Page 1

IMPORTANT:

READ THIS MANUAL COMPLETELY BEFORE

INSTALLING OR OPERATING YOUR LIFT

Model

TLT210

-AS

pictured

LAUNCH

Installation, Operation & Maintenance Manual

Two Post Surface Mounted Lifts

LAUNCH TECH USA INC.

TLT210-A TLT210-AS TLT210-XT TLT211-AS

10,000 lb. Capacity 10,000 lb. Capacity 10,000 lb. Capacity 11,000 lb. Capacity

2,500 lbs. per Arm 2,500 lbs. per Arm 2,500 lbs. per Arm 2,750 lbs. per Arm

1820 S Milliken Ave. Ontario, California 91761 Telephone: 562 463-1580 Fax: 562 463-1590

www.launchtechequipment.com

Page 2

ALI Lifting it Right

safety manual

ALI S

afety Tips card

Series, ALI Uniform Warning Label Decals/Placards

Vehicle Lifting Points/Quick

American National Standard for Automotive Lifts

-

Safety Requirements for Operation, Inspection and Maintenance

American National Standard for Automotive Lifts

-

Safety Requirements for Operation, Inspection and Maintenance

American National Standard for Automotive

ALI Lifting it Right safety manual

ALI Safety Tips card

American National

Inspection and Maintenance

ALI Uniform Warning

Label Decals/Placards

Vehicle Lifting Points/Quick Reference Guide for Frame

Engaging Lifts

Safety Requirements

for the Lockout/Tagout of Energy Sources

OWNER / EMPLOYER OBLIGATIONS

1. The Owner/Employer shall ensure that lift operators are qualified and that

they are trained in the safe use and operation of the lift using the

manufacturer’s operating instructions; ALI/SM 93-1,

; ALI/ST-90

American National Standard for Automotive Lifts - Safety

Requirements for Operation, Inspection and Maintenance; ALI/WL

frame engaging lifts, ALI/LP-GUIDE,

Reference Guide for Frame Engaging Lifts.

2. The Owner/Employer shall establish procedures to periodically inspect the

lift in accordance with the lift manufacturer’s instructions or ANSI/ALI

ALOIM-2008,

; ANSI/ALI ALOIM-2008,

; and in the case of

; and

the Employer shall ensure that the lift inspectors are qualified and that

they are adequately trained in the inspection of the lift.

3. The Owner/Employer shall establish procedures to periodically maintain

the lift in accordance with the lift manufacturer’s instructions or ANSI/ALI

ALOIM-2008,

the Employer shall ensure that the lift maintenance personnel are qualified

and that they are adequately trained in the maintenance of the lift.

4. The Owner/Employer shall maintain the periodic inspection and

maintenance records recommended by the lift manufacturer’s instructions

or ANSI/ALI ALOIM-2008,

Lifts - Safety Requirements for Operation, Inspection and

Maintenance.

; and

5. The Owner/Employer shall display the lift manufacturer’s operating

instructions; ALI/SM 93-1,

; ANSI/ALI ALOIM-2008,

Standard for Automotive Lifts - Safety Requirements for Operation,

; ALI/WL Series,

; and in the case of frame engaging lifts, ALI/LP-

GUIDE,

in a conspicuous location in the lift area convenient to the

operator.

6. The Owner/Operator shall provide necessary lockout/tagout means for

energy sources per ANSI Z244.1-1982 (R1993),

, before beginning any lift

repairs and maintenance.

; ALI/ST-90

2

Page 3

7. The Owner/Employer shall not modify the lift in any manner without the

prior written consent of the manufacturer.

IMPORTANT SAFETY INSTRUCTIONS

1. When using this lift, basic safety precautions should always be

followed, including the following:

2. Read all instructions in this manual and on the lift thoroughly before

installing, operating, servicing or maintaining the lift.

3. Care must be taken as burns can occur from touching hot parts.

4. Do not operate equipment with a damaged cord or if the equipment has

been dropped or damaged – until it has been examined by a qualified

service person.

5. Do not let a cord hang over the edge of the table, bench, or counter or

come in contact with hot manifolds or moving fan blades.

6. If an extension cord is necessary, a cord with a current rating equal to or

more than that of the equipment should be used. Cords rated for less

current than the equipment may overheat. Care should be taken to

arrange the cord so that it will not be tripped over or pulled.

7. Always unplug equipment from electrical outlet when not in use. Never

use the cord to pull the plug from the outlet. Grasp plug and pull to

disconnect.

8. Let equipment cool completely before putting away. Loop cord loosely

around equipment when storing.

9. To reduce the risk of fire, do not operate equipment in the vicinity of open

containers of flammable liquids (gasoline).

10. Adequate ventilation should be provided when working on operating

internal combustion engines.

11. Keep hair, loose clothing, fingers, and all parts of body away from moving

parts.

12. To reduce the risk of electric shock, do not use on wet surfaces or expose

to rain.

3

Page 4

ALWAYS WEAR SAFETY GLASSES.

NOTE:

Caution!

13. Use only as described in this manual. Use only manufacturer’s

recommended attachments.

14.

impact resistant lenses, they are not safety glasses.

Everyday eyeglasses only have

15. Inspect lift daily. Do not operate if it malfunctions or problems have been

encountered.

16. Never attempt to overload the lift. The manufacturer’s rated capacity is

shown on the identification label on the power side column. Do not

override the operating controls or the warranty will be void.

17. Before driving vehicle between the towers, position the arms to the drivethrough position to ensure unobstructed clearance. Do not hit or run over

arms as this could damage the lift and/or vehicle.

18. Only trained and authorized personnel should operate the lift. Do not allow

customers or bystanders to operate the lift or be in the lift area.

19. Position the lift support pads to contact the vehicle manufacturers

recommended lifting points. Raise the lift until the pads contact the

vehicle. Check pads for secure contact with the vehicle. Check all arm

restraints and insure they are properly engaged. Raise the lift to the

desired working height.

20. Some pickup trucks may require an optional truck adapter to clear running

boards or other accessories.

21.

22.

engaged.

Always use all 4 arms to raise and support vehicle.

Never work under the lift unless the mechanical safety locks are

23. Note that the removal or installation of some vehicle parts may cause a

critical load shift in the center of gravity and may cause the vehicle to

become unstable. Refer to the vehicle manufacturer’s service manual for

recommended procedures.

24. Always keep the lift area free of obstruction and debris. Grease and oil

spills should always be cleaned up immediately.

25. Never raise vehicle with passengers inside.

26. Before lowering check area for any obstructions.

27. Before removing the vehicle from the lift area, position the arms to the

drive-thru position to prevent damage to the lift and /or vehicle.

4

Page 5

ATTENTION!

Failure to

28. Do not remove hydraulic fittings while under pressure.

WARNING!

provide the recommended mounting surface

could result in unsatisfactory lift performance, property damage, or personal injury.

Failure by purchaser to

LOCATION

This lift has been evaluated for indoor use only with an operating ambient temp. range of 5 - 40°C (41-

104°F)

For additional safety instructions regarding lifting, lift types, warning labels,

preparing to lift, vehicle spotting, vehicle lifting, maintaining load stability,

emergency procedures, vehicle lowering, lift limitations, lift maintenance,

good shop practices, installation, operator training and owner/employer

responsibilities, please refer to “Lifting It Right” (ALI/SM) and “Safety Tips”

(ALI/ST) and vehicle lift points for service garage lifting SAE J2184.

For additional instruction on general requirements for lift operation, please

refer to “Automotive Lift-Safety Requirements for Operation, Inspection and

Maintenance” (ANSI/ALI ALOIM).

Installation shall be performed in accordance with ANSO/ALI ALIS, Safety

Requirements for Installation and Service of Automotive Lifts.

This lift is intended for indoor installation only. It is

prohibited to install this product outdoors. Operating environment

temperature range should be 41 – 104 °F (5 – 40 °C).

adhere will result in decertification, loss of warranty, and

possible damage to the equipment.

5

Page 6

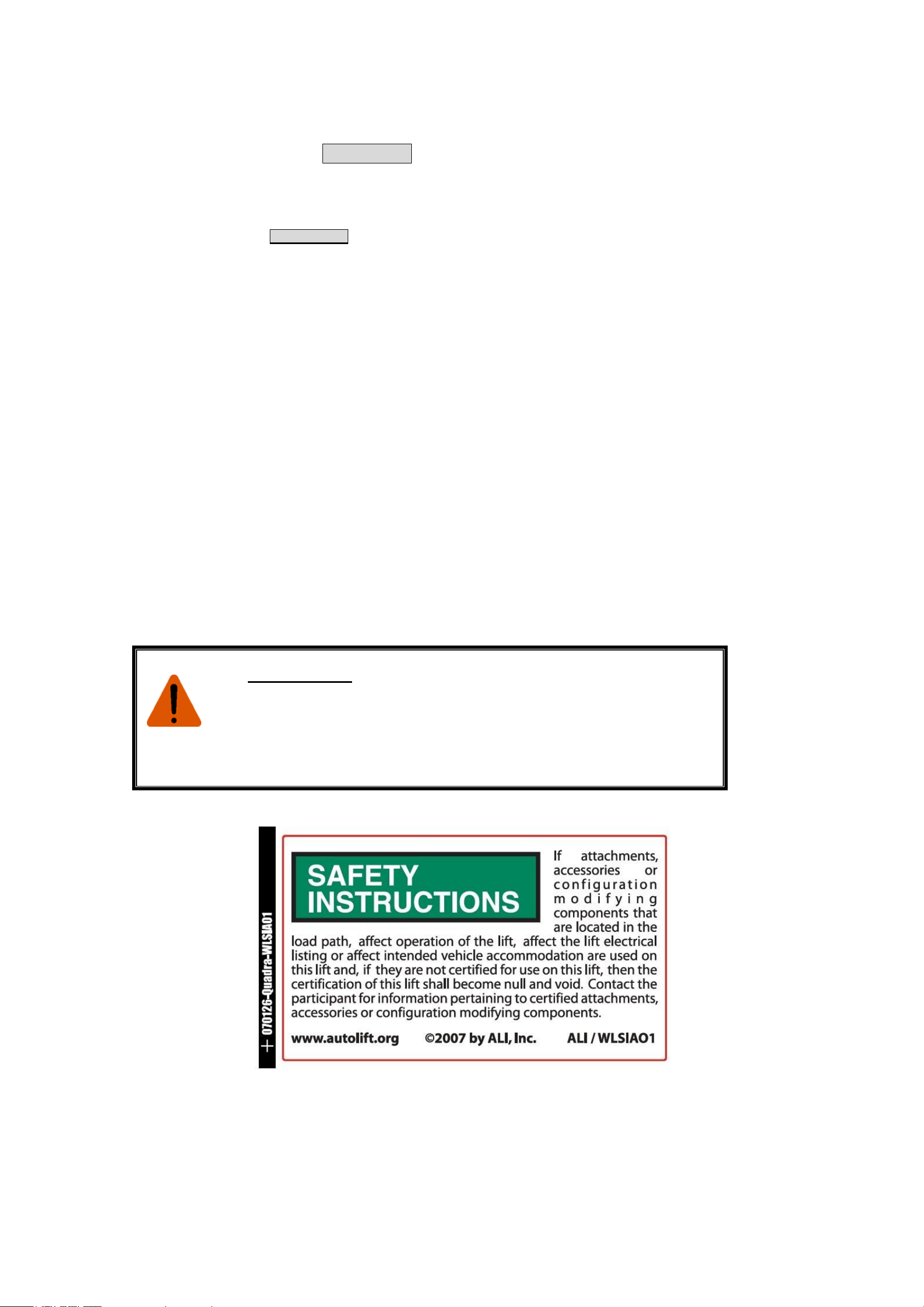

REFERENCE: AUTOMOTIVE LIFT INSTITUTE (ALI)

SAFETY AWARENESS

SAVE THESE INSTRUCTIONS

Note: Some images in this manual are generic and may not resemble

the lift you have purchased.

6

Page 7

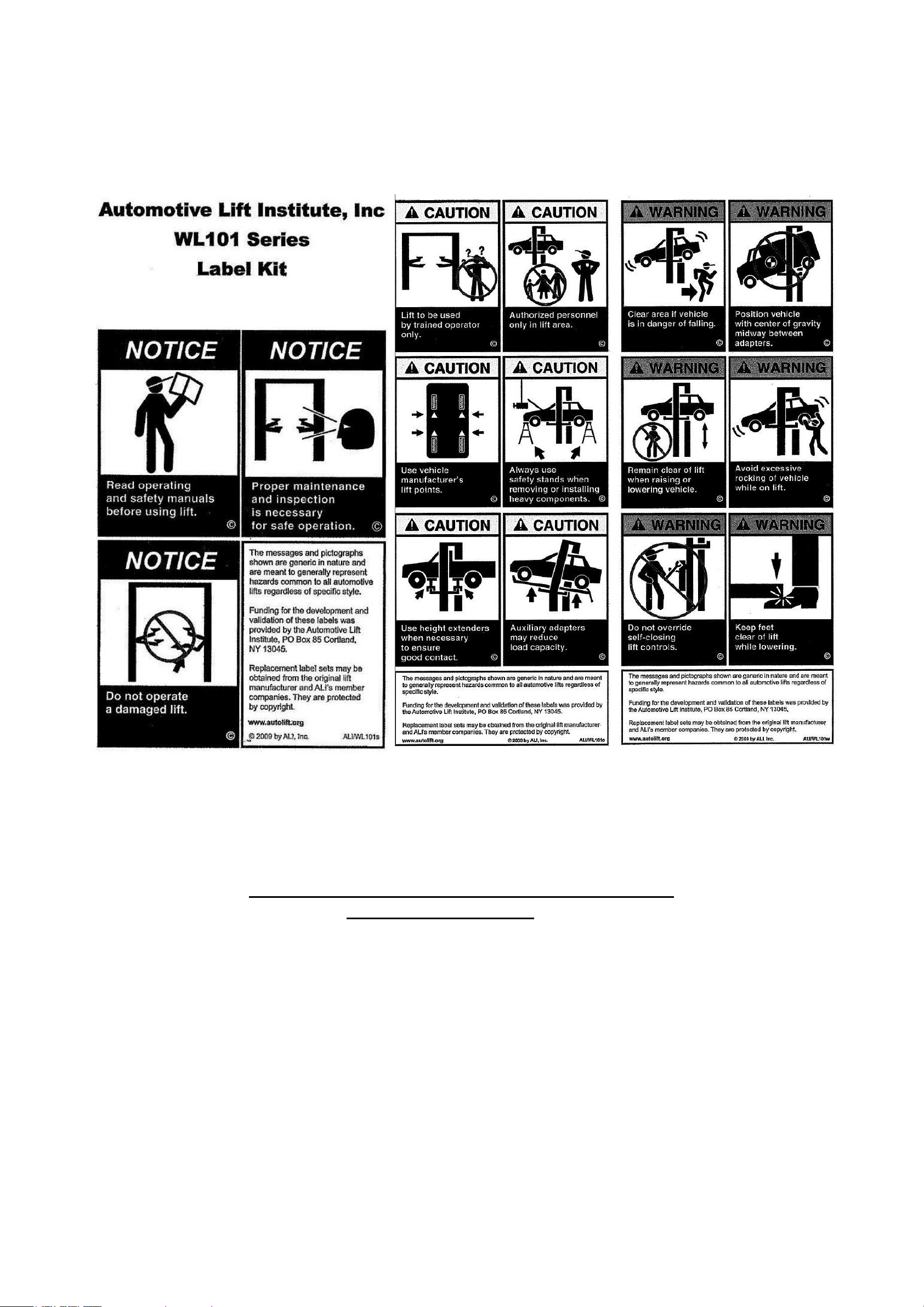

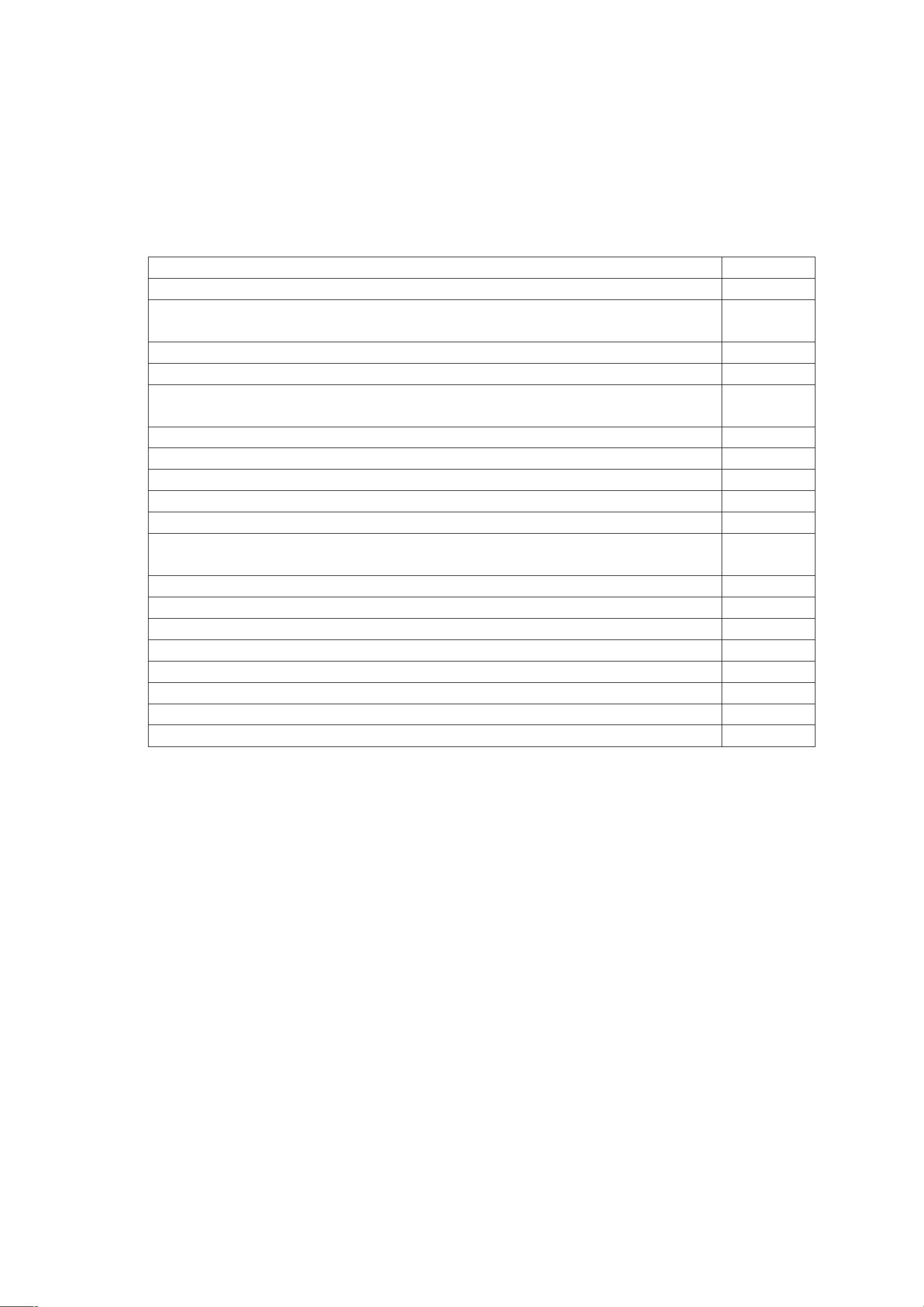

SPECIFICATIONS

A. Maximum Lifting Height

B. Minimum Column Height

C. Cylinder Full Height

D. Total Width

E. Drive-Thru Clearance

F. Floor to Overhead Switch

G. Front Arm Reach (min / max)

H. Rear Arm Reach (min / max)

I. Screw Pad Height

J. Inside Column Width

Electric Hydraulic Power Unit

Voltage

Rise Speed

Max. Load Per Arm

Minimum Ceiling Height Required

Narrow Bay Setting

Maximum Column Height

Power Unit Operating Pressure

TLT211- AS 11,000 lb. Capacity TLT210- AS / XT 10,000 lb. Capacity TLT-210- A / XT 10,000 lb. Capacity

75.6" (1920mm) 76.4" (1940mm) 76.4" (1940mm)

143" (3634mm) 143" (3634mm) 143" (3634mm)

145.2" (3688mm) 145.2" (3688mm) 145.2" (3688mm)

137.8" (3500mm) 136.6" (3470mm) 137.9" (3502mm)

96" (2438mm) 98.4" (2500mm) 88" (2235mm)

140" (3556mm) 140" (3556mm) 140" (3556mm)

23.6"(600mm) / 39.4" (1000mm) 23.6"(600mm) / 43.5" (1105mm) 23.6"(600mm) / 43.5" (1105mm)

38.6" (980mm) / 61.8" (1570mm) 38.6" (980mm) / 61.8" (1570mm) 38.6" (980mm) / 61.8" (1570mm)

4.3" (110mm) to 7.5" (190mm) 4.3" (110mm) to 7.5" (190mm) 4.3" (110mm) to 7.5" (190mm)

108" (2742mm) 110.2" (2800mm) 101.9" (2588mm)

2 HP 2 HP 2 HP

208-230Volt/60hz./Single Phase 208-230Volt/60hz./Single Phase 208-230Volt/60hz./Single Phase

54 Seconds 54 Seconds 54 Seconds

2750 Lbs. (1247 Kilos) 2500 Lbs. (1134 Kilos) 2500 Lbs. (1134 Kilos)

143.9" (3655mm) 143.5" (3644mm) 143.5" (3644mm)

Non-Adjustable Deduct 5.9" (149mm) Deduct 5.9" (149mm)

149" (3784mm) 149" (3784mm) 149" (3784mm)

2750 PSI 2700 PSI 2750 PSI

LAUNCH TECH USA

Figure 1

TLT Series Specifications

Rise height measured with footpads in the highest position.

Lift capacity rating is based on loads equally distributed on all four arms.

Lifting and lowering speeds may vary depending on the weight of the vehicle.

7

Page 8

The main structural components and parts

PACKING LIST

The complete lift is contained in two (2) packages:

1.

are packed in a steel frame.

2. Power Unit Box including Shutoff Switch and all Documents

Main Structural Components and Parts

1pc. - Power side tower and carriage assembly

1pc. - Slave side tower and carriage assembly

1pc. - Overhead Beam

1pc. - Actuator Bar w/ foam

1pc. - Power side column extension

1pc. - Slave side column extension

2pc. - Two front arm assembles (Three piece design)

2pc. - Two rear arm assembles (Two piece design)

2pcs. - Safety Covers w/Decals

1pc. - Hardware Package w/Packing List

1pc. - Actuator Extension

1pc. - Actuator Mounting Bracket

1pc. - Safety Release Cable

2pc. - Hydraulic Hose (Long)

2pc. - Hydraulic hose (Short)

2pcs. - Equalizing Cable w/Hex Nuts

1pc. - ALI manual “Lifting It Right”

1pc. - Automotive Lift Safety Tips

1pc. - Automotive Lift, Operation, Inspection and Maintenance Manual

1pc. - ALI” Quick Reference Guide

1pc. - Owner’s manual

1pc. - Warranty Statement and Warranty Registration Instructions

1pc. - Power Unit Box with Microswitch and Document Package

8

Page 9

IMPORTANT:

j. Pry Bar

INSTALLATION REQUIREMENTS AND TOOLS

FOUNDATION

It is the user’s responsibility to provide a satisfactory installation

area for the lift. Lifts should only be installed on level concrete floors with a

minimum thickness of four inches (4") or 102 mm. Concrete must have a minimum

strength of 3500 psi should be aged thirty (30) days prior to installation. Please

consult the architect, contractor or engineer if doubt exists as to the strength and

feasibility of the floor to enable proper lift installation and operation.

A qualified person should be consulted to address seismic loads and other local

or state requirements.

It is the user’s responsibility to provide all wiring for electrical hook-up prior to

installation and to insure that the electrical installation conforms to local building

codes. Where required, it is the user’s responsibility to provide an electrical

isolation switch located in close proximity to the lift that will enable emergency

stop capability and isolate electrical power from the lift for any servicing

requirements.

TOOLS

a. 16ft. Measuring Tape

b. Chalk Line

c. Rotary Hammer Drill

d. 3/4” diameter or 19mm diameter Masonry Drill Bit

e. Hammer

f. SAE Wrenches and Ratchet Set

g. Metric Wrenches and Ratchet Set

h. 2ft. Level

i. 4ft. Level

k. 12ft. Step Ladder

l. Side Cutters

m. Screwdrivers

n. 4” x 4” Wooden Blocks (for unpacking)

o. 4 gal. ISO 32 Hydraulic Fluid

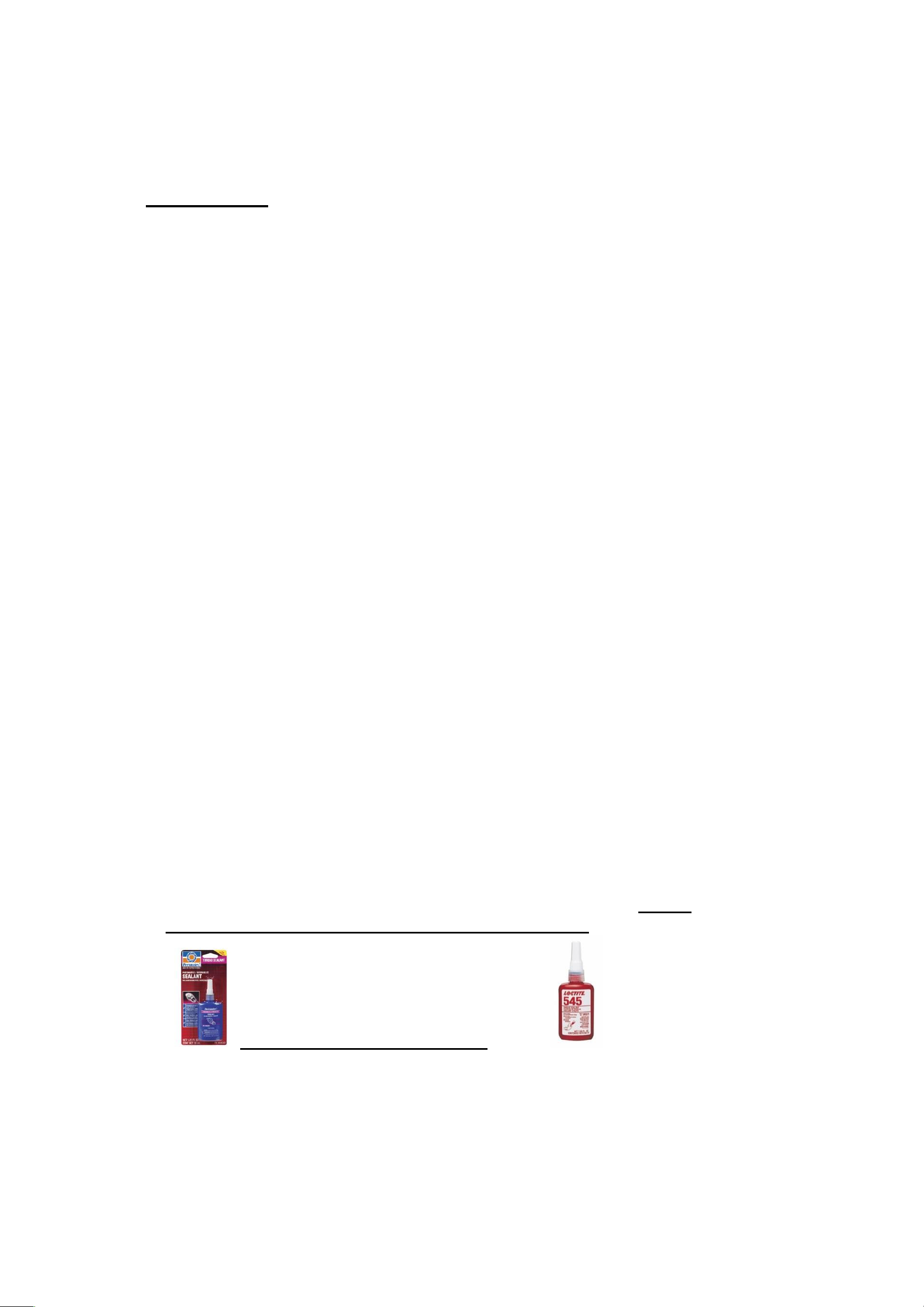

p. Torque Wrench

q. Hydraulic Fitting Sealant Compound ( DO NOT USE TEFLON TAPE) Launch

*Tech USA recommends Permatex brand part number 54540

OR Loctite brand 545 thread sealant

9

Page 10

Check for any freight damages.

NOTE:

MANUFACTURER IS NOT RESPONSIBLE FOR ANY FREIGHT DAMAGE.

INSTALLATION INSTRUCTIONS

When the lift arrives on site:

Read the owner’s manual and make sure the installation instructions are

fully understood.

inspected as soon as it is received. The signed bill of lading is

acknowledgement by the carrier of receipt in good condition of shipment

covered by our invoice .If any of the goods called for on your bill of lading

are shorted or damaged, do not accept them until the carrier makes a

notation on the freight bill of the missing or damaged goods. Do this for

your own protection. Check the contents of the accessory and hardware

boxes to make sure no parts are missing.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAMAGE AFTER

The shipment should be thoroughly

YOU HAVE GIVEN THE CARRIER A CLEAR RECEIPT. THE LIFT

UNPACKING PROCEDURE

Important! Place the main structural components on wooden blocks so

that the steel shipping frames can be removed.

Remove Power Unit Box.

Remove the plastic wrapping.

Remove the cross member, and the actuator bar.

Remove the arms and parts boxes

Unbolt the steel shipping frames.

Lay each tower on the floor with the carriage side up.

Check the installation area for obstructions. (Lights, Heating Ducts,

Ceiling, Floor Drains, etc.)

10

Page 11

IMPORTANT:

Note: Leave any additional room for any

Important Notice: For narrow bay installation, deduct

BAY LAYOUT

installing or servicing a vehicle lift.

Prepare the bay by selecting the location of the lift relative to the walls.

Clear the installation area of all packaging materials to avoid trip

hazards.

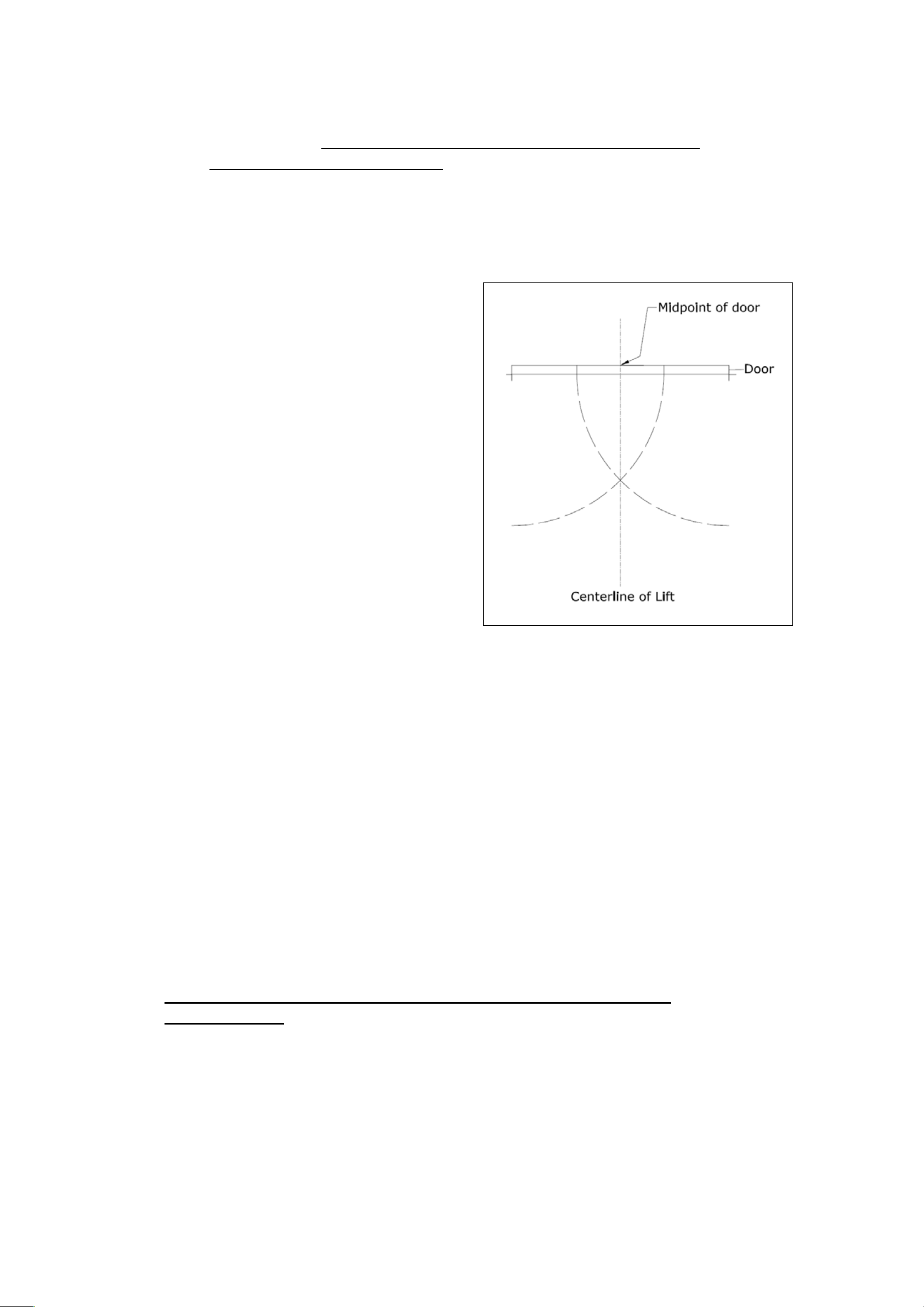

Measure midpoint of door.

Using measuring tape, scribe

two arcs, equal distance from

the midpoint.

The centerline of the lift occurs

Always wear PPE (Personal Protection Equipment) when

between the intersection of the

arcs and the midpoint of the door.

desired aisle or work area.

Recommended minimum clearance

around lift is three feet (3 ft.) and

above lift is four inches (4”).

Ensure clearance conforms to local

building and fire codes.

Figure 2

Measure the specified distance to draw a second chalk line at 90° for locating the

lift towers. Refer to Figure 3 and Figure 4 and Figure 5 below for correct

measurements.

The lift is centered between the door and the walls of the area.

Mark chalk lines at the exact position of each baseplate to show that when

installing the columns each baseplate will be position properly.

All the dimensions are based on the external border of the base plate.

The lift layout is very important. If not done properly, problems may

occur during the final assembly and operation

5.9” (150 mm) from

the width layouts.

11

Page 12

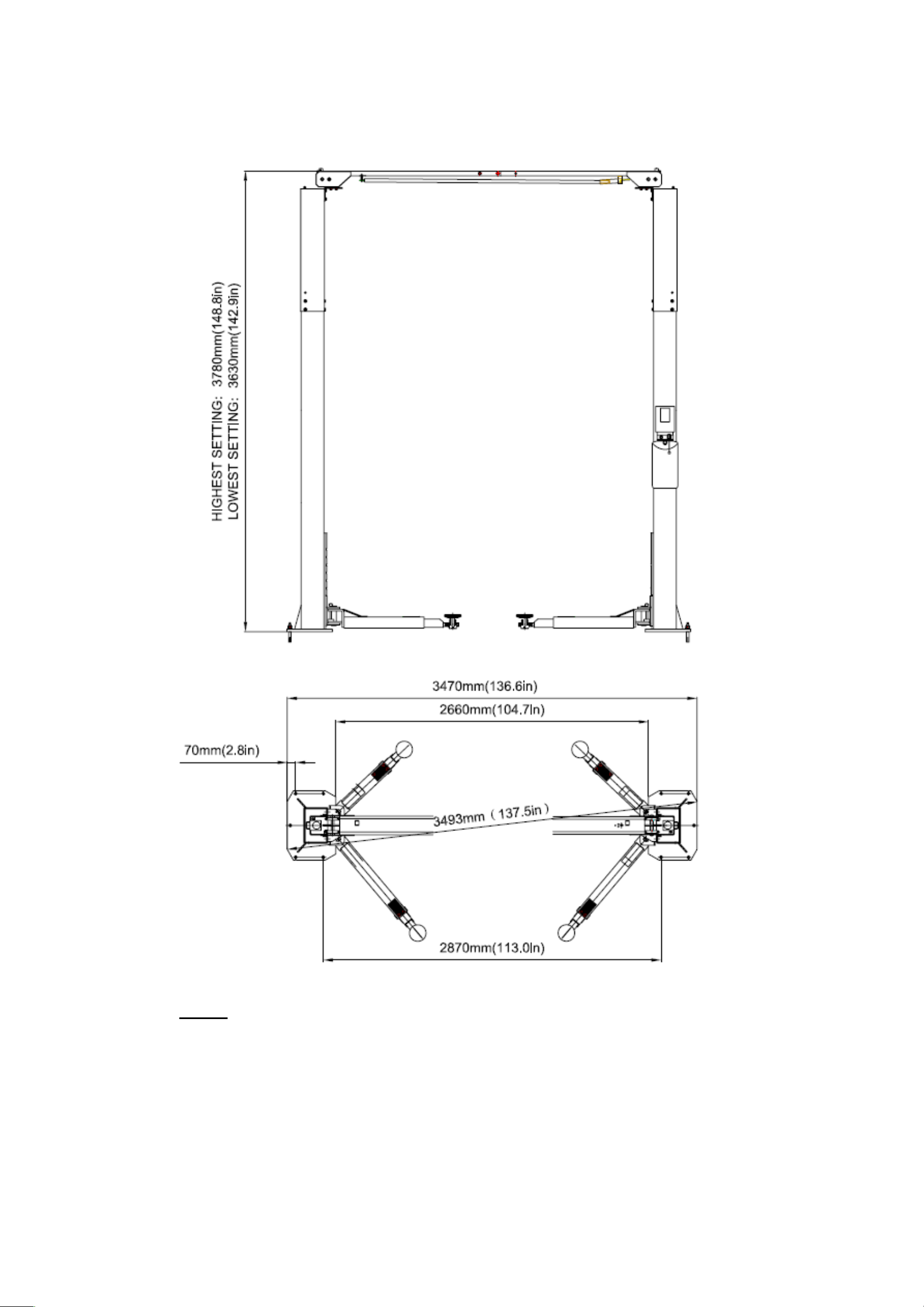

Figure 3

TLT210-AS or TLT210-XT Bay Layout

Deduct 150mm/5.9 in. from the width dimensions for the narrow installation

12

Page 13

Deduct

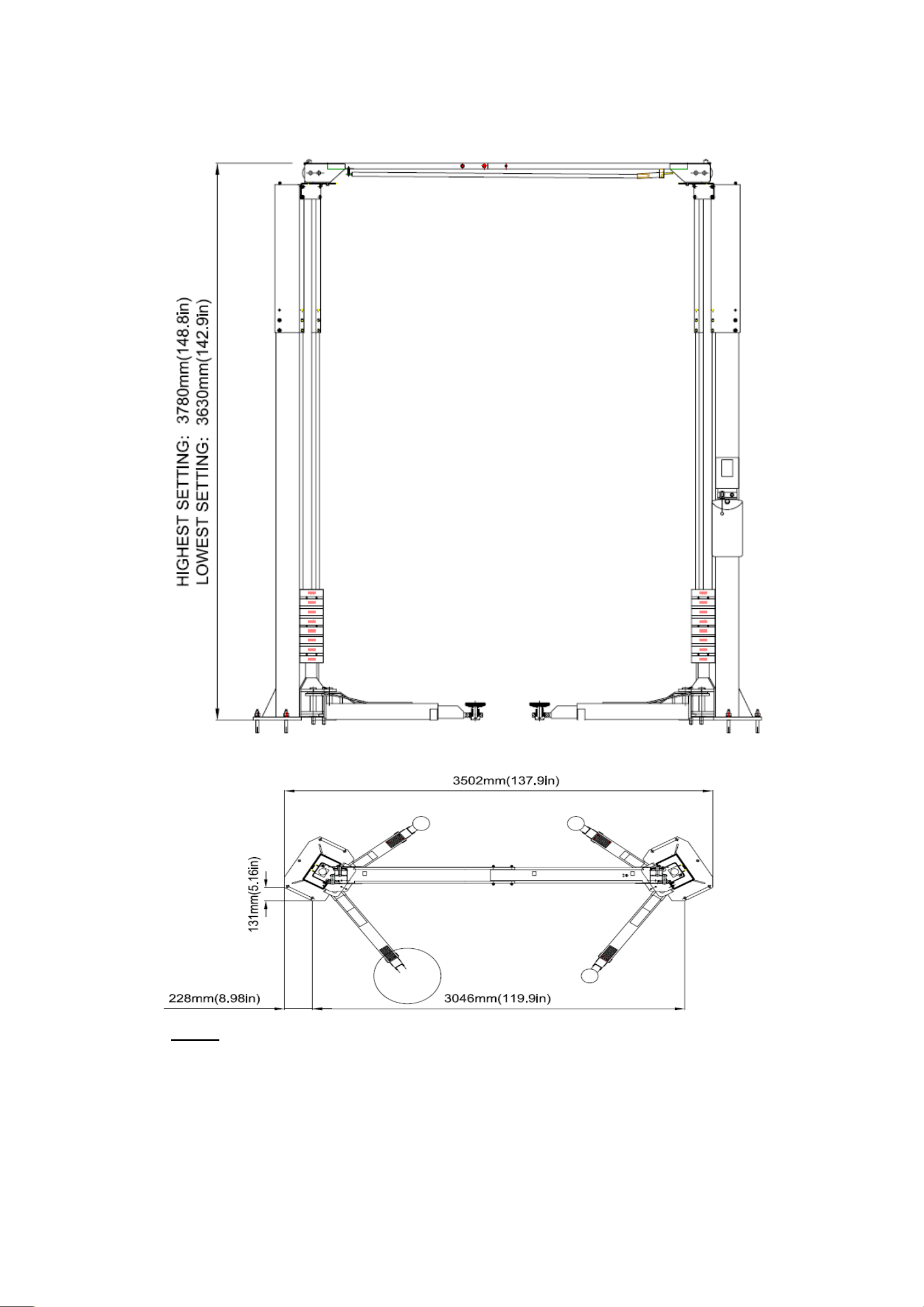

Figure 4

TLT210-A or TLT210-XT Bay Layout

150mm/5.9 in. from the width dimensions for the narrow installation

13

Page 14

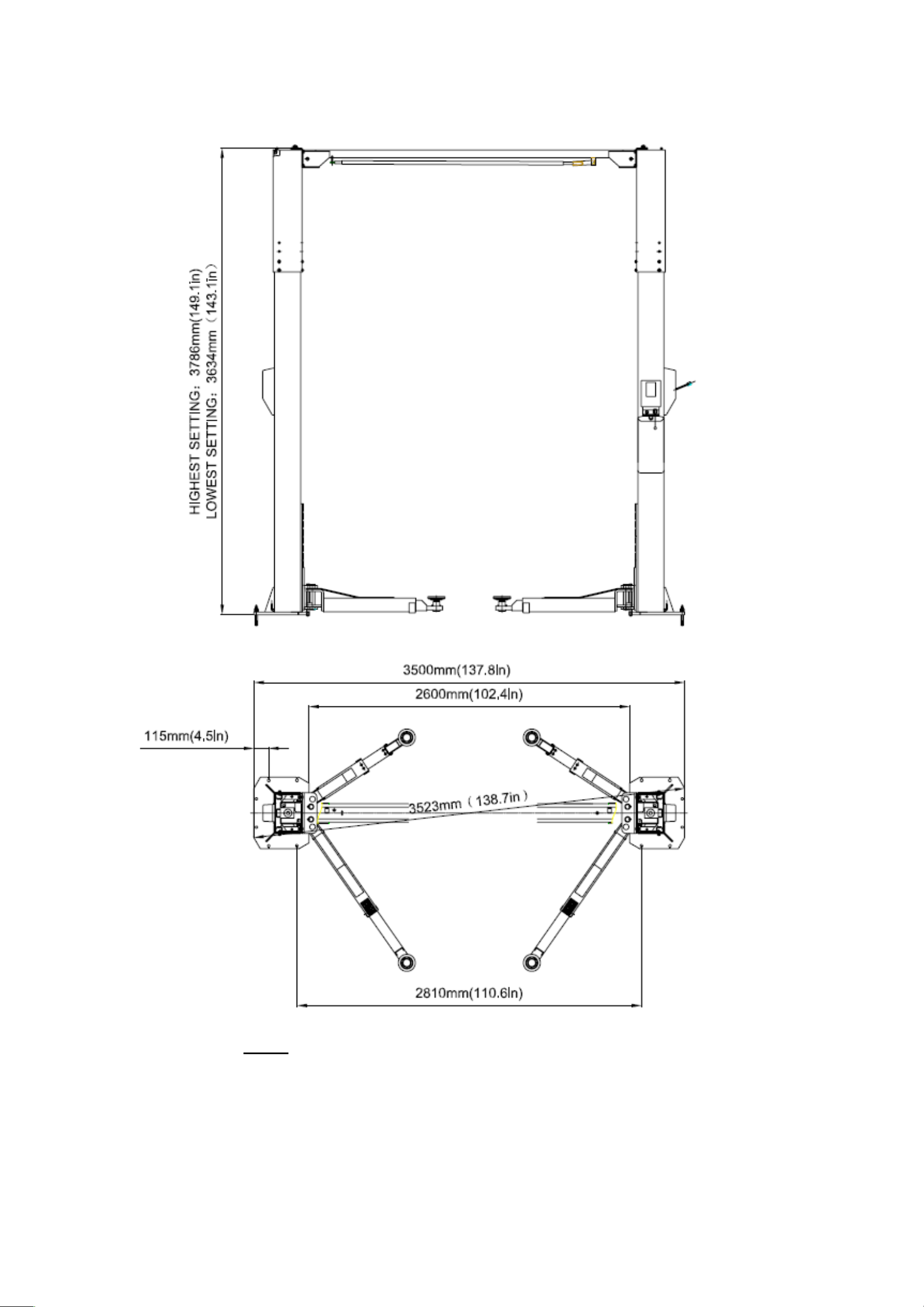

Figure 5

TLT211-AS Bay Layout

Note: There is no narrow bay setting on the TLT211-AS

14

Page 15

It is recommended that the TLT211

AS the bolts may

power side column is installed the slave column is raised into

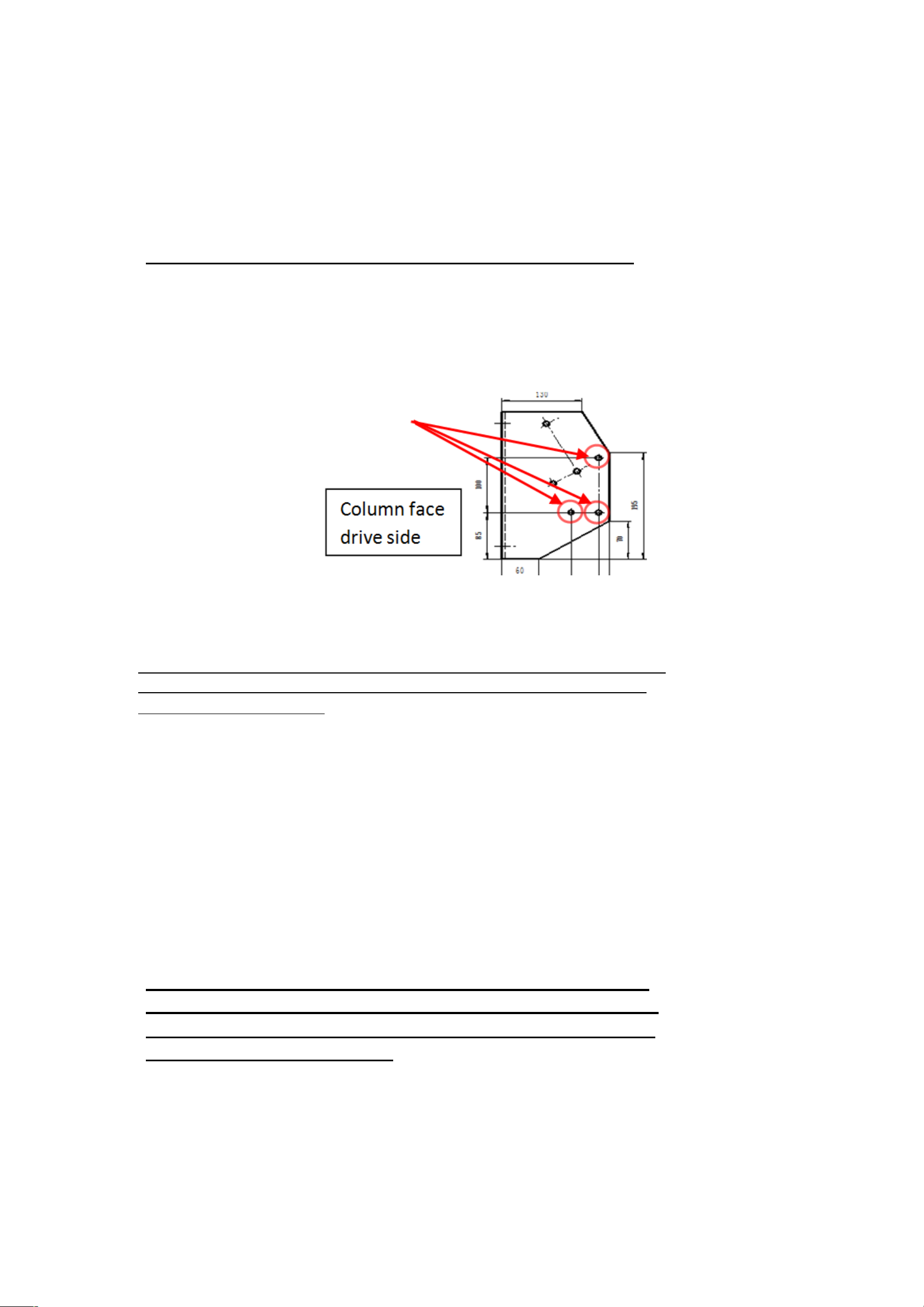

COLUMN ASSEMBLE

Assemble the column extensions and the positive carriage stop brackets to each

column using 12 sets of 12x35 hex bolts, flat washers, lock washers and nuts.

Repeat for opposite column and extension. Determine if the lift will be in the tallest

or lowest position at this time. Note that the TLT211-AS column extensions are

already assembled and may be preassembled at either the short or tallest position.

-AS lift be installed at the tallest position to

accommodate large and taller vehicles. Recheck the bolt tightness on the TLT211-

have loosened from shipping and handling. See illustration

below for reference. (Tallest position shown below)

INSTALLING THE COLUMNS

Raise the completed power side column upright to the chalked location. Align

the baseplate of column with the chalk line layout. Using the baseplate as a

template, drill holes into the concrete slab and use the five concrete anchor

Note: If theTLT-211AS lift is

installed at the tallest position,

this carriage stop bracket is

not to be used.

bolts to attach the column to the floor. (Note: the TLT211-AS lift uses six (6)

anchor bolts) During the drilling process, do not allow any movement of the

column from the chalk line.

Note: Power side column should always be installed first. After the

but not anchored to the floor. Installing the overhead beam must be

completed before the slave side column is anchored to the floor.

Use a four foot level on both sides of the column and use shims under

position

baseplate to level the column in both directions. Ensure that the base plate is

completely supported by shims including near the center where it does not

contact the floor.

15

Page 16

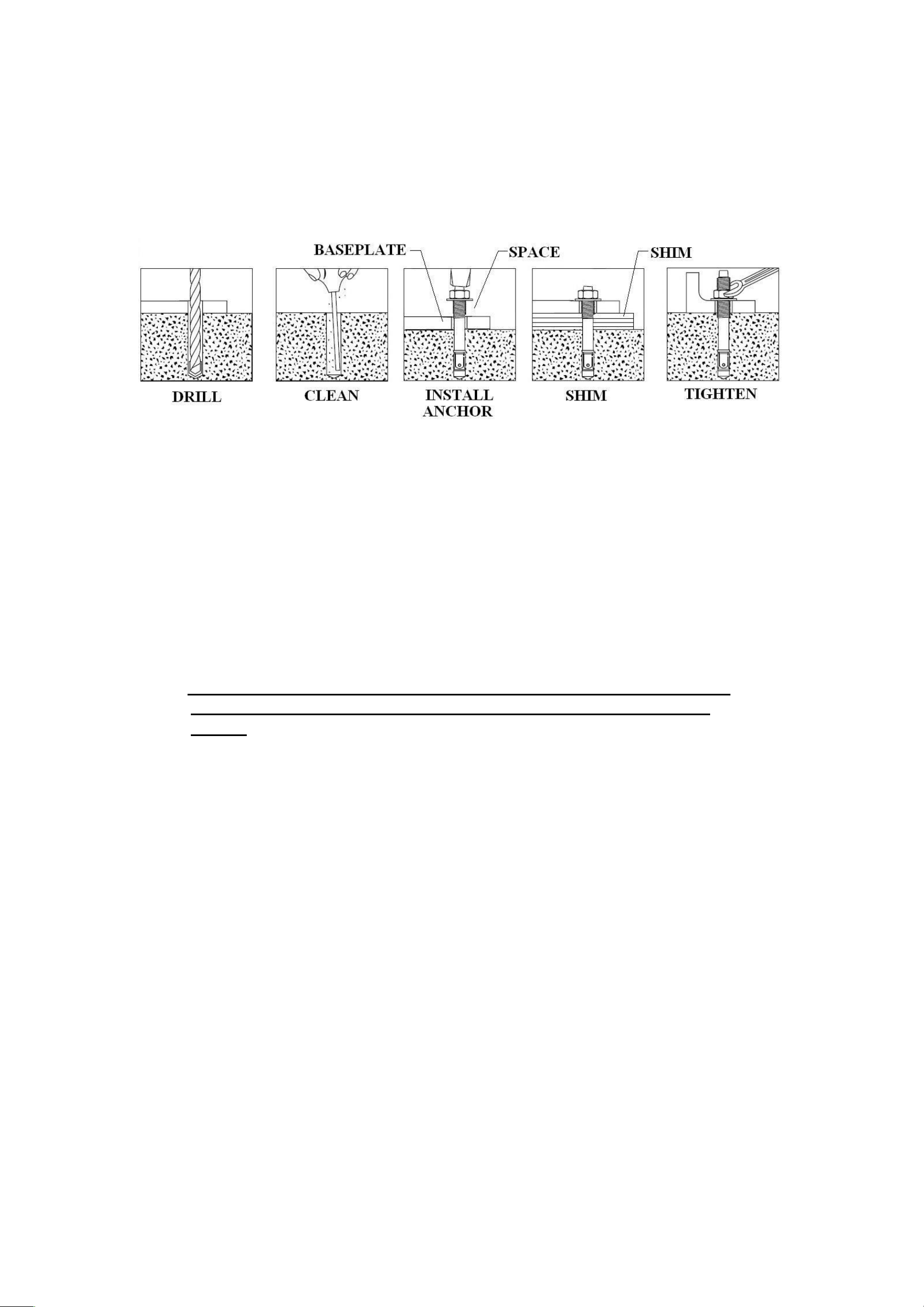

Hand tighten all anchor bolts.

Torque all anchor bolts to

125 ft.

-

lbs.

NOT USE AN IMPACT GUN TO INSTALL OR TIGHTEN THE ANCHOR

BOLTS.

Supplier for further details).

Refer to Bay Layout Figures about to ensure that the column is still in the

proper position before the anchor bolts are installed

Prior to installing anchors, assemble the nut and washer onto anchors. A

minimum of six threads must be visible below the surface of the nut. Refer to

the figure below while reading through the following instructions.

Using a ¾” concrete drill bit and rotary hammer drill, drill ¾” holes for the

anchor bolts on the power side column. Drill through the concrete floor. (In

case longer anchors are required, supplied anchors can be hammered

through concrete).

Clean out the drilling dust from the holes and place anchor bolts into the

hole. Add the washers and nut to the so that the top of the anchor bolt and

top of the nut are flush with each other then hammer in the anchor bolts

until they make contact with the baseplate.

Check that the column is level front to rear and side to side. Adjust

shims as required.

column is level as you proceed.

USE ONLY A TORQUE WRENCH TO TIGHTEN THE ANCHOR BOLTS DO

continually checking that the

If anchor bolts do not tighten to 125 ft.-lbs. OR project more than 2 ¼”

above the concrete surface due to floor slope, the concrete should be

replaced by an appropriate concrete pad. (Consult Product Manufacturer

At this time the slave column should be raised into position and aligned with chalk

marks on the floor. DO NOT ANCHOR THE SLAVE COLUMN AT THIS TIME. Use

caution to not move the slave column as is may tip over.

16

Page 17

photos below.

Note:

INSTALLING THE OVERHEAD BEAM

After positioning the slave column at the designated chalk location; assemble the

overhead beam on the shop floor to either the narrow or widest lift width hole

positions as determined by the chalk line measurements. See the photo below for

illustration.

Photo below shows the overhead

beam assembled at the widest

(most common) position.

While the overhead beam is still on the shop floor install the provided 4 pulleys

(sheaves). Two (2) pulleys on each side of the overhead beam using the parts

shown below. Note: Asymmetric installation (rotated column position as shown in

figure 5) requires the pulleys to be installed offset to each other using two (2)

axles and related parts. Symmetric installation (as shown in figure 4) requires the

pulleys to be installed on a common axle using the related parts. See related

Some TLT210 series models may already

have the pulleys installed. The TLT211-AS model has

the pulleys pre-installed at the factory. If this is case,

disregard the instructions below and proceed to the

next phase of installation.

17

Page 18

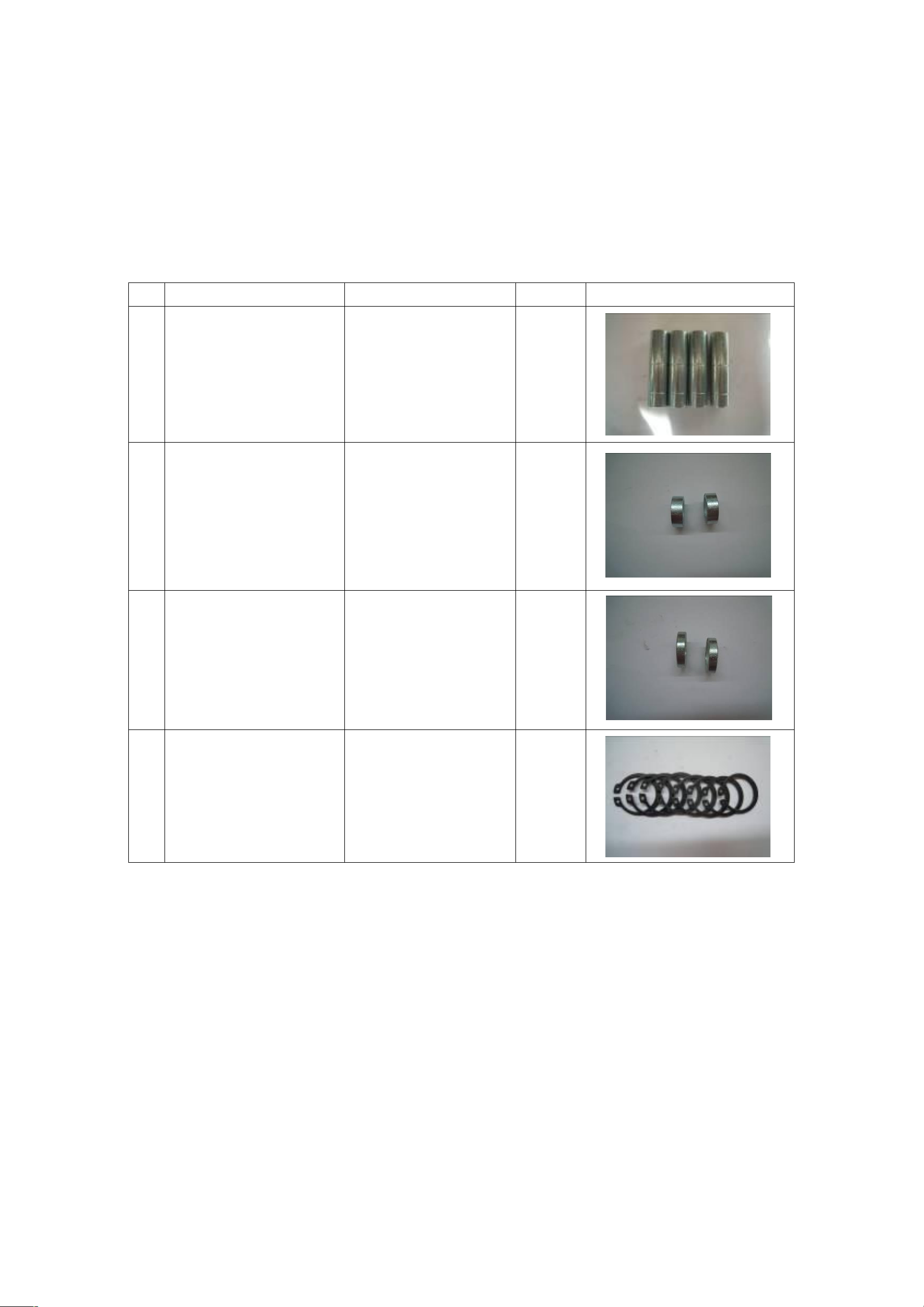

ASYMMETRIC PULLEY INSTALLATION

Use the 4 pulleys (sheaves) located in the parts packaging combined with the

parts in the packet marked “Asymmetric Installation” to install the pulleys for an

Asymmetric configuration. Below is what is contained in the asymmetric parts

packet.

No.

1

Name and Specs

Asymmetric shaft

Part Number

103200966

Qty.

4

Picture

2

3

Spacer Ⅱ

Spacer Ⅰ

(Narrow)

(Wide)

201011257

201011258

2

2

4 Retainer Ring 25

103050035

8

18

Page 19

Asymmetric Pulley Configuration Continued….

The photo below illustrated the proper alignment and placement of the pulleys into

the overhead beam. Note that the outer pulley is positioned on the overhead

beam in the outer most axle holes and that it is closest to the front of the lift. The

inner pulley is positioned in the inner most axles holes and is mounted toward the

rearward area of the lift. When installing the opposite set of pulleys they must

correspond exactly as the first set of pulleys that you installed.

Note: Inner pulley is

facing to the rear of the lift

Symmetric Pulley Assemble shown on the following page

Note: Outer pulley is

facing to front of the lift

19

Page 20

SYMETRIC PULLEY INSTALLTION

Use the 4 pulleys (sheaves) located in the parts packaging combined with the

parts in the packet marked “Symmetric Installation” to install the pulleys for a

Symmetric configuration. Below is what is contained in the symmetric parts

packet.

No.

1

Name and Specs

Symmetric shaft

Part Number

103200967

Qty.

2

Picture

2

3

Spacer Ⅱ

(Wide)

Spacer Ⅰ

(Narrow)

201011257

201011258

2

2

4

Cotter Pin 5x40

103060349

4

5 Retainer Ring #25 103050035 4

20

Page 21

Symmetric Pulley Installation Continued…

The photos below illustrate the proper alignment and placement of the pulleys

(sheaves) into the overhead beam. Note that both pulleys are positioned on the

overhead beam sharing a common axle and the axle is positioned in the outer

most axle holes and that is closest to outer most area of the overhead beam.

Install both sets of pulleys on each end of the over beam to exactly match each

other.

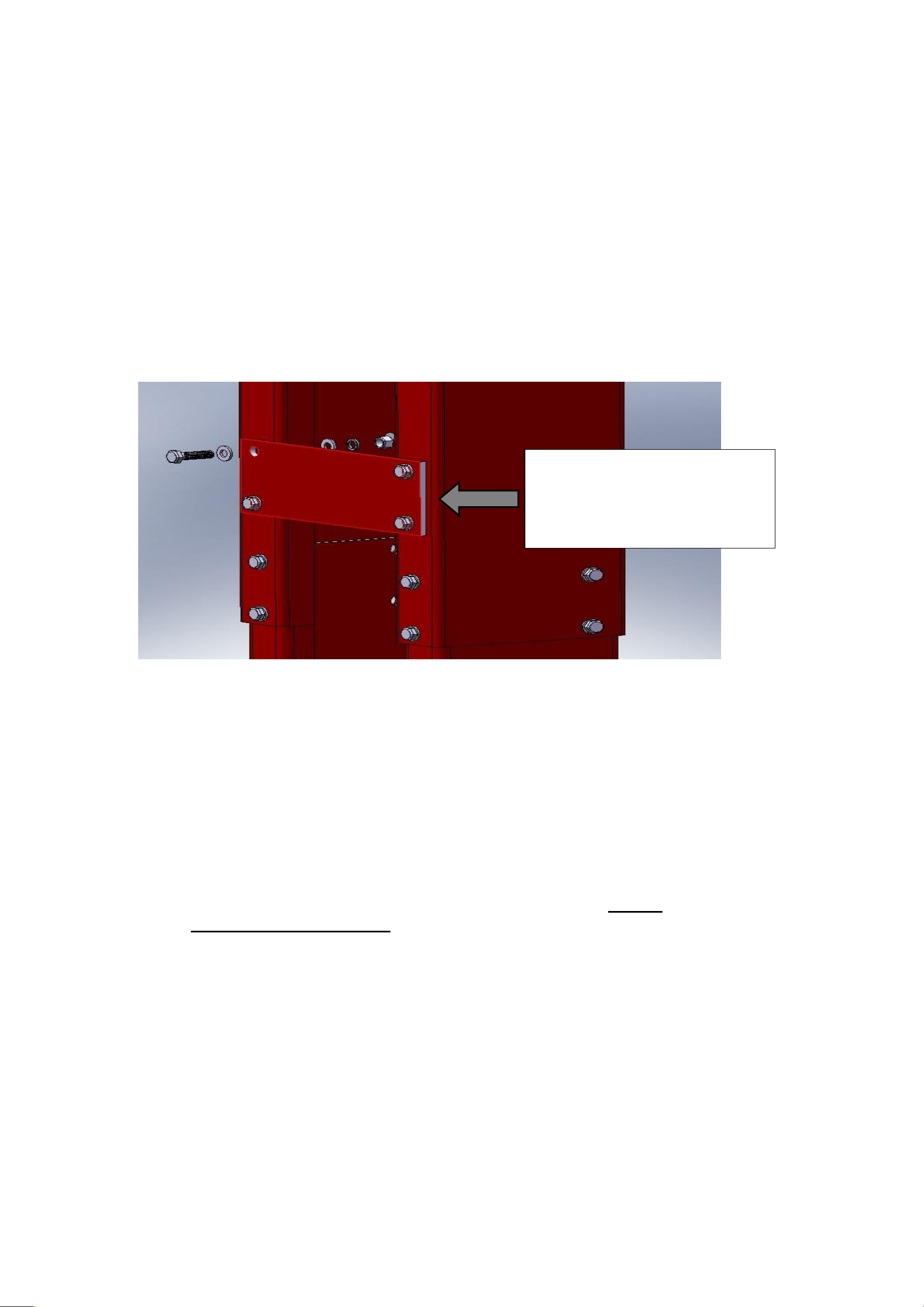

ASYMETRIC OVERHEAD BEAM INSTALLATION

Lift the overhead beam to the level of the column tops and use the provided

fasteners to attach it to the upper columns and the transitional brackets. If you are

installing for an Asymmetric configuration the column mounting bolts must be

aligned as show below. IMPORTANT: HAND TIGHTEN THE BOLTS ONLY AT

THIS TIME

The drawing below outlines where the overhead beam bolt positions are used on

the transitional brackets

Figure

21

Page 22

IMPORTANT: HAND TIGHTEN THE BOLTS ONLY AT THIS TIME

Note:

After the slave side column has been installed proceed back to

proceeding to the next section.

SYMETRIC OVERHEAD BEAM INSTALLATION

Lift the overhead beam to the level of the column tops and use the fasteners to

attach it to the upper columns and the transitional brackets. If you are installing for

a Symmetric configuration the column mounting bolts must be aligned as show

below.

The drawing below outlines where the overhead beam bolt positions are used on

the transitional brackets

Figure 6

When installing the overhead beam, ensure the microswitch support (It is the U-

shaped bracket welded to the bottom of the overhead beam) is adjacent to the

power side column location. This will allow you to route the microswitch cord

through the end of the overhead beam and down the outside of the power unit

column.

Since the idler column is not secured to the floor by the bolts at this stage,

be careful to not move the idle column as it is not anchored to the floor.

SLAVE SIDE COLUMN INSTALLATON

Measure the distance between the top and bottom of each column to insure the

columns are parallel to each other. Finish leveling, anchor bolt drilling, shimming if

needed and the anchor bolt installation of the slave side column at this time as

instructed above for the power unit column..

the overhead beam section and tighten all connection bolts and

nuts of the overhead beam and the transitional brackets before

22

Page 23

Note: The Electrical Shutoff Switch cord will be connected when the power unit is

Power Unit Column

Slave Side Column

Shut

-

Off Switch

Padded Shut

-

Off Bar

INSTALLING THE PADDED SAFETY BAR AND SHUTOFF SWITCH

Install the safety shut-off electrical switch to the bracket on the underside of the overhead

beam adjacent to the power unit column. Use the provided shoulder bolt and cotter pin to

attach to the bracket and then route the electrical cord up into the overhead beam via the

small hole next to the bracket. When this is done the shut-off switch will be in a vertical

position. When the shut-off bar is installed shut off bar will protrude into the open end of the

safety switch as shown in the photo below.

Electrical Safety

After inserting the rounded end of the shut off bar into the electrical switch (as shown

above) connect the flatted end of the padded shut off bar to the underside of the

overhead beam adjacent to the slave side column using the provided should bolt and

nut. See photo below for reference.

installed.

Shoulder Bolt

23

Page 24

Note: For the widest and ta

INSTALLING THE EQUALIZATION CABLES

llest configuration the cables must be connected to the

lowest innermost hole inside the carriage. For either the narrow or shortest

configuration the cables must be connected to the middle hole inside the carriage. For

both the narrow and shortest configuration the cables must be connected to the top

hole inside the carriage and you must use the cable tube extensions (They look like a

1”x6” diameter pipe) so the cable bolts can be tightened.

24

Page 25

25

Page 26

HYDRAULIC HOSE INSTALLATION

Refer to the drawing below for the hydraulic hose location.

Please reference the hydraulic hose instructions preceding the drawing.

Figure 7

26

Page 27

Note: The hydraulic hose that go through the overhead beam must be positioned inside the

Hydraulic Hose Installation continued…

After referring to the drawing above install the hydraulic hoses in this sequence.

Notice: DO NOT USE TYFLON TAPE ON ANY HIGH PRESSURE FITTTINGS. THIS ABOVE

GROUND TWO POST LIFT UTILIZATES ONLY HIGH PRESSURE HYDRAULIC OIL FITTINGS.

TYFLON TAPE IS ONLY DESIGNED FOR LOW PRESSURE WATER PIPE. Use only high

pressure oil sealant compound to the male and female threads. Failure to properly seal the hydraulic

lines and fittings could result in hydraulic leaks and or hydraulic failure. Hydraulic leaks due to

improper installation will not be covered by warranty or any manufacturer liability.

1. Remove the plastic pugs from the base of the hydraulic cylinders and attach the two (2)

flow control valves. (Item #107 above) Use a high pressure oil sealant when installing

these valves to prevent leakage. Be careful to not over tighten these threads.

2. Install the short hydraulic hose (Item # 106 above) to the power side column cylinder

connecting at the flow control valve.

3. Install the “T” fitting to the short hydraulic hose. (Item 105 above)

4. Connect the long hydraulic hose (Item #104 above) to the “T” fitting.

5. Connect the medium length hose (Item #112) to the long hydraulic hose using the hose

connector (Item # 111) midpoint inside of the overhead beam assemble.

6. Connect the medium length hydraulic hose to the flow control valve (Item #107) on the

slave side column.

hose brackets mounted in the base of the overhead beam to protect the hoses from rubbing

on the equalizing cables. Use the provided plastic zip ties to attach the hose to the three (3)

brackets to prevent movement. See photo below for reference.

27

Page 28

Shutoff Switch Electrical Cord

Steel Cable

Single Point Lock Release Cable

Hydraulic Hose

Plastic Tie

SAFETY SHUTOFF SWITCH

It is very important to keep proper clearance between shutoff switch electrical cord

and the steel cable. Use the provided plastic ties to connect the electrical cord and

hose together to avoid any possible damage caused by interference between the

electrical cord and the steel cable.

The electrical cord will route over the outer edge of the overhead beam as shown

above and downward to the power unit junction box.

28

Page 29

Note:

Push Start Button

Lowering Lever

POWER UNIT INSTALLATION

1) Remove the power unit from the shipping box.

2) Remove the red plastic plug on the oil tank.

3) Remove the black breather cap on the lower section of the oil tank.

4) Install the black breather cap into the fill hole at the top of the tank.

5) Install the red plastic plug into the hole at the bottom of the tank.

6) After removing the plastic plug on the side of the power unit valve body

install the 90 degree hydraulic fitting using high pressure sealant compound.

DO NOT USE TEFLON TAPE.

7) Use the provided bolts and washers to secure the power unit to the power

unit mounting bracket.

8) Use 5/16x18 bolts and washers (see fig. 8) to secure the power unit.

Figure 8

After the securing the power unit to the column, remove the black breather cap and

fill the reservoir with approx. 4.5 gallons (18 liters) of ISO-32 hydraulic oil (10

weight hydraulic oil) DO NOT USE TRANSMISSION FLUID or reclaimed hydraulic

oil. Use of transmission fluid or reclaimed hydraulic oil will void the manufacturer’s

warranty.

Use caution to avoid dust and other pollutants mixing with the hydraulic oil

while filling the power unit by using a clean funnel and clean paper strainer.

After the power unit has been mounted, install and connect the one remaining short

hydraulic hose to the 90 degree elbow and connect to the “T” fitting.

For lifts that have an SPX brand power unit, review the wiring diagram that is

attached to the inside cover of the push button junction box.

29

Page 30

certified electrician

CONNECTING THE POWER SUPPLY

1) A

the overhead Shutoff Switch to the electrical supply.

must connect the 230Volt/1Ph power unit and

2) Remove the sealed cover on the electrical junction box on the power

unit and connect the wiring according to the wiring diagram. See

Figure 9

3) A power supply switch is required to be installed near the lift for

rapidly disconnecting the electrical power supply during maintenance

or in case of emergency.

Figure 9

Note: Motor damage due to improper wiring is not warranted. Verify if the oil

tank is full; do not operate if there is no oil. After pressing the up button, if

the power unit does not run or makes unusual noises or has excessive heat

stop the power unit immediately and check of proper electrical connections.

30

Page 31

HYDRAULIC SYSTEM BLEEDING

Crack the bleeder valve located at the top of both cylinders (approx. ¼ turn)

Power up 2”-3”. You should hear air escaping around the bleeder valve.

Repeat 3 – 4 times or until only oil is coming out of the bleeder valve.

Tighten the bleed screw and lower the lift and recheck oil tank level.

31

Page 32

and screws

Hose cover cutout

Unit shown

After bleeding the hydraulic system and checking for leaks, install all of the

metal hose covers. In the parts box you will find small threaded bolts with

the top of the bolt drilled and taped. Install these bolts into the predrill holes

on the side of each column. On the power unit side at the hydraulic “T” fitting

a special hose cover with a cutout to allow for the “T” connectors shall be

used. Cover each section of the hose and then use the marching bolts to

attach the hose covers to the special predrilled bolts. Reference the photo

below that shows the “T” fitting and hose covers.

Hose from the Power

Hose cover studs

32

Page 33

not used on the overhead beam.

SAFETY RELEASE CABLE ROUTING AND ADJUSTMENT

The mechanical safety automatically engages. To release the mechanical safety,

you must first raise the lift approximately 2”, and then pull the safety release lever

down. This disengages the power side safety locks and activates the safety cable to

release the slave side safety lock.

Included in the parts packaging you will find the extra-long steel single point lock

release cable, cable clamps and four (4) metal cable guides and two (2) white nylon

cable guides with two (2) small retaining rings.

Using the provided bolts attach one metal cable guide to the inner edge at the top of

each column. Attach another metal cable guide to the outer inside edge of the

overhead beam. See the photo below for reference.

Single Point Lock Release Cable

Guides mounted to the column

and to the overhead beam. Mount

as shown to both columns. For the

TLT211-AS model a cable guide is

33

Page 34

Next route the steel cable under the nylon cable guide as shown above on the

Attach the two (2) provided white nylon cable guides using the retaining rings onto

the horizontal metal post just above the carriage locking mechanism on the slave

side column. Inspect the metal post for any paint overspray and clean with

sandpaper if necessary. Use a small amount of general purpose grease on the metal

post prior to installing these cable guides. Attach the steel cable to the large metal

post on the slave side column side using the provided cable clamps. See the photo

below for reference.

Slave Side Column

inside of the column and up into the bottom hole of the metal cable guide on the

mounted on top of the column. Continue to route the cable over the top of the metal

roller wheel on the metal cable guide and over the top of the metal cable guide

mounted on the overhead beam and exit on the metal cable guide hole as shown in

the metal cable guide photo above. Complete the routing of the cable across the

overhead beam and down the power unit column repeating the same route used on

the slave side column. Route the steel cable through the white nylon cable guide

ABOVE the carriage release on the power unit side and then connect the cable as

shown below.

34

Page 35

Power Unit Column

Adjust the slack in the single point lock cable at the power unit side so that when the

release lever is pulled down both carriage locks will disengage. Tighten the cable

clamps and install the carriage lock covers on each side with the four (4) provided

screws. (Factory tip: Adjust the cables to release the locks just before the lock

release lever has reached maximum travel…this prevents overstretching the cable).

At this time install the carriage lock covers and install the release lever on the power

unit column.

INSTALLING THE LIFT ARM ASSEMBLES

All four (4) arms come completely assembled. The long 2-piece arms are mounted

to the rear of the lift and the shorter 3-piece arms are mounted to the front of the lift.

Insert the arm assembles in the correct gaps in the carriage. Align the holes in the

carriage with the holes in the carriage and insert the metal arm pivot pins. Repeat

for all arms. When the arms pivot pins have been installed use the provided metal

retaining rings and attach them to the grooves in the bottom edge of the arm pivot

pins to prevent these pivot pins from moving upward. See photo below for

reference.

35

Page 36

FOOTPAD EXTENSION STORAGE

Attach the two (2) footpad extension storage brackets one to each column using the

two (2) metal screws. Store the footpad extensions as show in the photo below.

At this time operate the lift up and down 2-3 times and re-adjust the

equalization cables if needed so the carriage locks engage equally.

36

Page 37

"Lifting it Right"

"Safety Tips"

NOTE:

Lift Point

Guide

FINAL CHECK OF ASSEMBLED LIFT

1. Final dimension check after anchoring

2. Check for hydraulic leaks.

3. Ensure cables are properly routed and free from

obstructions.

4. Check jam nuts on cables are tightened.

5. Check for oil leaks.

6. Check adjustment of safety release cable to ensure both

sides are working properly.

7. Re-check level of towers.

8. Check torque of anchor bolts.

9. Check all fasteners, tighten if necessary.

10. Check shut off at top of stroke to ensure lift shuts off.

11. Check proper operation of arm restraints.

12. Operate lift to full stroke then lower to ground while checking

for proper functionality.

13. Check proper operation of arm restraints.

14. Ensure all documents listed below are given to the owner.

15. Operation Manual

16. ANSI / ALI Lift It Right Manual

17. ANSI / ALI Safety Tip Card

18. ANSI / ALI ALIS Safety Requirements for Installation

19. ANSI / ALI Quick Reference Guide

20. Train end user on operation of lift.

OPERATING INSTRUCTIONS

Read and understand all safety and operation labels on the lift. Refer to the

manual and

important instructions and information.

card supplied to you for additional

Some vehicles may have the manufacturer's Service Garage Lift Point

locations identified by triangle shape marks on its undercarriage (reference SAE

J2184). Also, there may be a label located on the right front door lock face

showing specific vehicle lift points. If the specific vehicle lift points are not

identified, refer to the "Typical Lift Points" figure below or the ANSI/ALI

included with your lift.

37

Page 38

1. Position arms to drive-thru position.

2. Refer to supplied literature prior to loading vehicle. Center the vehicle

between the lift posts.

3. Only lift the vehicle on the manufacturers recommended lift points. Refer

to supplied lift points guide (reference ANSI/SAE J2184-1992).

4. Locate lift pads on auto manufacturer's recommended lift points. Once

you have correctly positioned the lift arms, ensure that all arm restraints

are properly engaged.

5. Raise the vehicle by pushing the "UP" button on the power pack until

the vehicle's suspension has left the ground.

6. Inspect to make sure there is no interference with any objects and for

proper engagement of the lifting pads.

7. Shake vehicle moderately by pushing on either the front or rear bumper.

Visually inspect the lifting pads again. If the vehicle starts slipping on the

lifting pads, or otherwise appears unstable on the lift, you have positioned

the swing arms and adapters incorrectly. Carefully lower the lift and start

over.

8. When satisfied, continue lift the vehicle to the desired working height,

lower onto the mechanical safety using the lowering lever.

9. Once vehicle is ready to be removed, raise lift so that the mechanical

safety can be released. Pull down and hold the mechanical safety release

lever, then press the hydraulic lowering lever until the lift has fully

collapsed to the grounds and the arm restraints are disengaged.

10. Swing the lift arms to the drive-thru position prior to moving the vehicle.

38

Page 39

OPERATION TEST WITH VEHICLE

Prior to starting this section, please refer to Section 2 of this manual for important

safety instructions.

1. Lower lift to ground.

2. Drive vehicle on to lift and locate the arms as per the “Lift it Right” manual.

3. Raise lift to and lower onto 3-4 lock positions during full rise to ensure all

locks are working correctly.

4. Re-adjust cables if necessary while vehicle is on.

5. Check lowering speed and smooth decent rate.

6. Lower lift to ground and drive vehicle off lift.

If any problems occur during the final checkout or operation of the lift please

contact your lift distributor, sales representative or the manufacturer.

39

Page 40

Refer to

MAINTENANCE GUIDELINES

SAFETY INSTRUCTIONS

Section 2 for more Safety Instructions.

Read operating and safety manuals before using any lift.

Do not operate a lift that has been damaged or is in disrepair.

Proper inspection and maintenance is necessary for safe operation.

PERIODIC MAINTENANCE

DAILY:

1. Check all hydraulic lines and fittings for pinch points , damage , cracks or leaks

2. Check all electrical wiring for pinch points , cracks or damage

3. Check all moving parts for uneven or excessive wear

4. Repair or replace all damaged, defective, worn or broken components immediately.

5. Check the telescopic arms for movement. Clean any grease or oil from the lifting

adapters.

6. Raise and lower the lift at the beginning of each shift, without a vehicle on, to verify the lift

is leveled and operating properly.

EVERY TWO MONTHS:

1. Clean and re-grease slide block channels inside of both columns

2. Grease arm pins

3. Lubricate safety dogs and check safety release cable adjustment

4. Check arm restraints and lubricate

5. Check anchor bolts and re-torque if required

EVERY FOUR MONTHS:

1. Dismantle and clean inner arms

2. Lubricate cable pulleys

3. Check equalizing cable adjustment

EVERY YEAR:

1. Inspect lift as per Automotive Lift Operation, Inspection and Maintenance (ALOIM)

EVERY TWO YEARS:

1. Change hydraulic fluid

LUBRICATION:

Where grease is required > multi-purpose lithium grease

Where lubricating oil is required > multi-purpose SAE 30 lubricating oil

Where hydraulic oil is required > ISO 32 10W - non detergent hydraulic oil

NOTE: If the lift locks, while in the fully raised position this will indicate

that the hydraulic system has not been inspected or maintained as

recommended. This is a safety back-up system. If you are unclear

call your local representative immediately.

40

Page 41

Broken wires

Excessive wear of wires

Rust on sheave stack and ropes

WIRE ROPES

Wire ropes are critical to safe and reliable performance of your lift.

Cables are expendable items and should be replaced as a set.

WIRE ROPE CONDITION GUIDE

Typical good

cable

Cable with

necking

(Pictures above are of a 4-Post Lift, conditions still apply to 2-Post Lifts)

Corrugated sheave groove

41

Page 42

9.2, Fig.75

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

WIRE ROPE REPLACEMENT CRITERIA:

If any cable is found to be in need of replacement, the entire

cable set, pulleys and safety rollers must be replaced

immediately.

See cable conditions guide.

In the following table, "lay" means the distance

measured along a line parallel to the axis of the

rope in which the strand makes one complete turn

about the axis of the rope, or the wires make a

complete turn about the axis of the strand.

The wire rope must be removed from service if one or more of the following criteria

are met:

More than six randomly distributed broken wires in one rope lay or 6d length.

More than three broken wires in one strand in one rope lay or 6d length.

Three or more broken wires at rope terminations.

One outer wire broken at the point of contact with the core of the rope which has

worked its way out of the rope structure and protrudes or loops out from the rope

structure

Heavy rusting, corrosion, or pitting. A light surface corrosion on outer wires is normal.

Wear or scraping of one-third of the original diameter of outside individual wires

Excessive stretch. It is normal for new cable to require adjustment during “break-in”,

after which small periodic adjustments may be required. However, if a cable that has

been in service for 6 months should suddenly require frequent adjustments or has

used all the cable adjustment available, all cables must be replaced immediately.

Deformed strands, kinking, crushing, bird-caging, or any other damage or distortion

of wire rope structure

Variations in diameter (necking) or any change from normal appearance

Reductions from nominal diameter of more than 1/32" (for cables 3/8" to 1/2" dia.

inclusive)

End attachments cracked, deformed or worn

WIRE ROPE INSPECTION

Inspect wire rope cables for wear or damage. Wipe cables with a rag to detect

hard to see small broken or frayed cable strands. See chapter

ANSI/ALI ALOIM standard.

and

42

Page 43

WIRE ROPE LUBRICATION

Lubricate wire ropes with lift in both lowered and raised position, by spraying

them with wire rope lubricant (i.e. 2001 MONOLEC®) and wiping the cable down.

WIRE ROPE ADJUSTMENT

Adjust cables if lifting is uneven or lift is not level (See chapter 7.15.3). Never

make adjustments with weight on lift. If running out of adjustment threads, cables

need to be replaced. Do not add washers or other spacers to re-use previously

used adjustment threads.

Wire rope tension adjustment should be performed when installing the lift and

every three months.

43

Page 44

MAINTENANCE SCHEDULE

Maintenance

and Training

Performed

Date

By

Notes

44

Page 45

TROUBLESHOOTING GUIDE

PROBLEM REASON SOLUTION

Power Unit (Motor) not

running.

Power Unit (Motor) runs but

lift does not go up.

Bad Fuse or Circuit breaker. Replace bad fuse or reset circuit

Incorrect voltage to motor. Provide proper voltage to motor.

Improper wiring. Have certified electrician check

Power Unit up switch not

functioning.

Overhead Microswitch not

functioning.

Power Unit motor burned out. Replace motor.

Low oil level. Fill reservoir with proper

Lowering valve remains open. Repair or replace oil valve.

breaker.

wiring.

Replace Power Unit up switch.

Replace overhead Microswitch.

hydraulic oil.

Pump sucking air. Tighten all fittings and suction

lines.

Lift goes up slowly or oil

coming out from filler cap.

Lift doesn’t come down. Dirt in directional valve Call installer to clean valve. (Do

Safety Locks do not engage. Safety lock jammed. Oil or replace pin to free Safety

Safety Lock does

not disengage.

Lift goes up unlevel. Equalizing cables are loose. Adjust equalizing cables to

Lift goes up with chatter or

Air in hydraulic fluid lines Bleed hydraulic lines (Call

installer).

not attempt to open hydraulic

lines unless vehicle is secure)

Lock.

Check or replace spring.

Safety lock is being limited Check for any obstructions.

correct tension.

Floor unlevel. Shim lift to make towers level.

(Do not exceed ½” of shimming).

Low oil level. Fill reservoir to correct level with

does not fully rise.

Air in hydraulic fluid

lines/cylinder.

Anchor bolts do not stay tight. Holes are too large. Relocate lift using proper size

Incorrect concrete floor

specification (Thickness and

holding strength).

Noticeable Deflection of Arm

or arm dragging on floor.

Lift out of plumb. Plumb columns.

Unlevel floor. Replace floor of shim columns.

Worn arm or carriage holes. Replace parts.

Worn carriage slide blocks. Replace side blocks.

Bent arm (Overloaded). Replace arm. Also check

proper hydraulic oil.

Bleed hydraulic lines. (Call

installer).

drill bit.

Break existing floor and pour

new pad for lift.

damage to carriage.

45

Page 46

Accessible

Conveniently located to facilitate the application of lockout devices

Located outside any hazardous area.

At a convenient manipulating height (i.e. not overhead, on ladders or

Capable of being locked or otherwise secured in an effective

LOCK OUT AND TAG OUT INSTRUCTIONS

IMPORTANT: This machine does not have integral devices that will isolate

the electrical, pneumatic, stored and hydraulic energy source. Appropriate

isolation or blocking devices must be used that have the provisions to be

switched in the off position and locked in that position.

ALL MAINTANANCE AND SERVICE MUST BE PERFORMED BY A

QUALIFIED PERSON.

ALL MAINTANANCE AND SERVICE MUST BE PERFORMED WITH THE LIFT

UNLOADED.

IT IS THE SHOP OWNERS RESPONSIBILITY TO ENSURE ENERGY

ISOLATING DEVICES ARE:

during service and maintenance

under machinery)

Adequately labeled or marked. Identification shall include machine

ID, energy type and magnitude.

isolating position.

Effective hazardous energy control procedures will protect employees during

machine and equipment servicing and maintenance where the unexpected

energization, start up or release of stored energy could occur and cause injury,

as well as while working on or near exposed de-energized electrical conductors

and parts of electrical equipment. Hazards being guard against include being

caught in, being crushed by, being struck by, being thrown from, or contacting

live electrical circuits/parts.

In preparation for lockout, an initial survey must be made to locate and identify all

energy isolating devices to be certain which switch, valve, or other energy

isolating devices apply to the machine / equipment to be locked out. More than

one energy source (electrical, hydraulic, pneumatic, or others) may be involved.

SHUT DOWN PROCEDURE

Notify all affected employees that a lockout or tagout system is going to be

utilized and the reason for. The authorized employee shall know the type

46

Page 47

ELECTRICAL:

and magnitude of energy that the lift utilizes and shall understand the

associated hazards.

button to disconnect the raise and lower functions.

Located at the user control panel, press the “E-STOP”

ELECTRICAL ENERGY IS STILL PRESENT AT THE LIFTS

ELECTRICAL PANEL WHEN THE EMERGENCY STOP

BUTTON IS PRESSED. ELECTRICAL ENERGY MUST BE

TURNED OFF AND ISOLATED AT THE DISCONNECT

PANEL PRIOR TO PERFORMING SERVICE OR

MAINTANANCE ON THE LIFT.

ISOLATION AND VERIFICAITON PROCEDURES:

Table 1: ISOLATION AND VERIFICATION PROCEDURES:

ENERGY TYPE

AND SOURCE

STORED

ENERGY

AND

HYDRAULIC

PRESSURE

3000-5000

PSI

LOCKOUT

LOCATION

(TO BE

COMPLETED

BY END

USER)

PROCEDURE FOR LOCING OUT

AND OR RELEASING ENERGIES

LOWER THE LIFT TO ITS

LOWEST REST POSTION. IF THE

LIFT MUST BE SERVICED OR

MAINTAINED IN THE RAISED

POSITION, ENSURE THAT THE

LIFT IS PLACED ON THE

MECHANICAL LOCKS.

FOR SCISSOR LIFTS,

ADDITIONAL SUPPORT WITH

SUPPLEMENTARY JACK

STANDS, BLOCK AT THE

SLIDERS AND A COME ALONG

SECURED BETWEEN THE

SCISSORS.

FOR 4-POST LIFTS, ADDITIONAL

SUPPORT WITH

SUPPLEMENTARY JACK

STANDS.

VERIFY PROCEDURES

VERIFY THAT THE LIFT IS (IF

APPLICABLE):

CONTACTING THE

MECHANICAL LOCKS,

RESTING ON THE

SUPPLEMENTARY JACK

STANDS,

BLOCKS ARE SECURLY PLACED

COME ALONG IS SECURED

BETWEEN THE SCISSORS.

47

Page 48

ELECTRICAL

240VOLTS

PNEUMATIC

UPTO

160PSI

AT THE LIFT, PRESS THE

EMERGENCY STOP BUTTON

COMPLETELY TO DE-ENERGIZE

THE CONTROL BUTTONS (IF

APPLICABLE).

AT THE DISCONNECT PLANEL,

PLACE THE DISCONNECT

HANDLE IN OFF POSITION.

ATTACH A MULTIPLE LOCUOUT

ATEMPT TO RESTART THE

SYSTEM, THE SYSTEM MUST

NOT START. VISUALLY VERIFY

OPEN DISCONNECTS AND

LOCKING DEVICE INSTALLED.

DEVICE. LOCK AND TAG.

DANGER: LINE SIDE OF

DISCONNECT REMAINS

ENERGIZED

SLOWLY CLOSE LOCKOUT

VALVE TO RELEASE AIR

PRESSURE GRADUALLY.

ATTACH MULTIPLE LOCKOUT

DEVICE, LOCK AND TAG.

DANGER: LINE SIDE OF

DISCONNECT REMAINS

PRESSURIZED

VERIFY THE VALVE IS CLOSED

AND LOCKOUT DEVICE IS

PROPERLY ATTACHED.

OPERATE THE PNEUMATIC

SYSTEM TO ENSURE THE

SYSTEM IS DE-ENERGIZED. IT

MAY BE NECESSARY TO BLEED

THE SYSTEM OF REMAINING

COMPRESSED AIR, THIS CAN

BE PERFORMED AT THE BASE

OF THE WATER SEPARATOR

BOWL.

RETURNING TO SERVICE:

Check the lift and the immediate area around the lift to ensure that

nonessential items,, tools and parts are removed and that the lift

components are operationally intact.

Check the work area to ensure that all employees have been safely

positioned or removed from the work area.

Notify all employees that the lockout/tagout is going to be removed and

the lift is going to restarted.

Remove the lockout/tagouts in the reverse order as the installation.

Verify the proper operation of the equipment.

Notify affected employees that the maintenance/service is completed and

the machine is ready for operation.

48

Page 49

EMERGENCY OPERATION:

If the lift becomes inoperative in the raised position, it is best to wait until the

electrical power is restored before lowering the vehicle. However, if it’s critical to

safety that the lift be lowered, the following steps should be taken.

WARNING: DO NOT LOOSEN OR REMOVE HYDRAULIC

CONNECTIONS OR FITTINGS UNDER PRESSURE. SERIOUS

INJURY OR DEATH COULD OCCUR.

NOTE: Safely performing this process requires 3 people. All personnel

should stay clear of the path of the lift. All tools and other non-secured

items should be removed from the surface of the runways.

1) Survey the area surrounding the lift; remove any items and personnel from

area before proceeding with this procedure.

2) Perform the appropriate lockout/tag out procedure on the electrical

energy.

3) Use a second person standing at a safe distance away from the lift to

keep watch on the area, lift, vehicle and other personnel throughout the

process. This person should signal the person performing the procedure

to stop if necessary.

4) Use a caution tape or similar to barrier the area around the lift to avoid

personnel from accidently entering the area while this process is being

performed.

5) Do not proceed with this procedure if you are unfamiliar with the lift or its

function.

IF THE MECHANICAL LOCKS ARE NOT ENGAGED:

1) Pull safety release lever simultaneously pressing the descent lever on the

power pack.

2) Keep a close eye on the movement of the lift and the position of the

vehicle; release descent lever if any abnormal movement is detected.

3) Continue until the lift is fully lowered.

4) Once power is restored follow the lockout/tag out procedure to return the

lift back into service.

IF THE MECHANICAL LOCKS ARE ENGAGED:

Various methods can be used to raise the lift in order to get sufficient clearance

to disengage the mechanical locks. The safest method would employ temporary

electrical power to the lift using a portable power generator. Any electrical

connections should be done by a licensed electrician; lockout/tag out procedures

should also be employed at this time.

This process should only be performed by a trained professional. Contact

customer service or a local service professional for further assistance.

49

Page 50

PARTS VIEW AND IDENTIFICATION

Part numbers with an “A” is for the TLT211-AS Model

50

Page 51

107A

Part numbers with an “A” are for the TLT211-AS Model

51

Page 52

201

201A

Parts numbers with an “A” are for the TLT211-AS model

226

209

227

208

228

223A

230

223

231

234

229

233

210

235

205

206

207

204

202

215

217

232

225

225A

224

224A

214

211

221

220

216

218

212

213

219

219A

222

222A

52

Page 53

53

Page 54

No. Part Number Part Number Updated

201024604

1

201624622

201624620

201014670

3

201024624

4

6

201024608

103010432

201024604

201024785

201024622

201024620

201014670

201024624

201024608

103010432

Column for TLT210-AS Power Unit Side

Column for TLT210-AS Idler

Column for TLT211-AS Idler

Column for TLT211-AS Power Unit Side

Column extension

Column extension for TLT211- AS

Power unit bracket

screw M5×12

7 103040132 103040132 Flat washer

8 201013268 103203019 Lateral positioning plate

9 103020188 103020188 Bolt M5×10

10 201011739 201011739

Connection bracketⅠ

Part Description

11 103020164 103020164 Bolt M12×35

12 103040044 103040044 Spring washer

13 103040110 103040110 Flat washer

14 103030129 103030129 Nut M12

15 103040123 103040123 Flat washer 10

16 103040122 103040122 Spring sealer, GB/T93-1987 11

17 103020207 103020207 Bolt M10×20

18 201011740 201011740

Connection bracketⅡ

19 201011154 201011154 Reinforcement plate

20 103020100 103020100 Bolt M8×25

21 103040134 103040134 Flat washer 8

22 103040141 103040141 Spring washer, 8

23 103020171 103020171 Bolt M6×12

24 201024606 201024606 Cable guide block

25 103020163 103020163 Bolt M6×25

201021179 201021179 Outer overhead beam bracket

26

201624629 201024629 Overhead Beam for the TLT211-AS

27 201020809 201020809 Inner overhead beam bracket

28 201011257 201011257 Sheave Spacer, Power Side, 8mm

29 103200699 103200699 Bush, SF-2 2520

30 201013282 103203017 Sheave

31 103050035 103050035 Elastic ring, 25,GB/T894.1- 1987

32 103200966 103200966 Asymmetric shaft

33 201011258 201011258 Spacer I

34 103200967 103200967 Symmetric shaft

35 103020126 103020126 Bolt M12×25

54

Page 55

201014671

36

201014680

37

104130196

38

39 201014672

40 201014673

41 103030018

201014671

201014680

104130196

102100206

Shutoff bar

Shutoff Bar for the TLT211-AS

Sleeve(inner hole Ф22), L=1.8M

Limit switch TS-10 Limit switchSP-1403-14

201014672 Switch bracket

103202751 Switch shaft

103030018 Nut M5

42 103060342 103060342 Cotter pin 3×26, GB91-87

43 201011477 201011477 Shutoff shaft

44 103260260 103260341 Cable assembly

103260341 103260341 Use this # after August 2013

45 103020117 103020117 Anchor bolt M19×140

46 201014674 201025080 Column long hood at three-way fitting

201025177 TLT210-AS Idler column bottom hood

47 201014675 201025081 Column long hood

48 201014676 201025082 Column short hood

49 201014685 103202748 Shaft for Hose hood

101

102

M-4509-0200

AC-10AH RV21

104120132 104120132 Power unit hose L=880

Bucher Power Unit

SPX Power Unit

104120159 TLT211-AS hose

103

104

105

106

103202113 103202113 Adjustable right angle fitting

104120134 104120134 Overhead beam hose, L=5370

103100294 103100294 Three-way fitting

104120133 104120133 Hose, L=930

103100322 103100322 Flow control fitting assembly

Use # this after August 2013

103100327 103100327

Flow control fitting assembly

107

103100323 103100323 Flow control fitting for the TLT211-AS

Use this # after August 2013

10300328 103100328

Flow control fitting for the TLT211-AS

109

111

112

103202112 103202112 Cylinder

103100295 103100295 Straight fitting

104120135 104120135 Idler column hose L=4250

104120160 TLT211-AS Idler column hose L=4130

TLT211-AS high setting hose,

104120161

TLT211-AS-50-03- A, L=270

201

201024611 201024611 Carriage

201021093 TLT211-AS Carriage

202

104990132 104990132 Slide block, strengthen nylon

55

Page 56

202

204

104990132

104990135

104990134

201011855

104990132

104990135

104990134

201025138

Slide block, strengthen nylon

TLT211-AS slide block Ⅰ

TLT211-AS slide block Ⅱ

Top board

201025139 TLT211-AS Top board

205

206

207

208

103010473 103010473 Screw M10×30

103040122 103040122 Spring sealer, GB/T93-1987 11

103040123 103040123 Ring GB/T95-1985 11

104130191 104130192 TLT series Anti Shock Pad

104130372 N/A

209

210

211

212

103010539 103010539 Screw M8×12

103202184 103202184 Restraint shaft assembly

103060376 103060376 Pin 5×32

103060355 103060355 Cotter pin, 3.2×30

213

214

215

103201914 103201914 Spring

103201744 103201744 Small gear block

201010982 103202280 Pin shaft

103202778 TLT211-AS Pin shaft

216

217

218

219

103010443 103011102 Bolt M10×25

103201771 103201771 Big gear block

103050030 103050030 Retaining ring 40

201021763 201021763 Long female arm

201624631 201024631 Long female arm for TLT211- AS

220

221

222

104130186 104130186 Arm rubber pad

103010608 103010608 Bolt M6×10

201021532 201021532 Long male arm

201024632 201024632 Long male arm for the TLT211- AS

223

201024616 201024616 Front female arm

201624634 201024634 Front female arm for the TLLT211-AS

224

201024645 201024645 Front middle arm

201024632 201024635 Front middle arm for the TLT211-AS

225

201024646 201024646 Front male arm

201024636 201024636 Front male arm for the TLT211-AS

226

227

228

229

230

104130315 104130315 Rubber pad

201021561 201021561 Threaded rod assembly

103202107 103202107 Dual-threaded adjustment sleeve

103202106 103202106 Support bracket

103050091 103050091 Retaining ring, 30

56

Page 57

231

232

233

234

103050090

201014690

201014691

201011475

103050090

103203210

103203209

201011475

Retaining ring, 45

Long extension tube(optional)

Short extension tube(optional)

Positioning plate

103010586 103010586 Bolt M8×12-12.9

Asymmetric adjustable bushing for asymmetric

235

201011741 103203213

installation

201011742 201011742 Adjustable bushing for narrow style installation

401

402

403

404

405

104090074 104090074 Lock release mechanism hood

201012086 103203057 Lock release plate

201020584 103203056 Cam (Power side)

103201450 103201450 Torsion springⅠ

103201451 103201451

Torsion springⅡ

406

407

408

409

412

413

414

415

416

417

418

419

420

103201455 103201455 Lock release plate shaft

202010074 103203055 Lock Release roller

103201454 103201454 Lock release latch

103260186 103260186 Latch cover BM10×50(black)

201011156 103203061 Adjustment washer I

104130210 104130210 Small rubber pad

103050021 103050021 Retaining ring 9

103060333 103060333 Pin, 6×40

103260179 103260179 Cable Clamp 3

Cable, F1.4, L=8901

101060019 101060019

Cable, Ф1.6mm, L=8300mm

103201478 103201478 Cable clamp f2

103050025 103050025 Retaining ring 20

103010393 103010393 Screw,M8×12

421

422

103040134 103040134 Washer C, 8

104090073 104090073 Idler lock release mechanism hood

Revised March 2014 Installation Instructions

57

Loading...

Loading...