Page 1

GED

DEFENDER

90

WORKSHOP MANUAL SUPPLEMENT

Publication

Number

110

SLR

621

130

EN

WS

1

Published by the

Technical Publications Department

@

Copyright Land Rover

1990

of

Land Rover

West Midlands,

Lode Land

Sol

ihul

892

8NW

England

I

Page 2

.

Page 3

CONTENTS

...

.....

-

..

;,TI

,::-...$,.

......

........

,..

,.

.....

'U

.

..I-',

Section

Number

01

:

L

04

INTRODUCTION

-

General information

-

Poisonous substances

-

Fuel Handling

-

Sealants

-

Disposal

-

Abbreviations and symbols

-

Special tools

-

Vehicle identification numbers

-

Copyright

G

E

N

-

Tdi engine data

-

Fuel

-

Cooling system

-

Clutch

of

ERAL

system

oil

and fluids

SPECIFICATION

Page

DATA

9-12

9

9

9

05

06

109

L

12

E

N

G

I

N

E

T

U

N

I

N

G

DATA

T

O

R

Q

U

E

WRENCH

I

RECOMMENED LUBRICANTS, FLUIDS AND CAPACITIES

-

Tdi engine lubricants

-

Capacities

-

Anti-freeze

SETTING

ENGINE

-

Camshaft - remove and refit - including front cover

-

Power steering pump bracket - remove and

-

Cylinder head - remove and refit

-

Camshaft timing belt - renew

-

Tdi engine - overhaul

refit

oil

seals/timing belt and gears

17

-

18

17

-

ia

17 - 18

30

31

32

34

35

..:r

...

,

_

,.

5..

19

1

FUEL SYSTEM

-

Fuel

injection pump - remove and refit

-

Air cleaner - remove and refit

-

-

~ur-bo charger- remove and retit

-

Intercooler - remove and refit

:i'

.

,.

-

..

81

84

a5

86

Page 4

Section

Number

26

I

C

O

O

L

I

N

G

SYSTEM

Page

e

..

-7

30

157

86

>

-

Engine protection

-

Drain and

-

Fan cowl - remove and refit

-

Fan and coupling - remove and refit

-

Radiator - remove and refit

-

Water pump - remove and refit

I

MANIFOLDS

I

STEERING

ELECTRICAL EQUIPMENT

refill

AND

EXHAUST

87

87

a8

88

89

90

..

-

-

Page 5

a

DEFENDER

INTRODUCTION

01

-

.I

INTRODUCTION

This Workshop Manual Supplement

maintenance

Individuals who undertake their own repairs should have some skill and training, and limit repairs to

components which could not affect the safety

safety critical items such as steering, brakes, or suspension should be carried out by a Land Rover

Dealer. Repairs to such items should

WARNINGS and CAUTIONS are given throughout this Supplement

WARNING: Procedures which must

CAUTION: This calls attention to procedures which must be followed to avoid damage

NOTE: This calls attention to methods which make a job easier to perform.

REFERENCES

References to the left

unless otherwise stated. With the engine and gearbox assembly removed, the water pump end

is

referred to as the front.

To

reduce repetition, some operations covered in this Manual do not include reference to testing the vehicle

after repair. It

of

the vehicle is carried out particularly where safety related items are concerned.

of

Land

Rover

vehicles.

or

right hand side in the supplement are made when viewing the vehicle from the rear

is

essential that work is inspected and tested after completion and

is

designed to assist skilled technicians in the efficient repair and

of

the vehicle

NEVER

be

be attempted by untrained individuals.

followed precisely to avoid the possibility

or

its passengers. Any repairs required to

in

the following form:

of

personal injury.

to

components.

if

necessary a road test

of

the engine

DIMENSIONS

to

The dimensions quoted are

brackets following the dimensions, have been converted from the original specification.

REPAIRS AND REPLACEMENTS

When replacement parts are required it

Attention

and accessories: Safety features embodied in the vehicle may be impaired

fitted. In certain territories, legislation prohibits the fitting

specification. Torque wrench values given in the Workshop Manual supplement must

Locking devices, where specified, must be fitted.

removal it must

specified in the Workshop Manual Supplement.

PO

Many liquids and other substances used in motor vehicles are poisonous and should under no circumstances

be consumed and should be kept away from open wounds. These substances among others include

anti-freeze, brake fluid,

adhesives.

AS

B

IS

0 N 0

EST0

is

particularly drawn

be

replaced with a new one. Certain fasteners must not be re-used. These fasteners are

US SUBSTANCES

fuel,

S

design engineering specification. Alternative unit equivalents, shown in

is

essential that genuine Land

to

the following points concerning repairs and the fitting

of

parts not to the vehicle manufacturer's

If

the efficiency

windscreen washer additives, air conditioning refrigerant, lubricants and various

Rover

parts are

if

other than Land Rover parts are

of

a locking device

used.

of

replacement parts

be

strictly adhered

is

impaired during

to.

WARNING: Some components on the vehicle, such as gaskets and friction surfaces (brake linings, clutch

discs) may contain asbestos. inhaling asbestos dust

essential precautions must

1.

Work out

2.

Dust found on the vehicle

and not by blowing.

3.

Dust waste should

4.

If

any cutting, drilling etc.,

and

of

doors

on1 hand tools

be

observed:

or

in a well ventilated area and wear a protective mask.

or

produced during work on the vehicle should be removed by vacuuming

be

dampened, placed in a sealed container and marked

is

attempted on materials containing asbestos the item should be dampened

or

low speed power tools used.

is

dangerous to your health and the following

to

ensure safe disposal.

1

Page 6

101

I

INTRODUCTION

FUEL HANDLING PRECAUTIONS

e

DEFENDER

The following information provides basic precautions which must

also outlines the other areas

This

information

of

made

Fuel vapour is highly flammable and in confined spaces

When fuel evaporates it produces

a readily ignitable mixture. The vapour

be

dangerous.

Always have a

or

WARNING:

the battery terminal could ignite

BEFORE

when fuel systems are being dismantled all forms

head

NO

HAVING HAD SPECIALIST TRAINING.

HOT

your local fire station.

distributed throughout a workshop by air current, consequently, even a small spillage

when dismantling fuel systems and in areas where fuel containers are stored.

carrying out work on a fuel system. Whenever fuel

-

lamps used must be flameproof and kept clear

ONE

SHOULD BE PERMWrED

FUEL HANDLING

is

issued

fire

extinguisher containing

It

is

imperative that the battery

of

risk which must not

for

basic guidance only, and in any

150

times its own volume in vapour, which when diluted with air becomes

is

heavier than air and will always fall to the lowest level. It can readily

FOAM

fuel vapour in the atmosphere. Always disconnect the vehicle battery

TO

REPAIR COMPONENTS ASSOCIATED

be

CO

is

not disconnected during fuel system repairs as arcing at

ignored.

is

also

GAS,

of

ignition must be extinguished

of

spillage.

be

observed

case

of

doubt, appropriate enquiries should be

very

explosive and toxic.

or

POWDER

is

being handled, transferred

if

close at hand when handling fuel,

WITH

fuel is to be handled safely. It

of

fuel

is very

or

or

removed, any

FUEL

WITHOUT

stored,

or

FIRST

Before

be adhered to.

i

FUEL TRANSFER

WARNING:

The transfer

transfer tank must

including attention

FUEL TANK REMOVAL

A

FUEL TANK REPAIR

Under

commencing any operation requiring fuel drainage from fuel tanks, the following procedures should

1.

Allow sufficient time for the fuel to

2.

Vent system by removing the fuel cap in a

drainage.

Fuel

must not be extracted or drained from any vehicle while it is standing over a pit.

of

fuel from the vehicle

be

used according to the transfer tank manufacturef s instructions and local regulations,

to

grounding

fuel vapour label should be attached to the fuel tank upon removal from the vehicle.

no

circumstances should a repair to any tank be attempted.

of

cool,

thus avoiding contact with hot fuels.

well

ventilated area. Replace cap until commencement

fuel

tank must be carried out in a well ventilated area. An approved

tanks.

of

tank

p

i.

..

:’”

3

Page 7

e

DEFENDER

INTRODUCTION

101

-

<,,

.

RECOMMENDED

A

number

work. These items include:

COMPOUND.

obtaining supplies, contact one

Marston Lubricants Limited

Hylo

Cale Lane, New Springs

Wigan, WN2

Tel: 0942 824242

Fax: 0942 826653

Telex: 67230

USED ENGINE

Prolonged and repeated contact with engine

-skin, leading to dryness, irritation and dermatitis. In addition,

contaminants which may cause skin cancer. Adequate means

be provided.

Health Protection Precautions

of

House

SEALANTS

branded products are recommended in this Supplement

HYLOMAR GASKET AND JOINTING COMPOUND

They should be available locally from garage equipment suppliers.

of

the following companies

IJR

OIL

HANDLING PRECAUTIONS

or

motor

for

Northern Adhesives Limited

Prudhoe

Northumberland

NE42 6NP

Tel:

0661

Fax:

0661 35839

oil

will result in the removal

used

of

for

use during maintenance and repair

advice and the address

32014

engine

skin protection and washing facilities should

oil

and

HYLOSIL

If

there

of

of

natural fats from the

contains potentially harmful

RN

SILICON

is

any problem

the nearest stockist.

1. Avoid prolonged and repeated contact with

2. Wear protective clothing, including impervious gloves where applicable.

3. Do not put oily rags in pockets.

4. Avoid contaminating clothes, particularly

5.

Overalls must be cleaned regularly. Discard unwashable clothing and

6.

First aid treatment must be obtained immediately for open cuts and wounds.

7.

Use barrier creams, before each work period, to help the removal

8.

Wash with soap and water

Preparations containing lanolin replace the natural skin

D

O

9.

10.

11.

12. Where there is a

DISPOSING

Environmental protection precaution

It

is

Dispose

S

P E CI FICATIO N

not use petrol, kerosene, diesel fuel,

If

skin disorders develop, obtain medical advice.

Where practicable, degrease components prior to handling.

risk

shields; in addition an

OF

USED

OILS

illegal to pour used

of

used

oil

oil

through authorised waste disposal contractors.

to

ensure all

of

eye

contact,

eye

wash facility should be provided.

AND FLUIDS

and other fluids onto the ground, down sewers or drains,

eye

oils,

particularly used engine

underwear, with

oil

is

removed (skin cleansers and nail brushes

gas

oil,

thinners

oil.

oils

which have been removed.

or

solvents

.

protection should be worn, for example, goggles

oils.

oil

impregnated footwear.

of

oil

from the skin.

for

washing the skin.

or

will

help).

or

face

into waterways.

..

Purchasers are advised that the specification details set out in this Supplement apply to a range

and not

The Manufacturers

in such manner

Manufacturer's policy

While every

Manufacturer

any inaccuracy

to

any one.

effort

For

the specification

resetve the right to vary their specifications with

as

they think fit. Major

of

constant product improvement.

is

made to ensure the accuracy

or

Dealer, by whom this Supplement is supplied, shall in any circumstances be held liable for

or

the consequences thereof.

of

a particular vehicle, purchasers should contact their Dealer.

or

without notice, and at such times and

as

well

as

minor changes may be involved in accordance with the

of

the particulars contained in this Supplement, neither

of

vehicles

the

3

Page 8

INTRODUCTION

01

COPYRIGHT

Q

Rover Group Ltd

All

rights reserved.

any form, electronic, mechanical, photocopying, recording

Rover

Group Ltd.

1990

No

part

of

this publication may be produced, stored

in

a

or

other means without

e

retrieval system or transmitted

prior

DEFENDER

written permission

in

of

SPECIAL

The use

carried out efficiently, and safely. Where the

be used to avoid the possibility

ACCESSORIES AND CONVERSIONS

Land

should be carried out to any vehicle produced by Land Rover which could affect the safety

its passengers.

T

Land

Before fitting any accessory

accessory

WARNING:

vehicle. Land Rover

may occur as

conversions to Land

SERVICE

of

approved special service tools is important.

Rover

vehicles are designed and constructed for a

Rover

has

or

TOOLS

of

personal injury

tested and approved a large number

or

commencing any conversion work to any Land Rover vehicle,

conversion

DO

NOT

a

direct result

is

approved by Land

FIT

unapproved accessories

will

not accept any liability

of

fitment

Rover

vehicles.

of

They

are essential

use

of

special service tools i specified, only these tools should

or

damage

of

Rover.

or

conversions, as

for

death, personal

non-approved accessories

to

components.

variety

accessories and conversions, suitable for this vehicle.

of uses but no alterations

if

service operations are to be

they

could affect the safety

injury

or

damage to property which

or

the carrying out

or

conversions

of

the vehicle or

CHECK

of

non-approved

that

of

the

the

4

Page 9

DEFENDER

INTRODUCTION

n

01

,-

'

..

.

.-

.

a:.;

,;.:

.:..,*-:.

'

I:

.I

%

1.

.

..

.:,

,I

.....

..

...

.....

..

ABBREVIATIONS AND SYMBOLS

Across flats (bolt size)

After bottom dead centre

After top dead centre

Alternating current

Ampere

Ampere hour

Before

Before

Bottom dead centre

Brake horse power bhP

British Standards

Carbon monoxide

Centimetre

Centigrade (Celsuis)

Cubic centimetre

Cubic inch

Degree (angle)

.

Degree (temperature)

Diameter

Direct current

Electronic Control Unit

Electronic Fuel Injection

Fahrenheit

Feet

Feet

Fifth

First

Fluid ounce

Foot pounds (torque)

Fourth

Gramme

Gramme (mass)

Gallons gal

Gallons (US)

High tension (electrical)

Internal diameter

Inches

Inches

Kilogramme

Kilogramme (mass.) kg

Kilogramme centimetre (torque)

Kilogramme per square millimetre

Kilogramme per square centimetre

Kilogramme metres (torque)

Kilometres

Kilometres per hour

Kilovolts

Left-hand steering

Left-hand thread

Litres

..............................................................

.................................................

bottom dead centre

top dead centre

..........................................................

............................................................

...........................................

.............................................................

.....................................................

...............................................................

.......................................................................

per

minute

...............................................

.....................................................................

......................................................................

.......................................................

..................................................................

(force)

.....................................................

......................................................

................................................................

..................................................

of

mercury

....................................................................

(force)

...........................................................

................................................................

...................................................................

..........................................

..............................

.....................................

..............................................

............................

...................................

.........................................

............................................

...................................................

..............................................

..............................................

................................................

.................................

...................................

...................................

........................................

....................................

................................................

..........................................

..............................................

..............................................

...................

...............

..............

...........................

.........................................

..........................................

............................................

ABDC

ATDC

a.c.

amp

amp hr

BBDC

BTDC

BDC

CO

cm3

deg or

deg

or

dia.

d.c.

E.C.U.

E.F.I.

ft/min

5th

fl

ft

4th

US gal

H.T.

I.D.

in. Hg

kg

kgf.cm

kgf/mm2

kgf/cm2

kgf.m

km

km/h

LHStg

LHThd

litre

AF

BS

cm

C

in3

O

O

F

ft

1st

oz

Ib

g

f

g

in

f

kV

Low tension

Maximum

Metre

Millilitre

Millimetre

Miles per gallon

Miles per hour

Minute (angle)

Minus

Negative (electrical)

Newton meters (torque)

Number

Ohms

Ounces

Ounces

Ounce inch (torque)

Outside diameter

Part number

Percentage

.....................................................................

Pints Pt

Pints (US)

Plus (tolerance)

Positive (electrical)

Pound

Pounds inch (torque)

Pound

Pounds per square inch

Ratio

........................................................................

Reference

Revolution per minute

Right-hand

Second (angle)

Second (numerical order)

Specific gravity

Square centimetres

Square inches

Standard wire gauge

Synchroniser/Synchromesh

Third

...................................................................

Top dead centre

United Kingdom

Vehicle Identification Number

Volts

......................................................................

Watts

....................................................................

SCREW TH READS

American Standard Taper Pipe

British Standard Pipe

Unified Coarse

Unified Fine

..........................................................

.........................................................

.....................................................................

................................................................

...........................................................

.................................................

...................................................

.........................................................

(of

tolerance)

...............................................

................................................

....................................

..............................................................

...............................................................

(force)

(mass)

....................................................

......................................................

......................................

.............................................

.................................................

............................................................

........................................................

.....................................................

................................................

(force)

.......................................................

......................................

(mass)

.........................................................

....................................

...........................................................

.....................................

...........................................................

.......................................................

...................................

................................................

.............................................

.......................................................

.......................................

.........................

................................................

..................................................

............................

..........................

...........................................

.................................................

.......................................................

1.t.

ma.

mi

mm

mpg

mPh

Nm

No.

ohm

ozf

oz

ozf.in.

O.D.

Part

No.

US pt

Ibf

in.lbf.

P.S.I.

ref.

r.p.m

RH

2nd

sp.gr.

cm2

in2

s.w.~.

synchro.

3rd

TDC

UK

VIN

W

NPTF

BSP

UNC

UNF

m

'

-

-

%

+

+

Ib

:

I'

v

5

Page 10

loll

INTRODUCTION

e

DEFENDER

Special

The use

carried out efficiently, and safely. Where special tools are specificed,

avoid the possibility

they save can

Every special

which has not been tested and approved by us. New tools are only introduced where an operation cannot

satisfactorily carried out using existing tools or standard equipment. The user

is

necessary and that it wilt perform accurately, efficiently and safely.

Special tools bulletins

All

should be placed with the local

distributor may order direct from

The tools recommended in this Workshop Manual Supplement are listed in a multi-language illustrated

catalogue obtainable from Messers. V. L. Churchill at the above address under publication number VLC

23721187

Erdington, Birmingham, 624

of

approved special service tools

of

personal injury

be

considerable.

tool

is

designed with the

will

be

issued periodically giving details

orders and enquiries from the United Kingdom should be sent direct to

V.

L. Churchill distributor, where one exists. Countries where there

V.

or

from Land

Rover

Merchandising Service, quoting publication number SMR

OQ5.

is

or

close

L.

Churchill Limited,

Service

important. They are essential

damage to the components.

co-operation

PO

Tools

only these

of

Land Rover, and

of

new tools

Box

3,

Daventry, Northants, England,

if

service

Also

as

V.

operations are to

tools

should be used to

the amount

no

tools

is

therefore assured that the

they are introduced.

L.

Churchill. Overseas orders

of

is

put into production

681

MI,

be

time which

is

no

NNI

1

4NF.

PO

Box

534,

be

tool

6

Page 11

DEFENDER

LOCATION

OF

VEHICLE IDENTIFICATION & UNIT NUMBERS

101

..

~.,..

..

.I

).

.

b: : ..,

..

...

,.

...

..

..

.

..

.

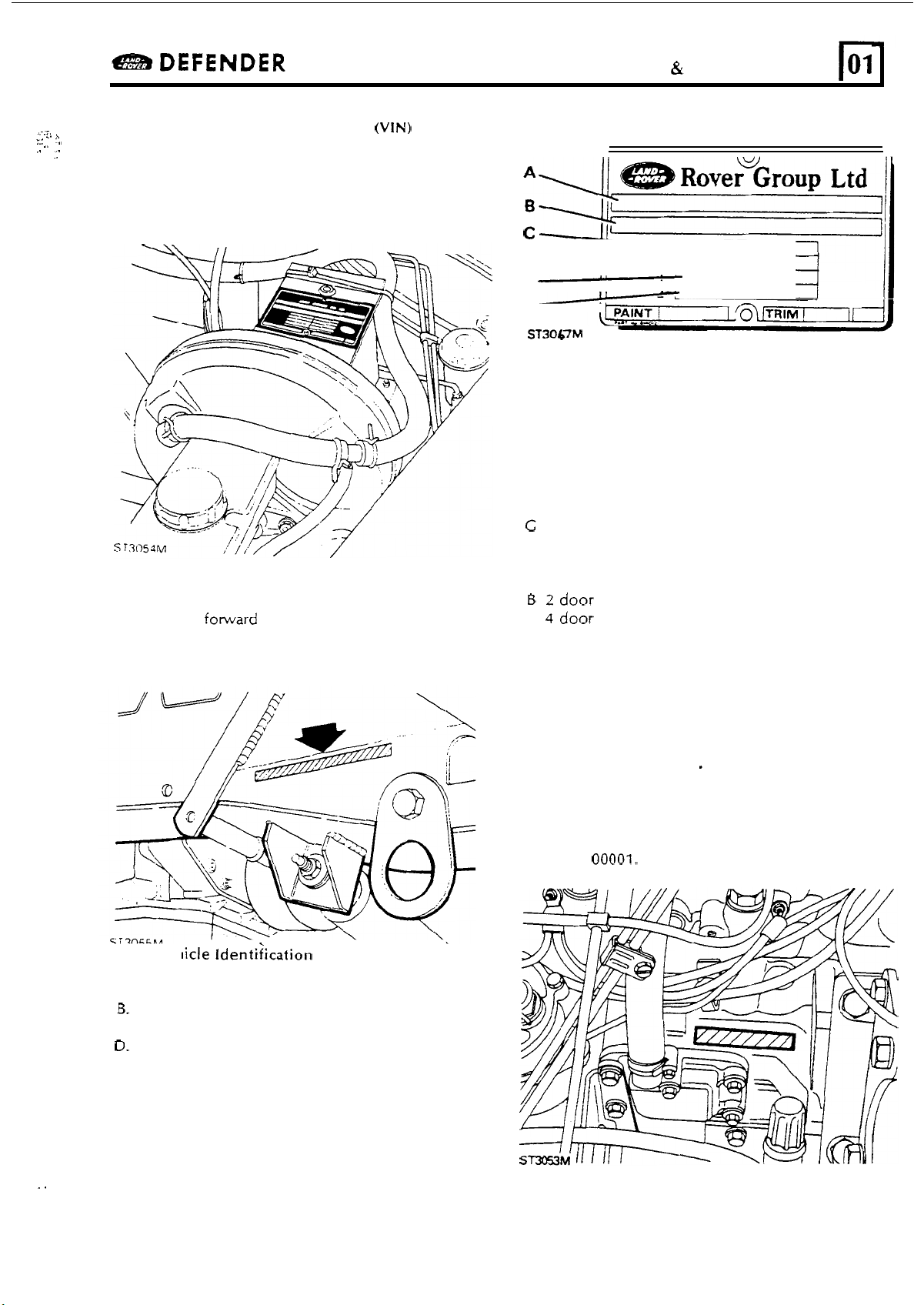

VEHICLE IDENTIFICATION NUMBER (VIN)

The Vehicle Identification Number and the

recommended maximum vehicle weights are

of

stamped on a plate riveted to the top

box

behind the brake servo

The number

of

the chassis forward

is

also stamped on the right-hand

of

the spring mounting turret.

the pedal

Always quote this number when writing to Land

Rover.

side

E

F

ST3067M

The Vehicle Identification Number identifies the

manufacturer, model range, wheel

engine, steering, transmission, model name and

place

of

the coding process.

SAL World manufacturer identifier

LD Land Rover

C

Class

V

Class

H

Class

A

Basic

B

2door

M 4door

H High Capacity

F

Tdi or

8

5

speed LHD or

7

5

speed RHD

H

1991

A

Solihull site

PAINT

0

TRIM

base,

body type,

manufacture. The following example shows

100

inch

90

inch

110

inch

MY

..

Key

to

Veh

iicle

ldentiiication Number Plate

A.

Type approval

B.

VIN

(minimum

of

17

digits)

C. Maximum permitted laden weight

D. Maximum vehicle and trailer weight

E.

Maximum road weight - front axle

F.

Maximum road weight - rear axle

for

\

vehicle

ENGINE SERIAL NUMBER - Tdi ENGINE

The engine number

block on the right hand side

is

stamped on the cylinder

of

the engine above

the camshaft front cover plate. Commencing Serial

Number

IIL

00001.

7

Page 12

L

01

LOCATION

OF

VEHICLE IDENTIFICATION & UNIT NUMBERS

e

DEFENDER

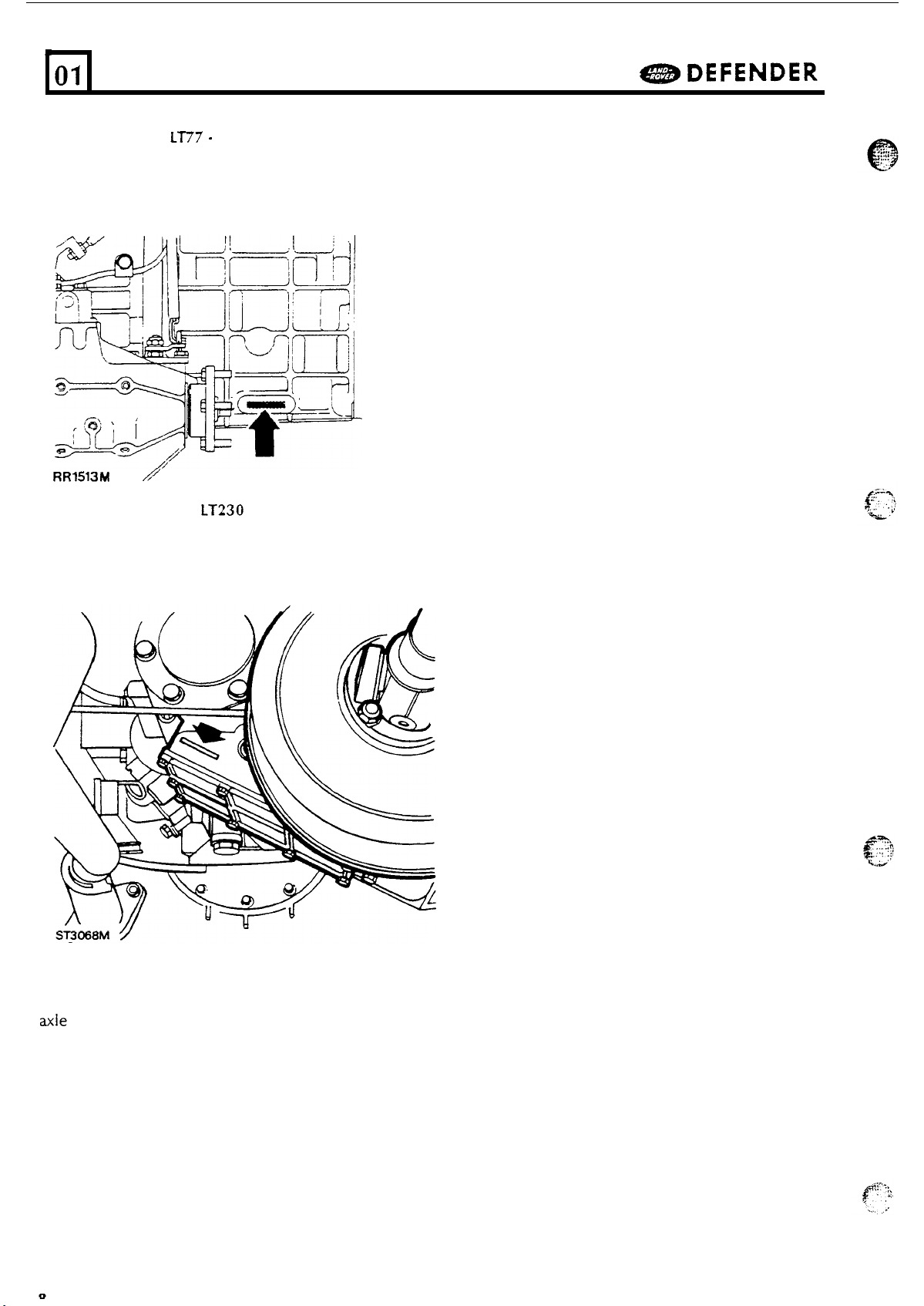

MAIN GEARBOX

The serial number

bottom right hand side

RR1513M

.

TRANSFER GEARBOX

The serial number

of

the gearbox casing

bearing housing adjacent

LT77

is

1'

is

-

5

SPEED

stamped on a cast pad on the

of

the gearbox.

-------

LT230

stamped on the

below

the mainshaft rear

to

the bottom cover.

left

hand side

FRONT AND REAR AXLES

Serial number

axle tube.

is

stamped on top

of

the

left

hand

Page 13

e

Tdi

Type

Number

Bore

Stroke

Capacity

Compression ratio

Valve operation

Turbo charger

Crankshaft

DEFENDER

ENGINE

.................................................................................

of

cylinders

..................................................................................

...............................................................................

............................................................................

...................................................................

.........................................................

............................................................

................................................................

G

ENE

RA

L

S

P

E

C

IFI

C

A

T

ION

D

A

Direct injection, turbocharged, intercooled

4

90,47 mm (3.562 in)

97,OO mm (3.822 in)

2495 cc

19.5:l

O.H.V. pushrod operated

Carrett T25

+

-

0.5:l

T

A

n

I04

I

Main journal diameter

Regrind dimensions

Crankpin journal diameter

Regrind dimensions

1

Crankshaft end thrust

Crankshaft end float

Main bearings

Number and type

Diametrical clearance

Connecting rods

Length between centres

Diametrical clearance (big-end bearings)

End float on crankpin

Pistons

Type

.................................................................................

Skirt

diametrical clearance

(at right angle to gudgeon pin

Maximum height above combustion face

......................................................

..........................................................

................................................

..........................................................

.......................................................

.........................................................

.............................................................

........................................................

...................................................

..........................

.......................................................

.........................................

........................

63,475 - 63,487 mm (2.499 - 2.4993 in)

63,2333 . 63,246 mm (2.4895 - 2.490 in)

0.010'in U/S bearings

Use

58,725 - 58,744

58,4708 . 58,49985 mm (2.30200 . 2.30275

Use

0.010

Taken on thrust washers

0,05 . 0,15 mm (0.002 - 0.006 in)

5 halved shells with

0,0792 - 0,0307

175,38 - 175,43 mm (6.905 - 6.907 in)

0,025 . 0,075 mm (0.001 . 0.003 in)

0,15 - 0,356 mm (0.006

Aluminium alloy, combustion chamber in crown

0,025 . 0,05

0,8 mm (0.031 in)

mm

(2.312 - 2.31275 in)

in U/S bearings

of

oil

grooves

mm

(0.0031 - 0.0012 in)

.

mm

(0.001 . 0.002 in)

centre main bearing

0.01

4 in)

in)

Gudgeon pins

.................................................................................

Type

Fit

in piston

Diameter

Clearance in connecting rod

Pistons rings

Type

.

Top

-

Second

.

Oil

control

Cap in

-

Top

-

Second

-

Oil

control

-:.

:.,a:

i.

I

:

,

'

Clearance in piston grooves:

.

Top

.

Second

.

Oil

control

......................................................................

...........................................................................

............................................

................................................................................

...........................................................................

.....................................................................

bore:

................................................................................

...........................................................................

.....................................................................

................................................................................

...........................................................................

.....................................................................

Floating

Hand push in

30,1564 - 30,1625 mm

0,0036 - 0,0196 mm (0.00014 - 0.00077 in)

Chamfered friction edge, chrome plated

Taper faced

Expander ands rails

0,40 . 0,65

0,30

0,3 - 0,6 mm (0.011

0,167 . 0,232 mm (0.0065 - 0.0091 in)

0,05 . 0,08 mm (0.0019 . 0.0031 in)

0,05

mm

(0.0157 . 0.0255 in)

-

0,50

mm (0.0118 - 0.0196 in)

.

0,08

mm

(0.0019 . 0.0031 in)

.

0.023

(1.1

8726

in)

-

7.1

8750 in)

9

Page 14

04

GENERAL

SPECIFICATION

DATA

e

DEFENDER

Camshaft

Timing Belt

Location

End float

Number

Material

Valves

Tappet clearance:

.

Inlet and exhaust

Seat angle:

.

Inlet

-

Exhaust

Head diameter:

.

Inlet

.

Exhaust

Stem diameter:

-

.

Inlet

-

Exhaust

Valve lift:

.

Inlet

.

Exhaust

Cam lift

.

Inlet

.

Exhaust

Valve head stand down

-

Inlet and exhaust

Valve spring length fitted

lubrication

.......................................................................

...........................................................................

...........................................................................

of

bearings

............................................................................

................................................................................

...........................................................................

................................................................................

...........................................................................

................................................................................

...........................................................................

................................................................................

...........................................................................

................................................................................

...........................................................................

.........................................................

............................................................

............................................................

.................................................

30 mm (1.2 in dry toothed belt

Right hand side (thrust side)

0,l - 0,2 mm (0.004 - 0.008 in)

4

Steel shell, white metal lined

0,20 mm (0.008 in)

30"

45

O

39,35 - 39,65 mm (1.549 - 1.560 in)

36,35 - 36,65 mm (1.431 - 1.443 in)

7,960 - 7,975 mm (0.313 - 0.314 in)

-

7,940

9,93 mm (0.401 in)

10,26 mm (0.404 in)

6,81 mm (0.268 in)

7,06 mm (0,278 in)

0,9

40,4 mm (1.590 in) at pressure

7,960 mm (0.212 - 0.313 in)

-

1,l

mm (0.035 - 0.040 in)

of

29.5 kg (65

.

Ib)

......

(-?$

........

..

.- .

.-

System

Pressure, engine warm at

normal operating speeds

Oil

-

-

-

-

-

Oil

Relief

-

-

Oil

Engine

..............................................................................

..................................................

pump:

Type

...............................................................................

Drive

..............................................................................

End float

Radial clearance

Backlash

pressure

Full length

Compressed length at 2.58 kg (5.7 Ib) load

filter

of

both gears

or

gears

relief

valve spring:

of

valve

..................................................

gears

................................................

...........................................................

....................................................

......................................................................

............................................................................

oil

cooler

..............................................................

..................

Wet sump, pressure fed

25- 55

Double gear 10 teeth, sintered iron gears

Splined shaft from camshaft skew gear

0,026

0,025

0,l

Non-adjustable

67,82 mm (2.670 in)

61,23 mm (2.450 in)

Screw

Combined with coolant radiator and intercooler

p.s.i.

(1.76 - 3.86 kgf/cm2)

-

0,135 mm (0.0009 - 0.0045 in)

-

0,075 mm (0,0034 - 0.0067 in)

-

0,2 mm (0.0034 - 0,0067 in)

-

on disposable canister

10

Page 15

<..,

i..-

5,.

....

.

.

,

..*:;,:;

......

....

._.

........

'-

.

~.,.

,

48B

DEFENDER

FUEL

3

"'

I

SYSTEM - Tdi Engine

injection pump type

.........................................................

injection pump timing

injectors

Heater plugs

Fuel lift pump type

...........................................................................

.....................................................................

...........................................................

Fuel lift pump pressure

Fuel filter

Air

Turbo charger

..........................................................................

cleaner

........................................................................

...................................................................

......................................................

.....................................................

GENERAL

Bosch rotary

see

section

see

section

see

section

SPECIFICATION

VE4/11

05

05

05

F

(see section

05)

Mechanical with hand primer

42 - 55

kpa at

1800

rpm

Paper element in disposable canister

Paper element type

Carrett T25 (see section

05)

DAT

A

n

04

COOLING

System type

SYSTEM - Tdi engine

......................................................................

Pressurised, spill return, thermostatically controlled

water and anti freeze mixture. Pump assisted

thermosyphon. Coolant radiator combined with

cooler

Cooling fan

%

Pump type

Thermostat opening

Expansion tank cap pressure

CLUTCH

Type

.................................................................................

Centre plate diameter

Facing material

Number

Damper spring colour

Eelease bearing

......................................................................

........................................................................

.........................................................

............................................

-

Tdi engine

......................................................

..................................................................

of

damper springs

..............................................

......................................................

................................................................

7

ratio. Viscous coupling.

Centrifugal, impellor, belt driven.

88°C

15

Valeo iaphragm spring

235 mm

Verto F202 grooved

8

2

2

4

Ball journal

and turbo intercooler.

blade axial flow

395

mm diameter.

p.s.i. (system pressure)

(9.25

in)

off

white/green - suffix 'C'

off

pigeon blue - suffix

off

ruby

red

-

suffix

'B'

1.1:l

'A'

oil

drive

11

Page 16

p.

.-..

:

.!:.

.d

.

..I

Page 17

e

DEFENDER

ENGINE

TUNING

DATA

105

.

.

i-.

1..

....

3

ENGINE

Firing order

.......................................................................

injection pump timing

Timing marks:

Valve timing

......................................................................

injection timing

Tappet clearances inlet and exhaust

Valve timing: inlet Exhaust

.

Opens

.

Closes

.

Peak

.

Lift

............................................................................

............................................................................

...............................................................................

..................................................................................

Maximum governed speeds:

.

Full load (speed cut-off starts)

.

No

load (flight

..

Idle

speed

INJECTION PUMP

Makeltype

Direction

......................................................................

.........................................................................

of

rotation

Advance box (single stage)

Peak

pumping pressure

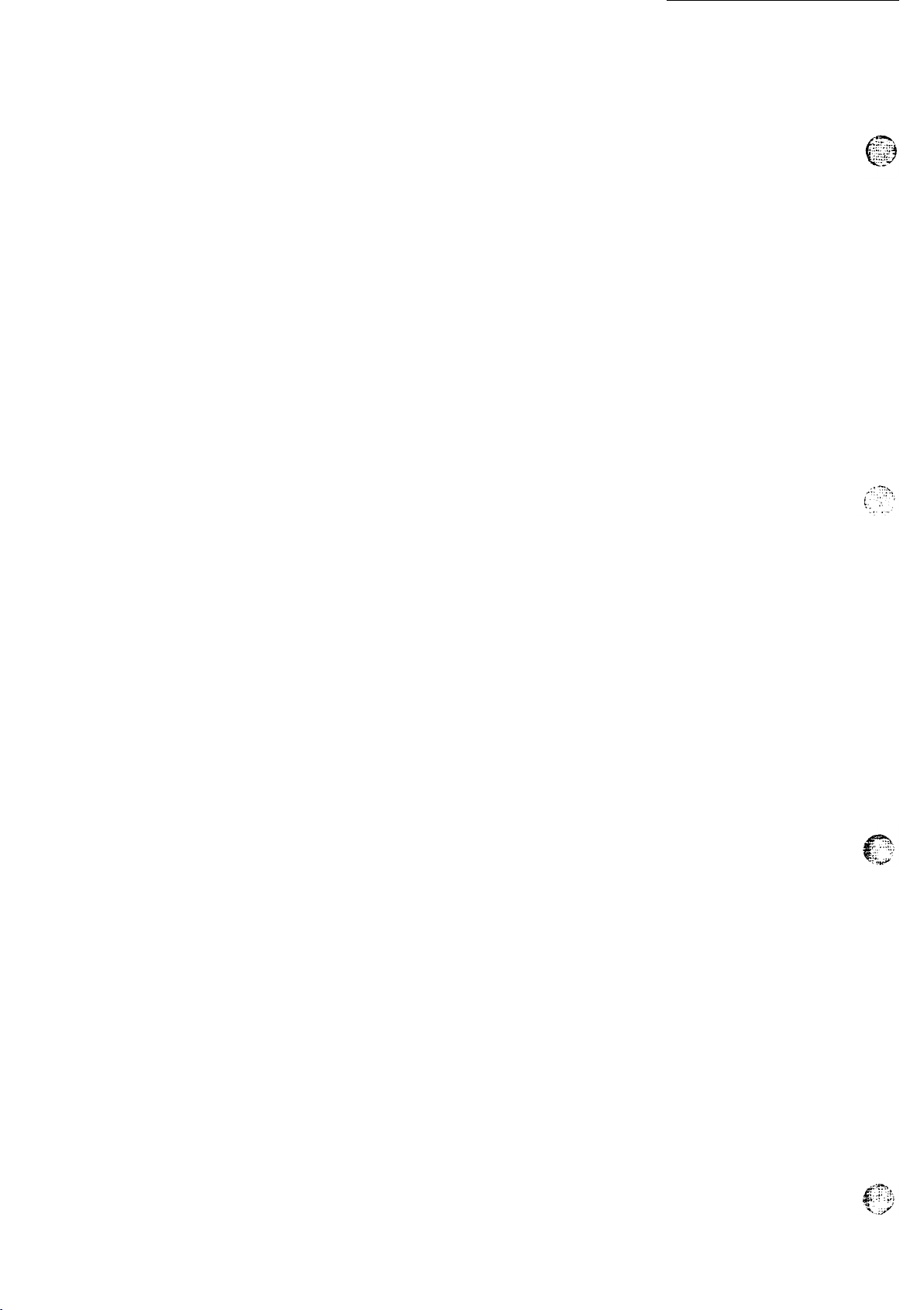

Tdi ENGINE TUNING

......................................................

................................................................

.................................

.......................................

speed)

....................................................

........................................................

..............................................

....................................................

DATA

1-3-4-2

1,54 mm lift at T.D.C.

Slot

for

peg in flywheel and TDC mark on front

pulley

Statically timed with special tool inserted in Bosch

pump hub

0,20 mm

16" B.T.D.C.

42" A.B.D.C.

(0.008

in) cold

51

13

"

"

B.B.D.C.

A.T.D.C.

103" A.T.D.C. 109" B.T.D.C.

9,93

mm

(0.401 in)

10,26 mm (0.404 in)

3800 r.p.m.

4100

.

4260 r.p.m.

780 . 800

Bosch rotary

rpm

VE

411

1

F

1900R 347-1 Type with boost

control and negative mechanical torque control.

Two speed mechanical governor with speed

advance and solenoid electrical shut

proof

sealing

on

flight speed and fuel adjustment

-

off. Tamper

screws

Clockwise, viewed from drive end

9" advance (7.38 mm)

650

bar

. ...

,.

I.

.

..

,

INJECTORS

Makeltype

Nozzle

.........................................................................

sizeltype

Nozzle holder

Opening pressure (working pressure)

.

,

injector pipe type

Injector pipe size

HEATER PLUGS

Makeltype

Time

TURBOCHARGER

Makeltype

.........................................................................

to

reach operating temperature

.........................................................................

Maximum boost pressure

Fuel specification

...............................................................

...................................................................

..............................

.............................................................

..............................................................

of

850°C

...............

.................................................

..............................................................

Bosch

two

spring (04321 93879 assembly number)

DSLA 145P208

KBEL

98 P52

initial pressure 200 atmospheres

Secondary 280 atmospheres

Guido high pressure

1,8

mm dia. Length 490 mm

Probe type, Beru

8

seconds

11

cold

volts

drawn steel

Carrett T25

0.82 bar (12 P.S.I.C.) measured at wastegate

actuator

Diesel 852869 (certain levels down

'T'

piece

to

45 with

adjustment

13

Page 18

.

Page 19

n

e

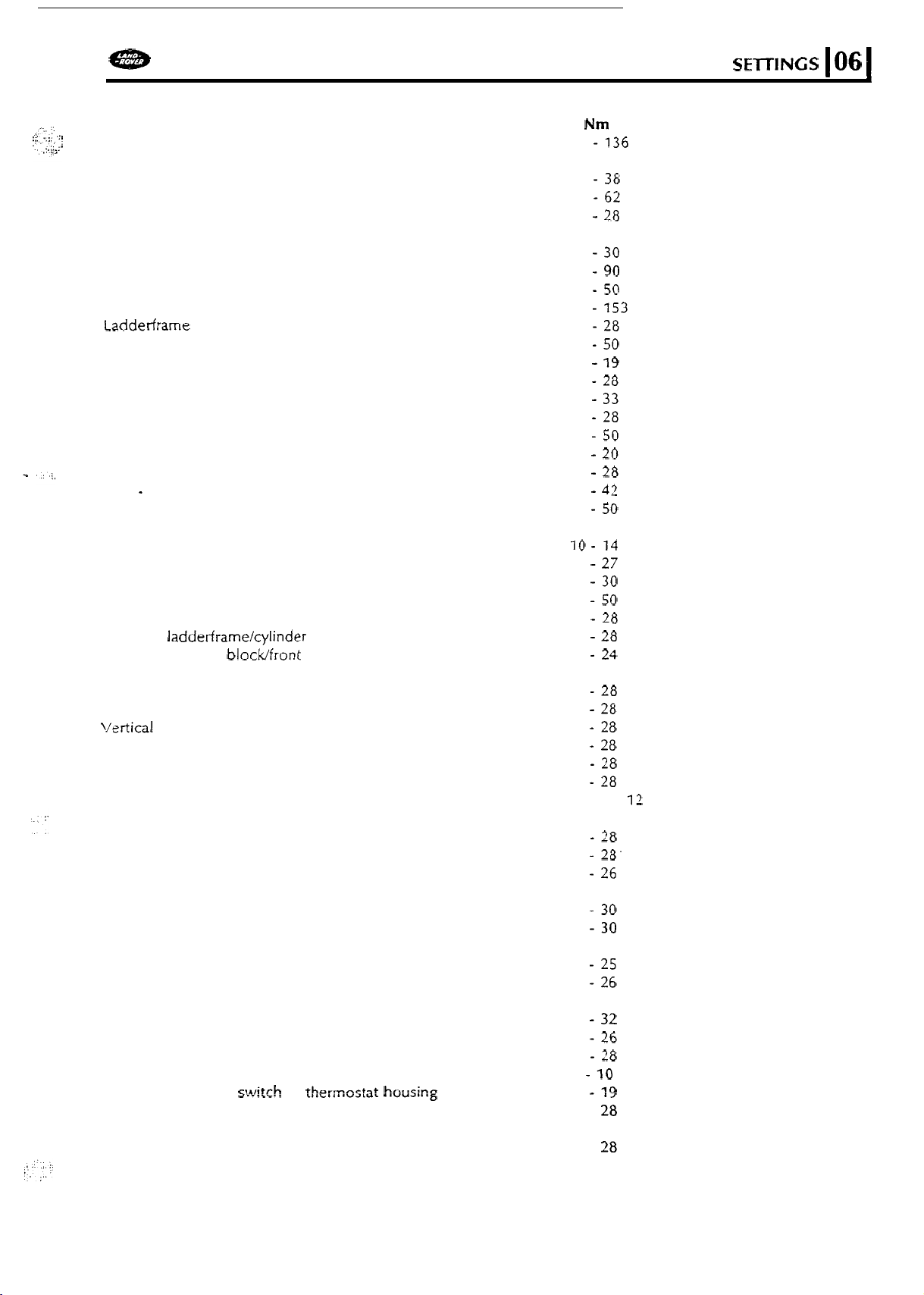

Tdi

Bearing cap

Camshaft thrust plate

Clutch cover plate to flywheel

Connecting rod

Dipstick tube assembly

Dipstick mounting bracket to

Earthing strap stud to cylinder block

Engine mounting

Housing flywheel to cylinder block

Flywheel to crankshaft

Ladderframe

Oil

Oil

Oil

Oil

Oil

Oil

Oil

*

Oil

Plug - blanking

Plug - drain

Plug . drain cylinder block

Plug - drain flywheel housing

Plug

Side

Starter motor

Sump to ladderframe

Sump

Sump

Support brackets

-

Vacuum pump

Vertical drive shaft gear to cylinder block

Alternator and heat shield to mounting bracket

Adjusting link

Adjusting link

Cylinder head

Breather cylcone

Engine lifting bracket

Electrical hamess clip

Exhaust manifold

Glow plug terminal

Glow

Heater stud (water)

Injector clamp stud to cylinder head

Injector clamp to injector

Inlet manifold to cylinder head

Rocker

Rocker

Tappet adjusting nut

Thermostat housing

Water outlet to thermostat housing

water temperature

Cowl mounting bracket to front cover

Fan assembly

Front

Front

Front

injector pump to front cover

Injector pump stud

DEFENDER

ENGINE

to

cylinder block

to

cylinder block

to

cap

.............................................

to

foot

to

cylinder block

..............................................

to

cylinder block

filter

adaptor

pressure switch

pump

pump

pump

pump strainer to

squirt

strainer to mounting bracket

exhaust manifold

cover

relief

to

jet

.

inlet

cover

to

ladderframekylinder block

to

cylinder blocUfront cover

plug

cover

shaft to cylinder head

cover

cover

cover

to

cylinder block

...................................................

to pump body

valve plug

cylinder block

oil

pump

assembly

oil

oil

sump

manifold (boost take-off)

to cylinder block

to

to

cylinder block

gallery

.........................................

................................................

flywheel

housing

................................................

to

cylinder block

to

cylinder block

to

alternator

to

pas pump plate

to

cylinder block

to

rocker

to

cylinder head

to

cylinder head

to

cylinder head

nut

............................................

to

cylinder head

to

cylinder head

nut

to cylinder head

.................................................

to

cylinder head

switch

to

water pump hub

plate to cylinder block

plate to front cover

to

cylinder block

to

front

...................................

....................

.................................

cylinder block

inlet

.................

manifold

............

........................

...................

..........................

..................................

...........................

................................

........................................

......................................

.................................

..................

..............................

........................................

...................................

.......................

.....................................

............................

.........................

..........................

........................

..............................

................

.......................................

..............................

...............................

cover

.............................

.....................

.....................

...........................

......................................

........................

........................

...................................

................................

..................................

...................................

.......................

.........................

to

thermestat

heusing

.....................

............................

..........................

...............................

...................................

...................................

cover

............................

.......

....

TOR

139

See

3, 5

Q

Nm

130

.136

7-10

30 .38

56 .62

22 .28

7-10

21

.30

80

.90

40

.50

.153

22 .28

40 .50

15

.19

20 .28

27 .33

22 .28

40

.50

14 .20

22 .28

32 .42

40 .50

25

10

.14

23 .27

23 .30

40 .50

22 .28

22 .28

20 .24

22 .28

22 .28

22 .28

22 .28

22 .28

22 .28

section

7-10

22 .28

22 .28'

20 .26

3-5

15

.30

15

.30

6-10

20

.25

20 .26

.

4,

.32

28

22 .26

22 .28

7

.10

75

.73

.

28

22

22 . 28

22 . 28

22 . 28

22

.

28

22

.

28

-

10

6

5

U

E

12

W

R

E

N

C

H

SE~TINGS

106

I

15

Page 20

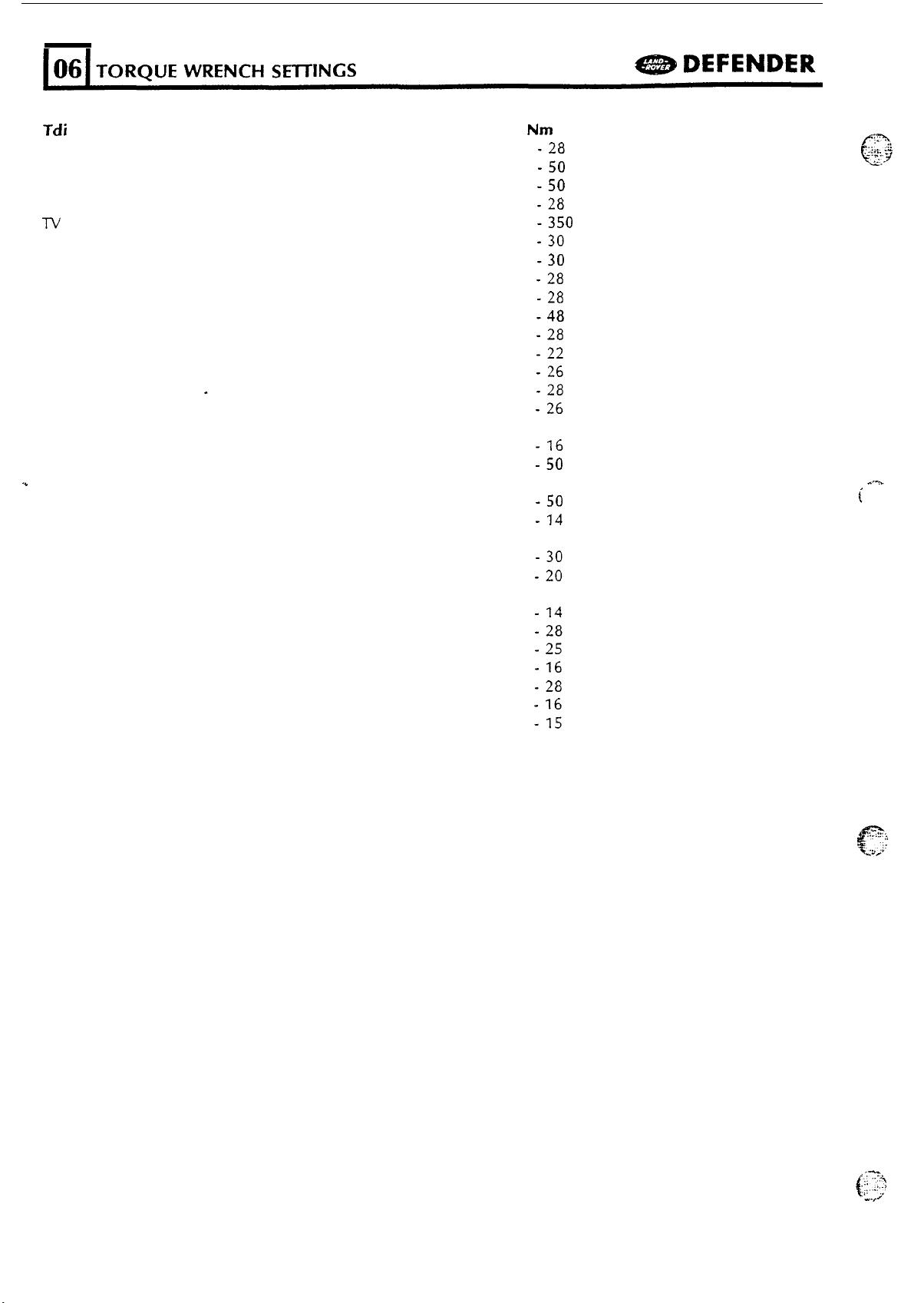

Tdi

ENGINE

Injector pump to support bracket

(continued)

............................

Tensioner (timing belt) to cylinder block

Timing pulley to camshaft

Timing pulley to injector pump hub

lV

damper pulley to crankshaft

Water pump to cylinder block

Water pump to cylinder block - stud

Water pump to front cover

Oil

drain adaptor to cylinder block - Turbo

Oil

drain pump to turbo

Oil

feed

pipe

adaptor to cylinder block . Turbo

Oil

feed

pipe

to turbo

Outlet elbow to turbo - nut

Outlet elbow to turbo - stud

Turbocharger to exhaust manifold

........................................

.........................

................................

..................................

.......................

......................................

...........................................

..............................................

.....................................

...................................

...........................

Belt tensioner assembly

to front cover plate compressor

Compressor to mounting bracket

-

Compressor mounting bracket

to front cover and plate

Banjo bolt - fuel pump

Banjo bolt - boost pipe

Banjo bolt - spill rail

Banjo bolt - fuel filter

...........................................

.............................................

............................................

.................................................

...............................................

Banjo bolt - injector spill rail

Fuel lift pump to fuel

filer

Fuel lift pump to cylinder block

...............................

............................

....................................

unions

.............................

...............................

Injector pipes to injectors and injector pump

P.A.S.

pump to mounting plate

P.A.S.

pump mounting plate to front

P.A.S.

pump pulley

to

hub

Tappet guide retaining screw

................................

cover

.......................................

...................................

.................

..............

......

..........

.............

Nm

22 .28

40 .50

40

.50

22 .28

333

.350

23

.30

23

.30

22 .28

22 .28

32

.48

22 .28

15

.22

21 .26

22 .28

21 .26

14

.16

40

.50

40 .50

10

.14

8

.

12

20

.30

14

.20

2

10

.14

22 .28

22 .25

14

.16

22 .28

14

.16

13

.15

(!?:

....

.....

.....

...%

i

&.~

::

.

Y

16

Page 21

e

DEFENDER

RECOMMENDED LUBRICANTS, FLUIDS AND CAPACITIES

109

I

.<-

.

.,..

,:;-

,

..~._

,....,.

.

,..

,w>;:.

-+-

-

.~

;:.!!

81'1

..

ENGINE OIL - Tdi ENGINES

The minimum performance level

specifications BLS 22.0L.09 and CCMC

oil

The engine

below,

can be obtained by the

of

Oils

Agip Superdiesel

BP

Caltex

Castrol Syntron

Century Superb

Duckhams

Esso

Super

Gulf Super Diesel

Mobil Delvac Super, Mobil

1

Kuwait Q8 Auto-4

Shell Rimula

Texaco Dieseltex

or

the

oils

to

BLS

Vanellus C3

RPM Delo 400*

Superlube

Oil

Formula 15Wl50

and filter must be changed every 10,000 km

clearly marked as meeting the required specification, should be used. Superior engine protection

use

meeting the above specifications are listed below:

22.OL.09tCCMC PD1

or

Sint Turbo Diesel

or

Visco

Diesel

X,

TXT,

Dynamax

QXR

or

Hypergrade

EX

2,

Superlube

or

Engine

or

Q8

Auto-7

X

or

Rotella

MTX

oil

required for satisfactory engine performance and protection

of

Super High Performance Diesel (SHPD)

or

GTX

+,

Ultra

Oil

T

1

Rally Formula or Mobil

PD1.

Oil

or

is

defined by

(6000

miles) and it

oils

-

SHPD

Agip Sigma Turbo

BP

Castrol Turbomax

Century Centurion

Caltex

Duckhams Fleetmaster SHPD or Fleetmaster Extra

Elf

Esso

Fina Kappa LDO

Gulf Superfleet Special

Mobil Delvac 1400 Super

Texaco Ursa Super TD

Shell

Total Rubia

Silkolene Turbolene

oils

to CCMC

Vanellus C3 Extra

RPM

Delo 450

Multiperformance 4D

Super Diesel

Myrina

TIR

is

important that only

to specification CCMC D3. Some

D3

Oil

TD or Special Diesel

or

Total Diesel

D

oils

Oil

listed

In markets where

Under severe operating conditions, eg.

ambient temperatures above 40°C

not exceed

requires a monthly

instructions may result

Oil

Viscosity - Ambient Temperatures Applications Chart

SPECIFICATION

Oils must meet

BLS.22.OL. 09

or

CCMC PD1

or

CCMC D3

oils

to the above specifications are not available use products to MIL-L-2104D

5000

km (3000 miles). Continuous

oil

and filter change. Failure to adhere to the recommended

in

premature engine wear

I

!jAE

v'scos'Ty

5Wf30

5Wi40

5Wt50

1

10Wi40

10W150

15Wl40

15Wt50

off

road in mud, airborne sand, dust, operating at high speeds in high

or

continual stoptstart operation, the

off

or

I

I

)

1

Owl30

)

)

)

)

or

API CD.

oil

and filter change period should

road operation in mud, dust and wading conditions

damage.

-30"

-20"

service

AMBIENT TEMPERATURE "C

-10"

0"

10

"

and operating

20

"

30

"

40

"

50

I

"

20Wf40

)

17

Page 22

CAPACITIES

The following capacity figures are approximate and are provided

or

using the dipstick

Engine sump

oil

level plugs

................................................................

Extra when filling following new filter

Transfer box

Cooling system

Anti-freeze

oil

................................................................

................................................................

as

applicable.

..............................

6,OO litres (10.56 pints)

0,85

2,30 litres

11,lO

as

a guide only.

litres (1.50 pints)

(4

pints)

litres (20 pints)

All

oil

levels

must be set

Ethylene Glycol based anti-freeze (containing no methanol) with non-phosphate corrosion inhibitors only are

suitable

inhibitors should

for

use

in

Tdi engines to ensure protection

be

used. Only anti-freeze, summer and winter even in climates where anti-freeze is not

of

the cooling system against frost and corrosion.

necessary.

One part anti

~

See cooling system section 26

-

freeze, one

part

water,

i.e.

50%

anti-freeze in coolant. Complete protection below -36°C.

for

engine protection information.

No

18

Page 23

...

..

I.,

;:,:;i

. . - ...

,

.

.

e

1’

.

.

,

,

DEFENDER

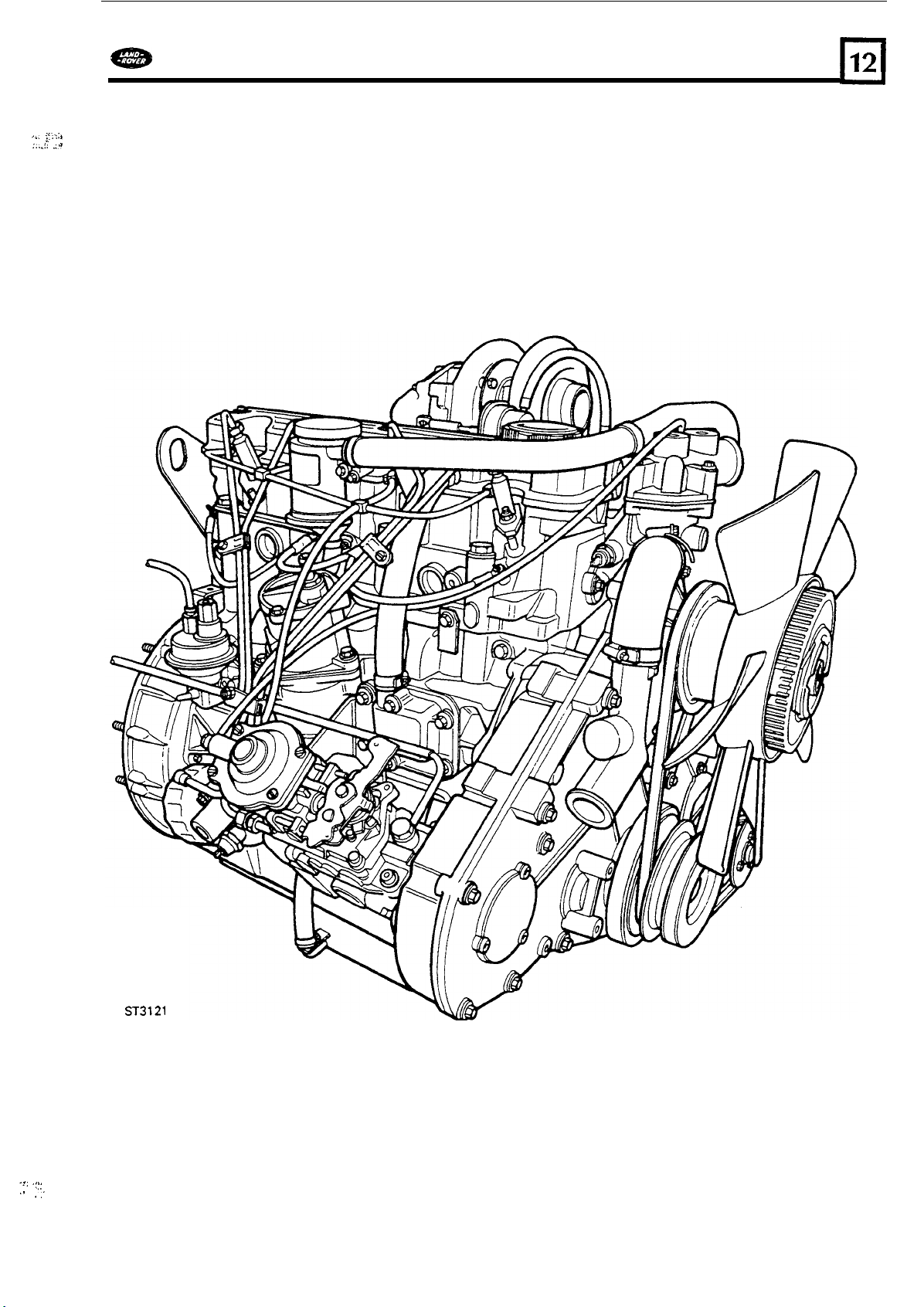

ENGINE

11

2

I

~I

:,

.

..

...

.,..

...

..._

.

..

ST3121

M

19

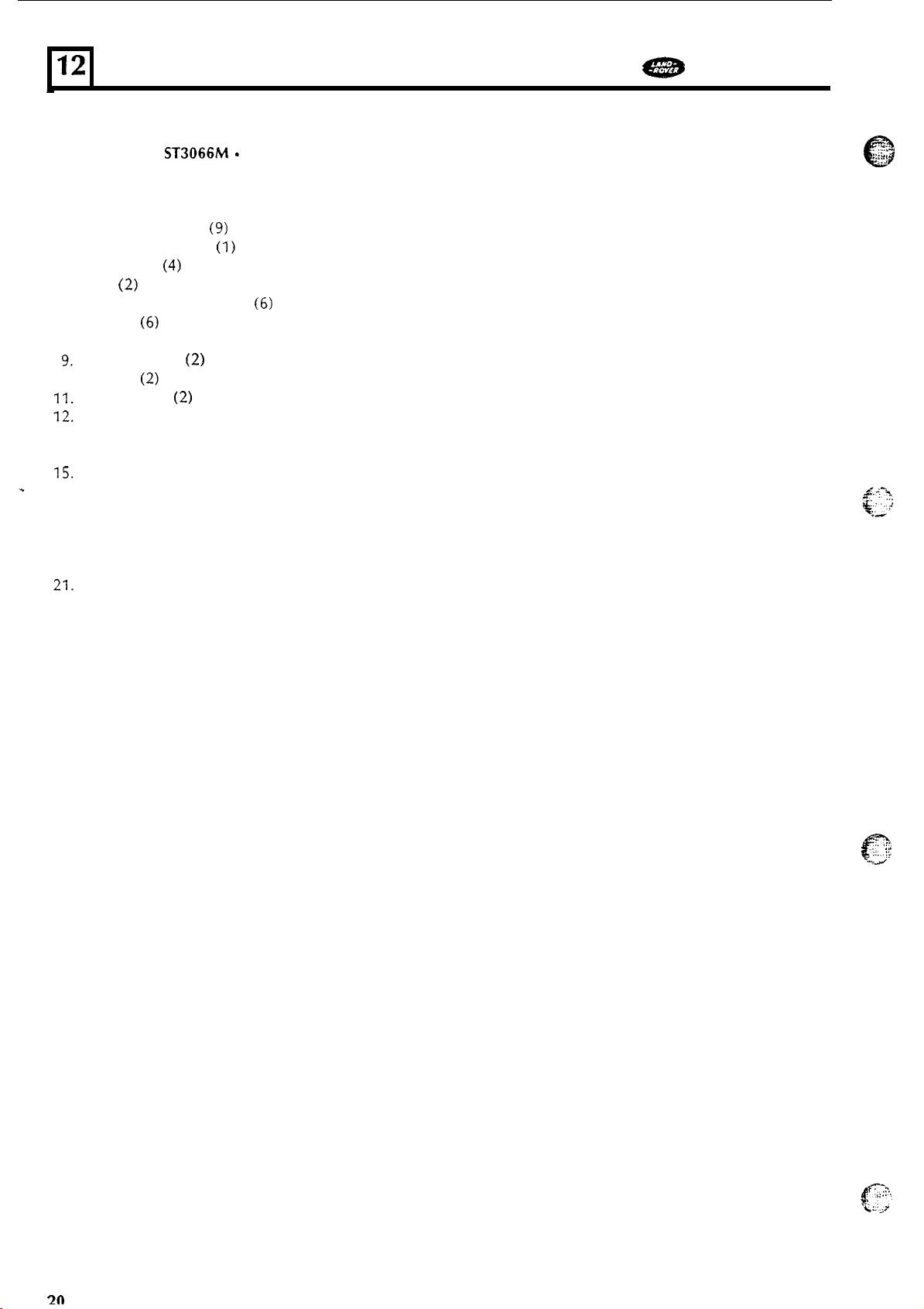

Page 24

12

ENGINE

_I

CLUTCH AND FLYWHEEL HOUSING

COMPONENTS

LAND ROVER Tdi engine

I

. Clutch housing

2.

Bell

housing stud (9)

3.

Starter motor stud

4.

Allen bolts

5.

Plug

(2)

ST3066M

(4)

6. Screw housing to block

7.

Washer (6)

8.

Bolt housing to block

9. Spring washer

10.

Bracket

11.

Harness clip

12.

Oil

seal

(2)

(2)

(2)

-

(1)

(6)

(2)

13. Flywheel

14. Starter ring

15. Reinforcing plate

Bolt

16.

flywheel to crank

17. Clutch cover

18.

Clutch plate

19. Dowel

20. Screw

21. Spring washer

e

DEFENDER

$"'!

...

..,

-->"d

2n

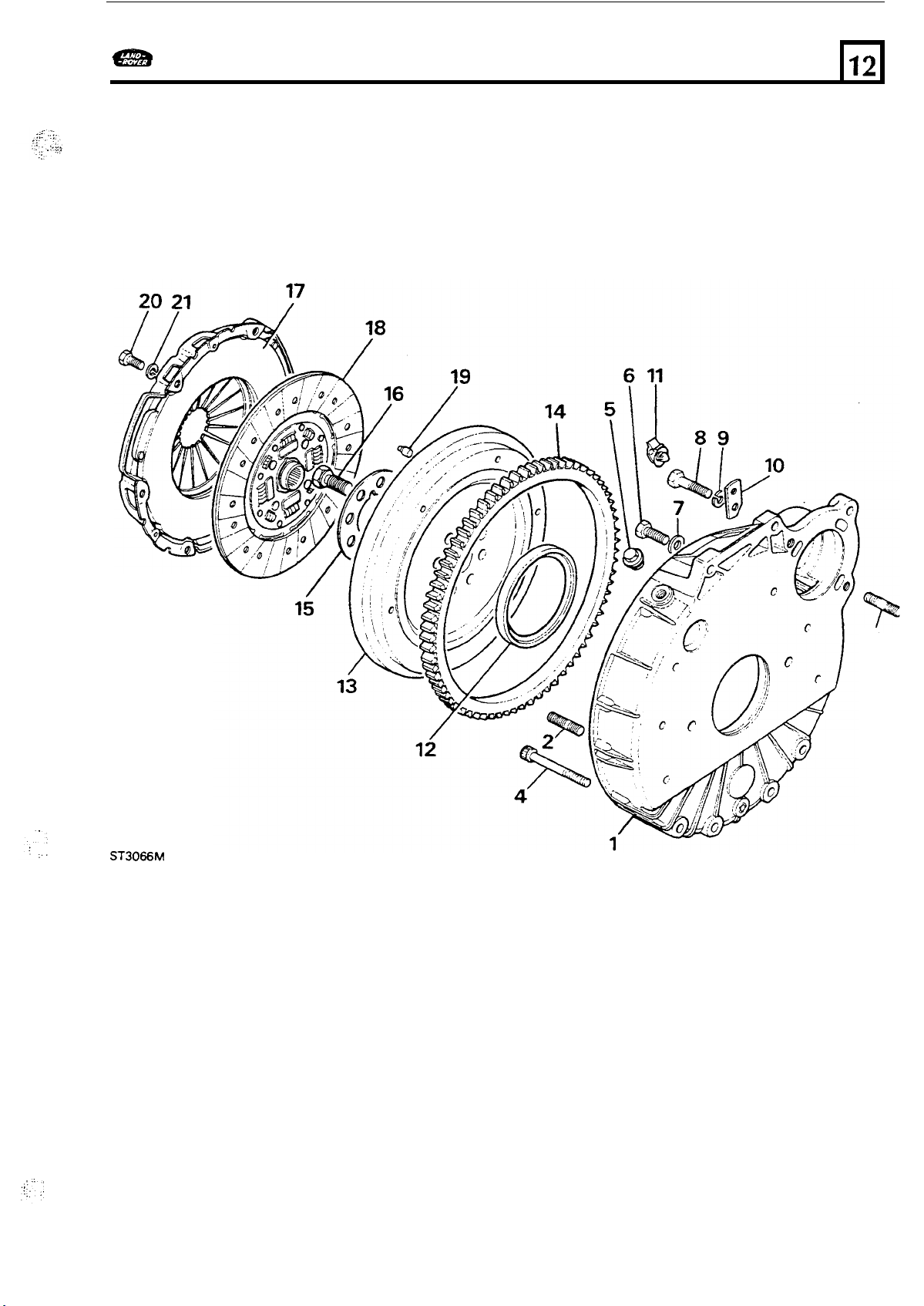

Page 25

.

DEFENDER

ENGINE

12

ST3066M

3

21

Page 26

12

ENGINE

DEFENDER

SUMP

LAND

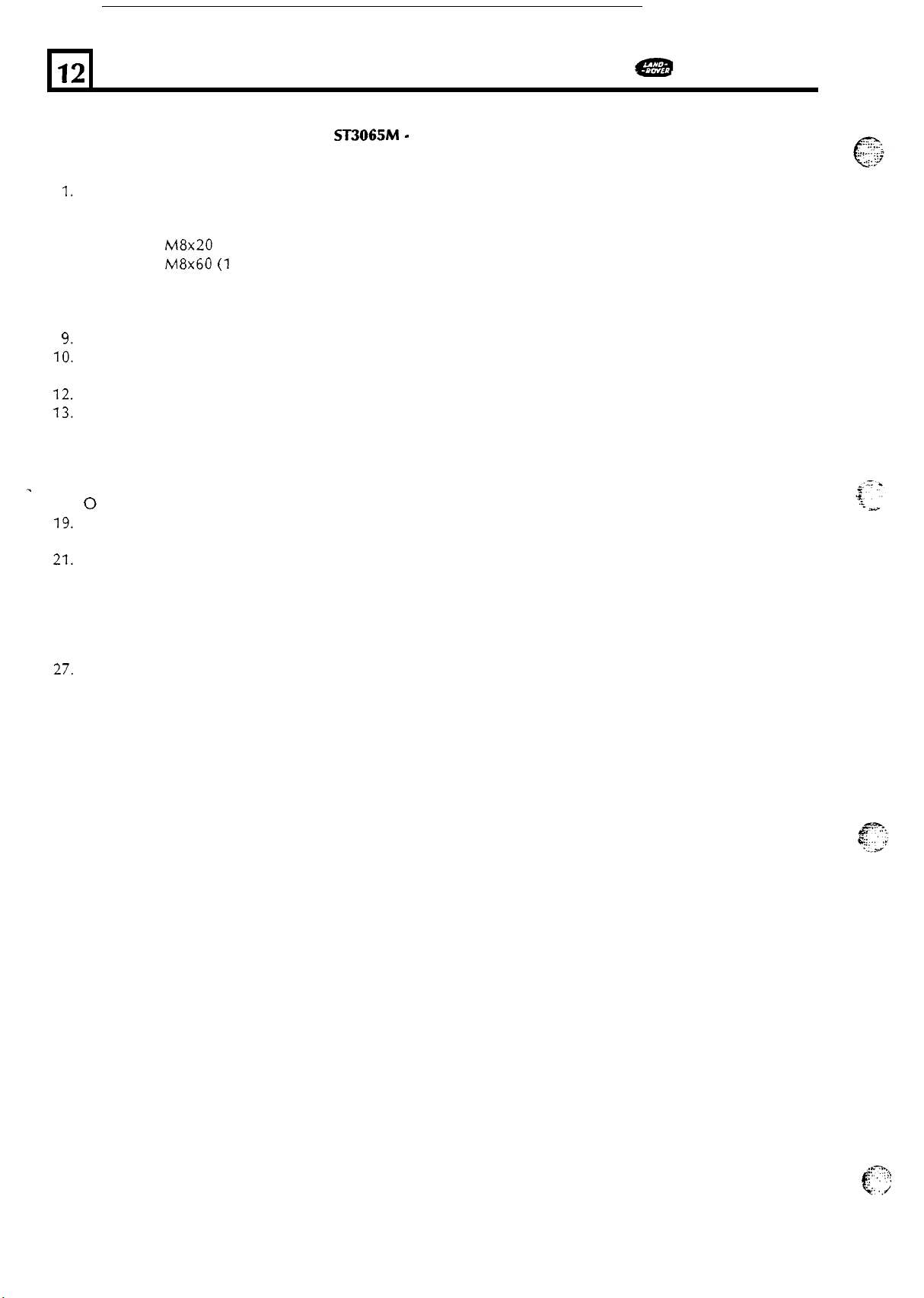

AND

OIL

ROVER

1.

Sump

2.

Drain plug

3.

Joint washer

4.

Flange bolt M8x20

5.

Flange bolt M8x60

Oil

6.

7.

Oil

8. Dowel

9.

Oil

10.

Spindle

11.

Screw

12. Spring washer

13.

Support bracket

14. Screw

15.

Lock washer

16.

Casket

17.

Filter

18. 0 ring

19. Lock washer

20. Screw

21. Spring washer

22. Plain washer

23. Drive shaft

24.

Oil

25. Spring

26. Joint washer

27.

Oil

Tdi

pump housing lower

pump housing upper

pump gears

relief

plunger

relief

plug

PUMP

engine

COMPONENTS

(8)

(1

2)

ST3065M

-

22

Page 27

.-:.:.

<

,.

.

.

,..

,+

' . :

,,.,x2.;:,,

,I.

..

,1:

.,~.

..

_

..

...

.

.

.,

-DEFENDER

16

ENGINE

n

12

ST3065M

24

\

4

4

5

23

Page 28

e

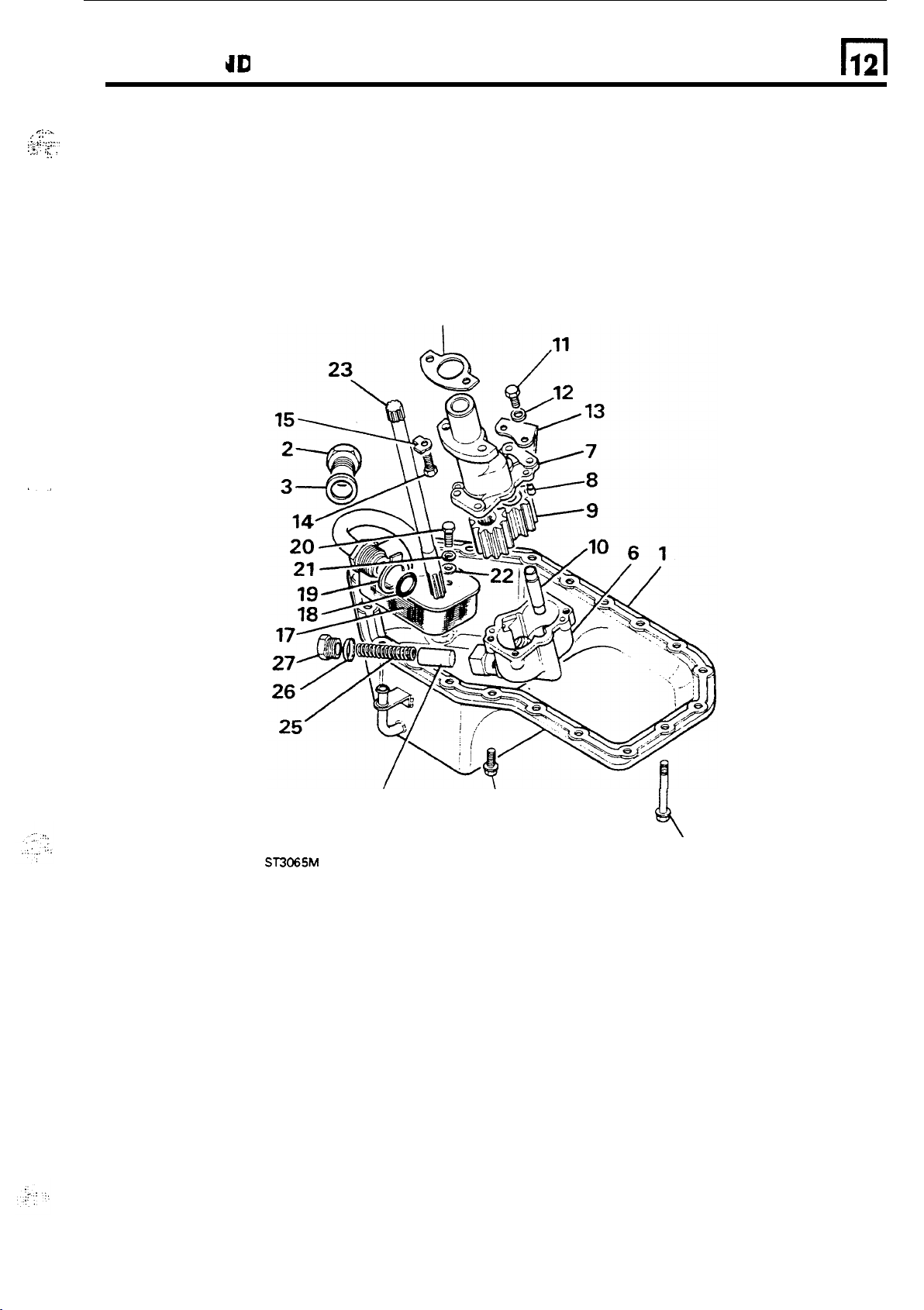

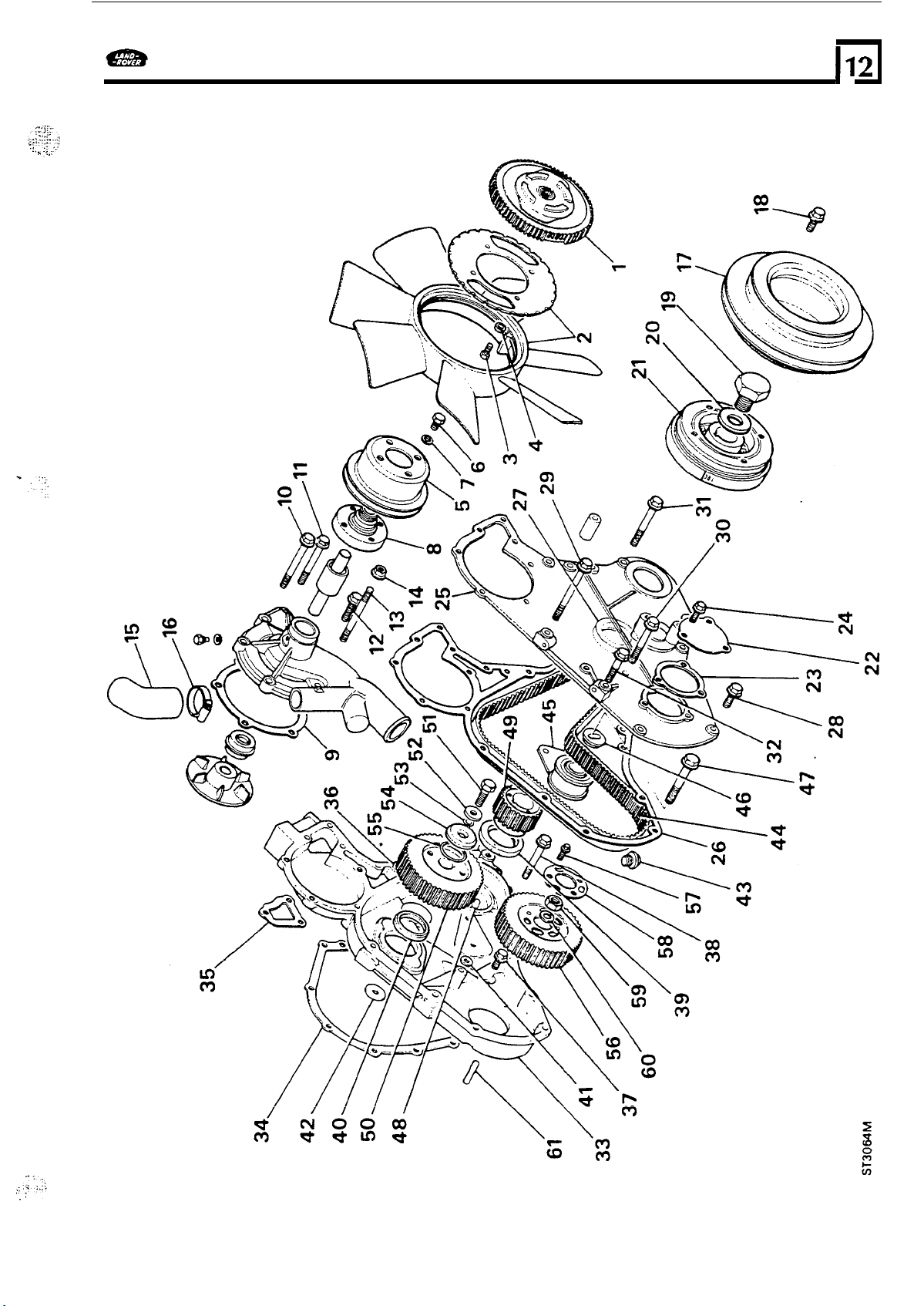

DEFENDER

FRONT COVER COMPONENTS ST3064M

ROVER Tdi

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

-

17.

7

8.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

Viscous unit

Fan

Bolt

Plain washer

Pulley

Screw

Spring washer

Water pump assembly

Gasket

Flange

Flange bolt

Flange screw

Stud

Flange nut

By pass hose

Hose

Crank pulley

Flange bolts

Crank pulley bolt

Washer

Torsional vibration damper

Inspection plate

Gasket

Flange screw

Front cover plate

Gasket

Cover plate seal

Flange screw

Flange bolt

Flange bolt

Flange bolt

Flange bolt

Front

Front cover gasket

Front

Front cover dowel

Flange screw

Flange

Crankshaft

Camshaft

Gasket

Gasket

Plug

Timing belt

Timing belt tensioner assembly

Slotted washer

Flange bolt

Tensioner pivot pin

Crankshaft gear wheel

Camshaft gear wheel

Bolt

engine

assemb!y

(4)

(4)

(4)

(4)

bolt

M8x85 (2)

M8x75

M8

M8

M8x35

(1)

(3)

clip

(4)

M6x20

M8x25 (3)

M8x100 (2)

M8x70

M8x75 (3)

M8x50

(3)

(2)

(1)

cover

covedwater inlet gasket

M8x20 (2)

bolt

M8x65

oil

seal

oil

seal

-

centre bolt

-

block front

M10x70

face

-

LAND

52.

Washer

53.

0

ring

54.

Retaining plate

0

55.

56.

57.

58.

59.

60.

61.

ring

Injection pump timing gear

Flange screw

(3)

Retaining plate

Nut

Spring washer

(3)

Stud injection pump to front cover

(3)

24

Page 29

DEFENDER

.

ENGINE

11

2

25

Page 30

12

ENGINE

a

DEFENDER

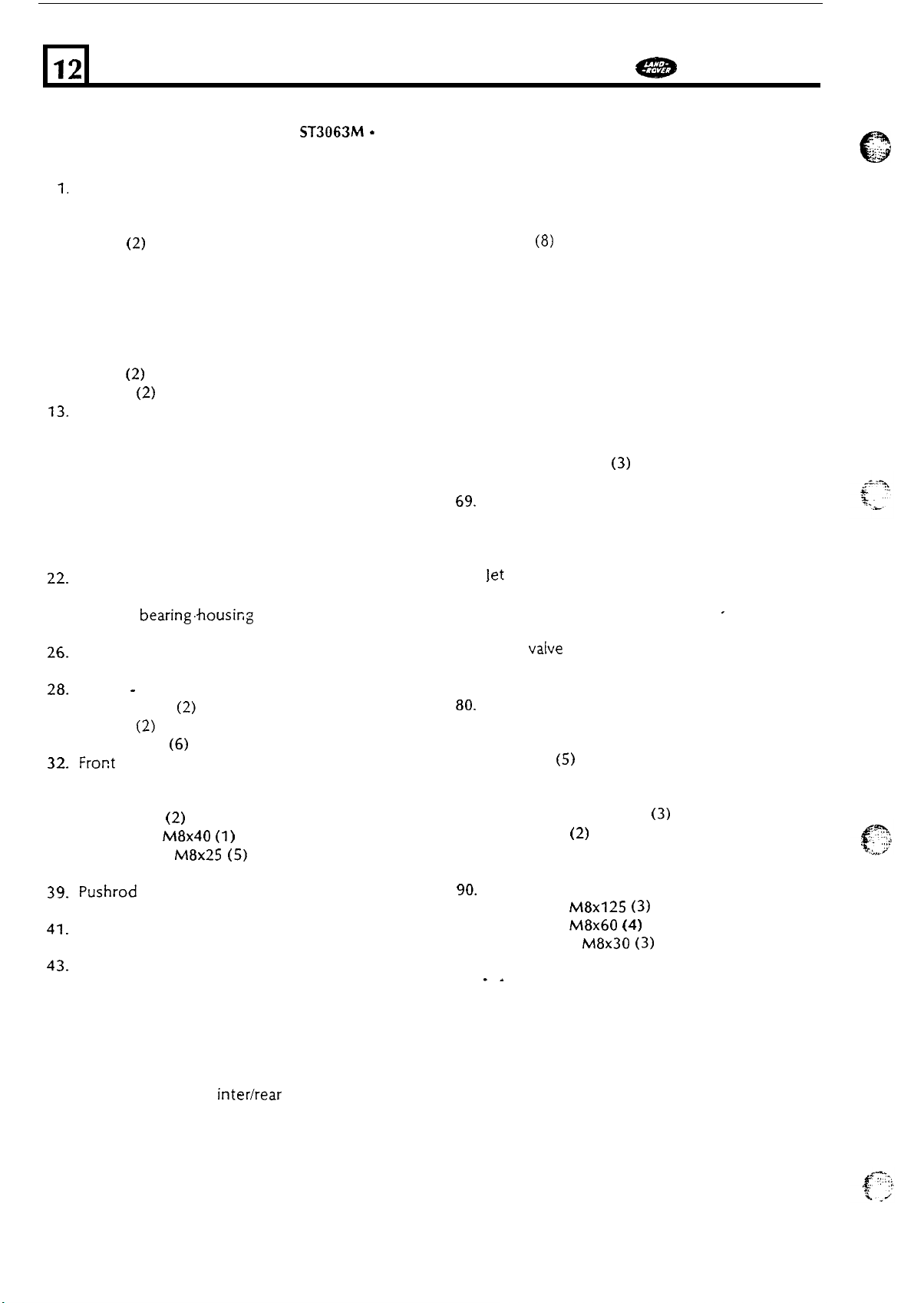

CYLINDER BLOCK COMPONENTS ST3063M

LAND

.

ROVER

Oil

1.

Oil filter adaptor

2.

Gasket

3.

Screw

4.

Spring washer

5.

Oil

6.

Thermostat bulb

7.

0

ring

8.

Spring

9.

Washer

10.

Screw

11.

Washer

12.

Oil pressure switch

13.

Copper washer

14.

Blanking plug

15.

Skew gear

16.

Dowel pin

17.

Bush

18.

Locking screw

19.

20.

0

ring

Snap ring

21.

Deep groove bearing

22.

Snap ring

23.

0

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

ring - bearinghousifig

Bearing housing

Rear

Casket

Dowel

Socket screw

Washer

Flange bolts

Froct side cover breather

Gasket

Baffle plate

Screw

Flange bolt

Flange screw

Cylinder block

Pushrod

Tappet slide

Roller

Tappet guide

Set bolt

Washer

Camshaft

Locking plate

Screw

Spring washer

Camshaft bearing

Camshaft bearing - interhear

Camshaft

Tdi

engine

filter

element

(2)

cooler

adaptor

(2)

(2)

-

external

-

internal

side

cover

-

flywheel housing

(2)

(2)

(6)

No.6

(2)

M8x40

M8x25

follower

(2)

key

(2)

(2)

-

(2)

(1)

(5)

front

(3)

-

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

. 63.

64.

65.

66.

67.

68.

69.

70.

71.

72.

73.

74.

75.

76.

77.

78.

79.

80.

81.

82.

83.

84.

85.

86.

87.

88.

89.

90.

91.

92.

93.

Piston

Piston rings

Gudgeon pin

Circlip

(8)

Connecting rod

Gudgeon pin bush

Connecting rod bolt

Big end bearing

Big end bearing cap

Connecting rod

nut

Crankshaft

Crankshaft main bearing

Main bearing cap - rear

Main bearing cap - centre

Thrust washers

Main bearing cap

(3)

Main bearing cap bolt

Crankshaft

key

Crankshaft dowel

Crankshaft bush

Packing strip

let adaptor

joint washer

Dowel

Joint washer

Relief

vaive assembly

Drain plug

joint washer

Dipstick tube

Dipstick

Oil gallery plug

cup plug

(5)

cup plug

Oil

gallery plug

Camshaft

Ring dowel

Oil

Oil

oil

feed plug

(2)

feed adaptor

drain adaptor

(3)

Ladder frame

Flange bolt

Flange bolt

Flange screw

M8x125

M8x60

M8x30 (3)

(3)

(4)

-.

0

I.

..

..

.

26

Page 31

e

DEFENDER

ENGINE

-

12

ST3063M

27

Page 32

ENGINE

12

Y

CYLINDER HEAD COMPONENTS ST3062M - LAND

ROVER Tdi

1.

3

-.

3.

4.

Washer

5.

6.

7.

8.

9.

10.

11.

12.

13.

Tappet adjuster screw

14.

15.

16.

-

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

Oil

Rocker

Rocker

Flange headed bolt

Sealing washer

Breather cyclone

Flange headed screw

Rocker

Rocker

Rocker

Rocker arm

Rocker

Locknut

Rocker

Rocker

Rocker

Rocker

Rocker

Exhaust manifold

Manifold stud

Self

Plair; washer

Stud turbocharger mounting

Inlet manifold

Manifold stud

Flarlge nut

Manifold gasket

Engine lifting brackets

Cylinder head

Cylinder head gasket

Head bolts

Head bolts

Head bolts

Adaptor cooling system

Ring dowel

Valve

Valve seat insert

Valve

Valve seat insert

Valve guide

Valve stem seal

Valve spring seat

Valve spring

Valve spring cup

Split cotters

Injector

Injector clamp

Injector clamp nut

engine

filler

cap

cover

cover

shaft bolt

shaft bolt

arm

RH

LH

arm bush

shaft

shaft spacer

shaft spring

shaft clamp

shaft seal

locking nut

M12

M12

M10

-

inlet

-

exhaust

gasket

(3)

(2)

-

exhaust

-

inlet

short

long

(4)

(4)

(10)

51.

Injector clamp stud

52.

Injector clamp dowel

53.

Injector sealing washer

54.

Spill return pipe

55.

Banjo bolt

56.

Copper washers

57.

Glow plug

58.

Glow plug cable

59.

Nut and washer

60.

Thermostat housing

61.

Casket

62.

Flange screw

63.

Thermostat

64.

Gasket

65.

Thermostat housing cover

66.

Flange bolt

67.

Thermal transmitter

68.

Joint washer

69.

Flange bolt

70.

Cup plug

71.

Cup plug

6mm

(3)

M6x40 (3)

(1)

(2)

e

DEFENDER

28

Page 33

6Z

c

Page 34

121

ENGINE

a

DEFENDER

The following list

of

sections

the

of

operations can be carried out with the engine installed using the appropriate

ENGINE

OPERATION

Cylinder Head

Heater plugs

injectors

Rocker

cover

Rocker shaft

Removing cylinder head

Front cover

oil

seals/timing beltlcamshaft

Water pump

Front cover plate

or

seal

Front pulley damper

Front cover

plate

Removing timing belt

Removing timing belt gears

Removing injection pump

Removing front cover

Vacuum

Fuel pump and

pump/skew gear/bush/oil filter adaptor

side

cover

Front side cover plate

Cam followers

Removing camshaft

Sump and

Removing

oil

oil

pump

pump

OVERHAUL PROCEDURE.

Remove Overhaul Refit

Page Page Page

41

44

38

38

38

39

39

40

40

40

40

40

41

-

43

44

44

-

46

46

46

47

48

48

42

45

72

78

66

63

70

76

62

63

-

80

80

79

78

76

-

70

66

69

69

68

66

67

66

-

65

65

62

62

72

72

77

66

64

The foregoing list

vehicle. Cross reference, where necessary,

procedure

12.41.05.

publication SMR

of

remove and refit operations are those which can

is

made

to

thr relevant instructions in the engine overhaul

Each operation

670

EN

RT