Page 1

S6161-LR-FSE-010

0910-LP-527-3200

OPERATION AND SERVICE MANUAL

FOR

SHIPBOARD ELECTRIC DROP-IN GRIDDLE

MODEL NUMBERS:

136TDI-VG, 148TDI-VG, 172TDI-VG,

LANG MANUFACTURING

DIVISION OF STAR MANUFACTURING INTERNATIONAL

10 SUNNEN DRIVE

ST. LOUIS, MO, 63143

DISTRIBUTION STATEMENT

THIS PUBLICATION IS REQUIRED FOR OFFICIAL USE OR FOR

ADMINISTRATIVE OR OPERATIONAL PURPOSES. DISTRIBUTION IS LIMITED

TO U.S. GOVERNMENT AGENCIES ONLY. OTHER REQUESTS FOR THIS

DOCUMENT MUST BE REFERRED TO COMMANDER, NAVAL SEA SYSTEMS

COMMAND, SEA 09, WASHINGTON, DC 20362

SUPERCEDURE NOTICE

CANCELS AND SUPERCEDES S6161-LR-FSE-010

DATED MARCH 2002

AND ALL CHANGES THERETO

Lang Manufacturing 10 Sunnen Drive, St. Louis, MO 63143

Part No. 2M-W357 Phone: 314-678-6315, Fax: 314-781-2714

Rev. - www.langworld.com April, 24, 2007

1

Page 2

MANUAL SUPPLEMENT FOR MARINE EQUIPMENT

THIS EQUIPMENT IS APPROVED FOR INSTALLATION ONLY ON

VESSELS GREATER THAN 65 FEET IN LENGTH IN

ACCORDANCE WITH USCG REGULATIONS IN TITLE 46 CFR 110-

113.

ANY WIRING USED IN THE INSTALLATION OF THIS APPLIANCE

MUST BE STRANDED COPPER.

2

Page 3

0910-LP-572-3200

APRIL 2007

IDENTIFYING TECHNICAL PUBLICATION SHEET

1. IDENTIFICATION DATA:

2. PURPOSE: THIS TECHNICAL PUBLICATION IS ISSUED FOR THE PURPOSE

OF IDENTIFYING AN AUTHORIZED TECHNICAL MANUAL FOR NAVY USE

AND FOR PROVIDING SUPPLEMENTAL TECHNICAL INFORMATION.

A. MANUFACTURER: STAR MFG. INTERNATIONAL.

B. CONTRACT NUMBER: _________________________________________

C. EQUIPMENT: GRIDDLE, SELF HEATING, ELECTRIC

D. REQUISITION NUMBER: NOT REFERENCED

E. NATIONAL STOCK NUMBER (NSN): ____________________________

F. TITLE: MAINTENANCE MANUAL FOR GRIDDLE, SELF HEATING,

ELECTRIC

G. DATE OF PUBLICATION: APRIL 2007

H. PREPARING ACTIVITY: DEFENSE GENERAL SUPPLY CENTER

I. APPLICABLE TMCR NUMBER: 860172

J. EXTENT OF PROPOSED SUPPLEMENTAL DATA (10% MAXIMUM): 1%

K. LIST OF TECHNICAL MANUAL FOR THIS EQUIPMENT PROCURED

UNDER ANOTHER CONTACT:

3. ADDITIONAL COPIES: ADDITIONAL COPIES ARE AVAILABLE FROM:

NAVAL PUBLICATION AND FORMS CENTER

5801 TABOR AVENUE

PHILADELPHIA, PA 19120-5099

4. COVER: THE TECHNICAL MANUAL OUTSIDE COVER SHALL CONTAIN

THE FOLLOWING STATEMENTS:

PUBLISHED BY DIRECTION OF COMMANDER, NAVAL SEA SYSTEMS

COMMAND

3

Page 4

S6161-LR-FSE-010

0910-LP-527-3200

APPROVAL AND PROCUREMENT RECORD

APPROVAL DATA FOR: GRIDDLE, SELF-HEATING, ELECTRIC

TITLE OF MANUAL: MAINTENANCE MANUAL FOR: GRIDDLE,

SELF-HEATING, ELECTRIC

APPROVAL AUTHORITY: NAVAL SHIP SYSTEMS ENGINEERING STATION

CONTRACT NUMBER NSN # OF UNITS APL/CID

DLA441-92-M-2844 7310-01-359-2844 6 LG72MDI

DLA441-92-M-Y175 7310-01-359-2845 13 LG36MDI

DLA400-86-D-0090 7310-01-104-1214 14 LG48M

REMARKS:

DATE: MARCH 2002

CERTIFICATION:

IT IS HEREBY CERTIFIED THAT THE TECHNICAL MANUAL PROVIDED

UNDER CONTRACT NUMBER DLA441-92-M-2844, DLA441-92-M-Y175, DLA40086-D-0090 FOR LANG LG72MDI, LG36MDI, AND LG48M HAS BEEN APPROVED

BY THE APPROVAL DATA SHOWN ABOVE:

______________________________

DIRECTOR, GOV’T CONTRACTS

LANG MANUFACTURING COMPANY

FSCM / CAGE #: 34931

4

Page 5

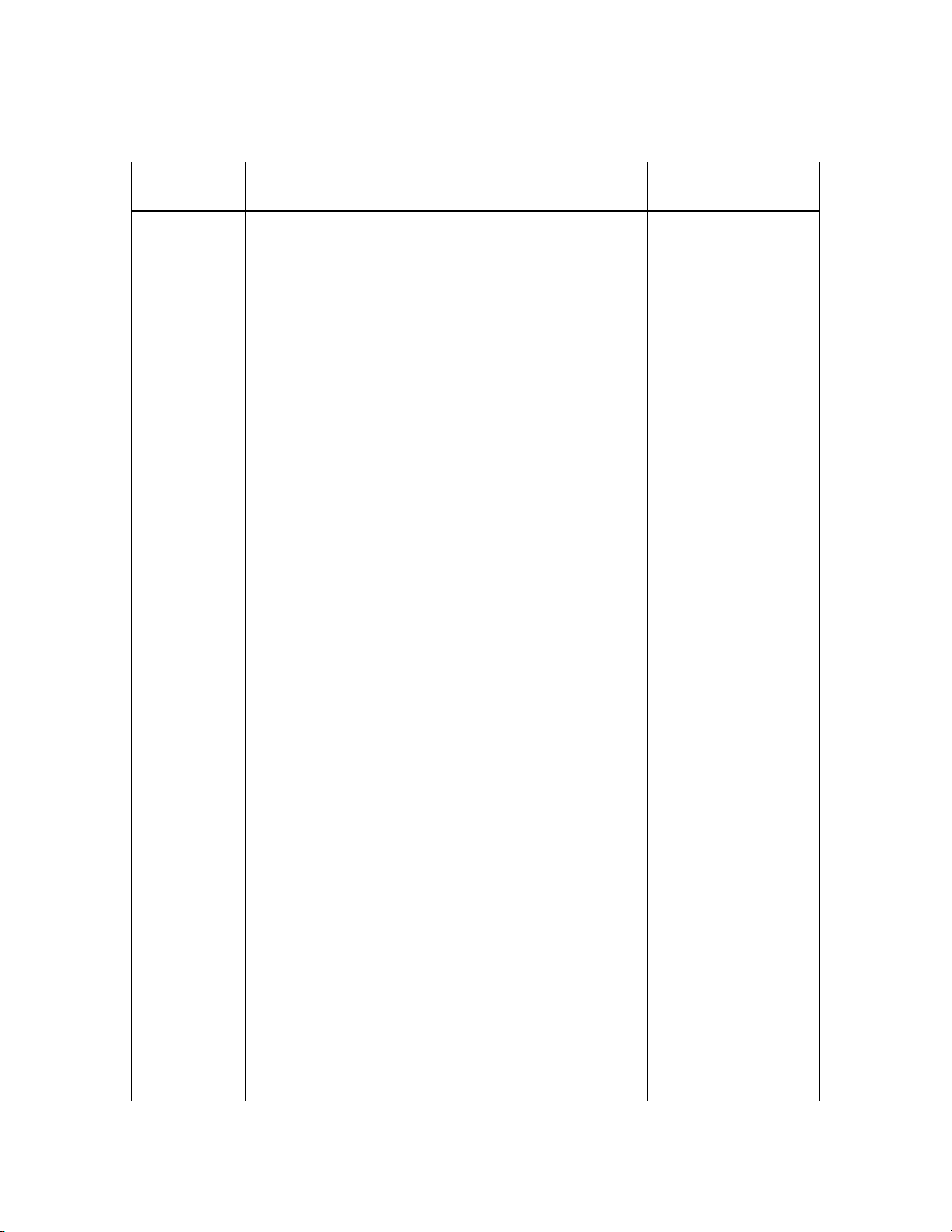

CHANGE RECORD

Change no. Date Title and/or Brief Description

Signature of

Validating Officer

5

Page 6

TABLE OF CONTENTS

CHAPTER PAGE

1. TABLE OF CONTENTS ............................................................................... 6

2. LIST OF ILLUSTRATIONS .......................................................................... 7

3. READ FIRST ................................................................................................. 8

4. SPECIFICATIONS ........................................................................................ 11

5. EQUIPMENT DESCRIPTION ...................................................................... 14

6. INSTALLATION ........................................................................................... 16

7. OPERATION .................................................................................................. 18

8. MAINTENANCE & TROUBLESHOOTING PROCEDURES .................... 19

9. PARTS LIST .................................................................................................. 24

10. WIRING DIAGRAMS ................................................................................... 26

11. WARRANTY ................................................................................................. 28

6

Page 7

LIST OF ILLUSTRATIONS

FIGURE # TITLE OF ILLUSTRATION PAGE #

1 Specification Sheets 11 to 20

2 MDI-36 Cut Out 21

3 MDI-48 Cut Out 22

4 MDI-72 Cut Out 23

5 Leg Pad Layout 27

6 Sensor Location (Calibration) 31

7 Wiring Diagram 208/240V 34

8 Wiring Diagram 480V 35

7

Page 8

IMPORTANT READ FIRST IMPORTANT

CAUTION: THE GRIDDLE IS EXTREMELY HEAVY. FOR SAFE

HANDLING, INSTALLER SHOULD OBTAIN HELP AS

NEEDED, OR EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A FORKLIFT,

DOLLY, OR PALLET JACK) TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

CAUTION: ANY STAND, COUNTER OR OTHER DEVICE ON

WHICH GRIDDLE WILL BE LOCATED MUST BE

DESIGNED TO SUPPORT THE WEIGHT OF THE

GRIDDLE(S).

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN

SNAP BACK WHEN CUT.

DANGER: THIS APPLIANCE MUST BE GROUNDED AT THE

TERMINAL PROVIDED. FAILURE TO GROUND THE

APPLIANCE COULD RESULT IN ELECTROCUTION

AND DEATH.

WARNING: INSTALLATION OF THE UNIT MUST BE DONE BY

PERSONNEL QUALIFIED TO WORK WITH

ELECTRICITY. IMPROPER INSTALLATION CAN

CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO EQUIPMENT. UNIT MUST BE INSTALLED IN

ACCORDANCE WITH ALL APPLICABLE CODES.

NOTICE: The data plate is located next to the grease drawer,

behind access panel. The griddle voltage, wattage,

serial number, wire size, and clearance specifications

are on the data plate. This information should be

carefully read and understood before proceeding

with the installation.

NOTICE: The installation of any components such as a vent

hood, grease extractors, fire extinguisher systems,

must conform to their applicable National, State and

locally recognized installation standards.

NOTICE: During the first few hours of operation you may

notice a small amount of smoke coming off the

griddle surface, and a faint odor from the smoke.

This is normal for a new griddle and will disappear

after the first few hours of use.

CAUTION: ALWAYS KEEP THE AREA NEAR THE APPLIANCE

FREE FROM COMBUSTIBLE MATERIALS.

CAUTION: KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN

AND DRY. IF SPILLS OCCUR, CLEAN IMMEDIATELY,

TO AVOID THE DANGER OF SLIPS OR FALLS.

8

Page 9

IMPORTANT READ FIRST IMPORTANT

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS.

NEVER SPRAY OR HOSE CONTROL CONSOLE,

ELECTRICAL CONNECTIONS, ETC.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES,

MUCOUS MEMBRANES AND CLOTHING.

PRECAUTIONS SHOULD BE TAKEN TO WEAR RUBBER

GLOVES, GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE

WARNING AND FOLLOW THE DIRECTIONS ON THE

LABEL OF THE CLEANER TO BE USED.

NOTICE: Service on this, or any other, LANG appliance must be

performed by qualified personnel only. Consult your

LANG authorized service agent directory or call the

factory at 314-678-6315 or www.langworld.com For the

service agent nearest you.

WARNING: BOTH HIGH AND LOW VOLTAGES ARE PRESENT

INSIDE THIS APPLIANCE WHEN THE UNIT IS

PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE

REPLACING ANY PARTS, DISCONNECT THE UNIT

FROM THE ELECTRIC POWER SUPPLY.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN

THOSE SUPPLIED BY LANG OR THEIR AUTHORIZED

DISTRIBUTORS CAN CAUSE BODILY INJURY TO THE

OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

9

Page 10

LANG MANUFACTURING COMPANY

MANUAL FOR MODEL ECO

ELECTRIC CONVECTION OVENS

ISSUE DATE FEBRUARY 1999

LANG MANUFACTURING COMPANY

10 SUNNEN DRIVE

ST. LOUIS, MO 63143

ELECTRIC GRIDDLES PER: MIL-G-2338L

MIL SPEC

TYPE I, SIZE 2* LG-36M 136T-M

TYPE I, SIZE 3* LG-72M 172T-M

TYPE I, SIZE 5* LG-24M 124T-M

TYPE I, SIZE 6* LG-48M 148T-M

TYPE II- Use the same model number as above Then add for:

TYPE III, SIZE 2* LGMDI36 136TDI-VG

TYPE III, SIZE 3* LGMDI72 172TDI-VG

TYPE III, SIZE 6* LGMDI48 148TDI-VG

LANG MODEL NUMBER STAR MODEL NUMBER

STYLE 1- with Stand

STYLE 2- with Castered Stand

STYLE 3- with Bolt Down Stand

* N.S.A. for “Naval Shipboard Application”. All components will fit through a 26” X 66” watertight door.

10

Page 11

LANG MANUFACTURING - A DIVISION OF STAR MANUFACTURING INT’L, INC. • 10 SUNNEN DR. ST. LOUIS, MO 63143

TOLL FREE: 800.264-7827 • FAX: 314-781-3636 • www.langworld.com

Item No.

Project

Quantity

Electric, Drop-In Model Griddles Model: [136,148,172]TDIG

MARINE CONSTRUCTION FEATURES

• 3/4” thick precision machined, polished steel cooking surface

• Full parameter stainless steel top mounting flange

• Full front 3-1/2” wide x 1” deep stainless steel grease trough

• 8 quart capacity grease drawer, with marine latch & fully enclosed, easily

removable sleeve [Two on 72” model]

• Fully enclosed control compartment

• Separate, insulated stainless steel griddle and control modules

PERFORMANCE FEATURES

• Thick griddle plate reduces hot & cold spots and retains heat

• Highly polished, recessed surface and continuously welded mounting

flange speeds cleanup

• Heating elements incoloy sheathed, for long life

• Elements are pressure clamped to bottom of griddle plate for more

even heating

• Recessed control panel protects control knobs

• Accurate temperature control between 175 and 450˚F

CONTROLS

• Independent temperature control every 12”

• Heat on pilot lights for each control

MARINE SHORT/BID SPECIFICATION

Griddle shall be a LANG Manufacturing Marine Model 1__

[Specify width: 36”, 48” or 72”]TDIG, with: thermostat controls

for each 12” of griddle width; 6-kW per foot of Incoloy sheathed

heating elements, pressure clamped to plate bottom; 3/4” thick

polished cooking surface; flanged flush-mount griddle surface

module and recessed control panel module for easy installation in

countertop.

MARINE PRODUCT WARRANTY

One year, parts & labor (Labor in U.S. only)

Sheet No. LMSP-G1 (rev. 07/07)

Model 136TDIG shown

MarineSeries

Model/Width Surface Area Controls kW Input*

❏ 136TDIG 828 sq. in. 3 18-kW

❏

148TDIG 1104 sq. in. 4 24-kW

❏

172TDIG 1656 sq. in. 6 18/18-kW**

SIZING AND PERFORMANCE GUIDE

* 6-kW per foot of griddle

** Power input, two power connections required

Page 12

LANG MANUFACTURING - A DIVISION OF STAR MANUFACTURING INT’L, INC. • 10 SUNNEN DR. ST. LOUIS, MO 63143

TOLL FREE: 800.264-7827 • FAX: 314-781-3636 • www.langworld.com

© 2004 Lang Manufacturing Company Printed in U.S.A. 10/04-M-12797

Due to continuous improvements, specifications subject to change without notice.

MARINE INSTALLATION REQUIREMENTS

• E 440V or 480V, 3-phase power connection

• E E Two electric connections required for 72” unit

• Installation in approved cabinet or galley work center. [Provided by others]

• See below for rough openings re q u i red for griddle and control panel module

• Consult marine codes for installation requirements

Sheet No. LMSP-G1 (rev. 07/07)

[3D & Front View 136TDIG] [3D & Front View 148TDIG] [3D & Front View 172TDIG]

Electric, Drop-In Model Griddles [ 1 3 6 , 1 4 8 , 1 7 2 ] T D I G

Model

Top-Rough Opening Controls-Opening

Clearance from

Weight

Freight

Width Depth Height Width

combustible surface

Actual Shipping

Class

136TDIG

36.8” 29.8” 6.1” 35.0” 295 lbs. 345 lbs.

85

935mm 756mm 156mm 889mm 120 kg 186 kg

148TDIG

48.8” 29.8” 6.1” 47.0” Sides: 2” 400 lbs. 450 lbs.

85

1240mm 756mm 156mm 1194mm Back : 2” 167 kg 239 kg

172TDIG

72.1” 29.5” 6.5”* 25.2”* 650 lb 700 lb

85

1831mm 748mm 164mm 641mm 295 kg 318 kg

* Two openings required in the Controls-Opening table for the 172TDIG model.

Model Volts AC - Hz Total kW Amps - Three Phase Amps - Single Phase

208 - 50/60 18.0 50.0 86.5

136TDIG

240 - 50/60 18.0 43.3 75.0

440 - 50/60 18.0 23.6 N/A

480 - 50/60 18.0 21.7 N/A

208 - 50/60 24.0 75.0 115.2

148TDIG

240 - 50/60 24.0 65.0 100.0

440 - 50/60 24.0 36.8 N/A

480 - 50/60 24.0 32.5 N/A

208 - 50/60 36.0 [18/18]** 50.0/50.0 86.5/86.5

172TDIG

240 - 50/60 36.0 [18/18]** 43.3/43.3 75.0/75.0

440 - 50/60 36.0 [18/18]** 23.6/23.6 N/A

480 - 50/60 36.0 [18/18]** 21.7/21.7 N/A

** Two connections.

Page 13

MDI-36 CUT OUT

21

Page 14

MDI-48 CUT OUT

22

Page 15

MDI-72 CUT OUT

23

Page 16

EQUIPMENT DESCRIPTION

INTRODUCTION

This manual contains the necessary information to install, operate, maintain, and service

the Lang self-heating electric griddles.

Replacement parts should be genuine Lang parts. Failure to use genuine Lang

replacement parts may result in malfunction of the appliance or possible injury to the

contractor or service technician.

PURPOSE AND FUNCTION

Electric griddles provide heated surface constantly regulated at a thermostatically set

temperature. They are designed to cook a wide variety of food products including, but

not limited to, eggs, hamburgers, fish, chicken and pancakes.

CAPABILITIES

These griddles are capable of cooking all types of products requiring contact wit a

heated surface.

ENVIRONMENTAL REQUIREMENTS

The following minimum spacing from combustible surfaces must be maintained:

Sides – 2 inches, Back – 2 inches

ITEMS FURNISHED (Listed by Type and Style)

Type I Griddle

Size 2, 5, 6

1 ea. Griddle

4 ea. Legs

2 ea. Manuals, Technical

Type I Griddle

Size 3

1 ea. Griddle

8 ea. Legs

2 ea. Manuals, Technical

Type II Griddle

Style 1

1 ea. Griddle

1 ea. Stand

1 ea. Stand Hardware

2 ea. Manuals, Technical

Type II Griddle

Style 2

1 ea. Griddle

1 ea. Stand

1 ea. Stand Hardware

2 ea. Swivel Casters

2 ea. Rigid Casters

2 ea. Manuals, Technical

24

Page 17

EQUIPMENT DESCRIPTION CONT’D

Type II Griddle

Style 3

1 ea. Griddle

1 ea. Bolt Down Stand

1 ea. Stand Hardware

2 ea. Manuals, Technical

Type III Griddle

Size 1 & 6

1 ea. Griddle

1 ea. Griddle Control Panel

2 ea. Manuals, Technical

Type III Griddle

Size 3

1 ea. Griddle

2 ea. Griddle Control Panel

2 ea. Manuals, Technical

ITEMS REQUIRED

An adequate supply of wire suitable for the loads and application specified on the data

sheet must be provided. The data sheet is on Page 4 of this manual.

TOOLS AND TEST EQUIPMENT REQUIRED

For Installation:

1 set – Open End Wrenches

1 ea. – Flat Blade Screwdriver

1 ea. – Phillips Screwdriver

1 ea. – Wire Cutter/Stripper

1 ea. – AMP Probe

1 ea. – Voltmeter

For Service: All of the above plus –

1 ea. – Needle Nose Pliers

1 ea. – Crimping Pliers

1 ea. – Allen Wrench Set

1 ea. – Temperature Meter

1 ea. – Very Small Flat Blade Screwdriver

CONTROLS

A mechanical snap action thermostat (100F-450F) controls each 12” section of the

griddle.

A red indicator lamp indicates that the griddle is heating.

25

Page 18

INSTALLATION

CAUTION: THE GRIDDLE IS EXTREMELY HEAVY. FOR SAFE

HANDLING, INSTALLER SHOULD OBTAIN HELP AS

NEEDED, OR EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY,

OR PALLET JACK) TO REMOVE THE UNIT FROM THE

SKID AND MOVE IT TO THE PLACE OF INSTALLATION.

CAUTION: ANY STAND, COUNTER OR OTHER DEVICE ON WHICH

GRIDDLE WILL BE LOCATED MUST BE DESIGNED TO

SUPPORT THE WEIGHT OF THE OVEN(S).

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN

SNAP BACK WHEN CUT.

DANGER: THIS APPLIANCE MUST BE GROUNDED AT THE

TERMINAL PROVIDED. FAILURE TO GROUND THE

APPLIANCE COULD RESULT IN ELECTROCUTION AND

DEATH.

WARNING: INSTALLATION OF THE UNIT MUST BE DONE BY

PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY.

IMPROPER INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO EQUIPMENT. UNIT

MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

NOTICE: The data plate is located next to the grease drawer,

behind access panel. The griddle voltage, wattage, serial

number, wire size, and clearance specifications are on the

data plate. This information should be carefully read and

understood before proceeding with the installation.

NOTICE: The installation of any components such as a vent hood,

grease extractors, fire extinguisher systems, must

conform to their applicable National, State and locally

recognized installation standards.

INSPECTION AND INSTALLATION

INSPECTION AND INSTALLATION

Upon receipt, check for freight damage, both visible and concealed. Visible damage

should be noted on the freight bill at the time of delivery and signed by the carrier's

agent. Concealed loss or damage means loss or damage which does not become

apparent until the merchandise has been unpacked. If concealed loss or damage is

discovered upon unpacking, make a written request for inspection by the carrier's agent

within 15 days of delivery. All packing mat erial should be kept for inspection. Do not

return damaged merchandise to Lang Manufacturing Company. File your claim with

the carrier.

LOCATION

Move the crate(s) containing the oven(s) as close to the place of installation as possible

before removing the protective crating. Uncrate the oven(s) and move them as close as

practical to the final installation site.

26

Page 19

INSTALLATION CONT’D

TYPE I

Screw legs into the 3/8-16 weld nuts provided on the underside of the griddle.

Place the griddle into its intended location.

A 1 1/4-inch conduit knockout through the back and the bottom of the griddle body is

located at the rear of the griddle. A 3-pole terminal block is provided for service

connections and can be accessed through a removable panel on the back of the griddle.

Use a supply wire suitable for at least 90 degree centigrade.

Sizes 2, 5, and 6 have one electrical connection and size 3 has two electrical

connections.

TYPE II

Construct stand and place into its intended location.

For bolt down legs see illustration below for dimensions.

Carefully place griddle onto its stand.

Electric connection can be made at the rear of the griddle.

Sizes 2, 5, and 6 have one electrical connection and size 3 has two electrical

connections.

TYPE III

Carefully cut the countertop and the control panel cutouts to the clearance dimensions

shown on the cutout illustrations.

The griddle will have a control box and a griddle portion. Disconnect as necessary.

Block the griddle over the hole in the top of the counter and put the gasket in place

under the flange that will support the griddle.

Position the control boxes close to there installed position. Attach the thermostat

capillary tubes to the griddle.

Drop the griddle into place and twist the hold-downs around the edge of the griddle

that is now below the counter to lock the griddle in place.

A separate box with a terminal block is provided for power connections.

The griddle may now be connected to power

27

Page 20

NOTICE: During the first few hours of operation you may notice a

small amount of smoke coming off the griddle surface,

and a faint odor from the smoke. This is normal for a new

griddle and will disappear after the first few hours of use.

CAUTION: ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE

FROM COMBUSTIBLE MATERIALS.

CAUTION: KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND

DRY. IF SPILLS OCCUR, CLEAN IMMEDIATELY, TO

AVOID THE DANGER OF SLIPS OR FALLS.

OPERATING INSTRUCTIONS

An understanding of how the griddle sections are controlled will be a valuable aid in

loading your griddle.

Each 12-inch section of your griddle is independently controlled by a temperature

controller. The temperature control sensor is mounted in the center of each cooking

section under the griddle plate.

If the product is loaded directly over the temperature sensor, that section will turn on

and the burner will heat the entire cooking section. If the product is loaded to the side,

front or back of the temperature sensor, the thermostat will react to the temperature

change much slower.

During slow periods with minimal loads, do not load directly over the thermostat

sensors as this will unnecessarily turn the burners on and overheat the remainder of the

section not being utilized.

Turn the product and continue cooking until it has reached its desired degree of

doneness.

Remove the product from the griddle.

When reloading the griddle, first use the griddle surface on which a previous load was

not placed. This will help insure the proper griddle temperature.

OPERATION

INITIAL START-UP

Prior to putting any griddle into full time operation at normal cooking temperatures, it

must be thoroughly "seasoned" and dried out. Moisture absorption in the closed

spaces, in the insulation and even inside the heating elements can cause future trouble

if not properly treated.

Before seasoning the griddle it is first necessary to remove the shipping preservative

from the griddle surface. To do this, add a mild detergent to hot water and wash the

griddle plate. Rinse with a damp sponge and dry with a clean rag.

To "season" the griddle, set the thermostat dial to 300. Allow unit to come up to

temperature and cycle off. Apply a thin coat of high-grade, non-salted vegetable oil to

the griddle surface. Rub the oil into the griddle surface with the flat side of a spatula

or a towel. Re-coat any dry spots that appear then wait 30 minutes and wipe off any

excess oil. Repeat these steps at 350, 400, and 450.

To “dry out” the Griddle, set the thermostat to 250 and turn on the power switch.

Allow the unit to cycle at least 15 minutes at this heat level. Reset the thermostat to

350 allowing the same time. Reset the thermostat to 450 and allow the unit to

maintain the temperature for a minimum of 4 hours. More time may be required if the

unit will be operating in a moist or humid environment.

If the unit is out of use for three or more days, a one-hour preheat schedule should be

used, especially when exposed to high humidity and/or cool temperatures.

28

Page 21

OPERATION CONT’D

NORMAL OPERATION

Each 12-inch section of your griddle is independently controlled by a temperature

controller. The temperature control sensor is mounted in the center of each cooking

section under the griddle plate.

Turn the griddle thermostat to the desired temperature and allow 30 minutes to preheat.

Once griddle has been preheated place product on the griddle and allow to cook.

29

Page 22

MAINTENANCE AND CLEANING

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS.

NEVER SPRAY OR HOSE CONTROL CONSOLE,

ELECTRICAL CONNECTIONS, ETC.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES,

MUCOUS MEMBRANES AND CLOTHING. PRECAUTIONS

SHOULD BE TAKEN TO WEAR RUBBER GLOVES,

GOGGLES OR FACE SHIELD AND PROTECTIVE

CLOTHING. CAREFULLY READ THE WARNING AND

FOLLOW THE DIRECTIONS ON THE LABEL OF THE

CLEANER TO BE USED.

NOTICE: Service on this, or any other, LANG appliance must be

performed by qualified personnel only. Consult your

LANG authorized service agent directory or call the

factory at 314-678-6315, or www.langworld.com For the

service agent nearest you.

WARNING: BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE

THIS APPLIANCE WHEN THE UNIT IS PLUGGED/WIRED

INTO A LIVE RECEPTACLE. BEFORE REPLACING ANY

PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC

POWER SUPPLY.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN

THOSE SUPPLIED BY LANG OR THEIR AUTHORIZED

DISTRIBUTORS CAN CAUSE BODILY INJURY TO THE

OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

DAILY CLEANING

Empty the grease drawer or whenever it is 3/4 full by pulling strait out toward the

front. It is easily removed for washing.

Clean the exterior of the appliance with Lang Mfg. Prima Shine (72804-41) cleaner to

maintain a gleaming appearance.

Keep the griddle surface clean. After each cooking load, scrape the griddle surface to

remove any carbonized grease

WEEKLY CLEANING

Once a week (or when necessary) the griddle surface should be cleaned and reseasoned. Use Lang Mfg Carbon Release (72804-32). Rub with the grain of the metal,

being careful not to scrape the splashguard.

Be sure to rinse thoroughly and re-season to prevent rusting and corrosion.

30

Page 23

MAINTENANCE AND CLEANING CONT’D

CALIBRATION CHECK

Set the griddle temperature to 350F on all sections (it should take approximately 22

minutes to reach temperature).

Let the griddle reach 350F and cycle off and on at least three times.

Measure 6” from the left, and 11 1/2” from the front of the plate for the first

checkpoint. This will check the center of the sensor for the first cooking section.

Each checkpoint is located every 12” to the right from the last point, and always 11

1/2” from the front. (See illustration below.)

CALIBRATION

A 1/16” flat blade screwdriver with a 2” shaft is required to make adjustments on the

thermostat.

Maintain the oven temperature at 350.

Without turning the thermostat, remove the knob.

Locate the adjustment screw at the base of the shaft and insert the screwdriver.

Grasp the shaft and turn the screwdriver counter clockwise to in crease temperature and

clockwise to decrease temperature (1/8 of a turn will move the temperature 5-7 in

either direction).

Reinstall the oven knob and recheck the oven temperature.

48"

2"

12"6" 12"

11

1/2"

11

1/2"

12"

6"

30"

5"

31

Page 24

MAINTENANCE AND CLEANING CONT’D

ELEMENT REMOVAL

Disconnect power from griddle.

Prop griddle plate up.

Disconnect power wire attached to heating element terminals. Mark or identify each

wire to ensure correct replacement on new heating element. Inspect for frayed ends,

broken strands and grease soaked insulation. Replace as necessary.

Remove the two sheet metal screws securing the thermostat capillary tube clip to the

element pan. Pull the clip and the tube down and out of the center slot of the element

pan. Take care not to break the capillary tube, as it may be brittle from prolonged

exposure to high temperature.

Remove the nuts and washers retaining the element pan and pressure plate.

Drop the element pan straight down until studs are cleared and pull forward out of

griddle body. The elements will normally drop down with the element pan and are

now accessible for replacement as necessary.

Compare voltage and wattage marking of old element with new one to ensure proper

replacement.

Reverse the removal procedure to install the new element. Be sure the nuts holding the

element pan are snug as this will assure proper contact between the element and

griddle plate. The capillary tube bulb must also be tightly clamped against the griddle

plate to obtain proper temperature control.

THERMOSTAT REPLACEMENT

Disconnect power from griddle.

Prop griddle plate up.

Loosen the two sheet metal screws securing the thermostat capillary tube clip to the

element pan. Gently pull the thermostat capillary tube from the clip.

Remove the two sheet metal screws from the rear of the control panel box and pull off

the box cover.

Remove thermostat control knob. Loosen and remove the two screws securing the

thermostat body to the front panel. Remove wires from thermostat terminals. Mark

for proper replacement.

Reverse this procedure for replacement.

PILOT INDICATOR REPLACEMENT

Disconnect power from griddle.

Prop griddle plate up.

Remove the two sheet metal screws from the rear of the control panel box and pull off

the box cover.

Remove the wires from the pilot indicator.

The pilot light is held firmly in place by means of a spring metal speed nut on the back.

Remove the pilot indicator by removing the speed nut and pulling it out through the

front. It may be necessary to break the pilot light in two to remover he speed nut.

Install the new pilot light and hold in place with speed nut.

Reverse the procedure to reinstall.

32

Page 25

TROUBLE SHOOTING

SYMPTOM PROBLEM REMEDY

Whole griddle will not heat Circuit breaker turned off

Griddle not turned on

Improper connection

Improperly Phased

Turn on

Turn on

Connect per wiring diagram

Phase per wiring diagram

One section will not heat. Defective elements

Defective thermostat

Griddle is burning product Griddle is out of calibration Calibrate

Griddle is undercooking product Griddle is out of calibration Calibrate

Indicator light will not come on Defective Indicator light Replace Indicator light

Replace elements

Replace thermostat

TECHNICAL DATA

Part# Description Volts Watts Amps

2N-11030-29 I/S Element 208/240 4500/5991 22/26

2N-11030-30 O/S Element 208 1491 8

2N-11030-31 Element 480 5991 12.5

2N-11030-04 Element 380 5991 16

GRIDDLE LINE AMPERAGE, AND WATTAGE

NOMINAL AMPS PER LINE

Type:

I, II, III

24” 12.0 50.0 28.8 28.8 43.3 25.0 25.0 21.7 12.5 12.5 57.7 50.0

36” 18.0 50.0 50.0 50.0 43.3 43.3 43.3 21.7 21.7 21.7 86.5 75.0

48” 24.0 75.0 75.0 50.0 65.0 65.0 43.3 32.5 32.5 21.7 115.4 100.0

72”

TOTAL

K.W.

#1 18.0 50.0 50.0 50.0 43.3 43.3 43.3 21.7 21.7 21.7 86.5 75.0

#2 18.0 50.0 50.0 50.0 43.3 43.3 43.3 21.7 21.7 21.7 86.5 75.0

208 Volt 240 Volt 480 Vol t

L1 L2 L3 L1 L2 L3 L1 L2 L3

THREE PHASE

SINGLE PHASE

208V 240V

33

Page 26

208/240 WIRING DIAGRAM

34

Page 27

480 WIRING DIAGRAM

35

Page 28

PARTS LIST April 18, 2007, Rev. –

Model: 136TDI-440VG, Thermostatic Drop-In Griddle

Part No. Description Vendor Vendor # QTY Applications

2E-30500-02 TRM STRP 4 POLE 30A 600V Cooper-Bussman TB30004-00

2E-30500-03 TRM STRP 6 POLE 30A 300V Cooper-Bussman TB30006

2E-30500-05 TRM STRP 8 POLE 30A 300V Cooper-Bussman TB30008

2E-30500-07 TRM BLOCK 3PLELRGE 125AMP All-West Fasteners 162-04-3L 1 136TDI-440VG

2J-31601-02 PILOT LT 480V 6LEAD BLK Solico 1854-1-20-20310 3 136TDI-440VG

2N-11030-31 ELMNT GRID 480V 5991W Caloritech Inc. IXI-11030-31 3 136TDI-480VG

2N-11030-48 ELE GRD 440V 5991W XL/LG Caloritech Inc. IXI-11030-48 3 136TDI-440VG

2P-50100-05 GROOVED GRIDDLE CLEANING Chef Aid MFG 50100-05

2P-50100-051 GROOVED GRIDDLE BRUSH REPL Chef Aid MFG 50100-051

2P-50100-052 GROOVED GRIDDLE BRUSH REPL Chef Aid MFG 50100-052

2T-30402-08 STAT ADJ 450o 72 C/T Invensys SP-173-72 3 136TDI-440VG

K9-50302-05 ELEMENT PAN ASSY XL/LG Star Mfg Int. 50302-05

K9-MDI-105-3 GRIDDLE PLATE ASSY 3' Star Mfg Int. MDI-105-3 1 136TDI-440VG

K9-MDI-212-2 GREASE BUCKET ASSY 2' Star Mfg Int. MDI-212-2 1 136TDI-440VG

Y9-70701-16 KNOB ASSY 450o A, Black Star Mfg. Int. 70701-16 3 136TDI-440VG

Model: 148TDI-440VG, Thermostatic Drop-In Griddle

Part No. Description Vendor Vendor # QTY Applications

2E-30500-02 TRM STRP 4 POLE 30A 600V Cooper-Bussman TB30004-00

2E-30500-03 TRM STRP 6 POLE 30A 300V Cooper-Bussman TB30006

2E-30500-05 TRM STRP 8 POLE 30A 300V Cooper-Bussman TB30008

2E-30500-07 TRM BLOCK 3PLELRGE 125AMP All-West Fasteners 162-04-3L 1 148TDI-440VG

2J-31601-02 PILOT LT 480V 6LEAD BLK Solico 1854-1-20-20310 4 148TDI-440VG

2N-11030-31 ELMNT GRID 480V 5991W Caloritech Inc. IXI-11030-31 4 148TDI-480VG

2N-11030-48 ELE GRD 440V 5991W XL/LG Caloritech Inc. IXI-11030-48 4 148TDI-440VG

2P-50100-05 GROOVED GRIDDLE CLEANING Chef Aid MFG 50100-05

2P-50100-051 GROOVED GRIDDLE BRUSH REPL Chef Aid MFG 50100-051

2P-50100-052 GROOVED GRIDDLE BRUSH REPL Chef Aid MFG 50100-052

2T-30402-08 STAT ADJ 450o 72 C/T Invensys SP-173-72 4 148TDI-440VG

K9-MDI-105-4 GRIDDLE PLATE ASSY 4' Star Mfg Int. MDI-105-4 1 148TDI-440VG

Y9-70701-16 KNOB ASSY 450o A, Black Star Mfg. Int. 70701-16 4 148TDI-440VG

36

Page 29

PARTS LIST June 1, 2011, Rev. –

Model: 172TDI-240VG, -440VG, -480VG Thermostatic Drop-In Griddle

Part No. Description Vendor Vendor # QTY Applications

2E-30500-07 TRM BLOCK 3PLELRGE 125AMP All-West Fasteners 162-04-3L 2 172TDI-440VG, 480VG

2J-31601-02 PILOT LT 480V 6LEAD BLK Solico 1854-1-20-20310 6 172TDI-440VG, 480VG

2J-31601-01 PILOT LT 250V 6LEAD BLK Solico 2152-1-23-20110 6 172TDI-240VG

2N-11030-31 ELMNT GRID 480V 5991W CCI Thermal Tech IXI-11030-31 6 172TDI-480VG

2N-11030-48 ELE GRD 440V 5991W XL/LG CCI Thermal Tech IXI-11030-48 6 172TDI-440VG, 480VG

2N-11030-12 ELE GRD SPECL 240V5991W CCI Thermal Tech IXI-L11030-12 6 172TDI-240VG

2P-50100-05 GROOVED GRIDDLE CLEANING Chef Aid MFG 50100-05

2P-50100-051 GROOVED GRIDDLE BRUSH REPL Chef Aid MFG 50100-051

2P-50100-052 GROOVED GRIDDLE BRUSH REPL Chef Aid MFG 50100-052

2T-30402-08 STAT ADJ 450o 72 C/T Invensys SP-173-72 6 172TDI-240VG, 440VG, 480VG

K9-MDI-105-6 GRIDDLE PLATE ASSY 6' Lang Mfg MDI-105-6 1 172TDI-240VG, 440VG, 480VG

K9-MDI-212-6 GREASE BUCKET ASSY MDI-72 Lang Mfg MDI-212-6 2 172TDI-240VG, 440VG, 480VG

Y9-70701-16 KNOB ASSY 450°F A, Black Lang Mfg. 70701-16 6 172TDI-240VG, 440VG, 480VG

37

Page 30

Lang Manufacturing Limited Warranty

to Commercial Purchasers*

(Domestic U.S., Hawaii, &

Canadian Sales only.)

Lang Manufacturing Equipment (“Lang

Equipment”) has been skillfully manufactured,

carefully inspected and packaged to meet rigid

standards of excellence. Lang warrants its

Equipment to be free from defects in material and

workmanship for (12) twelve consecutive months,

with the following conditions and subject to the

following limitations.

I. This parts and labor warranty is limited to Lang

Equipment sold to the original commercial

purchaser/users (but not original equipment

manufacturers), at its original place of installation, in

the continental United States, Hawaii and Canada.

Quartz elements are warranted for ninety( 9 0) day s

from the date of installation.

II. Damage during shipment is to be reported to the

carrier, is not covered under this warranty, and is the

sole responsibility of purchaser/user.

III. Lang, or an authorized service representative,

will repair or replace, at Lang’s sole election, and

Lang Equipment, including but not limited to, safety

valves, gas and electric components, found to be

defective during the warranty period. As to

warranty service in the territory described above,

Lang will absorb labor and portal to portal

transportation costs (time & mileage) for the first

(12) twelve months from the date of installation or

eighteen (18) months from date of shipment from

Lang Manufacturing, which ever comes first.

IV. This warranty does not cover routine general

maintenance, periodic adjustments, as specified in

operating instructions or manuals, and consumable parts

such as quartz elements, or labor costs incurred for

removal of adjacent equipment or objects to gain access

to Lang Equipment. This warranty does not cover

defects caused by improper installation, abuse, careless

operation, or improper maintenance of equipment.

V.

THIS WARRANTY IS EXCLUSIVE AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, EACH

OF WHICH IS HEREBY EXPRESSLY DISCLAIMED.

THE REMEDIES DESCRIBED ABOVE ARE

EXCLUSIVE AND IN NO EVENT SHALL LANG BE

LIABLE FOR SPECIAL, CONSEQUENTIAL OR

INCIDENTAL DAMAGES FOR THE BREACH OR

DELAY IN PERFORMANCE OF THIS WARRANTY.

VI. Lang Equipment is for commercial use only. If sold

as a component of another(OEM) manufacturer’s

equipment, or if used as a consumer product, such

Equipment is sold AS IS and without any warranty.

WARRANTY

38

Page 31

Page 32

Loading...

Loading...