Page 1

Installation,

Operation, Maintenance and

Service Instructions

Micro Bakery Proofer and Staging Cabinet

Model: MBPF 120, MBPF 220, MBPF 380

and MBSC

Star Manufacturing International 10 Sunnen Drive St. Louis, MO.63143-3800

Part Number: 2M-W743 Ph: 314-678-6315 Fax: 314-781-2714

Rev WWW.LANGWORLD.COM

July 21, 2007

Page 2

THE INFORMATION IN THIS MANUAL IS CRUCIAL AND MUST BE RETAINED

FOR FUTURE REFERENCE. READ, UNDERSTAND AND FOLLOW THE

INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL.

DANGER

WARNING

CAUTION

NOTICE

POTENTIALLY HAZARDOUS SITUATION, WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH.

POTENTIALLY HAZARDOUS SITUATION, WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY.

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY.

Helpful operation and installation instructions and tips are present.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

Model #: Purchased From:

Serial #:

Location:

Date Purchased:

Purchase Order #:

Star Manufacturing International 10 Sunnen Drive St. Louis, MO.63143-3800

Part Number: 2M-W743 Ph: 314-678-6315 Fax: 314-781-2714

Rev WWW.LANGWORLD.COM

Date Installed:

For Service, Call:

July 21, 2007

Page 3

TABLE OF CONTENTS

CHAPTER PAGE

Table Of Contents....................................................................................... 3

Read First ...................................................................................................4

Safety Procedures ...................................................................................... 6

Equipment Description................................................................................ 7

Unpacking................................................................................................... 7

Installation................................................................................................... 8

Initial Start Up ............................................................................................. 10

Cinnabon Operation Procedures ................................................................ 11

Operation .................................................................................................... 12

Maintenance & Cleaning............................................................................. 14

Troubleshooting .......................................................................................... 15

Parts List..................................................................................................... 16

Exploded Views .......................................................................................... 17

Wiring Diagram ........................................................................................... 20

ETL File# 3029573 3

Page 4

CAUTION

CAUTION

CAUTION

DANGER

WARNING

NOTICE

NOTICE

THE UNIT IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE

MATERIALS HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR

PALLET JACK) TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO

THE PLACE OF INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH THE UNIT WILL

BE LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE

UNIT.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN

CUT.

THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED.

FAILURE TO GROUND THE APPLIANCE COULD RESULT IN

ELECTROCUTION AND DEATH.

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED

TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO EQUIPMENT. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

The data plate is located on the left-hand side of the unit towards the front. The

unit voltage, wattage, serial number, wire size, and clearance specifications are

on the data plate. This information should be carefully read and understood

before proceeding with the installation.

The installation of any components such as a vent hood, grease extractors, fire

extinguisher systems, must conform to their applicable National, State and

locally recognized installation standards.

NOTICE

CAUTION

CAUTION

WARNING

CAUTION

During the first few hours of operation, you may notice a small amount of smoke

coming from the unit, and a faint odor from the smoke. This is normal for a new

unit and will disappear after the first few hours of use.

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR

FALLS.

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO

WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE

CLOTHING. CAREFULLY READ THE WARNING AND FOLLOW THE

DIRECTIONS ON THE LABEL OF THE CLEANER TO BE USED.

ETL File# 3029573 4

Page 5

NOTICE

WARNING

CAUTION

Service on this or any other, STAR appliance must be performed by qualified

personnel only. Consult your authorized service agent directory or call the

factory at 314-678-6315 or visit our website www.langworld.com or the service

agent nearest you

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS APPLIANCE

WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE

REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC

POWER SUPPLY.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

STAR OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE BODILY INJURY

TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND WILL VOID ALL

WARRANTIES.

ETL File# 3029573 5

Page 6

SAFETY PROCEEDURES

Lockout Procedure

1. Announce lockout to other personnel.

2. Turn both heat and control power off at main panel.

3. Test lockout by turning power switch on and observing if fan(s) come on. Check heater

circuit with voltmeter.

4. Perform necessary repairs or tests.

5. Turn power on at main panel.

6. Announce unit is “on” to other personnel.

Safety Precautions

The manufacturer, Star Manufacturing, hereby disclaims any and all responsibility for injury,

damage, loss or other claim that may occur to person or property form improper alteration,

modification, addition, operation, maintenance or service, whether it be mechanical, electrical,

fuel, operator motor or otherwise, which may occur from such improper alteration, modification,

addition, operation, maintenance or service to this piece of equipment.

Safety Considerations

Your Lang Proofing Cabinet is manufactured to rigid standards. This equipment is N.S.F., E.T.L

and C.E. listed and meets safety and sanitation standards.

The presence of safety equipment control and interlocks on an appliance and attendant

components of installation cannot in and of themselves, assure absolute safety of operation.

Diligent, capable, well-trained operators and maintenance personnel, as well as proper

programs of operation and maintenance, are essential to the safe and reliable operation of this

appliance.

A. The responsibility of the manufacturer

recommendations for the operation and maintenance of the appliance.

B. Trained qualified and factory-authorized personnel must perform all operation, maintenance

and repair of these appliances. It is the responsibility of the owner / operator

this happens.

C. A regular periodic program of cleaning, inspection and maintenance must be established

and comprehensive maintenance records maintained. It is the sole responsibility of the user

to establish, schedule and enforce the frequency and scope of these programs in keeping

with recommended practice and with due consideration given to actual operating conditions.

D. The appliance must be operated within the limits, which will not exceed the working limits of

any component within the appliance as a whole.

is to supply suitable, comprehensive instructions and

to ensure that

ETL File# 3029573 6

Page 7

Model: MBPF

Proofer, Micro Bakery

Exterior

The unit dimensions are 27⅞” (70.8cm) High with out legs, 46½”

(118.10cm) Deep, and 30⅛” (76.5cm) Wide.

The Sides, Bottom, and Rear wall are constructed stainless steel.

The unit door is designed with a single pane window.

Interior

The interior dimensions are 18¾” (47.625cm) Wide, 26” (66cm) Deep, and

26⅜” (67cm) High.

Controls

The unit power switch applies power to the temperature and humidity

controls.

The unit has both humidity (water) and air (heat) elements. Both elements

are easily accessible through the removable side panel.

An infinite switch that has a range from low to high controls the humidity

element.

Equipment Description

A thermostat that has a 140°F-temperature range controls the heating

element.

Receiving the Unit

Upon receipt, check for freight damage, both visible and concealed. Visible

damage should be noted on the freight bill at the time of delivery and signed

by the carrier's agent. Concealed loss or damage means loss or damage,

which does not become apparent until the merchandise has been

unpacked. If concealed loss or damage is discovered upon unpacking,

make a written request for inspection by the carrier's agent within 15 days of

delivery. All packing material should be kept for inspection. Do not return

damaged merchandise to Lang Manufacturing Company. File your claim

with the carrier.

Location

Prior to un-crating, move the unit as near its intended location as practical.

The crating will help protect the unit from the physical damage normally

associated with moving it through hallways and doorways.

Un-crating

The PFMB will arrive completely assembled inside a wood frame covered

by cardboard box and strapped to a skid. Remove the cardboard cover, cut

the straps and remove the wood frame.

Unpacking

ETL File# 3029573 7

Page 8

CAUTION

CAUTION

CAUTION

THE UNIT IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE

MATERIALS HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR

PALLET JACK) TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO

THE PLACE OF INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH THE UNIT WILL

BE LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE

UNIT.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN

CUT.

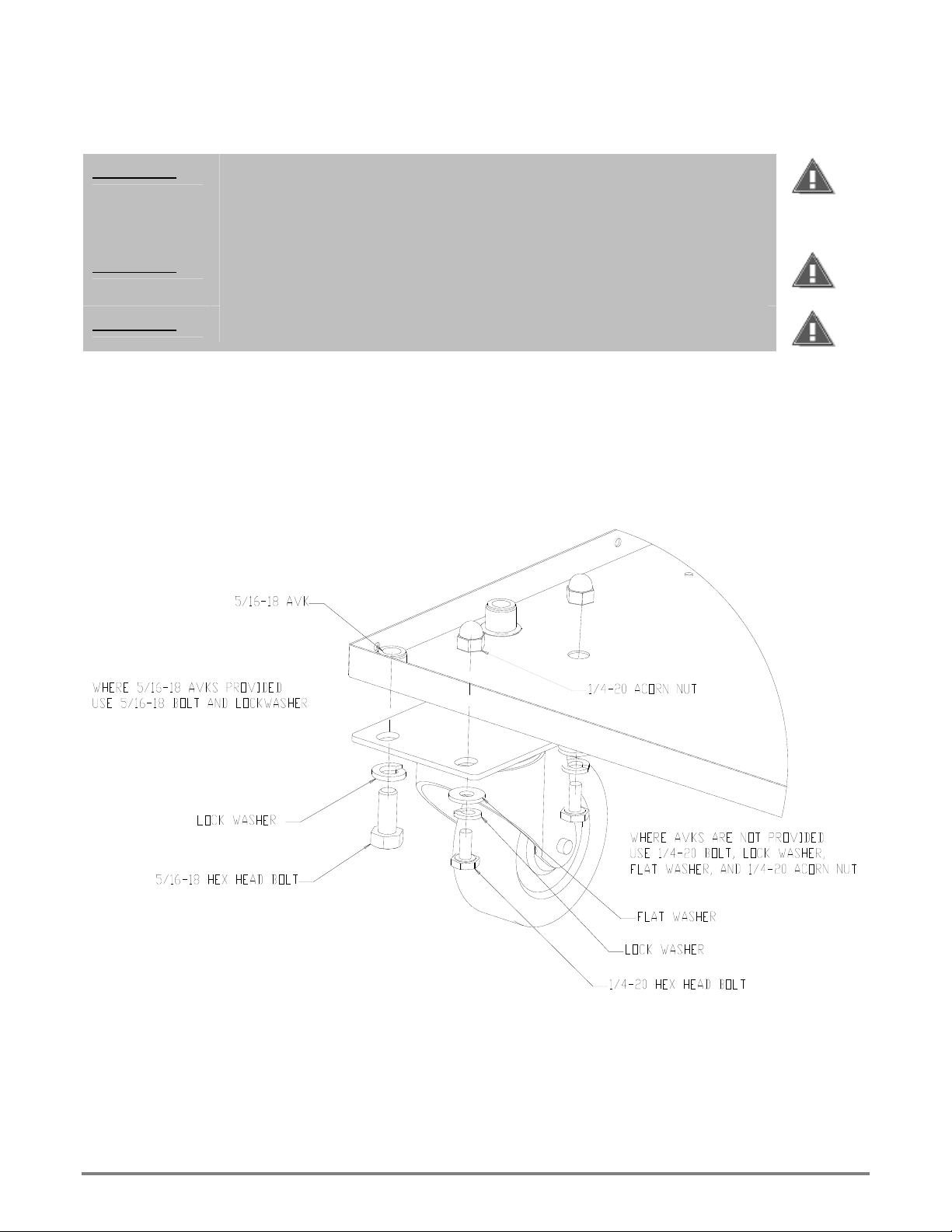

INSTALLING THE CASTERS

The PFMB comes standard with two swivel 4”and two rigid 4” casters that

can be mounted on the bottom of the unit.

Gently tip the unit onto its back. Bolt the swivel casters to the bottom front of

the unit and the rigid casters to the bottom rear of the unit. See illustration

below for reference.

Installation

ETL File# 3029573 8

Page 9

DANGER

Installation cont’d

THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED.

FAILURE TO GROUND THE APPLIANCE COULD RESULT IN

ELECTROCUTION AND DEATH.

WARNING

NOTICE

NOTICE

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED

TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO EQUIPMENT. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

The data plate is located on the left-hand side of the unit towards the front. The

unit voltage, wattage, serial number, wire size, and clearance specifications are

on the data plate. This information should be carefully read and understood

before proceeding with the installation.

The installation of any components such as a vent hood, grease extractors, fire

extinguisher systems, must conform to their applicable National, State and

locally recognized installation standards.

ELECTRICAL CONNECTION

Electrical service can be provided through a 5/8” knock out, which is located

at the back of the unit.

A terminal block is provided inside the unit for hook up and can be

accessed through the removable side panel.

STACKING

The MBPF (Micro Bakery Proofing Cabinet) and MBSC (Micro Bakery

Staging Cabinet) are both part of a modular baking system and are both

stackable.

To stack the MBSC on the top of the MBPF, tip the MBSC onto its top and

insert the four 3/8”-16 studs (pn: 2C-20108-11) into the AVK’s provided on

the underside of the MBSC.

Stack the MBSC onto the top of the MBPF and align the socket head screws

with the holes provided in the top of the MBPF.

To stack the EHS (oven) onto the MBSC, remove all racks and rack-slides

from the inside of the oven and gently tip it onto its back.

Insert the four 3/8”-16 studs (pn: 2C-20108-11) into the leg holes provided on

the underside of the ECOH.

Stack the ECOH onto the top of the MBSC and align the socket head screws

with the holes provided in the top of the HCMB.

VENTILATION AND CLEARANCES

Standard minimum clearance from combustible construction is as follows:

0” from side

0” from back

0” from floor

These units may be set directly, without legs, on a curbed base or noncombustible floor.

ETL File# 3029573 9

Page 10

NOTICE

Each unit is preheated, tested and calibrated at the factory before shipment.

However, due to temperature and climate changes during shipment the unit

can absorb moisture and should be dried out before attempting to proof.

Prior to putting any unit into full time operation at normal cooking

temperatures, it must be thoroughly "seasoned" or dried out. Moisture

absorption in the closed spaces and even inside the heating elements can

cause future trouble if not properly treated.

Before the initial use of the unit, the element must be thoroughly allowed to

dry out. This can be done by setting the thermostat to the maximum setting

and humidity control to the lowest setting. Allow the unit to saturate until all

vapor and condensation has been eliminated. For best operating results

allow the unit to thoroughly dry out for 8 to 12 hours.

If the unit is out of use for three or more days, a one-hour preheat schedule

should be used, especially when exposed to high humidity and/or cool

temperatures.

During the first few hours of operation, you may notice a small amount of smoke

coming from the unit, and a faint odor from the smoke. This is normal for a new

unit and will disappear after the first few hours of use.

Initial Start Up

ETL File# 3029573 10

Page 11

Cinnabon Operations

Cinnabon Micro Bakeries

Instructions

Proofing:

Proofer should be filled with HOT water first thing each morning. Controls should

be set at Medium-to-Medium Low----- Temperature 110 degrees.

Check water level midway through each day.

Drain water completely at end of day.

Cold Proofer:

Time clips will be placed under each pan (not inside the pan) in cold proofer to

allow expiration time to be easily read.

Cold proofer will hold a maximum of eight pans.

Baking---Oven:

The new Micro Lang Oven is equipped with four shelves. When baking place

one pan on each rack to ensure even baking. When volume levels require

additional baking you may bake two pans on every other shelf. Baking more will

result in uneven bakes. The control panel is identical to the full size oven and

should be used in the same manner.

ETL File# 3029573 11

Page 12

CAUTION

CAUTION

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR

FALLS.

GENERAL

The unit is designed to give well regulated, even heat. It should be

thoroughly preheated before being used. It is advantageous from the

operating cost standpoint, to operate with the thermostat set at the lowest

possible position that will satisfactory perform the proofing and with the door

shut during preheat and slack business periods.

OPERATION

STARTUP

1. Open the drop down door below the control panel and fill the water tray with

WARM water.

2. Set the Power Switch to the “ON” position.

3. Set the Temperature Dial to the desired temperature.

4. Set the Humidity Dial to the Medium position (adjust as necessary to gain

the desired humidity).

5. Allow the proofer to preheat for 1 hour.

6. Load product.

7. Shut door and keep closed.

8. Refill water pan as required during the day.

Proofing General

Proofing is one of the most important and delicate stages in baking. About 50%

of the product volume is created in the proofer. Proofing accelerates the

fermentation of yeast in a warm moist environment causing the dough to rise.

The temperature of the proofer should not be set higher then 100°F. The

humidity should be set at around medium. For optimum results, rolls should be

removed from the hot proofer and transferred to the cold proofer at minimum

proof. This will ensure that they can be held for 40 minutes without becoming

over-proofed.

ETL File# 3029573 12

Page 13

PROOFING SPECIFICS

There are many variables involved in the baking process. It is difficult to assign

proofing times, temperatures, and humidity levels. Here are some general

guidelines that may be helpful.

Temperature, age, and volume of dough should be the same to obtain similar

results (keep accurate records).

Never proof frozen dough before thawing. Thaw in a retarder set between 38°F

and 42°F for 12-16 hours. (A retarder is simply a high humidity level

refrigerator).

If dough had been retarded or refrigerated, allow some “Floor” time. (“Floor”

time is simply allowing the product to sit at room temperature). Thirty minutes is

usually sufficient. This allows the dough temperature to rise throughout

gradually.

Operation

Set humidity control just high enough so an undesirable crust is not

during the proofing process.

Different products are proofed at different temperatures ranging between 80°F

and 105°F. The lower temperatures are used for croissants or butter layered

pastries. Butter melts at 87°F. The higher proofing temperatures are used for

products such as breads and rolls. Never exceed 105°F; temperatures over

107°F will kill the fermentation process of the yeast.

A product has fully proofed when it doubles in size, appears loose, and feels

light and fluffy.

A product is under proofed if it has not doubled in size. An under proofed

product does not have an appealing appearance and will not expand to its full

size during baking.

A product is over proofed because of too much time in the proofing stage. It will

spread too much in the pan and fall when handled or baked.

formed

ETL File# 3029573 13

Page 14

Maintenance & Cleaning

WARNING

CAUTION

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO

WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE

CLOTHING. CAREFULLY READ THE WARNING AND FOLLOW THE

DIRECTIONS ON THE LABEL OF THE CLEANER TO BE USED.

DAILY CLEANING

The unit should be thoroughly cleaned once a day to insure against

accumulation of foreign material.

Always start with a cold unit.

The stainless exterior can easily be cleaned using Lang Mfg. Prime Shine

(72804-41) cleaner.

Always follow the cleaner manufacturer's instructions when using any

cleaner.

Care should be taken to prevent caustic cleaning compounds from coming in

contact with the aluminized inside of the unit.

The unit rack, rack slides and interior can be cleaned using Lang Mfg. Foam

Delux (72804-36) unit cleaner.

Always apply these cleaners when the unit is cold and rub in the direction of

the metal's grain.

WEEKLY CLEANING

To provide the proper atmosphere for proofing or holding, Lang has

designed a sealed cabinet.

A characteristic of the unit is an accumulation of water on the bottom of the

cabinet. This accumulation should be removed daily.

This is easily accomplished by simply removing the rack and rack slides from

the unit and sponging out any excess accumulation of water.

It may also be necessary to clean the water reservoir once a week to remove

any mineral deposits that may have built up after heavy use.

Remove the racks and right hand rack slide from the unit. Remove the four

wing nut screws on the right hand side of the unit. This will expose the water

reservoir.

Use a sponge and some mild soap and water to remove any mineral

deposits.

ETL File# 3029573 14

Page 15

Troubleshooting

Symptoms

What follows is a chart of Symptoms, Possible Causes, and Remedy’s to

aid in diagnosing faults with the unit.

Refer to the Symptoms column to locate the type of failure then to the

Possible Cause for the items to be checked. On the following pages is a

chart with the possible causes and the test to properly identify the problem.

SYMPTOM POSSIBLE CAUSE

Unit will not heat No power to Unit

Defective power switch

Defective thermostat

Defective heat element

Unit will not proof No power to unit

Defective power switch

Defective infinite switch

Defective water element

NOTICE

WARNING

CAUTION

TESTS

Service on this or any other, STAR appliance must be performed by qualified

personnel only. Consult your authorized service agent directory or call the

factory at 314-678-6315 or visit our website www.langworld.com for the

service agent nearest you.

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS

APPLIANCE WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE

RECEPTACLE. BEFORE REPLACING ANY PARTS, DISCONNECT THE

UNIT FROM THE ELECTRIC POWER SUPPLY.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

STAR OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE BODILY

INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

Possible Cause TEST

Defective Power Switch Check power switch for normal operation

Failed thermostat Check thermostat for correct voltage*

Verify calibration

Replace if necessary*

Failed element Check elements for correct voltage*

Remove the wires and check for continuity

across the element*

Failed infinite switch Check switch for correct voltage.

* A factory authorized service representative should perform this work.

ETL File# 3029573

15

Page 16

SK2269 Rev. A 6/03/08

Model:

MBPF Electric Proofer

PFMB Electric Proofer

1

2

32

33

3

4

11

23

24

25

30

25

31

26

28

29

27

12

13

14

15

18

17

6

5

7

8

9

10

16

19

20

21

22

See Detail B

SEE DETAIL

A

1

Page 17

PARTS LIST July 12 2007, Rev. B

MBPF Electric Proofer

Number

Key

Number

1 Q9-162-106 1 BODY TOP ALL

2 Q9-162-104 1 BODY REAR ALL

3 Q9-162-102 1 BODY RIGHT SIDE ALL

4 Q9-162-118 1 ACCESS COVER ALL

5 2T-30401-28 1 STAT FXD TEMP OPEN 160 ALL

6 2C-20103-06 2 SCRW SM PLT 6 X3/8 PHL ALL

7 2C-20103-02 1 SCRW SM PLT 10 X .5 PHLSL TP A MBPF-220V(QTY=5), MBPF-2/3VCN(QTY=5)

8 2E-31200-02 1 LUG GROUNDING UL APPROVED ALL

9 2C-20103-07 2 SCRW PHD SM 8 X PHL TYP A ALL

10 2E-30500-01 1 TRM STRP 2 POLE 30A 300V ALL

11 2P-72900-04 2 CSTER RIGID 3,5/16W TRD. ALL

12 2P-72901-17 2 CSTR SWVL W/BRK 35/16TRD ALL

2A-72500-05 4 LEG 4 W/BOLT DOWN ADJ MBPF-120VM

13 2C-20201-07 3 WSHR FLT 1/4 SAE PLTD MBPF-120VM (QTY=6)

14 2C-20202-05 4 WSHR PLT 1/4 LOCK SPLIT MBPF-120VM (QTY=7)

15 2C-20104-10 13 SCRW HXHD CAP 5/16 -18X 3/4 ALL

16 2K-70101-101 1 HOSE BARB 45 DEG ELBOW TO ALL

17 2V-70400-05 1 VALVE 1/4 MINI BALL ALL

18 2C-20204-01 2 WSHR LOCK SS #10 STD SPLIT ALL

19 2C-20301-11 2 NUT HEX 8-32 PLTD ALL

20 Q9-162-116 1 WATER ELEMENT MOUNT ALL

21 2N-11162-04 1 ELEMENT H2O PROOFER 120V MBPF-120V & CN & M

2N-11162-08 1 ELEMENT H2O PROOFER 240V MBPF-2/3VCN, 220V & CN

22 2N-11162-10 1 ELEMENT AIR, PFMB 120V MBPF-120V & CN & M

2N-11162-11 1 ELEMENT AIR, PFMB 220V MBPF-2/3VCN, 220V & CN

23 Q9-162-102 1 AIR DUCT COVER ALL

24 2C-20112-03 4 SCRW THUMB 1/4-20 X 1/2 SS ALL

25 2B-50200-96 1 RACK SLIDE-PFMB STAINLESS ALL

26 Q9-162-101 1 BODY FRONT ALL

27 Q9-162-711 1 WATER DOOR ASSY PFMB ALL

28 SEE DETAIL A 1 COMPONENT ASY PFMB 120V ALL

29 2C-20103-02 4 SCRW SM PLT 10 X .5 PHLSL TP A ALL

30 Q9-162-715 1 PROOFER DOOR ASSY PFMB ALL

31 Q9-162-103 1 BODY LEFT SIDE ALL

32 2K-70801-15 1 STRAIN RELIEF BUSH STRT ALL

33 2E-31107-02 1 CORD SET 14/3 X 8’ 15A MBPF-120V & CN & M

NI 2P-51001-37 1 SPRING SWT DR HINGE S/S ALL

NI 2U-30200-28 1 MOTOR PROOFER 120V W/FAN MBPF-120V & CN & M

NI 2U-30200-43 1 MOTOR PROOFER 240V W/FAN MBPF-2/3VCN, 220V & CN

NI Q9-162-170 4 MARINE LEG ADAPTER MBPF-120VM

NI Q9-162-720 1 MARINE LEG ASSEMBLY MBPF-120VM

NI Y9-70602-01-1 1 CATCH 1/4 BULLET W/CLIP ALL

Part

Number

Per

Unit

Description

2

Page 18

SK2271 Rev. A 6/03/08

Model:

MBPF Detail A & B

PFMB Detail A & B

4

3

2

1

5

6

7

8

9

10

11

12

13

14

15

18

19

16

17

DETAIL A

DETAIL B

3

Page 19

PARTS LIST June 3, 2008, Rev. B

MBPF Electric Proofer Controls Assembly

Number

Key

Number

1 2E-30303-19 1 SWT TOG ON-ON DPDT BLK ALL

2 2T-30402-39 1 STAT ADJ 0-140 F 60 CAP ALL

3 2E-30305-04 1 SWTINF120V15AMPINF120-252 MBPF-120V & CN & M

2E-30305-01 1 SWT INF 240V 15AMP MBPF-2/3VCN, 220V & CN

4 2J-30801-01 1 TIMER MECHANICAL LONG MBPF-120V & M, 220V

5 Q9-162-117-01 1 CONTROL PANEL W / TIMER ALL

6 2M-60301-157 1 LABEL PANEL PRFR M.B. MBPF-120V & M, 220V

2M-60301-144 1 LABEL PANEL CINNABON MBPF-120VCN, 2/3VCN & 220VCN

7 2R-70701-46 1 BK KNB WH RNG&ARR 3-16SH MBPF-120V & M, 220V

8 2R-70701-45 1 BK KNB BLUE RNG&ARR 1/4SH ALL

9 2R-70701-44 1 BK KNOB RED RNG & ARR 1/4 ALL

10 2C-20101-77 SCRW MS PLT 6-32 X 0.25 ALL

11 2J-31601-19 1 PILOT LT 125V 6LEAD WHITE MBPF-120V & CN & M

2J-31601-17 1 PILOT LT 250V 6LEAD WHITE MBPF-2/3VCN, 220V & CN

12 2J-31601-18 1 PILOT LT 125V 6LEAD GREEN MBPF-120V & CN & M

2J-31601-16 1 PILOT LT 250V 6LEAD GREEN MBPF-2/3VCN, 220V & CN

13 2C-20301-29 3 NUT HEX ACORN 1/4-20 S/S ALL

14 2P-72901-17 2 CSTR SWVL W/BRK 35/16TRD ALL

2P-72901-04 2 CSTER RIGID 3,5/16W TRD. ALL

15 2C-20202-08 13 WSHR PLT 5/16 LOCK SPLIT ALL

16 2C-20201-07 3 WSHR FLT 1/4 SAE PLTD ALL

17 2C-20202-05 3 WSHR PLT 1/4 LOCK SPLIT ALL

18 2C-20104-10 13 SCRW HXHD CAP 5/16-18X3/4` ALL

19 2C-20104-08 3 SCRW HXHD CAP PLT 1/4-20 ALL

Part

Number

Per

Unit

Description

4

Page 20

1

2

3

4

8

7

6

5

SK2271 Rev. - 7/10/07

Model:

MBSC Proofer Holding Cabinet

HCMB Proofer Holding Cabinet

5

Page 21

PARTS LIST June 3, 2008, Rev. B

MBSC, HCMB

PROOFER HOLDING CABINET

Number

Key

Number

1 Q9-163-701 1 BODY ASSEMBLY 11 3/8 TALL MBSC

Q9-163-701-1 1 BODY ASSEMBLY 13 3/8 TALL MBSCT

2 Q9-163-121 1 DOOR CATCH RH ARM 11 3/8 MBSC

Q9-163-121-1 1 DOOR CATCH RH ARM 13 3/8 MBSCT

3 Q9-163-704 1 DOOR ASSEMBLY 11 3/8 TALL MBSC

Q9-163-704-1 1 DOOR ASSEMBLY 13 3/8 TALL MBSCT

4 Q9-163-125 1 SHELF BOTH

5 2C-20301-07 2 NUT ACORN 1/4-20 PLTD BOTH

6 2C-20301-20 2 NUT LOCK STOVER 1/4-20 PLTD BOTH

7 2C-20111-01 2 SCRW HXHD CAP 1/4-20X1/2 SS` BOTH

8 Q9-163-122 1 DOOR CATCH LH ARM 11 3/8 MBSC

Q9-163-122-1 1 DOOR CATCH LH ARM 13 3/8 MBSCT

Part

Number

Per

Unit

Description

6

Page 22

Wiring Diagram

TB

TB - TERMINAL BLOCK

TS - TOGGLE SW ITCH

PL - PILOT LIGHT

TMST - THERMOSTAT

1

2

IC - INFINITE CONTROL

HE - HEATING ELEMENT

FM - FAN MOTOR

OTS - OVERTEMP STAT

TS

OTS

TS

3

5A 4

5

5

5

TMST

PL (POWER)

o

t

FM

4

7

HE (AIR)

6

4A

4

4

PL (HEAT)

IC

5

9

8

4

IC

HE (WATER)

ETL File# 3029573

21

Page 23

Page 24

STAR I NTERNATI ONAL H OLDI N GS IN C. COM PAN Y

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 678-6303

www.star-mfg.com

Loading...

Loading...