Page 1

Document 480081

Model XUEF-200, 300 and 400

Utility Fans

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

XUEF-200

XUEF-300 XUEF-400

General Safety Information

Only qualified personnel should install this fan.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if seismic

activity is present. If more information is needed,

contact a licensed professional engineer before

moving forward.

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC) and the

National Fire Protection Agency (NFPA), where

applicable. Follow the Canadian Electric Code

(CEC) in Canada.

2. The rotation of the wheel is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan wheel faster than max cataloged

fan RPM. Adjustments to fan speed significantly

effects motor load. If the fan RPM is changed, the

motor current should be checked to make sure it is

not exceeding the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to a duct while the fan is

running.

DANGER

Always disconnect, lock and tag power source

before installing or servicing. Failure to disconnect

power source can result in fire, shock or serious

injury.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive

atmospheres.

DANGER

Pour écarter les risques d’incendie, de choc

électrique ou de blessure grave, veiller à toujours

débrancher, verrouiller et étiqueter la source de

courant avant l’installation ou l’entretien.

ATTENTION

Lors de toute intervention sur la soufflante, le moteur

peut être suffisamment chaud pour provoquer

une douleur voire une blessure. Laisser le moteur

refroidir avant toute maintenance.

ATTENTION

Faire preuve de précaution dans les atmosphères

explosives.

Utility Fans 1

Page 2

Receiving

Upon receiving the product, check to ensure all

items are accounted for by referencing the delivery

receipt or packing list. Inspect each crate or carton

for shipping damage before accepting delivery. Alert

the carrier of any damage detected. The customer

will make a notation of damage (or shortage of items)

on the delivery receipt and all copies of the bill of

lading which is countersigned by the delivering

carrier. If damaged, immediately contact your Larkin

Representative. Any physical damage to the unit after

acceptance is not the responsibility of manufacturer.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited to

only items on the bill of lading.

Handling

Fans are to be rigged and moved by the lifting

brackets provided or by the skid when a forklift is

used. Location of brackets varies by model and size.

Handle in such a manner as to keep from scratching

or chipping the coating. Damaged finish may reduce

the ability of the fan to resist corrosion. Fans should

never be lifted by the shaft, fan housing, motor, belt

guard, windband or accessories.

Storage

• Rotate fan wheel monthly and purge bearings once

every three months

• Energize fan motor once every three months

• Store belts flat to keep them from warping and

stretching

• Store unit in location which does not have vibration

• After storage period, purge grease before putting

fan into service.

If storage of fan is in a humid, dusty or corrosive

atmosphere, rotate the fan and purge the bearings

once a month. Improper storage which results in

damage to the fan will void the warranty.

Fans are protected against damage during shipment.

If the unit cannot be installed and operated

immediately, precautions need to be taken to prevent

deterioration of the unit during storage. The user

assumes responsibility of the fan and accessories

while in storage. The manufacturer will not be

responsible for damage during storage. These

suggestions are provided solely as a convenience to

the user.

INDOOR -

fans and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain or snow. Temperatures

should be evenly maintained between 30° to 110°F

(-1° to 43°C), wide temperature swings may cause

condensation and “sweating” of metal parts. All

accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts allow cold parts to reach

room temperature. To dry parts and packages use a

portable electric heater to remove any moisture build

up. Leave coverings loose to permit air circulation and

to allow for periodic inspection.

The unit should be stored at least 3½ inches

off the floor on wooden blocks covered with moisture

proof paper or polyethylene sheathing. Aisles between

parts and along all walls should be provided to permit

air circulation and space for inspection.

The ideal environment for the storage of

(89 mm)

OUTDOOR - Fans designed for outdoor applications

may be stored outdoors, if absolutely necessary.

Roads or aisles for portable cranes and hauling

equipment are needed.

The fan should be placed on a level surface to prevent

water from leaking into the fan. The fan should be

elevated on an adequate number of wooden blocks

so it is above water and snow levels and has enough

blocking to prevent it from settling into soft ground.

Locate parts far enough apart to permit air circulation,

sunlight and space for periodic inspection. To

minimize water accumulation, place all fan parts on

blocking supports so rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Fan wheels should be blocked to prevent spinning

caused by strong winds.

Inspection and Maintenance During

Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At

each inspection, rotate the wheel by hand ten to

fifteen revolutions to distribute lubricant in motor and

bearings. If paint deterioration begins, consideration

should be given to touch-up or repainting. Fans with

special coatings may require special techniques for

touch-up or repair.

Utility Fans2

Page 3

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lintfree cloths. Polish any remaining rust from surface

with crocus cloth or fine emery paper and oil. Do not

destroy the continuity of the surfaces. Thoroughly

wipe clean with Tectyl® 506 (Ashland Inc.) or the

equivalent. For hard to reach internal surfaces or for

occasional use, consider using Tectyl® 511M Rust

Preventive, WD-40® or the equivalent.

Removing from Storage

As fans are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion until the fan equipment

goes into operation.

Prior to assembly and installation of the unit and

system components, inspect the fan assembly to

make sure it is in working order.

1. Check all fasteners, set screws on the fan, wheel,

bearings, drive, motor base and accessories for

tightness.

2. Rotate the fan wheel by hand and assure no parts

are rubbing. Access to the wheel is obtained

through a bolted panel located on the side of the

fan housing.

3. Ensure proper wheel settings for radial gap and

alignment. Refer to Radial Gap, Overlap and Wheel

Alignment section on page 9.

Table of Contents

General Safety Information .................... 1

Receiving ................................ 2

Unpacking ............................... 2

Handling ................................. 2

Storage .................................. 2

Inspection and Maintenance During Storage ...2-3

Removing from Storage ..................... 3

General Information

Unit and System Identification Tags ........... 4

Pre-Installation Information .................. 4

Electrical Disconnects ...................... 4

Moving Parts ............................. 4

Guards - Motor Cover, Weatherhood, Shaft,

Belt, Inlet or Outlet Guard .................. 4

Access Doors ............................. 4

Air Pressure and Suction .................... 4

Fans - Rigging and Lifting ..................... 5

Installation

Discharge Positions ........................ 5

Ducted Inlet Installations .................... 6

Ducted Outlet Installations ................... 6

Non-Ducted Installations .................... 6

Fan Drainage Piping and Trap Detail ........... 7

UL/cUL 762 Listed Fans for Restaurant Exhaust . 8

V-Belt Drives

Installation ............................... 8

Alignment of Pulleys and Belts ............... 8

Radial Gap, Overlap and Wheel Alignment

Radial Gap and Alignment ................... 9

Method for Centering Wheel ................. 9

Wheel Rotation ............................ 9

Field Coating Touch-Up Procedure for

Scratched Areas .......................... 10

Electrical Connections ...................... 10

Unit Start-Up

Visual Inspection of Equipment .............. 11

Check .................................. 11

Additional Steps for Initial Start-Up ........... 11

Vibration ................................. 12

Routine Maintenance and Operation

Fan Operation ........................... 12

Motors ................................. 12

Belt Drive Maintenance .................... 13

Variable Frequency Drive Operation .......... 13

Bearing Lubrication Schedule ............... 13

Wheel and Fastener Maintenance ............ 14

Bearing Replacement

Bearing Removal ......................... 14

Bearing Installation ....................... 15

Parts List ................................. 16

Troubleshooting ............................ 17

Maintenance Log .........................18-19

Our Commitment .....................Backcover

Utility Fans 3

Page 4

General Information

To ensure a successful installation, the instructions in

this manual should be read and adhered to. Failure to

comply with proper installation procedures may void

the warranty.

Unit and System Identification Tags

Each fan has a permanently affixed manufacturer’s

engraved metal nameplate containing the model

number and individual serial number.

The tag shown

is an example of

an identification

nameplate on the

fan. The information

provides general

details about the fan,

as well as containing specific information unique to

the unit. When contacting your Larkin representative

with future needs or questions, please have the

information on this label available. Tags are mounted

in an area which is clearly visible, usually on the side

of the fan cabinet.

Pre-Installation Information

Before installation, it is important to be certain the

mounting surface will bear the operating weight of the

unit. For proper unit operation, it is also important that

it be operated in a completely level position.

For further details on safety practices involving

industrial and commercial fans, please refer to AMCA

Publication410.

Guards – Motor Cover, Weatherhood,

Shaft, Belt, Inlet or Outlet Guard

Do not operate fans without proper protective devices

in place. Failure to do so may result in serious bodily

injury and property damage. Check local codes to

ensure compliance for all protective devices.

Access Doors

Before opening access doors, ensure the fan wheel

has stopped moving and that the wheel has been

secured from being able to rotate. Do not operate fan

without access door in its fully closed position.

Air Pressure and Suction

In addition to the usual hazards associated with

rotating machinery, fans also create a dangerous

suction at the inlet. Special caution needs to be used

when moving around a fan, whether it is in operation

or not. Before start-up, make sure the inlet area is

clear of personnel and loose objects.

Electrical Disconnects

All fan motors should have disconnects located in

close visual proximity to turn off electrical service.

Service disconnects shall be locked-out when

maintenance is being performed.

Moving Parts

All moving parts must have guards to protect

personnel. Refer to local codes for requirements as to

the number, type and design. Fully secure fan wheel

before performing any maintenance. The fan wheel

may start “free wheeling” even if all electrical power

has been disconnected. Before the initial start-up or

any restart, check the following items to make sure

that they are installed and secure.

• Do not spin fan wheel faster than the maximum

cataloged fan rpm.

• Adjustments to fan speed significantly affects

motor load. If the fan RPM is changed, the motor

current should be checked to make sure it is not

exceeding the motor nameplate amps.

Utility Fans4

Page 5

Fans – Rigging and Lifting

Installation

CAUTION

Fans should never be lifted by the shaft, motor,

motor cover or accessories.

Fans are to be rigged and moved by the lifting

brackets provided or by the skid when a forklift is

used. Location of brackets varies by model and size.

Handle in such a manner as to keep from scratching

or chipping the coating. Damaged finish may reduce

ability of fan to resist corrosion. See coating repair

section of this manual for details involving touch-up of

damaged surfaces.

• Use standard lifting and rigging practices.

• ALL lifting brackets on each component must be

utilized at the same time.

• Fan to be kept level during lifting and installation.

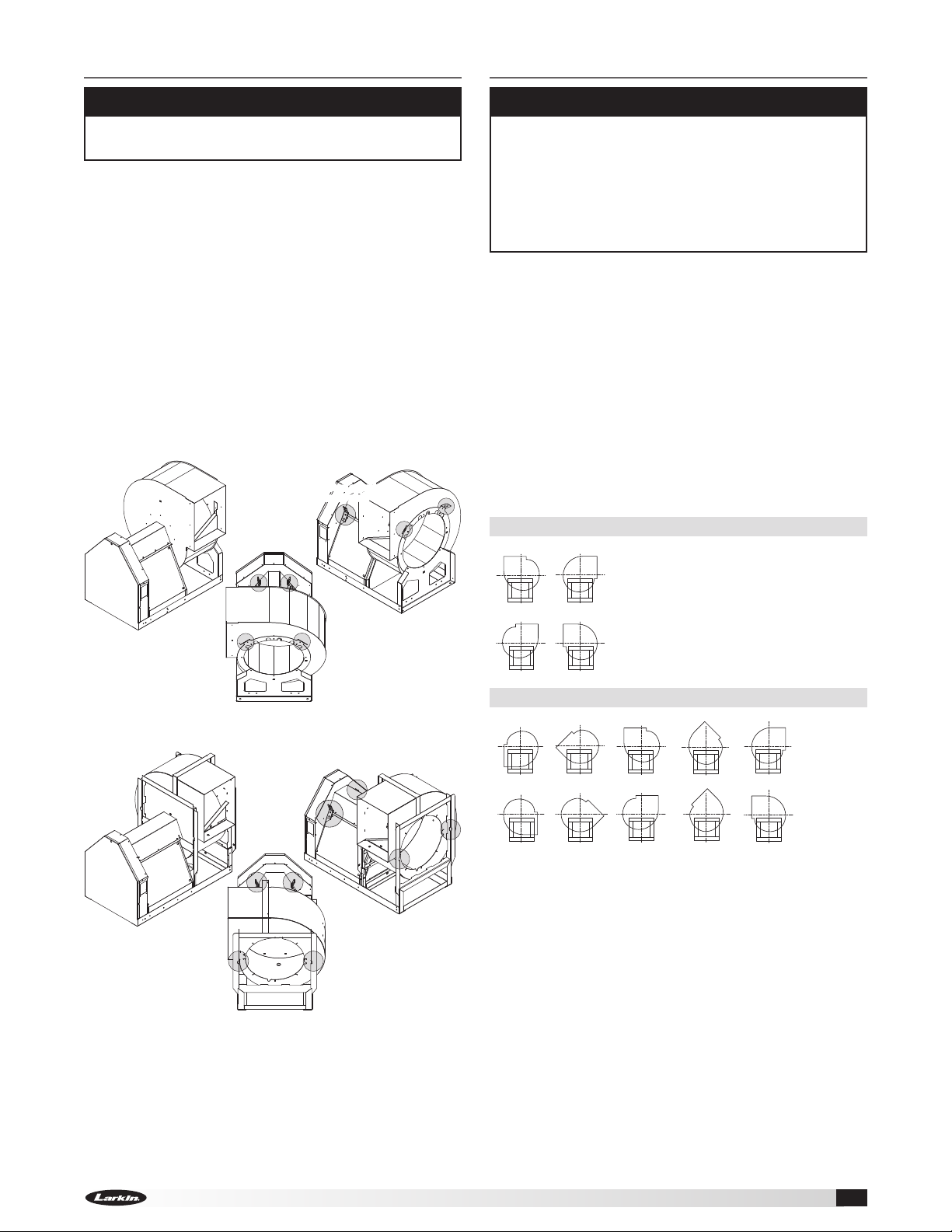

Shading indicates lifting point locations

XUEF-200 and XUEF-300

Lifting bracket on opposing side

Lifting bracket on opposing side

(not shown in this view)

(not shown in this view)

CAUTION

When installing a fan, ensure the proper protective

devices are used to protect personnel from

moving parts and other hazards. A complete line

of protective accessories are available from Larkin

including: inlet guards, outlet guards, belt guards,

shaft guards, protective cages and electrical

disconnects.

Move the fan to the desired location. Check and

tighten fasteners throughout the unit and then fasten

securely through mounting holes provided in the base

angles. The unit must be set level (shimming may be

necessary). Flexible duct connections and vibration

isolators should be used where noise is a factor.

The motor voltage and ampere rating must be

checked for compatibility with the electrical supply

prior to final electrical connection. Supply wiring to the

fan must be properly fused, and conform to local and

national electrical codes.

Discharge Positions

XUEF-200

CW UB

CW TH

XUEF-400

CCW UB

XUEF-300 and XUEF-400

CW BH

CCW BH

CCW TH

CW BAU

CCW BAU

CW UB

CCW UB

CW TAU

CCW TAU

CW TH

CCW TH

The discharge is factory set as specified by customer

order, however, certain sizes can be rotated to other

discharge positions in the field if necessary. If rotating

the fan housing, accommodations may need to be

made for the fan to drain properly. The XUEF-200,

all sizes and XUEF-300, sizes 24 and less, have field

rotatable housings. For the XUEF-400, rotatable

housings are standard sizes 30 and less, arrangement

10, and Class 0, I and II. Removal of the housing bolts

allows the discharge to be rotated to the clockwise

positions above. For DB discharge position, a portion

of the frame angle must be removed.

Fan rotation is always specified from the drive side of

the housing.

Utility Fans 5

Page 6

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Turning

Vanes

POOR

POOR

GOOD

Length of Straight Duct

GOOD

One fan

wheel

diameter

One fan

diameter

3/4 to

one fan

wheel

diameter

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Turning

Vanes

POOR

POOR

GOOD

Length of Straight Duct

GOOD

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Turning

Vanes

POOR

POOR

GOOD

Length of Straight Duct

3/4 to one

fan

wheel

diameter

3/4 to one

fan

wheel

diameter

One fan

diameter

3/4 to one

fan

wheel

diameter

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Turning

Vanes

POOR

POOR

GOOD

POOR

Length of Straight Duct

GOOD

One fan

wheel

diameter

3/4 to

one fan

wheel

diameter

One fan

diameter

3/4 to

one fan

wheel

diameter

SYSTEM EFFECT FACTORS CURVES

STATIC PRESSURE LOSS

1.2

1.0

0.8

0.6

0.4

0.2

0.0

CURVE 1

CURVE 2

CURVE 3

CURVE 4

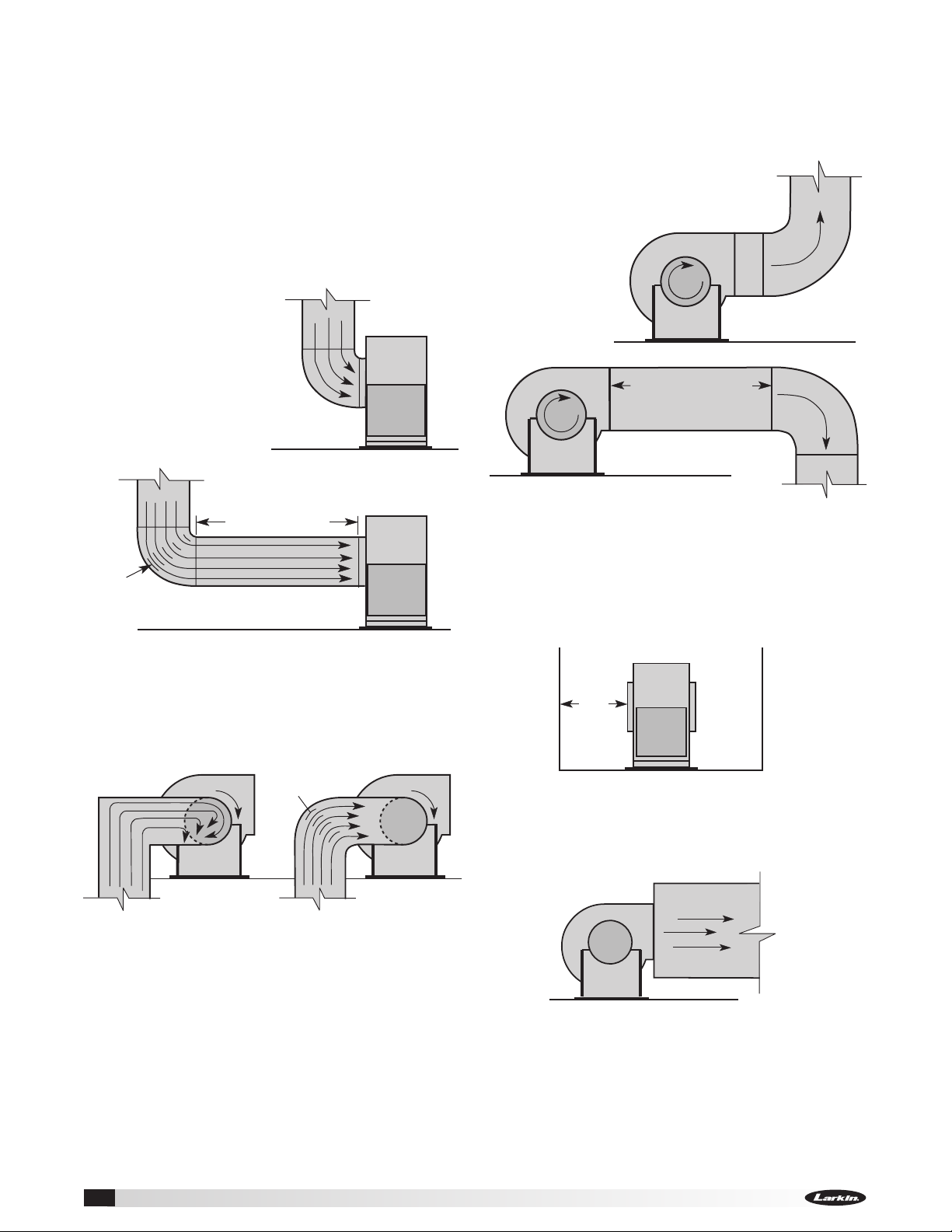

Installations with inlet or discharge configurations

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Turning

Vanes

POOR

POOR

GOOD

Length of Straight Duct

GOOD

3/4 to

one fan

wheel

diameter

SYSTEM EFFECT FACTORS CURVES

STATIC PRESSURE LOSS

1.2

1.0

0.8

0.6

0.4

0.2

0.0

CURVE 1

CURVE 2

CURVE 3

CURVE 4

that deviate from this manual may result in reduced

fan performance. Restricted or unstable flow at the

fan inlet can cause pre-rotation of incoming air or

uneven loading of the fan wheel yielding large system

losses and increased sound levels. Free discharge

or turbulent flow in the discharge ductwork will also

result in system effect losses. Refer to the following

diagrams for the most efficient installation conditions.

Ducted Inlet Installations

Inlet Duct Turns - Installation of a duct turn or elbow

too close to the fan inlet

reduces fan performance

because air is loaded

unevenly into the fan

wheel. To achieve full

fan performance, there

should be at least three

fan wheel diameters

between the turn or

elbow and the fan inlet.

POOR

Ducted Outlet Installations

Discharge Duct Turns - Duct turns located near the

fan discharge should always be in the direction of the

fan rotation.

Fan performance is reduced when duct turns

are made immediately off the fan

discharge. To achieve cataloged fan

performance there should be at least

three equivalent

duct diameters of

straight ductwork

between the fan

discharge and

any duct turns.

Three fan wheel diameters

Turning

Vanes

GOOD

Inlet Spin - Inlet spin is a frequent cause of reduced

fan performance. The change in fan performance is a

function of the intensity of spin and not easily defined.

The best solution is proper duct design and airflow

patterns. Turning vanes reduce the effects of inlet

spin.

t

a

t

i

o

n

Turning

Vanes

R

o

POOR

Utility Fans6

GOOD

R

o

t

a

t

Non-Ducted Installations

Inlet Clearance - Installation of a fan with an open

inlet too close to a wall or bulkhead will cause

reduced fan performance. It is desirable to have

a minimum of three-fourths of a wheel diameter

between the fan inlet and the wall.

i

o

n

Free Discharge - Free or abrupt discharge into a

plenum results in a reduction in fan performance. The

effect of discharge static regain is not realized.

3/4 to one

fan

wheel

diameter

Single Fan Installation

Page 7

Fan Drainage Piping and Trap Detail

(TRAP BY OTHERS)

ENERGY RECOVERY

PLENUM

SUBFLOOR

1.25 NPT

.75 NPT

*BASED ON STANDARD

VEKTOR ERS CURB HEIGHTS

*

*

ROOF

CURB

P.O.BOX 410 SCHOFIELD, WISCONSIN 54476-0410

TITLE

DRAWN BY

ECO

B

ENG. REF.

DATE

SUPERSEDES

SCALE

CAD DRAWING NO.

FAUST

06/29/2009

1/8

VK-ERS

N = Negative fan pressure (inches W.C.)

H = N - 0.5 inches minimum

H/2

H/2

H

1.25 inch minimum

N

FAN ON

FAN OFF

14.750

14.000

NOTE: INSULATION OR OTHER MEANS

OF FREEZE PROTECTION MAY BE

REQUIRED IN CERTAIN CLIMATES

(TRAP BY OTHERS)

ERS DRAIN SUBMITTAL

(by others)

Fans may have been supplied with an optional drain.

Drains are located at the underside of the scroll

housing. The drain may need to be connected to a

drainage system to ensure proper disposal of any

water or condensate that may occur.

• Drain connections are 1.0 inch MNPT

• Installed piping to have a downward angle to allow

for drainage

• Fill traps to recommended level before start-up

Note: A conservative method of trap design is to set

N = total static pressure.

Positive Pressure Trap

Connect

this end

to fan drain.

H/2 H/2

H

N

1.25 inch

minimum

N = Negative fan pressure (inches W.C.)

H = N - 0.5 inches minimum

Check local codes for proper disposal of drain water

which has been in contact with the exhaust air.

Fans used for grease exhaust need to be equipped

with a separate grease collector.

FAN ONFAN OFF

Utility Fans 7

Page 8

Installation of UL/cUL 762 Listed

**Per NFP

be a minimum of 40 in.

above the r

MOTOR

FAN

MOTOR

Fans for Restaurant Exhaust

The UL/cUL 762 listing for restaurant exhaust is

available on the XUEF-300 and 400.

UL/cUL 762 fans are listed for a maximum operating

temperature of 375°F

door and 1inch

(191°C)

(25.4mm)

outlet guard is strongly recommended when the fan

discharge is accessible. An upblast discharge is

recommended. The fan discharge must be a minimum

of 40 inches

(1016 mm)

exhaust duct must be fully welded to a distance of

18inches

40 in.**

(1016 mm)

(457mm)

Upblast Discharge

Weatherhood

A 96 the fan discharge must

oof surface.

(1016 mm)

above the roof surface.

and includes an access

drain connection. An

above the roof line and the

XUEF 300 and 400 models are

listed for grease removal (UL/cUL

762) File no. MH11745

Optional Companion

Flange

3 Wheel

Diameters

Duct

from

kitchen

hood

18 in.*

(457 mm)

*Per NFPA 96 the duct

must be of all-welded

construction to a

minimum distance of

18 inches (457 mm)

above the roof surface.

V-Belt Drives

V-Belt Drive Installation

1. Remove the protective coating from the end of the

fan shaft using mineral spirits or another similar

solvent. Check to ensure that the shaft is free of

nicks and burrs.

2. Slide sheaves on shafts. Do not drive

sheaves on as this may result in

bearing damage.

3. Align fan and motor sheaves

with a straight edge or

string and tighten.

4. Place belts over sheaves.

Do not pry or force belts,

as this could result in

damage to the cords in

the belts.

5. Adjust the tension until the belts appear snug. Run

the unit for a few minutes and allow the belts to

“Set” properly.

6. With the fan off and disconnect locked out, adjust

the belt tension by moving the motor pivot plate.

When in operation, the tight side of the belts

should be in a straight line from sheave to sheave

with a slight bow on the slack side.

Aligning Sheaves with

a Straight Edge

This drawing is for dimensional information only. See the latest edition

of NFPA 96 Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations for detailed installation instructions,

materials, duct connections and clearances.

Alignment of Pulleys and Belts

Check pulleys and belts for proper alignment to avoid

unnecessary belt wear, noise, vibration and power

loss. Motor and drive shafts must be parallel and

pulleys in line as shown in Figure 1.

CORRECT WRONG WRONG WRONG

Figure 1

The adjustable motor pulley is set at the factory for

the fan RPM specified by the customer. Fan RPM can

be increased by closing or decreased by opening the

adjustable motor pulley. Multi groove variable pitch

pulleys must be adjusted an equal number of turns

open or closed. Any increase in fan speed represents

a substantial increase in load on the motor.

To avoid motor overheating and possible burnout,

motor load amperes should always be checked and

compared to nameplate rating when fan speed is

increased.

Utility Fans8

Page 9

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

ta

t

io

n

R

o

ta

t

io

n

Backward Inclined

Forward Curved

Airflow

Airflow

Backward Inclined Forward Curved

Airflow

These are the original drawings on the Illustrator file

when I opened it. The IOM had the wheel layered on

top of the scroll.

I will incorporate the

wheel on the scroll

without creating

an additional

layer in the

InDesign file.

R

o

t

a

t

i

o

n

Airfoil

Forward Curved

Wheel

Cone

Wheel

Cone

Inlet

Cone

Inlet

Cone

Radial Gap, Overlap and Wheel Alignment

Wheels must rotate freely and not rub on the inlet

cone. ModelXUEF wheels overlap the inlet cone.

Refer to the table for the proper dimension.

Radial Gap and Alignment

Efficient fan performance can be maintained by having

the correct radial gap, overlap and wheel alignment.

These items should be checked after the fan has been

in operation for 24 hours and before start-up when the

unit has been disassembled.

Radial Gap: Adjust inlet cone

position such that the radial gap

between the wheel cone and inlet

cone is evenly distributed around

the wheel.

Radial gap is adjusted by

loosening the inlet cone/ring bolts

and centering the cone/ring on the

wheel. If additional adjustment is

required to maintain a constant

radial gap, loosening the bearing

bolts and centering the wheel is

acceptable as a secondary option.

Overlap: Overlap is adjusted by loosening the wheel

hub from the shaft and moving the wheel to the

desired position along the shaft.

The transition between the inlet cone and wheel

should be as shown; there is a smooth feel to the

profile when moving from one component to the other.

Method for Centering Wheel: On belt drive units,

centering can be accomplished by (a) loosening

the inlet cone bolts to move the inlet cone or by (b)

loosening the bearings in order to move the shaft.

Wheel and inlet cone overlap can be adjusted by

loosening the wheel hub set screws and moving the

wheel to the desired position. Tighten all fasteners

and set screws securely and realign drive pulleys after

adjustment.

Overlap

A

Radial

Gap

Radial

Gap

Straight

Straight

Edge

Edge

Wheel

Inlet

Inlet

Cone

Cone

Cone

Radial Gap and Overlap Dimensions

Overlap

Tolerance

XUEF-200 XUEF-300 XUEF-400

A Overlap

inches (mm)

206 306 - - 207 307 - - 208 308 - - -

15

210 310 4

407 1

408 2

409 3

410 3

212 312 412 4

213 313 413 4

215 315 415 5

216 316 416 5

218 318 418 6

⁄16 (125)3⁄8 (10)

7

⁄16 (37) 215⁄32 (63)1⁄8 (3)

11

⁄16 (68) 17⁄32 (31)1⁄8 (3)

11

⁄16 (94)7⁄32 (6)

11

⁄16 (94)7⁄32 (6)

1

⁄4 (108)

11

⁄16 (119)3⁄8 (10)

3

⁄16 (132)7⁄16 (11)

3

⁄4 (146)7⁄16 (11)

3

⁄8 (162)15⁄32 (12)1⁄8 (3)

220 320 420 7 (178)

13

222 322 422 7

324 424 8

327 427 9

330 430 10

333 433 11

336 436 12

340 440 14

344 444 15

349 449 17

⁄16 (198)17⁄32 (13)3⁄16 (5)

5

⁄8 (219)9⁄16 (14)

7

⁄16 (240)11⁄16 (17)1⁄4 (6)

9

⁄16 (268)11⁄16 (17)3⁄8 (10)

7

⁄16 (291)15⁄16 (24)3⁄8 (10)

3

⁄4 (324)15⁄16 (24)3⁄8 (10)

3

⁄16 (360)29⁄32 (23)3⁄8 (10)

9

⁄16 (395) 11⁄8 (29)3⁄8 (10)

1

⁄8 (435) 11⁄4 (32)1⁄2 (13)

13

⁄16 (478) 117⁄32 (39)1⁄2 (13)

18

15

⁄16 (532) 19⁄16 (40)1⁄2 (13)

20

11

⁄32 (9)

1

⁄2 (13)

1

⁄8 (3)

1

⁄8 (3)

1

⁄8 (3)

1

⁄8 (3)

1

⁄8 (3)

1

⁄8 (3)

1

⁄8 (3)

3

⁄16 (5)

1

⁄4 (6)

227⁄8 (581) 129⁄32 (48)1⁄2 (13)

1

⁄2 (648) 129⁄32 (48)1⁄2 (13)

25

Wheel Rotation

Rotation direction of the wheel is critical and incorrect

rotation will result in reduced air performance,

increased motor loading and possible motor burnout.

Check wheel rotation by momentarily energizing the

unit and noting if rotation is in the same direction as

the airflow at the outlet and conforms to the rotation

decal affixed to the unit.

Wheels as viewed from the drive side:

n

o

i

t

a

t

o

R

Backward Inclined

Airflow

n

o

i

t

a

t

o

R

Airfoil

Airflow

attached to the system for which they were

designed. Without proper system static pressure,

the motor could be overloaded.

Model XUEF units should be operated only when

NOTE

Utility Fans 9

Page 10

Field Coating Touch-Up Procedure

for Scratched Areas

Standard coating and color is Larkin’s RAL 7023

Concrete Grey. The procedure outlines the correct

method for repairing minor scratches in the coating.

TOUCH-UP PAINT REPAIR KIT CONTENTS

• One pint of Kem Kromik primer

- including a technical data sheet

• One pint of industrial enamel

- including a technical data sheet

• Four disposable foam brushes

• One sheet sandpaper

• Repair procedure details

1. Scuff affected area to be repaired using medium

sandpaper (provided) or medium scotch brite pad.

Feather the edges.

2. Clean affected area to be touched up using an

alkaline based cleaner and rinse.

3. Apply Kem Kromik primer using 1 inch foam

brush (provided). Follow technical data sheet

instructions.

4. Allow primer to dry a minimum of 2-1/2 hours

before top coating.

5. Apply topcoat with industrial enamel using 1 inch

foam brush (provided). Follow technical data

sheets instructions. Allow painted units to air-dry

and cure before putting into service. See enclosed

Technical Data sheets for detailed drying and cure

schedules at different temperatures.

To order additional coating repair kits please reference

Larkin’s part number HAZ2597 PNT FIELD REPAIR

KIT, RAL 7023 CONCRETE GREY. Please contact

factory with your fan’s serial number for colors other

than our standard.

Electrical Connections

Before electrical connections are made, the supply

voltage, phase and ampere capacity must be checked

for compatibility with the fan motor. In addition, the

supply wiring must be properly fused and conform

to local and national electrical codes. If the unit is

supplied with a safety disconnect switch, ensure

proper wiring to the fan motor. Be sure the disconnect

is switched to the “OFF” position before connecting

supply wires. If no disconnect is supplied, ensure the

supply wire is not live before connection. Supply wires

are then connected to the optional safety disconnect

switch (if supplied) or motor.

Utility Fans10

Page 11

Unit Start-Up

WARNING

Disconnect and secure to the OFF position all

electrical power to the fan prior to inspection

or servicing. Failure to comply with this safety

precaution could result in serious injury or death.

Visual Inspection of Equipment

The equipment type and arrangement should be

verified as ordered at once when it arrives at the

jobsite. When a discrepancy is found, the local Larkin

Sales Representative must be notified immediately so

that corrective action may be investigated, also verify

electrical conformance to specifications. Unauthorized

alterations and unauthorized backcharges will not be

recognized by Larkin, Industries.

After the unit has been assembled, installed and all

utilities have been hooked up, the unit is now ready

for operation.

Check

Before starting the unit, check the following:

1. Confirm that building supply voltage matches the

voltage for which the unit is wired.

2. Check all piping and wiring penetrations

made by contractors for water tightness. All

penetrations must be made watertight to prevent

water damage to the unit and building.

3. Rotate the fan wheel manually to be sure that it

is free to operate. Remove any dirt or debris that

may have accumulated during installation.

4. Check the fan bearing setscrews for tightness.

5. Check alignment of sheaves and V-belts (See

maintenance section).

6. Inspect all fasteners to ensure that none have

loosened during shipment.

7. Check flex coupling for proper alignment and

connect between motor shaft and fan shaft

(direct drive).

8. Check all guarding to ensure that it is securely

attached and not interfering with rotating parts.

9. Check all electrical connections for proper

attachment.

10. Check housing and ductwork, if accessible,

for obstructions and foreign material that may

damage the fan wheel.

11. Fill drainage piping trap.

Additional Steps for Initial Start-Up

1. Check for proper wheel rotation by momentarily

energizing the fan. Access to view the wheel can

be gained through the blower housing access

panel.

One of the most frequently encountered problems

are motors that are wired to rotate the wheel in

the wrong direction. This is especially true with

3-phase installations where the motor will run in

either direction, depending on how it has been

wired. To reverse rotation of a 3-phase motor,

interchange any two of the three electrical leads.

Single phase motors can be reversed by changing

internal connections as described on the motor

label or wiring diagram.

2. Fans with multi-speed motors should be checked

on low speed during initial start-up.

3. Check for unusual noise, vibration or overheating

of bearings. Refer to the “Troubleshooting” section

of this manual if a problem develops.

4. Grease may be forced out of the bearing seals

during initial start-up. This is a normal self-purging

feature for the type of bearing used on this

product.

Utility Fans 11

Page 12

Vibration

On start-up and during operation, the unit should

operate smoothly with minimal vibration. It is possible

that a higher degree of vibration may be experienced.

Excessive vibration if left unchecked, can cause a

multitude of problems, including structural and/or

component failure.

Common Sources of Vibration

1. Wheel Unbalance

2. Drive Pulley Misalignment

3. Incorrect Belt Tension

4. Bearing Misalignment

5. Mechanical Looseness

6. Faulty Belts

7. Drive Component Unbalance

8. Poor Inlet/Outlet Conditions

9. Foundation Stiffness

manual for corrective actions. If observation cannot

locate the source of vibration, a qualified technician

using vibration analysis equipment should be

consulted. If the problem is wheel unbalance, in-place

balancing can be done through the access panel

located on the side of each fan’s tubular housing.

Any correction weights added to the wheel should be

welded to either the wheel back (single-plane balance)

or to the wheel back and wheel cone (two-plane

balance).

The most common

sources of vibration

are listed.

Many of these

conditions can

be discovered by

careful observation.

Refer to the

troubleshooting

section of this

Routine Maintenance and

Operation

CAUTION

When performing any service to the fan, disconnect

the electrical supply and secure fan impeller.

Once the unit has been put into operation, a

routine maintenance schedule should be set up to

accomplish the following:

1. Lubrication of bearings and motor.

2. Wheel, housing, bolts and set screws on the entire

fan should be checked for tightness.

3. Any dirt accumulation on the wheel or in the

housing should be removed to prevent unbalance

and possible damage.

4. Inspect fan impeller and housing looking for fatigue,

corrosion, or wear.

Fan Operation

All fans should be run every thirty (30) days, or at least

“bumped” every thirty days. It is preferred that each

fan is run as this causes all electrical and mechanical

components to get up to temperature, displacing any

formed condensation, redistributes load on bearings,

and redistributes grease in the bearings (motor and

shaft bearings).

CAUTION

When operating conditions of the fan are to be

changed (speed, pressure, temperature, etc.),

consult manufacturer to determine if the unit can

operate safely at the new condition.

Motors

Motor maintenance is generally limited to cleaning

and lubrication. Cleaning should be limited to exterior

surfaces only. Removing dust and grease buildup

on the motor housing assists proper motor cooling.

Never wash-down motor with high pressure spray.

Greasing of motors is only intended when fittings are

provided. Many fractional motors are permanently

lubricated for life and require no further lubrication.

Motors supplied with grease fittings should be

greased in accordance with the manufacturer’s

recommendations. When motor temperature does not

exceed 104ºF (40ºC), the grease should be replaced

after 2000 hours of running time.

Direct drive systems have extended grease lines to

lubricate the motor without removal of any guarding.

Utility Fans12

Page 13

Belt Drive Maintenance

V-belt drives must be checked on a regular basis

for wear, tension, alignment and dirt accumulation.

Premature or frequent belt failures can be caused by

improper belt tension (either too loose or too tight)

or misaligned sheaves. Abnormally high belt tension

or drive misalignment will cause excessive bearing

loads and may result in failure of the fan and/or motor

bearings. Conversely, loose belts will cause squealing

on start-up, excessive belt flutter, slippage and

overheated sheaves. Either excessively loose or tight

belts may cause fan vibration.

When replacing V-belts on multiple groove drives

all belts should be changed to provide uniform

drive loading. Use a set of matched belts whenever

possible. Do not pry belts on or off the sheave.

Loosen belt tension until belts can be removed by

simply lifting the belts off the sheaves. After replacing

belts, ensure that slack in each belt is on the same

side of the drive. Belt dressing should never be used.

Do not install new belts on worn sheaves. If the

sheaves have grooves worn in them, they must be

replaced before new belts are installed.

The proper tension for operating a V-belt drive is

the lowest tension at which the belts will not slip at

peak load conditions. Belts are adjusted by raising or

lowering the motor

pivot plate. For

Deflection =

Belt Span

64

initial tensioning,

the proper

belt deflection

halfway between

sheave centers is

1/64-inch for each

inch of belt span.

Belt Span

Check belt tension two times during the

first 24hours of operation and periodically

thereafter.

Variable Frequency Drive Operation

For operation with variable frequency drive (VFD),

always check motor amps when adjusting the

operating frequency. Motor may be sized for the

original selected operating speed under 60 Hz.

Bypassing the VFD or increasing the speed from this

original selection, even if less than 60 Hz, may cause

motor to overload or failure. Consult factory with fan

serial number, before increasing the upper limiting

frequency.

Always check the fan rpm when adjusting the

operating frequency. Do not exceed maximum class

fan rpm of the wheel.

Bearing Lubrication Schedule

Shaft bearings are the most critical moving part of a

fan. Therefore, special attention should be given to

keeping the bearings clean and well lubricated. Proper

lubrication provides for reduction in friction and

wear, transmission and dissipation of heat, extended

bearing life and prevention of rust.

In order for a lubricant to fulfill these tasks, the proper

grease applied at regular intervals is required. See the

recommended bearing lubrication schedule below.

If unusual conditions exist (temperatures below 32°F

or above 200°F), moisture or contaminants - more

frequent lubrication is required.

Recommended Bearing Lubrication Schedule

Relubrication Schedule in Months

Standard Grease

Fan

RPM

To 250 12 12 12 12 12

500 12 12 11 10 8

750 12 9 8 7 6

1000 12 7 6 5 4

1250 12 6 5 4 3

1500 12 5 4 3 2

2000 12 3 3 2 1

2500 12 2 2 1 0.5

3000 12 2 1 0.5 0.25

3500 12 1 0.5 0.25 x

4000 12 0.5 0.25 x x

5000 12 0.25 x x x

Number

of Shots

• Lubrication interval is based on 12 hour per day operation

and maximum 160°F housing temperature. For 24 hour

per day operation, the interval should be cut in half.

• Lubricant should be added with the shaft rotating and

until clean grease is seen purging from the bearing.

The lubrication interval may be modified based on the

condition of the purged grease. If bearing is not visible to

observe purged grease, lubricate with number of shots

indicated in chart for bore size.

• For conditions including high temperatures, moisture, dirt

or excessive vibration, consult the factory for a specific

lubrication interval for your application.

• Lubricant should be a high quality lithium complex grease

conforming to NLGI Grade 2. Factory recommends

Mobilux EP-2.

• The use of synthetic lubricants will increase lubrication

intervals by approximately 3 times.

1/2 -1 1

4 8 8 10 16

In addition to lubricating the bearings at specified

intervals, set screws in the bearing collars should be

checked for tightness. A bearing collar which has

loosened will cause premature failure of the fan shaft.

Fasteners attaching the bearings to the drive frame

should also be checked.

Bearing Bore (inches)

1

⁄8 - 11⁄2 15⁄8 - 17⁄8 115⁄16 - 23⁄16 27⁄16 - 3

Utility Fans 13

Page 14

Wheel and Fastener Maintenance

Wheels require very little attention when exhausting

clean air, however, air heavily laden with grease or

dirt will tend to accumulate on the wheel causing

unbalance. Wheels exhausting dirty or grease-laden

air require frequent cleaning to assure smooth and

safe operation.

All fasteners, including set screws in the bearing

collars, should be checked for tightness each time

maintenance checks are performed.

A proper maintenance program will help preserve the

performance and reliability designed into the fan.

Utility Fans14

Page 15

Bearing Replacement

For Arr. 10

The intent of this procedure is to allow a field service

technician to replace bearings with the fan remaining

in place in its intended application. All work can

be conducted by accessing the bearings by either

removing a shaft guard, a weatherhood or working

under a weatherhood. This is dependent on the size

of the unit. This procedure assumes the power source

has been locked out prior to removing guards and

covers, belts and pulleys have been loosened and

removed properly and extended lubrication lines have

been disconnected at the bearing. In some cases,

it may be necessary to remove the fan inlet cone

and wheel if the bearings cannot be removed due to

corrosion or damage. See Radial Gap, Overlap and

Wheel Alignment on page 9 to the realign wheel upon

installation.

Bearing Removal

This procedure assumes proper safety measures have

been taken.

• Read and follow all instructions carefully.

• Disconnect and lock-out power before installation

and maintenance.

• Driven sheaves and belts have already been

removed.

• Shaft black coating can be removed with a solvent

similar to a brake/carburetor cleaner.

1. Scribe a line around the shaft by both bearings

and around the bearing base to the bearing

support or write down the measurement from the

end of the shaft to the bearings. This will help in

repositioning the new bearing and wheel cone

overlap.

2. Follow the bearing manufacturers’ procedures for

removal and installation.

3. Before removing the bearing bolts, make sure the

shaft is supported slightly. Remember to consider

the wheel weight on the shaft.

4. Remove both bearings from the shaft and clean/

remove any burrs using an emery cloth or file.

5. Clean mounting surface of any dirt or grease.

Bearing Installation

1. Before installing, read bearing manufacturers’

procedures. Before putting the new bearings on

the shaft, you may need to break what is called

swivel torque on the bearings (depending on style

of bearing). This is done by holding the bearing

housing securely and being able to move the

inner bearing race around freely.

2. Apply light film of oil on shaft, then gently slide

the new bearings onto the shaft.

Do not hammer bearing onto shaft!

3. Align bearings on shaft with the previous scribe

marks that are on the shaft and lock bearing to

shaft.

4. Put bolts into mounting surface and bearings. Do

not tighten.

5. Remove blocks if shaft is supported.

6. Set bearings on support with the scribed marks

locating the bearings. Make sure bearings are

square and level with the shaft.

7. Tighten bolts and torque bearing bolts, bearing

set screws/locking collars as per bearing

manufacturers’ procedures.

8. Rotate shaft by hand to help allow the bearings to

help set in. Also at this time, listen for any unusual

noises such as wheel rubbing on cone and any

bearing noise.

9. Connect extended lube lines in new bearings if

needed.

10. Reinstall the drive sheaves and belts. Check the

belt alignment.

11. Make sure to reinstall all guards and follow proper

safety measures before starting up the fan.

Utility Fans 15

Page 16

Parts List

Each fan bears a manufacturer’s nameplate with model number and serial number embossed. This information

will assist the local Larkin representative and the factory in providing service and replacement parts. Before

taking any corrective action, make certain unit is not capable of operation during repairs.

CAUTION

A fan manufactured with an explosion resistant

motor does not certify the entire unit to be explosion

proof. Refer to ULListing Mark for the fans

approved usage.

• XUEF-200

• XUEF-300

• XUEF-400

Shaft Pulley

Motor Pulley

Weatherhood

Components

(driven)

(driver)

Belt(s)

Drive Side Bearing

Opposite Drive Side Bearing

Fan Shaft

CAUTION

La présence d’un moteur antidéflagrant sur un

ventilateur ne garantit pas que tout l’appareil est

antidéflagrant. Pour connaître les emplois autorisés

de l’appareil, voir son marquage de conformité UL.

Heat Slinger (XUEF-300)

Rub Ring (XUEF-300)

Shaft Seal (XUEF-300)

Drive Frame Assembly

Motor

Outlet Flange

Outlet Guard

Scroll Housing

Wheel

Grease Container

(XUEF-300)

Grease Fan Brackets

(XUEF-300)

Inlet Cone

Inlet Flange

Inlet Companion

Flange

Inlet Guard

Utility Fans16

Page 17

Troubleshooting

WARNING

Before taking any corrective action, make certain

unit is not capable of operation during repairs.

Problem Cause Corrective Action

Wheel Rubbing Inlet

Excessive Noise

Low CFM

High CFM

Static Pressure Wrong

High Motor Amp Draw

Fan Doesn’t Operate

Overheated Bearing

Excessive Vibration

V-Belt Drive

Bearings

Wheel Unbalance Clean all dirt off wheel. Check wheel balance.

Fan Check wheel for correct rotation.

Duct System Higher pressure than design. Filters need replacement.

Fan Decrease fan speed.

Duct System

Duct system has more

or less restriction than

anticipated

Fan Check rotation of wheel. Reduce fan speed.

Duct System

Electrical Supply

Drive Check for broken belts. Tighten loose pulleys.

Motor

Lubrication Check for excessive or insufficient grease in the bearing.

Mechanical

Belts

System Unbalance

Avant d’entreprendre toute action corrective,

s’assurer que l’appareil ne pourra pas fonctionner

durant les réparations.

Adjust wheel and/or inlet cone.

Tighten wheel hub or bearing collars on shaft.

Tighten sheaves on motor/fan shaft. Adjust belt tension.

Align sheaves properly (see procedure).

Replace worn belts or sheaves.

Replace defective bearing(s). Lubricate bearings.

Tighten collars and fasteners.

Resize ductwork. Access door, filters, dampers not

installed.

Remove obstructions in system. Use correction factor to

adjust for temperature/altitude. Resize ductwork. Clean

filters/coils. Change fan speed.*

Resize ductwork. Check proper operation of isolation and

bypass dampers. Check filters and access doors.

Check fuses/circuit breakers. Check for switches turned

off or disconnected. Check for correct supply voltage.

Assure motor is correct horsepower and not tripping

overload protector.

Replace damaged bearing. Relieve excessive belt tension.

Align bearings. Check for bent shaft.

Adjust tightness of belts. Replacement belts should be a

matched set.

Check alignment of shaft, motor and pulleys. Adjustable

pitch pulleys with motors over 15 hp are especially

prone to unbalance. Check wheel balance, rebalance if

necessary.

AVERTISSEMENT

* AIways check motor amps and compare to nameplate rating. Excessive fan speed may overload the motor

and result in motor failure. Do not exceed the maximum cataloged rpm of the fan.

Utility Fans 17

Page 18

Maintenance Log

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Utility Fans18

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Page 19

Maintenance Log

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _______________ AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Utility Fans 19

Page 20

Larkin Industries, Inc.

114 David Green Rd., Birmingham, AL 35244

Phone: 1.800.322.4036 Fax: 1.205.987.0583

Email: Sales@larkinhoods.com

480081 • XUEF, Rev. 2, February 2015 Copyright 2015 © Larkin Industries, Inc.20

Loading...

Loading...