Service Manual for the Lang Models:

GCCO-AP, GCCO-C, GCCO-PP, GCCO-PT, GCCO-SII,

GCCO-T

Lang Manufacturing Company 6500 Merrill Creek Parkway Everett, WA 98203

Phone: 1-800-224-5264 Fax: 1-425-349-2733

www.langworld.com ©Copyright 2000

TABLE OF CONTENTS

CHAPTER PAGE

1. TABLE OF CONTENTS.......................................................................1

2. READ FIRST ....................................................................................... 2

3. EQUIPMENT DESCRIPTION..............................................................4

4. INSTALLATION...................................................................................6

5. START-UP...........................................................................................8

6. CONTROL PANEL LAYOUT...............................................................9

7. PROGRAMMING TERMS ................................................................... 15

8. PROGRAMMING................................................................................. 17

9. GENERAL OPERATION .....................................................................27

10. TYPICAL OPERATION ....................................................................... 29

11. SEQUENCE OF OPERATION.............................................................32

12. TROUBLESHOOTING......................................................................... 34

13. TECHNICAL DATA.............................................................................. 50

14. WIRING DIAGRAMS...........................................................................55

15. PARTS LIST........................................................................................61

1

IMPORTANT READ FIRST IMPORTANT

CAUTION:

CAUTION:

CAUTION:

DANGER:

WARNING:

EACH UNIT WEIGHS 500 LBS. FOR SAFE

HANDLING, INSTALLER SHOULD OBTAIN HELP AS

NEEDED, OR EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A FORKLIFT,

DOLLY, OR PALLET JACK) TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON

WHICH OVEN WILL BE LOCATED MUST BE

DESIGNED TO SUPPORT THE WEIGHT OF THE

OVEN.

SHIPPING STRAPS ARE UNDER TENSION AND CAN

SNAP BACK WHEN CUT.

THIS APPLIANCE MUST BE GROUNDED AT THE

TERMINAL PROVIDED. FAILURE TO GROUND THE

APPLIANCE COULD RESULT IN ELECTROCUTION

AND DEATH.

INSTALLATION OF THE UNIT MUST BE DONE BY

PERSONNEL QUALIFIED TO WORK WITH

ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

UNIT MUST BE INSTALLED IN ACCORDANCE WITH

ALL APPL I CABLE CO D E S .

WARNING:

WARNING:

NOTICE:

NOTICE:

NOTICE:

BEFORE LIGHTING, USE A SOAP AND WATER

SOUTION TO TEST ALL JOINTS FOR GAS LEAKS.

DURING INITIAL USE, OR AFTER SERVICE, IF PILOT

DOES NOT IGNITE ON FIRST TRY THE MAIN GAS

VALVE MUST BE TURNED OFF FOR AT LEAST FIVE

MINUTES.

The data plate is located above control panel behind

wire mesh screen. The oven voltage, BTU, serial

number, pipe size, and clearance specifi cat ion s are

on the data plate. This information should be

carefully read and understood before proceeding

with the installation.

The installation of any components such as a vent

hood, grease extractors, fire extinguisher systems,

must conform to their applicable National, State and

locally recognized installation standards.

During the first few hours of operation you may

notice a small amount of smoke coming off the oven,

and a faint odor from the smoke. This is normal for a

new oven and will disappear after the first few hours

of use.

2

IMPORTANT READ FIRST IMPORTANT

WARNING:

CAUTION:

CAUTION:

CAUTION:

NOTICE:

WARNING:

CAUTION:

KEEP WATER AND SOLUTIONS OUT OF CONTROLS.

NEVER SPRAY OR HOSE CONTROL CONSOLE,

ELECTRICAL CONNECTIONS, ETC.

ALWAYS KEEP THE AREA NEAR THE APPLIANCE

FREE FROM COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND

DRY. IF SPILLS OCCUR, CLEAN IMMEDIATELY, TO

AVOID THE DANGER OF SLIPS OR FALLS.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES,

MUCOUS MEMBRANES AND CLOTHING.

PRECAUTIONS SHOULD BE TAKEN TO WEAR RUBBER

GLOVES, GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE

WARNING AND FOLLOW THE DIRECTIONS ON THE

LABEL OF THE CLEANER TO BE USED.

Service on this, or any other, LANG appliance must be

performed by qualified personnel only. Consult your

authorized service station directory or call the factory at

1-800-224-LANG (5264), or WWW.LANGWORLD.COM for

the service station nearest you.

BOTH HIGH AND LOW VOLTAGES ARE PRESENT

INSIDE THIS APPLIANCE WHEN THE UNIT IS

PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE

REPLACING ANY PARTS, DISCONNECT THE UNIT

FROM THE ELECTRIC POWER SUPPLY.

USE OF ANY REPLACEMENT PARTS OTHER THAN

THOSE SUPPLIED BY LANG OR THEIR AUTHORIZED

DISTRIBUTORS CAN CAUSE BODILY INJURY TO THE

OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

3

EQUIPMENT DESCRIPTION

Lang Model: GCCO

GAS FULL SIZE CONVENTION OVEN

EXTERIOR

•

The oven exterior dimensions are 40” (100 cm) Wide, 32” (80 cm) High, 38” (95 cm) Deep. The Top,

Front, Back, and Sides are constructed of stainless steel with an aluminized bottom.

•

The oven doors come standard with a double pane window.

•

The door handle is constructed of Stainless Steel and Phonolic Tubing.

•

The oven cavity is insulated with high temperature insulation for efficiency and reduced heat loss.

INTERIOR

•

The oven cavity dimensions are 29” (72.5 cm) Wide, 20” (50.84 cm) High, 21” (53.38 cm) Deep.

•

The oven is designed for five shelves and comes with five Chrome Plated Racks.

•

The interior of the oven is constructed of porcelainized stainless steel.

OPERATION

•

The GCCO oven is a forced air convection oven with a vented oven cavity.

•

The air is driven by a 1/3 HP fan motor.

CONTROLS

The GCCO is available either with the Lang Accu-Plus (GCCO-AP), “Purple” Computer (GCCO-C),

“Purple Plus” Computer (GCCO-PP), “Platinum” Computer (GCCO-PT), Selectronic (GCCO-SII), AccuTemp (GCCO-T):

GCCO-AP

•

!

Easy to use manual control knobs.

!

Pulse and two speed fan.

!

Solid State temperature sensing and controls.

GCCO-C

•

!

Complete Computerized Controls with a Manual Override system.

!

Programmable up to 10 products with four “tiers” for each program.

!

Independent Shelf Timers for each Shelf.

!

Load Control through use of Cooking Curves.

!

Shelf Compe nsation Timing for uni form baking.

!

Single speed fan.

GCCO-PP

•

!

The Purple Plus offer the same great one touch system of the Purple, coupled with the advanced

backing capabilities of the new Platinum.

4

GCCO-PT

•

GCCO-SII

•

GCCO-T

•

EQUIPMENT DESCRIPTION CONT’D

!

Icon-driven (touch) panel allows for easy operation, also includes a manual

override system.

!

Day-Part Memory capabilities allow operators to “recall” the last daily

selections automatically.

!

Programmable up to 99 products, advanced baking capabilities include: a

12:59:59 timer with ten “tiers” .

!

Independent Shelf Timer for each Shelf.

!

Load Control through use of Cooking Curves.

!

Shelf Compe nsation Timing for uni form baking.

!

Dual speed fan.

!

Complete Computerized Controls.

!

Solid State temperature controls.

!

Easy to use manual control knobs.

!

Pulse and two speed fan.

5

INSTALLATION

RECEIVING THE OVEN

Upon receipt, check for freight damage, both visible and concealed. Visible damage should be noted on the

freight bill at the time of delivery and signed by the carrier's agent. Concealed loss or damage means loss

or damage, which does not become apparent until the merchandise has been unpacked.

If concealed loss or damage is discovered upon unpacking, make a written request for inspection by the

carrier's agent within 15 days of delivery. All packing material should be kept for inspection.

Do not return damaged merchandise to Lang Manufacturi ng Company. File your claim with the carrier.

Prior to un-crating, move the oven as near its intended location as practical. The crating will help protect

the unit from the physical damage normally associated with moving it through hallways and doorways.

LEG INSTALLATION

Legs are available for both the single and double deck installations. Single deck installations require a 27inch leg. Double deck installations require 6-inch legs or casters.

To install the 27-inch legs, place some cardboard on the floor and gently tip the oven onto its back. Fasten

two legs to the oven's front corners using the four 5/16 inch bolts provided in the leg kit. Lift the oven onto

its front legs and block the back up using one of the 27-inch legs set upside down in the center rear of the

oven body. Install the last 27-inch leg onto the oven body on the control side rear. Gently lift the oven

rear, remove the leg set to support the oven center and install it on the last rear corner.

To install the 6-inch legs or casters, attach the leg or caster to the leg supports supplied in the oven by

following the instructions in the box, then attach the leg support to the oven.

The adjustable feet on the bottom of each leg may be screwed in or out as necessary to level the oven.

A torpedo level placed on an oven rack will assist in leveling the oven.

STACKING THE OVENS

Remove all the plug buttons from the top of the lower oven.

Remove the stacking kit from the oven compartment of one oven and install the 1 1/4-inch plastic bushing

into the top of the lower oven.

Tip the top oven backwards and install two 3/8-inch socket head bolts, found in the stacking kit, into the

two front leg holes that match the holes in the top of the lower oven. Install the socket head bolts with the

heads of the bolt pointing away from the oven.

Lift the top oven and gently set on top of the lower oven so that the heads of the socket head bolts nest into

the holes in the top of the lower oven.

ELECTRICAL CONNECTION

The electrical connection must be made in accordance with local codes or in the absence of local codes

with NFPA No. 70 latest edition (in Canada use: CAS STD. C22.1).

The electrical service entrance is provided by a cord and plug located at the oven back directly behind the

control compartment.

Each oven requires a 115-volt grounded supply and 7.1 amps.

Supply wire size must be large enough to carry the amperage load for the number of ovens being installed.

Wire size information can be found on the oven data plate.

6

INSTALLATION CONT’D

GAS CONNECTION

This appliance is manufactured for use with the type of gas indicated on the data plate. Contact the factory

if the gas type does not match that which is on the data plate.

All gas connections must be in accordance with local codes and comply with the National Fuel Gas Code

ANSI Z223.1 latest edition.

An internal gas pressure regulator is located inside the control compartment.

Gas must be delivered to the appliance regulator at less than 1/2 pound of pressure and less than 1/2-inch

water column pressure drop.

The internal regulator is preset at the factory, however, due to gas pressure variations from area to area,

adjust the regulator to provide the manifold pressure indicated on the data plate. This should be 5 inches

water column for natural gas and 10 inch water column for propane. A 1/8-inch NPT tap is provided on the

main manifold for checking regulator pressure. Access the main manifold by removing the trim piece

below the oven doors.

When replacing the 1/8-inch plug in the main manifold a joint sealant that is resistant to the action of liquid

petroleum gas must be used.

The supply piping must be of sufficient size to provide 55,000 BTU/hr per oven. A 1/2-inch NPT

connection is provided at the rear of the oven directly behind the control compartment. Connect each oven

separately.

A gas shut off valve must be installed to the oven(s) and located in an accessible area.

This appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 PSGI (3.45 kPA) and the

appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply system at test pressures equal to or less than 1/2 PSIG (3.45

kPA).

Test for gas leaks. Use a commercial leak detector or a soap and water solution.

FLU EXTENSION

!

A flu extension must be installed on the lower oven of a stacked set.

!

The extension attaches to the flu opening of the lower oven and directs the flu products into the flu

opening of the upper oven.

!

This extension must be installed.

!

The ovens may now be set into position. Be careful if sliding the ovens, they are not designed to slide

over cracks or obstructions in the floor.

7

START-UPS

GCCO-AP / GCCO-C / GCCO-PP / GCCO-PT / GCCO-SII / GCCO-T

Convection Oven Start-Up

1) Verify connections at plug and terminal block

2) Incoming Gas - Water Column________

Natural Gas Propane

3) Incoming Voltage L1______

4) Motor amp draw ______

5) Are programs correct? Yes No

6) Verify actual temperature at 350 °F ________ °F.

Note:

Install thermocouple wire in center of oven cavity.

Let oven cycle off and on 3 times before recording temperature.

Set manual program in the computer for 350

Model #_______ Date_______ Serial #________

Store #___________ Tech Name___________________

Contact_______________ Company _________________________

Store Phone #___________ Service Company Phone #______________

Address_____________________

______________________

______________________

F

°°°°

8

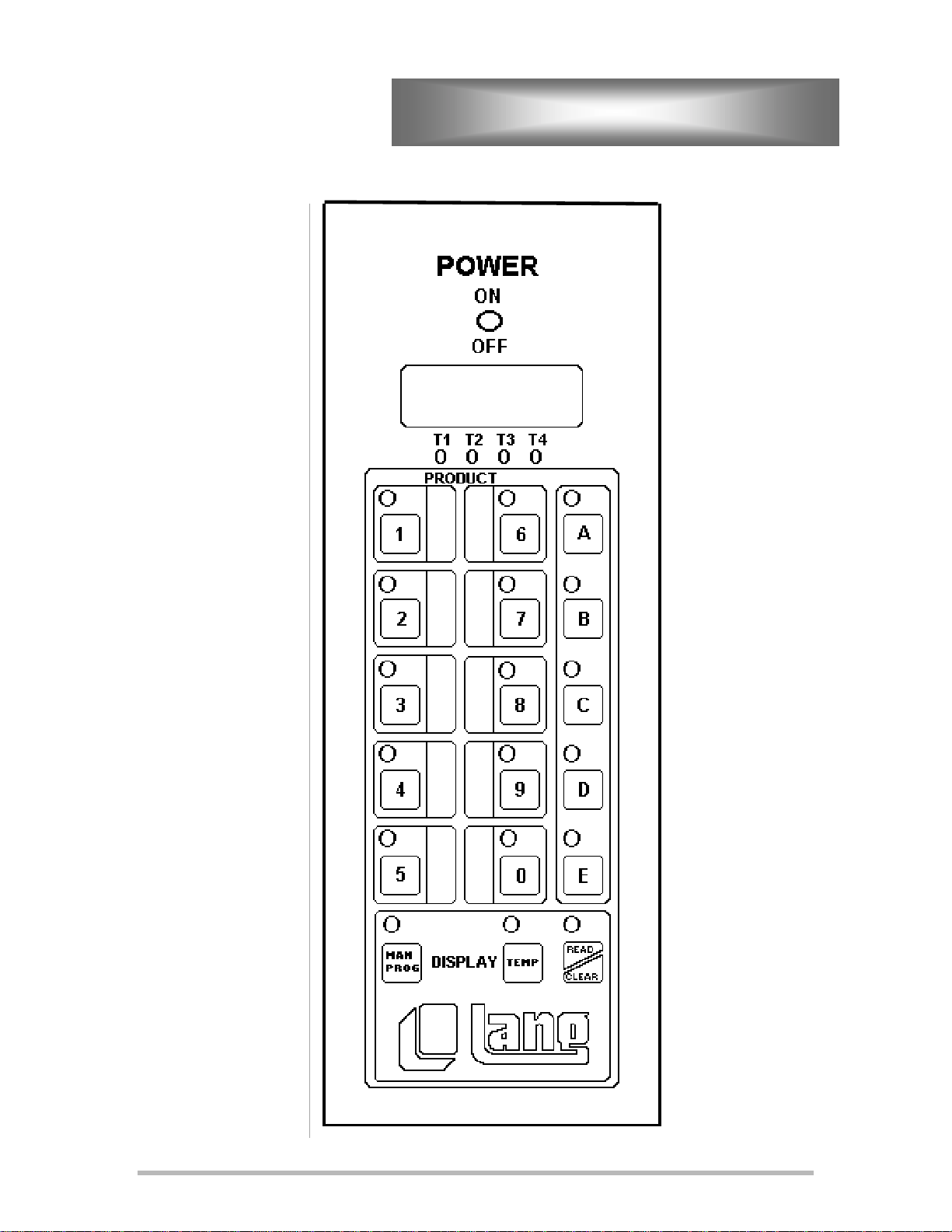

CONTROL P ANEL GCCO-AP

9

CONTROL PANEL LAYOUT GCCO-C

10

CONTROL PANEL LAYOUT GCCO-PP

11

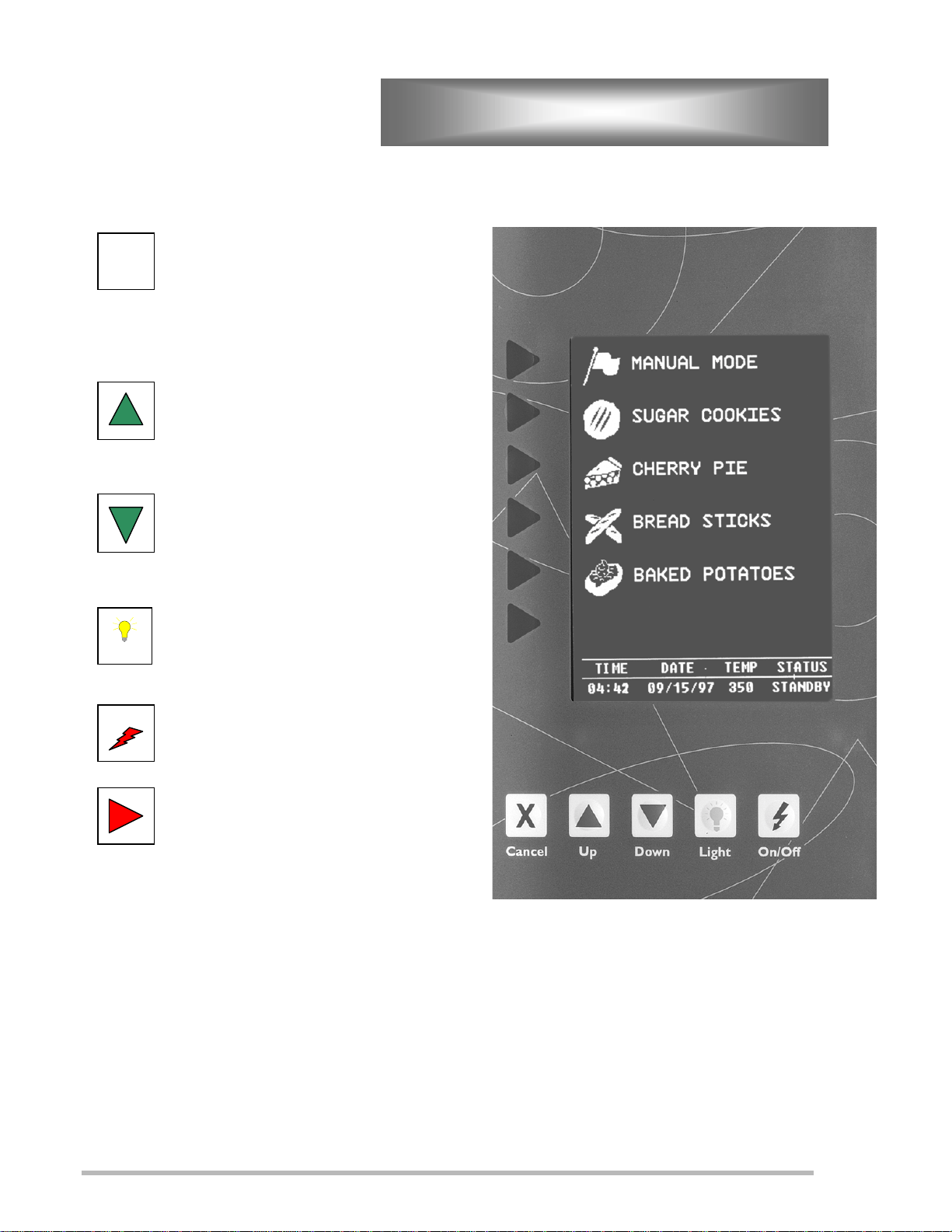

CONTROL PANEL LAYOUT GCCO-PT

When scrolling through

X

menus, this key will take you

to the previous screen.

When programming, this key

will advance you to the next

step.

Moves up through the

alphabet, numerals and

icons.

Moves down through the

alphabet, numerals and

icons.

Inspection light feature.

Light will turn off

automatically.

Turns the oven on and off.

When the oven is on, the

display screen will light up.

FUNCTION KEYS:

Keys are active when a

program option is displayed.

12

CONTROL PANEL GCCO-SII

13

CONTROL PANEL GCCO-T

14

Control Panel Buttons

PROGRAMMING TERMS

1 -0

A - E

Man Prog

READ/CLEAR

Temp

Product Buttons. These are the buttons where the product programs

are stored. Pressing a Product Button will heat the oven to the

programmed temperature.

Shelf Buttons. The control is capable of timing each shelf

individually. Pressing a Product Button then a Shelf Button will start

the countdown timer.

The MANUAL PROGRAM button allows the operator to enter a

temporary product program without being required to input the

programming code. The temporary program is erased when the oven

is turned off or when a new program is entered. Time and

temperature are the only parameters that can be entered in the Manual

Program mode.

The READ/CLEAR button has several functions.

•

It is always the first button pressed when entering

programming codes.

•

Pressing it twice then pressing a Product Button will "read-

back" the program in that product button.

•

Pressing and holding the button down until "

88888

" appears

in the display will cancel the current mode of the control and return

the display to "

Enter

".

When the Temperature Recall Button is pressed, the display will

indicate the internal oven temperature. When released the display

will revert to the previous readout.

Programming Terms

Cooking Curve

Cooking curve is a function of the computer that controls the cooking

time. If the temperature of the oven is lower than the programmed

temperature, the control will slow the timer down to compensate for

the lower cooking temperature. Cooking Curves from 0 - no time

adjustment to 7 - maximum adjustment are available. Cooking Curve

3 is the most commonly used. However, as a general rule the longer

the cooking time the lower the cooking curve, the shorter the cooking

time the higher the cooking curve.

15

PROGRAMMING TERMS CONT’D

FAN FUNCTION

TIER

The convection fan has two programmable options. Fan On (Fan 1)

runs the convection fan continuously. Fan Off (Fan 0) leaves the fan

off until heat is called for by the control. In a convection oven, the

fan must come On whenever the heat comes On. The convection fan

can not be turned Off continuously.

"Tiered" programming is the ability to change the cooking

temperature or fan function during the cooking cycle. As an

example, some products require the fan to be Off for the first half of

the cooking cycle then turn On for the last half, Tier 1 would be

programmed with the fan in the Off mode then Tier 2 would be fan

On. The Tier lamps located below the display (labeled T1, T2, T3,

and T4) will illuminate to indicate which Tier is being programmed

or which Tier the program is in during the cooking cycle.

16

PROGRAMMING GCCO-C

Programming Made Easy

The Lang Purple Oven

Single Tier Programs

Note: Make sure the oven is ON. There are 3 Steps to Programming the Lang Purple Oven: 1) Use the

“Password” to enter the Programming Mode, 2) Programming, and 3) exiting the Programming Mode.

Entering the Program Mode:

1. The display should read “Enter” before proceeding. If it does not, then hold the

Read/Clear button down just until “

8’s, remove your finger and “

2. Rapidly press the following buttons: “Read/Clear,” 1,6,2,7,3,8.

88888

Enter

” appears on the display. When you see the

” will appear on the display.

3. The display will now read “

PROD

.”

Programming a Product Button:

4. Press the number button you wish to program (program 1-10).

5. The display will now read “

to erase a preset program.

6. The display will now read “

7. The display will now read “

press 0 if the program requires the fan OFF.

8. The display will now read “

seconds. If the program requires minutes only, enter “00” after entering the minutes to

indicate zero seconds.

9. Now press the “E” button. This will lock in your just entered program and ask you for a

new product button to program. If you have more programs to enter, go back and follow

steps 4-9. If you are finished, proceed to step 10 to exit the programming mode.

000°F

.” Enter the new program baking temperature or 000

CC0-7

Fan01

0:00:00

.” Enter the new cooking curve (CC) number.

.” Press 1 if the program requires the fan ON, or

.” Enter the baking/cooking time in minutes and

Exiting the Programming Mode:

10. To exit the programming mode, simply press the “Read/Clear” button. The display will

now read “

program to operate the oven in the baking mode.

Enter

.” You are now in the normal operation mode. Press any preset

Note: Once you have exited the programming mode, you can double check your preset programs

by quickly pressing the “Read/Clear” button twice, and then quickly press the product number.

The program will then come up on the display, reading the program step-by-step.

17

PROGRAMMING GCCO-C CONT’D

GCCO-C PROGRAMMING CODES

Below are codes, which will allow you to configure the display or aid in the operation, and

troubleshooting of the oven.

The readout must display

readout displays any other word, reset the computer by pressing and holding the

display reads

“88888”

The control allows for a 3-second delay between each button push, if a delay of longer than 3 seconds

has occurred, the programming code must be re-entered.

The instructions call for pressing exactly what is shown under "PRESS".

CODE DESCRIPTION PRESS

• OPERATIONAL

Recall time remaining on a shelf Shelf

Cancel a shelf timer R/C, R/C, Shelf

• DISPLAY MODES

Countdown timer display R/C,4,8,4,8,4,8

"ENTER"

before the computer will accept any programming code. If the

then release. Display should now read

“ENTER”

“R/C”

button until

.

Shelf in use display R/C,0,9,0,9,0,9

Internal oven temperature display R/C,8,7,8,7,8,7

• PROGRAMMING

Enter programming mode R/C,1,6,2,7,3,8

Recall an existing product program R/C, R/C, P (Product programmed)

Erase a product program R/C,1,6,2,7,3,8 (P) (000)

Model identification R/C, D,C,D,C,D,C

Fan Setting ( HI or Both) R/C,E,D,C,B,A,1(high),2 (both)

Program download (Contact Factory) R/C, A, B, C, D, E, P

MAINTENANCE

•

Actual oven temperature

Return to ENTER

• SHELF COMPENSATION

Enter shelf co mpensation mode R/C, C, B, C, B, C, B

Set shelf compensations (I.E.) A,2,3,A

Return to ENTER R/C

R/C,3,4,5,6,7,8

R/C

18

ACTION DISPLAY

Turn the power switch on. If the oven is already on, press

the Read / Clear key until the following screen is

displayed.

Enter access code “

“C”.

Select

Select a number from 1-9 and press the key corresponding

to that number.

4.a If a product Key selected already has a program, the

screen will read

Enter a desired cooking / baking temperature. The screen

will automatically advance to the next display.

Enter the cooking time and then press

the next screen.

Enter the desired cooking curve. (Refer to sections 6.3 and

6.7 for more detail)

Select Fan speed. (Hi=1700 rpm, Low=1400)

Select Fan Pulse rate. (0 to 100%). 0=off unless calling for

heat. 100=on at all time.

NOTE:

will be on that many number of seconds in a 100-second

block. (E.g. 67%= on for 67 seconds in a 100 second

block)

If your press 1 you will go through the same sequence as

outlined above. If you press 2 the next display will

automatically appear.

Any number between 0-100 means that the fan

1 6 2 7 3 8”.

“E”

to advance to

PROGRAMMING GCCO-PP

SELECT PRODUCT OR

READ/CLEAR TO

PROGRAM

XX:XXPM XXXF

A: SET TIME

B: SET DATE

C: PROGRAM PRODUCTS

D: NEXT MENU

PRODUCT PROGRAM MODE

SELECT PRODUCT

NUMBER 1-9

ENTER COOKING TEMP

100 TO 450 F

NOX T1 XXXF

EDIT PRODUCT?

1=EDIT OR 2=DELETE

NXX TX XXXF CX

XX:XX:XX PXXX F-XX

ENTER COOKING TIME

HR:MIN:SEC

NOX T1 XXXF CO

ENTER COOKING CURVE

0 TO 100%

NOX T1 XXXF CXX

XX:XX:XX PXXX F-XX

ENTER FAN SPEED

1=HI 2=LOW

NOX T1 XXXF CXX

XX:XX:XX PXXX F-XX

ENTER FAN PULSE RATE

1 TO 100%

NOX T1 XXXF CXX

XX:XX:XX PXX F-XX

CONTINUE TO TIER 2

1=YES 2=NO

NOX T1 XXXF CXX

XX:XX:XX PXXX F-XX

A: SET TIME

B: SET DATE

C: PROGRAM PRODUCTS

D: NEXT MENU

19

1

STEP

Press the button

to Turn oven “ON

”

PROGRAMMING GCCO-PT

STEP

2

Select

Time/Date/Program

STEP

3

Select

STEP

Program Computer

4

Enter Access Code

ABCDEF

is the code.

Run Oven

Time / Date / Program

TIME DATE TEMP STATUS

00:04 01/01/09 96 STANDBY

Display Product

Timer Only

Set Time / Date

Program Computer

TIME DATE TEMP STATUS

00:05 01/01/09 96 PROGRAM

Press the up & down

arrow keys to scroll

through letters and

numbers, then pr ess

‘Enter’ to m ove the cursor

to the right.

Example:

Press up once for an A, then press

‘Enter’. Press up

twice for a B,

then press ‘Enter’. Continue through F.

The screen will advance automatically

when the code is entered correctly.

Enter Access Code

_

Use keys to select

then press enter

Enter

Press Cancel to Quit

20

PROGRAMMING GCCO-PT CONT’D

STEP

Select

STEP

Select

5

Program Products

6

Create New Product

Program Products

Edit Ready Zone

Edit Access Code

Enable Manual Product

Configure Time of Day

Create New Product

Edit Product

Delete Product

STEP

7

“Select Product Icon”

is the first screen when entering a

product program.

Scroll down until you find an

Icon that best resembles your

product. Scroll up to go

backward through the Icon list.

Press ‘Enter’ to select your Icon,

and move to the next screen.

Edit Product

Select Product Icon

Use keys to select

then press enter

Enter

21

PROGRAMMING GCCO-PT CONT’D

STEP

8

“Select Product Name” is where

you spell the name using the

up and down arrows to

select each letter. Then press

‘Enter’ to m ove the cursor to the

next space and a new letter.

_unconfigured is the

Note:

name that must be replaced with

your product’s name or blanks,

when the product name is

shorter than 13 letters.

Example:

only _unconfigured.

must be replaced by blanks). A

blank can be found before ‘A’

or after ‘9’ when scrolling.

There are 15 spaces available for your

product’s name.

APPLE PIE replaces

(ured

Select Product Name

_UNCONFIGURED

Use keys to select

then press enter

Enter

Press Cancel When Done

Select Product Temperature

100

STEP

9

“Select Product Temperature”

Use the up and down arrows

to select numbers, press ‘ Enter’ to

lock in each ch oice and move the

cursor to the next space.

The screen will automatically

advance after you enter the third

number.

Use keys to select

then press enter

APPLE PIE

TIER 1

Enter

22

PROGRAMMING GCCO-PT CONT’D

STEP

10

“Select Tier Cook Time”

Time is entered in

hours:minu te s: sec onds. The

maximum is 12:59:59.

Press ‘Enter’ to advance cursor to

the place you want to enter a

number.

Example: 45

Press ‘Enter’ twice to advance from

hours to minutes, then press the up

arrow four times for a 4, then ‘Enter’ to

advance the cursor. Then press the

up arrow five times for a 5, then

‘Enter’ to advance the cursor.

Since 0 is your next two numbers simply

press ’Enter’ again twice to advance the

cursor.

minutes: 00 seconds

Select Tier Cook Time

00:45:00

Use keys to select

then press enter

APPLE PIE

TIER 1

TEMP: 325F

Enter

STEP

“Select Cooking Curve”

Use the up and down arrows

11

Select Cooking Curve

000 %

Use keys to select

then press enter

to select numbers, press ‘ Enter’ to

lock in each ch oice and move the

APPLE PIE

cursor to the next space.

The cooking curve has been

established for your product, enter

TIER 1

TEMP: 325F TIME: 00:45:00

that number. It must be between 0

and 100.

Example: 80% (000%)

Press ‘Enter’ once to move cursor, scroll up to 8, press ‘Enter’ to move cursor, press

‘Enter’ again since 0 is the number showing and needed.

Enter

23

PROGRAMMING GCCO-PT CONT’D

12

Step

“Select Fan Speed”

The cursor will automatically

appear on High, that is your

default. Press ‘Enter’ to keep

High Fan and advance the screen,

or press either the up or

down arrow to move the cursor

to Low.

Press ‘Enter’ to advance to the

next screen.

Select Fan Speed

HIGH LOW

Use keys to select

then press enter

APPLE PIE

TIER 1

TEMP: 325F TIME: 00:45:00

COOKING CURVE:

Enter

40%

STEP

13

“Select Pulse Rate”

Use the up and down arrows

to select numbers, press ‘ Enter’ to

lock in each ch oice and move the

cursor to the next space.

The fan pulse rate has been

established for your product, enter

that number. It must be between 0

& 100.

100% is a default, if you are not

sure press ‘Enter’ three times to

advance the screen and maintain

100%.

Example: 50% (100%)

Scroll Down to get ‘0’, press ‘Enter’ to

move cursor, scroll up to 5, press

‘Enter’ to move cursor, press ‘Enter’

again since 0 is the number showing

and needed.

Select Pulse Rate

100%

Use keys to select

then press enter

MANUAL MODE

TIER 1

TEMP: 325F TIME: 00:45:00

FAN: HI

Enter

24

PROGRAMMING GCCO-PT CONT’D

STEP

14

“Correct”?

The cursor automatically appears

on YES. The com puter is asking

if the program displayed is what

you thought you entered. If any

part of that program is incorrect,

press either the up or down

arrows to move the curs or to NO.

Press ‘Enter’ when the cursor is at

your choice. Y ES will advance

the screen, NO will take you back

to the beginning and allow you to

correct any part of the program

you entered.

Correct?

YES NO

Use keys to select

then press enter

APPLE PIE

TIER 1

TEMP: 325F TIME: 00:45:00

FAN: HI RATE: 100%

COOKING CURVE: 40%

Enter

STEP

15

“Continue to Next Tier”

The cursor automatically appears

on NO. Press ‘Enter’ to end

programming or move the cursor

with the up or down arrows.

YES will repeat steps 9 through 15

for each Tier of the program.

Continue to Next Tier?

YES NO

Use keys to select

then press enter

APPLE PIE

TIER 1

TEMP: 325F TIME: 00:45:00

FAN: HI RATE: 100%

COOKING CURVE:

Enter

40%

25

PROGRAMMING GCCO-PT CONT’D

STEP

16

After programming the

last Tier, select NO

when asked

“Continue to Nex t

Tier”? The computer

will automatica lly

advance the screen to

program more products.

If no other products

need to be programmed,

press ‘Cancel’ three

times to adva nce screen

to the beginning.

STEP

17

Create New Product

Edit Product

Delete Product

Edit Product

You may now preh eat

the oven for any

products you have

programmed.

Select

Run Oven

Run Oven

Time / Date / Program

TIME DATE TEMP STATUS

26

GENERAL

OPERATIONS

Convection ovens constantly circulate air over the product. This strips away the thin layer of moisture and

cool air from the top of the product. Heat penetrates more quickly. Cooking times are shortened and

cooking temperatures are usually reduced.

To convert standard deck oven recipes to convection oven recipes, reduce the temperature 50 °F and the

time by 25%. Make adjustments as necessary, depending upon your results.

The lower the temperature the more even the bake.

Check the product halfway through the baking cycle. Look through the door windows. Opening the oven

door is not recommended.

If products are brown on the outside and not done on the inside, too high a temperature is being used.

Decrease the temperature 15-25 °F.

If products are pulling to the edge of pans or spilling, the oven is not leveled or the pans are warped.

Correct as necessary.

Load each shelf evenly. Spaces should be maintained equally between the pan and walls. Front and back.

This will allow an even distribution of airflow.

BAKING

Most baking should be done with the vent closed. Open the vent only with high moisture products to

avoid seepage around the front of the door.

Always weigh your product. This will give you a more consistent size, color and quality.

Center the pan in the oven. The better the air flow around the product, the better the bake.

The convection oven is a mechanical piece of equipment. The same control settings will always give the

same results. If the results vary, problems may be because of preparation, not the oven.

LOADING

Place product as close to oven as practical. Open oven doors and load quickly but carefully.

If only one pan is required, load on center shelf. If two pans are required, load on second and fourth shelf.

If three pans are required, load on top shelf, bottom shelf, and center shelf. If four pans are required, load

on top shelf, bottom shelf, and middle two shelves. If five shelves are required, space evenly in oven. (See

page 28 for more detail)

UNLOADING

It is a characteristic of all convection ovens to unload the top shelf before the bottom shelves. The rising of

heat and the hot oven ceiling causes the top shelf to bake quicker. This characteristic is more pronounced

when baking at higher temperatures and/or for prolonged periods of time.

27

ONE PAN

TWO PAN

THREE PAN

GENERAL CONT’D

FOUR PAN

FIVE PAN

28

TYPICAL OPERATION

GCCO-C STATUS DISPLAY

The Status Display informs the operator of the oven's status.

It can be used as a countdown timer, shelf in use or internal oven temperature display during the

cooking cycle (see GCCO-C Programming Codes).

The Display informs the operator when the oven is ready to bake, or if the oven is above or below the

programmed temperature.

Below is a list of displays and their definitions:

ENTER

ENTER

"

ENTERENTER

" The oven is energized and ready for an operator command.

PrEht

PrEht

"

PrEhtPrEht

rEAdY

rEAdY

"

rEAdYrEAdY

COOL

COOL

"

COOLCOOL

Hot

Hot

"

HotHot

ShELF

ShELF

"

ShELFShELF

hELP

hELP

"

hELPhELP

Cont

Cont

"

ContCont

"

ErrOr

ErrOr

ErrOrErrOr

"Stands for

heating to the programmed temperature.

” A product has been selected and the oven has preheated to the

programmed temperature. The oven is ready to load a product.

" The oven's internal temperature is below what is programmed.

" The oven's internal temperature is above what is programmed.

" A product selection has been made after the oven has preheated and the

computer is asking which shelf the product is placed on.

" There is a fault in the control system, the computer will not operate until

service is performed.

"Stands for

time being entered. The oven will operate continuously at the

programmed temperature.

" An entry has been made during the programming, which the computer

does not understand.

“PREHEAT”

“CONTINUOUS”

. A product has been selected and the oven is

. The oven has been programmed without a

GCCO-AP TYPICAL OPERATION SEQUENCE

ACTION RESULT

Turn power switch to ON. Control panel heat call light comes on.

Adjust proper temperature, between 140 & 450

degrees and allow to preheat up to 20 minutes.

Open oven doors and insert product, set timer up to

60 minutes.

Timer beeps continuously when done. Product should now be done.

Oven begins he ating.

Timer begins counting down.

29

TYPICAL OPERATIO N CONT’D

GCCO-C TYPICAL OPERATION SEQUENCE

ACTION RESULT

Turn power switch to ON. Control panel comes on, disp lay says

ENTER

ENTER

“

then

Press a prod uct button. Display says

heat to the programmed temperature.

Beeper sounds briefly.

Open the oven doors and load the product. Close the

door and press the product button again.

Display says

Beeper sounds briefly and disp lay says

ENTERENTER

”

, motor starts.

PREHT

PREHT

“

READY

READY

“

READYREADY

PREHTPREHT

”

”

.

(Preheat), oven begins to

88888

88888

“

8888888888

SHELF

SHELF

“

SHELFSHELF

”

and

”

.

Press the shelf button(s) which correspond to the

shelf positions which the product is loaded (A

equals the top shelf and E equals the bottom shelf).

Beeper sounds continuously.

Press the

Open oven door and remove the product, which

corresponds to flashing shelf button(s).

flashing

shelf button(s). Beeper stops. Display shows “

Display shows a countdown timer and begins to

count toward zero.

DONE

DONE

“

Display shows

shelves carry product or resume count down for

shelves that still have product cooking.

”

, shelf button( s) flash.

DONEDONE

READY

READY

READYREADY

GCCO-PP TYPICAL OPERATION SEQUENCE

ACTION RESULT

Turn power switch to ON. Control panel comes on, display says

PRODUCT OR READ/CLEAR TO PROGRAM

Press a prod uct button. Display says

XXX F”.

to the programmed temperature.

Beeper sounds briefly.

Open the oven doors and load the product. Close

the door and press the product button again.

Display says

START ”

Beeper sounds b riefly and display says

OVEN SHELVES PRODUCT X”

“PRODUCT X PREHEATING TO

Motor starts and oven begins preheating

“READY SELECT PRODUCT TO

.

.

” if no other

“SELECT

.

“SELECT

Press the shelf button(s) which correspond to the

shelf positions just left, which the product is loaded

(A equals the top shelf and E equals the bottom

shelf).

Beeper sounds continuously.

Press the

Open oven door and remove the product, which

corresponds to flashing shelf button(s).

flashing

shelf button(s). Beeper stops. Display shows “

Display shows a countdown timer and begins to

count toward zero.

Display shows

X, REMOVE PRODUCT”

PRODUCT TO START

product or resume count down for shelves that still

have product cooking.

30

“DONE PRESS SH ELF BUTTON

, shelf button(s) flash.

READY SELECT

” if no other shelves carry

TYPICAL OPERATIO N CONT’D

GCCO-PT TYPICAL OPERATION SEQUENCE

ACTION RESULT

Press the on switch. Control panel comes on, display says

Oven, Time Date Program

“Run Oven”.

Select

Select Product button next to Icon desired. Display says

Beeper sounds briefly.

Select Product to start. Display shows possible product selection for that

Select Product to start. Display says

Press Product button next to desired shelf. Display will show icon chosen and begin to count

Beeper sounds continuously.

Oven is ready for another product.

Display will show a list of product to choose.

“Preheating to XXXF”.

Display says

temperature.

down.

Display shows

product from that shelf.

“Ready”.

“Select shelf”.

“ DONE”

.

press button and remove

“LANG, Run

GCCO-SII TYPICAL OPERATION SEQUENCE

ACTION RESULT

Turn power switch to ON. Digital display reads “

000””.

Press Temp button and use arrows to adjust to

proper Temp between 150 & 450.

Beeper will sound for 3 seconds when preheated.

Open doors and insert product.

Press Time Button and use arrows to adjust to

desired time. Press Start / Stop Button.

Beeper sounds continuously

Button.

Press Start / Stop

Oven begins heating and displays “

Display will read preheated temperature.

Digital display will start countdown.

GCCO-T TYPICAL OPERATION SEQUENCE

ACTION RESULT

Turn power switch to ON.

Adjust proper temperature, between 140 & 450

degrees and allow to preheat up to 20 minutes.

Open oven doors and insert product, set timer up to

60 minutes.

Timer beeps continuously when done. Product should now be done.

Oven begins he ating.

Timer begins counting down.

pre

”.

31

SEQUENCE OF OPERATION GCCO-AP

Power switch turned to “ON” position.

Power to oven

120/24-volt

24 volts to 6 (Johnson Control),

Spark module begins sparking at pilot burner.

24 volts to pilot valve coil of

Pilot valve opens.

Gas flows to

Pilot burner lights.

Pilot light confirmed by spark module.

12 to 13 micro amps on pin 4 (Johnson Co nt rol), and

24 volts from pin 3 (Johnson Control) and

24-volt isolation

24 volts to pins 9 and 7 of

24 volts to

Motor relay

Temperature set on 12-position switch.

24 volts from circuit board to

temperature thermostat.

Main burner ignites.

light switch

transformer

pilot burner.

transformer

motor relay

closes energizing motor and closing centrifugal switch.

.

energized.

TH

(Channel Products), and

combination gas valve.

Sens

MV

(Channel products) to isolation transformer.

energizes.

circuit board

through door switch and pulse-fan switch.

MV

.

on combination valve through pulse-switch, centrifugal switch, and over

ground

(Channel products).

spark module.

of

32

SEQUENCE OF OPERATION GCCO-C

Power switch turned to “ON” position.

Power to oven

120 volts to rows

120/24-volt

24 volts to rows

24 volts to common of

24 volts to pin

24 volts to 6 (Johnson Control),

module.

Spark module begins sparking at pilot burner.

24 volts to pilot valve coil of

Pilot valve opens.

Gas flows to

Pilot burner lights.

Pilot light confirmed by spark module.

12 to 13 micro amps on pin 4 (Johnson Co nt rol), and

24 volts from pin 3 (Johnson Control) and

back-up toggle switch.

of

Back-up toggle switch “OFF”.

Circuit 1

24 volts across

24 volts to

Motor centrifugal switch closes.

Circuit 2

24 volts to terminal

Back-up

12 volts to

Computer starts.

Product selected from

24 volts from

motor, to main valve .coil of

Main valve opens.

Gas flows to

Main burners

Back-up toggle switch “ON”.

Circuit 1

24 volts to

Motor relay

Motor centrifugal switch closes.

Circuit 2

24 volts to

Temperature set on

24 volts from

centrifugal switch in motor to main valve coil of

Main valve opens.

Gas flows to

Main burners

light switch.

“A”

transformer

“C”

“A”

on

pilot burner.

“D”

motor relay

relay closes, energizing

TP1.

TP5

through safety thermostat, through centrifugal switch in

main burners.

light.

motor relay.

closes.

Back-up thermostat.

Back-up thermostat

main burners.

light.

“B”

and

and

back-up toggle switch.

back-up relay.

and

“B”

Control panel.

Back-up thermostat.

of 24 pin

energized.

“D”

of 24 pin

combination gas valve.

TP4, TP5,

through

back-up relay.

on

gas combination valve.

terminal block.

terminal block.

TH

(Channel Products), and

Sens

MV

(Channel products) to common

TP6.

and

door switch.

120/12 volt transformer.

through safety thermostat, through

Gas combination valve.

ground

(Channel products).

of

spark

33

SEQUENCE OF OPERATION GCCO-PP/PT

Oven plugged in.

120 VAC across “A” and “B” of 24 pin terminal block.

120 VAC across Common on light relay.

120 VAC across Common on cooling fan relay.

120 VAC to control transformer (120 / 24-12) and Component transformer (120 / 24).

Power switched to “ON” position.

24 VAC across JP1 and “C”.

24 VAC across “TH” and ground on spark module.

24 VAC across “PV” and ground on spark module.

24 VAC across “PV” on combination valve.

Pilot valve opens.

Pilot ignites.

Pilot confirmed.

12-13 micro-amps from “SENSE” on spark module.

24 VAC across “MV” on spark module.

Product selected.

24 VAC across JP12 and “C”.

24 VAC across motor relay coil.

Motor relay closes.

120 VAC to motor.

Motor starts.

24 VAC across “MV” to ground on spark module.

24 VAC across JP 2 to “C”.

24 VAC to “MV” on combination valve (through centrifical switch on motor).

Main valve opens.

Main burner ignites.

Back up toggle switch to “ON”.

24 VAC to “TH” on spark module.

24 VAC across “PV” on spark module to ground.

24 VAC to “PV” on combination valve.

Pilot valve opens.

Pilot ignites.

Pilot confirmed.

12-13 micro-amps from “SENSE” on spark module.

24 VAC across “MV” on spark module.

24 VAC to motor relay.

Motor relay closes.

120 VAC to motor.

Motor Starts.

24 VAC across “MV” to ground on spark module.

24 VAC across JP 2 to “C”.

24 VAC to “MV” on combination valve (through centrifical switch on motor).

Main valve opens.

Main burner ignites.

34

SEQUENCE OF OPERATION GCCO-SII

Power switch turned to “ON” position.

Power to oven

120/24-volt

24 volts to TH, and

Spark module begins sparking at pilot burner.

24 volts to pilot valve coil of

Pilot valve opens.

Gas flows to

Pilot burner lights.

Pilot light confirmed by spark module.

12 to 13 micro amps on pin 4 (Johnson Co nt rol), and

24 volts from pin 3 (Johnson Control) and

24-volt isolation

24 volts to pins 1 and 2 of

24 volts at motor out put (pin5) to ground.

24 volts to

Motor relay

Temperature set on circuit board.

24 volts at heat out put to ground.

24 volts from circuit board to

temperature thermostat.

Main burner ignites.

light switch

transformer

pilot burner.

transformer

motor relay

closes energizing motor and closing centrifugal switch.

.

energized.

ground

spark module.

of

combination gas valve.

Sens

MV

(Channel products) to isolation transformer.

energizes.

circuit board

through door switch and pulse-fan switch.

MV

.

on combination valve through pulse-switch, centrifugal switch, and over

(Channel products).

35

NO MOTOR

PROBABLE CAUSE CORRECTIVE ACTION

TROUBLESHOOTING GCCO-AP

Defective power switch

Defective Transformer

Gas supply turned off

Defective Pilot

Spark observed

No spark observed Turn oven on. Refer to wiring diagram and check for 24 VAC at the TH

!

Check power switch for normal operation. Replace as necessary.

!

Check Transformer for normal operation.

!

Turn gas supply on and check for proper gas pressure. 5” water

column for natural gas and 10” water column for propane.

!

Perform the following “trial ignition” and look and listen for spark:

Attempt to light the pilot burner. If the burner does not ignite

after 30 seconds, cycle power and repeat “trial ignition”. The

pilot may require several trials for ignition to bleed air from the

gas piping. After the ignition attempt, pilot should only require

2-5 seconds for normal start-up.

!

Check for 24 VAC at pilot valve.

If 24 VAC is measured

!

Check for pilot burner orifice blockage. Clean and repair as

necessary.

!

Perform trial ignition, as described in above section.

!

Replace gas valve.

Be sure oven is disconnected from power supply before

performing any repair work. Make sure that main gas is turned

off before disconnecting any valves.

If 24 VAC is not measured:

!

Check for 24 VAC at PV on spark module.

!

Check continuity on wire between PV on spark module and Pilot

Valve.

terminal on the spark module.

If 24 VAC is measured.

!

Check large orange wire from igniter module to pilot burner for

continuity, and for insulation breaks.

!

Replace wire as necessary.

!

Check spark electrode and hood of pilot burner.

!

Check spark gap. Clean and re-gap if necessary.

!

Check pilot burner for any evidence of moisture. Dry pilot if

necessary.

!

Replace spark module if above checks do not correct problem.

If 24 VAC is not measured.

!

Check 120/24 VAC transformer for 18.9 Ω on the primary coil and 1

Ω

on the secondary coil.

!

Turn unit back on and check primary coil for 120 VAC and secondary

for 24 VAC.

!

Replace transformer.

, turn oven off:

WARNING

Turn oven off:

Turn oven off:

36

TROUBLESHOOTING GCCO-AP CONT’D

PROBABLE CAUSE CORRECTIVE ACTION

NO HEAT

Igniter continues to spark after

pilot is lit

Defective Module

Defective Isolation Transformer

Defective Door switch

Defective Motor relay

Defective Motor

!

Check pilot for strong flame and good contact with sensor.

!

Check sense wire for 12 to 13 micro amps on spark module. (Johnson

Control spar k modules use “#4” terminal and Channel spark mod ul es

use “Sense” terminal).

!

Turn oven off and check sense wire for continuity.

!

Replace sense wire or spark module as necessary.

!

Confirm that there is a pilot ignition.

!

Check for 24VAC at “MV” to ground.

!

Confirm that transformer is getting voltage.

!

Check transformer for normal operation.

!

Confirm that Door switch is getting voltage.

!

Check door switch for normal operation.

!

Confirm that motor relay is getting power.

!

Check motor relay for normal operation. (24 VAC 39 Ω)

!

Confirm that motor is getting power.

!

Check motor for normal operation. (HIGH: P1-T7,T4) (LOW: P1-T9)

NOTE:

The motor needs to be operational before the oven will start heating.

PROBABLE CAUSE CORRECTIVE ACTION

Defective Probe

Defective Circuit board

Defective Centrifugal Switch

Defective Hi Limit Thermostat

Defective Solenoid Valve

Plugged Ma in Burner Orifice

!

Confirm that probe is operating properly. (See Technical Data)

!

Confirm that Heat Call light is on.

If no light is detected:

!

Check 12-position switch for normal operation. (See Technical Data)

If light is detected:

!

Check for 24VAC across heat output and “D” on 12 Pole terminal.

If voltage is not present:

!

Replace Circuit board.

If voltage is present:

!

Check over temperature thermostat for proper operation.

!

Check door switch for normal operation.

!

Confirm that when motor is running that there is continuity through

Centrifuga l switch.

!

Check Hi Limit Thermostat for continuity.

!

Confirm that Valve is getting voltage.

!

Check Valve for normal operatio n.

!

Clean orifice.

37

TROUBLESHOOTING GCCO-C

!

To help troubleshoot the oven you should perform the following “Manual Override” test:

!

Open drop down door located on the lower right side, directly below front panel.

!

Turn back up toggle (on/off) switch to “on” position.

!

Turn main power switch to “on” position.

!

Check oven for normal operation.

NO DISPLAY

PROBABLE CAUSE CORRECTIVE ACTION

Power switch is not turned on

Defective power switch

Defective back-up relay

Gas supply turned off

Pilot light fails to light

!

Turn power switch on.

!

Check power switch for normal operation. Replace as necessary.

!

Check relay for normal operation.

!

Check coil for 24 VAC.

If 24 VAC is measured.

!

Check coil for 80 Ω.

!

Replace as necessary.

If 24 VAC is not measured.

!

Verify that manual override switch is in “off” position.

!

Check manual override switch for normal operation.

!

Check wires for any shorts.

!

Turn gas supply on and check for proper gas pressure. 5” water

column for natural gas and 10” water column for propane.

!

Perform the following “trial ignition” and look and listen for spark:

Attempt to light the pilot burner. If the burner does not ignite

after 30 seconds, cycle power and repeat “trial ignition”. The

pilot may require several trials for ignition to bleed air from the

gas piping. After the ignition attempt, pilot should only require

2-5 seconds for normal start-up.

Turn oven off and:

38

TROUBLESHOOTING GCCO-C CONT’D

PROBABLE CAUSE CORRECTIVE ACTION

Spark observed

No spark observed Turn one on. Refer to wiring diagram and check for 24 VAC at the TH

!

Check for 24 VAC at pilot valve.

If 24 VAC is measured

!

Check for pilot burner orifice blockage. Clean and repair as

necessary.

!

Perform trial ignition, as described in above section.

!

Replace gas valve.

Be sure oven is disconnected from power supply before

performing any repair work. Make sure that main gas is turned

off before disconnecting any valves.

If 24 VAC is not measured:

!

Check for 24 VAC at PV on spark module.

!

Check conti nuity on wire between PV on spark module and Pilot

Valve.

terminal on the spark module.

If 24 VAC is measured.

!

Check large orange wire from igniter module to pilot burner for

continuity, and for insulation breaks.

, turn oven off:

WARNING

Turn oven off:

Igniter continues to spark after

pilot is lit

!

Replace wire as necessary.

!

Check spark electrode and hood of pilot burner.

!

Check spark gap. Clean and re-gap if necessary.

!

Check pilot burner for any evidence of moisture. Dry pilot if

necessary.

!

Replace spark module if above checks do not correct problem.

If 24 VAC is not measured.

!

Check 120/24 VAC transformer for 18.9 Ω on the primary coil and 1

Ω

on the secondary coil.

!

Turn unit back on and check primary coil for 120 VAC and secondary

for 24 VAC.

!

Replace transformer.

!

Check pilot for strong flame and good contact with sensor.

!

Check sense wire for 12 to 13 micro amps on spark module. (Johnson

Control spar k modules use “#4” terminal and Channel spark mod ul es

use “Sense” terminal).

!

Turn oven off and check sense wire for continuity.

!

Replace sense wire or spark module as necessary.

Turn oven off:

39

TROUBLESHOOTING GCCO-C CONT’D

PROBABLE CAUSE CORRECTIVE ACTION

Defective back-up relay

Defective control transformer

(12 VAC).

!

Check relay for normal operation (on GCCO ovens relay will be

energized in computer mode).

!

Check coil for 24 VAC.

If 24 VAC is measured.

!

Check coil for 80 Ω.

!

Replace if necessary.

If 24 VAC is not measured.

!

Verify that back up switch is in “off” position.

!

Check back -up switch for normal operation. ( DPDT)

!

Check any wires for short.

!

Check transformer for normal operation.

UNPLUG SECONDARY SIDE OF CONTROL TRANSFORMER

FROM CPU BEFORE PERFORMING ANY TESTS.

TURN UNIT OFF BEFORE CHECKING ANY RESISTANCE.

!

Check primary coil for 120 VAC and 154.1 Ω. Check secondary coil

for no less than 10.5 VAC and 1 Ω.

Turn oven off and:

NOTE:

CAUTION:

If voltage is measured on primary:

!

Check for vol t age on secondary.

!

Replace transformer.

If voltage is not measured on primary:

!

Check wires for any shorts.

40

TROUBLESHOOTING GCCO-C CONT’D

PROBABLE CAUSE CORRECTIVE ACTION

Defective rectifier

Note: Display should now be operating.

NO FAN-Manual Mode

PROBABLE CAUSE CORRECTIVE ACTION

Defective 120/24 VAC

transformer

!

Check for no less than 10.5 VAC on

!

If correct voltage is present at

unplug both ribbon connections from CPU and re-measure at

!

If voltage remains low at

!

If voltage a t

plug ribbon back in to CPU and disconnect from Interface board.

!

Re-measure at

!

If voltage dropped to below 5 VDC replace ribbon cable (31110-01).

!

If voltage remains at 5 VDC, plug ribbon back into Interface board

and measure for 5 VDC at

!

If voltage is present at

R/C

the

!

If LED segment does not illuminate or the LED is blank, replace

LED.

!

Check for 24 VAC on “C” and “D” of the terminal block.

TP2

increased to 5 VDC when ribbon was unplugged,

TP2

button on board if LED’s come on replace Interface board.

TP2

.

TP3.

TP3

and display is still not on, press and hold

TP1

and 5 VDC on

TP1

and present, but low at

replace CPU (40102-311).

TP2

TP2

.

TP2

.

Back-up relay not energizing

If 24 VAC is not measured:

!

Check secondary coil for 1 Ω.

!

Check primary coil for 18.9 Ω.

!

Replace transformer.

If 24 VAC is measured:

!

Check back-up relay for normal operation

!

Check for 24 VAC on relay coil.

If 240 VAC is measured:

!

Check back-up relay coil for 80 Ω.

!

Replace if defective.

If 240 VAC is not measured:

!

Check back-up switch (SPDT) for normal operation.

!

Replace if defective.

Turn off and:

Turn off and:

Turn unit off and:

.

41

TROUBLESHOOTING GCCO-C CONT’D

PROBABLE CAUSE CORRECTIVE ACTION

Motor contactor not energized

No voltage across contactor

points

!

Check for 24 VAC at contactor or relay coil.

If 24 VAC is not measured:

!

Check door switch for normal operation.

!

Check door switch for continuity.

!

Replace or adjust door switch.

If 24 VAC is measured:

!

Check contactor coil for continuity.

!

Replace if defective.

!

Check 120 VAC across “C” terminals of contactor.

If 120 VAC is not measured:

!

Check connection to main contactor (heat contactor).

If 208/240 VAC is measured:

!

Check across “NO” contacts. Should have 120 VAC.

Turn oven off and:

Turn unit off and:

Defective motor

Note: Motor should now be operating

!

Replace if defective.

!

Check for 120 VAC at motor.

If 120 VAC is measured,

!

Check motor wind in g ’s fo r co nti nui t y.

!

Replace if defective.

If120 VAC is not measured:

!

Check wiring between motor and contactor.

.

Turn oven off:

42

NO MOTOR COMPUTER MODE

PROBABLE CAUSE CORRECTIVE ACTION

TROUBLESHOOTING GCCO-C CONT’D

!

Check for 24 VAC at

No 24 VAC on Interface

board

If 24 VAC is not measured:

!

Confirm that back up relay is energizing.

!

Replace if defective.

If 24 VAC is measured:

!

Check for 24 VAC at

!

Replace Interface board if defective.

NO HEAT MANUAL MODE

NOTE: Fan must be operating before trouble shooting No heat.

PROBABLE CAUSE CORRECTIVE ACTION

Pilot burner fails to light

!

Perform the following “trial ignition” and look and listen for spark:

Attempt to light the pilot burner. If the burner does not ignite

after 30 seconds, cycle power and repeat “trial ignition”. The

pilot may require several trials for ignition to bleed air from the

gas piping. After the initial attempt pilot should only require 2-5

seconds for normal start up.

TP4

to common (

TP5.

“D”

).

Spark observed

!

Check for 24 VAC at pilot valve.

If 24 VAC is measured,

!

Check for pilot burner orifice for blockage. Clean and repair as

necessary.

!

Perform trial ignition as described in above section.

!

Replace gas valve.

BE SURE OVEN IS DISCONNECTED FROM POWER SUPPLY

BEFORE PERFORMING ANY REPAIR WORK. MAKE SURE

THAT MAIN GAS IS TURNED OFF BEFORE DISCONNECTION

If 24 VAC is not measured:

!

Check for 24 VAC at PV on spark module.

!

Check continuity on wire between PV on spark module and Pilot

Valve.

turn oven off:

WARNING

ANY VALVES.

43

TROUBLESHOOTING GCCO-C CONT’D

PROBABLE CAUSE CORRECTIVE ACTION

No Spark observed Turn oven on. Refer to wiring diagram and check for 24 VAC at the TH

terminal on the spark module.

Igniter continues to spark after

pilot is lit

If 24 VAC is measured,

!

Check large orange wire from igniter module to pilot burner for

continuity, and for insulation breaks.

!

Replace wire as necessary.

!

Check spark electrode and hood of pilot burner.

!

Check spark gap. Clean and re-gap if necessary.

!

Check pilot burner for any evidence of moisture. Dry pilot if

necessary.

!

Replace spark module if above checks do not correct problem.

If 24 VAC is not measured,

!

Check 120/24 VAC transformer of 18.9 Ω on the primary coil and 1

Ω

on the secondary coil.

!

Turn unit back on and check primary coil for 120 VAC and secondary

for 24 VAC.

!

Replace if necessary.

!

Check pilot for strong flame and good contact with sensor.

!

Check sense wire for 12 to 13 amps on spark module. (Johnson

Control spark mod ules use

“sense”

use

terminal).

Turn unit off and:

Turn oven off and:

“4”

terminal and Channel spark modules

Defective thermostat

Defective over-temp thermostat

!

Turn oven off and check sense wire for continuity.

!

Replace sense wire or spark module as necessary.

!

Turn unit off and check for continuity while cycling thermostat on

and off.

!

Replace if defective.

!

Check for 24 VAC on wire # 55 on MV of spark module to ground.

If 24 VAC is not measured,

!

Check for continuity through over-temp thermostat.

!

Replace if defective.

If 24 VAC is measured,

!

Check for co nt inuity on the gas solenoi d valve.

!

Replace if defective.

44

Turn oven off and:

Turn oven off and:

TROUBLESHOOTING GCCO-C CONT’D

PROBABLE CAUSE CORRECTIVE ACTION

Defective Centrifugal switch

NO HEAT Computer Mode

PROBABLE CAUSE CORRECTIVE ACTION

No 24 VAC on Interface board

!

Check for 24 VAC on wire # 55 on MV of spark module to ground.

If 24 VAC is not measured:

!

Check for 24 VAC on red wire coming out of motor to ground.

!

Replace if defective.

NOTE:

turning thermostat off wile oven is still on.

If 24 VAC is measured,

!

!

!

If 24 VAC is not measured:

!

•

You can check for continuity through Centrifugal switch by

Turn oven off and:

Check for co nt inuity on the gas solenoi d valve.

Replace if defective.

Check for 24 VAC at

Check back -up switch for normal operation.

If 24 VAC is measured:

TP4

to ground

.

!

Check for 24 VAC at

!

Replace Interface board if defective.

TP6.

45

DISPLAY LOCKS UP

PROBABLE CAUSE CORRECTIVE ACTION

TROUBLESHOOTING GCCO-C CONT’D

“Help” in display

88888” stuck in display

“

!

Check probe for proper resistance.

!

Check that probe connections are secure.

!

Push “TEMP” button on control board and check to see if temperature

rapidly descends. If temp does descend rapidly, replace ribbon cable.

!

Check to see that contactors/relays are not stuck in the closed

position.

!

Replace contactor if defective.

!

Check for foreign objects keeping contactor closed.

!

Check for stuck button b y pressing an y button

If computer beeps or chirps:

!

Check control panel transformer (12 VAC) for proper operation.

!

!

!

If computer does not beep or chirp:

!

TP1

Check

Check

Check

Check each button for movement.

for at least 10.5 VAC.

TP2

for at least 4.99 VDC.

TP3

for at least 4.97 VDC.

.

Display has shelf “A”

!

Check that p anel label has not been damaged in any way.

!

Replace button if defective.

!

Replace panel label.

!

Read Programming Codes.

46

ANOMALIES

PROBABLE CAUSE CORRECTIVE ACTION

TROUBLESHOOTING GCCO-C CONT’D

Oven temp is not the same as

Display temp.

!

Check probe for correct resistance

IF INCORRECT RESISTANCE IS MEASURED REPLACE

PROBE.

IF CORRECT RESISTANCE IS MEASURED:

!

Check across

IF 5 VDC IS MEASURED, OVEN MUST BE CALIBRATED:

!

Manually program oven for 350 °F.

!

Let oven cycle for 15 minutes.

!

Clear program and set oven for actual oven temp.

!

Locate pot on back of Interface board and adjust display by turning

screw.

NOTE: Clockwise increases, Counterclockwise decreases.

Approximately two degrees per turn. May require several minor

IF 5 VDC IS NOT MEASURED:

!

Check for 5 VDC at

IF 5 VDC IS NOT MEASURED:

!

Replace CPU.

TP3

for 5 VDC.(Must be at least 4.98).

adjustments.

TP2.

.

47

TROUBLESHOOTING GCCO-PP, GCCO-PT

No motor in computer mode

Note:

In computer mode, the motor runs only when a product button has been selected.

In thermostat mode the motor runs all the time, even when the door is open.

PROBABLE CAUSE CORRECTIVE ACTION

!

Verify product button has been pushed and display says preheating.

No Motor in computer mode

No motor in manual back-up

!

Check voltage at motor P1 – T7/T4.

!

If voltage is present, replace motor.

IF VOLTAGE IS NOT PRESENT:

!

Verify common and normally open is closed at Hi motor relay.

!

Verify 24V on coil of Hi motor relay.

!

Verify 24V at control transformer on the secondary side.

If voltage is not present, check primary side.

!

Check voltage at motor P1 – T7/T4.

!

If voltage is present, replace motor.

IF VOLTAGE IS NOT PRESENT:

!

Verify common and normally open is closed at Hi motor relay.

!

Verify ribbon cable connections.

!

Verify 24V on coil of Hi motor relay.

!

Verify 24V at control transformer on the secondary side.

If voltage is not present, check primary side.

CAUTION: Power must be disconnected at source when disconnecting any

ribbon cable or any connector from CPU or Display. Failure to do so will

result in damage to the Display board and CPU.

48

TROUBLESHOOTING GCCO-PP, GCCO-PT CONT’D

PROBABLE CAUSE CORRECTIVE ACTION

!

Verify voltage at computer transformer.

No Display

Can’t enter program in

Computer

No Heat in computer mode

(motor must be on)

!

Verify 12 VAC across Yellow – Yellow w/ Red stripe.

!

Verify 24 VAC across Yellow – Yellow.

!

Verify transformer connections at CPU.

!

If voltage is present replace CPU.

PRODUCT BUTTON MUST BE SELECTED.

!

If display is on, but no output from computer, jumper output on CPU.

!

If output comes on, replace CPU.

!

A button may be stuck in, replace button label.

!

Display has light letters, or blocks on display, adjust contrast.

!

Verify that Pilot is lighting.

!

Verify that Spark Module is operating.

!

Check for 24 volts on Main valve.

If voltage is not present:

!

Jumper JP11 on computer board.

!

If heat contactor comes on, replace CPU.

49

NO MOTOR

PROBABLE CAUSE CORRECTIVE ACTION

TROUBLESHOOTING GCCO-SII

Defective power switch

Defective Transformer

Gas supply turned off

Defective Pilot

Spark observed

No spark observed Turn oven on. Refer to wiring diagram and check for 24 VAC at the TH

!

Check power switch for normal operation. Replace as necessary.

!

Check Transformer for normal operation.

!

Turn gas supply on and check for proper gas pressure. 5” water

column for natural gas and 10” water column for propane.

!

Perform the following “trial ignition” and look and listen for spark:

Attempt to light the pilot burner. If the burner does not ignite

after 30 seconds, cycle power and repeat “trial ignition”. The

pilot may require several trials for ignition to bleed air from the

gas piping. After the ignition attempt, pilot should only require

2-5 seconds for normal start-up.

!

Check for 24 VAC at pilot valve.

If 24 VAC is measured

!

Check for pilot burner orifice blockage. Clean and repair as

necessary.

!

Perform trial ignition, as described in above section.

!

Replace gas valve.

Be sure oven is disconnected from power supply before

performing any repair work. Make sure that main gas is turned

off before disconnecting any valves.

If 24 VAC is not measured:

!

Check for 24 VAC at PV on spark module.

!

Check conti nuity on wire between PV on spark module and Pilot

Valve.

terminal on the spark module.

If 24 VAC is measured.

!

Check large orange wire from ignitor module to pilot burner for

continuity, and for insulation breaks.

!

Replace wire as necessary.

!

Check spark electrode and hood of pilot burner.

!

Check spark gap. Clean and regap if necessary.

!

Check pilot burner for any evidence of moisture. Dry pilot if

necessary.

!

Replace spark module if above checks do not correct problem.

If 24 VAC is not measured.

!

Check 120/24 VAC trasformer for 18.9 Ω on the primary coil and 1

Ω

on the secondary coil.

!

Turn unit back on and check primary coil for 120 VAC and secondary

for 24 VAC.

!

Replace transformer.

, turn oven off:

WARNING

Turn oven off:

Turn oven off:

50

TROUBLESHOOTING GCCO-SII CONT’D

PROBABLE CAUSE CORRECTIVE ACTION

Igniter continues to spark after

pilot is lit

Defective Module

Defective Isolation Transformer

Defective Circuit board

!

Check pilot for strong flame and good contact with sensor.

!

Check sense wire for 12 to 13 micro amps on spark module. (Johnson

Control spar k modules use “#4” terminal and Channel spark mod ul es

use “Sense” terminal).

!

Turn oven off and check sense wire for continuity.

!

Replace sense wire or spark module as necessary.

!

Confirm that there is a pilot ignition.

!

Check for 24VAC at “MV” to ground.

!

Confirm that transformer is getting voltage.

!

Check transformer for normal operation.

!

Check for 24 VAC across Motor output on board and “D” on 12position terminal block.

If no voltage is present:

!

Confirm that voltage is coming in from transformer.

!

Replace circuit board.

If voltage is present:

!

Check motor relay for normal operation. (24 VAC 35Ω)

!

Check door switch for normal.

!

Check motor for normal operation. (See Technical Data)

NO HEAT

NOTE:

PROBABLE CAUSE CORRECTIVE ACTION

Defective Probe

Defective Circuit board

Defective Centrifugal Switch

Defective Hi Limit Thermostat

Defective Solenoid Valve

Plugged Ma in Burner Orifice

The motor needs to be operational before the oven will start heating.

!

Confirm that probe is operating properly. (See Technical Data)

!

Confirm that Heat Call light is on.

If no light is detected:

!

Check 12-position switch for normal operation. (See Technical Data)

If light is detected:

!

Check for 24VAC across heat output and “D” on 12 Pole terminal.

If voltage is not present:

!

Replace Circuit board.

If voltage is present:

!

Check over temperature thermostat for proper operation.

!

Check door switch for normal operation.

!

Confirm that when motor is running that there is continuity through

Centrifuga l switch.

!

Check Hi Limit Thermostat for continuity.

!

Confirm that Valve is getting voltage.

!

Check Valve for normal operatio n.

!

Clean orifice.

51

TECHNICAL DATA

TRANSFORMER RESISTANCE

TRANSFORMER Input Primary Secondary Output

!

120/24 Volt 120 Volt

!

120/12 Volt 120 Volt

!

24/24 Volt 24 Volt

18.9

154.1

2.7

Ω

Ω

Ω

1

1

3.4

Ω

Ω

Ω

CONTACTOR RESISTANCE

CONTACTOR Coil

!

3 Pole 24 Volt coil

!

2 Pole 24 Volt coil (P & B) (PP & PT motor)

6

35

Ω

Ω

RELAY RESISTANCE

RELAY Coil

!

24 VAC

82

Ω

24 Volt

12 Volt

24 Volt

OVER-TEMP THERMOSTAT

OVER-TEMP

!

Wires Normally closed

DOOR SWITCH

!

Check switch between “COM” (common) and “NO” (normally open) contacts, insure switch closes

approximately 3 to 4 inches before door closes.

BLOWER FAN

!

Blower fan will rotate clockwise and should have a 5/8“ gap between it and the back wall of the can.

AUTO/BYPASS SWITCH