Page 1

Workshop Manual

Werkplaatshandboek

Manual d'Atelier

Werkstatthandbuch

Manuale d'Officina

Manual de Taller

Manual de Oficina

Page 2

DEFENDER 1999 & 2002 MY

WORKSHOP MANUAL SUPPLEMENT

& BODY REPAIR MANUAL

This Supplement supersedes Workshop Manual VDR 100250

and should be used in conjunction with the following Manuals:

Workshop Manual - Defender 300 Tdi LRL 0097

Overhaul Manual - R380 gearbox LRL 0003 3rd edition

Overhaul Manual - LT230T Transfer gearbox LRL 0081 3rd edition

Publication Part No. LRL 0410ENG (3rd Edition)

Land Rover 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form, electronic,

mechanical, recording or other means without prior permission from Land Rover.

Page 3

Page 4

CONTENTS

01 INTRODUCTION

04 GENERAL SPECIFICATION DATA

05 ENGINE TUNING DATA

07 GENERAL FITTING REMINDERS

09 LUBRICANTS, FLUIDS AND CAPACITIES

10 MAINTENANCE

12 ENGINE

17 EMISSION CONTROL

18 ENGINE MANAGEMENT SYSTEM

19 FUEL SYSTEM

26 COOLING SYSTEM

30 MANIFOLD AND EXHAUST SYSTEM

33 CLUTCH

37 MANUAL GEARBOX

41 TRANSFER GEARBOX

47 PROPELLER SHAFTS

57 STEERING

60 FRONT SUSPENSION

64 REAR SUSPENSION

70 BRAKES

76 CHASSIS AND BODY

77 PANEL REPAIRS

82 AIR CONDITIONING

84 WIPERS AND WASHERS

86 ELECTRICAL

88 INSTRUMENTS

01

04

05

07

09

10

12

17

18

19

26

30

33

37

41

47

57

60

64

70

76

77

82

84

86

88

Page 5

Page 6

01 - INTRODUCTION

CONTENTS

INFORMATION

INTRODUCTION 1..................................................................................................

DIMENSIONS 1.......................................................................................................

REFERENCES 1.....................................................................................................

REPAIRS AND REPLACEMENTS 1.......................................................................

POISONOUS SUBSTANCES 1..............................................................................

FUEL HANDLING PRECAUTIONS 2......................................................................

SYNTHETIC RUBBER 3.........................................................................................

RECOMMENDED SEALANTS 3.............................................................................

USED ENGINE OIL 3..............................................................................................

ACCESSORIES AND CONVERSIONS 4...............................................................

WHEELS AND TYRES 4.........................................................................................

STEAM CLEANING 4..............................................................................................

SPECIFICATION 4..................................................................................................

SPECIAL SERVICE TOOLS 4................................................................................

JACKING 5..............................................................................................................

HYDRAULIC VEHICLE RAMP (FOUR POST) 6.....................................................

TWO POST VEHICLE RAMPS 6............................................................................

DYNAMOMETER TESTING 6................................................................................

TOWING 7..............................................................................................................

TRANSPORTING THE VEHICLE BY TRAILER 7..................................................

JUMP STARTING 8................................................................................................

ABBREVIATIONS AND SYMBOLS USED IN THIS MANUAL 9.............................

CROSS REFERENCE OF EMISSION SYSTEM TERMINOLOGY 10....................

VEHICLE IDENTIFICATION NUMBER (VIN) 11.....................................................

LOCATION OF IDENTIFICATION NUMBERS 12...................................................

FAULT DIAGNOSTIC EQUIPMENT 13..................................................................

READING THIS SUPPLEMENT 14........................................................................

Page

Page 7

Page 8

INTRODUCTION

INTRODUCTION

This Workshop Manual Supplement covers vehicles

from 1999 and 2002 model year onwards. The Body

Repair Manual has also been incorporated into this

supplement. Amendments and additional pages will

be issued, when necessary, to ensure that the

supplement covers latest models.

This Supplement is designed to assist skilled

technicians in the efficient repair and maintenance of

Land Rover Defender vehicles.

Individuals who undertake their own repairs should

have some skill and training, and limit repairs to

components which could not affect the safety of the

vehicle or its passengers. Any repairs required to

safety critical items such as steering, brakes,

suspension or supplementary restraint system should

be carried out by a Land Rover Dealer. Repairs to

such items should NEVER be attempted by untrained

individuals.

WARNINGS, CAUTIONS and NOTES are given

throughout this Manual in the following form:

WARNING: Procedures which must be

followed precisely to avoid the possibility

of personal injury.

CAUTION: This calls attention to

procedures which must be followed to

avoid damage to components.

NOTE: This calls attention to methods

which make a job easier or gives helpful

information.

REFERENCES

References to the left or right hand side in the manual

are made when viewing the vehicle from the rear.

With the engine and gearbox assembly removed, the

crankshaft end of the engine is referred to as the front.

To reduce repetition, some operations covered in this

Supplement do not include reference to testing the

vehicle after repair.

It is essential that work is inspected and tested after

completion and if necessary a road test of the vehicle

is carried out, particularly where safety related items

are concerned.

REPAIRS AND REPLACEMENTS

When replacement parts are required it is essential

that Land Rover parts are used.

Attention is particularly drawn to the following points

concerning repairs and the fitting of replacement parts

and accessories: Safety features embodied in the

vehicle may be impaired if other than Land Rover

parts are fitted. In certain territories, legislation

prohibits the fitting of parts not to the vehicle

manufacturer’s specification. Torque spanner values

given in the Supplement must be strictly adhered to.

Locking devices, where specified, must be fitted. If the

efficiency of a locking device is impaired during

removal it must be replaced with a new one. Certain

fasteners must not be re-used. These fasteners are

specified in the Supplement.

DIMENSIONS

The dimensions quoted are to design engineering

specification. Alternative unit equivalents, shown in

brackets following the dimensions, have been

converted from the original specification.

POISONOUS SUBSTANCES

Many liquids and other substances used are

poisonous and therefore must not be consumed. It is

also advisable to keep all substances away from open

wounds. These substances among others include

anti-freeze, brake fluid, fuel, windscreen washer

additives, air conditioning refrigerant, lubricants and

various adhesives.

INFORMATION

1

Page 9

01

INTRODUCTION

FUEL HANDLING PRECAUTIONS

The following information provides basic precautions

which must be observed if fuel is to be handled safely.

It also outlines the other areas of risk which must not

be ignored.

This information is issued for basic guidance only, and

in any case of doubt, appropriate enquiries should be

made of your local Fire Officer or Fire Department.

Fuel vapour is highly flammable and in confined

spaces is also very explosive and toxic and when

diluted with air becomes a readily ignitable mixture.

The vapour is heavier than air and will always fall to

the lowest level. It can readily be distributed

throughout a workshop by air current, consequently,

even a small spillage of fuel is very dangerous.

Always have a fire extinguisher containing FOAM CO

GAS, or POWDER close at hand when handling fuel,

or when dismantling fuel systems and in areas where

fuel containers are stored.

WARNING: lt is imperative that the battery

is not disconnected during fuel system

repairs as arcing at the battery terminal

could ignite fuel vapour in the atmosphere.

Always disconnect the vehicle battery BEFORE

carrying out work on the fuel system.

Whenever fuel is being handled, transferred or

stored, or when fuel systems are being dismantled

all forms of ignition must be extinguished or

removed, any leadlamps used must be flame proof

and kept clear of spillage.

No one should be permitted to repair components

associated with fuel without first having had fuel

system training.

Hot fuel handling precautions

WARNING: Before commencing any

operation requiring fuel to be drained from

the fuel tank, the following procedure must

be adhered to:

1. Allow sufficient time for the fuel to cool, thus

avoiding contact with hot fuels.

2. Vent the system by removing the fuel filler cap in

a well ventilated area. Refit the filler cap until the

commencement of fuel drainage.

Fuel transfer

WARNING: Fuel must not be extracted or

drained from any vehicle while it is

standing over a pit.

2

The transfer of fuel from the vehicle fuel tank must be

carried out in a well ventilated area. An approved

transfer tank must be used according to the transfer

tank manufacturer’s instructions and local regulations,

including attention to grounding of tanks.

Fuel tank removal

A FUEL VAPOUR warning label must be attached to

the fuel tank upon removal from the vehicle.

Fuel tank repair

Under no circumstances should a repair to any tank

be attempted.

INFORMATION

2

Page 10

INTRODUCTION

SYNTHETIC RUBBER

Many ’0’ ring seals, flexible pipes and other similar

items which appear to be natural rubber are made of

synthetic materials called Fluoroelastomers. Under

normal operating conditions this material is safe, and

does not present a health hazard. However, if the

material is damaged by fire or excessive heat, it can

break down and produce highly corrosive Hydrofluoric

acid which can cause serious burns on contact with

skin. Should the material be in a burnt or overheated

condition handle only with seamless industrial gloves.

Decontaminate and dispose of the gloves immediately

after use.

If skin contact does occur, remove any contaminated

clothing immediately and obtain medical assistance

without delay. In the meantime, wash the affected

area with copious amounts of cold water or limewater

for fifteen to sixty minutes.

RECOMMENDED SEALANTS

A number of branded products are recommended in

this manual for use during maintenance and repair

work.

These items include:

HYLOMAR GASKET AND JOINTING COMPOUND

and

HYLOSIL RTV SILICONE COMPOUND.

They should be available locally from garage

equipment suppliers. If there is any problem obtaining

supplies, contact the following company for advice

and the address of the nearest supplier.

MARSTON LUBRICANTS LTD.

Hylo House,

Cale Lane,

New Springs,

Wigan WN2 1JR

USED ENGINE OIL

WARNING: Prolonged and repeated

contact with engine or motor oil will result

in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis.

Used engine oil contains potentially harmful

contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities should be provided.

Handling precautions

1. Avoid prolonged and repeated contact with oils,

particularly used engine oils.

2. Wear protective clothing, including impervious

gloves where applicable.

3. Do not put oily rags in pockets.

4. Avoid contaminating clothes, particularly

underwear, with oil.

5. Overalls must be cleaned regularly. Discard

unwashable clothing and oil impregnated

footwear.

6. First aid treatment must be obtained immediately

for open cuts and wounds.

7. Use barrier creams, before each work period, to

help the removal of oil from the skin.

8. Wash with soap and water to ensure all oil is

removed (skin cleansers and nail brushes will

help). Preparations containing lanolin replace the

natural skin oils which have been removed.

9. Do not use gasoline, kerosene, diesel fuel,

petrol, thinners or solvents for washing the skin.

10. If skin disorders develop, obtain medical advice.

11. Where practicable, degrease components prior

to handling.

12. Where there is a risk of eye contact, eye

protection should be worn, for example, goggles

or face shields; in addition an eye wash facility

should be provided.

Disposing of used oils

Environmental protection precaution

Tel 01942 824242

It is illegal to pour used oil onto the ground, down

sewers or drains, or into waterways.

Dispose of used oil through authorised waste disposal

contractors. If in doubt contact your Local Authority for

advice on disposal facilities.

INFORMATION

3

Page 11

01

INTRODUCTION

ACCESSORIES AND CONVERSIONS

DO NOT FIT unapproved accessories or conversions,

as they could affect the safety of the vehicle.

Land Rover will not accept liability for death, personal

injury, or damage to property which may occur as a

direct result of the fitting of non-approved conversions

to the vehicle.

WHEELS AND TYRES

WARNING: DO NOT replace the road

wheels with any type other than genuine

Land Rover wheels which are designed for

multi-purpose on and off road use and have very

important relationships with the proper operation

of the suspension system and vehicle handling.

Replacement tyres must be of the make and sizes

recommended for the vehicle, and all tyres must

be the same make, ply rating and tread pattern.

SPECIAL SERVICE TOOLS

The use of approved special service tools is

important. They are essential if service operations are

to be carried out efficiently, and safely. Where special

tools are specified, only these tools should be used

to avoid the posibility of personal injury or

damage to the components.Also, the amount of time

which they can save can be considerable.

Special tools bulletins will be issued periodically giving

details of new tools as they are introduced.

All orders and enquiries from the United Kingdom

should be sent direct to Cartool (UK) Ltd. Overseas

orders should be placed with the local Cartool

distributor, where one exists. Countries where there is

no distributor may order direct from:

Cartool (UK) Ltd.

Unit 3,

Sterling Business Park,

Brackmills,

Northampton,

England, NN4 7EX.

STEAM CLEANING

To prevent consequential rusting, any steam cleaning

within the engine bay MUST be followed by careful

re-waxing of the metallic components affected.

Particular attention must be given to the steering

column, engine coolant pipes and hose clips.

SPECIFICATION

The specification details and instructions set out in

this Supplement apply only to a range of vehicles and

not to any one. For the specification of a particular

vehicle purchasers should consult their Dealer.

The Manufacturer reserves the right to vary

specifications with or without notice, and at such times

and in such manner as it thinks fit. Major as well as

minor changes may be involved in accordance with

the Manufacturer’s policy of constant product

improvement.

Whilst every effort is made to ensure the accuracy of

the particulars contained in this Supplement, neither

the Manufacturer or Dealer, by whom this Supplement

is supplied, shall in any circumstances be held liable

for any inaccuracy or the consequences thereof.

The tools recommended in this Workshop Manual are

listed in an illustrated catalogue, obtainable from:

Land Rover Publications,

Character Mailing,

Heysham Road,

Bootle,

Merseyside, L70 1JL

INFORMATION

4

Page 12

JACKING

The following instructions must be carried out before

raising the vehicle off the ground.

1. Use a solid level ground surface.

2. Apply parking brake.

3. Select 1st gear in main gearbox.

4. Select Low range in transfer gearbox.

CAUTION: To avoid damage occurring to

the under body components of the vehicle

the following jacking procedures must be

adhered to.

DO NOT POSITION JACKS OR AXLE STANDS

UNDER THE FOLLOWING COMPONENTS.

Body structure

Bumpers

Fuel lines

Brake lines

Front radius arms

Panhard rod

Steering linkage

Rear Trailing links

Fuel tank

Engine sump

Gearbox bell housing

INTRODUCTION

Jack or support vehicle by axles only.

Vehicle jack

The jack provided with the vehicle is only intended to

be used in an emergency, for changing a tyre. Do

NOT use the jack for any other purpose. Refer to

Owner’s Manual for vehicle jack location points and

procedure. Never work under a vehicle supported by

the vehicle jack.

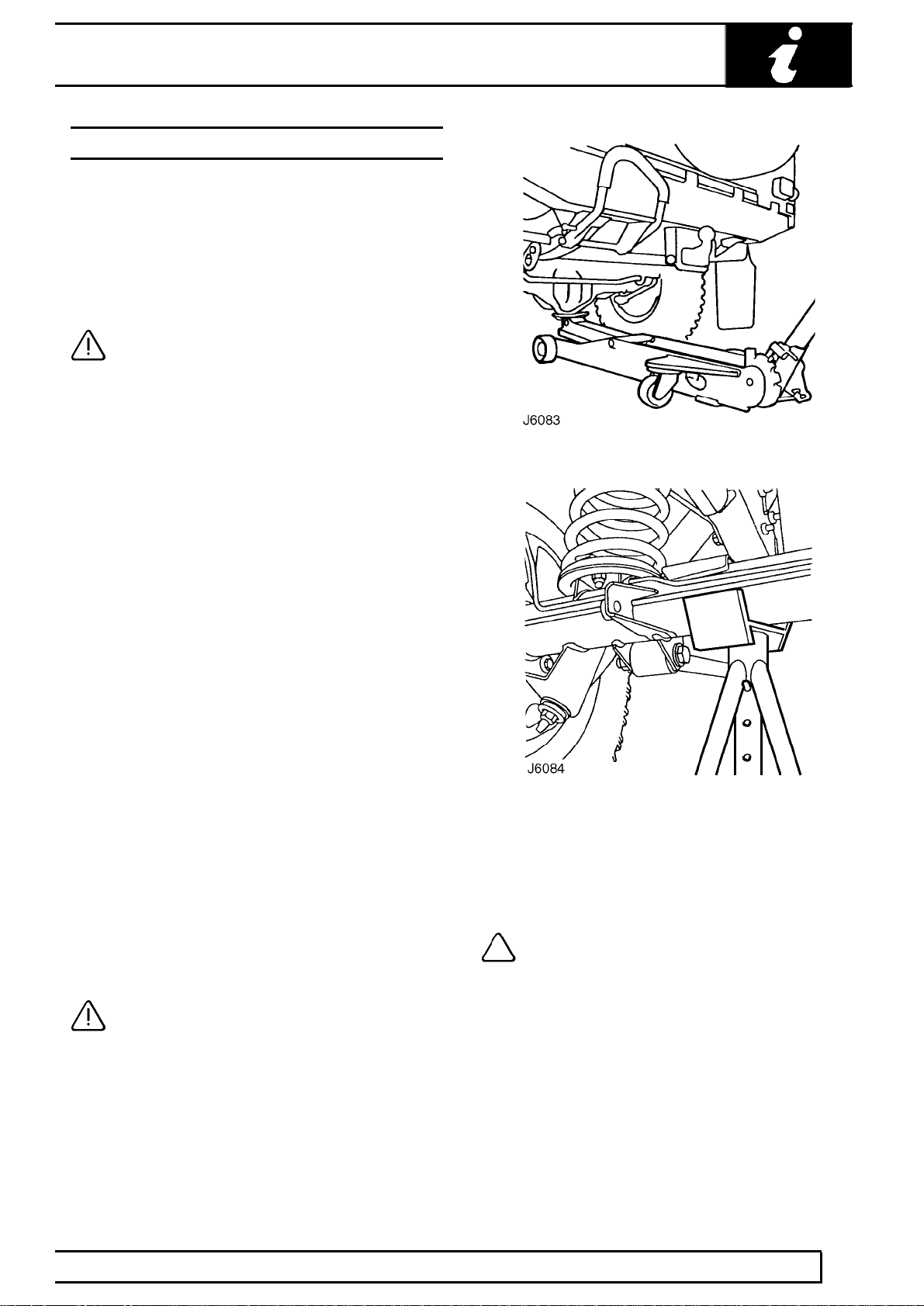

Hydraulic jack

A hydraulic jack with a minimum 1500 kg, 3,300 lbs

load capacity must be used, see illustration J6083.

CAUTION: Do not commence work on the

underside of the vehicle until suitable axle

stands have been positioned under the

axle, see J6084.

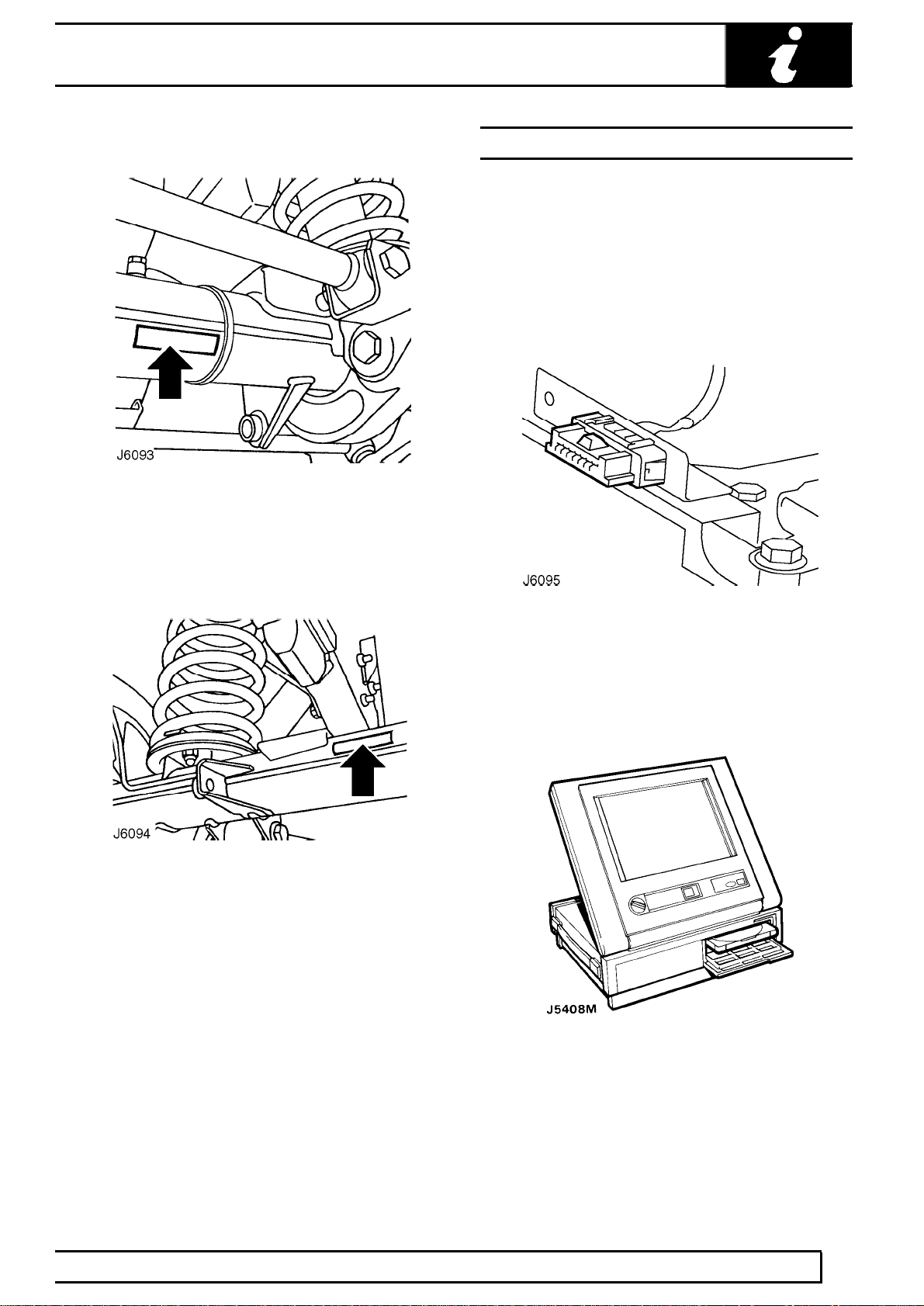

Raise the front of the vehicle

1. Position cup of hydraulic arm under differential

casing.

NOTE: The differential casing is not

central to the axle. Care should be taken

when raising the front road wheels off the

ground as the rear axle has less sway stiffness.

2. Raise front road wheels to enable an axle stand

to be installed under left hand axle tube.

INFORMATION

5

Page 13

01

INTRODUCTION

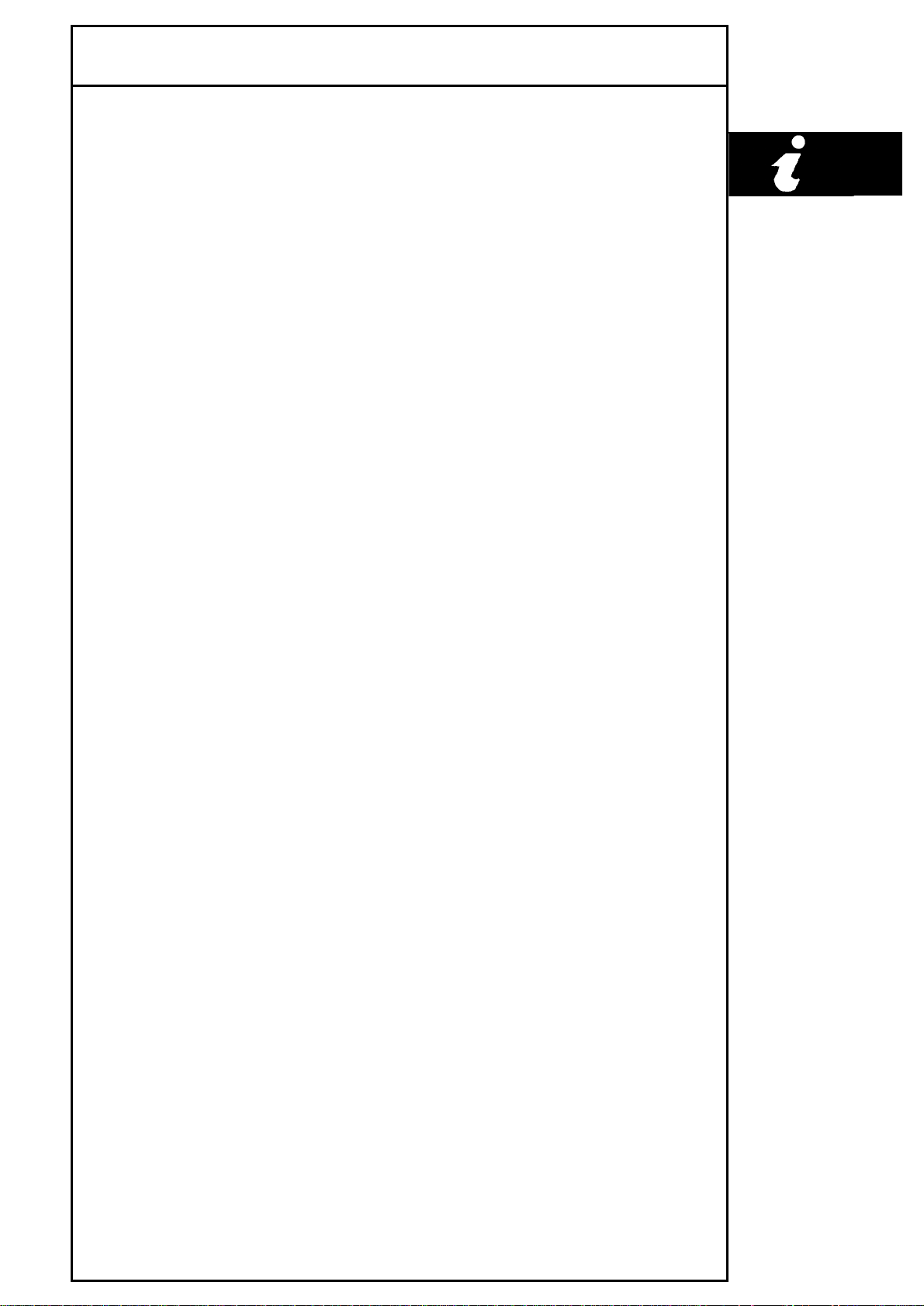

3. Position an axle stand under right hand axle

tube, carefully lower jack until axle sits securely

on both axle stands, remove trolley jack.

4. Before commencing work on underside of

vehicle re-check security of vehicle on stands.

5. Reverse procedure when removing vehicle from

stands.

Raise rear of vehicle

1. Position cup of hydraulic arm under differential

casing.

2. Raise vehicle to enable axle stands to be

installed under left and right hand axle tubes.

3. Lower jack until axle sits securely on axle

stands, remove trolley jack.

4. Before commencing work on underside of

vehicle re-check security of vehicle on stands.

5. Reverse procedure when removing vehicle from

stands.

HYDRAULIC VEHICLE RAMP (FOUR POST)

Use only a ’drive on’ type ramp which supports vehicle

on its road wheels. If a ’wheel-free’ condition is

required, use a ’drive on’ ramp incorporating a

’wheel-free’ system providing support beneath axle

casings. Alternatively, place vehicle on a firm, flat floor

and support on axle stands.

DYNAMOMETER TESTING

The front and rear axles cannot be driven

independently.

WARNING: DO NOT attempt to drive

individual wheels with vehicle supported

on floor jacks or stands.

Four wheel dynamometers

Provided that front and rear dynamometer rollers are

rotating at identical speeds and that normal workshop

safety standards are applied, there is no speed

restriction during testing except any that may apply to

the tyres.

Two wheel dynamometers

IMPORTANT: Use a four wheel dynamometer for

brake testing if possible.

If brake testing on a single axle rig is necessary it

must be carried out with propeller shaft to rear axle

removed, AND neutral selected in BOTH main

gearbox and transfer gearbox. When checking brakes,

run engine at idle speed to maintain servo vacuum.

If checking engine performance, the transfer box must

be in high range and propeller shaft to stationary axle

must be removed.

TWO POST VEHICLE RAMPS

The manufacturer of LAND ROVER VEHICLES

DOES NOT recommend using ’Two Post’ ramps

that employ four adjustable support arms. These

are NOT considered safe for Land Rover vehicles.

If vehicle is installed on a Two Post ramp

responsibility for safety of vehicle and personnel

performing service operations is in the hands of

the Service Provider.

INFORMATION

6

Page 14

INTRODUCTION

TOWING

CAUTION: The vehicle has permanent

four-wheel drive. The following towing

instructions must be adhered to:

Towing the vehicle on all four wheels with driver

operating steering and brakes.

1. Turn ignition key to position ’1’ to release

steering lock.

2. Select neutral in main gearbox and transfer

gearbox.

Rear suspended tow by breakdown vehicle

1. If the front axle is to be trailed turn ignition key to

position ’1’ to release steering lock.

2. Select neutral in main gearbox and transfer box.

CAUTION: The steering wheel and/or

linkage must be secured in a straight

ahead position. DO NOT use the steering

lock mechanism for this purpose.

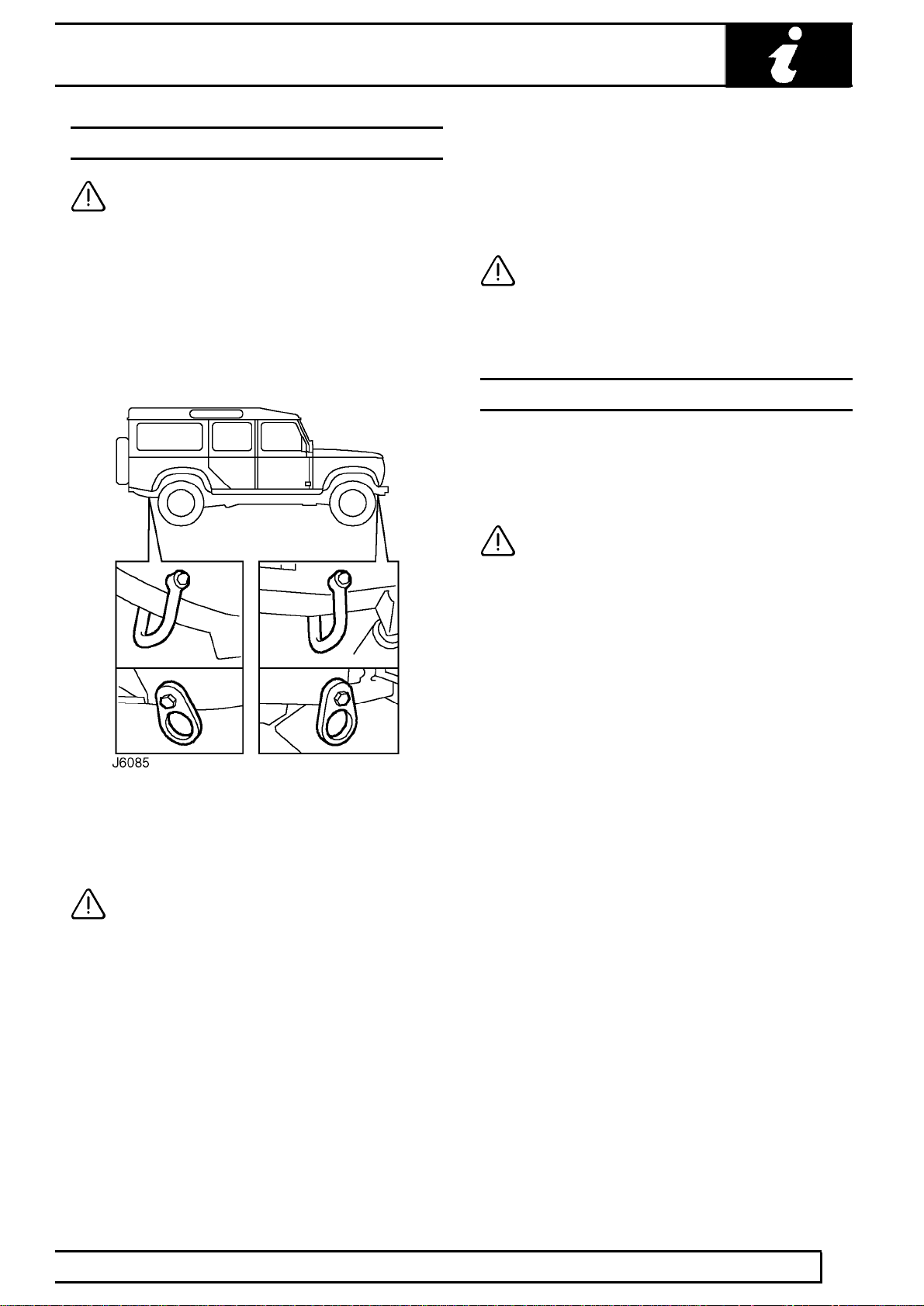

TRANSPORTING THE VEHICLE BY TRAILER

Lashing/towing eyes are provided on front and rear of

the chassis side members, see J6085, to facilitate the

securing of the vehicle to a trailer or other means of

transportation.

CAUTION: Underbody components must

not be used as lashing points.

Install vehicle on trailer and apply park brake. Select

neutral in main gearbox.

3. Secure tow rope, chain or cable to front towing

eyes (alternative types shown).

4. Release the parking brake.

CAUTION: The brake servo and power

assisted steering system will not be

functional without the engine running.

Greater pedal pressure will be required to apply

the brakes, the steering system will require

greater effort to turn the front road wheels.

The vehicle tow connection should be used only

in normal road conditions, ’snatch’ recovery

should be avoided.

INFORMATION

7

Page 15

01

JUMP STARTING

flames, sparks or lighted tobacco are brought

near battery. When charging or using a battery in

an enclosed space, always provide ventilation and

shield your eyes.

Keep out of reach of children. Batteries contain

sulphuric acid. Avoid contact with skin, eyes, or

clothing. Also, shield eyes when working near

battery to protect against possible splashing of

acid solution. In case of acid contact with skin,

eyes, or clothing, flush immediately with water for

a minimum of fifteen minutes. If acid is swallowed,

drink large quantities of milk or water, followed by

milk of magnesia, a beaten egg, or vegetable oil.

SEEK MEDICAL AID IMMEDIATELY.

To Jump Start - Negative Ground Battery

INTRODUCTION

WARNING: Hydrogen and oxygen gases

are produced during normal battery

operation. This gas mixture can explode if

WARNING: To avoid any possibility of

injury use particular care when connecting

a booster battery to a discharged battery.

WARNING: Making final cable connection

could cause an electrical arc which if

made near battery could cause an

explosion.

3. If booster battery is installed in another vehicle,

start engine and allow to idle.

4. Start engine of vehicle with discharged battery,

following starting procedure in Owners’ Manual.

1. Position vehicles so that jump leads will reach,

ensuring that vehicles DO NOT TOUCH,

alternatively a fully charged slave battery may be

positioned on floor adjacent to vehicle.

2. Ensuring that ignition and all electrical

accessories are switched off, that parking brake

is applied and neutral is selected, connect the

jump leads as follows;

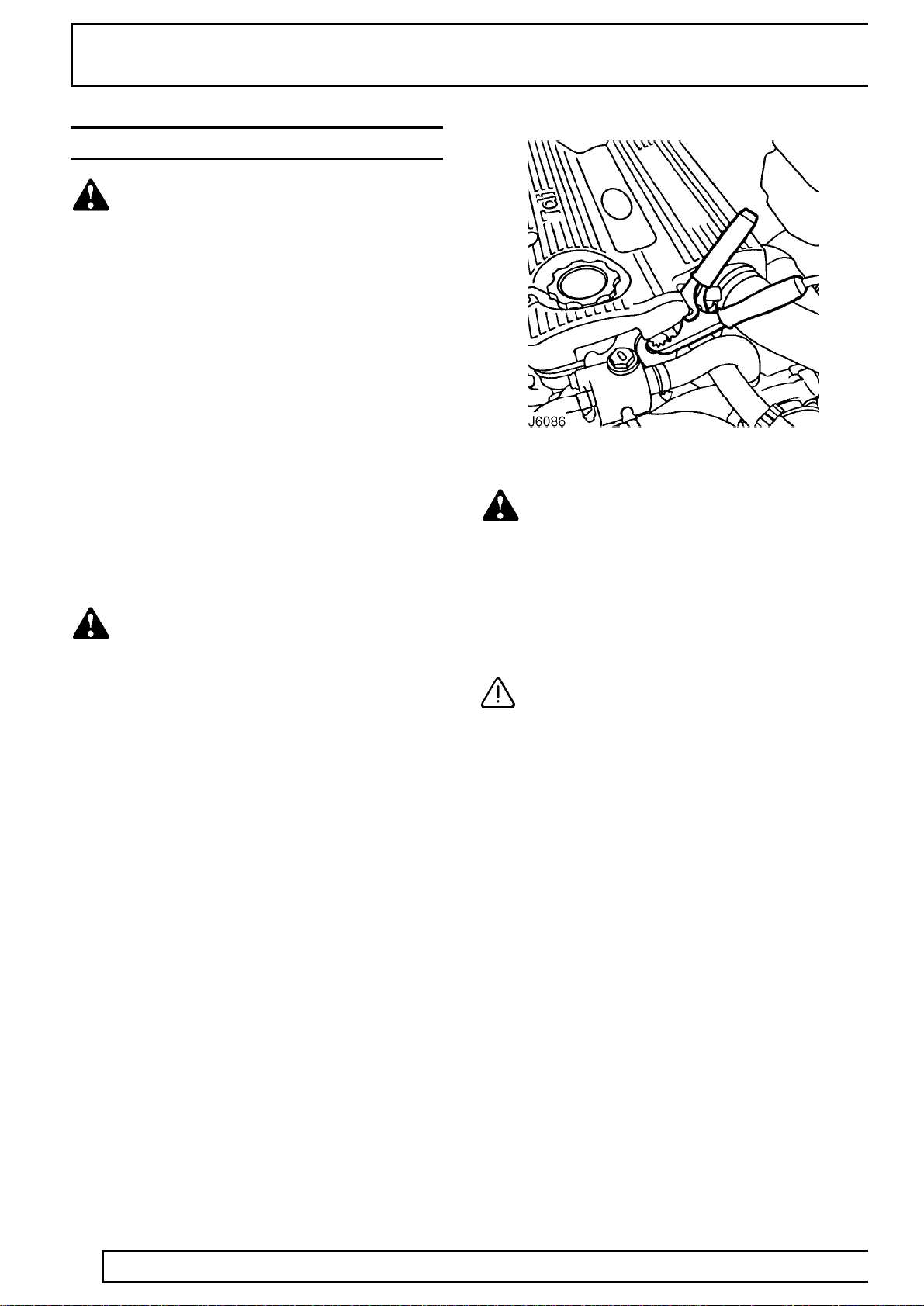

A. Connect one end of first jumper cable to positive

(+) terminal of booster battery.

B. Connect other end of first jumper cable to positive

(+) terminal of discharged battery.

C. Connect one end of second jumper cable to

negative terminal of booster battery.

D. Connect other end of second jumper cable to a

good earth point on the disabled vehicle (eg. engine

front lifting eye, as shown in J6086), NOT TO

NEGATIVE TERMINAL OF DISCHARGED

BATTERY. Keep jumper lead away from moving

parts, pulleys, drive belts and fan blade assembly.

CAUTION: If vehicle fails to start within a

maximum time of 12 seconds, switch

ignition off and investigate cause. Failing

to follow this instruction could result in

irrepairable damage to catalyst, if fitted.

5. Remove negative (-) jumper cable from the

engine and then terminal of booster battery.

6. Remove positive (+) jumper cable from positive

terminals of booster battery and discharged

battery.

INFORMATION

8

Page 16

ABBREVIATIONS AND SYMBOLS USED IN THIS MANUAL

INTRODUCTION

Across flats (bolt size) AF............................................

After bottom dead centre ABDC...................................

After top dead centre ATDC.........................................

Alternating current a.c..................................................

Ampere amp................................................................

Ampere hour amp hr....................................................

Before bottom dead centre BBDC................................

Before top dead centre BTDC......................................

Bottom dead centre BDC.............................................

Brake horse power bhp................................................

British Standards BS....................................................

Carbon monoxide CO..................................................

Centimetre cm.............................................................

Centigrade (Celsius) C................................................

Cubic centimetre cm

Cubic inch in

...................................................

...............................................................

Degree (angle) deg or °...............................................

Degree (temperature) deg or °.....................................

Diameter dia................................................................

Direct current d.c..........................................................

Electronic Control Unit ECU........................................

Fahrenheit F.................................................................

Feet ft...........................................................................

Feet per minute ft/min..................................................

Fifth 5th........................................................................

First 1st........................................................................

Fluid ounce fl oz..........................................................

Foot pounds (torque) lbf.ft............................................

Fourth 4th.....................................................................

Gramme (force) gf........................................................

Gramme (mass) g........................................................

Gallons gal...................................................................

High tension (electrical) H.T.........................................

Internal diameter I.D....................................................

Inches of mercury in. Hg..............................................

Inches in......................................................................

Kilogramme (force) kgf.................................................

Kilogramme (mass.) kg................................................

Kilogramme centimetre (torque) kgf.cm.......................

Kilogramme per square millimetre kgf/mm

Kilogramme per square centimetre kgf/cm

.................

.................

Kilogramme metres (torque) kgf.m..............................

Kilometres km..............................................................

Kilometres per hour km/h.............................................

Kilovolts kV...................................................................

Left-hand LH................................................................

Left-hand steering LHStg.............................................

Left-hand thread LHThd...............................................

Litres litre.....................................................................

Low tension l.t..............................................................

Maximum max.............................................................

Metre m........................................................................

Millilitre ml....................................................................

Millimetre mm...............................................................

Miles per gallon mpg....................................................

Miles per hour mph......................................................

Minute (angle) ’............................................................

Minus (of tolerance) -...................................................

Negative (electrical) -...................................................

Newton metres (torque) Nm........................................

Number No..................................................................

Ohms ohm...................................................................

Ounces (force) ozf.......................................................

3

Ounces (mass) oz........................................................

3

Outside diameter O.D..................................................

Part number Part No....................................................

Percentage %...............................................................

Pints pt.........................................................................

Plus (tolerance) +.........................................................

Positive (electrical) +....................................................

Pound (force) lbf..........................................................

Pounds inch (torque) lbf.in...........................................

Pound (mass) lb...........................................................

Pounds per square inch P.S.I......................................

Ratio :...........................................................................

Reference ref...............................................................

Revolution per minute rev/min.....................................

Right-hand RH.............................................................

Second (angle) "...........................................................

Second (numerical order) 2nd......................................

Specific gravity sp.gr....................................................

Square centimetres cm

Square inches in

...............................................

.........................................................

Standard wire gauge s.w.g..........................................

Synchroniser/Synchromesh synchro...........................

Third 3rd.......................................................................

Top dead centre TDC..................................................

United Kingdom UK......................................................

2

Vehicle Identification Number VIN...............................

2

Volts V.........................................................................

Watts W.......................................................................

SCREW THREADS

British Standard Pipe BSP...........................................

Unified Coarse UNC....................................................

Unified Fine UNF.........................................................

2

2

INFORMATION

9

Page 17

01

CROSS REFERENCE OF EMISSION SYSTEM TERMINOLOGY

INTRODUCTION

NEW TERM (ACRONYM)

Accelerator pedal (AP).................................................

Air cleaner (ACL)..........................................................

Air conditioning (A/C)...................................................

Battery positive voltage (B+)........................................

Closed loop (CL)..........................................................

Closed throttle position (CTP)......................................

Canister purge valve (CANPV)....................................

Data link connector (DLC)...........................................

Diagnostic trouble code (DTC).....................................

Distributor ignition (DI).................................................

Engine control module (ECM)......................................

Engine coolant level (ECL)...........................................

Engine coolant temperature (ECT)..............................

Engine speed (RPM)....................................................

Evaporative emission system (EVAP)..........................

Engine fuel temperature sensor (EFTS)......................

4th gear, 3rd gear etc. (4GR, 3GR)..............................

Fuel pump (FP)............................................................

Fan control module (FCM)...........................................

Generator (GEN)..........................................................

Ground (GND)..............................................................

Heated oxygen sensor (H02S)....................................

Idle air control (IAC)......................................................

Idle air control valve (IACV).........................................

Ignition control module (ICM).......................................

Intake air temperature (IAT).........................................

Manifold vacuum zone (MVZ)......................................

Mass air flow sensor (MAF).........................................

Open loop (OL)............................................................

Relay module (RM)......................................................

Solid state relay module (SSRM).................................

Three way catalytic converter (TWC)..........................

Throttle body (TB)........................................................

Throttle position sensor (TP)........................................

Transmission range (TR)..............................................

Wide open throttle (WOT)............................................

OLD TERM (ACRONYM)

Throttle pedal (-)..........................................................

Air cleaner (-)...............................................................

Air conditioning (AC)....................................................

Battery plus, bat +, bat feed (B+).................................

Closed loop (-).............................................................

Closed throttle, idle position (-)....................................

Charcoal canister purge valve (-).................................

Serial link (-)................................................................

Fault code (-)...............................................................

Electronic ignition (-)....................................................

Electronic control unit (ECU)........................................

Coolant level (-)...........................................................

Coolant temperature (temp).........................................

Coolant temperature thermistor (-)..............................

Engine speed (rev/min)................................................

Evaporative loss system (ELC)...................................

Fuel temperature thermistor (-)....................................

Fourth gear, 3rd gear (-)..............................................

Fuel pump (-)...............................................................

Condenser fan timer (-)................................................

Alternator (-)................................................................

Ground, earth (B-)........................................................

Lambda (02) sensor (-)................................................

Idle speed control (ISC)................................................

Stepper motor (-).........................................................

Ignition module (-)........................................................

Intake temperature/ambient temperature (-)................

Manifold depression, vacuum (-).................................

Air flow meter (-)..........................................................

Fault code display unit (-)............................................

Open loop (-)...............................................................

Relay (-).......................................................................

Control unit (-)..............................................................

Catalyst, catalytic converter (CAT)..............................

Throttle housing (-)......................................................

Transmission gear (-)...................................................

Full throttle, wide open throttle (WOT).........................

10

INFORMATION

Page 18

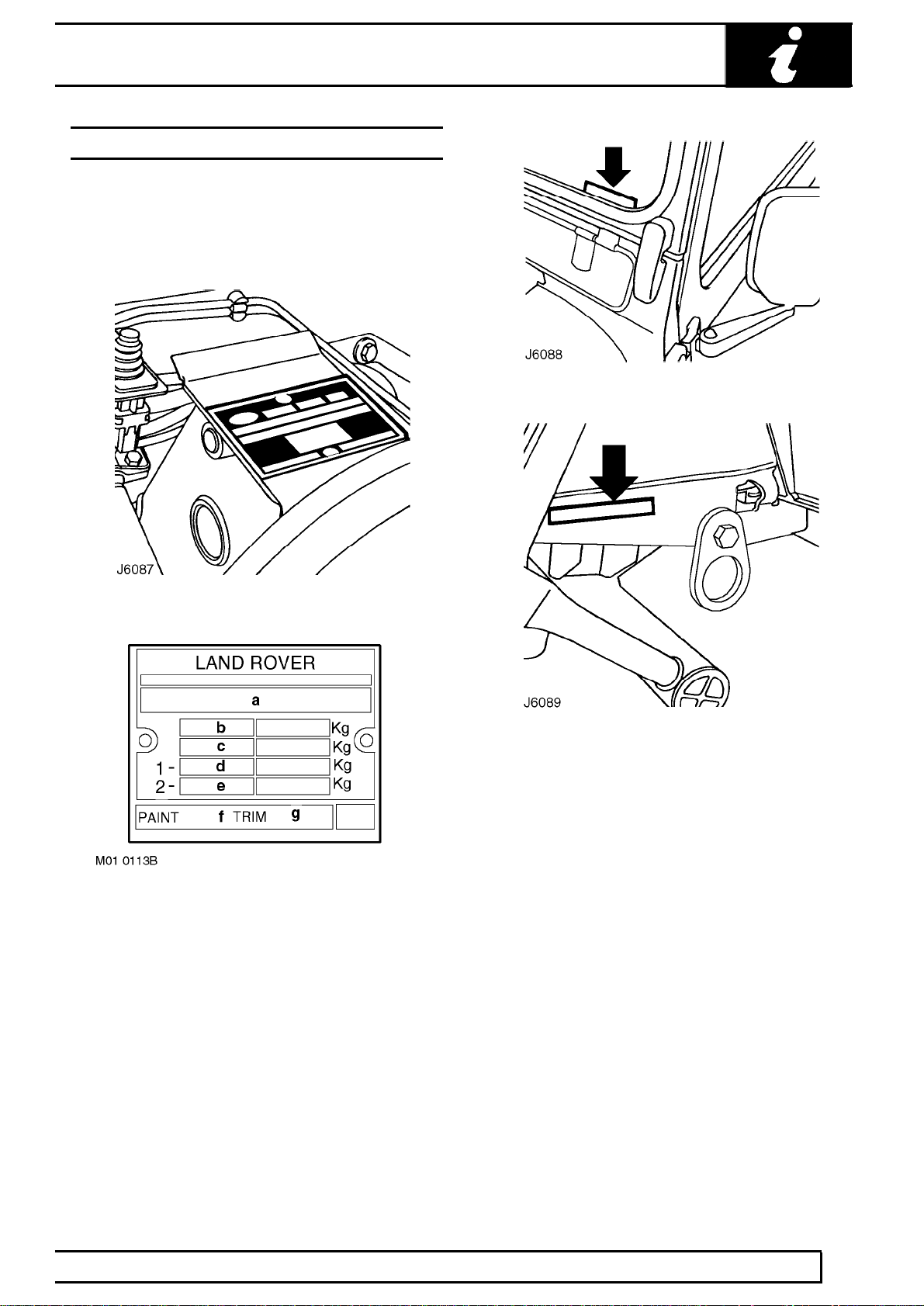

VEHICLE IDENTIFICATION NUMBER (VIN)

The Vehicle Identification Number and the

recommended maximum vehicle weights are stamped

on a plate riveted to the brake pedal box in the engine

compartment. The VIN is also stamped on a plate

visible through the LH side of the windscreen.

INTRODUCTION

a. Identification

b. Maximum permitted laden weight for vehicle

c. Maximum vehicle and trailer weight

d. Maximum road weight-front axle

e. Maximum road weight-rear axle

f. Paint code

g. Trim level

The number is also stamped on the RH side of the

chassis to the rear of the front lashing eye, see J6089.

The Vehicle Identification Number identifies the

manufacturer, model range, wheel base, body type,

engine, steering, transmission, model year and place

of manufacture. The following example shows the

coding process.

SAL LD H M 8 7 X A

SAL = World manufacturer identifier

LD = Land Rover Defender

H = 110 inch, V= 90inch, K= 130 inch

M = 4 door Station Wagon, A= 90 Soft Top, Hard Top,

Pick-up, B= 2 door Station Wagon, E= 2 door 130

Crew cab, F= 4 door 130 Crew cab, H= 130 High

Capacity Pick-up

8= Td5 engine.

7= RH drive, 5 speed manaul, 8= LH drive, 5 speed

manual

X= 1999 MY, volume build.

A= Solihull build, F= CKD, assembled locally from kit

INFORMATION

11

Page 19

01

INTRODUCTION

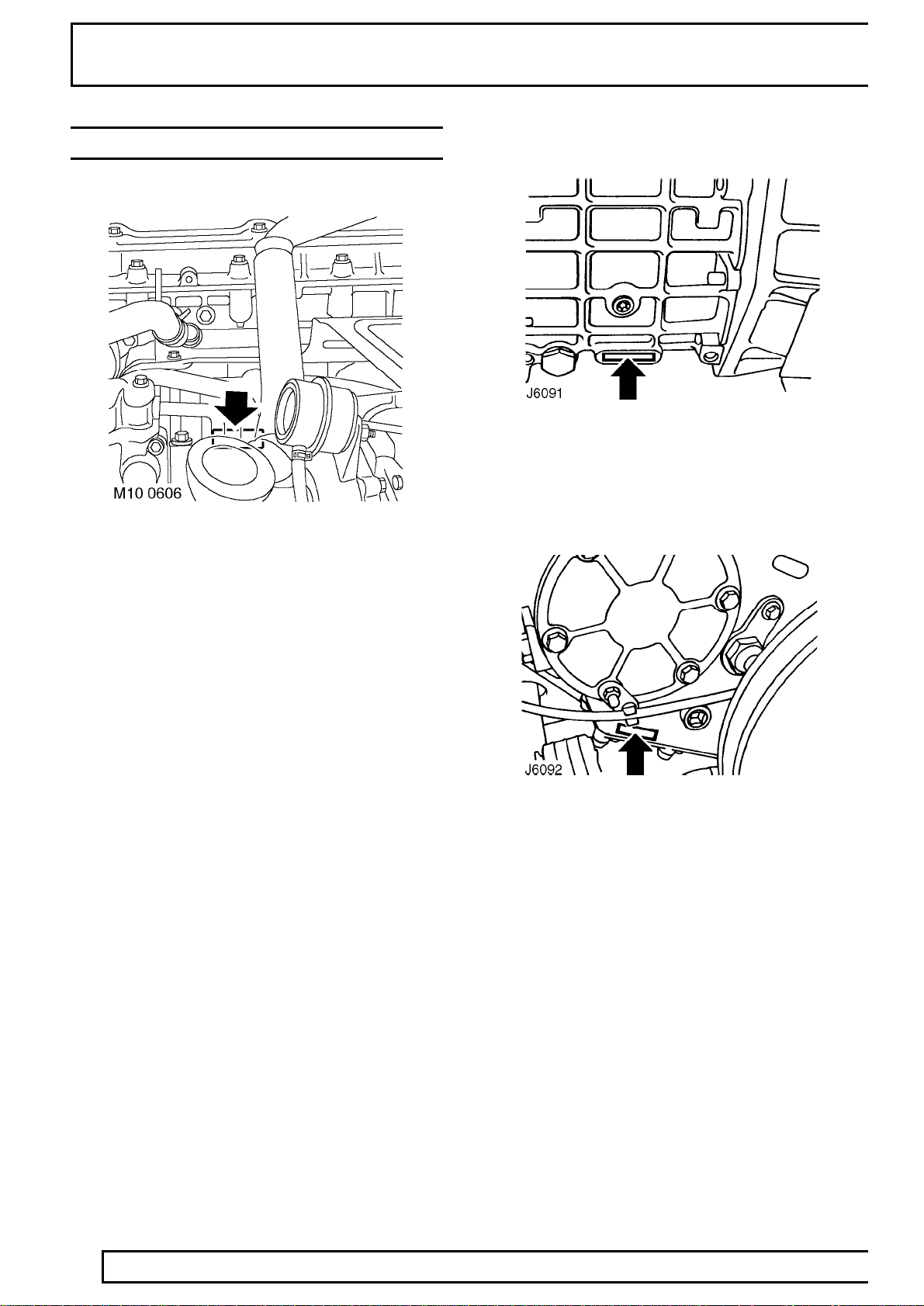

LOCATION OF IDENTIFICATION NUMBERS

Engine serial number - Td5 Engine

The Td5 engine number is stamped on the LH side of

the cylinder block, below the exhaust manifold.

Main gearbox R380 serial number

Stamped on a cast pad on the bottom RH side of the

gearbox.

Transfer gearbox LT230 serial number

12

The serial number is stamped on the LH side of the

gearbox casing below the mainshaft rear bearing

housing adjacent to the bottom cover.

INFORMATION

Page 20

INTRODUCTION

Front axle serial number

Stamped on the front of LH axle tube, inboard of

radius arm mounting bracket.

Rear axle serial number

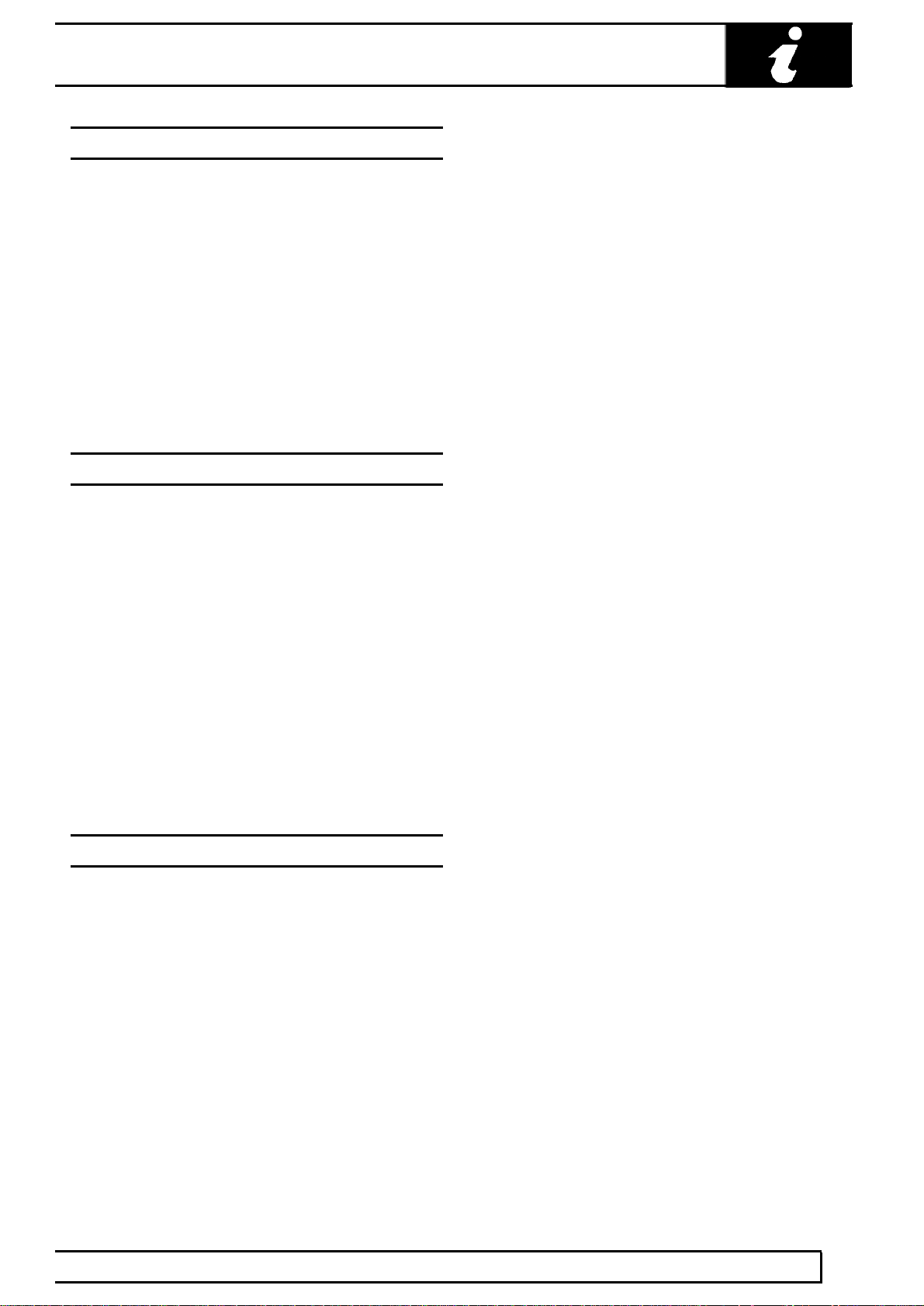

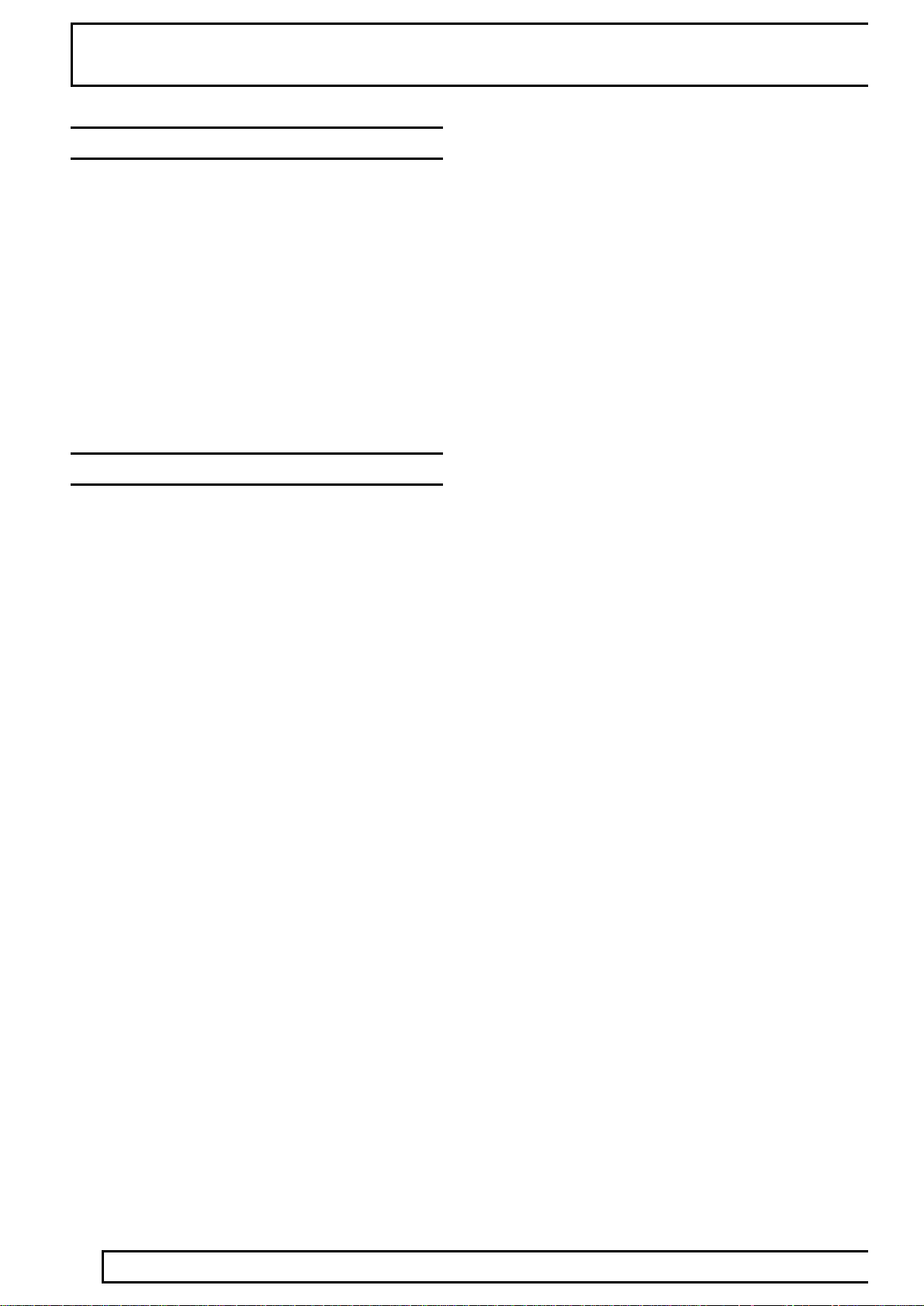

FAULT DIAGNOSTIC EQUIPMENT

TESTBOOK

For Defender models fitted with the vehicle Anti-theft

Immobilisation and Alarm System, diagnostic

equipment, named TestBook, is available to assist in

the diagnostic and fault finding abilities of the Dealer

workshop. A diagnostic connector, located under the

front centre seat, or cubby box, as shown below, is

provided to facilitate the procedures.

Stamped on the rear of LH axle tube, inboard of

spring mounting.

If an exhaust gas recirculation (EGR) system is fitted,

this too can be checked using TestBook. A diagnostic

connector, also located under the front centre seat or

cubby box, is provided.

Features of Testbook include :-

Fully upgradable support for the technician.

Structured diagnostics to accommodate all skill levels.

Touch screen operation.

Direct print out of screen information and test results.

INFORMATION

13

Page 21

01

READING THIS SUPPLEMENT

This Supplement is divided into sections shown on the

contents page, alongside a range of icons, familiar to

service technicians.

Relevant information is contained within each of these

sections. These are further divided into the following

sub-sections which appear at the foot of each page :-

Description and operation.

Adjustment.

Repair.

Overhaul.

To avoid repeating information through the sections,

where part of the repair operation impacts on another

section, a cross reference is given to direct the reader

to where the information is sited.

INTRODUCTION

For example:

The maintenance section states the need to renew

drive belt. A cross reference sites this information in:

Section 12 Engine

- Sub-section: Repair

14

INFORMATION

Page 22

04 - GENERAL SPECIFICATION DATA

CONTENTS

Page

INFORMATION

ENGINE - Td5 1......................................................................................................

FUEL SYSTEM - Td5 3...........................................................................................

COOLING SYSTEM - Td5 3....................................................................................

CLUTCH - Td5 3.....................................................................................................

TRANSMISSION - Td5 4.........................................................................................

STEERING 5...........................................................................................................

SUSPENSION 6......................................................................................................

ROAD SPRING DATA 6..........................................................................................

SHOCK ABSORBERS 7.........................................................................................

BRAKES 7...............................................................................................................

AIR CONDITIONING 8............................................................................................

WIPER MOTORS 8.................................................................................................

ELECTRICAL 8.......................................................................................................

BULBS 9.................................................................................................................

VEHICLE WEIGHTS AND PAYLOAD 10................................................................

TOWING WEIGHTS 11...........................................................................................

OFF-ROAD PERFORMANCE 11............................................................................

TYRE SIZE AND PRESSURES 12.........................................................................

WHEELS 12............................................................................................................

VEHICLE DIMENSIONS 13....................................................................................

Page 23

Page 24

GENERAL SPECIFICATION DATA

ENGINE - Td5

Type 2.5 litre in-line direct injection Diesel, turbocharged.................................................................................

Number of cylinders 5 in-line, No. 1 cylinder at front of engine.........................................................

Bore 84.450 mm (3.3248 in).................................................................................

Stroke 88.950 mm (3.5020 in)...............................................................................

Capacity 2498 cm3(152.5 in3)...........................................................................

Firing order 1 - 2 - 4 - 5 - 3.......................................................................

Compression ratio 19.5:1............................................................

Direction of rotation Clockwise viewed from the front of the engine...........................................................

Dimensions

Length 766 mm (30.1 in).....................................................................

Width 708 mm (27.8 in).......................................................................

Height 788 mm (31.0 in)......................................................................

Emissions standard :-

Engine Serial No. Prefixes 10P to 14P - EU2 Model ECD 2........

Engine Serial No. Prefixes 15P to 19P - EU3 Model ECD 3........

Lubrication

and intercooled

Type Wet sump, pressure fed.................................................................................

Pump type Eccentric rotor, crankshaft driven integral with stiffener........................................................................

Filter type:

Primary Centrifuge filter....................................................................

Secondary Disposable canister with full flow by-pass...............................................................

Pressure at idle (cold) 3.0 bar (43.5 lbf.in2)......................................................

Pressure at 3500 rev/min (hot) 1.5 - 3.0 bar (21.75 - 43.5 lbf.in2).........................................

Relief valve opening pressure 4.0 bar (58 lbf.in2)..........................................

Low oil pressure switch opening pressure 0.2 - 0.6 bar (3.0 - 8.8 lbf.in2).......................

Crankshaft

Main bearing journal diameter 61.9875 - 62.0125 mm..........................................

Crankpin journal diameter 53.99 - 54.01 mm................................................

Crankshaft end float 0.020 - 0.250 mm.........................................................

Main bearings

Number and type 6 half shells (5 main, 1 thrust)..............................................................

Pistons

Type Graphite compound skirt with combustion chamber in.................................................................................

Clearance in cylinder bore 0.172 - 0.206 mm (measured at bottom of skirt, 90° to...............................................

Diameter 84.270 - 85.254 mm (measured 90° to gudgeon pin,..........................................................................

plate.

crown.

gudgeon pin)

and 40.00 mm from bottom of skirt.)

INFORMATION

1

Page 25

04

Gudgeon pins

Type Fully floating, offset towards piston thrust side..................................................................................

Piston rings

Type

Upper compression Barrel edge, chrome plated.................................................

Lower compression Taper faced.................................................

Oil control Bevelled ring with spring................................................................

New ring to groove clearance

Upper compression Not measured.................................................

Lower compression 0.050 - 0.082 mm (0.002 - 0.003 in).................................................

Oil control 0.050 - 0.082 mm (0.002 - 0.003 in)................................................................

Piston ring fitted gap in cylinder bore

Upper compression 0.30 - 0.45 mm (0.0118 - 0.0177 in).................................................

Lower compression 0.40 - 0.60 mm (0.0157 - 0.0236 in).................................................

Oil control 0.25 - 0.40 mm (0.0098 - 0.0157 in)................................................................

GENERAL SPECIFICATION DATA

Camshaft

Drive Duplex chain.................................................................................

End float 0.6 - 0.16 mm...........................................................................

Number of bearings 6..........................................................

Tappets

Type Hydraulic lash adjusters with followers.................................................................................

Valves

Stem diameter

Exhaust 6.905 ± 0.008 mm (0.271 ± 0.0003 in)...................................................................

Inlet 6.915 ± 0.008 mm (0.272 ± 0.0003 in).........................................................................

Head diameter

Exhaust 31.7 mm (1.25 in)...................................................................

Inlet 34.7 mm (1.37 in).........................................................................

Seat face angle

Exhaust 45°...................................................................

Inlet 30°.........................................................................

Valve face angle

Exhaust 44°48’ ± 12’...................................................................

Inlet 29°48’ ± 12’.........................................................................

Valve springs

Type Parallel, single coil.................................................................................

INFORMATION

2

Page 26

GENERAL SPECIFICATION DATA

FUEL SYSTEM - Td5

Type Direct injection from pressure regulated supply with.................................................................................

Pressure regulator setting 4 bar (58 lbf.in2)................................................

Pump Electric two stage submersible................................................................................

Pump output

Low pressure 30 l/h (6.6 gal/h) at 0.5 bar (7.25 lbf.in2)..........................................................

High pressure 180 l/h (39.6 gal/h) at 4 bar (58 lbf.in2)..........................................................

Max consumption 30 l/h (6.6 gal/h).............................................................

Injectors Electronic unit injectors...........................................................................

Injector normal operating pressure 1500 bar (21750 lbf.in2)..................................

Filter In-line canister filter/water separator with water.................................................................................

COOLING SYSTEM - Td5

Type Pressurised spill return partial flow, thermostatically.................................................................................

Cooling fans 11 blade axial flow on viscous coupling and 11 blade.....................................................................

Electric cooling fan switching points

On Vehicle speeds of 50 mph (80 km/h) and below while...........................................................................

Off Vehicle speeds of 62.5 mph (100 km/h) and above or...........................................................................

Coolant pump Centrifugal impeller, belt driven from crankshaft...................................................................

Thermostat Waxstat with pressure relief valve.......................................................................

Thermostat opening temperature

Initial opening 82°C (179°F)..........................................................

Fully open 96°C (204°F)...............................................................

Expansion tank cap relief valve operating pressure 1.4 bar (20.3 lbf.in2).........

cooled return flow

detection

controlled

axial flow electric

ambient temperature is 28°C (82°F) or above

ambient temperatures of 25°C (77°F) and below

CLUTCH - Td5

Type Diaphragm spring, hydraulically operated with.................................................................................

Drive plate diameter 267 mm.........................................................

Pressure plate diameter 270 mm...................................................

self-centering pre-loaded release bearing

INFORMATION

3

Page 27

04

TRANSMISSION - Td5

Main gearbox

Type R380 Single helical constant mesh.......................................................................

Speeds 5 forward, 1 reverse, all synchromesh.............................................................................

Transfer box

Type LT230TE Two speed reduction on main gearbox output. Front.................................................................

Rear axle

Type Spiral bevel, fully floating shafts.................................................................................

Ratio 3.54:1.................................................................................

Front axle

GENERAL SPECIFICATION DATA

and rear drive permanently engaged via a lockable

differential

Type Spiral bevel, enclosed constant velocity joints, fully.................................................................................

Ratio 3.54:1.................................................................................

Propeller shafts

Type, front and rear Tubular 51 mm dia...........................................................

Universal joints Open type Hookes O3EHD.................................................................

floating shafts, 32° angularity of universal joint on full

lock

INFORMATION

4

Page 28

GENERAL SPECIFICATION DATA

STEERING

Power steering box

Make/type Adwest Varamatic - worm and roller box........................................................................

Ratio Variable: straight ahead 19.3:1 on lock 14.3:1.................................................................................

Steering wheel turns, lock-to-lock 3.375....................................

Steering pump

Make/type Hobourn-Eaton series 500........................................................................

Steering geometry

Steering wheel diameter 412 mm (16.22 in)..................................................

Toe-out measurement 0 to 2 mm toe out......................................................

Toe-out included angle 0° to 0° 20’.....................................................

Camber angle 0° *..................................................................

Castor angle 3° *.....................................................................

Swivel pin inclination static 7° *...............................................

* Check with vehicle on level ground, in unladen

condition and five gallons of fuel. Rock the front of the

vehicle up and down to allow it to take up a normal

static position.

Turning circle between kerbs

90 models:

265/75 x 16 tyres 12,65 m (41.5 ft)..............................................................

All other tyres 11,70 m (38.4 ft)...................................................................

110 models:

750 x 16 tyres 13,41 m (44 ft)..................................................................

130 models:

750 x 16 tyres 15,24 m (50 ft)..................................................................

INFORMATION

5

Page 29

04

SUSPENSION

Type Coil springs controlled by telescopic dampers front.................................................................................

Front Transverse location of axle by Panhard rod, and fore.................................................................................

Rear Fore and aft movement inhibited by two tubular trailing.................................................................................

ROAD SPRING DATA

90 (2400 Kg) Part No. Colour Code

Front - Driver’s side NRC 9446 Blue/green

Front - Passenger side NRC 9447 Blue/yellow

Rear - Driver’s side NRC 9448 Blue/red

Rear - Passenger side NRC 9449 Yellow/white

GENERAL SPECIFICATION DATA

and rear.

and aft location by two radius arms. Anti-roll bar fitted

as standard on 90 models with 265/75 tyres and 130

models.

links. Lateral location of axle by a centrally positioned

’A’ frame, upperlink assembly, bolted at the apex to a

ball joint mounting. Anti-roll bar fitted as standard on

90 models with 265/75 tyres, 110 models with self

levelling unit, and 130 models.

90 (2550 Kg)

Front - Driver’s side NRC 9446 Blue/green

Front - passenger side NRC 9447 Blue/yellow

Rear - Driver’s side NRC 9462 Green/yellow/red

Rear - Passenger side NRC 9463 Green/yellow/white

110 (3050 Kg)

Front - both sides NRC 8045 Yellow/yellow

Rear - both sides NRC 6904 Red/green

110 Levelled (2950 Kg)

Front - both sides NRC 8045 Yellow/yellow

Rear - both sides NRC 7000 Green/white

110 (3400 Kg)

Front - both sides NRC 8045 Yellow/yellow

Rear - both sides NRC 6904 Red/green

Rear helper springs - both sides RRC 3266 No colour code

110 (3600 Kg)

Front - Driver’s side NRC 9448 Blue/red

Front - passenger side NRC 9449 Yellow/white

Rear - both sides NRC 6904 Red/green

Rear helper springs - both sides RRC 3226 No colour code

130 (3500 Kg)

Front - driver’s side NRC 9448 Blue/red

Front - passenger side NRC 9449 Yellow/white

Rear - driver’s side NRC 6389 Red/red

Rear - passenger side NRC 6904 Red/green

Front/rear helper springs - both sides RRC 3266 No colour code

INFORMATION

6

Page 30

GENERAL SPECIFICATION DATA

SHOCK ABSORBERS

Type Telescopic, double-acting non-adjustable.................................................................................

Bore diameter 35.47mm...................................................................

BRAKES

Front brake

Caliper AP Lockheed, four opposed pistons..............................................................................

Operation Hydraulic, self adjusting.........................................................................

Disc 90 - Solid, outboard, 110/130 - Ventilated, outboard..................................................................................

Disc diameter 298 mm (11.73 in)...................................................................

Disc thickness 90 - 14,1 mm (0.56in), 110/130 - 24mm (0.95 in)..................................................................

Wear limit 1 mm (0.04in) per side of disc.........................................................................

Disc run-out maximum 0,15mm (0.006 in).....................................................

Pad area 58 cm2(9.0 in2)..........................................................................

Total swept area 801,3 cm2(124.2 in2)...............................................................

Pad material Ferodo 3440 non asbestos.....................................................................

Pad minimum thickness 3 mm (0.12in)...................................................

Rear brake

Caliper AP Lockheed opposed piston..............................................................................

Operation Hydraulic, self adjusting.........................................................................

Disc Solid, outboard..................................................................................

Disc diameter 90 - 290 mm (11.42 in), 110/130 - 298 mm (11.73)...................................................................

Disc thickness 90 - 12,5 mm (0.49 in), 110/130 - 14,1 mm (0.56 in)..................................................................

Wear limit 90 - 0,38 mm (0.015 in), 110/130 - 1,0 mm (0.04 in).........................................................................

Disc run-out maximum 0,15 mm (0.006 in).....................................................

Pad area 90 - 30,5 cm2(4.37 in2), 110/130 - 36,2 cm2(5.61 in2)..........................................................................

Total swept area 90 - 694 cm2(106.98 in2)...............................................................

Pad material Ferodo 3440 non asbestos.....................................................................

Pad minimum thickness UP TO 02MY - 3 mm (0.12 in)...................................................

Pad minimum thickness From 02MY - 2 mm (0.08 in)...................................................

Parking brake

Type Mechanical, cable operated drum brake on the rear of.................................................................................

Drum internal diameter 254 mm (10.0 in).....................................................

Width 70 mm (2.75 in)................................................................................

Pad material Ferodo 3611 non asbestos.....................................................................

Servo/master cylinder

per side of disc

the transfer gearbox output shaft

Manufacturer Lucas....................................................................

Servo type LSC 80........................................................................

Master cylinder type 25,4 mm (1.0 in) diameter, tandem.........................................................

Pressure reducing valve, failure conscious Cut-in pressure, 90 - 24 bar (360 Ibf/in2) ratio 4.0:1,......................

NOTE: * Pressure reducing valves are not fitted to all 110 specifications.

110 - 43 bar (645 Ibf/in2) ratio 2.9:1*

INFORMATION

7

Page 31

04

AIR CONDITIONING

System CFC free, expansion valve system.............................................................................

Compressor Nippon Denso.....................................................................

Refrigerant R134a CFC free.......................................................................

Charge quantity 750 g ± 50 g................................................................

Refrigerant oil ND-OIL 8...................................................................

WIPER MOTORS

Tailgate wiper motor

Make/type IMOS (non-serviceable)........................................................................

Running current, wet screen at 20°C ambient 1.0 to 2.8 amps.................

Wiper speed, wet screen at 20°C ambient 37 to 43 cycles per minute.......................

Windscreen wiper motor

GENERAL SPECIFICATION DATA

Make/type Lucas 14W uprated two speed........................................................................

Armature end float 0,1 to 0,2 mm............................................................

Brush length, minimum 4,8 mm....................................................

Brush spring tension 140 to 200 g........................................................

Resistance of armature winding

at 16˚C (69˚F) measured between adjacent

commutatator segments 0.23 to 0.35 ohms...................................................

Light running, rack disconnected: current at 13.5 V 2.0 amps.........

Wiper speed, wet screen, 60 seconds from cold Low speed - 45 ± 3 rev/min, High speed - 65 ± 5..............

ELECTRICAL

System 12 volt, negative ground.............................................................................

Battery

Make/type Delphi GP31........................................................................

Alternator

Type Nippon Denso.................................................................................

rev/min

Fuses

Type Autofuse (blade type) blow ratings to suit individual.................................................................................

Horns

Make/type Mixo TR99........................................................................

Starter motor

Make and type Bosch 12v.................................................................

INFORMATION

8

circuits

Page 32

GENERAL SPECIFICATION DATA

BULBS

REPLACEMENT BULBS TYPE

Headlamps 12V 60/55W Halogen

Front side lamps 12V 5W

Side repeater lamps 12V 5W

Tail lamps 12V 21W

Cente High Mounted Stop Lamp 12V 21W

Direction indicator lamps 12V 21W

Number plate lamp 12V 4W

Reverse lamp 12V 21W

Rear fog guard lamp 12V 21W

Interior roof lamps 12V 10W

Instrument illumination 12V 1.2W

Warning light panel 12V 1.2W

Hazard warning switch 12V 1.2W

CAUTION: The fitting of new bulbs with wattages in excess of those specified will result in damage

to vehicle wiring and switches.

INFORMATION

9

Page 33

04

VEHICLE WEIGHTS AND PAYLOAD

When loading a vehicle to its maximum (Gross Vehicle Weight), consideration must be taken of the unladen

vehicle weight and the distribution of the payload to ensure that axle loadings do not exceed the permitted

maximum values.

It is the customer’s responsibility to limit the vehicle’s payload in an appropriate manner such that neither

maximum axle loads nor Gross Vehicle Weight are exceeded.

Maximum EEC kerb weight and distribution - all optional equipment

VEHICLE AXLE WEIGHTS

90 models Station Wagon Utility

Front axle 1200 Kg (2645 lb)......................................................................... 1200 Kg (2645 lb)

Rear axle 1500 kg (3307 lb).......................................................................... 1500 Kg (3307 lb)

Gross vehicle weight 2550 Kg (5291 lb)........................................................ 2400 Kg (5622 lb)

110 models Station Wagon Utility

Front axle 1200 Kg (2645 lb)......................................................................... 1200 Kg (2645 lb)

Rear axle 1750 Kg (3858 lb).......................................................................... 1850 Kg (4078 lb)

Gross vehicle weight 2950 Kg (6503 lb)........................................................ 3050 Kg (6724 lb)

GENERAL SPECIFICATION DATA

130 models Utility

Front axle 1580 Kg (3483 lb).....................................................................................................................

Rear axle 2200 Kg (4850 lb)......................................................................................................................

Gross vehicle weight 3500 Kg (7716 lb)....................................................................................................

NOTE: Axle weights are not accumulative. The individual maximum axle weights and gross vehicle

weight must not be exceeded.

EEC VEHICLE KERB WEIGHTS

90 models Standard Heavy Duty

Soft top: 1770 Kg (3402 lb)............................................................................ 1993 Kg (4393 lb)

Pick-up: 1770 Kg (3402 lb)............................................................................ 1993 Kg (4393 lb)

Hard top: 1815 Kg (4001 lb).......................................................................... 1987 Kg (4380 lb)

Station wagon: 1870 Kg - 1885 Kg................................................................. 1989 Kg - 1998 Kg

(4122 lb - 4155 lb) (4385 lb - 4404 lb)

110 models

Soft top: 1885 Kg - 2080 Kg............................................................................ (4155 lb - 4585 lb)

High capacity pick-up: 1920 Kg - 2122 Kg...................................................... (4232 lb - 4678 lb)

Hard top: 1920 Kg - 2110 Kg.......................................................................... (4232 lb - 4651 lb)

Station wagon: 2055 Kg - 2229 Kg................................................................. (4530 lb - 4914 lb)

130 models

Crew cab and high capacity pick-up: 2177 Kg - 2286 Kg...........................................................................

(4667 lb - 5039 lb)

EEC kerb weight = Unladen weight + Full fuel tank + 75 Kg (165 lb).

INFORMATION

10

Page 34

GENERAL SPECIFICATION DATA

TOWING WEIGHTS

On-road Off-road

Unbraked trailers 750 Kg (1653 lb).............................................................. 500 Kg (1102 lb)

Trailers with overrun brakes 3500 Kg (7716 lb)............................................. 1000 Kg (2204 lb)

4 wheel trailers with coupled brakes * 4000 Kg (8818 lb).............................. 1000 Kg (2204 lb)

NOTE: * Only applies to vehicles modified to accept coupled brakes.

NOTE: All weight figures are subject to local restrictions.

OFF-ROAD PERFORMANCE

90 models

Max. gradient (EEC kerb weight) 45°.....................................

Approach angle:

Soft top and Pick-up (EEC kerb weight) 48°..................

Hard top and station wagon (EEC kerb weight) 51.5°......

Departure angle

Soft top and Pick-up (EEC kerb weight) 49°..................

Hard top and Station wagon (EEC kerb weight) 53°...............

Wading depth 500 mm (20 in)...................................................................

Min. ground clearance (unladen):

Soft top and pick-up 191 mm (7.5 in).................................................

Hard top and station wagon 229 mm (9.0 in).....................................

NOTE: Departure angles do not account for the addition of a tow hitch.

110 and 130 models

Max. gradient (EEC kerb weight) 45°.....................................

Approach angle (EEC kerb weight) 50°..................................

Departure angle (EEC kerb weight)

110 models 35°......................................................................

130 models 34°......................................................................

Wading depth 500 mm (20 in)...................................................................

Min. ground clearance (unladen 215 mm (8.5 in).......................................

NOTE: Departure angles do not account for the addition of a tow hitch.

INFORMATION

11

Page 35

04

GENERAL SPECIFICATION DATA

TYRE SIZE AND PRESSURES

90 models Front Rear

Normal - all load conditions

205/80 R16 Radial 1,9 bar.................................................. 2,6 bar

28 Ibf/in

2,0 kgf/cm

2

2

38 Ibf/in

2,7 kgf/cm

2

2

265/75 R16 Radial (multi terrain) 1,9 bar.......................... 2,4 bar

28 Ibf/in

2,0 kgf/cm

2

2

7.50 R16 Radial 1,9 bar...................................................... 2,6 bar

28 Ibf/in

2,0 kgf/cm

2

2

110 models

Normal - all load conditions

7.50 R16 Radial 1,9 bar...................................................... 3,3 bar

28 Ibf/in

2,0 kgf/cm

2

2

130 models

Normal - all load conditions

7.50 R16 Radial 3,0 bar...................................................... 4,5 bar

44 Ibf/in

3,1 kgf/cm

WARNING: Tyre pressures must be

checked with the tyres cold, as the

pressure is about 0,21 bar (3 Ibf/in2, 0,2

kgf/cm2) higher at running temperature. If the

vehicle has been parked in the sun or high

ambient temperatures, DO NOT reduce the tyre

pressures, move the vehicle into the shade and

wait for the tyres to cool before checking the

2

2

WARNING: Always use the same make and

type of radial-ply tyres, front and rear. DO

NOT use cross-ply tyres, or interchange

tyres from front to rear.

• If the the wheel is marked ’TUBED’, an inner

tube MUST be fitted, even with a tubeless tyre.

• If the wheel is marked ’TUBELESS’, an inner

tube must NOT be fitted.

pressures.

35 Ibf/in

2

2,5 kgf/cm

38 Ibf/in

2

2,7 kgf/cm

48 Ibf/in

2

3,4 kgf/cm

65 Ibf/in

2

4,6 kgf/cm

2

2

2

2

WHEELS

90 models

Steel wheel size:

Heavy duty - UK and Western Europe 6.5F X 16.............................

Other markets 5.5F X 16..................................................................

Alloy wheel size 7J X 16................................................................

110 models

Steel wheel size:

Heavy duty - UK and Western Europe 6.5F X 16.............................

Other markets 5.5F X 16..................................................................

130 models

Steel wheel size:

Heavy duty - UK and Western Europe 6.5F X 16.............................

Other markets 5.5F X 16..................................................................

INFORMATION

12

Page 36

GENERAL SPECIFICATION DATA

VEHICLE DIMENSIONS

90 models

Overall length:

Soft top and Pick-up 3722 mm (146.5 in)................................................

Hard top and Station wagon 3883 mm (152.9 in)....................................

Overall width: 1790 mm (70.5 in)...................................................................

Overall height:

Soft top 1965 mm (77.4 in)....................................................................

Pick-up and Station wagon 1963 mm (77.3 in)......................................

Hard top 1972 mm (77.6 in)...................................................................

Wheelbase 2360 mm (92.9 in).......................................................................

Track front/rear 1486 mm (58.5 in).................................................................

Width between wheel boxes 925 mm (36.4 in)............................................

110 models

Overall length:

Soft top and Pick-up 4438 mm (175 in)................................................

High capacity pick-up 4631 mm (182 in)..............................................

Hard top/Station and County 4599 mm (181 in)...................................

Overall width: 1790 mm (70.5 in)...................................................................

Overall height: 2035 mm (80.1 in)..................................................................