Launch CReader 6011, CReader 7001, CReader 7001F, CReader 8011, CReader 8001 User Manual

...Page 1

V1.00.001

2017-09-22

Note: This user manual applies to the following CReader models: CReader 6011,

CReader 7001, CReader 7001F, CReader 8001, CReader 8011, CReader 8021 and

CReader 9081. All illustrations and descriptions herein are only for reference. We

reserve the right to make changes due to software update without prior written

notice.

Page 2

LAUNCH

CReader Series English User’s Manual

I

Trademark Information

LAUNCH is a registered trademark of LAUNCH TECH CO., LTD. (LAUNCH) in

China and other countries. All other LAUNCH trademarks, service marks, domain

names, logos and company names referred to in this manual are either

trademarks, registered trademarks, service marks, domain names, logos and

company names of or are otherwise the property of LAUNCH or its affiliates. In

countries where any of the LAUNCH trademarks, service marks, domain names,

logos and company names are not registered, LAUNCH claims other rights

associated with unregistered trademarks, service marks, domain names, logos

and company names. Other products or company names referred to in this

manual may be trademarks of their respective owners. You may not use any

trademark, service mark, domain name, logo, or company name of LAUNCH or

any third party without permission from the owner of the applicable trademark,

service mark, domain name, logo, or company name. You may contact LAUNCH

at www.cnlaunch.com, or write to LAUNCH TECH. CO., LTD., Launch Industrial

Park, North of Wuhe Rd., Banxuegang, Longgang, Shenzhen, Guangdong, P.R.

China, to request written permission to use Materials on this manual for purposes

or for all other questions relating to this manual.

Copyright Information

Copyright © 2017 by LAUNCH TECH. CO., LTD. All rights reserved. No part of

this publication may be reproduced, stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical, photocopying and recording or

otherwise, without the prior written permission of LAUNCH. The information

contained herein is designed only for the use of this unit. LAUNCH is not

responsible for any use of this information as applied to other units.

General Notice

Other product names used herein are for identification purposes only and may

be trademarks of their respective owners. LAUNCH disclaims any and all

rights in those marks.

There is a possibility that this unit is inapplicable to some of the vehicle models

or systems listed in the diagnosis section due to different countries, areas,

and/or years. Do not hesitate to contact LAUNCH if you come across such

questions. We are to help you solve the problem as soon as possible.

Page 3

LAUNCH

CReader Series English User’s Manual

II

Disclaimer

To take full advantage of the unit, you should be familiar with the engine.

All information, illustrations, and specifications contained in this manual are

based on the latest information available at the time of publication. The right is

reserved to make change at any time without notice.

Neither LAUNCH nor its affiliates shall be liable to the purchaser of this unit or

third parties for damages, losses, costs or expenses incurred by purchaser or

third parties as a result of: accident, misuse, or abuse of this unit, or

unauthorized modifications, repairs, or alterations to this unit, or failure to

strictly comply with LAUNCH operating and maintenance instructions.

LAUNCH shall not be liable for any damages or problems arising from the use

of any options or any consumable products other than those designated as

Original LAUNCH Products or LAUNCH Approved Products by LAUNCH.

Safety Precautions and Warnings

To prevent personal injury or damage to vehicles and/or the tool, please read this

user’s manual first carefully and observe the following safety precautions at a

minimum whenever working on a vehicle:

Always perform automotive testing in a safe environment.

Do not attempt to operate or observe the tool while driving a vehicle. Operating

or observing the tool will cause driver distraction and could cause a fatal

accident.

Wear safety eye protection that meets ANSI standards.

Keep clothing, hair, hands, tools, test equipment, etc. away from all moving or

hot engine parts.

Operate the vehicle in a well-ventilated work area: Exhaust gases are

poisonous.

Put blocks in front of the drive wheels and never leave the vehicle unattended

while running tests.

Use extreme caution when working around the ignition coil, distributor cap,

ignition wires and spark plugs. These components create hazardous voltages

when the engine is running.

Put the transmission in P (for A/T) or N (for M/T) and make sure the parking

brake is engaged.

Keep a fire extinguisher suitable for gasoline/chemical/electrical fires nearby.

Don’t connect or disconnect any test equipment while the ignition is on or the

Page 4

LAUNCH

CReader Series English User’s Manual

III

engine is running.

Keep the tool dry, clean, free from oil/water or grease. Use a mild detergent on

a clean cloth to clean the outside of the tool, when necessary.

Page 5

LAUNCH

CReader Series English User’s Manual

IV

Table of Contents

1. Introduction ...................................................................................................... 1

2. General Information ......................................................................................... 2

2.1 On-Board Diagnostics (OBD) II .................................................................. 2

2.2 Diagnostic Trouble Codes (DTCs) ............................................................. 2

2.3 Location of the Data Link Connector (DLC) ............................................... 3

2.4 OBD II Readiness Monitors ....................................................................... 4

2.5 OBD II Monitor Readiness Status .............................................................. 5

2.6 OBD II Definitions ...................................................................................... 6

3. Product Descriptions ........................................................................................ 8

3.1 Outline of CReader 6011/7001/7001F/8001/8011/8021/9081 .................... 8

3.2 Specifications............................................................................................. 9

3.3 Accessories ............................................................................................... 9

4. Connection & Settings.................................................................................... 10

4.1 Connection .............................................................................................. 10

4.2 Settings ................................................................................................... 10

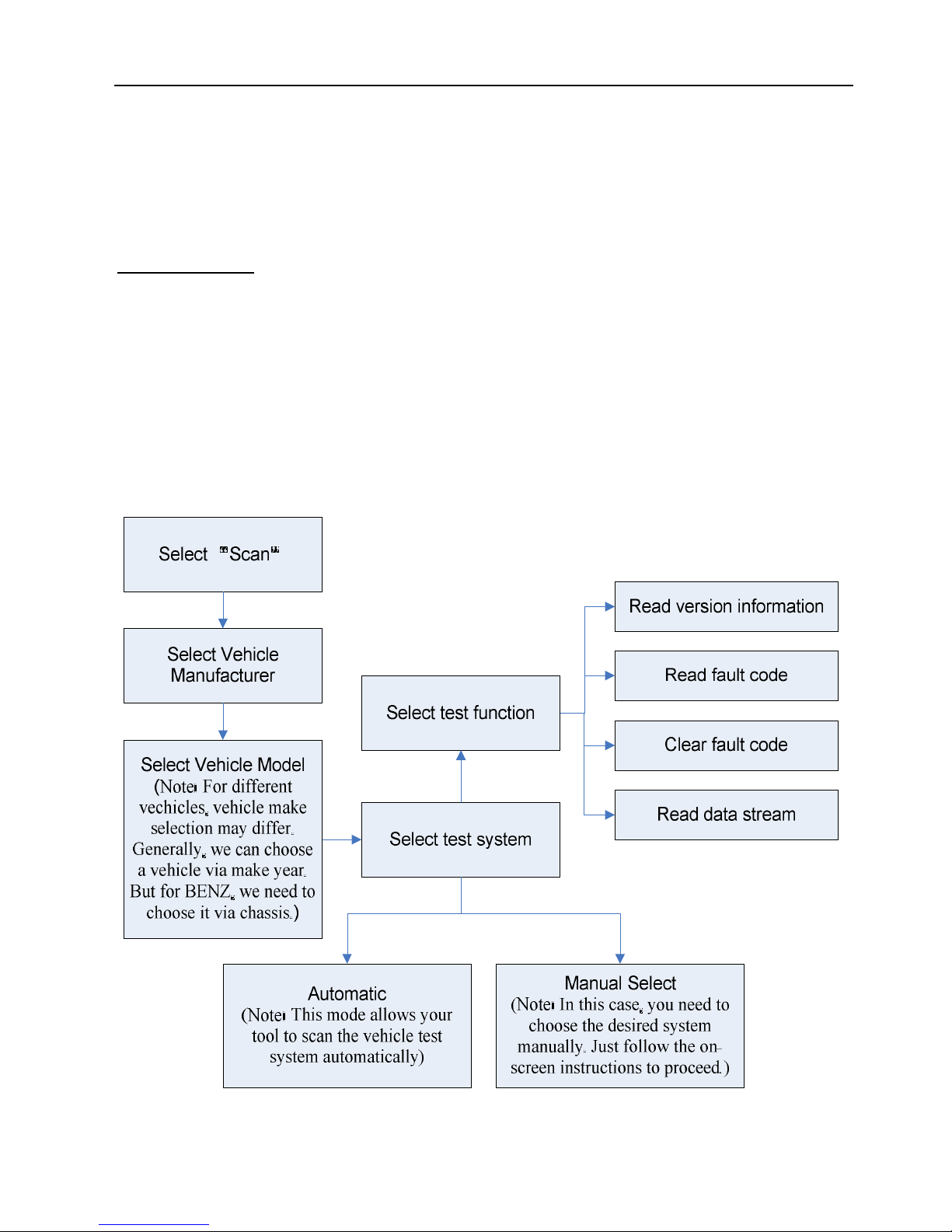

5. Diagnose ........................................................................................................ 12

5.1 OBDII/EOBD Diagnosing ......................................................................... 13

5.2 System Diagnosing (Only for CReader 6011/8001/8011/8021) ................ 16

5.2.1 Read Vehicle Information ................................................................ 17

5.2.2 Read Fault Code ............................................................................. 17

5.2.3 Clear Fault Code ............................................................................. 17

5.2.4 Read Data Stream .......................................................................... 17

5.3 Resetting (Only applies to CReader 7001/7011F/8001/8011/8021/9081) 17

5.3.1 Oil Reset Service (Only applies to CReader 7001/7011F/8001/8011/

8021/9081) .............................................................................................. 19

5.3.2 Electronic Parking Brake Reset (Only applies to CReader 7011F/

8001/8011/8021/9081) ............................................................................. 19

5.3.3 Steering Angle Sensor (Only applies to CReader 7011F/8021/9081)

................................................................................................................ 19

5.3.4 Battery Maintenance System Reset (Only applies to CReader 7011F/

8011/8021/ 9081) ..................................................................................... 19

Page 6

LAUNCH

CReader Series English User’s Manual

V

5.3.5 Diesel Particulate Filter (DPF) Regeneration (Only applies to

CReader 7011F/9081) ............................................................................. 20

5.3.6 Tire Pressure Monitor System Reset (Only applies to CReader 9081)

................................................................................................................ 20

5.3.7 ABS Bleeding (Only applies to CReader 7011F/9081) .................... 21

5.3.8 Gear Learning (Only applies to CReader 9081) .............................. 21

5.3.9 IMMO Service (Only applies to CReader 9081) .............................. 21

5.3.10 Injector Coding (Only applies to CReader 9081) ........................... 22

5.3.11 Electronic Throttle Position Reset (Only applies to CReader 9081)

................................................................................................................ 22

5.4 Review ..................................................................................................... 22

6. Help ............................................................................................................... 23

7. Register & Update .......................................................................................... 26

8. FAQ ............................................................................................................... 34

Page 7

LAUNCH

CReader Series English User’s Manual

1

1. Introduction

Featuring a 4.0” color LCD and similar appearance, each of CReader

6011/7001/7001F/8001/8011/8021/9081 supports all 10 modes of OBD II test for

a complete diagnosis.

CReader 6011

In addition to the full OBDII/EOBD diagnostic functions, CReader 6011 also

supports the diagnosis of the electronic control systems of vehicle, such as ABS

and SRS.

CReader 7001/7001F

In addition to the full OBDII/EOBD diagnostic functions, CReader 7001/7001F

also provides the oil lamp reset function. Moreover, CReader 7001F also supports

Engine Oil Lamp reset, EPB (Electronic Park Brake) reset, SAS (Steering Angle

Sensor) reset, BMS (Battery Management System) reset, DPF (Diesel Particulate

Filter) regeneration and ABS Bleeding.

CReader 8001/8011/8021

In addition to the full OBDII/EOBD diagnostic functions, CReader 8001/8011/8021

also supports the system diagnosis of ABS and SRS and provides the following

resetting functions:

Oil lamp reset

EPB (Electronic Park Brake) reset

SAS (Steering Angle Sensor) reset (Only available on CReader 8021)

BMS (Battery Management System) reset (Only available on CReader

8011/8021)

CReader 9081

In addition to the full OBDII/EOBD diagnostic functions, CReader 9081 also

provides 11 reset functions: Engine oil lamp reset, EPB (Electronic Parking Brake)

reset, SAS (Steering Angle Sensor), BMS (Battery Management System) reset,

DPF (Diesel Particulate Filter) regeneration, Tire Pressure Monitor System Reset,

ABS Bleeding, Electronic Throttle Position Reset, Gear Learning, IMMO and

Injector Coding.

There are two methods available to update the tool: via memory card or via USB

Page 8

LAUNCH

CReader Series English User’s Manual

2

cable. The memory card is highly recommended to update your tool.

Note: CReader 6011/7001/7001F/8001/8011/8021/9081 may automatically reset while

being disturbed by strong static electricity. THIS IS A NORMAL REACTION.

2. General Information

2.1 On-Board Diagnostics (OBD) II

The first generation of On-Board Diagnostics (OBD I) was developed by the

California Air Resources Board (ARB) and implemented in 1988 to monitor some

of the emission control components on vehicles. As technology evolved and the

desire to improve the On-Board Diagnostic system increased, a new generation of

On-Board Diagnostic system was developed. This second generation of

On-Board Diagnostic regulations is called “OBD II”.

The OBD II system is designed to monitor emission control systems and key

engine components by performing either continuous or periodic tests of specific

components and vehicle conditions. When a problem is detected, the OBD II

system turns on a warning lamp (MIL) on the vehicle instrument panel to alert the

driver typically by the phrase of “Check Engine” or “Service Engine Soon”. The

system will also store important information about the detected malfunction so

that a technician can accurately find and fix the problem. Here below follow three

pieces of such valuable information:

1) Whether the Malfunction Indicator Light (MIL) is commanded ‘on’ or ‘off’;

2) Which, if any, Diagnostic Trouble Codes (DTCs) are stored;

3) Readiness Monitor status.

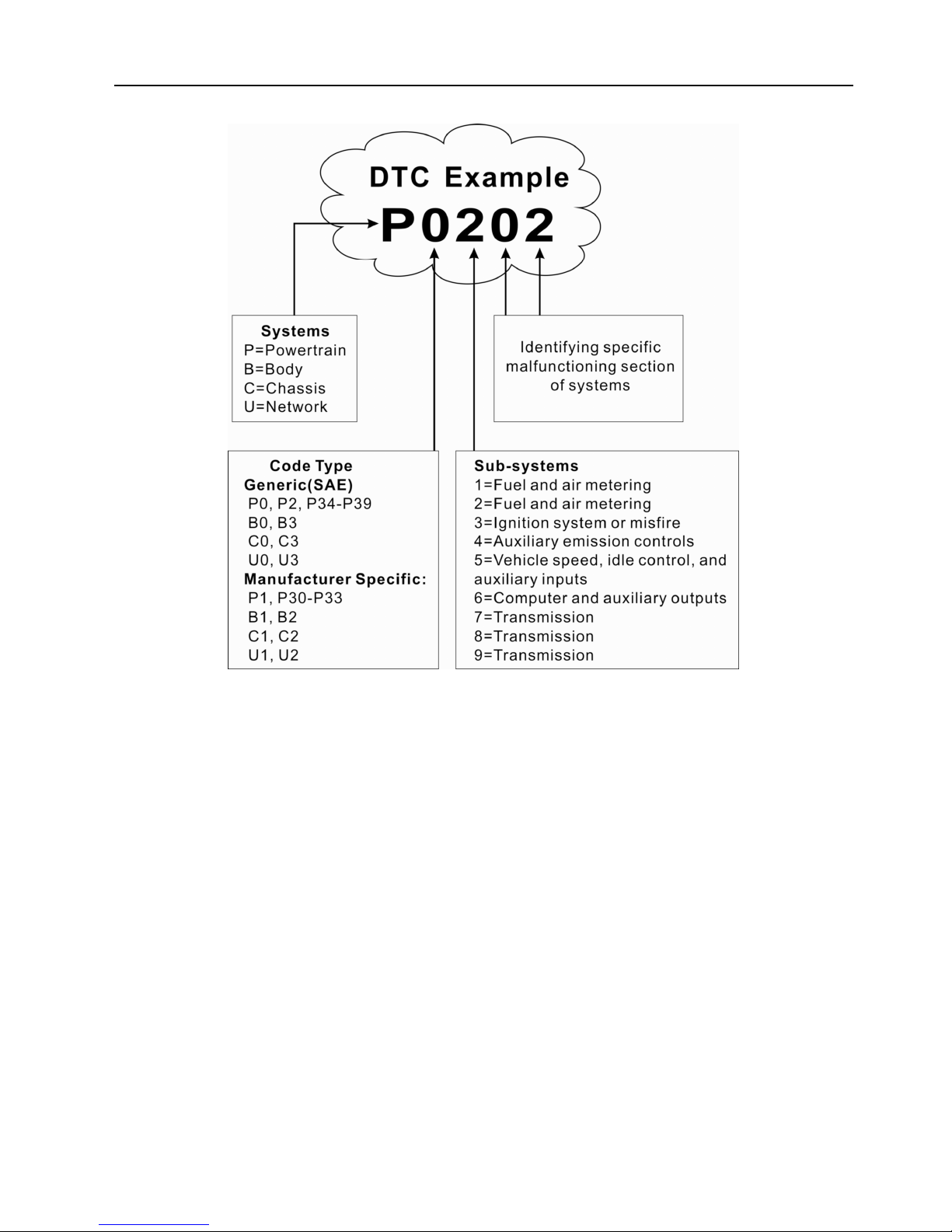

2.2 Diagnostic Trouble Codes (DTCs)

OBD II Diagnostic Trouble Codes are codes that are stored by the on-board

computer diagnostic system in response to a problem found in the vehicle. These

codes identify a particular problem area and are intended to provide you with a

guide as to where a fault might be occurring within a vehicle. OBD II Diagnostic

Trouble Codes consist of a five-digit alphanumeric code. The first character, a

letter, identifies which control system sets the code. The second character, a

number, 0-3; other three characters, a hex character, 0-9 or A-F provide additional

information on where the DTC originated and the operating conditions that caused

it to set. Here below is an example to illustrate the structure of the digits:

Page 9

LAUNCH

CReader Series English User’s Manual

3

Figure 2-1

2.3 Location of the Data Link Connector (DLC)

The DLC (Data Link Connector or Diagnostic Link Connector) is typically a 16-pin

connector where diagnostic code readers interface with the vehicle’s on-board

computer. The DLC is usually located 12 inches from the center of the instrument

panel (dash), under or around the driver’s side for most vehicles. If Data Link

Connector is not located under dashboard, a label should be there telling location.

For some Asian and European vehicles, the DLC is located behind the ashtray

and the ashtray must be removed to access the connector. If the DLC cannot be

found, refer to the vehicle’s service manual for the location.

Page 10

LAUNCH

CReader Series English User’s Manual

4

Figure 2-2

2.4 OBD II Readiness Monitors

An important part of a vehicle’s OBD II system is the Readiness Monitors, which

are indicators used to find out if all of the emissions components have been

evaluated by the OBD II system. They are running periodic tests on specific

systems and components to ensure that they are performing within allowable

limits.

Currently, there are eleven OBD II Readiness Monitors (or I/M Monitors) defined

by the U.S. Environmental Protection Agency (EPA). Not all monitors are

supported in every vehicles and the exact number of monitors in any vehicle

depends on the motor vehicle manufacturer’s emissions control strategy.

Continuous Monitors -- Some of the vehicle components or systems are

continuously tested by the vehicle’s OBD II system, while others are tested only

under specific vehicle operating conditions. The continuously monitored

components listed below are always ready:

1. Misfire

2. Fuel System

3. Comprehensive Components (CCM)

Once the vehicle is running, the OBD II system is continuously checking the

above components, monitoring key engine sensors, watching for engine misfire,

and monitoring fuel demands.

Non-Continuous Monitors -- Unlike the continuous monitors, many emissions and

Page 11

LAUNCH

CReader Series English User’s Manual

5

engine system components require the vehicle to be operated under specific

conditions before the monitor is ready. These monitors are termed

non-continuous monitors and are listed below:

1) EGR System

2) O2 Sensors

3) Catalyst

4) Evaporative System

5) O2 Sensor Heater

6) Secondary air Injection

7) Heated Catalyst

8) A/C system

2.5 OBD II Monitor Readiness Status

OBD II systems must indicate whether or not the vehicle’s PCM’s monitor system

has completed testing on each component. Components that have been tested

will be reported as “Ready”, or “Complete”, meaning they have been tested by the

OBD II system. The purpose of recording readiness status is to allow inspectors to

determine if the vehicle’s OBD II system has tested all the components and/or

systems.

The Powertrain Control Module (PCM) sets a monitor to “Ready” or “Complete”

after an appropriate drive cycle has been performed. The drive cycle that enables

a monitor and sets readiness codes to “Ready” varies for each individual monitor.

Once a monitor is set as “Ready” or “Complete”, it will remain in this state. A

number of factors, including erasing of Diagnostic Trouble Codes (DTCs) with a

code reader or a disconnected battery, can result in Readiness Monitors being set

to “Not Ready”. Since the three continuous monitors are constantly evaluating,

they will be reported as “Ready” all of the time. If testing of a particular supported

non-continuous monitor has not been completed, the monitor status will be

reported as “Not Complete” or “Not Ready.”

In order for the OBD monitor system to become ready, the vehicle should be

driven under a variety of normal operating conditions. These operating conditions

may include a mix of highway driving and stop and go, city type driving, and at

least one overnight-off period. For specific information on getting your vehicle’s

OBD monitor system ready, please consult your vehicle owner’s manual.

Page 12

LAUNCH

CReader Series English User’s Manual

6

2.6 OBD II Definitions

Powertrain Control Module (PCM) – It is the OBD II terminology for the on-board

computer that controls engine and drive train.

Malfunction Indicator Light (MIL) -- Malfunction Indicator Light (Service Engine

Soon, Check Engine) is a term used for the light on the instrument panel. It is to

alert the driver and/or the repair technician that there is a problem with one or

more of vehicle’s systems and may cause emissions to exceed federal standards.

If the MIL illuminates with a steady light, it indicates that a problem has been

detected and the vehicle should be serviced as soon as possible. Under certain

conditions, the dashboard light will blink or flash. This indicates a severe problem

and flashing is intended to discourage vehicle operation. The vehicle onboard

diagnostic system cannot turn the MIL off until the necessary repairs are

completed or the condition no longer exists.

DTC -- Diagnostic Trouble Codes (DTC) that identifies which section of the

emission control system has malfunctioned.

Enabling Criteria -- Also termed Enabling Conditions. They are the

vehicle-specific events or conditions that must occur within the engine before the

various monitors will set, or run. Some monitors require the vehicle to follow a

prescribed “drive cycle” routine as part of the enabling criteria. Drive cycles vary

among vehicles and for each monitor in any particular vehicle. Please refer to the

vehicle’s factory service manual for specific enabling procedures.

OBD II Drive Cycle -- A specific mode of vehicle operation that provides

conditions required to set all the readiness monitors applicable to the vehicle to

the “ready” condition. The purpose of completing an OBD II drive cycle is to force

the vehicle to run its onboard diagnostics. Some form of a drive cycle needs to be

performed after DTCs have been erased from the PCM’s memory or after the

battery has been disconnected. Running through a vehicle’s complete drive cycle

will “set” the readiness monitors so that future faults can be detected. Drive cycles

vary depending on the vehicle and the monitor that needs to be reset. For vehicle

specific drive cycle, consult the service manual.

Freeze Frame Data -- When an emissions related fault occurs, the OBD II system

not only sets a code but also records a snapshot of the vehicle operating

parameters to help in identifying the problem. This set of values is referred to as

Freeze Frame Data and may include important engine parameters such as engine

Page 13

LAUNCH

CReader Series English User’s Manual

7

RPM, vehicle speed, air flow, engine load, fuel pressure, fuel trim value, engine

coolant temperature, ignition timing advance, or closed loop status.

Fuel Trim (FT) -- Feedback adjustments to the base fuel schedule. Short-term fuel

trim refers to dynamic or instantaneous adjustments. Long-term fuel trim refers to

much more gradual adjustments to the fuel calibration schedule than short-term

trim adjustments. These long-term adjustments compensate for vehicle

differences and gradual changes that occur over time.

Page 14

LAUNCH

CReader Series English User’s Manual

8

3. Product Descriptions

3.1 Outline of CReader 6011/7001/7001F/8001/8011/8021/9081

Figure 3-1 CReader 6011/7001/7001F/8001/8011/8021/9081 Front View

Note: CReader 6011/7001/7001F/8001/8011/8021/9081 feature same appearance.

No.

Name Descriptions

A

DB-15 connector

To connect the tool to the vehicle's DLC (Data Link

Connector) via the diagnostic cable.

B

Diagnostic cable

1 LCD Indicates test results.

2 DTC(F1) To read the DTCs.

3 (ESC)

Exit the current program or return to the previous

screen.

4

/

Move cursor up and down for selection.

Page 15

LAUNCH

CReader Series English User’s Manual

9

/

Move cursor left or right for selection; Or turn page

up and down when more than one page is

displayed.

5

Memory card

slot

To insert the memory card to update your tool.

6 Mini USB port To connect to PC via USB cable for upgrading.

7 ER(F2) To erase the DTCs.

8 I/M(F3)

I/M refers to Inspection and Maintenance that is

legislated by the Government to meet federal

clean-air standards.

9 (F4) Help key

10 OK Confirms a selection (or action) from a menu list.

3.2 Specifications

Screen: 4.0” color LCD

Input voltage range: 9~18V

Working temperature: -10 to 50°C (14 to 122 F°)

Storage temperature: -20 to 70°C (-4 to 158 F°)

External Dimension: 195mm(L) x 86mm(W) x 32mm(H)

Weight: 460g

3.3 Accessories

1. CReader 6011/7001/7001F/8001/8011/8021/9081 handset

2. Diagnostic cable

3. User’s Manual

4. Memory card (Built-in)

5. Memory card reader

6. USB cable

Page 16

LAUNCH

CReader Series English User’s Manual

10

4. Connection & Settings

4.1 Connection

1. Turn the ignition off.

2. Locate vehicle’s DLC socket: Refer to Fig. 2-2 for the location. In case no DLC

is found, please refer to Automobile Repair Manual.

3. Plug one end of the diagnostic cable into the DB15 connector of the tool, and

connect the other end of the diagnostic cable into the vehicle’s DLC.

4. Turn the ignition on. Engine can be off or running.

5. The system starts initializing and then automatically enters the main menu

interface.

Figure 4-1

CAUTION: Don’t connect or disconnect any test equipment with ignition on or engine

running.

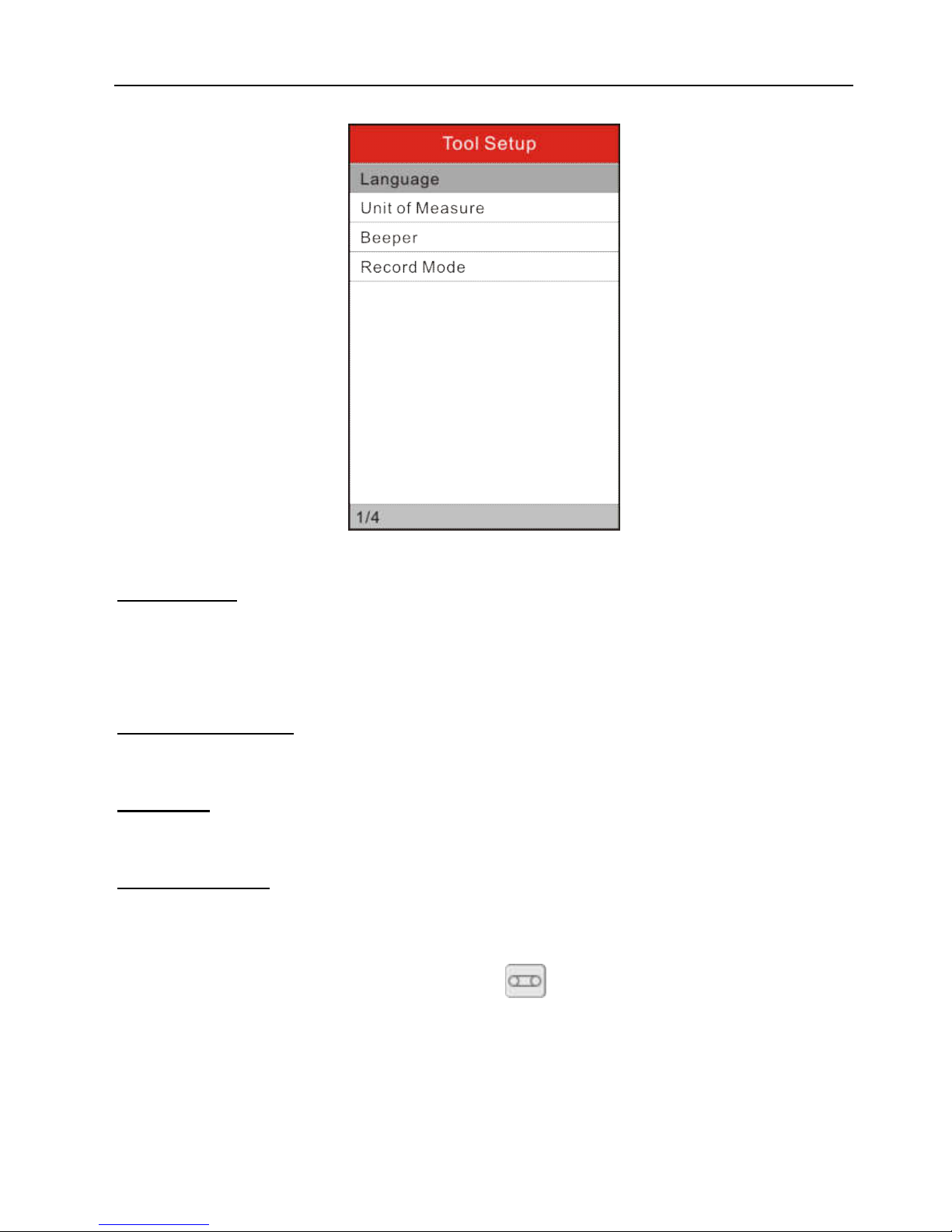

4.2 Settings

Select [Settings] in the main menu and press [OK], the system will enter the

following screen:

Page 17

LAUNCH

CReader Series English User’s Manual

11

Figure 4-2

1) Language

This option enables you to set the user interface language.

Note: Due to continuous software upgrade, language interface may differ from different

software versions.

2) Unit of Measure

This option allows you to set measurement unit.

3) Beeper

It is used to set On/Off the buzzer.

4) Record Mode

It is used to turn On/Off the data stream recording function.

Choose [Record Mode] and press [OK] to confirm. Press [OK] to switch between

On and Off. When recording is On, the

icon appears, and the tool can

record DTCs, data stream and freeze frames.

Page 18

LAUNCH

CReader Series English User’s Manual

12

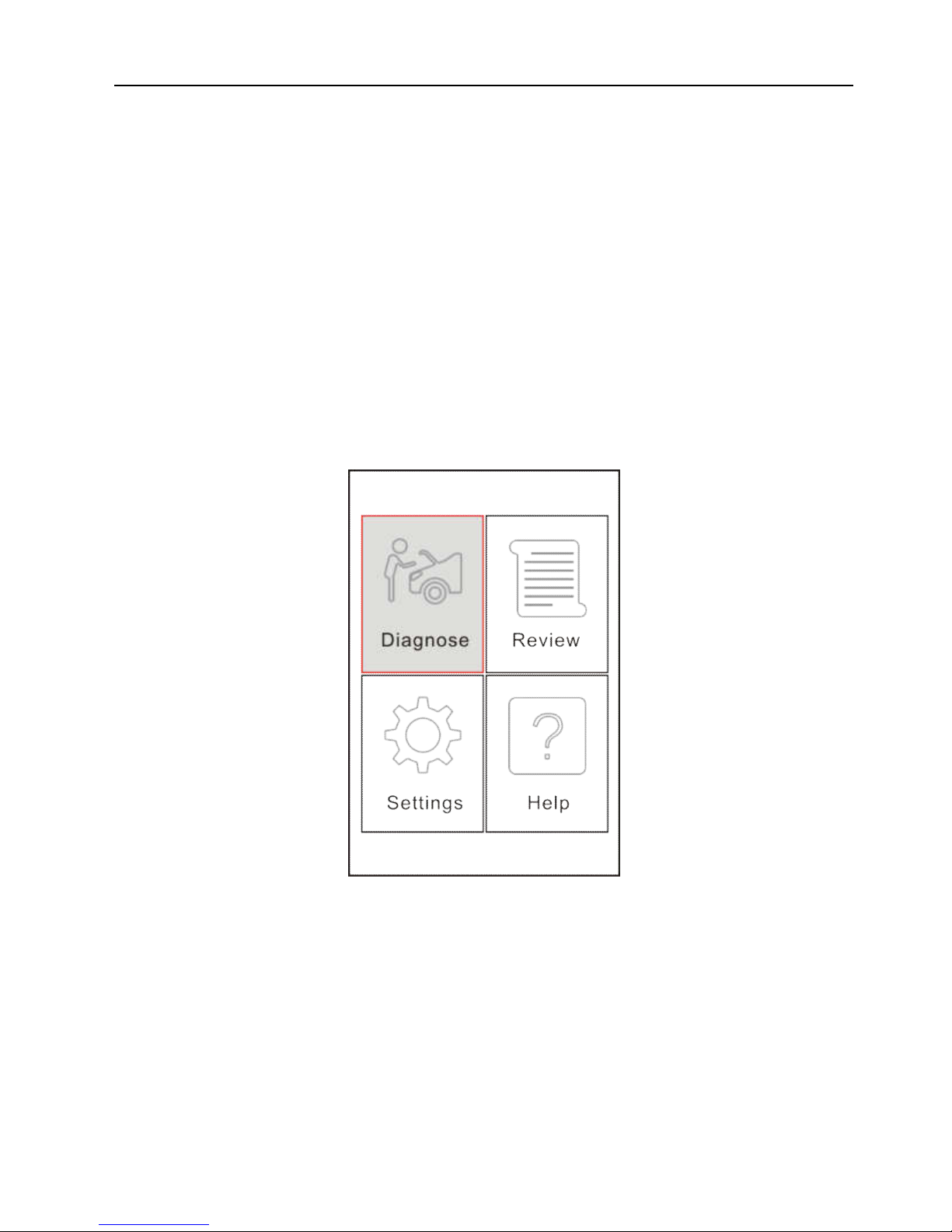

5. Diagnose

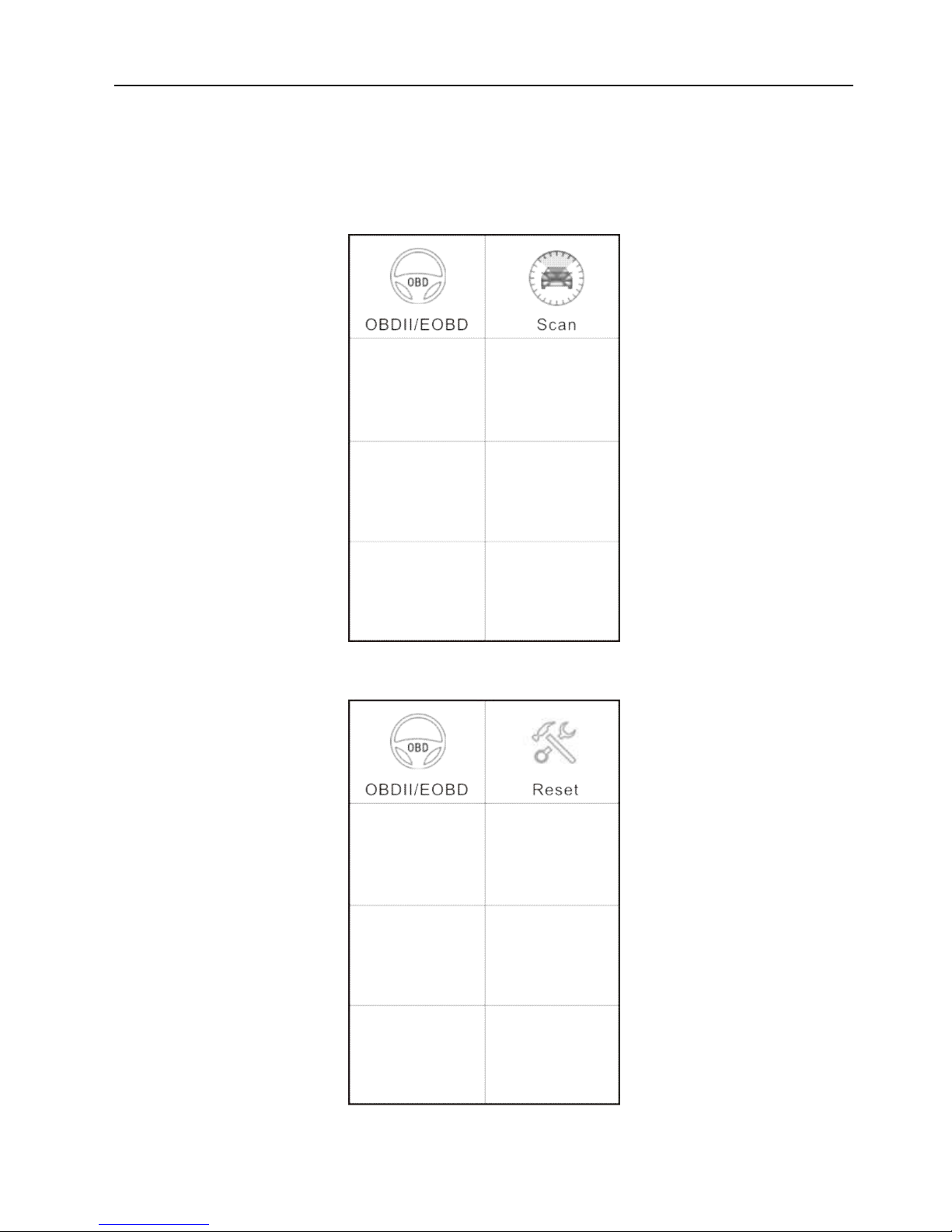

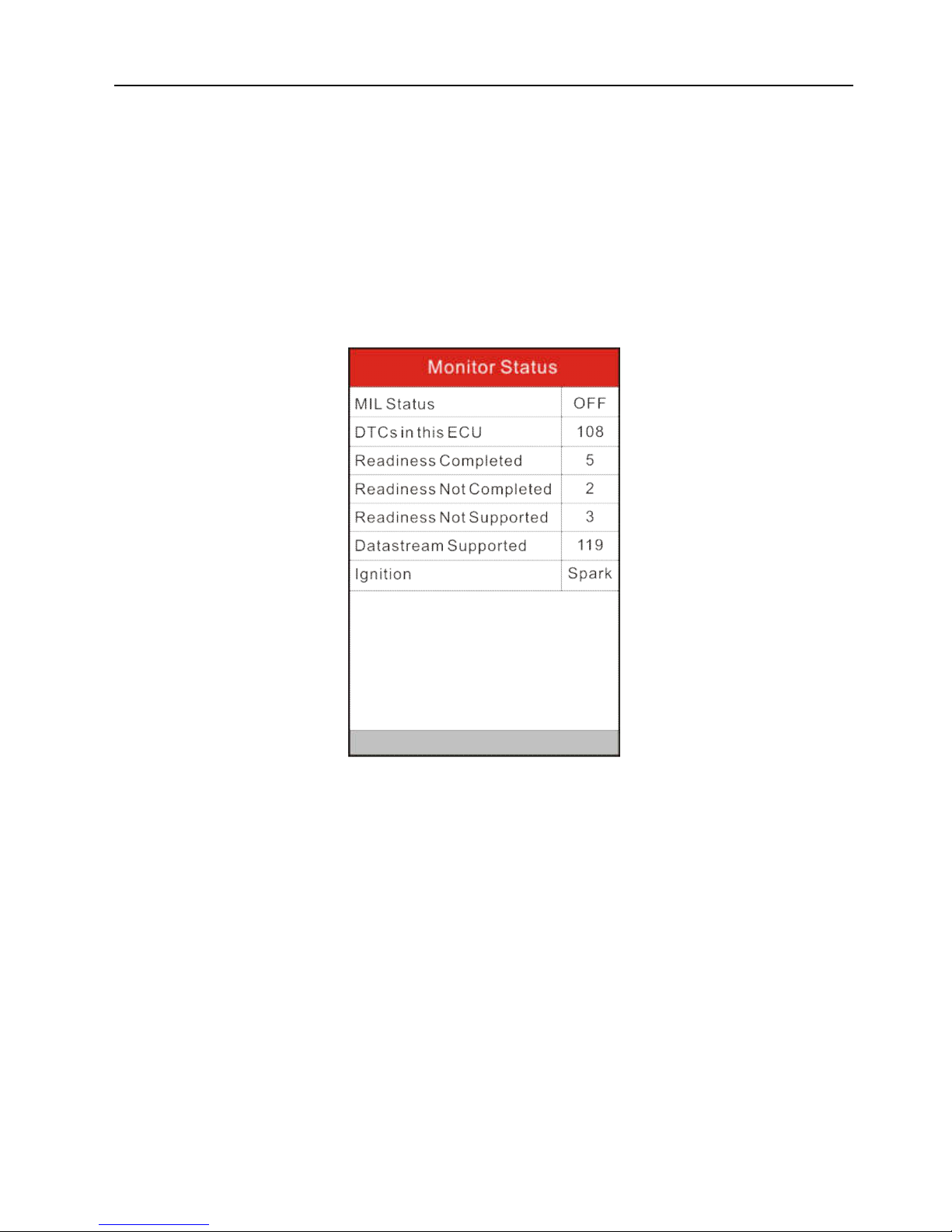

Select [Diagnose] in Main Menu and press [OK], the screen will display Monitor

Status interface as following figure 5-1:

Figure 5-1 (Only applies to CReader 6011/8001/8011/8021)

Figure 5-1 (Only applies to CReader 7001/7001F/9081)

Page 19

LAUNCH

CReader Series English User’s Manual

13

5.1 OBDII/EOBD Diagnosing

This option presents a quick way to check for DTCs, isolate the cause of the

illuminated Malfunction Indicator Lamp (MIL), check monitor status prior to

emissions certification testing, verify repairs, and perform a number of other

services that are emission-related.

In figure 5-1, highlight [OBD II/EOBD] and then press [OK], the screen will

automatically jump to figure 5-2:

Figure 5-2

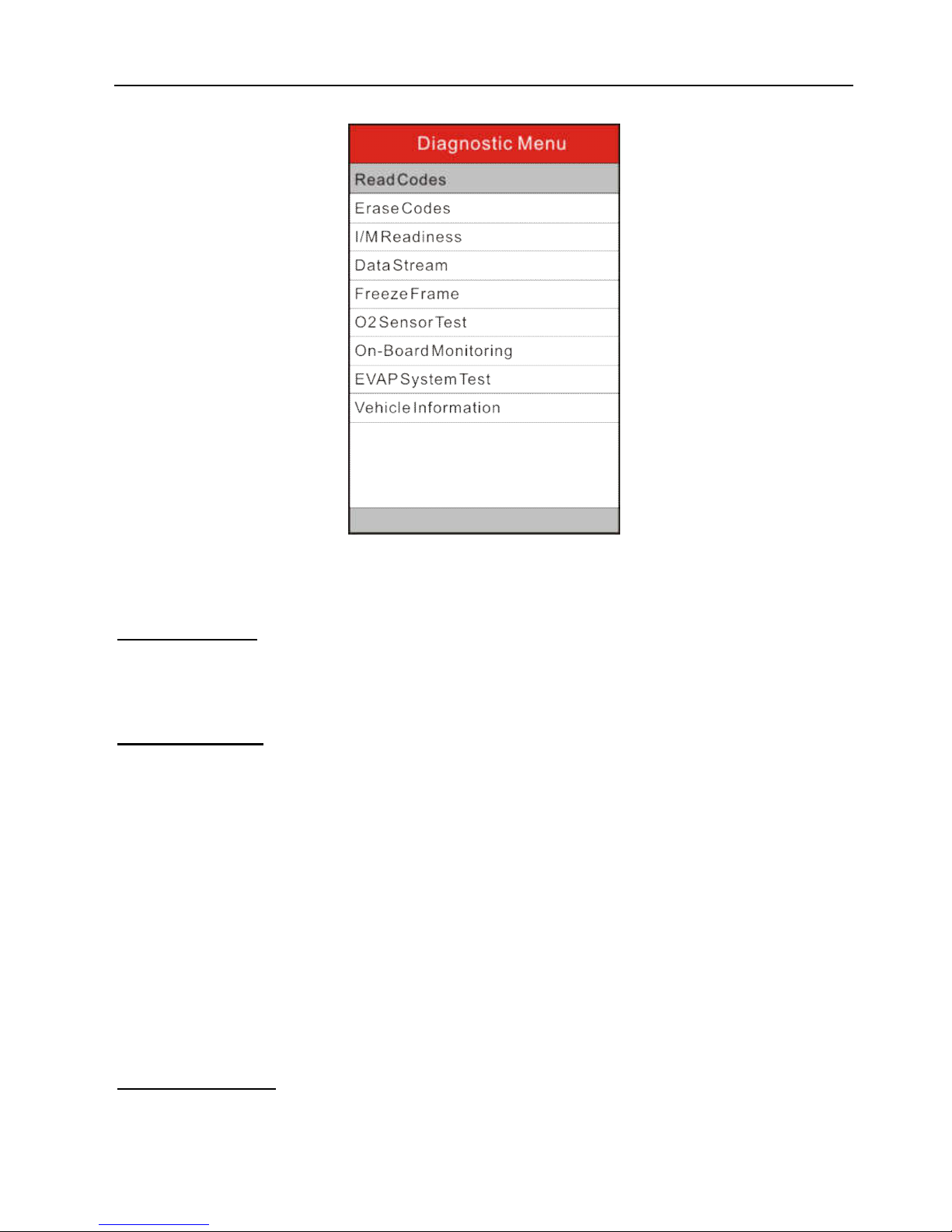

Press [OK], a screen similar to figure 5-3 will appear:

Page 20

LAUNCH

CReader Series English User’s Manual

14

Figure 5-3

It mainly includes the following functions:

1. Read Codes

This option is used to identify which section of the emission control system has

malfunctioned.

2. Erase Codes

After reading the retrieved codes from the vehicle and certain repairs have been

carried out, you can use this function to erase the codes from the vehicle. Before

performing this function, please be sure the vehicle’s ignition key is in the ON

position with the engine off.

Notes:

Before performing this function, make sure to retrieve and record the trouble codes.

After clearing, you should retrieve trouble codes once more or turn ignition on and

retrieve codes again. If there are still some trouble codes in the system, please

troubleshoot the code using a factory diagnosis guide, then clear the code and

recheck.

3. I/M Readiness

I/M refers to Inspection and Maintenance that is legislated by the Government to

Page 21

LAUNCH

CReader Series English User’s Manual

15

meet federal clean-air standards. I/M Readiness indicates whether or not the

various emissions-related systems on the vehicle are operating properly and are

ready for Inspection and Maintenance testing.

The purpose of the I/M Readiness Monitor Status is to indicate which of the

vehicle’s Monitors have run and completed their diagnosis and testing (as

described in Chapter 2.5), and which ones have not yet run and completed testing

and diagnosis of their designated sections of the vehicle’s emissions system.

I/M Readiness Monitor Status function also can be used (after repair of a fault has

been performed) to confirm that the repair has been performed correctly, and/or to

check for Monitor Run Status.

4. Data Stream

This option retrieves and displays live data and parameters from the vehicle’s

ECU.

5. View Freeze Frame

When an emission-related fault occurs, certain vehicle conditions are recorded by

the on-board computer. This information is referred to as freeze frame data.

Freeze Data is a snapshot of the operating conditions at the time of an

emission-related fault.

Note: If DTCs were erased, Freeze Data may not be stored in vehicle memory depending

on vehicle.

6. O2 sensor test

The results of O2 sensor test are not live values but instead the results of the

ECU’s last O2 sensor test. For live O2 sensor readings, refer to any of the live

sensor screens such as Graph Screen.

Not all test values are applicable to all vehicles. Therefore, the list generated will

vary depending on vehicle. In addition, not all vehicles support the Oxygen

Sensors screen.

7. On-board monitor test

This function can be utilized to read the results of on-board diagnostic monitoring

tests for specific components/systems.

8. EVAP System Test

The EVAP test function lets you initiate a leak test for the vehicle’s EVAP system.

Page 22

LAUNCH

CReader Series English User’s Manual

16

The tool does not perform the leak test, but signals to vehicle’s on-board

computer are to initiate the test. Before using the system test function, refer to the

vehicle’s service repair manual to determine the procedures necessary to stop the

test.

9. Vehicle Info

This option displays the vehicle information, such as VIN (Vehicle identification

Number), CID (Calibration ID) and CVN (Calibration Verification Number).

5.2 System Diagnosing (Only for CReader 6011/8001/8011/8021)

This function is specially designed to diagnose the two electronic control systems

[ABS (Anti-lock Brake System) + SRS (Supplemental Restraint System)] of single

vehicle model.

Figure 5-5

Page 23

LAUNCH

CReader Series English User’s Manual

17

Notes:

This function does not apply to CReader 7001, CReader 7001F and CReader 9081.

Before diagnosing, please make sure the diagnostic program corresponding to certain

vehicle model has been installed on your tool.

For vehicles manufactured by different manufacturers, it is possible that it has

different diagnostic menus.

5.2.1 Read Vehicle Information

This function is used to read the version information of system mode, vehicle VIN,

software and ECU.

5.2.2 Read Fault Code

This function displays the detailed information of DTC records retrieved from the

vehicle’s control system.

5.2.3 Clear Fault Code

After reading the retrieved codes from the vehicle and certain repairs have been

carried out, you can use this function to erase the codes from the vehicle. Before

performing this function, please be sure the vehicle’s ignition key is in the ON

position with the engine off.

5.2.4 Read Data Stream

This option retrieves and displays live data and parameters from the vehicle’s ECU.

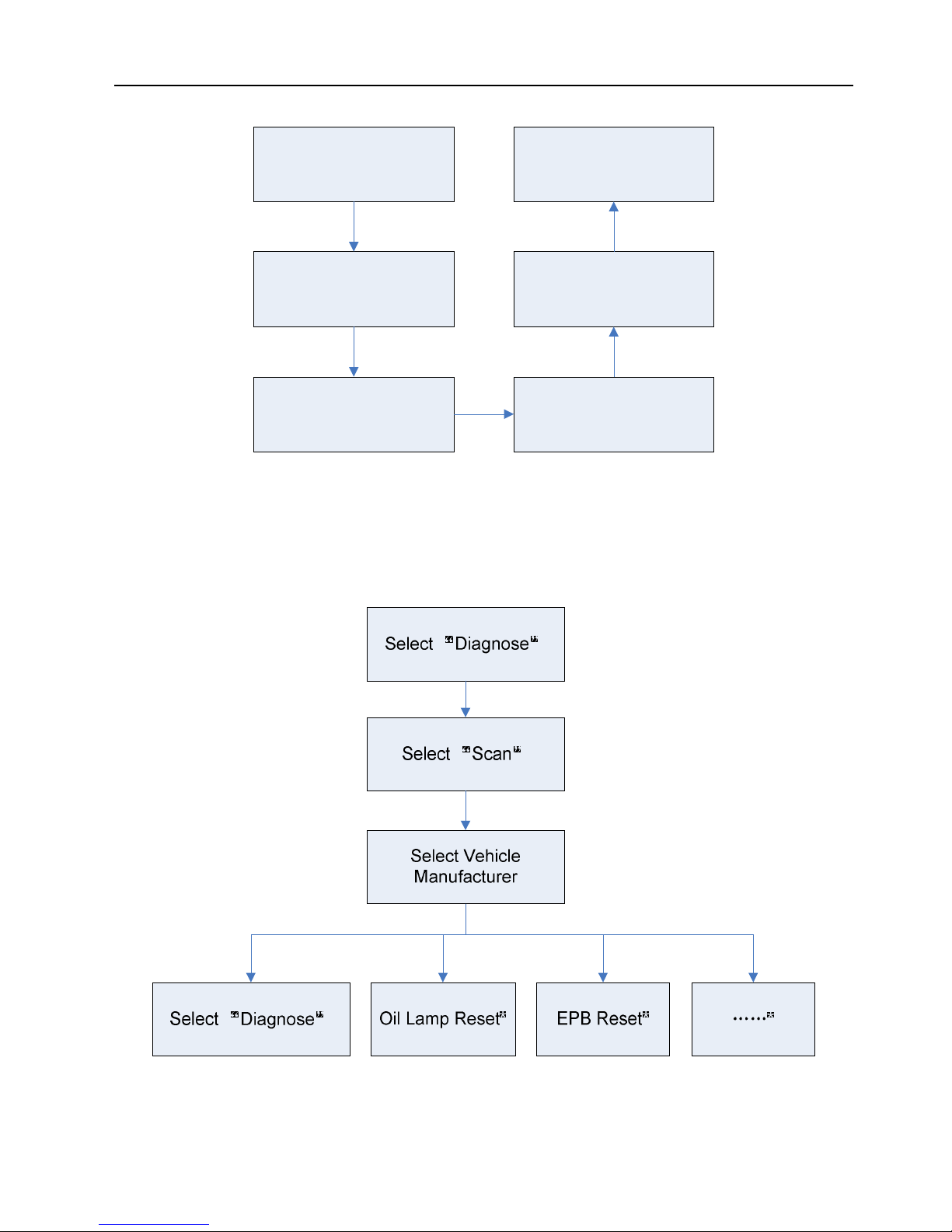

5.3 Resetting

(Only applies to CReader 7001/7011F/8001/8011/8021/9081)

There are two methods to reset service lamp: Manual reset or Auto reset. Auto

reset follows the principle of sending command from the tool to vehicle’s ECU to

do resetting. While using manual reset, users just follow the on-screen

instructions to select appropriate execution options, enter correct data or values,

and perform necessary actions, the system will guide you through the complete

performance for various service operations.

Note: This function is not available on CReader 6011.

For CReader 7001/7001F/9081, just follow the flowchart below to perform

resetting.

Page 24

LAUNCH

CReader Series English User’s Manual

18

Select “Diagnose”

Select “Reset”

(e.g. oil lamp reset etc.)

Select the desired reset

item (e.g. oil lamp reset

etc.)

Select the car brand

Select the service mode

(The available mode

varies from vehicle to

vehicle)

Follow the instructions

on the screen to operate

Figure 5-6 (For CReader 7001/7001F/9081)

For CReader 8001/8011/8021, the resetting function is loaded with each single

vehicle model and can be done in process of the System Scanning operation.

Refer to the following illustration to proceed.

Figure 5-6 (For CReader 8001/8011/8021)

Page 25

LAUNCH

CReader Series English User’s Manual

19

5.3.1 Oil Reset Service (Only applies to CReader 7001/7011F/8001/8011/

8021/9081)

This function allows you to perform reset for the engine oil life system, which

calculates an optimal oil life change interval depending on the vehicle driving

conditions and climate.

This function can be performed in the following cases:

1. If the service lamp is on, you must provide service for the car. After service,

you need to reset the driving mileage or driving time so that the service lamp

turns off and the system enables the new service cycle.

2. After changing engine oil or electric appliances that monitor oil life, you need to

reset the service lamp.

5.3.2 Electronic Parking Brake Reset (Only applies to CReader 7011F/8001/

8011/8021/9081)

1. If the brake pad wears the brake pad sense line, the brake pad sense line

sends a signal sense line to the on-board computer to replace the brake pad.

After replacing the brake pad, you must reset the brake pad. Otherwise, the car

alarms.

2. Reset must be performed in the following cases:

a) The brake pad and brake pad wear sensor are replaced.

b) The brake pad indicator lamp is on.

c) The brake pad sensor circuit is short, which is recovered.

d) The servo motor is replaced.

5.3.3 Steering Angle Sensor (Only applies to CReader 7011F/8021/9081)

To reset the steering angle, first find the relative zero point position for the car to

drive in straight line. Taking this position as reference, the ECU can calculate the

accurate angle for left and right steering.

After replacing the steering angle position sensor, replacing steering mechanical

parts (such as steering gearbox, steering column, end tie rod, steering knuckle),

performing four-wheel alignment, or recovering car body, you must reset the

steering angle.

5.3.4 Battery Maintenance System Reset (Only applies to CReader 7011F/

8011/8021/ 9081)

This function enables you to perform a resetting operation on the monitoring unit

of vehicle battery, in which the original low battery fault information will be cleared

Page 26

LAUNCH

CReader Series English User’s Manual

20

and battery matching will be done.

Battery matching must be performed in the following cases:

a) Main battery is replaced. Battery matching must be performed to clear original

low battery information and prevent the related control module from detecting

false information. If the related control module detects false information, it will

invalidate some electric auxiliary functions, such as automatic start & stop

function, sunroof without one-key trigger function, power window without

automatic function.

b) Battery monitoring sensor. Battery matching is performed to re-match the

control module and motoring sensor to detect battery power usage more

accurately, which can avoid an error message displaying on the instrument

panel.

5.3.5 Diesel Particulate Filter (DPF) Regeneration (Only applies to CReader

7011F/9081)

DPF regeneration is used to clear PM (Particulate Matter) from the DPF filter

through continuous combustion oxidation mode (such as high temperature

heating combustion, fuel additive or catalyst reduce PM ignition combustion) to

stabilize the filter performance.

DPF regeneration may be performed in the following cases:

a) The exhaust back pressure sensor is replaced.

b) The PM trap is removed or replaced.

c) The fuel additive nozzle is removed or replaced.

d) The catalytic oxidizer is removed or replaced.

e) The DPF regeneration MIL is on and maintenance is performed.

f) The DPF regeneration control module is replaced.

5.3.6 Tire Pressure Monitor System Reset (Only applies to CReader 9081)

This function allows you to quickly look up the tire sensor IDs from the vehicle’s

ECU, as well as to perform TPMS replacement and sensor test.

1. After the tire pressure MIL turns on and maintenance is performed, the tire

pressure resetting function must be performed to reset tire pressure and turn

off the tire pressure MIL.

2. Tire pressure resetting must be performed after maintenance is performed in

the following cases: tire pressure is too low, tire leaks, tire pressure monitoring

device is replaced or installed, tire is replaced, tire pressure sensor is damaged,

and tire is replaced for the car with tire pressure monitoring function.

Page 27

LAUNCH

CReader Series English User’s Manual

21

5.3.7 ABS Bleeding (Only applies to CReader 7011F/9081)

This function allows you to perform various bi-directional tests to check the

operating conditions of Anti-lock Braking System (ABS).

1. When the ABS contains air, the ABS bleeding function must be performed to

bleed the brake system to restore ABS brake sensitivity.

2. If the ABS computer, ABS pump, brake master cylinder, brake cylinder, brake

line, or brake fluid is replaced, the ABS bleeding function must be performed to

bleed the ABS.

5.3.8 Gear Learning (Only applies to CReader 9081)

The crankshaft position sensor learns crankshaft tooth machining tolerance and

saves to the computer to more accurately diagnose engine misfires. If tooth

learning is not performed for a car equipped with Delphi engine, the MIL turns on

after the engine is started. The diagnostic device detects the DTC P1336 'tooth

not learned'. In this case, you must use the diagnostic device to perform tooth

learning for the car. After tooth learning is successful, the MIL turns off.

After the engine ECU, crankshaft position sensor, or crankshaft flywheel is

replaced, or the DTC 'tooth not learned' is present, tooth learning must be

performed.

5.3.9 IMMO Service (Only applies to CReader 9081)

An immobilizer is an anti-theft mechanism that prevents a vehicle’s engine from

starting unless the correct ignition key or other device is present. Most new

vehicles have an immobilizer as standard equipment. An important advantage of

this system is that it doesn’t require the car owner to activate it since it operates

automatically. An immobilizer is considered as providing much more effective

anti-theft protection than an audible alarm alone.

As an anti-theft device, an immobilizer disables one of the systems needed to

start a car’s engine, usually the ignition or the fuel supply. This is accomplished by

radio frequency identification between a transponder in the ignition key and a

device called a radio frequency reader in the steering column. When the key is

placed in the ignition, the transponder sends a signal with a unique identification

code to the reader, which relays it to a receiver in the vehicle’s computer control

module. If the code is correct, the computer allows the fuel supply and ignition

systems to operate and start the car. If the code is incorrect or absent, the

computer disables the system, and the car will be unable to start until the correct

key is placed in the ignition.

To prevent the car being used by unauthorized keys, the anti-theft key matching

Page 28

LAUNCH

CReader Series English User’s Manual

22

function must be performed so that the immobilizer control system on the car

identifies and authorizes remote control keys to normally use the car.

When the ignition switch key, ignition switch, combined instrument panel, ECU,

BCM, or remote control battery is replaced, anti-theft key matching must be

performed.

5.3.10 Injector Coding (Only applies to CReader 9081)

Write injector actual code or rewrite code in the ECU to the injector code of the

corresponding cylinder so as to more accurately control or correct cylinder

injection quantity.

After the ECU or injector is replaced, injector code of each cylinder must be

confirmed or re-coded so that the cylinder can better identify injectors to

accurately control fuel injection.

5.3.11 Electronic Throttle Position Reset (Only applies to CReader 9081)

This function enables you to make initial settings to throttle actuators and returns

the “learned” values stored on ECU to the default state. Doing so can accurately

control the actions of regulating throttle (or idle engine) to adjust the amount of air

intake.

5.4 Review

This function is used to review or delete the recorded DTC, Data Streams and

Freeze Frame.

Page 29

LAUNCH

CReader Series English User’s Manual

23

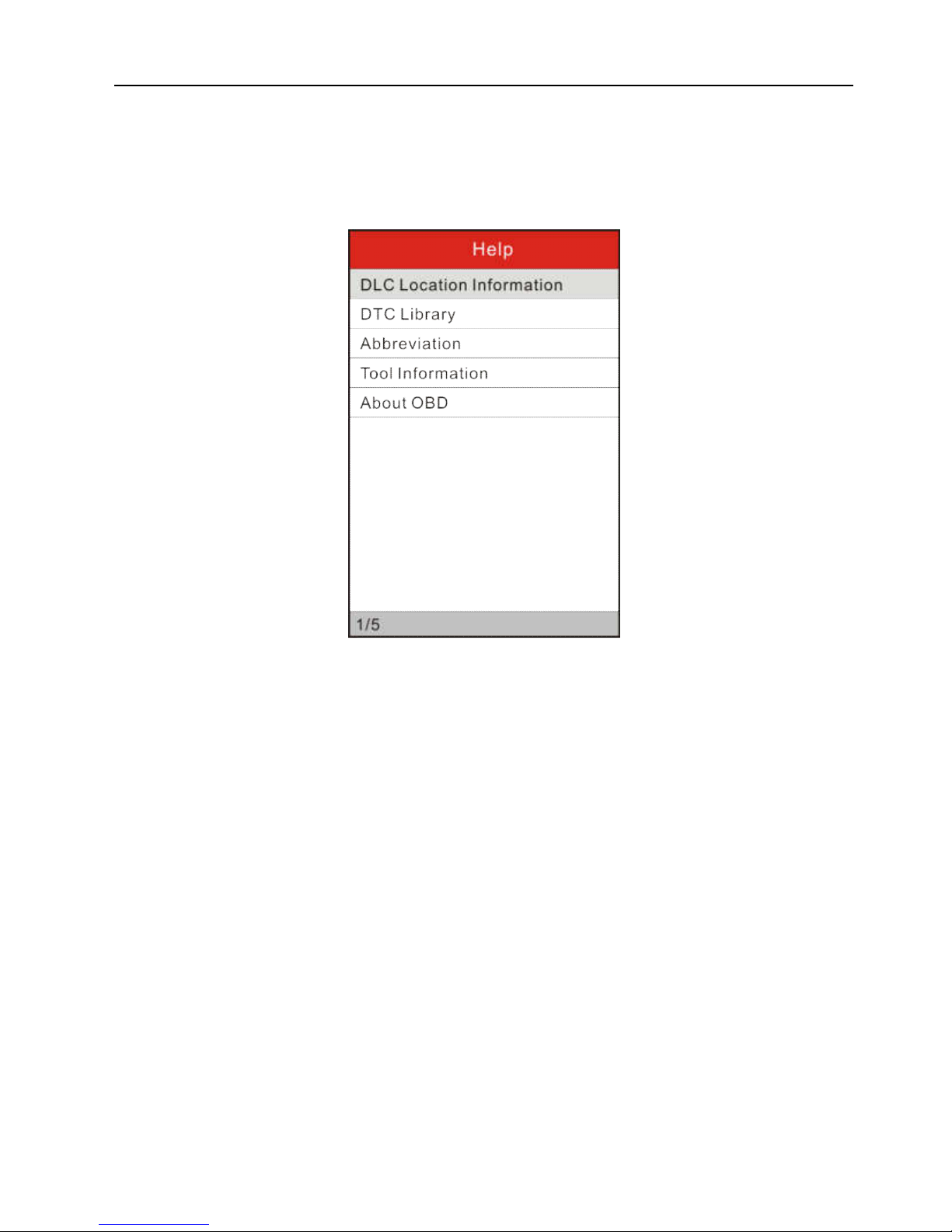

6. Help

This menu enables you to view tool information and OBD introduction.

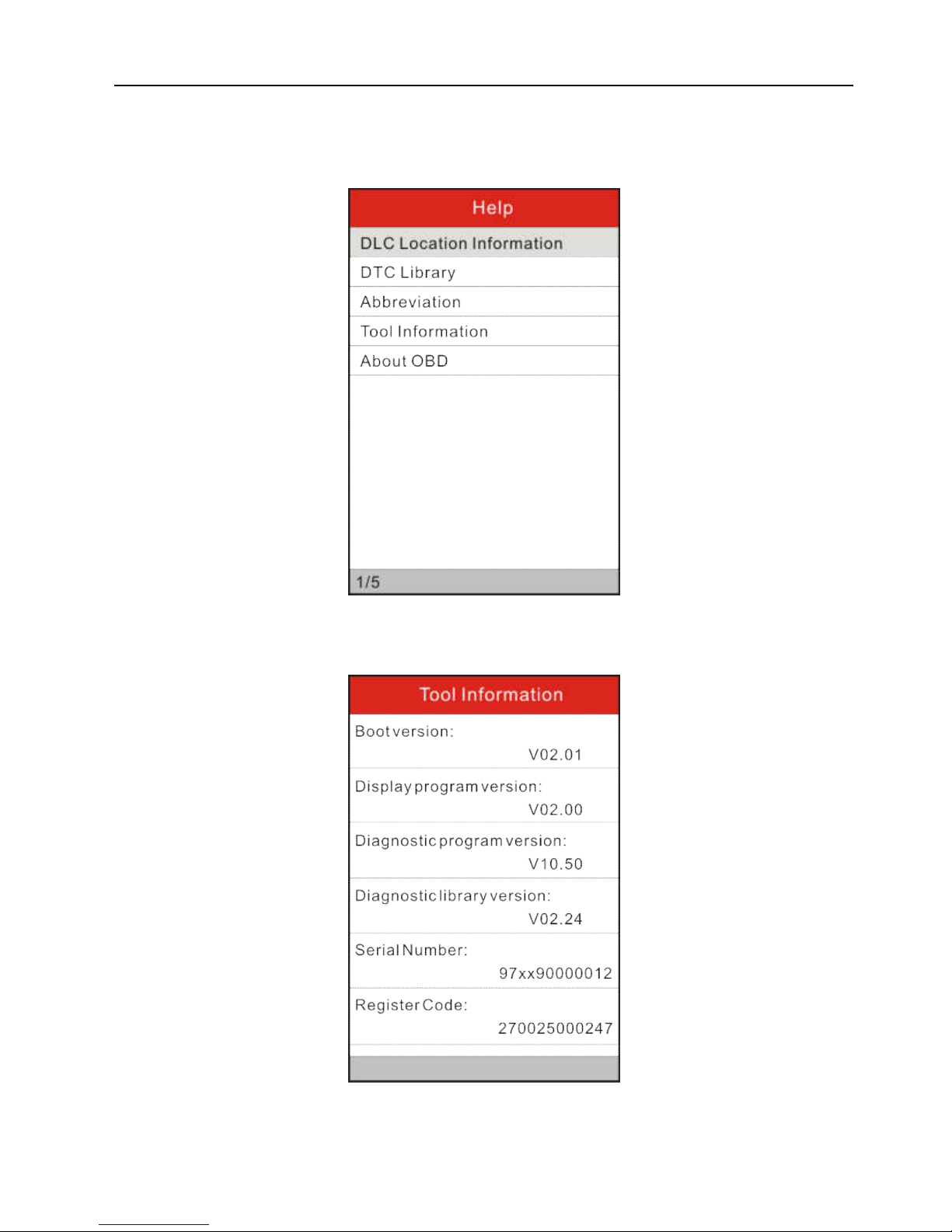

In main menu, select [Help] and press [OK] to enter figure 6-1.

Figure 6-1

6.1 DLC Location Information

This option helps you to find the location of the vehicle’s DLC.

6.2 DTC Library

In Figure 6-1, select [DTC Library] and press [OK] to enter the following screen.

Page 30

LAUNCH

CReader Series English User’s Manual

24

Figure 6-2

Press []/[] button to move the highlight bar to different position. Press []/[]

button to alter the value, then press [OK] button, the screen will display definition

of the DTC.

6.3 Abbreviation

This option allows you to view the full name and detailed explanation of the

automotive glossary abbreviations.

6.4 Tool Information

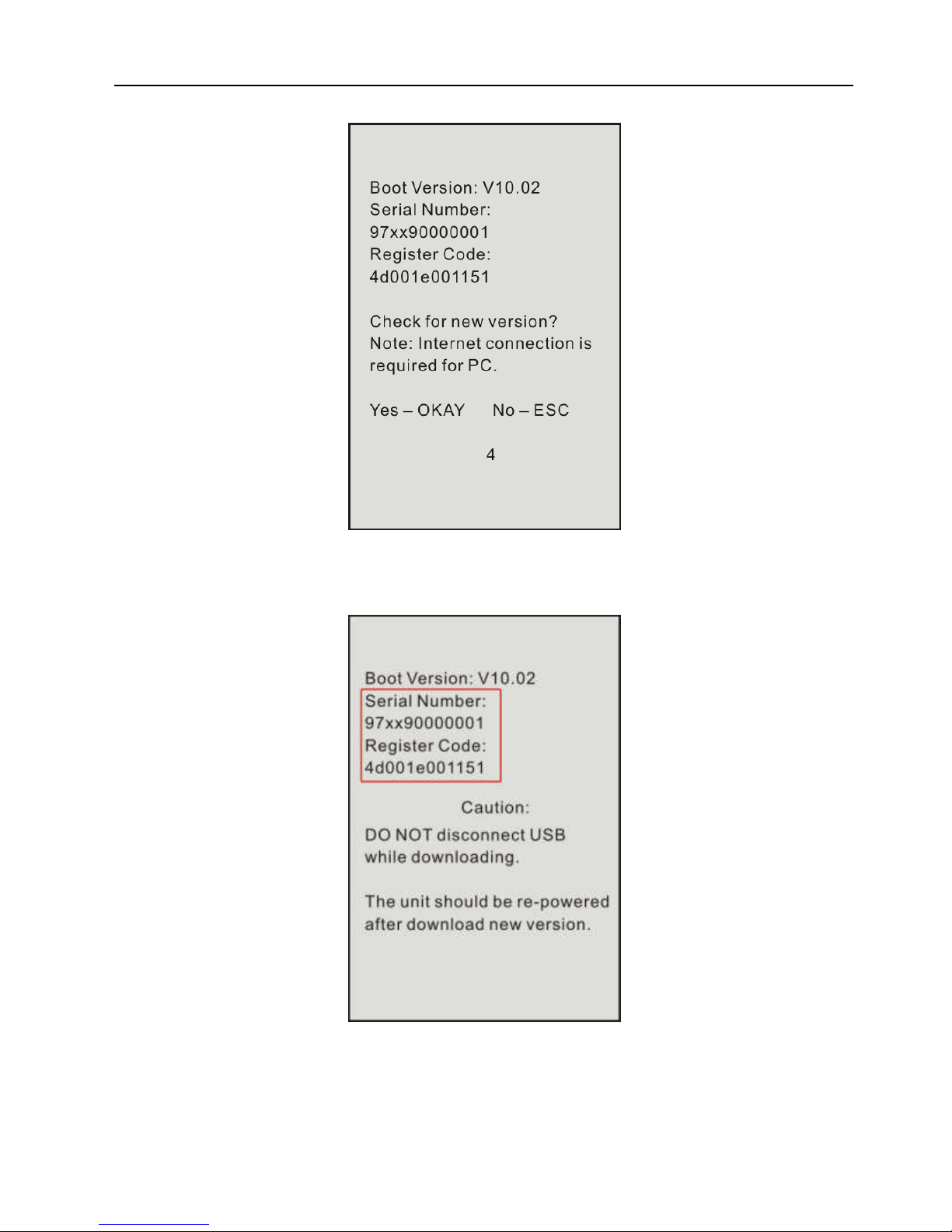

This option displays the related information of your tool.

In figure 6-1, select [Tool Information] and then press [OK].

Page 31

LAUNCH

CReader Series English User’s Manual

25

Figure 6-3

Note:

You are strongly recommended to note down the Serial Number and Register Code

in figure 6-3 since these 2 pieces of information are required while registering your tool.

6.5 About OBD

This option allows you to have a general knowledge of OBD.

Page 32

LAUNCH

CReader Series English User’s Manual

26

7. Register & Update

Prerequisite conditions:

1. System requirements: Windows XP, 7, 8 or Windows 10.

2. Go to http://mycar.x431.com, click “Products” -> “Creader Online” -> “CReader

6011/7001/8001/8011/8021/9081” to download the update tool and install it on

the computer.

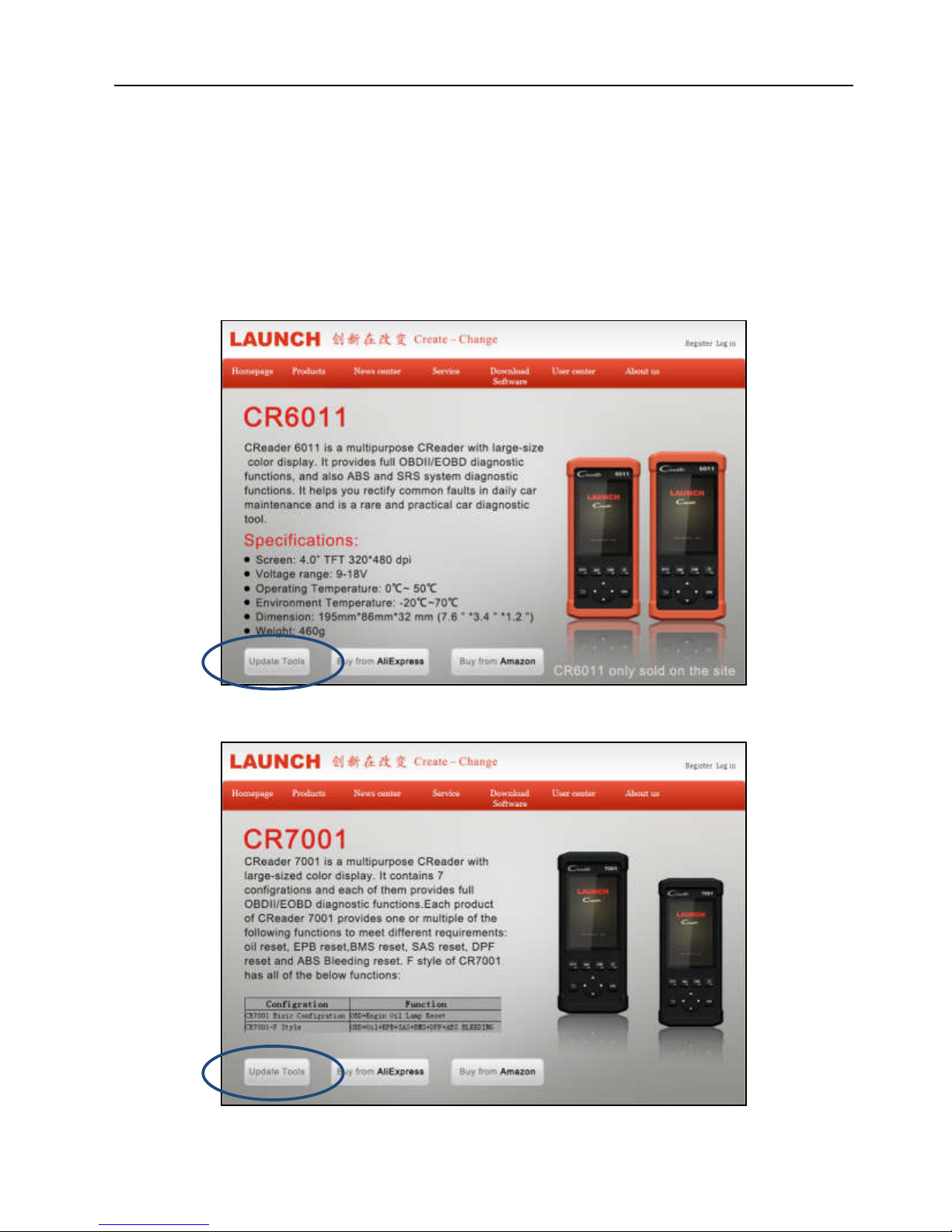

Figure 7-1 (For CReader 6011)

Figure 7-1 (For CReader 7001&CReader 7001F)

Page 33

LAUNCH

CReader Series English User’s Manual

27

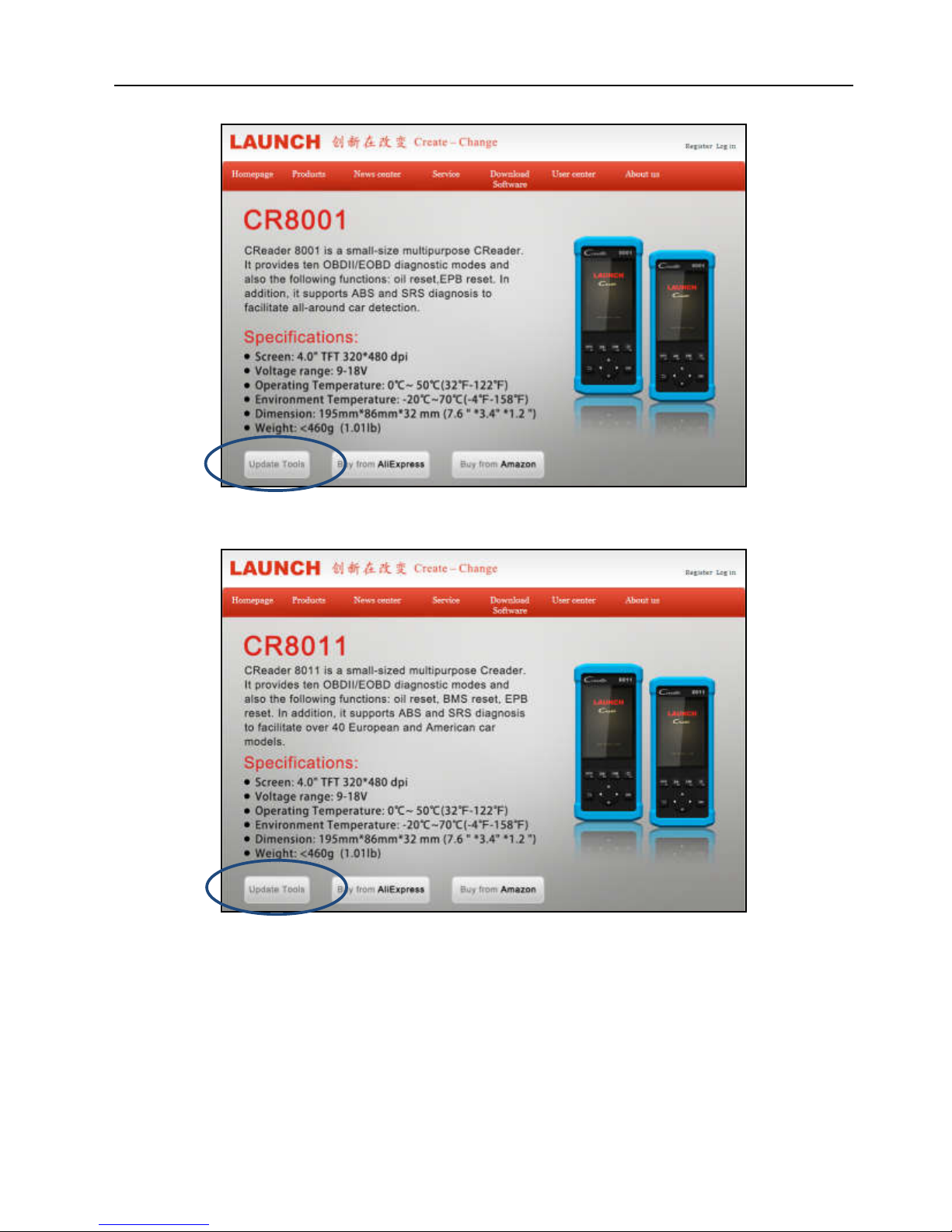

Figure 7-1 (For CReader 8001)

Figure 7-1 (For CReader 8011)

Page 34

LAUNCH

CReader Series English User’s Manual

28

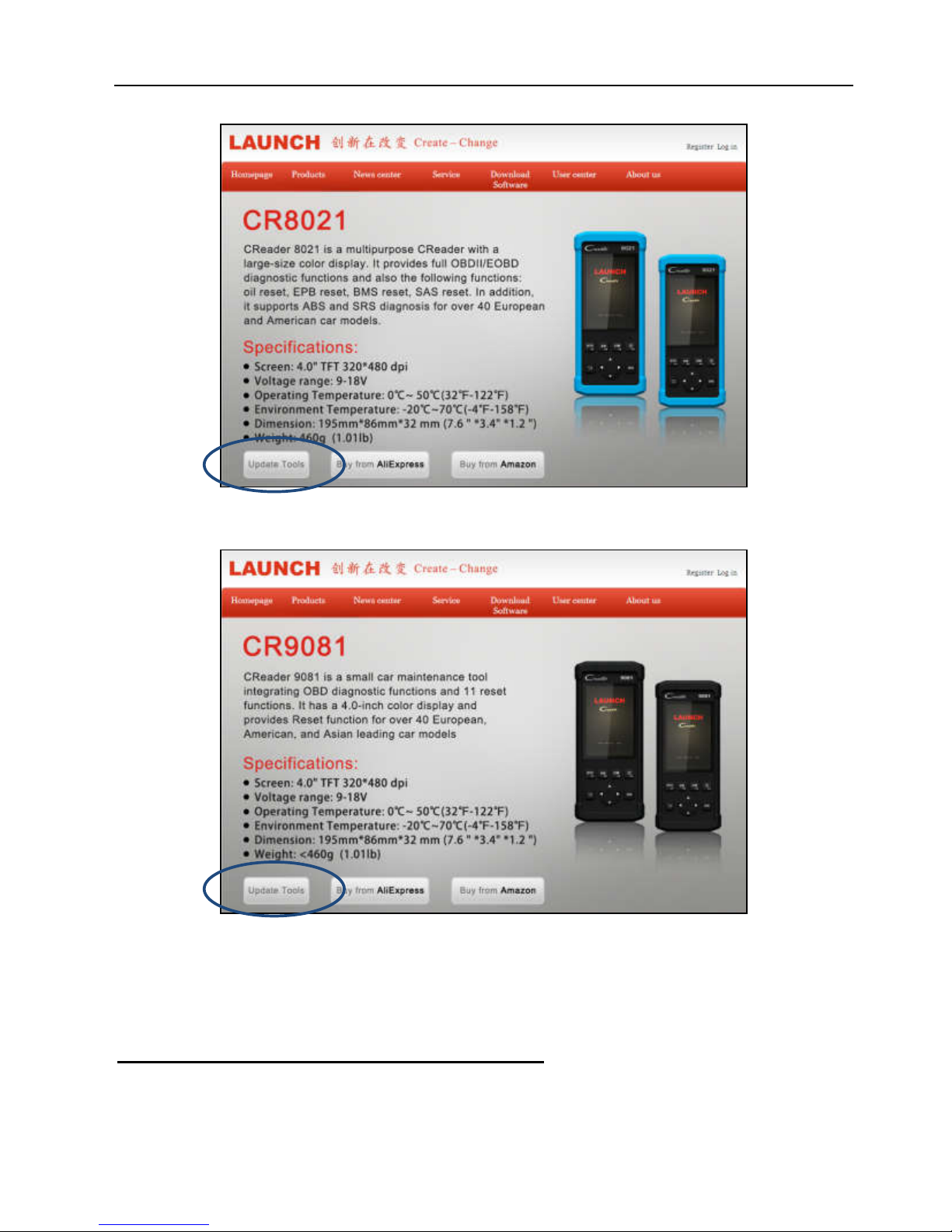

Figure 7-1 (For CReader 8021)

Figure 7-1 (For CReader 9081)

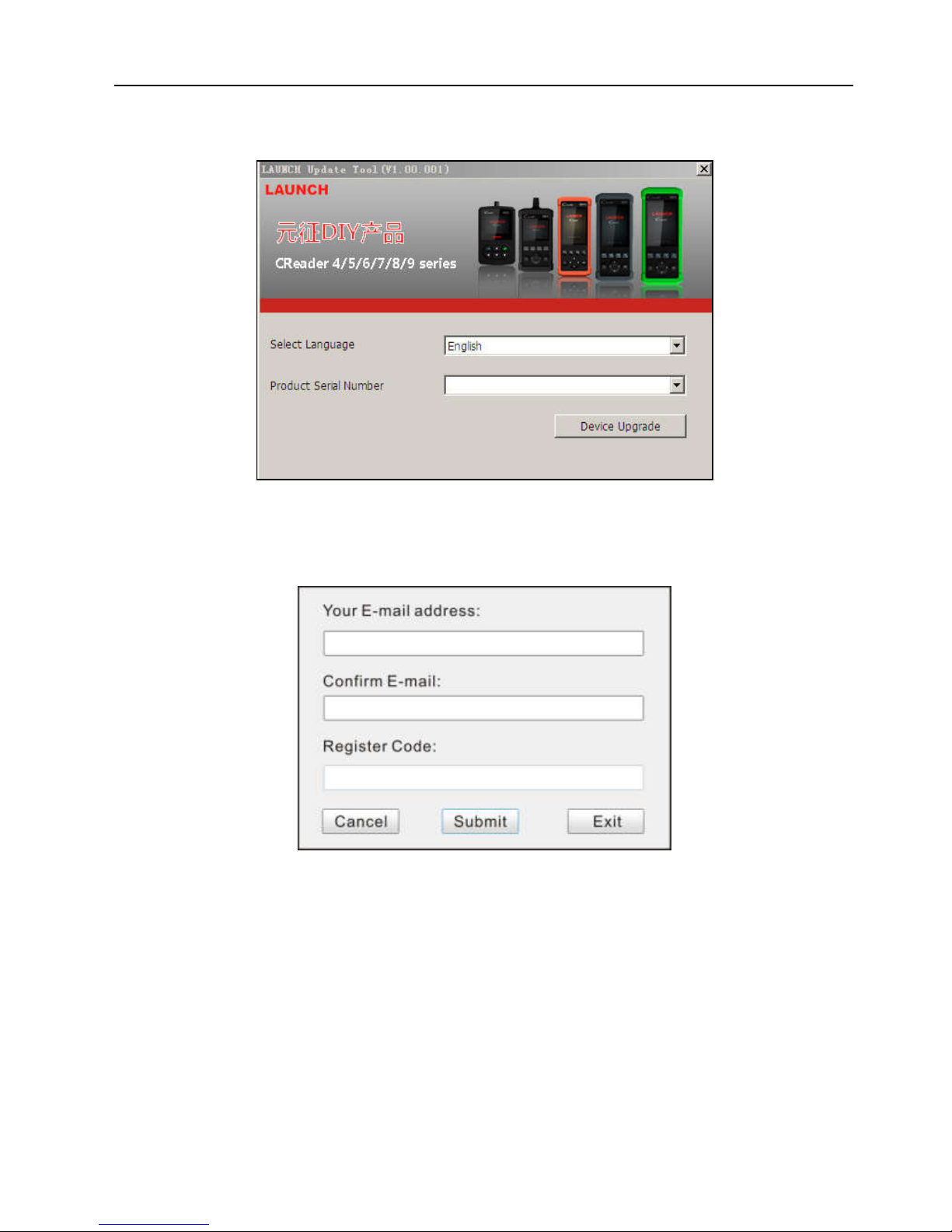

There are 2 methods available to update your tool. You may choose one of the

following to proceed.

Method 1: Via Memory Card (recommended)

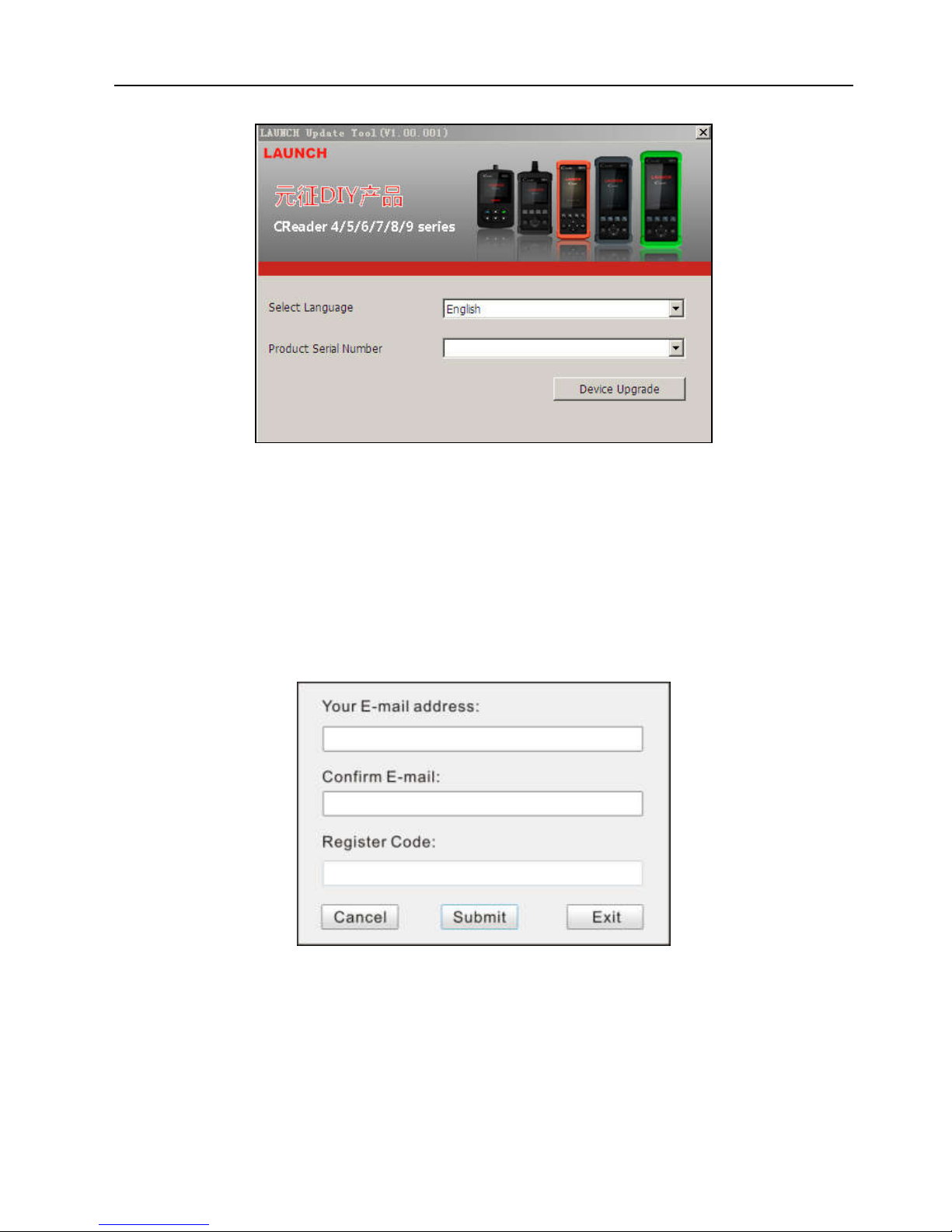

1. Launch the update tool, a screen similar to figure 7-2 will appear:

Page 35

LAUNCH

CReader Series English User’s Manual

29

Figure 7-2

2. In figure 7-2, type in the Product Serial Number (located at the back of the

tool).

Note: Once the S/N is entered, “Restore System” becomes activated, which is used to

restore system if a new memory card is replaced.

3. Click [Device Upgrade] to enter the sign-up page. Enter the information and

click [Submit] (refer to figure 7-3).

Figure 7-3

(If you need the Register Code, please refer to steps 4~7.)

(If you have the Register Code, directly proceed to step 8.)

4. The Register Code can be found in your tool. Connect one end of the USB

cable to your tool, and the other end on the computer.

Page 36

LAUNCH

CReader Series English User’s Manual

30

5. After the tool has powered up and entered the main menu screen, move the

highlight bar on the “Help” icon and press [OK].

Figure 7-4

6. Highlight the “Tool Information” in figure 7-4 and press [OK].

Figure 7-5

Page 37

LAUNCH

CReader Series English User’s Manual

31

7. The Register Code shown in figure 7-5 is the Register Code needed in step 3.

(Return to step 3 and input the Register Code and then proceed)

8. Install the memory card from the tool into the supplied memory card adaptor

and insert into the USB port of the computer.

9. Reopen the update tool, select the updates you would like to perform or click

"Select All", and then click [Download] to start downloading.

10. Once all steps are complete, reinsert the memory card into the tool and power

the tool via USB cable or via OBD II cable. A dialog box (Note: If only

diagnostic software is updated and no firmware package is downloaded, this

box will not appear) prompting you to update will pop up on the screen (See

figure 7-6), select [OK].

Figure 7-6

11. The registration process is complete, your tool is now ready for use.

Method 2: Via USB Cable

Note: Make sure the computer has an Internet connection.

1. Connect one end of the USB cable to the USB port of computer, and the other

end to the tool.

2. If a newer version is found, a screen similar to figure 7-7 appears.

Page 38

LAUNCH

CReader Series English User’s Manual

32

Figure 7-7

3. Press [OK] to configure this tool as a USB device. See figure 7-8.

Figure 7-8

Note: The Serial Number and Register Code shown in this figure are needed for inputting

in Steps 4-6.

Page 39

LAUNCH

CReader Series English User’s Manual

33

4. Launch the update tool, a screen similar to figure 7-9 will appear.

Figure 7-9

5. Type in the Serial Number. Click [Device Upgrade] to input the information

and click [Submit] to enter the update page.

Figure 7-10

6. Select the updates you would like to perform or click "Select All", and then

click [Download] to start downloading.

7. Once all steps are complete, restart your tool. It will prompt you to upgrade,

click [OK] to start updating. It may take several minutes to finish the update.

8. The update process is complete, your tool is now ready for use.

Page 40

LAUNCH

CReader Series English User’s Manual

34

8. FAQ

Here we list some frequently asked questions and answers relating to the tool.

Question: System halts when reading data stream. What is the reason?

Answer: It may be caused by a slackened connector. Please turn off the tool,

firmly connect the connector, and switch it on again.

Question: Screen of main unit flashes at engine ignition start.

Answer: Caused by electromagnetic disturbing, and this is normal phenomenon.

Question: There is no response when communicating with on-board computer.

Answer: Please confirm the proper voltage of power supply and check if the

throttle has been closed, the transmission is in the neutral position, and the water

is in proper temperature.

Question: Why are there so many fault codes?

Answer: Usually, it’s caused by poor connection or fault circuit grounding.

Page 41

LAUNCH

CReader Series English User’s Manual

35

Warranty

THIS WARRANTY IS EXPRESSLY LIMITED TO PERSONS WHO PURCHASE

LAUNCH PRODUCTS FOR PURPOSES OF RESALE OR USE IN THE

ORDINARY COURSE OF THE BUYER’S BUSINESS.

LAUNCH electronic product is warranted against defects in materials and

workmanship for one year (12 months) from date of delivery to the user.

This warranty does not cover any part that has been abused, altered, used for a

purpose other than for which it was intended, or used in a manner inconsistent

with instructions regarding use. The exclusive remedy for any automotive meter

found to be defective is repair or replacement, and LAUNCH shall not be liable for

any consequential or incidental damages.

Final determination of defects shall be made by LAUNCH in accordance with

procedures established by LAUNCH. No agent, employee, or representative of

LAUNCH has any authority to bind LAUNCH to any affirmation, representation, or

warranty concerning LAUNCH automotive meters, except as stated herein.

Order Information

Replaceable and optional parts can be ordered directly from your LAUNCH

authorized tool supplier. Your order should include the following information:

Quantity

Part number

Item description

Customer Service

If you have any questions on the operation of the unit, please contact local dealer,

or contact LAUNCH TECH. CO., LTD:

Tel: 86-755-84528767

E-mail: X431@cnlaunch.com

Page 42

LAUNCH

CReader Series English User’s Manual

36

Statement:

LAUNCH reserves the rights to make any change to product designs

and specifications without notice. The actual object may differ a little from the

descriptions in the manual in physical appearance, color and configuration. We

have tried our best to make the descriptions and illustrations in the manual as

accurate as possible, and defects are inevitable. If you have any question, please

contact local dealer or after-sale service center of LAUNCH. LAUNCH does not

bear any responsibility arising from misunderstandings.

Loading...

Loading...