Page 1

Installation, Operation, and

Maintenance

Instructions

Electric Marine Fryer

Model: 130F-208VM

130F-240VM

130F-440VM

130F-480VM

Star Manufacturing International 10 Sunnen Drive St. Louis, MO.63143-3800

Part Number: 2M-W479 Ph: 314-781-2777 Fax: 314-781-2714

Rev.A

WWW.STAR-MFG.COM May 15, 2007

Page 2

THE INFORMATION IN THIS MANUAL IS CRUCIAL AND MUST BE

RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND

AND FOLLOW THE INSTRUCTIONS AND WARNINGS CONTAINED

IN THIS MANUAL.

DANGER

WARNING

CAUTION

NOTICE

POTENTIALLY HAZARDOUS SITUATION, WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH.

POTENTIALLY HAZARDOUS SITUATION, WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY.

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY.

Helpful operation and installation instructions and tips are

present.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS NEAR THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

Model #: Purchased from:

Serial #: Location:

Date purchased: Date installed:

Purchase order #: For service, call:

WARNING

THIS EQUIPMENT IS APPROVED FOR INSTALLATION ONLY ON

VESSELS GREATER THAN 65 FEET IN LENGTH, IN

ACCORDANCE WITH USCG REGULATIONS IN TITLE 46 CFR

110-113

Page 3

TABLE OF CONTENTS

CHAPTER PAGE

1. Table Of Contents...................................................................................3

2. List Of Illustrations ..................................................................................4

3. Read First ...............................................................................................5

4. Specification Sheet .................................................................................7

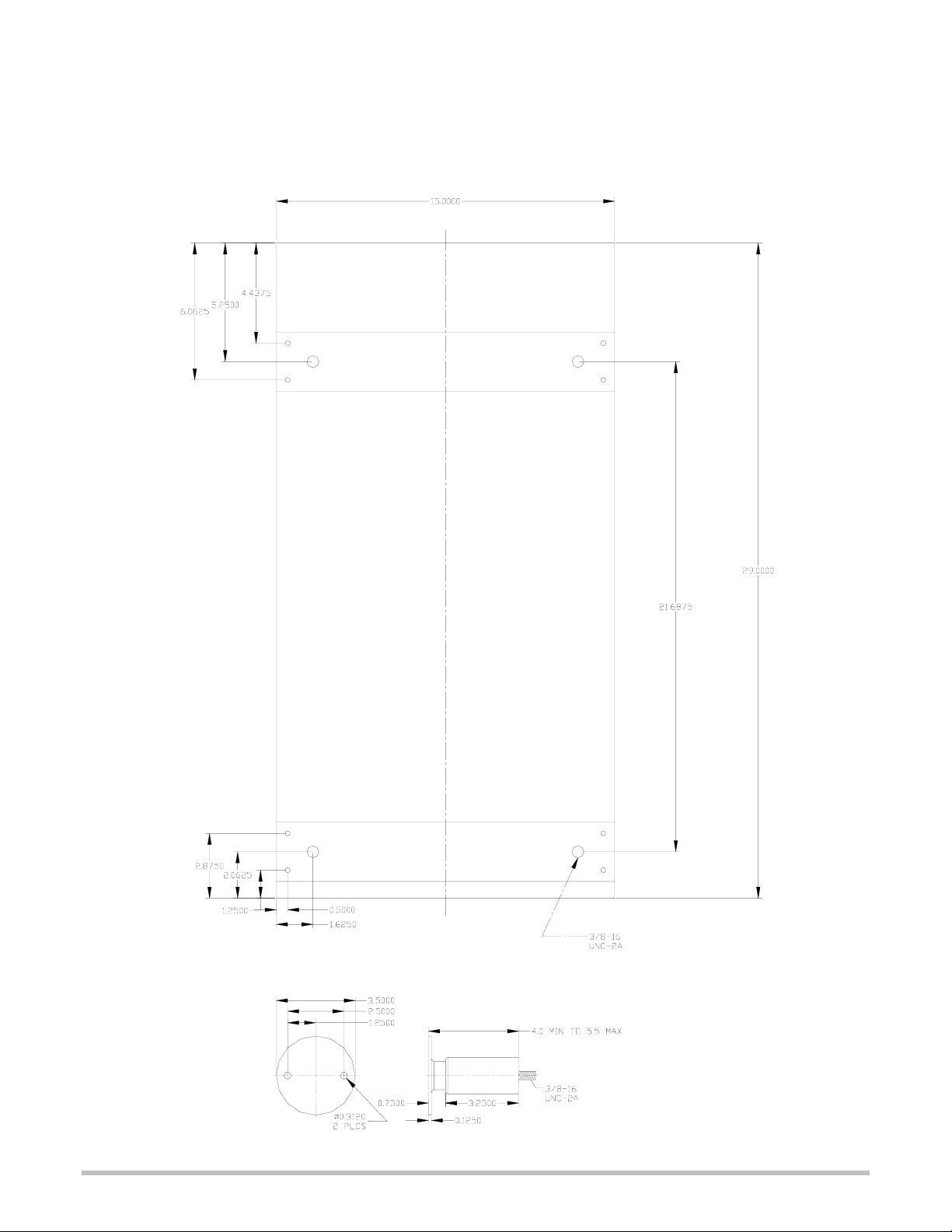

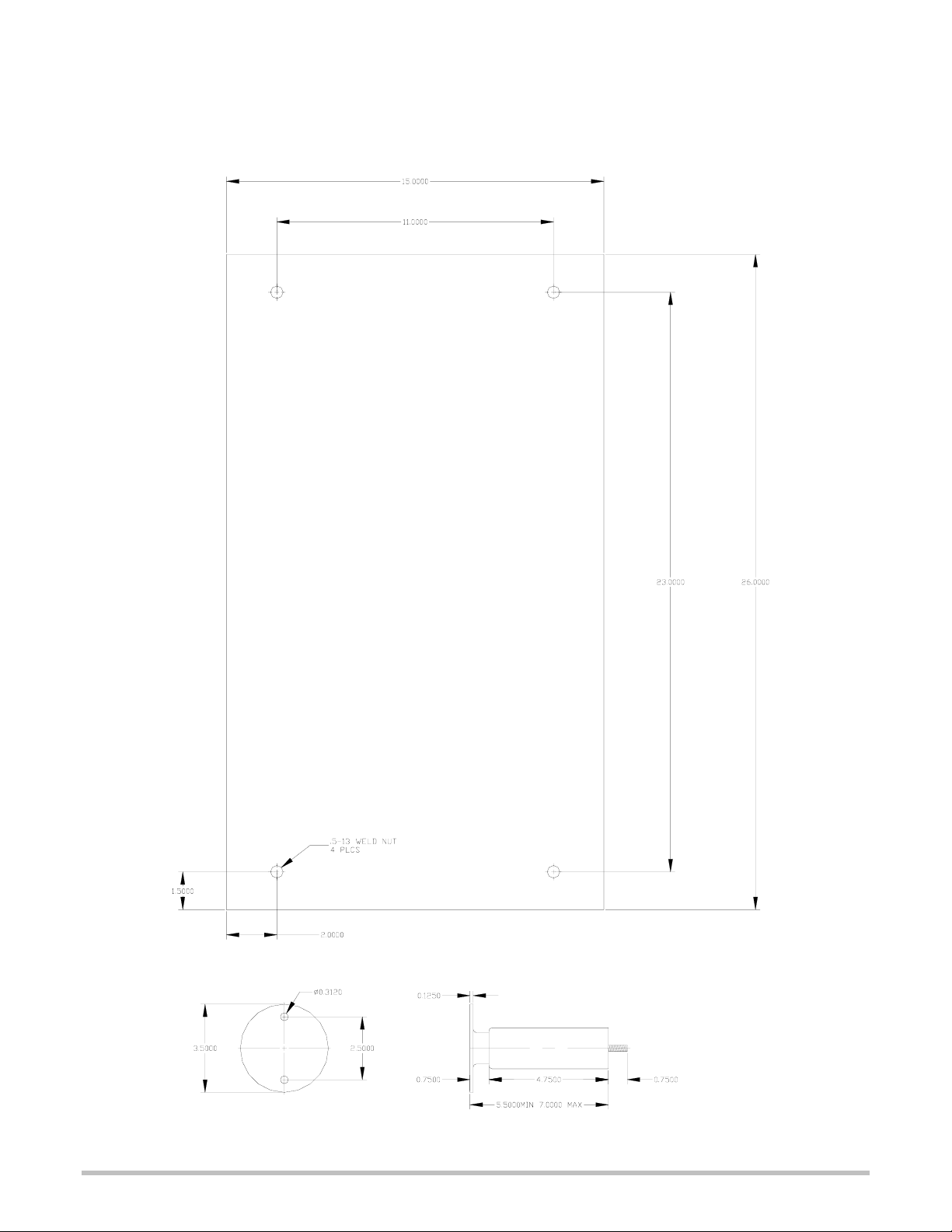

5. Leg Specification.....................................................................................9

6. Equipment Description............................................................................11

7. Unpacking...............................................................................................11

8. Installation............................................................................................... 12

9. Operation ................................................................................................13

10. Maintenance & Cleaning .........................................................................15

11. Wiring Diagram .......................................................................................18

3

Page 4

List Of Illustrations

Illustration Page

1. Specification Sheet .................................................................................7

2. Leg Layout ..............................................................................................9

3. Oil Fill Level ............................................................................................13

4. Wiring Diagram ....................................................................................... 18

4

Page 5

CAUTION

CAUTION

CAUTION

DANGER

EACH UNIT IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE

MATERIALS HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR

PALLET JACK) TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO

THE PLACE OF INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH THE FRYER WILL

BE LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE

FRYER.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN

CUT.

THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED.

FAILURE TO GROUND THE APPLIANCE COULD RESULT IN

ELECTROCUTION AND DEATH.

WARNING

NOTICE

NOTICE

WARNING

CAUTION

WARNING

WARNING

CAUTION

CAUTION

WARNING

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO EQUIPMENT. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

The data plate is located behind the access door, over the tank drain. The

fryer voltage, wattage, serial number, wire size, and clearance

specifications are on the data plate. This information should be carefully

read and understood before proceeding with the installation.

The installation of any components such as a vent hood, grease

extractors, fire extinguisher systems, must conform to their applicable

National, State and locally recognized installation standards.

MAKE SURE THE MAIN POWER SUPPLY TO THE FRYER IS TURNED OFF

AT THE SOURCE PRIOR TO CONNECTING POWER TO THE FRYER.

BE SURE THE POWER SUPPLY VOLTAGE MATCHES THE VOLTAGE

SPECIFIED ON THE DATA PLATE.

NEVER ENERGIZE THE HEATING ELEMENTS WITH NO OIL IN THE

KETTLE OR WITH THE OIL LEVEL MORE THAN 3-INCHES FROM THE

LOWER FILL LEVEL

ALWAYS TURN THE FRYER POWER SWITCH OFF BEFORE LIFTING THE

HEATING ELEMENTS OUT OF THE FRYER OIL.

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR

FALLS.

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

5

Page 6

CAUTION

NOTICE

WARNING

CAUTION

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO

WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE

CLOTHING. CAREFULLY READ THE WARNING AND FOLLOW THE

DIRECTIONS ON THE LABEL OF THE CLEANER TO BE USED.

Service on this or any other, STAR appliance must be performed by qualified

personnel only. Consult your authorized service agent directory or call the

factory at 1-800-807-9054 or visit our website WWW.STAR-MFG.COM. For the

service agent nearest you.

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS APPLIANCE

WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE

REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC

POWER SUPPLY.

DO NOT THROW ICE INTO THE FRYER BASKET

WHILE THE UNIT IS HOT. FAILURE TO COMPLY

MAY RESULT IN SERIOUS INJURY AND MAY

DAMAGE THE EQUIPMENT.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

Star Manufacturing OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE

BODILY INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT

AND WILL VOID ALL WARRANTIES.

6

Page 7

F-28SM & R-28SM

Leg Specification

7

Page 8

C-28SM

Leg Specification

FRYER BASE

8

Page 9

Equipment Description

Items

¾ 1 ea. C-28M or 1ea. F-28M or 1ea R-28M

¾ 4 ea. 6”, Bolt down legs (F-28M)

¾ 4 ea. 4”, Bolt down legs (C-28M)

¾ 1 ea. Operation Manual

¾ 1 ea. Marine Handle

Fryer Controls

The Fryer comes with a “ON / OFF toggle switch, one mechanical thermostat that has

a temperature range of 200°F -400°F and three indicator lamps for power, heat, and

over temp. In addition to the standard controls, the fryer comes with a power interrupt

terminal block, a shunt trip terminal block and an over temperature test switch.

9

Page 10

CAUTION

CAUTION

CAUTION

EACH IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE

MATERIALS HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR

PALLET JACK) TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO

THE PLACE OF INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH THE FRYER WILL

BE LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE

FRYER.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN

CUT.

Receiving the Fryer

Upon receipt, check for freight damage, both visible and concealed. Visible

damage should be noted on the freight bill at the time of delivery and signed

by the carrier's agent. Concealed loss or damage means loss or damage,

which does not become apparent until the merchandise has been unpacked.

If concealed loss or damage is discovered upon unpacking, make a written

request for inspection by the carrier's agent within 15 days of delivery. All

packing material should be kept for inspection. Do not return damaged

merchandise to Star Manufacturing Company. File your claim with the

carrier.

Location

Prior to un-crating, move the fryer as near its intended location as practical.

The crating will help protect the unit from the physical damage normally

associated with moving it through hallways and doorways.

Un-Crating

The fryer will arrive inside a wood frame covered by a cardboard box and

strapped to a skid. Remove the cardboard cover, cut the straps and

remove the wood frame. The fryer may now be removed from the skid.

Installing the Legs

To install the legs, place some cardboard on the floor and gently tip the

fryer portion onto its side. A threaded weld nut is provided in each of the

four corners of the unit. Thread each leg into the threaded weld nuts and lift

the fryer back onto the legs. (See “Leg Specification”).

Unpacking

10

Page 11

DANGER

Installation

THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED.

FAILURE TO GROUND THE APPLIANCE COULD RESULT IN

ELECTROCUTION AND DEATH.

WARNING

NOTICE

NOTICE

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO EQUIPMENT. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

The data plate is located behind the access door, over the tank drain. The

fryer voltage, wattage, serial number, wire size, and clearance

specifications are on the data plate. This information should be carefully

read and understood before proceeding with the installation.

The installation of any components such as a vent hood, grease

extractors, fire extinguisher systems, must conform to their applicable

National, State and locally recognized installation standards.

Electrical Connection

A 1¼” knockout is provided on the unit for electrical connection (see

“Specification Sheet for knockout location & wiring diagram for proper

terminal block connection & phasing).

The electrical connection must be made in accordance with local codes or

in the absence of local codes with National Electrical Code latest edition

(in Canada use: CSA STD. C22.1).

Safety Circuit Connections

Fire Control Shutoff

Two terminals are provided on the four pole terminal block for connection to

an external fire control system if required. A jumper is provided across two

of these terminals when the fryer leaves the factory. The jumper on this

terminal block is in series with the power switch circuit. If connection to a fire

control system is required, remove this jumper and supply a relay contact

closure to maintain this closed circuit. If the fire control system does not

have this type of output, a separate relay must be provided to interface the

system. DO NOT APPLY VOLTAGE TO THIS CONNECTION.

Shunt Trip Circuit

Two terminals are provided on the four pole terminal block for a shunt trip

circuit. Connect to the shunt terminals of the main circuit breaker.

The Fryer can now be connected to power.

CAUTION

BE SURE THE POWER SUPPLY VOLTAGE MATCHES THE VOLTAGE

SPECIFIED ON THE DATAPLATE.

11

Page 12

CAUTION

NEVER ENERGIZE THE HEATING ELEMENTS WITH NO OIL IN THE

KETTLE OR WITH THE OIL LEVEL MORE THAN 3-INCHES FROM THE

LOWER FILL LEVEL

Filling the Fryer

Fill the fryer with cooking oil. There are two fill marks on the sides of the kettle. The oil level

should be maintained between the upper and lower marks. When the elements are out of the

unit the oil should not sink below the bottom fill mark and when the elements are in the oil it

should not rise above the top fill mark.

Operation

Turning the Fryer On

The power switch on the control box at the front of the fryer energizes the control circuits.

When this switch is on, the “power” indicator lamp will be illuminated.

Setting the Temperature

Turn the temperature selector dial on the thermostat to the desired temperature setting. This

control is located above the elements at the rear of the kettle. The “heat” indicator lamp will

illuminate indicating power is applied to the heating elements.

Over-Temperature Indicator

The lamp marked “over temp” will illuminate if the oil reaches an over temperature condition.

The over temperature thermostat shuts off the fryer before the oil reaches a dangerously high

temperature.

CAUTION

ALWAYS TURN THE FRYER POWER SWITCH OFF BEFORE LIFTING THE

HEATING ELEMENTS OUT OF THE FRYER OIL.

Raising the Elements

The elements may be raised and locked in the up position. The latch is located on the rear top

surface of the fryer and may be activated by lifting the handle at either side of the fryer.

12

Page 13

Operation cont’d

Draining the Oil

A drain valve is provided at the left front of the fryer. A lever that is located inside the access

panel is used to open and close the drain valve.

To drain the oil, make sure that the valve is closed and the oil is cool. Remove the steel cap

from the drainpipe. Connect a drainpipe extension to the drainpipe. Move the lever into the

open position and allow draining. Close valve after draining is complete and replace the end

cap.

Controls

Power Switch- A toggle switch used to turn the unit on and off.

Pilot Lights- Lights that are located in the rear control panel area.

Power- Lights up when the power switch is in the “ON” position.

Heat- Lights up when the element contactors engage.

Over-temp- Lights up when the over-temperature thermostat trips.

NOTICE Follow all established safety precautions as described in you

operations manual.

Testing Procedures for the Lang Model 130F Safety System

Important: Heed warnings listed on pages 5 and 6 prior to proceeding with these test

procedures!

The limiting controls test switch, located at the front control panel, is a three-position switch used

to test the first limit thermostats. To test the first limit thermostat push the switch to position “1” and

hold until the audible alarm sounds and the over-temp light comes on (this will happen when the

oil reaches a temperature of approximately 450ºF (232ºC). Next release the switch, if all the power

to the fryer goes off, this indicates that the second over temperature has tripped as well – and has

caused the “shunt trip” circuit breaker to activate. Note the “shunt trip” breaker is not located within

the fryer.

If it is required that the second over temperature thermostat is tested independently (or if the

power remains on the fryer with the switch in its normal, center, position), allow the oil to cool to

approximately 400ºF (204ºC). Restore power to the unit by resetting the shunt trip circuit breaker

(if necessary). Pull the over-temp test switch to position “2” and hold until the “shunt trip” circuit

breaker is activated (this will happen, when the oil reaches a temperature of approximately 450ºF

(232ºC).

Allow the fryer to cool down. Restore power to the unit by resetting the “shunt trip” circuit breaker.

13

Page 14

Maintenance & Cleaning

CAUTION

CAUTION

WARNING

CAUTION

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR

FALLS.

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO

WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE WARNING AND

FOLLOW THE DIRECTIONS ON THE LABEL OF THE CLEANER TO BE

USED.

Fryer Cleaning

Daily Cleaning

It is recommended the fryer oil be kept as clean as possible by straining

regularly (several times a day) and filtering daily. This will lengthen the life of

your oil and improve the performance of the fryer.

Weekly or As Required

1. Turn power switch off.

2. Remove the baskets, let baskets drain and then set aside.

3. Raise heating elements out of oil and lock in up position.

4. Drain Oil (See Draining the oil on previous page).

5. Remove loose food particles from heating units with spatula and wire brush.

6. Flush out scrapings and sediment with a small quantity of hot oil, and allow

draining thoroughly.

7. Close drain valve and fill with a fryer cleaning agent or soapy solution of

non-corrosive grease dissolving cleaner.

8. Set thermostat to 250ºF (121ºC).and boil solution for 15 to 20 minutes.

9. Drain solution from kettle. Refill with water and add 1/2 cup of white vinegar

to neutralize alkaline left by soap. Bring solution to a boil and allow to stand

for a few minutes.

10. Drain kettle and rinse with clear, hot water. Dry kettle and heating units

thoroughly, and close drain valve.

11. Refill fryer with oil, and lower heating elements slowly.

12. Operate fryer as normal.

Emergency Lockout

Locate power disconnect at source and remove power from fryer.

Long Term Storage

Secure fryer from power.

Drain oil from kettle.

Apply a generous amount of Lang Mfg. Prima Shine (72804-41) to the

stainless steel.

14

Page 15

Maintenance & Cleaning cont’d

Temperature Control

A bulb thermostat located near the right heating element as the fryer is viewed from the front provides

temperature control. This thermostat controls the #1 contactor. The control portion of the thermostat is

located in the component box at the back of the fryer.

Over-Temperature Protection

The over-temperature thermostat is located next to the left heating element and provides protection in

case of malfunction of the temperature control. It will open both contactors removing all power from the

heating elements.

Optional Shunt Trip Protection

The shunt trip temperature thermostat located next to the center-heating element provides protection in

case of malfunction of the temperature control. It is used in conjunction with a shunt trip circuit, which will

disconnect power to the fryer at the circuit breaker.

Thermostat Bulbs Check

The three thermostat bulbs, (temperature control thermostat bulb, over-temp thermostat bulb and shunt

trip thermostat bulb), are all connected to the fryer heating elements. The brackets that hold these bulbs

in place should be checked on a regular basis for tightness. If any of the brackets/ bulbs become loose,

the brackets that hold the bulbs should be tightened right away.

Component Access

The temperature control thermostat, over temperature thermostat, and shunt trip thermostat are all

located in the component box at the back of the fryer as well as the indicator lamps. This box may be

removed by removing the 4 sheet metal screws located beneath the box on the left and right sides of the

fryer lower front. All other components are located at the base of the unit in the back or behind the

access panel in the front to the unit.

In the event the fryer is built into a location, all maintenance may be done from the front by removing the

oil pot to gain access to the components. To remove the pot, the control box must be removed as above.

Also, remove the small section of sheet metal baffle held on by 2 sheet metal screws, located just above

the drain valve. The front of the pot may now be lifted up and moved forward until the rear of the pot will

rotate up and out. The baffles behind the pot may be removed by taking out the 4 screws. This exposes

the components.

15

Page 16

Maintenance & Cleaning cont’d

Calibration

The Fryer calibration procedure consists of accessing and adjusting the

temperature thermostat. The temperature control thermostat is located behind

the component box on the top at the back of the fryer.

Calibration Check

¾ Remove the elements from the fryer tank and wrap a temperature-sensing

probe around the capillary tube of the temperature control thermostat.

¾ Place elements back in fryer tank and set thermostat to 350°F.

¾ Allow fryer to reach temperature and cycle for 15 minutes.

¾ After fryer has cycled for 15 minutes, record the on and off temperatures for

three cycles and average these temperatures together (add together and

divide by six), the temperature should be between 340-360°F.

Calibration Adjustment

The average temperature should only be off by 340-360°F (171-182ºC).. If

temperature is off then a 1/16” flat blade screwdriver with a 2” shaft is required

to make adjustments on the thermostat.

¾ Maintain the temperature at 350°F. (177ºC)

¾ Without turning the thermostat, remove the knob.

¾ Locate the adjustment screw at the base of the shaft and insert the

screwdriver.

¾ Grasp the shaft and turn the screw, counter clockwise to increase and

clockwise to decrease, (1/8 of a turn will move the temperature 5-7 °F in

either direction).

¾ Reinstall the oven knob and recheck the oven temperature.

NOTICE

WARNING

CAUTION

Troubleshooting

Service on this, or any other, STAR appliance must be performed by

qualified personnel only. Consult your authorized service agent directory or

call the factory at 1-800-807-9054 or visit our website WWW.STAR-MFG.COM for

the service agent nearest you.

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS APPLIANCE

WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE

REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC

POWER SUPPLY.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

Star Manufacturing OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE

BODILY INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT

AND WILL VOID ALL WARRANTIES.

Not Heating

Probable Cause Corrective Action

Incorrect wiring

Defective transformer

Defective Fuses

Defective Contactor

Defective Thermostat

Defective Element

Confirm that fryer is getting proper voltage.

Confirm that fryer is phased correctly.

Confirm that transformer is getting correct voltage.

Confirm that transformer is putting out correct voltage.

Replace fuses.

Confirm that contactor is getting correct voltage on the coil.

Confirm that thermostat is getting correct voltage.

Confirm that thermostat is operating properly.

Confirm that element is getting correct voltage

Check element for normal operation. (11.5 Amps )

16

Page 17

ELEMENT (208, 220, OR 240 V)

CIRCUIT BREAKER, 2/10 AMP

CONTACTOR, 3 POLE, 240 V COIL

BUZZER, 240 V

EL1

CB

C1 & C2

BZ

TB TERMINAL BLOCK, 3 POLE

LAMP, INDICATOR, HEAT, AMBER

LAMP, INDICATOR, POWER, GREEN

THERMOSTAT, HI-LIMIT, 450 F

THERMOSTAT, HI-LIMIT, 425 F

ELEMENT (208, 220, OR 240 V)

ELEMENT (208, 220, OR 240 V)

IL2

IL1

HL2

HL1

EL3

EL2

THERMOSTAT, REGULATING, 400 F

SWITCH, TOGGLE, HILIMIT BYPASS

SWITCH, TOGGLE, POWER

RELAY, 2 POLE, 240 V COIL

LAMP, INDICATOR, OVERTEMP, RED

TH

SW2

SW1

RE & RE2

IL3

C

ITEM DESCRIPTION

2,5

3,6

1,4

L2

L1

THREEL3PHASE

SERVICE CONNECTIONS

L1 L2 L3

TERMINAL BLOCK

C

CB

SW1-2

EL2

56

EL1

12

EL3

AMPS 3 PHASE

C

43

L1 L2 L3

33.3 33.3 33.3

26.5 26.5 26.5

28.9 28.9 28.9

12

10.2

12.0

TOTAL

2M-61116-20 Rev C

KW

4.0 4.0 4.0

4.0 4.0 4.0

3.4 3.4 3.4

L1-L2 L2-L3 L1-L3

208

220

240

VOLT

LANGSTAR

HL2

C28SM130FM

MODELS:

C28-Marine 208-240VAC

130F- Marine 208-240VAC

MODEL MODEL

C

SW1-1

C1

IL1

Tes t 1

Tes t 2

SW2

RE2

C2

IL2

t°

TH

Tes t 1

SW2

HL1

BZ

IL3

RE

SHUNT-TRIP CIRCUIT BREAKER

PROVIDED BY OTHERS

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

Page 18

ELEMENT (380,415, 440, OR 480 V)

CIRCUIT BREAKER, 2/10 AMP

CONTACTOR, 3 POLE, 240 V COIL

BUZZER, 240 V

ELEMENT (380,415, 440, OR 480 V)

ELEMENT (380,415, 440, OR 480 V)

LAMP, INDICATOR, HEAT, AMBER

LAMP, INDICATOR, POWER, GREEN

THERMOSTAT, HI-LIMIT, 450 F

THERMOSTAT, HI-LIMIT, 425 F

THERMOSTAT, REGULATING, 400 F

SWITCH, TOGGLE, HILIMIT BYPASS

SWITCH, TOGGLE, POWER

RELAY, 2 POLE, 240 V COIL

LAMP, INDICATOR, OVERTEMP, RED

C

10/6/2003

2,5

3,6

1,4

L2

L1

THREEL3PHASE

SERVICE CONNECTIONS

L1 L2 L3

TB

C

TB TERMINAL BLOCK, 3 POLE

BZ

CB

C1 & C2

EL1

EL2

EL3

HL1

HL2

ITEM DESCRIPTION

IL1

EL2

EL1

TR TRANSFORMER

14.0

56

EL3

43

12

15.3

14.0

15.3

AMPS 3 PHASE

L1 L2 L3

14.0

15.3

12.0

TOTAL

TH

SW2

SW1

RE & RE2

IL3

IL2

KW

4.0 4.0 4.0

4.0 4.0 4.0 12.0

L1-L2 L2-L3 L1-L3

415

380

VOLT

13.2

13.2

13.2

12.0

4.0 4.0 4.0

440

12.1

12.1

12.14.0 4.0 4.0 12.0480

2M-61116-21 Rev C

MODELS:

C28-Marine 380-480VAC

130F- Marine 380-480VAC

LANGSTAR

HL2

CB

C28SM130FM

MODEL MODEL

C

SW1-2

240

440/480

C1

TR

SW1-1

IL1

Tes t 1

Test 2

SW2

RE2

C2

IL2

t°

TH

Test 1

SW2

HL1

BZ

IL3

SHUNT-TRIP CIRCUIT BREAKER

RE

PROVIDED BY OTHERS

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

Page 19

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

SHUNT-TRIP CIRCUIT BREAKER

PROVIDED BY OTHERS

RE

TH

IL3

BZ

C

MODEL MODEL

SW1-1

IL1

TR

440/480

240

CB

Test 2

RE2

SW2

Tes t 1

C1

SW1-2

HL1

SW2

Test 1

t°

IL2

C2

130F- Marine 380-480VAC

2M-61116-21 Rev C

C28-Marine 380-480VAC

MODELS:

12.14.0 4.0 4.0 12.0480

12.1

12.1

C28SM130FM

440

4.0 4.0 4.0

12.0

13.2

13.2

13.2

415

4.0 4.0 4.0 12.0

14.0

14.0

14.0

380

4.0 4.0 4.0

12.0

15.3

15.3

15.3

VOLT

L1-L2 L2-L3 L1-L3

TOTAL

L1 L2 L3

LANGSTAR

KW

AMPS 3 PHASE

HL2

12

EL1

43

EL3

56

EL2

C

L1 L2 L3

THREEL3PHASE

L2

L1

2,5

3,6

1,4

TB

SERVICE CONNECTIONS

10/6/2003

C

TH

SW2

TR TRANSFORMER

ITEM DESCRIPTION

THERMOSTAT, REGULATING, 400 F

SWITCH, TOGGLE, HILIMIT BYPASS

SW1

RE & RE2

IL3

IL2

IL1

SWITCH, TOGGLE, POWER

RELAY, 2 POLE, 240 V COIL

LAMP, INDICATOR, OVERTEMP, RED

LAMP, INDICATOR, HEAT, AMBER

LAMP, INDICATOR, POWER, GREEN

HL2

HL1

EL3

EL2

EL1CBC1 & C2

THERMOSTAT, HI-LIMIT, 450 F

THERMOSTAT, HI-LIMIT, 425 F

ELEMENT (380,415, 440, OR 480 V)

ELEMENT (380,415, 440, OR 480 V)

ELEMENT (380,415, 440, OR 480 V)

BZ

TB TERMINAL BLOCK, 3 POLE

CIRCUIT BREAKER, 2/10 AMP

CONTACTOR, 3 POLE, 240 V COIL

BUZZER, 240 V

Page 20

Model Commercial & Marine

130F Counter Model Fryer

C28 Counter Model Fryer

SK2294 Rev. A 7/15/08

Marine Application

26

27

28 30 32 33 52

1

2

18

17

19

20

21

22

23

24

27

28

39

38

37

35

32

33

34

29

30

36

33

32

31

45

44

40

41

35

42

43

46

48

47

25

26

51

50

3

2

4

5

6

7

8

9

10

11

12

13

14

15

16

1

52

49

Page 21

PARTS LIST June 23, 2010, Rev B

Model No: 130F & C28

COMMERCIAL & MARINE ELECTRIC FRYER

130F Commerical & Marine Fryer

Fig No. Part No Qty Description Application

1 2J-30802-01-1 1 BUZZER, MECHANICAL 240V W/WIRE 130F 208VM, 240VM, 440VM, 480VM

2 2E-30600-10 1 RELAY 2PDT 240V 130F 208VM, 240VM, 440VM, 480VM

2T-30401-13

3

2T-30401-33 STAT FXD TMP NEGBIAS 490°F 130FM MARINE

O9-C28-130

4

O9-C28-130-1 HEAD WRAP FOR TEST SWITCH 130F 208VM, 240VM, 440VM, 480VM

O9-C28-135 2 HEAD END ALL MODELS

O9-C28-136

5

O9-C28-138 HEAD BOTTOM NO LIFT ALL MODELS

6 O9-C28-137 1 HEAD PIVOT ALL MODELS

7 2B-51100-02 1 BASKET HANGER ASSY (C28) ALL MODELS

8 O9-60102-114 2 CLAMP ALL MODELS

9 O9-C28-133 1 ELEMENT STOP A ALL MODELS

10 O9-C28-117 1 REAR COVER ALL MODELS

11 2E-30700-03 2 CONTC 3POLE 40A208-240VAC ALL MODELS

12 O9-C28-111-2 1 CONTACTOR MOUNT SPOTWELD ALL MODELS

13 2E-30500-09 1 TRM BLOCK 3 POLE SMALL 95 ALL MODELS

14 2E-30500-01 AR TRM STRP 2 POLE 30A 300V ALL MODELS

15 Y9-31200-02-1 1 GROUNDING LUG/+LABEL ALL MODELS

16 O9-C28-315 1 TRANSFORMER MOUNT 09-60102-327

17 O9-60102-322 1 CONTROL BOX ASSY, w/labels ALL MODELS

18 O9-C28-186 1 CONTROL BOX ASSY ALL MODELS

19 K9-60301-43-1 1 DIE CAST LOG + TINNERMAN ALL MODELS

20 2E-30303-06 1 SWT TOG ON-ON DPDT BLK ALL MODELS

21 2K-70302-15 1 PIPE NIPPLE 1X 2 1/2 BLK ALL MODELS

22 2V-70400-01 1 VALVE 1BALL NIC PLTD (NO ALL MODELS

23 O9-C28-109-01 1 VALVE ACCESS PNL ALL MODELS

24 2E-30900-15 2 FUSE 3 AMP AGC 130F 208V, 240V, 480V

25 2E-30901-02 2 FUS HLDR FOR 15AMP FUSE 130F 208V, 240V, 480V

26 2E-30303-13 1 SWT TOG ON-OFF-ON MOM MTL ALL MODELS

27 O9-50300-49 1 GRAB BAR ASSY 15 130F 208VM, 240VM, 440VM, 480VM

28 O9-C28-118 1 BUCKET WELDMENT ALL MODELS

29 O9-C28-182 1 ELEMENT ASSY. COMMERCIAL 130F 208V, 240V, 480V

30 O9-C28-181 1 ELEMENT ASSY. MARINE 130F 208VM, 240VM, 440VM, 480VM

31 O9-C28-174 1 EGO STAT HOLDER WELDMENT 130F 208V, 240V, 480V

32 O9-C28-184 2 OVER TEMP BULB BRKT 130F 208VM, 240VM, 440VM, 480VM

33 O9-C28-180 1 THERMOSTAT BULB BRKT ALL MODELS

34 O9-C28-154 1 ELEMENT HOLDER BACK ALL MODELS

35 2C-20301-45 6 NUT HEX 10-32 18-8 TOP ALL MODELS

36 O9-C28-153 1 ELEMENT HOLDER MIDDLE ALL MODELS

37 O9-C28-152 1 ELEMENT HOLDER FRONT ALL MODELS

38 2C-20111-02 1 SCRW HXHD CAP 1/4-20X3/4 ALL MODELS

1

1

1

STAT FXD TEMP 240VAC 450o 130F 208V, 240V, 480V

HEAD WRAP 130F 208VM, 240VM, 440VM, 480VM

HEAD PIVOT SUPPORT ALL MODELS

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

2

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Page 22

PARTS LIST June 23, 2010, Rev B

Model No: 130F & C28

COMMERCIAL & MARINE ELECTRIC FRYER

130F Commerical & Marine Fryer

Fig No. Part No Qty Description Application

39 O9-C28-158 1 HANDLE WELDMENT ALL MODELS

40 2C-20305-05 1 WELD NUT S/S 1/4-20 2-EAR ALL MODELS

41 2C-20303-01 1 NUT HX SS 1/4-20 ALL MODELS

42 O9-C28-155 2 ELEMENT CLAMP ALL MODELS

43 2C-20111-13 1 SCRW HXHD CAP 10-32X1 SS ALL MODELS

44 O9-C28-150 2 ELEMENT BRACKET SUPPORT ALL MODELS

45 2C-20111-09 AR SCRW HXHD CAP 10-32X1/2 ALL MODELS

2N-11110-39

2N-11110-43 ELMNT FRYER 208V 4KW C28 130F 208V AND 208VM

46

2N-11110-44 ELMNT FRYER 240V 4KW C28 130F 240V AND 240VM

2N-11110-45 ELMNT FRYER 380V 4KW C28 130F-380VM

2N-11110-47 ELMNT FRYER 440V 4KW C28 130F 440VM

47 2T-30402-12 1 STAT ADJ 400o 24 C/T ALL MODELS

48 2R-70700-01 1 KNOB BLNK UNIVERSAL BLACK ALL MODELS

2J-31601-15

2J-31601-16 PILOT LT 250V 6LEAD GREEN 130F 208VM, 240VM, 440VM, 480VM

49

2J-31601-20 PILOT LT 250V 6LEAD RED 130F 208VM, 240VM, 440VM, 480VM

Y9-31601-01-1 3 PILOT LT 250V W/TIN CLIP 130F 208V, 240V, 480V

50 O9-C28-131-2 2 OVERTEMP STAT INSULATOR ALL MODELS

51 O9-C28-131-1 2 O.T. STAT SPACER ALL MODELS

2E-31400-04

52

2E-31400-17 XFORMR 380/240VAC 100VA 130F-380VM

NI 2P-70900-01 1 CAP PLUG 1-5/16IDX1.89

3

1

1

ELMNT FRYER 480V 4KW C28 130F 480V AND 480VM

PILOT LT 250V 6LEAD AMBER 130F 208VM, 240VM, 440VM, 480VM

XFRMR 480/240VAC 100VA 130F-440VM, 480VM

2

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

2

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Page 23

Page 24

STAR MANUFACTURING

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(800) 807-9054 (314) 781-2777

Parts & Service (800) 807-9054

www.star-mfg.com

Loading...

Loading...