Page 1

xPico

Embedded Device Server

Integration Guide

Part Number 900-619

Revision L September 2017

Page 2

Intellectual Property

© 2017 Lantronix, Inc. All rights reserved. No part of the contents of this publication may

be transmitted or reproduced in any form or by any means without the written permission

of Lantronix.

Lantronix, xPico and DSTni are registered trademarks of Lantronix, Inc. in the United

States and other countries. DeviceInstaller is a trademark of Lantronix, Inc.

Patented: http://patents.lantronix.com; additional patents pending.

Wi-Fi is a registered trademark of Wi-Fi Alliance Corporation. Ethertronics is a trademark

of Ethertronics, Inc. Wanshih is a trademark of Wanshih Electronic Co., Ltd. Exar is a

trademark of Exar Corporation. SEMTECH is a trademark of Semtech Corporation. All

other trademarks and trade names are the property of their respective holders.

Contacts

Lantronix, Inc.

7535 Irvine Center Drive

Suite 100

Irvine, CA 92618, USA

Toll Free: 800-526-8766

Phone: 949-453-3990

Fax: 949-453-3995

Technical Support

Online: www.lantronix.com/support

Sales Offices

For a current list of our domestic and international sales offices, go to the Lantronix web

site at www.lantronix.com/about/contact

Disclaimer

All information contained herein is provided “AS IS.” Lantronix undertakes no obligation

to update the information in this publication. Lantronix does not make, and specifically

disclaims, all warranties of any kind (express, implied or otherwise) regarding title, noninfringement, fitness, quality, accuracy, completeness, usefulness, suitability or

performance of the information provided herein. Lantronix shall have no liability

whatsoever to any user for any damages, losses and causes of action (whether in

contract or in tort or otherwise) in connection with the user’s access or usage of any of

the information or content contained herein. The information and specifications

contained in this document are subject to change without notice.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one of the following measures:

xPico® Embedded Device Server Integration Guide 2

Page 3

1. Reorient or relocate the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

4. Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

This device is intended only for OEM Integrators. The OEM integrator should be aware of

the following important issues.

Labeling of the End Product (xPico Wi-Fi units only)

The label on the end product incorporating the xPico Wi-Fi module must clearly state that

it contains an FCC-approved RF module. Canada and Japan also require a similar

statement.

For example, “This product contains RF transmitter ID # (put FCC, IC, and/or Japan

module grant numbers here).” The label must include the ID numbers for the regions

where the end product is installed. The grant numbers are below.

xPico Wi-Fi FCC ID number: R68XPICOW

xPico Wi-Fi IC ID number: 3867A-XPICOW

xPico Wi-Fi Japan ID numbers: 201-135275

RSS-GEN Sections 7.1.4 and 7.1.5 Statement for Devices with Detachable Antennas (xPico

Wi-Fi units only)

This device has been designed to operate with the antennas listed in the Certificate, and

having a maximum gain of 2.88 dBi. Antennas not included in this list or having a gain

greater than 2.88 dBi are strictly prohibited for use with this device, unless system level

FCC approval is gained. The required antenna impedance is 50 ohms.

To reduce potential radio interference to other users, the antenna type and its gain

should be so chosen that the equivalent isotropically radiated power (EIRP) is not more

than that required for successful communication.

Integration Notes (xPico Wi-Fi embedded device server):

This module is authorized under limited module approval specified to mobile host

equipment. So, the antenna must be installed such that 20cm is maintained between

the antenna and users.

The transmitter module may not be co-located with any other transmitter or antenna.

As long as the two conditions above are met, further transmitter testing will not be

required. However, the OEM integrator is still responsible for testing their end product

for any additional compliance requirements required with this module installed (for

example, digital device emission, PC peripheral requirements, etc.)

In the event that these conditions cannot be met (for example certain laptop

configurations, general purpose PCMCIA or similar cards, or co-location with another

transmitter) and obtaining a separate FCC authorization will be required, then the

FCC authorization is no longer considered valid and the FCC ID cannot be used on

the final product (including the transmitter).

Changes or modifications to this device not explicitly approved by Lantronix will void

the user's authority to operate this device.

xPico® Embedded Device Server Integration Guide 3

Page 4

Note: With the purchase of any xPico family product, the OEM agrees to an OEM

Date

Rev.

Comments

April 2012

A

Initial release.

September 2012

B

Updated the reference schematic, mounting instructions and

compliance information.

January 2013

C

Updated xPico pin-out diagram.

July 2013

D

Updated to include xPico Wi-Fi part information.

August 2013

E

Updated to include Japanese certification number.

January 2014

F

Updated reference schematic information.

February 2014

G

Updated for firmware version 1.1.0.2R10.

June 2014

H

Updated Lantronix part number information.

December 2014

I

Updated for firmware version 1.3.0.1.

May 2015

J

Updated diagram dimensions and RX sensitivity information.

Added ISO/IEC Compliance information.

December 2015

K

Updated part number and module dimension information.

September 2017

L

Updated compliance information.

firmware license agreement that grants the OEM a non-exclusive, royalty-free

firmware license to use and distribute the binary firmware image provided, only to the

extent necessary to use the xPico hardware. For further details, please see the xPico

OEM firmware license agreement.

Warranty

For details on the Lantronix warranty policy, please go to our Web site at

www.lantronix.com/support/warranty

Revision History

.

For the latest revision of this product document, please check our online documentation

at www.lantronix.com/support/documentation

.

xPico® Embedded Device Server Integration Guide 4

Page 5

Table of Contents

Intellectual Property __________________________________________________ 2

Contacts ___________________________________________________________ 2

Disclaimer __________________________________________________________ 2

Warranty ___________________________________________________________ 4

Revision History _____________________________________________________ 4

List of Figures _______________________________________________________ 6

List of Tables ________________________________________________________ 7

1. Introduction 8

About the Integration Guide ____________________________________________ 8

Additional Documentation ______________________________________________ 9

2. Functional Description 10

xPico Features _____________________________________________________ 11

xPico Wi-Fi Features _________________________________________________ 11

xPico Block Diagram _________________________________________________ 13

xPico Wi-Fi Block Diagram ____________________________________________ 14

PCB Interface ______________________________________________________ 15

Mating Connector ___________________________________________________ 19

Antenna Interface (xPico Wi-Fi Units Only) _______________________________ 19

Antenna Placement (xPico Wi-Fi Units Only) ______________________________ 21

Ethernet Interface (xPico Wired Units Only) _______________________________ 21

Serial Interface _____________________________________________________ 23

USB Device Port (xPico Wi-Fi Units Only) ________________________________ 25

LEDs _____________________________________________________________ 26

General Purpose I/O Pins _____________________________________________ 26

Reset Pins _________________________________________________________ 27

Evaluation Board Schematics __________________________________________ 28

3. Mounting Instructions and PCB Footprint 33

To Access CAD Files ________________________________________________ 33

To Install the xPico or xPico Wi-Fi Module ________________________________ 33

Product Information Label _____________________________________________ 38

4. Specifications 39

Electrical Specifications ______________________________________________ 39

Technical Specifications ______________________________________________ 41

A: Compliance (xPico Embedded Device Server) 44

B: Compliance (xPico Wi-Fi Embedded Device Server) 46

xPico® Embedded Device Server Integration Guide 5

Page 6

List of Figures

Figure 2-1 xPico and xPico Wi-Fi Dimensions and Views ____________________ 12

Figure 2-2 xPico Block Diagram _______________________________________ 13

Figure 2-3 xPico Wi-Fi Block Diagram ___________________________________ 14

Figure 2-4 Reverse-SMA to U.FL(long) (Lantronix Part Number 500-180-R) _____ 20

Figure 2-5 U.FL to U.FL Cable (Lantronix Part Number 500-181-R) ____________ 20

Figure 2-6 Reverse-SMA to U.FL(short) (Lantronix Part Number 500-182-R) ____ 21

Figure 2-7 Ethernet Connection Example (xPico wired unit only) ______________ 23

Figure 2-8 Serial Port Example ________________________________________ 24

Figure 2-9 USB Device Interface Example (xPico Wi-Fi unit only) _____________ 25

Figure 2-10 Evaluation Board Schematic, Part 1 of 5 _______________________ 28

Figure 2-11 Evaluation Board Schematic, Part 2 of 5 _______________________ 29

Figure 2-12 Evaluation Board Schematic, Part 3 of 5 _______________________ 30

Figure 2-13 Evaluation Board Schematic, Part 4 of 5 _______________________ 31

Figure 2-14 Evaluation Board Schematic, Part 5 of 5 _______________________ 32

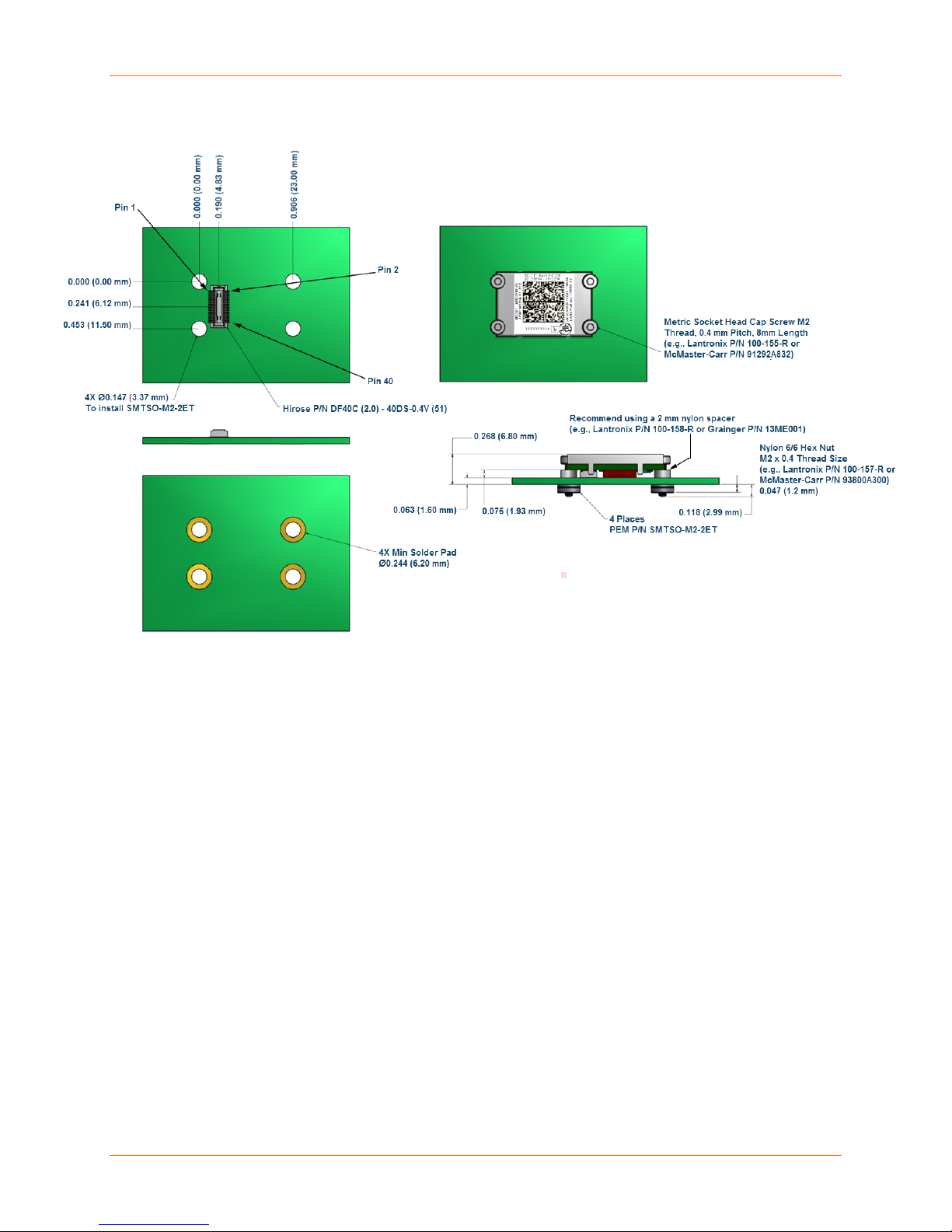

Figure 3-1 White Mounting Quick Clip Dimensions _________________________ 33

Figure 3-2 Aligning Mounting Clip Legs to Standoff Holes ___________________ 35

Figure 3-3 Mounting Instructions for PEM Standoff _________________________ 36

Figure 3-4 Hirose Connector Layout ____________________________________ 37

Figure 3-5 xPico Product Label ________________________________________ 38

Figure 3-6 xPico Wi-Fi Product Label ____________________________________ 38

Figure A-1 Certificate of Compliance for Halogen Free ______________________ 45

xPico® Embedded Device Server Integration Guide 6

Page 7

List of Tables

Table 1-1 xPico and xPico Wi-Fi Features _________________________________ 8

Table 2-1 xPico Part Numbers _________________________________________ 10

Table 2-2 xPico and xPico Wi-Fi Pin Connections _________________________ 15

Table 2-3 xPico (wired) PCB Interface Signals ____________________________ 16

Table 2-4 xPico Wi-Fi PCB Interface Signals _____________________________ 17

Table 2-5 xPico Wi-Fi External Antenna Options __________________________ 19

Table 2-6 Ethernet Interface Signals ____________________________________ 21

Table 2-7 Recommended Magnetic Modules

and Combo RJ45/Magnetic Module Connectors ___________________ 22

Table 2-8 xPico and xPico Wi-Fi Serial Port Signals ________________________ 23

Table 2-9 RS232 Connections (Serial Transceiver Required) ________________ 24

Table 2-10 RS422/485 Connections (Serial Transceiver Required) ____________ 24

Table 2-11 USB Host Port Signals ______________________________________ 25

Table 2-12 xPico Wi-Fi Status LED Output Signals _________________________ 26

Table 2-13 xPico Status LED Output Signals _____________________________ 26

Table 2-14 Ethernet Interface xPico Serial Port Signals _____________________ 26

Table 2-15 xPico Reset Signals ________________________________________ 27

Table 4-1 Absolute Maximum Ratings ___________________________________ 39

Table 4-2 xPico Wired Recommended Operating Conditions _________________ 39

Table 4-3 xPico Wi-Fi Recommended Operating Conditions _________________ 40

Table 4-4 xPico Wired Technical Specification ____________________________ 41

Table 4-5 xPico Wi-Fi Technical Specification _____________________________ 42

Table A-1 Electromagnetic Emissions ___________________________________ 44

Table A-2 Electromagnetic Immunity ____________________________________ 44

xPico® Embedded Device Server Integration Guide 7

Page 8

1. Introduction

Chapter 2 Section

xPico (wired)

xPico Wi-Fi

PCB Interface

X

X

Mating Connector

X

X

Antenna Interface

X

Antenna Placement

X

Ethernet Inteface

X

Serial Inteface

X

X

USB Device Port

X

LEDs X X

General Purpose IO Pins

X

X

Reset Pins X X

Reference Schematic

X

X

About the Integration Guide

This user guide provides the information needed to integrate the Lantronix® xPico®

embedded device servers into customer-printed circuit boards. This manual is intended

for engineers responsible for integrating the xPico embedded device server into their

product.

Note: This document includes support for xPico embedded device server

versions XPC100100B-01, XPC100100S-01, XPC100100K-02, XPC10010MB-01

and XPC10010MS-01, and xPico Wi-Fi embedded device server versions

XPW100100B-01, XPW100100S-01 and XPW100100K-02. For integration

information for the Lantronix xPico Wi-Fi SMT embedded device server modules,

XPCW1002 and XPC@10003, please reference document 900-714 xPico Wi-Fi

SMT Embedded Device Server Integration Guide.

The sections in chapter 2 provide board schematic and layout recommendations for both

xPico (wired) and xPico Wi-Fi® products. Some of the sections apply to xPico (wired)

only or xPico Wi-Fi units only. Signals that are unused for a particular product can be left

floating. If the application has the potential to use both components as a stuff option it is

recommended to follow the design guide for all of the sections. The table below lists

which sections are applicable to the xPico (wired) and xPico Wi-Fi products.

Note: “xPico” (wired) refers to the Ethernet-only versions of xPico embedded

device server.

Table 1-1 xPico and xPico Wi-Fi Features

xPico® Embedded Device Server Integration Guide 8

Page 9

Additional Documentation

Document

Description

Visit the Lantronix web site at www.lantronix.com/support/documentation for the latest

documentation and the following additional documentation.

1: Introduction

xPico Wi-Fi SMT

Embedded Device Server

User Guide

xPico Embedded Device

Server User Guide

xPico Wi-Fi Embedded

Device Server User Guide

xPico Embedded Device

Server Development Kit

Quick Start

xPico Embedded Device

Server Development Kit

User Guide

APS: Modbus Protocol

User Guide

DeviceInstaller™ User

Guide

Com Port Redirector User

Guide

Datasheet for the xPico Wi-Fi W1002 and W1003 SMT

modules.

Provides information needed to configure, use, and

update the xPico firmware.

Provides information needed to configure, use, and

update the xPico Wi-Fi firmware.

Provides the steps for getting the xPico device server up

and running.

Provides a detailed description of the xPico evaluation

kit hardware

Provides detailed information for installing and operating

the IAP device server using our Modbus firmware.

Provides instructions for using the Windows® based

utility to configure the xPico and other Lantronix device

servers.

Provides information on using the Windows based utility

to create a virtual com port.

xPico® Embedded Device Server Integration Guide 9

Page 10

Part Number

Description

XPC100100B-01

xPico Device Server Module, Extended Temp, AES Encryption, Bulk, RoHS

XPC100100S-01

xPico Device Server Module, Extended Temp, AES Encryption, Sample,

RoHS

XPC100100K-02

xPico Device Server Module Development Kit w/ Module, RoHS

XPW100100B-01

xPico Wi-Fi — IEEE 802.11 b/g/n Device Server Module, Extended Temp,

Bulk, RoHS

XPW100100S-01

xPico Wi-Fi — IEEE 802.11 b/g/n Device Server Module, Extended Temp,

Sample, RoHS

XPW100100K-01

xPico Wi-Fi — IEEE 802.11 b/g/n Device Server Development Kit w/ Module,

RoHS

XPC10010MB-01

xPico IAP Device Server Module, Extended Temperature, Modbus, RoHS,

Bulk

XPC10010MS-01

xPico IAP Device Server Module, Extended Temperature, Modbus, RoHS,

Sample

2. Functional Description

Designed for quick integration with minimal engineering effort, the chip-sized xPico

embedded device server provides simplicity and flexibility making it the easiest and

fastest networking-enabling module on the market.

xPico and xPico Wi-Fi device servers are extremely compact networking solution that

enables Ethernet or Wireless connectivity on virtually any device with a serial interface.

The included industry-proven Lantronix device server application and full IP stack allow

seamless remote access to device data simplifying design integration while providing

robust connectivity.

As one of the smallest embedded device servers in the world, xPico and xPico Wi-Fi

embedded device servers can be utilized in designs typically intended for chip solutions.

A key difference with the xPico device server is that there is virtually no need to write a

single line of code, translating to a much lower development cost and faster time-tomarket.

Table 2-1 xPico Part Numbers

xPico® Embedded Device Server Integration Guide 10

Page 11

xPico Features

The xPico device server contains Lantronix’s own DSTni® EX controller, with 256 KBytes

of SRAM, 16 KBytes of boot ROM, and integrated 10/100 PHY.

The xPico embedded device server also contains the following:

3.3-volt serial interface

8 Configurable I/O pins

All logic level I/O pins are 5V input tolerant

4-Mbit flash memory

Power supply filters

Reset circuit

+1.8V regulator

Note: The xPico embedded device server does not contain integrated Ethernet

magnetics. An external Ethernet magnetic module and RJ45 Jack is required to

interface to a standard 10/100Mbps Ethernet network.

The xPico unit requires +3.3-volt power and is designed to operate in an extended

temperature range (see technical data).

2: Functional Description

xPico Wi-Fi Features

The xPico Wi-Fi device server contains Cortex M3 ARM processor with 128KByte of

SRAM and 1MByte of embedded Flash memory. The unit also includes an 802.11 b/g/n

WLAN radio with a U.FL port for connection to an external antenna.

The xPico Wi-Fi embedded device server also contains the following:

3.3-volt serial interface

8 Configurable I/O pins

All logic level I/O pins are 5V input tolerant

8-Mbit flash memory (in addition to the 1MByte CPU embedded Flash)

Power supply filters

Reset circuit

Note: xPico Wi-Fi units do not contain an integrated antenna. An external

antenna is required for connection to a WLAN network.

The xPico Wi-Fi embedded device server requires +3.3-volt power and is designed to

operate in an extended temperature range (see technical data).

xPico® Embedded Device Server Integration Guide 11

Page 12

2: Functional Description

xPico Unit

xPico Wi-Fi Unit

Figure 2-1 xPico and xPico Wi-Fi Dimensions and Views

xPico® Embedded Device Server Integration Guide 12

Page 13

-

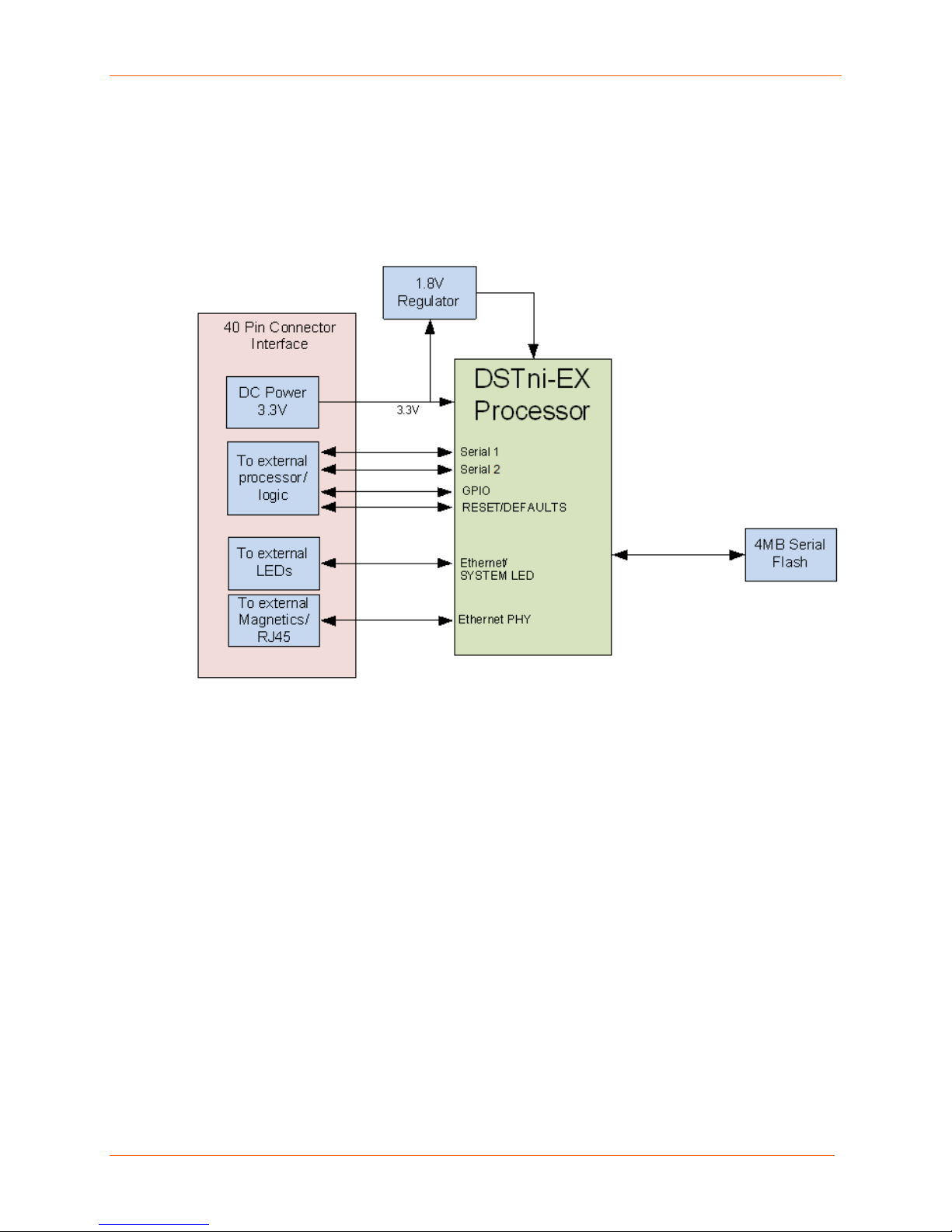

xPico Block Diagram

The following drawing is a block diagram of the xPico embedded device server showing

the relationships of the components.

2: Functional Description

Figure 2-2 xPico Block Diagram

xPico® Embedded Device Server Integration Guide 13

Page 14

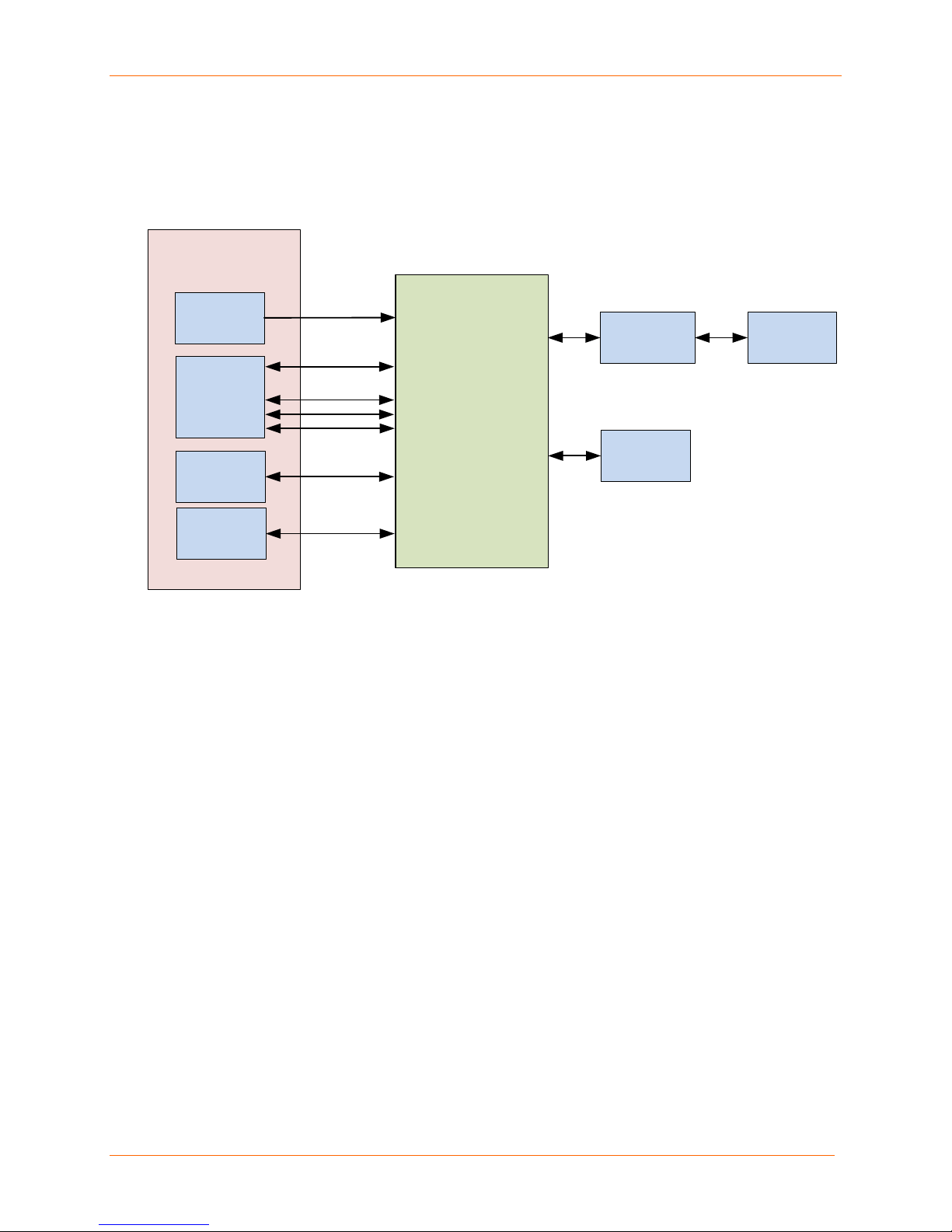

xPico Wi-Fi Block Diagram

DC Power

3.3V

8 Mb Serial

Flash

Cortex M3

Processor

To external

USB Device

3.3V

Serial 1

GPIO/SPI

40 Pin Connector

Interface

USB

To external

processor/

logic

To external

LED

SYSTEM LED

RESET/DEFAULTS

WAKE

802.11 b/g/n

Chipset

U.FL to

external

antenna

The following drawing is a block diagram of the xPico Wi-Fi embedded device server

showing the relationships of the components.

Figure 2-3 xPico Wi-Fi Block Diagram

2: Functional Description

xPico® Embedded Device Server Integration Guide 14

Page 15

PCB Interface

Pin#

xPico Wired

xPico Wi-Fi

Pin#

xPico Wired

xPico Wi-Fi

1

GND

GND 2

GND

GND

3

CP8

CP8/SPI_CS

4 LED1/LINK

LED1/WLAN_LED

5

RTS1

RTS1 6

LED0/SPEED

NC

7

RXD1

RXD1 8

LED2/ACTIVITY

NC

9

GND

GND 10

TXD1

TXD1

11

ETX-

NC 12

ETCT

NC

13

ETX+

NC 14

LED3/DUPLEX(OUT)

WKUP (IN)

15

GND

GND 16

CTS1

CTS1

17

ERX-

NC 18

ERCT

NC

19

ERX+

NC 20

SYS_LED

SYS_LED

21

GND

GND 22

Reserved

DDP

23

RXD2

RXD2 24

Reserved

DDM

25

TXD2

TXD2 26

CP2/INT

CP2/SPI_INT

27

CP7

CP7/SPI_SCK

28

CP3

CP3/MISO

29

+3.3V

+3.3V 30

CP4

CP4/MOSI

31

+3.3V

+3.3V 32

CP5

CP5

33

+3.3V

+3.3V 34

CP6

CP6

35

CP1

CP1 36

DEFAULT#(IN)

DEFAULT#(IN)

37

GND

GND 38

EXT_RESET#(IN)

EXT_RESET#(IN)

39

GND

GND 40

GND

GND

The xPico embedded device servers has a serial interface compatible with data rates up

to 921,600 bps (in high-performance mode). The serial signals (RX, TX, RTS, CTS, and all

CPs) are 3.3V CMOS logic level and 5V tolerant. The serial interface pins include +3.3V,

ground, and reset. The serial signals usually connect to an internal device, such as a

UART. For applications requiring an external cable running with RS-232 or RS422/485

voltage levels, the xPico device must interface to a serial transceiver chip. All

configurable I/O pins are 3.3V CMOS logic level and 5V input tolerant. The xPico unit

requires a mating connector. Customers should layout their PCB for Hirose part number

DF40C(2.0)-40DS-0.4V(51).

An external Ethernet magnetic module and RJ45 is required to interface the xPico

embedded device server to a standard 10/100Mbps Ethernet network.

An external antenna attached to the xPico Wi-Fi U.FL connector is required to connect to

an 802.11b/g/n wireless network.

Shown below is the xPico pin connection diagram highlighting the differences between

the xPico and xPico Wi-Fi embedded device server.

2: Functional Description

Table 2-2 xPico and xPico Wi-Fi Pin Connections

xPico® Embedded Device Server Integration Guide 15

Page 16

2: Functional Description

Signal Name

xPico

Pin #

Primary Function

Reset

State

Internal

Pull-up

Driver

Strength

GND

1

Signal Ground

GND

2

Signal Ground

CP8

3

Configurable I/O

Input

Active 56K

to 122K

4mA

LED1/LINK

4

Ethernet Link LED, active low

Output

8mA

RTS1

5

Serial ready to send/ serial

transmit enable

Output

2mA

LED0/SPEED

6

Ethernet speed LED, active

low

Output

8mA

RXD1

7

Serial receive data input 1

Input

Active 56K

to 122K

LED2/ACTIVITY

8

Ethernet Activity LED, active

low

Output

8mA

GND

9

Signal Ground

TXD1

10

Serial transmit data output 1

Output

2mA

TX-

11

Ethernet transmit differential

(neg)

Output

TCT

12

Ethernet transmit center tap

TX+

13

Ethernet transmit differential

(pos)

Output

LED3/DUPLEX

14

Ethernet Duplex LED, active

low

Output

8mA

GND

15

Signal Ground

CTS1

16

Serial Clear to Send

Input

Active 56K

to 122K

RX-

17

Ethernet receive differential

(neg)

Input

RCT

18

Ethernet receive center tap

RX+

19

Ethernet receive differential

(pos)

Input

SYSTEM_LED

20

System status LED, active

high

Input

Active 56K

to 122K

4mA

GND

21

Signal Ground

Reserved

22

Reserved for future use. Do

not connect.

RXD2

23

Serial receive data input 2

Input

Active 56K

to 122K

Reserved

24

Reserved for future use. Do

not connect.

TXD2

25

Serial transmit data output 2

Output

2mA

CP2/INT

26

Configurable I/O-External

interrupt input

Input

Active 56K

to 122K

4mA

Table 2-3 xPico (wired) PCB Interface Signals

xPico® Embedded Device Server Integration Guide 16

Page 17

2: Functional Description

Signal Name

xPico

Pin #

Primary Function

Reset

State

Internal

Pull-up

Driver

Strength

CP7

27

Configurable I/O

Input

Active 56K

to 122K

4mA

CP3

28

Configurable I/O

Input

Active 56K

to 122K

4mA

3V3

29

3.3V Input Power

CP4

30

Configurable I/O

Input

Active 56K

to 122K

4mA

3V3

31

3.3V Input Power

CP5

32

Configurable I/O

Input

10K

4mA

3V3

33

3.3V Input Power

CP6

34

Configurable I/O

Input

10K

4mA

CP1

35

Configurable I/O

Input

Active 56K

to 122K

4mA

DEFAULT#

36

Unit reset to default, active

default settings.

Input

Active 56K

GND

37

Signal Ground

EXT_RESET#

38

Unit hardware reset, active

low. Drive low to reboot unit.

Input

10K

GND

39

Signal Ground

GND

40

Signal Ground

Signal Name

xPico

Primary Function

Reset

Internal

down

Driver

GND

1

Signal Ground

GND

2

Signal Ground

CP8/SPI_CS

1

3

Configurable I/O/ SPI Chip

Select

Input,

floating

30K to 50K

8mA

LED1/WLAN_LED

4

WLAN Link, active low

Input,

floating

30K to 50K

8mA

RTS17

5

Serial ready to send/ serial

transmit enable

Input,

floating

30K to 50K

8mA

NC 6 No Connect

RXD1

7

Serial receive data input 1

Input,

floating

30K to 50K

NC 8 No Connect

GND

9

Signal Ground

TXD1

10

Serial transmit data output 1

Input,

30K to 50K

8mA

low.

Drive low to reset unit to

to 122K

Table 2-4 xPico Wi-Fi PCB Interface Signals

Pin #

State

Pull-up

Strength

/Pull-

xPico® Embedded Device Server Integration Guide 17

Page 18

2: Functional Description

Signal Name

xPico

Primary Function

Reset

Internal

down

Driver

floating

NC

11

No Connect

NC

12

No Connect

NC

13

No Connect

WKUP4 14

System Wake Up on Rising

Edge

Input,

floating

30K to 50K

GND

15

Signal Ground

CTS17

16

Serial Clear to Send

Input,

floating

30K to 50K

NC

17

No Connect

NC

18

No Connect

NC

19

No Connect

SYSTEM_LED

20

System status LED, active

high

Input,

floating

30K to 50K

8mA

GND

21

Signal Ground

DDP2 22

USB (positive)

RXD2

23

Serial receive data input 2

Input,

floating

30K to 50K

DDM2 24

USB Negative

TXD2

25

Serial transmit data output 2

Input,

floating

30K to 50K

8mA

CP2/INT

1

26

Configurable I/O-External

interrupt input

Input,

floating

30K to 50K

8mA

CP7/SPI_SCK

1

27

Configurable I/O/ SPI Clock

Input,

floating

30K to 50K

8mA

CP3/MISO

1

28

Configurable I/O/SPI Master

In-Slave Out

Input,

floating

30K to 50K

8mA

3V3

29

3.3V Input Power

CP4/MOSI

1

30

Configurable I/O/ SPI Master

Out-Slave In

Input,

floating

30K to 50K

8mA

3V3

31

3.3V Input Power

CP5

32

Configurable I/O

Input,

floating

30K to 50K

8mA

3V3

33

3.3V Input Power

CP6

34

Configurable I/O

Input,

floating

30K to 50K

8mA

CP1

35

Configurable I/O

Input,

floating

30K to 50K

8mA

DEFAULT#

36

Unit reset to default, active

Drive low to reset unit to

Input,

30K to 50K

Pin #

State

Pull-up

/Pull-

Strength

xPico® Embedded Device Server Integration Guide 18

low.

floating

Page 19

2: Functional Description

Signal Name

xPico

Primary Function

Reset

Internal

down

Driver

default settings.

GND

37

Signal Ground

EXT_RESET#

38

Unit hardware reset, active

low. Drive low to reboot unit.

Input

30K to 50K

GND

39

Signal Ground

GND

40

Signal Ground

Antenna Type

Peak Gain

Lantronix Part

Vendor

Vendor

Number

PCB Strip Antenna

With tape backing

1.5 to 2.5dBi, 2.39

XPW100A003-01-B

Ethertronics®

1001077

Pin #

State

Pull-up

Strength

/Pull-

Note 1: The xPico Wi-Fi SPI interface supports master only. Slave mode operation will be supported in a future firmware release.

Note 2: The xPico Wi-Fi USB interface is USB 2.0 full speed device. The device interface connector and power interface must be designed into the

mating board.

Note 3: xPico and xPico Wi-Fi embedded device servers may be designed into the same socket. Signals listed as no connect on xPico Wi-Fi

embedded device server may be connected on an xPico base design board. For example, xPico Wi-Fi pins 11, 12, 13, 17, 18, and 19 may connect

to an Ethernet magnetic module as designed for xPico (wired), however, Ethernet will not be available on those pins for xPico Wi-Fi.

Note 4: Pin 14 is the Ethernet duplex LED output on xPico (wired) and the system wakeup input on xPico Wi-Fi. For board designs supporting both

xPico (wired) and xPico Wi-Fi, a zero ohm resistor or removable jumper stuff option should be used to disconnect any on-board logic driving pin 14

when xPico (wired) unit is installed.

Note 5: The CP pins can be configured as pull-up or pull-down. T he WKUP pi n is not configurable and is always pull-down.

Note 6: The IO pins on xPico Wi-Fi embedded device server are configured as floating-input on reset until configured by firmware. For applications

requiring a high signal on power up, an external pull-up may be required or removeable jumper.

Note 7: It is highly recommended to connect RTS and CTS for serial port 1.

Note: For integration information for Lantronix xPico Wi-Fi SMT embedded

device server modules, XPC W1002 and XPC W1003 please reference the 900714 xPico Wi-Fi SMT Integration Guide.

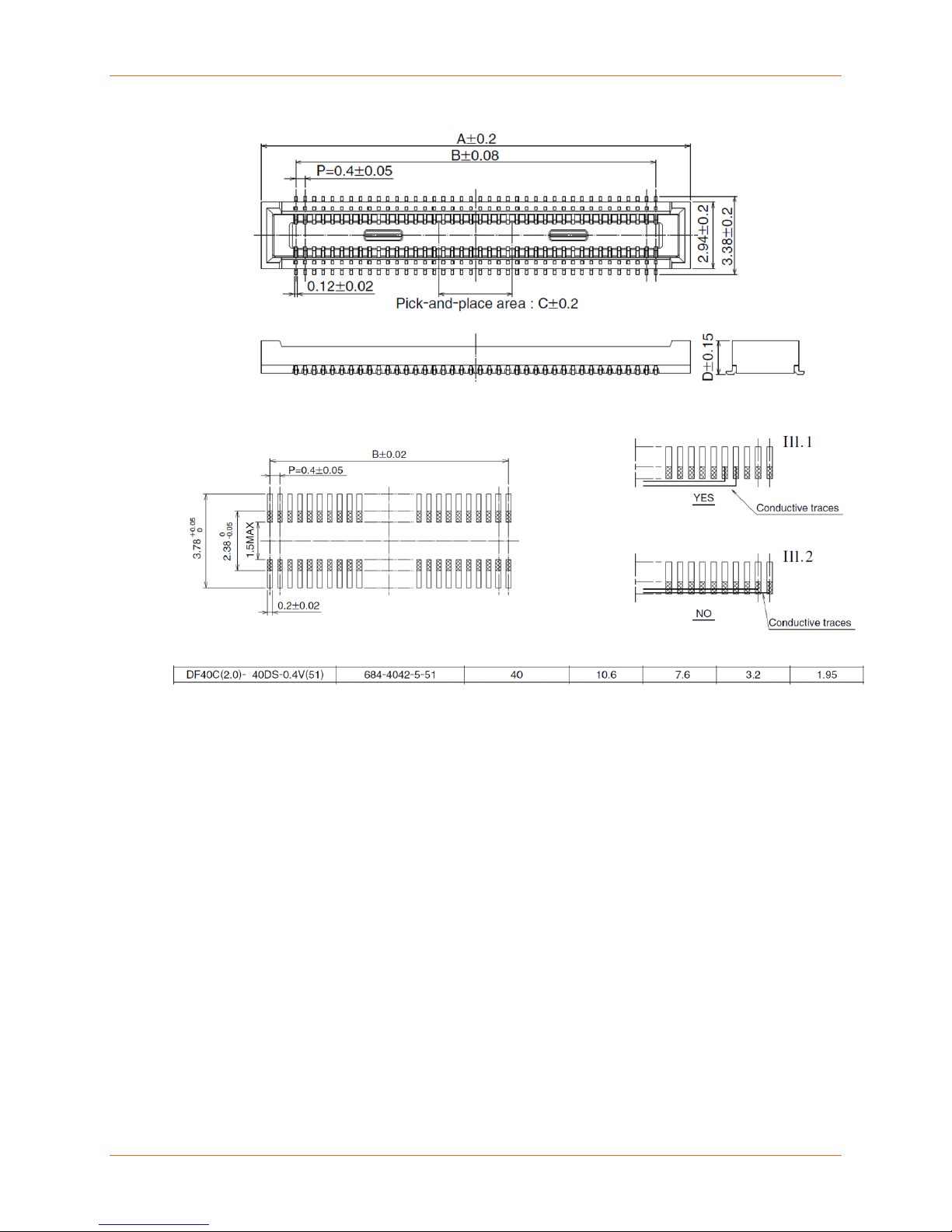

Mating Connector

The mating connector for the xPico and xPico Wi-Fi module is Hirose part number

DF40C (2.0)-40DS-0.4V (51). Special care must be taken when mating and unmating

the module to the mating connector. Refer to the Hirose DF40 data sheet below for

proper connector mating and unmating, along with the proper connector footprint.

Mating connector data sheet: http://www.hirose.co.jp/cataloge_hp/e68440018.pdf

Antenna Interface (xPico Wi-Fi Units Only)

The xPico Wi-Fi module has been certified using the external antennas listed below. Per

FCC guidelines, the xPico Wi-Fi certification remains valid if using an antenna of similar

type to the antennas below. If using an antenna of similar type to one of the antennas

below, but from a different manufacturer part number the antenna gain must be equal to

or less than specified in the table. Consult with your certification lab for more details.

Table 2-5 xPico Wi-Fi External Antenna Options

with 50mm cable to

U.FL connector

Typical

Ghz to 2.49 Ghz

Number

(50 piece bulk pack)

Part

xPico® Embedded Device Server Integration Guide 19

Page 20

2: Functional Description

Antenna Type

Peak Gain

Lantronix Part

Vendor

Vendor

Number

PCB Strip Antenna

Without tape backing

1.5 to 2.5dBi, 2.39

Ethertronics

1000668

Swivel type antenna,

2 dBi, 2.4 Ghz to

Ghz

930-033-R-ACC

Wanshih

WSS002

with 50mm cable to

U.FL connector

with RP-SMA(M)

connector

Typical

Ghz to 2.49 Ghz

2.5 Ghz, 2 dBi,

5.15 Ghz to 5.85

Number

(50 piece bulk pack)

Part

Note: The PCB strip antenna is available from Ethertronics, Inc. with or without

adhesive tape backing for mounting to a plastic case. For the component without

tape backing a non-conductive double sided adhesive tape can be used to fix the

antenna in place. The Ethertronics part numbers listed above come with a 50mm

U.FL cable attached to the PCB strip antenna. The 50mm cable length is the

minimum allowed cable length for use with the xPico Wi-Fi embedded device

server. For similar PCB strip antennas with longer cables consult with

Ethertronics, Inc. (www.ethertronics.com).

Lantronix provides a U.FL to Reverse SMA antenna cable in with the evaluation board

and sample kits for development work. These cables can be purchased from Lantronix

for production or supplied by an RF cable manufacturer. External antennas can be

purchased from the antenna vendor. Components for cable design should be selected

for low loss over the entire 2.4Ghz to 5.9Ghz signal range. The cable target impedence

should be 50 ohms.

Figure 2-4 Reverse-SMA to U.FL(long) (Lantronix Part Number 500-180-R)

Figure 2-5 U.FL to U.FL Cable (Lantronix Part Number 500-181-R)

xPico® Embedded Device Server Integration Guide 20

Page 21

Figure 2-6 Reverse-SMA to U.FL(short) (Lantronix Part Number 500-182-R)

Signal

Name

DIR

Contact

Primary Function

Signal Requirement

TX+

Out

13

Differential Ethernet

transmit data +

100 ohm differential with

TX-

TX-

Out

11

Differential Ethernet

transmit data -

100 ohm differential with

TX+

RX+

In

19

Differential Ethernet

receive data +

100 ohm differential with

RX-

RX-

In

17

Differential Ethernet

receive data -

100 ohm differential with

RX+

TCT

12

Ethernet transmit center

tap connection

Route > 20 mil width

RCT

18

Ethernet receive center tap

connection

Route > 20 mil width

Antenna Placement (xPico Wi-Fi Units Only)

When designing the xPico Wi-Fi module to a mating board, it is important to consider the

final installation of the unit and its location with respect to connecting access points. The

antenna should be placed so that it has as clear as possible path to the connecting

access point for maximum range. Avoid placing the antenna such that it is blocked by

metal walls or ground planes of adjacent circuit boards.

2: Functional Description

Ethernet Interface (xPico Wired Units Only)

The xPico embedded device server integrates an internal 10/100Mbps Ethernet MAC and

PHY. An external magnetic module and RJ45 is required in order to connect to a

standard 10/100Mbps Ethernet network.

Table 2-6 Ethernet Interface Signals

The xPico embedded device server provides a 10/100 Mbps Ethernet interface for

connection to an external network through external magnetics and an external RJ45.

The table below lists several magnetic modules and combination RJ45/magnetic jacks

that can be used with the xPico unit.

xPico® Embedded Device Server Integration Guide 21

Page 22

2: Functional Description

Type

Manufacturer

Part Number

Magnetic only (requires RJ45)

BI-Tech

HS91-011-80LFTR

Magnetic only (requires RJ45)

Mingtek

HN0013SG

Combination RJ45/Magnetic

Belfuse

08B0-1D1T-06-F

Combination RJ45/Magnetic

Midcom

MIC2411D-0117T-LF3

Magnetic for POE

PULSE

HX2019

Table 2-7 Recommended Magnetic Modules

and Combo RJ45/Magnetic Module Connectors

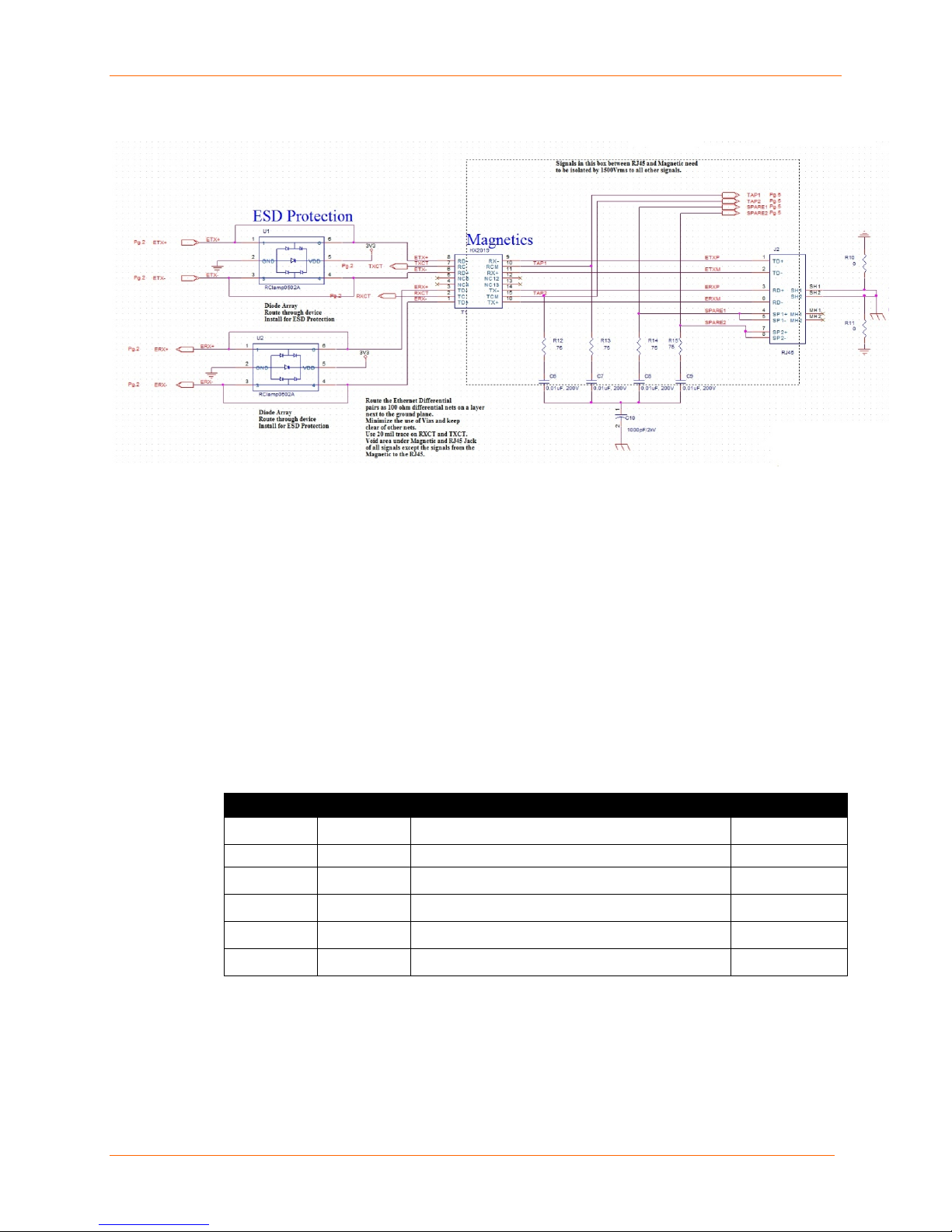

The Ethernet differential pair signals, ERX-/ERX+ and ETX-/ETX+ should be routed as

100-ohm differential pairs on a layer next to the signal ground plane. The use of vias on

these signals should be minimized. The center tap signal connections between the

magnetic and xPico (wired) module are required. Center tap signals RCT and TCT

should be routed with at least 20 mil trace thickness. The area between the magnetic

module and RJ45 jack, including the area under both, should be voided of all signals and

planes, except for the signals connecting to both. The signals connecting between the

RJ45 and magnetic are required to be isolated by 1500Vrms from all other signals and

planes, including chassis and signal ground. The connector shield should be connected

to chassis. It is recommended that 1206 resistor pads from chassis ground to signal

ground be placed next to each of the shield tabs. The resistor pads allow for 0 ohm

jumper, ferrite beads, or decoupling caps to be installed as needed for EMI/EMC

improvement.

The Ethernet LED signals should be routed to discrete LEDs or to the LED pins on the

RJ45 through 220 ohm or larger resistors. The LED signals are active low. The Ethernet

LED signals should be isolated from the signals that connect between the RJ45 and

magnetic module.

Also shown in the reference schematic is a recommended TVS array that can be used to

improve ESD and EFT in harsh environments. The device shown is Semtec

RCIamp0502A. This device features route through pin assignments allowing for the

Ethernet differential signal pairs to be routed without altering the trace impedance or

adding vias. Due to this routing, the device could be installed or depopulated as needed.

See the Lantronix app note, How to Connect a Lantronix Embedded Module to a

Wired Ethernet Port for more details on Ethernet connection and routing,

http://www.lantronix.com/pdf/appnotes/Connect-LTRX-Embed-Module-to-WiredEthernet_AN.pdf.

The xPico module can also be powered from POE using a POE magnetic and POE

powered device controller. Lantronix uses the Silabs, Si3402 POE controller to power

the xPico development board via POE. If using POE the Ethernet magnetic module

should be changed to a POE compatible module such as Pulse HX2019.

Refer to the evaluation board schematic in the xPico-DevKit_UG for an example circuit.

http://www.lantronix.com/pdf/xPico-DevKit_UG.pdf

.

Refer to the SiLabs data sheet for Si3402 for more information on using the SiLabs POE

controller.

xPico® Embedded Device Server Integration Guide 22

Page 23

Serial Interface

Signal

Pin

Description

Reset State

TXD1

10

Serial Transmit Data output

Output

RTS1

5

Serial Ready-to-Send / Serial Transmit enable

Output

RXD1

7

Serial Receive Data input

Input

CTS1

16

Serial Clear-to-Send

Input

TXD2

25

Serial Transmit Data output 2

Output

RXD2

23

Serial Receive Data input 2

Input

2: Functional Description

Figure 2-7 Ethernet Connection Example (xPico wired unit only)

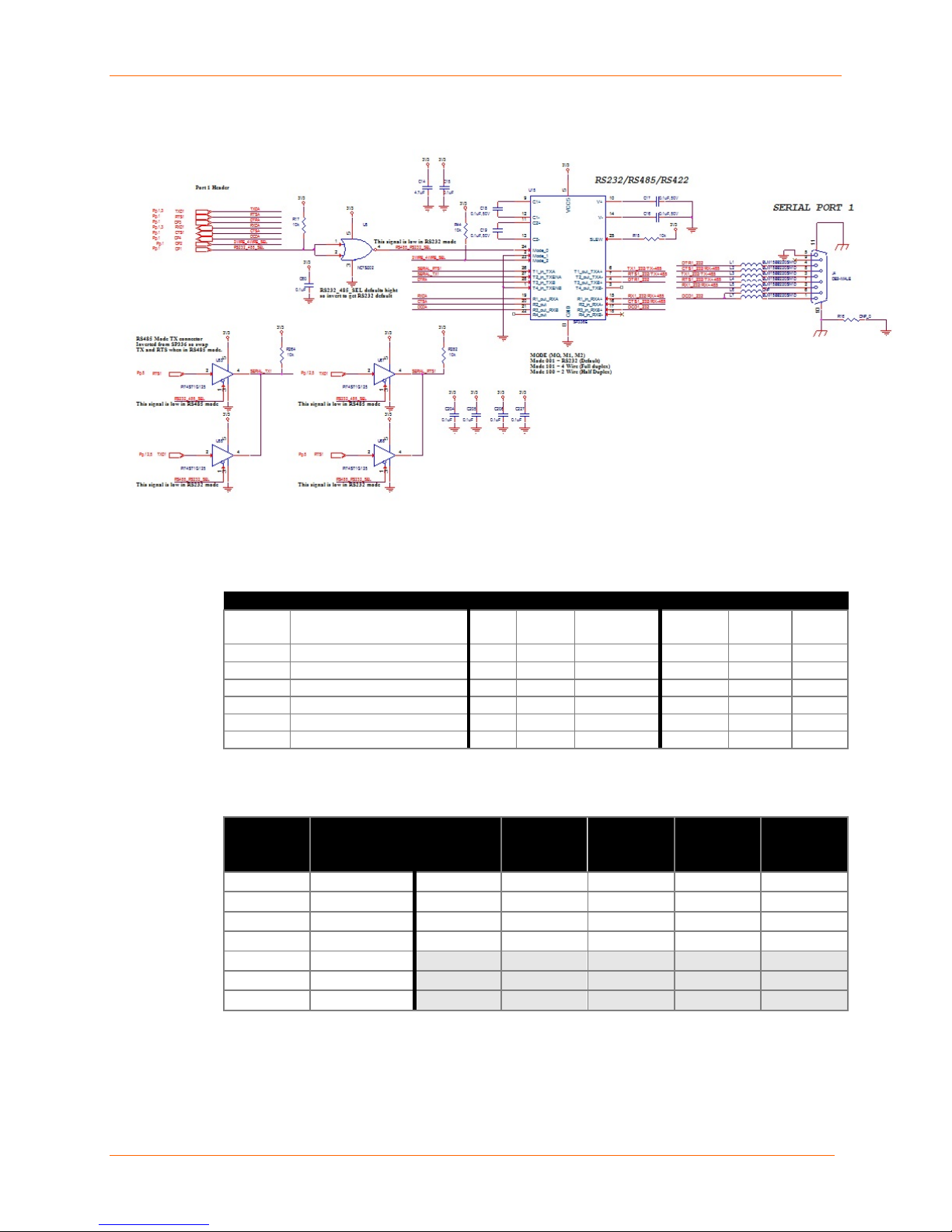

The xPico and xPico Wi-Fi embedded device servers have two external serial interfaces.

The signal levels on the serial interface are 3.3V logic level with 5V tolerant inputs. The

serial interfaces require an external transceiver in order to connect to external RS232,

RS485, or RS422 networks. The signals of Serial Port 1 may be connected as shown in

the reference schematic, Figure 2-8 serial port example, below. The transceiver shown

in the reference schematic is of type Exar, part number SP336. This transceiver is a

multiprotocol RS232, RS485, RS422 transceiver. Single protocol transceivers may be

used as required. The xPico interface may also be directly connected to the UART

interface of an external CPU. Serial Port 2 is a three wire interface only. It operates like

Serial Port 1, except it does not support hardware Flow Control (i.e. no RTS/CTS) and

modem control (i.e. no DTR/DCD). It is highly recommended to connect RTS and CTS

for serial port 1.

Table 2-8 xPico and xPico Wi-Fi Serial Port Signals

xPico® Embedded Device Server Integration Guide 23

Page 24

Figure 2-8 Serial Port Example

xPico Signal

DCE Connector

DTE Connector

Signal

(Logic)

Description

DB9

DB25

Signal

DB9

DB25

Signal

RXDx

Data In

2 3 RXDx

3 2 TXDx

TXDx

Data Out

3 2 TXDx

2 3 RXDx

RTSx

H/W Flow Control Output

7 4 RTSx

8 5 CTSx

CTSx

H/W Flow Control Input

8 5 CTSx

7 4 RTSx

CPx

Modem Control Input

1 8 DCDx

4

20

DTRx

CPy

Modem Control Output

4

20

DTRx

1 8 DCDx

xPico

(logic)

Description

RS485

DB25 4

DB25 2

DB9 4

DB9 2

TXDx

Data Out

TX+485

14

14 7 7

TXDx

Data Out

TX-485

15

15 3 3

RXDx

Data In

RX+485

21

14 2 7

RXDx

Data In

RX-485

22

15 8 3

RTSx

TX Enable

CPx

RS485 Select

CPy

RS485 2-wire

2: Functional Description

Signal

Table 2-9 RS232 Connections (Serial Transceiver Required)

Table 2-10 RS422/485 Connections (Serial Transceiver Required)

Signal

Wire

Wire

wire

wire

Note: The IO pins for xPico Wi-Fi embedded device server are set to floating

input on power up until configured by unit firmware. An external 100K ohm pullup may be required on the serial transmit signal to prevent downstream UART

devices from detecting false characters on initial power up.

xPico® Embedded Device Server Integration Guide 24

Page 25

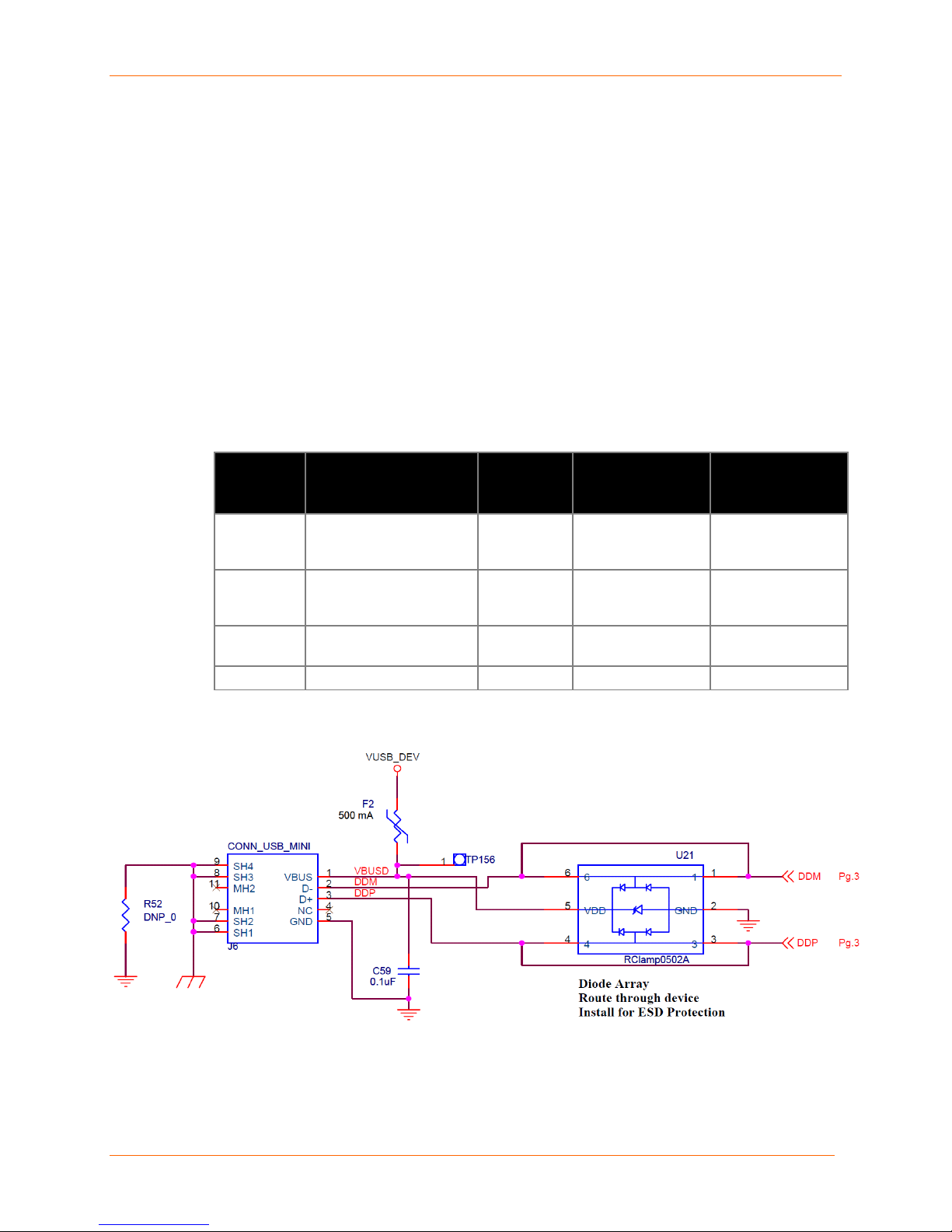

USB Device Port (xPico Wi-Fi Units Only)

The xPico Wi-Fi embedded device server has one USB2.0 Full Speed Device port

interfaces for connection to an upstream USB device. The port consists of a differential

pair, signals DDP and DDM. These signals should be routed as a 90 ohm differential pair

on a signal layer next to the signal ground plane. The use of vias should be minimized

on these signals. The USB signals can be connected to a USB Mini Type B USB port (as

shown in Table 2-12) directly to an IC with a USB host port. If connecting to an external

port that is user accessible it is recommended to add a TVS diode array to the signal nets

for ESD protection. The ESD array shown in the figure is of type Semtech

RCIamp0502A. This device features through pin routing to minimize trace impedance

changes and simplify routing. The footprint for the TVS array can be added to the PCB

and the part can be depopulated if it is not needed. It is recommended that the power

drawn off the USB Mini Type B connector be limited to less than 500mA per USB

requirements. If the USB device port is unused the DDP and DDM pins may be left

unconnected.

Table 2-11 USB Host Port Signals

2: Functional Description

Pin Name Description Connector

Pins

Signal

Requirement

Mini Type B

USB Device

connector pin

DDP USB Device Port

Positive pin

DDM USB Device Port

Negative pin

5V 5V power from USB

cable

Ground Signal Ground Ground Ground plane 5

Figure 2-9 USB Device Interface Example (xPico Wi-Fi unit only)

22 Route as 90 ohm

differential pair with

DDM signal

24 Route as 90 ohm

differential pair with

DDP signal

Current limit to 500

mA per port

3

2

1

xPico® Embedded Device Server Integration Guide 25

Page 26

LEDs

Signal

Pin

Description

LED1/WI-FI LED

4

WI-FI Status LED, active low

SYSTEM_LED

20

System status LED, active high

Signal

Pin

Description

LED0/SPEED

6

Ethernet speed LED, active low

LED1/LINK

4

Ethernet Link LED, active low

LED2/ACTIVITY

8

Ethernet Activity LED, active low

LED3/DUPLEX

14

Ethernet Duplex LED, active low

SYSTEM_LED

20

System status LED, active high

Signal

Pin

Description for xPico Wired

Description xPico Wi-Fi

Reset

State

CP1

35

Configurable I/O

Configurable I/O

Input

CP2/INT

input

input

CP3

28

Configurable I/O

Configurable I/O-SPI MISO

Input

CP4

30

Configurable I/O

Configurable I/O-SPI MOSI

Input

CP5

32

Configurable I/O

Configurable I/O

Input

CP6

34

Configurable I/O

Configurable I/O

Input

CP7

27

Configurable I/O

Configurable I/O-SPI Clock

Input

CP8

3

Configurable I/O

Configurable I/O-SPI Chip Select

Input

2: Functional Description

The xPico embedded device server contains several external signals that are intended to

drive external status LEDs. The LEDs are listed below. The signals may be connected

as shown in the reference schematic figure below.

Note: The System LED usually remains on. When the Default button is pressed

for 5-6 seconds, the System LED starts blinking every second to indicate the

default button can be released to complete resetting the unit to factory default.

The unit reboots after release of the Default button. A lit WLAN LED indicates

the STA interface is associated with an access point.

Table 2-12 xPico Wi-Fi Status LED Output Signals

Table 2-13 xPico Status LED Output Signals

General Purpose I/O Pins

xPico and xPico Wi-Fi unit contains eight pins which may be used as configurable inputs

or outputs. Listed below are the configurable I/O pins. These pins are 3.3V CMOS logic

level and 5V input tolerant.

Table 2-14 Ethernet Interface xPico Serial Port Signals

26 Configurable I/O-External interrupt

Note 1. For xPico Wi-Fi 5V tolerant pins, in order to sustain a voltage higher than Vcc+0.3, the internal pull-up/ pull-down resistors must be disabled.

Configurable I/O-SPI interrupt

Input

xPico® Embedded Device Server Integration Guide 26

Page 27

Reset Pins

Signal

Pin

Description

Reset

State

Internal pull-up

EXT_RESET#

38

Unit hardware reset, active low. Assert

be left floating.

Input

10K (xPico unit)

DEFAULT#

36

Unit reset to default, active low.

established.

Input

Active 56K to

WAKE (xPico

14

Toggle signal from low to high can wake

configuration settings.

Input

40K

The xPico and xPico Wi-Fi embedded device servers have two signals for use as reset

signals. Signal EXT_RESET# is a hardware controlled input signal that will reboot the

xPico processor when asserted low. Signal DEFAULT# is polled by the xPico software.

When DEFAULT# is asserted low for six seconds, the unit will reset the system to the

default manufacturing settings and reboot the unit. xPico Wi-Fi embedded device server

has an additional signal on pin 14 that can be used to wake up the unit processor when

the unit is in a sleep or power down state.

2: Functional Description

Table 2-15 xPico Reset Signals

Wi-Fi unit only)

low for a minimum of 50 milliseconds,

then release to reboot unit. Signal may

• For wired xPico units

Drive low and reboot the device to

reset unit to factory defaults.

• For xPico Wi-Fi units

While device is running, drive low for

greater than 6 seconds, then release

to reset unit to factory defaults. While

device is held in reset, drive low,

release reset to boot device with Line 1

CLI default settings (original

configuration is preserved), then

release after CLI session is

device from Sleep or Standby mode.

Hold low to allow device to enter Sleep

or Standby mode. Subject to

40K (xPico Wi-Fi

unit)

122K (xPico unit)

40K (xPico Wi-Fi

unit)

xPico® Embedded Device Server Integration Guide 27

Page 28

2: Functional Description

xPico® Embedded Device Server Integration Guide 28

Evaluation Board Schematics

Figure 2-10 Evaluation Board Schematic, Part 1 of 5

Page 29

2: Functional Description

xPico® Embedded Device Server Integration Guide 29

Figure 2-11 Evaluation Board Schematic, Part 2 of 5

Page 30

2: Functional Description

xPico® Embedded Device Server Integration Guide 30

Figure 2-12 Evaluation Board Schematic, Part 3 of 5

Page 31

2: Functional Description

xPico® Embedded Device Server Integration Guide 31

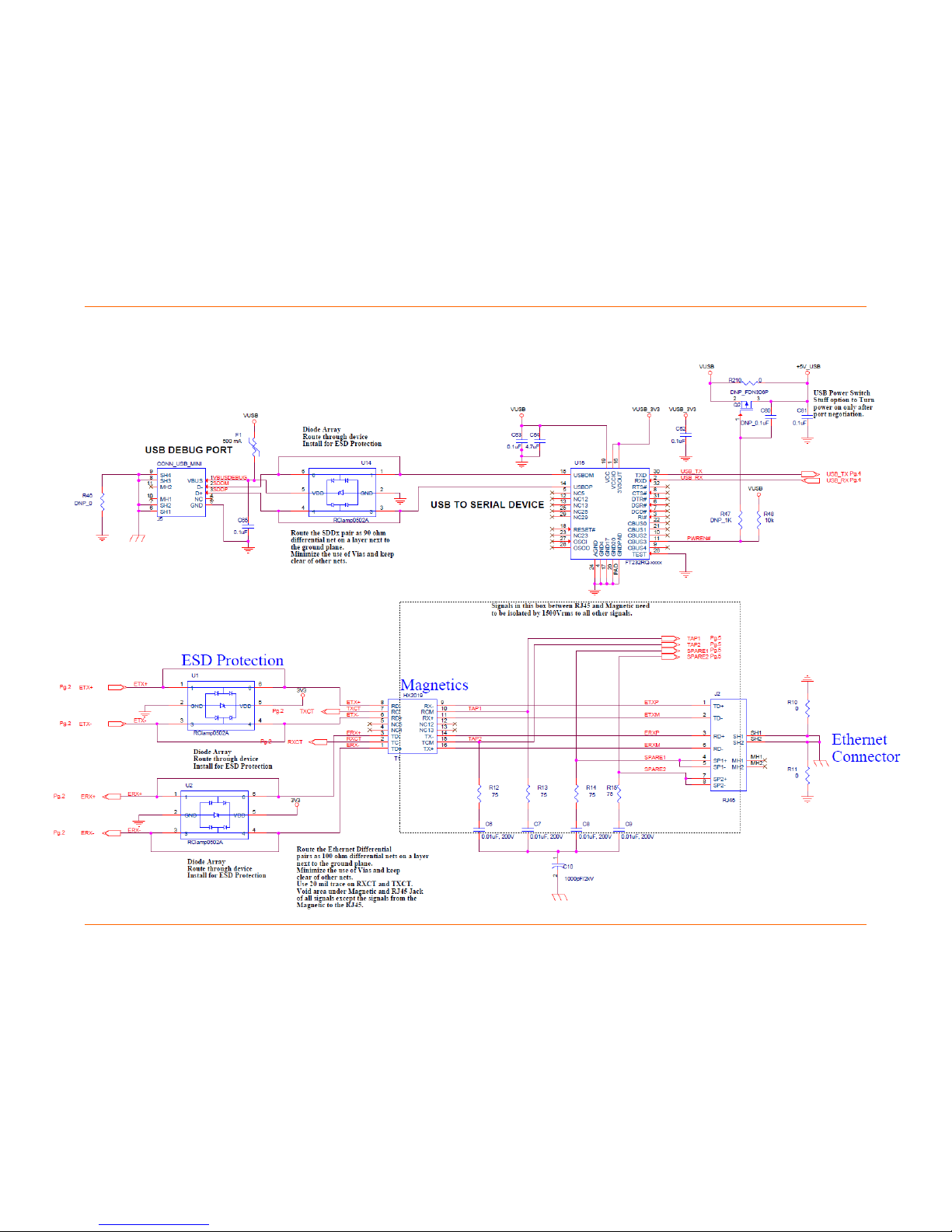

Figure 2-13 Evaluation Board Schematic, Part 4 of 5

Page 32

2: Functional Description

xPico® Embedded Device Server Integration Guide 32

Figure 2-14 Evaluation Board Schematic, Part 5 of 5

Page 33

3: Mounting Instructions and PCB Footprint

3. Mounting Instructions and PCB Footprint

The xPico embedded device server dimensions and mounting instructions are shown in

the following drawings below. You may also directly access the CAD files through the

Lantronix website.

Note: The mounting instructions in this section are applicable to both the xPico

and the xPico Wi-Fi embedded device servers though the xPico pictures below

are used to demonstrate installation.

For temperature environments up to +85° Celsius, it is recommended that the

mating PCB have its outer layers flooded with signal ground and a heat pad be

placed between the module and mating PCB. The recommended heat pad is

Lantronix part number XPC100A002-01-B. The ground flooding and heat pad

are only required for xPico Wi-Fi units in environments above +70°C. For

environments below +70°C the heat pad and ground flooding are not required.

To Access CAD Files

1. Go to http://www.lantronix.com/products/cad-visio.html.

2. Click Download CAD files here to access the Registration Form.

Figure 3-1 White Mounting Quick Clip Dimensions

xPico® Embedded Device Server Integration Guide 33

Page 34

3: Mounting Instructions and PCB Footprint

Module/Mounting

White

Module

To Install the xPico or xPico Wi-Fi Module

In the xPico embedded device server development kit (part number XPC100100K-02)

and xPico Wi-Fi development kit (XPW100100K-01), the xPico module comes installed to

the xPico Evaluation Board via the connector J1 (Hirose component). If ordered

separately, you may need to install it by following the directions below. The included

white Mounting Quick Clip is used to align and fasten the module to the evaluation board.

1. Place the module into the white mounting clip, lining up the clip legs and the four

module grooves so that the module is seated inside the white clip. For xPico Wi-Fi

unit connect the RF cable to the module U.FL connector prior to installing the Quick

Clip.

Mounting Clip

xPico/xPico Wi-Fi

2. Push the legs of the white clip inward to secure the module to the clip.

3. Flip over the module/mounting clip combination so that the product label displays on

top and the white mounting clip legs are pointed downward.

4. For xPico Wi-Fi embedded device server high temperature operation, above +70C, it

is recommended to place a heat pad between the module and the adjacent PCB. The

recommended heat pad is Lantronix part number XPC100A002-01-B (available in a 50

piece bulk pack).

5. Place the module/mounting clip combination so that the four mounting clip legs align

with the four standoff holes on the board surrounding the J1 connector

(see Figure 3-2). Make sure to properly orientate the module/mounting clip

combination on the board, so that the J1 connector/Hirose component is properly

aligned.

Clip Combination

xPico® Embedded Device Server Integration Guide 34

Page 35

3: Mounting Instructions and PCB Footprint

Figure 3-2 Aligning Mounting Clip Legs to Standoff Holes

6. Insert the white clip legs furthest from the J1 connector first and gently push down on

the xPico module above the J1 connector. Keep the module as level as possible

during installation.

Note: When removing the xPico embedded device server from the evaluation

board, gently tug the module. Do not use excessive force or attempt to remove

the xPico module by grasping and pulling the module from the short end opposite

the module connector as this may cause damage to the J1 evaluation board

connector.

xPico® Embedded Device Server Integration Guide 35

Page 36

3: Mounting Instructions and PCB Footprint

Figure 3-3 Mounting Instructions for PEM Standoff

xPico® Embedded Device Server Integration Guide 36

Page 37

3: Mounting Instructions and PCB Footprint

Figure 3-4 Hirose Connector Layout

xPico® Embedded Device Server Integration Guide 37

Page 38

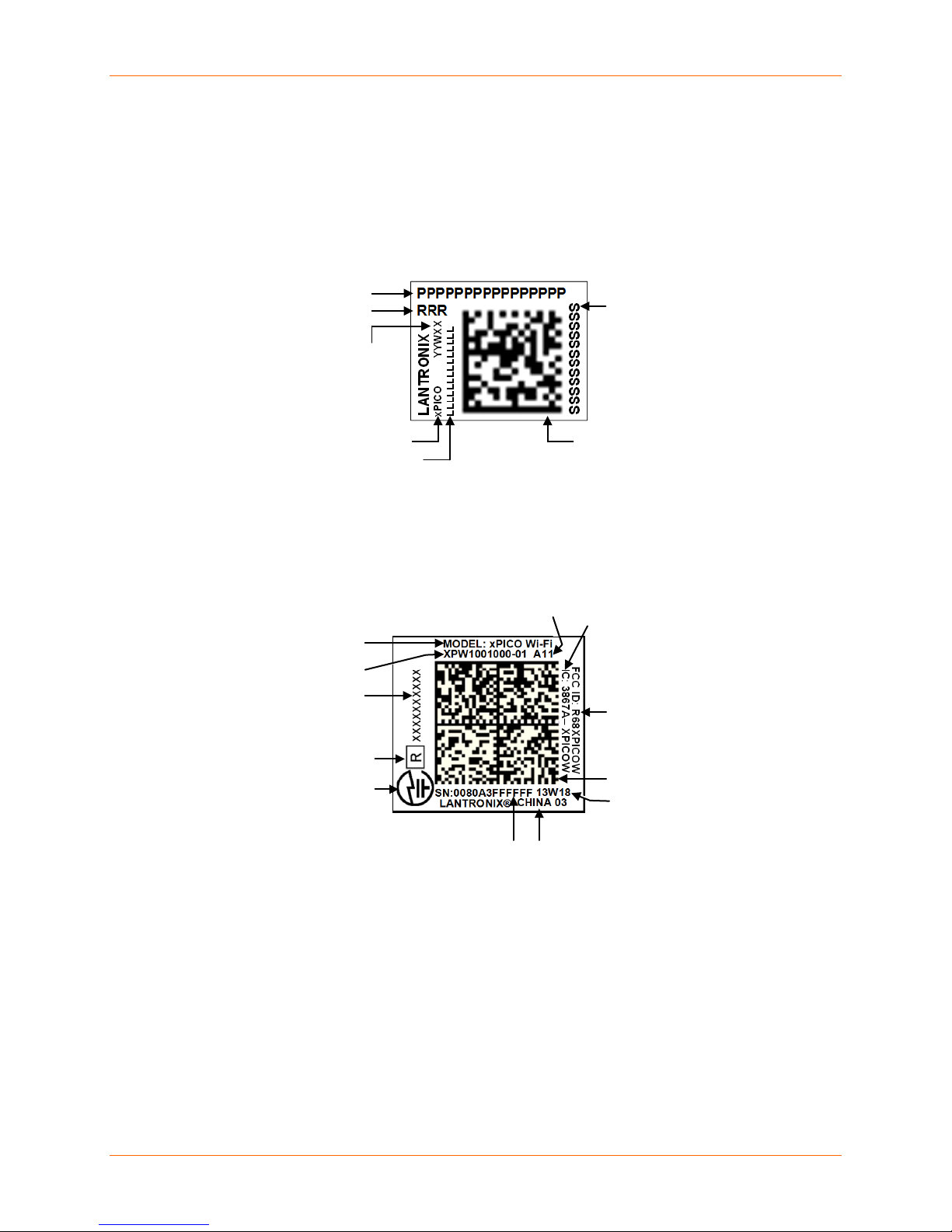

Product Information Label

Part Number

Date Code

Product Model

Country of Origin

Revision

MAC Address

Product Model

FCC Radio ID

Part Number

Japan Radio Equipment Mark

Japan Telecommunication Mark

Canada Radio ID

Manufacturing Date Code

Revision Number

The product information label contains important information about your specific unit,

such as its part number, revision, manufacturing date code, product model, country of

origin, datamatrix barcode and MAC address.

3: Mounting Instructions and PCB Footprint

Figure 3-5 xPico Product Label

Manufacturing

Lantronix

Datamatrix

Barcode

Figure 3-6 xPico Wi-Fi Product Label

Japan Certification Number

Lantronix Datamatrix Barcode

xPico® Embedded Device Server Integration Guide 38

Serial Number Country of Origin

Page 39

4. Specifications

Parameter

Symbol

Min

Max

Units

Supply Voltage

VCC 0 3.6

Vdc

Operating Temperature

-40

85

°C

Storage Temperature

-40

85

°C

Parameter

Symbol

Min

Typical

Max

Units

Supply Voltage

VCC

3.15

3.3

3.46

Vdc

Supply Voltage Ripples

V

CC_PP

2

%

100 BaseTX Active (Normal CPU Speed)

ICC

200

mA

10 BaseT Active (Normal CPU Speed)

ICC

220

mA

No Link (Normal CPU Speed)

ICC

150

mA

100 BaseTX Active (High CPU Speed)

ICC

240

mA

10 BaseT Active (High CPU Speed)

ICC

260

mA

No Link (High CPU Speed)

ICC

190

mA

100 BaseTX Active (Low CPU Speed)

ICC

170

mA

10 BaseT Active (Low CPU Speed)

ICC

190

mA

No Link (Low CPU Speed)

ICC

120

mA

Supply Reset Threshold

V

RST

2.7

Vdc

CPx Pull-ups, except CP5, CP6

RPU

56 122

Kohm

CP5,CP6 Pull-up

RPU 10 Kohm

CPx, RX

Input Low Voltage

V

0.8

Vdc

CPx, RX

Input High Voltage

V

2 5.5

Vdc

CPx, TX Output Low Voltage

(IOL = 4 mA)

V

0.4

Vdc

CPx, TX Output High Voltage

(IOH = -4 mA)

V

2.4

Vdc

Reset Pin Low Voltage

VRES_IL

0.36

Vdc

Reset Pin High Voltage

VRES_IL

2.0 3.46

Vdc

Electrical Specifications

Caution: Stressing the device above the rating listed in this table may cause

permanent damage to the xPico embedded device server. Exposure to Absolute

Maximum Rating conditions for extended periods may affect the xPico unit’s

reliability. For xPico Wi-Fi operation above +70° Celsuis, it is recommended that a

heat pad be placed between the module and mating PCB.

4: Specifications

Table 4-1 Absolute Maximum Ratings

Table 4-2 xPico Wired Recommended Operating Conditions

CP_IL

CP_IH

xPico® Embedded Device Server Integration Guide 39

CP_OL

CP_OH

Page 40

Table 4-3 xPico Wi-Fi Recommended Operating Conditions

Parameter

Symbol

Min

Typical

Max

Units

Supply Voltage

VCC

3.15

3.3

3.46

Vdc

Supply Voltage Ripples

V

CC_PP

2

%

TX Power @ 16.5dBm, 802.11b, 11Mbps

ICC

330

380

mA

TX Power @ 15dBm, 802.11g, 6Mbps

ICC

300

345

mA

TX Power @ 13dBm, 802.11g, 54Mbps

ICC

255

295

mA

TX Power @ 14.5dBm, 802.11n, MCS0

ICC

290

335

mA

TX Power @ 12dBm, 802.11n, MCS7

ICC

230

265

mA

RX Power @ 802.11b, 11Mbps

ICC

125

150

mA

RX Power @ 802.11g, 54Mbps

ICC

125

150

mA

RX Power @ 802.11n, MCS7

ICC

125

150

mA

Power Management State 1 @ 25°C

ICC

6

μA

Power Management State 1 @ +85°C

ICC

12

μA

Power Management State 1 @ -40°C

ICC

5

μA

Supply Reset Threshold

V

RST

Vdc

CPx Pull-ups/ Pull-downs

RPU

30

40

50

Kohm

CPx, RX

Input Low Voltage

V

-0.3 0.75

Vdc

CPx, RX

(1)

Input High Voltage

V

2 5.5

Vdc

CPx, TX Output Low Voltage

(IOL = 4 mA)

V

0.4

Vdc

CPx, TX Output High Voltage

(IOH = -4 mA)

V

2.4

Vdc

Reset Pin Low Voltage

VRES_IL

-0.3 0.8

Vdc

Reset Pin High Voltage

VRES_IL

2 Vcc+0.3

Vdc

4: Specifications

CP_IL

CP_IH

CP_OL

CP_OH

Note 1. For xPico Wi-Fi 5V tolerant pins, in order to sustain a voltage higher than Vcc+0.3, the internal pullup/pull-down resistors must be disabled.

xPico® Embedded Device Server Integration Guide 40

Page 41

Technical Specifications

Category

Description

CPU, Memory

Lantronix DSTni-EX 186 CPU, 256-Kbyte zero wait state SRAM, 512Kbyte flash, 16-Kbyte boot ROM

Firmware

Upgradeable via TFTP and serial port

Reset Circuit

Internal 200ms power-up reset pulse. Power-drop reset triggered at 2.6V.

External reset input causes an internal 200ms reset.

Serial Interface

CMOS (Asynchronous) 3.3V-level signals

Rate is software selectable: 300 bps to 921600 bps

Serial Line Formats

Data bits: 7 or 8 Stop bits: 1 or 2 Parity: odd, even, none

Modem Control

DTR/DCD, CTS, RTS <- Serial 1 only

Flow Control

Serial 1: XON/XOFF (software), CTS/RTS (hardware)

Serial 2: XON/XOFF (software)

Programmable I/O

8 PIO pins (software selectable), sink or source 4mA max.

Network Interface

10/100Mbps Ethernet, requires external magnetics and RJ45

Compatibility

Ethernet: Version 2.0/IEEE 802.3 (electrical), Ethernet II frame type

Protocols Supported

ARP, UDP/IP, TCP/IP, Telnet, ICMP, SNMP, DHCP, BOOTP, TFTP, Auto

IP, SMTP, and HTTP

LEDs

Link, Activity, Link Speed, Duplex, System Status logic level outputs

Management

Internal web server, SNMP (read only) Serial login, Telnet login

Security

Password protection, locking features, optional Rijndael 256-bit encryption

Internal Web Server

Serves static Web pages and Java applets

Storage capacity: 384 Kbytes

Weight

2.5 grams

Material

Metal shell

Temperature

Operating range:

-40°C to +85°C (-40°F to 185°F)

Warranty

For details on the Lantronix warranty policy, go to our web site at

www.lantronix.com/support/warranty.

Included Software

Windows 98/NT/2000/XP-based Lantronix® DeviceInstaller™

configuration software and Windows based Com Port Redirector

EMI Compliance

See A:Compliance.

4: Specifications

Table 4-4 xPico Wired Technical Specification

xPico® Embedded Device Server Integration Guide 41

Page 42

Table 4-5 xPico Wi-Fi Technical Specification

Category

Description

CPU, Memory

Cortex M3 CPU, 1MB Flash, 128KB+4KB SRAM, Additional 1MB on

board Flash

Firmware

Upgradeable via TFTP and serial port

WLAN Standards

802.11 b/g/n Wireless LAN with external antenna

Antenna Connector

U.FL connector for external antenna

Frequency Band

2.400Ghz to 2.484Ghz

Channel Support

Channel 1 to Channel 14

Modulation

DSSS, CCK, OFDM, BPSK, QPSK, 16QAM, 64QAM

Protocols Supported

ARP, UDP/IP, TCP/IP, Telnet, ICMP, SNMP, DHCP, BOOTP, TFTP,

Auto IP, SMTP, and HTTP

Data Rates 802.11b

1, 2, 5.5, 11 Mbps

Data Rates 802.11g

6, 9, 12, 18, 24, 36, 48, 54 Mbps

Date Rates 802.11n

HT20 MCS0 (6.5Mbps) to HT20 MCS7 (65Mbps)

802.11b, CCK Mode

Average Output Power

16.5 +/- 1.5dBm Typical @ 25C

802.11g, OFDM Mode

Average Output Power

15 +/- 1.5dBm, Typical @ 25C, 6Mbps

13 +/- 1.5dBm, Typical @ 25C, 54Mbps

802.11n, OFDM Mode

Average Output Power

14.5 +/- 1.5dBm, Typical @ 25C, MCS0

12 +/- 1.5dBm, Typical @ 25C, MCS7

802.11b

Average Output EVM

IEEE Spec -10dBm

802.11g

Average Output EVM

IEEE Spec, -5dB @ 6Mbps

IEEE Spec, -25dB @ 54Mbps

802.11n

Average Output EVM

IEEE Spec, -5dB @ MCS0

IEEE Spec, -28dB @ MCS7

802.11b, PER <8%

RX Sensitivity @ 1Mbps

-93dBm Typical

-89dBm Min

802.11b, PER <8%

RX Sensitivity @ 11Mbps

-88dBm Typical

-84dBm Min

802.11g, PER <10%

RX Sensitivity @ 6Mbps

-87dBm Typical

-83dBm Min

802.11g, PER <10%

RX Sensitivity @ 54Mbps

-74dBm Typical

-70dBm Min

802.11n, PER <10%

RX Sensitivity @ MCS0

-87dBm Typical

-83dBm Min

802.11n, PER <10%

RX Sensitivity @ MCS7

-71dBm Typical

-67dBm Min

Serial Interface

CMOS (Asynchronous) 3.3V-level signals

Rate is software selectable: 300 bps to 921600 bps

Serial Line Formats

Data bits: 7 or 8 Stop bits: 1 or 2 Parity: odd, even, none

Modem Control

DTR/DCD, CTS, RTS <- Serial 1 only

Flow Control

Serial 1: XON/XOFF (software), CTS/RTS (hardware)

Serial 2: XON/XOFF (software)

Programmable I/O

8 PIO pins (software selectable), sink or source 4mA max.

LEDs

WLAN Status, System Status logic level outputs

4: Specifications

xPico® Embedded Device Server Integration Guide 42

Page 43

4: Specifications

Category

Description

Management

Internal web server, SNMP (read only) Serial login, Telnet login

Security

Password protection, locking features, optional Rijndael 256-bit

encryption

Internal Web Server

Serves static Web pages and Java applets

Storage capacity: TBD Kbytes

Weight

2.5 grams

Material

Metal shell

Temperature

Operating range:

and mating PCB

Warranty

For details on the Lantronix warranty policy, go to our web site at

www.lantronix.com/support/warranty.

Included Software

Windows 98/NT/2000/XP-based DeviceInstaller configuration software

and Windows based Com Port Redirector

EMI Compliance

See A:Compliance.

-40°C to +85°C (-40°F to 185°F) with use of heat pad between module

xPico® Embedded Device Server Integration Guide 43

Page 44

Test Description

Specification

Test Method

Radiated Emissions

EN 55022:2010 Class B

CISPR 22:2008

Radiated Emissions

FCC 15.109(g):2012

CISPR 22:1997 Class B

ANSI C63.4:2009

Conducted Emissions

EN 55022:2010 Class B

CISPR 22:2008

Conducted Emissions

FCC 15.109(g):2012

CISPR 22:1997 Class B

ANSI C63.4:2009

Test Description

Specification

Test Method

Performance

Criteria

ESD

EN 55024:2010

IEC 61000-4-2:2008

2

Radiated Immunity

EN 55024:2010

IEC 61000-4-3:2010

1

EFT

EN 55024:2010

IEC 61000-4-4:2004

(Amended by A1:2010)

1

Surge

EN 55024:2010

IEC 61000-4-5:2005

1

Conducted Immunity

EN 55024:2010

IEC 61000-4-6:2008

1

Magnetic Field Immunity

EN 55024:2010

IEC 61000-4-8:2009

1

Voltage Interruptions

EN 55024:2010

IEC 61000-4-11:2004

3

Voltage Dips

EN 55024:2010

IEC 61000-4-11:2004

1

A: Compliance (xPico Embedded Device Server)

(According to ISO/IEC Guide 22 and EN 45014)

Manufacturer’s Name & Address:

Lantronix, Inc. 7535 Irvine Center Drive, Suite 100, Irvine, CA 92618 USA

Declares that the following product:

Product Name Model: xPico® Embedded Device Server

Conforms to the following standards or other normative documents:

Electromagnetic Emissions/Immunity:

Table A-1 Electromagnetic Emissions

Table A-2 Electromagnetic Immunity

xPico® Embedded Device Server Integration Guide 44

Page 45

Figure A-1 Certificate of Compliance for Halogen Free

Manufacturer’s Contact:

Lantronix, Inc.

7535 Irvine Center Drive

Suite 100

Irvine, CA 92618 USA

Tel: (800) 526-8766

Tel: (949) 453-3990

Fax: (949) 453-3995

xPico® Embedded Device Server Integration Guide 45

Page 46

B: Compliance (xPico Wi-Fi Embedded Device

Server)

xPico Wi-Fi and xPico Wi-Fi SMT compliance information can be found in the

xPico Wi-Fi Embedded Device Server User Guide

https://www.lantronix.com/support/documentation for the latest Lantronix documentation.

. Visit the Lantronix Web site at

xPico® Embedded Device Server Integration Guide 46

Loading...

Loading...