Page 1

IL1576

SELECTRONIC

GAS GRIDDLE

Commercial

224S

236S, 236SC 236SCHG, 236SHE, 236SHG

248S, 248SHE, 248SHG, 260S, 272S

Installation and

Operation

Instructions

2M-W360 Rev. G 11/20/09

148S

1

Page 2

SAFETY SYMBOL

Model No.:

Serial No.:

Voltage:

1-Phase or 3 Phase:

Purchased From:

Location:

Purchase Date:

Installed Date:

These symbols are intended to alert the user to the presence of important operating

and maintenance instructions in the manual accompanying the appliance.

FOR YOU R SAFTEY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINTIY OF THIS OR ANY OTHER APPLIANCE.

The installation of the Appliance must conform to the NATIONAL FUEL GAS CODE "ANSI Z223.1 - LATEST

EDITION" AND ALL LOCAL GAS COMPANY RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE CURRENT CAN/CGA-B149.1 NATURAL

GAS INSTALLATION CODE OR CAN/CGA-B149.2 PROPANE INSTALLATION CODE AND LOCAL CODES WHERE

APPLICABLE.

POST I N PROM INENT LOCAT ION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. THIS INFORMATION

SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER. AS A MINIMUM, TURN

OFF THE GAS AND CALL YOUR GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT.

EVACUATE ALL PERSONNEL FROM THE AREA.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION

& MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

WARN IN G

RISK OF FIRE OR ELECTRIC SHOCK

DO NOT OPEN

WARNING, TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE

CONTROL PANEL. NO USER-SERVICABLE PARTS INSIDE.

REPAIRS SHOULD BE DONE BY AUTHORIZED SERVICE PERSONNEL ONLY.

NOTICE

Using any part other than genuine Lang factory supplied parts relieves the manufacturer of all liability.

Lang reserves the right to change speci cations and product design without notice. Such

revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies and regulations, the

specifications contained in this sheet are subject to change without notice. While Lang

Manufacturing exercises good faith efforts to provide information that is accurate, we are

not responsible for errors or omissions in information provided or conclusions reached as a

result of using the speci cations. By using the information provided, the user assumes all risks in con-

nection with such use.

MAINTENANCE AND REPAIRS

Contact your local dealer for service or required maintenance. Please record the model number, serial

number, voltage and purchase & Installation Information in the area below and have it ready when you

call to ensure a faster service.

2

Page 3

PROBLEMS, QUESTIONS or CONCERNS

Before you proceed consult you authorized Lang service agent directory

or

Call the Lang Technical Service & Parts Department at 1-800-807-9054.

TABLE OF CONTENTS

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Equipment Description

Unpacking

Installation

V

Electrical & Gas Connection. . . . . . . . . . . . . . . . . . . . 8

Initial Start-Up

Initial Lighting Procedure

Seasoning Cooking Surface . . . . . . . . . . . . . . . . . . . . 9

Operation

Setting the Griddle

Suggested Times and Temperatures . . . . . . . . . . . . . . . 10

Loading the Griddle . . . . . . . . . . . . . . . . . . . . . . . . 11

Sequence of Operation

Power On

Maintenance

Daily Cleaning .

Weekly Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 13

Burner Air Shutter Adjustment . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

entilation & Clearence . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . 9

Temperature . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting

Symptoms / Possible Causes

Possible Causes / Test . . . . . . . . . . . . . . . . . . . . . . 15

Wiring Diagram

Exploded View & Parts List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . 18-28

NOTICE ServiceonthisoranyotherLangappliancemustbeperformedbyqualied

personnel only. Consult your Lang Authorized Service Agent Directory.

You can call our toll free number 1-800-807-9054 or visit our website

WWW.STAR-MFG.COM for the service agent nearest you.

3

Page 4

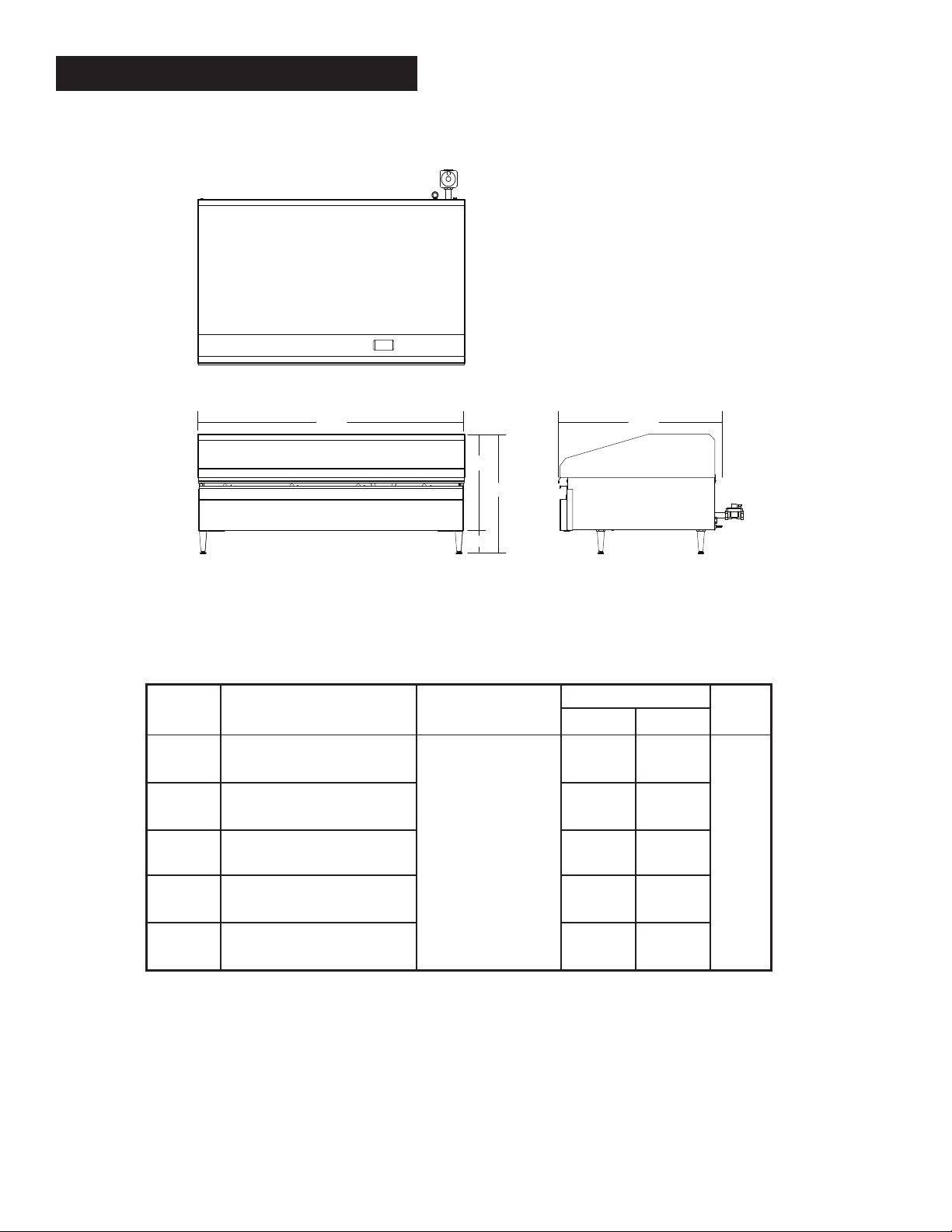

16.4”

4.0”

20.4”

30.4”

W”

Top

Front Side

IL1577

EQUIPMENT SPECIFICATIONS

Model

224S

236S

248S

260S

272S

Height x Width x Depth Clearance from Weight

16.4” x 24.1” x 30.4” 243 lbs. 280 lbs.

418mm x 613mm x 773mm 110 kg 127 kg

16.4” x 36.1” x 30.4” 368 lbs. 420 lbs.

418mm x 917mm x 773mm 167 kg 191 kg

16.4” x 48.1” x 30.4” Sides: 5” 448 lbs. 520 lbs.

418mm x 1222mm x 773mm Back: 5” 204 kg 236 kg

16.4” x 60.1” x 30.4” 556 lbs. 635 lbs.

418mm x 1527mm x 773mm 253 kg 289 kg

16.4” x 72.1” x 30.4” 689 lbs. 800 lbs.

418mm x 1832mm x 773mm 313 kg 364 kg

Freight

Class(Not including legs) combustible surface Actual Shipping

65

4

Page 5

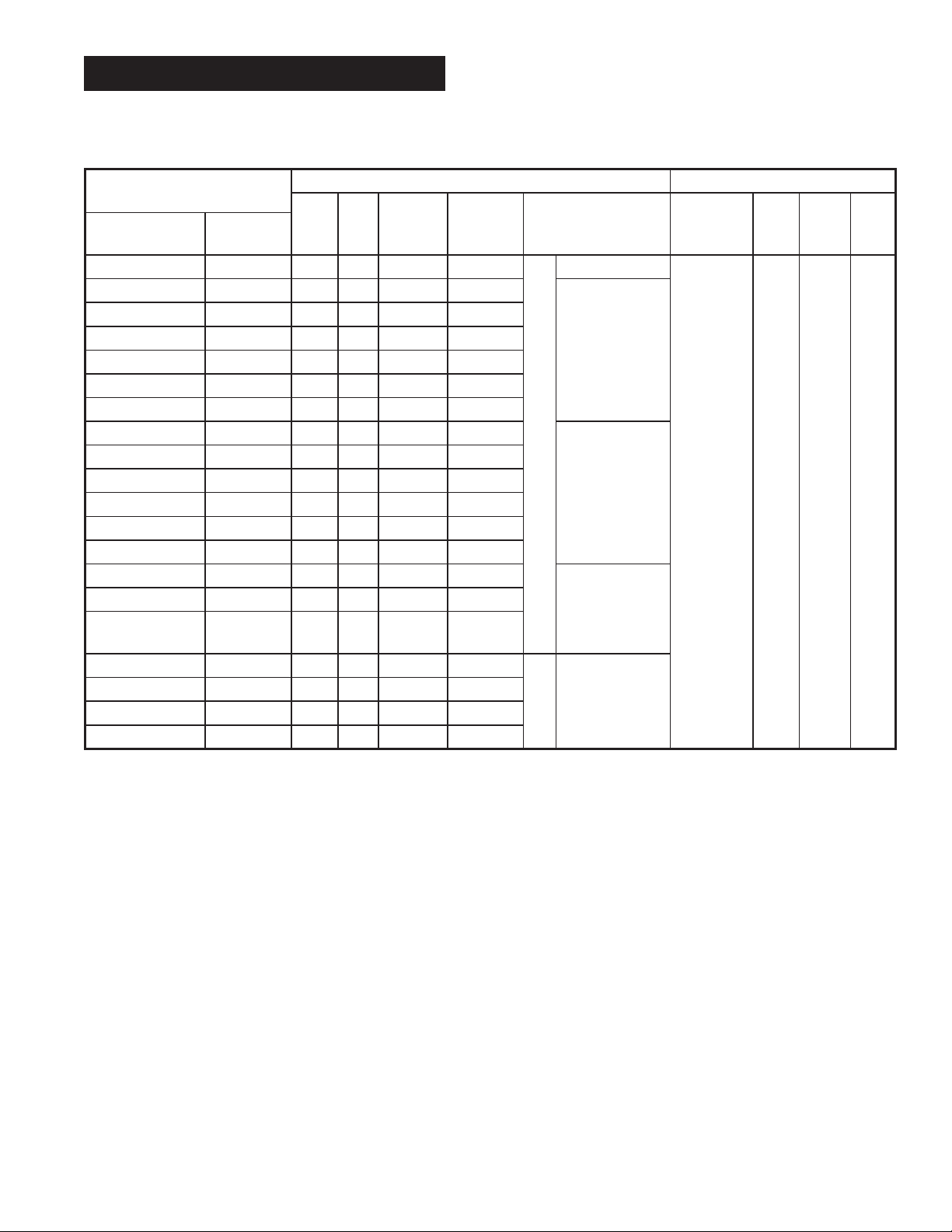

EQUIPMENT SPECIFICATIONS

SPECIFICATIONS

Gas Requirements Electrical Requirments

Previous

Model

224S-NAT G-2EI-N X 27,000 5 WC

236SC-NAT X 27,000 5 WC

236SCHG-NAT G-36TI-N X 27,000 5 WC

236SHE-NAT G-3EI-N X 27,000 5 WC

236SHG-NAT N/A X 27,000 5 WC

236S-LP G-3EI-P X 27,000 10 WC

236S-NAT G-3EI-N X 27,000 5 WC

248SHG-NAT G-4EI-N X 27,000 5 WC

248SHG-LP X 27,000 10 WC

248SHE-NAT X 27,000 5 WC

248S-LP G-4EI-P X 27,000 10 WC

248S-NAT G-4EI-N X 27,000 5 WC

248S-NATSC G-4EI-NSONC X 27,000 5 WC

260S-LP G-5EI-P X 27,000 10 WC

260S-NAT G-5EI-N X 27,000 5 WC

G-E-5EI-

260S-NATSC

272S-LP G-6EI-P X 27,000 10 WC

272S-NAT G-6EI-N X 27,000 5 WC

272S-NATSC G-G6EI-N X 27,000 5 WC

272SB-NAT X 27,000 5 WC

NSONC X 27,000 5 WC

NAT.

Gas

LP.

Gas

Burner

Input

Manifold

Press.

Gas Connection (3/4”

NPT) Voltage

50,000 BTU/hr

81,000 BTU/hr

1

108,000 BTU/hr

135,000 BTU/hr

2 162,000 BTU/hr

Total

kW Phase

115V/60Hz 0.5 1 2.0

Amps

/LineCurrent Model

5

Page 6

EQUIPMENT DESCRIPTION

IL1575

1” Griddle Surface

Gutter

Legs

Grease

Pan

Power

Indicator

Main

Power

Switch

Gas

Regulator

Section

Temp. Dial

Section

Power Switch

Panel Cover Removed for Clarity

Exterior Construction

The griddle dimensions are 17” (43.18cm) High, 30” (76.20cm) Deep, and width is dependent on the

actual model number.

The Sides, Bottom, and Rear wall are constructed of double wall stainless steel, which allows closer

installation to combustible surfaces.

The stainless steel drop-down door keeps the controls cool and control area clean.

The griddle surface is made of 1” thick, highly polished steel to reduce hot and cold spots, recovery

problems, warping, and ensure even heat to the edges of the griddle.

Controls

The Selectronic Griddle comes with the solid state controls which include:

Technical

GriddleGasandVoltageSpecications

NOTICE The data plate is on the right side of the griddle. The oven voltage,

• A Main Power Switch & Power Indicator for the entire unit.

• Each twelve-inch section has its own temperature selector switch that snaps into place to lock in

any temperature from 175°F to 450°F (79°C to 232°C) in 25° increments.

• Each twelve-inch section of the griddle is controlled by an area sensitive RTD probe, which can

sense and react to a temperature change of +/- 4°F.

• Griddle operates on either Natural gas or Propane. This must be specied when ordering. It is

shipped with a Power Cord and Plug attached.

• Floor space required is 30” (76.20cm) Deep, and width is 2 ft, 3ft, 4ft, 5ft, or 6ft depending on actual

model number.

• The griddle weighs 260, 390, 520, 650, 780 lbs. depending on actual model number.

The Lang Model can be connected to any 120 Volt source. The gas and electrical specications are

listed in the table on the previous page.

wattage,serialnumber,wiresize,andclearancespecicationsare

on the data plate. This information should be carefully read and

understood before proceeding with the installation.

6

Page 7

CAUTION

UNPACKING

Receiving the Griddle

Upon receipt, check for freight damage, both visible and concealed.

Visible damage should be noted on the freight bill at the time of delivery and

signed by the carrier’s agent. Concealed loss or damage means it does not

become apparent until the merchandise has been unpacked. If concealed

loss or damage is discovered upon unpacking, make a written request for

inspection by the carrier’s agent within 15 days of delivery. All packing

material should be kept for inspection. Do not return damaged

merchandise to Star Manufacturing Company. File your claim with the

carrier.

Location

Prior to un-crating, move the oven as near to its intended location as practical. The crating will help

protect the unit from the physical damage normally associated with moving it through hallways and

doorways.

Un-crating

The griddle will arrive completely assembled inside a wood frame and strapped to a skid.

Cut the straps and remove the wood frame.

The oven can now be removed from the skid.

THE UNIT IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR PALLET JACK)

TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH OVEN WILL BE

LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE GRIDDLE.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

VENTILATION & CLEARENCE

CLEARANCE

For use on non-combustible countertops only.

Combustible and non-combustible material must be at least 48” (120cm) from the top of the

appliance and 5” (150mm) from the sides and back. Adequate clearance should also be provided

for proper operation and servicing.

AIR SUPPLY

Make certain not to obstruct the ow of combustion and ventilation air. Provisions for adequate air

supply must be furnished. The legs supplied with the unit must be installed. Make certain that air

intake openings in the bottom of the appliance are not obstructed. They are essential for proper

combustion and operation of the appliance.

EXHAUST CANOPY

It is essential that facilities be provided over the griddle to carry off fumes and gases. However,

the unit should not be directly connected to a ue or stack.

7

Page 8

INSTALLATION

Electrical Connection

The griddle is supplied with a cord and plug. The receptacle is not provided with the griddle.

Follow the receptacle manufacturer’s instructions when connecting the receptacle to the power supply.

Gas Connection

This griddle is manufactured for use with the type of gas indicted on the nameplate.

Contact the factory if your type of gas does not match the nameplate data.

All gas connectors must be in accordance with local codes and comply with the National Fuel Federal

Gas Codes ANSI Z223.1 latest edition.

This appliance should be installed with a separate gas valve in the gas line ahead of the unit. Use a

3/4 inch or larger gas supply line.

Remove the 5/16 inch nuts securing the rear of burners. These nuts are for securing the main burners

during transportation only. The rear burner shield must be removed to gain access to the nuts.

A pressure regulator for the type of gas specied is supplied with each appliance.

This regulator must be installed in the gas supply line. (Note the direction of the gas ow arrow.)

The pressure in the manifold of the appliance should be tested with a manometer and the regulator

adjusted for proper pressure with the appliance operating at full re. A 1/8 inch NPT tap is provided in

the manifold for connecting a manometer.

Correct manifold pressures are:

5 inches water column for natural gas

10 inches water column for propane

When replacing the plug in the manifold, a pipe joint compound or sealant should be used that is

resistant to the action of liquid petroleum gas.

Initial adjustments are the responsibility of the installer and are not chargeable to Star Manufacturing

International.

After the griddle is in its nal position, adjust the legs to create 1/8 inch slant from back to front.

This will allow the grease to run into the grease gutter and provide the proper combustion air for the

burners.

DANGER: THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL

PROVIDED. FAILURE TO GROUND THE APPLIANCE COULD

RESULT IN ELECTROCUTION AND DEATH.

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING.

WARNING

IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL

AND/OR DAMAGE TO EQUIPMENT. UNIT MUST BE INSTALLED IN

ACCORDANCE WITH ALL APPLICABLE CODES.

NOTICE: The data plate is located inside the control compartment of each

griddle.Thegriddlevoltage,serialnumber,gasspecications,and

clearancespecicationsareonthedataplate.Thisinformation

should be carefully read and understood before proceeding with

the installation.

NOTICE: The installation of any components such as a vent hood, grease

extractors,reextinguishersystems,mustconformtotheir

applicable National, State and locally recognized installation

standards.

8

Page 9

INITIAL START UP

Initial Lighting Procedure

Clean the preservative coating from the griddle plate and splash guard. Add a mild detergent to hot

water and wash the griddle plate and splash guard. Rinse with a damp sponge and dry with a clean

rag.

WARNING: BEFORE LIGHTING, USE A SOAP AND WATER SOLUTION TO

TEST ALL JOINTS FOR GAS LEAKS.

• Plug the unit into a 115-volt power supply.

• Turn the ON-STANDBY toggle switch to ON.

• Set the temperature dials to the desired temperature.

• Turn the toggle switch to each section to ON.

• To turn the griddle off, simply turn the main toggle switch to STANDBY.

Seasoning the Griddle Plate (non chrome only)

• Set the temperature dials to 300°F (148°C).

• Observe the burners through the opening at the top of the control panel.

• When the burners go OFF, apply a thin coat of high-grade, non-salted vegetable oil to the

griddle surface.

• Rub the oil into the griddle surface with the at side of a spatula or a towel.

• Recoat any dry spots that appear then wait two minutes and wipe off any excess oil.

• Repeat the seasoning process at 350°F (176°C) and at 400°F (204°C).

NOTICE: Duringtherstfewhoursofoperationyoumaynoticeasmall

amount of smoke coming off the griddle, and a faint odor from

the smoke. This is normal for a new griddle and will disappear

aftertherstfewhoursofuse.

9

Page 10

OPERATION

Setting the Griddle Temperature

The suggested time and temperature chart (below) is provided as a guide for the products listed only.

If different temperature settings are to be used, select one side of the griddle and operate at the lowest

temperature. Adjoining sections should be set at progressively higher temperatures.

Do not try to operate the end sections hot and the center sections cool.

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF

CAUTION

SPILLS OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER

OF SLIPS OR FALLS.

SUGGESTED TIMES AND TEMPERATURES

TEMPERATURE

PRODUCTS

HAMBURGER

2 patties per LB 6 to 8

4 patties per LB 4 to 6

6 patties per LB 3 to 4

(F / C) TIME (MIN)

350°F (176°C)

STEAKS

1/2 to 3/4 inch thick, cooked

medium

3/4 to 1 inch thick, cooked

medium 8 to 10

Lamb Chops

Pork Chops 6 to 8

Salmon 6 to 8

Halibut

Snapper 6 to 8

Hashbrown Potatoes 375°F (190°C) 3 to 4

Bacon

Sausage Links or Patties 3 to 4

Ham (Pre-cooked) 375°F (190° C) 2

Eggs 275°F (135°C) 2 to 4

375°F (190°C)

350°F (176°C)

325°F (162°C)

350°F (176°C)

5 to 7

6 to 8

6 to 8

3 to 4

Note: The times and temperatures in this chart are intended as a general

guide and starting point. Your actual times and temperatures may vary from

this chart.

10

Page 11

OPERATION

Loading the Griddle

An understanding of how the griddle sections are controlled will be a valuable aid in loading your

griddle.

Each 12 inch section of your griddle is independently controlled. The temperature control sensor is

mounted under the griddle plate in the center of each cooking section.

If the product is loaded directly over the temperature sensor, that section will turn on and the

burner will heat the entire cooking section. If the product is loaded to the side, front or back of the

temperature sensor, the thermostat will react to the temperature change much slowly.

During slow periods with minimal loads, do not load directly over the thermostat sensors as this will

unnecessarily turn the burners on and overheat the remainder of the section not being utilized.

Turn the product and continue cooking until it has reached its desired degree of doneness.

Remove the product from the griddle.

When reloading the griddle, rst use the griddle surface on which a previous load was not placed.

This will insure you the proper griddle temperature.

11

Page 12

SEQUENCE OF OPERATION

Power On

When the griddle is connected to 115 Volt power, the spark module for each section starts sparking.

While they are sparking the solenoid valve for the pilot burners are energized.

When the individual pilot burners ignite, and the pilot ame is veried, the spark module will stop

sparking. Note: The pilot burners will remain lit until the griddle is removed from power or the gas is

shut off.

When the main switch is turned on, 24 Volts is applied to the temperature control circuit.

When one of the individual section’s switch is turned on, it provides power to the circuit board for that

section.

The operator can now set the temperature of that section by selecting it on the temperature dial.

When the temperature on the dial is set higher than the temperature of the griddle section the circuit

board will generate a “Heat call”. This call (24 VAC Signal) goes to the solenoid valve opening the

valve. The pilot burner ignites the main burner.

As the griddle section temperature increases the temperature sense probe resistance increases.

When the griddle section reaches the temperature set on the selector switch, the circuit board which

monitors the probe resistance will turn off the heat call and there by close the gas valve.

When the griddle temperature drops below the set temperature the circuit board generates a new

heat call and the sequence repeats.

12

Page 13

MAINTENANCE & CLEANING

Set Screw

Air Shutter

Burner

IL1578

Daily Cleaning (Non chrome only)

• Empty the grease drawer daily or whenever it is 3/4 full. It is easily removed for washing.

• Keep the griddle surface clean. After each cooking load, scrape the griddle surface to remove any

carbonized grease.

• Once a day or when necessary the non chrome griddle surface should be thoroughly cleaned and

seasoned again. Use a griddle stone, griddle pad, or liquid cleaner. Rub with the grain of the

metal, being careful not to scrape the splash guard.

• Chrome griddle surfaces can be scraped with a 4” wide Razor Sharp scrapper and wipe surface

with a damp cloth.

• Following the scraping, a damp cloth and non-silicated, non-abrasive, non-chlorinated cleaner such

as Bon-Ami may be used to wipe surface clean, followed by wiping with a clean wet cloth.

Weekly Cleaning (Non chrome only)

• A mild detergent with water or one of the many commercial cleaners may be used.

• Be sure to rinse thoroughly and coat the griddle with a thin lm of oil to prevent rusting,

non-chrome surfaces only.

• Clean the exterior of the appliance with hot water and a mild detergent to maintain a gleaming

appearance.

• Re-season the griddle plate after each cleaning, non-chrome surfaces only.

Burner Air Shutter Adjustment

• The air shutters are pre-set at the factory.

However, minor adjustments may be required in

the eld to accommodate differences in gas and

elevation.

• To adjust the air shutters, loosen the set screw

holding the air damper to the burner near the gas

inlet.

• Adjust the air mixture until the burner ame just

ickers on the burner. “Lift-off” or yellow ame

indicates improper shutter adjustment.

• Periodically inspect and clean the air shutters to

insure complete combustion.

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY

OR HOSE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

WARNING

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN

TO WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE WARNING AND

CAUTION

FOLLOW THE DIRECTIONS ON THE LABEL OF THE CLEANER TO

BE USED.

NOTICE: Never leave a chlorine sanitizer in contact with stainless steel

surfaces longer than 10 minutes. Longer contact can cause

corrosion.

13

Page 14

TROUBLESHOOTING

Symptoms

The chart below is to assist in the troubleshooting of the griddle.

Refer to the Symptoms column to locate the type of failure then to the Possible Cause for the items to be

checked.

To test for a possible cause, refer to the TEST section (on the following page) and locate the Possible Cause

then refer to test to identify test procedures.

SYMPTON POSSIBLE CAUSE

Entire griddle not lighting •

Power indicator is not lit •

Section will not heat •

Product burning •

Product under done •

Doesn’t ignite •

Failed regulator or plugged regulator vent

Failed transformer

•

No power to cord outlet

Griddle unplugged from outlet

•

Failed power cord or plug

•

Failed power switch

•

Failed pilot light

•

Failed gas valve

Failed spark module

•

Failed circuit board

•

Failed temperature sensor

•

Pluggedpilotorice

•

Product is cooked too long

Failed temperature sensor

•

Failed circuit board

•

Failed temperature selector

•

Open wire between selector and circuit board

•

Failed temperature sensor

Failed circuit board

•

Failed temperature selector

•

Incorrect Gas pressure

•

Failed igniter

Improper gas pressure

•

No power

•

Failed spark module

•

14

Page 15

TROUBLESSHOOTING CONT.

Possible Cause TEST

Failed Regulator •

Failed transformer •

Failed power cord or plug •

Failed power switch •

Failed pilot light •

Failed gas valve •

Failed igniter •

Failed spark module •

Failed circuit board •

Failed temperature sensor •

Failed temperature selector •

Open wire between selector and circuit board •

Incorrect gas pressure •

Pluggedregulatorvent,ororice •

TESTS

Replace regulator

Check transformer for correct voltage, replace as necessary

Check cord and plug for proper voltage

Check switch for continuity across poles

Check for continuity across pilot light leads

Remove the wires from the valve terminals and check for

continuity across the coil

Replace as necessary

Check for correct incoming voltage at module

Check for proper voltage and operation

Ohm sensor for correct resistance

Remove the wires and check the resistance on all settings

Replace as necessary

Adjust to correct pressure

Clean as necessary

NOTICE: Service on this, or any other, LANG appliance must be performed by

qualiedpersonnelonly.ConsultyourLANGauthorizedserviceagent

directory or call the factory at 1-800-807-9054, or WWW.STAR-MFG.COM

For the service agent nearest you.

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS

APPLIANCE WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE

WARNING

RECEPTACLE. BEFORE REPLACING ANY PARTS, DISCONNECT THE

UNIT FROM THE ELECTRIC POWER SUPPLY.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED

BY LANG OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE BODILY

CAUTION

INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

15

Page 16

16

25

WIRING DIAGRAM

Gas Griddle, Selectronic

224S, 236S, 248S, 260S, 272S

L G N

PILOT

BURNER

SINGLE

TRANSFORMER

2, 3, & 4FT

PILOT

VALVE

SPARK

MODULE

BURNER

VALVE

FLAME

SWITCH

FLAME

SWITCH

TERMINAL

BLOCK

L1

N

INDICATOR

LAMP

POWER CORD

12 POSITION

SWITCH

RTD

TEMPERATURE

CONTROL

BOARD

TEMPERATURE

CONTROL

BOARD

1

1

2

2

345

5

678

9

24V

120V

BURNER

VALVE

SPARK

MODULE

PILOT

BURNER

12 POSITION

SWITCH

RTD

NG

L

1

1

2

2

3

4

5

5

6

7

8

9

YEL

BLK

WHT

GRN

2 WHT

1 BLK

14 ORG

11 YEL

10 RED

13 YEL

12 RED

19

GRN

5 BLU

6 BLU

8 WHT

7 BLK

16 BLU

15 BLU

9 GRN

BLK

BLK

18

BLK

17

RED

YEL

4 RED

3 YEL

21 WHT

20 BLK

PILOT

BURNER

PILOT

BURNER

PILOT

BURNER

PILOT

BURNER

SPARK

MODULE

SPARK

MODULE

SPARK

MODULE

SPARK

MODULE

FLAME

SWITCH

FLAME

SWITCH

FLAME

SWITCH

FLAME

SWITCH

BURNER

VALVE

BURNER

VALVE

BURNER

VALVE

BURNER

VALVE

TEMPERATURE

CONTROL

BOARD

TEMPERATURE

CONTROL

BOARD

TEMPERATURE

CONTROL

BOARD

TEMPERATURE

CONTROL

BOARD

12 POSITION

SWITCH

12 POSITION

SWITCH

12 POSITION

SWITCH

12 POSITION

SWITCH

RTD

RTD

RTD

RTD

34 WHT47 WHT60 WHT73 WHT

33 BLK46 BLK

59 BLK

72 BLK

N

N

NN GGGG

L

L

L

L

22 GRN

35 GRN

48 GRN

61 GRN

74 GRN

27 ORG

40 ORG

53 ORG

66 ORG

79 ORG

29 BLU

28 BLU

42 BLU

41 BLU

55 BLU

54 BLU

68 BLU

67 BLU

81 BLU

80 BLU

23 RED

36 RED

49 RED62 RED

75 RED

24 YEL

37 YEL

50 YEL

63 YEL

76 YEL

25 RED

38 RED

51 RED

64 RED

77 RED

26 YEL

39 YEL

52 YEL

65 YEL

78 YEL

17

RED

17

RED

17

RED

17

RED

17

RED

18

BLK

18

BLK

18

BLK

18

BLK

18

BLK

19

GRN

19

GRN

19

GRN

19

GRN

19

GRN

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

333

3

4

4

4

4

5

5

5

5

5

5

6

6

6

5

5

6

7

7

7

7

8

8

8

9

9

8

9

9

2 FT

3 FT

4 FT

5 FT

6 FT

BLK

WHT

16

Page 17

21

NOITISOP

HCTIWS

LORTNOCPMET

DRAOB

HCTIWS

RENRUB

EVLAV

EMALF

HCTIWS

DTR

KRAPS

ELUDOM

TOLIP

RENRUB

21

NOITISOP

HCTIWS

LORTNOCPMET

DRAOB

HCTIWS

RENRUB

EVLAV

EMALF

HCTIWS

DTR

KRAPS

ELUDOM

TOLIP

RENRUB

21

NOITISOP

HCTIWS

LORTNOCPMET

DRAOB

HCTIWS

RENRUB

EVLAV

EMALF

HCTIWS

DTR

KRAPS

ELUDOM

TOLIP

RENRUB

1

2

5

4

3

1

9

01

8

7

4

5

6

2

3

1

2

5

4

3

1

9

01

8

7

4

5

6

2

3

1

2

5

4

3

1

9

01

8

7

4

5

6

2

3

RENRUB

EVLAV

REMROFSNART

TOLIP

EVLAV

ROTINGI

ROSNES

ROTICAPAC

HCTIWSRIA

REMROFSNART

REWOLB

FFOTUCOTUA

EVLAV

HCTIWSTLIT

ROTACIDNI

PMAL

HCTIWSREWOP

LANIMRET

KCOLB

DROCREWOP

DROCREWOP

NL GNL G NL G

ELDDIRG

XOBEGAIRRAC

DOOHLLEHSMALC

CON

NRG

THW

KLB

V42

V021

1LN

321

NRG

THW

KLB

V42

V021

NRG43

NRG7

NRG53

NRB71

NRB51

ULB61

KLB81

ULB91

THW6

KLB01

THW9

THW13

LEY21

KLB5

KLB8

LEY21

ELUDOMKRAPS

DNUORG

DNUORG

ROSNES

EVLAV

HT

TVH

NEHWWOTS

DESUTON

EDAPSDETALUSNI

SROTCENNOC

HTIWESUROF

REMITLANOITPO

YALER

NRG33

DER23

NRG52

NAT12

NAT22

DER32

NRG42

NRG62

NAT82

GRO72

LEY92

NRG03

LEY02

4NAT

3NAT

KLB1

THW2

THW

KLB

LEY

LEY

LEY3

ULB5

ULB6

DER4

KLB

KLB

THW8

KLB7

DER01

NRG9

THW12

KLB02

LEY11

LEY42

DER32

LEY31

DER21

GRO41

ULB51

ULB61

LEY62

DER52

ULB82

GRO72

ULB92

NRG22

KLB33

THW43

NRG53

ULB24

GRO04

LEY73

DER63

ULB14

LEY93

DER83

R

NRG91

DER71

KLB81

NRG91

DER71

KLB81

NRG91

DER71

KLB81

.CNILANOITANRETNIGNIRUTCAFUNAMRATS

EVIRDNENNUS01#

ASU,34136.OM,SIUOL.TS

: SJDRD .KC

ETAD :

LLEHSMALC42GSCHTIWELDDIRGSAG"63CINORTCELESD/W

7002/91/21

83W-22116-M2

510.±xxx.:DETONSSELNU:ECNARELOT

SELGNA 1

L'TNI.GFMRATSOTLAITNEDIFNOCNOITAMROFNISNIATNOCGNIWARDSIHT

DETTIMREPSISTNETNOCSTIFOERUSOLCSIDRONOITCUDORPERON.CNI

SNOISIVER

.ONTRAP

.ONLEDOM

ELTIT

LAIRETAM

HSINIF

.VER OCE/ETAD EGNAHCFONOITPIRCSED RD

17

Page 18

SK2404 Rev. - 10/06/08

Model: 224S thru 272S GAS SELECTRONIC GRIDDLE

1

2

3

5

6

7

9

10

11

14

15

16

17

18

19

20

21

22

23

24

25

SEE DETAIL A

13

12

8

4

Electrical Conduit

18

Page 19

PARTS LIST November 20, 2009, Rev. G

Model No: 224S-NAT

Selectronic Electric Griddle

Key

Number

1 K9-EZG-462-1 1 PLATE ASY 2’ SEL .5 GRV 224S-NAT

2 K9-41100-24 2 PROBE - ELECTRONIC #1517 224S-NAT

3 K9-EZG-232-01 2 WELD BURNER #42 224S-NAT

4 2V-80501-04 1 GAS REG 3/4X3/4 CLS I 224S-NAT

6 K9-EZG-397 1 CENTER BURNER BAFFLE D 224S-NAT

7 K9-EZG-400 1 END BURNER BAFFLE 224S-NAT

8 2A-Z0314 4 FOOT, 4” DIE CAST 224S-NAT

9 2E-30304-22 2 SWTCB175-450oFW/41100-13 224S-NAT

10 2K-70801-07 6 SPACER SUPPORT 1/2LG 224S-NAT

11 2E-40101-W19 2 CIRBD SI TEMP CNTRL NO 224S-NAT

12 2E-30303-18 2 SWTTOGON-OFFSPST1/4HP125V 224S-NAT

13 2E-30303-06 1 SWT TOG ON-ON DPDT BLK 224S-NAT

14 2J-31601-07 1 PILOT LT 28V 6 LEAD WHT 224S-NAT

15 K9-EZG-597 1 CONTROL PANEL ASSY 224S-NAT

16 2M-60301-131 1 LABEL - ON / STAND BY 224S-NAT

17 2E-30303-05 2 SWT PLATE ON/OFF 224S-NAT

18 2M-60301-29 2 PNLLBL SELCT SWTDIAL 450o 224S-NAT

19 2R-70701-28 2 KNB BLK 1/4BUSH2SETSCW@90 224S-NAT

20 K9-EZG-611-1 1 CONTROL PANEL COVER 2’ 224S-NAT

21 2M-60301-43 1 DIE CAST PLT LANG SATIN 224S-NAT

21 K9-60301-43-1 1 DIE CAST LOG + TINNERMAN 224S-NAT

23 2C-20103-02 AR SCRW SM PLT 10 X .5 PHLSL 224S-NAT

24 K9-EZG-349 1 GREASE DRAWER SLIDE 2’ 224S-NAT

25 K9-EZG-343 1 GREASE DRAWER ASSY 2’ 224S-NAT

NI 2C-9788 3 MAGNETIC CATCH W/STRIKE 224S-NAT

NI 2E-31107-02 1 CORD SET 14/3 X 8’ 15A 224S-NAT

NI 2E-EZG-712 2 HARNESS, SELECTRONIC 224S-NAT

NI 2K-70308-01 1 PIPE PLUG REG 1/8 NPT BLK 224S-NAT

NI 2M-60301-27 1 PNL LBL SLECTRONIC 4’ G4E 224S-NAT

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

19

Page 20

PARTS LIST November 20, 2009, Rev. G

Model No: 236S-LP, 236S-NAT, 236SC-NAT 236SCHG-NAT, 236SHE-NAT, 236SHG-NAT

Selectronic Gas Griddle

Key

Number

1 K9-EZG-464-1 1 PLATE ASY 3’ SEL .5 GRV 236S-NAT, 236S-LP

K9-EZG-464-01 1 PLATE ASY 3’ SEL .5 GRV 236SHG-NAT

K9-EZG-464-61 1 PLATE ASY 3’ SEL .5 GRV 236SCHG-NAT

K9-EZG-464-02 1 PLATE ASY 3’ SEL W/XLH-12 236SHE-NAT

2 K9-41100-24 3 PROBE - ELECTRONIC #1517 ALL

3 K9-EZG-232-01 3 WELD BURNER #42 ALL

4 2V-80501-04 1 GAS REG 3/4X3/4 CLS I 236S-NAT

2V-80501-05 1 GAS REG 3/4X3/4 CLS II 236S-LP

6 K9-EZG-391 1 CENTER BURNER BAFFLE B ALL

7 K9-EZG-400 2 END BURNER BAFFLE ALL

8 2A-Z0314 4 FOOT, 4” DIE CAST ALL

9 2E-30304-22 3 SWTCB175-450oFW/41100-13 ALL

10 2K-70801-07 9 SPACER SUPPORT 1/2LG ALL

11 2E-40101-W19 3 CIRBD SI TEMP CNTRL NO ALL

12 2E-30303-18 3 SWTTOGON-OFFSPST1/4HP125V ALL

13 2E-30303-06 1 SWT TOG ON-ON DPDT BLK ALL

14 2J-31601-07 1 PILOT LT 28V 6 LEAD WHT ALL

15 K9-EZG-600 1 SPOT CNTRL PNL 3’ SEL ALL

16 2M-60301-131 1 LABEL - ON / STAND BY ALL

17 2E-30303-05 3 SWT PLATE ON/OFF ALL

18 2M-60301-29 3 PNLLBL SELCT SWTDIAL 450o ALL

19 2R-70701-28 3 KNB BLK 1/4BUSH2SETSCW@90 ALL

20 K9-EZG-615 1 CONTROL PANEL COVER 3’ ALL

21 2M-60301-43 1 DIE CAST PLT LANG SATIN ALL

21 K9-60301-43-1 1 DIE CAST LOG + TINNERMAN ALL

23 2C-20103-02 AR SCRW SM PLT 10 X .5 PHLSL ALL

24 K9-EZG-355 1 GREASE DRAWER SLIDE ALL

25 K9-EZG-344 1 GREASE DRAWER ASSY ALL

NI 2C-9788 3 MAGNETIC CATCH W/STRIKE ALL

NI 2E-31107-02 1 CORD SET 14/3 X 8’ 15A ALL

NI 2E-EZG-712 3 HARNESS, SELECTRONIC ALL

NI 2K-70308-01 1 PIPE PLUG REG 1/8 NPT BLK ALL

NI 2M-60301-27 1 PNL LBL SLECTRONIC 4’ G4E ALL

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

20

Page 21

PARTS LIST November 20, 2009, Rev. G

Model No: 248S-LP, 248S-NAT, 248S-NATSC, 248SHG-NAT, 248SHE-NAT

Selectronic Gas Griddle

Key

Number

1 K9-EZG-467-01 1 PLATE ASY 4’SEL .5 GRV 248SHG-NAT

K9-EZG-467-02 1 PLATE ASY 4’SEL .5 GRV W/XLH12 248SHE-NAT

K9-EZG-467-1 1 PLATE ASY 4’SEL .5 GRV 248S-NAT/NATSC/LP

2 K9-41100-24 4 PROBE - ELECTRONIC #1517 248S

3 K9-EZG-232-01 4 WELD BURNER #42 248S

4 2V-80501-04 1 GAS REG 3/4X3/4 CLS I 248S-NAT

2V-80501-05 1 GAS REG 3/4X3/4 CLS II 248S-LP, 248SHG-LP

5 K9-EZG-388 1 CENTER BURNER BAFFLE A 248S

6 K9-EZG-391 1 CENTER BURNER BAFFLE B 248S

7 K9-EZG-400 2 END BURNER BAFFLE 248S

8 2A-Z0314 4 FOOT, 4” DIE CAST 248S

9 2E-30304-22 4 SWTCB175-450oFW/41100-13 248S

10 2K-70801-07 12 SPACER SUPPORT 1/2LG 248S

11 2E-40101-W19 4 CIRBD SI TEMP CNTRL NO 248S

12 2E-30303-18 4 SWTTOGON-OFFSPST1/4HP125V 248S

13 2E-30303-06 1 SWT TOG ON-ON DPDT BLK 248S

14 2J-31601-07 1 PILOT LT 28V 6 LEAD WHT 248S

15 K9-EZG-603 1 SPOT CNTRL PNL 4’ SEL 248S

16 2M-60301-131 1 LABEL - ON / STAND BY 248S

17 2E-30303-05 4 SWT PLATE ON/OFF 248S

18 2M-60301-29 4 PNLLBL SELCT SWTDIAL 450o 248S

19 2R-70701-28 4 KNB BLK 1/4BUSH2SETSCW@90 248S

20 K9-EZG-618 1 CONTROL PANEL COVER 4’ 248S-NAT/LP

21 2M-60301-43 1 DIE CAST PLT LANG SATIN 248S

K9-60301-43-1 1 DIE CAST LOG + TINNERMAN 248S

23 2C-20103-02 50 SCRW SM PLT 10 X .5 PHLSL 248S

24 K9-EZG-355 1 GREASE DRAWER SLIDE 248S

25 K9-EZG-344 1 GREASE DRAWER ASSY 248S-NAT/LP

K9-EZG-977 1 GREASE DRAWER ASSY 248S-NATSC

NI 2E-31107-02 1 CORD SET 14/3 X 8’ 15A 248S

NI 2K-70308-01 1 PIPE PLUG REG 1/8 NPT BLK 248S

NI 2M-60301-27 1 PNL LBL SLECTRONIC 4’ G4E 248S-NAT/LP

NI 2C-9788 3 MAGNETIC CATCH W/STRIKE 248S

NI 2E-EZG-712 4 HARNESS, SELECTRONIC 248S

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

21

Page 22

PARTS LIST November 20, 2009, Rev. G

Model No: 260S-LP, 260S-NAT, 260S-NATSC

Selectronic Gas Griddle

Key

Number

1 K9-EZG-470-1 1 PLATE ASY 5’SEL .5 GRV ALL

2 K9-41100-24 5 PROBE - ELECTRONIC #1517 ALL

3 K9-EZG-232-01 5 WELD BURNER #42 ALL

4 2V-80501-04 1 GAS REG 3/4X3/4 CLS I 260S-NAT

2V-80501-05 1 GAS REG 3/4X3/4 CLS II 260S-LP

5 K9-EZG-388 1 CENTER BURNER BAFFLE A ALL

6 K9-EZG-391 2 CENTER BURNER BAFFLE B ALL

7 K9-EZG-400 2 END BURNER BAFFLE ALL

8 2A-Z0314 4 FOOT, 4” DIE CAST 260S-NAT, 260S-LP

2R-200716 4 LEG, 2.5 IN METAL 260S-NATSC

9 2E-30304-22 5 SWTCB175-450oFW/41100-13 ALL

10 2K-70801-07 15 SPACER SUPPORT 1/2LG ALL

11 2E-40101-W19 5 CIRBD SI TEMP CNTRL NO ALL

12 2E-30303-18 5 SWTTOGON-OFFSPST1/4HP125V ALL

13 2E-30303-06 1 SWT TOG ON-ON DPDT BLK ALL

14 2J-31601-07 1 PILOT LT 28V 6 LEAD WHT ALL

15 K9-EZG-606 1 SPOT CNTRL PNL 5’ SEL ALL

16 2M-60301-131 1 LABEL - ON / STAND BY ALL

17 2E-30303-05 5 SWT PLATE ON/OFF ALL

18 2M-60301-29 5 PNLLBL SELCT SWTDIAL 450o ALL

19 2R-70701-28 5 KNB BLK 1/4BUSH2SETSCW@90 ALL

20 K9-EZG-620 1 CONTROL PANEL 5’ COVER 260S-NAT, 260S-LP

21 2M-60301-43 1 DIE CAST PLT LANG SATIN ALL

K9-60301-43-1 1 DIE CAST LOG + TINNERMAN ALL

23 2C-20103-02 AR SCRW SM PLT 10 X .5 PHLSL ALL

24 K9-EZG-355 2 GREASE DRAWER SLIDE ALL

25 K9-EZG-344 2 GREASE DRAWER ASSY ALL

NI 2C-9788 3 MAGNETIC CATCH W/STRIKE ALL

NI 2E-31107-02 1 CORD SET 14/3 X 8’ 15A ALL

NI 2E-EZG-712 5 HARNESS, SELECTRONIC ALL

NI 2K-70308-01 1 PIPE PLUG REG 1/8 NPT BLK ALL

NI 2M-60301-27 1 PNL LBL SLECTRONIC 4’ G4E ALL

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

22

Page 23

PARTS LIST November 20, 2009, Rev. G

Model No: 272S-NAT, 272S-LP, 272S-NATSC

Selectronic Gas Griddle

Key

Number

1 K9-EZG-473-1 1 PLATE ASY 6’SEL .5 GRV 272S

K9-EZGR-487-6 1 PLATE ASY 6’ SEL EZGR .5 272SB

2 K9-41100-24 6 PROBE - ELECTRONIC #1517 272S

3 K9-EZG-232-01 6 WELD BURNER #42 272S

4 2V-80501-04 1 GAS REG 3/4X3/4 CLS I 272S-NAT

2V-80501-05 1 GAS REG 3/4X3/4 CLS II 272S-LP

5 K9-EZG-394 2 CENTER BURNER BAFFLE C 272S

6 K9-EZG-391 2 CENTER BURNER BAFFLE B 272S

7 K9-EZG-400 2 END BURNER BAFFLE 272S

8 2A-Z0314 6 FOOT, 4” DIE CAST 272S

9 2E-30304-22 6 SWTCB175-450oFW/41100-13 272S

10 2K-70801-07 18 SPACER SUPPORT 1/2LG 272S

11 2E-40101-W19 6 CIRBD SI TEMP CNTRL NO 272S

12 2E-30303-18 6 SWTTOGON-OFFSPST1/4HP125V 272S

13 2E-30303-06 1 SWT TOG ON-ON DPDT BLK 272S

14 2J-31601-07 1 PILOT LT 28V 6 LEAD WHT 272S

15 K9-EZG-609 1 SPOT CNTRL PNL 6’ SEL 272S

K9-EZGR-609-1 1 SPOT CNTRL PNL 6’ SEL 272SB

16 2M-60301-131 1 LABEL - ON / STAND BY 272S

17 2E-30303-05 6 SWT PLATE ON/OFF 272S

18 2M-60301-29 6 PNLLBL SELCT SWTDIAL 450o 272S

19 2R-70701-28 6 KNB BLK 1/4BUSH2SETSCW@90 272S

20 K9-EZG-615 2 CONTROL PANEL COVER 3’ 272S

21 2M-60301-43 1 DIE CAST PLT LANG SATIN 272S

K9-60301-43-1 1 DIE CAST LOG + TINNERMAN 272S

23 2C-20103-02 AR SCRW SM PLT 10 X .5 PHLSL 272S

24 K9-EZG-355 2 GREASE DRAWER SLIDE 272S

K9-EZGR-352 2 SPOTWELD BUCKET SLIDE 272SB

25 K9-EZG-344 2 GREASE DRAWER ASSY 272S

K9-EZGR-338 2 SPOT GREASE DRAWER 272SB

NI 2C-9788 6 MAGNETIC CATCH W/STRIKE 272S

NI 2E-30501-03 2 TERM STRP 4 POLE W/PUSH 272SB

NI 2E-31107-02 1 CORD SET 14/3 X 8’ 15A 272S

NI 2E-EZG-712 6 HARNESS, SELECTRONIC 272S

NI 2K-70308-01 2 PIPE PLUG REG 1/8 NPT BLK 272S

NI 2M-60301-27 1 PNL LBL SLECTRONIC 4’ G4E 272S

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

23

Page 24

1

2

3

4

5

6

5

7

8

9

10

15

15

20

19

18

15

14

16

5

17

10

11

13

12

SK2405 Rev. -

10/23/08

Model: 224S thru 272S MANIFOLD ASSY

DETAIL

A

24

Page 25

PARTS LIST November 20, 2009, Rev. G

Model No: Detail A, Selectronic Gas Manifold Assy

224S & 236S Selectronic Gas Griddle

Key

Number

1 2C-20103-02 AR SCRW SM PLT 10 X .5 PHLSL Detail A 224S-NAT

2 2J-80201-24 1 PLT LT BURNR FR GEI12LEAD Detail A 224S-NAT

2 2J-80201-25 1 PLT LT BRNR GEI LT 12 3S2 Detail A 224S-NAT

3 K9-EZG-647 1 PILOT TUBE #4 Detail A 224S-NAT

4 2K-70101-07 1 BRAS TBE TEE 1/4CC Detail A 224S-NAT

5 2C-20102-04 0 SCRW PHD ST 8-32X.5 PLTD Detail A 224S-NAT

6 2E-31400-07 1 XFORMR120-208-240/24V40VA Detail A 224S-NAT

7 2J-80300-03 2 SPRK IGNITR MODULE SM2 Detail A 224S-NAT

9 2E-30501-03 1 TERM STRP 4 POLE W/PUSH Detail A 224S-NAT

11 2K-70101-11 3 BRAS TBE UNON 3/8CC-1/2 Detail A 224S-NAT

12 2V-80502-03 4 SLENOID VLVE 24VAC 1/2 Detail A 224S-NAT

13 2K-70101-12 2 BRAS TBE ELBW 3/8CC-1/2 Detail A 224S-NAT

15 2A-W1185 2 ORIFICE FITTING - 90 DEG Detail A 224S-NAT

17 K9-EZG-287 1 FLAME SWITCH MOUNT 2’ Detail A 224S-NAT

18 2V-80506-01 2 FLAME SWT 24 GAS GRID & Detail A 224S-NAT

19 K9-EZG-631 1 SOLENOID TUBE B Detail A 224S-NAT

20 K9-EZG-665 2 BURNER FEED TUBE #1 Detail A 224S-NAT

NI 2A-80400-11 2 ORIFICE HOOD .0935 #42 Detail A 224S-NAT

1 2C-20103-02 AR SCRW SM PLT 10 X .5 PHLSL Detail A 236S

2 2J-80201-24 3 PLT LT BURNR FR GEI12LEAD Detail A 236S

2J-80201-25 1 PLT LT BRNR GEI LT 12 3S2 Detail A 236S

3 K9-EZG-640 1 PILOT TUBE #2 Detail A 236S

K9-EZG-643 1 PILOT TUBE #3 Detail A 236S

K9-EZG-647 2 PILOT TUBE #4 Detail A 236S

4 2K-70101-07 2 BRAS TBE TEE 1/4CC Detail A 236S

5 2C-20102-04 14 SCRW PHD ST 8-32X.5 PLTD Detail A 236S

6 2E-31400-07 1 XFORMR120-208-240/24V40VA Detail A 236S

7 2J-80300-03 3 SPRK IGNITR MODULE SM2 Detail A 236S

9 2E-30501-03 1 TERM STRP 4 POLE W/PUSH Detail A 236S

10 K9-EZG-628 2 SOLENOID TUBE A Detail A 236S

11 2K-70101-11 4 BRAS TBE UNON 3/8CC-1/2 Detail A 236S

12 2V-80502-03 4 SLENOID VLVE 24VAC 1/2 Detail A 236S

13 2K-70101-12 3 BRAS TBE ELBW 3/8CC-1/2 Detail A 236S

14 K9-EZG-671 1 BURNER FEED TUBE #3 Detail A 236S

15 2A-W1185 3 ORIFICE FITTING - 90 DEG Detail A 236S

16 K9-EZG-668 1 BURNER FEED TUBE #2 Detail A 236S

17 K9-EZG-288 4 FLAME SWITCH MOUNT Detail A 236S

18 2V-80506-01 3 FLAME SWT 24 GAS GRID & Detail A 236S

19 K9-EZG-631 1 SOLENOID TUBE B Detail A 236S

20 K9-EZG-665 1 BURNER FEED TUBE #1 Detail A 236S

NI 2A-80400-11 3 ORIFICE HOOD .0935 #42 Detail A 236S-NAT

NI 2A-80400-12 3 ORIFICE HOOS .0595 #53 Detail A 236S-LP

NI 2A-80401-03 3 PILTBRNER ORIFICE .0115LP Detail A 236S-LP

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

25

Page 26

PARTS LIST November 20, 2009, Rev. G

Model No: Detail A, Selectronic Gas Manifold Assy

248S Selectronic Gas Griddle

Key

Number

1 2C-20103-02 9 SCRW SM PLT 10 X .5 PHLSL Detail A 248S-NAT

2 2J-80201-25 1 PLT LT BRNR GEI LT 12 3S2 Detail A 248S-NAT

2J-80201-24 3 PLT LT BURNR FR GEI12LEAD Detail A 248S-NAT

3 K9-EZG-640 1 PILOT TUBE #2 Detail A 248S-NAT

K9-EZG-643 1 PILOT TUBE #3 Detail A 248S-NAT

K9-EZG-650 1 PILOT TUBE #5 Detail A 248S-NAT

K9-EZG-653 1 PILOT TUBE #6 Detail A 248S-NAT

K9-EZG-647 3 PILOT TUBE #4 Detail A 248S-NAT

4 2K-70101-07 3 BRAS TBE TEE 1/4CC Detail A 248S-NAT

5 2C-20102-04 18 SCRW PHD ST 8-32X.5 PLTD Detail A 248S-NAT

6 2E-31400-07 1 XFORMR120-208-240/24V40VA Detail A 248S-NAT

7 2J-80300-03 4 SPRK IGNITR MODULE SM2 Detail A 248S-NAT

9 2E-30501-03 1 TERM STRP 4 POLE W/PUSH Detail A 248S-NAT

10 K9-EZG-628 2 SOLENOID TUBE A Detail A 248S-NAT

11 2K-70101-11 1 BRAS TBE UNON 3/8CC-1/2 Detail A 248S-NAT

2K-70101-11 2 BRAS TBE UNON 3/8CC-1/2 Detail A 248S-NAT

2K-70101-11 2 BRAS TBE UNON 3/8CC-1/2 Detail A 248S-NAT

12 2V-80502-03 1 SLENOID VLVE 24VAC 1/2 Detail A 248S-NAT

2V-80502-03 2 SLENOID VLVE 24VAC 1/2 Detail A 248S-NAT

2V-80502-03 2 SLENOID VLVE 24VAC 1/2 Detail A 248S-NAT

13 2K-70101-12 2 BRAS TBE ELBW 3/8CC-1/2 Detail A 248S-NAT

2K-70101-12 2 BRAS TBE ELBW 3/8CC-1/2 Detail A 248S-NAT

14 K9-EZG-671 1 BURNER FEED TUBE #3 Detail A 248S-NAT

15 2A-W1185 4 ORIFICE FITTING - 90 DEG Detail A 248S-NAT

16 K9-EZG-668 1 BURNER FEED TUBE #2 Detail A 248S-NAT

17 K9-EZG-288 4 FLAME SWITCH MOUNT Detail A 248S-NAT

18 2V-80506-01 4 FLAME SWT 24 GAS GRID & Detail A 248S-NAT

19 K9-EZG-631 2 SOLENOID TUBE B Detail A 248S-NAT

20 K9-EZG-665 2 BURNER FEED TUBE #1 Detail A 248S-NAT

NI 2A-80400-11 4 ORIFICE HOOD .0935 #42 Detail A 248S-NAT, 248SHG-NAT

NI 2A-80400-12 4 ORIFICE HOOS .0595 #53 Detail A 248S-LP, 248SHG-LP

NI 2A-80401-03 4 PILTBRNER ORIFICE .0115LP Detail A 248S-LP, 248SHG-LP

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

26

Page 27

PARTS LIST November 20, 2009, Rev. G

Model No: Detail A, Selectronic Gas Manifold Assy

260S Selectronic Gas Griddle

Key

Number

1 2C-20103-02 AR SCRW SM PLT 10 X .5 PHLSL Detail A 260S

2 2J-80201-24 4 PLT LT BURNR FR GEI12LEAD Detail A 260S

2J-80201-25 1 PLT LT BRNR GEI LT 12 3S2 Detail A 260S

3 K9-EZG-637 1 PILOT TUBE #1 Detail A 260S

K9-EZG-640 1 PILOT TUBE #2 Detail A 260S

K9-EZG-643 1 PILOT TUBE #3 Detail A 260S

K9-EZG-650 1 PILOT TUBE #5 Detail A 260S

K9-EZG-655 4 PILOT TUBE #9 Detail A 260S

K9-EZG-656 1 PILOT TUBE #10 Detail A 260S

4 2K-70101-07 4 BRAS TBE TEE 1/4CC Detail A 260S

5 2C-20102-04 0 SCRW PHD ST 8-32X.5 PLTD Detail A 260S

6 2E-31400-07 2 XFORMR120-208-240/24V40VA Detail A 260S

7 2J-80300-03 5 SPRK IGNITR MODULE SM2 Detail A 260S

9 2E-30501-03 2 TERM STRP 4 POLE W/PUSH Detail A 260S

10 K9-EZG-628 3 SOLENOID TUBE A Detail A 260S

11 2K-70101-11 6 BRAS TBE UNON 3/8CC-1/2 Detail A 260S

12 2V-80502-03 6 SLENOID VLVE 24VAC 1/2 Detail A 260S

13 2K-70101-12 5 BRAS TBE ELBW 3/8CC-1/2 Detail A 260S

14 K9-EZG-671 1 BURNER FEED TUBE #3 Detail A 260S

15 2A-W1185 5 ORIFICE FITTING - 90 DEG Detail A 260S

16 K9-EZG-668 2 BURNER FEED TUBE #2 Detail A 260S

17 K9-EZG-288 5 FLAME SWITCH MOUNT Detail A 260S

18 2V-80506-01 5 FLAME SWT 24 GAS GRID & Detail A 260S

19 K9-EZG-631 2 SOLENOID TUBE B Detail A 260S

20 K9-EZG-665 2 BURNER FEED TUBE #1 Detail A 260S

NI 2A-80400-11 5 ORIFICE HOOD .0935 #42 Detail A 260S-NAT

NI 2A-80400-12 5 ORIFICE HOOS .0595 #53 Detail A 260S-LP

NI 2A-80401-03 5 PILTBRNER ORIFICE .0115LP Detail A 260S

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

27

Page 28

PARTS LIST November 20, 2009, Rev. G

Model No: Detail A, Selectronic Gas Manifold Assy

272S Selectronic Gas Griddle

Key

Number

1 2C-20103-02 AR SCRW SM PLT 10 X .5 PHLSL Detail A 272S

2 2J-80201-24 4 PLT LT BURNR FR GEI12LEAD Detail A 272SB

2J-80201-24 6 PLT LT BURNR FR GEI12LEAD Detail A 272S

2J-80201-25 2 PLT LT BRNR GEI LT 12 3S2 Detail A 272S

3 K9-EZG-637 2 PILOT TUBE #1 Detail A 272S

K9-EZG-640 1 PILOT TUBE #2 Detail A 272S

K9-EZG-643 1 PILOT TUBE #3 Detail A 272S

4 2K-70101-07 4 BRAS TBE TEE 1/4CC Detail A 272S

5 2C-20102-04 0 SCRW PHD ST 8-32X.5 PLTD Detail A 272S

6 2E-31400-07 2 XFORMR120-208-240/24V40VA Detail A 272S

7 2J-80300-03 6 SPRK IGNITR MODULE SM2 Detail A 272S

9 2E-30501-03 1 TERM STRP 4 POLE W/PUSH Detail A 272S

2E-30501-03 2 TERM STRP 4 POLE W/PUSH Detail A 272SB

10 K9-EZG-628 4 SOLENOID TUBE A Detail A 272S

11 2K-70101-11 8 BRAS TBE UNON 3/8CC-1/2 Detail A 272S

12 2V-80502-03 8 SLENOID VLVE 24VAC 1/2 Detail A 272S

13 2K-70101-12 6 BRAS TBE ELBW 3/8CC-1/2 Detail A 272S

14 K9-EZG-671 2 BURNER FEED TUBE #3 Detail A 272S

15 2A-W1185 6 ORIFICE FITTING - 90 DEG Detail A 272S

16 K9-EZG-668 2 BURNER FEED TUBE #2 Detail A 272S

17 K9-EZG-288 6 FLAME SWITCH MOUNT Detail A 272S

18 2V-80506-01 6 FLAME SWT 24 GAS GRID & Detail A 272S

19 K9-EZG-631 2 SOLENOID TUBE B Detail A 272S

20 K9-EZG-665 2 BURNER FEED TUBE #1 Detail A 272S

NI 2A-80400-11 6 ORIFICE HOOD .0935 #42 Detail A 272S-NAT

NI 2A-80400-12 6 ORIFICE HOOS .0595 #53 Detail A 272S-LP

NI 2A-80401-03 6 PILTBRNER ORIFICE .0115LP Detail A 272S

NI 2E-40101-19 6 CIRBD SI TEMP CNTRL NO Detail A 272SB

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

28

Loading...

Loading...