Page 1

LAUNCH X-431 GDS Batterybox Manual

Precaution on Operation

z The appliance is a sophisticated electronic device, never have it clashed

when in use.

z Main unit screen may flash at the moment of engine ignition, which is

normal.

z You may unplug the main unit if the program can not be actuated or

confused screen occurs. Plug again to continue the operation.

z Make sure the appliance is properly connected to the DLC to avoid

communication interruptions.

z During operation, keep the screen upward and leveled.

z Be careful when plugging and unplugging the main cable and diagnostic

connector. Tighten the screw before operation to avoid unexpected

disconnecting and/or damage to the port.

z Handle with care. Avoid collision. Unplug the power after operation.

z Unplug the power cable by holding the connector, not the cable itself.

Page 2

LAUNCH X-431 GDS Batterybox Manual

Contents

1. Foreword ...................................................................................1

1.1 Product summary................................................................1

1.2 Scope...............................................................................1

1.3 Capability standard for vehicle battery test ................................2

2. Test environment and structure........................................................3

2.1 Test environment.................................................................3

2.2 Battery status and description................................................3

2.3 Batterybox structure and test accessories.................................4

3. Connections & Operations..............................................................6

3.1 Connection........................................................................6

3.2 Inside the vehicle test...........................................................6

3.2.1 Battery test...............................................................6

3.2.2 Charging system and starting system test...................... 11

3.4 Outside the vehicle test.......................................................14

3.5 Review version info............................................................16

4. Precaution items on battery test.....................................................18

Page 3

LAUNCH X-431 GDS Batterybox Manual

1. Foreword

1.1 Product summary

X-431 GDS i

s a new generation of sophisticated and

integrated automotive diagnostic product with colorful screen and powerful

functions developed by LAUNCH.

It provides an optional function of automotive battery test, which adopts the

latest state-of-the-art conductance testing technology in the world and can test

vehicle’s battery status. Two testing environments (Inside the Vehicle and

Outside the Vehicle) are available and applicable to battery test. In addition to

battery test, charging system and actuation system test can be done while

Inside the Vehicle is selected.

It supports various battery standards and specifications, including CCA, DIN,

IEC, EN, JIS, SAE and GB etc. It is specifically designed to help car owner,

repair workshop, battery factory use battery test instrument properly and

determine whether the battery is normal or not.

1.2 Scope

Battery test aims to check starting plumbic acid storage batteries for vehicles,

ship, boats and aviations, etc. It can test all kinds of batteries complying with

CCA, DIN, JIS, EN, GB and SA standards. For detailed test standards, please

refer to Table 1-1.

1

Page 4

LAUNCH X-431 GDS Batterybox Manual

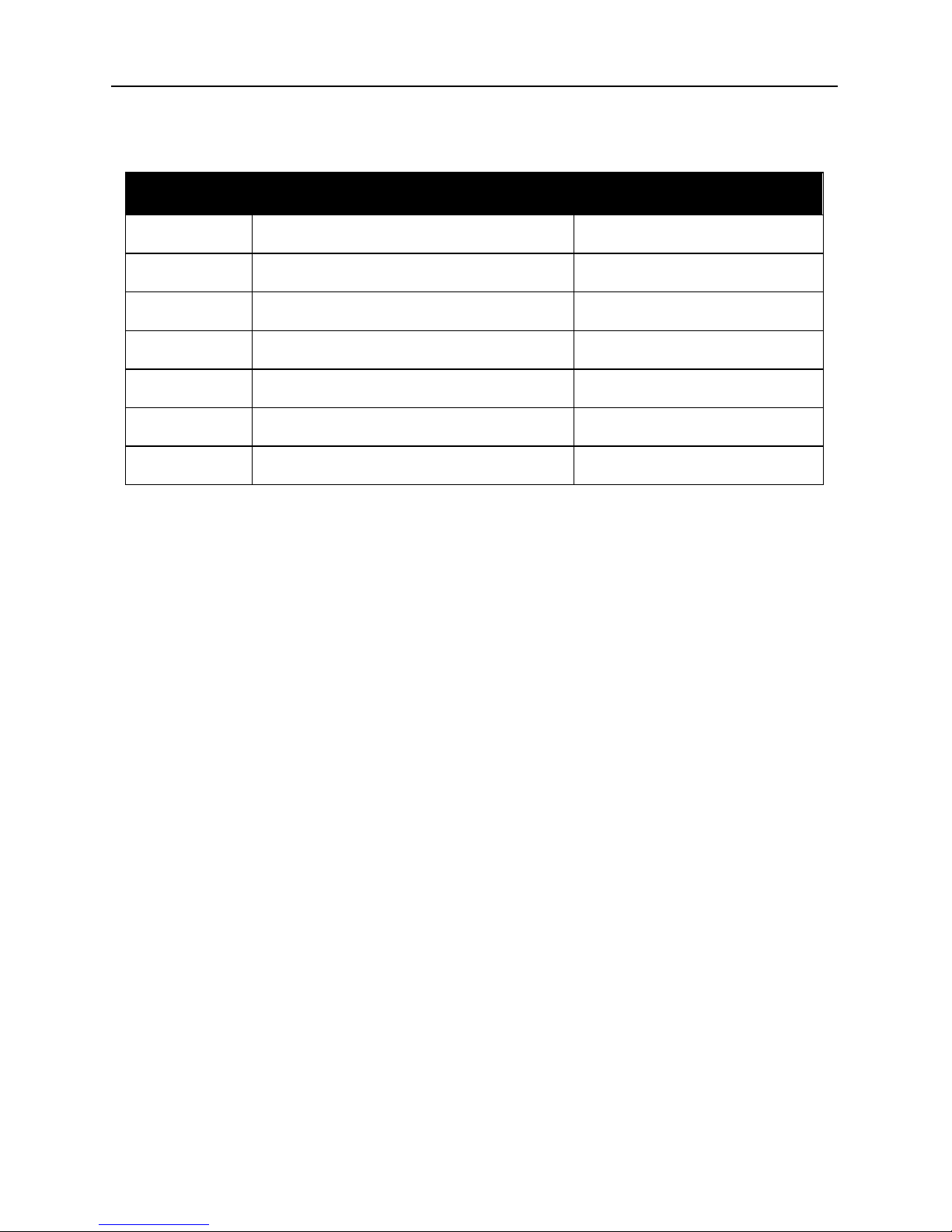

Table 1-1 Test standard

Standards Standard (Full name) Test capacity range

CCA Battery Council international

DIN Deutsche industry normen

JIS Japanese industry standard

EN Europe norm

IEC National electrical commission

GB Chinese national standard

SAE Society of Auto motive engine ers

100~1700

100~1200

26A17~245H52

100~1700

100~1200

100~1200

100~1700

1.3 Capability standard for vehicle battery test

The rated capacity range for vehicle battery varies with different test standards.

See Table 1 for details. If not specified, the rated capacity value is defaulted as

100~1700.

CCA:100~1700

DIN:100~1200

EN:100~1700

IEC:100~1200

GB:100~1200

SAE:100~1700

JIS:26A17~245H52

2

Page 5

LAUNCH X-431 GDS Batterybox Manual

2. Test environment and structure

2.1 Test environment

Inside the vehicle test indicates that the battery connects to loading devices,

such as engine, etc. After doing battery test, it can perform charging system

and actuation system test, which is proceeded as a whole simultaneously.

Charging system and actuation system test is not required but must not be

performed before battery test. Because it is difficult for vehicle technicians to

judge where is faulty exactly if they have the faintest idea of battery’s status

itself.

Outside the vehicle test indicates that the battery is disconnected from all

loading devices on vehicles. Therefore, only battery test is supported in this

condition.

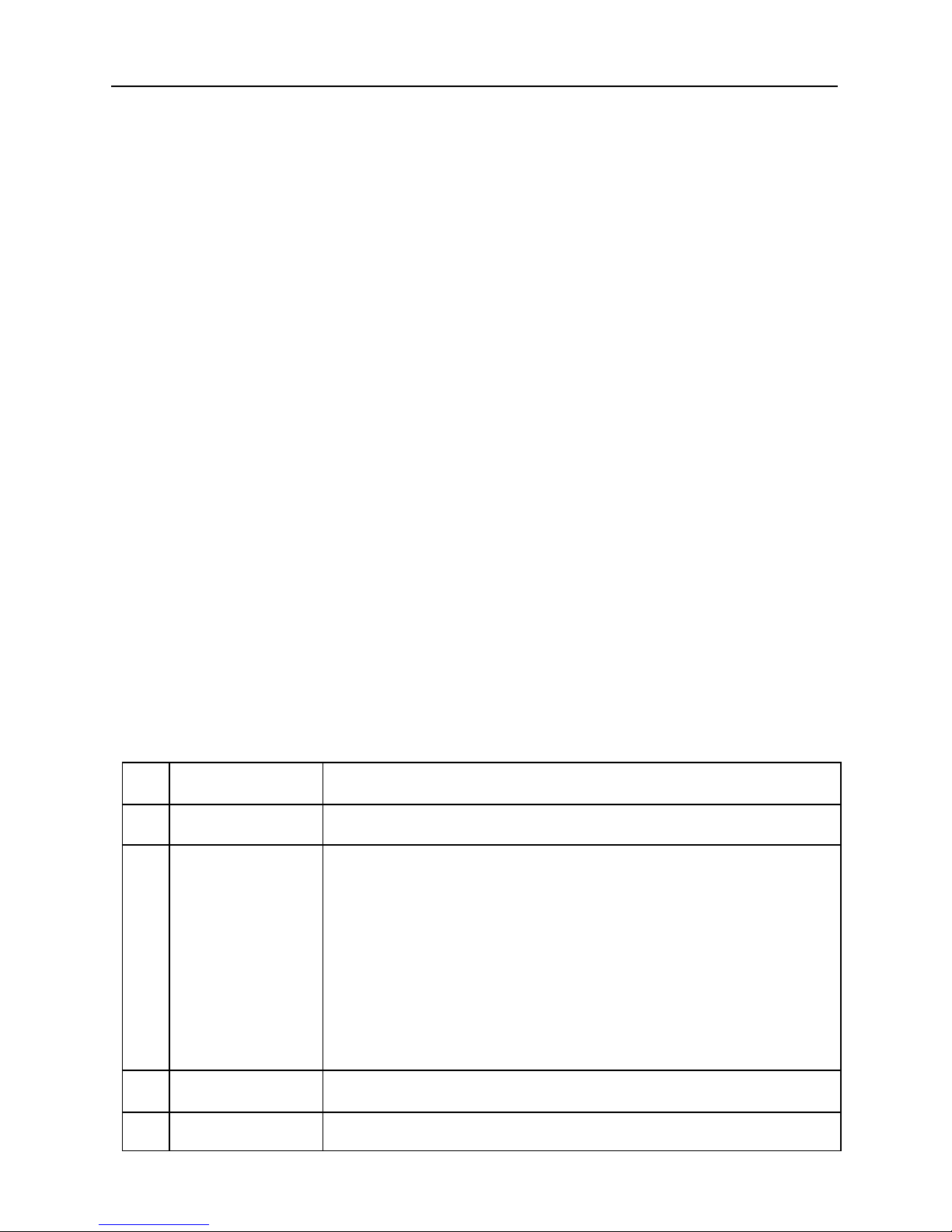

2.2 Battery status and description

There are mainly 5 states as follows:

No. States Descriptions

1 Good battery Indicates battery is normal.

2 Replace

battery

Indicates that battery is aged or becomes rejected, or

battery life cycle approaches to be exhausted. In this

case, battery voltage appears to be normal, but battery

3 Good-recharge Stands for low battery. The battery is good itself.

4 Charge-retest It is better for a few batteries to be fully charged before

itself is not well, i.e. battery polarity board has been

completely vulcanized or aged. Please replace battery

immediately.

3

Page 6

LAUNCH X-431 GDS Batterybox Manual

testing in order to avoid judging in error under special

conditions.

5 Bad cell Indicates one of the battery cells is bad and can not

work normally, but for which one is bad, it can’t be

verified. In this case, battery voltage is generally lower

than 11V, mainly resulting from internal circuitry

damage, such as short circuit, open circuit, dummy

weld etc.

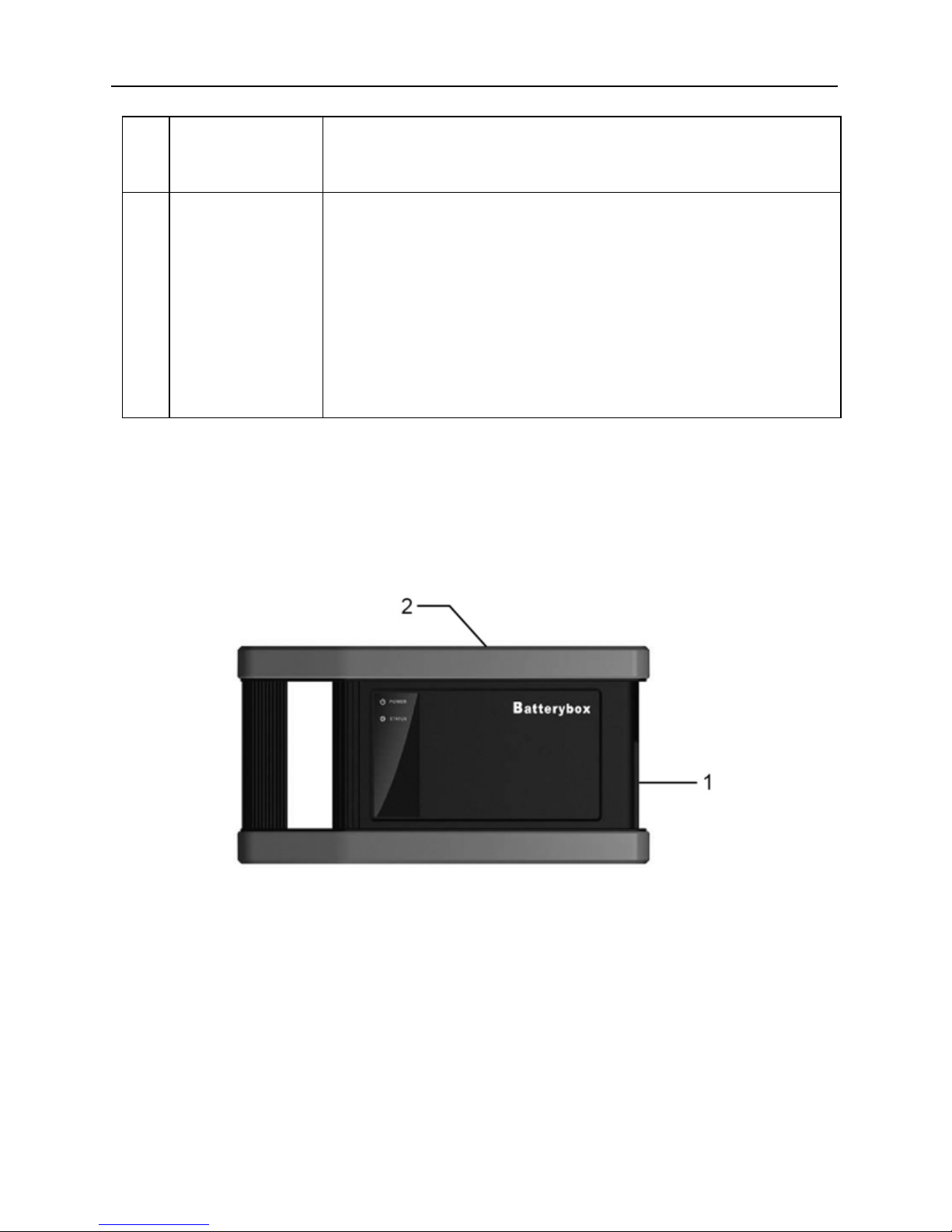

2.3 Batterybox structure and test accessories

2.3.1 Batterybox structure

Fig.2-1 Batterybox structure diagram

1. Battery connector: Connect to battery for battery test.

2. B type USB terminal: Connect to the GDS main unit with a USB cable.

4

Page 7

LAUNCH X-431 GDS Batterybox Manual

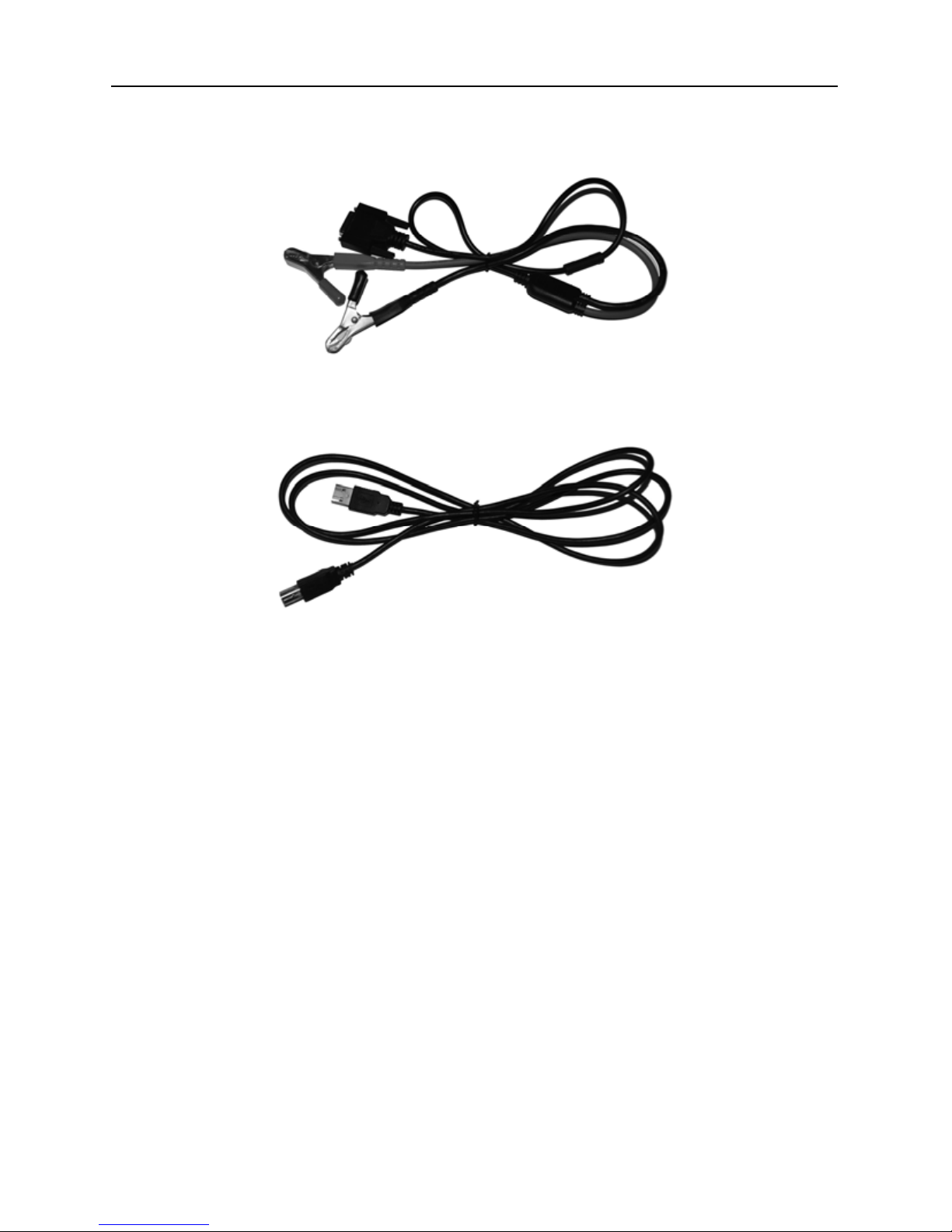

2.3.2 Test accessories

Fig. 2-2 Kelvin clip

Fig. 2-3 A/B cable

5

Page 8

LAUNCH X-431 GDS Batterybox Manual

3. Connections & Operations

3.1 Connection

Connect one end of the A/B cable to the B type USB terminal of the batterybox,

and then connect the other end to the USB port of GDS main unit. This

connection applies to outside the vehicle test and inside the vehicle.

Notes:

1. Wait about 10s and begin to communicate since the batterybox needs to

initialize after connection is complete, otherwise, communication may fail.

2. Red lamp on the batterybox means it has been successfully powered up; If

the green light is always on, it indicates the clip is well connected; while the

green light blinks, it indicates that the clip has poor contact. Do not perform

any test until the clip and A/B cable are properly connected.

3.2 Inside the vehicle test

Battery test and charging system & actuation system test can be done in this

mode.

3.2.1 Battery test

1. Enter battery test main menu, and select a desired test environment as

shown in Fig. 3-1.

6

Page 9

LAUNCH X-431 GDS Batterybox Manual

Fig. 3-1

Button Descriptions:

[System]: 3 submenus are available: Show desktop (return to desktop),

Version (view the current version info) and Exit program (exit the

current program).

[Help]: views introduction and operation guideline for battery test.

[Next]: proceed to the next operation.

[Reset]: stop all current operation and enter initializing interface.

Note: The sequences of inside the vehicle and outside the vehicle test are

almost the same, but under inside the vehicle condition, all loads in vehicles

must be powered off for getting an exact test value.

2. Firstly, detect whether floating electricity exists or not before testing. If yes,

turn on the headlamp to remove it. Otherwise, the system starts test

program directly.

7

Page 10

LAUNCH X-431 GDS Batterybox Manual

Select [Battery testing] > [Inside the vehicle], then click [Next], the system

starts detecting floating electricity automatically. A screen similar to Fig. 3-2

appears if floating electricity is detected.

3. Follow the

on-s

will be shown as below.

Fig. 3-2

creen instructions to turn on headlamp, then the interface

Fig. 3-3

8

Page 11

LAUNCH X-431 GDS Batterybox Manual

4. Once the floating electricity is removed, a prompt message box will appear

on the screen.

Fig.3-4

5. Follow the on-screen instructions to turn off the headlamp and click [OK],

the system will continue the testing. Click [Next], it will go into Selecting

testing standard screen. See Fig. 3-5

Fig. 3-5

9

Page 12

LAUNCH X-431 GDS Batterybox Manual

6. Select a testing standard except for JIS and click [Next], a screen similar

to Fig. 3-6 will appear. Users can adjust capacity size by tapping on << or

>> or by dragging the slider on the bar.

Fig. 3-6

If JIS is sel

ected, click [Next], the system will enter Select testing capacity

screen. Users can select corresponding standard capacity value according

to battery model marked on battery.

Fig. 3-7

10

Page 13

LAUNCH X-431 GDS Batterybox Manual

7. Click [Next] and the testing result will appear on the following screen.

Fig. 3-8

3.2.2 Charging system and starting system test

While performing this test, the battery’s charging voltage value and starting

voltage can be obtained in case of engine starting and accelerating. Based on

the data, the system will judge whether battery’s charging and actuation status

is normal or not.

1. The interface will display as Fig. 3-9 after the engine starts.

11

Page 14

LAUNCH X-431 GDS Batterybox Manual

Fig. 3-9

ectin

2. After det

g engine starting, follow the instructions on the screen to

increase the speed.

Fig. 3-10

3. The sys

tem begins to receive test data information after acceleration was

detected, as shown in Fig. 3-11.

12

Page 15

LAUNCH X-431 GDS Batterybox Manual

Fig. 3-11

4. Tested data will be shown on the screen, similar to Fig. 3-12.

Note: It is unnecessary to perform charging system and start system test after

finishing battery test, but battery test must be done before undergoing

charging system and starting system test.

Fig. 3-12

13

Page 16

LAUNCH X-431 GDS Batterybox Manual

3.4 Outside the vehicle test

It only applies to battery test and detecting floating electricity will be ignored

while performing battery test.

1. On Fig. 3-1, select [Outside the vehicle], and click [Next] to enter.

Fig.3-13

2. Select a

testing standard except for JIS and click [Next], the system will

enter a screen shown as Fig. 3-14. The capacity value can be adjusted by

touching << or >> or by dragging the slider on the bar.

Fig. 3-14

14

Page 17

LAUNCH X-431 GDS Batterybox Manual

If JIS is selected, click [Next], it will enter Select testing capacity screen.

Users can select corresponding standard capacity value according to

battery model marked on the battery.

3. Click [

Fig. 3-15

Next] and the testing results will appear on the following screen.

Fig. 3-16

15

Page 18

LAUNCH X-431 GDS Batterybox Manual

Button Descriptions:

[System]: 3 submenus are available: Show desktop (return to desktop),

Version (View the current version info) and Exit program (exit the

current program).

[Help]: views introduction and operation guideline for battery test.

[Print]: print test results.

[Retry]: display test results again.

[Reset]: stop all current operation and enter initializing interface.

Note: All buttons are invalid unless the print was completed.

3.5 Review version info

1. In Fig. 3-1, click [system], a pull-down menu will pop up.

Fig. 3-17

16

Page 19

LAUNCH X-431 GDS Batterybox Manual

2. Click [version], a message box will be shown on the following screen.

Fig. 3-18

17

Page 20

LAUNCH X-431 GDS Batterybox Manual

4. Precaution items on battery test

1. For the purpose of getting accurate test results, unless otherwise special

required, all loads need to be power off such as headlamp, engine etc.

before testing battery.

2. The operating time required for charging system and actuation system

test varies from person to person. If the engine does not start or

accelerate within 30 seconds, the system will prompt you “receiving

timeout” and return to the initial status.

3. Whether Engine is off or not has no influence on charging and actuation

test result after increased speed is detected, but other loads need to be

powered off.

4. The accuracy of battery voltage, charging voltage, start voltage is 0.01V in

test results; CCA (Cold Cranking Amps) precision is 5CCA.

5. Generally, charging voltage value is greater than starting voltage.

Charging voltage range is as follows: 13.8--14.5V for domestic vehicle;

13.3--15.5V for imported vehicles. The voltage varies with different car

models, so you have to judge based on related vehicle models. In general,

the DC voltage is stable, but it also varies with different revolution speed.

Starting voltage range: the value higher than 9.6V is regular, otherwise it

is too low. Due to different situations, whether the starting voltage is

higher or not does not mean the vehicles or batteries are faulty. For

detailed faults, other special equipments are needed. To validate the

accuracy of the value, the best method is to collect the signals of starting

and charging voltage and observe it on an oscillometer.

6. Generally, the voltage is lower than 11V for the bad cell battery, but it is

possible that the battery is completely exhausted or has a serious low

18

Page 21

LAUNCH X-431 GDS Batterybox Manual

capacity. In this case, just recharge your battery. Bad cell always happens

when the loads on a stopping vehicle are turned on for a long time.

7. Please note that it is normal for quick detecting of “Increase speed”

because it follows the theory of detecting “Increase speed”: if the detected

voltage is higher than the previous battery test voltage, the system will

prompt you a message of “Engine has been speeded”

8. It has no influence on test result in the event that engine’s output voltage

or engine revolution is not very stable. No matter whether the vehicle is

accelerated or not, the output voltage only differs within 0.2V.

9. While doing inside the vehicle test, Kelvin clip is always found to be in

poor contact. To remain it in good contact, please shake it several times

before testing. Take down the battery connector, and test it again, the

value probably varies. The deviation may arise from battery connector.

10. Pay more attention to connect the clip. The battery poles connect with

conductor, which makes the clip has a poor connection when testing

battery. A tolerance of dozens of CCA occurs if the clip is out of position,

or oil, dust attaches on the pole. The gear and main body of clip should be

fully matched with battery poles.

Notes:

1. Battery poles inside the vehicle are enveloped by connectors, which may

produce some errors for test results. The tolerance results from the

resistance of connectors. The greater the resistance value is, the greater

the tolerance becomes. But generally, the tolerance does not affect the

test conclusion.

2. Testing the battery separately generates an exact test result. The battery

box is a very useful auxiliary tool for quick test. If any problems were

found, test it separately for getting an exact test result.

19

Loading...

Loading...