Lang Manufacturing USN-50 Parts List

TM...................................

TECHNICAL MANUAL

MODEL DESCRIPTION

USN-50 Fryer, Deep-Fat, Electric w/Solid State Controls

440 Volt, 60 HZ, 3 Phase

NSN: _________________________

Commercial & Marine Cooking Equipment

Gas & Electric

Last Updated September 14, 2006

Installation

Operation

Maintenance

USN-50 FRYER

TABLE OF CONTENTS

TABLE OF CONTENTS............................................................................................................................1

WARNINGS................................................................................................................................................2

SPECIFICATIONS..................................................................................................................................... 3

INSTALLATION INSTRUCTIONS......................................................................................................... 4

DATAPLATE...............................................................................................................................................4

ELECTRICAL

Safety Circuit Connections........................................................................................................................4

Phasing And Ground Connection .............................................................................................................4

OPERATING INSTRUCTIONS...............................................................................................................5

LEVELS .............................................................................................................................................. 5

FILL

CONTROLS ................................................................................................................................................. 5

LIMITING

HEATING

DRAINING

MAINTENANCE INSTRUCTIONS......................................................................................................... 8

CLEANING..................................................................................................................................................8

TEMPERATURE

OVER-TEMPERATURE

COMPONENT

TECHNICAL

CALIBRATION ...........................................................................................................................................9

A. Checking Temperature....................................................................................................................... 10

B. Accessing Temperature Control Components....................................................................................10

C. Checking Probe ................................................................................................................................. 11

D. Checking Selector Switch..................................................................................................................12

E. Calibration of Temp Control Board .................................................................................................. 12

SERVICE ENTRANCE....................................................................................................... 4

CONTROLS ..............................................................................................................................6

ELEMENTS...............................................................................................................................7

THE FRYER OIL.....................................................................................................................7

CONTROL......................................................................................................................8

PROTECTION.................................................................................................... 8

ACCESS..............................................................................................................................9

SUPPORT.............................................................................................................................. 9

WIRING DIAGRAM................................................................................................................................ 13

PARTS LIST ............................................................................................................................................. 14

WARRANTY.............................................................................................................................................15

LANG MANUFACTURING

6500 Merrill Creek Parkway

Everett, WA 98203

FOR PARTS AND TECHNICAL SUPPORT CALL:

Toll Free: PH 800-224-5264

Direct Line: PH: 425-349-2400

Fax Number: PH: 866-723-0214

1

WARNINGS

IMPORTANT READ FIRST IMPORTANT

DANGER: 1.) THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL

PROVIDED. FAILURE TO GROUND THE APPLIANCE COULD

RESULT IN ELECTROCUTION AND DEATH.

WARNING: 1.) INSTALLATION OF THIS LANG FRYER MUST BE DONE BY

PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY.

IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL

AND/OR DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE

INSTALLED IN ACCORDANCE WITH ALL APPLICABLE CODES.

2.) ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

3.) BEFORE PERFORMING ANY WORK ON INTERNAL COMPONENTS,

DISCONNECT THE APPLIANCE FROM THE ELECTRIC POWER

SUPPLY.

4.) KEEP WATER AND SOLUTIONS OUT OF CONTROL AND

ELECTRICAL EQUIPMENT. NEVER SPRAY WATER ON THE

APPLIANCE WHICH MAY PERMIT LIQUID TO GET INTO THE

CONTROL AND ELECTRICAL EQUIPMENT AREAS.

CAUTION: 1.) KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR

FALLS.

2.) MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO

WEAR RUBBER CLOVES, GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE WARNING AND

FOLLOW THE DIRECTIONS ON THE LABEL OF THE CLEANER TO BE

USED.

3.) USE OF ANY REPLACEMENT PARTS OR OTHER THAN THOSE SUPPLIED

BY LANG OR THEIR AUTHORIZED DISTRIBUTOR CAN CAUSE BODILY

INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

NOTICE: 1.) NEVER LEAVE A CHLORINE SANITIZER IN CONTACT WITH STAINLESS

STEEL SURFACES LONGER THAN 10 MINUTES. LONGER CONTACT CAN

CAUSE CORROSION.

IMPORTANT: 1.) SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED

PERSONNEL WILL VOID ALL WARRANTIES.

2

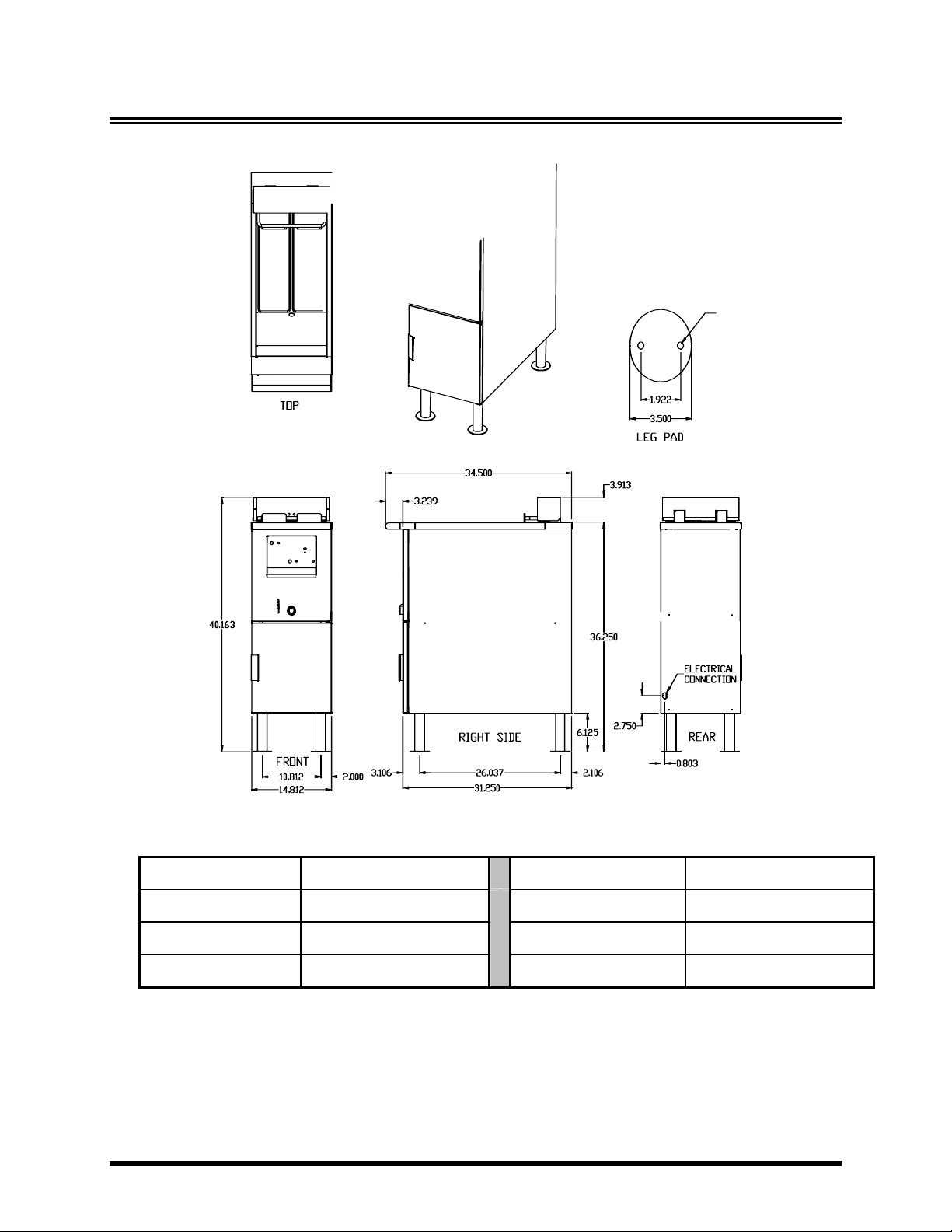

SPECIFICATIONS

POWER:

VOLTAGE

AMPS (1 PHASE)

AMPS (3 PHASE)

22 kW

440 VAC

50 Amps

43.3; 25; 25

Capacity

EIGHT

W

Ship Weight

Ship Dimensions

3

50 Lb. Oil

138 lb.

170 lb.

41” X 36” X 18”

INSTALLATION INSTRUCTIONS

DATAPLATE

Check the data plate located on the back of the machine for fryer electrical rating. Check power

source to insure that it is the correct voltage and current rating.

ELECTRICAL SERVICE ENTRANCE

Electrical service may be made through a standard 1¼ inch conduit. A hole is provided through

the rear panel. A knockout is also provided in the bottom rear of the fryer, so that power may be

brought in from below the unit. Plug the hole on the rear panel when using bottom power entry.

Check the National Electrical Code for fuse for circuit breaker requirements.

SAFETY CIRCUIT CONNECTIONS

Fire Control Shutoff

A four pole terminal block is provided behind the rear access cover for connection to an external

fire control system if required. A jumper is provided across two of these terminals when the

fryer leaves the factory. The jumper on this terminal block is in series with the power switch

circuit. If connection to a fire control system is required, remove this jumper and supply a relay

contact closure to maintain this closed circuit. If the fire control system does not have this type

output, a separate relay must be provided to interface the system. DO NOT APPLY

VOLTAGE TO THIS CONNECTION.

Shunt Trip Circuit

Two terminals are provided on the four pole terminal block for a shunt trip circuit. Connect your

115 volt shunt trip circuit to these terminals.

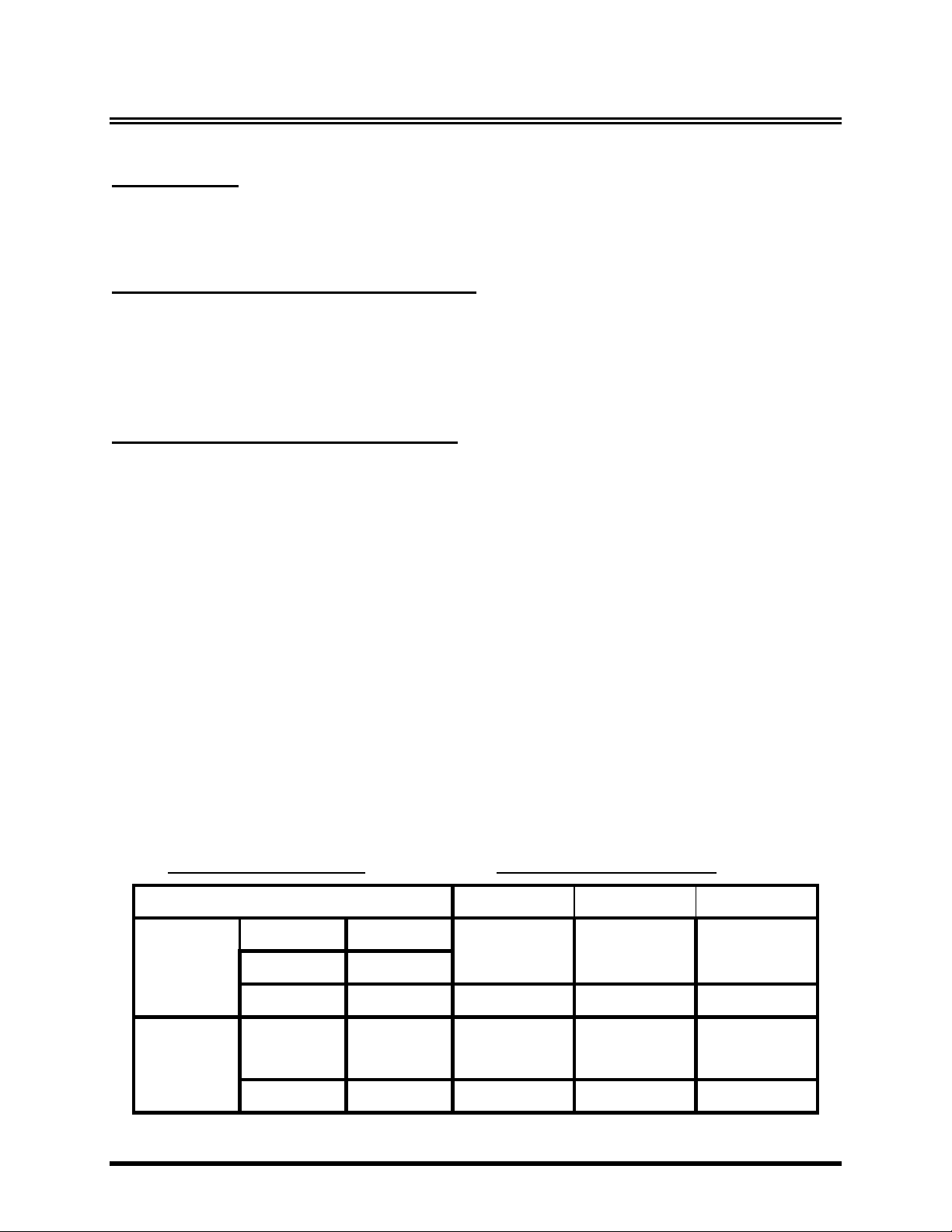

Phasing And Ground Connection

Connect a ground lead to the green ground lug provided in the rear compartment.

These fryers may be connected to either single or three phase power as indicated in the table

below:

SERVICE CONNECTION AMPS PER LINE @ 440VAC

THREE L1

PHASE L2

L3

SINGLE L1

PHASE L2

1 & 4

2 & A 43.3 25 25

3 & B

1, 3, A 50 50

2, 4, B

L1 L2 L3

4

Loading...

Loading...