Lasertex HPI-3D User Manual

Laser Measurement System HPI-3D

User

manual

www.lasertex.eu

www.lasertex.eu

Laser measurements systems.

Measurement systems with data acquisition.

Laser technique.

Research and Development Company Ltd.

UL. RADZIONKOWSKA 17,

51-506 WROCLAW, POLAND

Tel/fax. 071-3466684

email: lasertex@lasertex.com.pl

Laser Measurement System HPI-3D

User manual

Rev. E10

Wroclaw 2017

CONTENTS

www.lasertex.eu

1. INTRODUCTION ................................................................................................... 1-1

A. SAFETY CONSIDERATIONS ..................................................................................... 1-1

B. WARNINGS ............................................................................................................ 1-2

C. COMPLIANCE INFORMATION ................................................................................ 1-2

2. QUICK START ....................................................................................................... 2-1

A. MAIN FEATURES .................................................................................................... 2-1

B. HOW IT WORKS ...................................................................................................... 2-1

i. Linear optics ...................................................................................................... 2-2

ii. Angular optics ................................................................................................... 2-2

iii. Wollaston optics ........................................................................................... 2-4

C. HOW TO START ...................................................................................................... 2-5

3. PREPARATIONS ................................................................................................... 3-1

A. SOFTWARE INSTALLATION .................................................................................... 3-1

B. ELEMENTS OF THE LASER SYSTEM ........................................................................ 3-9

C. INTERFEROMETER SETUP FOR MEASUREMENT ...................................................... 3-12

D. POWERING THE SYSTEM ON ................................................................................ 3-16

i. Starting hardware ........................................................................................... 3-16

ii. Starting software ............................................................................................. 3-16

E. GETTING BASIC INFORMATION FROM THE SYSTEM. ............................................ 3-18

F. RECORDING MODE .............................................................................................. 3-25

G. FLAT MIRROR MEASUREMENTS - OPTION ............................................................ 3-25

4. BEAM ALIGNMENT ............................................................................................. 4-1

CONTENTS

www.lasertex.eu

A. INTRODUCTION ..................................................................................................... 4-1

B. ELECTRONIC ALIGNMENT TOOLS .......................................................................... 4-2

C. BASIC RULES OF BEAM ALIGNMENT ...................................................................... 4-2

D. PREPARATIONS ...................................................................................................... 4-4

i. Diaphragm ......................................................................................................... 4-4

ii. Laser head alignment elements .......................................................................... 4-6

iii. Electronic Beam Alignment tool ................................................................... 4-7

E. BEAM ALIGNMENT PROCESS FOR LINEAR OPTICS ................................................. 4-8

F. BEAM ALIGNMENT PROCESS FOR ANGULAR OPTICS ............................................. 4-9

G. BEAM ALIGNMENT PROCESS FOR WOLLASTON OPTICS ...................................... 4-12

H. BEAM ALIGNMENT OF LINEAR OPTICS WITH ANGLE ETALON ............................ 4-14

I. BEAM ALIGNMENT OF ANGULAR OPTICS WITH BEAM BENDER .............................. 4-17

i. Laser Head initially not aligned ...................................................................... 4-17

ii. Laser Head initially aligned ............................................................................ 4-20

5. MEASUREMENTS - POSITIONING ............................................................... 5-1

A. GENERAL DESCRIPTION ........................................................................................ 5-1

i. Positioning in brief ............................................................................................ 5-1

B. MEASUREMENT SETUP .......................................................................................... 5-4

i. Principles ........................................................................................................... 5-4

ii. Principles – base temperature compensation .................................................... 5-5

iii. Measurement Setup Preparations ................................................................. 5-6

C. SOFTWARE DESCRIPTION ..................................................................................... 5-10

i. Introduction..................................................................................................... 5-10

ii. Display Panel .................................................................................................. 5-10

iii. Positioning Plot Panel ................................................................................. 5-11

iv. Positioning Measurement Values Panel ......................................................... 5-12

v. Positioning Control Panel ............................................................................... 5-12

vi. Pull down menu - File ..................................................................................... 5-15

vii. CNC path generation .................................................................................. 5-15

viii. Compensation table preparation .................................................................. 5-17

CONTENTS

www.lasertex.eu

ix. Pull down menu - Edit .................................................................................... 5-18

x. Machine error limits ........................................................................................ 5-19

xi. Positioning points generation ......................................................................... 5-21

xii. Configuration of Positioning measurement ................................................ 5-22

xiii. Pull down menu – Measurement ................................................................ 5-28

D. PREPARATIONS FOR MEASUREMENT ................................................................... 5-29

i. Measurement window ..................................................................................... 5-29

ii. 1D and 3D measurements ............................................................................... 5-30

iii. Measurements in machine coordinate system ............................................. 5-30

iv. Setting measurement points ............................................................................ 5-31

E. RULES OF AUTOMATIC POSITIONING MEASUREMENT ........................................ 5-31

F. REMARKS ON MEASUREMENTS AND ON DATA ANALYSIS .................................. 5-32

G. MACHINE ERROR COMPENSATION ..................................................................... 5-37

i. Absolute and Incremental data formats .......................................................... 5-38

ii. Siemens data format ........................................................................................ 5-39

iii. Fanuc data format ....................................................................................... 5-40

6. MEASUREMENTS – DYNAMIC POSITIONING ......................................... 6-1

A. GENERAL DESCRIPTION ........................................................................................ 6-1

i. Positioning in brief ............................................................................................ 6-1

B. MEASUREMENT SETUP .......................................................................................... 6-4

i. Principles ........................................................................................................... 6-4

ii. Principles – base temperature compensation .................................................... 6-5

iii. Measurement Setup Preparations ................................................................. 6-6

C. SOFTWARE DESCRIPTION ....................................................................................... 6-9

i. Introduction..................................................................................................... 6-10

ii. Display Panel .................................................................................................. 6-10

iii. Positioning Plot Panel ................................................................................. 6-11

iv. Positioning Control Panel ............................................................................... 6-12

v. Pull down menu - File ..................................................................................... 6-13

vi. CNC path generation ...................................................................................... 6-13

CONTENTS

www.lasertex.eu

vii. Compensation table preparation .................................................................. 6-15

viii. Pull down menu - Edit ................................................................................ 6-16

ix. Configuration of Positioning measurement .................................................... 6-17

D. PREPARATIONS FOR MEASUREMENT ................................................................... 6-18

i. Measurement window ..................................................................................... 6-18

ii. Measurements in machine coordinate system ................................................. 6-19

E. RULES OF AUTOMATIC POSITIONING MEASUREMENT ........................................ 6-19

F. REMARKS ON MEASUREMENTS AND ON DATA ANALYSIS .................................. 6-20

G. MACHINE ERROR COMPENSATION ..................................................................... 6-21

i. Absolute and Incremental data formats .......................................................... 6-22

ii. Siemens data format ........................................................................................ 6-23

iii. Fanuc data format ....................................................................................... 6-24

7. MEASUREMENTS - STRAIGHTNESS ............................................................ 7-1

A. GENERAL DESCRIPTION ........................................................................................ 7-1

B. MEASUREMENT SETUP – ANGULAR OPTICS ......................................................... 7-1

i. Principles ........................................................................................................... 7-1

ii. Application Notes .............................................................................................. 7-4

iii. Measurement Setup Preparations ................................................................. 7-5

C. MEASUREMENT SETUP – WOLLASTON OPTICS ..................................................... 7-8

i. Principles ........................................................................................................... 7-8

ii. Application Notes ............................................................................................ 7-11

iii. Measurement Setup Preparations ............................................................... 7-12

D. MEASUREMENT SETUP – 3D METHOD ................................................................ 7-15

i. Principles ......................................................................................................... 7-15

ii. Application Notes ............................................................................................ 7-15

iii. Measurement Setup Preparations ............................................................... 7-16

E. SOFTWARE DESCRIPTION ..................................................................................... 7-18

i. Introduction..................................................................................................... 7-19

ii. Display Panel .................................................................................................. 7-20

iii. Straightness Plot Panel ............................................................................... 7-21

CONTENTS

www.lasertex.eu

iv. Operation Mode Panel .................................................................................... 7-24

v. Straightness Measurement Values Panel ....................................................... 7-25

vi. Straightness Control Panel ............................................................................. 7-27

vii. Straightness pull-down menus .................................................................. 7-28

viii. Reports ......................................................................................................... 7-31

F. STRAIGHTNESS MEASUREMENTS PROCEDURE .................................................... 7-32

i. Measurement procedure – Angular optics - preparations .............................. 7-32

ii. Measurement procedure – Angular optics ...................................................... 7-34

iii. Measurement procedure – Wollaston optics – preparations ....................... 7-34

iv. Measurement procedure – Wollaston optics ................................................... 7-35

v. Measurement procedure – 3D method - preparations .................................... 7-35

vi. Measurement procedure – 3D method ............................................................ 7-35

8. MEASUREMENTS - FLATNESS ....................................................................... 8-1

A. GENERAL DESCRIPTION ........................................................................................ 8-1

B. MEASUREMENT SETUP .......................................................................................... 8-1

C. SOFTWARE DESCRIPTION ....................................................................................... 8-4

D. ALIGNMENT OF OPTICS FOR THE FLATNESS MEASUREMENTS .............................. 8-8

i. Optical path alignment of the axis “1”. ............................................................ 8-9

ii. Optical path alignment of the axes: “3”, “6”, “8”. ........................................... 8-9

iii. Optical path alignment of the axes: “5” and “7” ........................................ 8-10

iv. Optical path alignment of the axes: “2” and “4” ............................................ 8-11

E. MEASUREMENT PROCEDURE ............................................................................... 8-12

9. MEASUREMENTS – PITCH/YAW .................................................................... 9-1

A. GENERAL DESCRIPTION ........................................................................................ 9-1

B. MEASUREMENT SETUP .......................................................................................... 9-1

C. SOFTWARE DESCRIPTION ....................................................................................... 9-3

D. MEASUREMENT PROCEDURE ................................................................................. 9-8

10. MEASUREMENTS - SQUARENESS .......................................................... 10-1

A. GENERAL DESCRIPTION ...................................................................................... 10-1

CONTENTS

www.lasertex.eu

B. MEASUREMENT SETUP ........................................................................................ 10-1

C. SOFTWARE DESCRIPTION ..................................................................................... 10-5

D. ALIGNMENT OF OPTICS FOR THE SQUARENESS MEASUREMENTS ....................... 10-9

E. MEASUREMENT PROCEDURE ............................................................................. 10-11

11. MEASUREMENTS - PARALLELISM ......................................................... 11-1

A. GENERAL DESCRIPTION ...................................................................................... 11-1

B. MEASUREMENT SETUP ........................................................................................ 11-1

C. SOFTWARE DESCRIPTION ..................................................................................... 11-5

D. ALIGNMENT OF OPTICS FOR THE PARALLELISM MEASUREMENTS ...................... 11-9

E. MEASUREMENT PROCEDURE ............................................................................. 11-12

12. MEASUREMENTS - VIBRATION .............................................................. 12-1

A. GENERAL DESCRIPTION ...................................................................................... 12-1

B. MEASUREMENT SETUP ........................................................................................ 12-1

C. SOFTWARE DESCRIPTION ..................................................................................... 12-4

D. MEASUREMENT PROCEDURE ............................................................................... 12-8

13. MEASUREMENTS - DYNAMIC ................................................................. 13-1

A. GENERAL DESCRIPTION ...................................................................................... 13-1

B. MEASUREMENT SETUP ........................................................................................ 13-1

i. Dynamic measurements of distance, velocity or acceleration ........................ 13-1

ii. Dynamic measurements of angle ................................................................... 13-4

iii. Dynamic measurements of straightness (Wollaston) ................................. 13-6

C. SOFTWARE DESCRIPTION ..................................................................................... 13-8

D. MEASUREMENT PROCEDURE ............................................................................. 13-12

14. MEASUREMENTS – ANGULAR POSITIONING .................................. 14-1

A. GENERAL DESCRIPTION ...................................................................................... 14-1

B. MEASUREMENT SETUP ........................................................................................ 14-1

i. Characteristics of Wally – Rotary Measurement System ............................... 14-3

ii. Theory of operation .......................................................................................... 14-6

iii. Rotary measurements – hardware preparations ......................................... 14-7

CONTENTS

www.lasertex.eu

iv. Rotary measurements – battery charging...................................................... 14-10

v. Rotary measurements – elimination of error sources ................................... 14-10

C. SOFTWARE DESCRIPTION ................................................................................... 14-11

i. Connecting with Wally ................................................................................. 14-11

ii. Measurements of the rotation angle .............................................................. 14-12

iii. Measurements of angular positioning ...................................................... 14-15

iv. Pull down menu - File ................................................................................... 14-15

v. CNC path generation for in-axis measurements ........................................... 14-16

vi. CNC path generation for off-axis measurements .......................................... 14-19

vii. Pull down menu - Edit .............................................................................. 14-27

viii. Machine error limits .................................................................................. 14-29

ix. Positioning points generation ....................................................................... 14-30

x. Configuration of Positioning measurement .................................................. 14-31

xi. Pull down menu – Measurement .................................................................. 14-33

D. MEASUREMENT PROCEDURE ............................................................................. 14-34

i. Rules of automatic positioning measurement ............................................... 14-34

ii. Remarks on measurements and data analysis ............................................... 14-35

15. MEASUREMENTS - VELOCITY ................................................................. 15-1

A. GENERAL DESCRIPTION ...................................................................................... 15-1

B. MEASUREMENT SETUP ........................................................................................ 15-1

C. SOFTWARE DESCRIPTION ..................................................................................... 15-3

D. MEASUREMENT PROCEDURE ............................................................................... 15-8

16. CONNECTING LASER HEAD TO MACHINE ........................................ 16-1

A. GENERAL DESCRIPTION ...................................................................................... 16-1

B. EXTENSION CONNECTOR .................................................................................... 16-2

i. Extension Connector pinout ............................................................................ 16-2

ii. Extension Cable EX1 ....................................................................................... 16-3

iii. Encoder type outputs ................................................................................... 16-6

C. HPI-3D IN A MACHINE CONTROL LOOP ........................................................... 16-10

17. CONFIGURATION ........................................................................................ 17-1

CONTENTS

www.lasertex.eu

18. PRINCIPLES OF OPERATION .................................................................... 18-1

A. THE RULES OF LASER DISPLACEMENT MEASUREMENTS ...................................... 18-1

B. THE CONSTRUCTION OF REAL INTERFEROMETERS .............................................. 18-2

C. THE INFLUENCE OF THE OUTSIDE CONDITIONS ON THE MEASUREMENT ACCURACY

18-5

D. THE ACCURACY OF LASER INTERFEROMETERS .................................................... 18-6

i. Errors caused by the environment .................................................................. 18-6

ii. Dead path error ............................................................................................... 18-6

iii. Cosine error ................................................................................................. 18-7

iv. Abbe error ........................................................................................................ 18-8

v. Laser stability error ......................................................................................... 18-9

vi. Other errors ..................................................................................................... 18-9

vii. A summary of laser measurement system errors ...................................... 18-10

19. TROUBLESHOOTING .................................................................................. 19-1

20. TECHNICAL DATA ....................................................................................... 20-1

A. SYSTEM SPECIFICATIONS ..................................................................................... 20-1

B. LASER HEAD ........................................................................................................ 20-1

C. LASER HEAD OUTPUTS - ANALOG ...................................................................... 20-2

D. LASER HEAD OUTPUTS – DIGITAL, TYPE 1 .......................................................... 20-2

E. LASER HEAD OUTPUTS – DIGITAL, TYPE 2 .......................................................... 20-2

F. LASER HEAD OUTPUTS – EXTENSION CONNECTOR PINOUT .............................. 20-3

G. SYSTEM WORK CONDITIONS ................................................................................ 20-4

H. POWER SUPPLY .................................................................................................... 20-4

I. PC INTERFACE ..................................................................................................... 20-4

J. ENVIRONMENT COMPENSATION ......................................................................... 20-4

21. INDEX ..................................................................................................................... 1

INTRODUCTION

1-1 www.lasertex.eu

1

1. INTRODUCTION

Laser measurement system HPI-3D is a two frequency laser interferometer

intended to be used mainly in machine geometry measurements. Its small size and

low weight simplify transportation and make the instrument especially useful for

service applications. Software version for Windows XP/Vista/7/8 and automation of

many measurement processes make the interferometer easy to use. Software,

compliant with ISO 230-2 and similar norms, enable making rapports and diagrams.

It is possible to choose statistical results processing according to norms: ISO 230-2

(European), VDI/DGQ 3441 (German), NMTBA (USA), BSI BS 4656 Part 16 (British)

and PN-93 M55580 (Polish).

Laser Measurement System HPI-3D is highly configurable device although

already in its basic configuration it allows performing the complicated measurements

at highest possible precision. Available options will be described below in this user

manual.

Very good technical parameters of the interferometer allow using it in scientific

laboratories, for precision positioning, for scaling optical and magnetic measurement

systems, etc.

a. Safety considerations

The Laser Interferometer HPI-3D is a Safety Class I product designed and

tested in accordance with international safety standards. It is also a Class II Laser

product conforming to international laser safety regulations. The instrument and the

manual should be inspected and reviewed for safety markings and instructions

before operation.

INTRODUCTION

1-2 www.lasertex.eu

1

b. Warnings

Although the laser measurement system HPI-3D is design to be used in harsh

environment, the following conditions must be met:

The Laser Head must not be put near strong magnetic fields.

The head should not be unscrewed from its base and if it is, it may not be put

on a heat sink (e.g. thick metal plate).

The head must not be thrown or dropped.

Keep the optical components clean and avoid scratching them.

When the optics is dusted, clean it with pure alcohol.

Do not use the system beyond its work conditions.

c. Compliance Information

INTRODUCTION

1-3 www.lasertex.eu

1

EC-DECLARATION OF CONFORMITY 2012

Wroclaw, 2012-04-20

Manufacturer

LASERTEX Co LTD.

Radzionkowska 17

51-506 Wrocław

Poland

Hereby certifies on its sole responsibility that the following product:

Laser Measurement System HPI-3D

which is explicitly referred to by this Declaration meet the following directives and standard(s):

Directive 2006/95/EC

Electrical Apparatus

Low Voltage Directive

- EN 61010-1:2011

Directive 2006/42/EU

Machinery Directive

- EN 60825-1:2007

Directive 2004/108/EU

Electromagnetic Comatibility:

- EN 61326-1:2006

- EN 61000-4-2:2011

- EN 61000-4-6:2007

- EN 61000-4-8:2010

- EN 61000-4-11:2007

- EN 55011:2007

- EN 55022:2011

Documentation evidencing conformity with the requirements of the Directives is kept available for

inspection at the above Manufacture.

President, Janusz Rzepka PhD

QUICK START

2-1 www.lasertex.eu

2

2. QUICK START

The information presented in this chapter is only for quick start. More detailed

information can be found in the following chapters.

a. Main features

The HPI-3D is a device for contact measurement of the velocity of the moving

object.

The device operates according to the laser interferometer principle (see

Principles of Operation chapter). The Doppler shift phenomenon is used.

The basic measurement unit is the wavelength of the laser, i.e. 632nm.

The functionality of the instrument depends on the type of used optical

components.

The HPI-3D is can be used either as a stand alone device or with a PC

computer and the dedicated HPI Software.

b. How it works

The HPI-3D measures shift of the moving element in relevance to the reference

element as shown in the figure 2.1. It is important to notice, that the relative

movement and not the absolute position of any of the elements is detected!

QUICK START

2-2 www.lasertex.eu

2

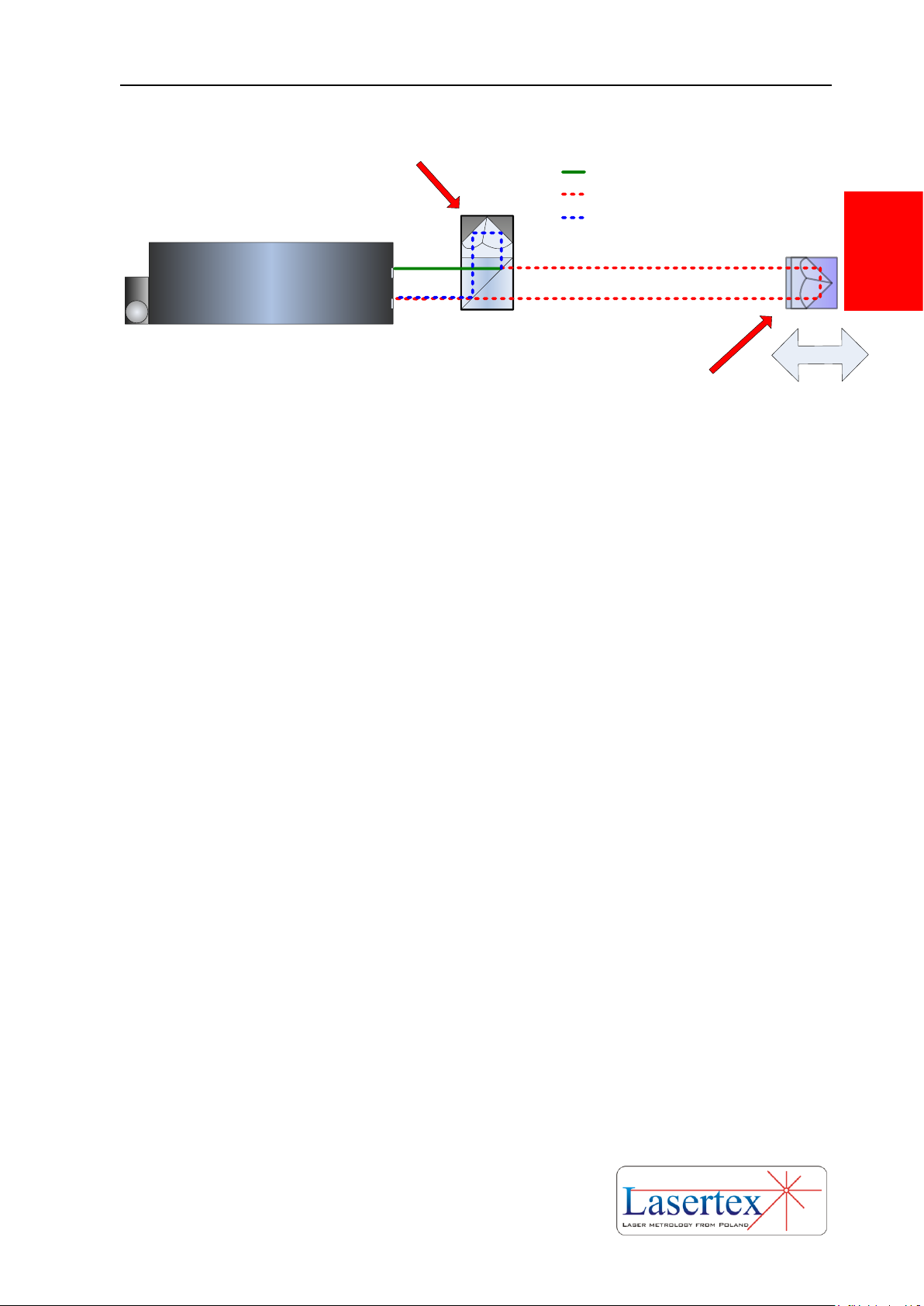

LASER HEAD

Horizontal & Vertical polarization

Horizontal polarization

Vertical polarization

Reference element

Moving element

FIG. 2.1. ILLUSTRATION OF THE PRINCIPLE OF OPERATION - LINEAR OPTICS

i. Linear optics

i. To the linear optics belong Linear Interferometer IL1 and Linear

Retroreflector RL1.

The operation of the HPI-3D with the linear optics used is shown in the figure

2.1. The laser outputs the laser beam consisting of two polarizations: Horizontal (H)

and Vertical (V). The Reference element (IL1) splits the beam into two parts. The H

polarized beam is reflected back to laser and the V polarized beam is directed into the

measurement path. The frequency of the V beam is changed according to the Doppler

Effect when the moving element is in motion.

The linear optics is mainly used for measurement of:

Shift

Velocity

Acceleration

Vibrations

Straightness with 3D method

Squareness with 3D method (RE3D element required)

Parallelism with 3D method (RE3D element required)

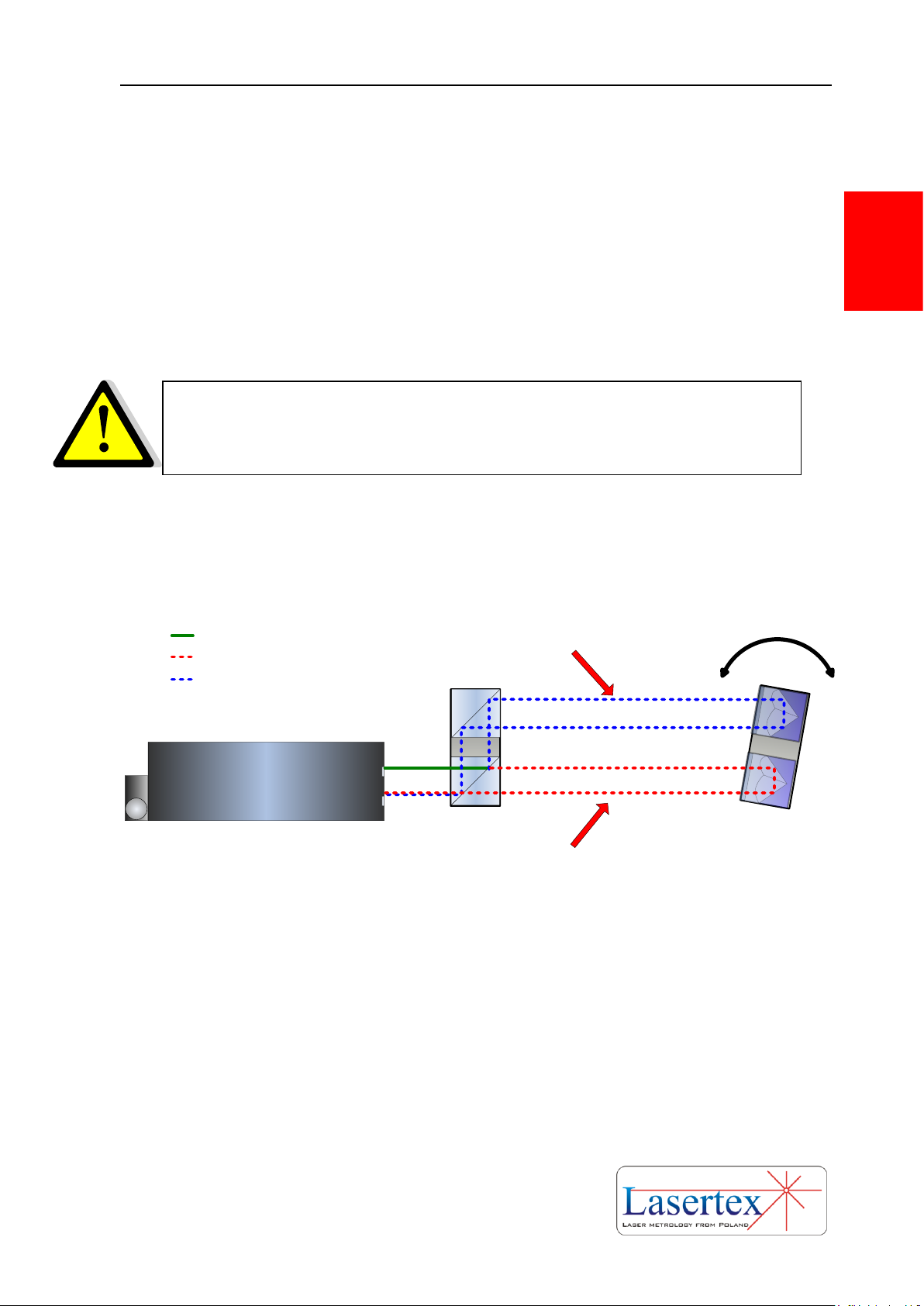

ii. Angular optics

To the angular optics belong Angular Interferometer IK1 and Angular

Retroreflector RK1.

QUICK START

2-3 www.lasertex.eu

2

The operation of the HPI-3D with the angular optics used is shown in the

figure 2.2. The laser outputs the laser beam consisting of two polarizations:

Horizontal (H) and Vertical (V). The IK1 splits the beam into two parts. Both beams

are directed into the measurement path but are parallel shifted by 50.8 mm. The

frequency of both beams is changed according to the Doppler Effect when the RK1

element is in motion.

The frequency change of both beams is the same when RK1 and IK1 are shifted

linearly. In this case no measured signal is detected by the laser head.

The laser detects movement only when the IK1 and RK1 are rotated against

each other. In this case the frequency change of the H beam is different from the

frequency change of the V beam.

RK

1

IK1

LASER HEAD

Horizontal & Vertical polarization

Horizontal polarization

Vertical polarization

Beam Path 1

Beam Path 2

FIG.2.2. ILLUSTRATION OF THE PRINCIPLE OF OPERATION - ANGULAR OPTICS

The angular optics is mainly used for measurement of:

Small angles

Straightness with Angular method

Flatness

Pitch

Yaw

The laser head with angular optics is insensitive to linear

movements.

QUICK START

2-4 www.lasertex.eu

2

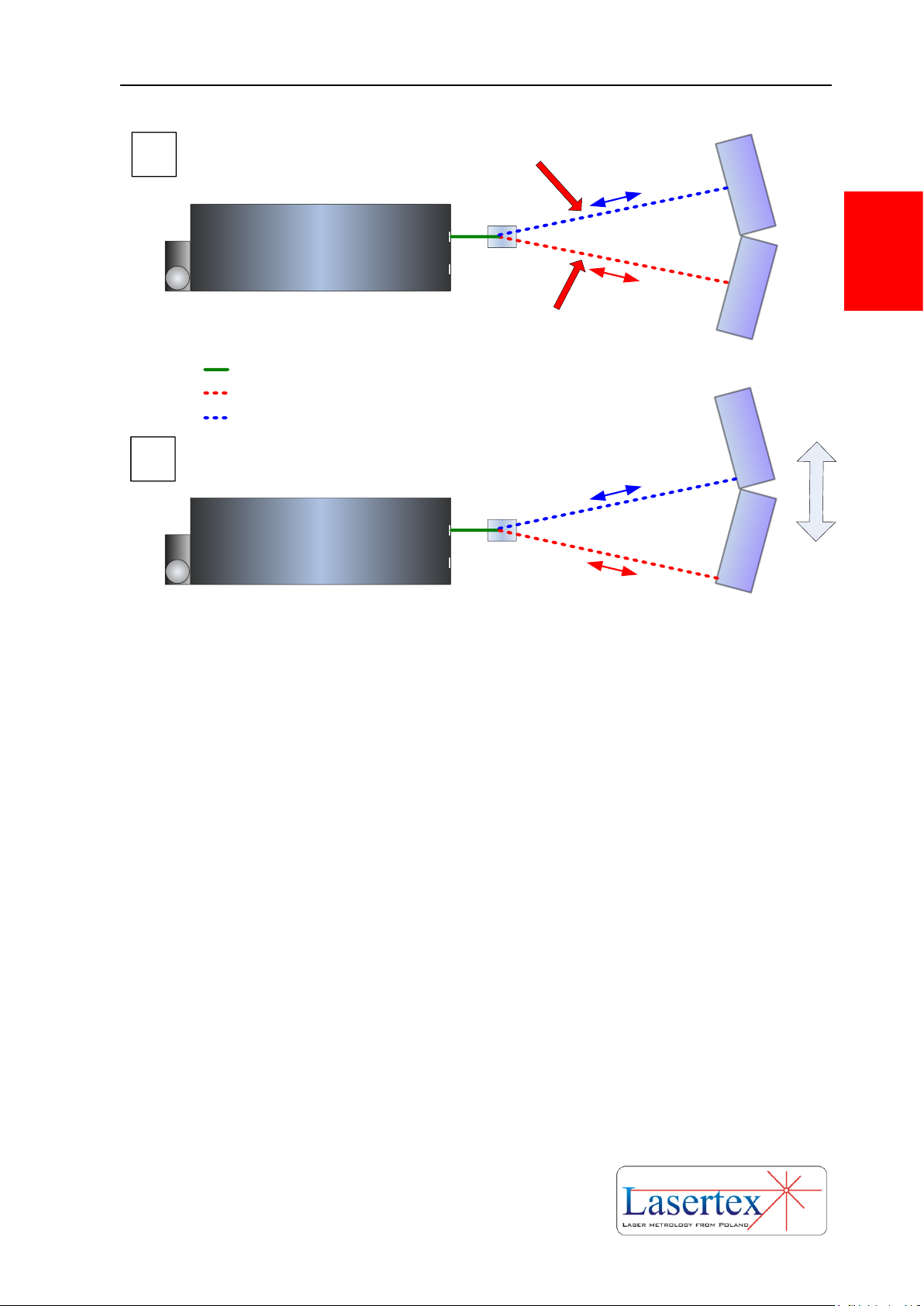

iii. Wollaston optics

To the angular optics belong Wollaston Prism WP2 and Wollaston

Retroreflector WRP2.

The operation of the HPI-3D with the Wollaston optics used is shown in the

figure 2.3. The laser outputs the laser beam consisting of two polarizations:

Horizontal (H) and Vertical (V). The WP2 splits the beam into two parts. Both beams

are directed into the measurement path. There is a certain angle between the beams.

The frequency of both beams is changed according to the Doppler Effect when the

WP2 element is in motion.

The frequency change of both beams is the same when WP2 and WP2 are

shifted linearly. In this case no measured signal is detected by the laser head.

The laser detects movement only when the WP2 is moved perpendicular to the

beam from the laser. In this case the frequency change of the H beam is different from

the frequency change of the V beam, because the lengths of beam paths 1 and 2 are

different – see figure 2.3

The laser head with Wollaston optics is insensitive to linear

movements.

QUICK START

2-5 www.lasertex.eu

2

LASER HEAD

WP2

WRP2

LASER HEAD

WP2

WRP2

Horizontal & Vertical polarization

Horizontal polarization

Vertical polarization

Beam Path 1

Beam Path 2

A

B

FIG.2.3. ILLUSTRATION OF THE PRINCIPLE OF OPERATION - WOLLASTON OPTICS.

BEAMS RETURING TO THE LASER ARE IN THE PLANE OF THE DRAWING.

The Wollaston optics is mainly used for measurement of:

Straightness with Wollaston method

Axes squareness (with REW element)

Axes parallelism (with REW element)

c. How to start

QUICK START

2-6 www.lasertex.eu

2

1. Install HPI software from CD or from www.lasertex.eu

LASER HEAD

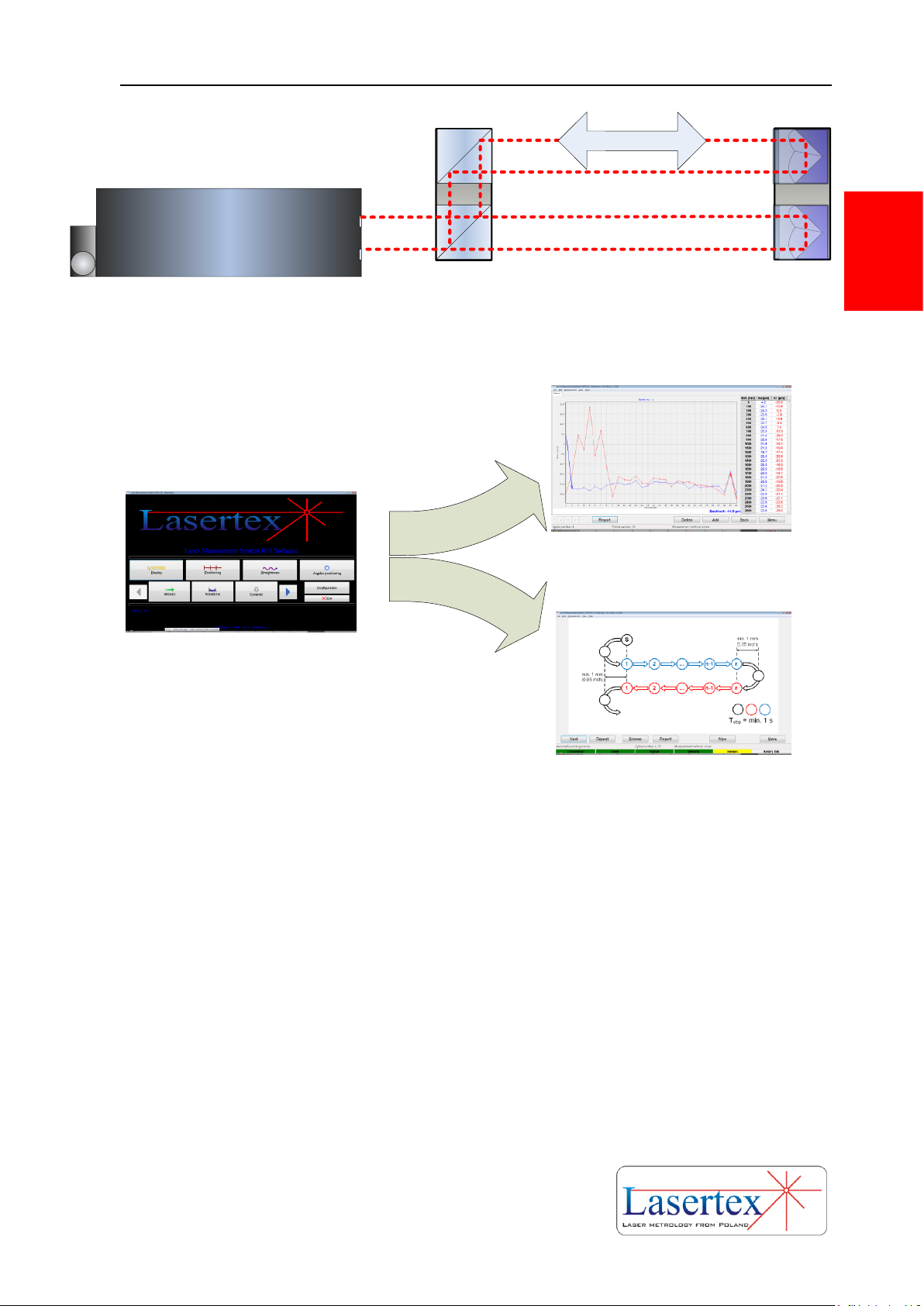

2. Mount Laser Head, and optical elements on the measured

machine. Connect power supply to the Laser Head.

LASER HEAD

USB

Bluetooth

3. Run HPI Software and connect PC with laser over

USB or over Bluetooth interface

QUICK START

2-7 www.lasertex.eu

2

LASER HEAD

4. Align optical path

5. Start measurements

PREPARATIONS

3-1 www.lasertex.eu

3

3. PREPARATIONS

The Laser Interferometer HPI-3D requires an installation of software "HPI

Software” on a hard disc of a PC computer. The hardware requirements are:

Windows XP/Vista/7/8 system,

CR-ROM

Pentium processor, 1 GHz or better

SVGA graphic card

USB 2.0 or Bluetooth 2.0

a. Software installation

The software installation package is located on the USB memory stick that is

included to the measurement system. HPI_Software_Install application can be

launched from the USB memory. The installation process should start automatically.

FIG. 3.1. ICON OF THE SETUP APPLICATION.

Following components have to be installed for proper operation of HPI-3D

system:

HPI Software application,

Directory of the languages Languages,

FTDI Driver for USB,

documents folder with the manual and other documents (depending on a

system version),

Database BDE (Borland Database Environments)

PREPARATIONS

3-2 www.lasertex.eu

3

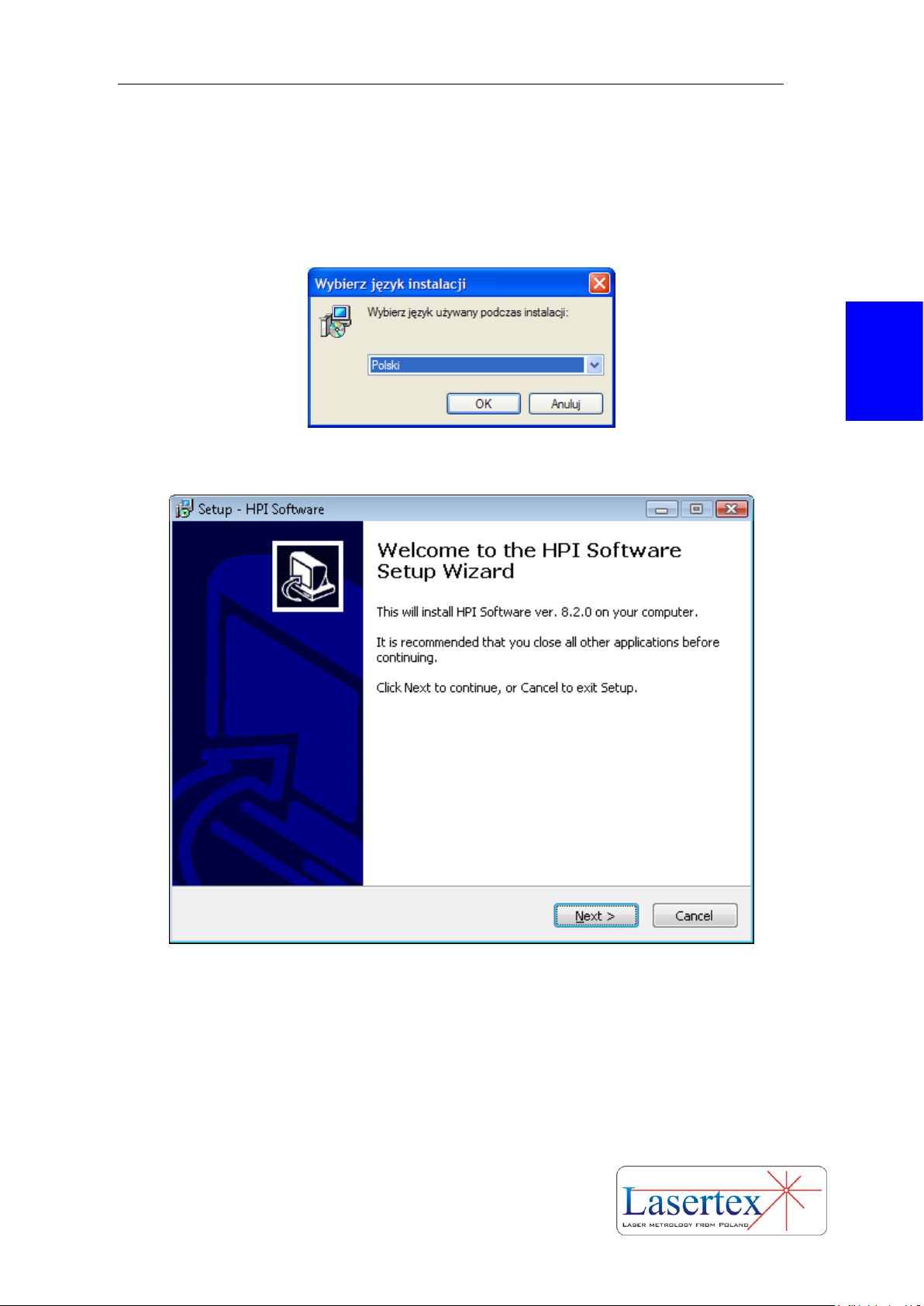

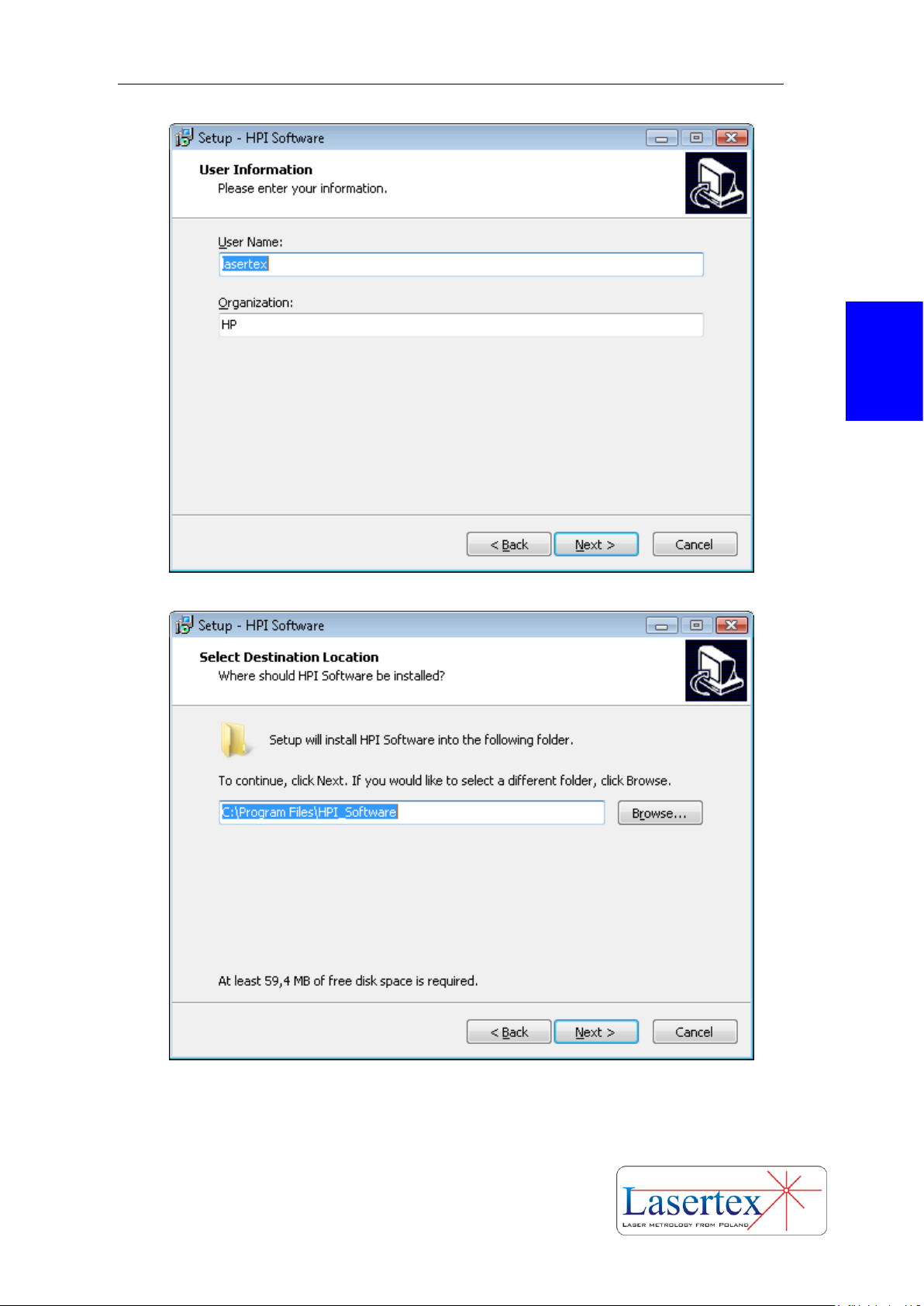

During the installation process necessary parameters have to be set by the user.

In the figure 3.2 there is shown a first windows that appears during installation. It

allows choosing the installation language.

FIG.3.2. INSTALLATION LANGUAGE SETUP WINDOW.

FIG.3.3. WELCOME WINDOW.

PREPARATIONS

3-3 www.lasertex.eu

3

FIG.3.4. USER INFORMATION WINDOW.

FIG.3.5. PROGRAM DESTINATION FOLDER WINDOW.

PREPARATIONS

3-4 www.lasertex.eu

3

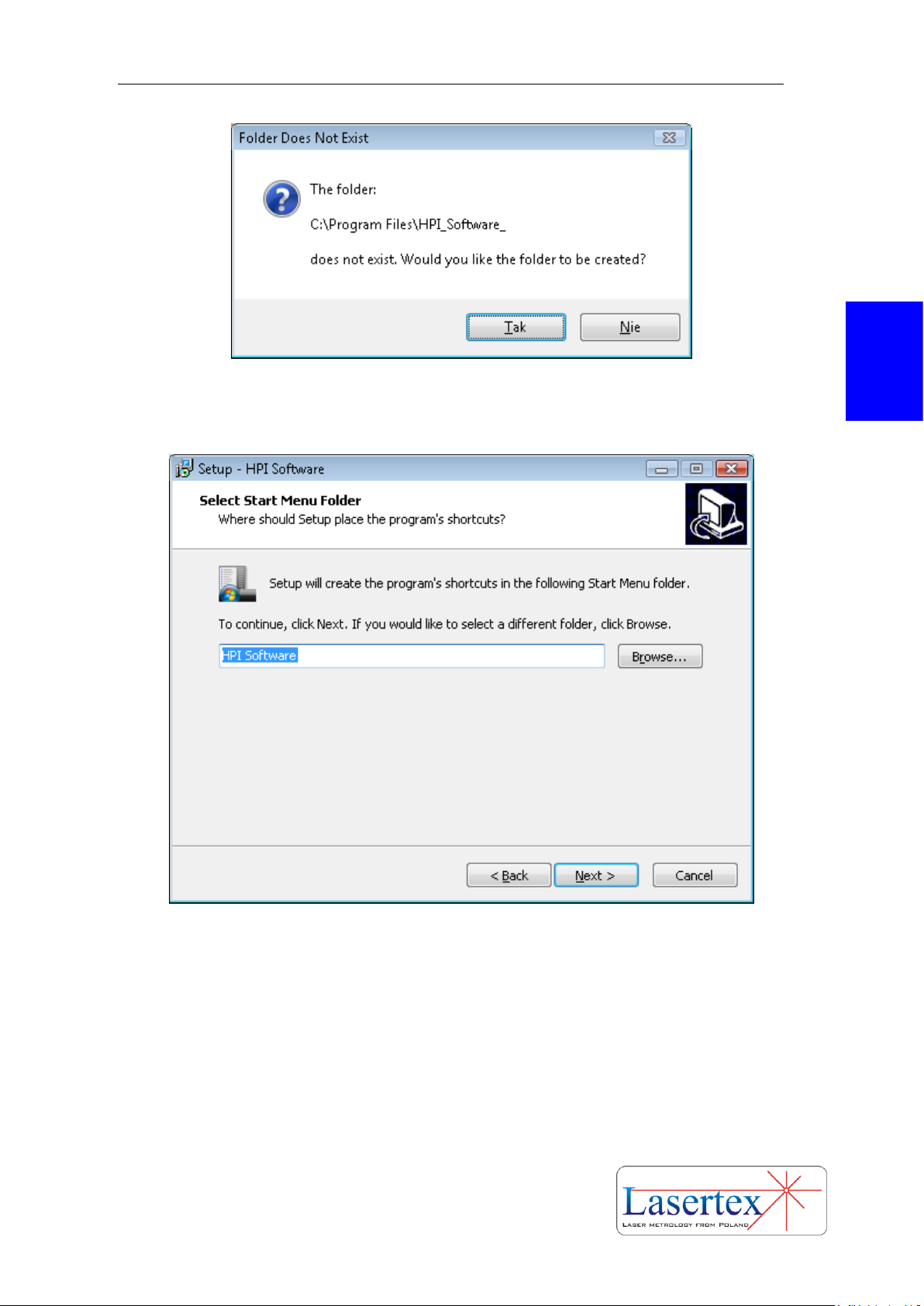

FIG.3.6. WINDOW APPEARING WHEN THE FOLDER NAME DOES NOT EXISTS IN THE CURRENT

INSTALLATION PATH.

FIG.3.7. MENU START FOLDER SLECTION WINDOW.

PREPARATIONS

3-5 www.lasertex.eu

3

FIG.3.8. DESKTOP ICON SETUP WINDOW.

FIG.3.9. WINDOW WITH INSTALLATION INFORMATION.

PREPARATIONS

3-6 www.lasertex.eu

3

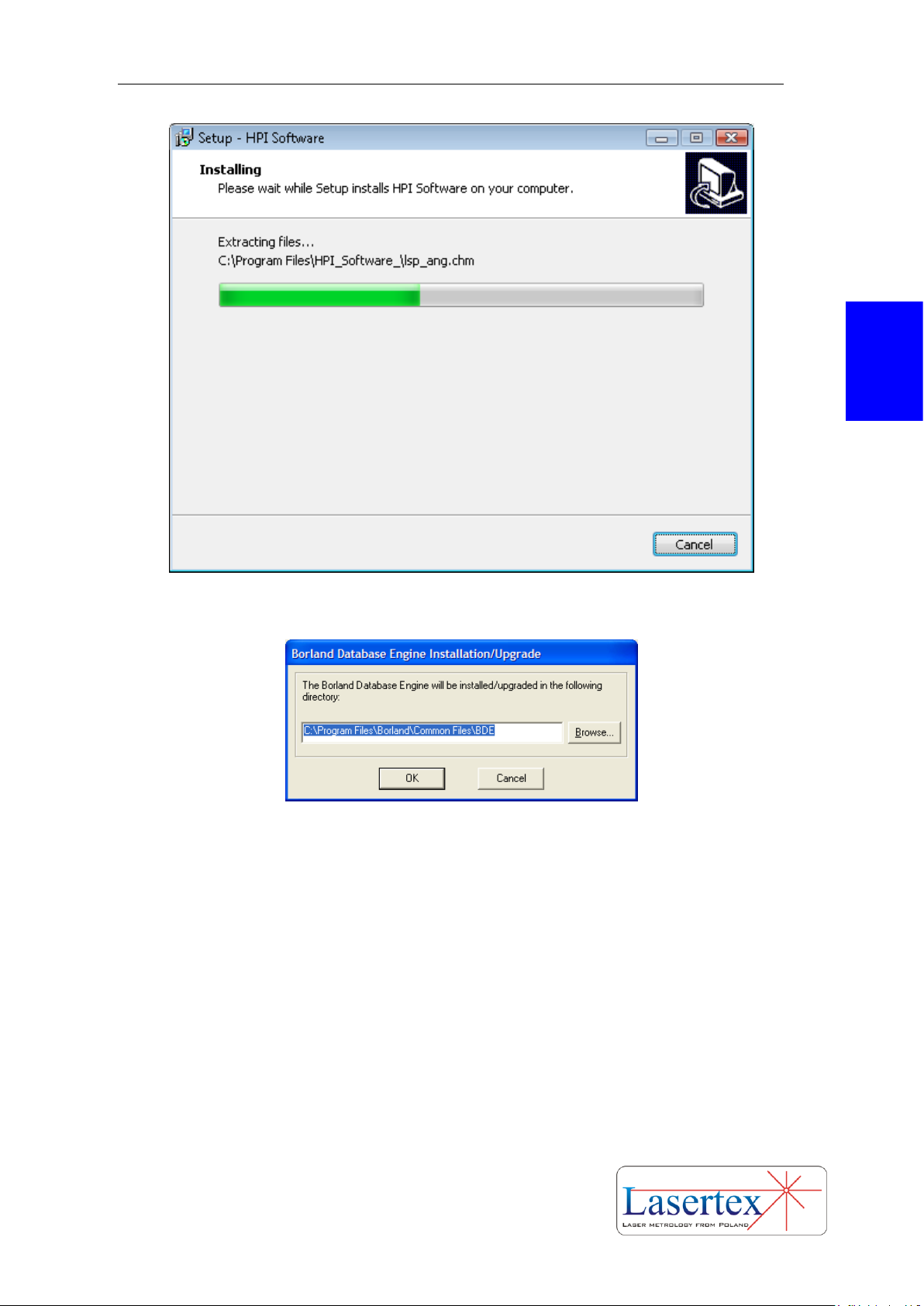

FIG.3.10. INSTALLATION WINDOW DURING DATA COPY OPERATION.

FIG.3.11. BDE (BORLAND DATABASE ENVIRONMENT) DESTINATION FOLDER WINDOW.

PREPARATIONS

3-7 www.lasertex.eu

3

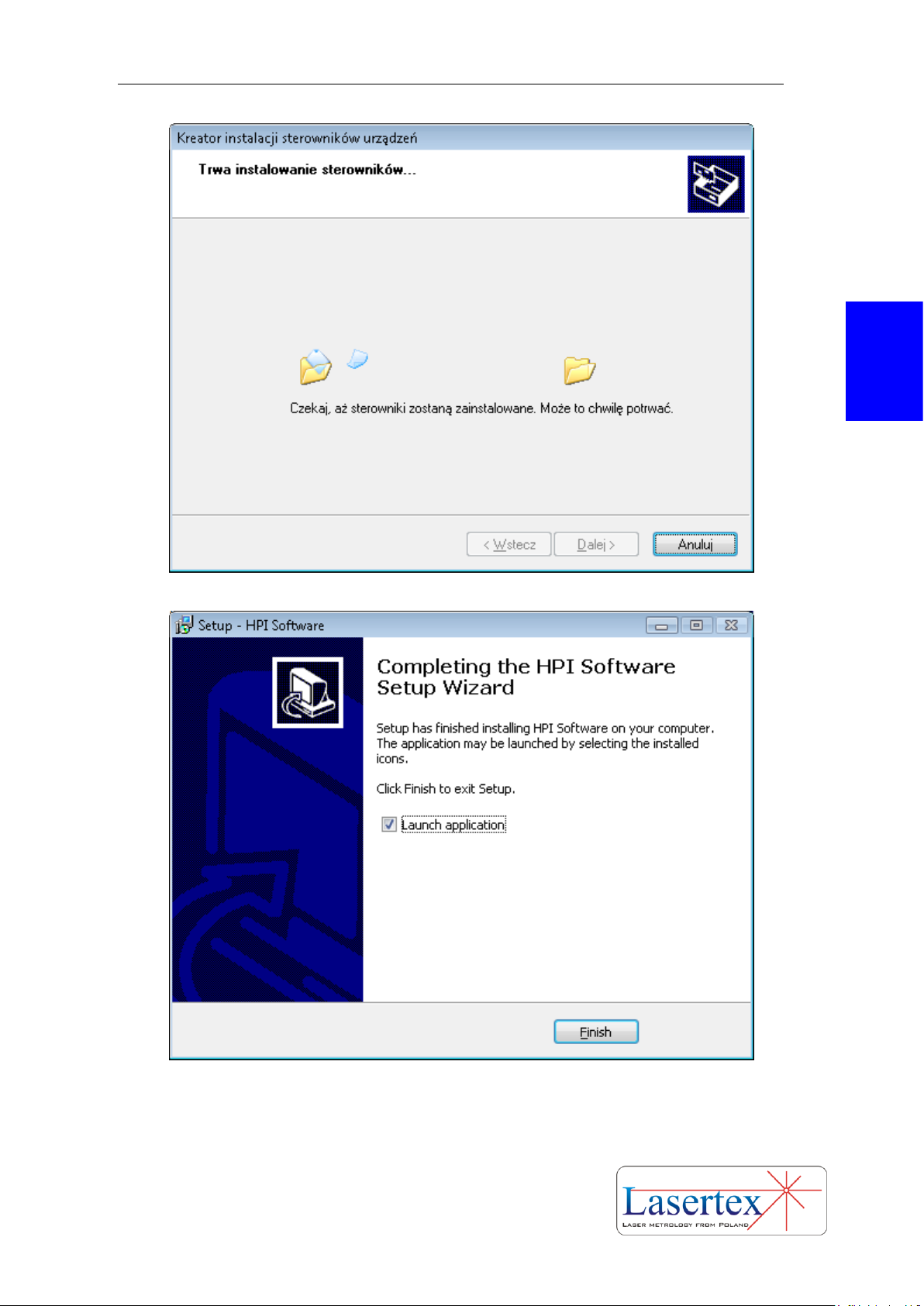

FIG.3.12. FTDI DRIVER INSTALLATION.

FIG.3.13. INSTALLATION SUMMARY WINDOW

PREPARATIONS

3-8 www.lasertex.eu

3

In most cases, the installation is semi-automatic requiring only confirmation by

the Enter key.

When the software is installed on the computer, also drivers should be

installed. To complete this process, the system has to be connected by a USB cable to

your PC. Driver installation is performed automatically by Windows.

FIG.3.14. MESSAGE APPEARING WHEN THE NEW USB DEVICE IS FOUND.

FIG.3.15. MESSAGE APPEARING WHEN THE DRIVER FOR HPI-3D DEVICE IS INSTALLED.

The HPI Software application can be launched from the HPI Software folder

located in Programs tab in Windows Start Menu (assuming that the installation

settings are not changed). The application can also be launched from the desktop, if

the shortcut is created during installation.

FIG.3.16. ICON OF HPI SOFTWARE APPLICATION.

In order to uninstall the HPI Software application please choose Uninstall HPI

Software from Menu Start.

FIG.3.17. ICON OF HPI SOFTWARE DEINSTALLATION APPLICATION

PREPARATIONS

3-9 www.lasertex.eu

3

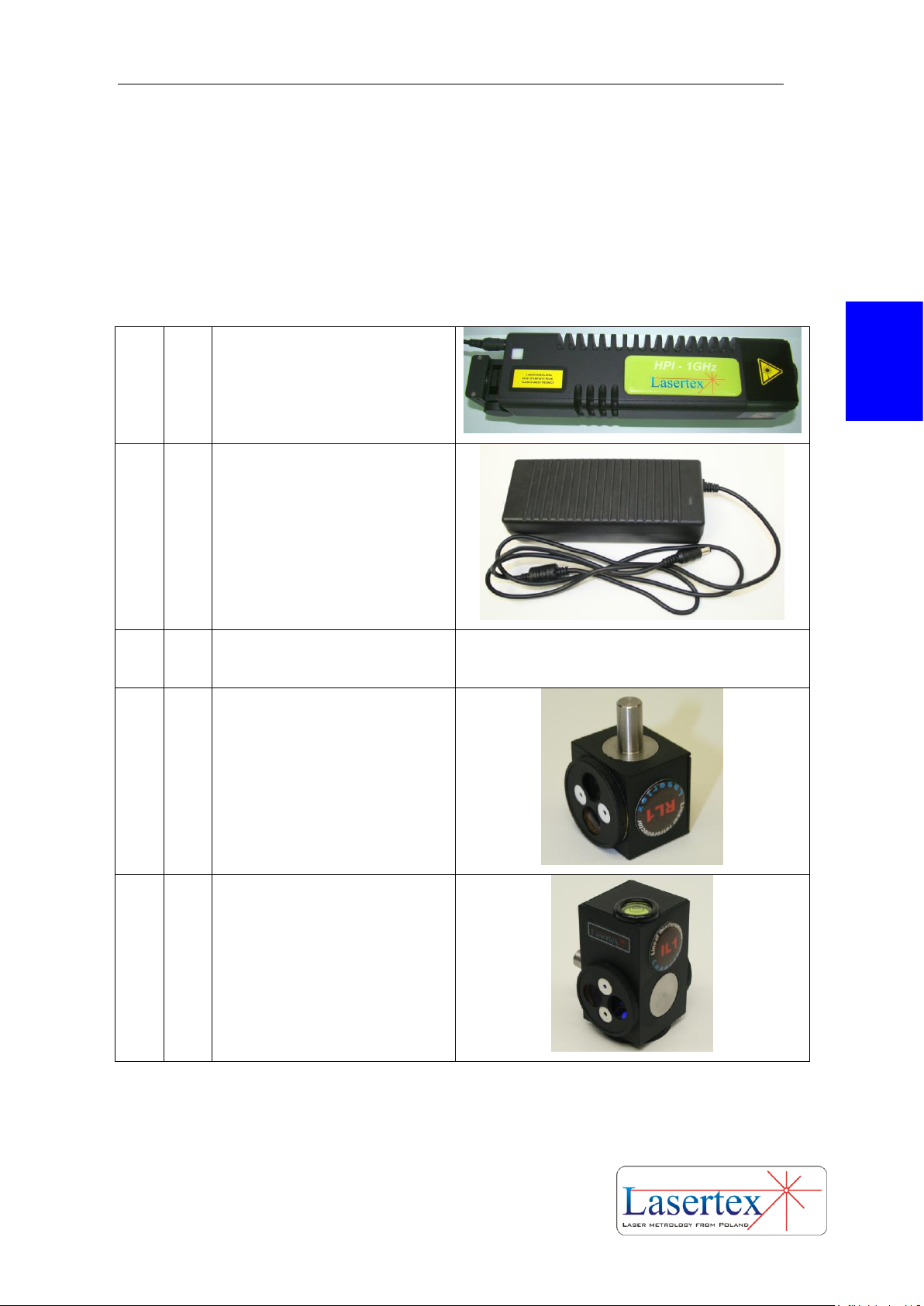

b. Elements of the Laser System

Number of the system elements is configurable and its configuration is related

to the required application. Following items are included in the standard set (for

linear measurements):

1.

1

pcs

Laser head

2.

1

pcs

Power Supply

3.

1

pcs

Tripod stand

4.

1

pcs

Linear retro-

reflector RL1

5.

1

pcs

Linear

interferometer IL1

Loading...

Loading...