Page 1

LAUNCH TLT830WA Product Manual

Copyright reserved! Without the written agreement of

Launch Shanghai Machinery Co., Ltd. (hereinafter

called “Launch”), no company or individual is

allowed to copy and backup this manual in any form

(electronic, mechanical, photocopy, recording or other

forms). This manual is specifically designed for the

use of Launch product, and our company doesn’t

undertake any responsibility for various consequences

caused as a result of applying it to the guidance of

operating other equipment.

In case of the equipment damage or loss due to the

accident of the user himself or third party, abuse or

misuse of this equipment, unauthorized change and

repair of this equipment, or not conforming to the

Launch has registered its trademark in China and

several foreign countries, with the symbol of

LAUNCH. Other trademarks, service symbol, domain

name, icon, and company name of Launch mentioned

in this manual belong to the property of Launch and

its subsidiary companies. In the countries where

Launch’s trademark, service symbol, domain name,

icon and company name haven’t been registered,

Launch declares its ownership on such unregistered

trademark, service symbol, domain name, icon and

company name. The trademarks of other products and

company names mentioned in this manual still belong

to the originally registered companies. Without prior

written agreement of the owner, nobody can use the

trademark, service symbol, domain name, icon and

operation and maintenance requirement of Launch,

Launch and its branches won’t undertake any

responsibility for the expenses and expenditures

generated.

For the equipment damage or problem caused as a

result of using other optional accessories or

consumables instead of original Launch product or its

recognized product, Launch won’t undertake any

responsibility.

Official statement: The purpose of other- productnames mentioned in this manual is to describe how to

use this equipment. Their registered trademarks still

belong to the original companies.

company name of Launch and other companies

mentioned in this manual. If you have any question,

please visit website of Launch:

http://www.cnlaunch.com or write to Sales Dept. of

Launch Shanghai Machinery Co., Ltd. at No. 661

Baian Road, International Automobile City Auxiliary

Parts Park, Anting Town, Jiading District, Shanghai

City to contact Launch

The product consists of the People's Insurance

Company underwriting

This equipment is for the use of professional technical

personnel or maintenance personnel.

Registered Tradem ark

i

Page 2

LAUNCH TLT830WA Product Manual

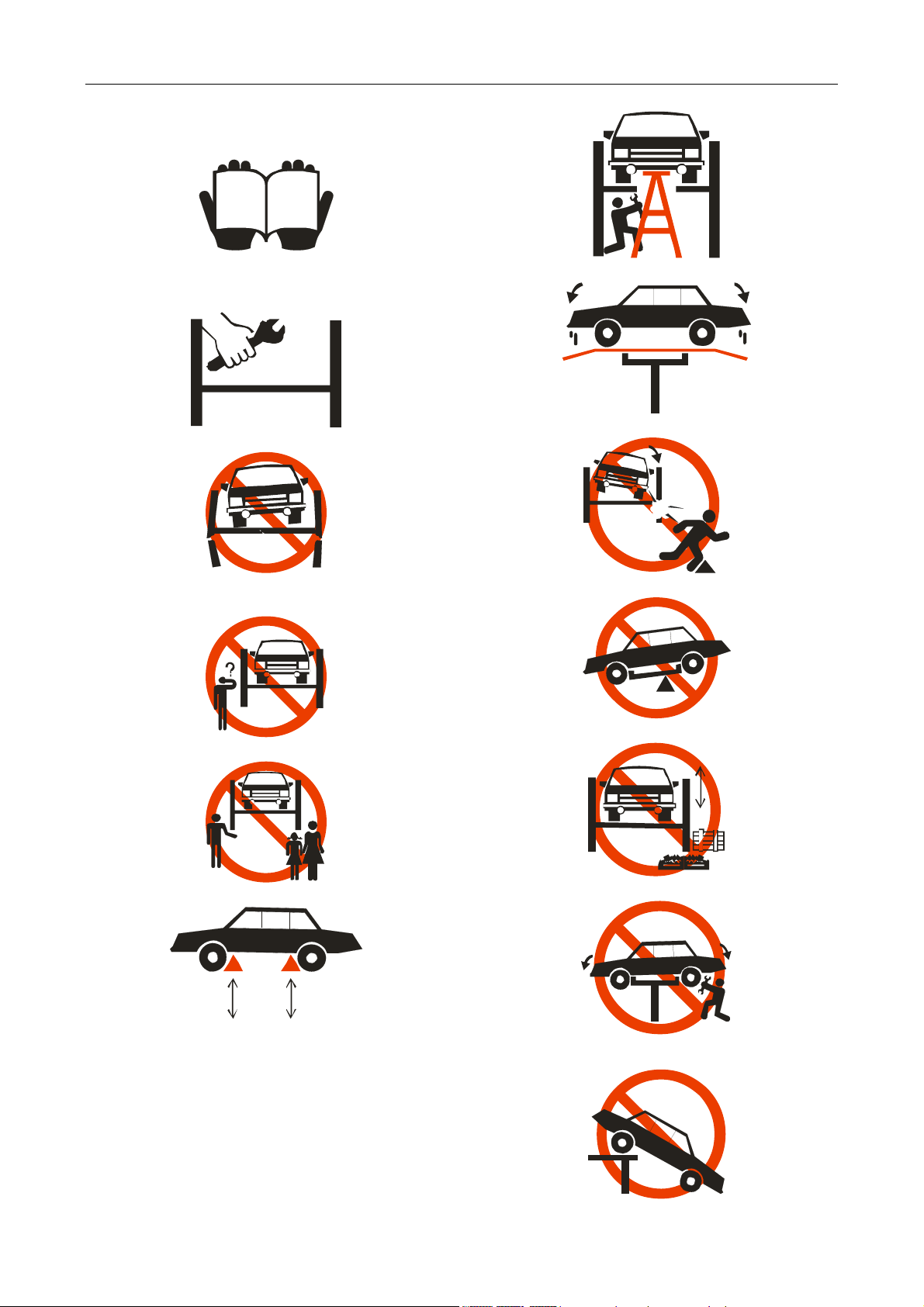

Caution labeling exemplify

(1)Read operating and safety manuals before using lift!

(2)Proper maintenance and inspection is necessary for

safe operation!

(3)Don not operate a damaged lift!

(4)Lift can be used by trained operators ONLY!

(8)Auxiliary adapters would reduce load capacity!

(9)keep area clear!

(10)the central of gravity should be between two arms!

(5)only Authorized personnel can be in the lift area!

(6)use commend lifting points!

(7)use bracket to help disassembly or installation!

(11)keep the area clean!

(12)do not shake the vehicle!

(13)do not lift single side of vehicle!

ii

Page 3

LAUNCH TLT830WA Product Manual

(14)keep feet clear when lowering!

(15)When lifting or lowering, don’t stand under the lift!

iii

Page 4

LAUNCH TLT830WA Product Manual

Table of Contents

1 NOTE ...............................................................................................................................................1

2 GENERAL INFORMATION.........................................................................................................2

2.1 APPLICATION..........................................................................................................................................................2

2.2 FEATURES..............................................................................................................................................................2

2.3 TECHNICAL SPECIFICATIONS .................................................................................................................................2

2.4 ENVIRONMENT REQUIREMENTS ............................................................................................................................. 2

3 STRUCTURE AND WORKING PRINCIPLE............................................................................3

3.1 STRUCTURE............................................................................................................................................................3

3.2 ELECTRICAL DIAGRAM ..........................................................................................................................................4

3.2 HYDRAULIC DIAGRAM............................................................................................................................................5

3.3 HYDRAULIC COMPONENTS IN CONTROL DESK ..................................................................................................... 5

3.4 PNEUMATIC DIAGRAM............................................................................................................................................ 6

3.5 OPERATION DESCRIPTION...................................................................................................................................... 6

4 INSTALLATION AND COMMISSIONING AND UNPACKING.............................................7

4.1 PLEASE GET THE FOLLOWING TOOLS READY FOR INSTALLATION:.....................................................................7

4.2 UNPACKING............................................................................................................................................................7

5. EQUIPMENT INSTALLATION..................................................................................................7

5.1 BASIC REQUIREMENTS...........................................................................................................................................7

5.2 INSTALLATION PROCEDURES.................................................................................................................................7

6 OPERATION.................................................................................................................................13

6.1 INSPECTION BEFORE OPERATION ........................................................................................................................13

6.2 OPERATIONAL PROCEDURES .............................................................................................................................. 13

6.3 SAFETY PRECAUTIONS ........................................................................................................................................ 13

7 ADJUSTING..................................................................................................................................14

7.1 PREPARATIONS .................................................................................................................................................... 14

7.2 ADJUSTMENT PROCEDURES................................................................................................................................14

8 PARTS LIST..................................................................................................................................15

8.1 HOST ASSEMBLY..................................................................................................................................................16

8.2 AUXILIARY ENGINE ASSEMBLY .............................................................................................................................21

8.3 DISTRIBUTION OF HYDRAULIC AND PNEUMATIC COMPONENTS........................................................................... 25

9 TROUBLESHOOTING ...............................................................................................................28

10 MAINTENANCE........................................................................................................................29

10.1 DAILY MAINTENANCE......................................................................................................................................... 29

10.2 MONTHLY MAINTENANCE ..................................................................................................................................29

10.3 BIANNUAL MAINTENANCE .................................................................................................................................29

10.4 MAINTENANCE FOR 3 YEARS OR 5000 TIMES OPERATIONS............................................................................ 29

11 STORAGE AND SCRAPPING..................................................................................................29

11.1 STORAGE............................................................................................................................................................29

11.2 SCRAPPING ........................................................................................................................................................29

#2 LITHIUM LUBRICANTS ...........................................................................................................................................30

N32 MECHANIC OIL (FOR WINTER)............................................................................................................................30

N46 MECHANICAL OIL (FOR SUMMER)......................................................................................................................30

iv

Page 5

LAUNCH TLT830WA Product Manual

1 Note

Warning

z This manual is an important part of the product. Please read and understand it thoroughly.

z Keep the manual for future use in inspection and maintenance.

z Do not use the product for any other purposes.

z The manufacturer is not responsible for any damage caused by improper use or uses other than

the designed purpose.

Precautions

z Only well-trained personnel can operate the lift. Any changes to the components or use for other

purpose without the consent of the manufacturer may cause direct or indirect damage to the

product.

z Do not expose the lift to extreme temperature or humidity. Keep it away from heating device,

faucet, humidifier or furnace.

z Do not install the lift outdoors or expose it to rain. If it is really necessary to do so, a special order

should be made from the manufacturer.

z Keep the lift away from the dust, ammonia, alcohol, thinner and spray adhesive.

z Keep away from the lift when it is in operation.

z Inspection of the lift should be carried out regularly. Do not operate a damaged lift or a lift with

broken parts. All the parts are only replaceable with the parts provided by the manufacturer.

z Do not overload the lift. The maximum lifting weight is clearly marked on the nameplate.

z Do not operate the lift when there are personnel in the vehicle.

z Keep the lifting area clear of obstacle, grease, oil, garbage and other substances.

z Use the lifting point recommended by the auto manufacturer. Keep the support in close contact

with the vehicle.

z Use appropriate tools and safety protection equipments such as overall and working boots.

z Pay special attention to the safety labels on the control desk.

z Keep hands and other body parts away from the moving parts of a lift in operation.

z Do not remove or override safety protection of the lift.

z Hydraulic oil for the lift is N32 or N46 mechanical oil. Pay attention to the safe data as described in

this manual.

z For the sake of technical improvements, Launch (Shanghai) Machinery Co., Ltd reserves the right

to change the specifications without prior notice.

1

Page 6

LAUNCH TLT830WA Product Manual

2 General Information

2.1 Application

This lift is designed for the purpose of lifting light vehicles under 3.5 tons for vehicle test, service

and cleaning.

This machine can also be used as a lifting devise in production lines, for material transportation

and work piece assembly.

2.2 Features

1 Dual layer scissor lift,with front wheel turn table, side slide plate for rear-wheel, rolling bridge jack,

suitable for four - wheel alignment.

2 The lift features advanced design, durability, and compact layout.

3 Can be installed both under and above ground

4 Hydraulic system keeps both platforms level.

5 Mechanical protection device throughout the travel distance.

6 Automatic height limiting device, protect machine from damage

7 Automatic lubricating system and oil-less bearings

2.3 Technical Specifications

Max. Lifting

Height (mm)

Max.

Lifting

Weight

Lifting

Time

(sec)

Lowering

Time

(sec)

Power

(kw)

Numbe

r of

Platfor

Platform Size

(mm)

Overall

Weight (kg)

Synchroniz

ation

Precision

Rolling

bridge jack

height

(kg)

Small

scissor

450

Big

scissor

1850

Electric specifications:

Motor (Optional): 2.2kw

Voltage options: Single-phase/3-phase 220v/380v 50Hz

Noise

Noise emission at workstations < 75dB (A)

Hydraulic System

Max. Working Pressure: 22 MPa, Flow rate: 5-6L/min.

Pneumatic System

Working Pressure: 5 kg/cm

3500 ≤30 ≥20

2.2

3500 ≤60 ≥20

voltage: According to customer demand

2

ms

1400×580

2

4500×580

1950

(mm)

≤40

difference

(mm)

≤8

2.4 Environment requirements

Temperature: 0℃ ~ +40℃

Relative Humidity: ≤80%

Transportation/Storage Temperature: -25℃~+55℃

Temperature ≥30℃

Altitude: ≤2000m(78740″)

2

Page 7

LAUNCH TLT830WA Product Manual

3 Structure and Working Principle

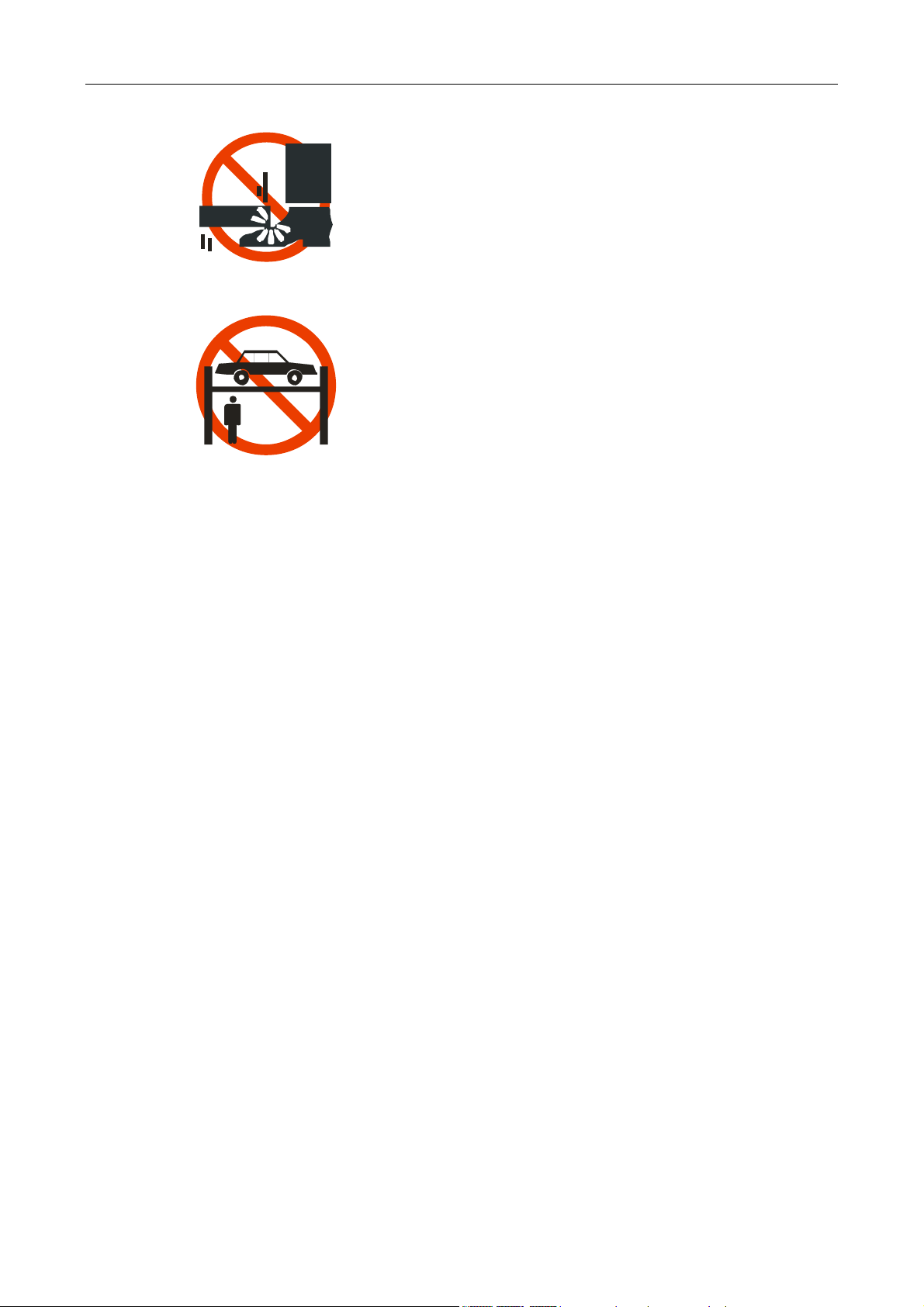

3.1 Structure

4500

1400

≥450

4660

330-1850

605

780

605

Fig1

3

Page 8

LAUNCH TLT830WA Product Manual

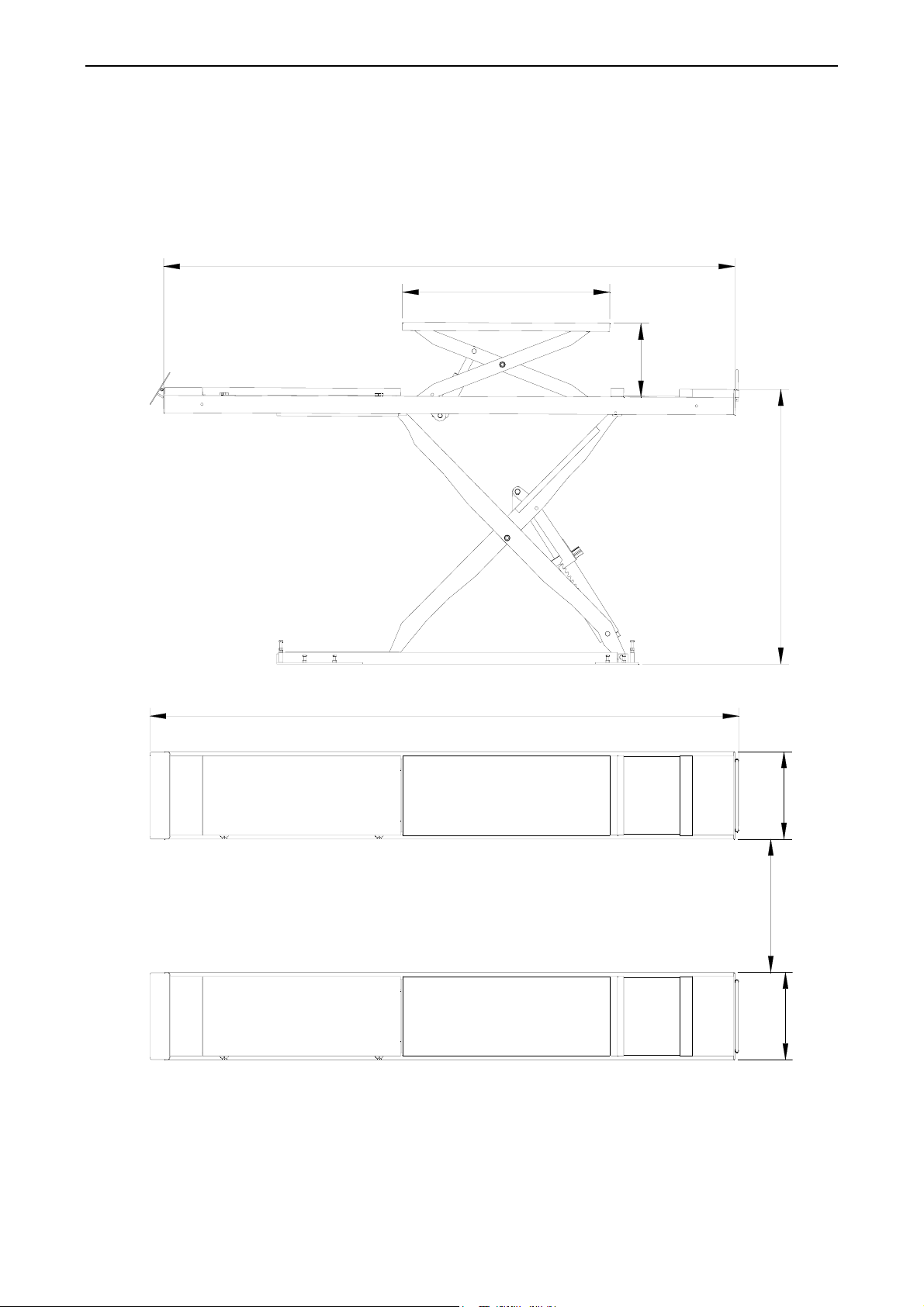

3.2 Electrical Diagram

AC200V/220V/380V

AC110V/220V 1PH

SA2

KM

FR

PEL1

U

U

M

3~

T

~

380

PEL1

~

27

VD

H

lowering

electric

relay

Bidirectional

valve II

Bidirectional

valve I

smaller

cylinder

valve II

valve II

buzzer

lowering

valve I

small air

cylinder

valve I

electric

relay

time

relay

KM-contactor

U

1

~

220V

2

U

M

1~

H-buzzer

YA-electron magnetic valve

Fig 2

Big scissor lifting procedure: turn the switch(SA1)to“I”position,When the UP button SB1 is pressed

the contactor KM will close. The motor will drive the pump and send oil to the cylinder. Main two-way solenoid

valve YA2 coil pick-up, which will in turn raise the platform upward;Once the UP button SB1 is released,

contactor KM will be open and the power to the motor will be cut off to stop the platform. Keep pushing button

SB1; the platform will reach a position so that limit switch SQ1 is triggered. Then SQ will open to stop the

motor and the platform to protect the machine from damaged.

Safety procedure:Release button SB1 when the platform reaches a desired height and press SAFETY

LOCK button SB3 to actuate lowering solenoid valve YA1 and the safety ratchet will be engaged by lowering.

Before servicing the car, make sure the safety lock is functional.

Big scissor lower procedure:After service is completed, push the UP button SB2, time contactor KT and

contactor KM will close. The motor will drive the pump to send oil to the cylinder, Main two-way solenoid

valve YA2 coil pick-up, which will in turn push the platform upward 2 seconds (adjustable) to release the safety

ratchet. Meanwhile small YA3 air cylinder valve electrical connection is established, the safety cover is fully

open. After 2 seconds contactor KT will open. The motor and the platform will stop. And at the same time,

lowering solenoid valve YA1 begins to work so that the platform will start to go down (See Figure 2)

Small scissor lifting procedure:turn the switch to “II” position,When the UP button SB1 is pressed the

contactor KM will close. Auxiliary two-way solenoid valve YA5 coil pick-up,which will in turn raise the platform

upward;Once the UP button SB1 is released, contactor KM will be open and the power to the motor will be cut

off to stop the platform. Keep pushing button SB1; the platform will reach a position so that limit switch SQ1 is

triggered. Then SQ will open to stop the motor and the platform to protect the machine from damaged.

Safety procedure:Release button SB1 when the platform reaches a desired height and press SAFETY

LOCK button SB3 to actuate lowering solenoid valve YA4 and the safety ratchet will be engaged by lowering.

Before servicing the car, make sure the safety lock is functional.

Small scissor lowering procedure:Push the UP button SB2, time contactor KT and contactor KM will close.

The motor will drive the pump to send oil to the cylinder, auxiliary two-way solenoid valve YA5 coil pick-up,

which will in turn push the platform upward 2 seconds (adjustable) to release the safety ratchet. Meanwhile

small YA6 air cylinder valve electrical connection is established, the safety cover is fully open. After 2 seconds

contactor KT will open. The motor and the platform will stop. And at the same time, lowering solenoid valve

YA4 begins to work so that the platform will start to go down (See Figure 2).

Stop procedure: Press stop button SB4 when needed.

4

Page 9

LAUNCH TLT830WA Product Manual

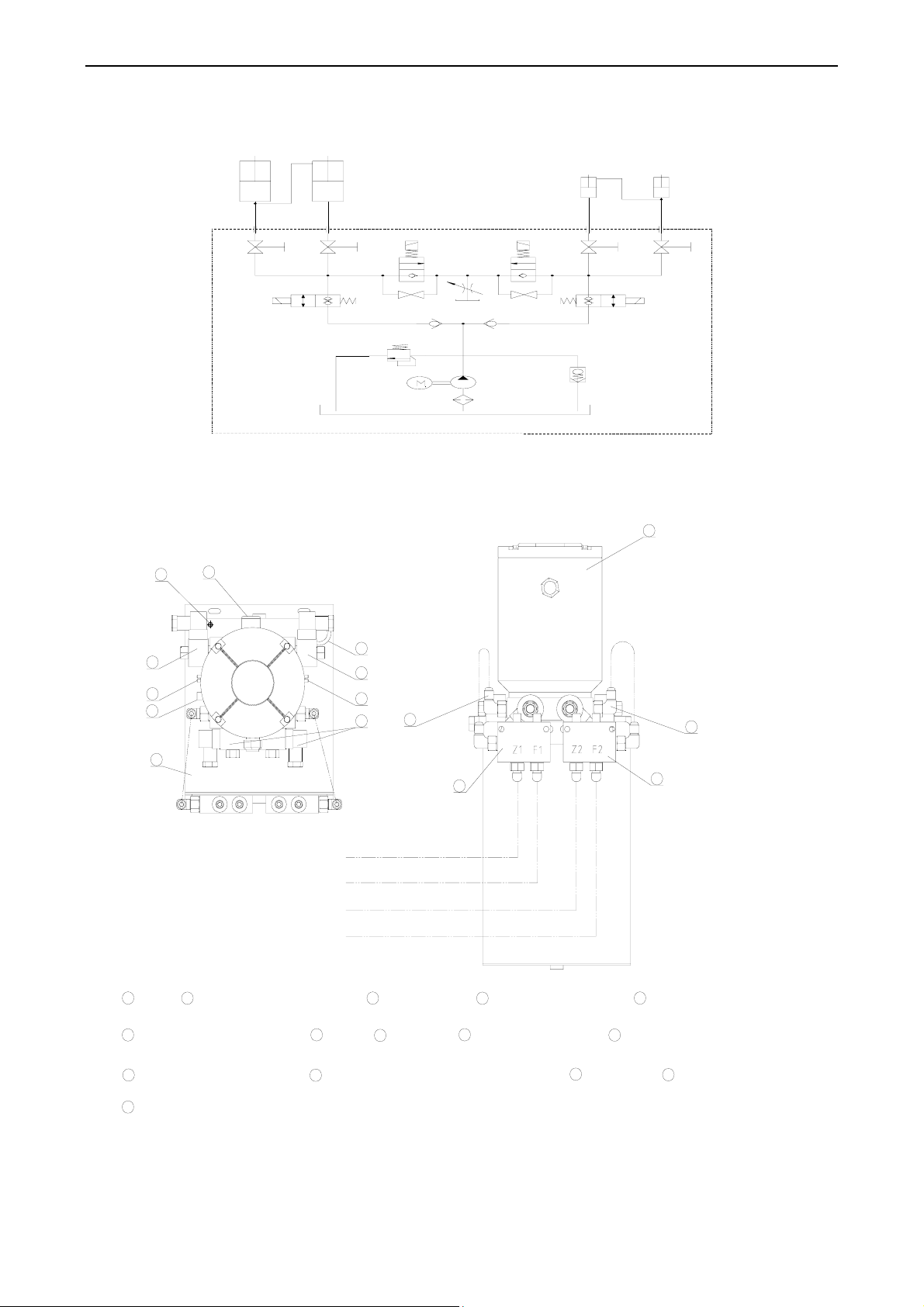

3.2 Hydraulic Diagram

Z1 Z2F1 F2

PP

11

11

10

12

1111

10

8

1

9

5

4

1

7

9

7

3

2

Fig3

3.3 Hydraulic Components in Control Desk

Top view

15

8

2

12

13

7

9

11

10

3

8

6

1

6

14

5

4

NO.1(Z1)

NO.2(F1)

NO.3(Z2)

NO.4(F2)

motor

1

6

Small scissors oil interface

11

bigscissor emergency lowering

handle

System pressure control valve

15

NO.1(Z1):big scissor main cylinders hydraulic tubing

NO.2(F1):big scissor offside cylinders hydraulic tubing

big scissor control solenoid

2

valve

7

Oil cap

bismall scissor emergency lowering handle

12

big scissor oil

3

interface

Exhaust Oil

8

Port

big scissor high pressure

Small scissors and high

4

pressure cut-off valve

Small scissor control

9

5

cut-off valve

check valve

10

solenoid valve

13

Speed control

tank(Oil capacity:15L)

14

valves

NO.3(Z2):small scissor main cylinders hydraulic tubing

NO.4(F2):small scissor offside cylinders hydraulic tubing

Fig 4

Under normal working conditions, the main cycle of the combined valve 5 is open, while the subsidiary

5

Page 10

LAUNCH TLT830WA Product Manual

cycle is closed. Small scissor main high pressure valve 4 is opened, deputy valve is turned off (to open valve

counterclockwise, clockwise to turn off) If lifting hydraulic system failure or power outage, need to use the Jack

to move the insurance top gear, chocked with object to avoid insurance teeth meshing in the descent, then

rotate emergency back-port 12 to lowering the Small scissor lift. Then rotate emergency back-port 11 to

lowering the big scissor lift. System for lowering speed can be adjusted by adjusting the throttle valve 13.

During the adjustment process and adding oil, the operator should be careful.

Hydraulic oil leveling:

To fill oil to slave cylinder of the big scissor, open the deputy valve and close main high-pressure valve 5,

then push the big scissor's up button to filling and adjusting. If too much oil is added, press the DOWN button

to discharge oil to ensure the two platforms at same height. To fill oil to slave cylinder of the small scissor, open

the deputy valve and close main high-pressure valve 4, then push the small scissor's up button to filling and

adjusting. If too much oil is added, press the DOWN button to discharge oil to ensure the two platforms at

same height. After finishing the adjustment, open the main cycle and turn the subsidiary off.(see fig4)

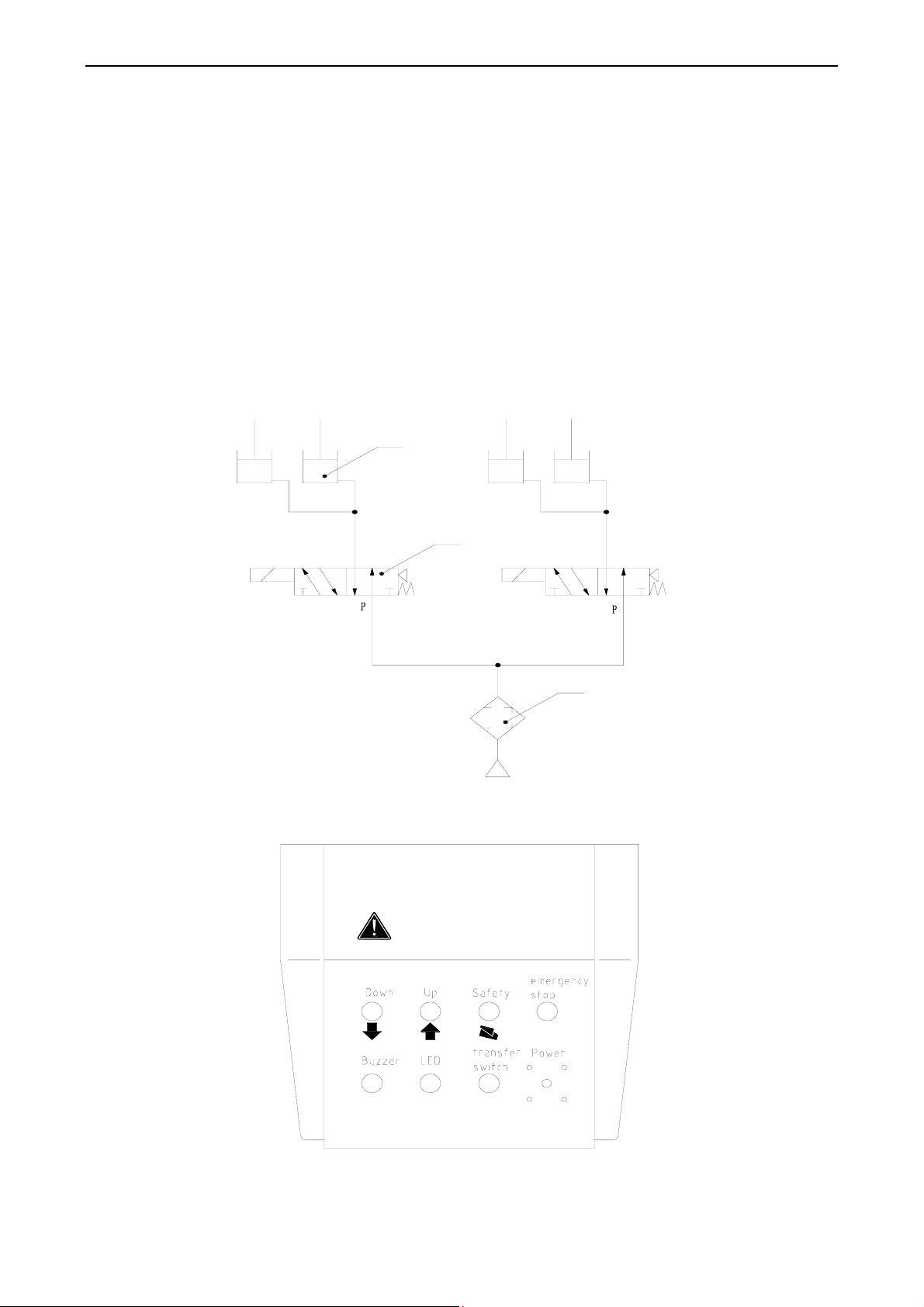

3.4 Pneumatic Diagram

Cylinder

3.5 Operation description

Valve

Air source

TLT830WA

Attention:

Pay attention to balance during up and down。

Note things around when lowering the lift。

Safety locking device is engaged,in this case staff allowed work

under the car。

Filter

Fig 5

6

Page 11

LAUNCH TLT830WA Product Manual

4 Installation and commissioning and Unpacking

4.1 Please get the following tools ready for installation:

Tools Specifications

Level Bar L=400(15.7″)

Chalk Line 10mm (0.4″)

Taper Plunger Chip

Hammer 1.5 kg (3 lb)

Crescent Wrench 40mm(1.6″)

Open end Wrench Set 11mm-23mm(0.43″-0.9″)

Allen Wrench Set 2mm~12mm

Screwdriver 150mm(5.9″)

Rotary Hammer Drill 20mm(0.8″)

Hard Alloy Drill Bit Φ19mm(0.75″)

Frame Level(JB3239-83) L*W*H=300x40x300(11.8″x 0.16″x 11.8″)

4.2 Unpacking

The lift is delivered in three separate boxes: 2 platforms (with hydraulic hoses) and 1 control desk.

Unpack according to the instructions on the packages. Remove the packing materials and check for

damage and loss of components.

To avoid accidents from occurring, keep the packing material away from children. The packing materials

need to be disposed of properly if they may contaminate the environment.

5. Equipment installation

5.1 Basic requirements

y The lift can only be installed on concrete floor with a minimal thickness of 200mm(7.9″),and at least

7 days of solidification time.

y The strength of the concrete ground should exceed 3000PSI(2.1kgf/mm2)。

y The tolerance of the concrete floor levelness should not exceed 5mm(0.2″)。Slight slope can be

corrected with shims. Excessive slope on the ground will greatly affect the performance of the lift. In

this case, new concrete slab should be made.

y Inspect for possible hindrance such as low ceiling, overhead pipelines in the work area, passageways

and escapes. The working area of the lift should be 4.2M(165.4″)high to give enough space.

y Allow enough space(at least 2M(78.7″)) at the front and back of the lift so that operation should not

be hindered. (see fig6)

y Power supply: Put the power source in place before installation. All the wiring should be performed by a

qualified electrician.

5.2 Installation Procedures

5.2.1 Tunnel Installation

Tunnel positioning mode is the same as the normal positioning, but tunnel positioning is more difficult

than the usual ones because to avoid cars slipping, the hanging plates hidden component need to be

replaced. Tunnel size see fig 6, normally only few people install the lift without the hanging plates hidden

7

Page 12

LAUNCH TLT830WA Product Manual

component in the tunnel. Location of tunnel floor dimensions refer to figure 7

Warnings:

♦ The depth of the pits should over 200mm,The strength of the concrete ground should

be great than 3000PSI(2.1kg/mm2),and the tolerance of the concrete floor levelness

should not exceed 5mm(0.2″)。

♦ Use the lifting equipment to put the host and vice machine into the pit

400Min

wall

1800Max

φ 100

20

2000Min

°

5

4

780670 670

900

330

800Min

4600

480

Fig 6

5.2.2 Above floor installation

♦ Equipment installation shown in figure 7,total width with 2530 mm ( 99.6 '' ), draw two

parallel lines on top of the concrete slab ( 1# and 2# ), error in 3mm ( 0.1 in ).

♦ And then draw the four parallel lines ( A, B, C, D ), and 1# and 2# perpendicular to the

line

♦ According to figure 7 put the host and auxiliary machines in the wireframe

8

Page 13

LAUNCH TLT830WA Product Manual

Master

1

.

7

6

2

car direction

3

1

6

-

φ

2

0

1998

543

480

2585

Fig 7

Attention:

♦ All dimensions are based on outer boundary of the base plate.

♦ Ensure that the overall error control within 6mm(0.24″)

♦ Draw a layout is very important. If not, problems will arise in the final assembly and

operation

5.2.3 Control Desk Installation

z According to the situation on the ground to determine the positions of electronic control boxes and

determine power supply requirements for local use, according to the diagram requirements

Slave

1565 235

25

549

599 800

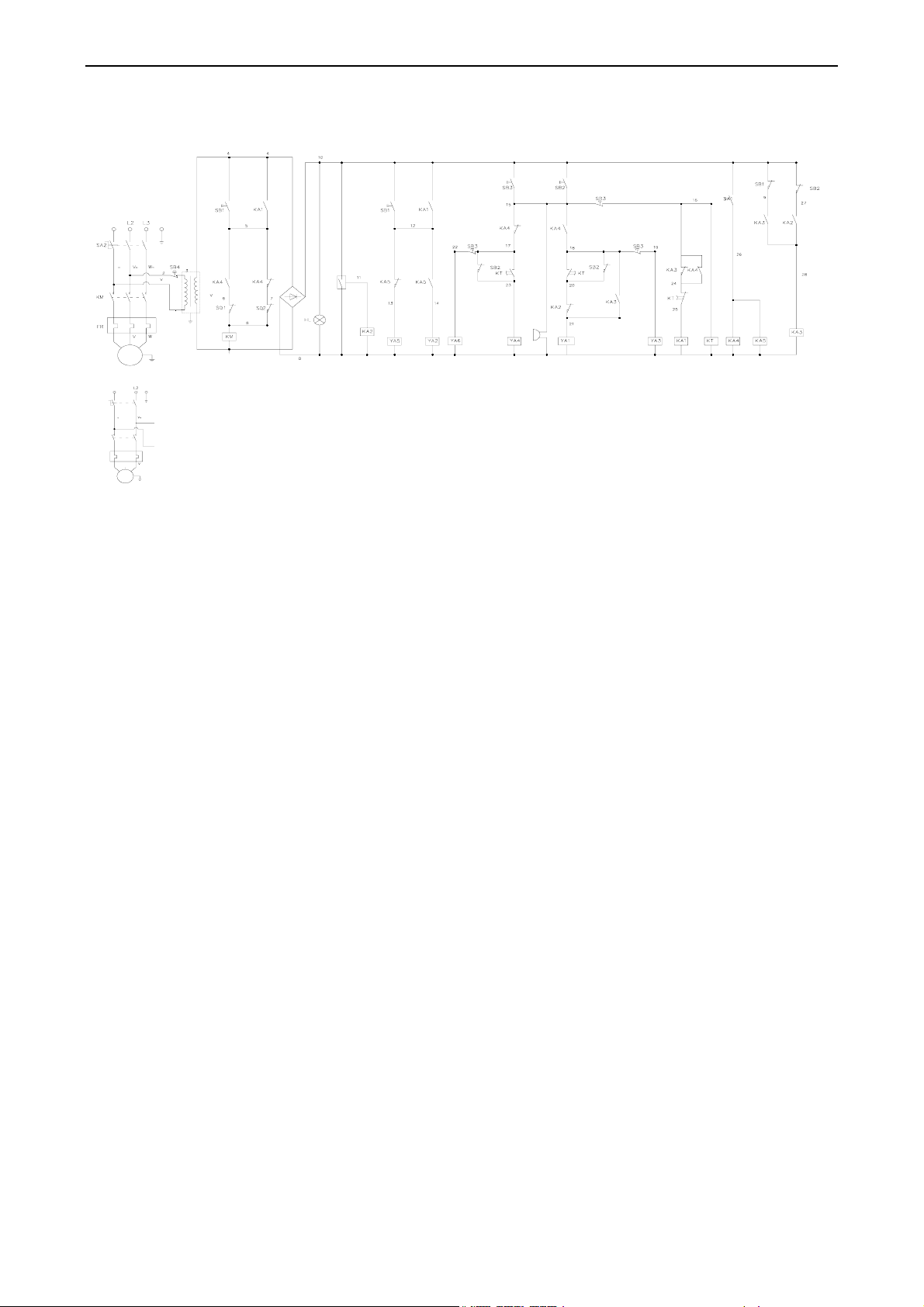

z Wiring diagram shown in figure 8.

z After opening the side door of electronic control box, connect the limit switch cable to terminals (5,7)

on the big scissor, connect the limit switch cable to terminals (6,7)on the small scissor. Then use

4x2.5mm2 wire (Supplied by the customers themselves) respectively to connect the terminals L1, L2, L3,

PE. Check the correct connection before let the power on; open the control box to turn on the power

switch, now the power indicator light on the operator panel is on.

9

Page 14

LAUNCH TLT830WA Product Manual

z Requirements for the lifting machine control box installed near the power control switch, for maintenance

and emergency cut off power supply circuit. Electrical components damage due to error wire connection is

not covered by warranty.

z Oil Injection capacity as required. Do not start the motor without oil

z Fill hydraulic oil N32 or N46 (approximate 20L) into the oil tank (using oil gauge to check the level). Pay

special attention to avoid dust and contaminants into the oil.

z After hoses are assembled, press up button to check power system. If motor does not run, or gets

abnormal noise, or motor runs but lift does not go up or motor heats up. The power must be cut off and

check the wiring connection.

PE

T

~

380

~

27

VD

H

~

electric

relay

23

lowering

valve

II

Bi directional

valve

II

lowering

valve

I

22

small

air

cylinder

valve

II

Bi directional

valve I

small

air

cylinder

valve

I

141921

Bi directional

valve I

0

smaller

cylinder

valve

II

13

Optical

switch

Bi directional

valve II

switch

II

lowering

valve

II

607811

buzzer lowering

limit

switch

Ilimit

valve I

small

air

cylinder

valve I

electric

relay

time

relay

Fig 8

Notice:

High Voltage inside the control desk! Wiring should be performed carefully

5.2.4 Hydraulic Hose Connection

z TLT835WA Hydraulic pipeline as shown in figure 9。To inject hydraulic oil into the tank in accordance with

the requirements and capacities, then connect the hydraulic hose Z1 to hydraulic pipe fitting Z1 inside

the control box and tighten the fitting, Check the status of the combined valve. (Main cycle is opened and

the subsidiary is closed.)

z Press UP button,Test power supply unit:If the motor does not run, abnormal noise, the motor is running

but the table does not raise abnormal motor heat. At this point should be immediately shut down and

check the electrical connections are correct

z Press UP button, raise the host platform to 1.5 m (59') high, press the safety lock button, makes

machinery insurance work

10

Page 15

LAUNCH TLT830WA Product Manual

z Follow the wiring diagrams connect the hydraulic hose F1 to hydraulic pipe fitting F1 inside the control box,

the same, connect hose Z2 and F2 to hydraulic pipe fitting Z2 and F2 and tighten the fitting

Small scissort master cylinder

big scissor offside cylinder

Small scissor offside cylinder

big scissort master cylinder

NO.1(Z1)

NO.2(F1)

NO.3(Z2)

NO.4(F2)

T-fitting

pump

station

YJF

Fig 9

z Turn off the main high pressure cut-off valve on the big scissor, open the duty high pressure cut-off valve,

Press UP button, raise the auxiliary platform to 1.5 m (59') high, press the lowering button, makes

machinery insurance work. Requires host and auxiliary safety gear meshing at the same height position

so that the small scissor can be adjusted.

z Press UP button,raise the host platform of the small scissor to 0.35M(13.8″)high,Turn off the main

high pressure cut-off valve on the big scissor, open the duty high pressure cut-off valve,Press UP button,

raise the auxiliary platform to the same height. Turn the main and auxiliary high pressure valve to a

working state

z The oil pipe in the machine should be installed reliably and securely, avoid squeezing the pipe when the

machine is lowering Cause damage to the pipe affect the normal use of the device

z Turn the main and auxiliary high pressure valve to a working state after all the oil pipe have been

installed.

z For surface mounting, after piping connected to the slot cover plate must be installed

5.2.5 Anchoring

z Wrap the oil fittings, cable connections and joints of the lift to prevent dusts from getting in.

z With the help of the holes on the base plate, drill and install the anchor bolts. In the process of drilling,

make sure that there is no movement at the base frames. Fasten the base frames of the lift to the pits with

11

Page 16

LAUNCH TLT830WA Product Manual

drilling

clean

fastening

16 M16x160mm(M0.63″x6.3″) anchor bolts(Fig.11)

z Rotate adjustment screws on the base plate; adjust the plat until they are leveled.

And the host and auxiliary table height difference is not greater than 3mm(0.1″)。Choose the right thickness

of steel plate as a gasket (accessories) put it under the base plate; gasket should be inserted with both sides

of expansion bolts.

z Tighten out the nuts to fix the base frames on the pits.

z If installed on the ground, then follow the steps above to install anchor bolts of the approach plate.

M16x160mm(M0.63"x6.3")

150

φ22

expanding

Fig 10

Cautions:

z To ensure safety and performance, follow the installation procedures step by step.

z Wear safety goggles。

z Use strong alloy drill bit with a diameter of 17mm(0.7″). Do not use worn-out drill bit

z Keep the hammer drill upright with the surface of the hole.

z Keep hammer drill going by itself. Do not apply extra pressure.

z The depth of the hole depends on the length of the bolt. It is advisable that the bolts above the base

frames should be around 30mm. (1.2″)

z Remove the dust from the holes.

z Tap the bolt into the hole, insert and hit the core until the bolt fully expands

z Tighten out the bolts with torque wrench with a capacity of 80N.M

5.2.6 Air Hose Connection

z Connect the hoses according to the pneumatic diagram

z Keep the output pressure of the air source at 5kg/cm2.

z Press down button to check if the air cylinder acts correctly. If not, please check the hose connection.

12

Page 17

LAUNCH TLT830WA Product Manual

6 Operation

6.1 Inspection before operation

z Check for the synchronized and steady movement of the platforms.

z Check the sensibility and reliability of safety ratchet.

z Review the platforms reach the highest position ( 1850mm 72.8 ), the platform will automatically stop

rising

z Check if two small platforms up and down movement is consistent and smooth

z Check when small platforms rose to the highest position(450mm 17.7″),whether the platform is

automatically stopped rising

z View cylinders, tubing and connectors with or without leakage

z Check solenoid valve, air cylinder, pressure - regulating valve, connector has no leakage phenomenon

z Check the motor, gear pump operation sound is normal

z Check the slide plate for proper action

z Check the emergency stop button is working correctly

6.2 Operational Procedures

z Vehicle into the lift machine speed should be kept under 5km/h, confirm that the slide latch plates are

plugged in.

z When the vehicle is stopped, the front wheel is located at the centre of the turn plates, pull your hand

brakes

z Press the up button, rise the vehicle to 200mm~300mm (7.9″~11.8″)

z Check whether the vehicles and lifting machine level and have no abnormal state。

z Continue pressing the up button, to lift the vehicle up to its required height。

z Press the lock button,bring down the platform, safety gear meshing and keep the platform level on both

sides

z Press the small scissors lift button to remove the tire

z Check there are no foreign objects around or below the lift before start to repair and maintain the vehicle,

make sure there is no abnormal state and then press the down button; lowering down to the initial

position.

6.3 Safety Precautions

z The hydraulic relief valves are well-adjusted before leaving factory. The manufacturer will not be

responsible for any damage caused by unauthorized adjustment.

z Check the safety lock ratchets are engaged before going about any under-car jobs

z Before the small scissors lift the vehicle up, suitable pad must be selected. Place rubber pads on the

platforms and spread them for maximal support.。

z In case of any leakage in the hydraulic system, fix the problem and refill the oil to the proper level.

z When you press the lock button,after the safety gear on both side meshing,immediately release the

button,otherwise the cylinder back oil will be too much. After the completion, press the lowering button

(big scissor), circuit settings for the cylinder cannot supply enough oil to make the platform rise to

disengage the safety gear. At this point, platform could not be descended or only one side of safety gear

disengaged, and the other side still engaged, which leads to only one platform descended, and the

vehicle will rollover. (See hydraulic schematic diagram)

13

Page 18

LAUNCH TLT830WA Product Manual

7 Adjusting

7.1 Preparations

z Move the contact surface of in roller filling in 2# lithium grease, from left to right scrolling surface evenly.

z Add 2# lithium grease at the joints of the machines.

z Fill up the tank with hydraulic Oil N32 or N46(Depending on the season and the local temperature)

7.2 Adjustment Procedures

z Check if all the connection bolts are tightly fastened

z If there is air in hydraulic system due to new installation, air bleeding performance is needed. The air in

the master cylinder can be bled after the platform goes up and down several times. The air in the slave

cylinder can be bled out by following steps: lift master platform close to the maximal height; adjust the

main high-pressure valve until it is turned off, open the deputy valve; press the UP button to raise the

slave platform reaches near the maximal height, press the DOWN button to lower slave platform to the

bottom. Repeat three more times, all the air in the slave cylinder can be bled after the operation.

z Adjust the amount of auxiliary engine oil, to let the platforms stop at appropriate height。

z Turn the high-pressure valve to working status.

z Press UP button, the platforms begin to raise, release the UP button, the platforms stop moving. Press

the safety lock button, scissor lock down. Then, press the DOWN button, the platforms will raise a little to

disengage to safety claw, meanwhile the safety cop is opened, lift will be lowered.

z The same operation on the small platform.

z Adjust position of the mounting plate equipped with a limit switch make sure the platforms up to the

proper height, limit switch is triggered, pumping station stop working; cutting off cylinder oil, platform stop

rising and thus play a role in protecting the machine.

Notice:

z Attention should be paid to the position of oil pipes and hydraulic hose when the platforms move to the

minimal height for the first time. Make sure they do not get stuck with platforms moving downwards.

z When bleeding the air in the slave cylinder, do not lift Master Platform to the maximal height. Otherwise,

the limit switch is triggered, the power will be cut off and Slave Platform can't move.

z When bleeding the air in the slave cylinder lift Slave Platform to highest position, and then release the UP

button. Otherwise Oil pressure may damage the hydraulic cylinder

14

Page 19

LAUNCH TLT830WA Product Manual

8 Parts List

This parts list is only to be used by maintenance and servicing personnel.

The manufacturer is not responsible in case it is used for any other purposes.

If any parts get damaged, please order from your dealer or Launch Tech.

15

Page 20

LAUNCH TLT830WA Product Manual

8.1 Host Assembly

No ERP Code Name

1

2

3

4

5

307041275

307041276

307041277

307041278

307041279

HG-DJ-2000-22 Side board weldi ng pa rt

HG-DJ-2000-5 Roller pad

HG-DJ-9000B Main connecting rod

HG-DJ-9000A Vice connecting rod

Offside cylinder for auxiliary machinery

16

Page 21

LAUNCH TLT830WA Product Manual

6

7

8

9

10

11

12

13

14

15

16

17

18

19

307041280

307041281

307041282

307041283

307041284

103050035

103050014

307041285

307041286

307041287

307041288

307040756

307041289

307041290

HG-DJ-9000A-9 Rolling bridge jack wheel

HG-DJ-9000C Rolling bridge jack welded cover

HG-DJ-2000-24 Cushion blocks for turn table

HG-DJ-2000-26 Block

HG-DJ-4000-2 Twisted axis for auxiliary machinery

GB894.1-86 Circlip for shaft A 25

GB894.1-86 Circlip for shaft A 30

HG-DJ-4000-8 Cylinder hinge axis for auxiliary machinery

HG-DJ-4000-7 Cylinder hinge axis for auxiliary machinery

HG-DJ-4000-3 Center shaft for auxiliary machinery

HG-DJ-4000-11 Shim B

GB/T889.1-20001 Hexagon flange lock nut; M24

HG-DJ-2000-25 Guide block

HG-GSDJ-5000-27 Slide rack assembly(With core rivet)

20

21

22

23

24

25

26

27

28

29

30

31

32

33

307040763

103010356

307041291

307041292

103020096

103030127

307040817

307041293

307041294

307041295

103010156

103010423

307041296

103010469

JB/T7940.4-1995 Seal oil cup 8

GB/T70.1-2000 Screw M8×16

GB/T97.1-2002 Flat Washer A 8×1.6

GB/T859-1987 Spring washer 8×1.6

GB/T70.1-2000 Screw M8×30

GB/T41-20001 Nut C M8

Limit switch

HG-DJ-2000-30 Limit switch frame for rolling jack

GB/T859-1987 Spring washer 4×0.8

GB/T6170-20001 Nut A&B M4

GB/T818-2000 Screw M4×30

GB/T818-2000 Screw M4×6

GB/T97.1-2002 Flat Washer A 4×0.8

GB/T77-2000 Screw M8×12

34

35

36

37

38

39

307041297

307040760

307041298

307041299

307041300

307041301

Slide bolt

SSA20-15

GB/T818-2000 Screw M5×20

GB/T97.1-2002 Flat Washer A 5×1

GB/T859-1987 Spring washer 5×1.1

HG-4635DJ-5000-26 Sideslip spring

17

Page 22

LAUNCH TLT830WA Product Manual

40

41

42

43

44

45

46

47

48

49

50

51

52

103260099

103200699

103260114

103010313

307041302

307041303

307041304

307041305

103050025

103010435

307041306

307041307

307041308

Non-lubricated bearing SF-2 2528

Non-lubricated bearing SF-2 2520

Non-lubricated bearing SF-2 3020

GB/T70.1-2000 Screw M6×25

HG-DJ-2001A Main girder 4.5

HG-DJ-2000-36 Front pipe

HG-DJ-7000-00 Welded baffle plate 4.5

HG-DJ-7000-05 Stop plate shaft

GB894.1-86 Circlip A 20×1

GB/T818-2000 Screw M5×30

GB/T889.1-20001 Hexagon flange lock nu t M5

HG-DJ-2000-29 Sliding block

HG-DJ-4000-12 Shim C

18

Page 23

LAUNCH TLT830WA Product Manual

No ERP Code Name

1

2

3

4

5

6

7

8

9

10

307041309

307041310

307041311

307041312

307041313

307041314

307041315

307041288

307040756

307041316

HG-DJ-1000B Main connecting rod

HG-DJ-1000A Slave connecting rod

HG-DJ-4000-14 Lower block

HG-DJ-4000-13 Upper bloc k

Non-lubricated bearing SF-2 3467

HG-DJ-11000-4 W elding safety catch for host machine

HG-DJ-4000-4 Center shaft for host machine

HG-DJ-4000-11 Shim B

GB/T889.1-20001 Hexagon flange lock nu t M24

HG-DJ-4000-1 Hinge axis for host machine

19

Page 24

LAUNCH TLT830WA Product Manual

11

12

13

14

15

16

17

18

19

20

21

22

23

24

307041317

307041318

307041089

103260104

103260108

307040763

307041319

307041320

103010313

307041321

307041322

307041323

103010425

307041324

HG-DJ-4000-5 Cylinder hinge axis

HG-DJ-4000-6 Hinge axis for rod

SSA32-30 Master air cylinder

Non-lubricated bearing SF-2 3040

Non-lubricated bearing SF-2 3025

JB/T7940.4-1995 Seal oil cup 8

JB/T7940.2-1995 Joint grease Cup M8X1

GB/T12-1988 Bolt M6×16

GB/T70.1-2000 Screw M6×25

GB/T97.1-2002 Flat Washer A 6×1.6

GB/T859-1987 Spring washer 6×1.3

Non-lubricated bearing SF-2 3625

GB/T818-2000 Screw M4×10

Master cylinder

25

26

27

28

29

30

31

32

33

34

35

36

37

38

307041325

103010437

103050014

307040790

307040791

307041326

307041327

103010505

307041328

103030131

307040802

103020081

307041329

307041291

Pipe clasp

GB/T818-2000 Screw M6×10

GB894.1-86 Circlip for shaft A 30

GB894.2-86 Circlip for shaft B 34

GB894.2-86 Circlip for shaft B36

HG-DJ-11000A Square tube welding for master cylinder

HG-DJ-3000 Integral base

Anchor bolt M16X150

HG-DJ-3000-1 1 L o wer fri ct i o n pad

GB/T41-20001Nut C M16

GB/T5781-2000 Thread C M16×50

GB/T5781-2000 Thread C M16×80

GB/T70.1-2000 Screw M8×8

GB/T97.1-2002 Flat Washer A 8×1.6

20

Page 25

LAUNCH TLT830WA Product Manual

8.2 Auxiliary engine assembly

No ERP Code Name

1

2

3

4

5

6

307041330

307041276

307041277

307041278

307041331

307041280

HG-DJ-2000 Auxiliary crossbeam 4.5

HG-DJ-2000-5 Roller pad

HG-DJ-9000B Master connecting rod for host machine

HG-DJ-9000A Vice connecting rod for auxiliary machinery

Main cylinder for auxiliary machinery

HG-DJ-9000A-9 Rolling bridge jack wheel

21

Page 26

LAUNCH TLT830WA Product Manual

7

8

9

10

11

12

13

14

15

16

17

18

19

20

307041282

307041283

307041284

103050035

103050014

307041285

307041286

307041287

307041288

307040756

307041289

103010313

307041290

307040763

HG-DJ-2000-24 Cushion blocks for turn table

HG-DJ-2000-26 Block

HG-DJ-4000-2 Twisted axis for auxiliary machinery

GB894.1-86 Circlip for shaft A 25

GB894.1-86 Circlip for shaft A 30

HG-DJ-4000-8 Cylinder hinge axis for auxiliary machinery

HG-DJ-4000-7 Cylinder hinge axis for auxiliary machinery

HG-DJ-4000-3 Center shaft for auxiliary machinery

HG-DJ-4000-11 Shim B

GB/T889.1-20001 Hexagon flange lock nut M24

HG-DJ-2000-25 Guide block

GB/T70.1-2000 Screws M6×25

HG-GSDJ-5000-27 Slide rack assembly(With core rivet)

JB/T7940.4-1995 Seal oil cup 8

21

22

23

24

25

26

27

28

29

30

31

32

33

34

103010356

307041291

307041292

103020096

103030127

307040817

307041294

307041296

103010469

307041297

307040760

307041298

307041299

307041300

GB/T70.1-2000 Screws M8×16

GB/T97.1-2002 Flat Washer A 8×1.6

GB/T859-1987 Spring washer 8×1.6

GB/T70.1-2000 Screws M8×30

GB/T41-20001 Nut C M8

Limit switch

GB/T859-1987 Spring washer 4×0.8

GB/T97.1-2002 Flat Washer A 4×0.8

GB/T77-2000 Screws M8×12

Slide bolt

SSA20-15

GB/T818-2000 Screws M5×20

GB/T97.1-2002 Flat Washer A 5×1

GB/T859-1987 Spring washer 5×1.1

35

36

37

38

39

40

307041304

307041303

307041305

103010435

307041306

103050025

HG-DJ-7000-00 Welded baffle plate 4.5

HG-DJ-2000-36 Front pipe

HG-DJ-7000-05 Stop plate shaft

GB/T818-2000 Screws M5×30

GB/T889.1-20001 Hexagon flange lock nu t M5

GB894.1-86 Circlip A 20×1

22

Page 27

LAUNCH TLT830WA Product Manual

41

42

43

44

45

46

47

48

49

50

51

307041301

103260099

103200699

103260114

103010423

307041275

307041281

307041332

103010377

307041307

307041308

HG-4635DJ-5000-26 Sideslip spring

Non-lubricated bearing SF-2 2528

Non-lubricated bearing SF-2 2520

Non-lubricated bearing SF-2 3020

GB/T818-2000 Screws M4×6

HG-DJ-2000-22 Side slide plate welding part

HG-DJ-9000C welded cover of rolling jack

Limit mounting plate

GB/T818-2000 Screws M4×16

HG-DJ-2000-29 Block

HG-DJ-4000-12 Shim C

No ERP Code Name

1

2

3

4

307041309

307041310

307041311

307041312

HG-DJ-1000B Main connecting rod

HG-DJ-1000A Vice connecting rod

HG-DJ-4000-14 Lower block

HG-DJ-4000-13 Upper bloc k

23

Page 28

LAUNCH TLT830WA Product Manual

5

6

7

8

9

10

11

12

13

14

15

16

17

18

307041333

307041314

307041315

307041288

307040756

307041316

307041317

307041318

307041089

103260104

103260108

307040763

307041319

307041320

HG-DJ-11000 Square tube welding for offside cylinder

HG-DJ-11000-4 Welding safety catch for host machine

HG-DJ-4000-4 Center shaft for host machine

HG-DJ-4000-11 Shim B

GB/T889.1-20001 Hexagon flange lock nut M24

HG-DJ-4000-1 Hinge axis for host machine

HG-DJ-4000-5 Cylinder hinge axis

HG-DJ-4000-6 Hinge axis for rod

SSA32-30 Master air cylinder

Non-lubricated bearing SF-2 3040

Non-lubricated bearing SF-2 3025

JB/T7940.4-1995 Seal oil cup 8

JB/T7940.2-1995 Joint grease cup M8X1

GB/T12-1988 Bolt M6×16

19

20

21

22

23

24

25

26

27

28

29

30

31

32

103010313

307041321

307041322

307041323

103010425

307041334

307041325

103010437

103050014

307040790

307040791

307041335

307041327

103010505

GB/T70.1-2000 Screws M6×25

GB/T97.1-2002 Flat Washer A 6×1.6

GB/T859-1987 Spring washer 6×1.3

Non-lubricated bearing SF-2 3625

GB/T818-2000 Screws M4×10

Non-lubricated bearing SF-2 3456

Pipe clasp

GB/T818-2000 Screws M6×10

GB894.1-86 Circlip for shaft A 30

GB894.2-86 Circlip for shaft B 34

GB894.2-86 Circlip for shaft B 36

offside cylinder

HG-DJ-3000 Integral base

Anchor bolt M16X150

33

34

35

36

37

38

307041328

103030131

307040802

103020081

307041329

307041291

HG-DJ-3000-11 Lower friction pad

GB/T41-20001 Nut C M16

GB/T5781-2000 Thread C M16×50

GB/T5781-2000 Thread C M16×80

GB/T70.1-2000 Screws M8×8

GB/T97.1-2002 Flat Washer A 8×1.6

24

Page 29

LAUNCH TLT830WA Product Manual

8.3 Distribution of hydraulic and pneumatic components

216

218

203

215

221

206

212

211

Distribution of hydraulic parts

No ERP Code Name

201

217

213

210

220

206

Power unit (380V50Hz three phase)

218

203

214

209

219

204

208

Power unit (220V50Hz single phase)

Power unit (220V60Hz three phase)

Power unit (220V60Hz single phase)

Power unit (200V60Hz three phase)

201

202

205

218

203

207

202

203

204

205

206

207

208

209

210

211

212

213

214

307041336

103040157

103100160

103202175

103040158

307041337

307041338

307041339

307041340

307041341

307041342

307041343

307041324

pe 0.5M high-pressure oil pipe

Pad assembly 14

Corner joint

Converting valve block

Pad assembly 16

C type bended 4.8M high-pressure oil pipe

C type 3.6M high-pressure oil pipe

C type bended 0.35M high-pressure oil pipe

C type bended 5.8M high-pressure oil pipe

C type bended 8.2M high-pressure oil pipe

C type bended 1.55M high-pressure oil pipe

C type bended 4.7M high-pressure oil pipe

Master cylinder for big scissor

25

Page 30

LAUNCH TLT830WA Product Manual

215

216

217

218

219

220

221

307041335

307041331

307041279

103100162

103990055

103100161

103160043

Offside cylinder for big scissor

Master cylinder for small scissor

Offside cylinder for small scissor

M14x1.5 Straight joint

T-fitting

Throttle joint components

Throttle valve

Distribution of pneumatic parts

No ERP Code Name

301

302

303

304

305

306

307

308

309

310

311

102160383 Two-linkage piece for air supply

102990071 Fitting APL6-02

102160380 T- Fitting APE6

102990066 Silencer

103200654

103160033 Electromagnetic valve 4V210-08-DC24V

103100073 Plug 1/4″

104990092 Air pipe PU0604

307041089 SSA32-30 Air cylinder

102990070 Fitting APL6-01

307040760 SSA Thin cylinder

Plug 1/8″

26

Page 31

LAUNCH TLT830WA Product Manual

407

413

402

401

8765

KA5

415

123

9101112

13144

2223

8765

KA4

408

123

8765

KA3

9101112

13144

TLT830WA

Attention:

Pay attention to balance during up and down。

Note things around when lowering the lift。

Safety locking device is engaged,in this case staff allowed work

under the car。

Down Up

Buzzer LED

406

008101113141921

0

0

1

123

123

8765

8765

KA2

KA1

9101112

9101112

13144

13144

Safety

transfer

switch

405

TC

AC

2

+

7

123

123

8765

KT

9101112

9101112

13144

13144

412

1110 12

403

404

emergency

stop

Power

414

20 21

L12 L21

W21 V21

L1L2 L3

PE

KM

L1L2 L3

PE

VUW

409

RD

410

A1A2

411

Distribution of electrical parts

No ERP Code Name

401

402

403

404

405

406

407

408

409

410

411

102100083 ButtonLA39-22/g

102100085 ButtonLA39-22/r

102100084 ButtonLA39-11/K

102100090 Emergency stop buttonLA39-11/r

307040820 Transformation buttonAPT-LA39

102990065 LED DC24V

103180018 Terminal

102130034 Transformer JCY5-100 220V,380V/27V

102150053 Fuse RT18-32

102110059 Contactor s-p11 AC24V

102110067 Time relay H3Y-2 DC24V 0-10S

416

418

417

412

413

414

415

102110051 intermediate relay MY4NJ DC24V

102270004 Rectifier KBPC25-10

102100087 Power switch LW39B-16

102140018 Buzzer

27

Page 32

LAUNCH TLT830WA Product Manual

416

417

418

102100121

307040818 Optical switch

limit switch 1

limit switch 2

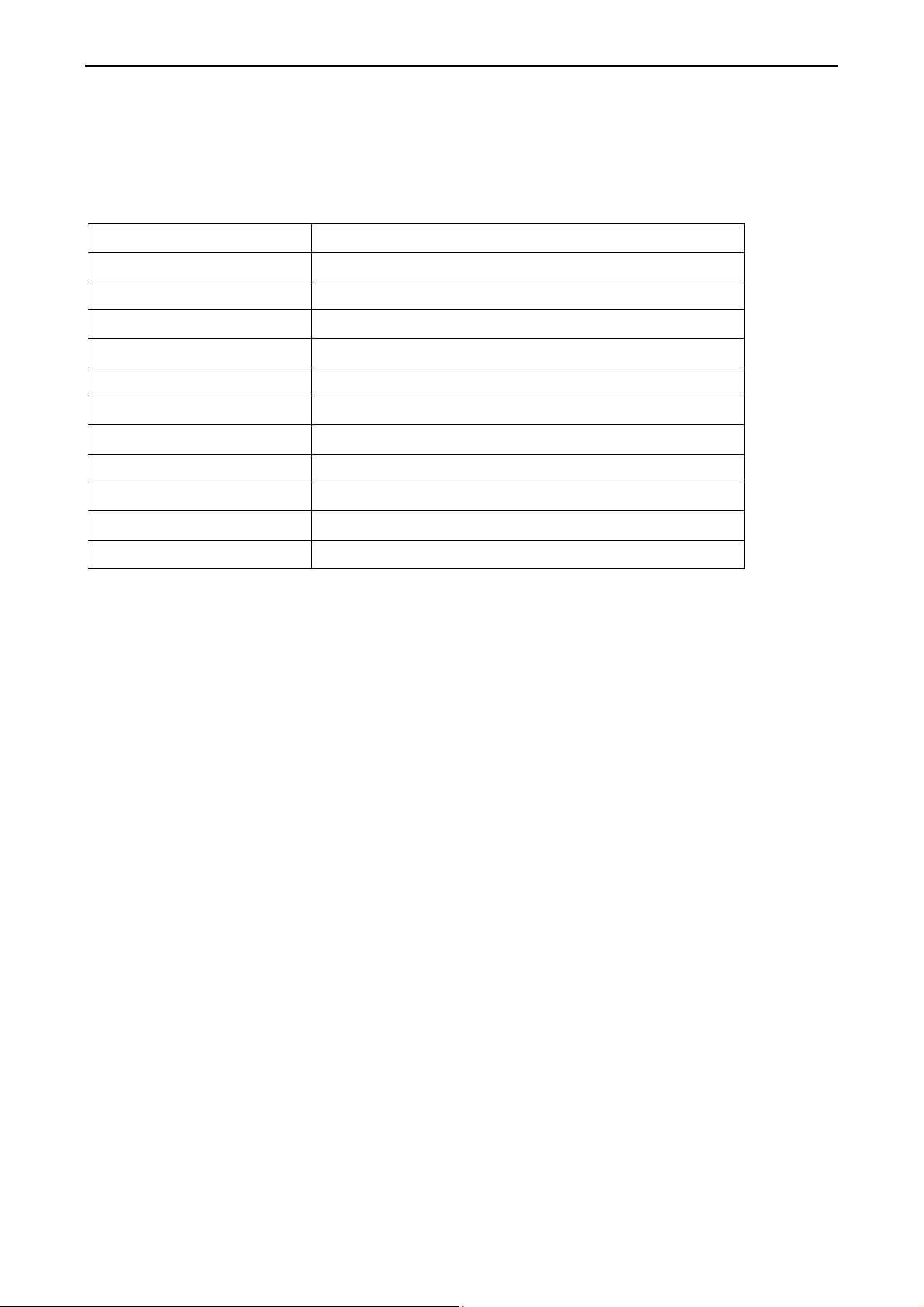

9 Troubleshooting

Symptoms Reasons Solutions

The motor does not

work.

The motor works,

but the platforms do

not move, or can

only go up slowly.

Check the fuse and limit switch.

Voltage is not correct.

Electrical wiring is wrong.

Motor is broken.

The motor rotates in the wrong

direction.

Oil level is too low.

Height limit switch is stuck or

damaged.

Repair or change the fuse or limit switch.

Supply power of correct voltage.

Fix the wiring.

Change motor.

Exchange wiring of motor to change

direction.

Add oil.

Repair or replace the height limit switch.

The motor works,

but the platforms

can not lift the

vehicle.

The lift is too slow in

lowering.

The platforms are

not synchronized.

The voltage to the motor is too low.

Pressure of relief valve is not right.

The lift is overloaded

The hydraulic pump is damaged.

There is foreign substance in the

lowering solenoid valve.

Lowering speed valve is turned too

low.

There is air in upper chamber of

Master Cylinder or Slave Cylinder.

The oil supply can't be cut off because

of the leakage of stop valve.

Leakage in hydraulic system

The air pressure regulating valve is

Supply motor with correct voltage.

Adjust the pressure of relief valve.

Check the weight of the vehicle.

Replace the hydraulic pump.

Clean the lowering solenoid valve.

Turn the lowering speed valve up.

Air bleeding performance is needed. The

air in the master and slave cylinder can be

bled after the platform goes up and down

several times.

Replace stop valve.

Replace the seal or the cylinder.

Adjust air pressure to 5kg/cm2

Safety ratchets

cannot be separated

from serration.

closed or too low.

The Solenoid air valve is damaged.

The LOCK button is pressed for too

long time.

28

Replace the solenoid air valve.

Release the LOCK button immediately after

the safety ratchets are fully engaged.

Page 33

LAUNCH TLT830WA Product Manual

10 Maintenance

10.1 Daily Maintenance

z Keep the lift clean. Make sure power is cut off before cleaning the lift.

z Keep the working area clean. Excessive dust in the work area will shorten the lifespan of the lift.

z Before operation, inspect and keep all the safety devices of lift in order. If any problems are found, adjust, maintain or

replace the parts timely.

z Make sure that the pits are kept dry and clean.

z Inspect if there is leakage in the air valve and if it is well-lubricated.

10.2 Monthly Maintenance

z Refasten the anchor bolts.

z Check all the hoses and fittings for possible wearing and leakage. If any leakage is found to be caused by worn sealing

parts, replace with parts meeting the specifications.

z Check if the roller slide is well-lubricated with high-quality #2 lithium lubricant.

z Apply #2 lithium lubricants on a monthly basis.

10.3 Biannual Maintenance

z Check all the moving parts for possible wearing, interference and damage.

z Inspect the lubrication of all the rollers. If the roller is dragged along in lifting or lowering, apply lubricant to the roller

shaft.

z At the end of the first six months, clean the hydraulic system and replace the hydraulic oil. Replace the hydraulic oil

with N32 hydraulic oil in winter and N46 in summer.

10.4 Maintenance for 3 Years or 5000 Times Operations

z Replace the bushings at all joints.

z Replace all seals

z Replace the rollers.

11 Storage and Scrapping

11.1 Storage

When the lift needs to be stored for a long time:

z Unplug from power socket.

z Lubricate all the parts, including all the contact surface of the rollers.

z Bleed oil from tanks.

z Cover the lift with plastic hood.

11.2 Scrapping

When the lift has exceeded its lifespan and can not be used any more, disconnect it from the electrical supply and dispose of

as required by the local regulations.

29

Page 34

LAUNCH TLT830WA Product Manual

TLT830WA Hydraulic Oil Data

#2 Lithium Lubricants

Item

Conical degree(1/10mm)

Dropping point ℃

Erosion(T2 Copper Plate,100 ℃,24h)

Copper Screening(100℃,22h)% 4

Evaporation(100℃,22h)% 2

Oxidizing Stability(99℃,100 h) 0.2

Non-corrosibility(52℃,48) Grade 1

Foreign substance(Microscopic method)/

(number/cm³)

Above 10µm

Above 25µm

Above 75µm

Above 125µm

Specifications

278

185

No Change

5000

3000

500

0

Relative Viscosity

(-15℃,10s-1 ),/(Pa·s)

Less than

Humidity Loss(38℃,1h)(%)

less than

N32 Mechanic Oil (for winter)

Item

Moving Viscosity 40℃

Pour / ℃ ≤-15

Flash point / ℃ ≥175

N46 Mechanical Oil (for summer)

Item

Moving Viscosity 40℃

Pour / ℃ ≤-9

Flash point / ℃ ≥185

800

8

Specifications

28.8~35

Specifications

41.4~50.6

30

Loading...

Loading...