Page 1

Micro125

Embedded Device Server

Integration Guide

Part Number 900-587

Revision C December 2015

Page 2

Copyright and Trademark

Date

Rev.

Comments

March 2011

A

Initial Release

April 2011

B

Updated serial interface information.

C

Updated reset input tolerance information.

© 2015 Lantronix, Inc. All rights reserved. No part of the contents of this publication may

be transmitted or reproduced in any form or by any means without the written permission

of Lantronix. Printed in the United States of America.

Lantronix is a registered trademark of Lantronix, Inc. in the United States and other

countries. DeviceInstaller is a trademark of Lantronix, Inc.

Patented: patents.lantronix.com

Ethernet is a trademark of XEROX Corporation. UNIX is a registered trademark of The

Open Group. Windows is a trademark of Microsoft Corporation.

Contacts

Lantronix Corporate Headquarters

7535 Irvine Center Drive

Suite 100

Irvine, CA 92618, USA

Toll Free: 800-526-8766

Phone: 949-453-3990

Fax: 949-453-3995

Technical Support

Online: www.lantronix.com/support

Sales Offices

For a current list of our domestic and international sales offices go to the Lantronix web

site at www.lantronix.com/about/contact

Disclaimer and Revisions

; Additional patents pending.

.

Operation of this equipment in a residential area is likely to cause interference, in which

case the user, at his or her own expense, will be required to take whatever measures

may be required to correct the interference.

Changes or modifications to this device not explicitly approved by Lantronix will void the

user’s authority to operate this device.

The information in this guide may change without notice. The manufacturer assumes no

responsibility for any errors which may appear in this guide.

December 2015

Micro125 Embedded Device Server Integration Guide 2

Page 3

Contents

Copyright and Trademark ............................................................................................. 2

Contacts ........................................................................................................................ 2

Disclaimer and Revisions .............................................................................................. 2

List of Figures ................................................................................................................ 4

List of Tables ................................................................................................................. 4

1: Introduction 5

Embedded Integration Kits ............................................................................................ 5

About the Integration Guide .......................................................................................... 5

Chapter Summaries ...................................................................................................... 6

Additional Documentation ............................................................................................. 6

2: Description and Specifications 7

The Micro125 ................................................................................................................ 7

Layout and Dimensions ................................................................................................ 8

Connectors .................................................................................................................... 9

Ethernet Interface ........................................................................................................ 10

Status LEDs ................................................................................................................ 11

Product Information Label ........................................................................................... 12

Technical Specifications ............................................................................................. 12

3: Integration Guidelines 14

Power Supply .............................................................................................................. 14

Network Connector ..................................................................................................... 14

Virtual Ground ............................................................................................................. 15

Serial Signals .............................................................................................................. 15

Additional Emission Improvements ............................................................................. 15

4: Test Bed 16

Board Layout ............................................................................................................... 16

Test Bed Connectors .................................................................................................. 17

A: Compliance and Warranty Information 18

Compliance Information .............................................................................................. 18

RoHS Notice ......................................................................................................... 19

Warranty ...................................................................................................................... 19

Micro125 Embedded Device Server Integration Guide 3

Page 4

List of Figures

Figure 2-1 Micro125 Board Layout ............................................................................................................... 8

Figure 2-2 Micro125 Top View ...................................................................................................................... 8

Figure 2-3 Micro125 Connector End View .................................................................................................... 9

Figure 2-4 Micro125 Connectors .................................................................................................................. 9

Figure 2-5 RJ45 Ethernet Connector .......................................................................................................... 10

Figure 2-6 Micro125 Status LEDs ............................................................................................................... 11

Figure 2-7 Product Label ............................................................................................................................. 12

Figure 3-1 Multi-Layer Board Strategy ........................................................................................................ 15

Figure 4-1 Carrier Board ............................................................................................................................. 16

Figure 4-2 Pin Configurations ..................................................................................................................... 17

List of Tables

Table 1-1 Micro125 Part Num ber s ................................................................................................................ 5

Table 2-1 Micro125 Connector Pinouts ...................................................................................................... 10

Table 2-2 Micro125 Status LEDs ................................................................................................................ 11

Table 2-3 Micro125 Technical Specifications ............................................................................................. 12

Table 4-1 Micro125 Test Bed Connectors .................................................................................................. 17

Micro125 Embedded Device Server Integration Guide 4

Page 5

Part Number

Description

MO00AA003-01R

Micro125, No RJ45 connector, No LEDS, with TTL pin header, RoHS

MO00AA0E3-01R

AES Encrypted Micro125, No RJ45 connector, No LEDS, with TTL pin

header, RoHS

MO11AA003-01R

Micro125 with RJ45 connec tor, LEDS, with TTL pin header, RoHS

MO11AA0E3-01R

AES Encrypted Micro125 with RJ45 connector, LEDS, with TTL pin

header, RoHS

MO22AA003-01R

Micro125, Pin header for Ethernet, Pin header for LED connection,

with TTL pin header, RoHS

MO22AA0E3-01R

AES Encrypted Micro125, Pin header for Ethernet, Pin header for LED

connection, with TTL pin header, RoHS

1: Introduction

Embedded Integration Kits

The Embedded Integration Kit provides a simple method of evaluating our Micro125

embedded device server. This product allows software engineers to test our device

servers with their products prior to the hardware development of those products.

Each kit contains an embedded device server, board carrier unit, and all the connectors

needed to interface our product with your serial device.

The Embedded Integration Kits include the following:

An embedded device server: Micro125

Board carrier unit with serial (DB9) interface. (Some carriers also have RJ45

Ethernet)

Power supply

CAT5 Ethernet cable, RJ45M/M, 10-foot

10-foot serial cable, DB9 (cable end depends on kit)

DB9 to DB-25 converter

About the Integration Guide

This guide provides the information needed to install and test the Micro125 embedded

device server on the Evaluation Board. The intended audience is the engineer

responsible for integrating the device server into your product.

This document covers the following Micro125 Device Server part numbers:

Table 1-1 Micro125 Part Numbers

Micro125 Embedded Device Server Integration Guide 5

Page 6

Chapter Summaries

Chapter

Description

2: Description and

Specifications

Describes and provides information about the Micro125

device server.

3: Integration Guidelines

Provides general guidelines to help you integrate the

Micro125 board into your design.

4: Test Bed

Describes the board layout and connectors of the test bed.

A: Compliance and Warranty

Information

Describes the compliance and warranty information.

Document

Description

Micro125 User Guide

Provides information needed to configure, use, and update

the Micro125 firmware.

Device Installer User

Guide

Provides instructions on using the Windows-based uti lity

used to configure Lantronix embedded device servers.

Com Port Redirector

User Guide

Provides information on using the Window s-ba sed uti lity to

create a virtual com port.

The remaining chapters in this guide include:

Additional Docume ntation

1: Introduction

Visit the Lantronix website at www.lantronix.com/support/documentation for the latest

documentation and the following additional documentation.

Micro125 Embedded Device Server Integration Guide 6

Page 7

2: Description and Specifications

The Micro125 embedded device server provides an integrated solution to add proven

Ethernet connectivity to an existing design quickly and economically, and with a high

level of flexibility.

The Micro125

The Micro125 contains Lantronix’s own DSTni controller, with 256 Kbytes of SRAM,

16 Kbytes of boot ROM, and an integrated 10/1 00 PH Y.

The Micro125 also contains the following:

RJ45 (10/100Base-T) ethernet network interface

TTL level (asynchronous) serial interface

Two serial ports

Accepts 5 VDC regulated Input power

Flash ROM for easy software upgrades

Serial channel status, Ethernet link status, and diagnostic LEDs

The Micro125 requires 5 VDC ±5% at ~ 210mA power and is designed to operate in an

extended temperature range (see Technical Specifications on page Error! Bookmark

not defined.).

Micro125 Embedded Device Server Integration Guide 7

Page 8

Layout and Dimensi ons

The Micro125 integrates into products quickly and easily. Serial interfacing is

accomplished via a TTL connector, and for Ethernet access, an optional RJ45

(10/100Base-T) connector is available. The orientation of its interface pins can be

specified to fit your product. It requires 5 volts DC of regulated power with maximum

current of 210mA.

2: Description and Specifications

Figure 2-1 Micro125 Board Layout

The following drawing is a top view of the Micro125.

Figure 2-2 Micro125 Top View

Micro125 Embedded Device Server Integration Guide 8

Page 9

The following drawing shows the connector end view of the board with the LEDs and

CON1

(TTL)

111

212

CON2

(RJ45)

CON3

12

34

12

78

S1

CON4

(LEDs)

RJ45 connector installed. The drawing on the right shows the dimensions for CON1 (DIL

2 x 6).

Connectors

2: Description and Specifications

Figure 2-3 Micro125 Connector End View

The Micro125 has four connectors: a TTL serial port (CON1), a 10/100Base-T RJ45

Connector (CON2), and/or pins instead of the RJ45 connector (CON3) and LEDs

(CON4).

Figure 2-4 Micro125 Connectors

The Micro125 that comes with the integration kit is factory configured. When ordering the

Micro125 for production use, each connector can be specified as follows:

Pins on/off the board and top/bottom (Figure 2-2 and Figure 2-3)

LEDs on/off the board

RJ45 on/off the board

Contact Lantronix for information about ordering the Micro125 with customized connector

configurations.

The Embedded Integration Kit (part number Micro-Kit) includes the Micro125 embedded

Micro125 Embedded Device Server Integration Guide 9

device server. Refer to the following table for a listing of its pinouts.

Page 10

2: Description and Specifications

CON1

(DIL 2 x 6 Pins)

CON2

(RJ45) Connector

CON3 (2 x 2 Pins

CON4 (2 x 4 Pins in place

Pin

Signal

Pin

Signal

Pin

Signal

Pin

Signal

1

+5VDC

1

Tx+ 1 Tx+ 1 +3.3 VDC

2

GND

2

Tx- 2 Tx- 2 +3.3 VDC

3

RxA (input)

3

Rx+ 3 Rx+ 3 LED3

(Diagnostics)1

4

TxA (output)

4

None 2

5)

4

Rx- 4 LED1 (Channel 1) 1

5

RTSA (output)

5

None (tied

to Pin 4)

5

+3.3 VDC

6

DTRA (output)

6

Rx-

6

+3.3 VDC

7

CTSA (input)

7

None (tied

to Pin 8)

7

LED2 (Channel 2) 1

8

DCDA (input)

8

None (tied

to Pin 7)

8

LED4 (Link) 1

9

Reserved

10

RESET (pull

tolerant.

11

RxB (input)

12

TxB (output)

1

Current limiting resistor on board is 220 Ohms.

A = Port (Channel) 1 B = Port (Channel) 2

1 8

1 - TX+

2 - TX3 - RX+

6 - RX-

Table 2-1 Micro125 Connector Pinouts

TTL Serial Port

low to reset)

Note: the reset

input is 3.3V

10/100Base-T

(tied to Pin

in place of RJ45)

of LEDs)

2

150 Ohms exist between the Pin 4/5 node and the Pin 7/8 node.

Ethernet Interf ace

The standard Micro125 ships with an RJ45 10/100Base-T Ethernet connector (CON2). At

the time of ordering, you can specify whether to include this RJ45 connector. You can

use CON3 as an alternative.

Figure 2-5 RJ45 Ethernet Connector

Micro125 Embedded Device Server Integration Guide 10

Page 11

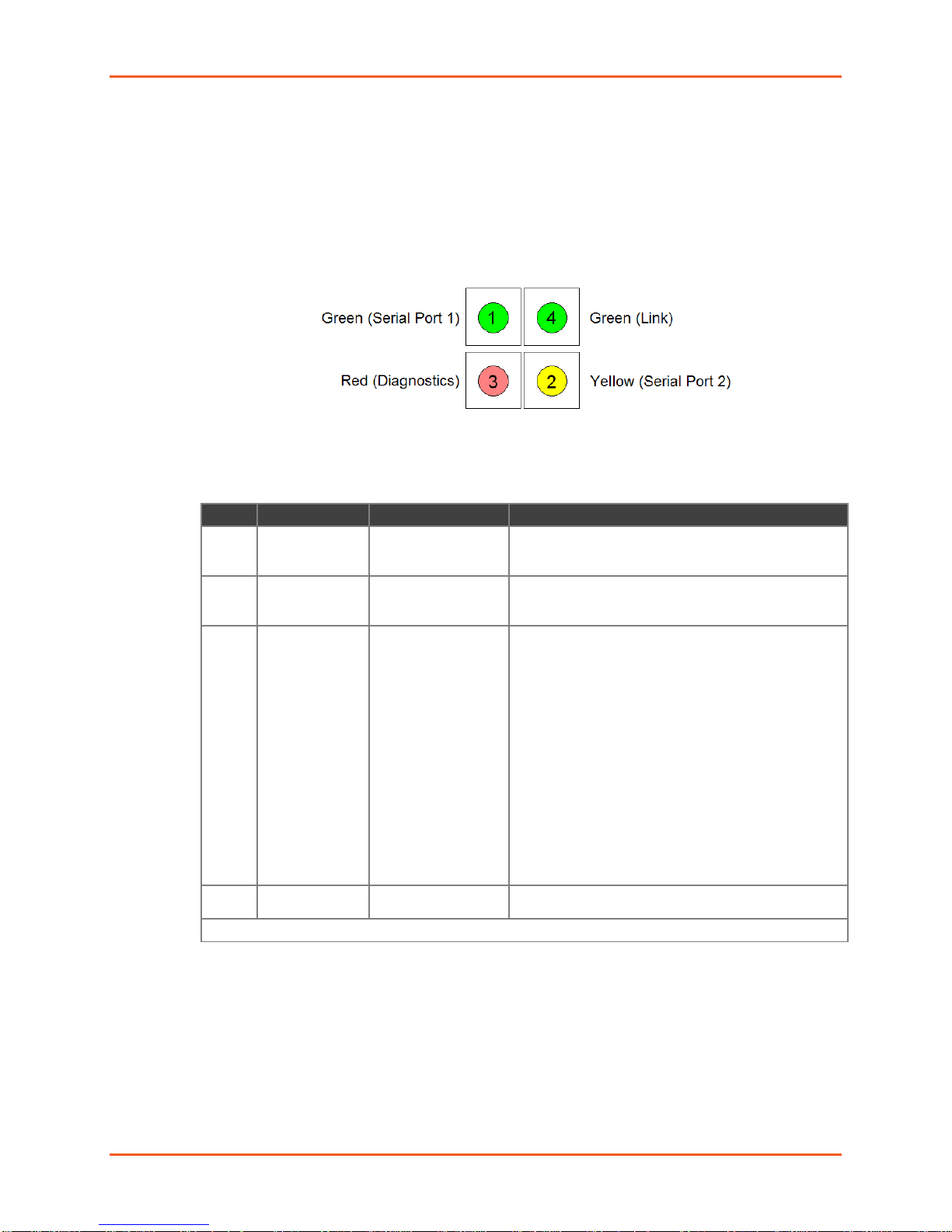

Status LEDs

LED

Description

Location

LED Functions

1

SerialPort

Status

CON 4, Pin 4

Lights solid green to indicate Channel 1 is idle.

the network and active.

2

SerialPort

Status

CON 4, Pin 7

Lights solid yellow to indicate Channel 2 is idle.

the network and active.

3

Diagnostics

CON 4, Pin 3

Blinks or lights solid red in combination with the

4

Network Link

Status

CON 4, Pin 8

Lights solid green to indicate network port is

connected to the network.

*non-fatal error

The Micro125 carrier board has four status LEDs: serial port (Channel) 1 status, serial

port (Channel) 2 status, diagnostics, and network link status. See the following table for a

complete description of LED functions and pinout locations.

2: Description and Specifications

Figure 2-6 Micro125 Status LEDs

Table 2-2 Micro125 Status LEDs

(Channel) 1

(Channel) 2

Blinks green to indicate Channel 1 is connected to

Blinks yellow to indicate Channel 2 is connected to

green (Channel 1) LED to indicate diagnostics and

error detection.

Red solid, green (Channel 1) blinking:

1x: EPROM checksum error

2x: RAM error

3x: Network controller error

4x: EEPROM checksum error

5x: Duplicated IP address on the network*

6x: Software does not match hardware*

Red blinking, green (Channel 1) blinking:

4x: Faulty network connection*

5x: No DHCP response received*

Micro125 Embedded Device Server Integration Guide 11

Page 12

Product Informa ti on Label

Category

Description

CPU, Memory

Lantronix DSTni-EX 186 CPU, 256-Kbyte zero wait state SRAM, 512-Kbyte flash,

16-Kbyte boot ROM

Firmware

Upgradeable via TFTP and serial port

Serial Interface

2 TTL serial interfaces (Asynchronous).

Note: the reset input is 3.3V tolerant.

Serial Line Formats

Data bits: 7 or 8

Parity: odd, even, none

Board Dimensions

Height: 1.575in (40.00 mm)

Width: 1.935in (49.15 mm) (See Drawing)

Weight

0.7 ounces

Modem Control

DTR, RTS, CTS, DCD

Flow Control

XON/XOFF (software), CTS/RTS (hardware), None

Network Interface

RJ45 (10/100Base-T) Ethernet

Compatibility

Ethernet: Version 2.0/IEEE 802.3

Power Requirements

5VDC (±5%) regulated @ 210mA

Protocols Supported

ARP, UDP/IP, TCP/IP, Telnet, ICMP, SNMP, DHCP, BOOTP, TFTP, Auto IP, and

HTTP

LEDs

Channel 1 (solid Green = idle, blink = active)

Network Link (Green)

Management

Internal web server, SNMP (read only)

Serial login, Telnet login

Security

Password protection, opti onal Rijndael 256-bit encryption

Internal Web Server

Serves static Web pages and Java applets

Storage capacity: 384 Kbytes

Temperature

Standard Temperature Operating Range: 0° to 70°C (32° to 158°F)

Revision Number

MAC Address

Part Number

Manufacturing Date

The product information label contains important information about your specific unit,

such as its product number, revision number, manufacturing date and mac address.

2: Description and Specifications

Figure 2-7 Product Label

Technical Specifications

5V-level input signals. 3.3 V-level out put sig nal s. Through-hole plated pins, DIL.

Stop bits: 1 or 2

Table 2-3 Micro125 Technical Specifications

Channel 2 (solid Yellow = idle, blink = active)

Diagnostics (Red, in combination with Channel 1)

Micro125 Embedded Device Server Integration Guide 12

Page 13

2: Description and Specifications

Category

Description

Storage Temperature Range: -40° to 85°C (-40° to 185°F)

Emissions

FCC Part 15 Subpart B

EN 61000-6-3: 2001

Immunity

EN 55024: 1998 +A1: 2001 +A2: 2003

EN 61000-6-2: 2001

Compliance

Industry Canada ICES-003 Issue 4 February 2004

CISPR 22: 2005 Information Technology Equipment

VCCI V-3/2010.04

AS/NZS CISPR 22: 2009

EN 55022: 2006 + A1:2007

EN 61000-3-2: 2006

EN 61000-3-3: 2008

EN 61000-4-2: 1995 + A2: 2001

EN 61000-4-3: 2006 + A1: 2008

EN 61000-4-4: 2004

EN 61000-4-5: 2006

EN 61000-4-6: 2007

EN 61000-4-8: 1994 + A1: 2001

EN 61000-4-11: 2004

Micro125 Embedded Device Server Integration Guide 13

Page 14

3: Integration Guidelines

This chapter provides general guidelines to integrate the Micro125 board into your

design, and help you reach the necessary standards for your applications.

Power Supply

The Micro125 runs at 5 VDC nominal, ±5%. The current consumption varies for the

different products and depends upon their operating conditions. Refer to the current

requirements listed in the product specification to design an appropriate power supply.

To maintain the necessary voltage, provide ground to the appropriate connector header

with a low inductance and low DC resistance path. The best solution is a solid ground

plane.

Place a de-coupling capacitor pair as close as possible to the connector headers of the

board’s power supply. We recommend a ceramic (X7R material or equivalent, value

μF to 0.1 μF) and a low DC resistance (electrolytic or tantalum value

0.022

μF to 100 μF) capacitor.

10

Network Connector

If you use the on-board RJ45 connector, we suggest that you provide ground level to the

plated mounting hole near the RJ45. That shielded cable will be tied to the appropriate

level, however the virtual ground is also provided there.

If you want to add an RJ45 connector, we recommend that it be at least partially shielded

in case it will be used in a noisy environment. (Please refer to the product-specific

section.)

Take care regarding the trace length and routing for the two differential pairs, TX and RX.

Neither of them may cross or run in parallel with any digital signal nor run through a

digital ground or power plane. The trace length inside of the unit running from the device

server to the RJ45 should be as short as possible. The trace length may have an impact

on signal quality (link length), especially if internal ambient noise is a factor.

If trace length cannot be shortened, or the internal noise frequencies are hitting the

carrier frequency or the multiples of these (depending on the product and operating mode

either 10MHz or 100MHz and up to the 11th overtone), we suggest a different strategy.

Use a multi-layer board and a separated shield layer on the solder and assembly sides of

the board, which are routed in the inner layers. (Refer to the following figure.) These

shield layers can either be connected to the RJ45s shield or to a virtual ground signal

provided by the device server.

Micro125 Embedded Device Server Integration Guide 14

Page 15

3: Integration Guidelines

Figure 3-1 Multi-Layer Board Strategy

Virtual Ground

The device server provides a virtual ground at a (plated) mounting hole. It is a ground

imitation. It uses the tap of two capacitors (ceramic 0.1 μF) conducted symmetrically to

ground and VCC. In the absence of a solid ground (earth), this virtual ground can be

used for shielding or balancing metal parts of the case.

Serial Signals

Device server TTL-level serial input and output signals are protected by 220-Ohm

resistors. These resistors provide a simple output shortage protection for infinite duration

(by limiting the current). They also reduce conducted interferences at higher frequencies

to the base board.

Additional Emission Improvements

Depending on the voltage regulator used and bas e bo ar d design, the pow er supp l y cord

may sometimes emit conducted interferences. If the voltage level there is low, common

mode chokes are the appropriate barrier to avoid these frequencies being emitted via the

power cord as an antenna.

Common mode chokes help pass the conducted emission requirements of the EN55022

for frequencies below 30 MHz. Metal cases or partial metal shielding inside the unit can

also help to reduce emission levels so that even more stringent standards can be

passed.

Micro125 Embedded Device Server Integration Guide 15

Page 16

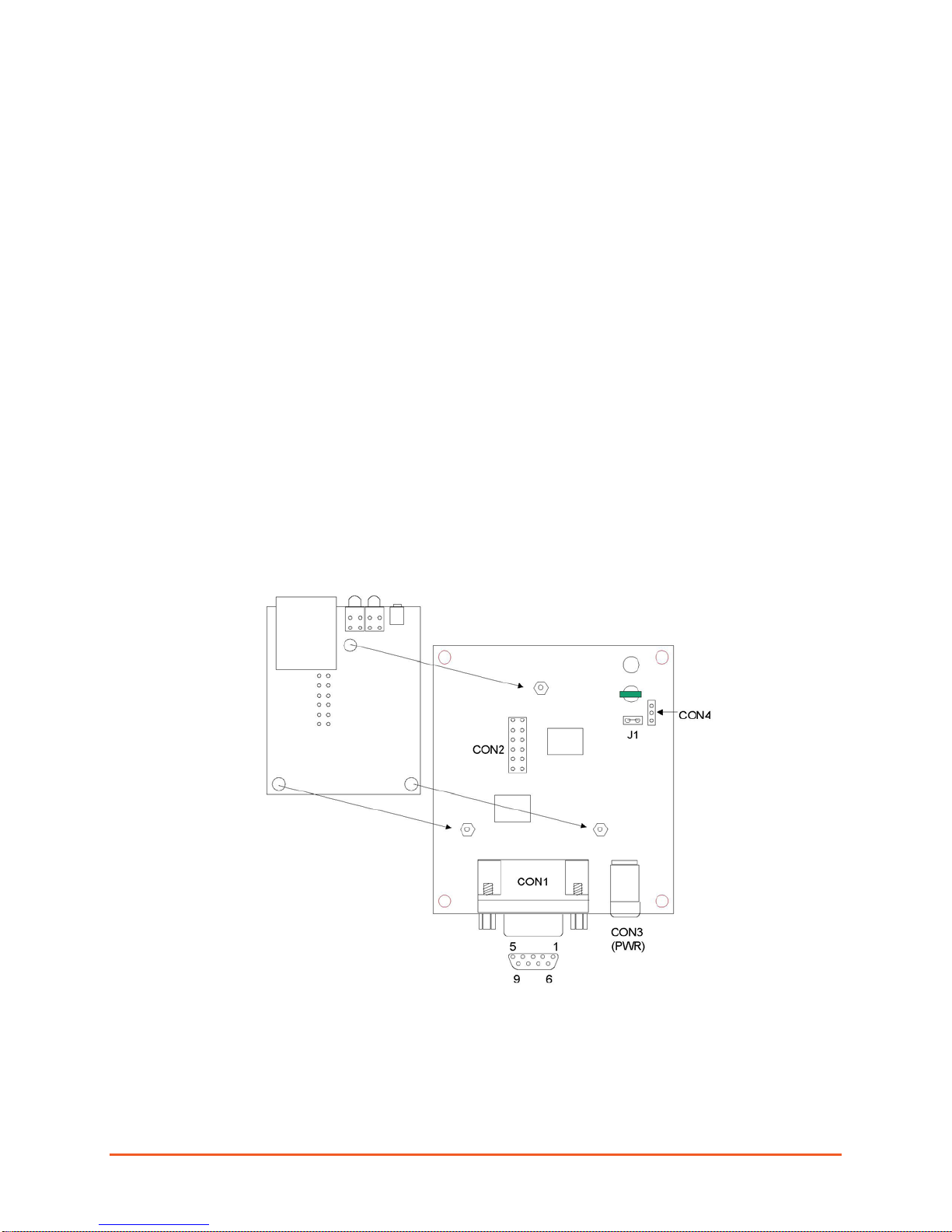

4: Test Bed

The Micro125 Embedded Integration Kit includes a test bed (carrier board) that provides

serial connections to the device server. The Micro125 device server provides a network

10/100Base-T RJ45. The test bed contains a power LED, TTL to RS-232 and RS-232 to

TTL conversion hardware, a 3-pin connector for the second serial port, and mounting

hardware for the Micro125.

The test bed allows software engineers to immediately begin developing and testing

software applications for the device server, rather than delaying the process until the

hardware interface for their product is complete.

Board Layout

Install the Micro125 onto the carrier board as shown below.

Figure 4-1 Carrier Board

Micro125 Embedded Device Server Integration Guide 16

Page 17

Test Bed Connectors

CON1 Serial Port

(Channel) 1a

CON2 TTL Interface

CON4 Serial Port

(Channel) 2b

Pin

Signal

Pin

Signal

Pin

Signal

1

DTRA (output)

1

+5 VDC

1

TxB (output)

2

TxA (output)

2

GND

2

RxB (input)

3

RxA (input)

3

TxA (output)

3

GND

4

DCDA (input)

4

RxA (input)

5

GND

5

CTSA (input)

6

None

6

DCDA (input)

7

CTSA (input)

7

RTSA (output)

8

RTSA (output)

8

DTRA (output)

9

None

9

None

10

None

11

TxB (output)

12

RxB (input)

a. CON1 Serial Port (Channel) 1 is also designated as A.

b. CON4 Serial Port (Channel) 2 is also designated as B.

A: Compliance and Warranty Information

Figure 4-2 Pin Configurations

The Micro125 test bed has four connectors: CON1 (Serial Port 1 or Channel 1), CON2

(TTL Interface), CON4 (Serial Port 2 or Channel 2), and CON3, which is a 5VDC power

supply connector.

This RS-232 level serial interface is implemented with a DB9F connector. The Micro125

converts the RS-232 serial transmit and receive data of this interface to Ethernet protocol

transmit and receive data. The DB9 connector was selected for compatibility with most

PC serial interface ports using a straight through cable.

Table 4-1 Micro125 Test Bed Connectors

Micro125 Embedded Device Server Integration Guide 17

Page 18

A: Compliance and Warranty Information

Compliance Inf ormation

(According to ISO/IEC Guide 22 and EN 45014)

Manufacturer’s Name & Address

Lantronix 167 Technology Drive, Irvine, CA 92618 USA

Declares that the following product:

Product Name Model: Micro125 Embedded Device Server

Conforms to the following standards or other normative documents:

Emissions

FCC Part 15 Subpart B, Class B

Industry Canada ICES-003 Issue 4 February 2004

CISPR 22: 2005 Information Technolog y Equipment

VCCI V-3/2010.04

AS/NZS CISPR 22: 2009

EN 55022: 2006 + A1:2007

EN 61000-3-2: 2006

EN 61000-3-3: 2008

EN 61000-6-3: 2001

Immunity

EN 55024: 1998 +A1: 2001 +A2: 2003

EN 61000-4-2: 1995 + A2: 2001

EN 61000-4-3: 2006 + A1: 2008

EN 61000-4-4: 2004

EN 61000-4-5: 2006

EN 61000-4-6: 2007

EN 61000-4-8: 1994 + A1: 2001

EN 61000-4-11: 2004

EN 61000-6-2: 2001

Micro125 Embedded Device Server Integration Guide 18

Page 19

A: Compliance and Warranty Information

• Lead (Pb)

• Mercury (Hg)

• Polybrominated biphenyls (PBB)

• Cadmium (Cd)

• Hexavalent Chromium (Cr (VI))

• Polybrominated dip he n yl eth ers (PB D E )

Product Family Name

Toxic or hazardous Substances and Elements

Lead

Mercury

Cadmium

Hexavalent

(Cr (VI))

Polybrominated

Polybrominated diphenyl

UDS1100 and 2100

0 0 0 0 0

0

EDS 0 0 0 0 0 0

MSS100 0 0 0 0 0 0

IntelliBox 0 0 0 0 0 0

XPress DR & XPress-DR+

0 0 0 0 0

0

SecureBox 1101 & 2101

0 0 0 0 0

0

WiBox 0 0 0 0 0 0

UBox 0 0 0 0 0 0

MatchPort 0 0 0 0 0 0

SLC 0 0 0 0 0 0

XPort 0 0 0 0 0 0

WiPort 0 0 0 0 0 0

SLB 0 0 0 0 0 0

SLP 0 0 0 0 0 0

SCS 0 0 0 0 0 0

SLS 0 0 0 0 0 0

DSC 0 0 0 0 0 0

PremierWave

0 0 0 0 0

0

Micro125 0 0 0 0 0 0

RoHS Notice

All Lantronix products in the following families are China RoHS-compliant and free of the following hazardous substances and

elements:

(Pb)

O: toxic or hazardous substance contained in all of the homogeneous materials for this part is below the limit requirement in SJ/T11363-2006.

X: toxic or hazardous substance contained in at least one of the homogeneous materials used for this part is above the limit requirement in SJ/T11363-2006.

(Hg)

(Cd)

Chromium

biphenyls (PBB)

ethers (PBDE)

Manufacturer’s Contact

Lantronix

7535 Irvine Center Drive

Suite 100

Irvine, CA 92618, USA

Toll Free: 800-526-8766

Phone: 949-453-3990

Fax: 949-453-3995

Warranty

For details on the Lantronix warranty replacement policy, please go to our Web site at

www.lantronix.com/support/warranty

Micro125 Embedded Device Server Integration Guide 19

.

Loading...

Loading...