Page 1

Instructions

Engine Timing Tool Set

- for VAG

Part No. 3472

Please refer to www.lasertools.co.uk/toolpoint

to check the most up to date product applications.

www.lasertools.co.uk

Page 2

Introduction

Essential tools for VAG petrol and diesel engines, from 1996 onwards. The kit also includes

tools suitable for older models with 1.9 diesel engines. Set includes crankshaft pulley locking

tools for round (T10050) sprockets at 12 o’clock position.

www.lasertools.co.uk

2

Page 3

Components

Ref. Code OEM Ref Description

A C203

B C216 3359 | T20102 | U-40074 Injection Pump Pulley Timing Pin

C C095 T10008 | 310-084 | (23-058) Tensioner Locking Tool

D C096 T10016 Camshaft Locking Tool

E C157 T10050 | 310-085 | (23-059) Camshaft Locking Tool

F C162 3418 | T20038 Camshaft Setting Bracket

G C061 2064 | U-20003 Injection Pump Pulley Timing Pin

H C070 2065A | U-40021 Camshaft Setting Bracket

I C158 Setscrew M5 x 55mm

J C159 T20046 Stud and Nut

K C284 T20046 Camshaft Tensioner Pin

L C161 3369 Support Guides

3387 | V.159 | T 10020 |

U-30009

www.lasertools.co.uk

Tension Wrench

3

Page 4

Applications

Make, Model, Year Engine Codes

1,2 TDI PD

ANY

AYZ

1,4

AFK

AHW

AKQ

APE

AQQ

ARR

AUA

AUB

AXP

BBY

BBZ

BCA

BKY

BUD

BXW

CGGA

CGGB

CMAA

1,4 TDI PD

AMF

ATL

BHC

1,6

AEH

AHL

AJV

AKL

ALZ

ANA

APF

ARC

ARM

ATN

AUR

AUS

AVU

AVY

AWH

AYD

AZD

BAD

BCB

BFQ

BFS

BGU

BSE

BSF

CCSA

CHGA

CMXA

Volkswagen

4

Audi

Seat

Skoda

80 1982 - 1996

90 1986 - 1991

100 1978 - 1994

200 1982 - 2001

A2 2000 - 2006

A3 1993 - 2010

A4/ quattro 1994 - 2008

A6/ quattro 1994 - 2002

Cabriolet 1995 - 2000

Alhambra 1996 - 2010

Altea/Altea XL 2004 - 2013

Arosa 1999 - 2005

Cordoba 1993 - 2009

Exeo 2009 - 2010

Fabia 1999 - 2007

Ibiza 1993 - 2015

Inca 1996 - 2004

Leon 1999 - 2013

Octavia 1997 - 2012

Toledo 1994 - 2009

Fabia 1999 - 2015

Octavia 1997 - 2013

Praktik 2007 - 2015

Roomster 2006 - 2015

Superb 2001 - 2008

Beetle 1998 - 2011

Bora 1998 - 2005

Caddy 1980 - 2015

Fox 2005 - 2007

Golf 1980 - 2013

Jetta I/II 1980 - 1992

Jetta 2004 - 2017

LT 1982 - 1996

Lupo 1998 - 2005

Passat 1980 - 2010

Polo 1995 - 2014

Santana 1980 - 1988

Sharan 1995 - 2010

Touran 2003 - 2010

Transporter T3/T4 1981 - 2003

Transporter T5 2003 - 2015

Vento 1991 - 1998

www.lasertools.co.uk

1,6 D/ Turbo

1V

CR

CS

CY

JK

JP

JR

JX

ME

RA

SB

1,7 SDI

AKW

AHB

AHG

AKU

KY

1,9 D/ Turbo

1Y

1Z

AAZ

AFF

AFN

AHH

AHU

AVG

1,9 SDI

AGP

AQM

ASY

AYQ

1,9 SDI/ TDI

1X

1Y

1Z

AAZ

ABL

AEF

AEY

AFN

AGD

AHH

AHU

ALE

ASX

AVG

1,9 TDI / TDI PD

AGR

AHF

AJM

ALH

ANU

ARL

ASV

ASZ

ATD

ATJ

AUY

AVB

AVF

AWX

AXR

BSW

BTB

BVK

2,0

AEG

APK

AQY

ATM

AXA

AZH

AZJ

AZM

BBX

BEH

BSX

2,0 D/ Turbo

CN

DE

NC

2,4 D

3D

AAS

1G

1S

AAB

ACL

ACT

AJA

DV

DW

Page 5

Instructions

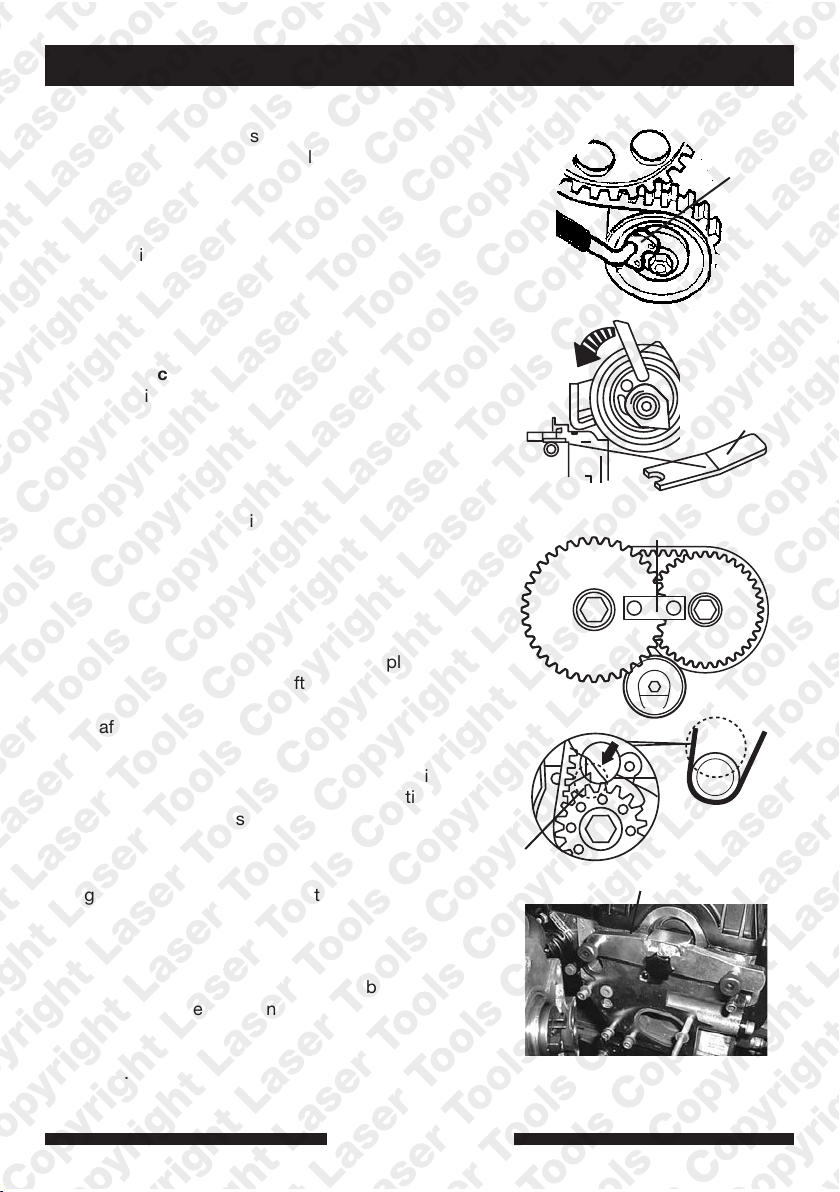

Tension Wrench This wrench is used when fitting

timing belts, and is necessary for holding and

positioning the belt tensioner pulley in alignment whilst

the centre nut is tightened.

Injection Pump Pulley Locking Pin is used to lock the

timing position of the camshaft to the injection pump

and is for two-part sprockets which are retained by

three bolts. The pin is specially hollowed to prevent fuel

pushing the pin back out.

Tensioner Locking Tool is inserted into the automatic

tensioner unit after the tension has been released but

before the timing belt is removed.

This tool is left in place until the tension has been reset after fitting the new belt.

A

C

Camshaft Locking Tool is fitted through the two

camshaft sprockets and located in the cylinder head to

set the correct timing before the timing belt and /or

exhaust camshaft belt is removed.

Crankshaft Locking Tool is used to set the crankshaft

timing position during both removal and replacement

of the timing belt.The crankshaft is first turned to TDC

on N0.1 cylinder, checking the timing marks on the

camshaft sprocket hubs are aligned.

Slide the crankshaft locking tool into position ensuring

that the triangular mark/ arrow on the tool ( positioned

on the left behind the handle) aligns with the timing

mark on the crankshaft sprocket.

Camshaft Setting Bracket enables the correct engine

timing to be conducted following the simple removal

of the vacuum pump and saves time and expense

because it is not necessary to remove the camshaft

cover and gasket.

When the timing belt has broken or has been removed

this tool can be used with an open-ended spanner to

turn the camshaft to the correct timing position. Then

the two Dowel Screws are attached to enable correct

alignment.

D

E

F

www.lasertools.co.uk

5

Page 6

Instructions

Camshaft Setting Bracket is used to set the correct

timing position of the camshaft.

The centre part of the bracket fits into the slotted end

of the camshaft.

The ends of the bracket locate on the cylinder head.

The correct alignment is achieved by placing equal

thickness of shim/feeler gauge between both ends

of the bracket and the cylinder head.

M5 x 55mm. Stud and Nut Is used to apply pressure

to the tensioner plunger to release the tension from the

timing belt.

Camshaft Tensioner Pin.

This is used inconjuncion with the above Stud

and Nut and locks the tensioner adjuster in the

retracted position to permit the old timing belt

to be removed and the new timing belt to be fitted.

H

K

J

J

A

M5 x 60mm. Setscrew is used to lock the viscous fan

coupling whilst it is being un-screwed, using a suitable

hexagon key.

Support Guides. Some cars require the front panel to

moved forward to enable access to the engine.

www.lasertools.co.uk

6

L

Page 7

www.lasertools.co.uk

7

Page 8

Safety Warnings - please read

• If the engine has been identified as an

Interference engine, damage to the engine

will occur if the timing belt has been

damaged. A compression check of all

the cylinders should be taken before the

cylinder head (s) are removed.

• Do not turn crankshaft or camshaft when

the timing belt/chain has been removed.

• To make turning the engine easier,

remove the spark plugs/glow plugs or

injectors.

• Observe all tightening torques.

• Do not turn the engine using the camshaft

or any other sprocket.

• Disconnect the battery earth lead (check

Radio code is available).

Our products are designed to be used correctly and with care for the purpose for which they

are intended. No liability is accepted by the Tool Connection for incorrect use of any of our

products, and the Tool Connection cannot be held responsible for any damage to personnel,

property or equipment when using the tools. Incorrect use will also invalidate the warranty.

If applicable, the applications database and any instructional information provided has been

designed to offer general guidance for a particular tool’s use and while all attention is given

to the accuracy of the data no project should be attempted without referring first to the

manufacturer’s technical documentation (workshop or instruction manual) or the use of a

recognised authority such as Autodata.

It is our policy to continually improve our products and thus we reserve the right to alter

specifications and components without prior notice. It is the responsibility of the user to

ensure the suitability of the tools and information prior to their use.

• Do not use cleaning fluids on belts,

sprockets or rollers.

• Some toothed timing belts are not

interchangeable. Check the replacement

belt has the correct tooth profile.

• Always mark the belt with the direction of

running before removal.

• Do not lever or force the belt onto its

sprockets.

• Do not use timing pins to lock the

engine when slackening or tightening the

crankshaft pulley bolts.

• ALWAYS REFER TO A REPUTABLE

MANUFACTURERS WORKSHOP

MANUAL.

www.lasertools.co.uk

3472_Instructions_V3

Loading...

Loading...