Page 1

Volumetric Post-Mix Valve

STANDARD LEVER

Operation Manual

PN: 28-0301/04

SELF-SERVE LEVER

MODEL NO.

PORTION CONTROL

PUSH

PUSH BUTTON

Lancer Corp.

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Manual PN: 28-0301/04

APRIL 2012

FOR QUALIFIED INSTALLER ONLY

“Lancer” is the registered trademark of Lancer © 2014 by Lancer, all rights reserved.

Page 2

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product and should be handed over to the operator after the installation and preserved for any further consultation that may be necessary. Please read carefully the guidelines and warnings contained herein as they are intended to provide the user with essential information for the continued safe use

and maintenance of the product. In addition, it provides GUIDANCE ONLY to the user on the correct services and site

location of the unit.

The installation and relocation, if necessary, of this product must be carried out by qualied personnel with up-to-date

safety and hygiene knowledge and practical experience, in accordance with current regulations.

TABLE OF CONTENTS

SPECIFICATIONS................................................................................................................................3

1. PRICIPLE OF OPERATION........................................................................................................4

2. CLEANING AND SANITIZING INSTRUCTIONS.......................................................................5

3. VALVE SETUP.............................................................................................................................7

4. SYRUP RESTRICTOR SETTING...............................................................................................7

5. SYRUP PURGE PLUG...............................................................................................................7

6. PROGRAMMER OPERATING PROCEDURES.........................................................................8

7. PORTION CONTROL PROGRAMMING PROCEDURES..........................................................9

8. COVER AND ID PANEL...........................................................................................................10

9. VALVE.......................................................................................................................................11

10. LEVER ARM.............................................................................................................................11

11. NOZZLE/DIFFUSER.................................................................................................................12

12. CIRCUIT BOARD......................................................................................................................12

13. FLOWMETER...........................................................................................................................13

14. FLOW WASHER ASSEMBLY...................................................................................................14

15. SYRUP REGULATOR...............................................................................................................14

16. WATER SOLENOID ACCESS..................................................................................................15

17. WATER SOLENOID ASSEMBLY..............................................................................................17

18. SYRUP BODY ACCESS...........................................................................................................18

19. SYRUP SOLENOID ACCESS..................................................................................................20

20. SYRUP SOLENOID ASSEMBLY..............................................................................................21

21. TROUBLESHOOTING..............................................................................................................22

22. APPLIANCE DISPOSAL..........................................................................................................25

23. VOLUMETRIC VALVE ASSEMBLY..........................................................................................26

2

Page 3

ABOUT THE VALVE

THE VOLUMETRIC VALVE DISPENSES POST-MIX BEVERAGES ACCURATELY OVER A BROAD RANGE

OF PRESSURES AND SYRUP VISCOSITIES. CONFIGURATIONS, FROM A CUP LEVER TO A PORTION

CONTROL PANEL INTERFACE, ALLOW THE VOLUMETRIC VALVE TO FIT MANY DIFFERENT

APPLICATIONS. THE VOLUMETRIC VALVE MOUNTS TO A STANDARD LEV® BACK BLOCK AND

UTILIZES THE SAME COVER AS THE LEV®.

SPECIFICATIONS

FINISHED DRINK FLOW RATES:

• 3.0 ounces per sec (88.7 ml/sec), Standard

• 2.25 ounces per sec (66.5 ml/sec)

• 1.50 ounces per sec (44.4 ml/sec)

PRESSURE REQUIREMENTS:

Flowing pressure (at the valve)

Minimum Maximum

Water 40 psig 110 psig

(2.8 Kg/cm2) (7.7 Kg/cm2)

Syrup (Sugar) 20 psig 70 psig

(1.4 Kg/cm2) (4.9 Kg/cm2)

Syrup (Diet) 10 psig 70 psig

(0.7 Kg/cm2) (4.9 Kg/cm2)

ELECTRICAL REQUIREMENT:

24 VAC, 50/60 Hz

MOUNTING

Mounts on the same hole pattern with the same mounting screws as the following valves: Lancer LEV®

Cornelius SF-1 Dole SEV McCann Turbo Flo Jr. Dole FFV

MAINTENANCE TOOLS

When troubleshooting and accessing the Volumetric Valve, the following tools will be needed:

Standard

• #2 Phillips Head Screw Driver • Flat End Screw Driver

• Dow Corning® 111 Valve Lubricant & Sealant

• Volumetric Valve Hand Held Programmer (Lancer PN 52-1420/02; CCPN 532179)

Optional

• 3/16 inch Hex Socket Driver • Ohmmeter

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly inspected before shipment. At the time of

shipment, the carrier accepts responsibility for the unit. Upon receiving the unit, carefully inspect the carton

for visible damage. If damage exists, have the carrier note the damage on the freight bill and le a claim with

carrier. Responsibility for damage to the dispenser lies with the carrier.

3

Page 4

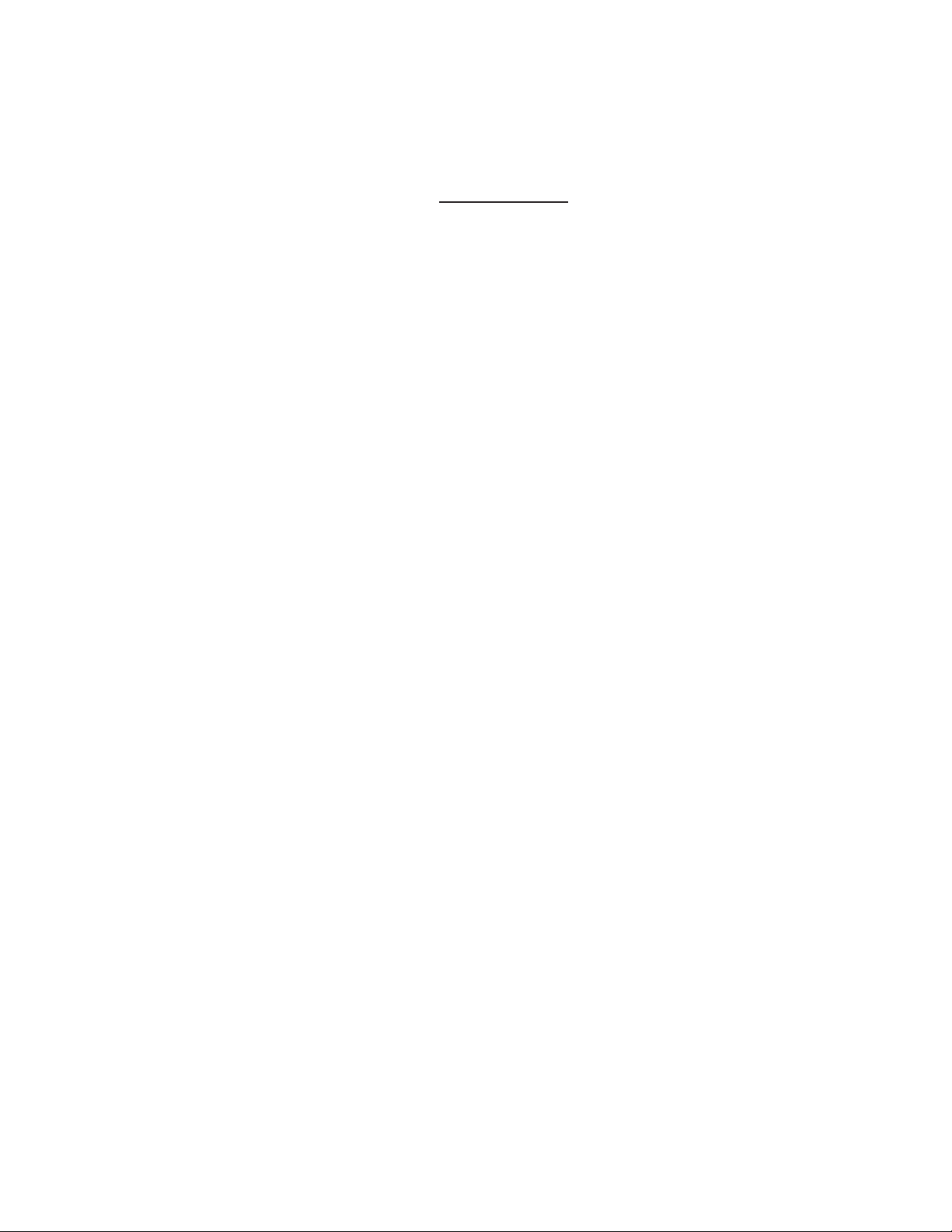

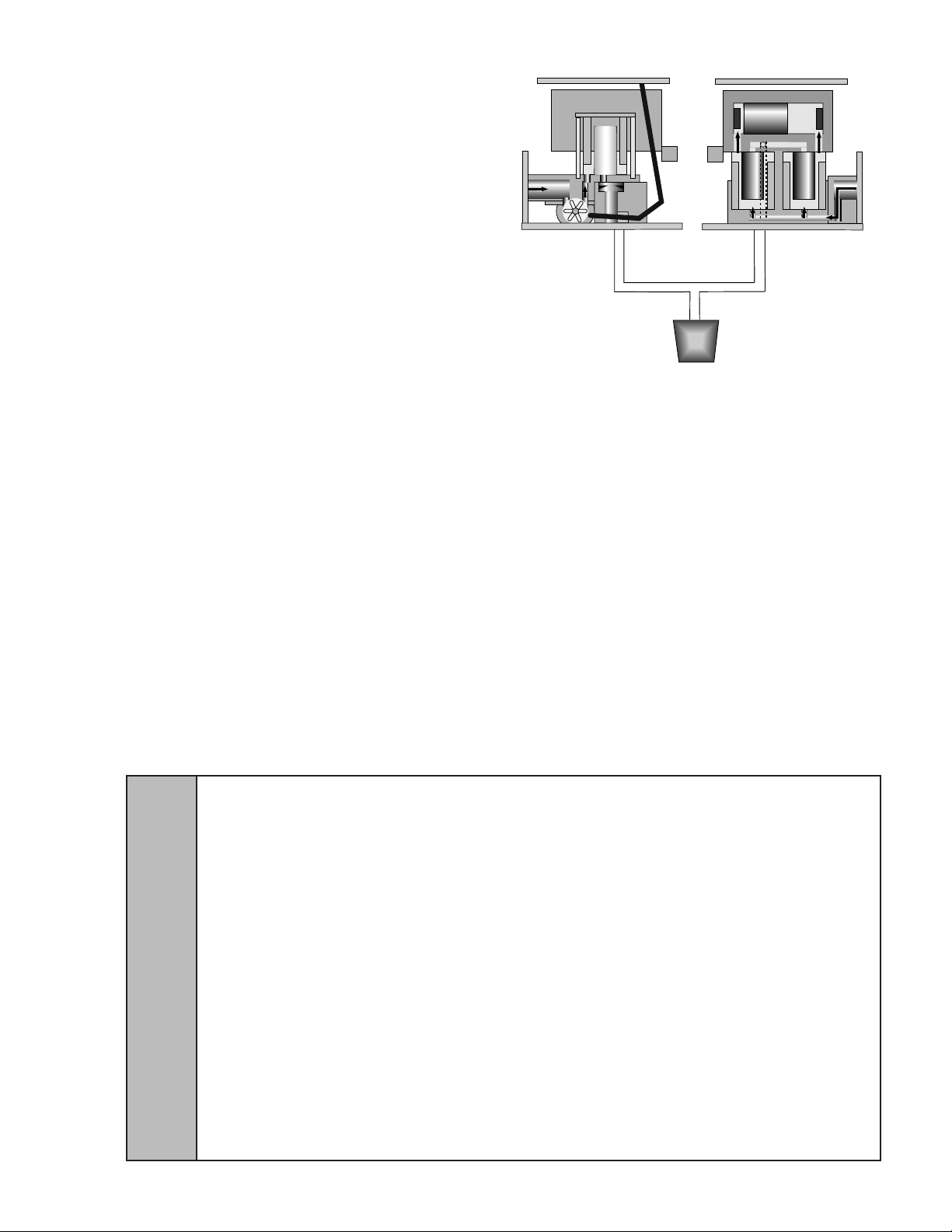

1. PRINCIPLE OF OPERATION

Syrup Chamber

Piston

Components:

S1

S1

S2

S2

Circuit Board

FIGURE 1. COMPONENTS

Water Syrup

Measuring

System

Water

Solenoid

Flowmeter

Flow Washer

Nozzle

W1

W1

S1

S1

S2

S2

Injecting

System

Syrup Solenoids

A. Three systems in the Volumetric Valve work together to maintain an accurate syrup to water ratio:

• The circuit board with its computer.

• The water measuring system.

• The syrup injecting system.

B. Set the ratio by using the hand held programmer (Lancer PN 52-1420/02; CCPN 532179).

C. When a customer activates the valve, the water starts owing to the nozzle. The ow washer en-

sures that the water does not ow too fast.

D. The paddle wheel in the owmeter begins to spin, sending signals to the circuit board (see below).

E. The computer on the circuit board monitors the signals and determines when to inject syrup into the

water stream. The circuit board energizes one syrup solenoid and then the other. This alternating

action injects a metered amount of syrup into the water. This happens seven to eight (7-8) times a

second (see Fig. 2 and 3).

F. The circuit board indicates which solenoid is activated with the LEDs mounted on the front of the

board. The green LED corresponds to the water solenoid and the red LEDs correspond to the syrup

solenoids.

FIGURE 2. OPERATION DIAGRAM - VALVE ON FIGURE 3. OPERATION DIAGRAM - VALVE ON

4

Page 5

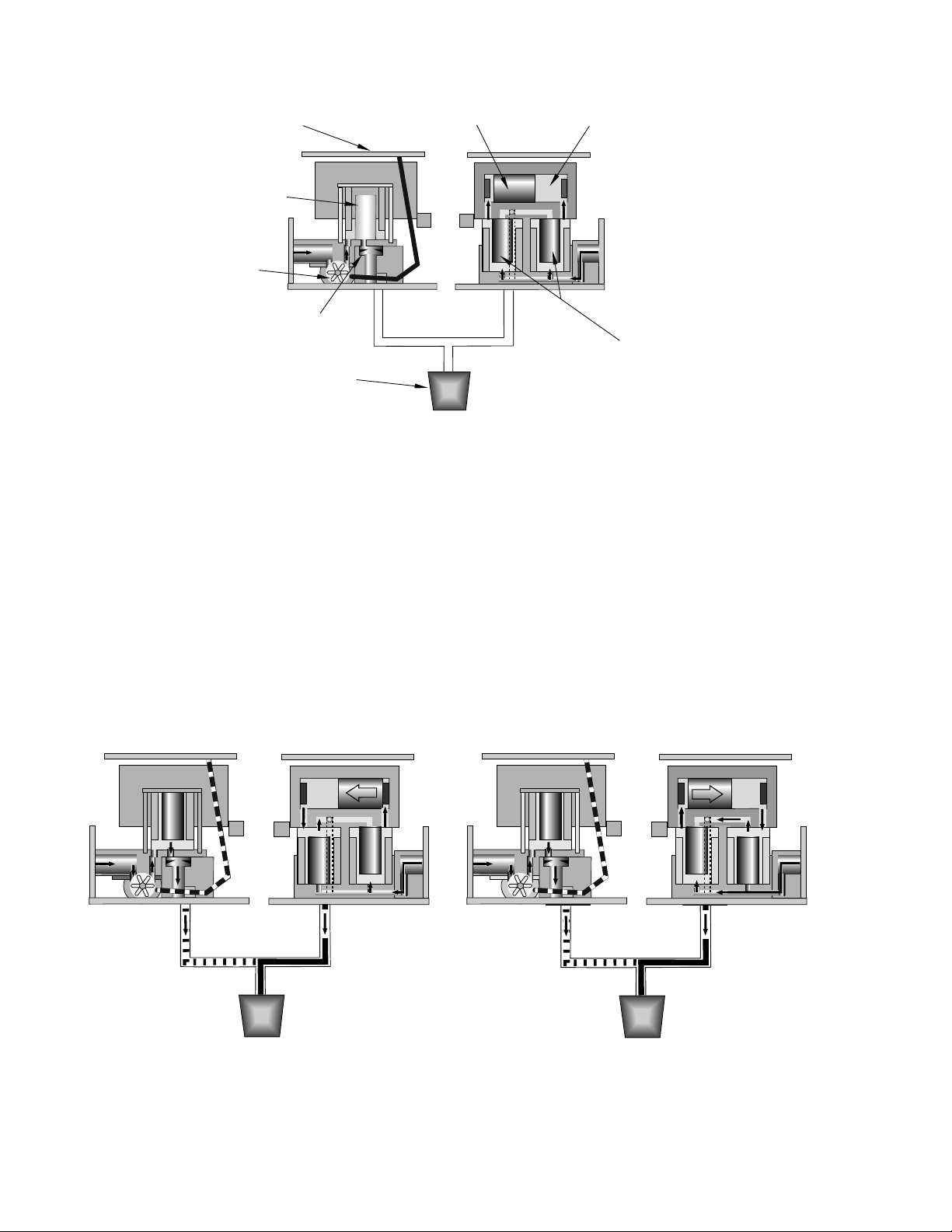

S1

S1

S2

S2

W1

W1

2. CLEANING AND SANITIZING INSTRUCTIONS

GENERAL INFORMATION

A. The cleaning and sanitizing procedures

provided pertain to the Lancer equipment

identied by this manual. If other

equipment is being cleaned, follow the

guidelines established by the manufacturer

for that equipment.

B. Lancer equipment (new or reconditioned) is

shipped from the factory cleaned and

sanitized in accordance with NSF

guidelines. The equipment must be cleaned

and sanitized after installation is complete.

The operator of the equipment must provide

continuous maintenance as required by this

manual and state and local health

department guidelines to ensure proper

operation and sanitation requirements are

FIGURE 4. OPERATION DIAGRAM - VALVE OFF

maintained.

C. Cleaning and sanitizing should be accomplished only by trained personnel. Sanitary gloves are to

be used during cleaning and sanitizing operations. Applicable safety precautions must be observed.

Instruction warnings on the product being used must be followed.

2.1 CLEANING SOLUTION

Mix a mild, non-abrasive detergent (e.g. Sodium Laureth Sulfate, dish soap) with clean, potable

water at a temperature of 90 to 110°F (32 to 43°C). The mixture ratio is one ounce of cleaner to two

gallons of water. Prepare a minimum of ve gallons of cleaning solution. Do not use abrasive

cleaners or solvents because they can cause permanent damage to the unit. Ensure rinsing is

thorough, using clean, potable water at a temperature of 90 to 110 degrees F. Extended lengths of

product lines may require additional cleaning solution.

2.2 SANITIZING SOLUTION

Prepare sanitizing solutions in accordance with the manufacturer’s written recommendations and

safety guidelines. The solution must provide 50 to 100 parts per million (PPM) chlorine (e.g. Sodium

Hypochlorite or bleach). A minimum of ve gallons of sanitizing solution should be prepared. Any

sanitizing solution may be used as long as it is prepared in accordance with the manufacturer’s

written recommendations and safety guidelines, and provides 50 to 100 parts per million (PPM)

chlorine.

!

WARNING IF A POWDER SANITIZER IS USED, DISSOLVE IT THOROUGHLY WITH HOT WATER PRIOR TO

ADDING TO THE SYRUP SYSTEM. ENSURE SANITIZING SOLUTION IS REMOVED FROM THE DISPENSER AS

INSTRUCTED. AVOID GETTING SANITIZING SOLUTION ON CIRCUIT BOARDS. DO NOT USE STRONG BLEACHES

OR DETERGENTS; THESE CAN DISCOLORAND CORRODE VARIOUS MATERIALS. DO NOT USE METAL

SCRAPERS, SHARP OBJECTS, STEEL WOOL, SCOURING PADS, ABRASIVES, OR SOLVENTS ON THE

DISPENSER. DO NOT USE HOT WATER ABOVE 140° F (60° C). THIS CAN DAMAGE THE DISPENSER.

ADVERTENCIA SI SE USA UN HIGIENIZADOR EN POLVO, DISUÉLVALO BIEN EN AGUA ANTES DE AGREGARLO

AL SISTEMA DE CONCENTRADO. EL USO DE AGUA CALIENTE CONTRIBUYE A DISOLVER LOS HIGIENIZADORES

EN POLVO. ASEGÚRESE DE HABER ELIMINADO LA SOLUCIÓN DE ESTERILIZACIÓN DEL

DISPENSADOR DE ACUERDO CON LAS INSTRUCCIONES. LOS RESIDUOS DE LA SOLUCIÓN DE

ESTERILIZACIÓN REPRESENTAN UN PELIGRO PARA LA SALUD. EVITE QUE LA SOLUCIÓN DE ESTERILIZACIÓN

LLEGUE A LAS PLACAS DE CIRCUITOS. NO USE LAVANDINAS NI DETERGENTES QUE PODRÍAN QUITAR EL

COLOR Y CORROER DISTINTOS MATERIALES. NO USE RASPADORES METÁLICOS, OBJETOS FILOSOS, LANA

DE ACERO, ESTROPAJOS, ABRASIVOS NI SOLVENTES EN EL DISPENSADOR. NO USE AGUA CALIENTE A MÁS

DE 140 ºF (60 ºC). PODRÍA DAÑAR EL DISPENSADOR.

AVERTISSEMENT AVANT L’INJECTION DANS LE SYSTÈME, IL FAUDRA QUE LA POUDRE SEPTIQUE SOIT

DISSOLUE ENTIÈREMENT DANS CHAUDE. L’EAU CHAUDE PERMETTRA UN MEILLEUR PROCÈS DE

DISSOLUTION. SUIVANT LES INSTRUCTIONS JOINTES, IL EST IMPÉRATIF QUE LA SOLUTION SEPTIQUE SOIT

ENTIÈREMENT ENLEVÉE. EVITEZ DE METTRE LA SOLUTION EN CONTACT AVEC LES CIRCUITS. N’UTILISEZ PAS

DE JAVELLISANTS OU DEDÉTERGENTS FORTS; CEUX-CI PEUVENT DÉCOLORER ET CORRODER DIVERS

MATÉRIAUX. N’UTILISEZ PAS DE RACLEURS EN MÉTAL, D’OBJETS POINTUS, DE LAINE D’ACIER, DE TAMPONS À

RÉCURER, D’ABRASIFS OU DE SOLVANTS SUR LE DISTRIBUTEUR. N’UTILISEZ PAS DE L’EAU CHAUDE DE PLUS

DE 140 DEGRÉS F (60 DEGRÉS C). CECI PEUT ENDOMMAGER LE DISTRIBUTEUR.

5

Page 6

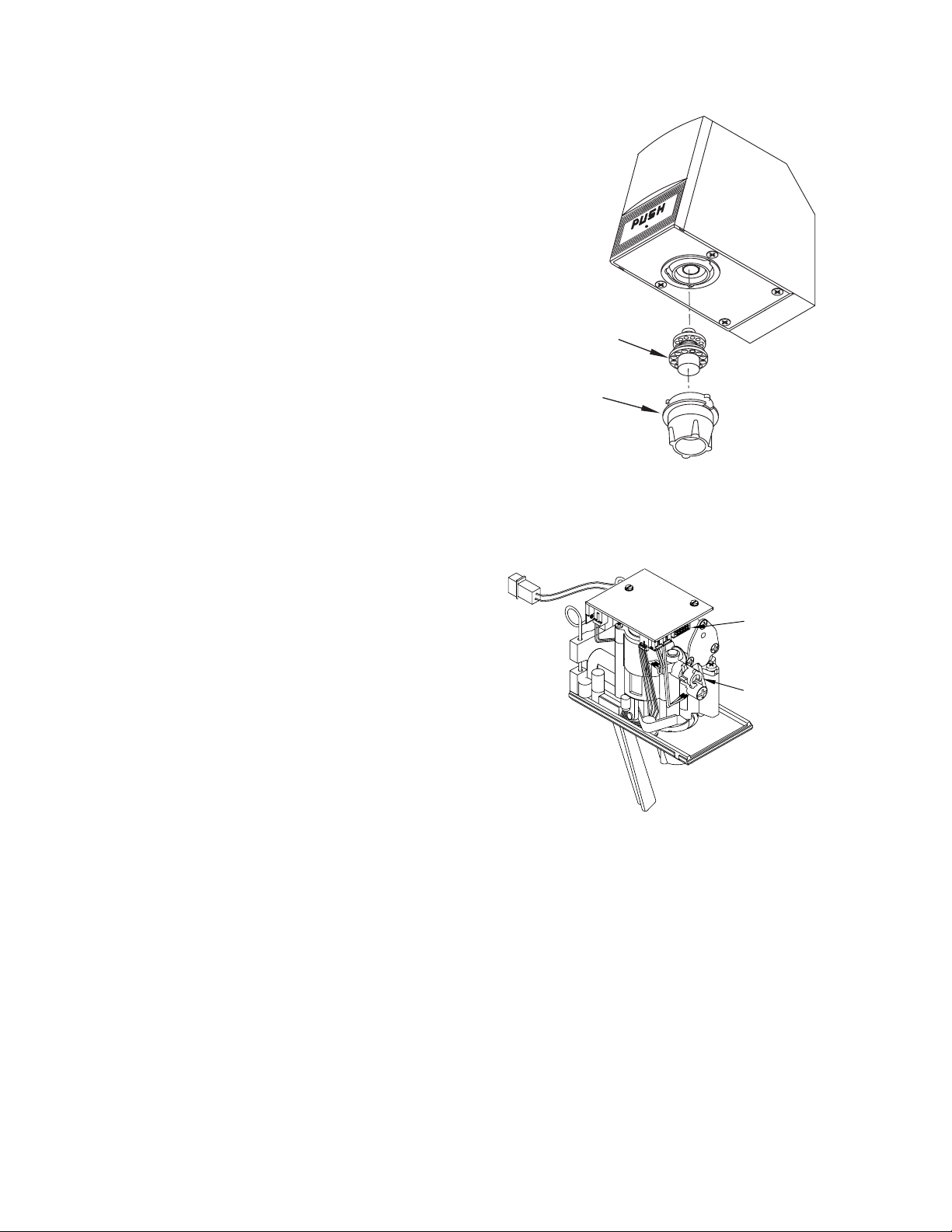

2.3 DAILY NOZZLE/DIFFUSER CLEANING (SEE FIGURE 5)

NOTE: Part Number in ( ) is a Coca-Cola PN

Plug (Programmer,

Syrup Restrictor

Portion Control,

Pushbutton, Syrup

Purge Plug)

Use the following procedures to clean the nozzle, and the

FIGURE 5. NOZZLE/DIFFUSER

diffuser assembly, each day:

A. Remove nozzle by twisting it counter-clockwise and

pulling it down.

B. Pull the diffuser assembly down to remove it from the

valve.

C. Wash the nozzle and diffuser with warm water.

D. If needed, apply 111 lubricant to the o-ring on the

diffuser assembly. Next, carefully press it into the

diffuser mounting area on the underside of the valve.

E. Install the nozzle by inserting it into the bottom plate

and twisting it clockwise to lock it in place.

2.4 MONTHLY NOZZLE/DIFFUSER SANITIZING

A. Disconnect power, so the valve will not be

Diffuser Assembly

54-0176/04

(24245)

inadvertently activated while cleaning.

B. Remove nozzle by twisting it counter-clockwise and

pulling it down.

C. Pull the diffuser assembly down to remove it from the

Nozzle

05-2053/01

(24246)

valve.

D. Wash the nozzle and diffuser with the cleaning

solution.

E. Immerse the nozzle and diffuser in a bath of the sanitizing solution for 15 minutes.

F. While the parts are in the sanitizing solution,

visually inspect around the nozzle mounting

FIGURE 6. NOZZLE/DIFFUSER

area on the valve for syrup residue. Using a

cloth or nozzle brush and warm water, clean

this area.

G. Wipe off the dispensing lever and any other

areas that may have been splashed by syrup.

H. Wearing sanitary gloves, remove, drain, and air

dry the nozzle and diffuser.

I. Wearing sanitary gloves, carefully press the

diffuser into the mounting area on the

underside of the valve.

J. Wearing sanitary gloves, install the nozzle by

inserting it into the bottom plate and twisting it

clockwise to lock it in place.

K. Connect power and replace cover. Valve is

ready for operation.

L. Draw drinks to ush residual sanitizing solution. Taste the beverage to verify that there is no off

taste. If an off taste is found, additional ushing may be required.

2.5 VALVE AND SYSTEM SANITIZING

A. The complete valve and dispenser system must be sanitized during initial installation. Follow

the manufacturer’s instructions when scheduling and conducting dispenser sanitizing. The

valve must be sanitized once every two weeks. The valve may remain on the dispensing tower

during the sanitizing process.

B. For syrup side line priming, and cleaning and sanitization procedures, refer to the Syrup Purge

Plug (Lancer PN 52-1912) in the Valve Set-Up Section.

6

Page 7

52-1912

SYRUP PURGE

3. VALVE SETUP

The following steps provide an overview of the valve set-up procedures:

A. Mount valve on back block (see Section 9).

B. Verify that power supply is 24 VAC, 50/60 Hz, then connect to valve.

C. Connect water (soda) and syrup supplies. Flowing pressures must meet valve specications (see

Specications, Page 3).

D. Set ratio and select carbonation. See Section 6 for hand held programmer procedures.

E. Set the syrup restrictor for either diet or sugar syrup (see Section 4).

F. Purge syrup lines using the hand held programmer (see Section 6).

G. Install valve cover, and if necessary, connect ID panel (see Section 8).

H. Activate valve to test dispensing.

4. SYRUP RESTRICTOR SETTING

A. SUGAR SYRUP AND DIET SYRUP FROM FIGALS: Restrictor out and down. Syrup restrictor is not

in use.

B. DIET SYRUP FROM BAG-IN-A BOX: Restrictor in and up. Syrup restrictor is in use.

5. SYRUP PURGE PLUG

A. The Syrup Purge Plug (PN 52-1912), places the valve in continuous syrup side operation.

B. The targeted uses for the purge plug consist of priming the syrup line on an initial Volumetric Valve

install, and for cleaning and sanitization of the syrup side of the dispensing unit.

5.1 OPERATION OF THE SYRUP PURGE PLUG

CAUTION VALVE CONSUMES 12VA IN A CONTINUOUS SYRUP SIDE OPERATION. USING A STANDARD 75VA

TRANSFORMER, UP TO SIX (6) VOLUMETRIC VALVES CAN BE OPERATED IN SYRUP PURGE MODE

SIMULTANEOUSLY.

PRECAUCIÓN LA VÁLVULA CONSUME 12VA EN UNA OPERACIÓN LATERAL DE OPERACIÓN DEL JARABE, US-

ANDO UN TRANSFORMADOR ESTÁNDAR DE 75VA, SE PUEDEN OPERAR HASTA SEIS (6) VÁLVULAS

VOLUMÉTRICAS SIMULTÁNEAMENTE EN UN MODO DE PURGA DEL JARABE.

!

ATTENTION LA PUISSANCE ÉLECTRIQUE CONSOMMÉE PAR L’ÉLECTRO-VANNE EST DE L’ORDRE DE 12

VOLTS-AMPÈRES EN COURS DE TRAITEMENT CONTINU DU CÔTÉ SIROP. LORSQU’UN TRANSFORMATEUR

STANDARD DE 75 VOLTS-AMPÈRES SERA UTILISÉ, JUSQU’À SIX (6) VANNES VOLUMÉTRIQUES POURRONT

ÊTRE MISES EN OEUVRE SIMULTANÉMENT EN MODE PURGE.

A. Turn off electrical power to all valves.

B. Install syrup purge plugs into the valve or

valves to be primed or sanitized. The syrup

purge plug installs in the ten-pin connector of

the Volumetric Valve circuit board.

C. Turn on electrical power to the valves. At this

time, the syrup side of the valves will begin

continuous operation.

D. When through with the priming or sanitization

operation, syrup purge operation can be

stopped either of two ways:

Method 1: Turn off electrical power to all valves,

remove syrup purge plugs from the valves.

Turn on electrical power to all valves. Tap valve

lever or push button to ensure proper operation

of all valves.

Method 2: Remove syrup purge plug from the valves while they are in purge operation. In this

case, the valve may continue in the purge mode for up to six (6) seconds after removal of the

E. Using a standard 75 VA transformer, up to six (6) Volumetric Valves can be operated in the

plug (this is normal). Tap valve lever or push button to ensure proper operation of all valves.

syrup purge mode simultaneously.

FIGURE 7. SYRUP PURGE PLUG

7

Page 8

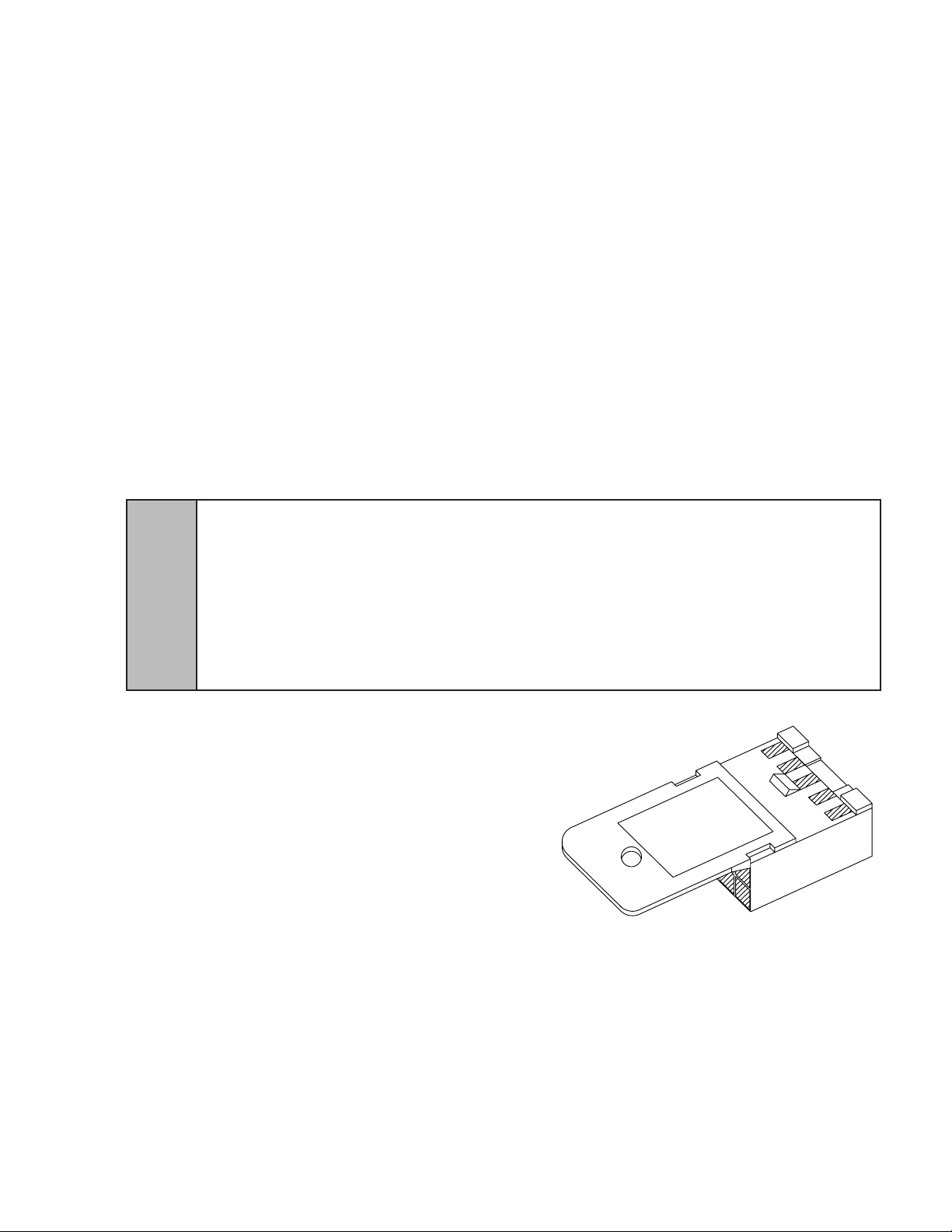

6. PROGRAMMER OPERATING PROCEDURES

6.1 CONNECTING

A. Remove the ID panel from the front of the valve.

B. Insert the programmer’s 10-pin connector into the ID

Panel plug on the front of the circuit board.

C. When properly connected, the programmer will run

a self diagnostic test. The display will show all “8”s

with the decimal points lighted.

After three (3) seconds, the display indicates the

setting of the dip switches.

D. If the programmer does not run its diagnostic test

properly, disconnect it and try plugging it in again. If

the programmer still fails, replace the programmer.

6.2 FUNCTIONS

Read Memory: Press to read and display the current settings programmed into the valve

memory (i.e., S/W revision, ratio, and carb/non carb settings).

Read Dip Switches: Press to read the dip switch settings. NOTE: Dip Swiches were used on

some eld test valves (refer to PN 28-0301, 12/20/95)

FIGURE 8 - HANDHELD PROGRAMMER

Write Memory: Press to write the programmer’s displayed ratio and carbonation settings into

the valve’s memory.

Timed 5 Second Water: Press to pour water for ve (5) seconds. The programmer will dis

play the ratio, the counts from the owmeter, the ow rate in oz/sec, and the ow rate in ml/

sec.

Timed 5 Second Pour: Press to dispense a ve (5) second pour of water and syrup for ratio

testing. When complete, the programmer displays the ratio, carbonation settings, and total

Flowmeter counts.

Syrup Purge: Press and release to dispense a six (6) second syrup purge. Continue holding

to purge syrup from system.

Ratio + (Plus): Pressing this button will increase the ratio number on the display.

Ratio - (Minus): Pressing this button will decrease the ratio number on the display.

Carb Toggle: Press to toggle the carbonation setting from carbonated “C” to non-carbonated

water “n”.

Pour/Stop: Press this button to manually pour a mixed drink. This button will also stop a

timed pour.

8

Page 9

6.3 SETTING THE RATIO/CARBONATION

A. Connect the programmer to the Valve.

B. Press the [Read Mem] button.

C. Press the [Ratio +] or the [Ratio -] key until the desired ratio is displayed.

D. Verify drink type. Press [Carb Toggle] to select [C] for carbonated or [n] for non-carbonated.

E. Press the [Enter] button to program the valve with the setting on the display

F. Verify Ratio by pressing [Read Mem].

G. Disconnect the programmer.

7.0 PORTION CONTROL PROGRAMMING PROCEDURES

The following procedures describe the operation and programming of portion control ID panels for the

Volumetric Valve.

7.1 OPERATION

A. Cup buttons are Small, Medium, Large, Extra-Large.

B. Press and release the desired cup size. Valve will ll cup as programmed (See below).

C. Pour/Cancel Button

1. Push and release to cancel or stop valve dispensing.

2. Push and hold for continuous pour.

D. Water Button

1. Push and hold for continuous water pour.

2. Valve will dispense carbonated or non-carbonated water, depending on its location on the

dispenser.

7.2 TEACH AND LEARN PORTION CONTROL PROGRAMMING

In this mode, the valve will record (learn) the steps to ll each cup size, including the top off

delay time. When activated, the valve dispenses the appropriate drink volume. If a top off has been

entered, the valve will pause for the programmed length of time. Finally, the valve will dispense the

correct top off amount.

A. Initial Install Procedure

1. Simultaneously, press and hold the small cup button and the extra-large cup button

switches on the portion control until the LED light in center of module starts blinking, then

release switches. The blinking LED indicates that the set mode is active.

2. Put desired amount of ice in cup, place cup under valve and push selected size button

(small, medium, large, or extra-large). Hold button in until cup lls to desired portion, then

release button.

3. Top off: If a top off is not needed, go to Step 4. Wait for foam to settle, then actuate button

again to top off. NOTE: Only one (1) top off is allowed.

4. Repeat steps 2 and 3 for other drink sizes. Go to Step 5 to exit program mode.

5. Press and release pour/stop button to return the portion control to the operational mode.

Blinking LED light will go out.

6. Repeat steps 1 through 5 for remaining valves.

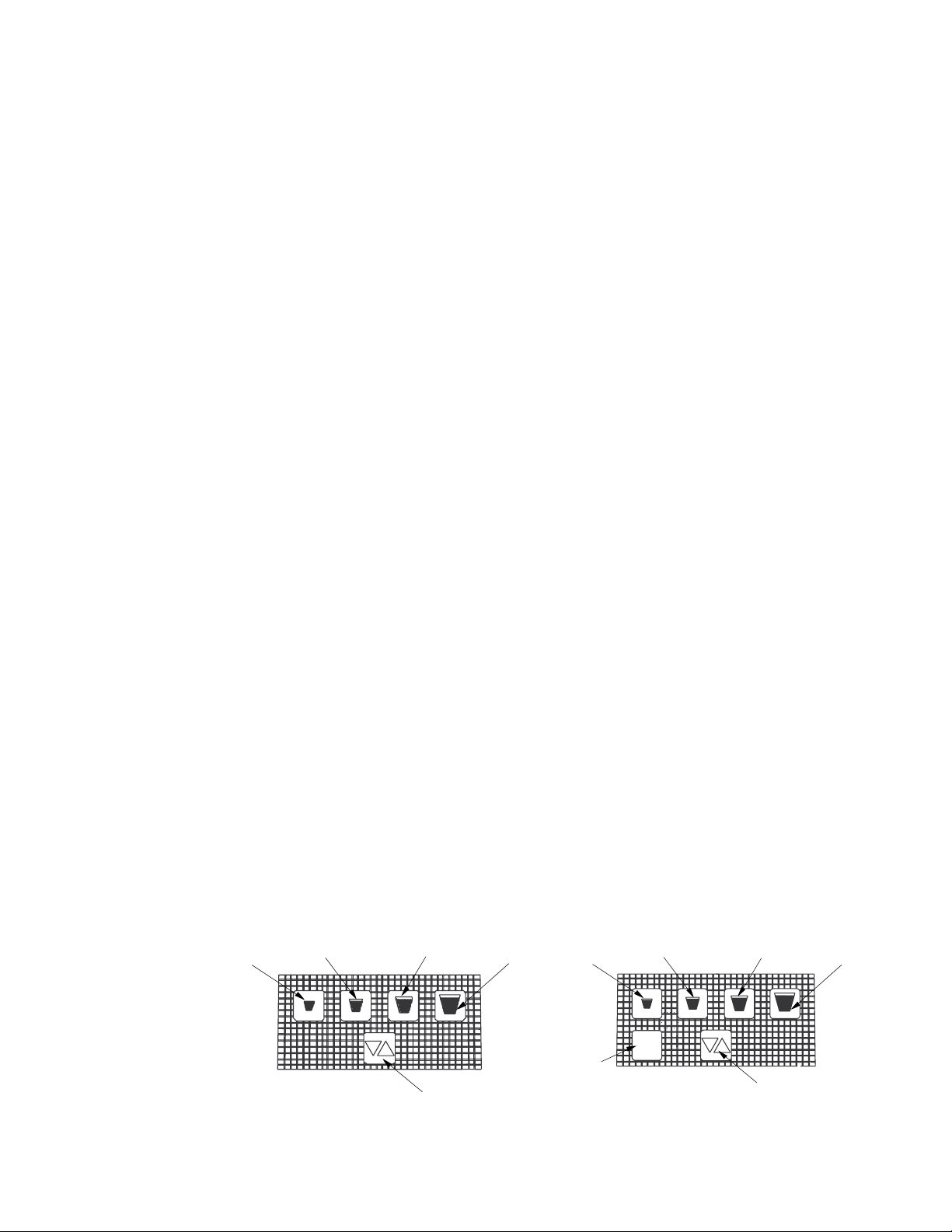

FIGURE 9 - PORTION CONTROL,

CUP BUTTONS

Small

Cup Button

Medium

Cup Button

Large

Cup Button

Pour/Stop

Cup Button

Extra-Large

Cup Button

FIGURE 10 - PORTION CONTROL,

CUP BUTTONS,WITH WATER

Small

Cup Button

Water

Button

Medium

Cup Button

water

Large

Cup Button

Pour/Stop

Cup Button

Extra-Large

Cup Button

7.3 TO CHANGE DISPENSE SIZE

Use procedures in the Initial Install Procedure discussed above; it is not necessary to reprogram

every size.

9

Page 10

7.4 CALIBRATED CUP PORTION CONTROL PROGRAMMING

In this mode, the valve adds the volume from each programming step to the total drink size. When

activated, the valve dispenses the total drink, without pauses.

A. Simultaneously, press and hold the small and large buttons (see Figures 9 and 10) on the

portion control until the LED light in the center starts blinking, then release switches.

B. Place volume cup under nozzle of valve to be calibrated.

C. Press appropriate size switch and ll volume cup to a point just short of the calibration mark on

the volume cup. The LED will stay lighted constantly while programming an individual cup size.

D. Let foam settle, jog size switch until liquid reaches the calibration mark on the volume cup.

E. Press pour/stop button to end programming for selected cup size. LED will start blinking.

F. To program another cup size, repeat steps B through E, this section (above).

G. To exit the calibrated cup programming mode, press the pour/stop button when the LED is

blinking. If the LED is lighted constantly, press the pour/stop button once to end the cup size

program (LED starts blinking) and again to exit the program mode (LED off).

8. COVER AND ID PANEL

8.1 REMOVAL

A. ID panel: Slide ID panel up until it detaches from cover.

CAUTION PULL CAREFULLY, IF WIRES FOR A PUSHBUTTON OR PORTION CONTROL ARE ATTACHED.

PRECAUCIÓN TIRE CUIDADOSAMENTE SI ESTÁN ADHERIDOS LOS CABLES A UN BOTÓN DE EMPUJE O UN

CONTROL DE PORCIÓN.

!

B. ID panel connector (If applicable): The circuit board connector on the Volumetric Valve has an

properly connected. The interlock feature consists of a recess in the circuit board connector

When removing the connector, it is important to hold the housing and not the wires. The

housing easily slides out of the circuit board connector by placing a very slight downward

pressure onto the housing as it is removed (see Figure 12).

NOTE: Pulling straight out while holding onto the wires is not recommended and will likely cause

C. Cover: Loosen, but do not remove, cover screw. Pull cover straight up, until it is clear of the

NOTE: Push Button ID panel or lever must be connected to run “Syrup Pour” test from dip

switches. Push Button ID panel or lever must be disconnected to use the hand held programmer.

ATTENTION SI L’ENSEMBLE EST RELIÉ PAR FILS À UN BOUTON-POUSSOIR DE COMMANDE OU À UNE

COMMANDE DE RÉGLAGE DE DÉBIT INDIVIDUEL, LE TIRER DÉLICATEMENT.

interlock feature that acts to keep an ID panel plug or Hand Held Programmer (HHP) plug

housing and a raised tab on the housing plug. See Figure 11, for the raised tab conguration.

damage to the valve, ID panel and/or HHP cable.

valve body.

FIGURE 11 FIGURE 12

Raised Tab,

Housing Plug

10

Slight downward pressure here,

while pulling housing straight out

PUSH

Page 11

8.2 INSTALLATION

Lever Arm

NOTE: Part Number in ( ) is a Coca-Cola PN

54-0125/01 Shown

(24234 Shown)

A. Plug the ID panel connector (if applicable) into the front of the circuit board.

B. Slide cover over valve, making certain that wires do not get pinched.

NOTE: If solenoids were replaced or moved, ensure terminal blocks do not interfere with cover.

Check for proper orientation.

C. Tighten cover screw.

CAUTION DO NOT PINCH OR DAMAGE ID PANEL WIRES DURING INSTALLATION.

PRECAUCIÓN NO PERFORE O DAÑE LOS CABLES DEL PÁNEL DURANTE LA INSTALACIÓN.

!

ATTENTION S’ASSURER DE NE PAS PINCER OU ENDOMMAGER LES FILS DU PANNEAU ÉLECTRIQUE

ID LORS DU MONTAGE.

D. Align the bottom of the ID panel with the guide slots on the front of the cover. Slide the ID panel

down into place.

NOTE: Attach the ID panel connector before installing cover to keep wires out of the way.

9. VALVE

9.1 REMOVAL FROM BACK BLOCK

FIGURE 13

I.D. Panel, Large Pushbutton

A. Remove cover and ID panel (see Section 8).

B. Turn back block shut-offs to the closed position.

C. Activate the valve (press lever arm or pushbutton) to

relieve pressure.

D. Unplug 24 Volt supply.

E. Raise valve retainer. NOTE: The retainer cannot be

pulled up until the back block shut-offs are properly

closed.

Valve with

Cover in Place

F. Pull the valve off of the back block.

9.2 MOUNTING ON BACK BLOCK

A. Check o-rings on back block. Replace o-rings, if

necessary.

B. Apply 111 Lubricant to o-rings, if necessary.

C. Press valve into the back block.

D. Lower the valve retainer to lock the valve in place.

E. Turn the back block shut-offs to the open position.

F. Connect the 24 Volt supply to the plug on the circuit

board.

G. Install cover and ID panel.

FIGURE 14

10. LEVER ARM

10.1 REMOVAL

A. Remove cover and ID panel (see Section 8).

B. Remove valve from back block (see Section 9).

C. Insert lever arm into bottom plate and snap

pivot axle into back of valve as shown in

Figure 14.

10.2 INSTALLATION

A. With the valve detached from the back block,

insert the magnet end of the lever arm into the

hole on the bottom, backside of the valve.

B. Pull the lever arm back while pushing it into the valve, so the pivot axle can be positioned over

the slot formed by the valve body and bottom plate. Release the valve to allow the pivot axle to

be seated in the slot.

C. Mount valve in back block.

D. Install ID panel and cover.

11

Page 12

NOTE: Part Number in ( ) is a Coca-Cola PN

11. NOZZLE/DIFFUSER

11.1 REMOVAL

A. Remove nozzle, by twisting it counter-clockwise and

pulling it in a downward direction (see Figure 15).

B. Remove the diffuser assembly, by pulling it in a

downward direction.

11.2 ASSEMBLY

A. Slide o-ring into the groove on the end of the diffuser

assembly, if necessary.

B. Apply 111 Lubricant to o-ring, as required.

C. Insert diffuser assembly carefully into the underside of

the valve.

D. Install nozzle by inserting it into the bottom plate and

twisting it in a clockwise direction to lock it into place.

12. CIRCUIT BOARD

12.1 REMOVAL

A. Unplug 24 Volt supply.

B. Use a at end screw driver to remove each of the

screws holding the circuit board in place.

C. Disconnect the solenoids and owmeter from the

circuit board, by pressing each connectors locking tab

and pulling it down out of its socket.

D. Lift the circuit board off of the valve.

12.2 INSTALLATION

A. Plug the connector from the rear syrup

solenoid into the receptacle on the underside of

the circuit board near the rear of the valve.

B. Plug the connector from the soda solenoid into

the receptacle located at the front, left corner of

the circuit board.

NOTE: Each solenoid plugs into the nearest circuit

board socket.

C. Plug the connector from the front syrup

solenoid into the receptacle between the soda

solenoid connector and the 10-pin connector

on the front of the circuit board.

D. Plug the 4-pin connector from the owmeter

in the 4-pin receptacle near the front corner of

the circuit board.

E. Position circuit board on the mounting posts on

top of the syrup body 10-pin connector to the

front.

F. Secure circuit board with two (2) screws.

G. Connect 24 Volt supply.

FIGURE 15

Diffuser Assembly

54-0176/04

(24245)

Nozzle

05-2053/01

(24246)

FIGURE 16

Programmer Plug, ID Panel

Front Syrup Solenoid

Plug, Rear Syrup Solenoid

Plug, Flowmeter

Plug, Water Solenoid

12

Page 13

13. FLOWMETER

Circuit Board

13.1 REMOVAL

A. Remove cover and ID panel (see Cover and

ID Panel, Section 8).

B. Remove valve from back block (see Valve,

Section 9).

C. Remove nozzle/diffuser (see Nozzle/ Diffuser,

Section 11).

D. Remove lever arm, if applicable (see Lever Arm, Section 10).

E. Remove four (4) screws holding the bottom plate in place.

F. Pull bottom plate off.

CAUTION USE CARE WHEN REMOVING THE SCREWS TO AVOID

DAMAGING THE FLOWMETER SENSOR WIRES.

PRECAUCIÓN TENGA CUIDADO CUANDO RETIRE LOS TORNILLOS

PARA EVITAR DAÑAR LOS CABLES DEL SENSOR DEL FLUXÓMETRO.

!

G. Remove four (4) screws holding the owmeter body in place.

H. Carefully pull the owmeter body and o-ring off of the valve.

owmeter body as ball bearings are snapped into place.

ATTENTION LORSQU’IL S’AGIRA DE DÉPOSER LES VIS, IL

CONVIENDRA DE PRENDRE SOIN DE NE PAS ENDOMMAGER LES FILS

DU CAPTEUR DUDÉBITMÈTRE.

Use caution to not pull the rotor and bearings out of the

Screw

04-0640

(24208)

FIGURE 17

52-2345/05

(24155)

13.2 INSTALLATION

A. Place the o-ring in the groove in the owmeter body.

CAUTION DO NOT PINCH THE FLOWMETER O-RING DURING INSTALLATION. THE O-RING MUST STAY IN THE

GROOVE ON THE FLOWMETER BODY.

PRECAUCIÓN NO PELLIZQUE EL ANILLO O- DEL FLUXÓMETRO DURANTE LA INSTALACIÓN. EL ANILLO

O- DEBE MANTENERSE EN LA RANURA SOBRE EL CUERPO DEL FLUXÓMETRO.

!

ATTENTION FAIRE ATTENTION DE NE PAS PINCER LE JOINT TORIQUE DU DÉBITMÈTRE LORS DU MONTAGE.

LE JOINT TORIQUE DEVRA RESTER LOGÉ DANS LA RAINURE PRÉVUE SUR LE CORPS DU DÉBITMÈTRE.

B. If necessary, carefully apply a small amount of 111 Lubricant to o-ring. NOTE: Do not get

lubricant in the owmeter.

C. With the wires exiting toward the front of the valve, carefully press the owmeter sub-assembly

into place on the underside of the valve body. The at surface of the owmeter must be ush

against the mounting surface of the valve body.

D. Install four (4) screws to hold the owmeter in place. Gently position the sensor wires so they

are not pinched or scraped when the screws are installed. NOTE: The owmeter screws are

5/8” long, and are longer than the bottom plate screws.

E. Thread the connector attached to the owmeter sensor wires through hole on the valve body

that is in front of ow washer mounting port (see Figure 18).

F. Place the owmeter sensor wires around the outside of the ow washer mounting port, so that

they will not interfere with the bottom plate installation.

CAUTION DO NOT PINCH ANY WIRES WITH THE BOTTOM PLATE.

PRECAUCIÓN NO PELLIZQUE NINGÚN CABLE CON EL FONDO.

!

G. Line up holes on the bottom plate with the screw holes on the underside of the valve body. The

H. Secure bottom plate in place with four (4) screws.

I. Replace nozzle/diffuser and lever arm (if applicable).

J. Install ID panel and cover.

ATTENTION VEILLER À CE QUE L’EMBASE NE VIENNE PAS PINCER LES FILS.

raised sections around the screw holes should t completely in the counterbores on the bottom

plate.

13

Page 14

14. FLOW WASHER ASSEMBLY

NOTE: Part Number in ( ) is a Coca-Cola PN

Thread Flowmeter wires though

14.1 REMOVAL

A. Remove cover and ID panel (see Cover and ID Panel, Section 8).

B. Remove valve from back block (see Valve, Section 9).

C. Remove nozzle/diffuser (see Nozzle/ Diffuser, Section 11).

D. Remove lever arm, if applicable (see Lever Arm, Section 10).

E. Remove four (4) screws holding the bottom plate in place.

F. Pull bottom plate off.

G. Pull the ow washer assembly out of its port, next to the nozzle mount on the underside of the

valve. The ow washer assembly will be one of the following:

1. Gray, 3.0 ounce/sec product ow.

FIGURE 18 - FLOW WASHER/SYRUP PLUG ACCESS

2. White, 2.25 ounce/sec product ow.

3. Red, 1.5 ounce/sec product ow.

Valve Body at this point.

14.2 INSTALLATION

A. Install o-rings, if necessary.

B. Apply 111 Lubricant to the o-rings, if necessary.

C. Install the appropriate ow washer assembly

into the keyed port on the underside of the

valve body.

NOTE: The ow washer has a at side and a

concave side. The ow washer must be installed

with the concave side facing the small diameter

hole in the ow washer retainer.

D. Place the owmeter wires around the outside of

the ow washer mounting port, so that they will

not interfere with the bottom plate installation.

E. Line up holes on the bottom plate with the

screw holes on the underside of the valve body.

The raised sections around the screw holes

should t completely in the counterbores on the

bottom plate.

CAUTION DO NOT PINCH ANY WIRES DURING INSTALL

PRECAUCIÓN NO NO PELLIZQUE NINGÚN CABLE

DURANTE LA INSTALACIÓN.

!

ATTENTION VEILLER À NE COINCER AUCUN FIL LORS

DU MONTAGE.

F. Secure bottom plate in place with four (4)

screws.

G. Mount valve in back block.

H. Replace nozzle/diffuser and lever arm (if

O-Ring

02-0003

(10049)

Regulator Plug

(some models)

05-0779/01

(24236)

Flow Washer Assy

54-0192 (Red)

(24237)

Flow Washer Assy

54-0193 (White)

(24238)

Flow Washer Assy

54-0194 (Gray)

(24239)

Bottom Plate

05-0960/01

(24244)

Screw

04-0633/01

(24209)

O-Ring

02-0005

(10050)

Diffuser Assembly

54-0176/04

(24245)

Nozzle

05-2053/01

(24246)

applicable).

I. Install ID panel and cover.

15. SYRUP REGULATOR

15.1 REMOVAL

A. If the syrup regulator plug or its o-rings need to be replaced, remove the valve from the back

block and take off the bottom plate.

B. Pull the regulator plug from the regulator port near the back of the underside of the valve body.

NOTE: There is nothing mounted inside the regulator port.

14

Page 15

NOTE: Part Number in ( ) is a Coca-Cola PN

15.2 INSTALLATION

A. Install o-rings in groove on regulator plug.

B. Apply 111 Lubricant to the o-ring.

C. Insert regulator plug into keyed hole on the

underside of the valve body.

D. Place the owmeter wires around the outside

of the ow washer assembly, so that they will

!

not interfere with the bottom plate installation.

CAUTION DO NOT PINCH ANY WIRES DURING INSTALL

PRECAUCIÓN NO NO PELLIZQUE NINGÚN CABLE

DURANTE LA INSTALACIÓN.

ATTENTION VEILLER À NE COINCER AUCUN FIL LORS

DU MONTAGE.

Thread

Flowmeter

wires though

Valve Body

at this point

Flowmeter

O-Ring

02-0354

E. Line up holes on the bottom plate with the

Flowmeter

Body

54-0126/01

Bottom Plate

05-0960/01

(24244)

!

screw holes on the underside of the valve body.

CAUTION BOTTOM PLATE HOLDS THE REGULATOR

PLUG AND THE FLOW WASHER RETAINER IN PLACE.

DO NOT PRESSURIZE UNTIL BOTTOM PLATE IS FIRMLY

ATTACHED.

PRECAUCIÓN LA PLACA INFERIOR SOSTIENE LA

CLAVIJA DEL REGULADOR Y LA ARANDELA DE

RETENCIÓN DEL FLUJO EN SU LUGAR. NO LA

PRESIONE HASTA QUE LA PLACA INFERIOR SE HAYA

COLOCADO FIRMEMENTE.

ATTENTION L’EMBASE MAINTIENT LE CLAPET DU

RÉGULA-TEUR AINSI QUE LE COLLIER DE RETENUE DU

RÉDUCTEUR DE PRESSION EN PLACE. NE PAS METTRE

SOUS PRESSION AVANT QUE L’EMBASE NE SOIT

SOLIDEMENT FIXÉE.

F. Secure bottom plate in place with four (4)

screws.

G. Mount valve on back block.

H. Replace nozzle/diffuser and lever arm (if

applicable).

I. Install ID panel and cover.

16. WATER SOLENOID ACCESS

16.1 REMOVAL

A. Disconnect valve from back block (see Valve,

Section 9).

B. Remove circuit board (see Circuit Board, Section 12).

FIGURE 19 - FLOWMETER ACCESS

Screw

04-0549

(24242)

Screw

04-0633/01

(24209)

O-Ring

02-0005

(10050)

Diffuser Assembly

54-0176/04

(24245)

Nozzle

05-2053/01

(24246)

CAUTION AVOID DAMAGING OR DROPPING THE SOLENOID OR COMPONENTS WHEN THE RETAINER IS

REMOVE.

PRECAUCIÓN EVITE DAÑAR O TIRAR EL SOLENOIDE O LOS COMPONENTES CUANDO RETIRE EL

RETENEDOR.

!

ATTENTION ÉVITER D’ENDOMMAGER OU DE FAIRE TOMBER L’ÉLECTROVANNE OU AUTRES COMPOSANTS

LORSQUE.

C. Remove three (3) screws holding the water solenoid retainer in place. Remove the retainer.

D. Take the water solenoid assembly out of the valve.

15

Page 16

16.2 INSTALLATION

If a water seat is already installed, skip to Step H.

A. Put o-ring in groove on water seat.

CAUTION USE CARE TO NOT DAMAGE SEATING AREA WHILE INSERTING WATER SEAT INTO VALVE BODY.

PRECAUCIÓN TENGA CUIDADO DE NO DAÑAR EL ÁREA DE ASIENTO MIENTRAS QUE INSERTA EL ASIENTO

DE AGUA DENTRO DEL CUERPO DE LA VÁLVULA.

!

B. Apply 111 Lubricant to outside edges of o-ring.

C. Carefully press water seat into the hole at the base of the water solenoid mounting area in the

D. If necessary, install ow washer (See Flow Washer Assembly, Section 14).

!

E. Place the owmeter wires around the outside of the ow washer assembly, so that they will not

F. Secure bottom plate in place with four (4) Screws.

G. Apply 111 Lubricant to the outside edge of o-ring on the water solenoid sub-assembly.

!

H. Turn valve body over and insert water solenoid sub-assembly into the hole where the water

I. Place the water solenoid retainer on top of the solenoid and install three (3) screws. The water

J. Install the circuit board.

K. Reconnect the valve.

ATTENTION VEILLER À NE PAS ENDOMMAGER LA ZONE D’ÉTANCHÉITÉ À L’EAU LORS DE L’INSERTION DU

SIÈGE DANS LE CORPS DE LA VANNE.

valve body. Make certain that the water seat remains completely inserted into the hole. Apply

more lubricant to the o-ring, if necessary,

CAUTION DO NOT PINCH ANY WIRES DURING INSTALL

PRECAUCIÓN NO NO PELLIZQUE NINGÚN CABLE DURANTE LA INSTALACIÓN.

ATTENTION VEILLER À NE COINCER AUCUN FIL LORS DU MONTAGE.

interfere with the bottom plate installation.

CAUTION DO NOT GET LUBRICANT ON THE SPRING OR CORE IN THE SOLENOID.

PRECAUCIÓN NO PERMITA QUE EL LUBRICANTE SE INTRODUZCA EN EL RESORTE O EN EL CORAZÓN DEL

SOLENOIDE.

ATTENTION FAIRE ATTENTION DE NE PAS RÉPANDRE DE LA GRAISSE SUR LE RESSORT OU LE

NOYEAU-PLONGEUR DE L’ÉLECTRO-AIMANT.

seat is mounted. Carefully twist the solenoid while pressing it into place, so that the o-ring does

not get pinched. The terminal block on the side of the solenoid must be on the outside edge of

the valve body, turned so that it touches the single solenoid retainer post towards the front of

the valve. Hold the solenoid in place until the retainer is rmly mounted.

solenoid sub-assembly must remain rmly seated during installation to avoid damaging the

o-ring. Tighten each screw a little at a time, so that the retainer stays perpendicular to the water

solenoid.

16

Page 17

17. WATER SOLENOID ASSEMBLY

Screw

NOTE: Part Number in ( ) is a Coca-Cola PN

17.1 DISASSEMBLY

A. Remove the core/spring assembly from the solenoid.

B. Slide the o-ring off the end of the solenoid.

C. Lift the solenoid washer off the end of the solenoid.

CAUTION THE PLUG NUT MAY PULL OUT OF THE COIL, WHEN TRYING TO LOOSEN. THE COIL CAN BE

DAMAGED IF DROPPED.

PRECAUCIÓN LA TUERCA DE LA CLAVIJA PUEDE ZAFARSE DE LA BOBINA, CUANDO SE TRATA DE

AFLOJARLA. SI SE CAE LA BOBINA SE PUEDE DAÑAR.

!

ATTENTION IL SERA POSSIBLE QUE L’ÉCROU DE BLOCAGE DE LA BOBINE SE DÉSOLIDARISE DE CETTE

DERNIÈRE LORS DU DESSERRAGE DE L’ENSEMBLE. VEILLER À NE PAS FAIRE TOMBER LA BOBINE, AU RISQUE

DE L’ENDOMMAGER.

D. Carefully hold the wire terminal block on the side of the coil while pulling the solenoid bonnet

to loosen the water plug nut. When the water plug nut has been pulled out of the coil enough,

remove it and the bonnet by hand.

17.2 ASSEMBLY

A. Slide o-ring into the groove on the water plug nut.

B. Slide bonnet over coil.

C. Apply 111 Lubricant to o-ring in plug nut.

D. Press plug nut into top of coil/bonnet assembly.

E. Place solenoid washer on bottom end of the coil/bonnet assembly.

F. Place o-ring over end of coil extending through the solenoid washer.

G. Insert core/spring assembly into the end of the solenoid assembly.

NOTE: Water and syrup solenoid coils are interchangeable.

FIGURE 20 -WATER SOLENOID ACCESS FIGURE 21 - WATER SOLENOID ASSEMBLY

04-0640

(24208)

Circuit Board

64-5040

(24155)

Plug Nut

10-0868

O-Ring

02-0538

(10061)

Screw

04-0637

(24221)

Solenoid

Retainer

05-0707

(24222)

Water

Solenoid

Assembly

Soda Seat

05-0706

(24233)

O-Ring

02-0005

(10050)

Bonnet,

Solenoid

81-0404/01

(24224)

Coil

12-0132/04-01

(24225)

Washer,

Solenoid

04-0820/01

(24226)

O-Ring

02-0109

(17428)

Core/Spring

Assembly

82-1624/03

(24229)

NOTE: Part Number in ( ) is a Coca-Cola PN

17

Page 18

18. SYRUP BODY ACCESS

18.1 REMOVAL

A. Remove valve from back block (see Valve, Section 9).

B. Remove circuit board (see Circuit Board, Section 12).

C. Remove nozzle/diffuser (see Nozzle/Diffuser, Section 11).

D. Remove lever arm, if applicable (see Lever Arm, Section 10).

E. Remove four (4) screws holding the bottom plate in place.

F. Pull bottom plate off.

G. Remove two (2) screws located at front and rear of syrup body.

H. Turn valve assembly over and remove the two (2) screws on the underside of the main body,

holding the syrup body in place.

CAUTION PARTS OF THE SYRUP SOLENOIDS MAY FALL OUT WHEN THE SYRUP BODY IS REMOVED.

PRECAUCIÓN PARTES DE LOS SOLENOIDES DEL JARABE SE PUEDEN CAER CUANDO SE RETIRA EL

CUERPO DEL JARABE.

!

I. Lift the syrup body subassembly off of the syrup solenoids.

J. Pull the syrup down tube restrictor assembly out of the port on the side of the syrup body.

18.2 INSTALLATION

A. If necessary, install an o-ring on either end of the syrup down tube restrictor assembly.

B. Apply 111 Lubricant around each end of the syrup down tube restrictor, if necessary.

C. Insert syrup down tube restrictor assembly into port on the side of the syrup body

sub-assembly.

D. Apply 111 Lubricant to the outside edge of o-ring on the syrup solenoids.

ATTENTION CERTAINS COMPOSANTS DES ÉLECTRO-AIMANTS DU CÔTÉ SIROP POURRONT TOMBER

LORSQUE LE CORPS DE LA VANNE SERA DÉPOSÉ.

CAUTION DO NOT GET LUBRICANT ON THE SPRING OR CORE IN THE SOLENOID.

PRECAUCIÓN NO PERMITA QUE EL LUBRICANTE SE INTRODUZCA EN EL RESORTE O EN EL CORAZÓN DEL

SOLENOIDE.

!

E. Rotate the front syrup solenoid until its terminal block rests in groove, towards the syrup down

F. Rotate the back syrup solenoid, so that its terminal block rests against the water solenoid

retainer mount.

ATTENTION FAIRE ATTENTION DE NE PAS RÉPANDRE DE LA GRAISSE SUR LE RESSORT OU LE NOYEAU-

PLONGEUR DE L’ÉLECTRO-AIMANT.

tube port.

CAUTION SYRUP SOLENOIDS MUST BE SEATED AGAINST MAIN BODY. IF SOLENOIDS BECOME UNSEATED,

SEE SYRUP SOLENOID ACCESS, INSTALLATION, SECTION 19.

PRECAUCIÓN LOS SOLENOIDES DEL JARABE DEBEN ESTAR ASENTADOS CONTRA EL CUERPO PRINCIPAL.

SI LOS SOLENOIDES NO ESTÁN ASENTADOS, VEA EN LA SECCIÓN 19 DE LA INSTALACIÓN EL ACCESO A LOS

SOLENOIDES DE

!

ATTENTION LES ÉLECTRO-AIMANTS DU CÔTÉ SIROP DEVRONT RESTER PLAQUÉS CONTRE LE CORPS

PRINCIPAL. SI LES ÉLECTRO-AIMANTS SORTENT DE LEUR SIÈGE, CONSULTEZ LES INSTRUCTIONS RELATIVES

À LEUR ACCÈS ET MONTAGE CONTENUES DANS LA SECTION 19.

G. Carefully press the syrup body sub-assembly into place on top of the syrup solenoids. If the

syrup body will not smoothly press into place, then apply more 111 Lubricant to the solenoid

o-rings, so that they will not be pinched.

1. Make certain the syrup down tube restrictor assembly goes into the down tube port on the

valve body.

2. Hold the syrup body rmly in place until the mounting screws are completely installed.

NOTE: Mounting screws must be tight. Loose screws will cause leaks and alter valve

performance.

H. Install screw at front and rear of syrup body.

18

Page 19

18.2 SYRUP BODY INSTALLATION - CONTINUED

Screw

I. Install two (2) screws on the underside of the main body, to secure syrup body.

J. Install circuit board (see Circuit Board, Section 12) and secure with two (2) screws.

K. Place the owmeter wires around the outside of the ow washer assembly, so that they will not

interfere with the bottom plate installation. Connect to circuit board.

CAUTION DO NOT PINCH ANY WIRES DURING INSTALL

PRECAUCIÓN NO NO PELLIZQUE NINGÚN CABLE DURANTE LA INSTALACIÓN.

!

ATTENTION VEILLER À NE COINCER AUCUN FIL LORS DU MONTAGE.

L. Line up holes on the bottom plate with the screw holes on the underside of the valve body.

M. Secure bottom plate with four (4) screws.

N. Install nozzle/diffuser

O. Install lever arm, if applicable.

FIGURE 22 - SYRUP BODY ACCESS

Circuit Board

64-5040

(24155)

Syrup Body

Subassembly

82-1117/02

(24217)

Down Tube

Restrictor

Assembly

54-0190

(24220)

04-0640

(24208)

Screw

04-0549

(24242)

19

Bottom Plate

05-0960/01

(24244)

Screw

04-0633/01

(24209)

O-Ring

02-0005

(10050)

Diffuser

Assembly

54-0176/04

(24245)

Nozzle

05-2053/01

(24246)

Screw

04-0637

(24221)

Page 20

19. SYRUP SOLENOID ACCESS

O-Ring

Bottom Plate

Screw

Syrup

Syrup Down Tube

Syrup Body

Screw

Screw

Circuit Board

Nozzle

Diffuser

Screw

O-Ring

05-2053/01

(24246)

Assembly

54-0176/04

(24245)

02-0005

(10050)

04-0637

(24221)

04-0633/01

(24209)

02-0005

(10050)

05-0960/01

(24244)

Restrictor Assembly

54-0190

(24220)

Subassembly

82-1117/02

(24217)

Solenoid

Subassembly

04-0459

(24242)

64-5040

04-0640

(24208)

(24155)

19.1 REMOVAL

A. Remove valve from back block (see Valve,

B. Remove circuit board (see Circuit Board,

Section 12).

C. Remove nozzle/diffuser (see Nozzle/ Diffuser,

D. Remove lever arm, if applicable (see Lever

E. Remove four (4) screws holding the bottom

F. Pull bottom plate off.

G. Remove the two (2) screws that hold the syrup

H. Turn valve assembly over and remove the two

I. Lift the syrup body off of the syrup solenoids.

!

J. Lift each syrup solenoid out of the valve.

NOTE: The o-ring mounted under neath the

solenoid may stick to the solenoid when it is

removed.

19.2 INSTALLATION

A. Install an o-ring over the port in the bottom of

B. Apply 111 Lubricant to the outside edges of the

C. Insert syrup solenoid sub-assembly into the rear mounting area on the main body. Twist the

D. Insert syrup solenoid sub-assembly into the front mounting area on the main body. Twist the

E. Apply 111 Lubricant around each of the o-rings on the syrup down tube.

FIGURE 23 - SYRUP SOLENOID ACCESS

Section 9).

Section 11).

Arm, Section 10).

plate in place.

body in place.

(2) screws, on the underside of the main body,

holding the syrup body in place.

CAUTION PARTS OF THE SYRUP SOLENOIDS MAY

FALL OUT WHEN THE SYRUP BODY IS REMOVED.

PRECAUCIÓN PARTES DE LOS SOLENOIDES DEL

JARABE SE PUEDEN CAER CUANDO SE RETIRA EL

CUERPO DEL JARABE.

ATTENTION CERTAINS COMPOSANTS DES

ÉLECTRO-AIMANTS DU CÔTÉ SIROP POURRONT

TOMBER LORSQUE LE CORPS DE LA VANNE SERA

DÉPOSÉ.

each syrup solenoid mounting area on the

main body. Ensure that o-ring seats to bottom

of mounting port.

o-rings.

solenoid while pushing it into place to avoid pinching the o-ring at the bottom of the mounting

area. Turn the solenoid, so that the terminal block rests against the water solenoid retainer

post.

solenoid while pushing it into place to avoid pinching the o-ring at the bottom of the mounting

area. Turn the solenoid so that the terminal block rests in groove towards, but not over, the

syrup down tube port.

!

CAUTION DO NOT GET LUBRICANT ON THE SPRING OR CORE IN THE SOLENOID.

PRECAUCIÓN NO PERMITA QUE EL LUBRICANTE SE INTRODUZCA EN EL RESORTE O EN EL CORAZÓN DEL

SOLENOIDE.

ATTENTION FAIRE ATTENTION DE NE PAS RÉPANDRE DE LA GRAISSE SUR LE RESSORT OU LE NOYEAU-

PLONGEUR DE L’ÉLECTRO-AIMANT.

20

Page 21

O-Ring

Plug Nut

O-Ring

Solenoid

Coil

O-Ring

Core/Spring

Solenoid

02-0005

(10050)

10-0280/04

(24230)

02-0538

(10061)

Bonnet

81-0407/01

(24224)

Washer

04-0820/01

(24226)

12-0132/04-01

(24225)

Assembly

82-1624/03

(24229)

02-0109

(17428)

19.2 SYRUP SOLENOID INSTALLATION - CONTINUED

F. Insert syrup down tube into port on the side of the syrup body sub-assembly.

G. Apply 111 Lubricant to the outside edge of o-ring on the syrup solenoids.

H. Carefully press the syrup body sub-assembly into place on top of the syrup solenoids. If the

syrup body will not smoothly press into place, then apply more 111 Lubricant to the solenoid

o-rings, so that they will not be pinched. Make certain the syrup down tube goes into the down

tube port on the valve body. If the solenoid assembly becomes unseated, remove solenoid

assembly and repeat Steps A through D above. Hold the syrup body rmly in place until the

mounting screws are completely installed.

I. Install two (2) upper screws located at front and rear of syrup body.

J. Install two (2) screws on the underside of main body, to secure the syrup body.

K. Place the owmeter wires around the outside of the ow washer assembly, so that they will not

interfere with the bottom plate installation.

CAUTION DO NOT PINCH ANY WIRES DURING INSTALL

PRECAUCIÓN NO NO PELLIZQUE NINGÚN CABLE DURANTE LA INSTALACIÓN.

!

L. Line up holes on the bottom plate with the screw

ATTENTION VEILLER À NE COINCER AUCUN FIL LORS DU MONTAGE.

FIGURE 24 - SYRUP SOLENOID ASSEMBLY

holes on the underside of the main body.

M. Secure bottom plate in place with four (4) screws.

N. Install nozzle/diffuser

O. Install lever arm, if applicable.

P. Install circuit board (see Circuit Board, Section 12).

20. SYRUP SOLENOID ASSEMBLY

20.1 DISASSEMBLY

A. Remove the core/spring assembly from the solenoid.

B. Slide the o-ring off the end of the solenoid.

C. Lift the solenoid washer off the end of the solenoid.

D. If the o-ring remains in the end of the syrup plug nut or

on the post inside the syrup solenoid mounting area on

the main body, remove it.

CAUTION THE PLUG NUT MAY PULL OUT OF THE COIL, WHEN

TRYING TO LOOSEN. THE COIL CAN BE DAMAGED IF DROPPED.

PRECAUCIÓN LA TUERCA DE LA CLAVIJA PUEDE ZAFARSE DE

LA BOBINA, CUANDO SE TRATA DE AFLOJARLA. SI SE CAE LA

BOBINA SE PUEDE DAÑAR,

!

ATTENTION IL SERA POSSIBLE QUE L’ÉCROU DE BLOCAGE

DE LA BOBINE SE DÉSOLIDARISE DE CETTE DERNIÈRE LORS

DU DESSERRAGE DE L’ENSEMBLE. VEILLER À NE PAS FAIRE

TOMBER LA BOBINE, AU RISQUE DE L’ENDOMMAGER.

E. Carefully hold the wire terminal block on the side of the

coil while pulling the solenoid bonnet to loosen the

syrup plug nut. When the syrup plug nut has been

pulled out of the coil enough, remove it and the bonnet

by hand.

20.2 ASSEMBLY

A. Slide o-ring into the groove on the syrup plug nut.

B. Slide bonnet over coil.

C. Apply 111 Lubricant to o-ring in plug nut, then press plug nut into top of coil/bonnet assembly.

D. Place solenoid washer on bottom end of coil/bonnet assembly.

E. Place o-ring over end of coil extending through solenoid washer.

F. Insert the core/spring assembly into the end of the solenoid assembly.

NOTE: Water and syrup solenoid coils are interchangeable.

21

Page 22

21. TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE VERIFICATION SOLUTION

Drink Ratio Incorrect

(Weak or Strong);

Programmer available

A. Syrup restrictor

incorrectly set.

A. Check location of restrictor.

Restrictor must be in and up for diet bag-

in-box (BIB) applications, directly above

theletter ‘D’ in the syrup down tube

assembly. Restrictor must be down and

out for non-diet drinks, directly below the

letter “S” in the syrup down tube

assembly.

A. Position restrictor correctly.

Drink Ratio Incorrect

Weak or Strong);

Programmer

unavailable

B. Flow washer bad

(if installed).

C. Insufcient syrup

pressure.

D. Syrup obstructed.

E. Incorrect ratio

setting in memory.

F. Flowmeter

malfunctioning.

A. Syrup restrictor

incorrectly set.

B. Water ow over 2.7 oz/sec on a timed

pour.

C. Run syrup purge test on hand held

programmer. Output syrup should be

approx. 3 oz.

D. Incorrect ratio measurement after

circuit board replaced.

E1. Plug in programmer and press ‘Read

Memory’, and ratio and/ or carbonation

setting incorrect.

E2. Reprogramming of ratio and/or

carbonation setting does not work.

F. All other items above checked.

A. Check location of restrictor.

Restrictor must be in and up for diet

bag-in-box (BIB) applications, directly

above the letter “D” in the syrup down

tube assembly.

B. Replace ow washer assembly, or

install one if needed.

C. Increase dispensing system syrup

pressure.

D. Disassemble syrup side and

remove obstruction.

E1. Reprogram valve’s memory by

using “+/- keys, Carb Toggle and

‘Write Memory’.

E2. Replace circuit board.

F. Replace owmeter assembly

A. Position restrictor correctly.

B. Flow washer bad

(if installed)

C. Insufcient syrup

pressure.

D. Syrup obstructed.

side and remove

obstruction.

E. Flowmeter

malfunctioning

B. Water ow over 2.7oz/sec on a timed

pour. Flow washer installed correctly.

C. Run syrup purge test on hand held

programmer. Output syrup should be

approx. 3 oz.

D. Incorrect ratio measurement after

circuit board replaced.

E. All other items above checked.

22

B. Replace ow washer assembly,

or install one if needed.

C. Increase dispensing system syrup

pressure.

D. Disassemble syrup side and remove obstruction.

E. Replace owmeter assembly.

Page 23

SYMPTOM POSSIBLE CAUSE VERIFICATION SOLUTION

Nothing Dispenses

When Valve Activated

A. Circuit Board

malfunctioning

A. Programmer does not light up 24 volt

supply connected. NOTE: For Valves

made on/after Nov 2011, the amber

(orange) LED does not light up AND the

24 VOLT supply is connected.

A. Check fuser, or replace circuit

board.

Valve Dispenses

Water Only

B. Soda & front

syrup solenoid wires

plugged into wrong

connector.

C. Water solenoid

malfunctioning.

D.Water Solenoid

Core defective

E. Circuit board

malfunctioning.

F. Circuit board

misaligned. Lever not

making contact with

circuit board sensor.

A. Syrup shut-off on

back block is closed.

B. Out of syrup.

C, Syrup solenoid

unplugged.

D. Flowmeter

unplugged.

E. Flowmeter

connector wet.

F. Circuit board

malfunctioning.

G. Flowmeter rotor

obstructed, does not

turn freely.

H. Bad Flowmeter

Sensor.

I. Bad Syrup Solenoid.

J. Syrup solenoid core

is defective.

K. Syrup side of valve

obstructed.

B. ‘5 sec water’ button on programmer

dispenses small amount of syrup. Green

and red LEDs light up.

C. Programmer lights up, but does not

dispense water with ‘5 sec water’. Shutoffs are open. Green LED lights up.

D. Rubber poppet in core is swollen or

deformed. Green LED lights up.

E. New ratio cannot be entered w/

programmer.

F. Circuit board not screwed all the way

down. Board misaligned with holes and

mounting posts.

A. Coils click when activated by

programmer ‘syrup purge’. Green & Red

LEDs light up.

B. Syrup purge draws no syrup &

shut-off is open.

C. No clicking sound when ‘syrup purge’

activated.

D. Flow rates (0) after programmer ‘5

sec water’ pour. Green LED lights up.

E. Flow rate zero (0) after programmer

‘5 sec water’ pour. Circuit board wet. No

LEDs light up.

F. Programmer does not light up when

plugged in.

G. Flow rate zero (0) after programmer

‘5 sec water’ pour.

H. Flow rate zero (0) after programmer ‘5

sec water’ pour. Green LED lights up.

I. No clicking sound when ‘syrup purge’

activated & coils properly connected.

Green & Red LEDs light up.

J. Rubber poppet in core is swollen or

deformed.

K. Coils click when “syrup purge’

activated, shut-off is open, and syrup

supply is full. Green & Red LEDs light

up.

B. Connect soda and front syrup to

correct connectors.

C. Replace water solenoid.

D. Replace core.

E. Replace circuit board.

F. Ensure board is aligned & screw in

board all the way down.

A. Open syrup shut-off on mounting

block.

B. Replace BIB or nal.

C. Plug in syrup solenoid.

D. Plug in owmeter connector.

E. Unplug. Dry connector. Shake

water out of plug.

F. Replace circuit board.

G. Remove obstruction or replace

owmeter.

H. Replace owmeter assembly.

I. Replace syrup solenoid.

J. Replace core.

K. Disassemble syrup side &

remove obstruction.

23

Page 24

SYMPTOM POSSIBLE CAUSE VERIFICATION SOLUTION

Valve Dispenses

without Prompt/

Request

A. Lever arm or lever

spring damaged.

B. Push Button/

Portion Control

malfunctioning.

C. Circuit Board

malfunctioning.

D. Moisture in plug

(pushbutton

programmer) on front

of circuit card.

A. Top end of lever arm does not return

to back of valve.

B. Valve stops, when panel unplugged

from circuit board.

C. Valve pours with lever arm retracted,

or pushbutton/portion control unplugged.

D. Circuit board covered with water

A. Replace lever arm and/or lever

spring.

B. Replace panel.

C. Replace circuit board.

D. Unplug. Dry out connector.

Shakewater out of plug.

Valve Pours

Erratically

Water Leak A. Screw(s) loose.

A. Connectors loose.

B. Pushbutton

malfunctioning.

C. Connectors wet.

D. Circuit board

malfunctioning.

E. Air in lines.

B. O-ring seal is bad.

C. Flowmeter body is

broken.

D. Debris in water

solenoid.

A. Solenoid, owmeter, and/or pushbutton connectors not plugged into circuit

board completely.

B. Valve pours erratically when pushed.

C. Circuit board covered with water or

syrup.

D. Valve pours erratically after

pushbutton replaced and connections

cleaned.

E. Hissing sound heard out of valve.

A. Water solenoid or owmeter screws

turn easily.

B. Water leaks past o-ring, after screws

have been tightened.

C. Crack visible in owmeter body.

D. Water leaks through nozzle.

A. Insert connectors until locking tabs

engage.

B. Replace pushbutton.

C. Unplug all connectors. Dry out

and blowdry. Shake water out of

plug.

D. Replace circuit board.

E. Continue to pour until air is purged

from lines.

A. Tighten screw(s).

B. Replace o-ring.

C. Replace owmeter assembly.

D. Remove debris from water

solenoid.

E. Valve body broken.

Syrup Leak A. Screw(s) loose.

B. O-ring seal is bad.

C. Syrup body is

cracked.

D. Debris in syrup

solenoid.

E. Valve body broken.

E. Water continues to leak, after items

(above) have been checked.

A. Syrup body or syrup retainer screws

turn easily.

B. Syrup leaks past o-ring, after screws

have been tightened.

C. Crack visible in syrup body.

D. Syrup leaks through nozzle.

E. Syrup continues to leak, after items

(above) have been checked.

24

E. Replace valve.

A. Tighten screw(s) to 9 inch-pounds.

B. Replace o-ring.

C. Replace syrup body assembly.

D. Remove debris from Syrup Solenoid.

E. Replace valve.

Page 25

NOTES

22. APPLIANCE DISPOSAL

To prevent possible harm to the environment from improper disposal, recycle the unit

by locating an authorized recycler or contact the retailer where the product was pur

chased. Comply with local regulations regarding disposal of the refrigerant and

insulation.

25

Page 26

23. VOLUMETRIC VALVE ASSEMBLY

2

48

47

44

13

16

16

21

22

23

19

20

24

25

26

3

46

45

4

49

50

37

7

5

6

15

11

14

37

8

9

8

10

42

62

11

1

63

66

61

6

5

3

51

26

22

24

23

25

12

52

21

20

27

28

17

18

16

30

ER

WAT

53

54

SODA

55

PUSH

31b

64

31a

65

43

34a

34b

34c

3

32

33

36

35

3

16

40

41

16

29

37

38

39

17

56

PUSH

WATER

58

WATER

57

PUSH

SODA

59

60

SODA

26

Page 27

23. VOLUMETRIC VALVE PARTS LIST

Item Part No. Description CCUSA

R 1 52-2345/05 PCB Assy 24155

2 04-0640 Screw, 4 - 20 24208

R 3 04-0633/01 Screw, 6 - 19 x 0.437 24209

4 03-0188 Spring, Lever 24210

R 5 03-0187 Retainer, Syrup 24211

6 02-0221 O-Ring 22363

R 7 54-0115/01 Body Assy, Meter 24212

Assy, Syrup

8 02-0264 O-Ring 24213

R 9 81-0298 Sleeve, Syrup 1070147

10 81-0347 Piston 24215

R 11 05-0940/02 Retainer, Piston 24216

R 12 04-0302 Screw 21691

R 13 54-0175 Tube, Down, Syrup,

Restrictor

R 14 05-1094 Restrictor, Syrup 24219

15 02-0085 O-Ring 10060

16 02-0005 O-Ring 10050

17 04-0637 Screw 24221

18 05-0707 Retainer, Soda, 24222

Solenoid

R 19 10-0877/03 Plug Nut, Soda, 1071045

Solenoid

R 20 02-0538 O-Ring 10061

R 21 81-0289 Bonnet, Sub-assy, 24214

Solenoid

R 22 12-0132/01-01 Coil 24225

R 23 04-0600 Washer, Solenoid 24226

24 02-0109 O-Ring 17428

R 25 23-1071 Core Assy 1071046

R 26 03-0180 Spring, Core 24228

R 27 10-0280/02 Plug Nut, Syrup 24230

28 03-0233 Retainer, Valve 24231

R 29 54-0178 Main Body Assy 24232

30 05-0706 Seat, Soda 24233

R 31a 54-0125/01 Lever Arm 24234

R 31b 54-0195 Self-Serve Lever 24235

32 05-0779/01 Plug, Regulator 24236

33 02-0003 O-Ring 10049

34a 54-0192 Flow Washer Assy, 24237

Red, 1.50 Ounces

34b 54-0193 Flow Washer Assy, 24238

White, 2.25 Ounces

34c 54-0194 Flow Washer Assy, 24239

Gray, 3.00 Ounces

R 35 54-0126 Meter Assy(Includes #36)

R 36 02-0354 O-Ring

37 04-0549 Screw, 6 - 19 X 0.625 24242

R 38* 05-1102 Filler, Plate, Bottom 24243

R 39 05-0960/01 Plate, Bottom 24244

R 40 54-0176/01 Diffuser, Body Assy 24245

R 41 05-2053 Nozzle 24246

R 42 54-0190 Down Tube, 24220

Restrictor Assy

R 43 82-0274 Mounting Block 19810

Item Part No. Description CCUSA

R 43 82-0274 Mounting Block 19810

R 44 05-0266/01 Valve Stem, 12270

Mounting Block

R 45 05-0267 Washer 12286

R 46 02-0047 O-Ring 15175

R 47 04-0269 Screw 19894

R 48 03-0087 Retainer, Valve, 12263

R 48 03-0087 Retainer, Valve, 12263

Mounting Block

R 49 05-0265/01 Mounting Block 12189

R 50 02-0126 O-Ring 10706

R 51 54-0029/02 Cover Sub-assy 23984

R 52 05-0287/02 ID Panel 21432

R 53 52-1571 ID Panel, 24251

Water Button

R 54 52-1572 ID Panel, 24252

Soda Button

R 55 52-1399 ID Panel, 24253

Push Button

R 56 52-1573 ID Panel, 24254

Push Button, Water

R 57 52-1574 ID Panel, 24255

Push Button, Soda

R 58 52-1575/02 ID Panel, 24256

Portion Control,

R 59 52-1576/02 ID Panel, 24257

Portion Control,Water

R 60 52-1577/02 ID Panel, 24258

Portion Control,Soda

R 61 82-1117/02 Meter Assy, Syrup 24217

R 62 82-1624 Core/Spring Assy 24229

(Includes Items 25 & 26)

R 63 05-1187 Cover, Programmer 1071044

Plug

R 64 52-2491 Harness Assy,Syrup Purge

R 65 05-1958 Holder. Purge Switch,

Volumetric Valve

R 66 12-0348 Fuse, 5 Amp, 5X15, 1070729

Fast Acting

R -- 52-1420/02 Hand Held 532179

Programmer Assy

*Model 150P - Pushbutton only

R in margin indicates change or revision

27

Page 28

Lancer Corp.

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Loading...

Loading...