Page 1

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Important Safety Precautions

Important: To avoid personal injury, property damage, or accidental damage to

the product, read all of the information in this section before using the product.

Never collide, throw, or puncture the tool, and avoid falling, extruding and

bending it.

Do not insert foreign objects into or place heavy objects on your device.

Sensitive components inside might cause damage.

Do not use the tool in exceptionally cold or hot, dusty, damp or dry

environments.

In places using the tool may cause interference or generate a potential risk,

please turn it off.

This tool is a sealed unit. There are no end-user serviceable parts inside. All

internal repairs must be done by an authorized repair facility or qualified

technician. If there is any inquiry, please contact the dealer.

Never place the tool into apparatus with strong electromagnetic field.

Keep the tool far away from magnetic devices because its radiations can

damage the screen and erase the data stored on the tool.

DANGER: Do not attempt to replace the internal rechargeable lithium battery.

Contact the dealer for factory replacement.

CAUTION: Please use the included battery and charger. Risk of explosion if

the battery is replaced with an incorrect type.

Precautions on Using This Tool

Before using this tool, please read the following safety information carefully.

Always perform automotive testing in a safe environment.

If the VCI (Vehicle Communication Interface) device is not in use for a long

period of time, it is suggested to unplug the connector from vehicle’s DLC to

conserve battery power.

Wear an ANSI-approved eye shield when testing or repairing vehicles.

The vehicle shall be tested in a well-ventilated work area, as engines produce

various poisonous compounds (hydrocarbon, carbon monoxide, nitrogen

oxides, etc.)

Do not connect or disconnect any test equipment while the ignition is on or

the engine is running.

Put blocks in front of the drive wheels and never leave the vehicle unattended

i

Page 2

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

while testing.

Keep the tool dry, clean, free from oil, water or grease. Use a mild detergent

on a clean cloth to clear the outside of the equipment as necessary.

Do not drive the vehicle and operate the tool at the same time. Any distraction

may cause an accident.

Keep clothing, hair, hands, tools, test equipment, etc. away from all moving or

hot engine parts.

Before starting the engine, put the gear lever in the Neutral position (for

manual transmission) or in the Park (for automatic transmission) position to

avoid injury.

To avoid damaging the tool or generating false data, please make sure the

vehicle battery is fully charged and the connection to the vehicle DLC (Data

Link Connector) is clear and secure.

Automotive batteries contain sulfuric acid that is harmful to skin. In operation,

direct contact with the automotive batteries should be avoided. Keep the

ignition sources away from the battery at all times.

Precautions on Operating Vehicle’s ECU

Do not disconnect battery or any wiring cables in the vehicle when the ignition

switch is on, as this could avoid damage to the sensors or the ECU.

Do not place any magnetic objects near the ECU. Disconnect the power

supply to the ECU before performing any welding operations on the vehicle.

Use extreme caution when performing any operations near the ECU or

sensors. Ground yourself when you disassemble PROM, otherwise ECU and

sensors can be damaged by static electricity.

When reconnecting the ECU harness connector, be sure it is attached firmly,

otherwise electronic elements, such as ICs inside the ECU, can be damaged.

ii

Page 3

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Table of Contents

1 INTRODUCTION

1.1 P

RODUCT PROFILE

EATURES

1.2 F

ECHNICAL SPECIFICATIONS

1.3 T

1.3.1 Display tablet ..................................................................................... 2

1.3.2 VCI device ......................................................................................... 3

........................................................................................ 1

..................................................................................... 1

................................................................................................. 1

....................................................................... 2

2 KNOWLEDGE OF X-431 EURO TAB II

ISPLAY TABLET

2.1 D

OCKING STATION (OPTIONAL

2.2 D

2.3 VCI D

2.3 P

3 INITIAL SETUP

3.1 C

3.2 P

3.3 S

3.4 A

3.5 C

3.6 N

4 GETTING STARTED

4.1 D

4.2 R

4.3 D

4.4 C

EVICE

ACKAGE LIST

HARGING THE TABLET

OWER ON/OFF

CREEN LAYOUT

DJUSTING SCREEN BRIGHTNESS

HANGING LANGUAGE

ETWORK SETUP

IAGNOSTIC FLOWCHART

EGISTER & DOWNLOAD DIAGNOSTIC SOFTWARE

4.2.1 User registration .............................................................................. 14

4.2.2 Home screen ................................................................................... 17

4.2.3 Vehicle menu layout ........................................................................ 19

4.2.4 Diagnostics toolbar .......................................................................... 20

IAGNOSIS METHODS

ONNECTIONS

4.4.1 Preparation...................................................................................... 21

4.4.2 DLC location ................................................................................... 21

4.4.3 Vehicle connection (For Passenger Vehicle Version) ...................... 21

4.4.3 Vehicle connection (For Commercial Vehicle / Gasoline & Diesel

Version) .................................................................................................... 23

........................................................................................ 5

............................................................................................... 8

........................................................................................... 9

........................................................................................ 11

............................................................................ 11

....................................................................................... 11

...................................................................................... 11

.............................................................................. 12

..................................................................................... 13

................................................................................. 14

......................................................................... 14

............................................................................... 20

......................................................................................... 21

....................................................... 4

) ................................................................... 7

............................................................. 12

..................................... 14

iii

Page 4

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

5 DIAGNOSIS

5.1 I

5.2 L

............................................................................................. 24

NTELLIGENT DIAGNOSIS

OCAL DIAGNOSIS

........................................................................... 24

.................................................................................... 27

5.2.1 Health Report (Quick Test) .............................................................. 32

5.2.2 System Scan ................................................................................... 36

5.2.3 System Selection ............................................................................ 37

5.3 R

EMOTE DIAGNOSIS

................................................................................. 46

5.3.1 Interface layout................................................................................ 46

5.3.2 Add friends ...................................................................................... 47

5.3.3 Start instant messaging ................................................................... 49

5.3.4 Launch remote diagnosis (Device-To-Device) ................................. 50

5.3.5 Launch remote diagnosis (Device-To-PC) ....................................... 53

5.4 H

OW TO VIEW DIAGNOSTIC HISTORY

OW TO FEEDBACK DIAGNOSTIC LOGS

5.5 H

?....................................................... 55

? ................................................... 56

6 SPECIAL (RESET) FUNCTION (ONLY FOR PASSENGER

VEHICLE/GASOLINE & DIESEL VERSION)

6.1 O

IL RESET SERVICE

LECTRONIC PARKING BRAKE RESET

6.2 E

TEERING ANGLE CALIBRATION

6.3 S

6.4 ABS B

6.5 T

6.6 G

6.7 IMMO S

6.8 I

6.9 B

6.10 D

6.11 E

6.12 G

6.13 AFS (A

6.14 S

6.15 S

LEEDING

IRE PRESSURE MONITOR SYSTEM RESET

EAR LEARNING

ERVICE

NJECTOR CODING

ATTERY MAINTENANCE SYSTEM RESET

IESEL PARTICULATE FILTER

LECTRONIC THROTTLE POSITION RESET

EARBOX MATCHING

DAPTIVE FRONT-LIGHTING SYSTEM) RESET

UNROOF INITIALIZATION

USPENSION CALIBRATION

................................................................................. 59

................................................................ 60

........................................................................................ 60

...................................................................................... 60

........................................................................................ 61

.................................................................................... 61

(DPF) R

............................................................................. 63

........................................................................ 63

..................................................................... 63

................................................ 58

........................................................ 59

................................................ 60

................................................... 62

EGENERATION

............................... 62

............................................... 62

.................................. 63

7 SOFTWARE UPDATE

7.1 U

PDATE DIAGNOSTIC SOFTWARE &

ET FREQUENTLY USED SOFTWARE

7.2 S

ENEW SUBSCRIPTION

7.3 R

............................................................................... 64

APP ................................................... 64

.......................................................... 64

............................................................................. 65

iv

Page 5

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

8 ADAS

9 SENSORBOX (TOOLBOX)

10 MULTIMETER (TOOLBOX)

11 BATTERYBOX (TOOLBOX)

....................................................................................................... 67

....................................................................... 69

RODUCT SUMMARY

9.1 P

9.2 S

TRUCTURE & ACCESSORIES

9.2.1 Sensorbox structure ........................................................................ 70

9.2.2 Sensorbox accessories ................................................................... 71

9.3 S

ENSOR SIMULATION

9.3.1 Connections .................................................................................... 72

9.3.2 Simulation test................................................................................. 73

9.3.3 Precautions on checking vehicle sensor .......................................... 77

................................................................................ 69

................................................................... 70

............................................................................... 72

..................................................................... 79

AIN MENU

10.1 M

10.2 T

EST SAMPLE

............................................................................................ 79

........................................................................................ 80

.................................................................... 82

11.1 P

RODUCT SUMMARY

EST ENVIRONMENT

11.2 T

11.2.1 Test environment ........................................................................... 83

11.2.2 Battery status and description ....................................................... 83

11.3 B

ATTERYBOX STRUCTURE & ACCESSORIES

11.3.1 Batterybox structure ...................................................................... 84

11.3.2 Test accessories ............................................................................ 84

ONNECTIONS & OPERATIONS

11.4. C

11.4.1 Connection .................................................................................... 85

11.4.2 Inside the vehicle test .................................................................... 85

11.4.3 Outside the vehicle test ................................................................. 88

11.5 P

RECAUTIONS ON BATTERY TEST

.............................................................................. 82

............................................................................... 83

............................................. 84

............................................................... 85

........................................................... 88

12 OSCILLOSCOPE (TOOLBOX)

12.1 I

NTRODUCTION

TRUCTURE & ACCESSORIES

12.2 S

12.2.1 Scopebox structure ....................................................................... 92

12.2.2 Scopebox accessories .................................................................. 93

12.3 C

ONNECTION & INITIAL USE

12.3.1 Probe Compensation..................................................................... 96

12.3.2 Connection .................................................................................... 97

....................................................................................... 91

................................................................ 91

................................................................. 92

.................................................................... 96

v

Page 6

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

12.3.3 Initial interface introduction .......................................................... 100

12.4 O

PERATIONS

12.4.1 Channel selection and attributes setting ...................................... 102

12.4.2 Auto ............................................................................................. 107

12.4.3 View Settings .............................................................................. 107

12.4.4 Measure ...................................................................................... 108

12.4.5 File management ........................................................................ 110

12.4.6 Expert reference .......................................................................... 111

........................................................................................ 102

13 AUTOMOTIVE IGNITION WAVEFORM (TOOLBOX)

13.1 S

ECONDARY-DISTRIBUTOR IGNITION ANALYSIS

ECONDARY-SIMULTANEOUS IGNITION ANALYSIS

13.2 S

ECONDARY-DIRECT IGNITION ANALYSIS

13.3 S

13.4 W

AVEFORM ANALYSIS MODE

14 USER INFO

14.1 MY R

14.2 VCI ..................................................................................................... 128

14.3 A

14.4 F

14.5 MY N

14.6 D

14.7 V

14.8 MY O

14.9 S

14.10 P

14.11 C

14.12 S

14.12.1 Units .......................................................................................... 131

14.12.2 Shop Information ....................................................................... 131

14.12.3 Printer Set ................................................................................. 131

14.12.4 Clear Cache .............................................................................. 132

14.12.5 About ......................................................................................... 132

14.12.6 Diagnostic Software Auto Update .............................................. 132

14.12.7 Login/Exit from current account ................................................. 133

.......................................................................................... 126

......................................................................................... 126

EPORT

CTIVATE

IX CONNECTOR FIRMWARE/SYSTEM

ATA STREAM SAMPLE

EHICLE VOLTAGE

UBSCRIPTION RENEWAL CARD

VCI ...................................................................................... 128

EWS

............................................................................................ 129

............................................................................... 129

........................................................................................... 129

RDER

ROFILE

............................................................................................ 130

HANGE PASSWORD

ETTINGS

.......................................................................................... 130

................................................................. 120

......................................................................... 129

.......................................................................... 130

............................................... 118

.................................................... 129

............................................................ 130

.............................. 113

....................................... 113

................................... 116

15 OTHER MODULES

15.1 E

.................................................................................................. 134

MAIL

............................................................................... 134

vi

Page 7

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

15.2 B

ROWSER

15.2.1 Open browser.............................................................................. 134

15.2.2 Download files ............................................................................. 135

15.3 T

EAMVIEWER

15.3.1 TeamViewer QuickSupport .......................................................... 135

15.3.2 TeamViewer ................................................................................ 136

15.4 S

YSTEM

ILE EXPLORER

15.5 F

15.6 S

YNCHRONIZATION

16 FAQ

..................................................................................................... 139

............................................................................................ 134

....................................................................................... 135

OTA U

PGRADE

.................................................................................... 138

....................................................................... 137

............................................................................... 138

vii

Page 8

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

1 Introduction

1.1 Product Profile

Featuring customized Android operating system, 2.0GHz 8-core CPU and 10.1”

sunlight readable capacitive display screen with a resolution of 1920 x 1200

pixels, X-431 EURO TAB II has functions of vehicle diagnosis, oscilloscope,

ignition, sensor, multimeter, browser and battery test etc.

It supports WLAN connection, which enables you to surf the Internet, update

App and diagnostic software online, search repair information anytime and

anywhere, getting your job faster and easier.

Through the wireless communication between the VCI device and display tablet,

it achieves full car model and full system vehicle trouble diagnosis, which include

Reading DTCs, Clearing DTCs, Reading Data Stream, Actuation Test and

Special Functions.

Moreover, taking advantage of the mobile Internet, it also integrates One-click

Update, Remote Diagnosis, Repair Data and TeamViewer, which helps to

diagnose vehicle issues more efficiently, and greatly increase customer’s

retention and boost shop revenue.

1.2 Features

1. Diagnose:

Intelligent Diagnosis: This module allows you to use the VIN information of

Local Diagnosis: VINscan quick test and manual diagnosis are available.

Remote Diagnosis: This option aims to help repair shops or technicians

Reset: All kinds of common maintenance and reset items including Oil

One-click Update: Lets you update your diagnostic software online.

the currently identified vehicle to access its data (including vehicle

information, historical diagnostic records) from the cloud server to perform

quick test.

Diagnosis functions include: Read DTCs, Clear DTCs, Read Data Stream,

Special Functions etc.

launch instant messaging and remote diagnosis, making the repair job

getting fixed faster.

lamp reset, DPF regeneration, ABS bleeding can be done.

1

Page 9

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Diagnostic History: This function provides a quick access to the tested

vehicles and users can choose to view the test report or resume from the

last operation, without the necessity of starting from scratch.

Diagnostic Feedback: Enables you to submit the vehicle issue to us for

analysis and troubleshooting.

Pre- and Post- Repair Result Comparison: By comparing the pre-repair

and post-repair report, you can clearly determine which vehicle issues

have been fixed and which remained unsolved.

Diagnostic Feedback: Enables you to submit the vehicle issue to us for

analysis and troubleshooting.

Vehicle Coverage: Quick dial to view the vehicle models that the tool

covers.

2. ADAS calibration: Optional. This function needs to be activated before normal

use and only works with the LAUNCH-specific ADAS calibration tool.

3. Web browser: Users can make online search and visit any website.

4. File Manager: Lets you manage files or downloaded files stored in memory

card efficiently.

5. Settings: To configure your personalized tablet.

1.3 Technical Specifications

1.3.1 Display tablet

CPU 8-core Processor, 2.0GHz

Display

Memory 4GB

Hard disk 64GB

Connectivity

10.1 inch touch screen with a resolution of 1920 x

1200P

WLAN (802.11 b/g/n/ac)

Universal serial BUS Ports (1 x Type-C + 1 x

Type-A)

BT 2.1 + EDR & 4.0 BLE

2

Page 10

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Camera 8MP front-facing camera + 13MP rear-facing camera

Sensor

Operating Temp.

Storage Temp. -20℃ ~ 70℃(-4 ~158℉)

1.3.2 VCI device

Working Voltage DC 9V ~ 36V

RAM

ROM 8GB

USB Type B x 1

Bluetooth BLE 4.0 + EDR

Wi-Fi 2.4G/5GHz Dual Frequency

Power ≤

Working Temp.

Dimension 200mm x 75mm x 40mm

Gravity Accelerometer

3-Axis Acceleration Sensor

-10℃ ~ 50℃(14 ~122℉)

256MB

6.6W

-10℃ ~ 50℃

3

Page 11

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

2 Knowledge of X-431 EURO TAB II

There are two main components to the X-431 EURO TAB II system:

Display Tablet – the central processor and monitor for the system (See

Chapter “2.1”).

Fig. 2-1 Display tablet

Docking Station – the device for accessing vehicle data (See Chapter “2.2”).

Fig. 2-2

VCI Device – the device for accessing vehicle data (See Chapter “2.3”).

Fig. 2-3

4

Page 12

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

2.1 Display Tablet

Fig. 2-4 Top & Front Views

Memory Card Slot

1

Type C Charging Port Reserved for charging the tablet.

2

Power/Screen Lock

3

Button

Volume Buttons

4

To store the memory card for storage

expansion.

To turn the tablet on/off with long press, or

lock the screen with short press.

To adjust the volume.

*Note: Press and hold [POWER] and [VOL -]

5

Page 13

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

key to capture the current screenshot.

Reserved for add-on modules (such as

Data I/O Port

5

Microphone

6

Charging LED

7

10.1" Capacitive

8

Touch Screen

Ambient Light

9

Sensor

Front View

10

Batterybox, Scopebox and Sensorbox), and

other devices with similar port.

It illuminates red while the tablet is charging.

Once charging is finished, it will illuminate

solid green.

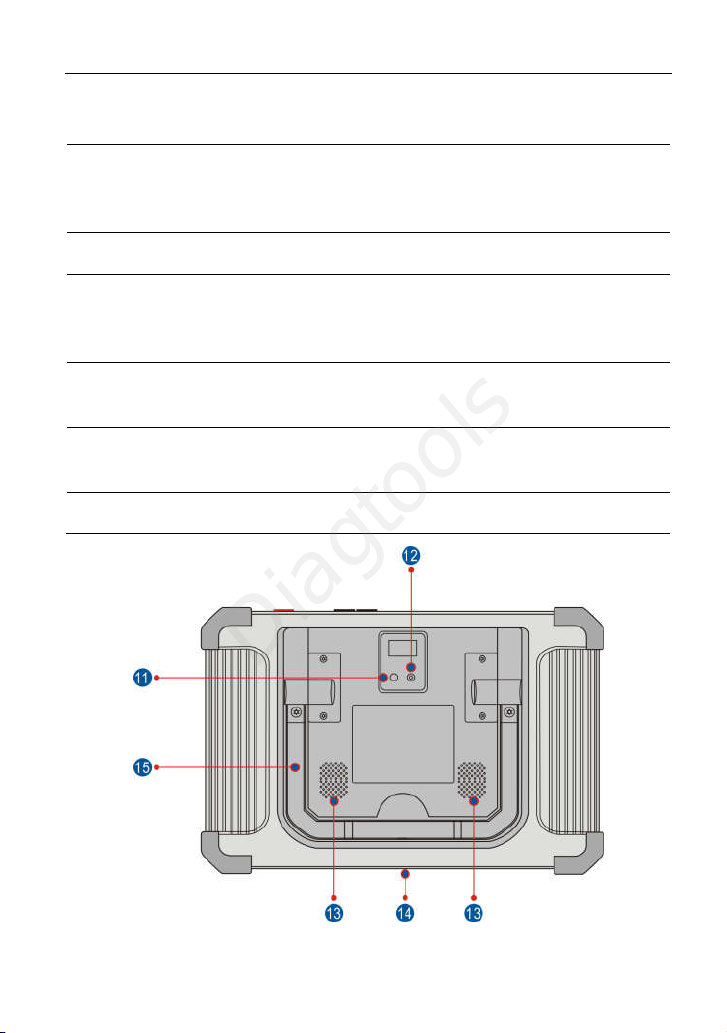

Fig. 2-5 Rear View

6

Page 14

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Rear Camera

11

Camera Flash

12

Audio Speaker

13

Charging Slot

14

15 Adjustable kickstand

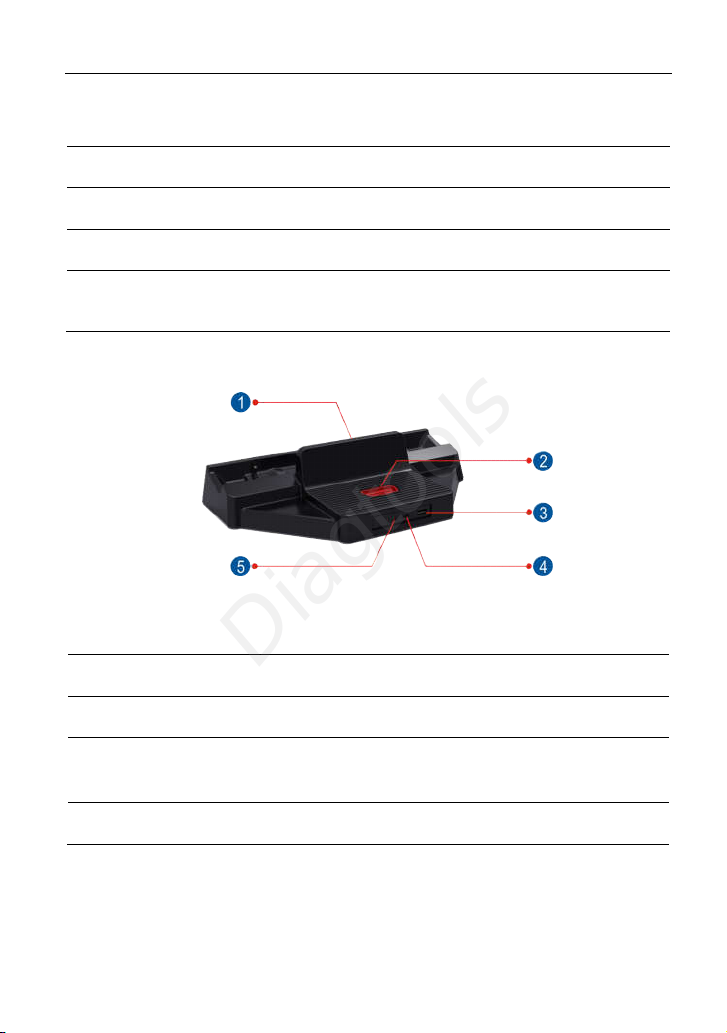

2.2 Docking Station (Optional)

Charging Slot

1

OBD16 Socket

2

DC 5V OUT Port

3

Type C Charging Port

4

docking station through connection to AC outlet.

Power LED

5

-- To charge the tablet.

-- To store the VCI device to avoid loss.

-- (Reserved for charging other USB devices only.)

-- Illuminates solid green when it is powered up.

Flip out it to any angle and work comfortable

at your desk, or hang it on automotive part.

Fig. 2-6

-- Use the power adaptor to supply power to the

7

Page 15

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

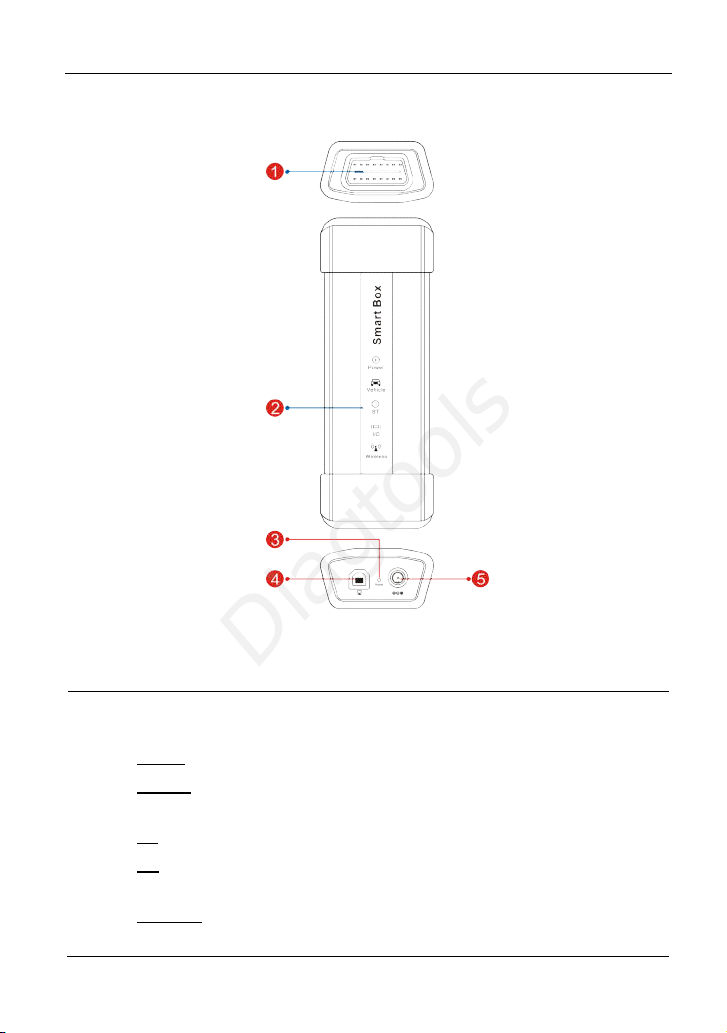

2.3 VCI Device

Fig. 2-7

1 Diagnostic socket -- For connecting the diagnostic cable.

-- Enables users to easily identify the working status of the VCI

LEDs

device. It is defined as follows (From the top to the bottom):

Power: It illuminates solid red when the device is powered on.

Vehicle: While communicating with the vehicle, the indicator lights up

2

and flashes. Otherwise, it will not illuminate.

BT: Blue indicates the device is working in Bluetooth mode.

I/O: It lights up when the device is connected to the diagnostic tool via

data cable.

Wireless: It lights up when the device works in wireless

communication mode.

8

Page 16

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

3 Reset hole -- For resetting the VCI device.

Data I/O port -- For connecting it to the handset via data cable (optional)

4

to perform vehicle diagnosis.

5 DC-IN power jack -- For connecting the power adaptor.

2.3 Package List

Common accessories are same, but for different destinations, the accessories

may vary. For detailed accessory items, please consult from the local agency or

check the packing list supplied with the package box together.

No.

1 Display tablet

2 VCI device

3 Docking station

4

5 OBD I adaptor

6

7

8 Power adaptor

9 Password envelope

Item Description Qt.

OBD II extension

cable

Cigarette lighter

cable

Battery clamps

cable

For analyzing the vehicle data and indicating

the test results.

For connecting to vehicle’s OBD II DLC to

access vehicle’s live data.

(Optional. To charge the tablet.)

For connecting the VCI device for extension

purpose.

For connecting the non-16pin connector to

the VCI device.

Optional. To supply power to the non-16pin

connector through connection to the

vehicle’s cigarette lighter receptacle.

Optional. To supply power to the non-16pin

connector through connection to the

vehicle’s battery.

For charging the tablet.

A piece of paper bearing Product S/N and

Activation Code, which is needed for

product registration.

1

1

1

1

1

1

1

1

1

9

Page 17

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Non-16pin adaptor

10

cable kit

Optional. For connecting to Non-OBD II

vehicle DLC.

1

10

Page 18

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

3 Initial Setup

3.1 Charging The Tablet

*Notes:

•

Only use the included power adaptor to recharge the tablet. Use of any other

adaptor will damage the tool. We assume no responsibility for damage or loss

resulting from using other similar adaptors other than the specified one.

•

Always charge on a non-flammable surface in a well-ventilated area.

To check the battery power level, press and hold the Power button about 3

seconds to turn on the tablet. Power level is indicated as a percentage in the

upper right corner of the screen. If the power level drops below 10% while the

tablet is on, a “Connect Charger” notification will appear on the screen.

1. Connect one end of the power adaptor to DC IN port of the tablet, and the

other end to the AC outlet.

2. If appears on the screen, it indicates it is being charged. If the logo

changes into , it indicates that the battery is fully charged.

3. Disconnect the power adaptor from the AC outlet.

3.2 Power On/Off

1. Press and hold the POWER button for about 3 seconds to turn on the tablet.

The system starts initializing and then enters the Home screen.

2. To turn the tablet off, press and hold the POWER button until an option menu

appears. Tap “Power Off”.

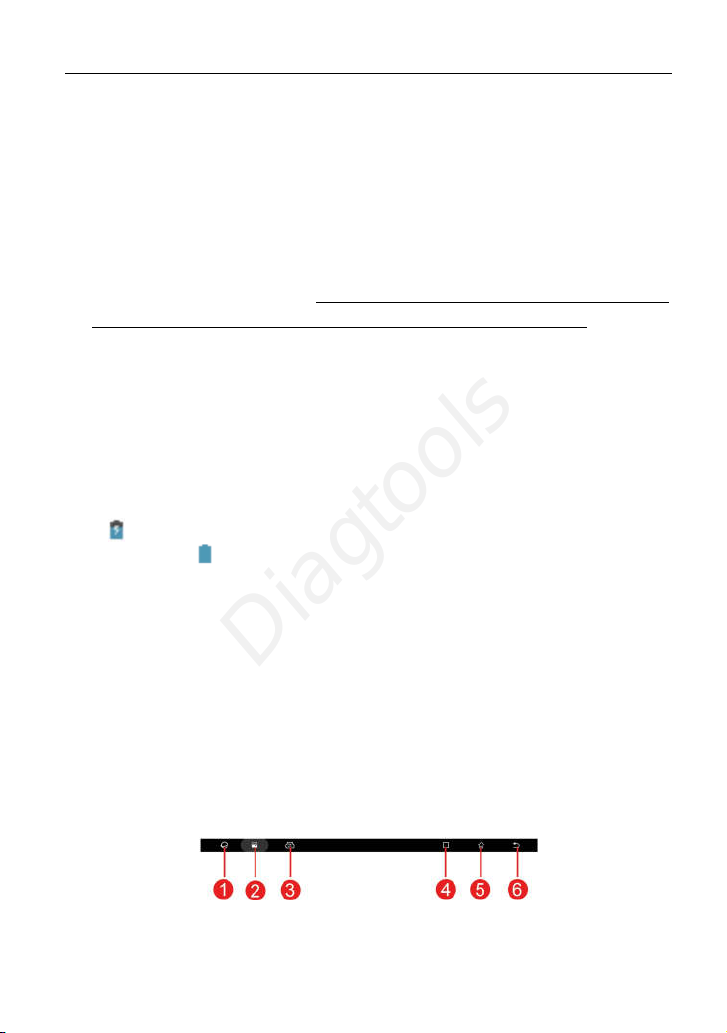

3.3 Screen Layout

On-screen keys and status bar are as follows:

Fig. 3-1

11

Page 19

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Tap to visit the official website.

1

Tap

2

screenshots are stored in the Screenshots folder.

to capture the current screen and all captured

3

4

5

6

shows whether the VCI device is connected properly or not.

Tap to display a list of applications that are currently running

or recently used. To open an application, tap it. To remove an

application, swipe it upwards.

Tap to jump to the Home screen.

Tap to return to the previous screen or exit the application.

3.4 Adjusting Screen Brightness

The tablet is equipped with a built-in light intensity sensor. It can adjust the

screen brightness according to the ambient light intensity automatically.

Alternatively, you can also adjust it manually.

1. On the Home screen, tap

2. Drag the slider to adjust it.

Alternatively, user may also slide the “Automatically brightness” switch to ON,

and the system will automatically adjust the screen brightness.

*Tips: Reducing the brightness of the screen is helpful to save the power of the tablet.

Tablet Settings -> Display -> Brightness

.

3.5 Changing Language

The handset supports multiple languages. To change the language of the tablet,

please do the following:

1. On the Home screen, tap

2. Tap the desired language from the list and the system will change to the

chosen language.

Tablet Settings -> Language

.

12

Page 20

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

3.6 Network Setup

The tablet has built-in wireless communication module that can be used to get

online. Once you’re online, you can register the tablet, browse the Internet, get

and update apps and send email on your network.

*Note: Once WLAN is set as ON, the tablet will consume more power. While WLAN

keeps unused, please turn it off to conserve battery power.

1. On the Home screen, tap

2. Tap or slide the WLAN switch to ON, the tablet starts searching for all

available wireless LANs.

3. Choose the desired access point / network,

If the network you chose is open, you can connect directly;

If the selected network is encrypted, you have to enter the right security

key (network password).

When this tool is in range, it will connect to the previously linked network

automatically.

Tablet Settings

->

WLAN

.

13

Page 21

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

4 Getting Started

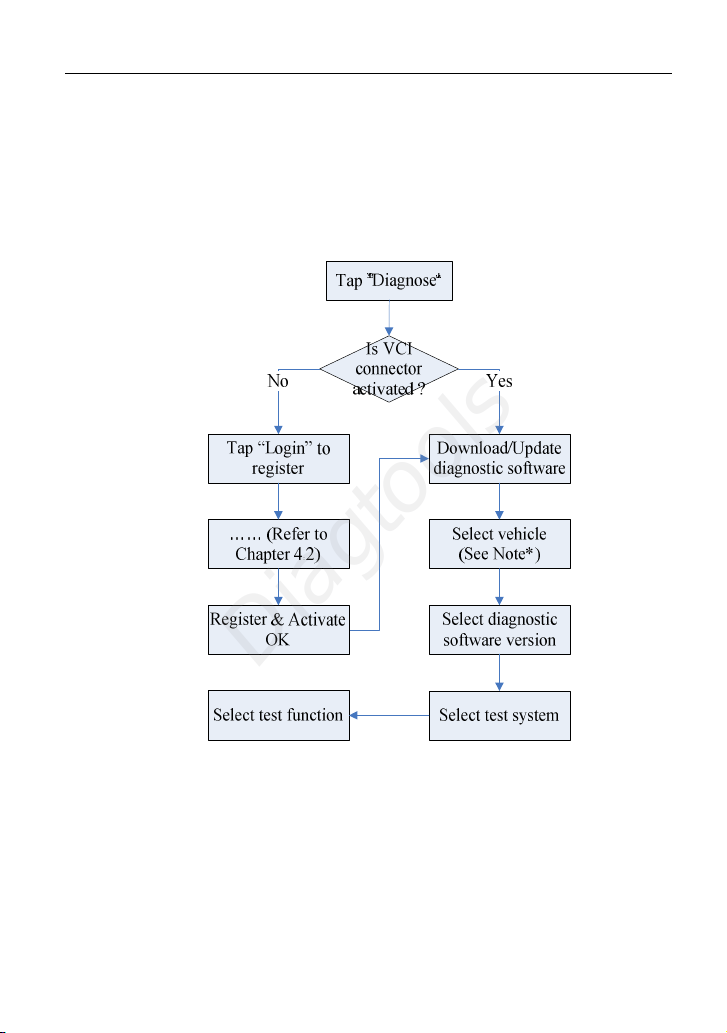

4.1 Diagnostic Flowchart

For new users, please follow the operation chart shown in Fig. 4-1 to start using

this tool.

Fig. 4-1

*Note: If “VIN Scan” or “Intelligent Diagnosis” is selected to diagnose a vehicle, this

step shall not apply.

4.2 Register & Download Diagnostic Software

4.2.1 User registration

After the tablet is initialized, a screen similar to the following appears.

14

Page 22

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 4-2

(If you are a new user, follow A to proceed.)

(If you have registered to be a member, go to B to login the system directly.)

(In case you forgot password, refer to C to reset a new password.)

A. If you are a new user, tap “New Registration” to enter sign-up page. See Fig.

4-3.

Fig. 4-3

In Fig. 4-3, fill in the information in each field (Items with * must be filled). After

inputting, tap “Register”, a screen similar to the following will appear:

15

Page 23

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 4-4

In Fig. 4-4, input the Serial Number and Activation Code, which can be found in

the password envelope.

Product SN

*Note: To exit and activate it later, tap “Skip”. In this case, you can activate your VCI by

tapping “Activate VCI” in “User Info”. For details, please refer to Chapter 14.3.

Tap “Activate” to finish your registration. A popup displays to ask you to update

the diagnostic software.

Fig. 4-5

Fig. 4-6

16

Product SN

Activation code

Page 24

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

To update the diagnostic software, tap “Yes” to enter the vehicle software

download screen. Tap “Update” to start downloading. To pause downloading,

tap “Stop”. To resume, tap “Continue”. When download is complete, the system

will install the software package automatically.

*Note: When downloading the diagnostic software or checking for updates, make sure

the tablet has a strong WLAN connection. It may take several minutes to finish it,

please be patient to wait.

To download and install the software later, tap “No”. In this case, enter the Home

screen and tap “Software Upgrade” to download the diagnostic software.

B. If you have registered to be a member, input your name and password, and

then tap the “Login” button to enter the main menu screen directly.

*Note: The tablet has an auto-save function. Once the username and password are

correctly entered, the system will automatically store it. After initial setup, it is no

longer necessary to input the account information manually to log in.

C. If you forgot the password, tap “Retrieve password” and then follow on-screen

instructions to set a new password.

4.2.2 Home screen

It mainly includes the following items:

Fig. 4-7

17

Page 25

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Name Description

This module allows you to obtain vehicle data from the

cloud server to perform quick test via reading VIN,

Intelligent

Diagnose

Local Diagnose To diagnose a vehicle manually.

Reset

ADAS

Software Update To update vehicle diagnostic software and APK.

which provides a perfect solution to various defects

resulting from step-by-step menu selection. In addition,

user can also check the historical repair records online

through this module.

To perform all kinds of common repair & maintenance

items, including electronic throttle position reset, ABS

bleeding, DPF regeneration, oil lamp reset etc.

*Note: This module only applies to Passenger Vehicle

/Gasoline & Diesel Version.

This module provides quick access to the ADAS

calibration function of different vehicle models.

This function only works with the X-431 ADAS PRO

calibration tool (sold separately).

*Note: To ensure a normal use, this function needs to be

activated using the ADAS Activation Card.

This option aims to help repair shops or technicians

Remote Diagnose

Feedback

Maintenance

Toolbox

User Info

launch instant messaging and remote diagnosis,

making the repair job getting fixed faster.

To feed back the recent 20 diagnostic logs to us for

issue analysis.

Abundant maintenance data are available, which helps

repair professionals diagnose and repair vehicles

efficiently, accurately and profitably.

Includes Camera, Browser, Oscilloscope, Ignition,

Sensor, Multimeter, Battery etc.

To manage VCI, diagnostic reports & records, change

password, configure printer, sample data and logout /

18

Page 26

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

login etc.

Vehicle Coverage

Tablet Setting Configures the system setting of the tablet.

Other Modules

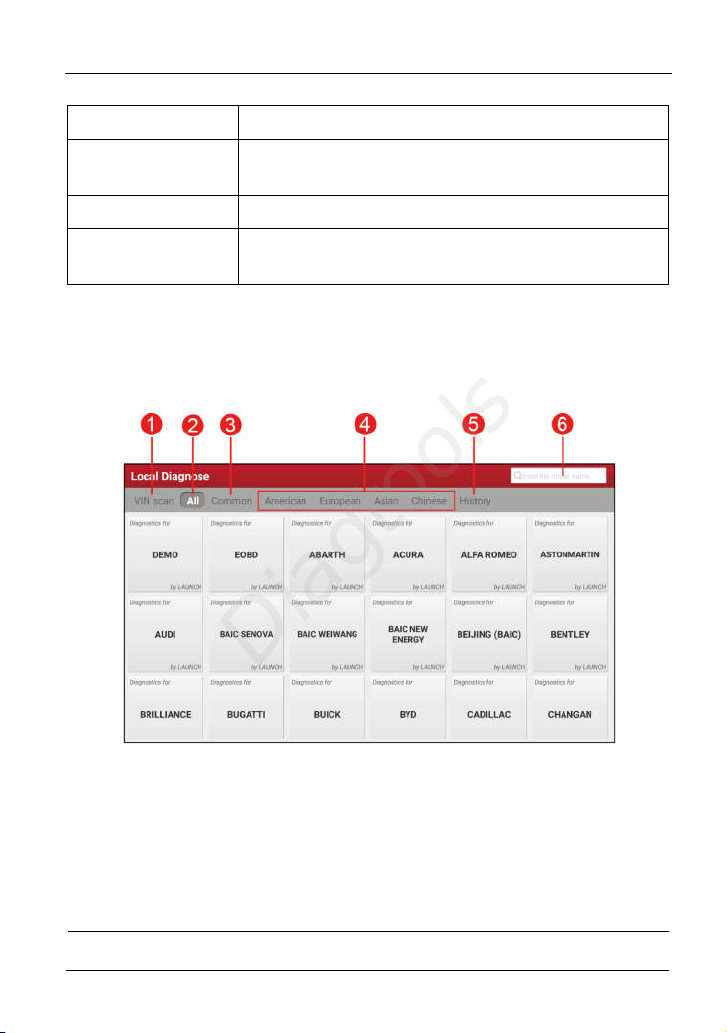

4.2.3 Vehicle menu layout

After downloading the diagnostic software, you can go to “Local Diagnosis” to

check if all software are completely downloaded and installed.

Tap “Local Diagnosis”, a screen similar to the following figure appears:

To check the vehicle models supported on the X-431

EURO TAB II.

Includes TeamViewer, Email, Browser, and product

manual etc.

Fig. 4-8

VIN Scan

code of your vehicle. OBD VIN and INPUT VIN are included. This

function does not apply to the commercial vehicles.

1

*Note: Before using this function, the corresponding diagnostic software and

Auto search file need to be downloaded on your tool first while downloading

the diagnostic software.

2 All

button: Tap it to scan the Vehicle Identification Number (VIN)

Tab: Displays all the vehicle makes in the vehicle menu.

19

Page 27

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

3 Common

Regional buttons: Tap different buttons to switch to corresponding

4

vehicles. If you have purchased a Gasoline & Diesel Version, a

Heavy-duty tab will appear next to the regional button.

History Button: Generally once a vehicle diagnosis is performed, the

tablet will record the every details of diagnostic process. This function

5

provides a quick access to the previously tested vehicles. Testing can

be resumed from the previous operation without starting from scratch.

Search bar: Input the desired vehicle model to quickly locate it.

6

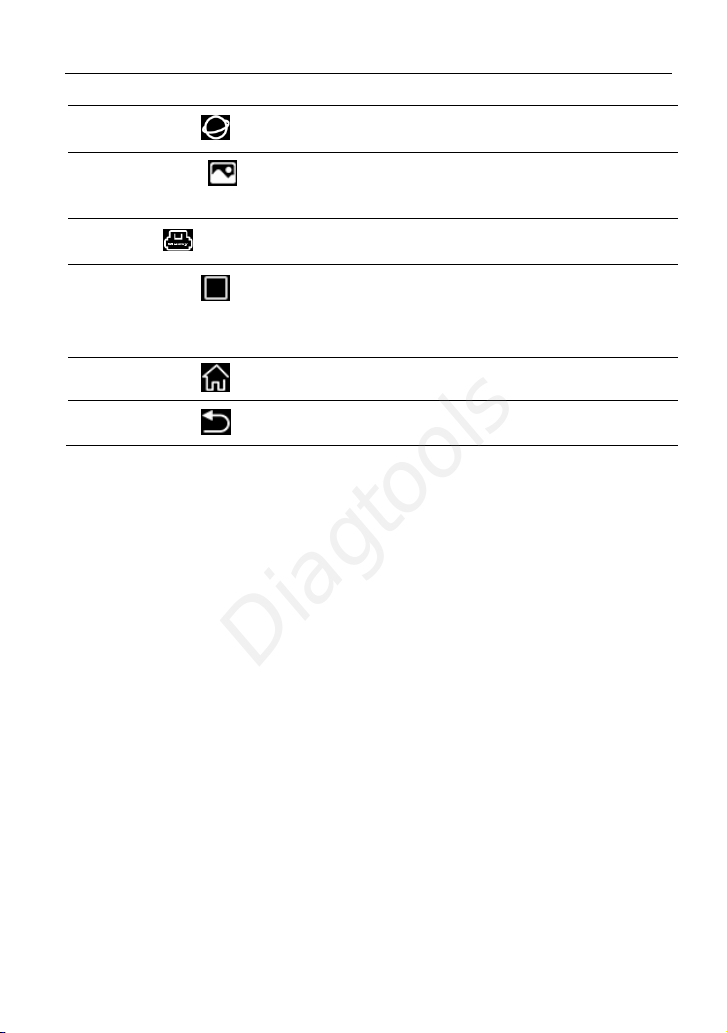

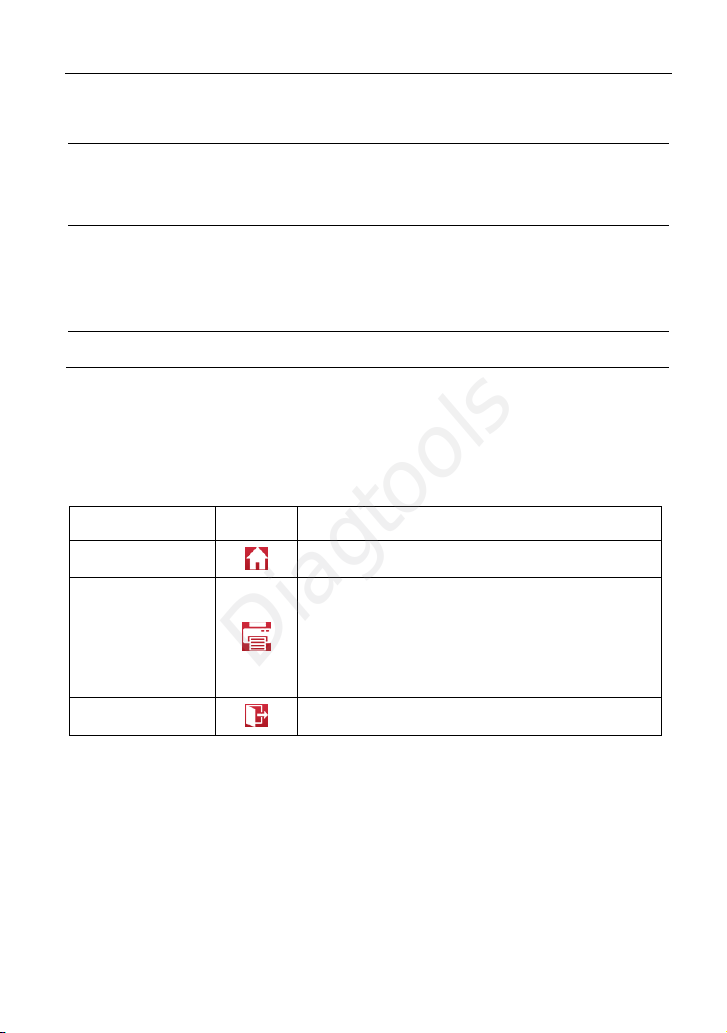

4.2.4 Diagnostics toolbar

The diagnostics toolbar contains a number of buttons that enable various

procedures. It is displayed at the top of the vehicle diagnostic screen throughout

the whole diagnostic session. Refer to the table below for a brief description of

the functions of the diagnostics toolbar buttons:

Name Icon Function

Home

Print

Tab: Displays all frequently-used vehicle makes.

Return to the Home screen.

Tap to print the current screen. To perform

printing, you need to purchase an extra

specific MINI printer separately and then

properly configure the wireless printer following

the steps described in Chapter 14.12.3.

Exit

Exit the diagnostic application.

4.3 Diagnosis Methods

The tablet supports 2 communication methods with the VCI device: WLAN

(wireless) and wired (data cable). You may choose any one of the methods to

diagnose a vehicle.

*Notes:

To obtain stable communication, you are strongly recommended to perform the

vehicle diagnosis via data cable. In this case, the data cable is required to connect

the VCI device and the tablet.

20

Page 28

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

When all communication methods are applied at the same time, the system will

use the wired communication as the default priority.

4.4 Connections

4.4.1 Preparation

Normal testing conditions

Turn on the vehicle power supply.

Throttle should be in a closed position.

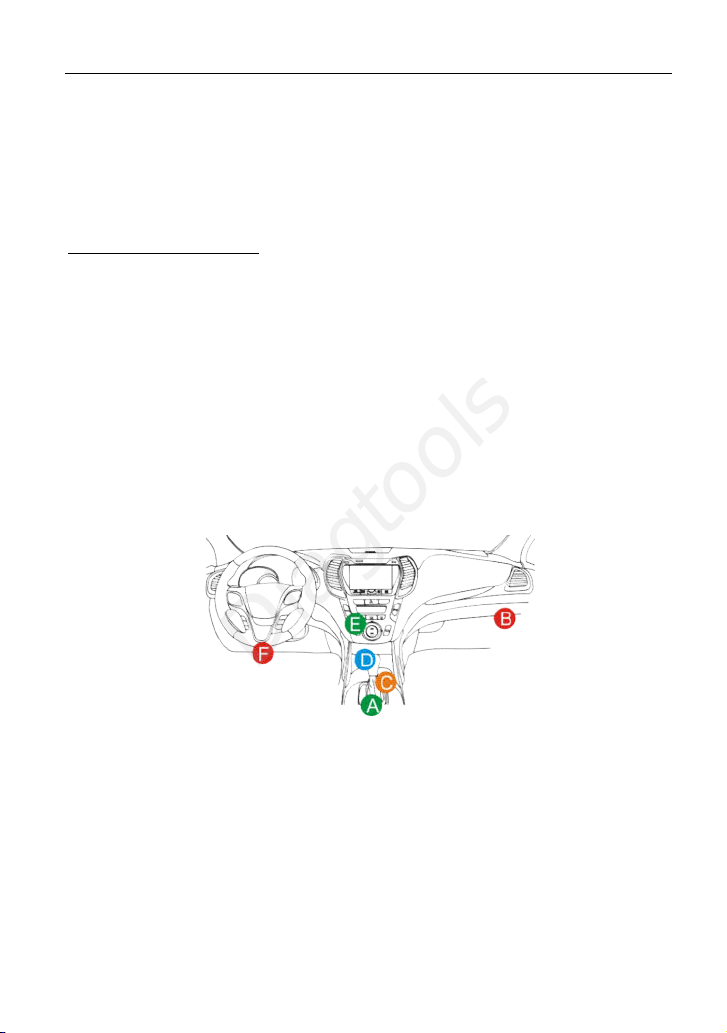

4.4.2 DLC location

The DLC (Data Link Connector) is typically a standard 16 pin connector where

diagnostic code readers interface with the vehicle’s on-board computer. The

DLC is usually located 12 inches from the center of the instrument panel (dash),

under or around the driver’s side for most vehicles. If Data Link Connector is not

located under dashboard, a label should be there telling location. For some

Asian and European vehicles, the DLC is located behind the ashtray and the

ashtray must be removed to access the connector. If the DLC cannot be found,

refer to the vehicle’s service manual for the location.

Fig. 4-9

4.4.3 Vehicle connection (For Passenger Vehicle Version)

The method used to connect the diagnostic connector to a vehicle’s DLC

depends on the vehicle’s configuration as follows:

A vehicle equipped with an OBD II management system supplies both

communication and 12V power through a standardized DLC.

A vehicle not equipped with an OBD II management system supplies

communication through a DLC connection, and in some cases supplies 12V

power through the cigarette lighter receptacle or a connection to the vehicle

battery.

21

Page 29

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

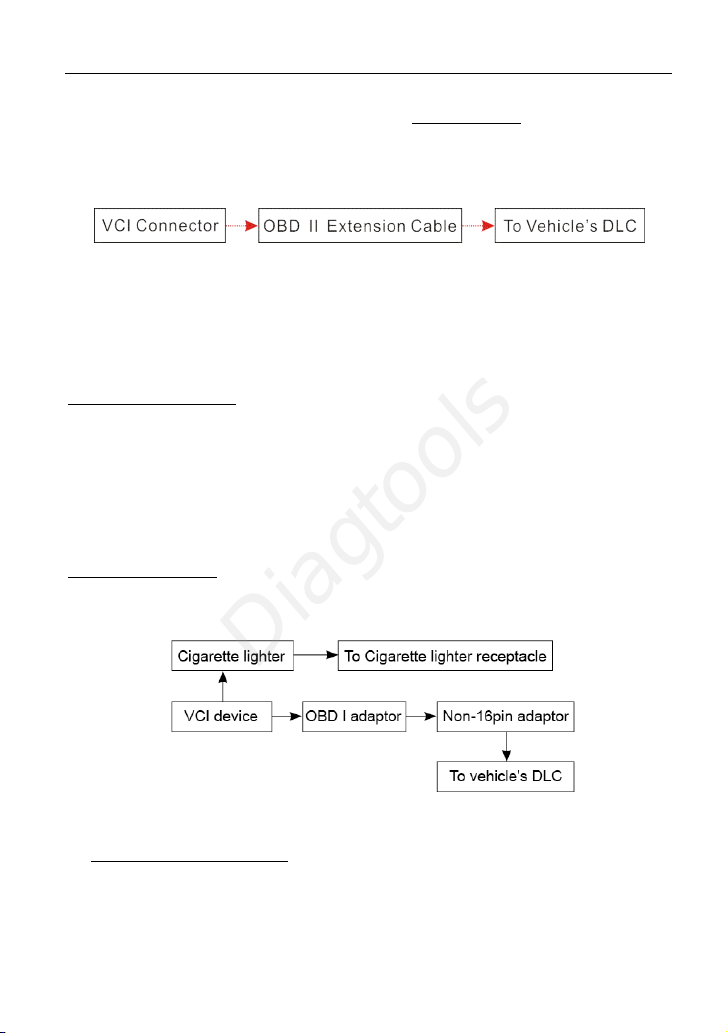

Follow the steps mentioned below to connect OBD II vehicle:

1. Locate vehicle’s DLC socket.

2. Plug the VCI device into the vehicle’s DLC socket (It is suggested to use the

OBD II extension cable to connect the VCI device and DLC socket).

Fig. 4-10

3. Choose one of the two ways to obtain power from:

A. Power adaptor: Connect one end of the included power adaptor to

charging port of the tablet, and the other end to AC outlet.

B. Internal battery pack

For non-OBDII vehicle, proceed as follows:

1. Locate vehicle’s DLC socket.

2. Select the corresponding non-16pin connector.

3. Plug the non-16pin end of the connector into the DLC socket, and the other

end to the OBD I adaptor, and then tighten the captive screws.

4. Connect the other end of the adaptor to the included VCI device.

5. To supply power to OBD I adaptor from:

A. Cigarette Lighter: Connect one end of the cigarette lighter cable to vehicle’s

cigarette lighter receptacle, and the other end to the DC-IN jack of the VCI

device.

Fig. 4-11

B. Battery Clamps Cable: Connect one end of the battery clamps cable to

vehicle’s battery, and the other end to the power jack of OBD I adaptor.

22

Page 30

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 4-12

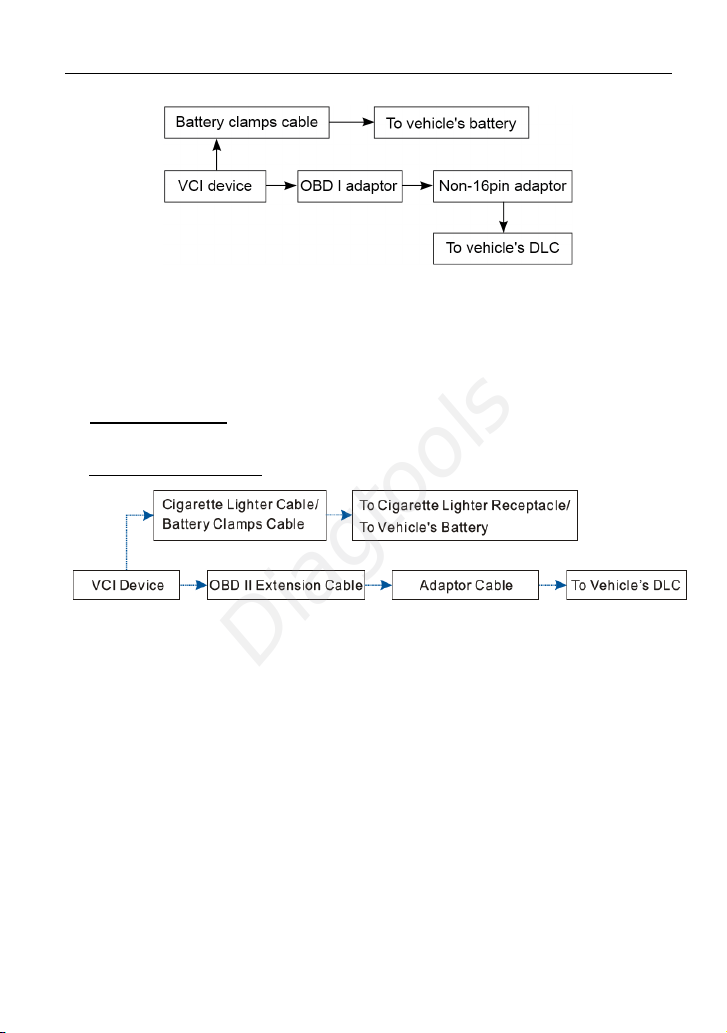

4.4.3 Vehicle connection (For Commercial Vehicle/ Gasoline & Diesel

Version)

The method used to connect the VCI device to a vehicle’s DLC depends on the

vehicle’s configuration as follows:

A. For OBD II vehicle, directly plug the VCI device into the vehicle’s DLC (OBD II

extension cable is recommended).

B. For non-OBD II vehicle, follow either of the ways to proceed:

Fig. 4-11

23

Page 31

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

5 Diagnosis

5.1 Intelligent Diagnosis

Through simple wireless communication between the tablet and VCI device, you

can easily get the VIN (Vehicle Identification Number) information of the

currently identified vehicle. Once the VIN is successfully identified, the system

will retrieve it from the remote server and then guide you to vehicle information

page without performing the step-by-step manual menu selection.

The vehicle information page lists all historical diagnostic records of the vehicle,

which lets the technician have a total command of the vehicle faults. In addition,

a quick dial to local diagnosis and diagnostic function are also available on this

page for reducing the roundabout time and increasing productivity.

*Notes:

•

Before using this function, please make sure the VCI device is properly connected

to the vehicle’s DLC. For detailed connection, see Chapter 4.3.3.

•

A stable network connection is required for this function.

Follow the steps below to proceed.

1. Tap “Intelligent Diagnose” on the home screen.

Fig. 5-1

2. The system starts connecting the VCI and decoding the VIN.

24

Page 32

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

A. If the VIN can be found from the remote server database, a screen similar to

Fig. 5-2 displays:

Fig. 5-2

• Tap “Diagnostic” to start a new diagnostic session.

• Tap “Maintenance record” to view its historical repair record. If there are

records available, it will be listed on the screen in sequence of date. If no

records exist, the screen will show “No Record”.

Fig. 5-3

• Tap “View record” to view the details of the current diagnostic report.

• To perform other functions, tap “Quick access” to directly go to the function

selection screen. Choose the desired one to start a new diagnostic

session.

25

Page 33

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

B. If the handset failed to access the VIN information, the screen will display as

below:

Fig. 5-4

In this mode, you need to input the VIN manually or tap to scan it.

1) Tap “ “ to launch the VIN recognition module.

Fig. 5-5

Place the VIN inside the viewfinder rectangle to scan it. The most

recognizable location for this number is in the top left corner on the

vehicle’s dashboard. Other locations include the driver’s door or post, and

the firewall under the hood.

26

Page 34

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

• If you have scanned the VIN of the vehicle, tap to choose it from

the record list.

• In case the handset failed to detect it, tap to enter it manually.

• To turn the flash on, tap .

After scanning, the screen automatically displays the result.

Fig. 5-6

• If the VIN scanned is incorrect, tap the result field to modify it and then

tap “OK”. If the VIN exists on the remote server, the system will enter

the vehicle information screen. See Fig. 5-2.

• To scan it again, tap “REPEAT”.

2) Input the VIN, and tap “OK”, the system will automatically identify the

vehicle model and directly navigate to the vehicle information page.

In general, vehicle identification numbers are standardized - all contain 17

characters. VIN characters may be capital letters A through Z and numbers

1 through 0; however, the letters I, O and Q are never used in order to avoid

mistakes of misreading. No signs or spaces are allowed in the VIN.

Tap “SKIP” to go to Diagnostics main menu screen.

5.2 Local Diagnosis

Tap “Local Diagnose” to enter the vehicle selection page.

27

Page 35

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-7

2 approaches are provided for you to access the vehicle diagnostic software.

Choose either one of the following ways:

A) VIN Scan

VINSCAN enables you to access it more quickly. In this case, automatic scan

(Camera Scan) and manual input (INPUT VIN) are available.

In Fig. 5-7, tap “VIN Scan”, the screen displays as follows:

Fig. 5-8

Camera Scan: In this mode, you need to place the VIN inside the viewfinder

rectangle to scan it.

28

Page 36

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-9

Place the VIN inside the viewfinder rectangle to scan it. The most recognizable

location for this number is in the top left corner on the vehicle’s dashboard. Other

locations include the driver’s door or post, and the firewall under the hood.

•

indicates the camera is in character pattern recognition mode (default

mode).

• Tap to switch the camera to barcode pattern recognition mode.

• If the ambient light is too weak, please turn the camera flash on.

• If you have scanned the VIN of the vehicle, tap VIN record icon to select

it from the record list.

• In case the handset failed to identify it, tap to enter it manually.

• Tap to toggle between the different display mode.

After scanning, the screen automatically displays the result.

29

Page 37

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-10

If the VIN scanned is incorrect, tap the result field to modify it and then tap

“OK”. If the VIN exists on the remote server, the system will enter the vehicle

information screen.

To scan it again, tap “REPEAT”.

INPUT VIN: In this mode, you need to input the VIN manually. In general, vehicle

identification numbers are standardized - all contain 17 characters. VIN

characters may be capital letters A through Z and numbers 1 through 0; however,

the letters I, O and Q are never used in order to avoid mistakes of misreading.

No signs or spaces are allowed in the VIN.

Tap “INPUT VIN”, input the VIN and tap “Confirm”. The system will automatically

identify the vehicle model and directly navigate to the function selection page.

Fig. 5-11

B) Manual Selection

Tap a corresponding diagnostic software logo, and then follow the on-screen

30

Page 38

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

instruction to access the diagnostic software.

Take Demo as an example to demonstrate how to diagnose a vehicle.

1). Select diagnostic software version: Tap the “DEMO” to go to Step 2.

more than one version is available on this handset, it will be listed on the screen.)

Fig. 5-12

On-screen Buttons:

Vehicle Coverage:

software covers.

What’s new:

Introduction:

Tap to read some precautions on using the current diagnostic software.

Note:

Confirm:

2). Select test item: Select the desired test item to proceed.

Tap it to go to next step.

Tap to view the vehicle models that the current diagnostic

Tap to view the optimized items and enhancements.

Tap to check the software function list.

(*Note: If

31

Page 39

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-13

5.2.1 Health Report (Quick Test)

This function varies from vehicle to vehicle. It enables you to quickly access all

the electronic control units of the vehicle and generate a detailed report about

vehicle health.

Tap “Health Report”, the system starts scanning the ECUs. Once the scanning is

complete, a screen similar to the following appears:

Fig. 5-14

In the above figure, the tested system with fault code appears in red and the

32

Page 40

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

system with OK displays in white (normally).

*Note: Diagnostic Trouble Codes or Fault Codes can be used to identify which engine

systems or components that are malfunctioning. Never replace a part based only on the

DTC definition. Retrieving and using DTCs for troubleshooting vehicle operation is

only one part of an overall diagnostic strategy. Follow testing procedures (in vehicle’s

service manual), instructions and flowcharts to confirm the locations of the problem.

On-screen Buttons:

: Tap to display the details of DTCs existing in the current system. Tap to

hide it.

Highlight certain DTC item, and tap to open the browser to retrieve it in

Google engine.

Tap to select other test functions.

Enter:

Fig. 5-15

To save the current data in text format.

Report:

*Note: Diagnostic report is classified into three categories:

Post-Repair

the report type will be appended as a tag on the upper right corner of the diagnostic

report for easier identification.

report and

Diagnostic Scan

. No matter which type you saved the report as,

33

Pre-Repair

report,

Page 41

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-16

Tap to select the report type from the option list and input the required

information, and then tap “OK”.

*Note: To facilitate the comparison of the pre-repair and post-repair reports and get

accurate test result, please make sure you saved the right type of the diagnostic report.

To save the report as a common diagnostic report, select “Diagnostic Scan”.

34

Page 42

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-17

Enter the shop name, address line, technician (tap “Add” to create a pull-down

list) and customer name and then tap “OK” to confirm and navigate to the report

details page.

*Note: Alternatively you can also set the workshop information in “User Info” ->

“Settings” -> “Print Information”.

Once you configured the information, it will be automatically generated every time you

saved the diagnostic report. All vehicle and workshop information will be appended as

tags on the diagnostic report.

To ignore the workshop information, tap “Skip” to go to the report details page.

On the report details page, tap “Save” to save it. All diagnostic reports can be

accessed from “User Info” -> “My Reports” -> “Diagnostic Report”.

Help: Tap to view the help information of the selected DTC item.

Compare Results: Tap to select the pre-repair report to compare. By comparison

of the pre- and post- repair reports, you can easily identify which DTCs are

cleared and which remain unfixed.

*Note: Before performing this function, please make sure that:

•

You have saved a pre-repair report of the currently tested vehicle, and

•

You have already made some repairs and service and cleared the DTCs after the

pre-repair reported is generated. Otherwise, no differences exist between the pre-

and post- repair reports.

35

Page 43

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-18

Clear DTCs:

*Note: Clearing DTCs does not fix the problem(s) that caused the code(s) to be set. If

proper repairs to correct the problem that caused the code(s) to be set are not made, the

code(s) will appear again and the check engine light will illuminate as soon as the

problem that cause the DTC to set manifests itself.

5.2.2 System Scan

This option allows you to quickly scan which systems are installed on the

vehicle.

In Fig. 5-13, tap “System Scan”, the system start scanning the systems. Once

the scanning is complete, the screen will display the result.

Tap to clear the existing diagnostic trouble codes.

36

Page 44

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-19

Tap the desired system to advance to the test function selection page. For

detailed operations on test function, please refer to Chapter 5.2.3.

5.2.3 System Selection

This option allows you manually select the test system and function step by step.

In Fig. 5-13, tap “System Selection”, the screen displays as follows:

Fig. 5-20

Swipe the screen from the bottom to view the vehicle system on the next page.

Tap the desired system (take “ECM” for example) to jump to the test function

37

Page 45

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

page.

Fig. 5-21

*Note: Different vehicle has different diagnostic menus.

A. Version Information

This function is used to read the version information of system mode, vehicle

VIN, software and ECU.

In Fig. 5-21, tap “Version Information”, the screen displays the ECU information.

B. Read Fault Code

This function displays the detailed information of DTC records retrieved from the

vehicle’s control system.

*Note: Retrieving and using DTCs for troubleshooting vehicle operation is only one

part of an overall diagnostic strategy. Never replace a part based only on the DTC

definition. Each DTC has a set of testing procedures, instructions and flow charts that

must be followed to confirm the location of the problem. This information can be found

in the vehicle’s service manual.

In Fig. 5-21, tap “Read Fault Code”, the screen will display the diagnostic result.

38

Page 46

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-22

On-screen Buttons:

Freeze Frame:

conditions are recorded by the on-board computer. This information is referred

to as freeze frame data. Freeze frame data includes a snapshot of critical

parameter values at the time the DTC is set.

Tap to view the help information.

Help:

Code Search:

online.

To save the current data in text format. All reports are saved under the

Report:

tab “Diagnostic Report” in “My Report” from “User Info” menu. For details on

report operations, please refer to Chapter 14.1 “My Report”.

When an emission-related fault occurs, certain vehicle

Tap it to search for more information about the current DTC

C. Clear Fault Code

After reading the retrieved codes from the vehicle and certain repairs have been

carried out, you can use this function to erase the codes from the vehicle. Before

performing this function, please be sure the vehicle’s ignition key is in the ON

position with the engine off.

Clearing DTCs does not fix the problem(s) that caused the code(s) to be set. If

proper repairs to correct the problem that caused the code(s) to be set are not

made, the code(s) will appear again and the check engine light will illuminate as

soon as the problem that cause the DTC to set manifests itself.

In Fig. 5-21, tap “Clear Fault Code”, a confirmation dialog box pops up on the

39

Page 47

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

screen.

Tap “Yes”, the system will automatically delete the currently existing trouble

code.

*Note: After clearing, you should retrieve trouble codes once more or turn ignition on

and retrieve codes again. If there are still some trouble codes in the system, please

troubleshoot the code using a factory diagnosis guide, then clear the code and recheck.

D. Read Data Stream

This option lets you view and capture (record) real-time Live Data. This data

including current operating status for parameters and/or sensor information can

provide insight on overall vehicle performance. It can also be used to guide

vehicle repair.

*Note: If you must drive the vehicle in order to perform a troubleshooting procedure,

ALWAYS have a second person help you. Trying to drive and operate the diagnostic

tool at the same time is dangerous, and could cause a serious traffic accident.

In Fig. 5-21, tap “Read Data Stream”, the system will display data stream items.

Fig. 5-23

On-screen Buttons:

Select Page

stream item, just check the box before the item name.

Select All:

stream item, just check the box before the item name.

: Tap it to select all items of the current page. To select certain data

Tap it to select all items of the current page. To select certain data

40

Page 48

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Unselect:

OK:

After selecting the desired items, tap “Confirm” to enter the data stream reading

page.

Notes:

1. If the value of the data stream item is out of the range of the standard (reference)

2. The indicator 1/X shown on the bottom of the screen stands for the current

There are 3 types of display modes available for data viewing, allowing you to

view various types of parameters in the most suitable way.

Value – this is the default mode which displays the parameters in texts and

Graph – displays the parameters in waveform graphs.

Combine – this option is mostly used in graph merge status for data

On-screen Buttons:

Tap it to deselect all data stream items.

Tap it to confirm and jump to the next step.

Fig. 5-24

value, the whole line will display in red. If it complies with the reference value, it

displays in blue (normal mode).

page/total page number. Swipe the screen from the right/left to advance/return to the

next/previous page.

shows in list format.

comparison. In this case, different items are marked in different colors.

: Tap it to view the waveform graph of the current data stream item.

41

Page 49

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-25

• Min/Max: Tap to define the maximum/minimum value. Once the value

goes beyond the specified value, the system will alarm.

*Note: The real time (Live Data) vehicle operating information (values/status) that the

on-board computer supplies to the tool for each sensor, actuator, switch, etc. is called

Parameter Identification Data (PID).

: Tap it to view the waveform.

Graph

Fig. 5-26

• Combine: This option is mostly used in graph merge status for data

42

Page 50

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

comparison.

• Value: Tap to display the parameters in texts.

• Customize: Tap , a pull-down list of the data stream items appears on the

screen. Select (Maximum 4 data stream items can be selected) /deselect

the desired items and then screen will display/remove the waveforms

corresponding to these items immediately.

Fig. 5-27

Compare Sample

customized and saved in process of DS sampling will be imported into the

“Standard Range”(See below) column for your comparison.

*Note: Before executing this function, you have to sample the values of data stream

items and save it as a sample DS file.

: Tap it to select the sample DS file, the values you

43

Page 51

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-28

: To save the current data as a diagnostic report. All diagnostic reports

Report

can be accessed from “User Info” -> “My Reports” -> “Diagnostic Report”.

: Tap to start recording diagnostic data. Recorded live data can serve as

Record

valuable information to help you in troubleshooting of vehicle problems. All

diagnostic records can be replayed from “User Info” -> “My Reports” ->

“Diagnostic Record”.

*Note: The saved file follows the naming rule: It begins with vehicle type, and then the

product S/N and ends with record starting time (To differentiate between files, please

configure the accurate system time).

: Tap to view the help information.

Help

Save Sample

data stream items and save it as DS sample file. Each time you run the data

stream items, you can call out the corresponding sample data to overwrite the

current standard range.

Tap it to start recording the sample data (*Only data stream items with

measurement units will be recorded), and the screen displays as below:

: This item enables you to customize the standard range of live

44

Page 52

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-29

Once recording is complete, tap to stop it and navigate to the data revision

screen.

Fig. 5-30

Tap the Min./Max. value to change it. After modifying all desired items, tap

“Save” to save it as a sample DS file. All DS files are stored under the “Data

Stream Sample” file in “User Info.”

E. Actuation Test

This option is used to access vehicle-specific subsystem and component tests.

45

Page 53

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Available test vary by vehicle manufacturer, year, and model.

During the actuation test, the tablet outputs commands to the ECU in order to

drive the actuators, and then determines the integrity of the system or parts by

reading the ECU data, or by monitoring the operation of the actuators, such as

switching a injector between two operating states.

In Fig. 5-21, tap “Actuation Test”, the system will display the actuation test item.

Simply follow the on-screen instructions and make appropriate selections to

complete the test. Each time when an operation is successfully executed,

“Completed” displays.

5.3 Remote Diagnosis

This option aims to help repair shops or technicians launch instant messaging

and remote diagnosis, making the repair job getting fixed faster.

Tap “Remote Diagnosis” on the Home screen, the screen appears blank by

default.

5.3.1 Interface layout

Fig. 5-31

1 Search bar

Directly input the username of the X-431 EURO TAB II to

start searching, and then tap the desired one to add it into

46

Page 54

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

your friend list.

2 Home button Tap it to navigate to the Home screen.

3 Message tab

4 Contact tab Tap to enter the friend list.

Remote

5

switch

5.3.2 Add friends

Tap “Contact” to enter the contact page. By default it appears blank.

In the search bar, input the partner’s username and tap “Search” button next to

the search bar to starts searching from Launch’s golo business database.

The partner must be the users who have registered their Launch’s diagnostic

tools. They may be the following:

Workshop

Technician

golo users

Once the result matches the keyword, a screen similar to the following will

appear:

Once an incoming message reaches, a red dot will appear

on the upper right corner of the tab.

Tap to slide the switch to ON, the tablet keeps online and

becomes accessible on the web client. In this case, inform

the technician of your product S/N, and he/she will control

your device remotely.

47

Page 55

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-32

Tap the user avatar, the following screen displays.

Fig. 5-33

Tap “Add friend” to send your request.

Once the partner receives the request, a beep will sound. Tap the “Message”

tab:

• Once the partner agreed your request, he/she will automatically be listed in

the Contact tab.

• If a technician sent you a friend request, you can tap “Agree” to confirm and

his/her name will appear in the friend list (Contact). Or tap “Ignore” to ignore

48

Page 56

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

this request.

5.3.3 Start instant messaging

*Note: The I/M (Instant Messaging) function is open to all users who had Launch’s

diagnostic tool equipped with this module.

After adding your friends, tap the desired one’s photo to enter a screen similar to

the following:

Fig. 5-34

Tap the input field and use the on-screen keyboard to enter the text message,

and then tap “Send” to send it.

Tap to send the voice message.

Tap to send the emoj.

Tap to call out more function options.

Fig. 5-35

49

Page 57

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

File: Choose diagnostic reports or local files to send.

Picture: Choose screenshots or pictures to send.

Remote Diagnostic: To start a remote diagnostic session. For details, refer to

Chapter 5.3.4.

Camera: Open camera to take pictures.

5.3.4 Launch remote diagnosis (Device-To-Device)

The tablet is allowed to launch remote diagnosis with other diagnostic tools

(including but not limited to the X-431 EURO TAB II) of Launch family, which are

equipped with this module.

* Note: Before performing this operation, please make sure the following no matter

which side sends the remote request:

Turn on the vehicle power supply.

Throttle should be in a closed position.

The VCI device should be properly connected to the vehicle’s DLC and a successful

communication is required.

In Fig. 5-35, tap “Remote Diagnostic”, a pull-down menu including the following

options appears:

Fig. 5-36

These options are defined as follows:

Actions Results

Send remote

diagnostic reservation

Request control

remote device

Tap it and input the reservation title or scheduled date

of the remote diagnosis, and then tap “Confirm” to

send.

Request to control the partner’s device remotely to

help him diagnose the vehicle.

*Notes:

Remote diagnosis has the same diagnostic steps as

50

Page 58

X-431 EURO TAB II User Manual

manual diagnosis.

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

In process of remote diagnosis, tap the button to

send a voice message.

Once vehicle diagnosis is complete, a report will be

created. Input your comments on this report, and then

tap “Send Report” to send it to the partner.

Tap “Request control remote device”

Wait for partner’s confirmation

Start connecting after request confirmed

Start Diagnosis

If you need support, just use this option to invite a

technician to perform a remote control on your tool.

*Notes:

Remote diagnosis has the same diagnostic steps as

manual diagnosis.

Invite remote

diagnostic assistant

In process of remote diagnosis, tap the button to

send voice message.

Once you received the report from the partner, tap

“View Report” to view details. All diagnostic reports

are saved under the “Remote Diagnostic Reports” tab

of “My Reports” in “User Info”.

Generate diagnostic report

51

Page 59

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Cancel To cancel this operation.

52

Page 60

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

5.3.5 Launch remote diagnosis (Device-To-PC)

Except that the remote diagnosis can be done between different Launch’s

diagnostic tools that come loaded with the module, user also can ask for remote

control from PC client technician.

Fig. 5-37

Tap the “Web Remote” tab, the screen displays as follows:

53

Page 61

X-431 EURO TAB II User Manual

(c) Launch & Diagtools. Tel. +37167704152, +37129416069. www.diagtools.lv

Diagtools

Fig. 5-38

1. Slide the switch “Allow device to be connected to the WEB client remote

diagnostic device” to ON so that the partner can find and access to this

device while using the PC.

2. Notify the partner of the PC client website http://remote.x431.com/cn/. When

the partner opens the link, the PC displays as below: