Lang G-5EDSI Service Manual

Service Manual for the Lang Models:

G-2TI, G-3TI, G-4TI, G-5TI, G-6TI

G-2TDSI, G-3TDSI, G-4TDSI, G-5TDSI, G-6TDSI

G-2EI, G-3EI, G-4EI, G-5EI, G-6EI,

G-2EDSI, G-3EDI, G-4EDSI, G-5EDSI, G-6EDSI

AGC

Lang Manufacturing Company 6500 Merrill Creek Parkway Everett, WA 98203

Phone: 1-800-224-5264 Fax: 1-425-349-2733

www.langworld.com ©Copyright 2000

TABLE OF CONTENTS

CHAPTER

1. TABLE OF CONTENTS .......................................................................1

2. READ FIRST ........................................................................................2

3. EQUIPMENT DESCRIPTION...............................................................4

4. INSTALLATION....................................................................................5

5. START-UP ...........................................................................................6

6. GENERAL OPERATION ......................................................................8

7. SEQUENCE OF OPERATION .............................................................10

8. TROUBLESHOOTING .........................................................................12

9. TECHNICAL DATA...............................................................................16

10. WIRING DIAGRAMS ............................................................................20

11. PARTS LIST.........................................................................................25

PAGE

1

IMPORTANT READ FIRST IMPORTANT

CAUTION: EACH UNIT IS EXTREMLY HEAVY. FOR SAFE

HANDLING, INSTALLER SHOULD OBTAIN HELP AS

NEEDED, OR EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A FORKLIFT,

DOLLY, OR PALLET JACK) TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

CAUTION: ANY STAND, COUNTER OR OTHER DEVICE ON

WHICH GIDDLE WILL BE LOCATED MUST BE

DESIGNED TO SUPPORT THE WEIGHT OF THE

GRIDDLE.

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN

SNAP BACK WHEN CUT.

DANGER: THIS APPLIANCE MUST BE GROUNDED AT THE

TERMINAL PROVIDED. FAILURE TO GROUND THE

APPLIANCE COULD RESULT IN ELECTROCUTION

AND DEATH.

WARNING: INSTALLATION OF THE UNIT MUST BE DONE BY

PERSONNEL QUALIFIED TO WORK WITH

ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

UNIT MUST BE INSTALLED IN ACCORDANCE WITH

ALL APPLICABLE CODES.

WARNING: BEFORE LIGHTING, USE A SOAP AND WATER

SOUTION TO TEST ALL JOINTS FOR GAS LEAKS.

WARNING: DURING INITIAL USE, OR AFTER SERVICE, IF PILOT

DOES NOT IGNITE ON FIRST TRY THE MAIN GAS

VALVE MUST BE TURNED OFF FOR AT LEAST FIVE

MINUTES.

NOTICE: The data plate is located left end of griddle behind

control door. The griddle voltage, gas specs, serial

number, pipe size, and clearance specifications are

on the data plate. This information should be

carefully read and understood before proceeding

with the installation.

NOTICE: The installation of any components such as a vent

hood, grease extractors, fire extinguisher systems,

must conform to their applicable National, State and

locally recognized installation standards.

NOTICE: During the first few hours of operation you may

notice a small amount of smoke coming off the

griddle plate, and a faint odor from the smoke. This

is normal for a new griddle and will disappear after

the first few hours of use.

2

IMPORTANT READ FIRST IMPORTANT

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS.

NEVER SPRAY OR HOSE CONTROL CONSOLE,

ELECTRICAL CONNECTIONS, ETC.

CAUTION: ALWAYS KEEP THE AREA NEAR THE APPLIANCE

FREE FROM COMBUSTIBLE MATERIALS.

CAUTION: KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND

DRY. IF SPILLS OCCUR, CLEAN IMMEDIATELY, TO

AVOID THE DANGER OF SLIPS OR FALLS.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES,

MUCOUS MEMBRANES AND CLOTHING.

PRECAUTIONS SHOULD BE TAKEN TO WEAR RUBBER

GLOVES, GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE

WARNING AND FOLLOW THE DIRECTIONS ON THE

LABEL OF THE CLEANER TO BE USED.

NOTICE: Service on this, or any other, LANG appliance must be

performed by qualified personnel only. Consult your

authorized service station directory or call the factory at

1-800-224-LANG (5264), or WWW.LANGWORLD.COM for

the service station nearest you.

WARNING: BOTH HIGH AND LOW VOLTAGES ARE PRESENT

INSIDE THIS APPLIANCE WHEN THE UNIT IS

PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE

REPLACING ANY PARTS, DISCONNECT THE UNIT

FROM THE ELECTRIC POWER SUPPLY.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN

THOSE SUPPLIED BY LANG OR THEIR AUTHORIZED

DISTRIBUTORS CAN CAUSE BODILY INJURY TO THE

OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

3

EQUIPMENT DESCRIPTION

GAS GRIDDLE

EXTERIOR

♦ Griddle

¾ The griddle dimensions are 17” (43.18cm) High, 30” (76.20cm) Deep, and width is dependent on

the actual model number.

¾ The Sides, Bottom, and Rear wall are constructed of double wall stainless steel, which allows

closer installation to combustible surfaces.

¾ The griddle surface is made of 1” thick, highly polished steel to reduce hot and cold spots, recovery

problems, warping, and ensure even heat to the edges of the griddle.

♦ AGC Hood

¾ The Hood dimension (not including griddle) are 19 1/2” (49.5cm) High with hood down, 38 3/8”

(97.5cm) High with hood up, 36 7/8” (93.5cm) Deep, and 23 7/8” (58.6cm) Wide.

¾ The Hood wrap is constructed of stainless steel and uses infrared heat to broil the product.

CONTROLS

The Gas Griddle is available either with the Lang Accu-Temp controls (G-2TI, G-3TI, G-4TI, G-5TI, G6TI), the Lang Accu-Temp Direct Spark controls (G-2TDSI, G-3TDSI, G-4TDSI, G-5TDSI, G-6TDSI), the

Lang Selectronic controls (G-2EI, G-3EI, G-4EI, G-5EI, G-6EI,), and the Lang Selectronic Direct Spark

controls (G-2EDSI, G-3EDSI, G-4EDSI, G-5EDSI, G-6EDSI):

♦ G-TI (Thermostatic ignition)

¾ Each twelve-inch section has its own easy to use manual thermostat with a temperature range from

175°F to 450°F in 50° increments.

¾ Each twelve-inch section has it’s own individual burner for high efficiency, quick recovery and

outstanding performance.

♦ G-TDSI (Direct Spark, Thermostatic ignition)

¾ Same dependable control features as the G-TI with the convenience of the direct spark ignition

system.

♦ G-EI (Electronic ignition)

¾ Each twelve-inch section has its own temperature selector switch that snaps into place to lock in

any temperature from 175°F to 450°F in 25° increments.

¾ Each twelve-inch section of the griddle is controlled by an area sensitive RTD probe, which can

sense and react to a temperature change of +/- 4°F.

¾ Each twelve-inch section has it’s own individual burner for high efficiency, quick recovery and

outstanding performance.

♦ G-EDSI (Direct Spark, Electronic ignition)

¾ Same great control features as the G-EI with the convenience of the direct spark ignition system.

4

INSTALLATION

RECEIVING THE GRIDDLE

Upon receipt, check for freight damage, both visible and concealed. Visible damage should be noted on the freight

bill at the time of delivery and signed by the carrier's agent. Concealed loss or damage means loss or damage, which

does not become apparent until the merchandise has been unpacked.

If concealed loss or damage is discovered upon unpacking, make a written request for inspection by the carrier's

agent within 15 days of delivery. All packing material should be kept for inspection.

Do not return damaged merchandise to Lang Manufacturing Company. File your claim with the carrier.

Prior to un-crating, move the griddle as near its intended location as practical. The crating will help protect the unit

from the physical damage normally associated with moving it through hallways and doorways.

ELECTRICAL CONNECTION

The griddle is supplied with a cord and plug. The receptacle is not provided with the griddle.

Follow the receptacle manufacturer’s instructions when connecting the receptacle to the power supply.

GAS CONNECTION

This griddle is manufactured for use with the type of gas indicted on the nameplate. Contact the factory if your type

of gas does not match the nameplate data.

All gas connectors must be in accordance with local codes and comply with the National Fuel Federal Gas Codes

ANSI Z223.1 latest edition.

This appliance should be installed with a separate gas valve in the gas line ahead of the unit. Use a 3/4 inch or larger

gas supply line.

Remove the 5/16 inch nuts securing the rear of burners. These nuts are for securing the main burners during

transportation only. The rear burner shield must be removed to gain access to the nuts.

A pressure regulator for the type of gas specified is supplied with each appliance.

This regulator must be installed in the gas supply line. (Note the direction of the gas flow arrow.) The pressure in

the manifold of the appliance should be tested with a manometer and the regulator adjusted for proper pressure with

the appliance operating at full fire. A 1/8 inch NPT tap is provided in the manifold for connecting a manometer.

Correct manifold pressures are:

5 inches water column for natural gas

10 inches water column for propane

When replacing the plug in the manifold, a pipe joint compound or sealant should be used that is resistant to the

action of liquid petroleum gas.

Initial adjustments are the responsibility of the installer and are not chargeable to Lang Manufacturing Company.

After the griddle is in its final position, adjust the legs to create 1/4 inch slant from back to front. This will allow the

grease to run into the grease gutter and provide the proper combustion air for the burners.

5

GAS GRIDDLE

1) Verify connections at plug and terminal block

2) Incoming Volt - Single Phase L1______

3) Gas pressure is set for 4.5” WC (Natural Gas), 9” WC (Propane).

Ensure that the regulator is installed in the correct direction.

4) Ensure Griddle body is tilted 1/8” lower in front. Confirm there is

4” clearance below Griddle.

5) Ensure that burner flame is stable and not lifting off of burner.

Flame should light around the “U” of each burner with no hesitation.

Height of flame should be 1 1/4” to 1 1/2” from burner surface.

Flames must not lift off of burner ports.

START-UPS

6) Ensure that spark electrode does not continue to spark after ignition.

The tip of the spark electrode and sensor electrodes must have flame

on them and glowing red.

7) Verify actual temperature at 350 °F ________ °F.

Note: Install thermocouple wire in center of 12” section for that

control area. Let griddle cycle off and on 3 times before recording

temperature.

Model #_______ Date_______ Serial #________

Store #___________ Tech Name___________________

Contact_______________ Company _________________________

Store Phone #___________ Service Company Phone #______________

Address_____________________

______________________

______________________

6

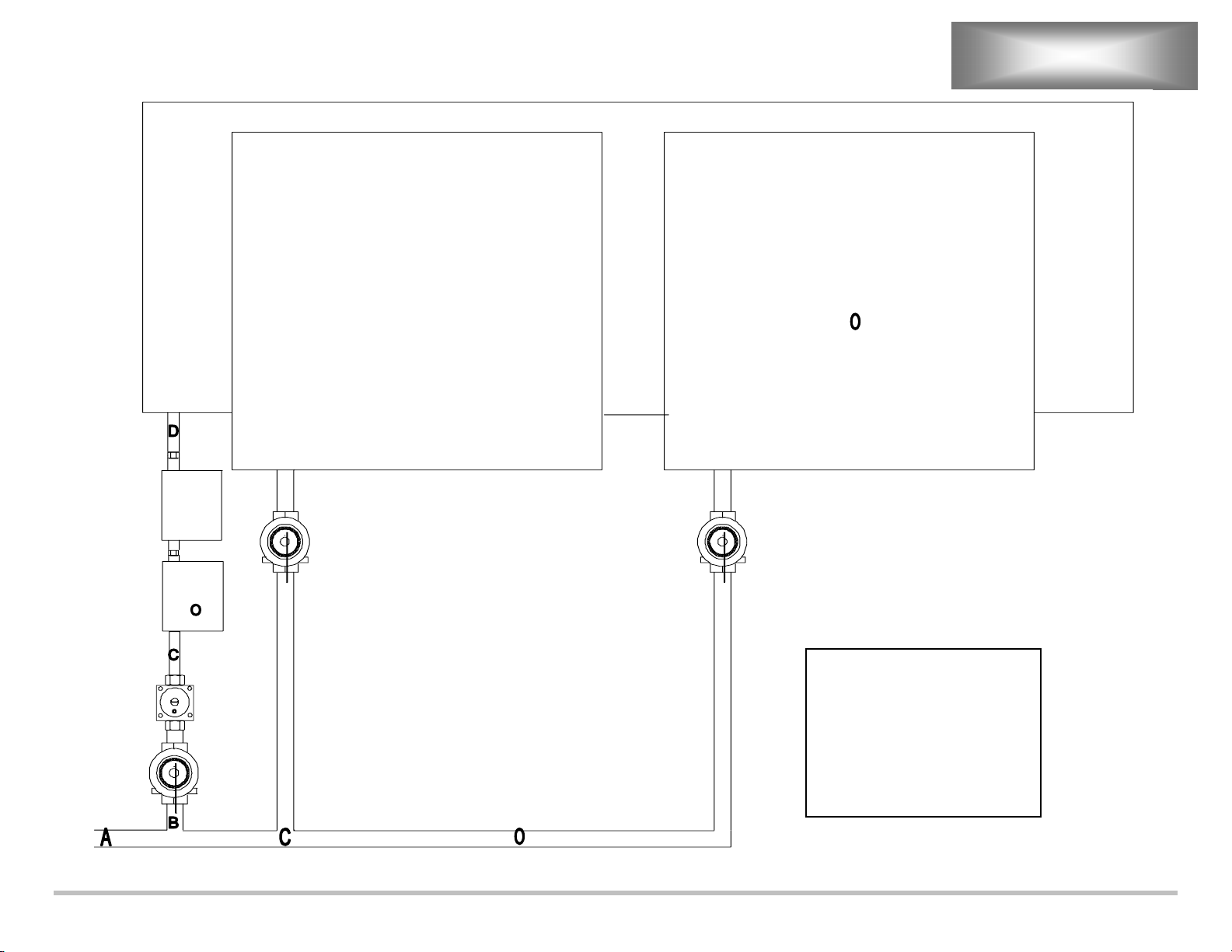

AGC START-UPS

Griddle / Charbroiler

AGC AGC

ACV

ACV

Regulator

Manual Shut-off

Legend:

ACV = Automatic Cut-off Valve

A = 1” Pipe

B = Reduction to ¾” Pipe

C = Reduction to ½” Pipe

D = Increase to ¾” Pipe

O = Optional Second AGC Parts

7

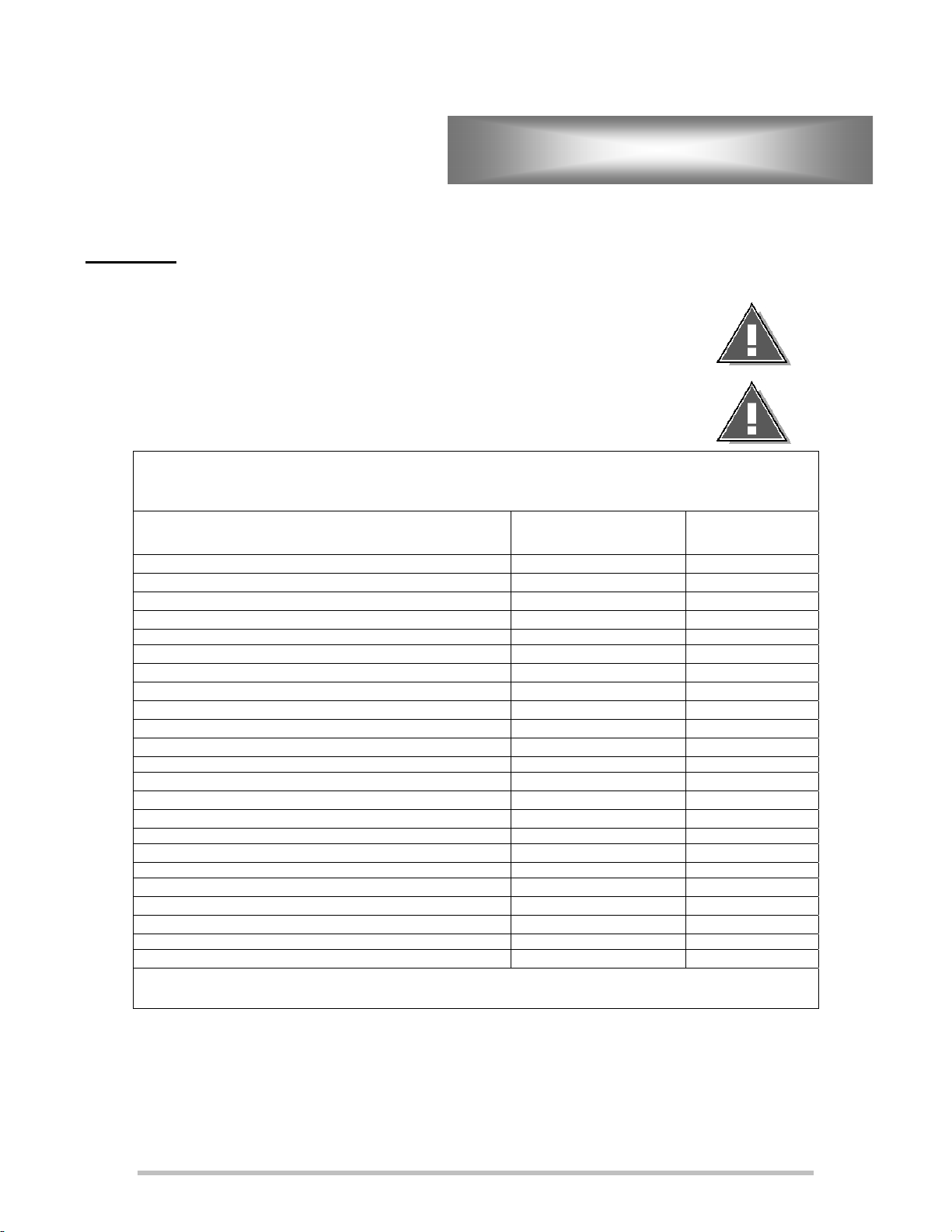

GENERAL

GENERAL

The suggested time and temperature chart (below) is provided as a guide for the products

listed only.

CAUTION: ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE

FROM COMBUSTIBLE MATERIALS.

CAUTION: KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND

DRY. IF SPILLS OCCUR, CLEAN IMMEDIATELY, TO

AVOID THE DANGER OF SLIPS OR FALLS.

SUGGESTED TIMES AND TEMPERATURES WITHOUT AGC

HOOD

PRODUCTS

HAMBURGER

2 patties per LB 350 6 to 8

4 patties per LB 350 4 to 6

6 patties per LB 350 3 to 4

STEAKS

1/2 to 3/4 inch thick, cooked medium 375 5 to 7

3/4 to 1 inch thick, cooked medium 375 8 to 10

Lamb Chops 350 6 to 8

Pork Chops 350 6 to 8

Salmon 350 6 to 8

Halibut 325 6 to 8

Snapper 325 6 to 8

Hashbrown Potatoes 375 3 to 4

Bacon 350 3 to 4

Sausage Links or Patties 350 3 to 4

Ham (Pre-cooked) 375 2

Eggs 275 2 to 4

Note: The times and temperatures in this chart are intended as a general guide and starting point. Your

actual times and temperatures may vary from this chart.

If different temperature settings are to be used, select one side of the griddle and

operate at the lowest temperature. Adjoining sections should be set at

progressively higher temperatures. Do not try to operate the end sections hot and

the center sections cool.

TEMPERATURE

(F)

350

TIME (MIN)

8

Loading...

Loading...