Page 1

LaserSpeed LS8000-3

INSTRUCTION HANDBOOK

- installation, setup and technical reference (for qualified personnel only)

www.betalasermike.com

Manual Part Number: 93463 • Manual Drawing Number: 0921-01561 • English • Revision A• © Copyright Sep 2007

Page 2

Declaration of Conformity

LaserSpeed 8000-3 Instruction Handbook

Contents

Part No. 93463 / Drawing No. 0921-01561 Page 2 of 221 Revision A (Sep 2007)

Page 3

LaserSpeed 8000-3 Instruction Handbook

Contents

Contents ...............................................................................................................................3

Proprietary Statement..........................................................................................................7

European Commission Requirements................................................................................8

Safety Information................................................................................................................9

Intended Use .......................................................................................................................................9

Laser Classification ...........................................................................................................................10

Laser Safety Precautions ..................................................................................................................11

Labels and Safety Features ..............................................................................................................12

LS8000-3 Labels.....................................................................................................................12

LS8000-3E Labels ..................................................................................................................13

LS8000-3X Labels ..................................................................................................................13

Introduction ........................................................................................................................14

System Overview................................................................................................................14

Principle of Operation ........................................................................................................................14

Contents

Installing the System .........................................................................................................16

Mounting the Gauge ..........................................................................................................................16

Mounting Distance ..................................................................................................................17

Laser Safety............................................................................................................................17

Environmental Conditions.......................................................................................................17

Ambient Temperature ................................................................................................17

Coolant ......................................................................................................................17

Air Wipe / Quick Change Window .............................................................................18

Steam & Mist .............................................................................................................18

Mounting Location ..................................................................................................................19

Twinner Lines .........................................................................................................................20

Aligning the Gauge ............................................................................................................................20

Aligning the Gauge ............................................................................................................................21

Gauge Orientation ..................................................................................................................23

Connecting Power to the Gauge .......................................................................................................24

Connecting to Outputs.......................................................................................................................25

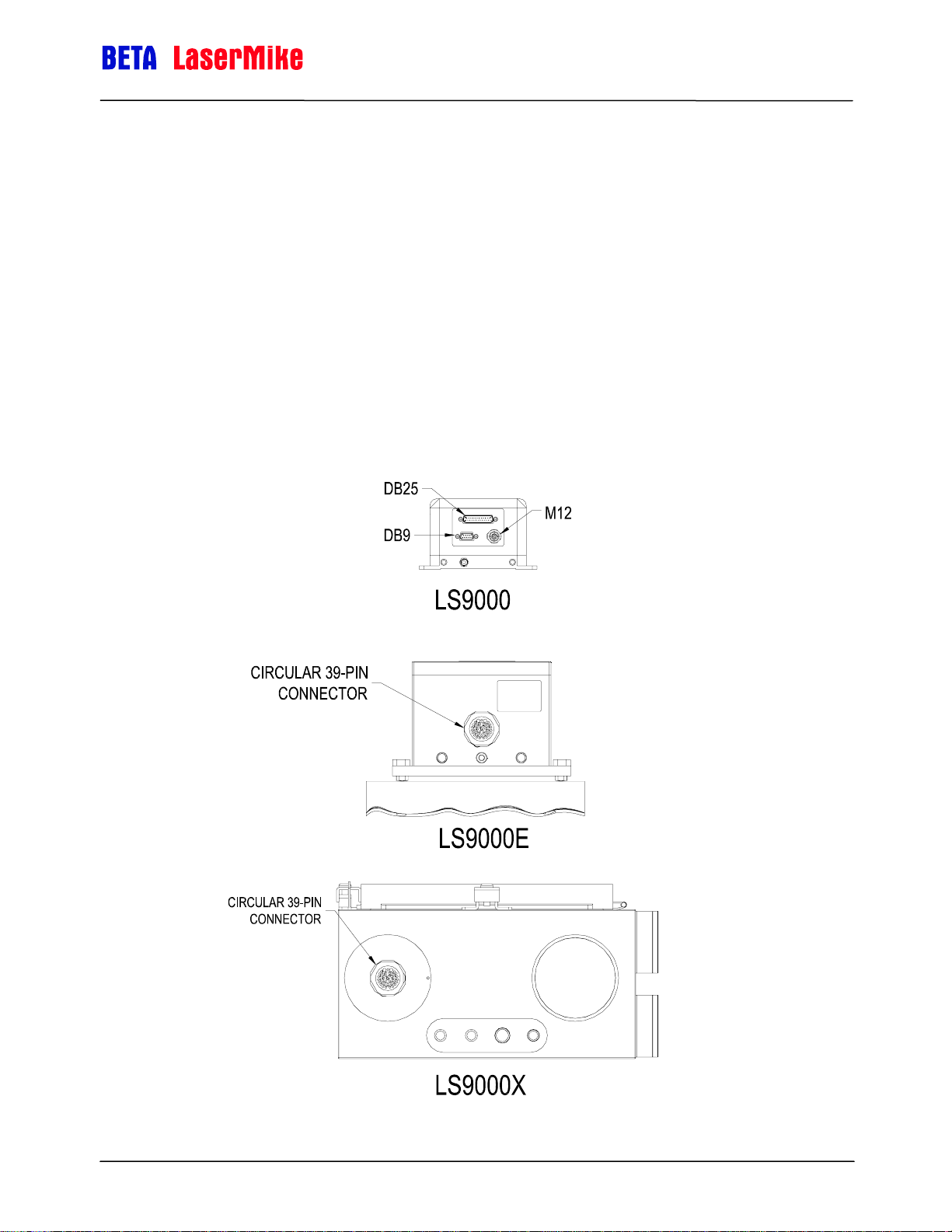

LS8000-3 25-Pin Connector Pinout........................................................................................26

LS8000-3 9-Pin Connector Pinout..........................................................................................27

LS8000-3 M12 Connector Pinout ...........................................................................................27

LS8000-3E/LS8000-3X Connector Pinout..............................................................................28

LS8000-3E/LS8000-3X Breakaway Cable Pinout ..................................................................30

Maximizing Performance ...................................................................................................................31

Material Present Adjustment ..................................................................................................32

Material Present Dropout Time Selection...............................................................................32

Validation Time Limit Selection ..............................................................................................32

Starting/Ending Length Correction .........................................................................................33

Interfacing with the LS8000-3............................................................................................ 34

LS8000-3 Interface Connectors ........................................................................................................34

DB25 Connector .....................................................................................................................35

RS-232 Transmit and Receive (Pins 1-2)..................................................................36

High Speed Pulse Output (Pins 3, 5, 7, 9) ................................................................37

User Scaleable Pulse Output (Pins 15, 4, 6, 8).........................................................38

Part No. 93463 / Drawing No. 0921-01561 Page 3 of 221 Revision A (Sep 2007)

Page 4

LaserSpeed 8000-3 Instruction Handbook

Contents

Differential vs. Single Ended Pulse Outputs..............................................................38

Quadrature Output Phase Relationships...................................................................39

Quadrature Outputs at Extremely Low Pulse Frequencies .......................................41

Material Present Input (Pin 10)..................................................................................43

Connecting Material Present Switches......................................................................46

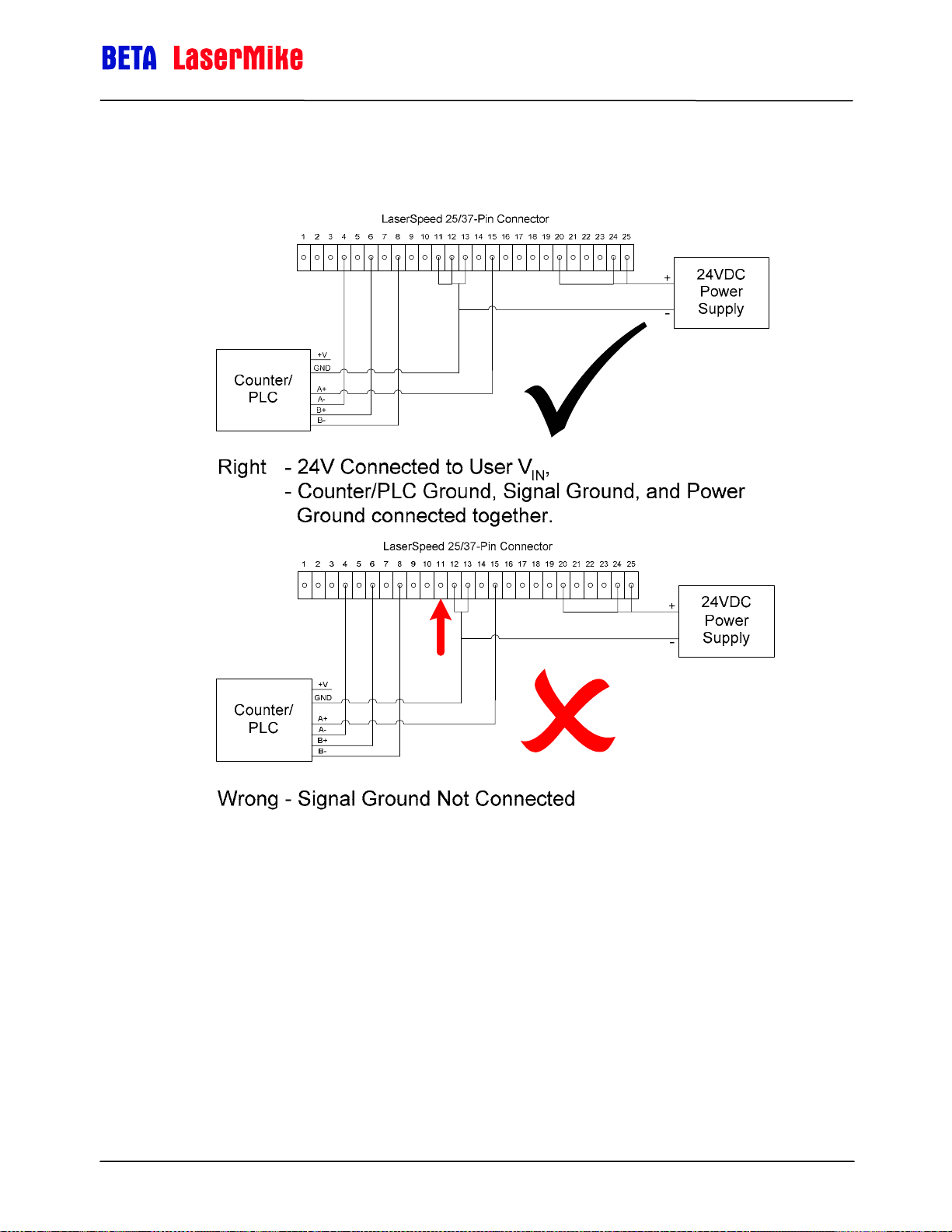

Signal Grounds (Pins 11, 19, 21) ..............................................................................49

Measurement Direction Input (Pin 14).......................................................................51

Laser Interlock (Pin 16) .............................................................................................52

Shutter Control (Pin 17) .............................................................................................53

Length Reset Input (Pin 18).......................................................................................53

User V

Index (Printer) Pulse Output (Pins 22-23) .................................................................55

+24V

DB9 Connector .......................................................................................................................56

RS-422 Transmit (+/-) and Receive (+/-) (Pins 1-4) ..................................................56

Analog Output Voltage/Ground (Pins 6-7).................................................................57

Measurement Synchronization Input (Pins 8-9) ........................................................59

M12 Ethernet Connector ........................................................................................................60

LS8000-3 M12 Connector Pinout ..............................................................................60

LS8000-3 Interface Cables................................................................................................................61

DB25 Cables...........................................................................................................................61

Ethernet Cables ......................................................................................................................61

Heavy Industrial Cables..........................................................................................................62

Breakaway Cables..................................................................................................................63

Low Temperature Breakaway Cable .........................................................................64

High Temperature Breakaway Cable ........................................................................64

Breakaway Cable Mounting Bracket .........................................................................65

LS8000-3 Breakout Assemblies ........................................................................................................66

DB25 Breakout Assemblies....................................................................................................67

Mounting Dimensions for: 85328, 85329...................................................................67

DB37 Breakout Assemblies....................................................................................................68

Mounting Dimensions for: 85321, 85322, 85323, 85324 ..........................................68

Breakout Assembly Pinouts....................................................................................................69

RS-232 Connector .....................................................................................................69

RS-422 Connector .....................................................................................................69

Ethernet Connector ...................................................................................................70

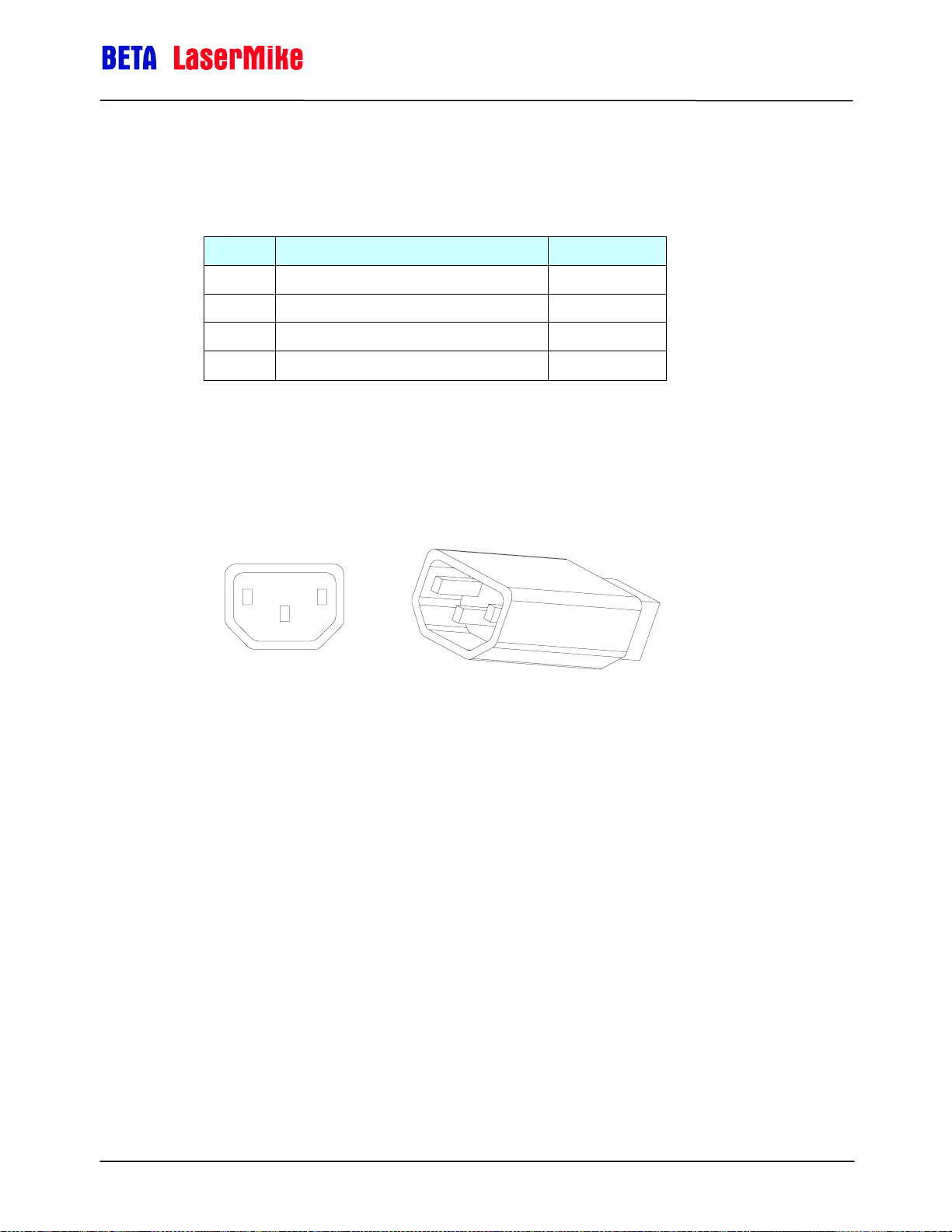

Breakout Assembly A/C Power Connector................................................................70

Application Interfaces ........................................................................................................................71

Light Stack Interface ...............................................................................................................71

Thermostat Interface...............................................................................................................73

Index Pulse & Length Thresholds...........................................................................................74

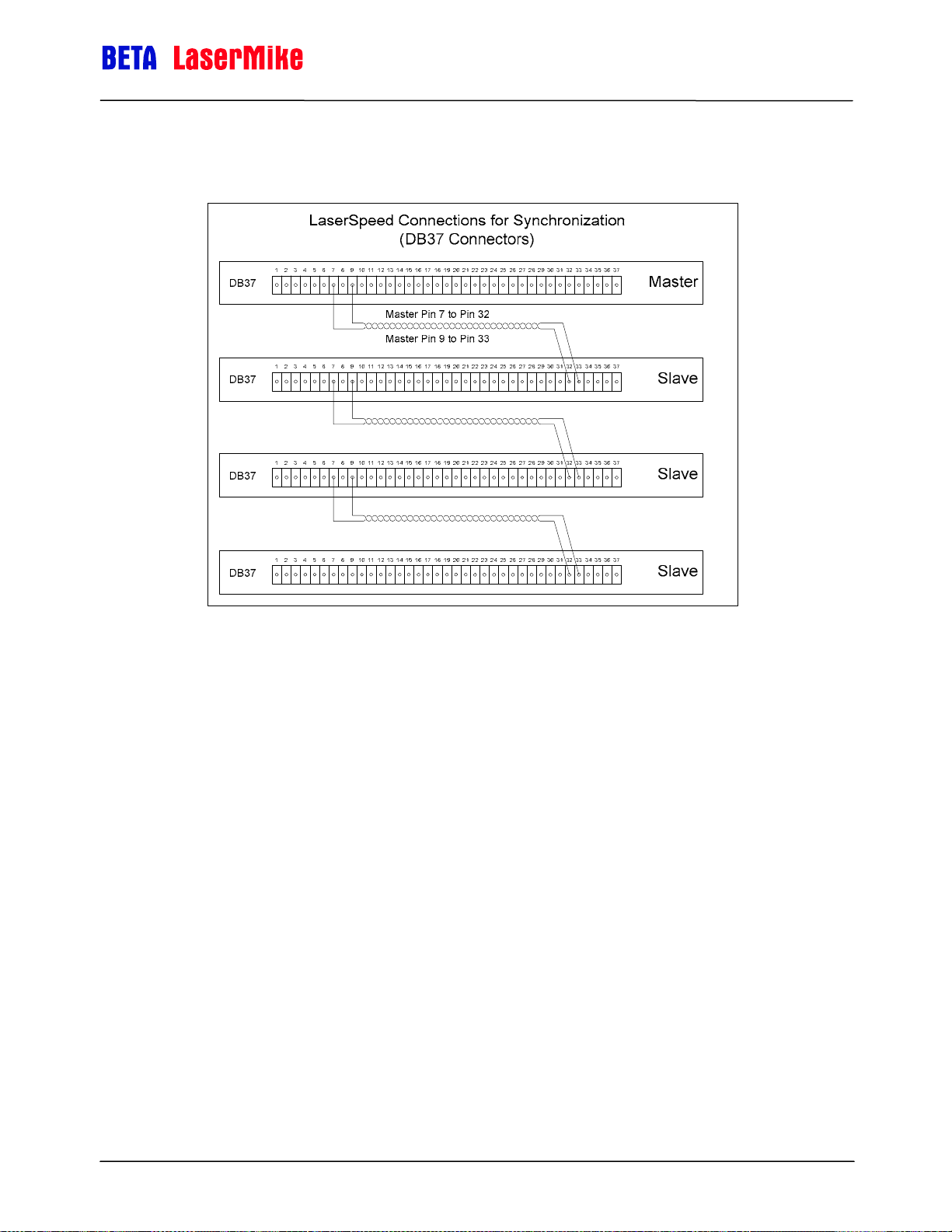

Gauge-Gauge Synchronization ..............................................................................................75

Banner D10 Through Beam Switch...................................................................................................77

Single through beam...............................................................................................................77

Dual through beam (uses two D10 modules) .........................................................................77

Banner Retroflective Switch (Picodot)...............................................................................................78

DataPro 1000 ....................................................................................................................................79

DataPro 3000 ....................................................................................................................................80

DataPro 5000 BB ..............................................................................................................................81

DataPro 5000 DN ..............................................................................................................................82

DataPro 5000 DN – Beckhoff I/O ......................................................................................................83

Domino A Series ...............................................................................................................................84

Durant President Series ....................................................................................................................85

Hengstler 723.1 .................................................................................................................................87

Imaje S4/S8 .......................................................................................................................................88

MI800.................................................................................................................................................89

(Pin 20)........................................................................................................54

IN

Power Input (Pins 24-25) and Power Grounds (Pins 12-13) ........................55

DC

Part No. 93463 / Drawing No. 0921-01561 Page 4 of 221 Revision A (Sep 2007)

Page 5

LaserSpeed 8000-3 Instruction Handbook

Newport P6000A ...............................................................................................................................90

Red Lion PAXI ...................................................................................................................................91

Siemens Counter Module 450-1 .......................................................................................................92

Siemens Counter Module 6ES5 385-8MB11 ....................................................................................93

TrueMeter ..........................................................................................................................................94

LaserTrak Software............................................................................................................95

LaserTrak for Windows .....................................................................................................................95

Installing the LaserTrak Software......................................................................................................95

System Requirements ............................................................................................................95

Software Installation Procedure..............................................................................................96

Starting LaserTrak ..................................................................................................................96

Chart Recorder Screen .....................................................................................................................99

Gauge Info ..............................................................................................................................99

Gauge Status........................................................................................................................100

LaserTrak Toolbar ................................................................................................................101

LaserTrak Menus..................................................................................................................101

File Menu .................................................................................................................101

Tools Menu ..............................................................................................................102

LaserTrak Configuration Screens....................................................................................................106

Standard Operating Parameters...........................................................................................109

Output Configuration Parameters.........................................................................................110

Advanced Operating Parameters .........................................................................................111

Chart Recorder Toolbar ........................................................................................................114

Displaying Data ...............................................................................................................................115

Chart Display ........................................................................................................................115

Monitor Display .....................................................................................................................117

Length Mode Display............................................................................................................118

Contents

RS-232/RS-422 Communication ......................................................................................121

Baud Rate & Framing ......................................................................................................................121

Serial Commands to set Baud Rate & Framing ...................................................................121

Baud Rate & Framing Settings .............................................................................................122

RS-232 Maximum Cable Lengths.........................................................................................122

Baud Rate Indication on Power Up .................................................................................................123

Automatic Baud Rate Detection ...........................................................................................124

Communication Protocol .................................................................................................................125

Communication Protocol: Command Descriptions..........................................................................127

Real-Time Data Timing ...................................................................................................................164

Communication Protocol: Command List ........................................................................................165

Ethernet Communication................................................................................................. 167

Supported Protocols ........................................................................................................................167

COM LED ........................................................................................................................................167

Configuration Settings .....................................................................................................................167

IP Address Configuration ................................................................................................................168

DHCP ..............................................................................................................................................168

Ping Example using DHCP...................................................................................................169

Telnet Example using DHCP................................................................................................170

Manually Configured IP Address.....................................................................................................170

Configuring the IP Address with LaserTrak ..........................................................................171

Configuring the IP Address with HyperTerminal ..................................................................171

Ping / ICMP .....................................................................................................................................172

Ping Example using Manual IP Address ..............................................................................172

TCP Communications .....................................................................................................................173

UDP Communications .....................................................................................................................173

Part No. 93463 / Drawing No. 0921-01561 Page 5 of 221 Revision A (Sep 2007)

Page 6

LaserSpeed 8000-3 Instruction Handbook

UDP Command Example .....................................................................................................174

UDP Real-Time Measurement Example ..............................................................................175

UDP Discovery Beacon ...................................................................................................................176

Discovery Beacon Format ....................................................................................................176

Discovery Beacon Response Format ...................................................................................177

UDP Discovery Beacon Example .........................................................................................178

Transmitted Discovery Beacon................................................................................178

Received Discovery Beacon Responses ................................................................179

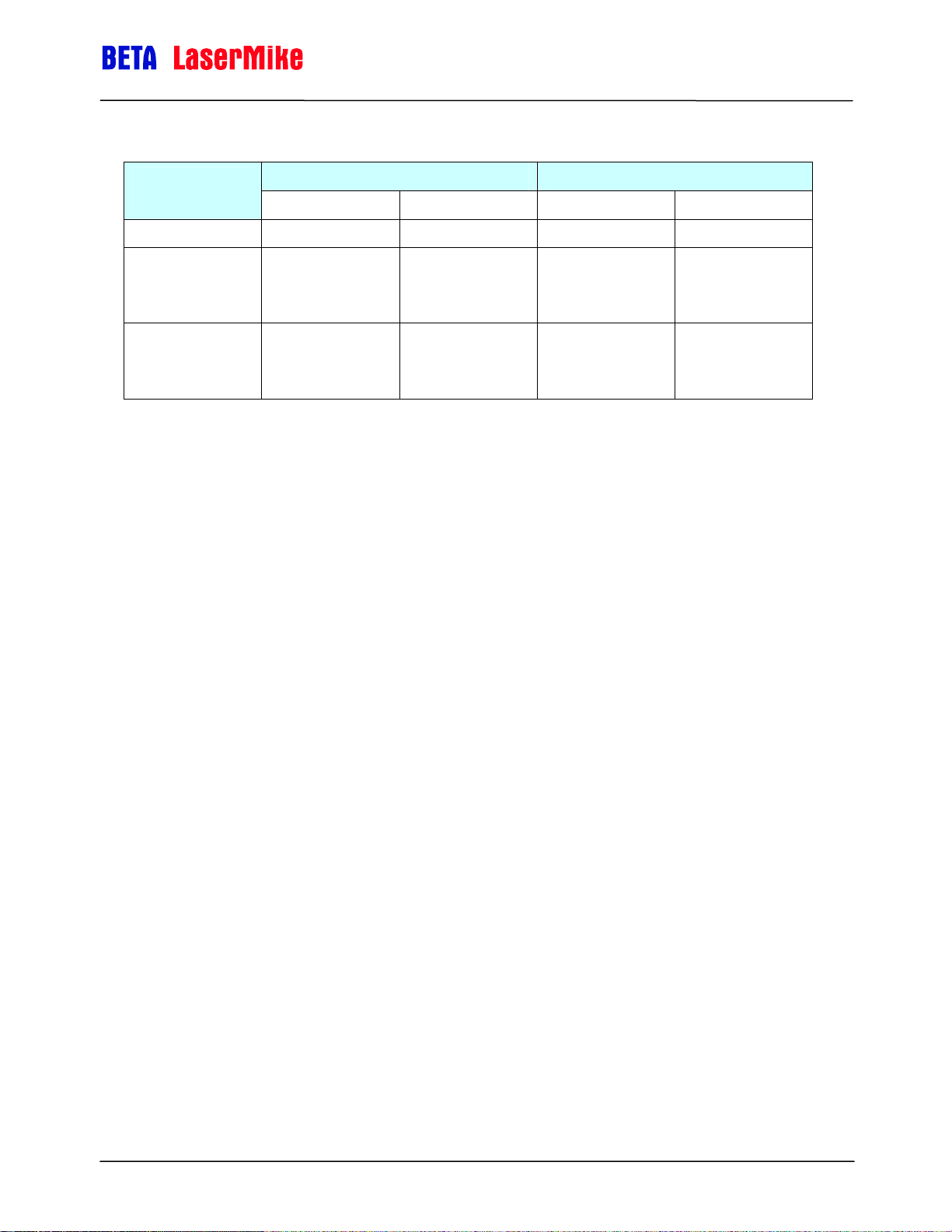

Specifications...................................................................................................................184

General Specifications ....................................................................................................................184

LS8000-3 Specifications..................................................................................................................185

LS8000-3E Specifications ...............................................................................................................186

LS8000-3X Specifications ...............................................................................................................187

LS8000-3 Features..........................................................................................................................188

Appendix A: LS8000-3 Dimensions & Installation Drawings.........................................189

Appendix B: LS8000E Dimensions & Installation Drawings ......................................... 192

Appendix C: LS8000X Dimensions & Installation Drawings ......................................... 198

Contents

Appendix D: Supply Voltage Requirements................................................................... 202

Dual Conductor Supply ...................................................................................................................202

Voltage Drop using Single Supply/Single Return .................................................................202

Quad Conductor Supply..................................................................................................................203

LaserSpeed Cables .........................................................................................................................204

Appendix E: Troubleshooting Guide ..............................................................................205

Communications..............................................................................................................................205

Quality Factor/Valid Measurements ................................................................................................209

Measurements.................................................................................................................................214

Miscellaneous..................................................................................................................................217

Ethernet ...........................................................................................................................................218

Index..................................................................................................................................220

Part No. 93463 / Drawing No. 0921-01561 Page 6 of 221 Revision A (Sep 2007)

Page 7

LaserSpeed 8000-3 Instruction Handbook

Proprietary Statement

Proprietary Statement

Manufacturer/Distributor

Beta LaserMike Inc, 8001 Technology Blvd, Dayton, OH 45424, USA

About This Manual

This manual contains descriptions, drawings, and specifications for a Beta LaserMike product. Equipment or products made prior to or

subsequent to the publication date of this manual may have parts, features, options, or configurations that are not covered by this manual.

Specifications contained herein are subject to change by Beta LaserMike without prior notice. Beta LaserMike is not responsible for errors or

omissions that may be contained herein or for incidental or consequential damages in connection with the furnishing or use of this information.

Comments or suggestions for possible improvements to the manual are appreciated. Please email us at

manualfeedback@betalasermike.com.

The information contained in this manual is the property of Beta LaserMike. The information disclosed in this document is furnished in confidence

and upon the condition that individual and corporate intellectual rights, whether patented or not, will be respected. If this document is supplied on

removable media (e.g. CD), an electronic copy (stored on-site) and one printout is permitted. If this document is supplied in printed form, no part

of this document may be reproduced or scanned without the prior written consent of Beta LaserMike. This document may not be distributed or

circulated to third parties.

Limited Warranty

Beta LaserMike will correct by repair, or at Beta LaserMike‘s option, by replacement, F.O.B Beta LaserMike’s plant, any defect in workmanship or

material in any equipment manufactured by Beta LaserMike which appears under normal and proper use within twelve months from the date of

shipment (eighteen months for OEM’s), provided Beta LaserMike is given reasonable opportunity to inspect the alleged defective equipment at

the place of its use and under conditions of its use.

EXCLUSIONS: This warranty does not cover products which have been modified, altered, or repaired by any other party than Beta LaserMike or

its authorized agents. Furthermore, any product which has been, or is suspected of being damaged as a result of negligence, misuse, incorrect

handling, servicing, or maintenance; or has been damaged as a result of excessive current/voltage or temperature; or has had its serial

number(s), any other markings, or parts thereof altered, defaced, or removed will also be excluded from this warranty.

WARRANTY SERVICE AT CUSTOMER SITE: Warranty service performed at the customer’s facility will be free of charge for parts and labor;

however, the customer will be liable for transportation and living expenses of personnel dispatched to effect such repair. A purchase order or

other written confirmation of the acceptance of these charges, signed by an authorized individual, will be required prior to commencement of

repairs. Additional charges may be assessed the customer if: 1) The equipment is not made available on a timely basis, 2) The equipment is

found to be without fault, and/or 3) It is determined the equipment is not under warranty, whether by expiration of the warranty or any act which

voids the warranty.

OTHER THAN AS SET FORTH HEREIN, BETA LASERMIKE MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, OF MERCHANTABILITY

AS TO THE EQUIPMENT MANUFACTURED BY IT, AND THERE ARE NO EXPRESSED OR IMPLIED WARRANTIES WHICH EXTEND

BEYOND THE DESCRIPTION ON THE FACE THEREOF. Beta LaserMike’s obligation to correct defects in such equipment by repair or

replacement in accordance with the foregoing provisions is in lieu of any other warranties, expressed or implied, and in no event shall Beta

LaserMike be liable for incidental or consequential damages. No service of Beta LaserMike’s equipment is permitted during the warranty period

without the specific written consent of Beta LaserMike.

Service

Your instrument was carefully inspected electrically and mechanically prior to shipment. It should be free of surface mars and scratches, and it

should be in perfect working order upon receipt. If any indication of damage is found, file a claim with the carrier immediately, prior to using the

instrument. If no damage is apparent, proceed by using this manual to install and setup this instrument.

Save the shipping carton and packing material for future storing or shipment of the instrument. If, at some future time, the instrument must be

returned to the factory for service, include a full description of the instrument failure and the mode of operation the instrument was in at the time

of failure. Also include a contact person to discuss the instrument failure.

When returning the instrument to Beta LaserMike, first contact your local Beta LaserMike Service Department for a Return Material Authorization

(RMA). The RMA number is needed for proper handling of returned equipment. Ship the instrument in the original carton, or, if the original carton

is unavailable, ship in a carton providing sufficient protection. Send the instrument to the Asia, Europe, or USA office (addresses listed on the

outside cover of this manual), whichever is closest to you or to the office indicated by your sales engineer. Place the RMA number on the outside

of the carton, and include a purchase order number and any other information specific to your instrument. Field warranty service is available, if

the customer pays travel expenses by advance purchase order. All service operations should be performed by skilled electronics technicians,

who have been trained by Beta LaserMike.

Part No. 93463 / Drawing No. 0921-01561 Page 7 of 221 Revision A (Sep 2007)

Page 8

LaserSpeed 8000-3 Instruction Handbook

European Commission Requirements

European Commission Requirements

This equipment is intended for use in a heavy industrial environment. The equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to other equipment. There is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to other equipment the user is

encouraged to try to correct the interference by one or more of the following measures:

- Re-orientate or relocate the equipment.

- Increase the separation between the pieces of equipment.

- Connect the pieces of equipment on separate mains circuits.

- Ensure that the relevant items of equipment are properly and securely earthed to a common earth point using adequately sized cable or other

means of connection.

Where supplied or specified, shielded interconnection cables must be employed with this equipment to ensure compliance with the pertinent RF

limits. Changes or modifications not expressly approved by the company could void the user’s authority to operate the equipment.

This product has been rigorously tested to comply with the European EMC (Electromagnetic Compatibility)

LaserMike recommends that any non-Beta LaserMike peripheral equipment is CE marked for the Heavy Industrial environment (EN50082-2).

Beta LaserMike also recommends that any cables not supplied by Beta LaserMike, but used for powering Beta LaserMike equipment, be built

using good EMC practices (i.e. cables with braided shield, and connectors with 360° termination of the braid to a metal/metalised shell connector

at both ends). If you have any questions regarding this, contact the Beta LaserMike Service Department.

Directive. With regard to this, Beta

Part No. 93463 / Drawing No. 0921-01561 Page 8 of 221 Revision A (Sep 2007)

Page 9

LaserSpeed 8000-3 Instruction Handbook

Safety Information

• Under NO circumstances should the earth safety connections

be broken – internal damage to sensitive electronic components

may occur and at worst electrocution to personnel may result.

• This equipment must be earthed/grounded.

• Relays and associated wiring are rated for SELV levels i.e. 60

VDC & 30 VAC RMS. These levels must not be exceeded.

• Maintenance, repairs and electrical connections should be

performed by a suitably qualified person for the country of

installation.

• Input power to the equipment is of direct current type

designated by the symbol on equipment housing and shown

below.

Safety Information

Reference: IEC 60417-5031

• The equipment contains a slow blow type fuse to protect against

input power overloads and is not user replaceable.

Intended Use

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Part No. 93463 / Drawing No. 0921-01561 Page 9 of 221 Revision A (Sep 2007)

Page 10

Laser Classification

LaserSpeed 8000-3 Instruction Handbook

Safety Information

The Model LS8000-3 Non-contact Length and

Speed Gauge (Model LS8000-3) is classified as a

IIIb laser device. This category contains infrared and

visible laser devices with powers up to 500 mW.

VISIBLE AND INVISIBLE

LASER RADIATION

AVOID EXPOSURE TO BEAM

CLASS 3B LASER PRODUCT

PEAK POWER 50mW

WAVELENGTH 650-810 nm

The optical gauge in the system uses a 50 mW

Complies with EN60825-1:2001. Complies with 21 CFR 1040.10

solid-state laser device operating between 760 and

800 nm (near infrared region of the spectrum).

A class IIIb product must have the following safety

and 1040.11 except for deviations pursuant to Laser Notice

No. 50, dated J uly 26, 2001.

WARNING - NO USER SERVICEABLE

PAR TS. RE F ER SE RVI CI NG TO

QUALIFIED SERVICE PERSONNEL.

features:

A 5-second delay after power-up before laser radiation is emitted from

the gauge.

An indicator light to inform personnel near the gauge that laser

radiation is being emitted.

A mechanical device to physically block the laser beam from exiting the

gauge.

An interlock circuit to shut off the laser when the circuit is opened.

All hazards must be properly identified with warning labels.

These basic safety features are incorporated to promote safe operation of the

laser.

A class IIIb laser must also have a key switch to power the laser, ensuring that

only trained personnel can operate the instrument. Because the location of the

gauge can often make it difficult to access a key switch, the key switch needs

to be installed by the final user. It should be placed in a location that will be

readily accessible to the operators. For more information on installing the laser

key switch, see the Installing the System

section.

The user of a laser device must comply with a different set of regulations.

Many countries and individual states have passed legislation regarding the use

of laser products.

Part No. 93463 / Drawing No. 0921-01561 Page 10 of 221 Revision A (Sep 2007)

Page 11

LaserSpeed 8000-3 Instruction Handbook

The following system specifications will help establish appropriate safety

measures.

Maximum Laser Power 0.050 watt

Laser Wavelength 0.785 micrometer

Laser Spot Size (Elliptical) 3 x 1.5 millimeters

Beam Divergence 0.5 milliradians

Pulse Rate Continuous wave

Maximum radiance (power

divided by spot-size area)

0.050 Watt/0.141372 cm

[0.3536 W/cm2]

2

Laser Safety Precautions

The laser beam in the optical gauge is very powerful and can permanently

damage eyes not protected by laser safety glasses. To avoid exposing

yourself to hazardous radiation, you must take these precautions:

Safety Information

• Never look into the laser beam. If you must look at the beam,

view it from an angle and in the direction in which the beam is

travelling.

• The beams emitted from the Model LS8000-3 are invisible to the

unaided eye. Return the beam shutter to the closed position

when the system is not in use or during setup.

• Ensure that all direct reflections are blocked.

• Remove all rings, watches, or jewellery from your hands when

working on or near the gauge—can cause hazardous reflections.

• Never install the instrument at eye level.

• Operate the system only with people who have been instructed

in laser safety.

• Post warning signs and lights that are active when laser is

operating.

Part No. 93463 / Drawing No. 0921-01561 Page 11 of 221 Revision A (Sep 2007)

Page 12

LaserSpeed 8000-3 Instruction Handbook

If your country or state has no regulations governing the safe use of lasers,

Beta LaserMike recommends that you follow the guidelines specified by the

American National Standard for the safe use of lasers (ANSI Z136.1–1986).

For a copy of this document, write to:

Laser Institute of America

13501 Ingenuity Drive, Suite 128

Orlando, Florida 32826

1-800-345-2737

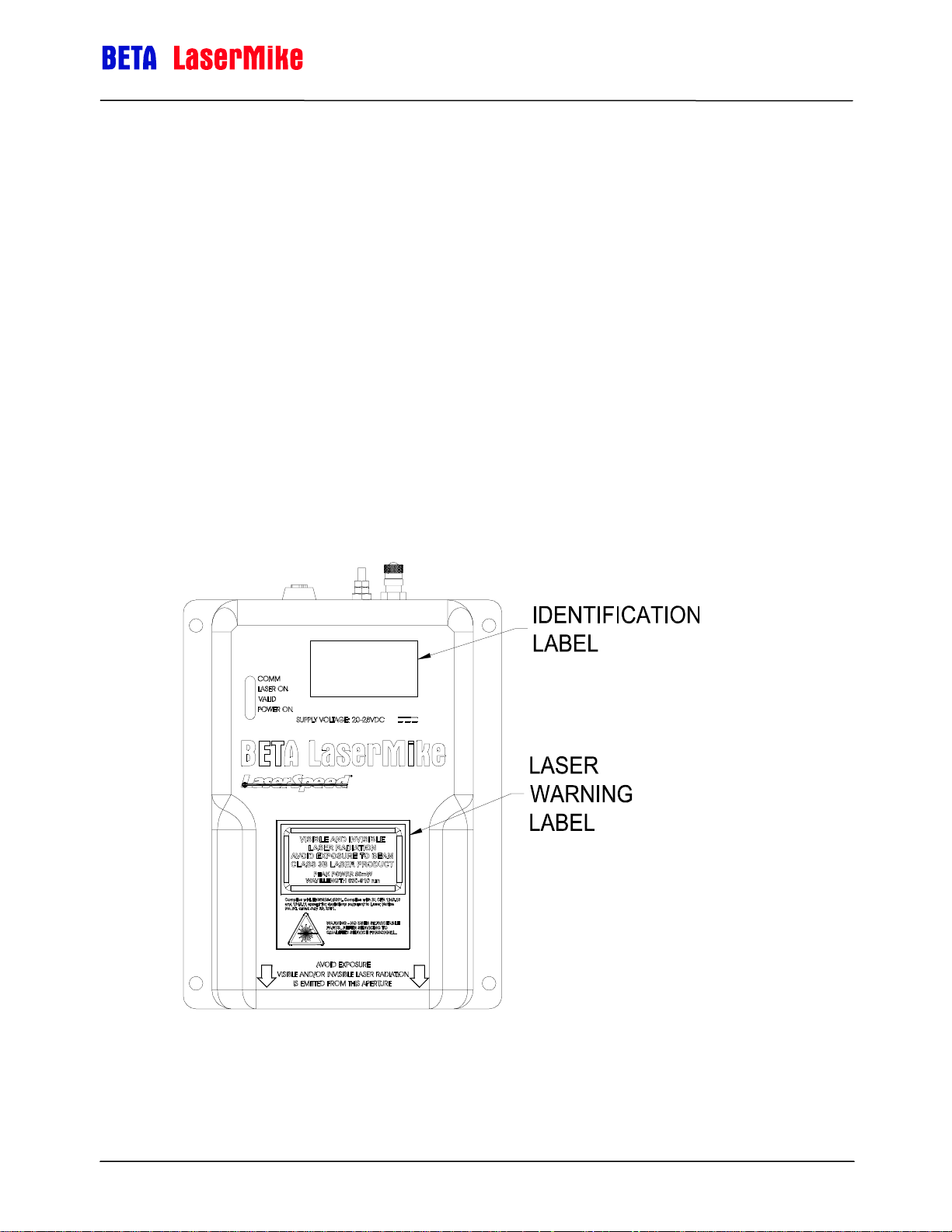

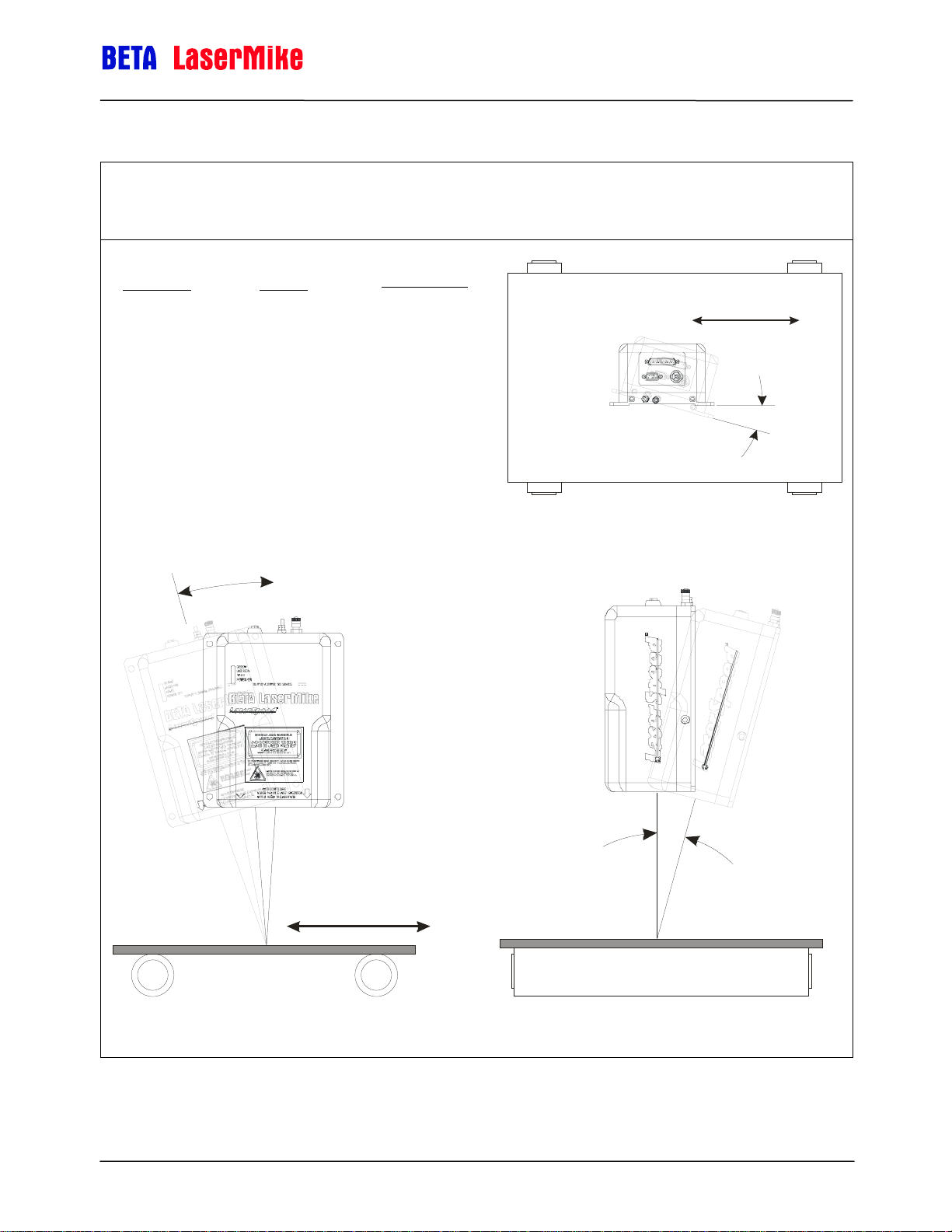

Labels and Safety Features

This section acquaints you with the advisory and identification labels on the

instrument and the safety features incorporated into the design of the

instrument. The following figures show the advisory and identification labels

on the Model LS8000-3.

Safety Information

LS8000-3 Labels

Part No. 93463 / Drawing No. 0921-01561 Page 12 of 221 Revision A (Sep 2007)

Page 13

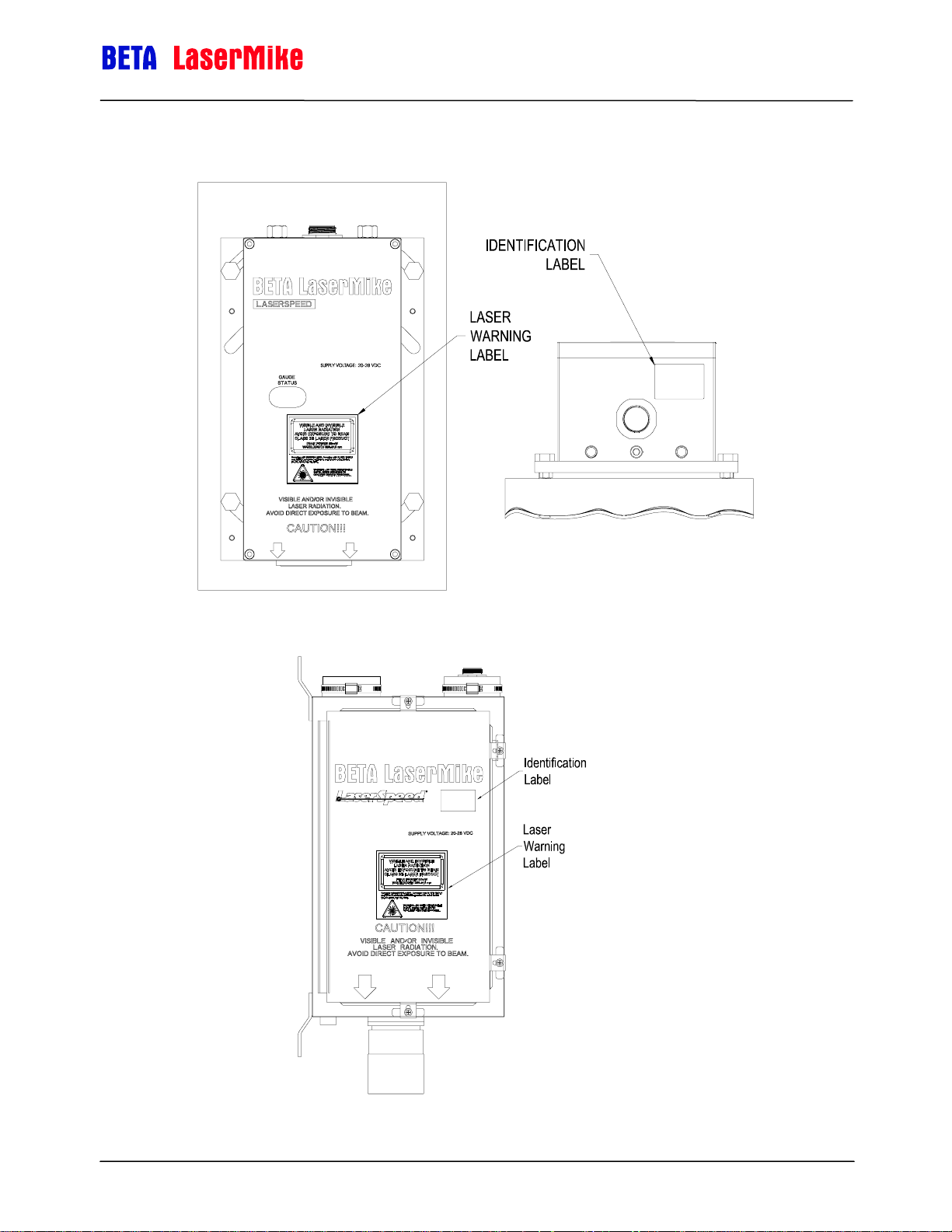

LS8000-3E Labels

LaserSpeed 8000-3 Instruction Handbook

Safety Information

LS8000-3X Labels

Part No. 93463 / Drawing No. 0921-01561 Page 13 of 221 Revision A (Sep 2007)

Page 14

LaserSpeed 8000-3 Instruction Handbook

Introduction

This manual describes the installation and setup of the LaserSpeed 8000

gauge. For daily routine usage, see the LaserSpeed 8000 Operator Guide.

The Model LS8000-3 LaserSpeed® Non-contact Length and Speed gauge is

an industrial, Laser-Doppler based instrument that measures the velocity and

length of material. Due to the nature of the laser-based measurement, there is

no physical contact with the material. This eliminates the problems of wheel

wear and slippage that plague mechanical/encoder based length

measurement systems.

System Overview

The Model LS8000-3 is a stand-alone instrument that requires only 24 VDC

input power to operate. The system has a variety of industrial outputs. Also, a

variety of information including length, velocity, system operating parameters,

and setup parameters can be read and configured using the communications

interfaces.

Introduction

The LS8000-3 is permanently calibrated to a NIST traceable standard at the

factory. Aside from periodic cleaning of the optical window, the LS8000-3

does not require maintenance.

See the Specifications section at the end of this manual.

Principle of Operation

LaserSpeed utilizes dual-beam interferometer technology to provide accurate

velocity readings. The measured velocity is integrated over time to measure

the length of moving objects. The opto-electronic portion of the LS8000-3

generates a laser beam that is split and then crossed in space. The two

crossing beams interact, producing a fringe pattern that is orthogonal to the

plane of the two beams.

Light is scattered when material passes through the measurement region. This

scattered light is collected by the gauge and converted to electrical signals.

The frequency of the electrical signal contains information with regards to the

velocity of the material. The signal processor converts the electrical signals to

frequency information that is directly proportional to the velocity of the material

moving through the laser beams. The signal processor converts the frequency

information into velocity information and updates user outputs. In order to

determine if there is an object in the measurement area, the gauge measures

the amount of reflected laser light.

Part No. 93463 / Drawing No. 0921-01561 Page 14 of 221 Revision A (Sep 2007)

Page 15

LaserSpeed 8000-3 Instruction Handbook

g

λ

System Overview

Resultin

Electrical Signal

κ

with Frequency ( )f

t

Measurement Region

Side View

Material Surface

Material Movement

Fringe distance (d) is a function of laser wavelength

(λ) and beam angle (κ):

Period is the inverse of frequency:

Velocity is distance divided over time:

t1=

v =

Top View

d

=d

f

d

t

κ

sin2

Velocity is integrated to find Length

Part No. 93463 / Drawing No. 0921-01561 Page 15 of 221 Revision A (Sep 2007)

T

⋅=

dtvL

∫

0

Page 16

LaserSpeed 8000-3 Instruction Handbook

Installing the System

This section describes mounting, alignment and other installation concerns for

the LS8000-3.

The installation can be broken down into five steps:

Mounting the gauge

Aligning the gauge

Connecting power to the gauge

Connecting to the outputs

Maximizing gauge performance

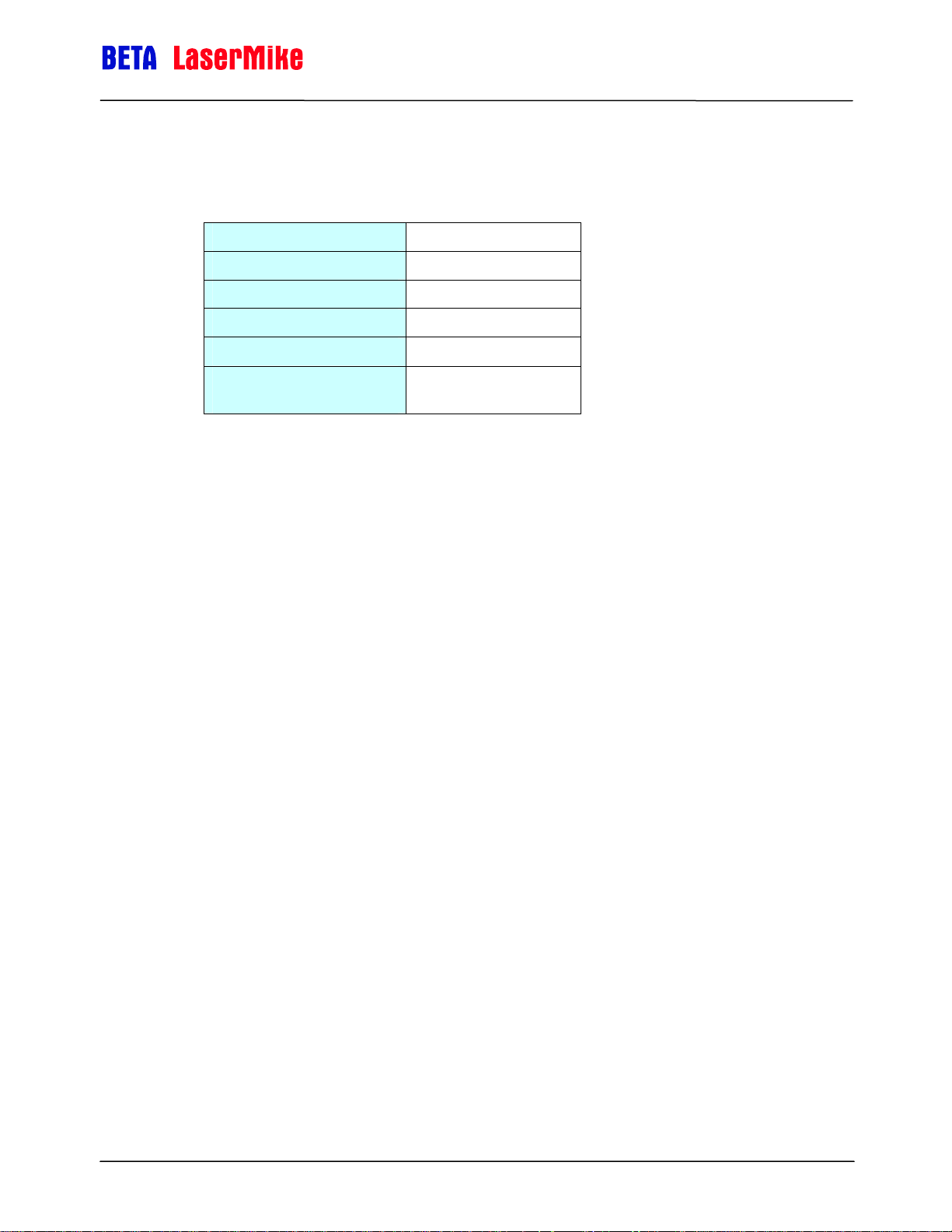

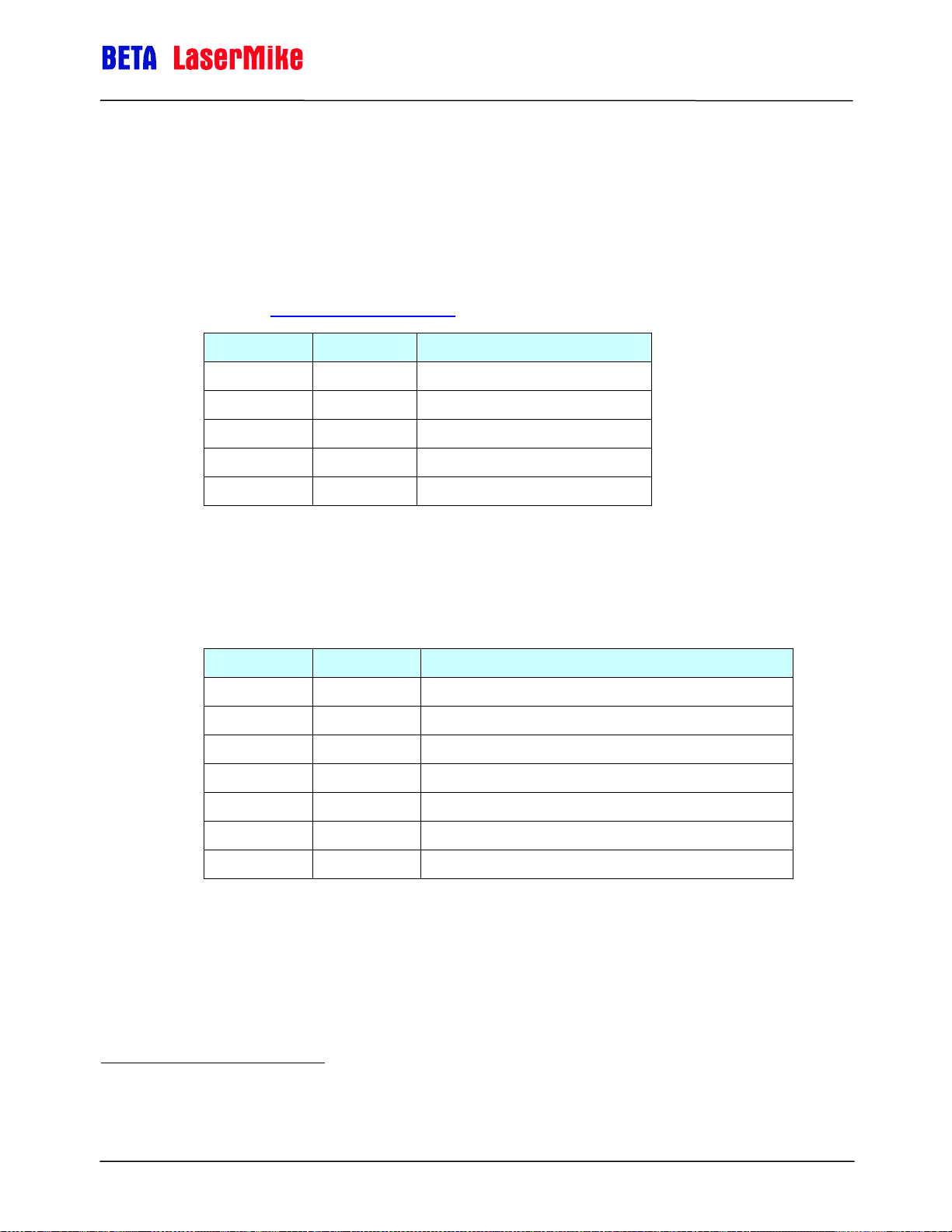

Mounting the Gauge

Installing the System

The LS8000-3 must be placed at the correct standoff distance from the moving

material. A series of LaserSpeed gauges provide a variety of standoff

distances and depths of field.

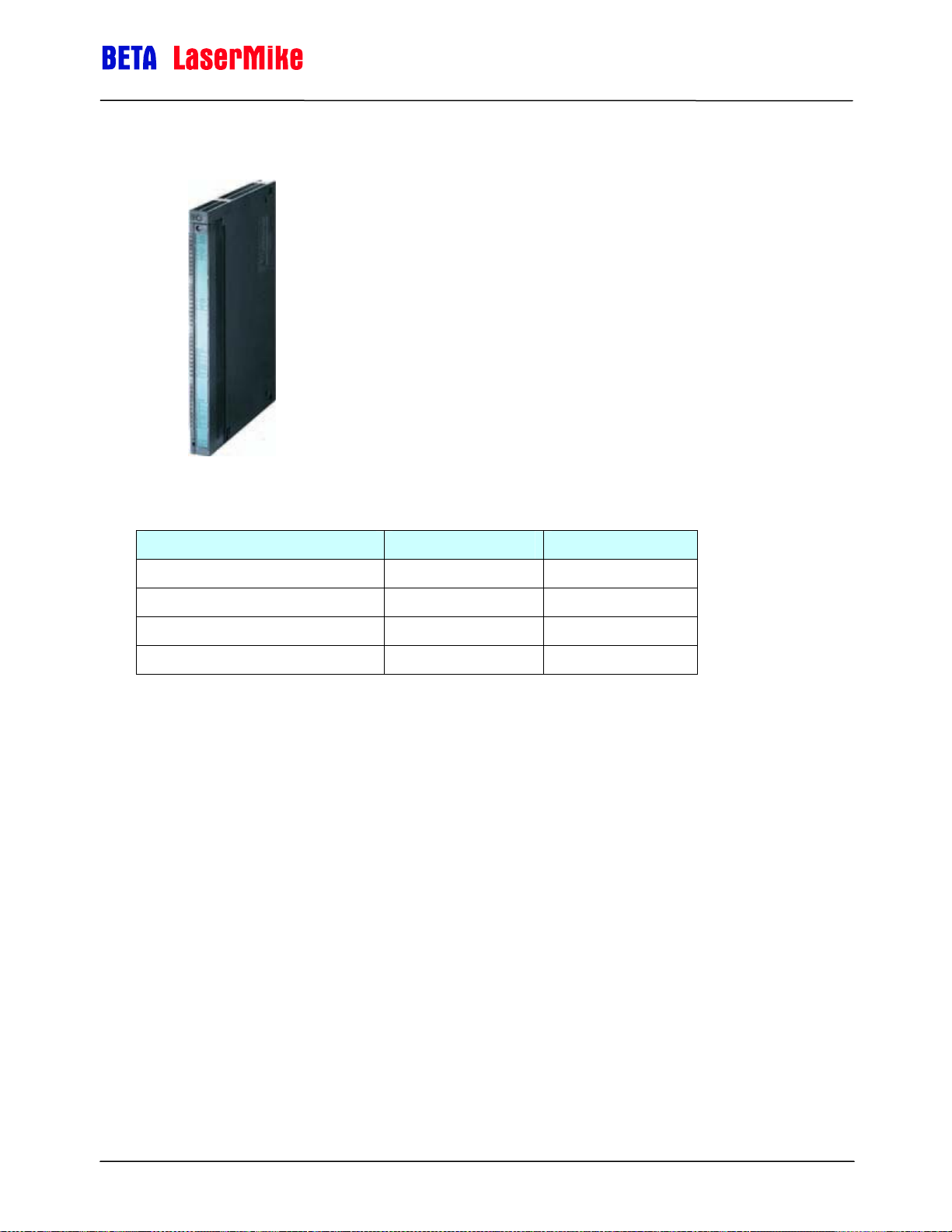

Model Standoff Distance Depth of Field

LS8000-303 300mm (11.8 in) 35mm (1.4 in)

LS8000-306 600mm (23.6 in) 50mm (2.0 in)

LS8000-310 1000mm (39.4 in) 100mm (3.9 in)

LS8000-315 1500mm (59.0 in) 200mm (7.9 in)

LS8000-320 2000mm (78.7 in) 200mm (7.9 in)

LS8000-325 2500mm (98.4 in) 200mm (7.9 in)

Please refer to the following Appendices for mounting dimensions and

installation drawings:

Model Section

LS8000 Appendix A

LS8000E Appendix B

LS8000X Appendix C

Part No. 93463 / Drawing No. 0921-01561 Page 16 of 221 Revision A (Sep 2007)

Page 17

LaserSpeed 8000-3 Instruction Handbook

Mounting Distance

When the material is within the depth of field, the gauge makes accurate

measurements. Since the best signal comes from the center of the depth of

field, the center is the source of the best measurements. This is because the

two laser beams totally overlap at the center of the beam crossings and all of

the laser power is used to form fringes.

At the edges of the depth of field, however, some beam-crossing areas

overlap and some do not. The areas that overlap form fringes and thus yield

useful Doppler signals; the areas that do not overlap do not form fringes;

rather, they produce only noise with no Doppler signals. Any measurements

made outside the depth of field may not be reliable.

Laser Safety

When mounting of the gauge, ensure that the laser beams are blocked by

machinery or beam blocks when material is not present in the measurement

area.

Installing the System

Environmental Conditions

Ambient Temperature

All LaserSpeed gauges have a built-in cooling system for applications in which

ambient temperatures exceed 45ºC.

Cooling fluids can be routed through the gauge using the 1/8-inch NPT fittings

(1/4" NPT on LS8000E and LS8000X) on the back of the gauge. Typical flow

rates of 1.5 litres/minute for water and 50 liters/minute for air are sufficient.

There is minimal pressure drop through the gauge, so supply pressure can be

very low.

Ensure that the water temperature is above the condensation temperature or

dew point, to prevent condensation from collecting on the front window of the

gauge. If water condenses on the optical window, the laser beams could be

blocked, resulting in reduced performance or loss of function.

Coolant

In applications with coolants on the material, an air jet may be required to

remove the coolant from the measurement area. Since the speed of the

coolant is generally different from that of the material, erroneous

measurements could result. When incorporating an air jet, be sure to blow the

coolant from the measurement volume at 90° from the material’s motion. If the

Part No. 93463 / Drawing No. 0921-01561 Page 17 of 221 Revision A (Sep 2007)

Page 18

LaserSpeed 8000-3 Instruction Handbook

coolant is blown off in the same direction the material is moving, the air

velocity can add or subtract from the material’s velocity; this too may cause

erroneous measurements.

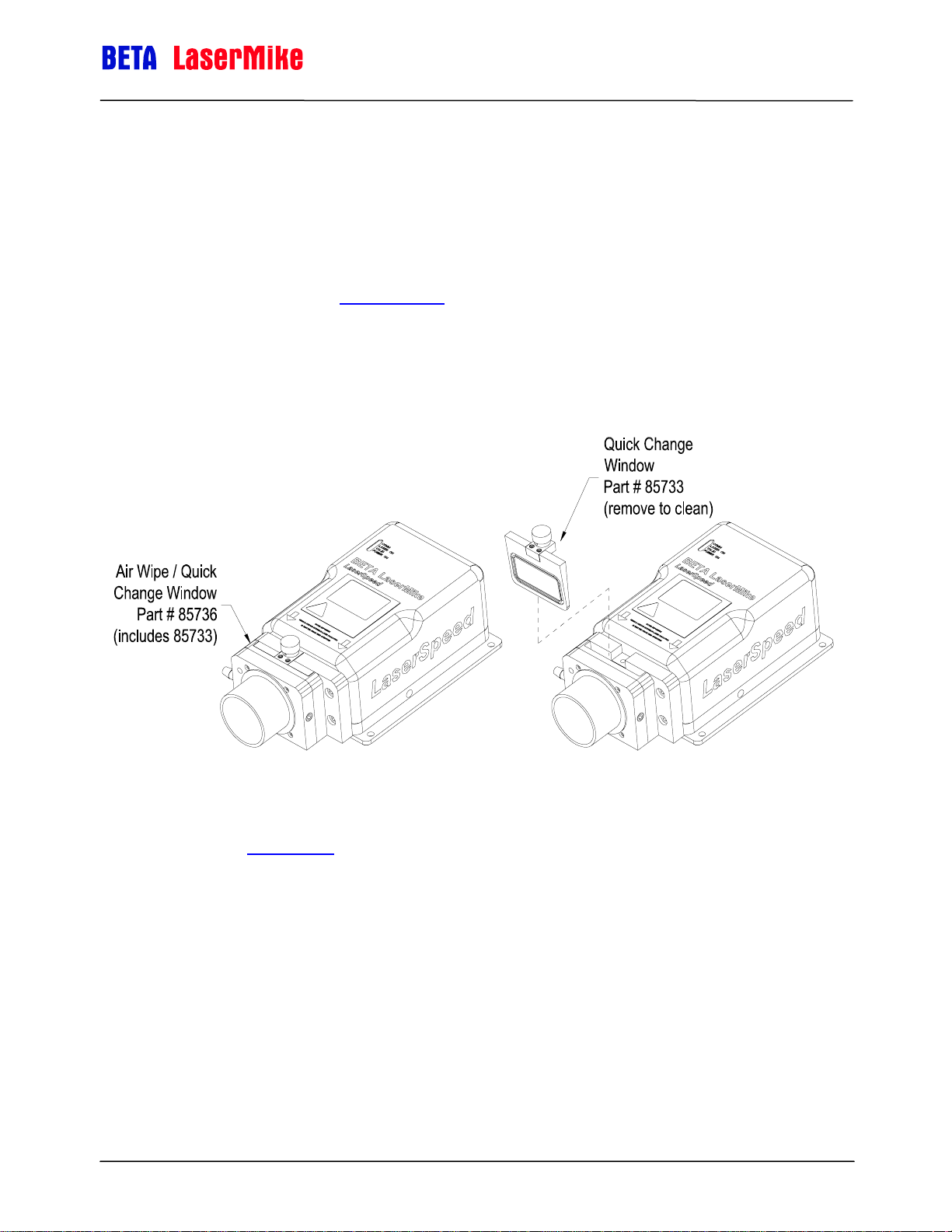

Air Wipe / Quick Change Window

To prevent dust, dirt, and moisture from accumulating on the optical window

the gauge can be fitted with an Air Wipe/Quick Change Window. Clean,

instrument grade air (see Specifications

pressure over the window to keep it clean. The window can be removed for

easy cleaning. A clean, soft cloth should be used to clean the window. If an

abrasive cloth is used, the optical coating may be damaged, leading to poor

measurements. When replacing the window, put a small amount of vacuum

grease on the O-Ring.

section for details) is blown at low

Installing the System

For measurements and details about removing the Air Wipe/Quick Change

Window, see Appendix A

.

Steam & Mist

Steam or mist is sometimes present in some applications. The air-wipe is not

designed to clear steam or mist between the gauge and material, but only to

keep contaminants from depositing on the optics window. Another means of

removing steam or mist may need to be used. The steam or mist may be light

enough to allow the laser beams to pass through without interference. If this is

not true, a fan may be used to clear out the steam or mist between the gauge

and housing. If a fan is not adequate or practical, an “air purge” can be

installed to clear the beam path. Contact your Beta LaserMike representative

Part No. 93463 / Drawing No. 0921-01561 Page 18 of 221 Revision A (Sep 2007)

Page 19

LaserSpeed 8000-3 Instruction Handbook

for more details. When mounting the gauge, be aware of the environment in

which the gauge is operating. Steam, mist, coolant on the material, ambient

temperature, scale and slag may all affect the performance of the gauge.

These environmental conditions may need to be modified as mentioned above

in order to maximize the performance of the gauge.

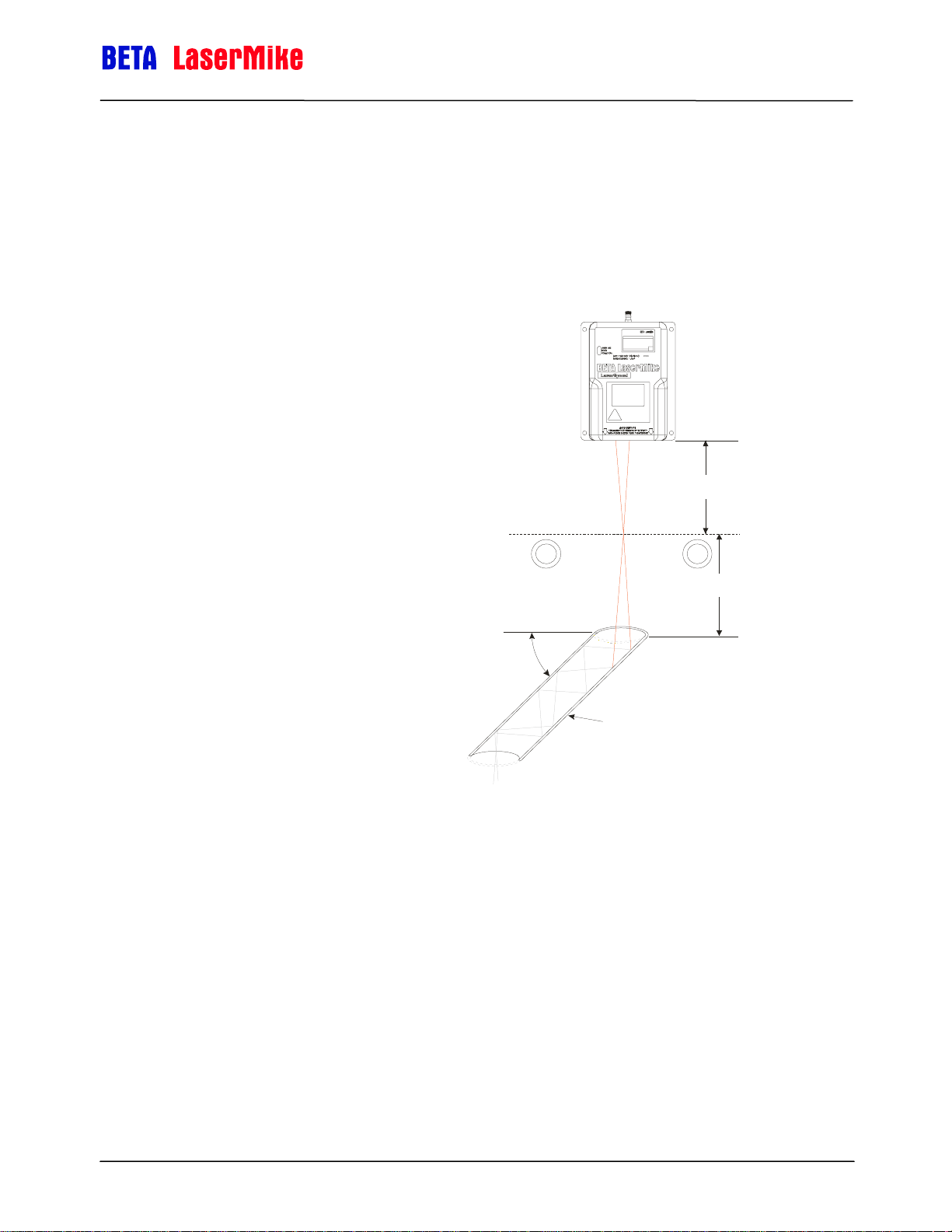

Mounting Location

When mounting the gauge over the

material, be sure the gauge is not

directly over a roller or some other

device. If the laser beam from the gauge

strikes an object, it may detect a false

Material Present. In this case, the gauge

will not be able to detect when the

actual material is not in the

measurement volume.

Installing the System

Standoff

Distance

A device that captures most of the laser

light is called a beam dump and may be

required (see figure). A suitable beam

Standoff

Distance

dump is a large-diameter pipe, 150

millimeters (6 inches) or larger, angled

at 45° from the laser beams. A rusty

Cut at 45

º

pipe is an excellent beam dump. If scale

can deposit in the base of the beam

dump, the pipe may need to be cleaned

periodically to prevent false Material

Beam Dump

Open Both Ends

Present readings. The beam dump

should be far enough from the gauge

that it cannot be measured. A good guideline is to place the beam dump at

least double the standoff distance from the gauge.

PAS SL INE

Rollers

Part No. 93463 / Drawing No. 0921-01561 Page 19 of 221 Revision A (Sep 2007)

Page 20

LaserSpeed 8000-3 Instruction Handbook

t

r

p

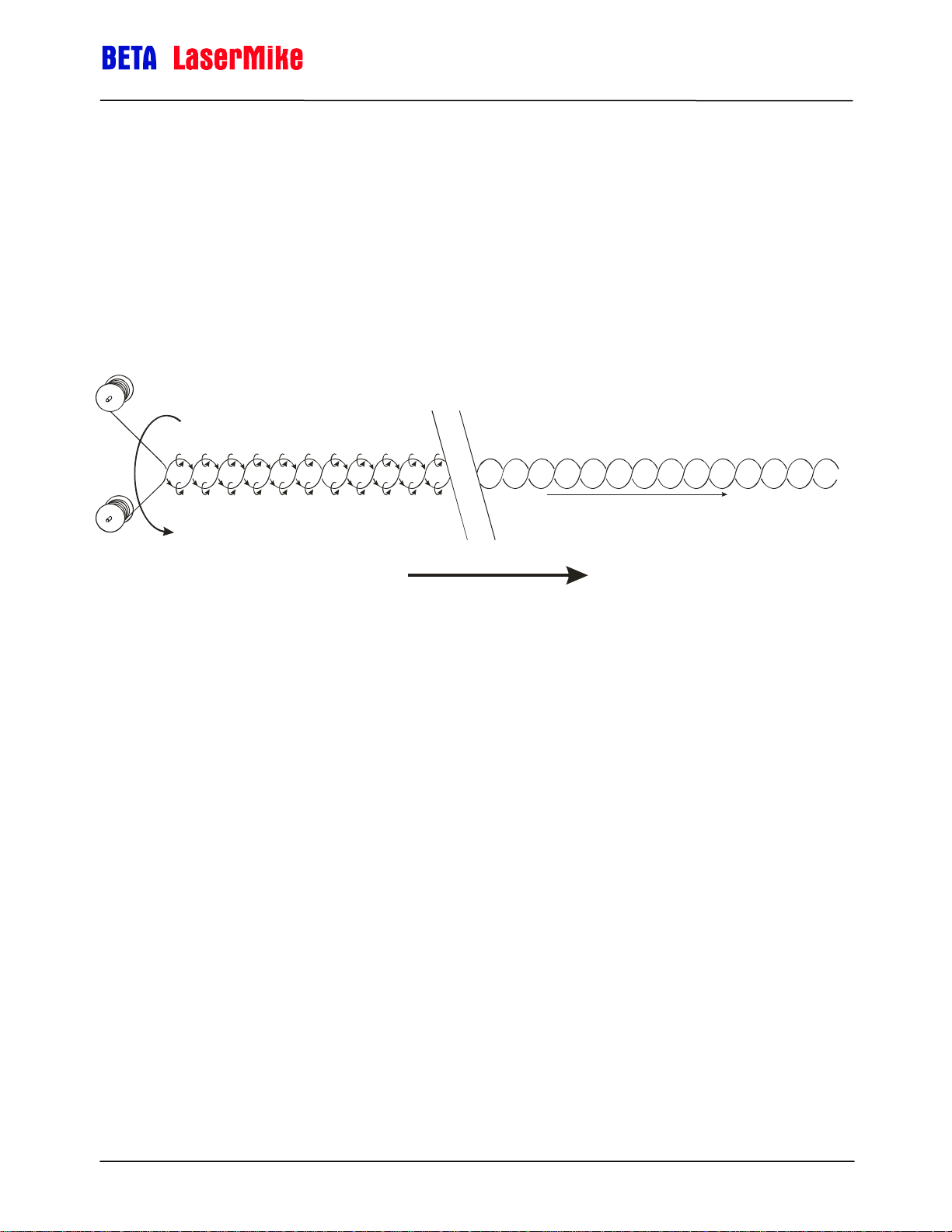

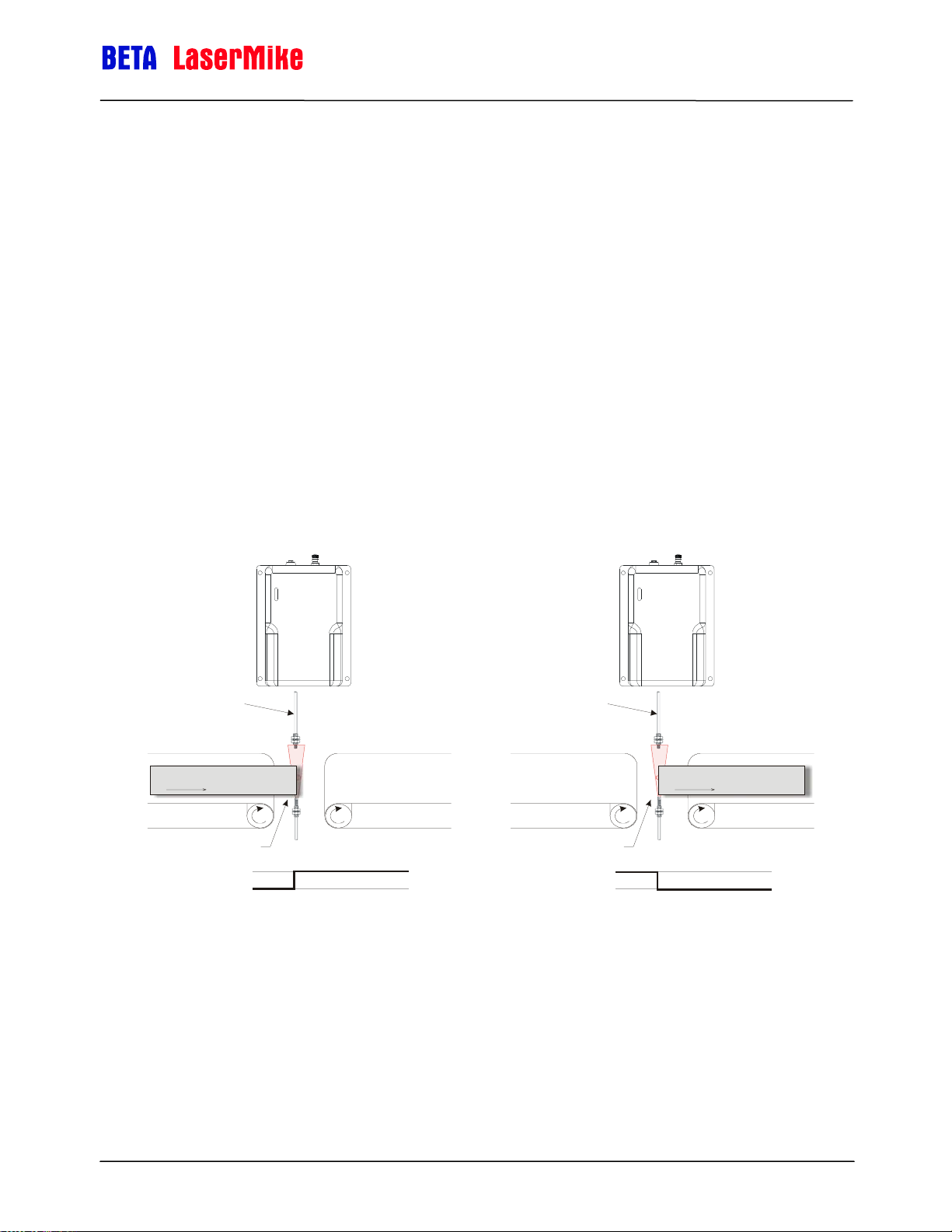

Twinner Lines

When mounting the gauge on a twinner line, the gauge should be positioned

far enough from the twinner that the twist is set. If the gauge is placed close to

the twinner, it may not be able to measure due to excessive vibration and the

spin imparted on the wire due to the twisting motion. Moving the gauge down

the line farther from the twinner may improve the gauge's ability to make

measurements.

Installing the System

Near Twinne

Wires spin and

corkscrew (make it

look like wires are

not moving)

Near Takeu

Twist is set, wires not

spinning or corkscrewing.

Line Movemen

Part No. 93463 / Drawing No. 0921-01561 Page 20 of 221 Revision A (Sep 2007)

Page 21

LaserSpeed 8000-3 Instruction Handbook

Aligning the Gauge

Once the gauge is mounted at the proper standoff distance, the critical

alignment angles need to be checked. To obtain accurate results, the LS80003 must be mounted so the surface being measured is perpendicular to the

optical axis. The best method to ensure this is to place a level alongside the

gauge. The material being measured should be parallel to the front face of the

gauge and the material motion should be parallel to the base of the gauge.

The velocity measurement, which is made in the plane of the two laser beams,

is the rate at which the material passes the fringes of the beams. When the

motion of the material is perpendicular to the fringes, the velocity

measurement is considered calibrated. If the fringes are at an angle to the

motion of the material (angular rotation), measurement errors occur. The

measured velocity equals the actual velocity multiplied by the cosine of the

angle by which the alignment deviates from the direction of material

movement.

Installing the System

Three types of misalignment are possible. Two of the three are responsible for

measurement errors: rotation about the optical axis and tilt in the plane of the

beams. The errors are proportional to the sine of the misalignment angle.

Misalignment will always make the gauge measure velocities and lengths that

are too low.

Part No. 93463 / Drawing No. 0921-01561 Page 21 of 221 Revision A (Sep 2007)

Page 22

LaserSpeed 8000-3 Instruction Handbook

r

r

Installing the System

Types of Gauge Misalignment

Measured Velocity = Actual Velocity x cos(A) x cos(B)

Error Angle

(Degrees)

0

0.25

0.50

0.75

1.0

2.0

3.0

4.0

5.0

10

Cosine

1

0.99999

0.99996

0.99991

0.99985

0.99939

0.99863

0.99756

0.99619

0.98481

Speed and

Length Error

(%)

0

-0.001

-0.004

-0.009

-0.015

-0.061

-0.137

-0.244

-0.381

-1.519

Material Movement

A

Rotat ion About Optical Axis

- Causes Measurement Erro

B

C

Material Movement

Not perpendicular to Material Motion

- Causes Measurement Error

Part No. 93463 / Drawing No. 0921-01561 Page 22 of 221 Revision A (Sep 2007)

Material Movement

into/out of page

Not perpendicular to material edges

- No measurement erro

Page 23

LaserSpeed 8000-3 Instruction Handbook

G

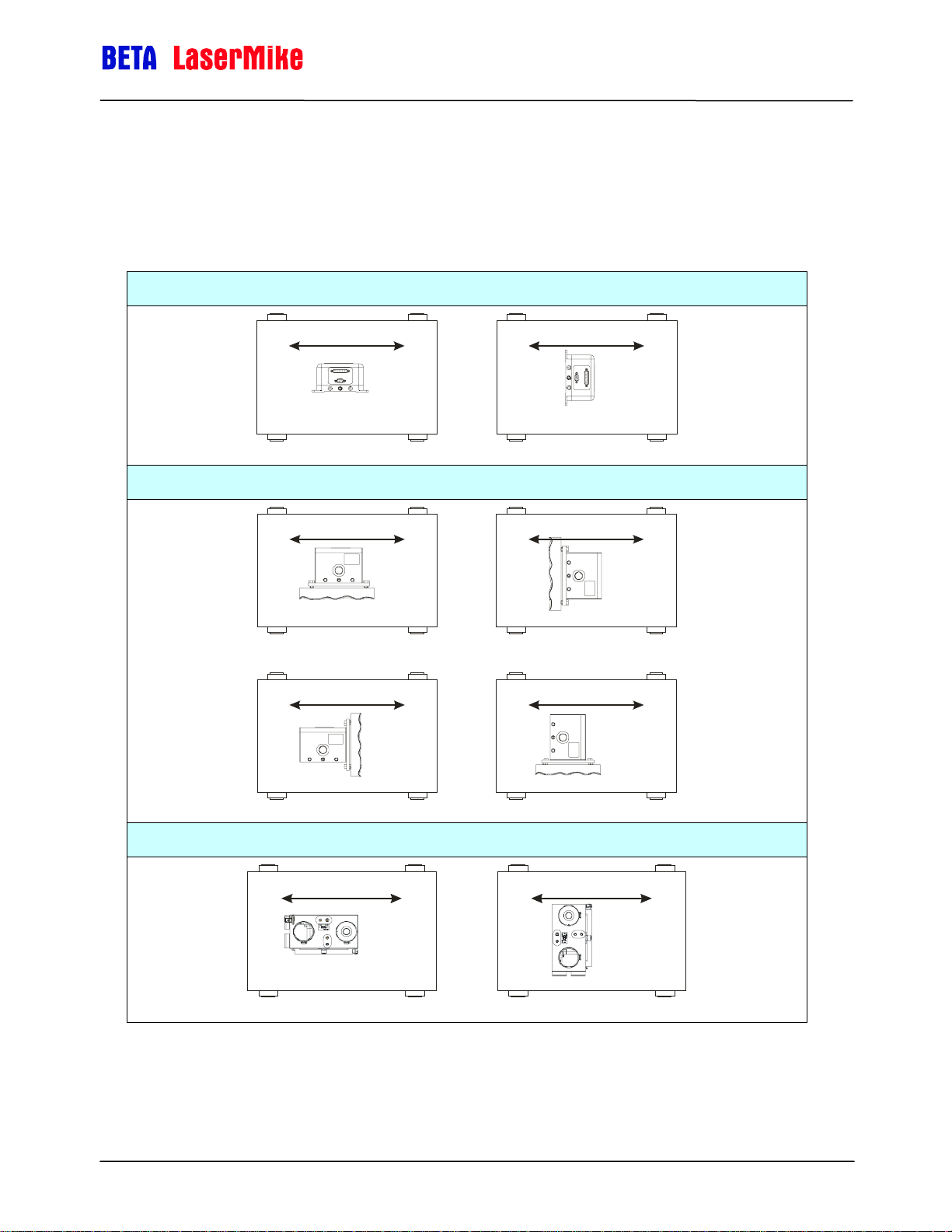

Gauge Orientation

The LaserSpeed gauge must be mounted such that the material to be

measured moves in a direction parallel to the bottom of the LS8000-3, as

shown below.

LS8000-3

Installing the System

Material Movement

☺

Material Movement

3

RIGHT WRONG

LS8000-3E – can be mounted either from the bottom or the side

Material Movement

☺

3

RIGHT WRONG

Material Movement

☺

3

RIGHT

LS8000-3X

Material Movement

Material Movement

WRON

2

2

2

Material Movement

☺

Material Movement

3

RIGHT

Part No. 93463 / Drawing No. 0921-01561 Page 23 of 221 Revision A (Sep 2007)

2

WRONG

Page 24

LaserSpeed 8000-3 Instruction Handbook

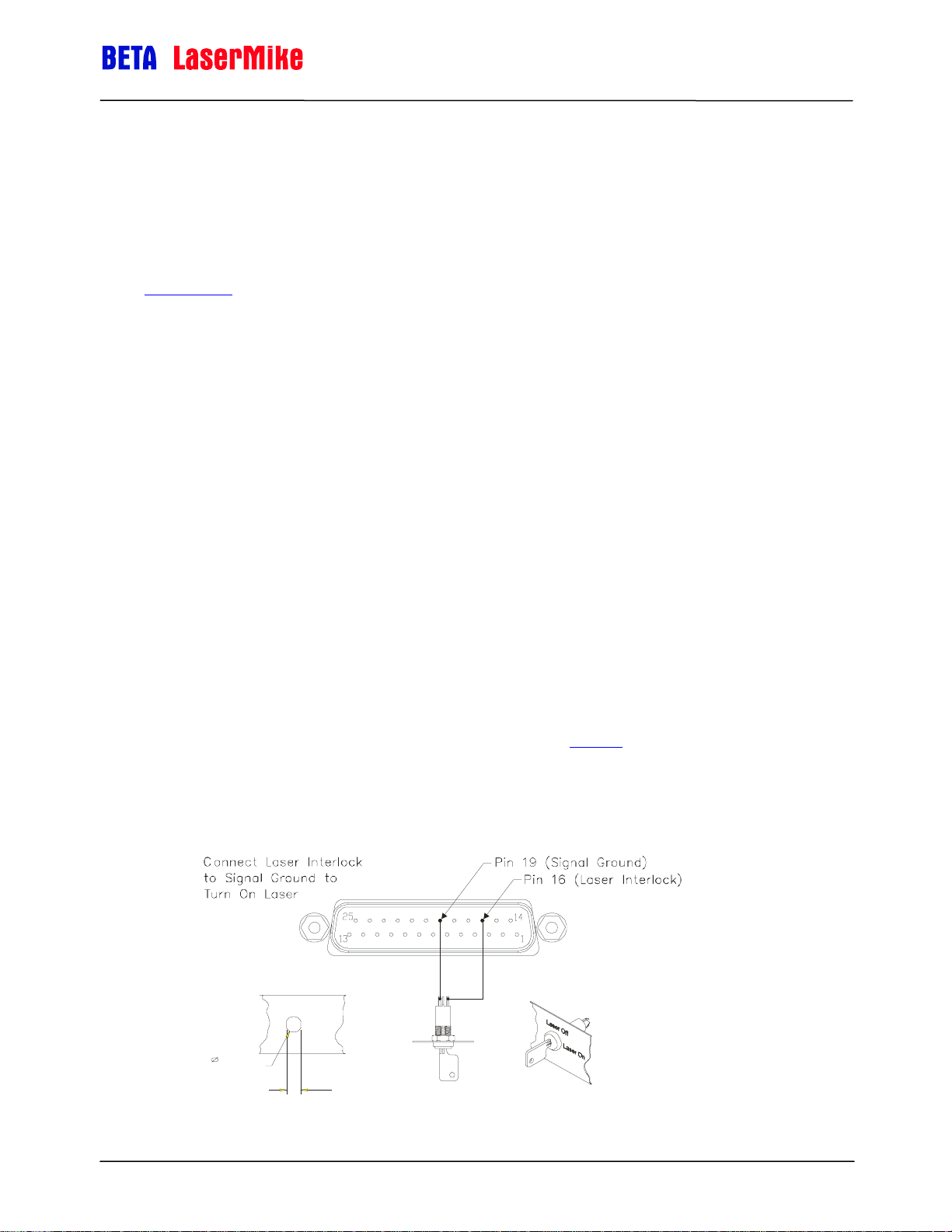

Connecting Power to the Gauge

The gauge requires a 20–28 VDC (nominal 24 VDC) supply to be connected to

Pin 24 and/or Pin 25 with the corresponding ground to Pin 12 and/or Pin 13 of

the 25-pin D-sub connector. The supply should be able to drive at least 2

Amps. For detailed information on supplying power to the gauge, see

Appendix D

Notes: Do not attach wires to the gauge while power is applied. Make all

The LS8000-3 is classified as a kit, according to CDRH regulations. It is your

responsibility to install a key switch to control the operation of the device. The

key switch should be installed as shown in the following figure. It is in line with

the 24-volt supply line that will service to power the device. The recommended

key switch can be found in the accessory kit. The key switch should be

mounted in a convenient location that does not require exposure to the laser

beams. After installation, label the panel as to which position corresponds to

“Laser On” and “Laser Off.”

.

wiring connections with power turned off. The gauge contains internal

fusing (3A, 125 V) on the 24 VDC supply line. This fuse is not user

serviceable.

Installing the System

The following figure shows the correct installation of the recommended switch

(C&K Components part number YM06132C205NQ). If another type of key

switch is used, it should be verified that the key is removable only in the “Laser

Off” position.

For more information on laser safety issues, refer to the Safety

section at the

beginning of this manual.

Warning: A key switch must be installed and labelled correctly to ensure

proper protection of personnel working with the laser.

Panel Cutout

for Keyswitch

Laser Off

Lase r On

0.50in

[12.7mm]

0.42in

[10.7mm]

Part No. 93463 / Drawing No. 0921-01561 Page 24 of 221 Revision A (Sep 2007)

Page 25

LaserSpeed 8000-3 Instruction Handbook

Connecting to Outputs

On the LS8000-3 model, the outputs of the gauge are contained on the 9-pin

and 25-pin D-sub connectors, and the M12 D-Coded Ethernet connector. On

the LS8000-3E and LS8000-3X, all outputs are contained on a 39-pin circular

connector. Their pin values are shown in the following tables. Each signal is

explained in detail in the Interfacing with the LS8000-3 section.

Note: In order for the LS8000-3 to be operational, pins 16 and 17 must

be connected to signal ground. These signals operate the internal

laser shutter and the laser interlock. When these connections are

open, the laser will not turn on and the shutter will not open. You

must provide the correct signals to operate the gauge.

Installing the System

Part No. 93463 / Drawing No. 0921-01561 Page 25 of 221 Revision A (Sep 2007)

Page 26

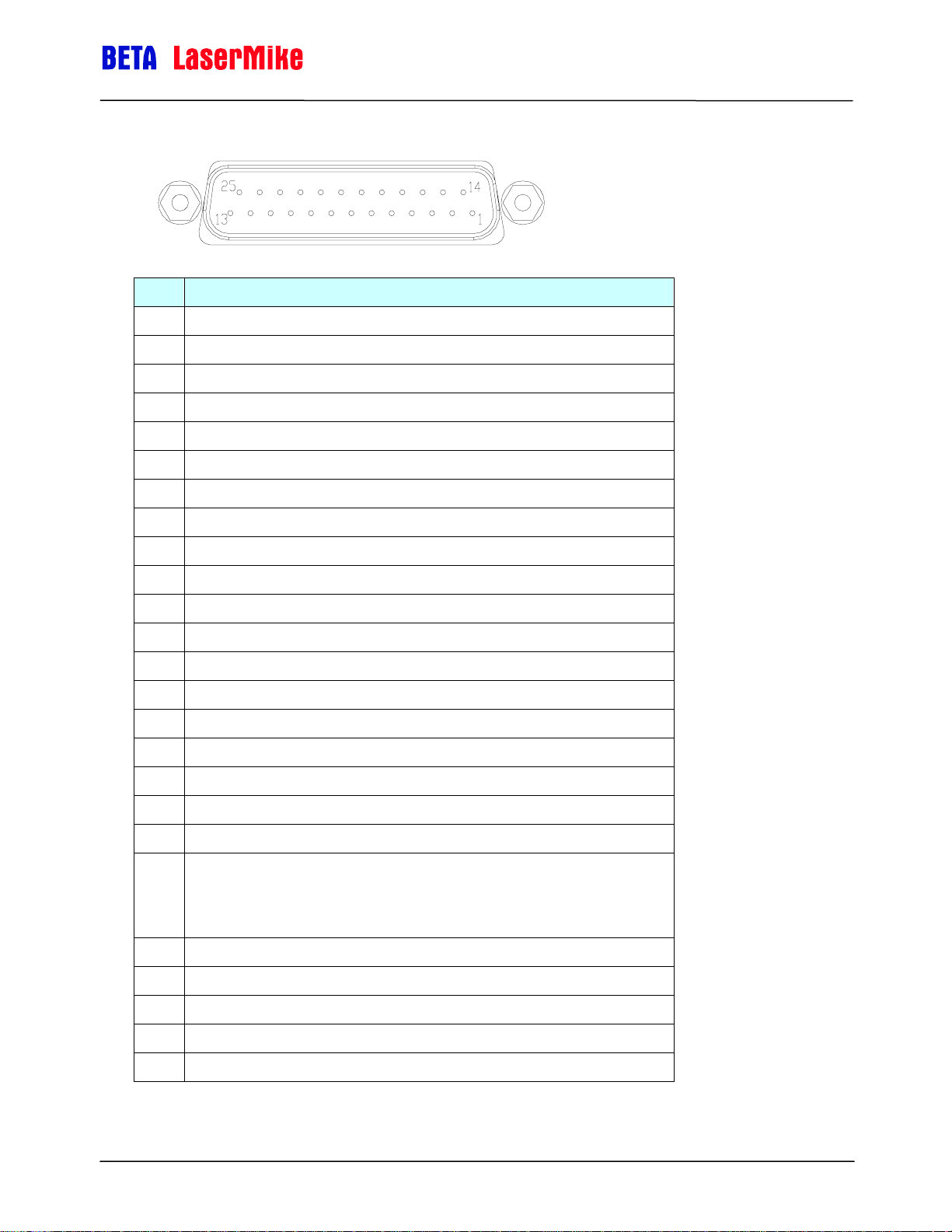

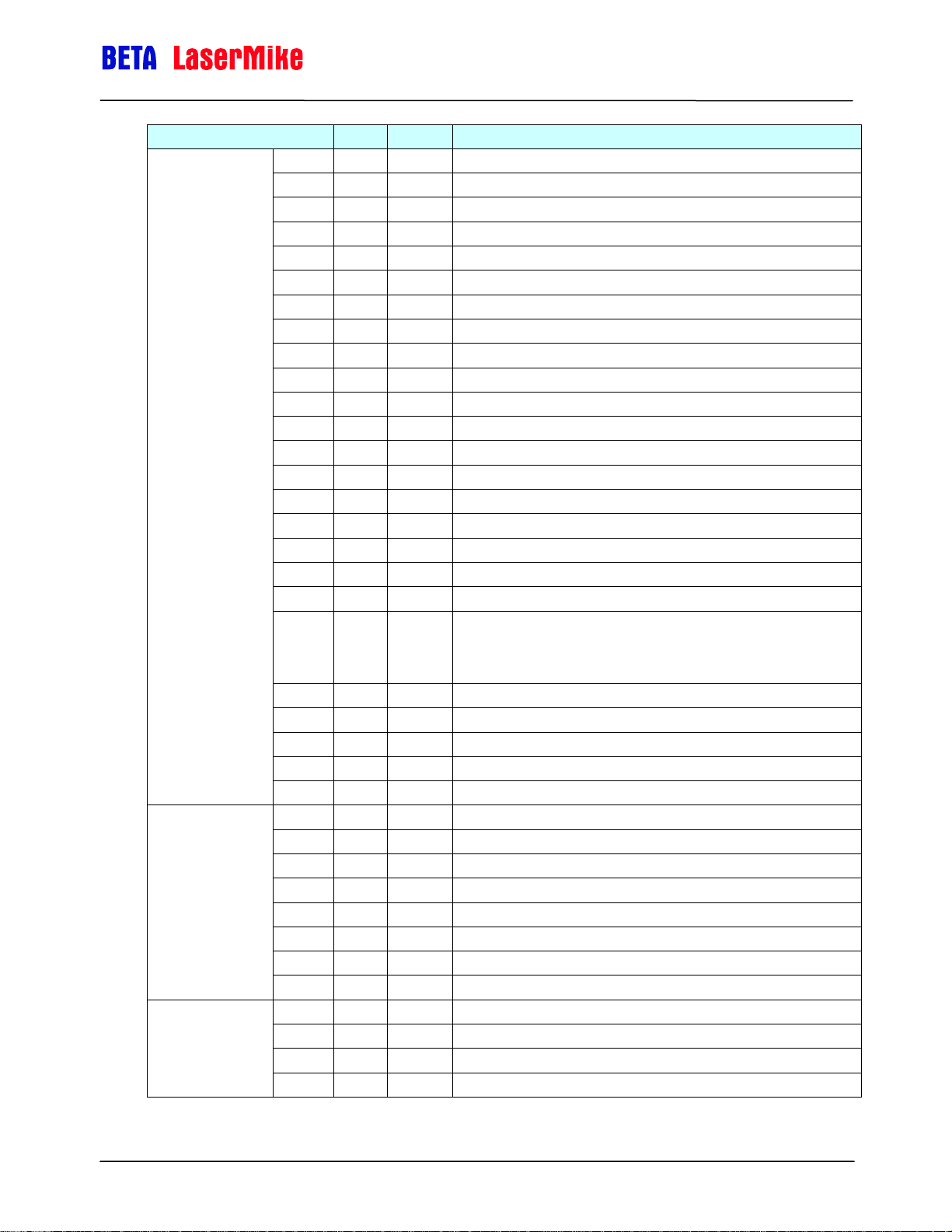

LS8000-3 25-Pin Connector Pinout

Pin Description

1 RS-232 Transmit (from LS8000-3 to host)

2 RS-232 Receive (from host to LS8000-3)

3 Phase A True – High Speed Output (RS-422 Drivers)

4 Phase A False – User Scaleable (5-24V Output)

5 Phase A False – High Speed Output (RS-422 Drivers)

6 Phase B True – User Scaleable (5-24V Output)

7 Phase B True – High Speed Output (RS-422 Drivers)

LaserSpeed 8000-3 Instruction Handbook

Installing the System

8 Phase B False – User Scaleable (5-24V Output)

9 Phase B False – High Speed Output (RS-422 Drivers)

10 Material Present Input (5-24V Input)

11 Signal Ground for Inputs/Outputs/Serial

12 Power Ground for 24V Input

13 Power Ground for 24V Input

14 Measurement Direction Input (5-24V Input)

15 Phase A True – User Scaleable (5-24V Output)

16 Laser Interlock (Connect to Signal Ground to Turn On Laser)

17 Shutter Control (Connect to Signal Ground to Open Shutter)

18 Length Reset Input (5-24V Input)

19 Signal Ground for Inputs/Outputs/Serial

20 User VIN – Voltage input for Isolated Pulse Outputs (5 to 28V DC). The

voltage supplied will be the voltage level of the pulse outputs supplied by

the LS8000-3. If a Voltage is not supplied, the pulse outputs will be

approximately 4.5V.

21 Signal Ground for Inputs/Outputs/Serial

22 Index Pulse True - User Scaleable (5-24V Output)

23 Index Pulse False - User Scaleable (5-24V Output)

24 24V Fused Input

25 24V Fused Input

Part No. 93463 / Drawing No. 0921-01561 Page 26 of 221 Revision A (Sep 2007)

Page 27

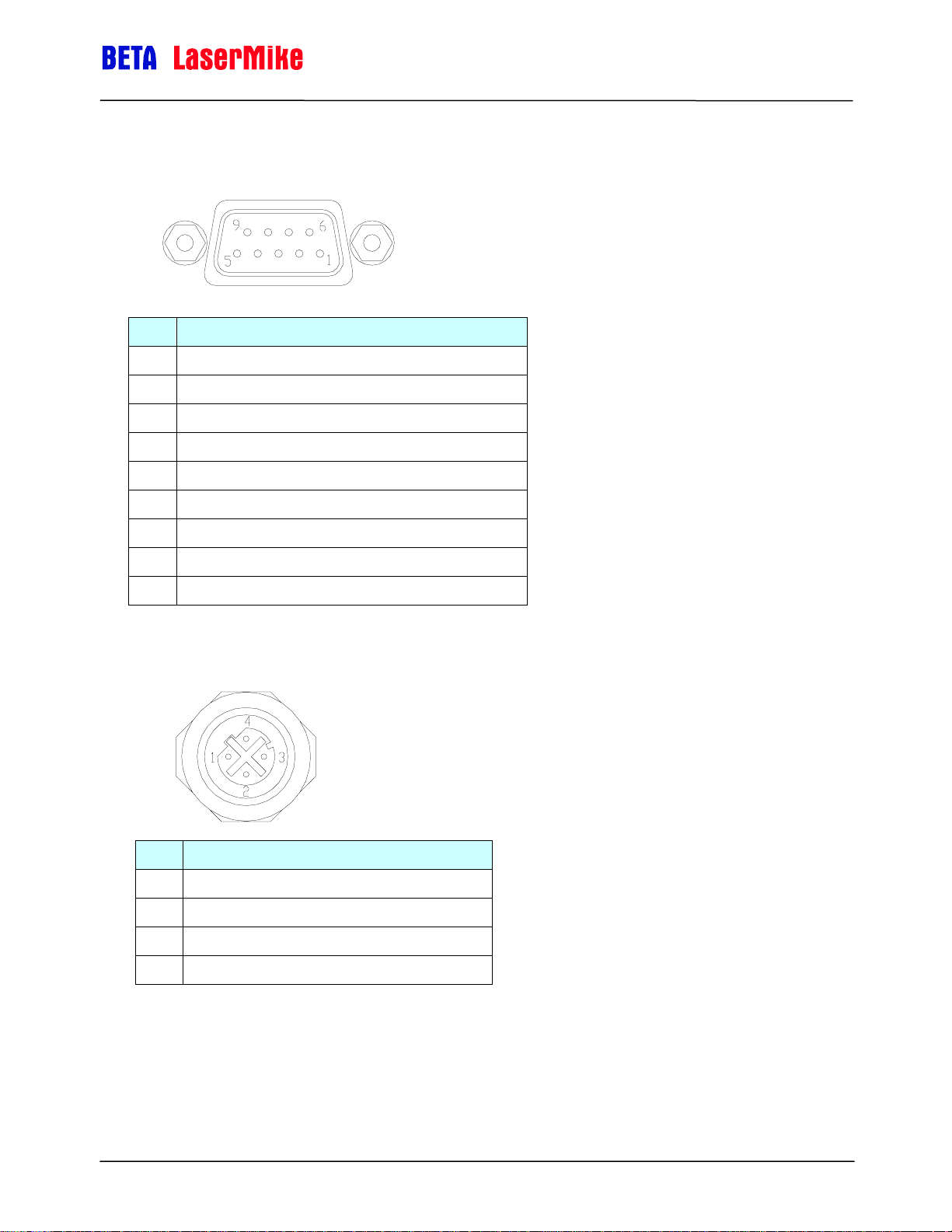

LS8000-3 9-Pin Connector Pinout

Pin Description

1 RS-422 Transmit + (from LS8000-3 to host)

2 RS-422 Transmit – (from LS8000-3 to host)

3 RS-422 Receive + (from host to LS8000-3)

4 RS-422 Receive – (from host to LS8000-3)

5 Signal Ground for Inputs/Outputs/Serial

6 Analog Output Voltage

LaserSpeed 8000-3 Instruction Handbook

Installing the System

7 Analog Output Ground

8 Measurement Synchronization Input +

9 Measurement Synchronization Input -

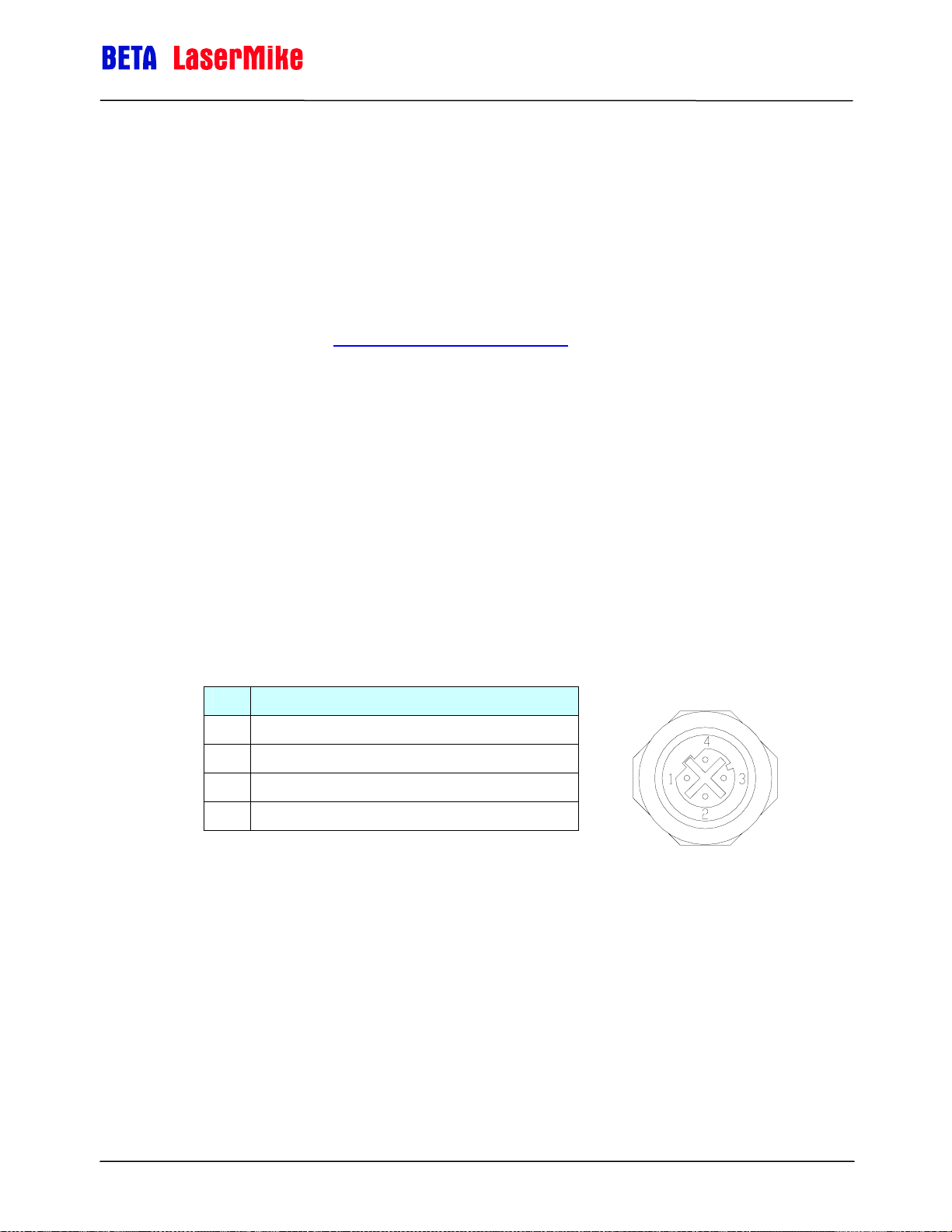

LS8000-3 M12 Connector Pinout

Pin Description

1 Ethernet TX+ (from LS8000-3 to host/switch)

2 Ethernet RX+ (from host/switch to LS8000-3)

3 Ethernet TX- (from LS8000-3 to host/switch)

4 Ethernet RX- (from host/switch to LS8000-3)

Part No. 93463 / Drawing No. 0921-01561 Page 27 of 221 Revision A (Sep 2007)

Page 28

LaserSpeed 8000-3 Instruction Handbook

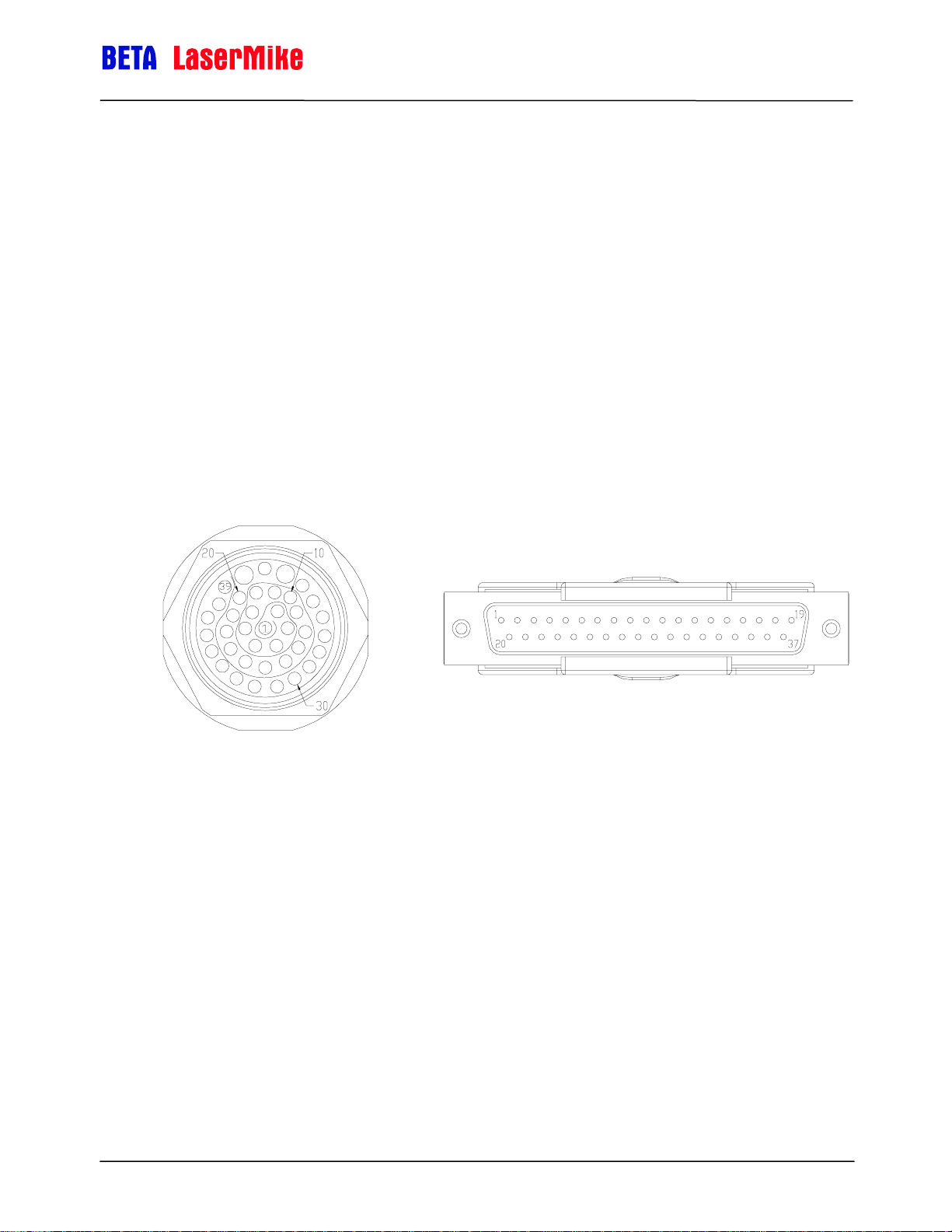

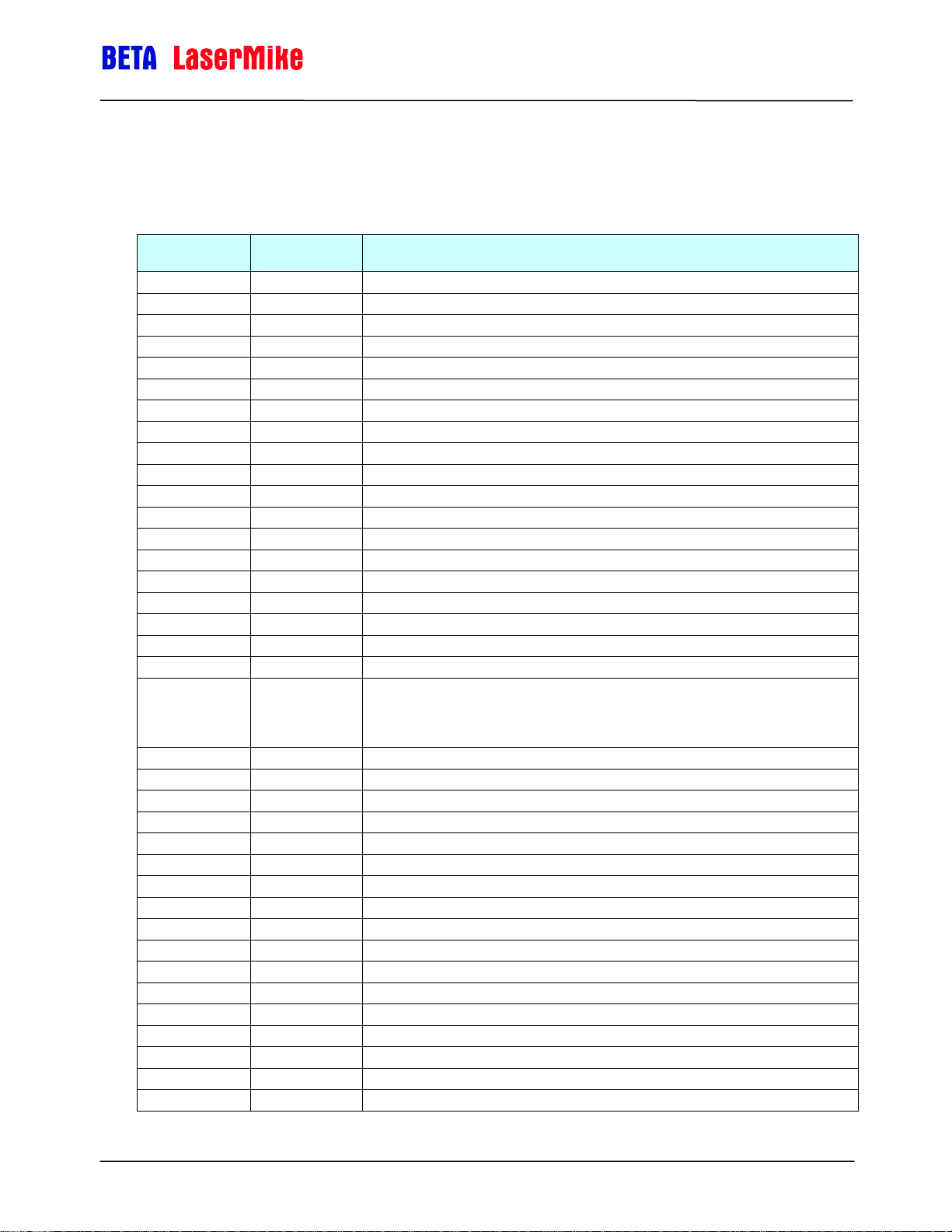

LS8000-3E/LS8000-3X Connector Pinout

The LS8000-3E/LS8000-3X cables have a circular 39-pin military connector on

the gauge end and a DB37 connector on the opposite end. The pinouts of

both connectors are listed below. Pins 21 and 23 of the circular connector are

not internally connected. The 39-pin military connector is internally connected

to the LS8000-3 DB25, DB9, and M12 connectors. These connections are

listed in the following table.

Installing the System

LS8000-3E/X Circular Connector DB37 Cable Connector Pin Locations

Part No. 93463 / Drawing No. 0921-01561 Page 28 of 221 Revision A (Sep 2007)

Page 29

LaserSpeed 8000-3 Instruction Handbook

Installing the System

LS8000-3 Connector Pin DB37 39-Pin Description

1 1 1 RS232 Transmit (from LS8000-3 to host)

2 2 2 RS232 Receive (from host to LS8000-3)

3 3 3 Phase A True – High Speed Output (RS-422 Drivers)

4 4 4 Phase A False – User Scaleable (5-24V Output)

5 5 5 Phase A False – High Speed Output (RS-422 Drivers)

6 6 6 Phase B True – User Scaleable (5-24V Output)

7 7 7 Phase B True – High Speed Output (RS-422 Drivers)

8 8 8 Phase B False – User Scaleable (5-24V Output)

9 9 9 Phase B False – High Speed Output (RS-422 Drivers)

10 10 10 Material Present Input (5-24V Input)

11 11 11 Signal Ground for Inputs/Outputs/Serial

12 12 12 Power Ground for 24V Input

13 13 13 Power Ground for 24V Input

DB25

DB9

M12

14 14 14 Measurement Direction Input (5-24V Input)

15 15 15 Phase A True – User Scaleable (5-24V Output)

16 16 16 Laser Interlock (Connect to Signal Ground to Turn On Laser)

17 17 17 Shutter Control (Connect to Signal Ground to Open Shutter)

18 18 18 Length Reset Input (5-24V Input)

19 19 19 Signal Ground for Inputs/Outputs/Serial

User VIN – Voltage input for Isolated Pulse Outputs (5 to 28V

20 20 20

21 21 22 Signal Ground for Inputs/Outputs/Serial

22 22 24 Index Pulse True - User Scaleable (5-24V Output)

23 23 25 Index Pulse False - User Scaleable (5-24V Output)

24 24 26 24V Fused Input

25 25 27 24V Fused Input

1 26 28 RS422 Transmit + (from LS8000-3 to host)

2 27 29 RS422 Transmit – (from LS8000-3 to host)

3 28 30 RS422 Receive + (from host to LS8000-3)

4 29 31 RS422 Receive – (from host to LS8000-3)

6 30 32 Analog Output Voltage

7 31 33 Analog Output Ground

8 32 34 Measurement Synchronization Input +

9 33 35 Measurement Synchronization Input -

1 34 36 Ethernet TX+

2 35 37 Ethernet RX+

3 36 38 Ethernet TX-

4 37 39 Ethernet RX-

DC). The voltage supplied will be the voltage level of the pulse

outputs supplied by the LS8000-3. If a Voltage is not supplied,

the pulse outputs will be approximately 4.5V.

Part No. 93463 / Drawing No. 0921-01561 Page 29 of 221 Revision A (Sep 2007)

Page 30

LaserSpeed 8000-3 Instruction Handbook

LS8000-3E/LS8000-3X Breakaway Cable Pinout

LaserSpeed breakaway cables have 39-pin military connectors on both ends

(male on one end and female on the other) and have pinouts identical to the

standard gauge cable.

Installing the System

39-Pin Male

1 1 RS232 Transmit (from LS8000-3 to host)

2 2 RS232 Receive (from host to LS8000-3)

3 3 Phase A True – High Speed Output (RS-422 Drivers)

4 4 Phase A False – User Scaleable (5-24V Output)

5 5 Phase A False – High Speed Output (RS-422 Drivers)

6 6 Phase B True – User Scaleable (5-24V Output)

7 7 Phase B True – High Speed Output (RS-422 Drivers)

8 8 Phase B False – User Scaleable (5-24V Output)

9 9 Phase B False – High Speed Output (RS-422 Drivers)

10 10 Material Present Input (5-24V Input)

11 11 Signal Ground for Inputs/Outputs/Serial

12 12 Power Ground for 24V Input

13 13 Power Ground for 24V Input

14 14 Measurement Direction Input (5-24V Input)

15 15 Phase A True – User Scaleable (5-24V Output)

16 16 Laser Interlock (Connect to Signal Ground to Turn On Laser)

17 17 Shutter Control (Connect to Signal Ground to Open Shutter)

18 18 Length Reset Input (5-24V Input)

19 19 Signal Ground for Inputs/Outputs/Serial

20 20

22 22 Signal Ground for Inputs/Outputs/Serial

24 24 Index Pulse True - User Scaleable (5-24V Output)

25 25 Index Pulse False - User Scaleable (5-24V Output)

26 26 24V Fused Input

27 27 24V Fused Input

28 28 RS422 Transmit + (from LS8000-3 to host)

29 29 RS422 Transmit – (from LS8000-3 to host)

30 30 RS422 Receive + (from host to LS8000-3)

31 31 RS422 Receive – (from host to LS8000-3)

32 32 Analog Output Voltage

33 33 Analog Output Ground

34 34 Measurement Synchronization Input +

35 35 Measurement Synchronization Input 36 36 Ethernet TX+

37 37 Ethernet RX+

38 38 Ethernet TX39 39 Ethernet RX-

39-Pin

Female

Description

User VIN – Voltage input for Isolated Pulse Outputs (5 to 28V DC). The

voltage supplied will be the voltage level of the pulse outputs supplied by the

LS8000-3. If a Voltage is not supplied, the pulse outputs will be

approximately 4.5V.

Part No. 93463 / Drawing No. 0921-01561 Page 30 of 221 Revision A (Sep 2007)

Page 31

LaserSpeed 8000-3 Instruction Handbook

Maximizing Performance

The system is now at the point where it can be powered on and the laser

activated so beams are emitted from the front of the gauge. Be sure that the

laser interlock and shutter control circuits are functioning properly.

When Pin 16 is connected to GND (Pin 11, 19, or 21), the laser

becomes operational.

When Pin 17 is connected to GND (Pin 11, 19, or 21), the shutter will

open.

Check the key switch to verify the laser power can be controlled.

Warning: Avoid exposure to the beam. Never look directly into the laser

beams, even when wearing protective eyewear. Eye damage

could result.

Installing the System

Note: There may be some delay time between when the system is powered

on, and when the laser comes on. There is a 7 second delay after

power is applied to the laser (key switch on, laser interlock closed)

before the laser turns on. The laser will also not turn on until the

laser temperature controller stabilizes. This may take a few minutes

after power is initially applied. The standoff distance can be verified

by using a business card or sheet of white paper. Both beams can

be viewed and the area where the beams overlap is the active

measurement region. The location where the overlap of the beams is

smallest is the center of the measurement region. This location

corresponds to the standoff distance and is where the beams should

intersect the product.

The configuration and setup of the gauge can be verified and/or changed

using the supplied LaserTrak Software or directly using the serial commands

listed in the Communication Protocol

approaches requires a computer with an RS-232 serial port connected to pins

1 and 2 of the 25-pin D-sub connector, or an RS-422 serial port connected to

pins 1-4 of the 9-pin D-sub connector.

Once proper communication is established (see the See the LaserTrak

Software section for help), it is recommended to check the Quality Factor (QF).

QF can be checked using LaserTrak, and viewing the chart recorder screen. If

it is below 15, try to move the product or the gauge slightly (adjust the

standoff) and look for improvements in QF. Once QF is maximized, change

the line speed and look for a corresponding velocity change on the chart

recorder.

section. Utilizing either one of these

Part No. 93463 / Drawing No. 0921-01561 Page 31 of 221 Revision A (Sep 2007)

Page 32

LaserSpeed 8000-3 Instruction Handbook

Alternatively, the analog port can be configured to output QF on a 0–1 V scale.

The QF can then be monitored by connecting a panel meter to the analog

output and displaying the voltage. A third method of monitoring the Quality

Factor is to reassign one of the pulse outputs to output the Quality Factor as a

frequency output.

To ensure quality measurements, the laser beams must maintain “contact”

with the product. If the product exhibits large movements during operation, it

should be stabilized with external roller guides. Beta LaserMike offers optional

product guides. Contact your local Beta LaserMike sales representative or the

factory for additional information.

Material Present Adjustment

The intensity of the light reflected from the measurement area can be used to

determine whether material is in the measurement zone or not. To

compensate for varying reflectivity of different materials, it is often necessary

to adjust the threshold of the light detection circuit. This adjustment can be

made with a serial command or by using the LaserTrak software.

Installing the System

Material Present Dropout Time Selection

If you are taking measurements and the Material Present signal is lost for less

than the selected Material Present dropout time, the loss is considered to be a

momentary loss of signal and is ignored. If the signal is lost for longer than the

selected Material Present dropout time, it is considered the end of the material.

This function is very useful when making length measurements on poor

reflecting material.

Validation Time Limit Selection

The validation time limit is used to start making length calculations. Two

conditions are necessary to start a length measurement: Material Present and

valid velocity data. When material enters the measurement volume, the

system determines the time between the Material Present signal and the first

valid data. If the time is less than or equal to the validation time limit

(selectable via LaserTrak or ‘G’ command), then the start-up length-correction

is calculated and a length measurement is initialized. If the time between the

Material Present signal and the first valid velocity data is longer than the

validation limit, then the length calculation is aborted and an error or fault is

sent. This error is sent by setting the length output (either in continuous output

mode or Final Length Mode) to all 9’s.

Part No. 93463 / Drawing No. 0921-01561 Page 32 of 221 Revision A (Sep 2007)

Page 33

LaserSpeed 8000-3 Instruction Handbook

Starting/Ending Length Correction

The Validation Time Limit feature is used because the Material Present signal

tells the gauge that material is indeed moving through the measurement zone.

If valid velocity measurements cannot be made, then a small amount of length

will not be accumulated which, in turn, will cause a length error. This may or

may not be a problem, depending on the velocity of the material when it

passes through the measurement volume during this time. The start-up

length-correction is executed to obtain a more accurate length reading. Each

measurement update is divided into small subintervals. When the Material

Present signal is received within an update period, the time it was received is

recorded with a subinterval clock. The length is calculated by using valid

velocity and integrating over the time measured with the subinterval clock. For

example, if the material speed is 10 meters per minute and material enters the

measurement volume in the middle of the 1-millisecond update period, the

subinterval time of 0.5ms is used to calculate length rather than the 1millisecond period. In this case, a 0.083 mm correction would be made. The

same type of correction is made when the material leaves the measurement

volume.

Installing the System

If problems are encountered during any of the installation steps, contact Beta

LaserMike for assistance.

Part No. 93463 / Drawing No. 0921-01561 Page 33 of 221 Revision A (Sep 2007)

Page 34

LaserSpeed 8000-3 Instruction Handbook

Interfacing with the LS8000-3

Interfacing with the LS8000-3

The LS8000-3 has a variety of outputs that allow length and velocity data to be

transmitted to external devices or control algorithms. All of these signals are

located on the connector(s) on the back of the instrument.

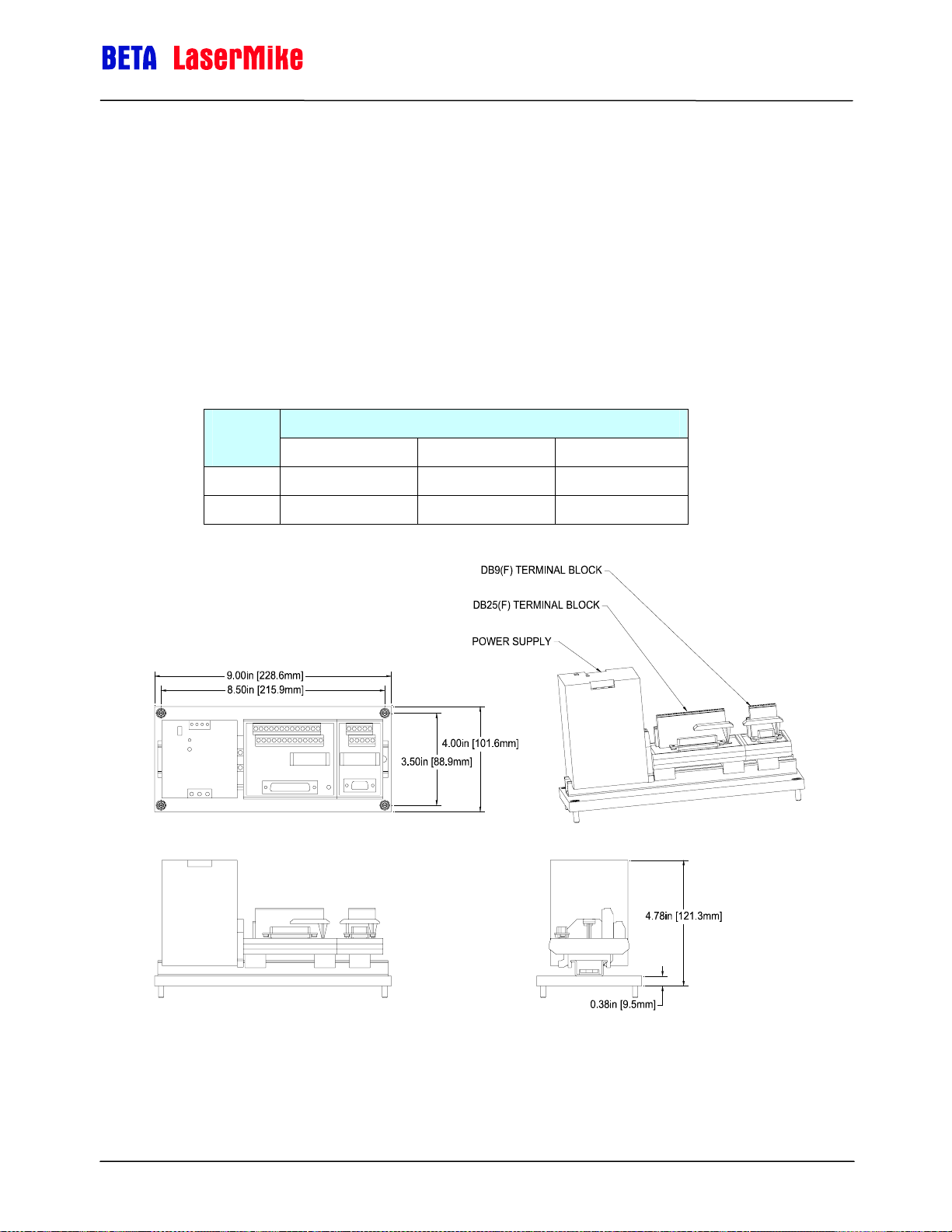

LS8000-3 Interface Connectors

The LS8000-3 has three interface connectors:

Connector Gender Signals

DB25 Male

DB9 Male

M12 Female D-Coded Ethernet

Quad Pulses, RS-232, Interlocks,

Power

RS-422, Analog, Measurement

Synchronization

LS8000-3 Rear Panel Connectors

Part No. 93463 / Drawing No. 0921-01561 Page 34 of 221 Revision A (Sep 2007)

Page 35

LaserSpeed 8000-3 Instruction Handbook

Interfacing with the LS8000-3

DB25 Connector

The 25-pin interface port contains pins which deliver the quadrature pulse

outputs, RS-232 serial communications, safety interlock signals, and the 24 V

supply required to power the gauge. Several inputs are available for operation

of the instrument. The connector is a standard 25-Pin male D-Sub connector.

The connector is shown below looking at the gauge's rear panel with the

gauge base plate down.

Pin Description

1 RS232 Transmit (from LS8000-3 to host)

2 RS232 Receive (from host to LS8000-3)

3 Phase A True – High Speed Output (RS-422 Drivers)

4 Phase A False – User Scaleable (5-24V Output)

5 Phase A False – High Speed Output (RS-422 Drivers)

6 Phase B True – User Scaleable (5-24V Output)

7 Phase B True – High Speed Output (RS-422 Drivers)

8 Phase B False – User Scaleable (5-24V Output)

9 Phase B False – High Speed Output (RS-422 Drivers)

10 Material Present Input (5-24V Input)

11 Signal Ground for Inputs/Outputs/Serial

12 Power Ground for 24V Input

13 Power Ground for 24V Input

14 Measurement Direction Input (5-24V Input)

15 Phase A True – User Scaleable (5-24V Output)

16 Laser Interlock (Connect to Signal Ground to Turn On Laser)

17 Shutter Control (Connect to Signal Ground to Open Shutter)

18 Length Reset Input (5-24V Input)

19 Signal Ground for Inputs/Outputs/Serial

20 User VIN – Voltage input for Isolated Pulse Outputs (5 to 28V DC). The voltage

supplied will be the voltage level of the pulse outputs supplied by the LS8000-3.

If a Voltage is not supplied, the pulse outputs will be approximately 4.5V.

21 Signal Ground for Inputs/Outputs/Serial

22 Index Pulse True - User Scaleable (5-24V Output)

23 Index Pulse False - User Scaleable (5-24V Output)

24 24VDC Fused Input

25 24VDC Fused Input

Part No. 93463 / Drawing No. 0921-01561 Page 35 of 221 Revision A (Sep 2007)

Page 36

LaserSpeed 8000-3 Instruction Handbook

Interfacing with the LS8000-3

RS-232 Transmit and Receive (Pins 1-2)

The LS8000-3 has an RS-232 serial port which can be used to receive

measurement data, or to configure settings. The LS8000-3 will connect to any

DB9 RS-232 port with a straight-through cable. A null modem is not required.

Connections between the gauge and Industry standard pin outs for RS232

serial are given in the following tables:

RS-232 Serial Pinouts – LS8000-3 to Computer DB9 Connector

Gauge DB25 Pin

Number

1 RS-232 Transmit 2 RS-232 Receive

2 RS-232 Receive 3 RS-232 Transmit

11, 19, or 21 Signal Ground 5 Signal Ground

Gauge Signal

Description

Computer DB9

Pin Number

Computer Signal

Description

RS-232 Serial Pinouts – LS8000-3 to Computer DB25 Connector

Gauge DB25

Pin Number

1 RS-232 Transmit 3 RS-232 Receive

2 RS-232 Receive 2 RS-232 Transmit

11, 19, or 21 Signal Ground 7 Signal Ground

Gauge Signal

Description

Computer DB25

Pin Number

Computer Signal

Description

LaserTrak can be used to communicate with the LS8000-3 over the RS-232,

RS-422, and Ethernet ports. Please see the RS232/RS422 Communication

section for details on the Communication Protocol.

Part No. 93463 / Drawing No. 0921-01561 Page 36 of 221 Revision A (Sep 2007)

Page 37

LaserSpeed 8000-3 Instruction Handbook

Interfacing with the LS8000-3

High Speed Pulse Output (Pins 3, 5, 7, 9)

This quadrature pulse output is a high-speed RS-422 drive output with an

output rate up to 5MHz. This pulse output uses an RS-422 transceiver to

generate its output signals, and so should be connected to an RS-422

transceiver on the receiving end. These pulse outputs can be connected to a

PLC high speed counter card for fine length resolution and high-speed velocity

measurement.

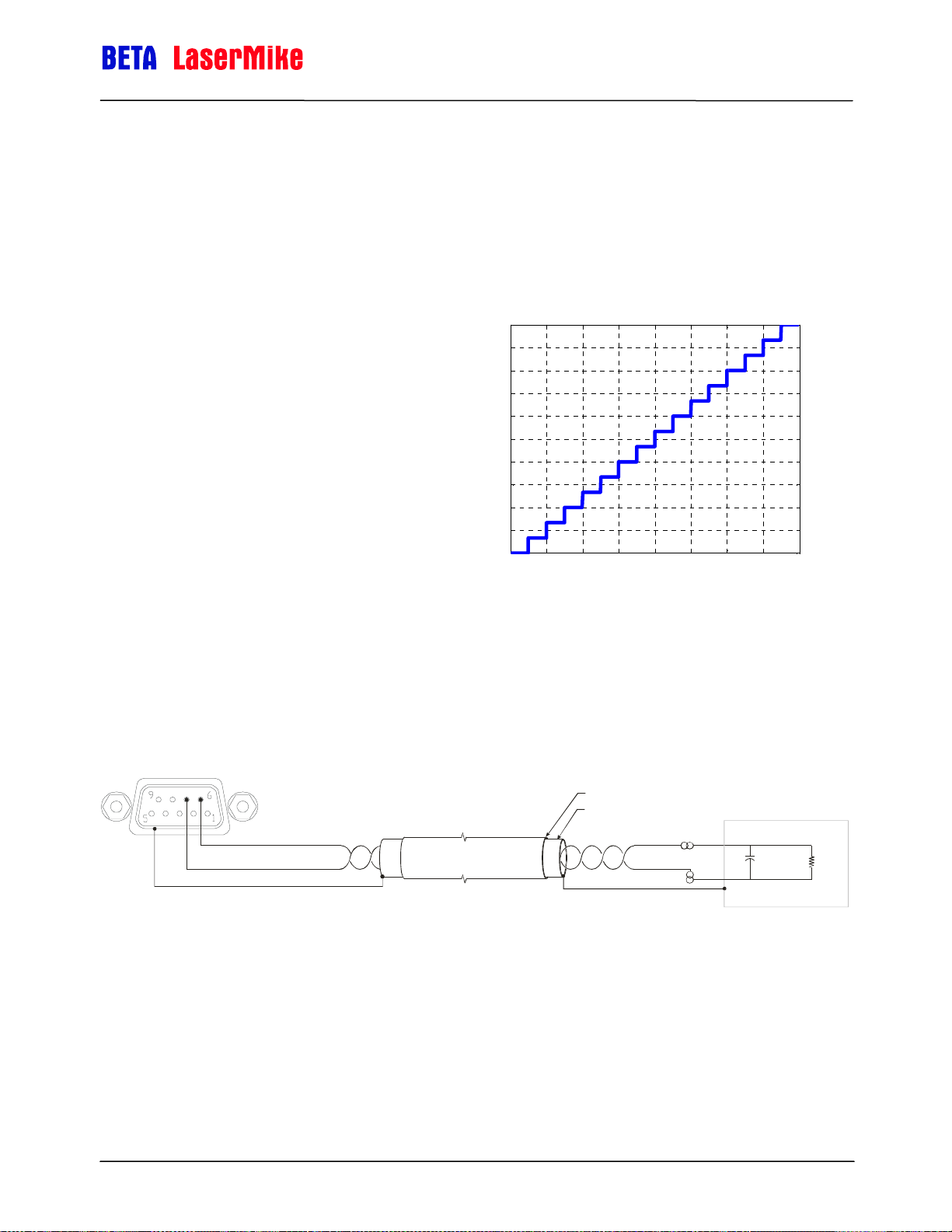

If you need to convert the differential RS-422 level pulse signals to TTL levels,

Beta LaserMike recommends that you use the following circuit:

PHASE_A_TRUE

PHASE_A_FALSE

PHASE_B_TRUE

PHASE_B_FALSE

100

100

8

7B

6

5

8

7B

6

5

+5V

0.1uF

1

+5V

A

Z

Y

A

Z

Y

GND

4

+5V

1

+5V

GND

4

RO

2

MAX3462/MAX3467

or eq ui va lent

3

DI

0.1uF

RO

2

MAX3462/MAX3467

or eq ui va lent

3

DI

PHASE_A_TTL

PHASE_B_TTL

The High Speed Pulse Output can be reconfigured to output several different

status outputs using the High Speed Pulse Output Configuration setting.

See the Configuration Settings

section for details.

Part No. 93463 / Drawing No. 0921-01561 Page 37 of 221 Revision A (Sep 2007)

Page 38

LaserSpeed 8000-3 Instruction Handbook

Interfacing with the LS8000-3

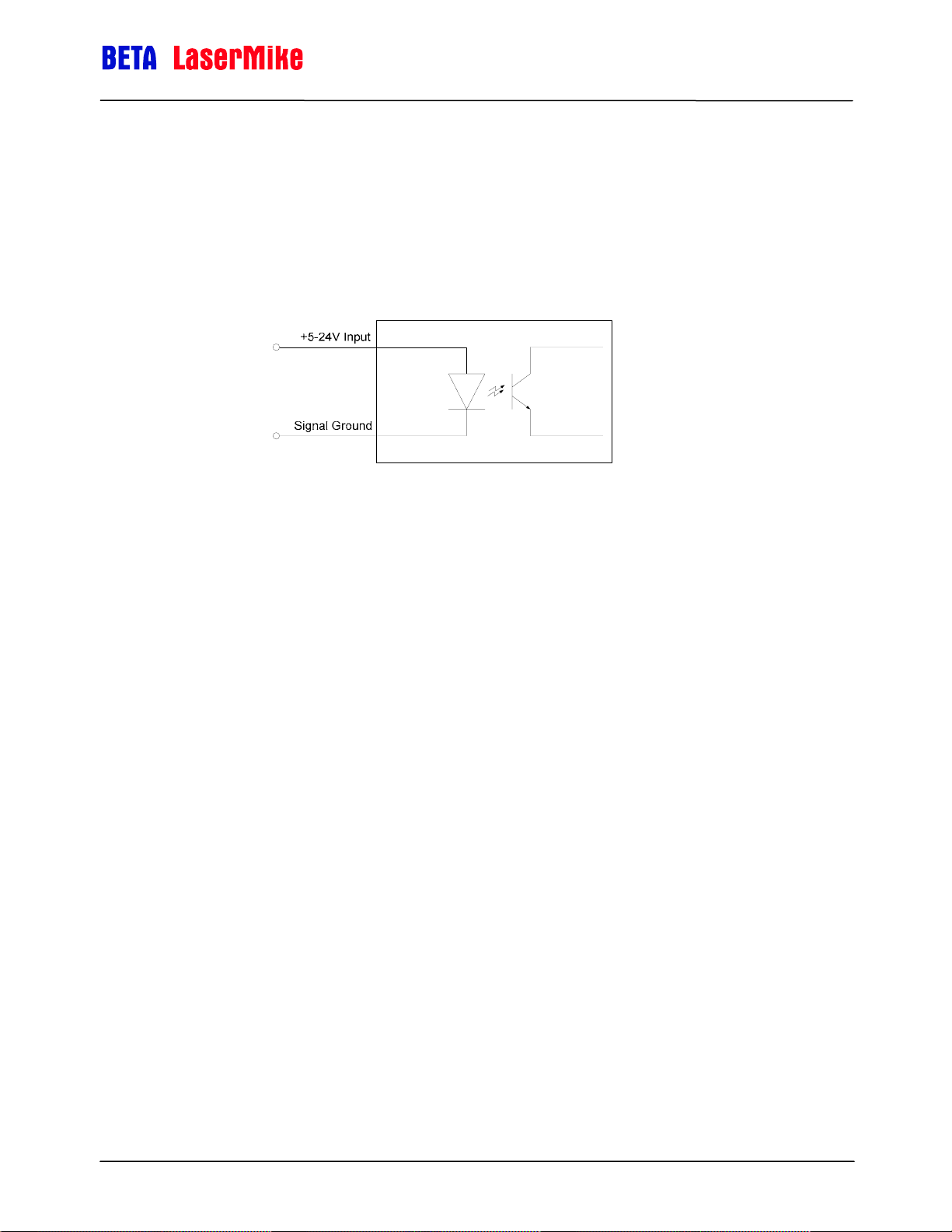

User Scaleable Pulse Output (Pins 15, 4, 6, 8)

This pulse output is a user-defined 5-24V voltage output with output rates up

to 250 kHz. The output voltage is derived from the User V

outputs are opto-isolated signals with a voltage level determined by the

voltage supplied on Pin 20 (referenced to User-Ground (pin 11, 19, or 21.) An