Page 1

*Read these instructions

before placing unit in service.

**Keep these and other materials with the unit in a

binder near the machine for

easy reference by supervisors and operators.

***You will need the manual for the information of

the machine, such as safety

warning and precautions,

assembly, operating, maintenance and parts list / assembly diagrams.

****Keep your invoice

with this manual for future

reference. Manufacturer

shall not be liable for any

injury to persons on damage

to thins caused by failure to

comply with these regulations and can cancel warranty coverage.

Operation Manual

Installation, Operation, Maintenance

TWC-512RMB

Tire Changer

Page 2

(1) Technical Data

Model

Electric Requirements See the manufacturer’s serial plate

Max. Wheel Diameter 42‖

Max. Wheel Width 14‖

Outside Clamping—Rim sizes 11‖ ~ 21‖

Inside Clamping—Rim sizes 13‖ ~ 23‖

Max Inflation Pressure 116-145PSI (8-10 Bar)

Bead Breaker Force 2500kgs

Max Rotating Torque (Turntable) 795 ft.lbs (1078N.m)

Noise Level

<70db

Overall Dimensions (L x W x H)

Shipping Weight 385kg

Voltage 0.9 ~ 1.1 of nominal voltage

Frequency 0.98~1.02 of nominal frequency

Ambient Temperature 5~40°C

Operation Humidity 30~95%

Installation altitude NOT exceed 1000m

Transport / Storage temperature -25~55°C

(2) ASSEMBLY INSTRUCTION

Fig.1

2-1 Transport

When transporting the machine it must be handle with a forklift truck with the forks

Positioned as show as in the Fig.1.

2-2 Unpacking

When unpacking, check to make sure all parts shown on the spare parts List/Assembly. Diagrams are included. If any parts

are missing or broken, please call the manufacturer or the dealer as soon as possible.

(3) Workplace Requirements

The machine’s workplace requires 1400(width)×1685(depth) with at least 500 mm of clear space from each wall. Place the tire

changer on a firm, smooth and unbroken floor. Drill four holes in the floor corresponding to the holes pre-drilled in the base of

the machine. Holes should be 80mm deep. Its diameter is 10mm. Then insert the expansion plugs and lighten with the 10mm

spanner.

Page 3

(4) Product description

1

2

3

4

5

6

7

8

9

11

13

14

15

16

17

18

19

12

10

1.padel(rotating) 2.turntable 3.padel (clamping) 4.Jaw 5.padel (title back)

6.vertical column 7.padel (bead

breaker)

8.shovel arm 9.ULMH 10.hexagonal column

11.control handle 12.slide arm 13.HDFRL 14. shovel 15.rubber wheel support

16.DAAR 17.LPJP 18.BBSPP 19. Inflation gun

Page 4

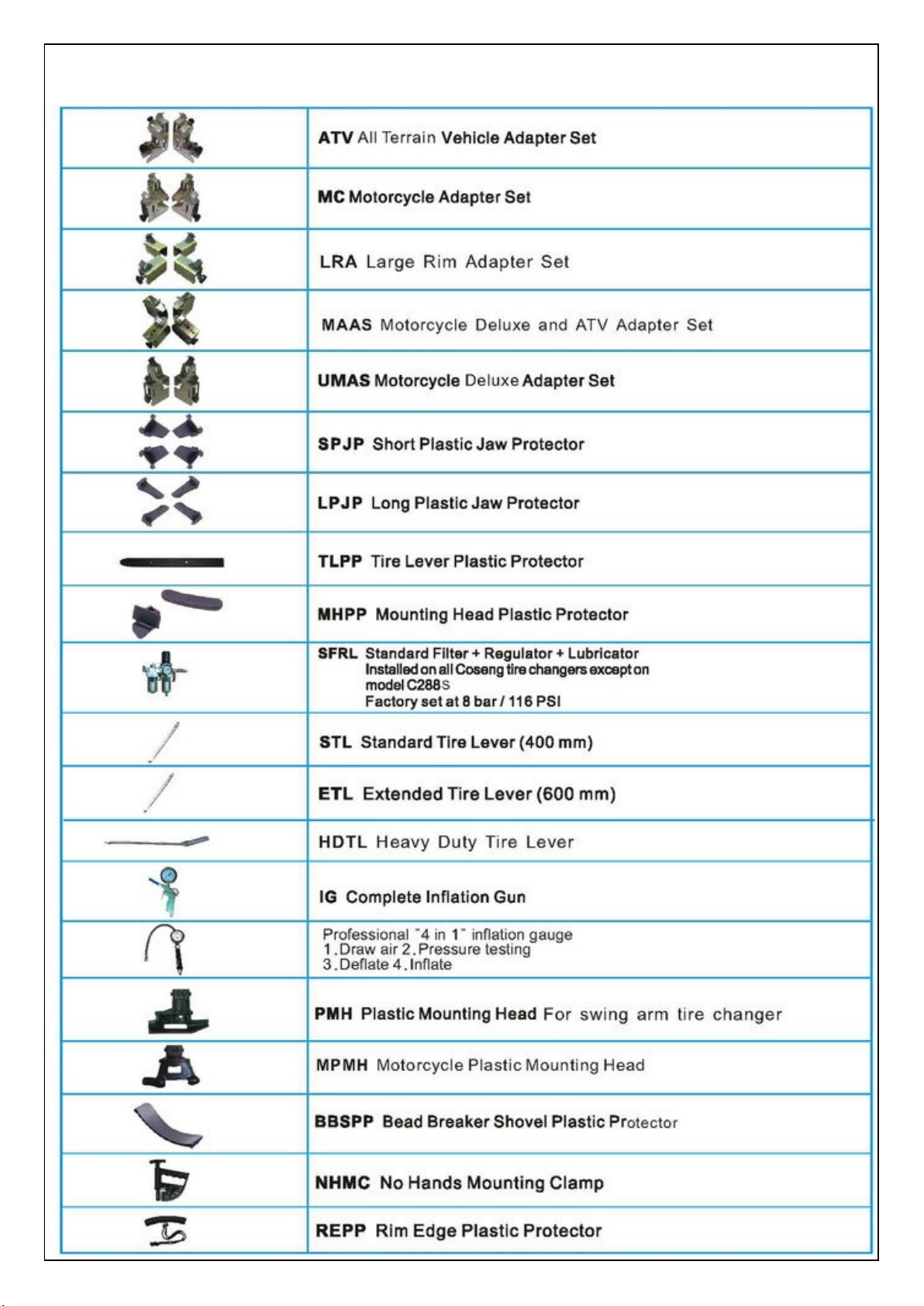

(5) Optional Upgrade Accessories

Page 5

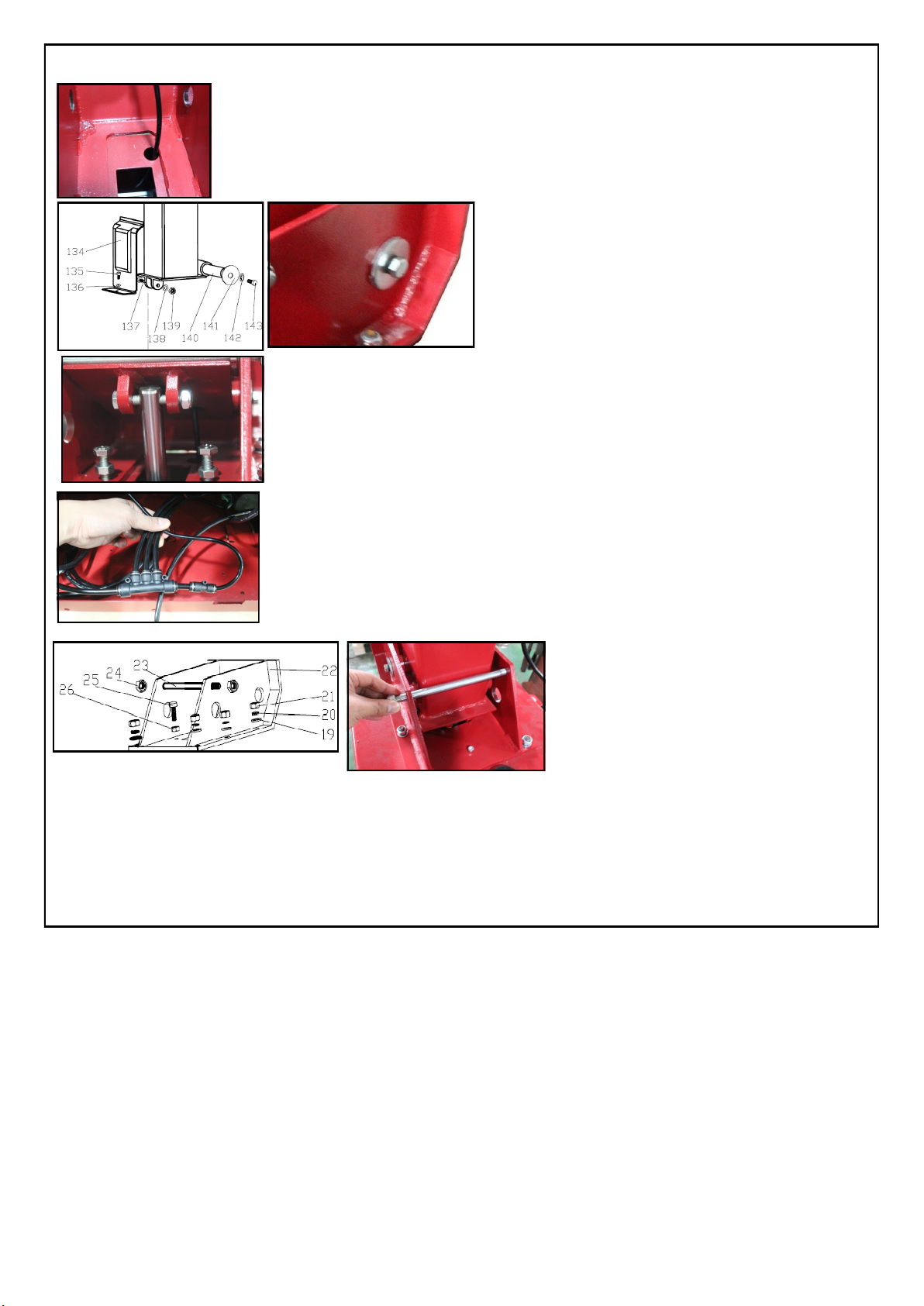

Step 1. With assistance, place the vertical column in its tilt back seat on the Body Assembly. Push the air hose

through the large round hole into the body.

Step 2. Insert the pin (140) through the column and fasten it with

screws (143) and washers (142).

Step 3. Using the screw (137) tighten with the self-locking nut (139) and washer (138) to connect the pin

of the post tilting cylinder.

Step 4. Remove the four screws from the left side cover and remove it. Connect the air hose from the column to the 6mm connector.

Step 5. Replace the side cover and fasten with its screws.

Step 6. Install the plastic guard (134) and fix it with the screws and washer (135,136).

Step 7. Install the stopper bolt (23) with self lock nut

(24). Don’t too tight.

5-2 Pneumatic link up

1) Push the clamping pedal all the way down to ensure that the jaws on the turntable do not open unexpectedly.

2) Connect the inflation gun, if it is to be installed, to its connector.

3) Connect the tire changer to a compressed air network (suggested working pressure from 8bar) using the connector. Use a compressed air

hose with on inside diameter of 7~8 mm.

5-3 Electric link up

1) Before making any electric link up, check to be certain that the main voltage corresponds to what is stamped on the voltage tag.

2) It is absolutely essential that the system is equipped with a good grounding circuit.

3) The machine must be connected to a power supply line circuit bracket set for 30mA

(6) Assembly procedure

Page 6

(7) Bead Loosening and Demounting

This machine may operate differently from machines you

have previously operated. Practice with a regular steel

wheel and tire combination to familiarize yourself with

the machine’s operation and function.

A. Remember to remove all weights from both sides of

the wheel. Weights left on backside of wheel may cause the

wheel to be clamped unleveled. This may result in the combination mount/demount head contacting the rim causing

scratches. On alloy wheels, always rotate the wheel one turn

after setting the Mounting head to insure proper wheel

chucking.

B. Always review with the owner any nicks and

scratches on expensive wheel and tire combinations prior to

servicing.

C. Review the custom and special wheel section of this

manual prior to servicing custom or special tire/wheel combinations.

Loosening the beads on a partially or fully inflated tire is

unsafe and causes excess movement and friction against

the bumper pads and excessive wear on pivots. Deflate

the tire completely to prolong the life of your machine.

1. Deflate the tire completely by removing the valve core

from the valve stem (figure 1). Be cautious and do not smoke

as a flammable gas could have been introduced into the tire

at some time.

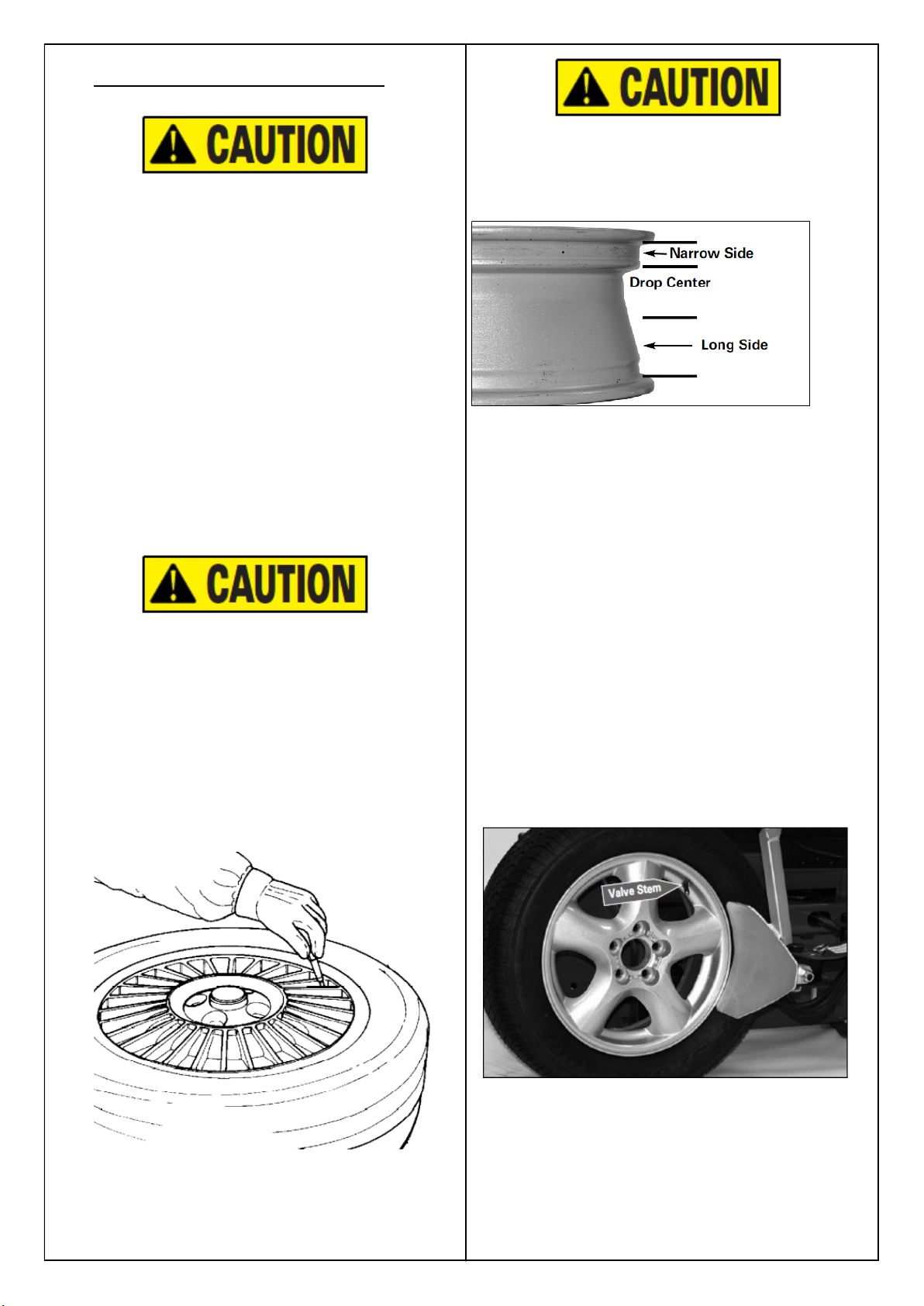

Tires are always installed and removed from the rim’s

narrow side.

D. Always loosen the bead on the narrow side of the

wheel’s drop center first (tire removed in figure 2 for clarity).

Figure 2 - Determine Narrow Side of Wheel

Figure 1 - Remove Valve Core to Deflate Tire

E. The clamps on the table top may extend beyond the

table top itself. To avoid damaging the clamps, move them

to their full inward position before positioning a tire for bead

loosening.

F. Use extra care in positioning the bead loosener shoe

on larger wheels/tires, and on alloy wheels. Make sure the

shoe rests next to but not on the rim, and not on the tire

sidewall.

2. Pull the bead loosener shoe away from the machine and

roll wheel into position. The valve stem should be in the 2

o’clock position to accommodate a possible asymmetric

safety hump type rim. Position the bead loosener shoe

against the tire next to, but not on, the rim. Press the bead

loosener foot pedal to actuate the shoe and loosen the bead.

It may be necessary

to loosen the bead in multiple locations around the tire

(figure 3).

3. Turn the wheel around and repeat loosening procedure

on the other side of the wheel (figure 4). This should be the

long side of the drop center (figure 2).

Figure 3 - Position Tire and Bead Loosener Shoe

Page 7

1. it is important to understand that tires and / or tire beads do not stretch. It is nearly impossible to mount

dismount the top bead of the tire unless the to bead of the tire is positioned deep into the drop center area

of the wheel.

2. Find the position of the drop center on the wheel. Clearly identify the drop center, narrow side and wide

side flanges.

3. The tire must always be demounted or mounted with wheel positioned on the turntable with narrow side

facing upward and the deepest part of the drop center facing upward.

Warning—the wheel illustrated above in diagram A has little or no prominent drop center. These are

not dot approved wheel configurations. The tire or wheel—or both—can be damaged during mounting procedures causing the tire to explode under pressure, resulting in serious injury or death.

Important note –most aftermarket and many OEM performance wheels are REVERSE DROPCENTER configurations. These wheels must be mounted on the turntable with the hub or wheelface positioned downward on the turntable and the narrow side and deep art of the drop center facing

upward.

(8)Important

Page 8

4.Place tire/wheel assembly on table top with mount-

ing side up

5. use the clamp control pedal to move the clamps in-

ward or outward.

6. apply tire manufacturer’s approved rubber lubri-

cant liberally to entire circumference of both beads

after loosening bead and placing on table top. Using

the mount/ demount roller to hold down the top bead

while rotating the turntable will make lubrication

easier.

7. move the tower forward by depressing the tower tilt pedal

then press the control button to unlock the horizontal slide.

Pull the mount/demount head forward.

(9) How to demount and mount a tire

with using ULMH

9.1 before demount, make sure the bead is loose. Please

use the bead breaker to loose the bead. Then lubricate the

bead where hook push down.

9.2 if machine equips assistance arm, press down the

bead to show the bead lip

and gap. Then use the hand

control valve push down

the hook. (left picture). Return assistance arm.

9.3 the hook maybe not

under the bead lip because the bead is thick or

long. Please step on the

rotation pedal to counter

clockwise spin the tire.

9.4 during the rotation,

the tension of bead will

be bounced, so the hook

automatically is under

the bead lips.

Page 9

9.5 use a hand control valve to

raise up the hook, the bead lip

is the top of rim’s edge.

9.6 some tires such as runflat ,or low profile tires

needs extra force to reduce

stresses. Use the assistance

arm to press down on the

tire opposite the mounting

head to allow the bead to

utilize the drop center area

of the rim, this position reduce stresses in the bead and

allows an easier bead lift.

9.7 lubricate bead lip area

before rotate the wheel.

Lubricating the bead can

decrease the friction between hook, bead and rim.

It must be lubricated well.

9.8 during the demount,

bead lip maybe not jump

up the top of rim, please

use plastic bead lifting

lever to insert the gap between bead and rim. Hold

that position (see left picture) to keep bead is top of

the rim.

9.9 rotate the tire. Then

top bead lip is completed

loose.

9.10 use the hand control

valve to push down the

hook (lift picture).

9.11 use the hook to pull

out the bottom bead lip.

9.12 lubricate the hook

and bottom bead lip to

decrease frication during

the demounting.

9.13 lubricate the vertical

sleeve if bead is wider.

9.14 rotate the wheel to

demount the bottom bead

lip.

Page 10

(11) bead installation

(10) Mounting

Notice: check the wheel and bead any possible damage that maybe cause rick

11.1 first install bottom bead tip on the rim.

11.2 rotate the wheel and bottom bead will automatic pull

down. Depress table top pedal and rotate wheel to mount

lower bead. Use drop center of wheel by forcing down on

tire just ahead of the mounting tool, and follow as tire rotates. Rotate table top until lower bead is mounted.

11.3 the top bead lip must place on the ULMH tail. rotate the table top until the valve stem is directly across

from the mount head. Lift the upper bead up and over

the rear of the mount head. With assistance arm press

down on the tire between the mount head and the valve

stem to hold the tire in the drop center. Depress table

top pedal and rotate tire until bead is mounted. Be careful to ensure bead stays in the rim drop center in the

area ahead of Mounting head

11.4 If table top rotation stalls, reverse the table top momentarily until tire bead is again loose on the wheel. Reposition tire on Mounting head, make sure bead is correctly

positioned in drop center of the wheel; then attempt

mounting again.

11.5 For low profile or stiff sidewall tires, it may be advantageous to use the bead lifting tool to initially hold the upper bead down in the drop center.

Page 11

(10) Bead Sealing

1. Position valve stem in front of operator and connect the

inflation hose with the clip-on chuck. Hold tire up against

upper edge of the wheel. Be sure tire’s top bead does not cover

the bottom of the valve stem (figure 19).

Figure 19 - Lift Tire Upwards for Bead Sealing

2. Depress inflation pedal to position 2 and hold about one

second to begin air flow through tire valve, then depress

pedal to position 3 and hold briefly — less than one full

second. The blast of air from the jets will expand tire and

seal the beads.

3. Release the inflation pedal and allow it to return to position 1. Verify that both beads are completely sealed to the

wheel. Repeat these steps if beads have not sealed. It may

be necessary to wait a few seconds for the air storage tank

pressure to recover before attempting again.

1. Once tire pressure is indicated on the air gauge (inflation

pedal in position 1; foot removed from pedal), continue to

inject air into the tire (inflation pedal position 2) in short

intervals. Check the pressure frequently. Stand back during

bead seat. Keep hands, arms, and entire body away from tire

during this procedure (figure 20). Tire beads should move

outward and ―pop‖ into their bead seat position as pressure

inside the tire increases. If this does not happen, a problem

exists. Investigate carefully.

Use of bead sealing jets without a tire in place can cause

dirt and debris to be blown into the air with enough force

to injure operator and/or bystander. Do not use the bead

sealing control position to inflate a tire.

S. This unit is equipped with a pressure limiter to assist

the operator with proper tire inflation. When the inflation

pedal is held in position 2, the pressure limiter cycles the

machine between position 2 (inflation) and position 1 (at rest,

no airflow to tire). This cycling helps to prevent over inflation of the tire. Tires can still be over inflated and explode

with the use of this pressure limiter if all of the instructions in

this manual are not followed completely. The pressure limiter will keep most car and light truck tires from inflating

beyond 60 PSI (smaller tires may reach higher pressures). It

is the operator's responsibility to follow all instructions and

to control inflation pressure as specified in these instructions.

Check the function of the pressure limiter regularly and

maintain it according to the instructions provided in this

manual for safe and proper operation. Do not tamper with or

attempt to adjust the pressure limiter. Tires requiring inflation beyond 60 PSI should be inflated in a safety cage.

T. If tire and wheel are properly lubricated and operator

cannot achieve bead seal after three or four attempts, the

valve core may be removed from the valve stem to allow

more air flow into the tire to assist with bead seal. After

bead seal is achieved, remove the clip-on chuck and reinstall the valve core. Reattach the clip-on chuck after core

is installed.

Figure 20 - Stand Back during Bead Seat

(9) Inflation

Tire inflation is performed in three steps: BEAD SEAL,

BEAD SEAT, and INFLATION. These steps are explained

in detail on page 12. Read the explanation of each step and

understand them thoroughly before proceeding.

The inflation pedal, located at the rear of the left side of the

machine, controls the flow of air through the inflation hose,

and has three positions. Note: The clip-on chuck on the end

of the hose should always be an open/freeflow style with all

parts in proper working order.

Position 1 - Tire Pressure – With the inflation hose

attached to the tire valve and the pedal in this position, the air

gauge will register the air pressure in the tire. Whenever your

foot is removed from the pedal, it will return to this position.

Position 2 - Tire Inflation – This is the first activated

position. With the inflation hose attached to the tire valve and

the pedal in this position, line pressure is allowed to flow

through the valve system and into the tire for inflation. Correct tire pressure is not indicated on the gauge in this position.

Position 3 - Bead Sealing – This is the second and last

activated position. With the inflation hose attached to the tire

valve and the pedal in this position, line pressure is allowed

to flow through the valve and to the airflate bead seal jets on

the table top for bead sealing.

1. If the rim has been clamped from the outside for

tire mounting, release the clamps, lift the tire, and move the

clamps to the center of the table top.

Page 12

(11) Stages of Inflation on a Conventional Tire and Rim

Review these descriptions and diagrams carefully. Refer to them as necessary during bead sealing, bead seating, and inflation to

verify that you are proceeding properly and safely.

Bead Sealing

Bead sealing is the process of capturing air pressure between the tire and the rim. The tire will usually contain about 1/2 to 2 PSI

at initial bead seal.

Bead Seating

Bead seating usually occurs on the long tapered side of the wheel first and the shorter side last. Bead seating will usually require

at least 7 PSI in the tire. 40 PSI is the maximum safe pressure at this stage regardless of tire operating pressure. Most European

import cars and many aftermarket alloy wheels are very tight and can be difficult to bead seat. Also note that asymmetrical hump

and run-flat tires are extremely difficult to bead seat. Follow tire manufacturer’s recommended procedure for bead seating.

Inflation

After the beads are seated, the tire is ready to be inflated. Do not inflate the tire above the manufacturer’s recommended pressure

as stamped on the tire sidewall. The typical inflation pressure for automobile tires is between 24 and 45 PSI. Light truck inflation

pressure typically covers a wider range.

Page 13

4-IN-1 Tire Inflating Gun

instruction

(IP, or IT system will not include 4IN1 Tire inflating Gun)

Introduction

Under-inflation burns more fuel and leads to shortened tire life. Check your tire pressure at least

once a month. Every liter of fuel consumed by a small vehicle releases 2.4 kg of C02 or a truck 12

kg into the environment, contributing to climate change.

This Tire Inflation Gun is a vacuum gun, inflating gun, a deflating gun and a tire pressure meter allin-one. The Gun has durable steel construction with no moving parts to wear out.

Inflating Chuck

Vacuum Cap

Gauge

Intake

Trigger

3600 Rotatable

Inflating Chuck

Vacuum Cap

Gauge

Intake

Trigger

3600 Rotatable

Features

- Four functions works on tire maintenance; (1) vacuuming tire air, (2) inflating tire air, (3)deflating tire air and (4)measuring

tire pressure.

- This Gun has a chuck with a 13/15mm diameter, 400/1000mm long hose for 360 degree rotatable which allows it to connect

to a tire valve conveniently.

- A built-in large dual scales (0-16 bar/0-240 psi) gauge makes air pressures easy to read.

- This Gun can be used not only on automotive tires also in the other fields.

- This Gun facilitates users while changing a truck’s inner tire.

Operation

Vacuum Tire : Connect air source (Nitrogen) into the Gun’s intake valve, and inflating chuck into car tire chuck valve in appropriate places.

Spin the rotatable vacuum cap and press the trigger. Then, you can see the indicator of the meter move to bottom left, start vacuuming. Once

complete the vacuuming, spin back the rotatable vacuum cap, then can do tire inflation.

Measure Tire Pressure: Connect inflating chuck into car tire chuck valve in appropriate place, the meter will start indicating the tire pressure.

Deflate Tire: When you need to deflate an over-inflated-pressure tire, press the trigger to the half while inflating the tire till reaching the desired

tire pressure.

Inflate Tire: Connect air source (Nitrogen) into the Gun’s intake valve, and inflating chuck into car tire chuck valve in appropriate places. Turn

OFF the rotatable vacuum cap and press the trigger. Then, you can see the indicator of the meter move to top right, start inflating the tire.

Page 14

DAAR ARM INSTRUCTION MANUAL

1.GENERAL

The DAAR ARM has been designed as a tire changer accessory to help the operator to mount or demount tires.

Before any operation of this machine,the operator is requested to read the manual carefully. Do not attempt

any operations that are not stated in this handbook!Otherwise,the machine fail to operating correctly,

causing injuries or machine damages,we shall not be liable for that accidents!

Please keep this manual handy for consulting.

2. TECHNICAL PARAMETERS

Working Air Pressure

8~10 bar

Net Weight 100kg

Noise Level

LpA<70Db(A)

3. SAFETY REGULATIONS

The operator must be a well –trained professional personnel.

This device could only function when work together with our tire changer.

We won’t responsible for any unauthorized modifications.

4. INSTALLATION

NOTICE:

The installations of this auxiliary device should be done by an professional

personnel.

Before any assemblies,turn off the power of both electricity and compressed air.

!

TRANSPORTAION

Move the machine with a forklift truck as illustrated in Fig.1.

UNPACKING

Remove the packaging carefully and check the machine, if there are any damages or defects,please

contact with us or with the dealer timely.

Please keep the packaging out of the children’s reach.

Please keep the packaging for possible future needs

Page 15

4.3 WORKPLACE REQUIREMENTS

Fig.2 shows maximum machine space requirements and minimum distance of 500mm from walls.

Screw M10

Screw M10

4.4 ASSEMBLY

The following steps show how to install the DAAR ARM.

1)Disconnect the tire changer from the electric power source and the compressed air circuit.

2)for installation of DAAR ARM. Pull the DAAR ARM to right side of machine. Using a M10 Screw mount

the tire changer.

3)Connect the air hose (Ø8mm) that introduced through the rear hole of the box with the corresponding

joint of T-union.

4)For IT version, connect the hose (Ø6mm) through the body to the fittings of the five-way valve ac-

cording to corresponding marks.

for installation of DAAR ARM. Pull the DAAR ARM to right side of machine. Using a M10 Screw mount the

tire changer.

Page 16

5. LAYOUT OF FUNCTIONAL PARTS

Right picture shows functional members of the DAAR ARM

1. valve Control Unit

2. axle guideboard

3. back swing arm

4. axle guard cover

5. shaft

6. bead roller

7. cylinder

8. bead breaker handle

9. u shape arm

10. mounting block

11. disk handle

12. bead breaker disk

1

1

2

1

4

1

5

1

6

1

7

1

8

1

9

1

10

11

12

3

1

6. SPECIFECATION OF SWITCH LEVEL

Controlling the switch level could attain the rise or decline of the tool holding arms.

7. TRIAL OPERATION

The operations of the DAAR Arm need the power both of electricity and compressed air.

The DAAR Arm must connect with air compressor, and 8 bar air pressure is desirable.

8. SAFETY REGULATIONS

WARNING:

Unreadable or missing warning labels must be replaced immediately.

Operations are not permitted when one or more labels are missed.

It is not allowed to prevent the view of the operator to see the labels when running the machine.

It’s reasonable to set up some labels as right picture shows.

!

9. OPERATIONS

The DAAR ARM has been designed to facilitate the operations of wheel locking and mounting/demounting

the tire on or from the rim. These operations,especially with low profile or very wide sports car tires or with

very hard beads,can be very difficult. In any case,the DAAR ARM would make these jobs easier on any

type of wheel.

Page 17

9.1 CLAMPING THE TIRE

Correctly follow this manual, release the beads both side of the tire.

It’s more forceful to use the DAAR ARM. Clamping the tire from out-

side is recommended. (Plastic protections are available ).

1. Depress the corresponding pedal to open the jaw and turn the

spindle to its non-working position.

2. lay the wheel onto the turntable, depress the corresponding

pedal to close or open the jaws for the clamping of the rim.

9.2 DEMOUNTING THE TIRE

1. Firstly break and loosen the beads if it is necessary.

Loosen the locking nut to lower the pressing roller, make sure the roller is above

the tire and not touching it.

Turn the switch level to bottom, lower the tool holding arm 1 to press the tire with

pressing roller. Depress the corresponding pedal to turn the turntable to loosen

the bead. Turn the turntable repeatedly if it is necessary.

NOTICE:

Before any operations, lubricate the bead of the wheel.

After loosen the bead, raise tool arms and begin the next demounting.

Demount the upper bead.

Close the mounting head to the upper bead as the manual stated.

Move the pressing roller near the mounting head, depress the bead for the convenience of position-

ing the mounting head, and then insert the level into the clearance between the rim and bead.

Raise the auxiliary arms, swivel the tool holding arm 2 to the opposite side, control the mounting head,

insert it into the

drop-center rim, and the tire will slide into the center drop. This could

get enough space for operations.

Pull out the bead with the help of mounting head and hang it on the

mounting head.

Raise the auxiliary arm, push the mounting head to its non-working po-

sition.

Depress the pedal to turn the turntable; the upper bead will be detached

off.

3. Loosen the second bead if it is necessary.

Push away the switch arm and tool holding arm3.

Position the bead-breaking disc under the tire, and make sure it close

to the tire other than touch the tire.

Insert the level into the special hole and exert an inner-toward force to as-

sure the bead breaking disc touch against the lower bead tightly. Depress the pedal to turn the turntable, meanwhile raise the auxiliary

arms slowly to detach the lower bead.

Page 18

NOTICE:

For some tires could be disassembled by only using the bead breaking disc, so it is enough continue the

third step until the tire was detached off.

Combination with the bead-breaking disc make it is easer to demount the wider tires and sport car tires.

Raise the lower bead up to center drop of the rim with the help of the bead-breaking disc.

Hook the detached part of tire on the mounting head.

Remove the bead-breaking disc; turn the turntable clockwise until the lower bead comes off the rim.

9.3 MOUNT TIRES

1) Set up the first bead according to instruction

2) WARNING!

Push away the tool holding arms to avoid danger of collision!

Move the mounting head and depress it to a depth of 3 cm blow the

upper side of the rim.

DANGER!

3) Please pay special attention during this procedure,pressing the

rim with the mounting head is not permitted. It will lead to danger.

Keep away hands from the mounting head.

4) Depress the corresponding pedal to turn the turntable, the

mounting head mechanism will turn also. Depress the tire blow into

the rim. During this procedure,it is free from any human interference

or other assistors.

10. TROUBLESHOOTING AND MAINTENANCE

Phenomena

Switch level is not flexible

Analysis

1)Disconnected with compressed air

2)Air hose is folded or broken

3)Valve is broken

Solution

1)Connect with the compressor according to the manual

2)Inspect the air hose, replace the broken hose and joint

3)Please contact with the department of after sale

Loading...

Loading...