Lang Manufacturing LRP Service Manual

Installation, Operation, & Maintenance

Model: LRP,

Electric Lang Proofer Series

Lang Manufacturing Company 6500 Merrill Creek Parkway Everett, WA 98203

Part # 60806-09 Phone: 425-349-2400 Fax: 425-349-2733

Rev. New WWW.LANGWORLD.COM © Copyright 2002

THE INFORMATION IN THIS MANUAL IS CRUCIAL AND MUST BE RETAINED FOR

FUTURE REFERENCE. READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

DANGER

WARNING

CAUTION

NOTICE

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH.

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY.

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY.

Helpful operation and installation instructions and tips are

present.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

Model #: Purchased From:

Serial #:

Location:

Date Purchased:

Purchase Order #:

ETL File E8138 Rev. A 2001

Date Installed:

For Service, Call:

2

TABLE OF CONTENTS

CHAPTER PAGE

TABLE OF CONTENTS ...................................................................................... 3

READ FIRST ........................................................................................................ 4

SAFETY PROCEEDURES................................................................................... 6

EQUIPMENT DESCRIPTION ............................................................................. 7

GENERAL DESCRIPTION.................................................................................. 8

GENERAL OPERATION..................................................................................... 9

GENERAL MAINTENANCE .............................................................................. 10

ASSEMBLY.......................................................................................................... 11

INSTALLATION.................................................................................................. 27

WIRING DIAGRAMS.......................................................................................... 28

PARTS LIST ......................................................................................................... 30

WARRANTY........................................................................................................ 33

IMPORTANT READ FIRST IMPORTANT

WARNING

WARNING

WARNING

MOVING PARTS HAZARD. FOLLOW LOCKOUT PROCEDURES BEFORE

REMOVING AIR DUCT OR EVAPORATOR FAN GUARDS

ELECTRICAL HAZARD BEHIND UPPER FRONT TRIM. FOLLOW LOCKOUT

PROCEDURES BEFORE SERVICING.

THE LANG LRP SERIES PROOFER PRODUCES HUMIDITY WHICH WILL

NATURALLY CONDENSE AND ACCUMULATE WATER ON THE INTERIOR

FLOOR CAUSING IT TO BECOME SLIPPERY. ADJACENT EXTERIOR

FLOOR MAY ALSO BECOME SLIPPERY. USE EXTREME CAUTION WHEN

WALKING IN OR AROUND THIS APPLIANCE.

DANGER

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

WARNING

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

For best results- Always allow your proofer to reach set temperature and

humidity before putting product in.

For best results- Proof at lower temperatures rather than higher.

To dry proof: Set humidity to the lowest setting (either 45% or less). At

this setting the humidity generator is turned off and will not produce

humidity.

When the actual humidity is less than 46% display will show 45. When the

actual humidity is higher than 45%, display will show the actual humidity.

Service on this or any other LANG equipment must be performed by

qualified personnel only. Consult your authorized service agency

directory or call the factory at 1-800-224-LANG (5264), or

WWW.LANGWORLD.COM for the service agency nearest you

For units needing more than one piece of trim to span one side, join the

two pieces by overlapping with the ceiling trim cap.

TO REDUCE THE RISK OF FIRE, THE APPLIANCE IS TO BE MOUNTED ON

FLOORS OF NON-COMBUSTIBLE CONSTRUCTION WITH NONCOMBUSTIBLE FLOORING AND SURFACE FINISH AND WITH NO

COMBUSTIBLE MATERIAL AGAINST THE UNDERSIDE THEREOF, OR ON

NON-COMBUSTIBLE SLABS OR ARCHES HAVING NO COMBUSTIBLE

MATERIAL AGAINST THE UNDERSIDE THEREOF. SUCH CONSTRUCTION

SHALL IN ALL CASES EXTEND NOT LESS THAN 12 INCHES BEYOND THE

EQUIPMENT ON ALL SIDES.

CAUTION

CAUTION

ETL File E8138 Rev. A 2001

THIS APPLIANCE, WHEN INSTALLED, MUST BE ELECTRICALLY

GROUNDED IN ACCORDANCE WITH LOCAL CODES, OR IN THE

ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL CODE,

ANSI/NFPA 70-1996.

FOR INSTALLATION IN CANADA THE INSTALLATION MUST BE IN

ACCORDANCE WITH CAN/CGA-B149.1&2 OF THE INSTALLATION CODE,

AND LOCAL CODES WHERE APPLICABLE. ALL ELECTRIC WIRING MUST

BE IN ACCORDANCE WITH THE CURRENT CANADIAN ELECTRICAL

CODE, C22.1 PART 1. GROUNDING THIS APPLIANCE MUST CONFORM

TO CANADIAN ELECTRICAL CODE, CSA C22.2.

4

IMPORTANT READ FIRST IMPORTANT

WARNING

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED

TO WORK WITH ELECTRICITY AND PLUMBING IMPROPER

INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND /OR DAMAGE

TO EQUIMENT. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICAL CODES

ETL File E8138 Rev. A 2001

5

SAFETY PROCEEDURES

WARNING

WARNING

WARNING

MOVING PARTS HAZARD. FOLLOW LOCKOUT PROCEDURES BEFORE

REMOVING AIR DUCT OR EVAPORATOR FAN GUARDS

ELECTRICAL HAZARD BEHIND UPPER FRONT TRIM. FOLLOW LOCKOUT

PROCEDURES BEFORE SERVICING.

THE LANG LRP SERIES PROOFER PRODUCES HUMIDITY WHICH WILL

NATURALLY CONDENSE AND ACCUMULATE WATER ON THE INTERIOR

FLOOR CAUSING IT TO BECOME SLIPPERY. ADJACENT EXTERIOR

FLOOR MAY ALSO BECOME SLIPPERY. USE EXTREME CAUTION WHEN

WALKING IN OR AROUND THIS APPLIANCE.

Lockout Procedure

1. Announce lockout to other personnel.

2. Turn both heat and control power off at main panel.

3. Clear unit of all personnel.

4. Test lockout by turning power switch on and observing if control panel displays or fan(s) come on.

Check heater circuit with voltmeter.

5. Perform necessary repairs or tests.

6. Clear unit of personnel before restarting.

7. Turn power on at main panel.

8. Announce unit is “on” to other personnel.

Safety Precautions

The Manufacturer, Lang Manufacturing, hereby disclaims any and all responsibility for injury, damage,

loss or other claim that may occur to person or property from improper alteration, modification, addition,

operation, maintenance or service, whether it be mechanical, electrical, fuel, operator motor or otherwise,

which may occur from such improper alteration, modification, addition, operation, maintenance or service

to this piece of equipment.

Safety Considerations

Your Lang LRP Proofer is manufactured to rigid standards. This equipment is E.T.L. listed and meets

safety and sanitation standards.

The presence of safety equipment control and interlocks on an appliance and attendant components of

installation cannot in and of themselves, assure absolute safety of operation. Diligent, capable, well

trained operators and maintenance personnel, as well as proper programs of operation and maintenance,

are essential to the safe and reliable operation of this appliance.

A. The responsibility of the manufacturer

recommendations for the operation and maintenance of the appliance.

B. Trained qualified and factory-authorized personnel must perform all operation, maintenance and

repair of these appliances. It is the responsibility of the owner / operator

happens.

C. A regular periodic program of cleaning, inspection and maintenance must be established and

comprehensive maintenance records maintained. It is the sole responsibility of the user

schedule and enforce the frequency and scope of these programs in keeping with recommended

practice and with due consideration given to actual operating conditions.

D. The appliance must be operated within the limits, which will not exceed the working limits of

any component within the appliance as a whole.

is to supply suitable, comprehensive instructions and

to ensure that this

to establish,

ETL File E8138 Rev. A 2001

6

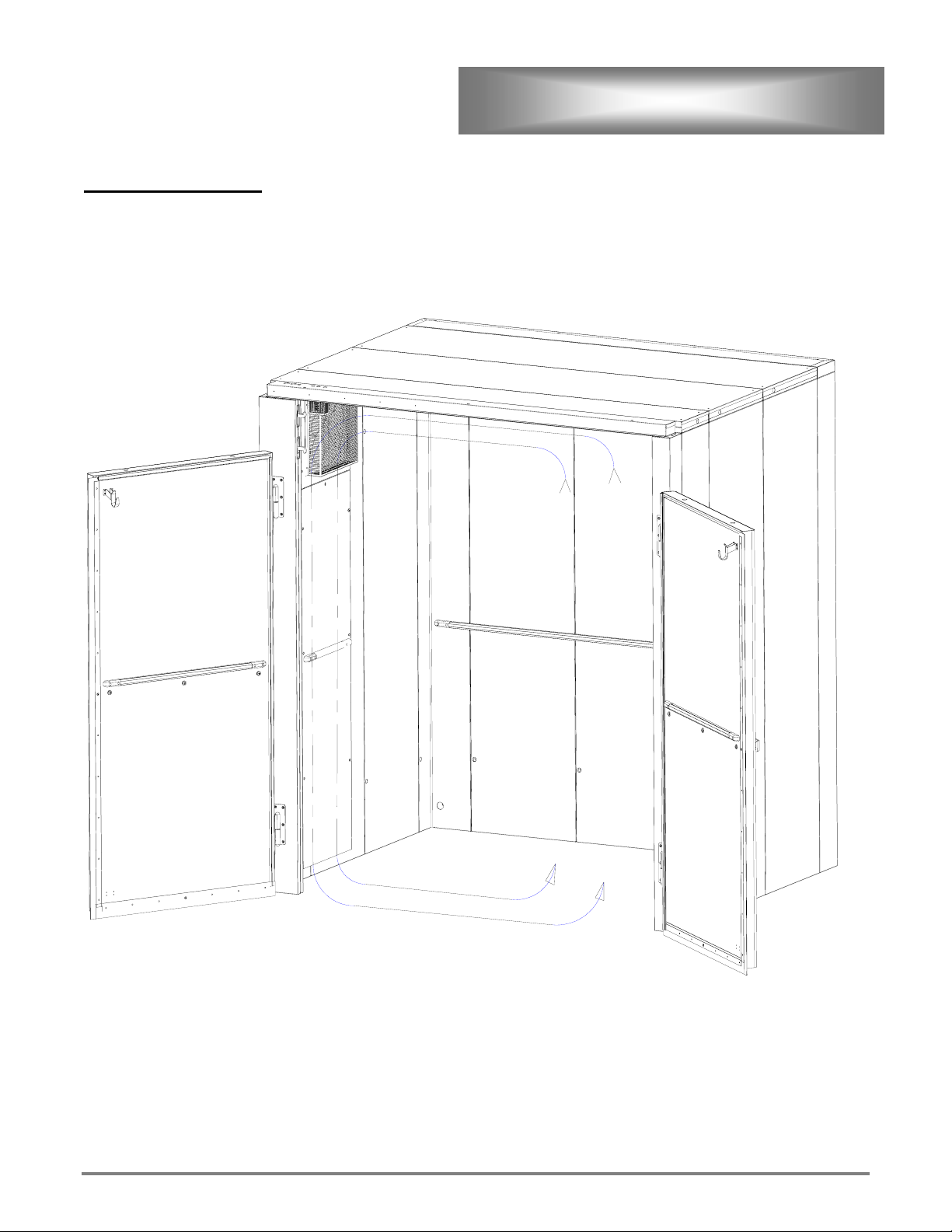

EQUIPMENT DESCRIPTION

Exterior

LRP-1

• The Proofer exterior dimensions are 38.4” (97.5 cm) wide x 91.5” (232.5 cm) high x depth is dependent

upon model number [39.3”(100 cm) to 129.3” (328.5cm)]. The Top, Front, Back, and Sides are

constructed of stainless steel.

LRP-2

• The Proofer exterior dimensions are 78.8” (200 cm) wide x 91.5” (232.5 cm) high x depth is dependent

upon model number [39.3”(100 cm) to 129.3” (328.5cm)]. The Top, Front, Back, and Sides are

constructed of stainless steel.

All Units

• Modular design allows for a wide variety of sizes.

• The proofer door is constructed of stainless steel and comes with both single and double doors.

Interior

LRP-1

• The Proofer interior dimensions are 33.1” (84 cm) wide x 74.1” (188.1 cm) high x depth is dependent

upon model number [22.1”(56 cm) to 112.1” (284.7 cm)]. The Top, Front, Back, and Sides are

constructed of stainless steel.

LRP-2

• The Proofer interior dimensions are 68.1” (173 cm) wide x 74.1” (188.25 cm) high x depth is dependent

upon model number [27.1”(68.8 cm) to 117.1” (297.4 cm)]. The Top, Front, Back, and Sides are

constructed of stainless steel.

All Units

• Floor level loading.

Cabinet

Rigid, formed stainless steel panels filled with polyurethane foam insulation re-joined with camlocks and

sealed with gaskets to form a strong, energy efficient, tight and sanitary enclosure.

Doors

The welded stainless steel doors are polyurethane foam-filled. Door bumpers on the inside protect the

finish.

Controls

• The microprocessor based digital controls are mounted for ease above the left-hand door. Power and light

switches are located between the control and the door.

• Digital read-out with solid state temperature sensing and controls.

Air-Duct(s)

Each proofer comes with one or two air ducts. These air ducts perform the tasks of heating, humidifying

and circulating the air within the unit. Each duct contains a heater plate, spray nozzle, drain pan and fan.

ETL File E8138 Rev. A 2001

7

GENERAL DESCRIPTION

Theory of Operation

The Lang Proofer is a controlled atmosphere chamber. Temperature and humidity can be set

independently to meet your particular proofing needs. The air temperature is increased as the air duct

heater in energized. Humidity is increased as water is sprayed in the air duct. Air is circulated

continuously to provide positive movement from bottom to top, creating a uniform distribution of warm,

moist air.

ETL File E8138 Rev. A 2001

8

GENERAL OPERATION

DANGER

NOTICE

NOTICE

NOTICE

NOTICE

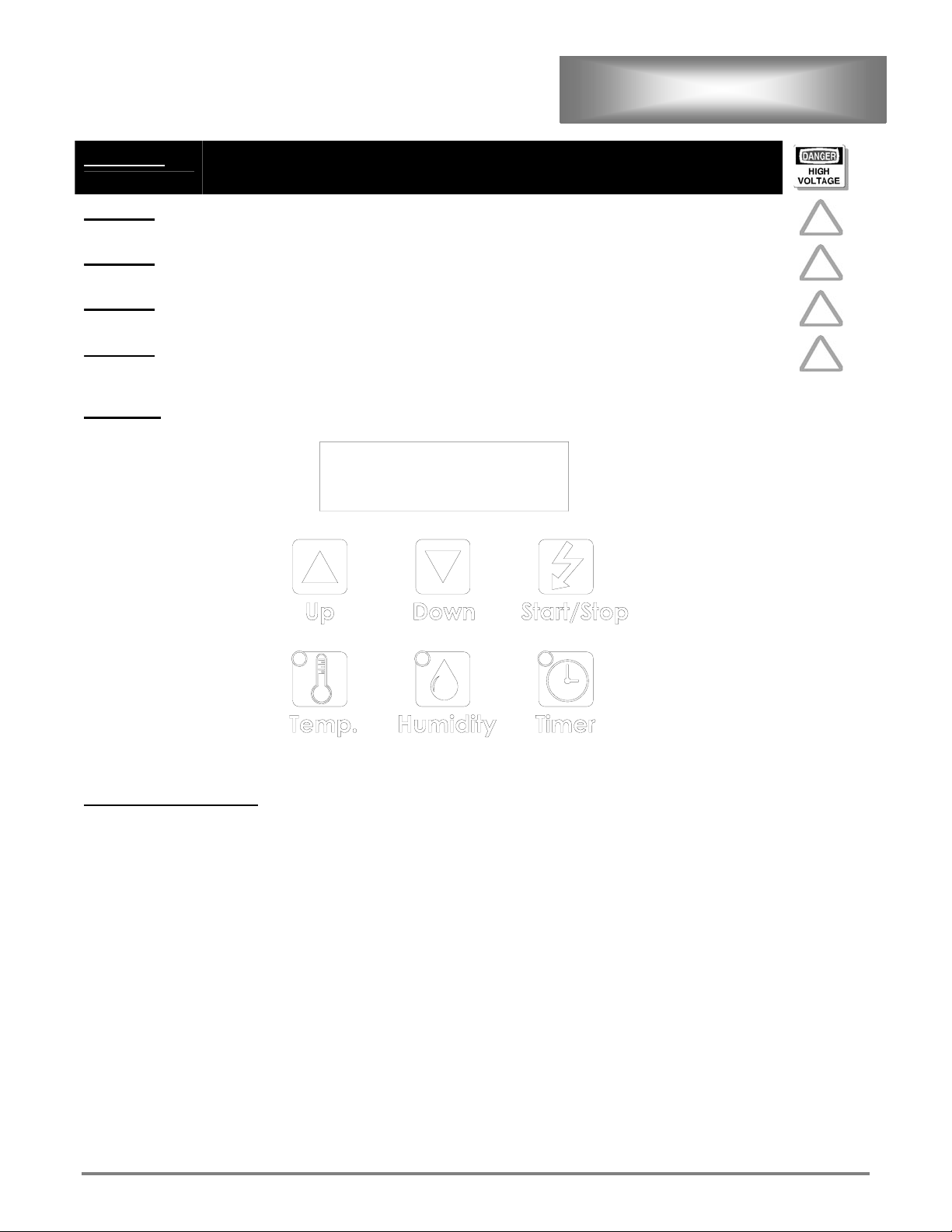

Controls

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

For best results- Always allow your proofer to reach set temperature and

humidity before putting product in.

For best results- Proof at lower temperatures rather than higher.

To dry proof: Set humidity to the lowest setting (either 45% or less). At this

setting the humidity generator is turned off and will not produce humidity.

When the actual humidity is less than 46% display will show 45. When the

actual humidity is higher than 45%, display will show the actual humidity.

BASIC OPERATION

1. Turn power switch to “ON” position.

2. Press “Temp.” button.

3. Set temperature to desired temperature (80°F-120°F) using the “Up” or “Down” buttons.

4. Press “Humidity” button

5. Set Humidity to desired humidity (50%-100%) using the “Up” or “Down” buttons.

6. Press “Timer” button.

7. Set time to desired time using the “Up” or “Down” buttons.

8. Place product in proofer.

9. Press “Start / Stop” button and timer will begin counting down.

10. When buzzer sounds, press stop button and remove product from proofer.

11. To check actual temperature press “Temp.” button twice. Flashing display will indicate actual

temp.

12. To check actual humidity press “Humidity.” button twice. Flashing display will indicate actual

Humidity.

ETL File E8138 Rev. A 2001

9

WARNING

GENERAL MAINTENANCE

THE LANG LRP SERIES PROOFER PRODUCES HUMIDITY WHICH WILL

NATURALLY CONDENSE AND ACCUMULATE WATER ON THE INTERIOR

FLOOR CAUSING IT TO BECOME SLIPPERY. ADJACENT EXTERIOR

FLOOR MAY ALSO BECOME SLIPPERY. USE EXTREME CAUTION WHEN

WALKING IN OR AROUND THIS APPLIANCE.

NOTICE

Service on this or any other LANG equipment must be performed by

qualified personnel only. Consult your authorized service agency directory

or call the factory at 1-800-224-LANG (5264), or WWW.LANGWORLD.COM

for the service agency nearest you

Every Day

Clean interior and exterior of proofer.

Every Six Months

Have factory authorized service personnel check proofer for proper temperature readings, air duct drain, heater plate,

spray nozzle.

As Needed

Clean interior and exterior walls and replace light bulb or any other components as needed.

Specifications

Temperature, humidity, and timer setting ranges:

Thaw:

80-120°F (18-66°C)

50-95% Relative Humidity

Proof:

Timers:

Power:

Water:

ETL File E8138 Rev. A 2001

80-120°F (18-46°C)

50-95% Relative Humidity

0-99 Hours and 0-59 Minutes

Varies depending on model and size (See data plate located on the underside of the valence

for the specific ratings or contact the factory for the information needed if the data plate is

not legible).

.73 gallons per hour maximum per air duct (2 ducts maximum) @ 30 PSI.

1.70 gallons per hour maximum per air duct (2 ducts maximum) @ 80 PSI.

10

Loading...

Loading...