Page 1

LAUNCH Tyre Changer(TWC Series)

General Notice

Trademark Information

is a registered trademark of LAUNCH

TECH. CO., LTD. (LAUNCH for short) in China and

other countries. All other LAUNCH trademarks,

service marks, domain names, logos, and company

names referred to in this manual are either

trademarks, registered trademarks, service marks,

domain names, logos, company names of or are

otherwise the property of LAUNCH or its affiliates. In

countries where any of the LAUNCH trademarks,

service marks, domain names, logos and company

names are not registered, LAUNCH claims other

rights associated with unregistered trademarks,

service marks, domain names, logos, and company

names. Other products or company names referred to

in this manual may be trademarks of their respective

owners. You may not use any trademark, service

mark, domain name, logo, or company name of

LAUNCH or any third party without permission from

the owner of the applicable trademark, service mark,

domain name, logo, or company name. You may

contact LAUNCH by visiting Launch at

http://www.cnlaunch.com, or writing to LAUNCH,

Xinyang Building, Bagua 4th Road, Shenzhen,

Guangdong Province, P. R. C., to request written

permission to use Materials on this manual for

purposes or for all other questions relating to this

manual.

Copyright Information

Copyright © 2000 by LAUNCH TECH. CO., LTD. All

rights reserved. No part of this publication may be

reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise,

without the prior written permission of LAUNCH. The

information contained herein is designed only for the

use of this unit. LAUNCH is not responsible for any

use of this information as applied to other units.

Neither LAUNCH nor its affiliates shall be liable to the

purchaser of this unit or third parties for damages,

losses, costs, or expenses incurred by purchaser or

third parties as a result of: accident, misuse, or abuse

of this unit, or unauthorized modifications, repairs, or

alterations to this unit, or failure to strictly comply with

LAUNCH operating and maintenance instructions.

LAUNCH shall not be liable for any damages or

problems arising from the use of any options or any

consumable products other than those designated as

Original LAUNCH Products or LAUNCH Approved

Products by LAUNCH.

Other product names used herein are for

identification purposes only and may be

trademarks of their respective owners.

LAUNCH disclaims any and all rights in

those marks.

i

Page 2

LAUNCH Tyre Changer(TWC Series)

Safety Precautions

Attention

l This manual is a necessary part of the product.

Please read carefully.

l Keep the manual for later use when maintaining

the machine.

l This machine can only be used for the

designated purposes. Never use it for any

other purpose.

l The manufacturer is not held responsible for the

damage incurred by improper use or use other

than the intended purpose.

Precautions

l The equipment can only be operated by qualified

personnel with special training. Modification to

any components or parts, or use the machine for

other purpose without either obtaining the

agreement from the producer, or observing the

requirement of the instructions may lead to direct

or indirect damage to the equipment.

l The machine should be installed on the stable

ground.

l Keep the back panel 0.75M away from the wall

for good ventilation. Enough room should be left

on both sides of the machine for convenient

operation.

l Do not put the machine in a place with high

temperature or moisture, or near the heating

system, water tap, air-humidifier or chimney.

l Do not put the machine near the window with

sunlight. Protect the unit with a curtain or

shield if necessary.

l Avoid lots of dust, ammonia, alcohol, thinner or

spraying binder.

l People who are not operating the machines

should be kept away when it is used.

l Use appropriate equipment and tools, protective

and safety equipment, including eyeglasses,

earplugs and working boots.

l Pay special attention to the marks on the

machine.

l Do not touch or approach the moving parts by

hand during operating.

l Do not remove the safety device or keep it from

working properly.

l Use #2 lithium lubricants (grease) only within the

safety range. Refer the appendix for the safety

data.

l Before moving the tyre changer, contact

maintenance personnel.

ii

Page 3

LAUNCH Tyre Changer(TWC Series)

MAX 10bar

of

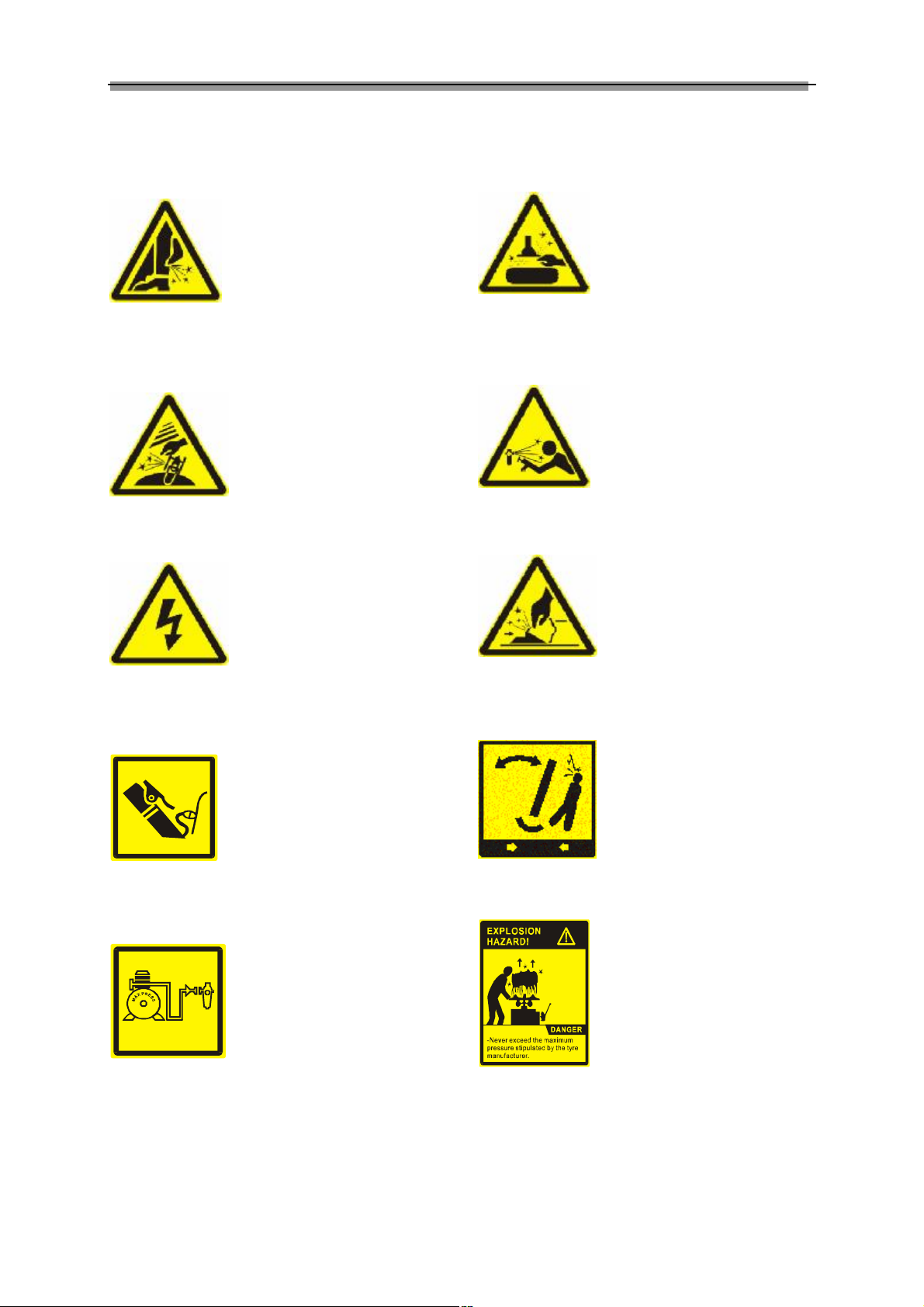

² Caution should be taken

when separating the tyre

bead from rim. The bead

breaker shoe will move

rapidly and forcefully when

the pedal is depressed.

Keep hands and other parts

of body away from moving

parts.

² If the clamping cylinder is

working when bead

breaking, to avoid

squeezing hands,

remember to keep hands

away from the sidewalk

tyre.

² High voltage power!

Danger!

² This is where the

compressed air gun is

connected with the air pipe.

Connect the compressed air

gun with the air connector.

² The pressure of the

compressed air should not

exceed 10 bar.

Description of Safety Signs

² To prevent accidents from

occurring, make sure to

keep hands and other parts

of the body away from

moving parts when

fastening the mounting

head or when the turntable

is running.

² Be careful when connecting

and disconnecting air

source. Exhaust the air in

the cylinder completely

when maintaining the air

pipes to prevent accidents

from occurring.

² Don’t keep hands or other

body parts between the

clamping jaw and clamping

rim.

² Pay attention to the safety

regulations in the swinging

area of the tilting post to

avoid accidents from

happening.

² Before inflating check if the

clamping rim and the tyre

match each other, and if

they are in good condition.

Any negligence may result

in fatal explosion. Similar

accident may occur if the

inflating air exceeds the

allowed tire pressure.

iii

Page 4

LAUNCH Tyre Changer(TWC Series)

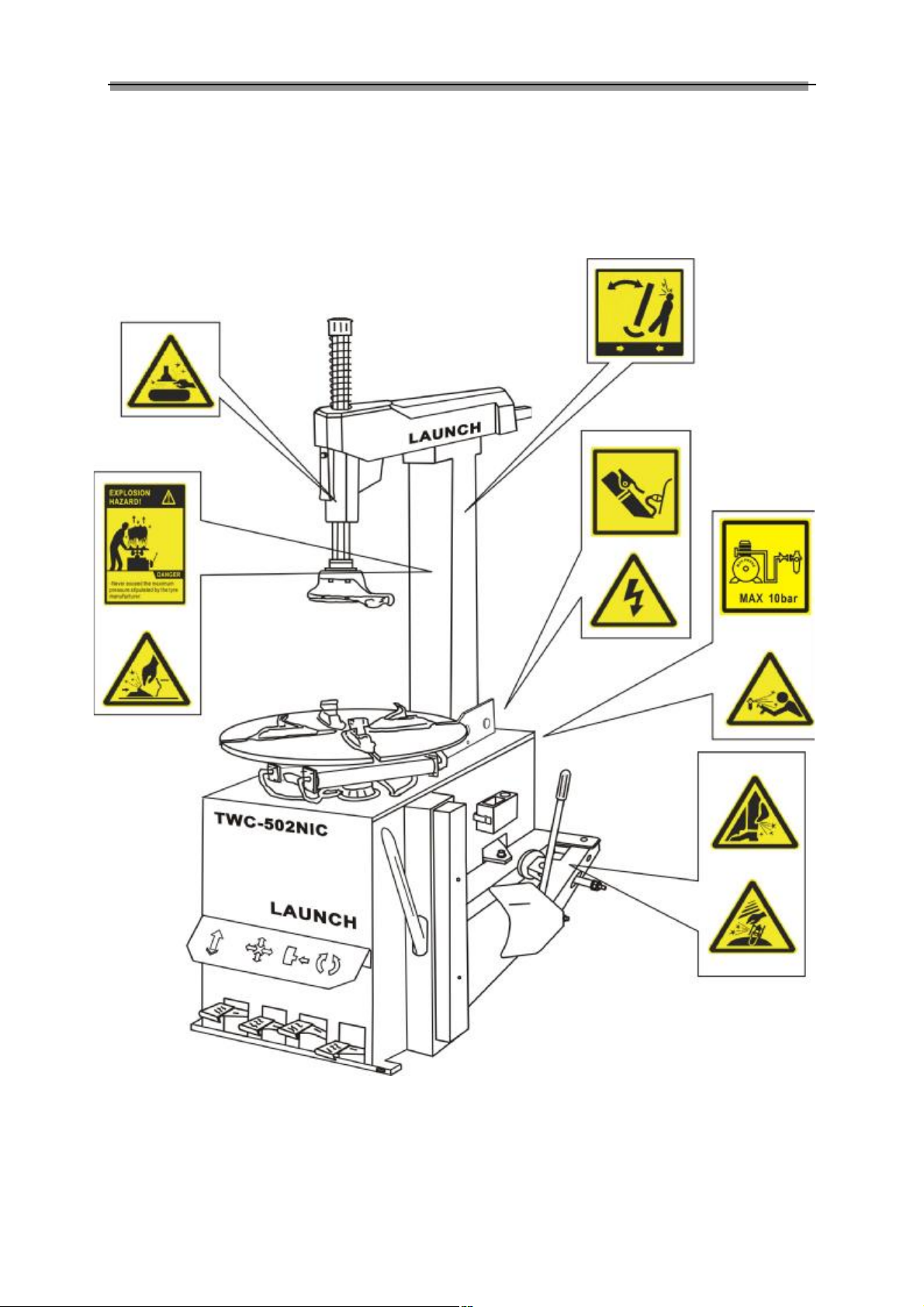

The Position of Safety Signs

Take TWC-502NIC as example:

u Please replace the safety signs if it gets blurred or lost.

u When one or more safety signs get lost, don’t operate the machine.

u The safety signs must be kept within the sight of the operator.

iv

Page 5

LAUNCH Tyre Changer(TWC Series)

Table of Contents

General Information………………………………1

Rules to Name TWC Series….………….…1

Usage… …………………………….……….…2

Features …………………………………...…..2

Technical Specifications………………………..2

Applicable Range……………………...…..2

Working Conditions……………..………….2

Main Structure ……………………...……..…3

Operation ………..……………………..………4

General Regulation…………………….….. 4

Demounting Tyre………………………….….. 4

Mounting Tyre …………………………………6

Inflating Tyre ………………………………..… 7

Right Supplementary Arm……………………8

Left Supplementary Arm……………………11

Troubleshooting ……………………………14

Maintenance………………………………..…15

Optional Device- Digital Inflator….……...…17

Storing ……………………………..………….18

TWC Series Oil Safety Data…………...….19

TWC Series Circuit Diagram….. .. ... ....…20

TWC Series Pneumatic Diagram. ..... ..….23

v

Page 6

LAUNCH Tyre Changer(TWC Series)

General Information

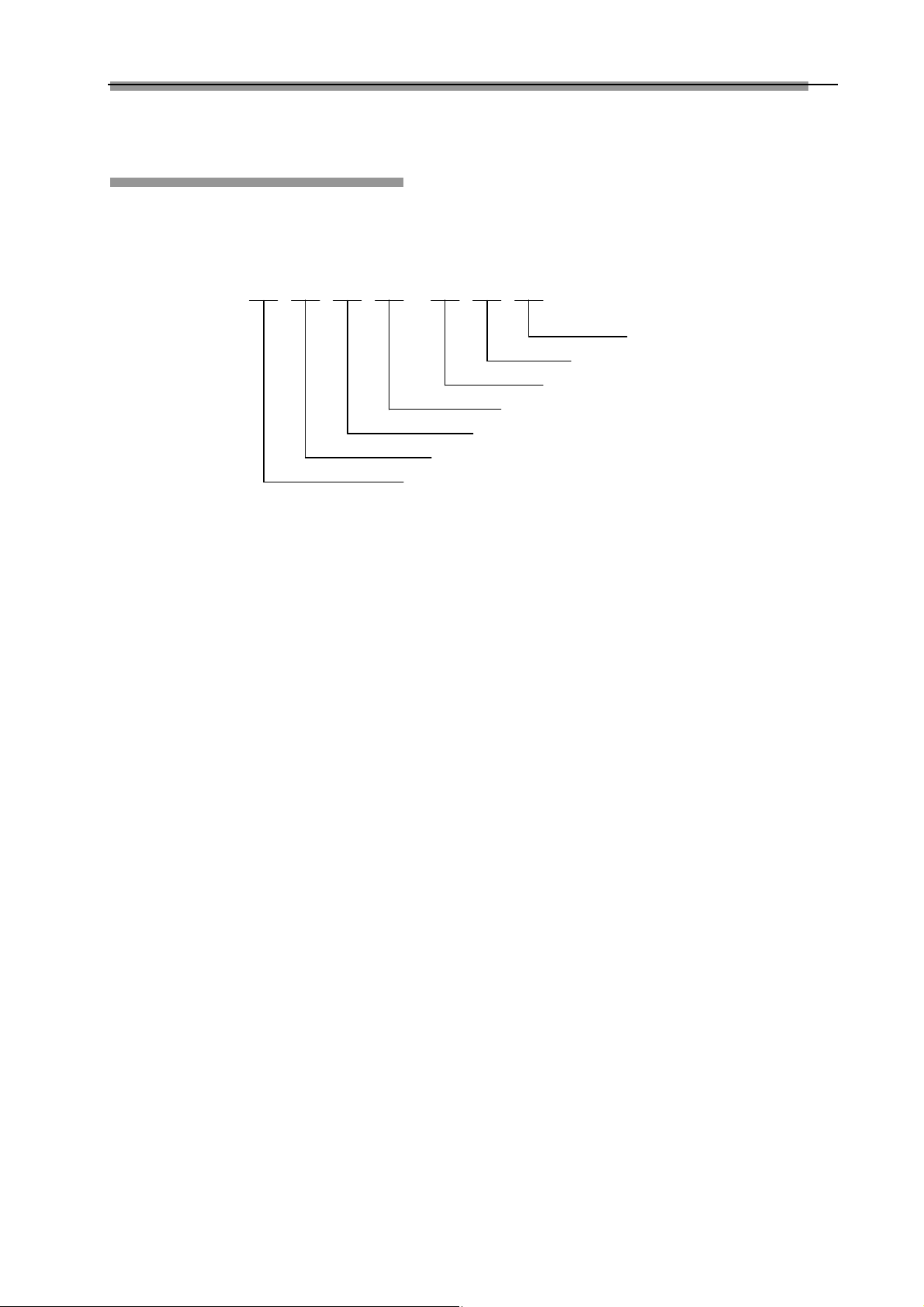

Rules to name TWC series

TWC- means tyre changer

T W C – 5 0 2 R D B +

⑦

⑥

⑤

④

③

②

①

Meaning of code:

①- for rim clamping diameter: 4 stands for 10” ~19”(20”);

5 stands for 10” ~23”(24”);

6 stands for 10” ~26”;

②- for shape of turntable: 0 stands for round turntable;

1 stands for square turntable;

2 stands for cross turntable;

3 stands for asymmetric turntable;

③- post working mode: 1 stands for swing arm (semi-automatic);

2 stands for tilting arm(automatic);

3 stands for swivel arm (automatic)

④- for supplementary arm information: R stands for right supplementary arm;

L stands for left supplementary arm;

D stands for double supplementary arm;

N stands for none supplementary arm;

⑤- for inflating device: I stands for inflating gun;

M stands for meter inflating box;

D stands for digital inflating gauge (LED display);

⑥- for inflating mode: B stands for quick inflator;

C stands for normal inflating;

⑦- for roller set: + stands for roller set;

For example:

TWC-502RDB+--------- the tyre changer’s rim clamping diameter is 10″-23″(24″). It is equipped with round turntable, tilting

post(automatic), right supplementary arm, digital inflating box(LED display), quick inflator and roller set.

1

Page 7

LAUNCH Tyre Changer(TWC Series)

Applicable Range

Usage

TWC series are used for demounting, mounting and

inflating tyres of small and medium vehicles.

Mount/demount help device and quick-inflating device

features simple operation and high reliability. In addition, it

can also be a great help in car repair garage and tyre

dealers.

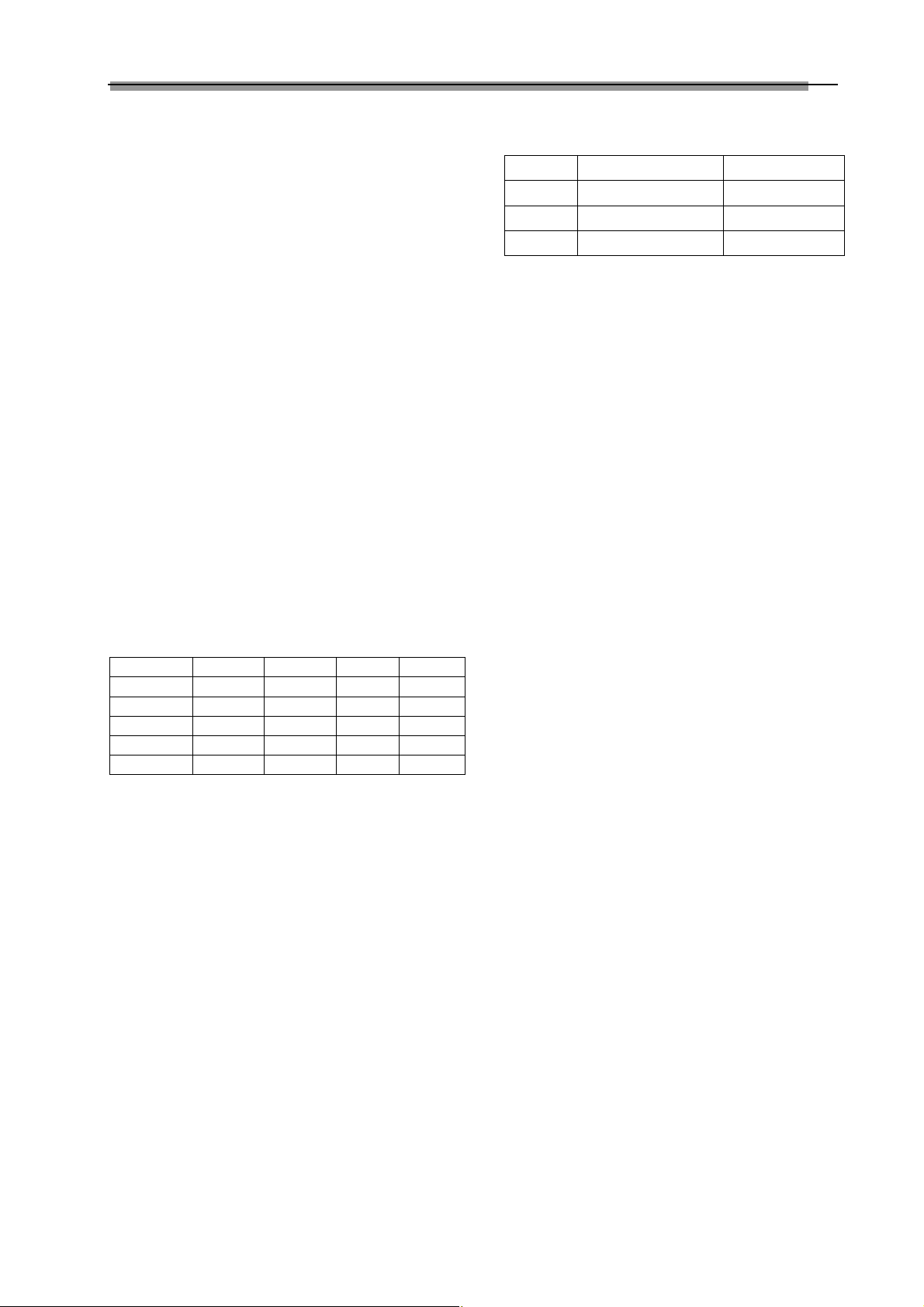

Model Max wheel diameter

4 series 960mm(38")

5 series 960mm(38")

6 series 1050mm(41")

Max rim width

360mm(14")

380mm(15")

380mm(15")

Working conditions

Features

l Integrate demounting, mounting and inflating, wide

rim diameter capacity

l The steel mount/demount is cast from excellent alloy

material with special shape and durable performance.

The supplied plastic mount/demount head with the

equipment is made from special engineering plastic

that has enough intensity and will not damage the

tyre or the rim.

l The two clamping cylinder ensures accurate central

alignment, so that the rim can be held tightly.

l Pedal set designed for ergonomical use

l With adjustable opening, bead breaker is

suitable for tyres of different sizes

l Tyre lever and lubricant box within the reach of

operator technical specifications

Working temperature: -40℃-45℃

Transport/store temperature: -40℃-55℃

Humidity: 30-95%

Altitude: less than 1000m

Technical data

Model Height Length Width Weight

TWC4*1** 1705mm 1020mm 810mm 204kg

TWC4*2** 1725mm 1020mm 810mm 218kg

TWC5*1** 1820mm 1015mm 870mm 228kg

TWC5*2** 1880mm 1350mm 950mm 320kg

TWC6*2** 1880mm 1350mm 950mm 340kg

Electric specifications

Voltage alternatives:

A C110V(±5%) 60Hz(±1Hz)

AC220V(±5%) 50Hz(±1Hz)

AC230V(±5%) 60Hz(±1Hz)

Power: 1.1Kw

Phase: Single

RPM of turntable: 6-8r/min

Air supply

Working pressure: 8-10bar

Bead breaker force: 14075N

Noise

Working noise: <70dB(A)

2

Page 8

LAUNCH Tyre Changer(TWC Series)

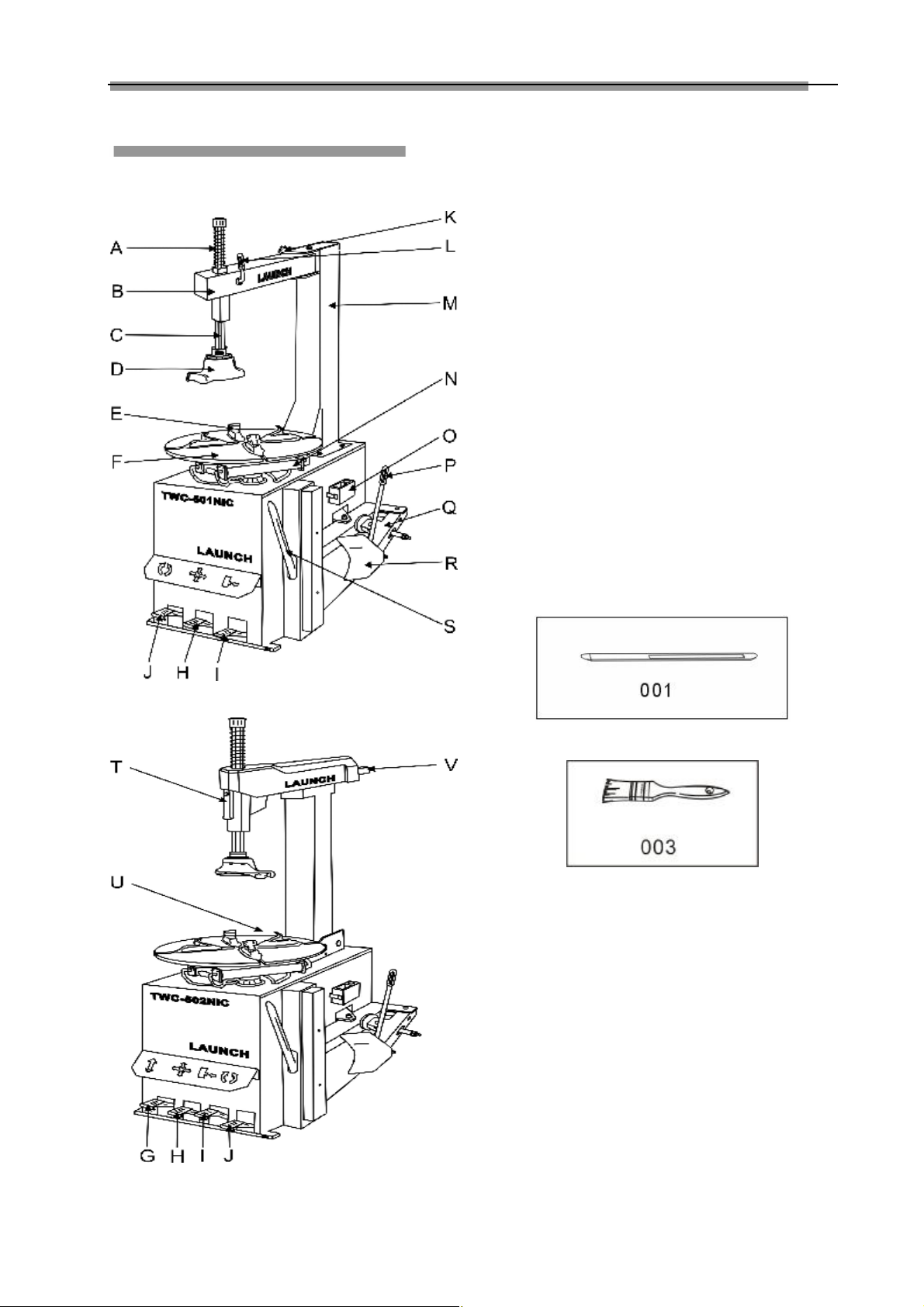

Main Structure

The main structure is shown in Fig. 01.

A. Return spring

B. Swing arm

C. Hexagonal column

D. Mount/demount head

E. Clamping jaw

F. Turntable

G. Tilting post control pedal

H. Clamping cylinder control pedal

I. Bead breaker control pedal

J. Turntable control pedal

K. Knob

L. Locking lever

M. Post

N. Clamping cylinder

O. Lubricant box

P. Bead breaker handle

Q. Bead breaker arm

R. Bead breaker shoe

S. Tyre lever

T. Locking handle

U. Air pressure regulator, gauge and lubricator assembly

V. Horizontal arm.

Accessories provided are shown in Fig.02

001-Tyre lever

002-Brush

Fig.01-1

Fig.02-a

Fig.02-b

Fig.01-2

3

Page 9

LAUNCH Tyre Changer(TWC Series)

Operation

Attention:

The machine is only to be operated by specially

trained and authorized personnel. Use appropriate

equipment, tools and personal protective equipment,

such as eye-glasses, ear-plugs and working boots,

when operating the tyre changer. Make sure that the

power, air sources and the oil level in the oil cup are

in accordance with the requirements.

General Regulations

l To avoid damage when mounting and demounting

tyre, especially the alloy ones, use the tyre lever

offered by manufacturer.

l For easier demounting and better protection of the

tyre and rim, lubricate the area between the rim and

tyre bead, where the bead breaker shoe goes in,

with industrial lubricant or thick soap solution.

l Pay special attention to rotary direction marked on

some flanges or tyres.

l Fit the tyre on the rim of matched size.

l Check for damages (distortions, surface damages,

excessive runout, erosion or overall wear) before

demounting.

l Never ignore the mounting and demounting

requirements of the special wheel.

l When inflating the tyre, make sure the pressure

increases in an even way. Pay attention to status of

the tyre bead.

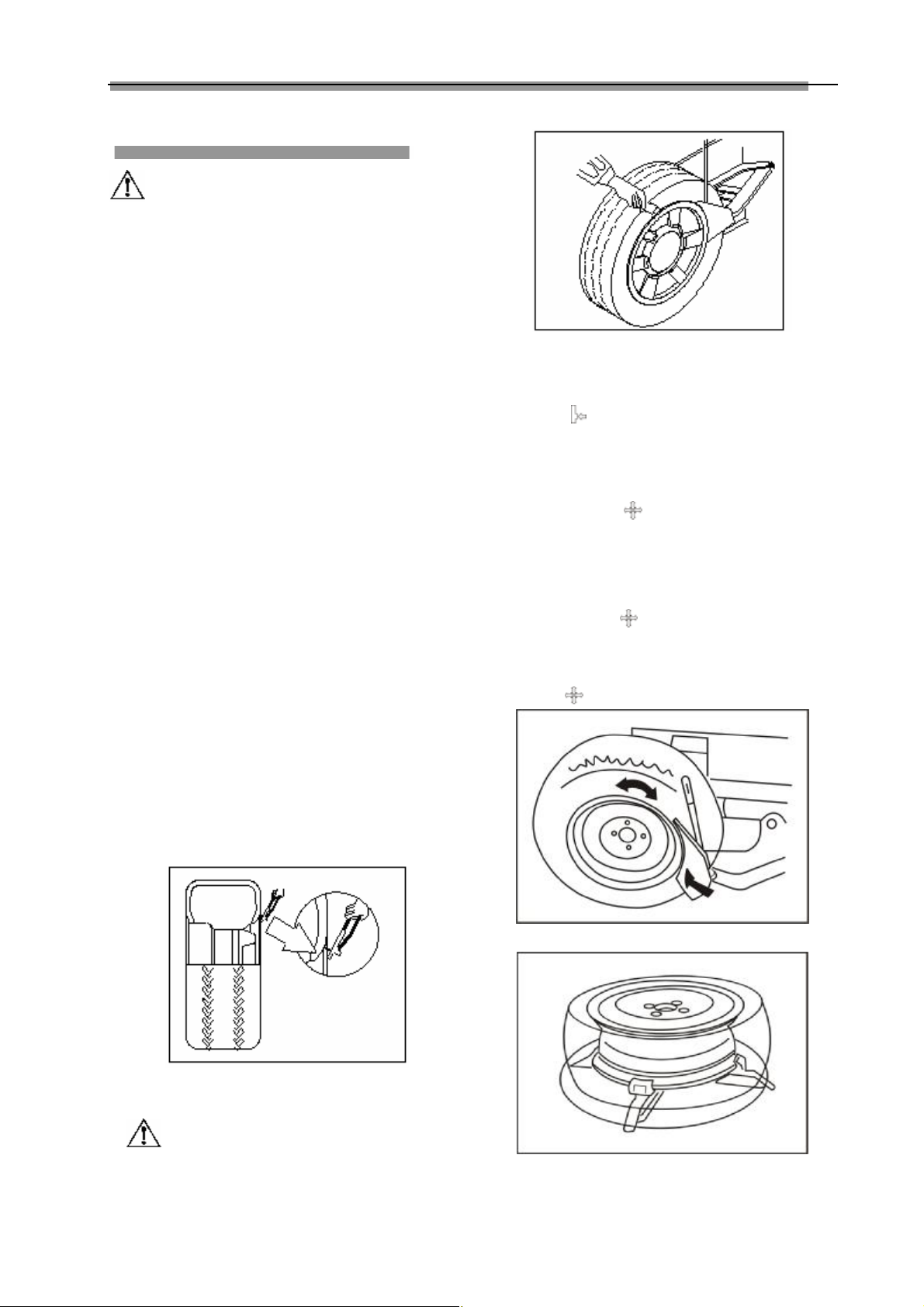

tyre bead from wear. (Fig. 04).

Fig.04

l Place the tyre between the bead breaker shoe and

rubber pad and position the bead breaker shoe max

1 cm away from the rim flange (Fig. 05). Depress

pedal “ ” to unseat bead from rim.

l Repeat the above steps to unseat bead thoroughly

from the rim.

l Place the wheel on the turntable. For the asymmetric

deep groove rim, keep the narrow rim upward.

l Depress pedal “ ” to the end to clamp the rim.

Attention: Different types of clamping can be chosen

in accordance with different rims.

Ø In case of inward clamping, shrink the jaws

together, place the wheel on the turntable and

depress pedal to clamp.

Ø In case of outward clamping, enlarge the jaws

outward (2-3cm away from periphery of the rim)

and place the wheel on the turntable and depress

pedal to clamp it (Fig. 06).

Demounting Tyre

Preparing

l Deflate the tyre thoroughly.

l Remove all the foreign substance and weights from

the rim (Fig. 03).

Fig.03

Demounting

Attention:

Lubricate the bead with a brush dipped in soap

solution before bead breaking in order to protect

Fig.05

Fig.06

4

Page 10

LAUNCH Tyre Changer(TWC Series)

Tyre changer with swing arm:

l Pull back the swing arm(3, fig.07) to working position,

adjust hexagonal column(4) up and down to make

mount/demount head 1-2 mm away from rim flange

to protect rim(fig.09), turn knob (12)to lock swing arm,

and turn locking handle(2) clockwise to lock

hexagonal column.

Tyre changer with tilting post:

l Depress pedal “ “ to restore the tilting post to its

working position (Fig.08).

l Press the hexagonal column and adjust hexagonal

column and horizontal arm to make mount/demount

head 1-2 mm away from rim flange to avoid

scratching rim(fig.09). Press button (a) (fig.08) on the

locking handle to lock the hexagonal column.

Attention:

The angle of the mount/demount head has been

adjusted by manufacturer according to standard rim

(15"). Re-adjustment may be necessary to prevent

scratching the tyre when the rim is extremely large or

small.

Lift the tyre bead onto the demount/mount head with tyre

lever( to make it easy, press down the tyre opposite to the

mount/demount head)(fig.10) Depress pedal “ ” to

turn the turntable clockwise until bead is unseated. To

avoid damage to the tube when where is one, it is

advisable to place the air inflating valve about 10 mm

(fig.11) away from the mount/demount head.

Fig.07

Fig.08

Caution:

In case the demounting is hindered, stop the machine

immediately. Lift up the pedal “ ” to turn the

turntable counter-clockwise to clear away the

hindrance.

l If there is tube in the tyre, remove it first.

l Lift the lower tyre bead so that the rim at the relative

side enters the groove (fig.12), use tyre lever to lift

the lower bead onto the mount/demount head.

l Depress pedal “ ” to separate the lower bead from

rim.

l Depress pedal “ “ to loose the jaw to take the

rim off.

Fig.10

Fig.11

Fig.09

5

Page 11

LAUNCH Tyre Changer(TWC Series)

Fig.12

Caution:

Keep hands and the rest of human body away from

the moving parts of the machine. Never wear necklace,

bracelet or loose clothes when operating the machine

as it may cause danger!

Mounting tyre

Attention:

Check the size of tyre and rim to see if they match

each other.

l Clamp the rim tightly in the same way as demounting

tyre.

l Use lubricant such as thick soap solution on the tyre

and the rim.

Tyre changer with swing arm:

l Place the tyre onto the rim at an angle to the

turntable, left side higher, pull back the swing arm in

working position.

Tyre changer with tilting post:

l Place the tyre onto the rim at an angle to the

turntable, front side higher(fig.13), depress down

pedal “ “ to restore the post (fig.13), adjust the

mount/demount head to right position, finally, press

locking button.

Fig.14

l Adjust relative position between the tyre and the

mount/demount head to position the tyre bead above

the left lip of the head (fig.15A) and below the right

lip(fig.15B).

Fig.15

l Press down the sidewall of the tyre. Depress the

pedal “ “ to turn the turntable clockwise, making

the lower tyre bead fall into the rim groove

completely.

l If a tube needs to be installed in the tyre, check first

for the possible damages. Round it onto the rim.

Make sure to keep the tube in the right position

throughout the mounting process.

l To install the upper tyre bead and adjust position of

the tyre bead (same as mount of the lower tyre bead

in Fig. 15). Draw out the roller and keep its side

surface 1—2cm away from margin of the rim. Place

the press block on the upper bead 20cm clockwise

away from the mount/demount head. Press the

control lever to make the press block go down

5—7cm to press the sidewall by hands to seat tyre

bead into the rim groove (Fig. 16).

Fig.13

6

Page 12

LAUNCH Tyre Changer(TWC Series)

manufacturer’s requirements. The pressure should

not exceed 3.5 bar. The user may adjust the

reducing valve in the machine to get different

pressures according to requirements.

Quick-inflation:

l If the tyre is tubeless or the tyre does not match the

rim hermetically, inflation method above-mentioned

will has no effect. In this case, the quick-inflation

should be adopted. The quick-inflation method is to

depress pedal “ ” to lock the rim, then depress the

Fig.16

l Depress the pedal “ “ to turn the turntable while

keeping pressing on the tyre. When only 10—15cm

is left, slow down to avoid damage of the tyre bead.

Stop the motor if there is any indication for damage.

Lift the pedal “ ” by foot to turn the turntable

counter-clockwise. Try again after making the tyre

back to the original shape.

Attention:

u If the rim size does not change, it is not

necessary to loose the locking handle

after finishing the mount and demount of

the tyre and adjust the mount/demount

head before mount and demount of tyre.

The operation will be continued by

depressing the column tilting control

pedal to make the titling column let go

and restore automatically.

u Make sure nobody is behind the tilting

post when depressing pedal (G).

u In the process of clamping, keep head

and hands away from the area between

the tyre and the horizontal arm in case

injury would be incurred.

inflation pedal on right-hand of the cabinet to its

end quickly and loose the pedal immediately. The

quick-inflation is finished with a rat-tat.

Attention:

Make sure that the tyre is clamped tightly, otherwise it

has danger of death.

Warning: Danger of explosion!

The safety procedures should be closely followed.

Review and abide by the following instructions.

Otherwise serious injury or death can be resulted.

The manufacturer shall not be held responsible for

any possible accident when the safety procedures are

not followed.

u Carefully check the dimensions of rim and

tyre to see if they match each other. Check

and make sure that the tyre is not worn or

damaged before inflation.

u When a high pressure is required, remove the

tyre from the tyre changer and resume the

inflation in a special protective hood.

u Be careful when inflating the tyre. Keep

hands and other parts of human body away

from tyre.

Inflating tyre

Danger!!

Inflating can be highly dangerous. Take precautions

and pay close attention to the procedures. Check

pressure gauge and air circuit are in good condition

before inflating.

The machine is equipped with a gauge to read the

pressure in the tyre.

l Loose the wheel on the turntable.

l Connect the outlet of the inflating device to the air

inflation valve as shown in Fig.17.

l Slowly and repeatedly depress the inflation pedal (to

avoid over-high pressure) to make sure that the

reading on pressure gauge within the

Fig.17

7

Page 13

LAUNCH Tyre Changer(TWC Series)

Right Supplementary Arm

Structure (Fig.18)

Demounting Tyre

l After breaking bead from the rim completely

following procedures described in last chapter, use

the supplementary arm to simple operation.

l Use the cone to simple operation of outward

clamping. Open the jaws outward (2-3cm away from

periphery of the rim) and place the wheel on the

turntable. Draw out the back swivel arm, fit and aim

the cone at the central hole of the wheel (fig.19),

press down the control lever to keep the rim close to

the jaws, and depress pedal “ ” to clamp it

(fig.20), remove the cone.

Fig.19

Fig.18

a- Slider

b- Press block

c- Fore swivel arm

d- Control box

e- Roller

f- Cone

g- Disk

h- Control lever

i- Back swivel arm

j- Sliding guide

k- Post weldment

l- Slide board

m- Roller arm

n- Disk arm

o- Lifting cylinder

Operation

Attention:

Ø The supplementary arm is specially designed for

TWC series pneumatic tyre changer of LAUNCH.

Never mount it on other machines, otherwise,

LAUNCH shall not liable for any accidents.

Ø The supplementary arm unit has function of

automatic self-centering. The back swivel arm

moves to center of turntable, it will lock

automatically. Lift the control lever to unlock.

Fig.20

l Draw out the roller and make it close to the tyre bead.

Press down the control lever to move the roller

downward 3-5cm, depress the pedal “ “ to turn

the turntable clockwise lubricating the tyre bead by a

brush (fig.21).

8

Page 14

LAUNCH Tyre Changer(TWC Series)

tubed tyre, it is advisable to keep the air inflation

valve to the right of the mount/demount head about

10 cm away to avoid damaging.

l If there is tube in the tyre, remove it first.

l Draw out the disk, and make the disk under the

lower bead, but not under rim. Insert the tyre lever

between the head and bead and press it down. Lift

the control lever up to break the bead from rim

groove. Make the lower tyre bead opposite to

mount/demount head enter into the rim groove, and

prize the lower tyre bead onto the ball protuberance

Fig.21

(fig.24).

l Adjust the mount/demount head to right position and

lock it following the procedures in last chapter.

l Insert the tyre lever into between the mount/demount

head and the tyre bead. Lift the control lever to move

the roller to its none working position (fig.22).

Fig.22

Turn the swivel arm, and place the press block on the tyre

opposite to the mount/demount head. Lower down the

control lever to press down the block 5-6cm, then prize the

tyre bead onto the mount/demount head(fig.23). (The

positions of the mount/demount head and tyre bead are

described in last chapter.)

Fig.23

l Move the press block to its none working position,

depress the pedal “ “ to turn the turntable

clockwise until the rim is separated. In case of a

Fig.24

l Restore the disk and depress pedal “ “ until the

lower tyre bead is separated from the rim. Depress

the pedal “ ” to lose jaws, finally remove the tyre

and rim.

Attention:

Keep hands and other body parts away from the

moving parts of the machine. Never wear

necklace, bracelet or loose clothes when

operating the machine as it may cause danger!

Mounting tyre

Attention:

Check the size of tyre and rim to see if they match

each other.

l Seat the lower bead following procedures in last

chapter.

l If it is a tubed tyre, check first for the possible

damages. Round it onto the rim. Make sure to

keep the tube in the right position throughout the

mounting process.

l To seat the upper tyre bead, place the tyre well and

readjust position of the tyre bead (same as mount of

the lower tyre bead). Draw out the roller and make

its side surface 1—2cm away from margin of the rim.

Place the press block on the upper bead 20cm

clockwise away from the mount/demount head.

Press the control lever to make the press block go

down 5—7cm to seat tyre bead into the rim groove

9

Page 15

LAUNCH Tyre Changer(TWC Series)

(Fig. 25).

Left Supplementary Arm

Structure (fig.27)

Fig.25

l Depress the pedal “ ” to turn the turntable

clockwise. When only 10—15cm(Fig.26) is left, slow

down to avoid damage of the tyre bead. Stop the

motor once there is any indication for damage. Lift

the pedal to turn the turntable counter-clockwise. Try

again when the tyre is back to the original shape.

Fig.26

10

a- Post

b- Cone

c- Hood

d- Sliding guide

e- Spacer pin

f- Back swivel arm

g- Control box

h- Control lever

i- Fore swivel arm

j- Disk

k- Disk arm

l- Roller

m- Cylinder

1- Locking clip

2- Knob

3- Roller

Fig.27

Page 16

LAUNCH Tyre Changer(TWC Series)

②,③, press down locking clip and move the roller

Operation

Attention:

to the position 2-3cm away from rim. Lower down

control lever to depress down tyre 3-5cm as ④,

finally, pull out the knob as ⑤.

Ø The supplementary arm is specially designed for

TWC series pneumatic tyre changer of LAUNCH.

Never mount it on other machines, otherwise,

LAUNCH shall not liable for any accidents.

Ø The supplementary arm unit has function of

automatic self-centering. The back swivel arm

moves to center of turntable, it will lock

automatically. Lift the control lever to unlock.

Demounting Tyre

l After breaking bead from the rim completely

following procedures described in chapter operation,

use the supplementary arm to simple operation.

l Use the cone to simple operation of outward

clamping. Open the jaws outward(2-3cm away from

periphery of the rim) and place the wheel on the

turntable. Draw out the back swivel arm., fit and aim

the cone at the central hole of the wheel (fig.28),

press down the control lever to keep the rim close to

the jaws, and depress pedal “ ” to clamp it

(fig.29), remove the cone.

Fig.28

Fig.30

l Depress the pedal “ “ to turn the turntable

clockwise, lubricating the bead with brush.(fig.31)

Fig.31

l Adjust the mount/demount head to right position and

lock it following the procedures in chapter operation.

l Move the front swivel arm to the position as in figure

32, pull out spacer pin as ①, press down the knob

as ②, lower down control lever as ③ to press down

tyre 3-5cm, insert tyre lever between the head and

the bead as ④, finally lift the lever to restore the

roller.

Fig.29

l Draw out the swivel arm and position it as in figure

30, press down the spacer pin (①,fig.30) to lock the

fore swivel arm under back swivel arm. Following

Fig.32

11

Page 17

LAUNCH Tyre Changer(TWC Series)

Turn the fore swivel arm, and place the press block on the

tyre opposite to the mount/demount head. Lower down the

control lever to press down the block 5-6cm, then prize the

tyre bead onto the mount/demount head with tyre

lever(fig.33). (The positions of the mount/demount head

and tyre bead are described in chapter operation.)

Fig.33

l Move the press block to its none working position,

depress the pedal “ “ to turn the turntable

clockwise until the rim is separated. In case of a

tubed tyre, it is advisable to keep the air inflation

valve to the right of the mount/demount head about

10 cm away to avoid damaging.

l If there is tube in the tyre, remove it first.

l Draw out the disk, and make the disk under the

lower bead, but not under rim. Insert the tyre lever

between the head and bead and press it down. Lift

the control lever up to break the bead from rim

groove. Make the lower tyre bead opposite to

mount/demount head enter into the rim groove, and

prize the lower tyre bead onto the ball protuberance

(fig.34).

Fig.34

l Restore the disk and depress pedal “ “ until the

lower tyre bead is separated from the rim. Depress

the pedal “ ” to lose jaws, finally remove the tyre

and rim.

Mounting tyre

Attention:

Check the size of tyre and rim to see if they match

each other.

l Seat the lower bead following procedures in chapter

operation.

l If it is a tubed tyre, check first for the possible

damages. Round it onto the rim. Make sure to

keep the tube in the right position throughout the

mounting process.

l To seat the upper tyre bead, place the tyre well and

readjust position of the tyre bead (same as mount of

the lower tyre bead). Draw out the roller and make

its side surface 1—2cm away from margin of the rim.

Place the press block on the upper bead 20cm

clockwise away from the mount/demount head.

Press the control lever to make the press block go

down 5—7cm to seat tyre bead into the rim groove

(Fig. 35).

Fig.35

l Depress the pedal “ ” to turn the turntable

clockwise. When only 10—15cm is left, slow down to

avoid damage of the tyre bead. Stop the motor once

there is any indication for damage. Lift the pedal to

turn the turntable counter-clockwise. Try again when

the tyre is back to the original shape.

12

Page 18

LAUNCH Tyre Changer(TWC Series)

Trouble Shooting

Symptom Cause Solution

Turntable can turn only in

one direction.

Turntable doesn’t turn. u Belt is damaged.

Turntable can not lock the

rim tightly.

Horizontal arm and

hexagonal column can’t be

locked.

Horizontal arm doesn’t move

after pushing or pulling.

Vertical shaft can not move

upwards or downwards.

Tilting post tilting is too fast

or too slow.

The locking valve is clogged

after the lever is pressed.

Pedal can not be restored to

its original position.

There is abnormal noise at

the moving part.

The motor does not turn or

the output torque is not

enough.

Cylinder is weak in output. u There is air leakage.

Air leakage is found. u Air hose is damaged.

u Power switch is damaged. u Replace the power switch.

u Power switch is damaged.

u There is problem with

motor.

u Belt is loose.

u Jaws are worn.

u Air leakage in clamping

cylinder.

u The locking square board

in wrong position.

u The locking hexagonal

board in wrong position.

u Square locking board is

not in correct position.

Hexagonal locking board

is not in correct position.

u The pushing cylinder

expels too much or too

little air.

u Pressure of compressed

air has not reached 8bar.

u O-ring of the valve is

damaged.

u There is problem with

airflow regulating valve.

u Return spring is damaged. u Replace the return spring.

u The fixing screw is loose.

u There is foreign matter

inside.

u The moving part is stuck.

u The capacitor is failed.

u The voltage is too low.

u The circuit is open.

u Mechanical hindrance is

causing the problem.

u The pressure of the

compressed air is not high

enough.

u The outlet of the air valve

is damaged.

u The gasket cement is

gone.

u Replace the belt.

u Replace the power switch.

u Check power wire of motor. If the motor

u Tension the belt.

u Replace the jaws.

u Replace the cylinder seal.

u Adjust them to right position according to

u Refer to the chapter “Maintenance”.

u Open the side cover of the cabinet,

u Replace the valve or O-ring.

u Adjust or replace the pressure regulating

u Replace the airflow regulating valve.

u Tighten the fixing screw.

u Get rid of the foreign matter.

u Get rid of the stuck point.

u Replace the capacitor.

u Pause and wait for the device to be

u Repair.

u Strengthen the seal.

u Fix the mechanical problem.

u Change the air source.

u Replace the related part.

u Add gasket cement.

u Add gasket cement.

is damaged, replace it.

this manual.

slightly adjust two air inflation regulators

by hand to smooth the movement, and

then tighten the cap.

valve.

restored.

13

Page 19

LAUNCH Tyre Changer(TWC Series)

Maintenance

Attention:

Only the specialized technician can perform the

maintenance. Before any maintenance, disconnect the

power and keep the plug within the sight of the

maintenance personnel. Shut off power and

compressed air, push the air valve switch to “Off”

position and depress pedal (H) for 3 or 4 times to

bleed the residual compressed air in the machine.

To keep the tyre changer in good condition and to prolong

the work life, it is necessary to do regular maintenance

according to the instructions on the user’s manual.

Otherwise, the normal operation and reliability of the

machine will be affected, or personal injury would be

caused.

l Keep the machine and working area clean, prevent

dust or foreign matter from entering the moving

parts.

l Keep the hexagonal column clean and dry (clean

with diesel as in Fig. 36).

l Keep the horizontal arm and horizontal pole clean

and lubricate them periodically so that it can move

expectably.

l Weekly clean the turntable, jaws, guideways (Fig.

37).

l Weekly clean and lubricate base pin.

l Weekly lubricate the faying surface between moving

parts and rubbing surface with lithium lubricant

(grease).

l Check the oil level in the oil cup regularly. If the oil

level does not reach the second line, fill SAE#20

(Fig.38).

l Regularly drain the condensed material in the air

cleaner.

l Regularly check and adjust the tension of the belt.

l Check all connecting parts and bolts regularly and

tighten them if necessary.

Fig.37

Fig.38

l Check and adjust the locking mechanism of

hexagonal column periodically to insure the

distance between hexagonal column and rim

(regularly 2~3 mm approximately) after the

hexagonal column is locked.

Attention:

Tighten the fixing screws (shown in Fig.39 as part A)

on the turntable after every 15 days of operation.

Fig.36

Fig.39

If the vertical clearance of the hexagonal column is

too much, adjust it according to the following steps:

l Shut off compressed air.

l Remove the protective hood of the hexagonal

column.

l Adjust the retaining nut of lead screw or the pushing

14

screw at the front of locking board by wrench.

l Turn on the compressed air and then check the

position after locking.

If the horizontal arm can not be moved smoothly or

Page 20

LAUNCH Tyre Changer(TWC Series)

the clearance is too much after locking, do the

adjustment according to the following procedures:

l Open the protective cover of the tilting post.

l Adjust the M6 screws at both ends by wrench and

push the arm at the same time until it can be

moved smoothly. Then tighten the nut.

l Adjust the screw at middle by wrench and lock the

horizontal arm to see the change until the

clearance is satisfactory. Then tighten the nut.

Periodically clean the control valves for clamping

jaws and bead breaker to insure their normal

operation.

l Remove the side cover of the cabinet.

l Loosen the control valve muffler and air bleed

valve muffler, and clean them with compressed air.

(Fig.40)

Fig.40

15

Page 21

LAUNCH Tyre Changer(TWC Series)

l An inflation pipe that is 9 meters in length is supplied

Optional Device – Digital

Inflator

Performances:

l Accurate measure make reading right and inflation

time short

l LED display clear, particular suitable for night and

outdoor reading

l Finish measuring air pressure and inflation at the

same time, making operation quick and convenient.

l May preset values of inflation and deflation. When

the inflation gun is inserted into the tyre (non-empty

tyre), the device will automatically test and decide

inflation or deflation. When pressure of the tyre

reaches the set value, it automatically stop and warn

by the buzzer. When the tyre is empty and the

“RUN/STOP” key is pressed, the tyre is

automatically inflated to preset value.

l It can pause when the tyre is inflated or deflated.

l The device has swift function of air pressure unit and

can show both Bar and Psi values.

l Beautiful appearance and convenient installation.

with the device. If extension of the pipe is necessary,

total length must not exceed 20 meters. Otherwise,

working precision will decrease, or even the device

can not work normally.

l When the device starts to work, the inflation gun

should be deflated and not connected with the tyre.

Thus, the zero air pressure is got correctly to ensure

precision.

l Connection between the inflation gun and the tyre

must be reliable and no leakage.

l When the device is used, its power supply must be

far from the large power electrical applications.

Starting and stopping of these applications can

interfere the device accidentally. When interfere

caused by the momentary failure of the power supply

appears, sometimes abnormal errors will happen in

the computer of the device. The case can be

recovered to normal situation by that the inflation

gun head is moved and the power supply is off and

then on.

l Unit conversion:

1Mpa=l0Bar

1Bar=14.5Psi

2

1Bar≈1Kg/cm

Specifications:

l Working Range:0~8Bar (0~116Psi)

l Precision:0.1Bar(1.45Psi)

l Air Source:Pressure 6~9Bar(87~130Psi)

Flow>0.2M3/min

l Inflation Speed:0.15 M3/min

l AC Supply:According to local power supply

l Working Temperature Range: -10℃—+50℃

l Humidity:<95%

l Power:20W

l Net Weight: 5Kg

l Dimensions :120×195×100mm

Use Precautions:

l Power supply must be connected with the ground

wire.

l See Figures 23 and 24 for pipeline connections of

the inflator.

l There are no air supplies for these serial products.

Air pressure of additive air supply must be under

9.5Bar. If not so, a reducing valve must be fixed at

input air pipe to ensure that the air pressure of

entering the inflator is under 9.5Bar.

l Compressed air must be passed the oil and water

separator (air pressure regulator, gauge and

lubricator assembly) at first, and then is connected

into the inflator to avoid eroding internal parts of the

device.

Fig.41

Operations:

l Air pressure unit is showed in “bar (b)” in this device.

It can be changed to “psi (p)” unit by that “bar/psi”

key is pressed.

l Choose right pressure according to specifications of

the tyre. Press “+” or “—” key to set right pressure

values that satisfy requirements of specifications of

the tyre.

l After the pressure value is set, connect the clamping

head of the inflation gun with the tyre. If the tyre own

16

Page 22

LAUNCH Tyre Changer(TWC Series)

pressure, the device will starts automatically. If the

tyre is empty, “RUN/STOP” key must be pressed one

time to start the device.

l When the device is working, it can be stopped if the

“RUN/STOP” key is pressed one time. If the

“RUN/STOP” key is pressed one time again, the

device starts again.

l When pressure of the tyre reaches to the preset

value, the buzzer works and the device stops.

Part Coding:

If necessary, please order parts from LAUNCH or dealers

according to part coding (16AG600AX).

Circuit Diagram:

Fig.42

Storing and Scrapping

Storing

When the equipment needs to be stored for a long time:

l Disconnect the power and compressed air.

l Lubricate all the parts: slide block and groove.

l Empty all the oil/liquid cups.

l Cover the equipment with plastic shield.

Scrapping

When the equipment can no longer be used, disconnect

the power and compressed air and dispose in

accordance with the local regulations.

17

Page 23

LAUNCH Tyre Changer(TWC Series)

TWC Series Oil Safety Data

No. 2 lithium lubricant

Item Quality Index

Cone penetration (1/10mm) 278

Drop point ℃ 185

Corrosion (T2 Copper, 100 , 24h)℃ No change in the copper

Wire separator (100 , 22h)%℃ 4

Evaporation (100 , 22h)%℃ 2

Oxidation stability (99 , 100h)℃ 0.2

Anti-erosion Grade I

Foreign substance (microscopic method)

Above 10 μm

Above 25 μm

Above 75 μm

Above 125 μm

Relative viscosity (-15 ,10s℃

-1

), /Pa·s) Lower than 800

Drip loss Lower than 8

Lower than 5000

Lower than 3000

Lower than 500

Lower than 0

SAE20 Lubricant

Density (15℃) 0.880

Flash point ℃ 213

Freezing point ℃ -21

Viscosity 40℃ 66.2

Viscosity 100℃ 8.2

Viscosity index 95

Item Quality Index

18

Page 24

LAUNCH Tyre Changer(TWC Series)

TWC Series Circuit Diagram

EN60947-3

EN60309

EN60947-2

Remarks

Remarks

EN60309

32A

Model

Model

32A/2P+E/230V/IP44

rated current 40A

Mennekes socket 536#

32A/2P+E/230V/IP44

Mennekes plug 274#

This protective circuit should be

fulfiled by the customer

Name

No.

:

protective current

QF1

industrial power

air-break switch

QF1

SOCKET

40A

19A

:

2

current

2.5mm

socket

switch

Name

SW1

industrial power plug

PLUG

turning,change the phase wire(Z1 and V1).

Remarks:if the motor movement is contrary to the right

32A

:

No.

industrial power plug

maximum current

111 3

1242 86 1O

9

75

Z1V1U4

U3

U2U1

AC110V

60Hz

19

Page 25

LAUNCH Tyre Changer(TWC Series)

EN60947-3

EN60309

EN60309

EN60947-2

Remarks

Remarks

This protective circuit should be

fulfiled by the customer

Model

Name

No.

:

QF1

protective current

20A

rated current 20A

air-break switch

QF1

16A

Model

Mennekes socket 536#

32A/2P+E/230V/IP44

32A/2P+E/230V/IP44

Mennekes plug 274#

socket

industrial power

SOCKET

32A

:

industrial power plug

maximum current

Name

No.

switch

SW1

industrial power plug

PLUG

AC230V

60Hz

2

1.5mm

9.1A

:

current

11

7 9

5

31

12

8 1O

42 6

turning,change the phase wire(Z1 and V1).

Remarks:if the motor movement is contrary to the right

Z1

V1

U3 U4

U2

U1

20

Page 26

LAUNCH Tyre Changer(TWC Series)

EN60947-3

EN60309

EN60947-2

Remarks

Remarks

EN60309

This protective circuit should be

fulfiled by the customer

Model

NameNo.

QF1

protective current:

rated current 20A

air-break switch

QF1

20A

Mennekes socket 536#

industrial power

16A

Model

32A/2P+E/230V/IP44

32A/2P+E/230V/IP44

Mennekes plug 274#

socket

switch

SOCKET

industrial power plug

maximum current:32A

11

Name

No.

12

SW1

industrial power plug

PLUG

turning,change the phase wire(Z1 and Z2).

Remarks:if the motor movement is contrary to the right

AC220V

50Hz

2

1.5mm

current:9.1A

9

5 7

1 3

21

1O

6 8

Z2Z1 U2

U1

2 4

Page 27

LAUNCH Tyre Changer(TWC Series)

Quick-inflating

TWC Series Pneumatic Diagram

P

A

φ14(fabric)

Gun Inflator

φ14(fabric)

A

φ8

S

P

PA

φ8

P

O

φ

8

Bead Breaking

φ8

φ8

φ

8

φ8

φ

8

P

A

φ35(fabric)

φ

10

φ

10

φ

10

φ

10

φ14

A

A

B

B

O

φ8

φ8

φ8

φ8

R

A

P

B

S

Jaw Clamping

R

φ6

A

P

B φ8

S

φ8

φ

8

R

A

P

B

S

φ8

φ8

A

B

φ6

A

B

Tilting Cloumn

φ6

φ6

B B

φ8

φ

8

Clamping

A

Help Lifting

B

φ6

φ6

S

B

P

A

R

A

φ6

22

Page 28

LAUNCH Tyre Changer(TWC Series)

Warranty

THIS WARRANTY IS EXPRESSLY LIMITED TO PERSONS WHO PURCHASE LAUNCH PRODUCTS FOR

PURPOSES OF RESALE OR USE IN THE ORDINARY COURSE OF THE BUYER’S BUSINESS.

LAUNCH electronic product is warranted against defects in materials and workmanship for one year (12 months) from

date of delivery to the user. This warranty does not cover any part that has been abused, altered, used for a purpose

other than for which it was intended, or used in a manner inconsistent with instructions regarding use. The exclusive

remedy for any automotive meter found to be defective is repair or replacement, and LAUNCH shall not be liable for any

consequential or incidental damages. Final determination of defects shall be made by LAUNCH in accordance with

procedures established by LAUNCH. No agent, employee, or representative of LAUNCH has any authority to bind

LAUNCH to any affirmation, representation, or warranty concerning LAUNCH automotive meters, except as stated

herein.

Disclaimer

THE ABOVE WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Order Information

Replaceable and optional parts can be ordered directly from your LAUNCH authorized tool supplier. Your order should

include the following information:

1. Quantity

2. Part number

3. Item description

Customer Service

If you have any questions on the operation of the unit, please contact us:

Tel: 86-755-82269474,

Fax: 86-755-82264570,

E-mail: overseasales@cnlaunch.com.

If your unit requires repair service, return it to the manufacturer with a copy of the sales receipt and a note describing

the problem. If the unit is determined to be in warranty, it will be repaired or replaced at no charge. If the unit is

determined to be out of warranty, it will be repaired for a nominal service charge plus return freight. Send the unit

pre-paid to:

Attn: Overseas Department

LAUNCH TECH. CO., LTD.

Xinyang Building,

Bagua 4th Road,

Shenzhen, Guangdong Province,

China

Loading...

Loading...