Landoll XL144, XLC144, XLD144, XLH144, XLO144 User Manual

X-Fold Pulverizer

Models: XL144, XLC144, XLD144, XLH144, and XLO144

Sizes: 28’, 30’, 32’, 34’, and 36’

Operator’s Manual

LANDOLL CORPORATION

1900 North Street

Marysville, Kansas 66508

(785) 562-5381

800-428-5655 ~ WWW.LANDOLL.COM

182rev0713 5J801

5J801182rev501

XL144 PULVERIZER

CONTENTS

Introduction -----------------------------------------------------------------------------------------------------------3

Location Reference ---------------------------------------------------------------------------------------- 3

Parts Ordering----------------------------------------------------------------------------------------------- 3

Safety Suggestions ----------------------------------------------------------------------------------------------- 4

Operating Instructions -------------------------------------------------------------------------------------------- 5

Designed Use ----------------------------------------------------------------------------------------------- 5

Tractor Preparation ---------------------------------------------------------------------------------------- 5

Bleeding Hydraulic Cylinders ---------------------------------------------------------------------------- 5

Field Operation ---------------------------------------------------------------------------------------------- 6

Hitch Adjustment (Used to Limit Soil Pushing) ------------------------------------------------------ 6

Transport (Manual Lock Models) ------------------------------------------------------------------------ 7

Transport (Automatic Lock Models) -------------------------------------------------------------------- 7

Storing Pulverizer with Drawbar Removed ---------------------------------------------------------- 7

Drawbar Attachment when Pulverizer is Stored ---------------------------------------------------- 7

Maintenance -------------------------------------------------------------------------------------------------------7A

Fasteners --------------------------------------------------------------------------------------------------- 7A

Tires ---------------------------------------------------------------------------------------------------------- 7A

Lubrication -------------------------------------------------------------------------------------------------- 7A

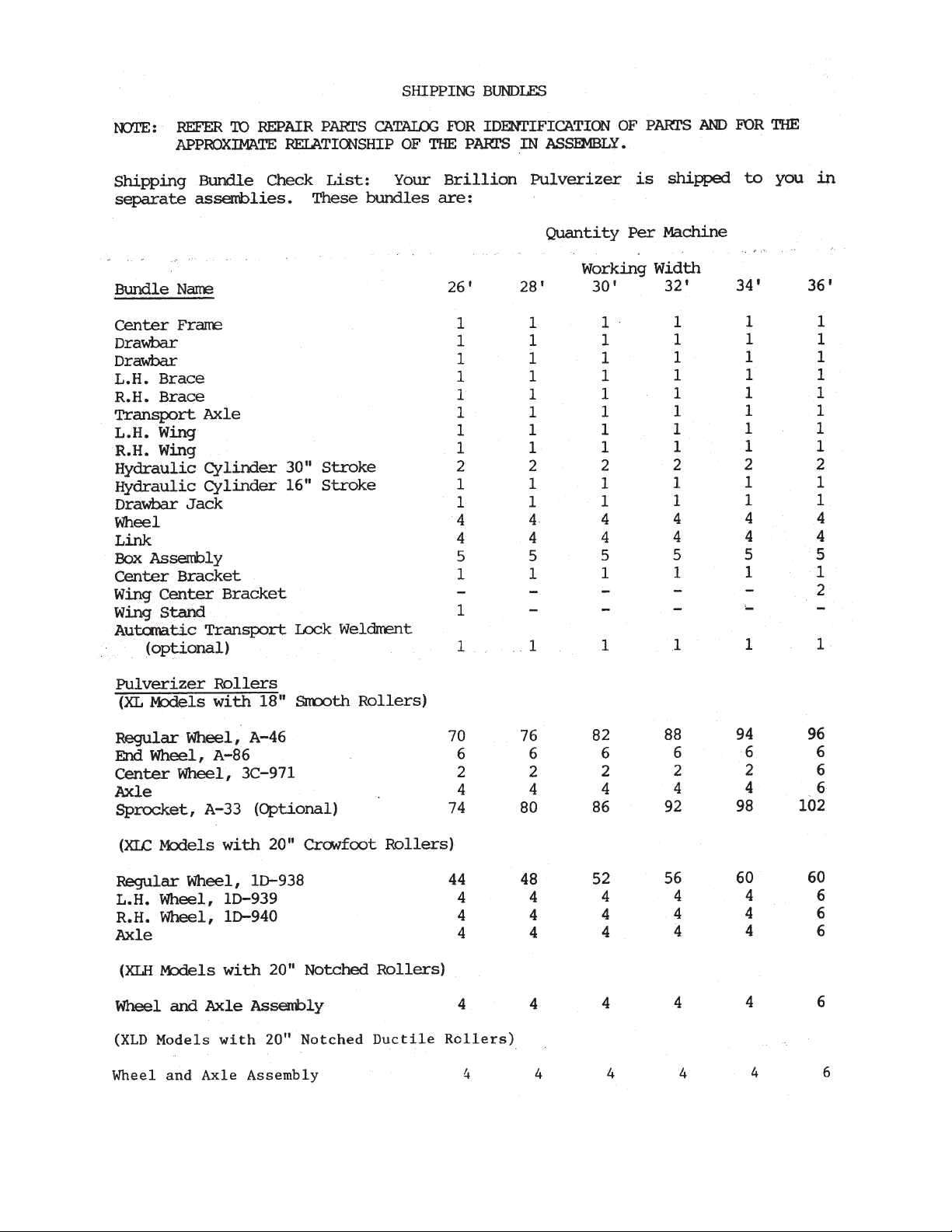

Shipping Bundles ------------------------------------------------------------------------------------------------ 7B

Setting Up Instructions ------------------------------------------------------------------------------------------- 8

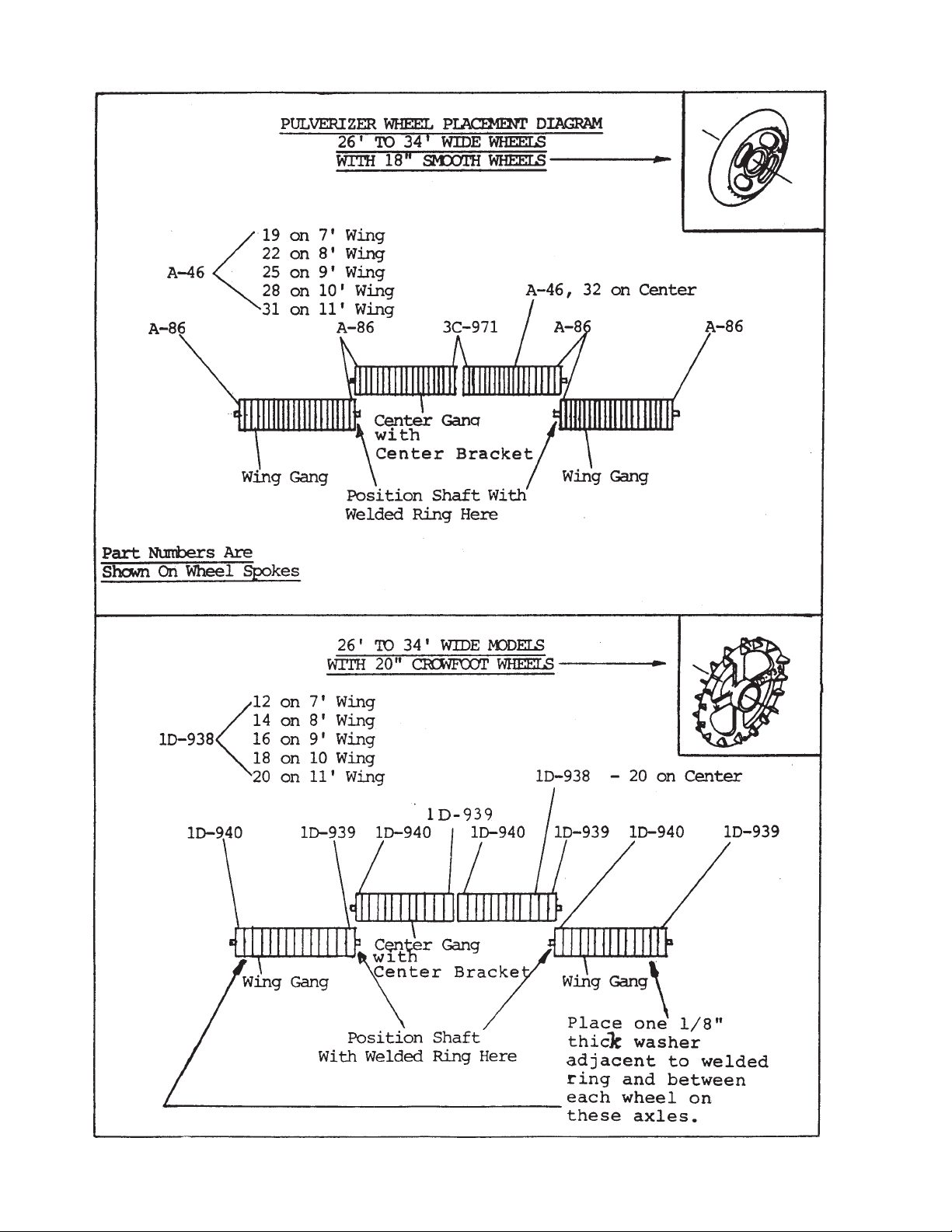

Wheel and Pipe Shaft Assembly ----------------------------------------------------------------------- 8

Frame Setup ------------------------------------------------------------------------------------------------12

LED Warning Lights---------------------------------------------------------------------------------------------------19A

Specifications -----------------------------------------------------------------------------------------------------20

Scraper Installation -----------------------------------------------------------------------------------------------22

Page I

5J801182rev0713

5J801182rev501

INTRODUCTION

Your Brillion Pulverizer is built with the best materials and workmanship available. It has been designed to

give years of trouble-free operation. Proper care and operation will insure that you receive the service and

long life built int this machine.

Study this manual carefully before attempting to assemble or operate the machine. A special section, “Setting

Up Instructions”, is included.

This safety alert symbol is used to call your attention to instructions concerning

personal safety. Federal law requires you to explain the safety and operating

instructions furnished with this machine to each employee before they are allowed

to operate the machine. These must be repeated to the employee at the start of

each season. Be sure to observe and follow the instructions for the safety of

anyone operating or near the machine.

Location Reference

Right hand, left hand, forward and rear refer to operator’s right, left, front and rear when he faces the same

direction as the machine will travel in the field.

Parts Ordering

When ordering parts for this machine, include the complete model number and serial number. Refer to the

name plate on the angled tube above the drawbar, left side, center section of the machine as indicated in the

diagram below. Please record these numbers upon taking delivery of the unit.

Pulverizer Model No. _______________________________

Serial No. _______________________________

Date Purchased_______________________________

Be sure to read the warranty card which is shipped with the machine. Return the proper portion of the card for

recording at the factory.

5J801182rev501

SAFETY SUGGESTIONS

Federal law requires you to explain the safety and operating instructions furnished with this machine to all

employees before they are allowed to operate the machine. These must be repeated to the employees at the

beginning of each season. Be sure to observe and follow the instructions for the safety of anyone operating or

near the machine.

Investigation has shown that nearly one-third of all farm accidents are caused by careless use of machinery.

You can do your part in improving safety by observing the following suggestions. Insist that all people working

with you or for you abide by them.

1. Do not stand between the tractor and implement when attaching or detaching implement unless both

are not moving.

2. Do not make adjustments or lubricate machine while it is in motion.

3. Do not allow anyone to ride on tractor or machine.

4. Always use transport lock when transporting machine.

5. Do not transport at speeds over 20 mph.

6. Avoid sudden stops or turns when transporting because weight of machine may cause operator to

lose control of tractor. Use a tractor heavier than machine. Do not allow tractor drawbar to swing

when transporting.

7. Use caution when towing behind articulated steering tractors; fast or sharp turns may cause the

machine to slip sideways.

8. When transporting the machine on a road or highway, use adequate warning symbols, reflectors,

lights, and slow moving vehicle signs as required.

9. Lower machine to ground when not in use.

10. Block machine so it will not roll when unhitched from tractor.

11. Relieve pressure in hydraulic lines before uncoupling hydraulic hoses from tractor. On most tractors

this can be done by operating valves after engine is stopped.

12. Securely block machine when working on or under it to prevent injury in case of hydraulic failure or

inadvertent lowering by another person.

13. Do not allow anyone near the machine when folding or unfolding the wings. Fold wings on as

level a surface as possible.

14. Install safety chain between the pulverizer and the tractor. See page 21 of this manual and/or tractor

manual.

15. Escaping hydraulic fluid under pressure can have sufficient force to penetrate the skin, causing

serious personal injury. Before applying pressure to the system, be sure all connections are tight and

that lines and hoses are not damaged.

16. Hydraulic fluid escaping from a very small hole can be almost invisible. Use a piece of cardboard or a

piece of wood, rather than hands, to search for suspected leaks.

5J801182rev501

Safety Signs & Decals

There are three levels of hazard intensity that appear with the safety alert symbol on safety decals: DANGER,

WARNING, and CAUTION. The level of hazard intensity is determined by the following definitions:

DANGER - Immediate hazards which WILL result in severe personal injury or death.

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION - A reminder of safety practices, or an alert to unsafe practices which could result in

personal injury.

Examine safety decals and be sure you have the correct safety decals for the machine. Keep these signs

clean so they can be observed readily. It is important to keep these decals cleaned more frequently than the

machine. Wash with soap and water or cleaning solution as required.

Replace decals that become damaged or lost.

Order decals through your BRILLION dealer.

When applying decals to the machine, be sure to clean the surface to remove any dirt or residue. Where

possible, sign placement should protect the sign from abrasion, damage, or obstruction from mud, dirty oil, etc.

These are the safety decals provided for the pulverizer. (Their locations are illustrated on the next page).

3J675

DANGER

FALLING WINGS CAN CAUSE INJURY

OR DEATH. STAND CLEAR WHEN WINGS

ARE BEING RAISED OR LOWERED.

3J675

BLEED THE AIR FROM WING LIFT CYLINDERS

BEFORE OPERATING. FAILURE TO DO SO WILL

ALLOW WINGS TO FREE-FALL AND MAY CAUSE

SERIOUS PERSONAL INJURY. SEE OPERATOR’S

MANUAL FOR CORRECT PROCEDURE.

DANGER

5J860

IMPORTANT

1. READ AND FOLLOW OPERATING INSTRUCTIONS IN THE MANUAL.

2. WHEN CHANGING FROM TRANSPORT POSITION TO FIELD POSITION, UNFOLD WINGS

COMPLETELY, THEN REVERSE THE HYDRAULIC LEVER TO ALLOW REMOVAL OF THE

CYLINDER TRANSPORT LOCK. AFTER THIS THE IMPLEMENT MAY BE COMPLETELY

LOWERED.

3. WHEN CHANGING FROM FIELD POSITION TO TRANSPORT POSITION, RAISE CENTER

SECTION COMPLETELY WITHOUT FOLDING THE WINGS. THEN INSTALL CYLINDER

TRANSPORT LOCK BEFORE FOLDING THE WINGS.

5J860

5J859

CAUTION

1. DO NOT ALLOW ANYONE TO RIDE ON THIS IMPLEMENT.

2. DO NOT TRANSPORT AT SPEEDS OVER 20 MPH.

3. DO NOT STAND BETWEEN TRACTOR AND IMPLEMENT WHILE TRACTOR IS MOVING.

4. WHEN SERVICING IN RAISED POSITION, PLACE BLOCKING UNDER ROLLERS.

5. WITH WINGS FOLDED AND WEIGHT ON CENTER ROLLER, THE IMPLEMENT IS

DRAWBAR LIGHT.

5J859

3J678

528934

528933

3J678

WARNING

DO NOT GO NEAR LEAKS

HIGH PRESSURE OIL EASILY PUNCTURES

SKIN CAUSING SERIOUS INJURY,

GANGRENE OR DEATH.

IF INJURED, SEEK EMERGENCY MEDICAL

HELP. IMMEDIATE SURGERY IS

REQUIRED TO REMOVE OIL.

DO NOT USED FINGERS OR SKIN TO

CHECK FOR LEAKS.

LOWER LOAD OR RELIEVE HYDRAULIC

PRESSURE BEFORE LOOSENING FITTINGS.

3K706

10813A

Page 4A

5J801182rev501

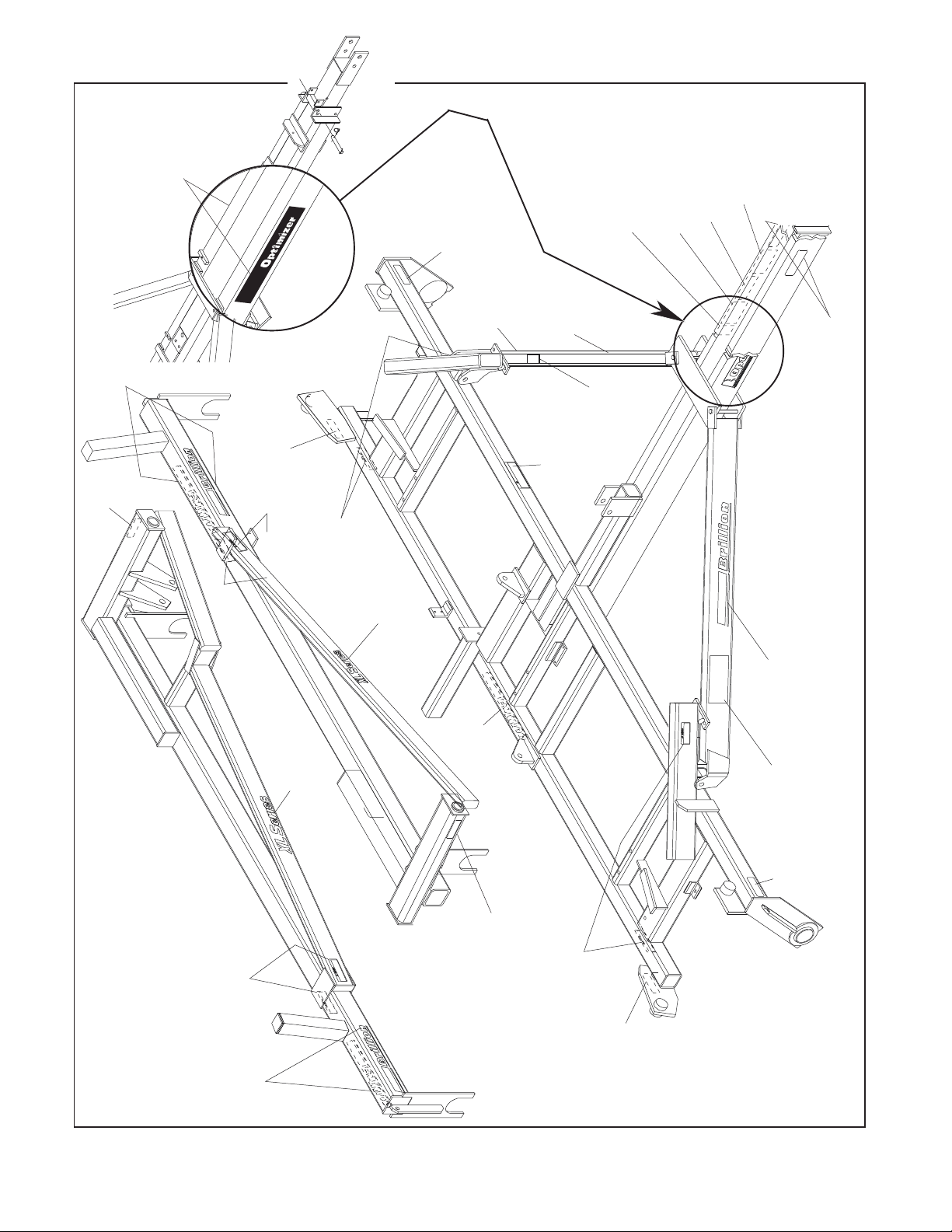

ADDITIONAL DECAL ON

4K036

BRILLION

528934

AMBER

OPTIMIZER MODEL

(Front & Back)

PULVERIZERS ONLY:

6K657

OPTIMIZER

(Both Sides)

528933

RED

REFLECTIVE

3J675

DANGER-FALLING

WINGS

(Front & Back)

528934

AMBER

REFLECTIVE

6J999

PULVERIZER FIELD

ADJUSTMENTS

4K036

BRILLION

3J678

DANGER

5J860-IMPORTANT

INSTRUCTIONS

5J859-CAUTION

3K706-DANGER

HYDRAULIC LEAKS

9J629-DANGER

8D387

PATENT

BLEED AIR

ELECTRICAL WIRES

DO NOT ALLOW...

528934 - AMBER

REFLECTIVE

(Both Sides)

PULVERIZER

4K157

XL SERIES

4K036

BRILLION

(Both Braces)

BRILLION

4K036

4K157

XL SERIES

6J999

PULVERIZER

FIELD

ADJUSTMENTS

528934

AMBER

LOCATIONS

DECAL

3J675

DANGER-FALLING WINGS

(Front & Back)

528934

AMBER

REFLECTIVE

3J675

DANGER-FALLING WINGS

528933

REFLECTIVE

RED

182rev0713

4K036

BRILLION

(Front & Back)

Page 4B

5J801

OPERATING INSTRUCTIONS

Designed Use

The folding pulverizer is designed to pull behind wide model field cultivators and discs. It can be used as an

individual unit with the tractor to prepare a seedbed or after seeding to breakdown and pulverizer large surface

clods. The long drawbar allows for easy, short turns when pulled behind other equipment.

Tractor Preparation

Lock tractor drawbar in center position. Do not allow the drawbar to wing, especially during

transport.

Pulverizer Preparation

Hydraulic oil capacity of pulverizer is approximately 4.8 gallons.

Clean hose fitting before connecting to tractor. It is also necessary during initial operation to watch tractor oil

level closely to avoid damage.

In field working position with the three cylinders at the end of their stroke the wing gang will be able to float

which allows them to follow the ground contour. At the same time the axle tires will be raised 4 inches off the

ground to avoid making tire tracks on the pulverized field.

Bleeding Hydraulic Cylinders

CAUTION: Escaping hydraulic fluid under pressure can have sufficient force to

penetrate the skin, causing serious personal injury. Relieve pressure in hydraulic lines

before uncoupling hydraulic hoses from tractor. On most tractors this can be done by

operating valves after engine is stopped. Before applying pressure to the system, be

sure all connections are tight and that lines and hoses are not damaged.

Hydraulic fluid escaping from a very small hole can be almost invisible. Use a piece of cardboard or a

piece of wood, rather than hands, to search for suspected leaks.

If injured by excaping fluid, see a doctor at once. Serious infection or recation can develop if proper

medical treatment is not administered immediately.

Bleed the air from the hydraulic system before moving the machine. Bleed the air from the transport system

first. This can be done by partially raising and lowering the machine slowly 5 or 6 times. Gradually increase

the length of stroke until the last two cycles are the full stroke on the cylinder.

Bleed the air from the wing folding system next. Raise center of machine, then push transport lock down.

Tighten the 1" nut in the transport cylinder anchor to hold the center up. For machines with manual transport

lock place or remove transport lock on hydraulic cylinder instead of tightening or loosening 1" nut. If the wings

are unfolded, begin partially folding them and then unfolding them again. When unfolding hold the tractor valve

to get the most oil in that side of the cylinder. Be careful that neither wing goes over 90°. Repeat this process

8 or 9 times gradually raising the wings closer to 90°. After bleeding procedure is complete loosen 1" nut in

the transport cylinder anchor to allow free movement.

If the wings were folded to start with, use the same procedures except start unfolding at the wings and then

refold them.

If it becomes necessary to drain the oil from one or more cylinder, it is important to bleed the air out of the

system before operating.

Change the machine from field position to transport position 2 to 3 times to insure the automatic transport lock

is functioning properly.

Page 5

5J801182rev501

Field Operation

Once the folding pulverizer has been transported to the field, unfold the wings completely. Reversing the hydraulic

level should allow the pair of compression springs to push transport lock up with automatic transport lock. After

this the implenent may be completely lowered. With manual transport lock reverse the hydraulic lever to allow

manual removal of cylinder transport lock.

During field operation, it is not necessary to raise the machine for turns, but turns should be as wide as possible.

Slow daown when operating on rocky soil.

HitchAdjustment (Used to Limit Soil Pushing)

The pulverizer drawbar can pivot vertically in field operation. The placenent of shims musst be identical on both

sides of pulverizer. See figure below for position of drawbar shims.

If the pulverizer continues to push soil, a 6J-194 manual valve kit can be added to hold the wings up at a preset

height. See setup instructions for installation. Raise wings to the desired height with tractor hydraulics and shut

off the valve. This allows some weight of the pulverizer wings to be transferred to the transport wheels, without

the hydraulic system raising the wings. With the tractor hydraulics being used to raise or lower the pulverizer the

outside end of the wings and the center frame will all raise or lower uniformly the same distance. The valve will

have to be opened to fold wings. When center section is raised slightly tire tracks of pulverizer will be left in the

field. Wing can float up with valve closed.

Page 6

5J801182rev501

Transport (With Manual Lock Models)

When changing from field position to transport position, raise center section completely without folding the

wings then install cylinder transport lock before folding the wings. Relieve the hydraulic pressure until the

cylinder transport lock is tight against the end of the cylinder barrel.

Transport (With Automatic Lock Models)

Fold the wings for transport. In transport relieve the hydraulic pressure until the cylinder transport lock is tight

against pin in the lift arm. There should be no need to do anything with pulverizer when going from field to

transport or transport to field.

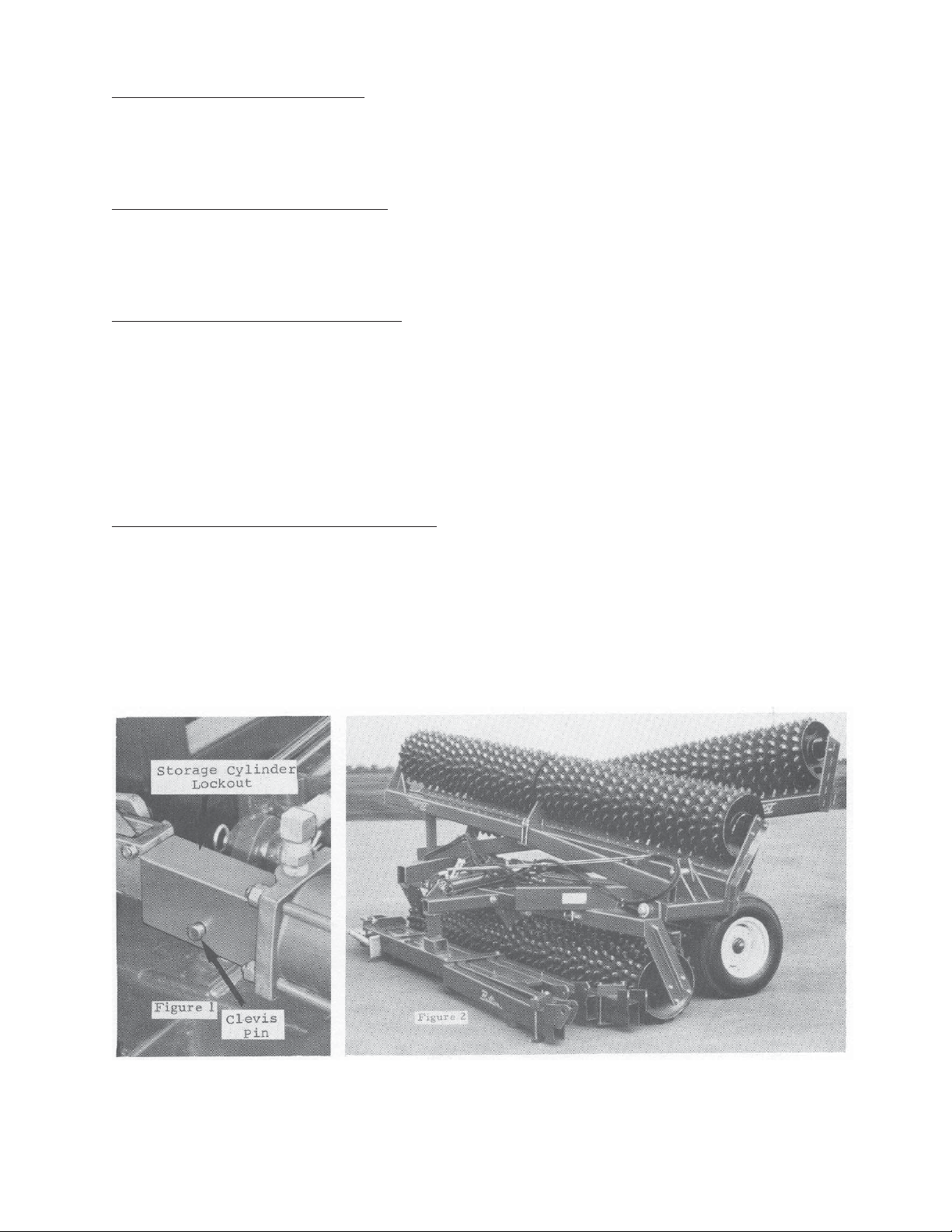

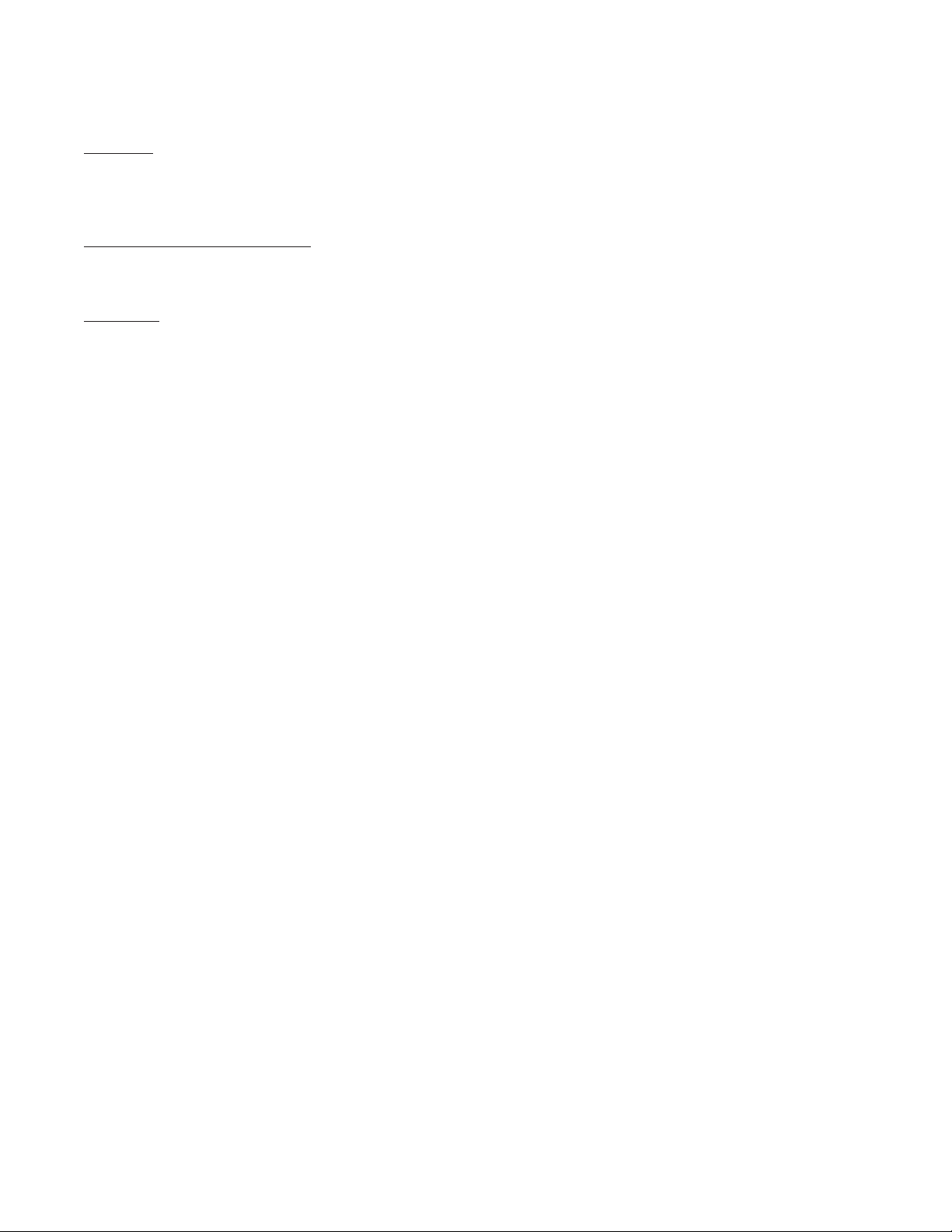

Storing Pulverizer With Drawbar Removed

Start with pulverizer in field position. It may be necessary to move some additional drawbar shims to the

bottom side of the drawbar braces. Install the storage cylinder lockout which is 5-1/2" long that is attached to a

hydraulic hose on the center cylinder. Fold the wings with the cylinder transport lock up, with 1" nut on center

cylinder anchor bolt tightened. Position pulverizer with tractor where it will be stored. Relive the hydraulic

pressure until the storage cylinder lockout is tight against the end of the cylinder barrel. Remove hydraulic line

brackets from the drawbar next. It is not necessary to break any hydraulic lines. Rest the hydraulic lines on

the center frame. The drawbar braces and drawbar can not be removed. For machines with manual transport

lock place or remove transport lock on hydraulic cylinder instead of tightening or loosening 1" nut.

Drawbar Attachment When Pulverizer Is Stored

Attach the drawbar and drawbar braces. Next assemble hydraulic lines to the drawbar. Refer to setup

instructions. Hitch tractor to drawbar. Raise center section and remove pulverizer from storage. Next unfold

wings completely then raise center section completely. Remove storage cylinder lockout and loosen 1" nut on

center cylinder anchor bolt slightly to allow free movement of transport lock. For machines with manual

transport lock place or remove transport lock on hydraulic cylinder instead of tightening or loosening 1" nut.

Page 7

5J801182rev501

MAINTENANCE

Fasteners

After a few hours of use check entire machine and tighten any loose nuts or bolts. Daily or periodic checks

should be made thereafter.

Tires For Dual Wheel Pulverizers

Recommended size of four tires are: 9.5L x 15 6 ply inflated to 28 psi or 11L x 15 6 ply inflated to 28 psi.

Lubrication

Grease zerk fittings daily. Locations are:

Transport axle bearings (bottom) - - - - 3

Hinge pins - - - - - - - - - - - - - - - 4 (2 per hinge)

The above items are not sealed and cannot be overgreased.

Wheel bearings should be repacked annually.

When Pulverizer is not used for some time, exposed cylinder rods should be cleaned and covered with a thick

coat of grease. This will prevent corrosion which will damage seals.

Page 7A

5J801182rev501

Page 7B

5J801182rev501

Page 8

5J801182rev501

Loading...

Loading...