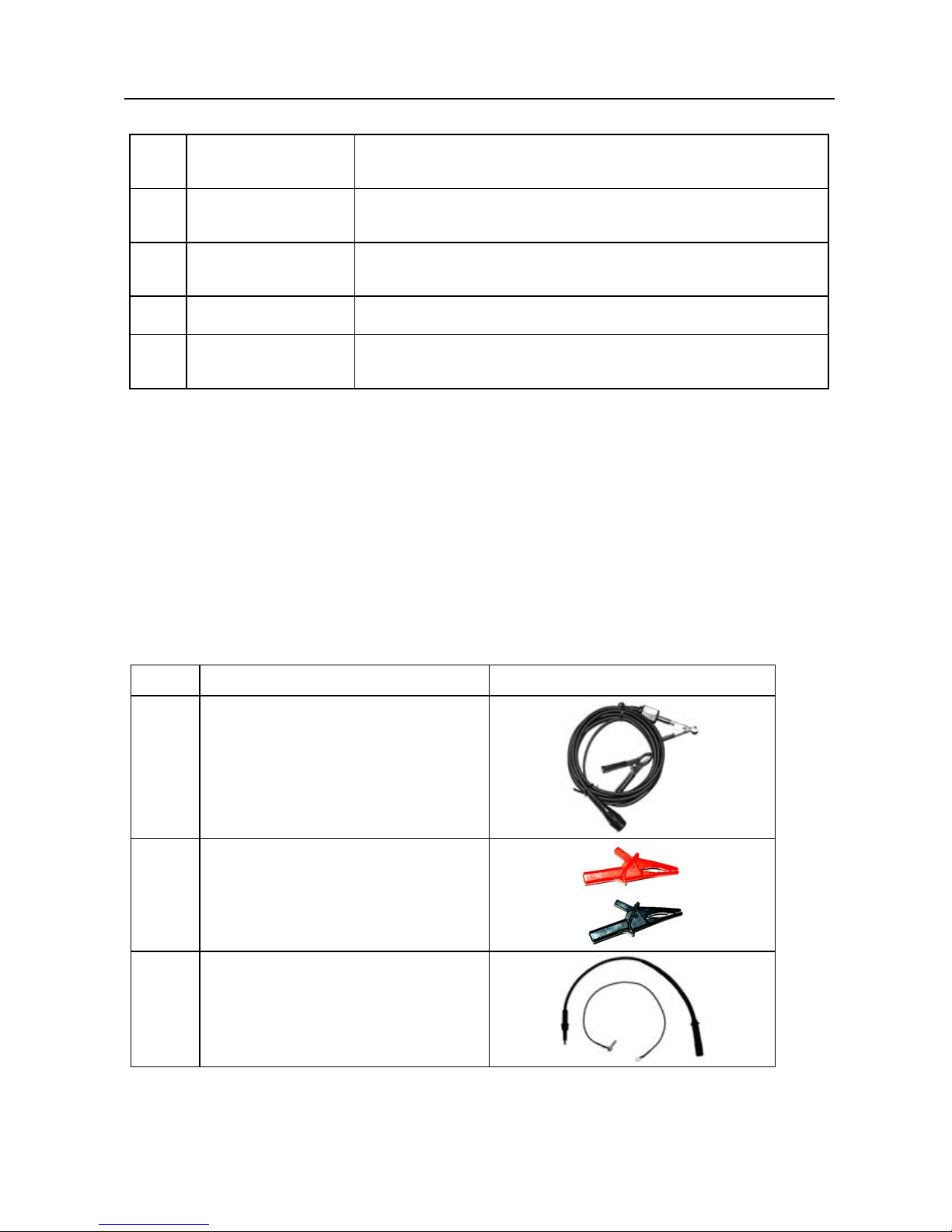

4

Page 7

LAUNCH X431 PAD Scopebox User’s Manual

4 6-way universal guide line for

4-channel oscilloscope

5 BNC to 4mm connector test

cable

6 Pin connector for 4-channel

oscilloscope

5

Page 8

LAUNCH X431 PAD Scopebox User’s Manual

6

3 Automotive Oscilloscope

3.1 Connection

X-431 PAD Scopebox should work with the X431 PAD main unit.

1. Firstly, power on the main unit (Connect one end of the power adaptor into

the power interface of main unit, and

the other end to the DC 12V power

supply. Alternatively it can be also powered by cigarette lighter cable and

double clip power cord).

2. Then plug one end of ground cable of oscilloscope into ex

ternal trigger

channel (GND), the other end should be grounded.

3. Connect one end of probe cable of oscilloscope

to the CH1, CH2, CH3, or

CH4 on oscilloscope module, and then connect the other end to related

signal terminal.

Warning: please use the specific capacitance probe when diagnosing the

ignit

ion high voltage line. Never connect the oscilloscope to the ignition

secondary circuit directly.

3.2 Initial interface introduction

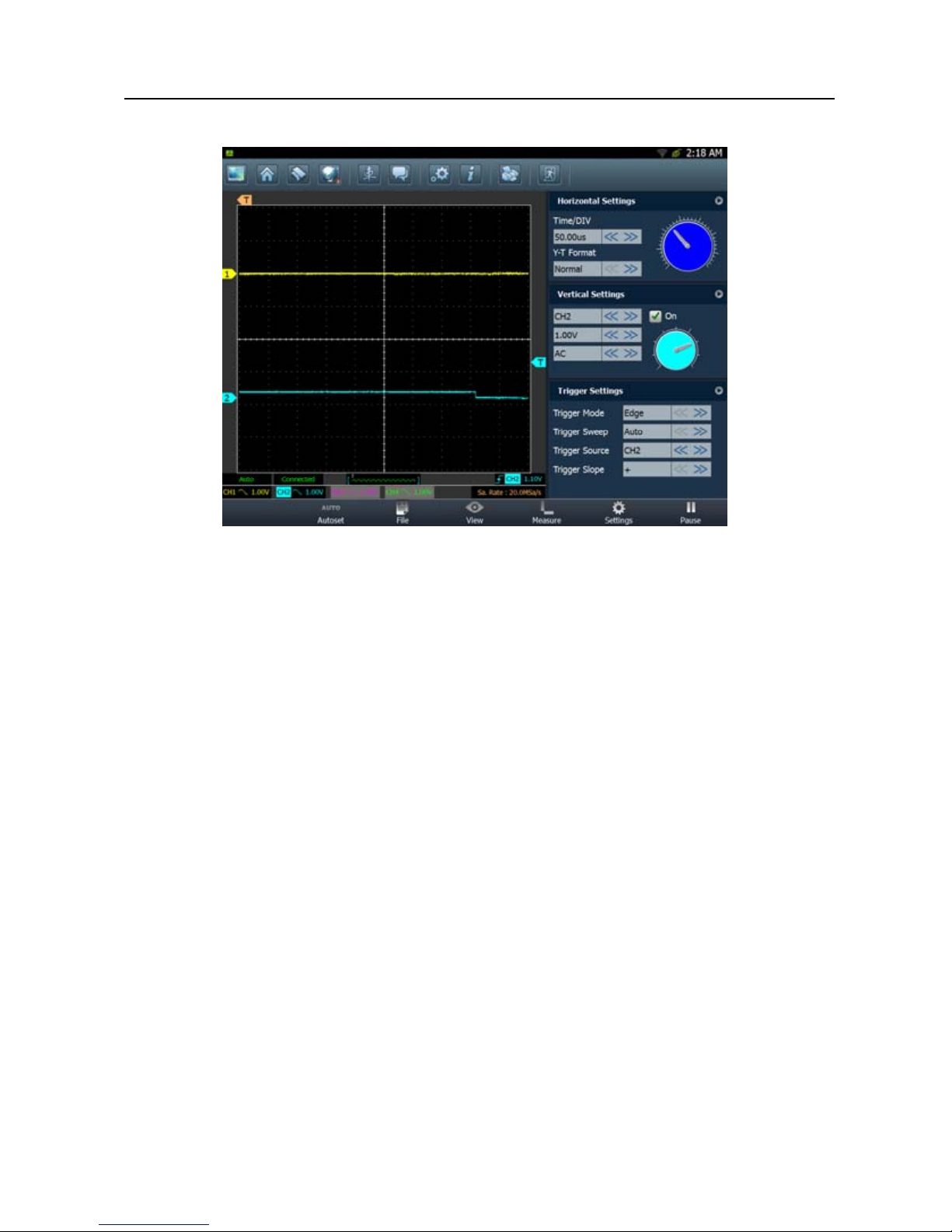

Fig. 3-1 displays the initial interface of oscilloscope.

Page 9

LAUNCH X431 PAD Scopebox User’s Manual

Fig.3-1

Button descriptions:

[Autoset]: It indicates a

u

to trigger setting. Based on the characteristics of

measured signal, the oscilloscope will automatically set the horizontal bas eline,

vertical sensitivity and trigger condition so that the waveform can be display ed.

[File]: provide

s

waveform record and waveform replay.

[View]:

Calibration and display settings are available.

[Measure]

: includes signa

l source measurement, cursor measurement and

clear measurement.

[Settings]: display

s or hides the parameter settings area including horizontal

settings, vertical settings and trigger settings.

[Start/stop]: start

s/stops collecting oscilloscope waveforms.

3.3 Operations

3.3.1 Channel selection and attributes setting

<1> Channel selection

There are two ways available for channel selection: (See Fig. 3-2)

A. Select from the channel column shown at the bottom of the waveform

7

Page 10

LAUNCH X431 PAD Scopebox User’s Manual

display area;

B. Select from Vertical settings.

Note: For better comparison and identification, each channel and waveform

are marked in dif

f

erent colors.

Fig.3-2

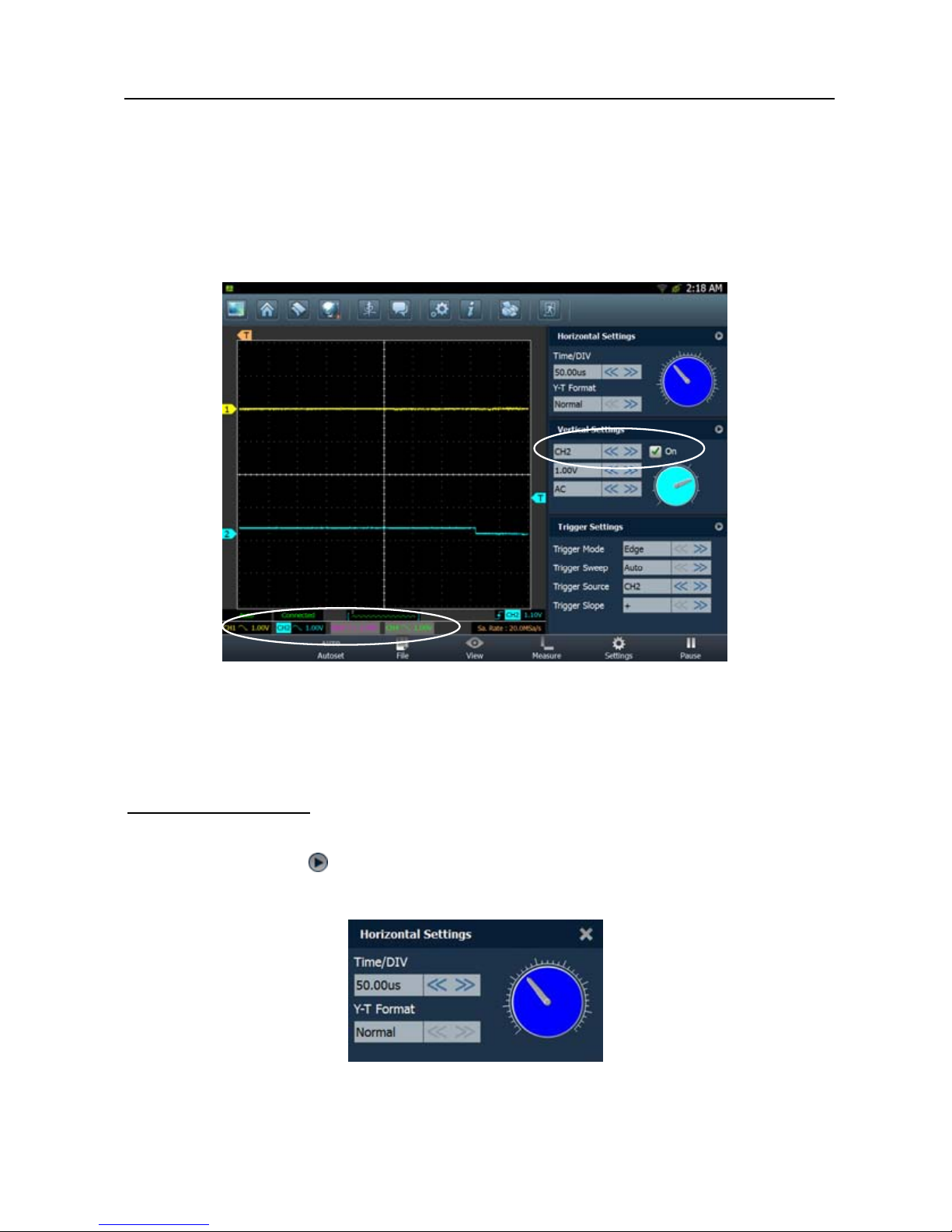

<2> Channel attributes setting

Channel attributes can be set via horizonta

l settings and vertical settings.

Horizontal Settings

User can make some settings directly by clicking << or >> next to options.

Alternatively

, Click

located in the upper right corner of the horizontal

settings to make more settings. See Fig. 3-3.

Fig. 3-3

8

Page 11

LAUNCH X431 PAD Scopebox User’s Manual

Options descriptions:

Time/DIV: click << or >> to adjust;

Y-T Format: click << or >> to adjust. It includes 3 options: Normal, Scan and

Scroll (from ri

ght to left).

V ertical Setting s

User can make some settings directly by clicking << or >> next to options.

Alternatively

, Click

located in the upper right corner of the vertical settings

to make more settings. See Fig. 3-4.

Fig. 3-4

Options descriptions:

A. Channel selection;

B. Channel switch selection;

C. Channel voltage adjustment;

D. Channel coupling modes sele

ction: DC,

AC or Ground;

E. Channel probe selection;

F. Bandwidth limit switch;

G. Channel reverse phase switch.

3.3.2 Trigger setting

Trigger indicates that when certain waveform meets the conditions that are

predefined according to the requirements, the oscilloscope captures the

waveform and its adjacent section, and then presents it on the screen.

<1> T r igger mo de

It is classified into 3 categories: Pulse Width and Edge.

[Edge]: It is the most common and ef

fective trigger mode, which is widely used

9

Page 12

LAUNCH X431 PAD Scopebox User’s Manual

in most applications. Edge trigger only detects the edges, polarities, and

voltage of signal. When the voltage of measured signal varies as identical as

the preset one (rising edge or falling edge), and the value becomes same as

trigger voltage, the oscilloscope will be triggered and capture the waveform.

[Pulse Width]: T

rigger happens when it reaches to the pulse width.

Fig. 3-5 and Fig. 3-6 show edge trigger, pulse widt

h trigger setting interfaces.

Fig. 3-5

Fig. 3-6

<2> Trigger Sweep

Auto, Normal and Single are included.

Auto: It indicates that no matter w

hether it meets the trigger conditions, it will

refresh the waveform in real time. In this case, the waveform displ ayed on the

screen seems swaying;

Normal: Only

it meet

s the trigger conditions can trigger be activated.

Otherwise the waveform will keep still.

Single: In this mode, it only

captures the waveform that generates for the first

time the trigger conditions are met, and then stops after finishing capture.

10

Page 13

LAUNCH X431 PAD Scopebox User’s Manual

<3> Trigger source

Trigger source means w hich channel signa l w ill be measured as trigger object.

Before making settings to trigger mode and v

oltage of certain channel, you

have to choose the target channel.

3.3.3 Auto calibration

This option enables you to obtain a precise measurement of measured signal.

Auto calibration mainly includes: calibration of analog channel, trigger voltage

calibration of trigger circuit and nonlinear calibration of horizontal baseline

movement.

Click “View” and then click [Calibration], a dialog box simil

ar to Fig. 3-8 will

appear.

Fig. 3-8

Check the box before the channel to select it. T

o select all, click [Check All]. To

deselect it, just click [Reverse]. After choosing the desired channel(s), click

[Start] to start calibration and [Calibration] button will be temporarily invalid

during calibrating. Click [Stop] to stop calibrating. Once it becomes active, it

indicates calibration has completed.

Notes: In process of calibration, make sure CH1/CH2/CH3/CH4 has no signal

11

Page 14

LAUNCH X431 PAD Scopebox User’s Manual

input. Moreover, calibration may take several minutes and please be patient to

wait.

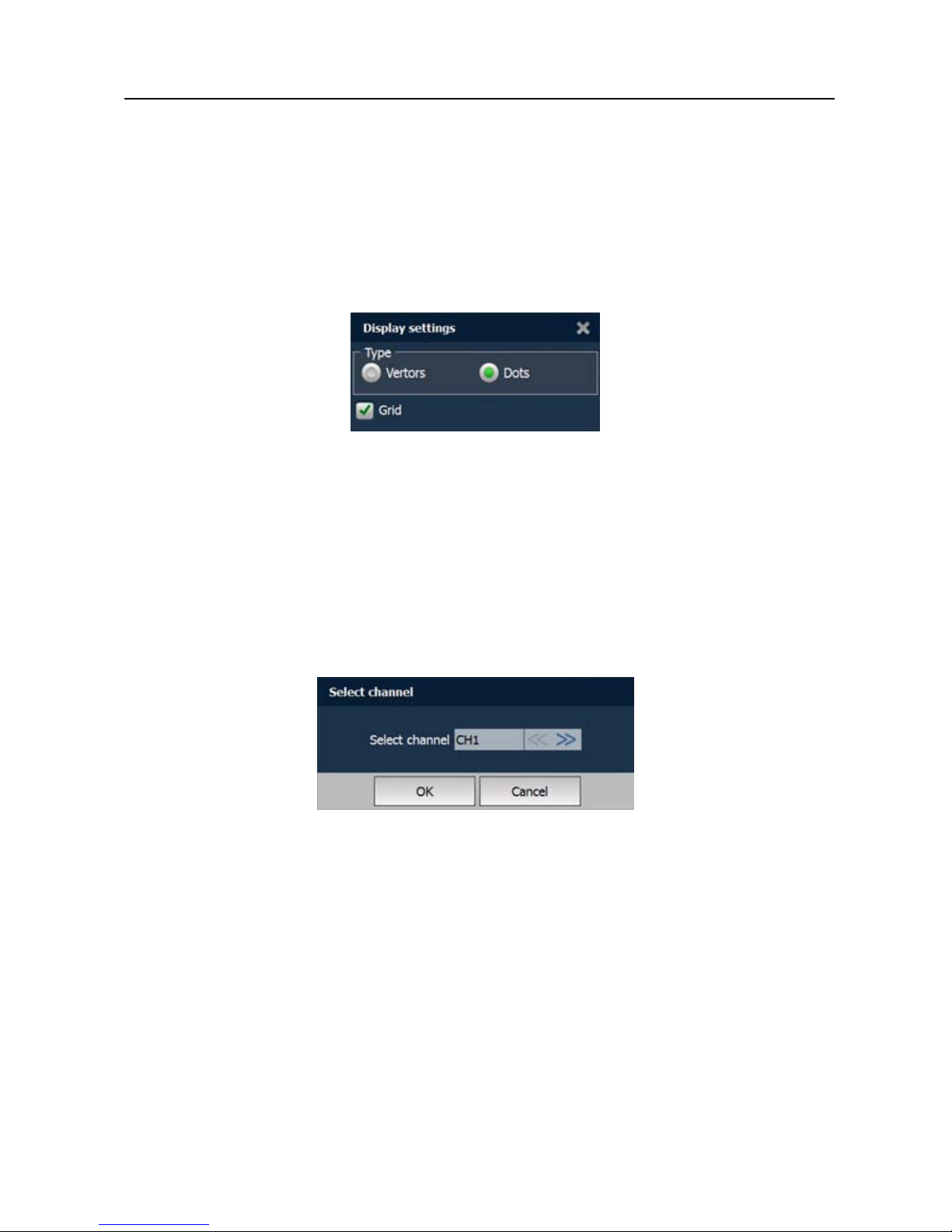

3.3.4 Display settings

Click “View” and then [Display settings] to enter the setting screen. See Fig.

3-9.

Fig. 3-9

Click “Vectors” or “Dots” to define display

mode. Check/uncheck the box

before Grid to open/close grid display.

3.3.5 Channel and cursor measurement

<1> Channel measurement

Click “Measure” and then [Source], a screen similar to Fig. 3-10 will appear.

Fig. 3-10

<2> Cursor measurement

Click “Measure” and then [Cursor Measure], a screen similar to Fig. 3-11 will

appear.

Not

e: if no desired channel is selected, the system will take the current source

as the default channel.

12

Page 15

LAUNCH X431 PAD Scopebox User’s Manual

Fig. 3-11 Fig. 3-12

Horizontal Measure is for voltage (see Fig. 3-11) and vertical measure is for

timebase (see Fi

g. 3-12).

Options descriptions:

[A Line / B Line move up / do wn]: fine adjustment for volt

age. A line is a solid

line and B line is a dotted line;

[A Line / B Line move left / right]: fine adju

stment for timebase. A line is a

solid line and B line is a dotted line.

<3> Clear Measurement

Click “Measure” and then [Clear Measure], the s

ystem will clear the

measurement result.

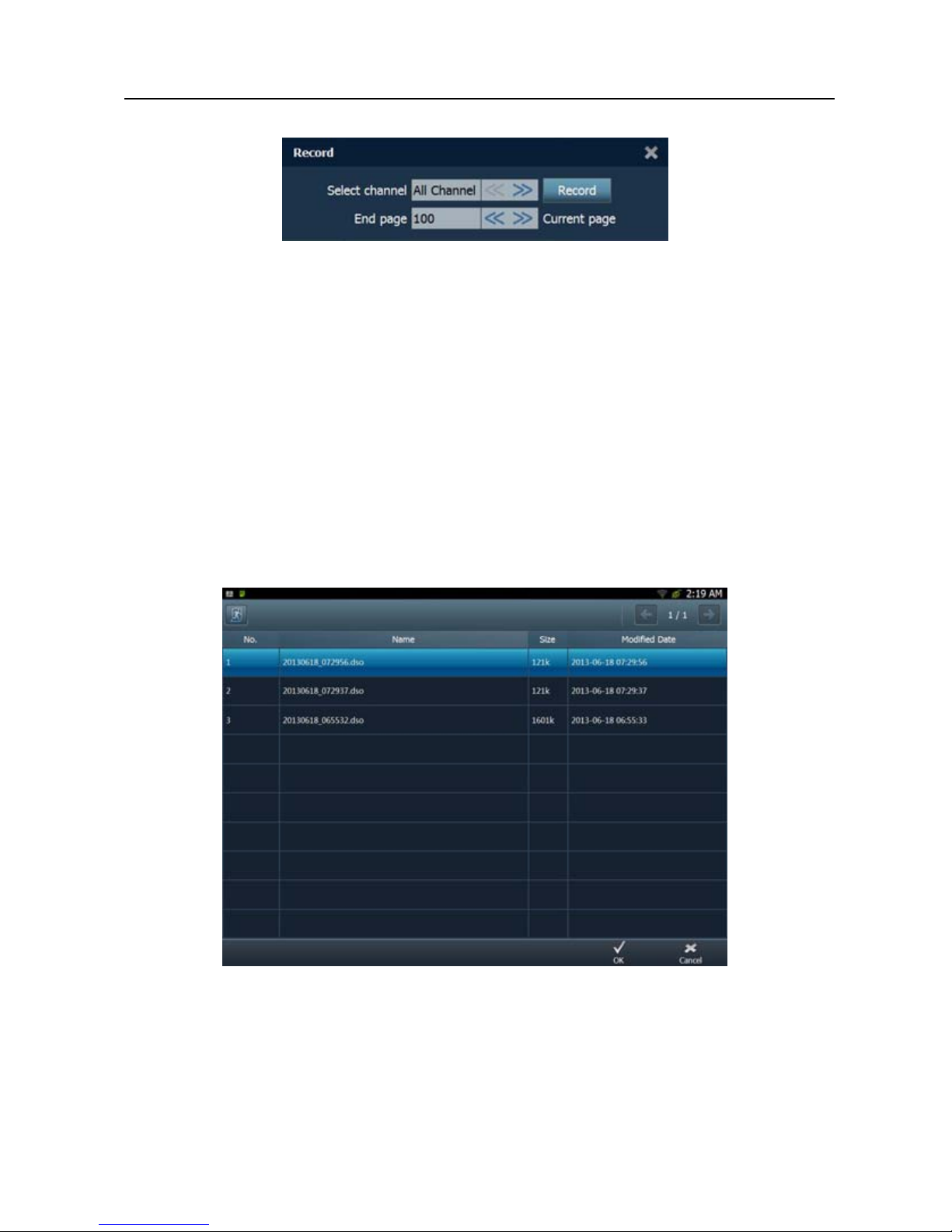

3.3.6 File management

<1> Record waveform

This function is used to record waveforms that are collected by oscilloscope at

a period, and save it as dat

a file which can be played back in future.

It can be performed only when the oscilloscope is collecting data in Normal

mode.

Click [File], then select [Record] from the pop-up menu to start recording.

See

Fig. 3-13.

13

Page 16

LAUNCH X431 PAD Scopebox User’s Manual

Fig.3-13

Click [Record] to start recording, and the Record button becomes S

top button.

Click [Stop] to stop recording. While recording, the recorded pages will be

shown on the screen.

<2> Import waveform for playback

The Import function enables you to import the stored waveform file for

playback and review

. During replaying, the oscilloscope stops collecting data

automatically.

Click [File], then select [Waveform replay] from the pop-up menu to enter

a

screen similar to Fig. 3-14.

Fig.3-14

Select the playback file first, and then click [OK] button to open the

waveform

file, then use channel attributes setting to adjust the waveform display.

To delete the waveform file, please enter “My Data” and choose the

14

Page 17

LAUNCH X431 PAD Scopebox User’s Manual

corresponding folder to perform delete operation.

<3> Print waveform

This option allows you to print out the latest collected dat

a while the

oscilloscope stops collecting dat a. While printin g, the oscilloscope should be in

stop mode.

Click

on the shortcut bar to start printing.

3.3.7 View the software version

Click to view the version information of the oscilloscope.

3.3.8 Exit the application

Click to exit the current application.

15

Page 18

LAUNCH X431 PAD Scopebox User’s Manual

16

4 Automotive Ignition waveform

The ignition system is the system which has greatest impact on the

performances of gasoline engine, as the statistical data shows that nearly half

of the failures are caused by poor work of electrical system. And the

performance tests of engine often start from the ignition system. Nowadays

ignition system includes distributor and distributorless. Distributorless includes

independent ignition and simultaneous ig nition.

1. Distributor ignition system i.e. contact break

er with contact-controlled

ignition system (commonly known as the platinum) and contact breaker

with noncontact-controlled ignition system combined with magnet, hall

components or infrared.

2. Independent ignition system: crankshaft sensor send out the ignition

timing si

gnal and cylinder identification signal so that the ignition system

can send out ignition signal to specified cylinder in specified time, each

cylinder has its independent ignition coil.

3. Simultaneous ignition system: two cylinders share one ignition coil, when

two c

ylinder pistons reach top dead center at the same time (one is

compression, another is the exhaust), two spark plugs will be ignited at

the same time, at this time, the ignition for the former cylinder is in

high-pressure low temperature gas mixture, the ignition is valid, while for

the latter one is in low-pressure high temperature exhaust gas, the

ignition is invalid.

X-431 PAD can test and analyze the secondary signal for various engine

ignit

ion systems.

4.1 Secondary-distributor ignition analysis

Connections: Plug the BNC end of secondary ignition pickup into

CH1/CH2/CH3/CH4 channel of Scopebox, then connect the high-voltage clip

to high-voltage line, and crocodile clips to groun d.

Tips: Common ignition sequence (the specific sequence is subject to the

actual engine ig

nition sequence)

Page 19

LAUNCH X431 PAD Scopebox User’s Manual

17

Four-stroke in-line four-cylinder: 1—2—4—3, or 1—3—4—2

Four-stroke in-line six-cylinder: 1—5—3—6—2—4, or 1—4—2—6—3—5

Four-stroke in-line eight-cylinder: 1—8—4—3—6—5—7—2

Five-cylinder: 1-2-4-5-3

V 6 engine: generally speaking, based on the person sitting on the driver cab,

if the right side

cylinder numbers on the right side, from the front to the back

are as follows: 1, 3, 5; and the cylinder numbers on the left side, from the front

to the back are as follows: 2, 4, 6; then the ignition sequence is: 1-4-5-2-

3-6. If the cylinder numbers on the right side, from the front to the back are as

follows: 2, 4, 6; and cylinder numbers on the left side, from the front to the back

are as follows:1, 3, 5; then the ignition sequence is: 1-6-5-4-3-2.

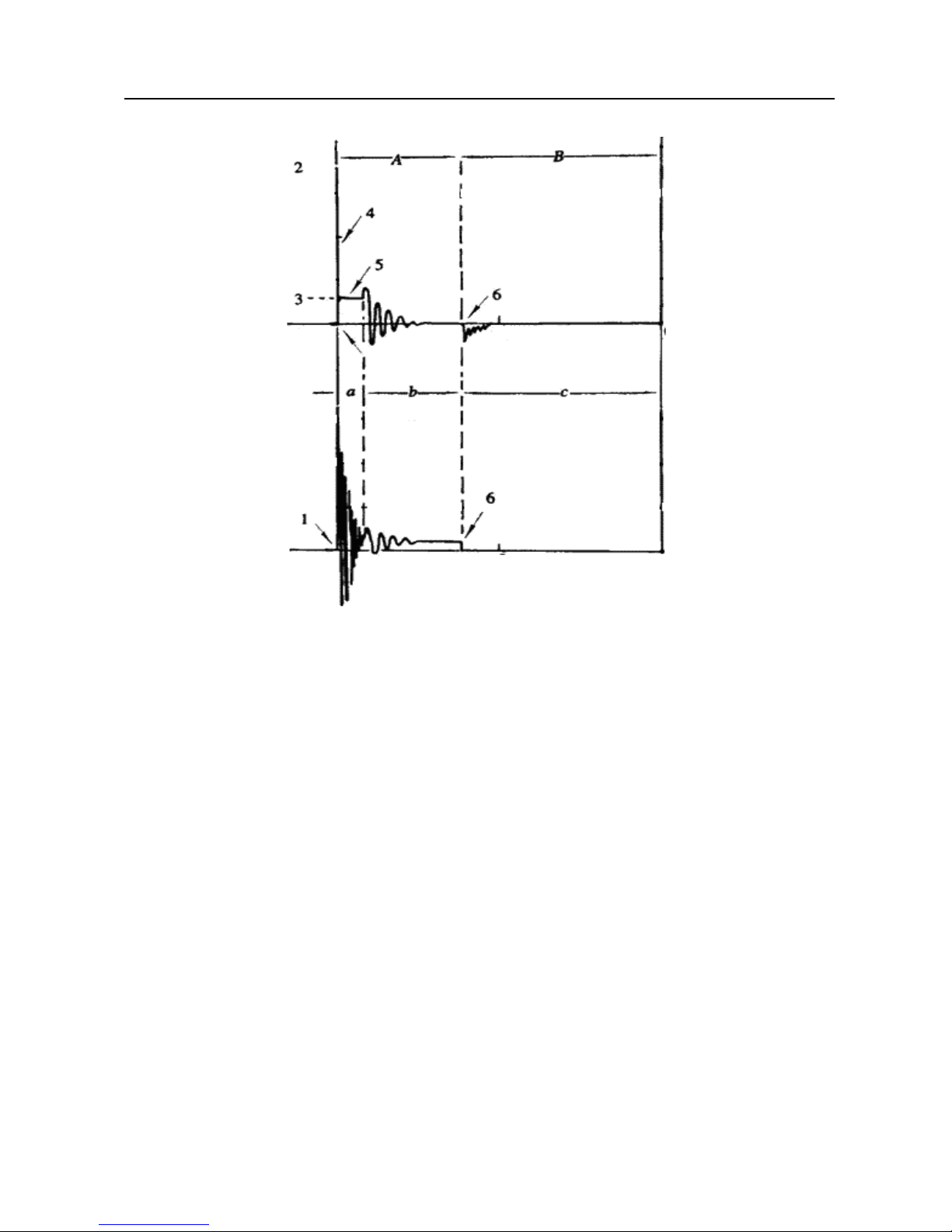

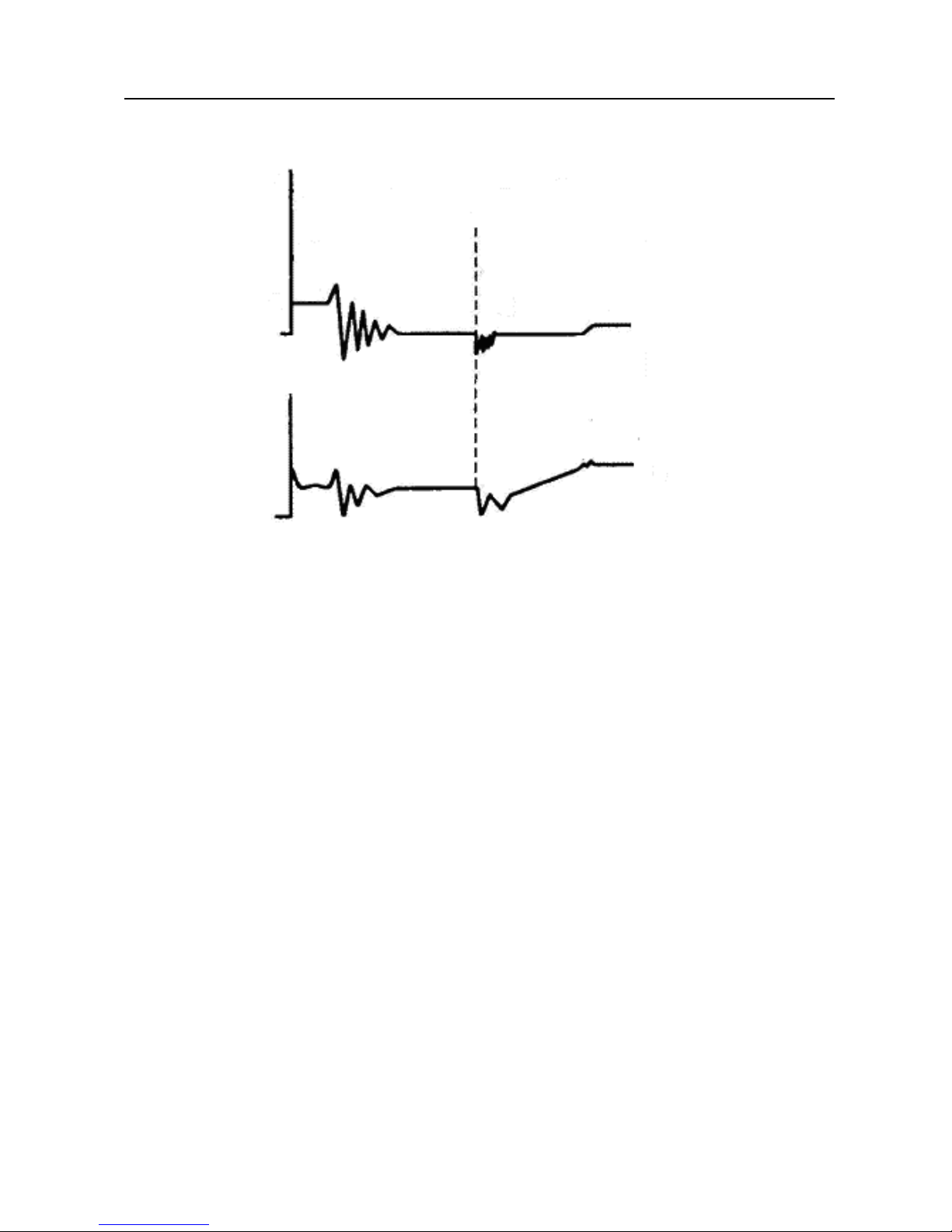

The Figure 4-1 below shows the normal ignition w aveform of distributor ignition

s

y

stem, the upper one is the secondary waveform, and the lower one is the

primary waveform.

The secondary waveform

A section is cont act open per iod; B section is make cont act perio d, which is the

magnetizing field of ignition coil.

Page 20

LAUNCH X431 PAD Scopebox User’s Manual

Fig. 4-1

1) Contact break point: the primary circuit of igniti

on coil cut off, the

secondary voltage was sensed and increased sharply

2) Ignition voltage: secondary coil volta

ge overcome the damper of high

voltage line, the contact breaker gap and the spark plug gap to release

magnetizing energy, 1-2 section is the breakdown voltage

3) Spark voltage: For the capacitor discharge voltage

4) Ignition voltage pulse: For the charge and discharge sections

5)

Spark line: The inductance discharge process, i.e. the mutual induct

ance

voltage of ignition coil maint ains the conduction of secondary circuit

6) Contact point close the current flow into

primary coil, the primary coil

oscillates due to the mutual inductance.

Primary ignition waveform

Section

a shows the voltage oscillation on the primary circuit due to the

magnetic induct

ion of spark in the duration;

Section b shows the damped oscillation genera

ted by remaining magnetic field

18

Page 21

LAUNCH X431 PAD Scopebox User’s Manual

energy after the spark;

Section c shows the make cont

act magneting period of primary coil.

Seen from the waveform, the amplitudes of breaker contact closed angle,

break angle and

breakdown voltage and spark voltage are very clear, besides,

the spark delay period and two oscillations can also be tested. For the ignition

system without faults, compared with the whole cycle, the cont act closed ang le

just 45%-50% (four-cylinder), 63%-70% (six-cylinder), or 64%-71%

(eight-cyliner); the breakdown voltage is over 15kv; the spark voltage is about

9kV, the spark period is greater than 0.8ms. If these values or waveform are

abnormal, it means there is fault or the system needs to be adjusted.

4.2 Secondary-simultaneous ignition analysis

Connections: Plug the BNC end of secondary ignition pickup into

CH1/CH2/CH3/CH4 channel of Scopebox, then connect the high-voltage clip

to high-voltage line, and crocodile clips to groun d.

Connection as shown in figure 4-2:

Fig. 4-2

19

Page 22

LAUNCH X431 PAD Scopebox User’s Manual

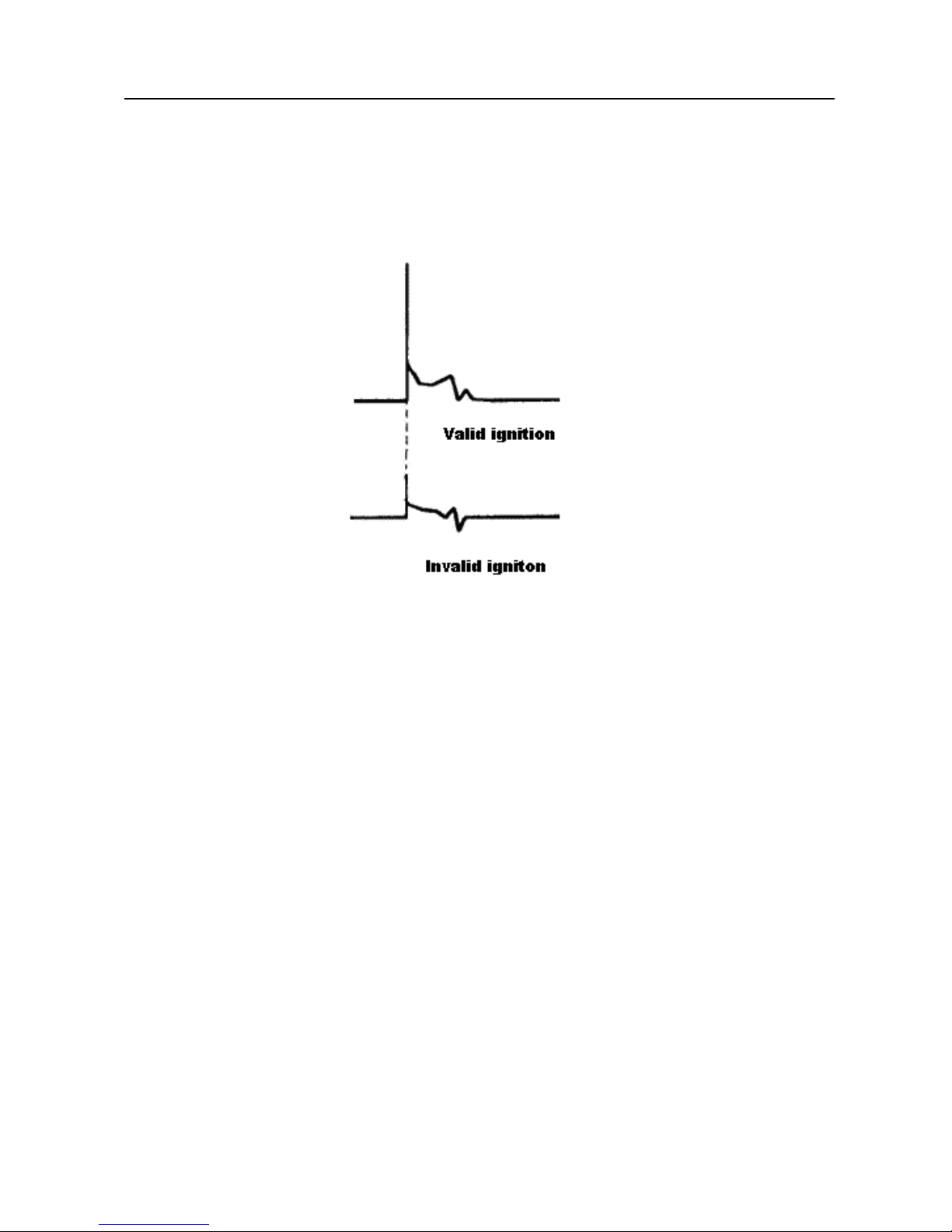

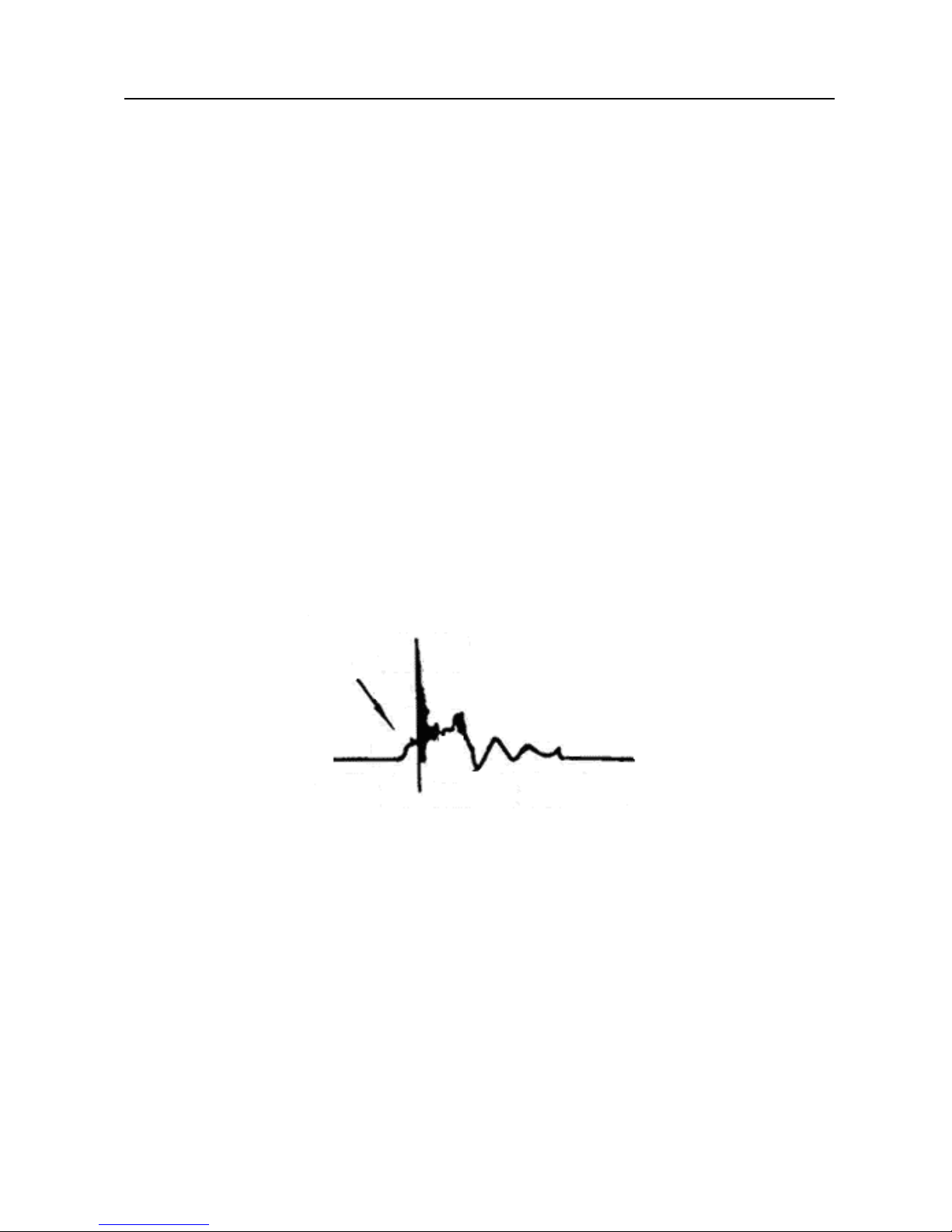

Fig. 4-3 below shows the valid and invalid ignition waveforms. Under the

working status of valid ignition, the breakdown voltage and spark voltage are

higher because the cylinder is filled with fresh combustible mixture gas, which

has a lower ionization level and vice versa.

Fig. 4-3

4.3 Secondary-direct ignition analysis

Connection:

1) When the high-voltage wire is exposed, plug the BNC end of secondary

ignit

ion pickup into CH1/CH2/CH3/CH4 channel of Scopebox, then

connect the high-voltage clip to high-voltage line, and crocodile clips to

ground.

2) If no high-voltage wire exposes, dismantle ignition coil of tested cylinder

and use direct

ignition extension cord. Connect one end to ignition coil

which should be grounded via direct ignition grounding wire, and insert the

other end into cylinder to joint with spark plug. Then plug the BNC end of

secondary ignition pickup into CH1/CH2/CH3/CH4 channel of Scopebox,

then connect the high-voltage clip to high-voltage line, and crocodile clips

to ground.

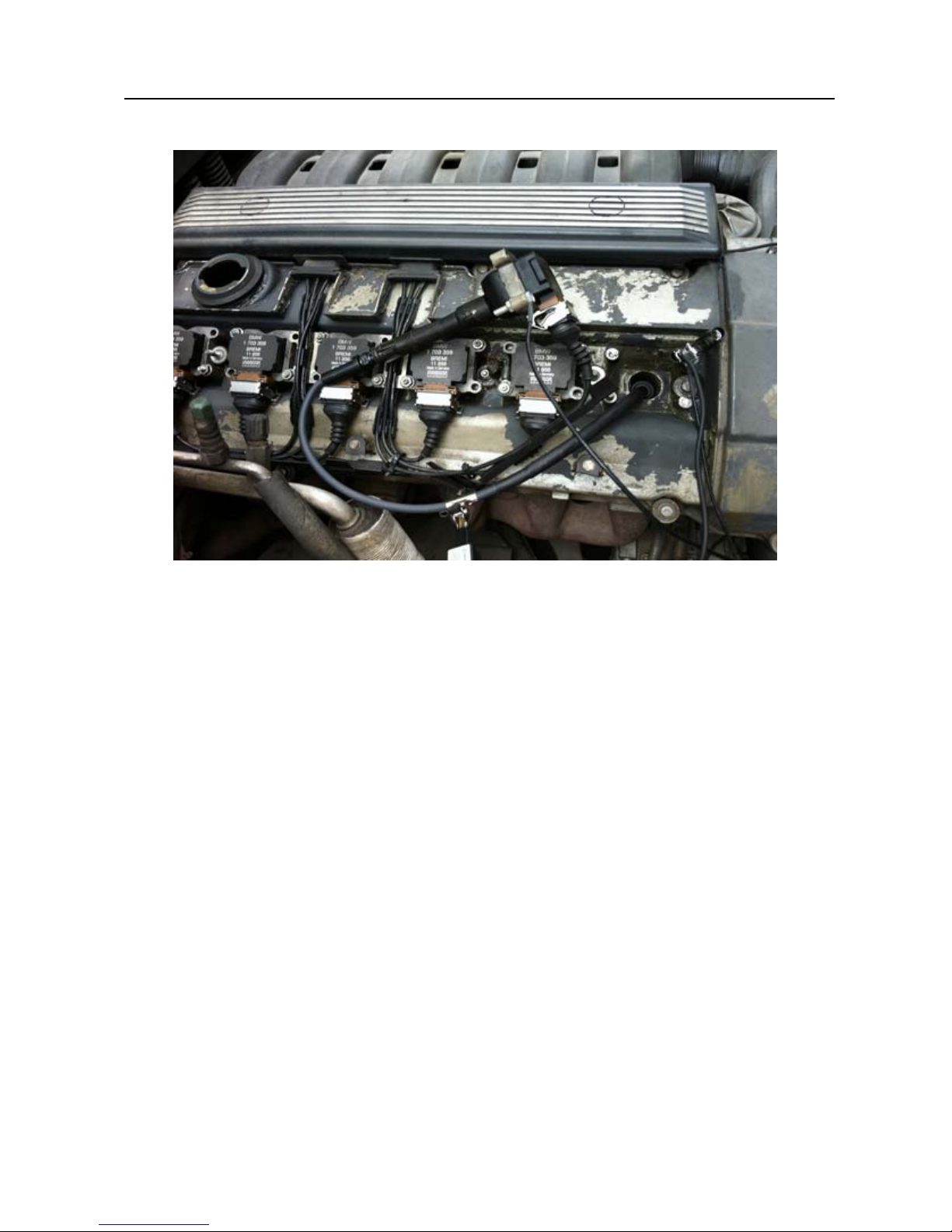

Connections are shown in Fig. 4-4:

20

Page 23

LAUNCH X431 PAD Scopebox User’s Manual

Fig. 4-4

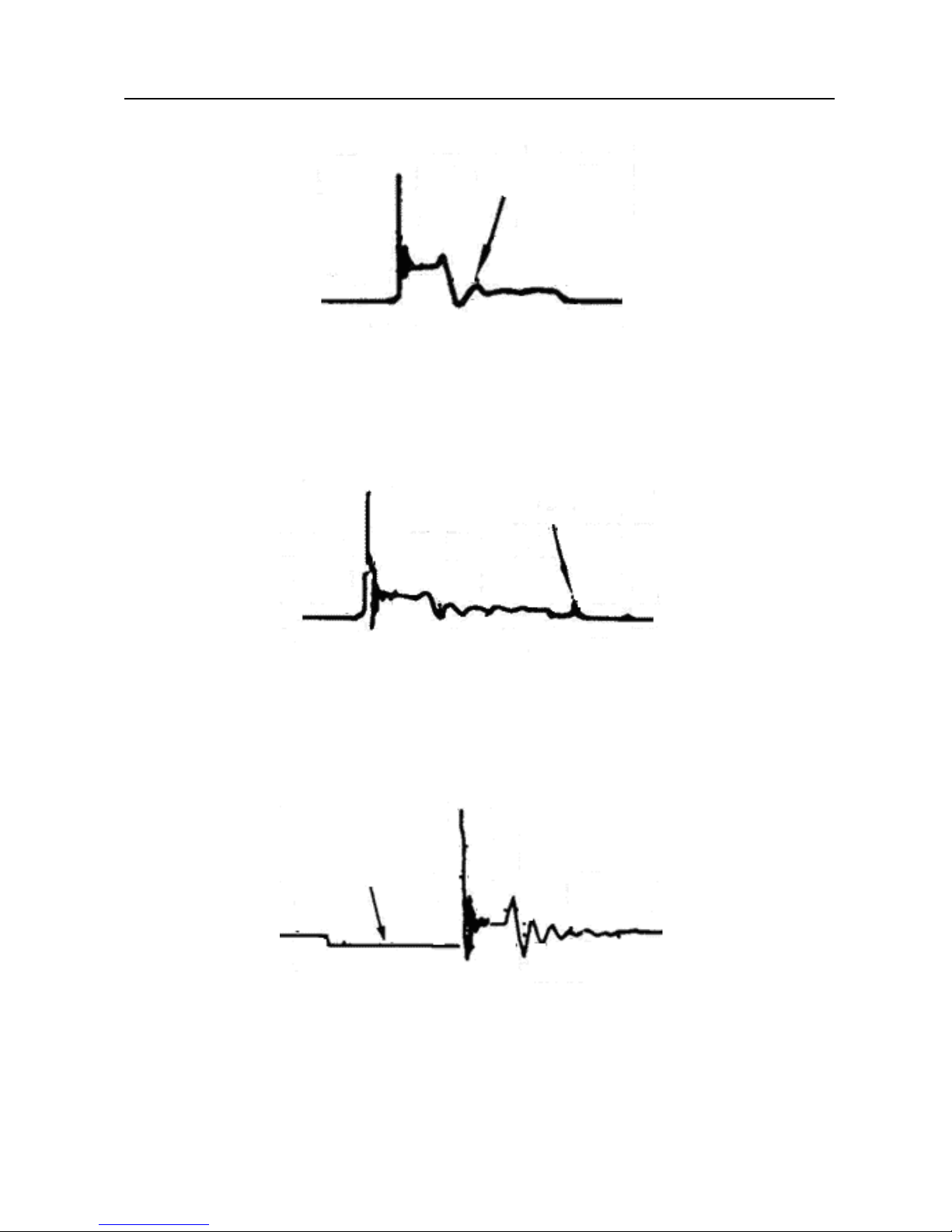

Fig. 4-5 shows the normal secondary (the upper one) and

(the lower one)

primary ignition waveform of direct ignition system. Beause the on/off of

primary circuit is not opening/closing of mechanical contact, but the conduction

of transistor. The primary voltage has no obvious oscillations within the

duration, but the voltage increases during the magnetization process due to

current limiting, and this change can cause corresponding fluctuations of

secondary voltage line as a result of induction of ignition coil.

21

Page 24

LAUNCH X431 PAD Scopebox User’s Manual

Fig. 4-5

4.4 Waveform analysis mode

The ignition secondary single-cylinder waveform test is mainly used to:

a. Analyze the ignition dwell angle of single cy

linder.(ignition coil charging

time)

b. Analyze the capability of ignition coil and secondary high tension circuit

(from ignition line

to ignition voltage line).

c. Find the improper mixture A/F ratio of single cylinder (from co

mbustion

line).

d. Analyze the capability of capacitance (platinum or ignition sy

stem).

e. Find the spark plug that causes misfire of the c

ylinder (from combustion

line).

This test can provide very meaningfu

l information about the combustion quality

for each cylinder. If necessary, this test can also be performed during driving.

Since the secondary ignition waveform is significantly affected by different

engines, fuel systems and ignition conditions, it is useful for detecting the faults

22

Page 25

LAUNCH X431 PAD Scopebox User’s Manual

23

of engine mechanical parts, fuel system components, and

ignition system

components. Different parts of the waveform can specify that some

components and systems on the specific cylinder have faults. Refer to the

instructions for various parts of waveform for the related component working

status of specific waveform section.

Test methods and conditions:

Start the engine or drive the vehicle accroding

to the driving performance fault

or poor ignition, etc. Confirm the consistence of judgement standard (the

amplitude, frequency, shape and pulse width, etc., for each cylinder), check

the fault of the waveform for corresponding components.

Waveform results: observe the ignition coil at the beginning of charging, the

relative cons

istent falling edge represents the dw ell angle and ignitio n timing of

each cylinder are precise.

Ignition line:

Observe the height consistence of flashover voltage. Too high flashover

voltage (even out of the oscillosco

pe screen) represents a high resistance

existed in the ignition secondary circuit (for example, open circuit, or damaged

spark plug or high voltage line, or too large time gap on spark plug), while the

too short sparking voltage represents the resistance of ignition secondary

circuit is lower than normal value (due to pollut ant and broken s park plug or the

high voltage line of spark plug has electric al leakage, etc.).

Spark or combustion voltage:

Observe the consistence of spark or combustion voltage, as it represents the

consistence of sp

ark plug and the air-fuel ratio of each cylinder. In case that

the mixing ratio is too lean, the combustion voltage will be lower than normal

value.

Combustion line:

Observe the spark or the combustion line which shall be clean with few clutter,

as lots

of clutter indicates the cylinder has poor ignition due to ignite too early,

damaged nozzle, pollutant spark plug, or other reasons. The duration of

combustion line indicates the mixing ratio of the cylinder is abnormal lean or

Page 26

LAUNCH X431 PAD Scopebox User’s Manual

rich. Too long combustion line (usually greater than 2ms) represents the mixing

ratio is rich, whereas too short of combustion line (usually less than 0.75ms)

represents the mixing ratio is lean.

Ignition coil oscillation:

Observe at least two oscillation w aveforms af ter the combustion line, which w ill

be better if more than three oscillation w

aveforms, as it represents the ignition

coil and capacitor (on Platinum or ignition system) are normal.

Primary voltage analysis

According to the faulty primary voltage waveform collected by the ignition

analysis, the rel

ated components and mechanical equipment status of ignition

system electrical circuit can be analyzed, which provides a reliable basis for

the adjustment and maintenance of power circuit to avoid the blind demolition.

The waveform shown on Fig. 4-6, appears a lot of clutter on the contact break

point, which is obviou

sly caused by the serious erosion on contact break point.

It can be verified via burnishing the contact or changing the circuit breaker.

Fig. 4-6

For the primary voltage waveform shown on Fig

. 4-7, the damped attenuation

cycles obviously reduced on the spark period, the amplitude became lower,

which is evidently caused by capacitor leakage.

24

Page 27

LAUNCH X431 PAD Scopebox User’s Manual

Fig. 4-7

The waveform on Fig. 4-8, shows the accide

ntal pumping during contact

closing period. The irregular beating is caused by insufficient spring force.

Fig. 4-8

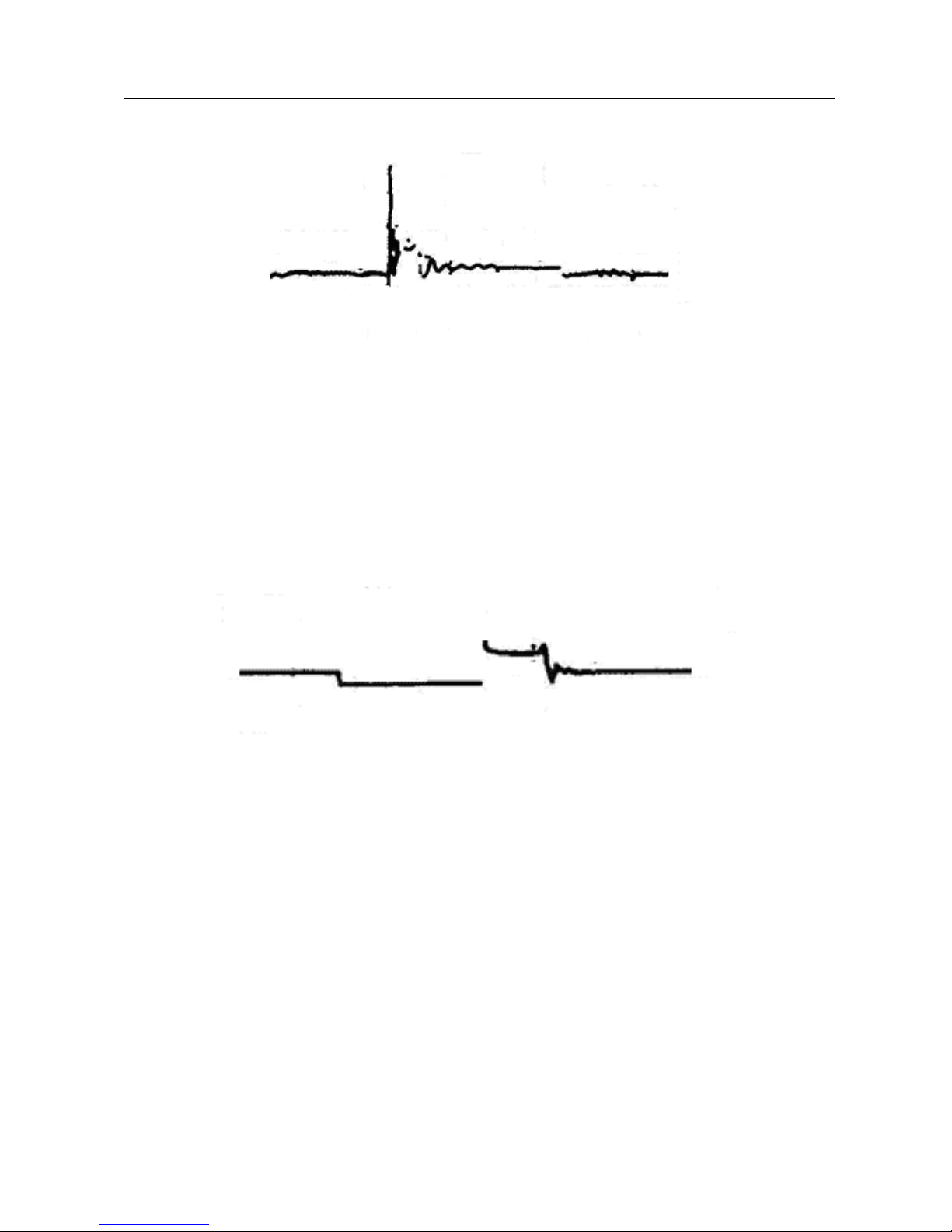

The curve on Fig. 4-9 shows the contact angle is too small during the

magnetizing per

iod, which is caused by too large contact gap.

Fig. 4-9

A lot of clutter will be display ed on the horizont

al section of primary waveform if

contact has poor grounding, as shown below figure 4-10.

25

Page 28

LAUNCH X431 PAD Scopebox User’s Manual

Fig.4-10

Fig. 4-11 shows the fault of low-voltage waveform in electronic ignitio

n system.

The voltage does not rise during magnetiz ing, w hich ind icates that the effect of

limitation of the circuit failed and no components on distributorless ignition

system can be adjusted. When this waveform is abnormal, you can only

replace the ignition coils, igniter, ignition signal generator and cam position

sensor, etc., one by one, to find out the faulty component or module.

Fig. 4-11

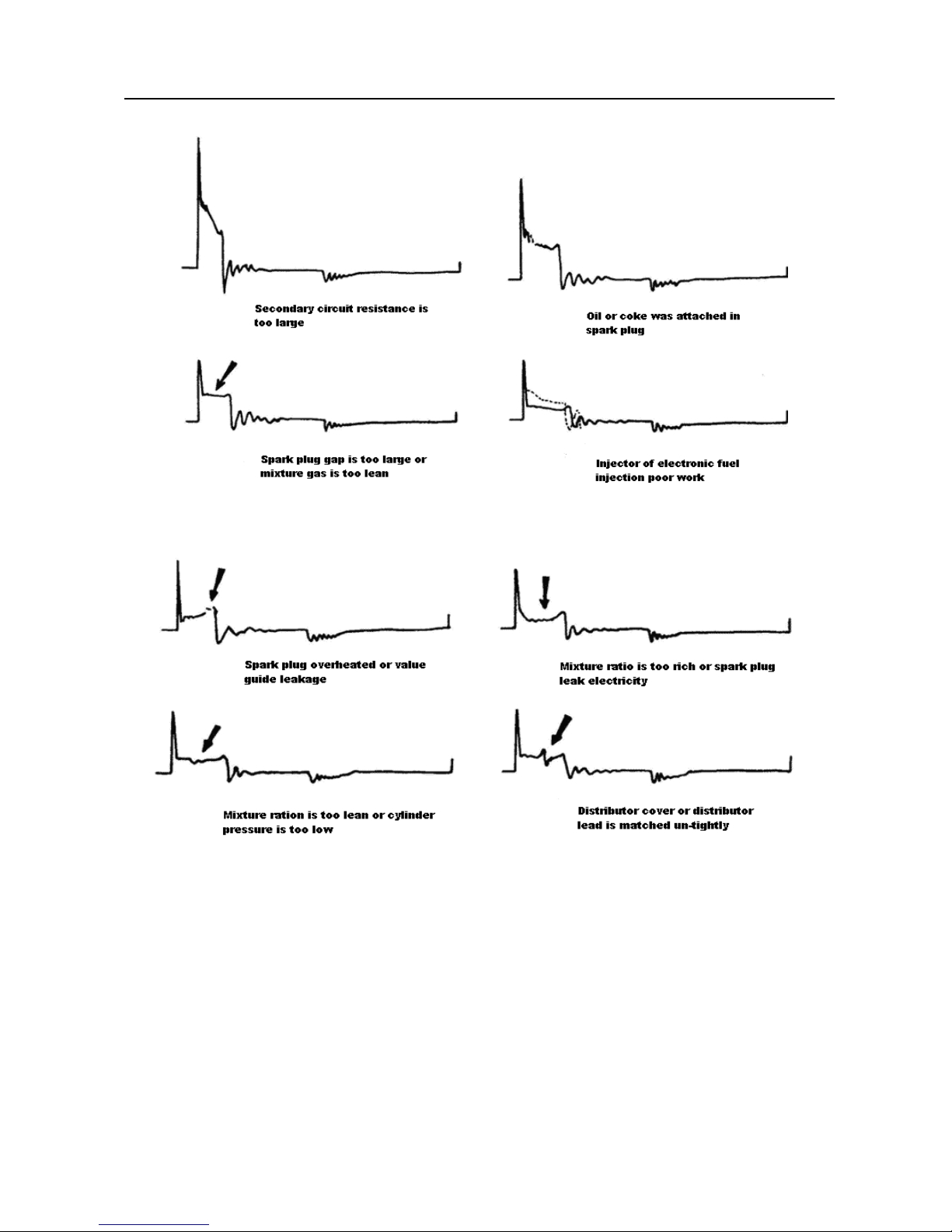

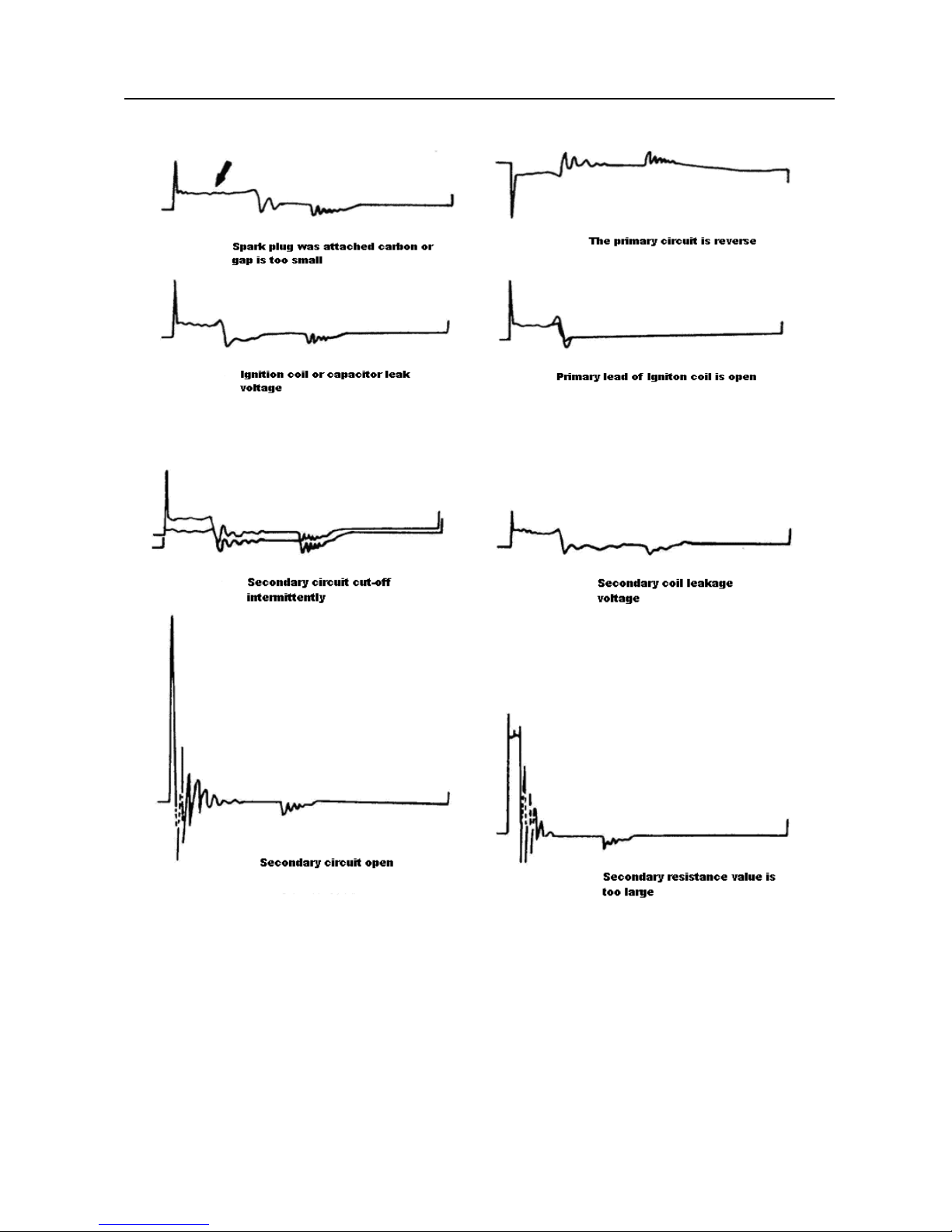

The secondary waveform is also affected by the spark plug, the combustion

process, mixt

ure gas composition, the engine thermal state of the ignition coil,

etc., which is more complicated. The following lists a large number of

measured secondary faulty waveform for reference. Since various factors lead

to the failures, Fig. 4-12 just shows the major possible factors for the failures.

26

Page 29

LAUNCH X431 PAD Scopebox User’s Manual

27

Page 30

LAUNCH X431 PAD Scopebox User’s Manual

Fig 4-12

28

Page 31

LAUNCH Android-based Scopebox User’s Manual

1 Foreword

1.1 Introductions

The scopebox is an optional add-on module for Launch’s

Android-based diagnostic tool, including automotive oscilloscope and

automotive ignition waveform.

Automotive oscilloscope can make the auto repair technician quickly judge

the faults on automotive electronic equipment and wiring, and the

oscilloscope sweep speed is far greater than the signal frequency of such

vehicles, usually 5-10 times of the measured signal. The automotive

oscilloscope not only can quickly acquire the circuit signal, but also can

slowly display the waveform to observe and analyze. It can also record and

store the tested signal waveform which can be recalled to observe for the fast

signal, having great convenience to failure analysis. Either high-speed signal

(e.g.: Injection nozzle, intermittent fault signal) or the slow-speed signal (e.g.

the throttle position change and the oxygen sensor signal) can be observed

through automotive oscilloscope in an appropriate waveform.

The electronic signal can be compared and judged via measuring five

parameters indexes. The five parameters are the amplitude (the maximum

voltage of signal), the frequency (the cycle time of signal), the shape (the

appearance of signal), the pulse width (the duty cycle or the time range of

signal), and the array (the repetition characteristic of signal), which can be

tested, displayed, saved by the automotive oscilloscope. Via the waveform

analysis can further detect the circuit fault on sensors, actuators, circuits, and

electronic control units, etc.

1.2 Product features

y Rapidly capture the circuit signal.

y Display waveform slowly for observation and analysis.

y Record and store the tested signal waveform for playback and failure

analysis.

y Detect, display and store all the electrical signal of five parameters, namely

Page 32

LAUNCH Android-based Scopebox User’s Manual

ampl

itude, frequency, shape, pulse width, and array.

1.3 Product function

Provides sp

ecialized automotive oscilloscope function and supports ignition

waveform analysis.

1.4 Technical parameters

Scopebox: 4 channels, highest sampling frequency 200MHZ, max. storage

depth 64MSa, 8-bit resolut ion.

Page 33

LAUNCH Android-based Scopebox User’s Manual

2 Structure and Accessories

2.1 Scopebox structure

Fig 2-1 Sc

opebox Structure Diagram

Table 2-1 sh ows the ports and indicators for the scopebox.

No. Name Description

1 CH1 Channel 1

2 CH2 Channel 2

3 CH3 Channel 3

4 CH4 Channel 4

5 External trigger External trigger signal

6 Fixed signal

generator

Generate a square signal with fixed 1K frequency.

Page 34

LAUNCH Android-based Scopebox User’s Manual

7

Power indicator It keeps steady red after the scopebox is powered

on.

8 Running

indicator

It remains steady green after the scopebox is

running.

9 Communication

indicator

It blinks in process of data commu nication.

10 Power interface Connect to power supply via the power adapter.

11 B-shaped USB

interface

Connect main unit via USB cable as separated

individual USB devices.

2.2 Scopebox accessories

The scopebox includes the sec ondary pickup c able for 4-chann el osc illoscope ,

crocodile clips for 4-channel oscilloscope, etc. See Tabl e 2-2.

As the product configuration can be different, the accessories included with the

product may differ from the accessories listed on this manual. Please see the

packing list attached to the product for the detailed a ccessories.

Table 2-2 Accessory checklist

No. Name Picture

1 Secondary ignition pickup for

4-channel oscilloscope

2 Crocodile clips for 4-channel

oscilloscope

3 Direct ignition extension cord

Page 35

LAUNCH Android-based Scopebox User’s Manual

4

6-way universal guide line for

4-channel oscilloscope

5 BNC to 4mm connector test cable

6 Pin connector suite for 4-channel

oscilloscope

Page 36

LAUNCH Android-based Scopebox User’s Manual

3 Automotive Oscilloscope

3.1 Connection

The scopebox should work with the Launch’s Android-based diagnostic tool.

1. Firstly, power on the diagnostic tool.

2. Then plug one end of ground cable of the scopebox into external trigger

channel (GND), the other end should b e grounded.

3. Connect one end of probe cable to the CH1, CH2, CH3, or CH4 on the

scopebox, and then connect the other end to related signal terminal.

Warning: Please use the specific capacitance probe when diagnosing the

ignition high voltage line. Never connect the scopebox to the ignition

secondary circuit directly.

3.2 Initial interface introduction

Fig. 3-1 displays the initial interface of the scopebox.

Fig. 3

-1

Page 37

LAUNCH Android-based Scopebox User’s Manual

No. Descri

ptions

1 Signal display area

2 Horizontal Settings: Controls the time base.

3 Vertical Settings: Controls the amplitude of the displayed signal.

4 Trigger Settings: Controls the start event of the sweep.

5 Channel Selection Button

6 Function Menu

[Auto]: It indicates auto trigger setting. See Chapter 3. 3.2.

[Ref]: There are expert reference and base reference

available. Expe rt reference enables you to re call your customized

expert database, whereas base reference provides automatic

pre-setting function of specialized sensors. See Chapter 3.3.6.

[File]: Provides save snapshot, snapshot manager, waveform

record and waveform replay. See Chapter 3.3.5.

[View]: Calibration and display settings are available. See

Chapter 3.3.3.

[Measure]: Includes signal source measurement, horizontal

measurement, vertical measurement and clear measurement. See

Chapter 3.3.4.

[Settings]: Shows/hides the parameter settings area

including horizontal settings, vertical settings and trig ger settings.

/ [Start/Stop]: Starts/stops collecting waveforms.

Page 38

LAUNCH Android-based Scopebox User’s Manual

3.3 Operations

3.3.1 Channel selection and attributes setting

<1> Channel selection

There are two ways av ailable for channel s election: (See Fig. 3-2)

A. Select from the channel tab shown at the bottom of the waveform display

area;

B. Select from Vertical settings.

Note: For better comparison and identification, each channel and waveform

are marked in different colors.

Fig.3

-2

<2> Channel attributes & trigger setting

Channel attributes can be set via horizontal settings and vertical settings.

Horizontal Settings

User can make some settings directly by tapping < or > next to options. See

Fig. 3-3.

Page 39

LAUNCH Android-based Scopebox User’s Manual

Fig. 3

-3

Options descriptions:

Menu Comments/Settings

Time/DIV

Horizontal sc ale. I f t he w aveform acquisition is stopped

(using the

/ button), the Time/DIV selector

expands or compresses the waveform.

Y-T format

The conventional oscil loscope display format. It shows

the voltage of a waveform record (on the vertical axis)

as it varies over time (on the horizontal axis).

Vertica

l Settings

The trigger determines when the scopebox starts to acquire data and display a

waveform. When a trigger is set up properly , it can conver t unstable displa ys or

blank screens into meaningful waveforms.

When the scopebox starts to acquire a waveform, it collects enough data so

that it can draw the waveform to the left of the trigger point. The scopebox

continues to acquire dat a w hile waiting for the trigger condition to occur. After it

detects a trigger, the scopebox continues to acquire enough data so that it can

draw the waveform to the right of the trigger point.

User can make some settings directly by tapping < or > next to options. See

Fig. 3-4.

Page 40

LAUNCH Android-based Scopebox User’s Manual

Fig. 3

-4

Options descriptions:

Menu Comments/Settings

Channel

To select the channel source.

Volts/DIV

It is defined as “Volts/Division” and mainly used to

change the resolution.

Coupling

Trigger coupling determines what part of the signal

passes to the trigger circuit. AC, DC and Ground are

included:

AC: Blocks the DC component of the input sign al;

DC: Passes both AC and DC components of the input

signal;

Ground: Disconnects the input signal.

Probe

When using a probe, the scopebox allows you to select

the attenuation factor for the probe. The attenuation

factor change s the vertica l scaling of t he scopebox so

that the measurement results reflect the actual voltage

levels at the probe tip.

BW Limit

ON: Limits the channel bandwidth to 20MHz to redu ce

display noise.

OFF: Get full bandwidth.

Invert ON: Turn on the invert function.

Page 41

LAUNCH Android-based Scopebox User’s Manual

OF

F: Restore to the ori gi nal display of the wa veform.

T ri

gger setting

Trigger indicates that when certain waveform meets the conditions that are

predefined according to the requirements, the scopebox acquires the

waveform and its adjacent section, and then presents it on the screen.

Fig. 3-5

1) If Edg

e trigger is selected (An edge trigger determines whether th

e

scopebox finds the trigger point on the rising or the falling edge of a signal.):

Menu Comments/Settings

Sweep

The sweep mode determines how the scopebox

behaves in the absence of a trigger event. The

scopebox provides three trigger modes: Auto, Normal,

and Single.

Auto: It allows the scopebox to acquire waveforms

even when it does not detect a trigger condition. If no

trigger condition occurs while the scopebox is waiting

for a specific pe r iod, it will force it self to trigger.

When forcing invalid triggers, the scopebox can not

synchronize the wa veform, and then waveform seems

to roll across the display. If valid triggers occur, the

Page 42

LAUNCH Android-based Scopebox User’s Manual

display becomes stable on the screen.

Normal: This mode allows the scopebox to acquire a

waveform only when it is trig gered. If no trigger occurs,

the scopebox keeps waiting, and the previous

waveform, if any, will remain on the display.

Single: In this mo de, it only acquires the waveform that

generates for the first time the trigger conditions are

met, and then stops after finishing capture.

Source

Select which channel as trigger signal.

Slope

+ : Trigger on rising edge

- : Trigger on falling edge

High Freq

Rejection

Reject high frequency signals when selected.

2) If Pulse Width trigger is selected (Pulse trigger occurs according to the

wi

dth of pulse. The abn ormal signals can be detected thro ugh setting up the

pulse width condition):

Menu Comments/Settings

Sweep

The sweep mode determines how the scopebox

behaves in the absence of a trigger event. The

scopebox provides three trigger modes: Auto, Normal,

and Single.

Auto: It allows the scopebox to acquire waveforms

even when it does not detect a trigger condition. If no

trigger condition occurs while the scopebox is waiting

for a specific period, it will force itself to trigger.

When forcing invalid triggers, the scopebox can not

synchronize the wa veform, and then waveform seems

to roll across the display. If valid triggers occur, the

display becomes stable on the screen.

Normal: This mode allows the scopebox to acquire a

Page 43

LAUNCH Android-based Scopebox User’s Manual

waveform only when it is trig gered. If no trigger occurs,

the scopebox keeps waiting, and the previous

waveform, if any, will remain on the display.

Single: In this mo de, it only acquires the waveform that

generates for the first time the trigger conditions are

met, and then stops after finishing capture.

Source

Select which channel as trigger signal.

Condition

To select pulse condition.

Pulse Width

Set required pulse width.

High Freq

Rejection

Reject high frequency signals when selected.

3.3.2 Auto

The scopebox has an Auto feature that sets up the scopebox autom atically to

display the input signal in a best fit.

Tap

, the scopebox may change the current settings to display t he signal.

It automatically adjusts the vertical and horizontal scaling, as well as the trigger

coupling, position, slope, level and mode settings.

3.3.3 View Settings

<1> Calibration

This option adjusts the scopebox’s internal circuitry to get the best accuracy.

Use this function to calibrate the Scopebox’s vertical and horizontal systems.

Tap

and then tap [Calibration], a dialog box similar to Fig. 3-6 will appear.

Page 44

LAUNCH Android-based Scopebox User’s Manual

Fig. 3-6

Check the box before the channel to select it. To deselect it, just uncheck it.

After choosing the desired channel(s), tap [Start] to start calibration and [Start]

button will be temporarily invalid during calibrating. Tap [Stop] to stop

calibrating. Once it becomes active, it indicates calibration has completed.

Notes: In proc ess of cali bration, make sure CH1/ CH2/CH3/CH4 has no signal

input. Moreover, calibration may take several minutes and please be patient to

wait.

<2> REF settings

Reference waveforms are saved waveforms to be selected for display. The

reference function will be available after saving the selected waveform to

non-volatile memory.

Tap

and then [REF] to enter the REF setting screen. See Fig. 3-7.

Page 45

LAUNCH Android-based Scopebox User’s Manual

Fig. 3

-7

Tap < or > to select the desired reference value for time/DIV and volts/DIV. To

show or hide the REF, just check/uncheck the box before On/Off.

<3> Display settings

Tap

and then [Display settings] to enter the setting screen. See Fig. 3-8.

Fig. 3-8

Select “Vectors” or “Dots” to display waveforms as vectors or dots.

Check/uncheck the box before Grid to turn on/off grid display.

3.3.4 Measure

<1> Channel source

Tap

and then [Source], a screen similar to Fig. 3-9 will appear.

Page 46

LAUNCH Android-based Scopebox User’s Manual

Fig. 3-9

<2> Horizontal / Vertical measure

Horizontal Measure / Vertical Measure are used to measure voltage parameter

and time parameter respectively. Drag A line upwards or downwards to control

voltage. Move A line left or right to fine-tune timebase. A line is a solid line and

B line is a dotte d line.

Tap

and then [Horizontal Measure], a screen similar to Fig. 3-10 will

appear.

Fig. 3-

10

Page 47

LAUNCH Android-based Scopebox User’s Manual

Not

e: If no desired channel is selected, the sy st e m will take t h e cu rr ent so u rce

as the default channel.

<3> Clear measure

Tap

and then [Clear Measure], the system will clear the measurement

result on screen.

3.3.5 File management

<1> Save snapshot

While viewing sampling data, tap

and then [Save Snapshot] to store the

current screen.

<2> Snapshot manager

While viewing sampling d ata, tap

and then [Snapshot Manager] to enter.

View, delete and edit operations are supported.

<3> Record waveform

This function is used to record input waveforms that are acquired by the

scopebox at a specific period, and save it as waveform file which can be

recalled in future.

It can be performed only w hen the scop ebox is coll ecting dat a in Norm al mode.

Tap

, then select [Record] from the pop-up menu to start recording. See

Fig. 3-11.

Page 48

LAUNCH Android-based Scopebox User’s Manual

Fig.3

-11

Tap [Start] to start recording with a minimum record length of 10 frames, and

[Stop] to stop recording. While recording, the recorded pages will be shown on

the screen.

<4> Load waveform for playback

The Import function enables you to import the stored waveform file for

playback and review. During replaying, the scopebox stops collecting data

automatically.

Tap

, then select [Waveform replay] from the pop-up menu to enter a

screen similar to Fig. 3-12.

Page 49

LAUNCH Android-based Scopebox User’s Manual

Fig.3

-12

Select the file first, and then tap

to open the waveform file. Tap to

starting the playback and tap

to stop it.

Fig.3

-13

To delete the waveform file, tap

.

Tap

to return to the previous screen.

Page 50

LAUNCH Android-based Scopebox User’s Manual

3.3.6 Expert Reference

<1> Expert Reference

By default, it appears blank. As a matter of fact, Ex pert reference database i s

generated by doing the fol lowi ng:

1. Open and edit a snapshot

;

2. Select “Joint the expert database” (refer to the following illustration), and

then tap

to save the waveform being displayed on the screen as REF.

Fig. 3-

14

Tap

and then [Expert Reference] to enter, the following operation can be

done:

: To load and recall the selected file.

: To delete the selected file.

: To edit the selected file.

<2> Base Reference

Preset waveforms of some sensors are available f or your reference.

Page 51

LAUNCH Android-based Scopebox User’s Manual

Fig. 3-15

3.3.7 Exit the application

Tap to exit the current appli c ati on.

Page 52

LAUNCH Android-based Scopebox User’s Manual

4 Automotive Ignition waveform

The ignition system is the system which has greatest impact on the

performances of gasoline engine, as the statistical data shows that nearly half

of the failures are caused by poor work of electrical system. And the

performance tests of engine often start from the ignition system. Nowadays

ignition system includes distributor and distributorless. Distributorless includes

independent ignition and simultaneous ignition.

1. Distributor ignition system i.e. contact breaker with contact-controlled

ignition system (commonly known as the platinum) and contact breaker

with noncontact-controlled ignition system combined with magnet, hall

components or infrared.

2. Independent ignition system: Each spark plug has its own individual coil

that sits right on top of it, also called coil on plug system. Crankshaft

sensor send out the ignition timing signal and cylinder identification signal

so that the ignition system can send out ignition signal to specifie

d

cylinder in specified time , each cylinder has its independent ignition coil.

3. Simultaneous ignition system: Two spark plugs share the same coil, also

called waste spark system. When two cylinder pistons reach top dead

center at the same time (one is compression, another is the exhaust), two

spark plugs will be ignit ed at the same time, at this time, the ignition for

the former cylinder is in high-p ressure low temperature gas mixture, th

e

ignition is val id, while for th e lat ter one is in low-pressure high te mperature

exhaust gas, the ignition is invalid.

The scopebox can test and analyze the secondary signal for various engine

ignition systems.

4.1 Secondary-distributor ignition analysis

Connections: Plug the BNC end of secondary ignition pickup into

CH1/CH2/CH3/CH4 channel of the scopebox, and then connect the

high-voltage clip to high-voltage line, and crocodile clips to ground.

Tips: Common ignition sequence (the specific sequence is subject to the

Page 53

LAUNCH Android-based Scopebox User’s Manual

actua

l engine ignition sequence)

Four-stroke in-line four-cylinder: 1-2-4-3, or 1-3-4-2

Four-stroke in-line six-cy linder: 1-5-3-6-2-4, or 1-4-2-6-3-5

Four-stroke in-line eight-cylinder: 1-8-4-3-6-5-7-2

Five-cylinder: 1-2-4-5-3

V 6 engine: Generally speaking, based on the person sitting on the driver cab,

if the right side cylinder numbers on the right side, from the front to the back

are as follows: 1, 3, 5; and the cylinder numbers on the left side, from the front

to the back are as follows: 2, 4, 6; then the ignition sequence is: 1-4-5-2-

3-6. If the cylinder numbers on the righ t side, fr om the front to the back are as

follows: 2, 4, 6; and cylinder numbers on the left side, from the front to the back

are as follows:1, 3, 5; then the ignition sequence is: 1-6-5-4-3-2.

The Figure 4-1 below show s the nor mal ignition waveform of distributor ignition

system, the upp er one is the secondary waveform, an d the lower one is the

primary waveform.

The secondary waveform

A se ction is co ntact open period; B sectio n is make contact period, which is the

magnetizing field of ignition coil.

Page 54

LAUNCH Android-based Scopebox User’s Manual

Fig. 4

-1

1) Contact break point: The primary circuit of ignition coil cut off, the

secondary voltage was sensed and increased sharply

2) Ignition voltage: Secondary coil voltage overcome the damper of high

voltage line, the contact breaker gap and the spark plug gap to release

magnetizing energy, 1-2 section is the breakdown voltage

3) Spark voltage: For the capacitor disch a rge vol tage

4) Ignition voltage pulse: For the charge and discharge section s

5) Spark line: The inductance discharge process, i.e. the mutual inductance

voltage of ignition coil maintains the conduction of secondary circuit

6)

Contact point close the current flow into primary coil, the primary coil

oscillates due to the mutual inductance.

Primary ignition waveform

Section a shows the voltage oscillation on the primary circuit due to the

magnetic induction of spark in the duration;

Section b shows the damped oscillation g enerated by remaining m agnetic field

Page 55

LAUNCH Android-based Scopebox User’s Manual

energy

after the spark;

Section c shows the make contact magnetic period of primary coil.

Seen from the waveform, the amplitudes of breaker contact closed angle,

break angle and breakdo wn vol tage and spark voltage are v ery cl ea r, besides,

the spark delay period and t wo oscill ation s can also be test ed. For the ig nition

system without faults, compared with the whole cycle, the contact closed angle

just 45%-50% (four-cylinder), 63%-70% (six-cylinder), or 64%-71%

(eight-cyliner); the breakdown voltage is over 15kv; the spark voltage is about

9kV, the spark period is greater than 0.8ms. If these values or waveform are

abnormal, it means there is fault or the system needs to be adjusted.

4.2 Secondary-simultaneous ignition analysis

Connections: Plug the BNC end of secondary ignition pickup into

CH1/CH2/CH3/CH4 channel of Scopebox, then connect the high-voltage clip

to high-voltage line, and crocodile clips to ground.

Connection as shown in figure 4-2:

Fig. 4

-2

Page 56

LAUNCH Android-based Scopebox User’s Manual

F

ig. 4-3 below shows the valid and invalid ignition waveforms. Under the

working status of valid ignition, the breakdo wn voltage and spark voltage are

higher because the cylinder is filled with fresh combustible mixture gas, which

has a lower ioni zation level and vice versa.

Fig. 4

-3

4.3 Secondary-direct ignition analysis

Connection:

1) When the high-voltage wire is exposed, plug the BNC end of secondary

ignition pickup into CH1/CH2/CH3/CH4 channel of Scopebox, then

connect the high-voltage clip to high-voltage line, and crocodile clips to

ground.

2)

If no high-voltage wire exposes, dismantle ignition coil of tested cylinder

and use direct ignition extension cord. Connect one end to ignition coil

which should be grounded via direct ignition grounding wire, and insert the

other end into cylinder to joint with spark plug. Then plug the BNC end of

secondary ignition pickup into CH1/CH2/CH3/CH4 channel of Scopebox,

then connect the high-voltage clip to high-voltage line, and crocodile clips

to ground.

Connections are shown in Fig. 4-4:

Page 57

LAUNCH Android-based Scopebox User’s Manual

Fig. 4

-4

Fig. 4-5 shows the normal secondary (the upper one) and (the lower one)

primary ignition waveform of direct ignition system. Because the on/off of

primary circuit is not opening/c losing of mechanical cont act, but the conduction

of transistor. The primary voltage has no obvious oscillations within the

duration, but the voltage increases during the magnetization process due to

current limiting, and this change can cause corresponding fluctuations of

secondary voltage line as a result of induction of igniti on co il .

Page 58

LAUNCH Android-based Scopebox User’s Manual

Fig. 4

-5

4.4 Waveform analysis mode

The ignition secondary si ng l e -cyl i nd er wave f orm test is mainly used to:

a. Analyze the ignition dwell angle of single cylinder.(ignition coil charging

time)

b. Analyze the capability of ignition coil and secondary high tension circuit

(from ignition line to ignition voltage line).

c. Find the improper mixture A/F ratio of single cylinder (from combustion

line).

d. Analyze the capability of capacitance (platinum or ignition system).

e. Find the spark plug that causes misfire of the cylinder (from combustion

line).

This test can provide very meaningful information about the combustion quality

for each cylinder. If necessary, this test can also be performed during driving.

Since the secondary ignition waveform is significantly affected by different

engines, fuel systems and ignition condi tions, it is useful for detecting the fault s

Page 59

LAUNCH Android-based Scopebox User’s Manual

of eng

ine mechanical parts, fuel system components, and ignition system

components. Different parts of the waveform can specify that some

components and systems on the specific cylinder have faults. Refer to the

instructions for various parts of waveform for the related component working

status of specific waveform secti o n.

Test methods and conditions:

Start the engine or drive the vehicle accroding to the driving performance faul t

or poor ignition, etc. Confirm the consistence of judgement standard (the

amplitude, frequency, shape and pulse width, etc., for each cylinder), check

the fault of the waveform for corresponding components.

Waveform results: Observe the ignition coil at the b eginning of charging, the

relative consistent falling edge re presen t s the dwell angle and ignition timing of

each cylinder are precise.

Ignition line:

Observe the height consistence of flashover voltage. Too high flashover

voltage (even out of the scopeb ox screen) re presents a high re sist ance existed

in the ignition secondary circuit (for example, open circuit, or damaged spark

plug or high v oltage line, or too large time g ap on spark plug), while the to o

short sparking voltage represents the resistance of ignition secondary circuit is

lower than normal value (due to pollutant and broken spark plug or the high

voltage line of spark plug has electrical leakage, etc.).

Spark or combustion voltage:

Observe the consistence of spark or combustion voltage, as it represents the

consistence of spark plug and the air-fuel ratio of each cylinder. In case that

the mixing ratio is too lean, the combustion voltage will be lower than normal

value.

Combustion line:

Observe the spark or the combustion line which shall be clean with few clutter,

as lots of clutter indicates the cylinder has poor ignition due to ignite too early,

damaged nozzle, pollutant spark plug, or other reasons. The duration of

combustion line indic ates the mixing ratio of the cylinder is abnormal l ean or

Page 60

LAUNCH Android-based Scopebox User’s Manual

ri

ch. Too long combustion line (usually greater than 2ms) represents the mixing

ratio is rich, whereas too short of combustion line (usually less than 0.75ms)

represents the mixing ratio is lean.

Ignition coil oscillation :

Observe at least two oscillation waveforms after the combustion line, which will

be better if more than three oscillation waveforms, as it represents the i gniti on

coil and capacitor (on Platinum or ignition system) are normal.

Primary voltage analysis

According to the faulty primary voltage waveform collected by the ignition

analysis, the related components and mechanical equipment status of ignition

system electrical circuit can be analyzed, which provides a reliable basis for

the adjustment and maintenance of power circuit to avoid the blind demolition.

The waveform shown on Fig. 4-6, appears a lot of clutter on the contact break

point, which is obviously caused by the serious erosion on contact break point.

It can be verified via burnishing the contact or changing the circuit breaker.

Fig. 4

-6

For the primary voltage waveform shown on Fig. 4-7, t he damped attenuation

cycles obviously reduced on the spark period, the amplitude became lower,

which is evidently caused by capacitor leakage.

Page 61

LAUNCH Android-based Scopebox User’s Manual

Fig. 4

-7

The waveform on Fig. 4-8, shows the accidental pumping during contact

closing period. The irregular beating is caused by insufficient spring force.

Fig. 4

-8

The curve on Fig. 4-9 shows the contact angle is too small during the

magnetizing period, which is caused by too large contact gap.

Fig. 4

-9

A lot of clutter will be displayed on the horizontal section of pr ima ry wave form if

contact has poor grounding, as shown below figure 4-10.

Page 62

LAUNCH Android-based Scopebox User’s Manual

Fig.4

-10

Fig. 4-11 shows the fault of low-voltage waveform in electronic ignition sys tem.

The voltage does not rise during magnetizing, which indicates that the effect of

limitation of the circuit failed and no components on distributorless ignition

system can be adjusted. When this waveform is abnormal, you can only

replace the ignition coils, igniter, ignition signal generator and cam position

sensor, etc., one by one, to find out the faulty component or module.

Fig. 4-1

1

The secondary waveform is also affected by the spark plug, the combustion

process, mixture gas composition, the engine thermal state of the igniti on coil,

etc., which is more complicated. The following lists a large number of

measured secondary faulty waveform for reference. Since various factors lead

to the failures, Fig. 4-12 just shows the major possible factors for the failures.

Page 63

LAUNCH Android-based Scopebox User’s Manual

Page 64

LAUNCH Android-based Scopebox User’s Manual

Fig 4-

12

Page 65

LAUNCH X431 GDS Scopebox Manual

1 Foreword

1.1 Introductions

X-431 GDS is a new generation of sophisticated and

integrated automotive diagnostic product with colorful screen

and powerful functions developed by LAUNCH, and Scopebox

is an optional function box for GDS, including automotive

oscilloscope and automotive ignition waveform.

Automotive oscilloscope can make the auto repair technician quickly

judged the faults on automotive electronic equipment and wiring,

and the oscilloscope sweep speed is far greater than the signal

frequency of such vehicles, usually 5-10 times of the measured

signal. The automotive oscilloscope not only can quickly capture the

circuit signal, but also can slowly display the waveform to observe

and analyze. It can also record and store the tested signal waveform

which can be played back to observe for the fast signal, having great

convenience to failure analysis. Either high-speed signal (e.g.:

injection nozzle, intermittent fault signal) or the slow-speed signal

(e.g. the throttle position change and the oxygen sensor signal) can

be observed through automotive oscilloscope in an appropriate

waveform.

The electronic signal can be compared and judged via measuring

five parameter

s indexes. The five parameters indexes are the

amplitude (the maximum voltage of signal), the frequency (the cycle

Page 66

LAUNCH X431 GDS Scopebox Manual

time of signal), the shape (the appearance of signal), the pulse width

(the duty cycle or the time range of signal), and the array (the

repetition characteristic of signal), which can be tested, displayed,

saved by the automotive oscilloscope. Via the waveform analysis

can further detect the circuit fault on sensors, actuators, circuits, and

electronic control units, etc.

1.2 Product features

z Rapidly capture the circuit signal.

z Display waveform slowly for observation and analysis.

z Record and sto

re the tested si

gnal waveform for playback and

failure analysis.

z Detect, display and store all

the electrical signal of five

parameters, namely amplitude, frequency, shape, pulse width,

and array.

1.3 Product function

Provides specialized automotive oscilloscope function and supports

ignition waveform analysis.

1.4 Technical parameters

Scopebox: 4 channels, highest sampling frequency 150MHZ, max

storage depth 64MSa, 8-bit resolution

Page 67

LAUNCH X431 GDS Scopebox Manual

2 Structure and Accessories

2.1 Scopebox structure

cture Diagram

Table 2-1 shows S Scopebox

Fig 2-1 Scopebox Stru

the ports and i

ndicators for X-431 GD

No. Name Description

1 CH1 Channel 1

2 CH2 Channel 2

3 CH3 Channel 3

4 CH4 Channel 4

5 External trigger External trigger signal

Page 68

LAUNCH X431 GDS Scopebox Manual

6 Fixed signal square signal with fixed 1K

generator

Generate a

frequency

7 Power indicator Oscilloscope power indicator, which will

be steady red after the oscilloscope is

powered on

8 Operating

indicator

The indicator will be steady green after

the oscilloscope operated.

9 Communica

indicator

tion After the data communication, the

indicator will blink (Green).

10 Power interface Connect to power supply via the power

adapter.

11 B-shaped USB

interface

Connect main unit via USB connect line

as separated individual USB devices

.2 S x acc

kup cable for 4-channel

nel oscilloscope, etc. See

th the product may differ from the accessories listed on

2 copebo essories

Scopebox includes the secondary pic

oscilloscope, crocodile clips for 4-chan

Table 2-2.

As the produc

t configuration can be different, the accessories

included wi

this manual. Please see the packing list attached to the product for

the detailed acc

essories.

Page 69

LAUNCH X431 GDS Scopebox Manual

Table 2-2 Accessory checklist

PictureNo. Name

1 Secondary ignition pickup for

4-channel oscilloscope

2 Crocodile clips for 4-channel

Oscilloscope

3 xtension cordDirect ignition e

4 6-way universal guide line for

4-channel oscilloscope

5 BNC to 4mm connector test

cable

6 Pin connector for 4-channel

oscilloscope

Page 70

LAUNCH X431 GDS Scopebox Manual

3 Automotive Oscilloscope

3.1 Connection

X-431 GDS Scopebox should work with the X431 GDS main unit.

1. Firstly, power on the main unit (Connect one end of the power

adaptor into the

power interface of main unit, and the other end

to the DC 12V power supply. Alternatively it can be also powered

by cigarette lighter cable and double clip power cord).

2. Then pl

ug one end of ground cable of oscilloscope into external

trigger

chann

el (GND), the other end should be grounded.

3. Connect one end of probe cable of oscilloscope to the CH1, CH2,

CH3, or

CH4 on oscilloscope module, and then connect the

other end to related signal terminal.

Warning: please use the specific capacitance probe when

diag

nosing the ignition high voltage line. Never connect the

oscilloscope to the ignition secondary circuit directly.

3.2 Initial interface introduction

Fig. 3-1 displays the initial interface of oscilloscope.

Page 71

LAUNCH X431 GDS Scopebox Manual

Fig.3-1

Button descriptions:

[System]: includes show des

ktop, Wi-Fi setting, current version and

exit the program.

[Help]: displays help files.

[File]: s

upports import waveform, store waveform, store graphics,

record wavefor

m, print waveform, show/hide the grid, display cached

interface, turn pages, and clear.

[Trigger]: The following options are available: one-channel trigger /

alternation t

rigger, trigger channel source, trigger types, trigger

modes, horizontal trigger hold-off setting and auto calibration.

[Measure]: measures the ti

me and the voltage for the waveforms.

[Start/stop]: starts/stops col

lecting oscilloscope waveforms.

[Expert]: provides automatic pre-setting function of specialized

sensors.

Page 72

LAUNCH X431 GDS Scopebox Manual

3.3 Operations

3.3.1 Channel selection and attributes setting

<1> Channel selection

There are two ways available for channel selection.

A. Select from the channel menu;

B. Select via each channle attribute button.

See Fig. 3-2.

Fig.3-2

<2> Channel attributes setting

Each channel features five attributes.

A. Channel switch selection.

B. Channel voltage adjustment: + indicates increase voltage by one

level, while –

indicates decrease voltage by one level.

C. Channel time-base adjustment: + means to increase time-base

Page 73

LAUNCH X431 GDS Scopebox Manual

by one level and – means to decrease time-base by one level.

D. Channel phase selection: normal phase or reverse phase.

E. Channel coupling modes selection: DC, AC, or Ground.

See Fig.

3-3 and Fig. 3-4 for channel 1 & channel 4 attributes setting

interfaces re

spectively.

Fig.3-3 Channel 1 attributes setting

Page 74

LAUNCH X431 GDS Scopebox Manual

Fig.3-4 Channel 4 attributes setting

3.3.2 Trigger setting

<1> Trigger source

Single channel trigger and alternation trigger are included.

[Single channel trigger]: collects all channels data by triggering one

channel;

[Alternation trigger]: Each channel collects data separately based on

its own channel

triggering, only for AUTO mode.

Fig. 3-5 and Fig. 3-6 show single channel trigger & alternation trigger

setting interface

s.

Page 75

LAUNCH X431 GDS Scopebox Manual

Fig.3-5 Single channel trigger

Fig.3-6 Alternation trigger

<2> Trigger channel

To set trigger mode and voltage for one channel, please select this

channel first. See button

[Trigger].

Page 76

LAUNCH X431 GDS Scopebox Manual

<3> Trigger type

Includes edge trigger and pulse trigger, see button [Time base].

[Edge trigger]: Touch [edge] to select rising edge or falling edge;

[Pulse trigger]: Touch button [pulse] to select. There are 6 modes

available.

<4> T

rigger mode

It falls into: Auto, Normal and Single trigger. See button [Auto].

[Auto]: continuous trigger. Automatically trigger when it meets the

trigger

condit

ions; otherwise, the trigger will be forced by system;

[Normal]: continuous trigger. Trigger only when the trigger conditions

are met,

or else trigger does not happen.

[Single]: single trigger. Only trigger once when the trigger conditions

are met.

<5> Horizontal trigger hold-off setting

This option allows you to set the horizontal trigger position of the

oscilloscope. It

can be set by clicking the trigger icon directly or

through the menu. See Fig. 3-7.

Page 77

LAUNCH X431 GDS Scopebox Manual

Fig.3-7

In Fig. 3-7, the yellow inverted triangle is the horizontal hold-off

pointer. Butt

on [Hold-off 50%] can coarsely tune the horizontal

trigger, and make fine adjustment in the horizontal trigger hold-off

zone.

<6> Auto calibration

Click [Auto calibrated] button, the oscilloscope will perform automatic

calibration. [Auto calibrate

d] button will be temporarily invalid during

calibrating. Once it becomes active, it indicates calibration has

completed. See Fig. 3-8.

Page 78

LAUNCH X431 GDS Scopebox Manual

Fig .3-8

3.3.3 Channel measurement

<1> Timebase measurement

Fig.3-9

Page 79

LAUNCH X431 GDS Scopebox Manual

Button descriptions:

[Timebase]: used to s

elect mode. When it is displayed as timebase,

it is in time measurement mode;

[A line]: enables you to select A\B measurement line. The currently

selected line i

s a solid line;

Left\Right move: fine adjutme

nt button for timebase;

A\B line: time measurement line;

Measurement value display area: an area for displaying time

measu

reme

nt result.

<2> Voltage measurement

Fig.3-10

Button descriptions:

[Voltage]: u

sed to select mode. When it is displayed as Volt, it is in

voltage meas

urement mode;

Page 80

LAUNCH X431 GDS Scopebox Manual

[A line]: enables you to select A\B measurement line. The currently

selected line is a solid line;

[Up/Down]: fine adjut

ment button for voltage.

3.3.4 Expert settings

This option is specially designed to measure related vehicle sensors.

After selecting one sensor

, the osicilloscope will be preset based on

preset value of this sensor.

Click [Expert] to enter the expert setting interface. See Fig.3-11.

Fig.3-11

In Fig.3-11, left side lists sensor list and right side displays current

sample wavefor

m of selected sensor.

Page 81

LAUNCH X431 GDS Scopebox Manual

3.3.4 File management

<1> Store picture

This option is designed to save the currently displayed waveforms as

graphic file. It can be performed when the oscilloscope stops

collecting data.

Touch [File], then select [Store picture] from the pull-down list. See

Fig. 3-12.

Fig.3-12

<2> Store waveform

This item is to save the currently displayed waveforms as data file

which can be pl

ayed back by oscilloscope. It can be performed when

the oscilloscope stops collecting data.

Touch [File], then select [Store waveform] from the pull-down list.

See Fig. 3-13

.

Page 82

LAUNCH X431 GDS Scopebox Manual

Fig.3-13

<3> Record waveform

This function is used to record waveforms that are collected by

oscilloscope at

a period, and save it as data file which can be played

back in future.

It can be performed when the oscilloscope stops collecting data.

Touch [File], then select [Record] from the pull-down list to start

recording. See

Fig. 3-14.

Page 83

LAUNCH X431 GDS Scopebox Manual

Fig.3-14

[Record/Stop]: starts / stops recording. While recording, the recorded

pages will be sh

own on the screen.

<4> Import waveform for playback

The Import function enables you to import the stored waveform file

for playback and review. It only works when the oscilloscope stops

collecting data.

Click [File], then select [Import] from the pull-down list. See Fig.

3-15.

Page 84

LAUNCH X431 GDS Scopebox Manual

Fig.3-15

To delete a waveform file, please select it first, then touch [Delete]

button.

Click [OK] button to open th

e waveform file, then use channel

attributes settin

g to adjust the waveform display, or touch [File]

->[Pre Pg.]\ [Next Pg.] to turn pages. See Fig. 3-16.

Page 85

LAUNCH X431 GDS Scopebox Manual

Fig.3-16

<5> Print waveform