Page 1

UNICORN TOWER

Operation Manual

PN: 28-0883/03

310

PN 85-3151R - VV

PN 85-3161R - LFCV

Technical Support/Warranty: 800-729-1550

“Lancer” is the registered trademark of Lancer © 2013 by Lancer, all rights reserved.

Lancer Corp.

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

custserv@lancercorp.com

lancercorp.com

Manual PN: 28-0883/03

DIGITAL RELEASE ONLY - MAY 2013

FOR QUALIFIED INSTALLER ONLY

Page 2

ABOUT THE UNICORN

The Unicorn Tower is designed using the highest quality materials and state-of-the-art technology to provide our

customers with consistent quality and a unique drink experience.

TABLE OF CONTENTS

SPECIFICATIONS ..............................................................................................................................3

WARNINGS/SAFETY/CAUTIONS .....................................................................................................4

ELECTRICAL WARNING .............................................................................................................4

WATER NOTICE............................................................................................................................5

ADA STANDARDS FOR ACCESSIBLE DESIGN..........................................................................5

DISPENSER INSTALLATION HIGHLIGHTS.................................................................................6

PRE-INSTALLATION CHECKLIST.................................................................................................7

1. INSTALLATION.............................................................................................................................8

1.1 UNPACKING THE DISPENSER...........................................................................................8

1.2 SELECTING A LOCATION FOR THE DISPENSER ............................................................8

1.3 ADA STANDARDS FOR ACCESSIBLE DESIGN.................................................................8

1.4 INSTALLATION OF THE UNIT.........................................................................................8-11

1.5 PLUMBING LINE CONNECTIONS.....................................................................................12

2. LINE RUN - RECIRCULATING SYSTEM....................................................................................13

3. CONNECTING TO ELECTRICAL POWER.................................................................................14

4. CLEANING AND SANITIZING INSTRUCTIONS........................................................................15

4.1 CLEANING & SANITIZING SOLUTIONS ..........................................................................15

4.2 DAILY CLEANING...............................................................................................................15

4.3 WEEKLY CLEANING & SANITIZING ................................................................................16

4.4 CLEANING AND SANITIZING BEVERAGE COMPONENTS - BAG-IN-BOX SYSTEMS..17

5. PROGRAMMING OVERVIEW ...................................................................................................18

5.1 PROGRAMMING WITH THE VOLUMETRIC HANDHELD PROGRAMMER.....................19

5.2 CONFIGURATION..........................................................................................................19-21

5.3 ADJUSTING WATER FLOW AND WATER TO SYRUP RATIO (BRIX) - LFCV ONLY ......22

5.4 OPERATION ......................................................................................................................22

6. TROUBLESHOOTING ...............................................................................................................23

7. DISPENSER DISPOSAL.............................................................................................................24

8. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS............................................24

TOWER, UNICORN, T/C, PC, CC, LFCV - SPARE PARTS LIST LIST

8.1 ELECTRONIC, LFCV SPARE PARTS................................................................................25

8.2 NOZZLE, LFCV SPARE PARTS ........................................................................................26

8.3 VALVE, LFCV SPARE PARTS ...........................................................................................27

8.4 WIRING DIAGRAM, LFCV..................................................................................................28

TOWER, UNICORN, T/C, PC, CC, VV - SPARE PARTS LIST

8.4 WIRING DIAGRAM, LFCV..................................................................................................28

8.5 ELECTRONIC, VV SPARE PARTS.....................................................................................29

8.6 NOZZLE, VV SPARE PARTS..............................................................................................30

8.7 WATER VALVE, VV SPARE PARTS...................................................................................31

SYRUP VALVE, VV SPARE PARTS ..................................................................................31

8.8 MISC, VV SPARE PARTS...................................................................................................32

8.9 WIRING DIAGRAM, VV .....................................................................................................33

8.10 COUNTER CUTOUT TEMPLATE.......................................................................................34

2

Page 3

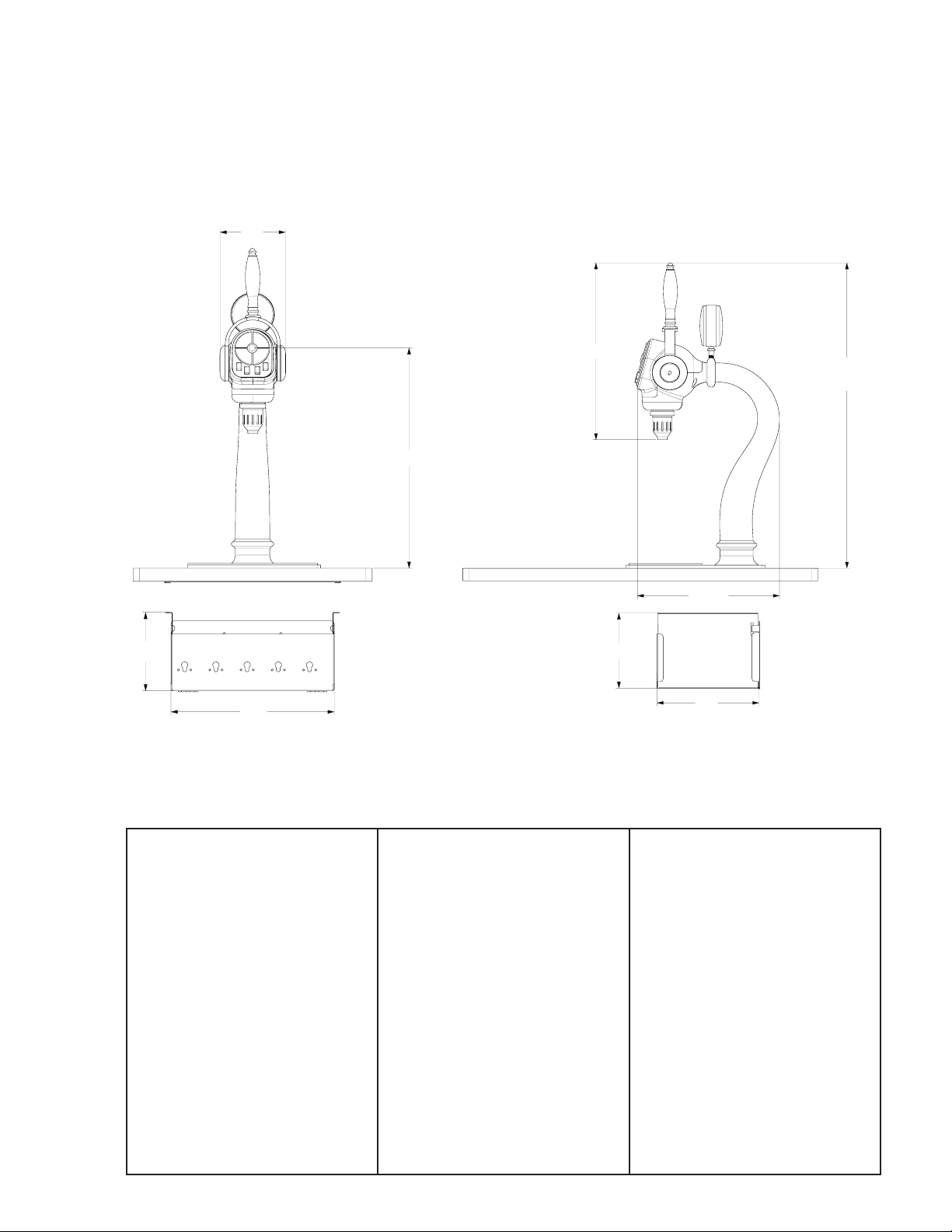

UNICORN TOWER SPECIFICATIONS

13.73

6.00

8.93

11.11

27.50 MAX

to

24.50 MIN

17.00

6.00

13.11

4.95

DIMENSIONS

Height: 25.4 in (645.2 mm)

Width: 4.95 in (125.7 mm)

Depth: 11.11 in (282.2 mm)

SPACE REQUIRED

Left Side: 6 in (152.4 mm)

Right side: 6 in (152.4 mm)

Top and Rear: 6 in (152.4 mm)

NORTH AMERICA ELECTRICAL

REQUIREMENTS:

120 VAC 50/60Hz

INTERNATIONAL ELECTRICAL

REQUIREMENTS:

Refer to ‘CONNECTING TO

ELECTRICAL SUPPLY’ on pg 13

NOTE: Portion Control Unit shown for

illustrative purposes only

Junction Box

Front View

Junction Box

Side View

WEIGHT

Shipping: 35 lbs (15.88 kg)

Counter Weight: 40 lbs (18.1 kg)

FITTINGS

Soda/Plain water inlet: 1/4” barb

Brand syrup inlets: 1/4” barb

OPERATING PRESSURES

Flow Rate:

2.0 ounces per second

(44.4 ml/sec)

PLAIN WATER

Min: 40 PSIG (0.276 MPA)

Max: 110 PSIG (0.756 MPA)

SYRUP

Min: 20 PSIG (0.137 MPA)

Max: 70 PSIG (0.482 MPA)

DIET SYRUP

Min: 10 PSIG (0.068 MPA)

Max: 70 PSIG (0.482 MPA)

3

Page 4

! !

WARNING/ADVERTENCIA/AVERTISSEMENT

! The dispenser is for indoor use only. This unit is not a toy. It should not be used by children or inrm persons

without supervision. This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety. This unit is not designed to

dispense dairy products. The min/max ambient operating temperature for the dispenser is 40 to 105 degrees F.

! El dispensador sólo debe usarse en interiores. Esta unidad no es un juguete. No la deben usar niños ni personas

discapacitadas sin supervisión. Esta unidad no está destinada al uso por parte de personas (incluso niños)

con capacidad física, sensorial o mental reducida, o sin experiencia y conocimientos sucientes, a menos que una

persona responsable de su seguridad les haya dado supervisión o capacitación en el uso de la unidad. Esta unidad

no ha sido diseñada para suministrar productos lácteos. La temperatura ambiente operativa mínima/ máxima para

el dispensador es de 40 a 105 grados F.

! Le distributeur est destiné à un usage à l’intérieur seulement. Cet appareil n’est pas un jouet. Il ne devrait pas être

utilisé par des enfants ou des personnes inrmes sans surveillance. Cet appareil n’est pas destiné à un usage par

des personnes (y compris les enfants) ayant des capacités physiques, sensorielles ou mentales réduites, ou

manquant d’expérience et de connaissances, à moins qu’elles obtiennent de la surveillance ou des instructions au

sujet de l’utilisation de l’appareil de la part d’une personne chargée de leur sécurité. Cet appareil n’est pas conçu

pour distribuer des produits laitiers. La température de service ambiante minimum/maximum pour le distributeur est

de 40 à 105 degrés F.

ELECTRICAL WARNING/ADVERTENCIA ELÉCTRICA/

F F

AVERTISSEMENT ÉLECTRIQUE

F Check the dispenser serial number plate for correct electrical requirements of unit. Do not plug into a wall

electrical outlet unless the current shown on the serial number plate agrees with local current available. Follow all

local electrical codes when making connections. Each dispenser must have a separate electrical circuit. Do not use

extension cords with this unit. Do not ‘gang’ together with other electrical devices on the same outlet. The keyswitch

does not disable the line voltage to the transformer primary. Always disconnect electrical power to the unit to prevent

personal injury before attempting any internal maintenance. The resettable breaker switch should not be used as a

substitute for unplugging the dispenser from the power source to service the unit. Only qualied personnel should

service internal components of electrical control housing. Make sure that all water lines are tight and units are dry

before making any electrical connections!

F Verique la placa con el número de serie del dispensador, donde encontrará los requisitos eléctricos correctos de

la unidad. No enchufe la unidad en un tomacorriente de pared a menos que la corriente indicada en la placa con el

número de serie concuerde con la corriente local disponible. Al hacer las conexiones, respete todos los códigos

eléctricos locales. Cada dispensador debe tener un circuito eléctrico independiente. No use extensiones con esta

unidad. No la conecte junto con otros dispositivos eléctricos al mismo tomacorriente. El interruptor de llave no corta

el voltaje de línea al transformador primario desconecte siempre la alimentación eléctrica a la unidad para evitar

lesiones personales antes de tratar de realizar tareas de mantenimiento. El disyuntor de sobrecarga reseteable no

se debe usar como sustituto para desenchufar el dispensador de la fuente de alimentación para realizar tareas de

servicio de la unidad. El servicio de los componentes internos de la caja de control eléctrico debe conarse

exclusivamente a personal calicado. Asegúrese de que todas las líneas de agua estén ajustadas y las unidades

estén secas antes de hacer conexiones eléctricas.

F Examinez la plaque de numéro de série du distributeur pour connaître les bonnes exigences en matière

d’électricité pour l’appareil. Ne le branchez pas à une prise électrique murale à moins que le courant indiqué sur la

plaque de numéro de série corresponde au courant local disponible. Respectez tous les codes électriques locaux

lorsque vous faites des connexions. Chaque distributrice doit avoir un circuit électrique séparé. N’utilisez pas

de cordons prolongateurs avec cet appareil. Ne pas le brancher avec d’autres appareils électriques sur la même

prise. L’interrupteur à clé ne coupe pas la tension secteur au transformateur primaire. Débranchez toujours

le courant électrique à l’appareil, an de prévenir des blessures, avant de faire un entretien interne quelconque. Le

disjoncteur réarmable ne devrait pas être utilisé au lieu de débrancher le distributeur de la source d’alimentation en

électricité pour faire de l’entretien/une réparation de l’appareil. Seul le personnel qualié devrait faire l’entretien/la

réparation des composants internes dans le logement des commandes électriques. Assurez-vous que toutes les

conduites d’eau sont étanches et que les appareils sont secs avant de faire des connexions électriques!

4

Page 5

! !

WATER NOTICE/AGUA AVISO/ PRÉAVIS DE L’EAU

! Provide an adequate potable water supply. Water pipe connections and xtures directly connected to a potable

water supply must be sized, installed, and maintained according to federal, state, and local laws. The water supply

line must be at least 3/8 inches (9.525 mm) pipe with a minimum of 20 PSI (0.137 MPA) line pressure, but not

exceeding a maximum of 50 PSI (0.345 MPA). Water pressure exceeding 50 PSI (0.345 MPA) must be reduced to

50 PSI (0.345 MPA) with the provided pressure regulator. Use a lter in the water line to avoid equipment damage

and beverage off-taste. Check the water lter periodically, as required by local conditions. The water supply must be

protected by means of an air gap, a backow prevention device (located upstream of the CO2 injection system) or

another approved method to comply with NSF standards. A leaking inlet water check valve will allow carbonated

water to ow back through the pump when it is shut off and contaminate the water supply. Ensure the backow

prevention device complies with ASSE and local standards. It is the responsibility of the installer to ensure

compliance.

! Proporcione un suministro adecuado de agua potable. La línea de suministro de agua debe ser de una tubería de

por lo menos 3/8 pulgadas (9.525 mm) con una presión de línea mínima de 20 PSI (0.137 MPA) , pero sin superar

el máximo de 50 PSI (0.345 MPA). La presión de agua que supere los 50 PSI se debe reducir a 50 PSI (0.345 MPA)

con un regulador de presión. Use un ltro en la línea de agua para evitar daños al equipo y cierto sabor raro en las

bebidas. Verique periódicamente el ltro de agua de acuerdo con las condiciones imperantes. El suministro de

agua debe estar protegido por una separación de aire, un dispositivo de prevención del contraujo (situado antes

del sistema de inyección de CO2) u otro método aprobado para cumplir las normas NSF. Si la válvula de retención

de entrada de agua tuviera pérdidas, permitiría el contraujo del agua carbonatada a través de la bomba cuando se

la detiene y contaminaría el suministro de agua. Asegúrese de que el dispositivo de prevención del contraujo

cumpla con las normas locales y de ASSE. Es responsabilidad del instalador cumplir con estos requisitos.

! Fournissez une alimentation en eau potable adéquate. Les connexions et les dispositifs de conduite d’eau

connectés directement à une alimentation en eau potable doivent être calibrés, installés et maintenus selon les lois

fédérales, provinciales et locales. La conduite d’alimentation en eau doit être un tuyau d’au moins 3/8 pouces (9.525

millimètres) avec une pression de ligne minimum de 20 LPC (0.137 MPA) , mais ne doit pas dépasser un maximum

de 50 LPC (0.345 MPA). Une pression d’eau de plus de 50 LPC (0.345 MPA) doit être réduite à 550 LPC (0.345

MPA) avec le régulateur de pression fourni. Utilisez un ltre dans la conduite d’eau pour éviter des dommages à

l’équipement et un goût des boissons qui n’est pas juste. Vériez le ltre à eau périodiquement, selon les exigences

des conditions locales. L’alimentation en eau doit être protégée au moyen d’un intervalle d’air, un disconnecteur

hydraulique (situé en amont du système d’injection de CO2) ou une autre méthode approuvée pour se conformer

aux normes de la NSF. Un clapet antiretour pour l’eau entrante qui fuie permettra à l’eau gazeuse de repasser par

la pompe quand elle est fermée et de contaminer l’alimentation en eau. Assurez-vous que le disjoncteur hydraulique

soit conforme aux normes de l’ASSE et locales. L’installateur est responsable d’assurer la conformité.

! !

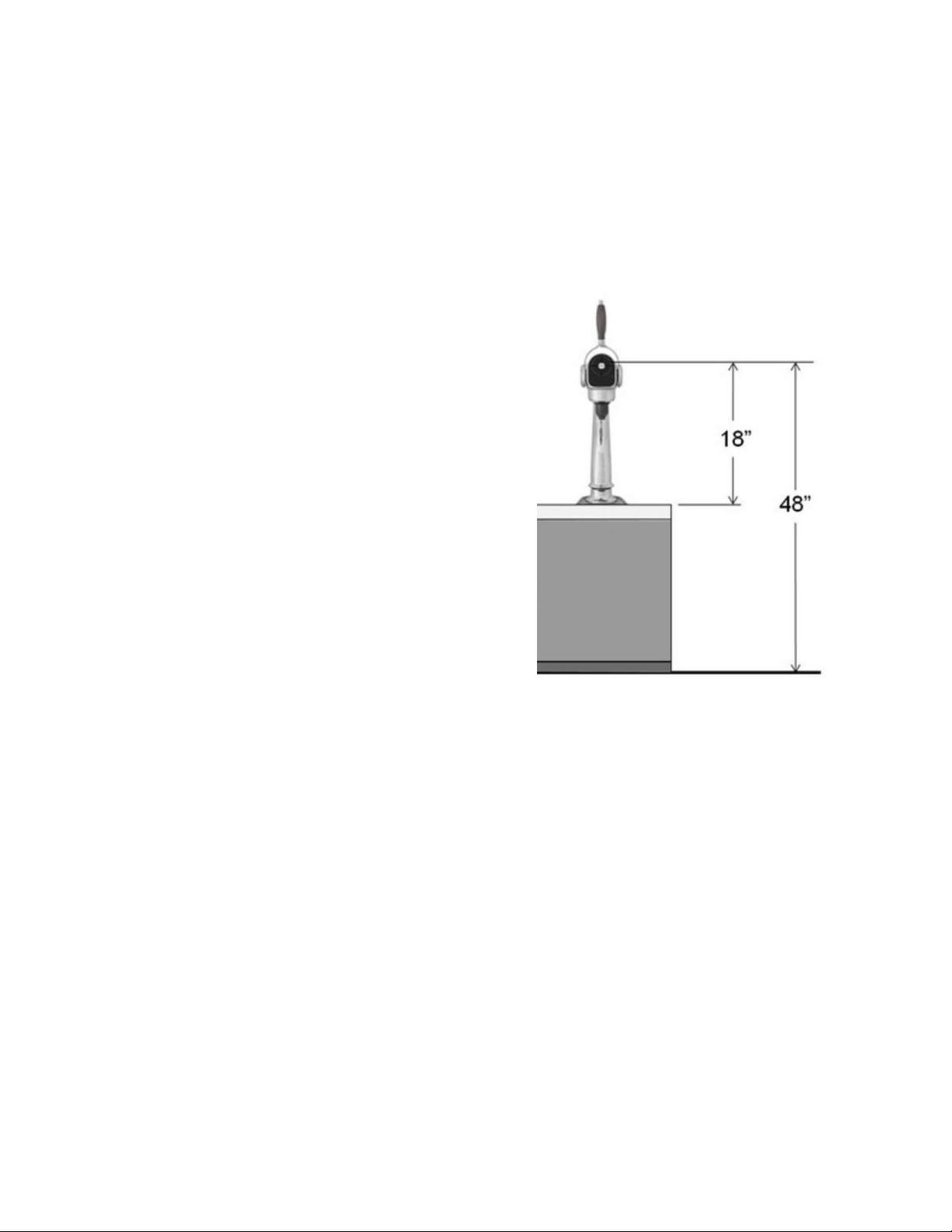

ADA STANDARDS FOR ACCESSIBLE DESIGN

To assure that beverage service is accessible to all customers, Lancer recommends that counter height

and equipment selection be planned carefully. The 2010 ADA Standards for Accessible Design states

the maximum reach height from the oor should be no more than 48” if touch point is less than 10” from the

front of the counter, or a maximum of 46” if the touch point is more than 10” and less than 27” from the front of the

counter (See Fig 1). For more information about the customer’s legal requirements for the accessibility of installed

equipment, refer to 2010 ADA Standards for Accessible Design - http://www.ada.gov.

5

Page 6

!

This unit has been factory sanitized per Lancer specications.

Listed below are critical elements which will aid in a successful installation.

1. If this dispenser is installed in an area that is susceptible to ±10% variation of the nominal line voltage, consider

installing a surge protector or similar protection device.

2. Supply Water Pressure: Minimum - 25 PSI (0.172 MPA); Maximum - 50 PSI (0.345 MPA); If pressure is over 50

PSIG (0.345 MPA), a water pressure regulator must be used.

3. Bag-in-box (BIB) syrup packages must be within 6 feet (1.83 m) from unit when internal syrup pumps are being

used.

4. Valve Adjustment: Make sure drink temperature is below 40°F (4.4°C) before adjusting brix.

DISPENSER INSTALLATION HIGHLIGHTS

!

!

Esta tin/dad ha sido saneada en fabrica por las especicaciones de Lancer.

A continuacion se relacionan 6 puntos importantes para una connecta instalacion.

1. Si la unidad va a ser instalada en un area en la que puedan darse variaciones de voltage de + 6 - 10% de su valor

nominal, se debe considerar la conveniencia de instalar un estabilizador de corriente o sistema de proteccion similar.

2. Presión de suministro del agua de red: Minimo 25 PSIG (0.172 MPA). Maximo 50 PSIG (0.345 MPA). En unidades

sin regulador de presión incorporado, si la presión del agua es superior a 50 PSIG (0.345 MPA) se debe usar un

regulador de presión.

3. Los envases de jarabe Bag-ln-Box deben setar situados a menos de 6 pies (2 metros) de la unidad cuando se

utilicen bombas de jarabe intemas.

4. Ajuste de las valvulas: Cerciórese de que la temperatura de la bebida es inferior a 4.4°C (40°F) antes de regular el

coeciente Brix.

REGLES DE SECURITE POUR L’NSTALLATION DU DISTRIBUTEUR DE SODAS

!

La proprètè da cet ensamable est assurè à I’usine sulvant les spècications èmis par Lancer .

Il est essentiel de respecter les 6 points suivants pour l’installation de l’appareil:

1. Si le distributeur es installè dans une zone ou la tension èlectrique nominale est susceptible de variations de (+)

10%, il est conseillè d’installer un appaeil de protection contre les sautes de courant.

2. Pression de l’eau: Minimum 25 PSIG (0.172 MPA); Maximum 50 PSIG (0.345 MPA). Sur les unitès qui n’ont pas

de règulateur de pression d’eau incorprè, si la pression d’H2O est supèrieure à 50 PSIG (0.345 MPA), un règulateur

de pression d’eau doit etre utilsisè.

3. Le sac dans les paquets de sirop doit etre à 1,83 m. au plus de l’unitè quand on utilise les pompes à sirop internes.

4. Règlage des valves: S’assurer que la tempèrature de la boisson est infèrieure a 4.4°C (40°F) avant de règler le

degrè Brix.

PUNTOS IMPORTANTES EN LA UNIDAD DISPENSADORA

!

!

6

Page 7

PRE-INSTALLATION CHECKLIST

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly inspected before shipment.

At the time of shipment, the carrier accepts responsibility for the unit. Upon receiving the

unit, carefully inspect the carton for visible damage. If damage exists, have the carrier note

the damage on the freight bill and le

a claim with carrier.

TOOLS & ACCESSORIES

CO2 Regulator Set Beverage Tubing

CO2 Supply Water Booster (if necessary)

Remote System Oetiker Clamps/Fittings

Wrenches Slotted Screwdriver

Tubing Cutters Drill

BIB SYSTEM

BIB Rack BIB Regulator Set

BIB Connectors - verify correct amount for syrup lineup

BIB Syrup Boxes Remote Cooling/Carbonation System

CONSIDER LOCATION OF THE FOLLOWING PRIOR TO INSTALL

Water supply lines Is the countertop at least 1 inch thick?

Grounded electrical outlet. Drain

Is there enough space to install the dispenserand the junction box?

THIS MANUAL APPLIES TO THE FOLLOWING UNITS

85-3151R-21-11111-00 TOWER, UNICORN, RECIRC, TC, PC, CC, VV-R, GI

85-3151R-21-11111 TOWER, UNICORN, RECIRC, TC, PC, CC, VV-R

85-3151R-20-11111-22 TOWER, UNICORN, TC, PC, CC, VV-R, AUS

85-3161R-21-11111 TOWER, UNICORN, TC, PC, CC, LFCV-R

85-3161R-21-11111-00 TOWER, UNICORN, TC, PC, CC, LFCV-R, GI

85-3161R-21-21222 TOWER, UNICORN, RECIRC, TC, PC, GB.LFCV-R

85-3161R-21-21222-00 TOWER, UNICORN, RECIRC, TC, PC, GB.LFCV-R, GI

85-3161R-21-23222 TOWER, UNICORN, RECIRC, TC, NOPC, GB, LFCV-R*

85-3161R-21-23222-00 TOWER, UNICORN, RECIRC, TC, NOPC, GB, LFCV-R, GI*

85-3161R-21-31332 TOWER, UNICORN, RECIRC, TC, PC, PI, LFCV-R

85-3161R-21-31332-00 TOWER, UNICORN, RECIRC, TC, PC, PI, LFCV-R, GI

85-3161R-20-31332-22 TOWER, UNICORN, RECIRC, T/C, PC, PI, LFCV-R, AUS

KEY

TC – Thru Counter PC – Portion Control NOPC – Non Portion Control (*Self serve)

R – Recirculation (RECIRC) AUS – Australia GI – No Transformer (International Only)

7

Page 8

1. INSTALLATION

1.1 UNPACKING THE DISPENSER

A. The Lancer dispenser is shipped in a corrugated shipping carton.

B. Remove dispenser from corrugated shipping carton.

C. Inspect unit and parts for concealed damage. If damage exists, notify delivering carrier and le

claim against the carrier.

1.2 SELECTING A LOCATION

A. Select a counter location which is near a properly grounded electrical outlet, and a water supply

that meets the requirements specied in Section 1.6.

B. Unit is designed to be supported by remote chiller system or remote ice cooled system. See the

manufacturer’s specications for installation.

1.3 ADA STANDARDS FOR ACCESSIBLE DESIGN

To assure that beverage service is accessible to all

customers, Lancer recommends that counter height and

equipment selection be planned carefully. The 2010 ADA

Standards for Accessible Design states that the maximum

reach height from the oor should be no more than 48” if

touch point is less than 10” from the front of the counter,

or a maximum of 46” if the touch point is more than 10”

and less than 27” from the front of the counter

(See Fig 1).

For more information about the customer’s legal

requirements for the accessibility of installed equipment,

refer to 2010 ADA Standards for Accessible Design http://www.ada.gov.

1.4 INSTALLATION OF THE UNIT

A. DRIP TRAY INSTALL

1. Inspect the counter location where the unit is to be installed. Verify the selected counter is

strong enough to safely support the weight of the installed unit, after the cutout for the unit

is made.

2. Use the Counter Cutout template provided in the Install Kit for correct dimensions.

NOTE: The ideal counter for installation should measure at least 1” thick.

3. Cut the required holes as shown on the Counter Cutout for the Drip Tray and Font Shank.

4. Place Drip Tray in the counter.

Figure 1

8

Page 9

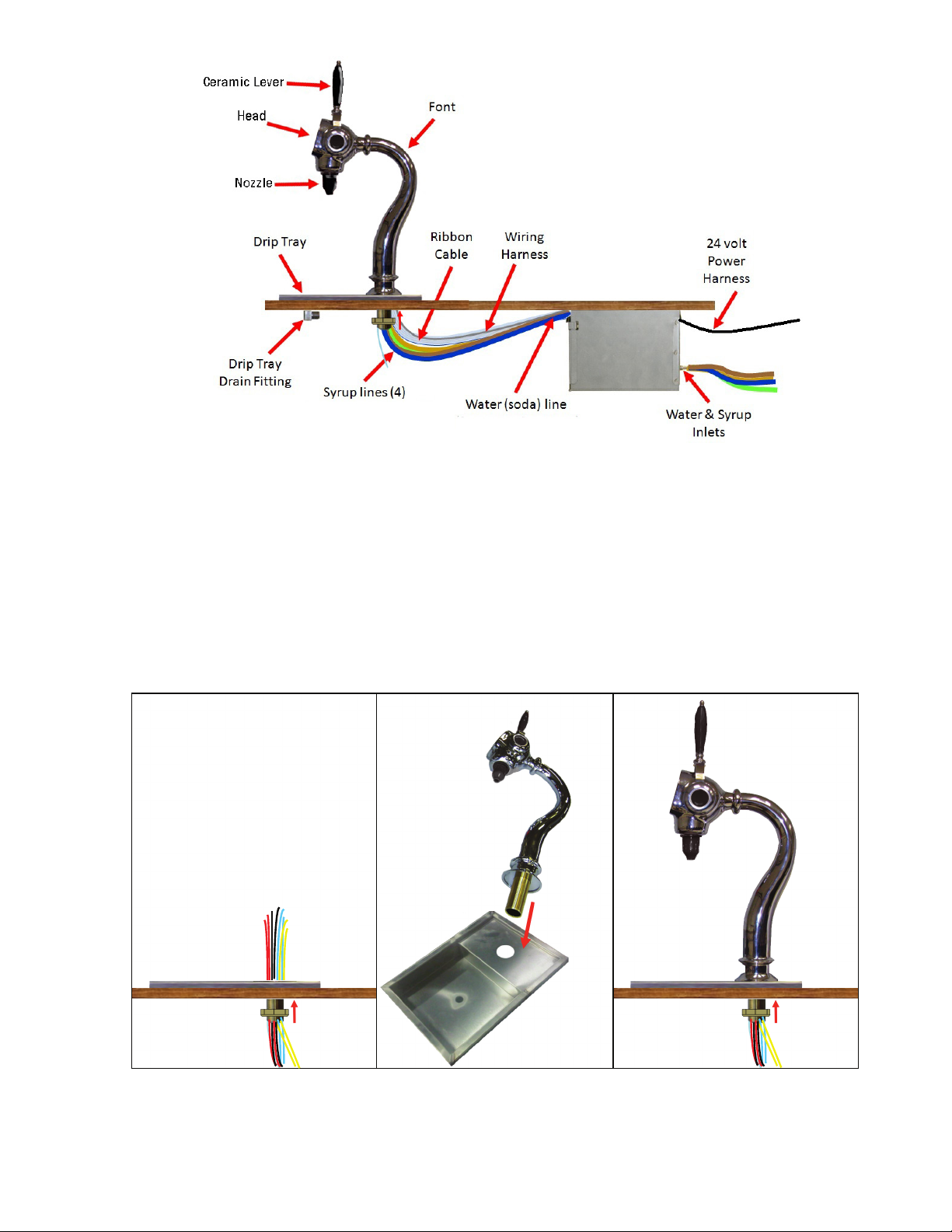

Figure 2. Unit Overview

1.4 INSTALLATION OF THE UNIT - CONTINUED

B. FONT INSTALLATION

1. Route ribbon cable, harness, and syrup/water lines through hole in the Tray Assembly

(Fig 3a).

2. Guide font shank through hole in the drip tray (Fig 3b). Position the font with the Selection

Buttons and Nozzle above the Drip Tray.

3. Route Ribbon Cable, Wire Harnesses and Plumbing Lines through the nut. Next, thread nut

on shank and tighten to secure font to counter (Fig 3c).

NOTE: To avoid damage to the ceramic lever, use caution to avoid over tightening.

Figure 3. Font Installation

Figure 3a Figure 3b Figure 3c

9

Page 10

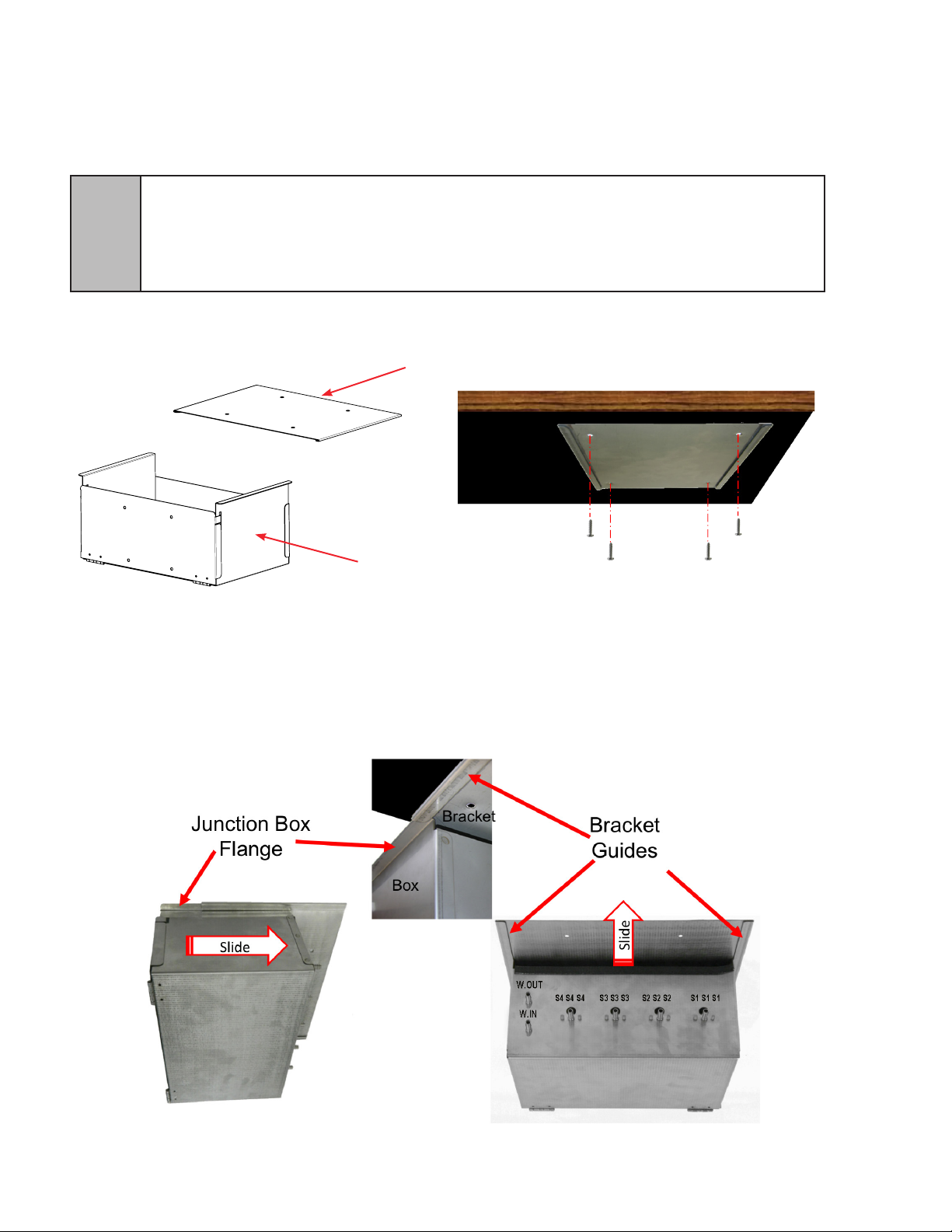

C. JUNCTION BOX INSTALLATION

NOTE: The Font Ribbon Cable, Harness, Syrup and Water lines are 36” inches length. Placement

of Junction Box must be under counter within 2’ of Font/Drip Tray Assembly. The Junction Box

slides on the hanging bracket to expose

components (Fig 4). It is recommended that the Junction Box is mounted with the inlet ttings fac-

ing the rear so the access panel can swing down to access the Box interior.

WARNING DO NOT INSTALL OR SET THE JUNCTION BOX ON THE GROUND. THIS IS A SHOCK HAZARD.

ADVERTENCIA ELÉCTRICA NO INSTALAR O CONFIGURAR LA CAJA DE EMPALME EN EL SUELO. SE TRATA

DE UN RIESGO DE DESCARGA ELÉCTRICA.

F

AVERTISSEMENT ÉLECTRIQUE NE PAS INSTALLER OU CONFIGURER LA BOÎTE DE JONCTION SUR LE TER-

RAIN. IL S’AGIT D’UN RISQUE DE CHOC ÉLECTRIQUE.

Figure 4

Mounting

Bracket

Figure 5

Junction

Box

1. Position the Mounting Bracket to ensure adequate slack remains for

connection lines to accommodate sliding the Box forward for servicing.

2. Secure the Mounting Bracket to bottom of counter with four screws (Fig 5).

3. Align the Junction Box anges with Bracket Guides, slide Box under counter

(Fig 6).

Figure 6

10

Page 11

RIBBON CABLE

PN 52-3346

POWER WIRE HARNESS

PN 52-3348

LFCV VALVE HARNESS

PN 52-3344

J8

J1

J3

RIBBON CABLE

PN 52-3346

POWER WIRE HARNESS

PN 52-3348

VV KIP SOLENOID

PN 52-3359

J8

J1

J3

VV SOLENOID

PN 52-3360

J4

VV WATER

PN 52-3361

J5

D. JUNCTION BOX WIRING CONNECTIONS

1. CONNECT THE FOLLOWING, FOR BOTH Volumetric (VV) AND Lancer Flow Control

Valve (LFVC) MODELS:

a. The various Syrup Valve Harnesses from the Unicorn Font to the appropriate

connection in the Junction Box. Refer to the Wiring Diagram in the Junction Box.

b. Connect the Medallion Harness (PN 52-3348) from the Unicorn Font to the appropriate

connection in the Junction Box.

c. Connect the Ribbon Cable (PN 52-3346) to the Main Board (PN 64-5048) space

labeled J8 (in the Junction Box).

d. Connect the Power Wire Harness (PN 52-3348) to the Main Board space labeled J1.

NOTE: DO NOT CONNECT TO POWER SOURCE AT THIS TIME.

e. For VV Models, continue to Step 3.

For LFCV, continue to Step 2.

Figure 7. LFCV

2. FOR LFCV MODELS ONLY:

a. Connect the LFCV Valve Harness (PN 52-3344) to the Selector Board space labeled J3.

b. Continue to SECTION E. JUNCTION BOX PLUMBING LINE CONNECTIONS

3. FOR VV MODELS ONLY:

a. Connect the VV KIP Solenoid Harness (PN 52-3359) to the Main Board space labeled J3.

b. Connect the VV Solenoid Harness (PN 52-3360) to the Main Board space labeled J4.

c. Connect the VV Water Harness (PN 52-3361) to the Main Board space labeled J5.

Figure 8. VV

11

Page 12

1.5 PLUMBING LINE CONNECTIONS

A. CONNECTING TO WATER SUPPLY

1. Use a tube cutter to cut tubing. Tubing cut with a saw will result in plastic shavings that

could plug the ow controls in the dispensing valve.

2. Provide an adequate potable water supply. Water pipe connections and xtures directly

connected to a potable water supply must be sized, installed, and maintained according

to federal, state, and local laws. An adequate potable water supply must be provided. It is

recommended that the supply shut-off is easily accessible. The water supply line must be at

least 3/8 inches (9.525 mm) pipe with a minimum of 20 PSI (0.317 MPA) line pressure, but

not exceeding a maximum of 50 PSI (0.345 MPA). Water pressure exceeding 50 PSI

(0.345 MPA) must be reduced to 50 PSI (0.345 MPA) with a pressure regulator. Use lter*

in the water line to avoid equipment damage and beverage off-taste.

* Filter of at least 100 mesh [100 strands per 25mm (one inch)] shall be installed

immediately upstream of all check valve type backow preventers used for water supply

protection. The screen shall be accessible and removable for cleaning or replacement.

Check the water lter periodically, as required by local conditions. The water supply must

be protected by means of an air gap, a backow prevention device (located upstream of

the CO2 injection system) or another approved method to comply with NSF standards. Do

not connect to a heated (hot) water source or a water source supplying soft water. This will

cause excessive foaming.

WARNING CHECK THE WATER FILTER PERIODICALLY, AS REQUIRED BY LOCAL CONDITIONS. IT IS THE

RESPONSIBILITY OF THE INSTALLER TO ENSURE COMPLIANCE.

ADVERTENCIA VERIFIQUE PERIÓDICAMENTE EL FILTRO DE AGUA DE ACUERDO CON LAS CONDICIONES

IMPERANTES. ES RESPONSABILIDAD DEL INSTALADOR CUMPLIR CON ESTOS

!

REQUISITOS.

AVERTISSEMENT VÉRIFIEZ LE FILTRE À EAU PÉRIODIQUEMENT, SELON LES EXIGENCES DES CONDITIONS

LOCALES. L’INSTALLATEUR EST RESPONSIBLE D’ASSURER LA CONFORMITÉ.

B. JUNCTION BOX PLUMBING LINE CONNECTIONS - FOR LFCV

NOTE: It is recommended that the that plumbing lines to font are routed out rear of Junction Box.

1. Insert the syrup and water lines (from the Unicorn Font) into the appropriate syrup and

water outlets on the rear of the Junction Box. Refer to Fig 5.

2. There are 2 (two) 1/4” OD Recirculating Water lines, labeled RECIRC. Plug both into the

John Guest Bulkhead Connectors. NOTE: Either RECIRC line can plug into the top.

3. Use the small diameter insulation accordingly to cover all water and syrup tubing.

4. Secure all the ttings in place with the red locking clips.

Figure 9

S4 S4 S4

S3 S3 S3

S2 S2 S2

S1 S1 S1

C. JUNCTION BOX PLUMBING LINE CONNECTIONS - VOLUMETRIC

NOTE: It is recommended that the that plumbing lines to font are routed out rear of Junction Box.

1. Insert the syrup and water lines (from the Unicorn Font) into the appropriate syrup and

water outlets on the rear of the Junction Box. Refer to Fig 5.

2. Connect the ‘H’ shaped water line to the John Guest Bulkhead Connectors. NOTE: Either

RECIRC line can plug into the top.

3. Secure all the ttings in place with the retainer clips.

12

Page 13

2. LINE RUN - RECIRCULATING SYSTEM

NOTE: REFER TO COOLING SYSTEMS MANUFACTURERS INSTALLATION INSTRUCTIONS.

A. SYRUP - Route and connect beverage tubing between Recirculating System Syrup Outlet and

Junction Box Inlet. Repeat for each syrup.

B. WATER - Route and connect beverage tubing between Recirculating System and Junction Box

Water Inlet and Outlets. Insulate the tubing.

C. DRAIN - Route and connect drain tubing between font drip tray and facility drain. Follow all local

health and safety codes when performing this step.

D. CONNECT ‘Y’ FITTING

1. Route and connect beverage tubing between recirculation outlet and ‘Y’ tting at Junction Box.

2. Route and connect beverage tubing between ‘Y’ tting at Junction Box and recirculation inlet.

3. Route and connect beverage tubing between ‘Y’ tting and Junction Box water inlet.

4. Insulate all tubing.

Figure 10

13

Page 14

3. CONNECTING TO ELECTRICAL SUPPLY

NOTE: In addition to the following, adhere to ELECTRICAL WARNINGS AND CAUTIONS, page 6.

NORTH AMERICAN UNITS REQUIREMENTS:

Plug the provided transformer (PN 25-0069/01) into the proper wall socket.

INTERNATIONAL TRANSFORMER (NOT PROVIDED) REQUIREMENTS:

Rated 50 VA or higher, primary voltage as required, and a Secondary Voltage 24VAC. Overcurrent and

surge protection is recommended. Connector wires for the transformer are included in the unit.

WARNING CHECK THE DISPENSER SERIAL NUMBER PLATE FOR CORRECT ELECTRICAL REQUIREMENTS

OF UNIT. DO NOT PLUG INTO A WALL ELECTRICAL OUTLET UNLESS THE CURRENT SHOWN ON THE SERIAL

NUMBER PLATE AGREES WITH LOCAL CURRENT AVAILABLE. THIS UNIT MUST BE PROPERLY ELECTRICALLY

GROUNDED TO AVOID POSSIBLE FATAL ELECTRICAL SHOCK OR SERIOUS INJURY TO THE OPERATOR. THE

POWER CORD HAS A THREE-PRONG GROUNDED PLUG. IF A THREE-HOLE GROUNDED ELECTRICAL OUTLET IS

NOT AVAILABLE, USE AN APPROVED METHOD TO GROUND THE UNIT. FOLLOW ALL LOCAL ELECTRICAL CODES

WHEN MAKING CONNECTIONS. EACH POWER SUPPLY MUST HAVE A SEPARATE ELECTRICAL CIRCUIT. DO NOT

USE EXTENSION CORDS. DO NOT “GANG” TOGETHER WITH OTHER ELETRICAL DEVICES ON THE SAME

OUTLET. THE KEYSWITCH DOES NOT DISABLE THE LINE VOLTAGE TO THE TRANSFORMER PRIMARY. ALWAYS

DISCONNECT POWER TO THE DISPENSER BEFORE ATTEMPTING ANY INTERNAL MAINTENANCE. ONLY

QUALIFIED PERSONNEL SHOULD SERVICE INTERNAL COMPONENTS OF ELECTRICAL CONTROL HOUSING.

MAKE SURE THAT ALL WATER LINES ARE TIGHT AND UNITS ARE DRY BEFORE MAKING ANY ELECTRICAL

CONNECTIONS!

ADVERTENCIA VERIFIQUE LA PLACA CON EL NÚMERO DE SERIE DEL DISPENSADOR, DONDE ENCONTRARÁ

LOS REQUISITOS ELÉCTRICOS CORRECTOS DE LA UNIDAD. NO ENCHUFE LA UNIDAD EN UN

TOMACORRIENTE DE PARED A MENOS QUE LA CORRIENTE INDICADA EN LA PLACA CON EL NÚMERO DE

SERIE CONCUERDE CON LA CORRIENTE LOCAL DISPONIBLE. ESTA UNIDAD DEBE ESTAR DEBIDAMENTE

CONECTADO A TIERRA PARA EVITAR POSIBLES CHOQUES ELÉCTRICOS MORTALES O LESIONES GRAVES AL

OPERADOR. LE BLOC D’ALIMENTATION DOIT ÊTRE MIS À LA TERRE ÉLECTRIQUEMENT CORRECTEMENT POUR

ÉVITER DES BLESSURES GRAVES OU UNE DÉCHARGE ÉLECTRIQUE MORTELLE. LE CORDON D’ALIMENTATION

A UNE FICHE À TROIS BRANCHES MISE À LA TERRE. SI AUCUNE PRISE DE COURANT ÉLECTRIQUE À TROIS

TROUS N’EST DISPONIBLE, UTILISEZ UNE MÉTHODE APPROUVÉE POUR METTRE L’UNITÉ À LA TERRE. AL

HACER LAS CONEXIONES, RESPETE TODOS LOS CÓDIGOS ELÉCTRICOS LOCALES. CADA DISPENSADOR

DEBE TENER UN CIRCUITO ELÉCTRICO INDEPENDIENTE. NO USE EXTENSIONES CON ESTA UNIDAD. NO LA

CONECTE JUNTO CON OTROS DISPOSITIVOS ELÉCTRICOS AL MISMO TOMACORRIENTE. EL INTERRUPTOR DE

F

LLAVE NO CORTA EL VOLTAJE DE LÍNEA AL TRANSFORMADOR PRIMARIO. DESCONECTE SIEMPRE LA

ALIMENTACIÓN ELÉCTRICA A LA UNIDAD PARA EVITAR LESIONES PERSONALES ANTES DE TRATAR DE

REALIZAR TAREAS DE MANTENIMIENTO. EL SERVICIO DE LOS COMPONENTES INTERNOS DE LA CAJA DE

CONTROL ELÉCTRICO DEBE CONFIARSE EXCLUSIVAMENTE A PERSONAL CALIFICADO. ASEGÚRESE DE QUE

TODAS LAS LÍNEAS DE AGUA ESTÉN AJUSTADAS Y LAS UNIDADES ESTÉN SECAS

ANTES DE HACER CONEXIONES ELÉCTRICAS.

EXIGENCES DE MISE À LA TERRE EXAMINEZ LA PLAQUE DE NUMÉRO DE SÉRIE DU DISTRIBUTEUR POUR

CONNAÎTRE LES BONNES EXIGENCES EN MATIÈRE D’ÉLECTRICITÉ POUR L’APPAREIL. NE LE BRANCHEZ PAS

À UNE PRISE ÉLECTRIQUE MURALE À MOINS QUE LE COURANT INDIQUÉ SUR LA PLAQUE DE NUMÉRO DE

SÉRIE CORRESPONDE AU COURANT LOCAL DISPONIBLE. L’UNITÉ DOIT ÊTRE MISE À LA TERRE

ÉLECTRIQUEMENT POUR ÉVITER UNE DÉCHARGE ÉLECTRIQUE MORTELLE OU DES BLESSURES GRAVES

POSSIBLES À L’OPÉRATEUR. LE BLOC D’ALIMENTATION DOIT ÊTRE MIS À LA TERRE ÉLECTRIQUEMENT

CORRECTEMENT POUR ÉVITER DES BLESSURES GRAVES OU UNE DÉCHARGE ÉLECTRIQUE MORTELLE. LE

CORDON D’ALIMENTATION A UNE FICHE À TROIS BRANCHES MISE À LA TERRE. SI AUCUNE PRISE DE

COURANT ÉLECTRIQUE À TROIS TROUS N’EST DISPONIBLE, UTILISEZ UNE MÉTHODE APPROUVÉE POUR

METTRE L’UNITÉ À LA TERRE. RESPECTEZ TOUS LES CODES ÉLECTRIQUES LOCAUX LORSQUE VOUS FAITES

DES CONNEXIONS. CHAQUE SOURCE D’ALIMENTATION DOIT AVOIR UN CIRCUIT ÉLECTRIQUE SÉPARÉ.

N’UTILISEZ PAS DE CORDONS PROLONGATEURS. NE BRANCHEZ PAS PLUSIEURS APPAREILS ÉLECTRIQUES À

LA MÊME PRISE DE COURANT. L’INTERRUPTEUR À CLÉ NE COUPE PAS LA TENSION SECTEUR AU

TRANSFORMATEUR PRIMAIRE. DÉCONNECTEZ TOUJOURS L’ALIMENTATION EN ÉLECTRICITÉ À LA

DISTRIBUTRICE AVANT DE FAIRE DE L’ENTRETIEN INTERNE. SEUL LE PERSONNEL QUALIFIÉ DEVRAIT FAIRE

L’ENTRETIEN/LA RÉPARATION DES COMPOSANTS INTERNES DANS LE LOGEMENT DES COMMANDES

ÉLECTRIQUES. ASSUREZ-VOUS QUE TOUTES LES CONDUITES D’EAU SONT ÉTANCHES ET QUE LES

APPAREILS SONT SECS AVANT DE FAIRE DES CONNEXIONS ÉLECTRIQUES!

14

Page 15

4. CLEANING AND SANITIZING INSTRUCTIONS

A. The cleaning and sanitizing procedures provided herein pertain to the Lancer equipment identied

by this manual. If other equipment is being cleaned, follow the guidelines established by the

manufacturer for that equipment.

B. Lancer equipment (new or reconditioned) is shipped from the factory cleaned and sanitized in

accordance with NSF guidelines. The equipment must be cleaned and sanitized after installation is

complete. The operator of the equipment must provide continuous maintenance as required by this

manual and state and local health department guidelines to ensure proper operation and sanitation

requirements are maintained.

C. Cleaning and sanitizing should be accomplished only by trained personnel. Sanitary gloves are to

be used during cleaning and sanitizing operations. Applicable safety precautions must be observed.

Instruction warnings on the product being used must be followed.

D. Other Required Supplies: 1) Clean cloth towels, 2) bucket, 3) extra nozzle, 4) sanitary gloves and 5)

Small brush PN 22-0017 from installation kit.

4.1 CLEANING AND SANITIZING SOLUTIONS

CLEANING SOLUTION: Mix a mild, non-abrasive detergent (e.g. Sodium Laureth Sulfate, dish

soap) with clean, potable water at a temperature of 90 to 110°F (32 to 43°C). The mixture ratio is

one ounce of cleaner to two gallons of water. Prepare a minimum of ve gallons of cleaning

solution. Do not use abrasive cleaners or solvents because they can cause permanent damage

to the unit. Ensure rinsing is thorough, using clean, potable water at a temperature of 90 to 110

degrees F. Extended lengths of product lines may require additional cleaning solution.

SANITIZING SOLUTION: Prepare sanitizing solutions in accordance with the manufacturer’s

written recommendations and safety guidelines. The solution must provide 50 to 100 parts per

million (PPM) chlorine (e.g. Sodium Hypochlorite or bleach). A minimum of ve gallons of sanitizing

solution should be prepared. Any sanitizing solution may be used as long as it is prepared in

accordance with the manufacturer’s written recommendations and safety guidelines, and

provides 50 to 100 parts per million (PPM) chlorine.

WARNING UNPLUG THE DISPENSER DURING SERVICING, CLEANING, AND SANITIZING.

ADVERTENCIA DURANTE EL SERVICIO, LA LIMPIEZA Y LA ESTERILIZACIÓN, DESENCHUFE EL DISPENSADOR.

F

4.2 DAILY CLEANING

A. Disconnect power to the unit.

B. Following the instructions as described in 4.1 above, mix

appropriate amount of cleaning solution in a clean

container. Place a small portion of the cleaning solution

C. Remove nozzle by twisting counterclockwise and pulling

D. Submerge the Nozzle in the container with the smaller

E. Use a clean cloth soaked in the cleaning solution to

F. Clean the font and all exterior stainless steel surfaces.

G. Wipe clean all splash areas using a damp cloth soaked

H. Clean beverage valves as specied by the valve

manufacturer.

AVERTISSEMENT DÉBRANCHEZ LE DISTRIBUTEUR PENDANT L’ENTRETIEN/LA RÉPARATION, LE NETTOYAGE

ET L’ASEPTISATION.

in separate clean container (at least 3 inches deep).

down (Fig 11).

portion of solution.

clean the font and all exterior stainless steel surfaces.

in cleaning solution.

Figure 11

Ceramic

Lever

Handle

Nozzle

Chrome

Disk

15

Page 16

4.3 WEEKLY CLEANING AND SANITIZING

WARNING IF A POWDER SANITIZER IS USED, DISSOLVE IT THOROUGHLY WITH HOT WATER PRIOR TO

ADDING TO THE SYRUP SYSTEM. ENSURE SANITIZING SOLUTION IS REMOVED FROM THE DISPENSER AS

INSTRUCTED. AVOID GETTING SANITIZING SOLUTION ON CIRCUIT BOARDS. DO NOT USE STRONG BLEACHES

OR DETERGENTS; THESE CAN DISCOLORAND CORRODE VARIOUS MATERIALS. DO NOT USE METAL

SCRAPERS, SHARP OBJECTS, STEEL WOOL, SCOURING PADS, ABRASIVES, OR SOLVENTS ON THE

DISPENSER. DO NOT USE HOT WATER ABOVE 140° F (60° C). THIS CAN DAMAGE THE DISPENSER.

ADVERTENCIA SI SE USA UN HIGIENIZADOR EN POLVO, DISUÉLVALO BIEN EN AGUA ANTES DE AGREGARLO

AL SISTEMA DE CONCENTRADO. EL USO DE AGUA CALIENTE CONTRIBUYE A DISOLVER LOS HIGIENIZADORES

EN POLVO. ASEGÚRESE DE HABER ELIMINADO LA SOLUCIÓN DE ESTERILIZACIÓN DEL

DISPENSADOR DE ACUERDO CON LAS INSTRUCCIONES. LOS RESIDUOS DE LA SOLUCIÓN DE

ESTERILIZACIÓN REPRESENTAN UN PELIGRO PARA LA SALUD. EVITE QUE LA SOLUCIÓN DE ESTERILIZACIÓN

LLEGUE A LAS PLACAS DE CIRCUITOS. NO USE LAVANDINAS NI DETERGENTES QUE PODRÍAN QUITAR EL

!

COLOR Y CORROER DISTINTOS MATERIALES. NO USE RASPADORES METÁLICOS, OBJETOS FILOSOS, LANA

DE ACERO, ESTROPAJOS, ABRASIVOS NI SOLVENTES EN EL DISPENSADOR. NO USE AGUA CALIENTE A MÁS

DE 140 ºF (60 ºC). PODRÍA DAÑAR EL DISPENSADOR.

AVERTISSEMENT AVANT L’INJECTION DANS LE SYSTÈME, IL FAUDRA QUE LA POUDRE SEPTIQUE SOIT

DISSOLUE ENTIÈREMENT DANS CHAUDE. L’EAU CHAUDE PERMETTRA UN MEILLEUR PROCÈS DE

DISSOLUTION. SUIVANT LES INSTRUCTIONS JOINTES, IL EST IMPÉRATIF QUE LA SOLUTION SEPTIQUE SOIT

ENTIÈREMENT ENLEVÉE. EVITEZ DE METTRE LA SOLUTION EN CONTACT AVEC LES CIRCUITS. N’UTILISEZ PAS

DE JAVELLISANTS OU DEDÉTERGENTS FORTS; CEUX-CI PEUVENT DÉCOLORER ET CORRODER DIVERS

MATÉRIAUX. N’UTILISEZ PAS DE RACLEURS EN MÉTAL, D’OBJETS POINTUS, DE LAINE D’ACIER, DE TAMPONS À

RÉCURER, D’ABRASIFS OU DE SOLVANTS SUR LE DISTRIBUTEUR. N’UTILISEZ PAS DE L’EAU CHAUDE DE PLUS

DE 140 DEGRÉS F (60 DEGRÉS C). CECI PEUT ENDOMMAGER LE DISTRIBUTEUR.

A. Disconnect power to the unit.

Figure 12

B. Following the instructions as described in 4.1 above,

mix appropriate amount of sanitizing solution in a clean

container. Place small portion of the cleaning solution in

a separate clean container (no less than 3 inches deep).

C. To remove the Nozzle (Fig 11) from the dispenser, grasp

the Nozzle and pull downward.

Notch

D. Submerge the Nozzle in the container with the smaller

portion of solution.

E. Place the Nozzle in the set aside portion of solution.

F. Grasp the Chrome Disks located on the right and left side of the dispenser head (Fig 11).

G. Rotate the Chrome Disks, slowly, in a counter-clockwise movement. NOTE: When facing unit,

the Left Disk will rotate towards the back (away from front). The Right Disk will rotate forward.

H. Stop rotating the disks when a square notch is visible on both the Left and Right side (Fig 12).

I. To remove the Handle, slowly pull the Handle up and away from the Unicorn dispenser.

J. Use the brush provided (PN 22-0017) to gently clean the side of the dispenser head.

Refer to the arrows in Figure 13.

K. To reinstall the Handle, align the Set Pins with the notch on both sides of the dispenser.

Gently push the Handle into place.

L. Rotate the Chrome Disks back into place. NOTE: Verify

square notches are not visible to prevent accidental

Figure 13

Handle removal.

M. Use a clean cloth soaked in the cleaning solution to

clean the font and all exterior stainless steel surfaces.

N. Remove the Cup Rest. Wipe clean the Drip Tray and

Cup Rest. Replace Cup Rest.

O. Wipe clean all the splash areas.

P. Clean beverage valves as specied by the valve

manufacturer.

16

Cleaning

Brush

Page 17

4.4 CLEANING AND SANITIZING BEVERAGE COMPONENTS - BAG IN BOX SYSTEM

NOTE: Extended lengths of product lines may require more time for ushing and rinsing lines than

described below.

A. Disconnect the syrup quick disconnect coupling from the syrup packages and connect the

coupling to a bag valve removed from an empty Bag-in-Box (BIB) package.

B. Place the syrup inlet line in a clean container lled with clean, potable, room temperature water.

C. Activate valve until water is dispensed. Flush and rinse line and ttings for a minimum of 60

seconds to remove all traces of residual product.

D. Following the instructions as described in 4.1 above, mix appropriate amount of cleaning

solution in a clean container. Place syrup inlet line in container lled with cleaning solution.

E. Activate valve and draw cleaning solution through lines for a minimum of 60 seconds. This will

ensure line is ushed and lled with cleaning solution. Allow line to stand for at least 30

minutes.

F. Place syrup inlet line in a clean container lled with clean, potable, water at a temperature of

90° to 110°F (32.2° to 43.3° C)

G. Activate valve to ush and rinse line and ttings for a minimum of 60 seconds to remove all

traces of cleaning solution. Taste dispensed product to ensure there is no off-taste. If off-taste is

found, additional ushing of syrup system may be required.

H. Following the instructions as described in 4.1 above, mix appropriate amount of sanitizing

solution in a clean container. Place syrup inlet line in container lled with sanitizing solution.

I. Activate valve and draw sanitizing solution through line for a minimum of 60 seconds. This will

ensure line is ushed and lled with sanitizing solution. Allow line to stand for at least 30

minutes.

J. Remove bag valve from quick disconnect coupling and reconnect syrup inlet line to syrup

package. Ready unit for operation.

K. Draw drinks to rell lines and to ush the chlorine sanitizing solution from the dispenser.

L. Test dispenser in normal manner for proper operation. Taste dispensed product to ensure there

is no off-taste. If off-taste is found, additional ushing of syrup system may be required.

M. Repeat cleaning, rinsing, and sanitizing procedures for each valve and each circuit.

!

CAUTION FOLLOWING SANITIZATION, RINSE WITH END-USE PRODUCT UNTIL THERE IS NO AFTERTASTE. DO

NOT USE A FRESH WATER RINSE. THIS IS A NSF REQUIREMENT. RESIDUAL SANITIZING SOLUTION LEFT IN THE

SYSTEM CREATES A HEALTH HAZARD.

PRECAUCIÓN DESPUÉS DE LA ESTERILIZACIÓN, ENJUAGUE CON EL PRODUCTO FINAL HASTA QUE

ELIMINAR EL SABOR QUE QUEDA. NO ENJUAGUE CON AGUA FRESCA. ÉSTA ES UNA EXIGENCIA DE NSF. SI

QUEDA SOLUCIÓN DE ESTERILIZACIÓN EN EL SISTEMA, GENERA UN PELIGRO PARA LA SALUD.

ATTENTION DÉFENSE DE RINCER L’OUTIL À L’EAU FRAICHE IMMÉDIATEMENT APRÈS UN TRAITEMENT

SEPTIQUE.EN CAS DE APRÈS-GOÛT, NE PURGER AVEC LE PRODUIT FINAL UNE EXIGENCE NSF.

17

Page 18

5. PROGRAMMING OVERVIEW

NOTE: Ratio will be set by either the LFCV or Volumetric method. Setting ratio will require syrup

separator (included with unit) and ratio cup (sold separately).

DEFINITIONS

Brand One of the four buttons around the water button

Brand 1 The brand button in the upper left quadrant

Brand 2 The brand button in the upper right quadrant

Brand 3 The brand button in the lower left quadrant

Brand 4 The brand button in the lower right quadrant

WAT Water button in the middle of the circle

Mode LED Red LED below the Size buttons

Brand LED Green LEDs in each brand quadrant

Water LED Green LED in the middle of the circle

P/C Pour/Cancel; depending on conguration, activated by the handle and/or holding the

Active Brand

Dispensing Pouring product or water, or waiting for a previously programmed settle time as part of a

portion control dispense

Figure 14. PROGRAM/OPERATION BUTTONS

Size SM, MD, LG, or XL

SM Small button

MD Medium button

LG Large button

XL Extra Large button

On (LED) indicates steady on state

Off (LED) indicates steady off state

Illuminated On, or blinking

BRAND 1

LED

BRAND 3

LED

SM

ON/OFF

LED

WAT

BRAND 2

LED

Carbonated

Water

BRAND 4

LED

XL

MD

LG

18

Page 19

5.1 PROGRAMMING wITH THE VOLUMETRIC HANDHELD PROGRAMMER

NOTE: REQUIRES VOLUMETRIC HANDHELD PROGRAMMER AND SELECTOR BOARD

(PN 64-5050) PROGRAMMER IS SOLD SEPARATELY FOR VV PROGRAMMING ONLY)

(C = CARBONATED; 5.00 = 5:1 RATIO)

A. Connect the Volumetric Handheld programmer (Fig 15) to

J2 on the Selector Board (Fig 16).

B. Connect the Selector Board Cable to the J8 on the Main

Board.

C. Select the valve for programming by adjusting the toggle

for the selected valve as shown in Fig 17.

D. Press [red mem] to read the valve ratio setting in

memory.

E. Press [carb toggle] button to choose between carbonated

(C) or non-carbonated rink (n).

F. Press [+] or [-] to raise or lower desired ratio.

G. Press ‘enter’ button to save the setting into the valve

memory.

AFTER PROGRAMMING IS COMPLETE

Figure 16. Selecter Board

Figure 17. Toggles Shown in

Position to Corresponding Valve

Toggle

Figure 15. VV Programmer

Figure 17. Main Board

Connect to

VV Programmer

Connect to

Main Board

5.2 CONFIGURATION

A. SW 1 ON THE MAIN BOARD

NOTE: Fig 18 displays all toggles are switched to ‘OFF’ mode for illustrative purposes.

1. Any changes to SW1 will cause the dispenser to reset.

2. Leave Toggle 1 in ‘OFF” position for LFCV Mode.

3. Switch Toggle 1 to ‘ON’ for Volumetric Mode.

4. If Toggle 2 is switched to ‘ON’, pressing a brand button in IDLE MODE will dispense

product.

5. Volumetric Mode Only: during a water manual dispense, if the volume of product dispensed

reaches 128oz, the water LED turns off and dispense stops.

B. IDLE MODE

This is the normal operating mode of the dispenser. At the start of IDLE MODE, the mode

LED is turned off.

1. Active brand is indicated by the illuminated LEDs. (ON - active/ OFF - not active).

Only one brand can be Active at a time.

19

Page 20

C. IDLE MODE - TO DEACTIVATE A BRAND, WHILE THE UNIT IS NOT DISPENSING

PRODUCT

1. Select an inactive Brand. This will activate the selected Brand and deactivate the formerly

Active Brand.

- To deactivate an Active Brand without selecting an inactive Brand, press the Active Brand

button for less than .35 seconds.

2. The Active brand automatically deactivates If the last recognized button press and the last

dispense were both at least 10 (ten) seconds prior.

D. MANUAL BRAND DISPENSE

1. Select the desired brand if it is inactive.

2. Pull and hold the handle to pour.

NOTE: Depending on conguration, press and hold any brand while idle to pour.

E. WATER DISPENSE

1. To dispense water manually, Press and hold WAT button. Water LED will illuminate (Active

Brands automatically deactivate). If P/C or WAT buttons are not pressed, the Water LED

will turn off and dispense stops.

2. During a manual dispense, if 60 (sixty) seconds elapse, the Water LED turns off and the

dispense stops.

F. PORTION CONTROL DISPENSE

1. Select a Brand.

2. Select a Size

NOTE: Depending on conguration, pressing and holding the active brand will stop a portion

dispense in progress

G. PURGE MODE

NOTE: Purge mode allows independent purging of water or syrup without shutting off the

back block.

1. If unit is in IDLE MODE without a selected Active Brand, AND has not dispensed since unit

was powered on, the PURGE MODE can be accessed by pressing and holding both

Brand 1 and Brand 4 buttons for 5 seconds.

2. During in Purge Mode, the Mode LED blinks at low duty cycle.

3. Press and hold WAT, to dispense water

4. Press and hold a Brand, to dispense syrup only

5. The unit will default to IDLE MODE automatically, if:

- the unit is NOT dispensing AND the last button press AND last dispense were both at

least 60 (sixty) seconds prior.

- the unit is NOT dispensing AND the handle is pulled.

H. TIMED POUR MODE

NOTE: Timed pour mode assists ow rate calibration

If unit is in IDLE MODE without an Active Brand, and has not dispensed product since the unit was

powered on, the TIMED POUR MODE can be accessed by pressing and holding both Brand 1 and

Brand 2 buttons for 5 seconds.

1. During TIMED POUR MODE, the Mode LED blinks rapidly.

2. Press WAT, to dispense water.

3. Press a Brand, to dispense syrup only for the selected Brand

4. Dispense ends after 8 seconds

5. The unit will default to IDLE MODE automatically, if:

- the unit is NOT dispensing AND the last button press AND last dispense were both at least

60 (sixty) seconds prior, unit will return to IDLE MODE.

- the unit is NOT dispensing AND the handle is pulled, the unit returns to IDLE MODE.

20

Page 21

I. PROGRAM MODE

NOTE: The unit supports separate portions with up to 1 topoff for each brand

If the unit has an Active Brand, the PROGRAM MODE can be accessed by pressing and holding

both the SM and XL buttons.

• During PROGRAM MODE, the Mode LED blinks.

• During PROGRAM MODE and its sub-modes, all dispenses use the Active Brand.

• During PROGRAM MODE and its sub-modes, the information stored for a Size is ONLY for the

Active Brand

1. Put desired amount of ice in cup, place cup under valve

2. Press and hold the size to be programmed until cup lls to desired portion

3. If a topoff is not recessary, return to Step 1 with a different size or press the Active Brand to exit

portion program mode and save the programmed sizes.

4. Wait for foam to settle, then press and hold the size again to top off.

5. Return to Step 1 with a different size or press the Active Brand to exit portion program mode

• The unit will default to IDLE MODE automatically, if the unit is NOT dispensing AND the last

button press AND last dispense

J. CALIBRATED CUP PORTION CONTROL PROGRAMMING FOR VOLUMETRIC MODE

NOTE: In this mode, the unit adds the volume from each programming step to the total drink size.

When the portion is dispensed from idle mode, the entire drink is dispensed without pauses.

If unit has an Active Brand selected, Calibrated Cup Portion Control Programming MODE can be

accessed by pressing and holding both the SM and LG buttons.

• During Calibrated Cup Portion Control Programming MODE, the Mode LED blinks.

• During Calibrated Cup Portion Control Programming MODE and its sub-modes, all dispenses use

the Active Brand.

• During Calibrated Cup Portion Control Programming MODE and its sub-modes, the information

stored for a Size is ONLY for the Active Brand.

1. Place volume cup under nozzle.

2. Press appropriate size and ll volume cup to a point just short of the calibration mark on the

volume cup. LED will turn ‘on’ while programming an individual cup size

3. Allow foam to settle, jog size button until liquid reaches the calibration mark on the volume cup.

4. Press the Active Brand to end programming the selected cup size. LED will return to blinking.

5. Start at step 1 with a different size or press the Active Brand to exit Program Mode and save

sizes.

• The unit will return to IDLE MODE automatically, if the unit’s last button press AND last dispense

were both at least 60 (sixty) seconds prior, the unit will save the programmed portions.

21

Page 22

5.3 ADJUSTING WATER FLOW AND WATER TO SYRUP RATIO (BRIX) - LFCV ONLY

The water ow should be adjusted to 1.75oz/seconds.) x 8 seconds = 14.00oz Ensure ice is on

the cold plate for a minimum of 1 (one) hour before valves are brix process. The drink temperature

should be no higher than 40°F (4.4°C) when the brix is set.

A. Remove nozzle by twisting counterclockwise and pulling down.

B. Install Lancer syrup separator (PN 82-3458) in place of nozzle.

C. Shut off syrup (Brand) supply to nozzle by closing shut-off at back block, disconnecting coil wire

at the plug connection or disconnecting BIB connector.

D. Hold a Lancer ratio cup under the syrup separator and dispense water into cup for eight

seconds. Water volume should be 14oz.

E. If water volume is not within specication, remove protective cap, and use a screwdriver to

adjust water ow control to 14oz in 8 seconds. Adjust water module ‘in’ (clockwise) to increase

the ow or ‘out’ (counter-clockwise) to decrease the ow.

F. With water volume correct, turn on syrup (brand) supply to nozzle by opening shut-off at back

block, re-connecting coil wire at plug connection or reconnecting BIB connector.

G. Hold the Lancer ratio cup under the syrup separator and activate valve. Water and syrup levels

must rise together in ratio cup

H. If syrup level is not even with water in the cup, adjust syrup ow rate (at module) so the water

and syrup levels are even at nish of pour. Use a screwdriver to adjust syrup ow control.

NOTE: To adjust syrup module, turn ‘in’ (clockwise) to increase the ow or ‘out’ (counter-clockwise)

to decrease the ow.

I. Once proper ratio is obtained, repeat to verify.

J. Repeat process for each syrup Brand.

K. Remove syrup separator.

L. Install nozzle.

5.4 OPERATION

A. Select desired Brand on the touch pad. Indicator light will activate.

B. Pull handle back to dispense drink.

22

Page 23

6. TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE VERIFICATION REMEDY

6.1

RATIO

INCORRECT

A. Wrong brand

programmed

B. Low syrup pressure

A. Use hand-held programmer

B. Run Syrup purge test using a handheld programmer

A. Enter correct ratio value

B. Increase pressure on BIB pump to

obtain 3.0 OZ on syrup purge

6.2

NOTHING

DISPENSED

C. Tolerance of parts

affecting ratio

D. Flowmeter problem.

A. No power

B. Mounting block

shut-offs closed

C. ID panel malfunction

D. Circuit board

malfunction

E. Water Solenoid

malfunction

F. Water core seal

defective

C. Syrup purge and programmed ratio

values are correct

D. Check the owmeter output

A. Green LED does not light up

B. Green LED lights up

C. Touch panel buttons do not activate

after programmer prompts valve

D. Programmer LED lights do not light up

E1. Green LED lights up, but product

does not dispense

E2. Red LED’S ash, but syup does not

dispense

F. Green LED lights up but product

does not dispense

C. Offset ratio value to obtain optimum

dispense ratio owmeter problem

D. Replace the valve body with a service

value

A. Plug in 24 volt power supply

B. Open mounting block shut-offs

C. Replace touch panel

D. Check fuse or replace circuit board

E1.Replace coil if resistance is ‘open’ or

‘shorted’

E2.Verify connectors are locked onto

sockets on circuit board

F. Replace core seal if rubber has

expanded

6.3

DISPENSES

WATER ONLY

6.4

DELAYED

WATER

SHUT- OFF

6.5

EXCESS

FOAM

A. Out of syrup

B. Shut-off on back

block not open

C. Core seal defective

D. Coil defective

A. Sunction between

core and plug nut

A. Flow rate

B. Portion Control is

not using the Top-Off

A. Red LED’S ash, but syup does not

dispense

B. Red LED’S ash, but syup does not

dispense

C. Red LED’S ash, but syup does not

dispense

D. Red LED’S ash, but syup does not

dispense

A. After 5 dispenes, there is a

siginicant delay in water shut-off

A. Diet drinks and rootbeer have more

foam

B. Portion settings should use a 75%^

pour delay, 25% top-off

A. Replace BIB or Figal

B. Open syrup shut-off on the back block

C. Replace core seal assy if rubber has

expanded

D1.Verify connectors are locked into

sockets on circuit board

D2. Replace coil if resistance is ‘open’ or

shorted

A. Replace water plug nut with vented

design

A. Change ow washer assy to lower

owrate

B. Reprogram portion control to include

optimum top-off

23

Page 24

7. DISPENSER DISPOSAL

To prevent possible harm to the environment from improper disposal, recycle the unit by

locating an authorized recycle outlet or contact the retailer where the product was

purchased. Comply with local regulations regarding disposal of the refrigerant and

insulation.

8. ILLUSTRATIONS AND PARTS LISTINGS

TOWER, UNICORN, T/C, PC, CC, LFCV - SPARE PARTS LIST LIST

8.1 LFCV ELECTRONIC SPARE PARTS ..............................................................................................24

8.2 LFCV NOZZLE SPARE PARTS .......................................................................................................25

8.3 LFCV VALVE SPARE PARTS ..........................................................................................................26

8.4 WIRING DIAGRAM, LFCV................................................................................................................27

TOWER, UNICORN, T/C, PC, CC, VV - SPARE PARTS LIST

8.5 VV ELECTRONIC SPARE PARTS....................................................................................................28

8.6 VV NOZZLE SPARE PARTS.............................................................................................................29

8.7 VV WATER VALVE SPARE PARTS .................................................................................................30

VV SYRUP VALVE SPARE PARTS...................................................................................................30

8.8 VV MISC SPARE PARTS .................................................................................................................31

8.9 VV WIRING DIAGRAM ....................................................................................................................32

8.10 COUNTER CUTOUT TEMPLATE ....................................................................................................33

24

Page 25

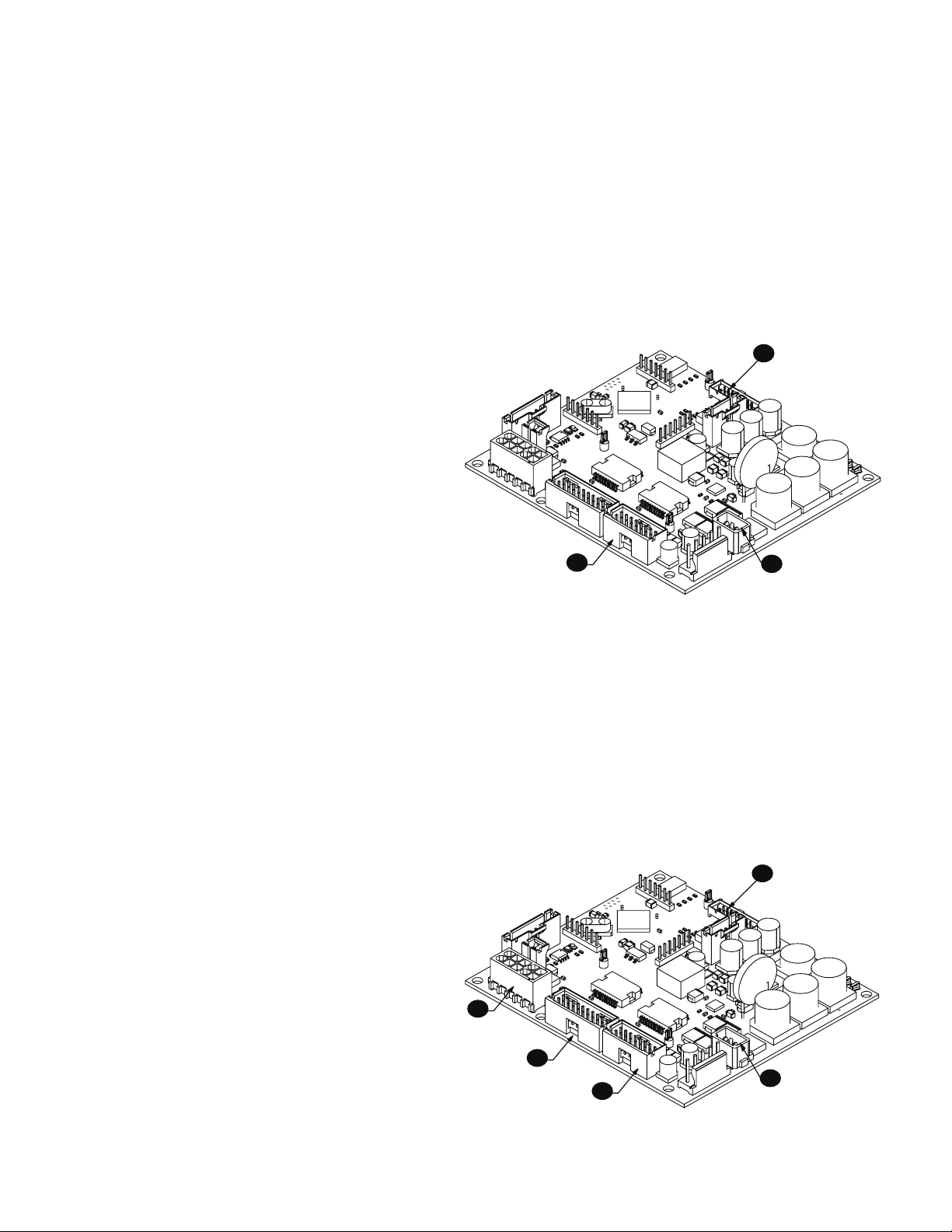

8.1 ELECTRONIC, LFCV SPARE PARTS

Item Part No. Description

1 52-3344 HARN, LFCV, THRU-CNTR VAL, UNICORN

2 52-3358 HARNESS, BYPASS, UNICORN

3 64-5048 PCB ASSY, MAIN BOARD, UNICORN

4 05-1678 STANDOFF, PCB, REV L CKNG

1

2

3

4

25

Page 26

8.2 NOZZLE, LFCV SPARE PARTS

1

2

3

4

Item Part No. Description

1 64-5057 PCB ASSY, TOUCH PAD, UNICORN,

W/ PORTION CONTROL

2 17-0647/01 SOLENOID,24 VDC, 1/8 NPT, 2WNC

3 05-2971 ELBOW, qUICK CONNECT,1/4 X 1/8

4 02-0214 O-RING,2-008,97-0999

5 81-0679 NOZZLE, ASSY, UNICORN

6 05-2956 NOZZLE, BLACK, UNICORN

05-2943 NOZZLE, RED UNICORN

5

6

26

Page 27

8.3 ELECTRONIC, LFCV SPARE PARTS

Item Part No. Description

1 01-2884 FITTING, JG,3/8X1/4,REDUCER, S/FIT

2 01-2806 JG BULKHEAD CONNECTOR,3/8 S/FIT X 3/8 S/FIT,79000217

3 19-0267/02 VALVE ASSY, LFCV,2.0 SODA, GRY, S

4 05-1385 ELBOW,.5 DOLE X .2 BARB, PLS

5 02-0089 O-RING,2-012,97-0999

6 19-0266/02 VALVE ASSY, LFCV,2.0 SYR, BLK, SC

7 04-1089 SCR, 10-32,RH, PH/SL, 1.000

8 82-2317/01 BLOCK, MOUNTING ASSY, SGL

9 02-0005 O-RING ,2 -010,97-0999

10 01-0012 ADAPTOR, 1/4 BARB X DOLE

4

5

6

7

1

2

8

9

10

27

Page 28

8.4 WIRING DIAGRAM, LFCV

28

Page 29

8.5 ELECTRONIC, VV SPARE PARTS

Item Part No. Description

1 52-3381 HARNESS, WATER MODULE, VV, RECIRC,

2 52-3359 HARN, SOLENOID, KIP, VV, UNICRN

3 52-3360 HARN, SOLENOIDS VV, UNICORN

4 52-3358 HARNESS, BYPASS, UNICORN

5 64-5048/02 PCB ASSY, MAIN BOARD, UNICORN

6 05-1678 STANDOFF, PCB, REV L CKNG

UNICORN

1

2

3

4

5

29

6

Page 30

8.6 NOZZLE, VV SPARE PARTS

11

1

3

5

2

4

6

7

9

12

8

10

Item Part No. Description

1 02-0371 WASHER, FLOW, 1.5, VOL VALVE

2 02-0089 O-RING, 2-012, 97-0999

3 02-0126 O-RING, 2-109, 97-0999

4 01-2762 FTG, SODA OUTLET, UNCRN

5 02-0005 O-RING, 2-010, 97-0999

6 02-0214 O-RING, 2-008, 97-0999

7 05-2929 FITTING, INLET, NOZZLE, SYRUP

8 04-1639 SCREW, 4-20X.250 IN, PH, PHILLIPS,

PLASTITIE, 18-8 SS

9 04-1640 SCR, M3X6MM, PH, PH,6H, S, ZP

10 30-10867 PLATE, MNTG, NOZZLE, UNICORN

11 81-0679 NOZZLE, ASSY, UNICORN

12 05-2956 NOZZLE, BLACK, UNICORN

05-2943 NOZZLE, RED UNICORN

30

Page 31

8.7 WATER VALVE, VV SPARE PARTS LIST

11

6

4

3

2

1

Item Part No. Description

1

1 05-1385 ELBOW, .5 DOLE X .2 BARB, PLS

2 02-0089 O-RING, 2-012,97-0999

3 19-0399 WATER MODULE, VOL,1.5-3.0

4 05-0967 RTNER, SOL VLV, BALL VLV, PREMIA

2

3

4

9

5

10

5

8

7

VV SYRUP VALVE SPARE PARTS LIST

Item Part No. Description

5 02-0005 O-RING ,2 -010,97-0999

6 05-1386 ELBOW,.375 DOLE X .2 BARB, PLS

7 19-0398 SYRUP MODULE, VOL,1.5-3.0

8 04-1089 SCR, 10-32,RH, PH/SL, 1.000

9 82-2317/01 BLOCK, MOUNTING ASSY, SGL

10 01-0012 ADAPTOR, 1/4 BARB X DOLE

11 04-0527 CAP, PROTECTIVE, 5HIP, 1/4 BARB

31

Page 32

8.8 MISC SPARE, VV PARTS LIST

Item Part No. Description

1 64-5057 PCB ASSY, TOUCH PAD, UNICORN, W/PORTION CONTROL

2 01-2757 FTG, WYE,.12ID, UNCRN

3 01-2806 JG BULKHEAD CONNECTOR, 3/8 S/FIT X 3/8 S/FIT, 79000217

1

2 3

32

Page 33

8.9 WIRING DIAGRAM, VV

33

Page 34

8.10 COUNTER CUTOUT TEMPLATE (not to scale)35NOTES

34

Page 35

Page 36

Lancer Corp.

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Loading...

Loading...