Landoll WLS360, WLS360-I User Manual

®

WL360 Folding Pulvi-Mulcher

Models: WL360 WLS360

WL360-I WLS360-I

Operators Manual

LANDOLL CORPORATION

1900 North Street

Marysville, Kansas 66508

(785) 562-5381

800-428-5655 ~ WWW.LANDOLL.COM

190rev0512 9J577

Table of Contents

Introduction…………………………………………………………………………… 3

Location Reference…………………………………………………………. 3

Parts Ordering……………………………………………………………….. 3

Safety Suggestions………………………………………………………………...... 4

Operating Instructions……………………………………………………………….. 5

Bleed Hydraulic Systems…………………………………………………... 5

Hydraulic Lift…………………………………………………………………. 5

Depth Control………………………………………………………………... 6

Transport Lock………………………………………………………………. 6

Packer Wheel Adjustment………………………………………………….. 6

Scraper Adjustment…………………………………………………………. 6

Land Leveler Bar…………………………………………………………….. 6

Maintenance…………………………………………………………………………… 7

Fasteners……………………………………………………………………… 7

Tires…………………………………………………………………………… 7

Lubrication……………………………………………………………………. 7

Spring Teeth………………………………………………………………….. 7

Shipping Bundles……………………………………………………………………… 8

Common Items………………………………………………………………… 8

Distinct Items According to Teeth…………………………………………… 9

Assembly Instructions………………………………………………………………… 10

Basic Machine………………………………………………………………… 10

Hydraulics……………………………………………………………………… 17

Flat Bar Hitch (Optional)……………………………………………………… 25

Front Scraper (Optional)……………………………………………………… 25

Land Leveler (Optional)………………………………………………………. 25

Rear Hitch

(Optional)…………………………………………………………. 25

Independent Tooth Control…………………………………………………… 27

Specifications…………………………………………………………………………… 29

Model Designation…………………………………………………………….. 29

Basic machine Specifications………………………………………………… 29

Options………………………………………………………………………….. 30

Conversion Kits for Independent Tooth Control……………………………. 30

190rev601 Page I 9J577

To

obtain

this

section,

manual

manual

"Assembly

are

maximum

carefully

not

understood,

benefits

before

Instructions",

INTRODUCTION

from

the

starting

is

contact

Brillion

assembly

included.

your

Pulvi-Mulcher,

or

If

local

Brillion

operation.

items

covered

please

dealer

A

study

special

in

this

Location

Right

operator

Parts

When

serial

of

of

ordering

the

the

Reference

hand,

when

Ordering

number.

center

unit.

This

instructions

requires

instructions

before

repeated

You

will

this

that

personal

left

hand

sitting

parts

frame

for

Refer

tube.

Pulvi-Mulcher

Serial

safety

they

to

find

manual.

follows

injury

and

in

this

to

the

Number

alert

that

are

the

it.

forward

the

machine,

name

Please

symbol

concerning

you

furnished

allowed

employees

this

It

Qperating

Model

symbol

is

important

Read

or

death.

designations

plate

record

is

personal

explain

with

to

at

it

and

position.

include

on

these

used

this

the

on

be

the

to

the

machine

operate

beginning

your

to

take

alert

are

the

complete

small

numbers

call

.

safety.

safety

it.

machine

note

to

those

gusset

upon

your

to

of

the

related

model

taking

attention

Federal

and

These

and

of

possibility

near

operating

all

employees

each

throughout

the

number

the

delivery

law

must

season.

message

to

the

and

front

to

be

of

Date

Be

sure

which

Return

card

190ev601 9J577

is

the

for

to

read

shipped

proper

recording

the

with

portion

Purchased

warranty

the

at

the

card

machine.

of

the

factory.

Page 3

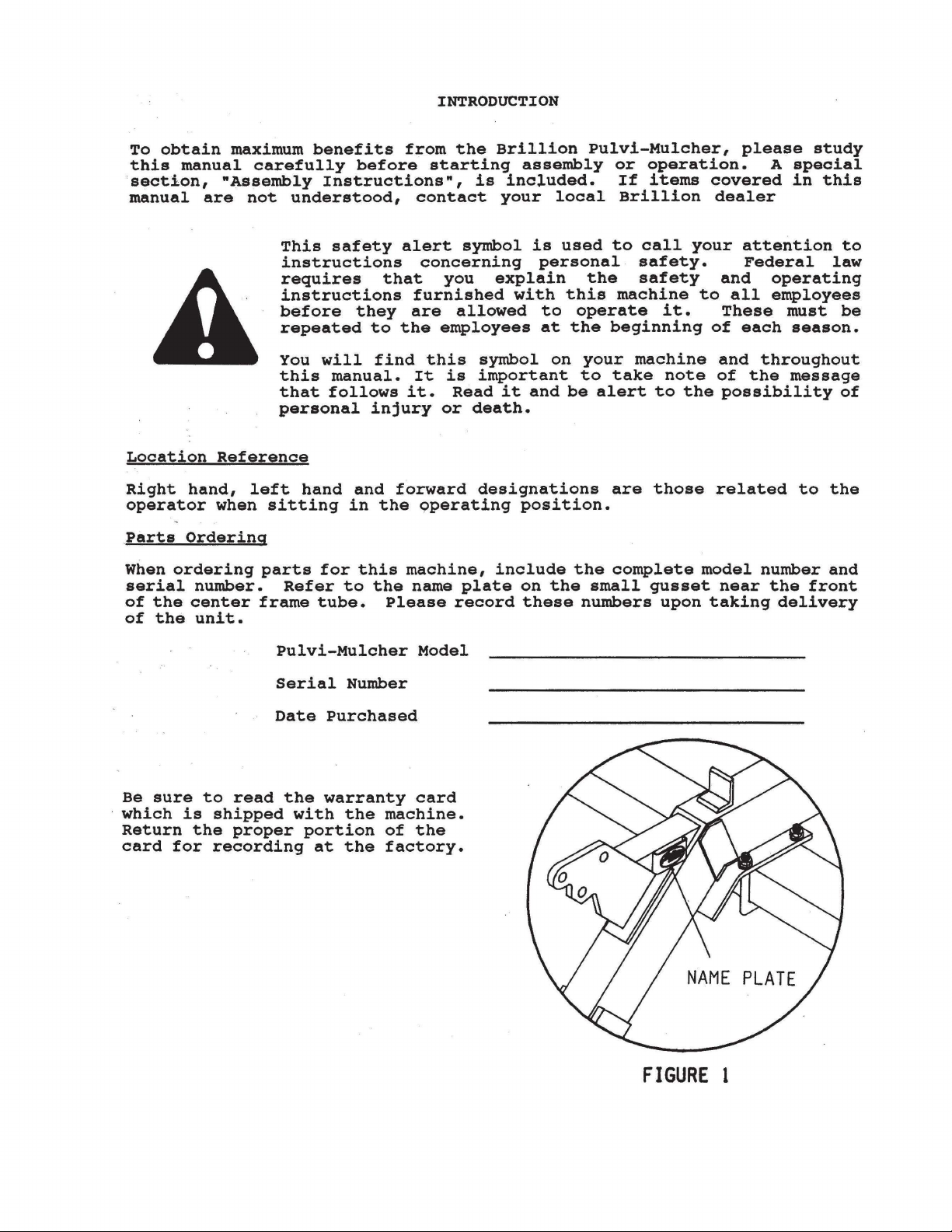

FIGURE

1

~

SAFETY

SUGGESTIONS

~

Investigation

caused

safety

working

1.

2.

3.

4.

S.

6.

7.

8.

by

by

with

Do

hot

detaching

Do

not

Do

not

Always

machine

the

transport

transport

Do

not

Avoid

cause

may

than

machine.

Use

caution

sharp

When

warning

required.

has

shown

careless

observing

you

or

stand

implement

make

allow

use

transport

sudden

turns

transporting

adjustments

anyone

transport

has

two

locks

stops

operator

when

may

symbols,

use

of

the

for

you

between

transport

axle,

and

at

or

to

Do

not

towing

cause

the

reflectors,

that

unless

to

the

speeds

turns

allow

nearly

machinery.

following

abide

the

or

ride

locks

locks,

as

well

lock

when

lose

control

tractor

behind

the

machine

machine

suggestions.

by

tractor

both

lubricate

on

tractor

when

transporting

as

pin

over

transporting

articulated

on

lights,

20 mph.

one-third

You

can

them.

and

are

not

machine

one

near

a

lock

must

be

of

tractor.

drawbar

to

slip

a

road

and

of

all

do

your

Insist

implement

moving.

while

or

machine.

the

each

pin

on

used.

because

to

swing

steering

sideways.

or

highway,

slow

moving

farm

when

machine.

hydraulic

the

Use a tractor

when

·

accidents

part

it

weight

tractors;

in

that

attaching · or

is

drawbar.

transporting.

use

vehicle

improving

all

people

in

motion.

This

cylinder

of

machine

heavier

fast

adequate

signs

ara

model

on

Both

.

or

as

9.

10.

11.

12.

13.

14.

15.

16.

17.

Lower

Block

Relieve

from

after

Securely

case

Use

roads

Escaping

penetrate

pressure

lines

Hydraulic

invisible.

hands,

Do

wings.

Do

bleeding

tractor.

of

of

not

not

machine

machine

engine

or

and

to

fold

pressure

block

hydraulic

a

safety

highways.

hydraulic

the

to

the

hoses

fluid

Use a

search

allow

or

the

air

to

ground

so

it

in

On

is

stopped.

machine

chain

skin,

system,

are

escaping

piece

for

anyone

unfold

from

will

hydraulic

most

failure

tractors

when

is

See

pg.

fluid

causing

not

suspected

near

the

the

when

be

damaged.

of

not

in

use.

not

roll

working

or

inadvertent

recommended when

7.

under

serious

sure

from

cardboard

the

wings

hydraulic

when

lines

pressure

machine

this

on

all

a

leaks.

or

operate

before

personal

very

can

connections

or a piece

system.

unhitched

uncoupling

be

or

under

lower~ng

can

small

when

the

done

it

towing

have

injury.

hole

of

folding

machine

from

by

to

sufficient

are

tractor.

hydraulic

operating

prevent

by

another

machine

Before

tight

can

wood,

or

unfolding

without

injury

on

force

applying

and

be

rather

hoses

valves

in

person.

public

to

that

almost

than

the

first

190ev601 9J577

Page 4

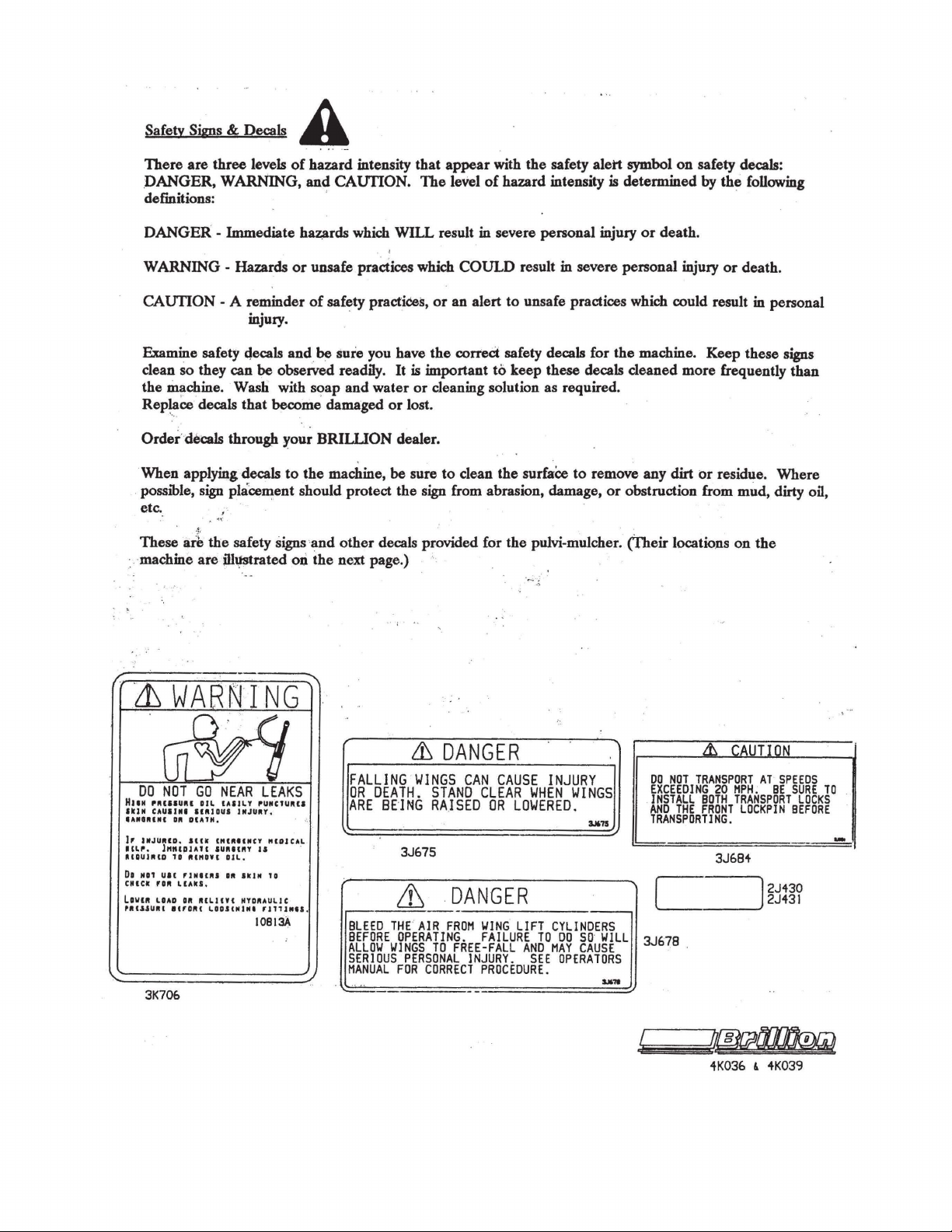

Safety Sims & De<ab A

There are three levels

of

hazard intensity that appear with the safety alert symbol on safety decals:

DANGER, WARNING, and CAUTION. The level

defmitions:

DANGER - Immediate hazards which WILL result

WARNING - Hazards

CAUTION - A reminder

or

unsafe practices which COULD result

of

safety practiees,

or

an alert to unsafe practices which could result in personal

injury. ·

Examine safety 4ecals

clean so they can be observed readily.

the

m~chine.

Rep~ce

Order

d~cals

Wash with s9ap and water

decals that become damaged

through your

·When applying decals

. possible, sign

etc.

These

plaee~ent

.

~

..

,.

,t,

ai~

the safety signs 'and other decals provided for the pulvi-mulcher. (Their locations on the

and

be sure you have the correct safety decals for the machine. Keep these signs

It

is

important

or

cleaning solution as required.

or

lost.

BRILUON

to

the machine, be sure

dealer.

. . .

to

should protect the sign from abrasion, damage,

machine are illt1strated oti the next page.)

of

hazard intensity

in

severe personal injury

in

to

keep these decals cleaned more frequently than

is

determined

or

death.

severe personal injury

clean the surfaee to remove any dirt

or

obstruction from mud, dirty oil,

by

the following

or

death.

or

residue. Where

Jp

IMJURlD.

ULP.

UOUUCO

D1

NDT

CUCk

lOIIIR

PIICUUNI

3K706

l""CDIAH

u ·

Ull

PDR

llAkS.

lOAD

IIPOIII

llU

Rl"DH

PIUUU

DR

C"CIIIlMCY

IUUIIIY

ftCLJUC

lODJINJHI

Oil.

IR

lkllt

NYDIIAUliC

"'OICAL

II

ID

P11111tU.

10813A

&

&

DANGER

DO

FALLING

OR

ARE

.

BLEED

BEFORE

ALLOW

SERIOUS

MANUAL

WINGS

DEATH.

BEiNG

3J675

ffi

THE

AIR

OPERATING.

WINGS

PERSONAL

FOR

CORRECT

CAN

STAND

RAJSED

TO

CLEAR

OR

.

DANGER

FROM

WING

FAILURE

FREE-FALL

INJURY.

PROCEDURE.

CAUSE

INJURY

WHEN

LOWERED.

LIFT

CYLINDERS

TO

DO

AND

MAY

SEE

OPERATORS

WINGS

:una

SO

WILL

CAUSE

NOT

EXCEEDING

INSTALL

AND

THE

TRANSPORTING.

r--~2J430

L_____)

3J67.8 .

CAUTION

TRANSPORT

BOTH

FRONT

AT

20

MPH;

TRANSPORT

LOCKPIN

3J681-

2J431

SPEEDS

BE

SURE

LOCKS

BEFORE

TO

-·

I

Page 4A

O[!][JlltJIJIJJrJ?iiJ

4K036

Ia

4K039

9J577190ev601

190ev601 9J577

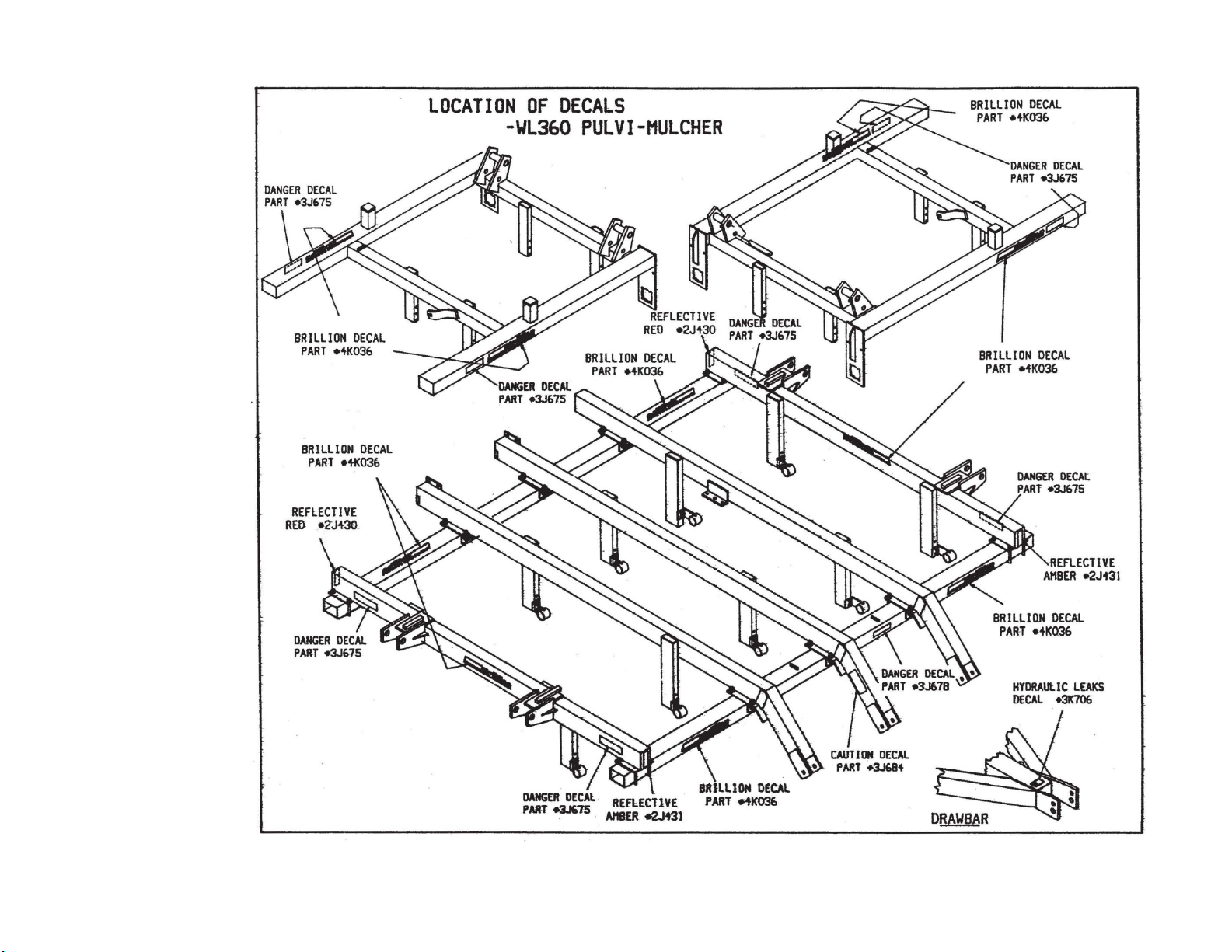

LOCATION

OF

-WL360

DECAlS

PULVI-HULCHER

BRILLION

PART

•+K036

DECAL

Page 4B

BRILLION

PART

•+K036

LEFT HAND WING

DECAL

RIGHT HAND WING

BRILLION

PART

DECAL

•+K036

DANGER

DECAl.

PMT •3.1615

REflECTIVE

Aft8ER

~1

HYDRAUliC

DECAL

•31C706

LEAKS

OPERATING INSTRUCTIONS

Bleeding

.

·

A

Bleed

cylinders,

linders

ly

be

gallons

tor

Hydraulic

This

circuit

The

the

retract

reconnected

oil

machine

other

Hydraulic

The

tractor,

opened,

must

before

The

flow

cylinder

may

first

be

wings

restrictor

cause

system

loosening

so

the

all

of

oil

level

Lift

controls

circuit

System

time

or

any

air

must

taken

they

to

is

have

depend

is

not

damage

by

rod

ends

cylinders

to

the

to

fill

avoid

hydraulically

the

folds

the

machine

time

be

not

to

been

upon

to

keep

full

to

removing

hose

lift

lift

ties

are

five

-

the

damage.

of

and

the

bled

raise

of

the

upward.

links.

hydraulic

unfolds

hydraulic

from

run

partway

the

passage

from

oil

machine.

the

rod

as

or

six

controlled

the

machine

is

connected

the

the

wings

free

the

end

needed,

Then,

times.

It

takes

systems.

the

circuit

system.

up

of

falling.

wing

pins

and

by

and

wings.

to

the

is

Care

up

over

7

or

8

times.

oil

through

If

will

fully

approximately

two

the

from

turning

Rod

Check

circuits.

drop

the

extend

ends

tooth

center

the

and

wing

those

may

your

depth.

a

and

then

7

trac-

One

fold

cyful-

u.s.

The

sequence

1.

2.

3.

Tooth

equipped

full

the

to

be

bar

necessary

in

During

up

the

operating

The

wings.

can

operating

transport

stop

the

completely

cylinder

the

on

the

teeth

second

be

Teeth

Machine

Drawbar

with

valve

preset

hydraulic

preset

field

transport

be

on

If

raised

for

depth

position

and

depth.

retracted.

permitting

position.

operation,

retracted

rocky

circuit

the

drooping

slightly

the

rotate

raises

cylinder

depth

allow

soil.

controls

first

out

is

controlled

stops.

before

the

In

operation,

the

pressure

it

wheels

and

of

with

circuit

of

on

transport

extends

Always

This

drawbar

is

for

wide

the

the

this

ground.

operating

tooth

in

to

hold

not

turns,

turns

folding

wings

circuit.

is

as

wheels.

to

level

by

four

raise

control

the

transport

turn

necessary

retracts

to

flex

the

but

be

and

is

undesirable,

follows:

machine.

hydraulic

the

~achine

the

machine

cylinders

and

tooth

to

it

is

made.

unfolding

cylinders

into

to

to

cylinders

the

providing

control

raise

recommended

Slow

small

cylinders

the

down

of

the

the

release

retract

must

drawthe

machine

that

when

the

wings

Page 5

9J577190ev601

A

Always

raised

the

roller

raise

into

and

transport

bearings

lower

the

position

and

the

wings

to

end

with

ease

roller

the

machine

the

clamps.

side

load

on

Depth

In

above,

front

shallower

links

through

lower

Transport

To

To

Control

addition

and

between

and

prepare

1.

2.

3.

NOTE:

prepare

there

rear

than

the

through

Lock

Raise

Fold

Install

rear

cylinder.

to

the

is

also

teeth.

the

the

inner

machine

machine

the

and

FAILURE

DAMAGE

for

field

hydraulic

the

The

front

front

or

shortest

the

end

for

transport:

wings.

the

pins

the

TO

TO

pin

LOCK

MACHINE.

operation:

option

rear

tooth

and

or

fully

in

in

BOTH

tooth

to

tooth

bar

rear

longest

tooth

hole

on

transport

the

the

TRANSPORT

depth

vary

bar

by

adjusting

in

the

hole

two

transport

linkage

control

the

can

bars.

links

to

under

LINKS

depth

be

the

Place

to

run

wheels.

links

the

MAY

mentioned

between

set

deeper.

deeper

connecting

the

pins

run

shal-

in

hitch

RESULT

the

or

the

IN

1.

2.

3.

Packer

Allow

If

wheels

er

axle

Scraper

Set

scrapers

wheels

the

axle

versible.

Land

Adjust

quired

lumps

ahead

damage

Leveler

that

of

Unfold

Raise

Remove

located

Wheel

just

will

the

job.

the

enough

become

and

Adjustment

pipe

leveler

are

the

leveler

tighten

move

Its

bar,

wings.

machine

transport

on

near

Adjustment

looseness

worn,

as

to

clear

back

and

wheel

Bar

bar

purpose

above

it

bar

the

is

slightly

lock

the

loosen

needed.

wheels

slightly,

hub.

to

the

is ·to

normal

set

and

possibly

pins

top

so

each

the

by

1/8

taking

Scrapers

highest

break

ground

too

low.

to

loosen

of

wheel

clamp

11

other

and

store

the

lugs.

at

to

3/16".

up

for

position

up

and

level.

Striking

transport

will

the

the

clearance

20"

that

scatter

If

large

parts

in

storage

turn

end

of

In

operation,

wheels

soil

of

the

lock

by

itself.

each

are

does

any

pushes

rocks

machine.

pin.

hole

roll-

between

re-

the

large

re-

will

190ev601 9J577

Page 6

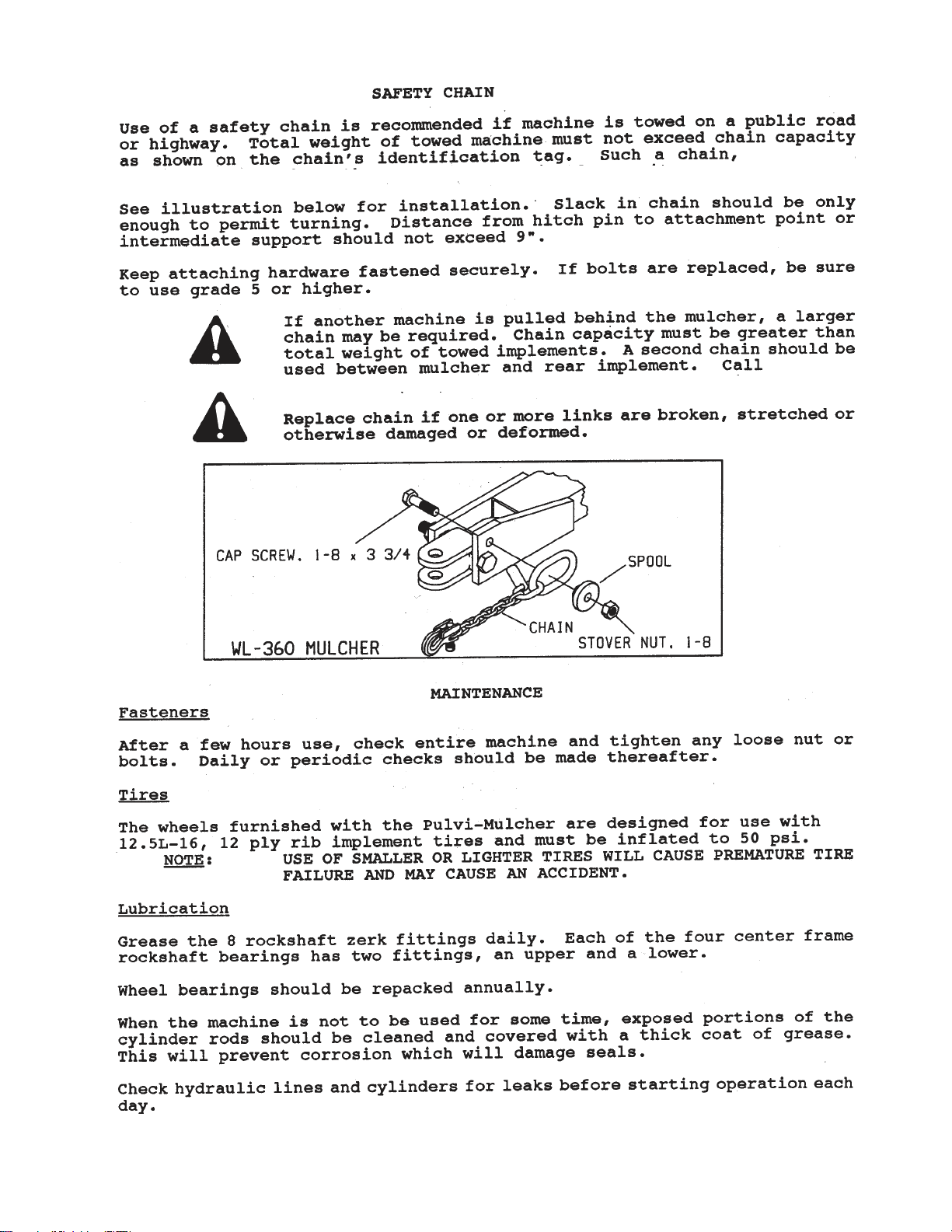

equipment.

is standard

your Brillion dealer if you are uncertain.

Page 7

9J577190ev601

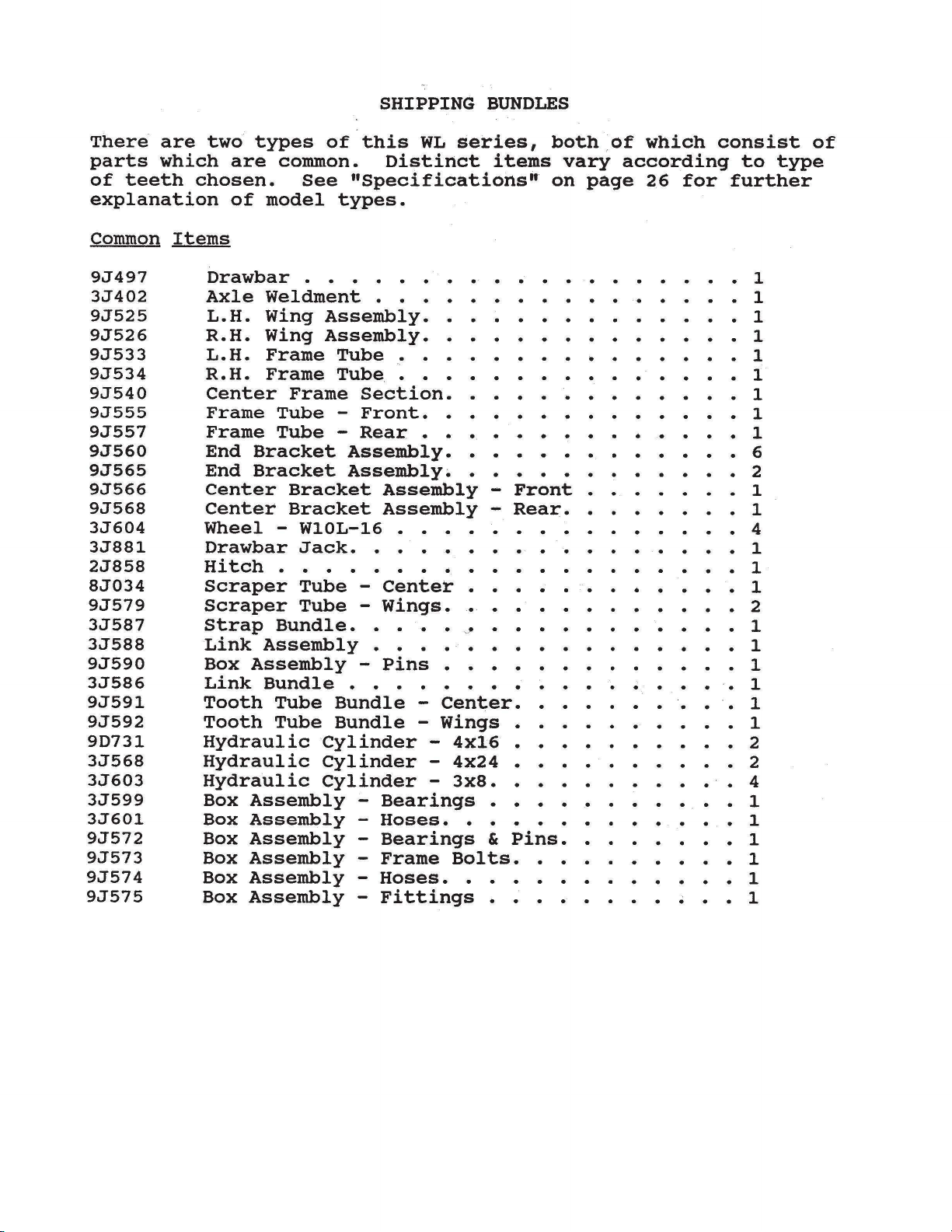

SHIPPING

BUNDLES

There

parts

of

are

which

teeth

explanation

Common

Items

9J497

3J402

9J525

9J526

9J533

9J534

9J540

9J555

9J557

9J560

9J565

9J566

9J568

3J604

3J881

2J858

8J034

9J579

3J587

3J588

9J590

3J586

9J591

9J592

90731

3J568

3J603

3J599

3J601

9J572

9J573

9J574

9J575

two

types

are

chosen.

of

model

Drawbar

Axle

L.H.

R.H.

L.H.

R.

Weldment

Wing

Wing

Frame

H.

Frame

Center

Frame

Frame

End

End

Bracket

Bracket

Center

Center

Wheel

Drawbar

Hitch

Scraper

Scraper

Strap

Link

Box

Link

Assembly

Assembly

Bundle

Tooth

Tooth

Hydraulic

Hydraulic

Hydraulic

Box

Box

Box

Box

Box

Box

Assembly

Assembly

Assembly

Assembly

Assembly

Assembly

of

common.

See

this

"Specifications••

WL

Distinct

series,

items

both,of

vary

on

according

page

which

26

for

consist

to

further

types.

. . . . . . . .. . . . . . . . . . . . 1

• • • • • • • • • • • . • • 1

Assembly.

Assembly.

Frame

Tube

Tube

Tube

Tube

-

-

. . • • . • • . . 1

. • . • • . • • . • • 1·

Section.

Front.

Rear

Assembly.

Assembly

Bracket

Bracket

- W10LJack.

. . . . . . . . . . . . . . . . . . . . 1

Tube

Tube

Bundle.

Assembly

Assembly

16

. . . • • • . . • 4

. . • • • • . • . • • . • 1

-

Center

-

Wings.

• . • • ,. • • • . • • • . • 1

• • • • • . . • . • • 1

. . • • • • • • • • • 1

. • • . • • . . 1

• • . • • . . . • 1

• • • • • • • • . • • . • • 1

• • • • • • 6

•••••••.•••••

-

-

Front

Rear.

• . . 1

• . • • • 1

. • • • . • . • • . . • 1

• . • • . • • • 2

• • • • . • • • • . • • • • • 1

-

Pins

• • • • • • • . . • • . . 1

• • • • • • • • • • • . • • • • • 1

Tube

Tube

Bundle

Bundle

Cylinder

Cylinder

Cylinder

-

Bearings

-

Hoses.

-

Bearings

-

Frame

-

Hoses.

-

Fittings

-

Center.

-

Wings

-

-

-

• • • . • • • • • 1

• • . • • . . • 1

4x16

4x24

3x8.

• • • . . • 2

• • . . . • 2

• • . .

.•.•

• • • • • . . • • . • 1

• • • • . • • • 1

&

Bolts.

Pins.

• • • . • • • 1

• 1

• • • • • • • • 1

• • • • • • . • • • • 1

of

type

2

4

190ev601 9J577

Page 8

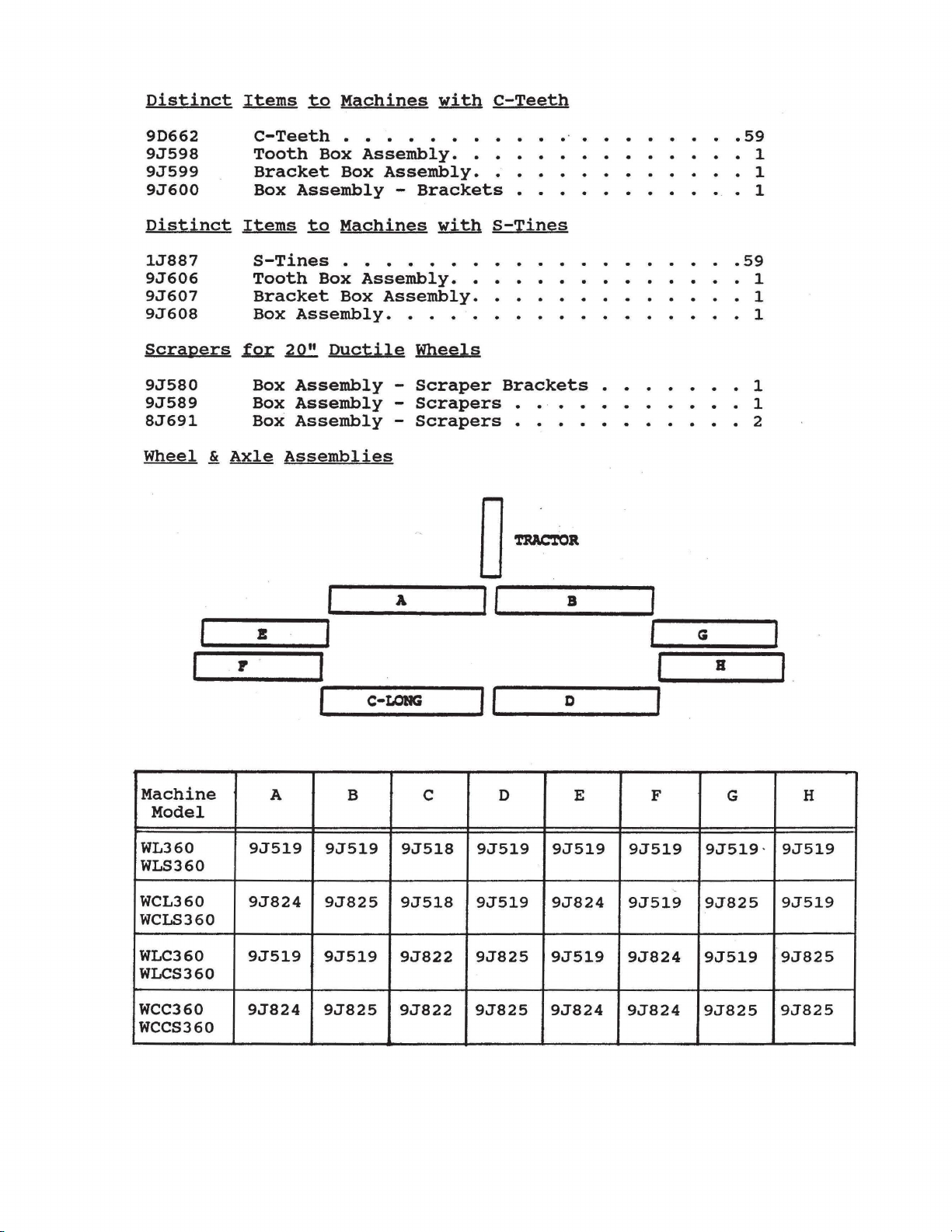

Distinct

Items

to

Machines

with

C-Teeth

9D662

9J598

9J599

9J600

Distinct

1J887

9J606

9J607

9J608

Scrapers

9J580

9J589

8J691

Wheel k Axle

C-Teeth

Tooth

Bracket

Box

Items

S-Tines

Tooth

Bracket

Box

~

Box

Box

Box

• • • • • • •

Box

Assembly

Box

Assembly

to

Machines

• • • • • • • •

Box

Assembly

Box

Assembly

~

Ductile

Assembly

Assembly

Assembly

Assemblies

•.•

Assembly

-

Brackets

with

•••

Assembly.

••.•••

Wbeels

-

Scraper

-

Scrapers

-

Scrapers

••

S-Tines

Brackets

. . . .

•

• . • . •

. . . . . 1

. . . . . 1

. . . . . . 1

•

••

..

59

. 1

. 1

59

• 1

• 1

. 1

• 2

~----~~----A----~'-'----8-----~----~

f

I

Machine

Model

WL360

WLS360

WCL360

WCLS360

WLC360

WLCS360

WCC360

WCCS360

!:

p

9J519

9J824

9J519

9J824

A

I

I

I

___

I

B

9J519

9J825

9J519

9J825

c_-LONG

___

c

9J518

9J518

9J822

9J822

.....

I

._I

___

D

9J519

9J519

9J825

9J825 9J824 9J824

c

__

E F

9J519 9J519 9J519

9J824

9J519

___.

9J519

9J824

I

f

I

,

G

H

G

9J825

9J519

9J825

I

I

·

9J519

9J519

9J825

9J825

H

Page 9

9J577190ev601

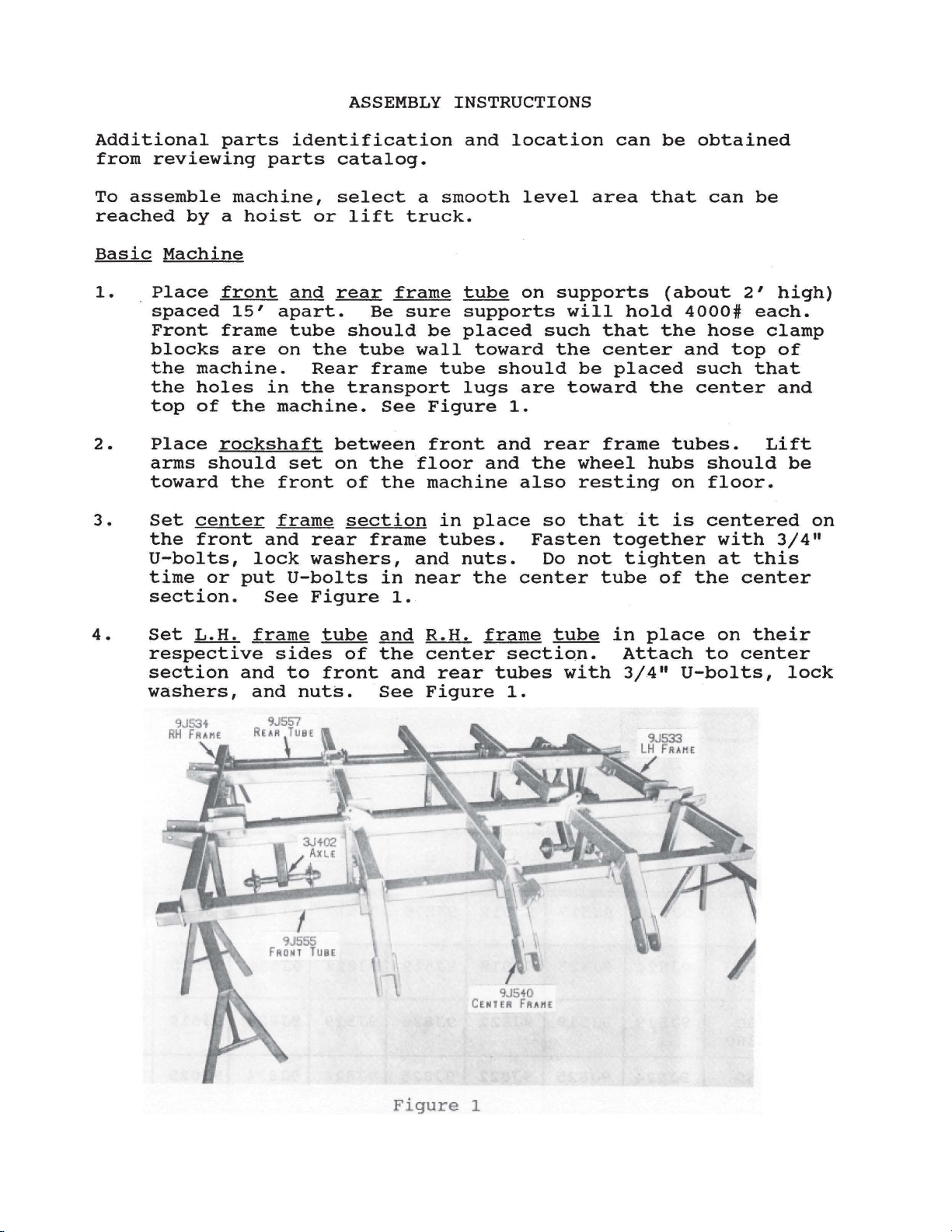

ASSEMBLY

INSTRUCTIONS

Additional

from

To

reviewing

assemble

reached

Basic

1.

Machine

Place

spaced

Front

blocks

the

the

top

2.

Place

arms

toward

3.

Set

the

U-bolts,

time

section.

parts

machine,

by

a

hoist

front

15'

frame

are

machine.

holes

of

the

rockshaft

should

the

center

front

or

put

identification

parts

or

and

apart.

tube

on

the

Rear

in

the

machine.

set

front

frame

and

rear

lock

washers,

U-bolts

See

Figure

catalog.

select

lift

rear

frame

Be

should

tube

frame

transport

See

between

on

the

of

the

section

frame

in

1.

a

smooth

truck.

sure

be

wall

tube

Figure

front

floor

machine

in

tubes.

and

near

and

location

level

tube

on

supports

placed

toward

should

lugs

are

1.

and

and

also

place

nuts.

the

center

supports

will

such

the

be

toward

rear

the

wheel

resting

so

that

Fasten

Do

not

can

area

hold

that

center

placed

frame

together

tighten

tube

that

the

hubs

it

be

obtained

(about

4000#

the

and

such

center

tubes.

on

is

of

the

can

be

2'

each.

hose

clamp

top

that

Lift

should

floor.

centered

with

at

this

center

high)

of

and

be

on

3/4"

4.

Set

L.H.

respective

section

washers,

frame

and

and

FKOII T

sides

to

nuts.

9J555

TUBE

tube

of

front

and

the

and

See

R.H.

center

rear

Figure

frame

section.

tubes

1.

tube

with

in

place

Attach

3/4

11

U-bolts,

to

on

their

center

lock

Figure

190ev601 9J577

Page 10

1

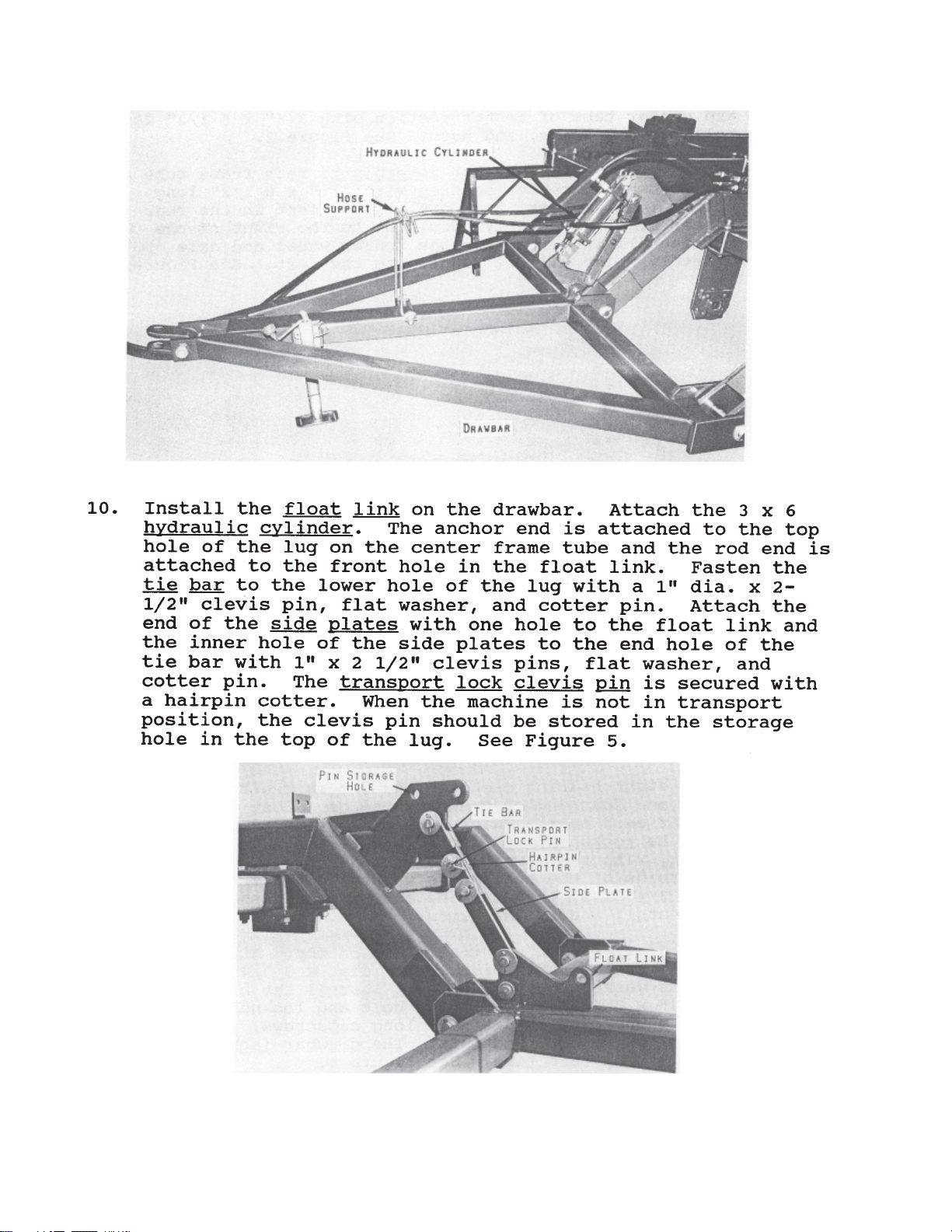

Figure 2

Figure 3

Page 11

9J577190ev601

Figure 4

Figure 5

190ev601 9J577

Page 12

Loading...

Loading...