Larkin EO Installation Manual

Commercial Kitchen Hood

Installation and Maintenance Manual

Receiving Shipments

Upon receiving unit, check for any interior or exterior damage, if found, report it to the carrier immediately. Check that all accessory items are accounted for and damage free.

Caution!

We strongly suggest hood Installation should only be performed by a qualified and licensed mechanical contractor who is familiar with the level of involvement for proper installation. Insure proper safety precautions are taken, permits are obtained, and code requirements are met.

Save these instructions. This document is the property of the owner of this equipment and is required for future maintenance. Leave this document with owner after installation or service has been completed.

2012

Table of Contents

Hood Installation..……………………………………………………………………….1

Basic Hanging Methods…………………...…….………..……………………………2

End-to-End Hoods….……………………………………………………………….…..3

Back-to-Back Hoods….……………………………………………………………….. 4

Grease Trough and Cup Installation………………………………………………….5

Back Return Plenum……………………………………………………………………6

Front Supply Plenum…………………………………………………………………...7

Splash Panels…………………………………………………………………………...8

Ceiling Enclosures………………………………………………………………………9

End Curtains……………………………………………………………………………..9

Duct Work………………………………………………………………………………10

Wiring……………………………………………………………………………………11

Maintenance……………………………………………………………………………12

Warranty………………………………………………………………………………..13

Trouble Shooting………………………………………………………………………14

Hood Installation Instructions

When uncrating, handling, or installing, the installer should exercise extreme caution to protect the stainless steel surfaces from damage, as they are costly to repair.

The installing contractor for the Kitchen Ventilation System is responsible for verifying field measurements of the constructed kitchen area. Consult project plans when determining exact location of the hood(s). Determine how the hood will be hung and prepare the structural support system using inserts, shields, angle iron, etc., and ½” threaded rod with turn buckles (hanging material by others). Verify that the materials used are sufficient to support the weight of hood and hanging system. (Refer to NFPA-96 for proper installation methods and materials.)

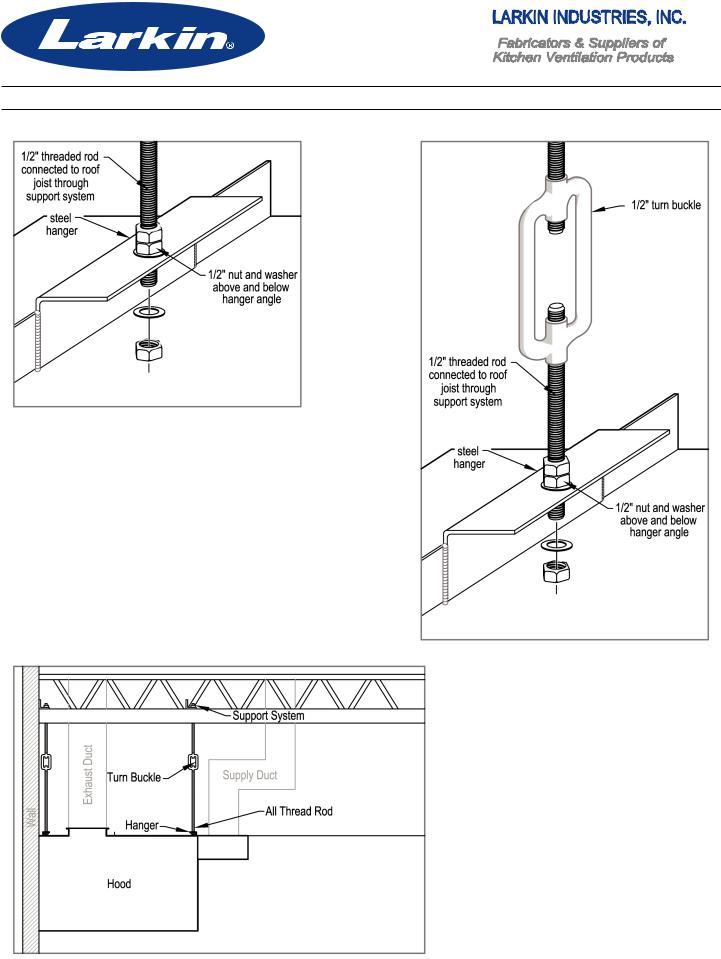

All Larkin Industries, Inc. hoods are provided with hanging brackets on top of hood, ½” threaded rod should be used with necessary nuts, washers, etc (see fig. 1). Turnbuckles are recommended for leveling (see fig. 2). Recommended mounting height from bottom edge of hood to the finished floor is 6’-6”, (18”

-24” from bottom edge of filter to cooking surface for Back Shelf type models). Hoods should be hung level, and where possible, the exhaust outlet should be in line with the exhaust fan opening. Duct runs, offsets, elbows, etc. should be simple and direct as possible (see fig. 3).

When preliminary preparations have been made, prepare the hood for lifting by providing necessary manpower, forklift, crane, duct jacks, etc. Be sure to provide adequate safeguards to prevent damage to the hood, property, and insure safety of personal (see pg 3&4 for multiple section hoods). If a Back

Return (BR) plenum is provided with the hood, this should be hung first at the standard hanging height (see pg 6). When all hanging material has been attached, lift the

hood in to position and secure to structural framing, leveling the hood by using the turnbuckles. Insure proper tension is placed on each hanging rod for even weight distribution. If the hood has a Front Perforated Supply Plenum (FPSP), this should be installed now (see pg 7). The grease trough needs to be attached to the bottom of filter rail, sloped toward the removable grease container for proper drainage. Attach grease container to the studs at the end of grease trough. Install light bulbs in light fixtures (bulbs by others). Use any well-recognized brand with a maximum of 100 watts.

Install exhaust ductwork. Exhaust duct systems must be continuously welded liquid tight per NFPA-96 requirements. Install supply ductwork (by others) per SMACNA guidelines.

Complete all electrical wiring based on installation wiring diagram provided (by certified electrician).

If hood is manufactured with factory pre-piped fire suppression system, a certified fire system distributor is responsible for final field hookup, testing, and certification of the system. If the hood is not provided with a fire suppression system, a certified fire suppression distributor must be contracted to install, test and certify a fire suppression system (by others).

Protect hood at all times by wrapping it in plastic or other suitable material, until all other work is accomplished and system is ready to be put into operation. Make sure to use stainless steel polish to clean hood. To prevent scratching do not use abrasives on hood.

Warning! Do not penetrate the integrity of the hood grease containment area when hanging hood. Penetrating the grease containment area will void warranty and listing on the hood.

1

Commercial Kitchen Hood

Basic Hanging Methods

Figure 1

Simple hanging method that requires all thread, two washers, and three ½” heavy nuts.

Figure 2

Example of using ½” turn buckle designed for easy adjustment of hood level.

Figure 3

An overview of using turn buckles

for hood installation. Methods of hood

Installations may vary depending on local code requirements.

Note: Hanging material provided by others.

2

Commercial Kitchen Hood

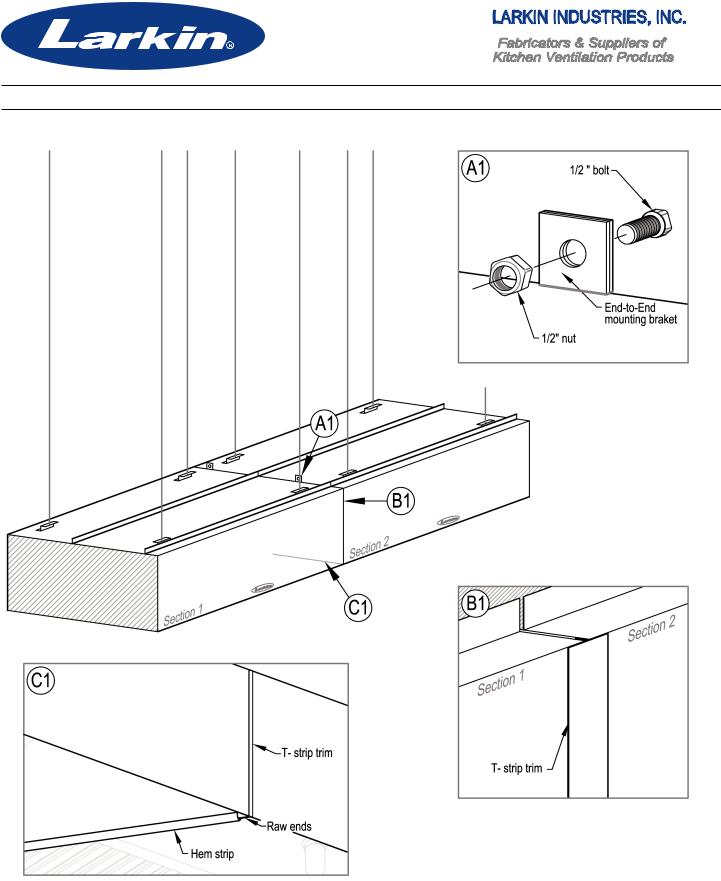

End-to-End Configuration

Align hoods and bolt together.

Slide hem strip over raw ends of hood sections and pop rivet in place.

3

Apply silicone to seam between hood sections. insert “T” strip and temporarily attach with tape.

After silicone has dried, remove tape.

Note: Hanging material provided by others.

Loading...

Loading...