Page 1

FLAVOR SELECT 22 (FS22)

ICE BEVERAGE DISPENSER

allation and Service Manual

Inst

LANCER

6655 Lancer Blvd.

Antonio, Texas 78219

San

o order parts, call

T

Customer Service: 800-729-1500

Warranty/Technical Support: 800-729-1550

Email: cust

serv@lancercorp.com

www.lancercorp.com

Manual PN: 28-0580/02

7/28/08

ISO 9001:2000

“Lancer” is the registered trademark of Lancer

Quality System Certified

© 2008 by Lancer, all rights reserved.

Page 2

TABLE OF CONTENTS

ABOUT THE FS22................................................................................................................3

FS22 DISPENSERS..............................................................................................................3

SPECIFICATIONS.................................................................................................................4

PRE-INSTALLATION CHECKLIST.......................................................................................5

COUNTER CUT

OUT.............................................................................................................6

SAFETY ................................................................................................................................7

ICE.........................................................................................................................................8

INSTALLATION ...............................................................................................................8

1.

1.1 SELECTING A LOCATION FOR THE DISPENSER................................................8

DRAIN SPIDER .....................................................................................................10

1.2

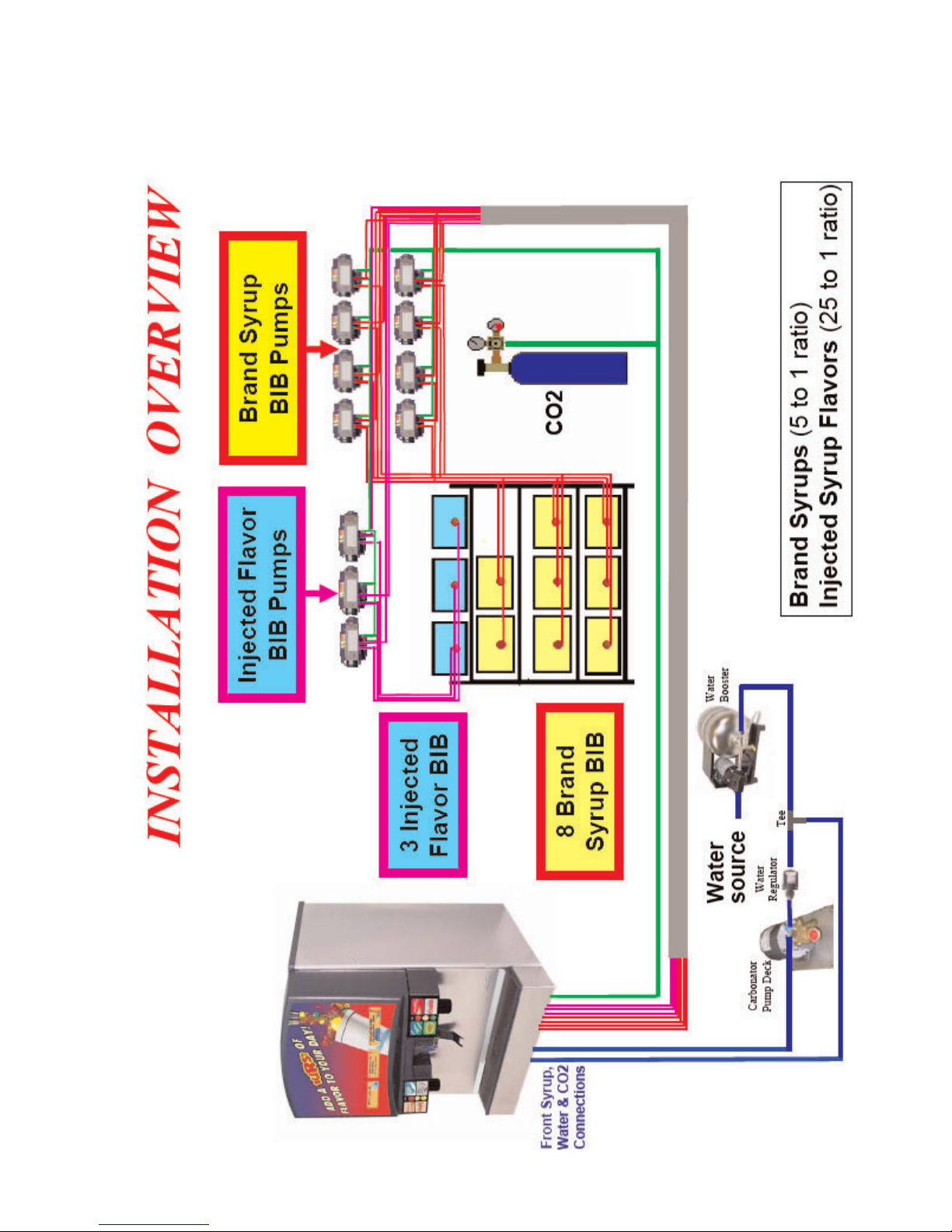

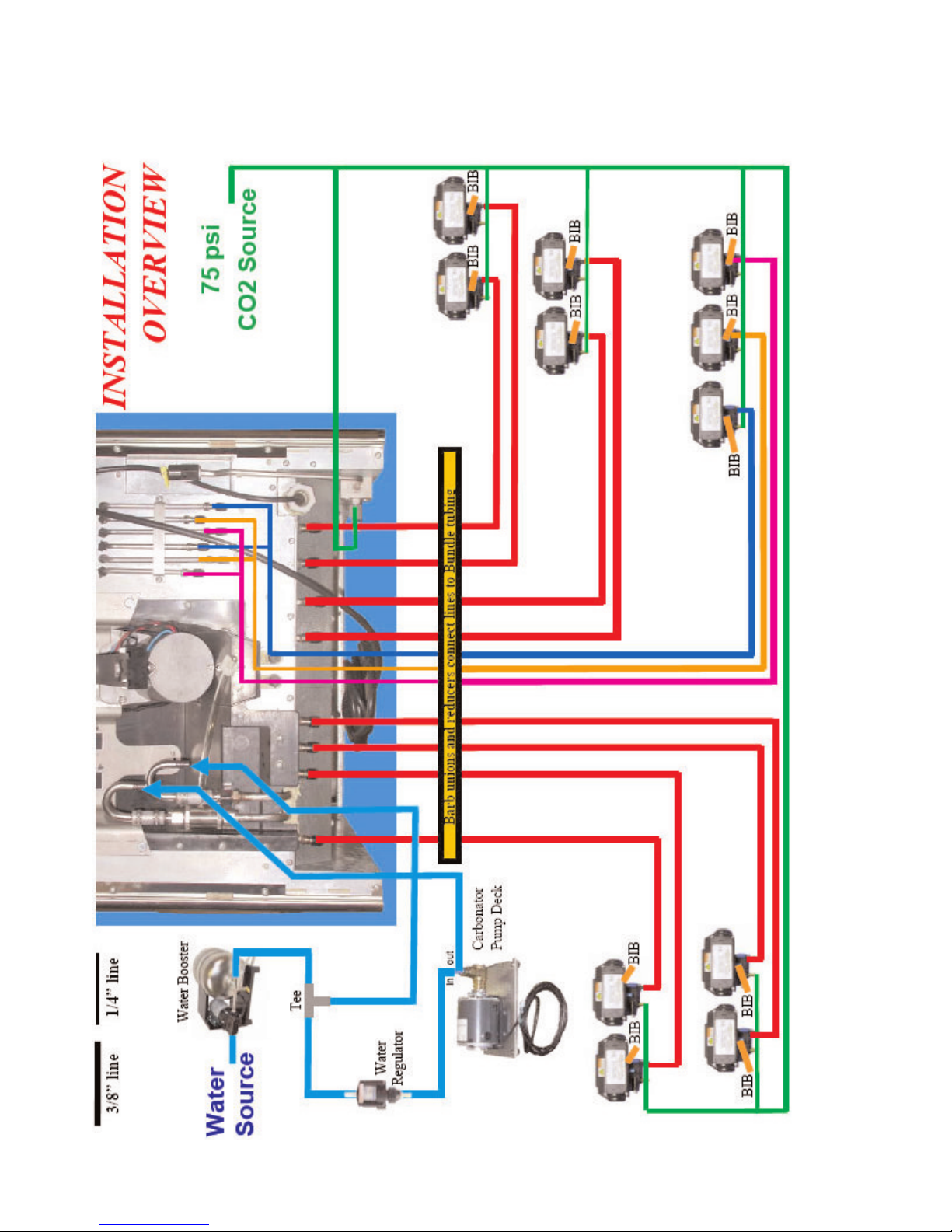

1.3 INSTALLATION OVERVIEW - 1.............................................................................11

ALLATION OVERVIEW - 2 ............................................................................12

INST

1.4

1.5 CONNECTING TO WATER SUPPLY LINES.........................................................13

1.6 CONNECTING CO2 ..............................................................................................14

CONNECTING

1.7

TO ELECTRICAL POWER ...........................................................14

1.8 INSTALLING THE FS22 DISPENSER...................................................................14

2. CLEANING AND SANITIZING ......................................................................................17

2.1

GENERAL

INFORMATION ....................................................................................17

2.2 CLEANING AND SANITIZING SOLUTIONS .........................................................18

2.3 DAILY CLEANING..................................................................................................18

ICE BIN CLEANING - PERFORM AT STARTUP AND MONTHLY........................19

2.4

2.5 CLEANING AND SANITIZING BEVERAGE COMPONENTS - BAG-IN-BOX

SYSTEMS

..............................................................................................................21

2.6 ICE CHUTE CLEANING ........................................................................................21

HOW TO OPERATE AND ADJUST THE DISPENSER ................................................22

3.

NORMAL OPERATION..........................................................................................22

3.1

3.2 PROGRAMMING AND SETUP SOFTWARE ........................................................22

PURGING THE CARBONATION SYSTEM ...........................................................24

3.3

PURGING THE WATER AND SYRUP SYSTEMS ................................................25

3.4

ADJUSTING WATER FLOW AND WATER TO SYRUP RATIO (BRIX) ................25

3.5

P.N. 28-0580/02

2

Page 3

TABLE OF CONTENTS

CARBONA

3.6

TROUBLESHOOTING

4.

ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS ..............................32

5.

FINAL ASSEMBLY............................................................................................32-33

5.1

TOR PUMP MODIFICATIONS .............................................................26

...................................................................................................27

5.2 ICE CHUTE ASSEMBLY........................................................................................34

PELLET ICE ASSEMBLY AND PARTS LISTING ..................................................35

5.3

LANCER FLOW CONTROL

5.4

WIRING DIAGRAM................................................................................................37

5.5

VALVE (LFCV)..........................................................36

5.6 PLUMBING DIAGRAM WITH VALVE WIRING......................................................38

ABOUT THE FS22

The FS22 is designed using the highest quality materials and st

providing our customers with consistent quality and a unique drink experience.

ate-of-the-art technology

FS22 DISPENSERS

85-14408-06-2 ICE BEVERAGE DISPENSER, ABOVE

COUNTER MUL

BRANDS / 6 FLA

85-14408N-06-2 ICE BEVERAGE DISPENSER, ABOVE

COUNTER MUL

BRANDS / 6 FLAVORS, 115V/60Hz

TIBRAND, 22 INCH WIDE, 8

VORS, 115V/60Hz

TIBRAND, 22 INCH WIDE, 8

CUBED ICE

PELLET ICE

.N. 28-0580/02

3

P

Page 4

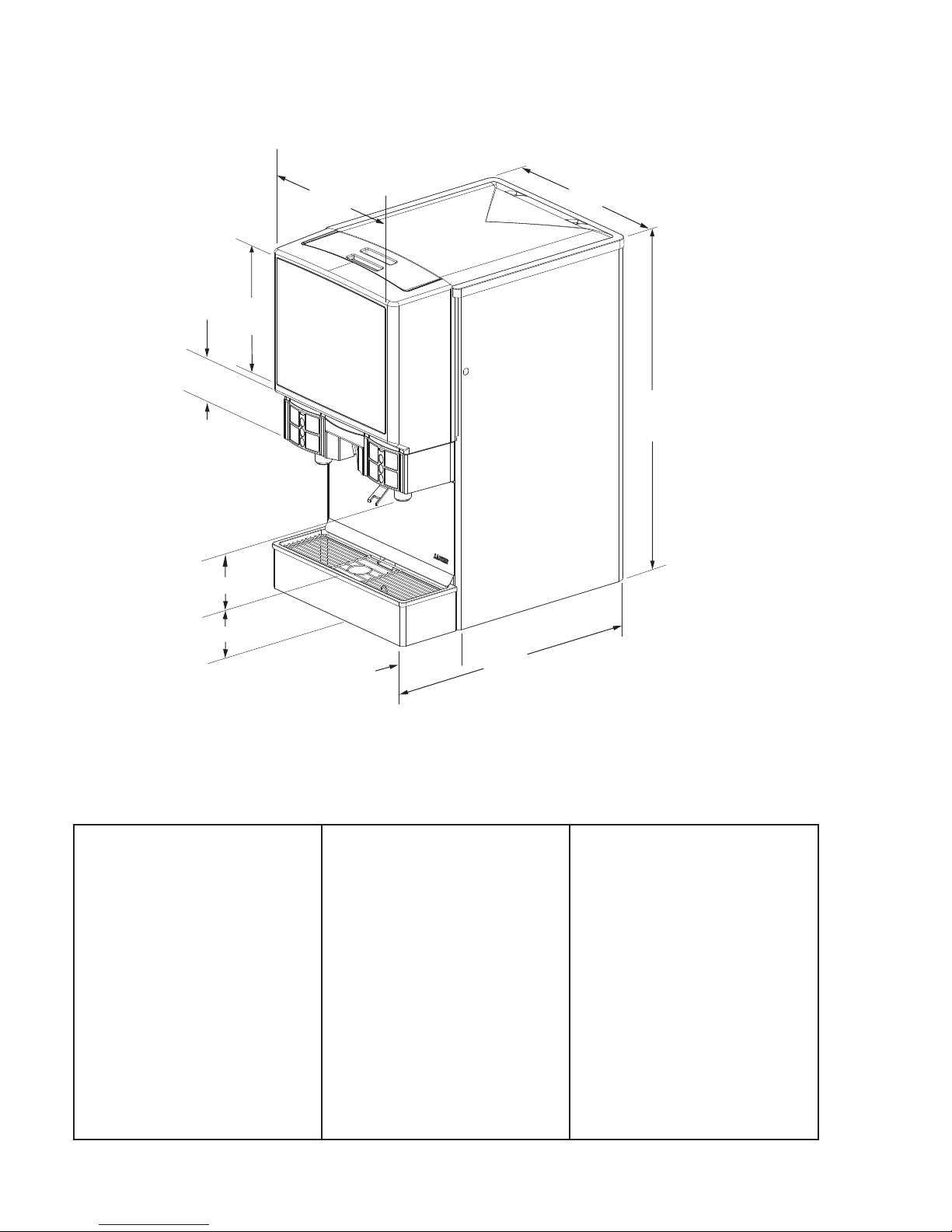

FS22 SPECIFICATIONS

17 5/8”

22”

(559 mm)

14 3/8”

(365 mm)

4 1/2”

(114 mm)

40 1/4”

( 986 mm)

7 1/2”

(190 mm)

30 1/2”

(775 mm)

5 1/8”

(130 mm)

10”

(254 mm)

DIMENSIONS

th:

id

W

Depth: 30.5 in (775 mm)

Height: 40.25 in (1022 mm)

SP

Lef

Right side: 1 in (25 mm)

Back: 1 in (25 mm)

T

Optional legs: 4 in (102 mm)

ELECTRICAL

1

805 W

22 in (559 mm)

ACE REQUIRED

t Side:

op:

15V

1 in (25 mm)

6 in (152 mm)

AC/60Hz, 7AMPs,

s

att

WEIGHT

ithout ice:

W

ith ice:

W

Shipping: 310 lbs (141 kg)

ICE

acity:

Cap

Dispensable: 170 lbs (77 kg)

FITTINGS

ater for carbonator inlet:

W

3/8” barb

Plain water inlet: 3/8” barb

Brand syrup inlets:3/8” barb

Injection flavor inlets:1/4” barb

CO

inlet: 3/8” barb

2

280 lbs (127 kg)

480 lbs (218 kg)

200 lbs (91 kg)

TER SUPPLY

PLAIN W

Min flowing pressure: 75 PSIG

(5.28 kg/cm2, 5.16 BAR)

CARBONA

Min flowing pressure: 25 PSIG

(1.76 kg/cm2, 1.72 BAR)

Max static pressure: 50 PSIG

(3.52 kg/cm2, 3.45 BAR)

CARBON DIOXIDE (CO2)

Min pressure: 70 PSIG

(4.92 kg/cm2, 4.83 BAR)

Max pressure: 80 PSIG

(5.62 kg/cm2, 5.52 BAR)

A

OR WATER SUPPLY

T

P.N. 28-0580/02

4

Page 5

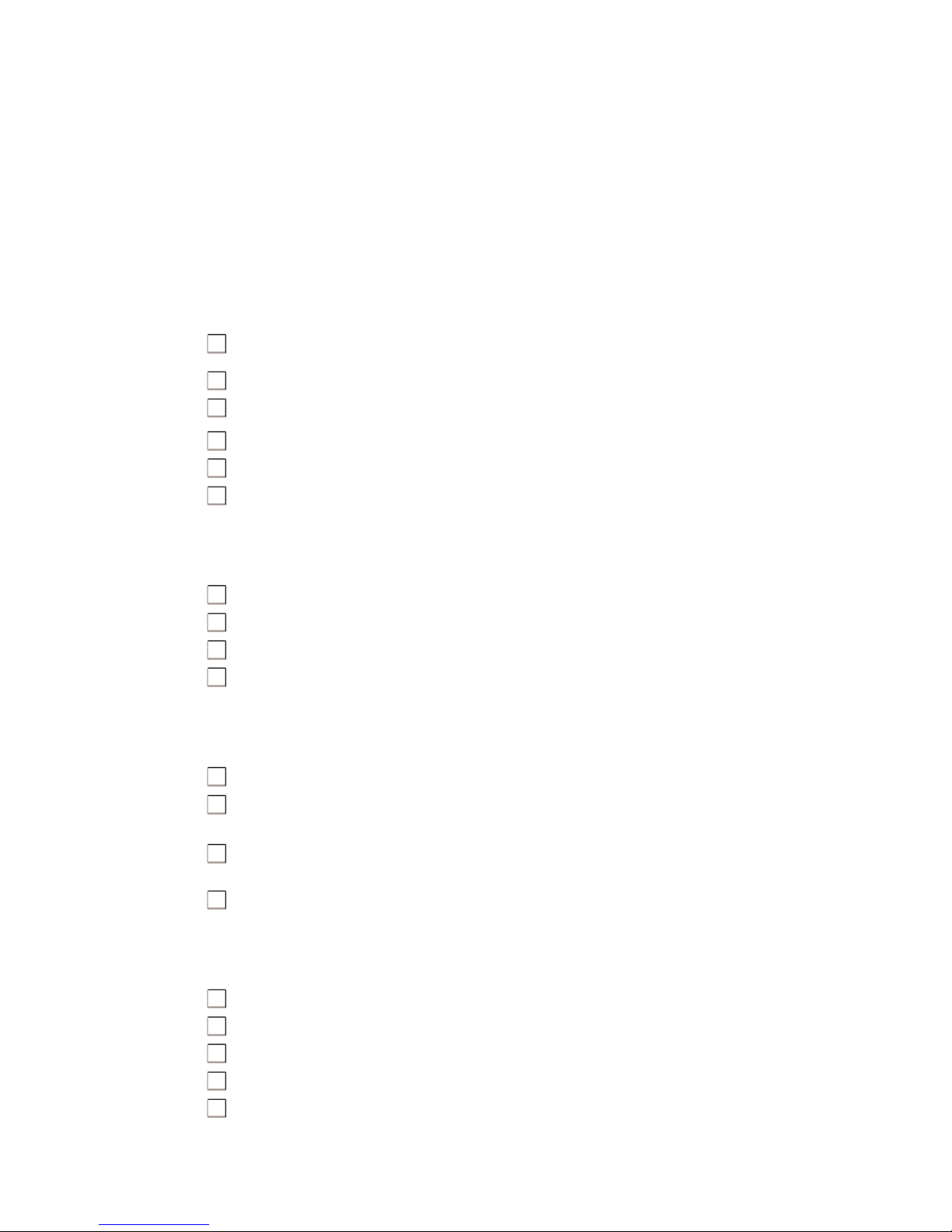

PRE-INST

ALLA

TION CHECKLIST

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly inspected before

shipment.

unit, carefully inspect the carton for visible damage. If damage exist

damage on the freight bill and file a claim with carrier

lies with the carrier

At the time of shipment, the carrier accepts responsibility for the unit. Upon receiving the

s, have the carrier note the

. Responsibility for damage to the dispenser

.

POST MIX

CO2Regulator Set

Beverage Tubing

CO2Supply

ater Booster

W

Oetiker Clamp

Water Regulator

ACCESSORIES:

s/Fittings

BIB SYSTEM:

BIB Rack

Regulator Set

BIB

BIB Connectors - ensure you have the correct connectors for syrup lineup.

Syrup Boxes

BIB

DOUBLE CHECK:

Is the countertop level?

Is there enough space to install the dispenser? Be sure to include space for a top-mounted

ice machine, if necessary.

Can the countertop support the weight of the dispenser? Be sure to include the weight of an

ice machine (if necessary) plus the weight of the ice.

Does the top-mounted ice machine have a minimum clearance on all sides?

CONSIDER THE LOCA

INST

ALLATION:

Water supply lines

Drain

Grounded electrical outlet

Heating and air conditioning duct

Direct sunlight (avoid) or overhead lighting

TION OF THE FOLLOWING BEFORE

s

5

P.N. 28-0580/02

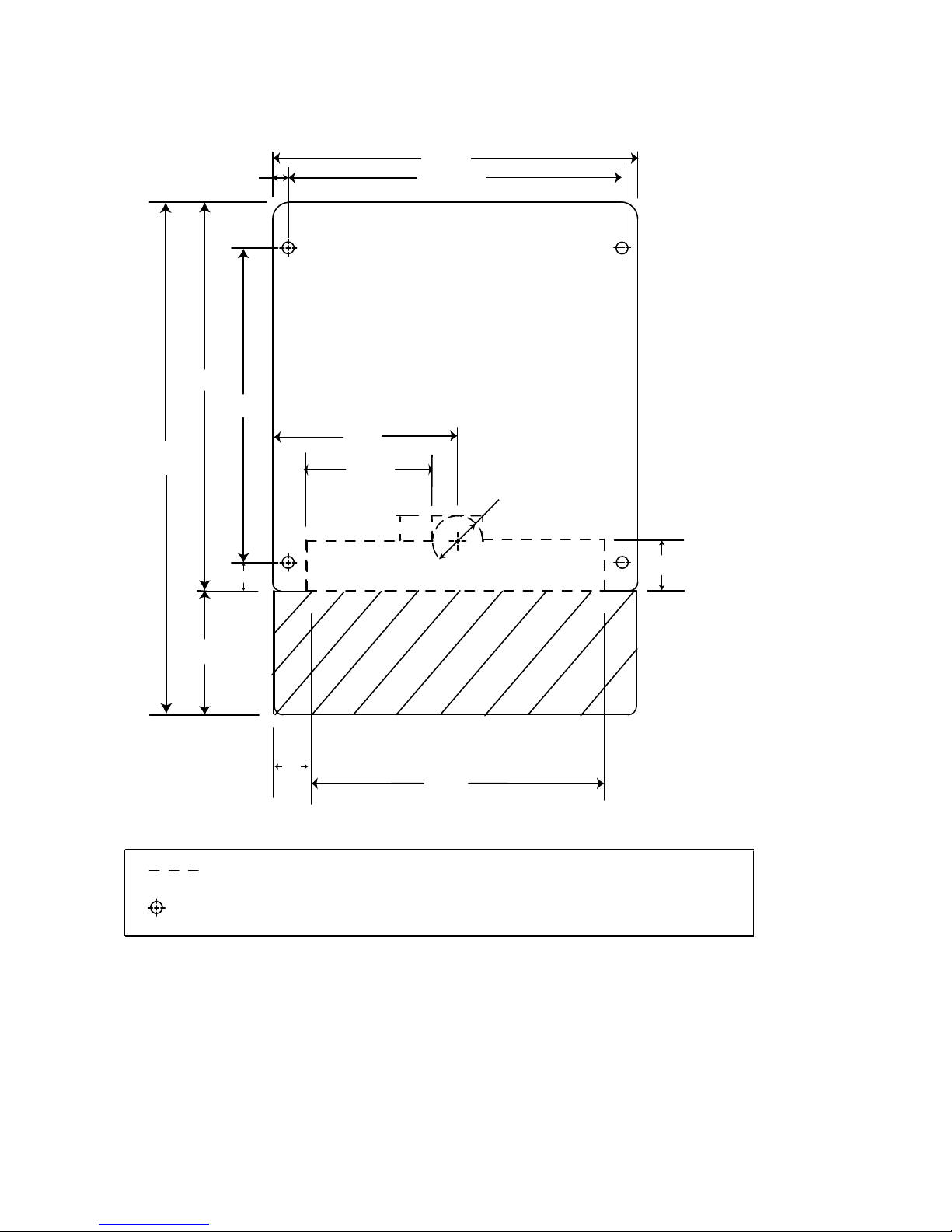

Page 6

v

v

v

v

v

v

v

v

v

h$)!-%4%2/04)/.!,

h

v

v

v

h

& 2 / . 4 / & $ ) 3 0 % . 3 % 2

/04)/.!,(/,%3&/2&!34%.).'$)30%.3%24/#/5.4%27)4(3#2%73

#54/54$!3(%$!2%!

$ 2 ) 0 4 2 ! 9

FS22 COUNTER CUTOUT

.N. 28-0580/02

P

6

Page 7

SAFETY

OMATIC AGITATION

AUT

The dispenser is equipped with automatic agitation and will activate

unexpectedly

artment. Unplug the dispenser during servicing, cleaning, and

comp

sanitizing.

To avoid personal injury, do not attempt to lift the dispenser without

assistance. For heavier dispensers, use a mechanical lift.

. Do not place hands or foreign objects in the ice storage

GROUNDING

The dispenser must be properly electrically grounded to avoid serious

injury or fatal electrical shock. The power cord has a three-prong

grounded plug. If a three-hole grounded electrical outlet is not available,

use an approved method to ground the unit. Follow all local electrical

codes when making connections. Each dispenser must have a separate

electrical circuit. Do not use extension cords. Do not connect multiple

electrical devices on the same outlet.

WAYS disconnect power to the dispenser before attempting any

AL

internal maintenance. The resett

as a substitute for unplugging the dispenser from the power source to

service the unit. Note: the keyswitch does not turn off power to the

dispenser

Only qualified personnel should service the internal components of the

dispenser. Avoid any contact with water when plugging in the dispenser.

. It must be physically unplugged.

able breaker switch should not be used

CARBON DIOXIDE

Carbon Dioxide (CO2) is heavier than air and displaces oxygen. CO2is a

colorless, noncombustible gas with a faintly pungent odor. High

percentages of CO2may displace oxygen in the blood. Prolonged

exposure to CO2can be harmful. Personnel exposed to high

concentrations of CO2gas will experience tremors which are followed

rapidly by a loss of consciousness and suffocation. S

be observed in the prevention of CO2gas leaks in the entire CO2and sof

drink system. If a CO2gas leak is suspected, immediately ventilate the

aminated area before attempting to repair the leak.

cont

The minimum/maximum ambient operating temperature

for the dispenser is 40 to 90 degrees F.

The dispenser is for indoor use only.

trict attention must

t

.N. 28-0580/02

7

P

Page 8

ICE

Dispensers using cubed ice may also use pellet ice if

properly configured (contact Lancer Customer Service or

your Sales Representative for more information).

Lancer dispensers will not dispense shaved or flaked ice.

Do not use bagged ice. Bagged ice will damage components.

1. INSTALLATION

LOCATION FOR THE DISPENSER

1.1 SELECTING

MAKE SURE THE LOCATION MEETS THESE REQUIREMENTS:

Access to a dedicated, grounded 20 AMP electrical outlet.

A.

A

Convenient to an open drain with access for soda, water

B.

Sufficient clearance above the dispenser for servicing.

C.

Counter can support the weight of the dispenser, the weight of the ice, and if

D.

necessary, an icemaker. The total weight may exceed 700 pounds (363 kg).

E. Sufficient clearance on the sides, top and back for icemaker ventilation and air

circulation. Refer to your icemaker manufacturer for specifications.

F. If an icemaker is not top-mounted on the dispenser, make sure to provide

ficient clearance (a minimum of 6 inches (40.6 cm)) to allow filling the

suf

dispenser with ice from a five gallon (19 liter) container.

G. AVOID DIRECT SUNLIGHT AND OTHER HEAT SOURCES.

THINGS TO CONSIDER:

Connecting lines can be run through the back of the dispenser or extend down

through a counter cutout.

or on an optional leg kit (PN 82-3484), if no icemaker is installed. If installed directly

on the counter, the dispenser must be sealed to the countertop.

ACKING THE DISPENSER:

UNP

The dispenser may be inst

, and syrup lines.

alled directly on the countertop

A. Set shipping carton upright on the floor.

B. Cut band and remove.

C. Open top of carton and remove interior p

D. Lift carton up and off of the dispenser.

E. Remove wood shipping base from the bottom of the dispenser. Support

dispenser while removing shipping base to prevent damage to the dispenser.

.N. 28-0580/02

P

acking.

8

Page 9

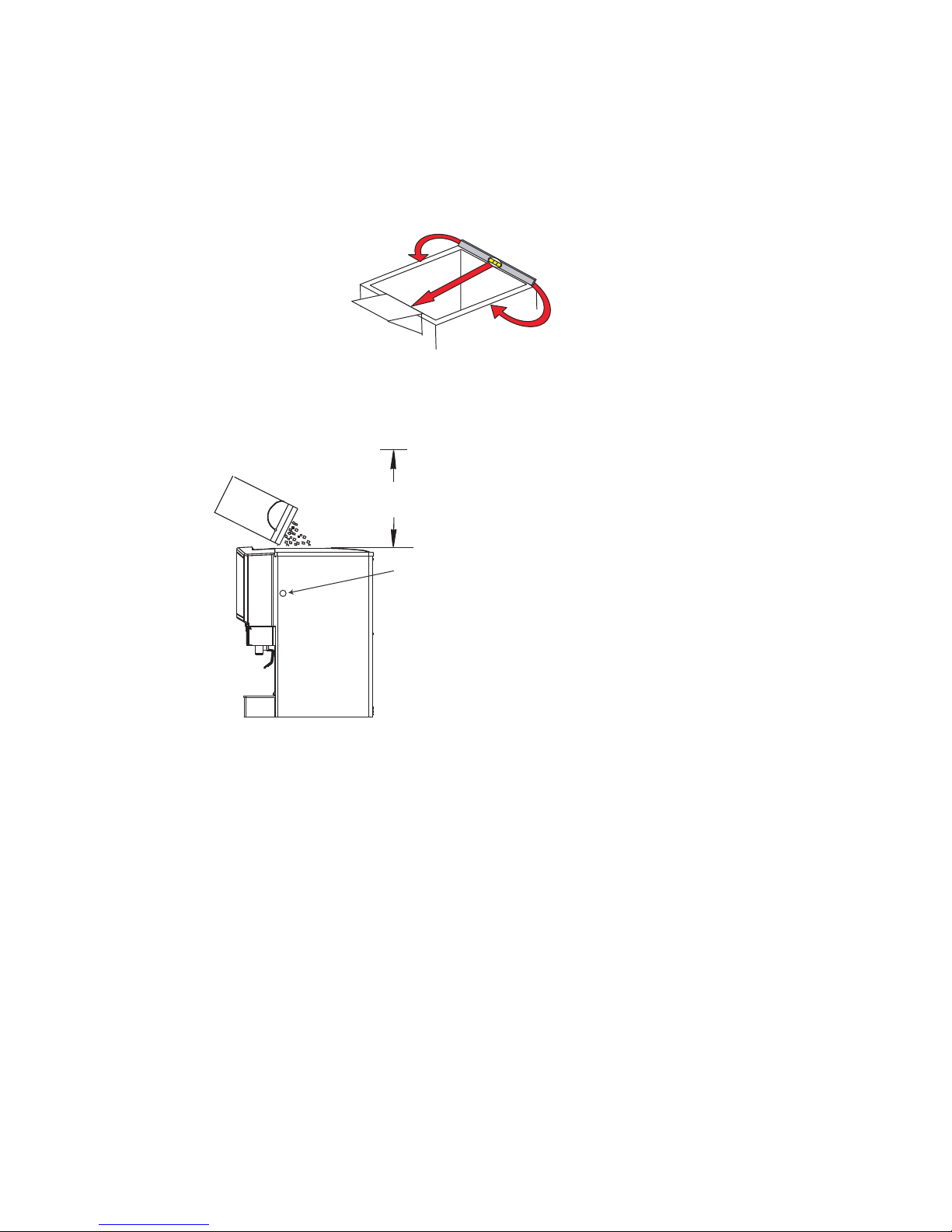

LEVELING

ENSURE SUFFICIENT CLEARANCE

FOR FILLING WITH ICE

FS22 DISPENSER, NO ICEMAKER

ENSURE KEYSWITCH

IS ACCESSIBLE

THE DISPENSER:

In order to facilit

ate proper dispenser drainage and carbonation, ensure that the

dispenser is level, front to back and side to side. Place a level on the top of the rear

edge of the dispenser

. The bubble must settle between the level lines. Repeat this

procedure for the remaining three sides. Level unit if necessary.

FS22 DISPENSER WITH ICEMAKER:

Install the icemaker per manufacturer specifications. Points of consideration include

drainage, ventilation, and drop zones.

An adapter plate is required when inst

Represent

ative or Lancer Customer Service for more information.

bin thermostat

A

your icemaker manufacturer to obt

Ensure the icemaker is inst

Ensure manual fill is accessible.

Clean and maint

is required in order to control the level of ice in the dispenser

ain

icemaker per manufacturer

alling an icemaker. Contact your Sales

. Contact

ain the correct bin thermostat.

alled properly to allow for removal of the merchandiser.

’s instructions.

.N. 28-0580/02

9

P

Page 10

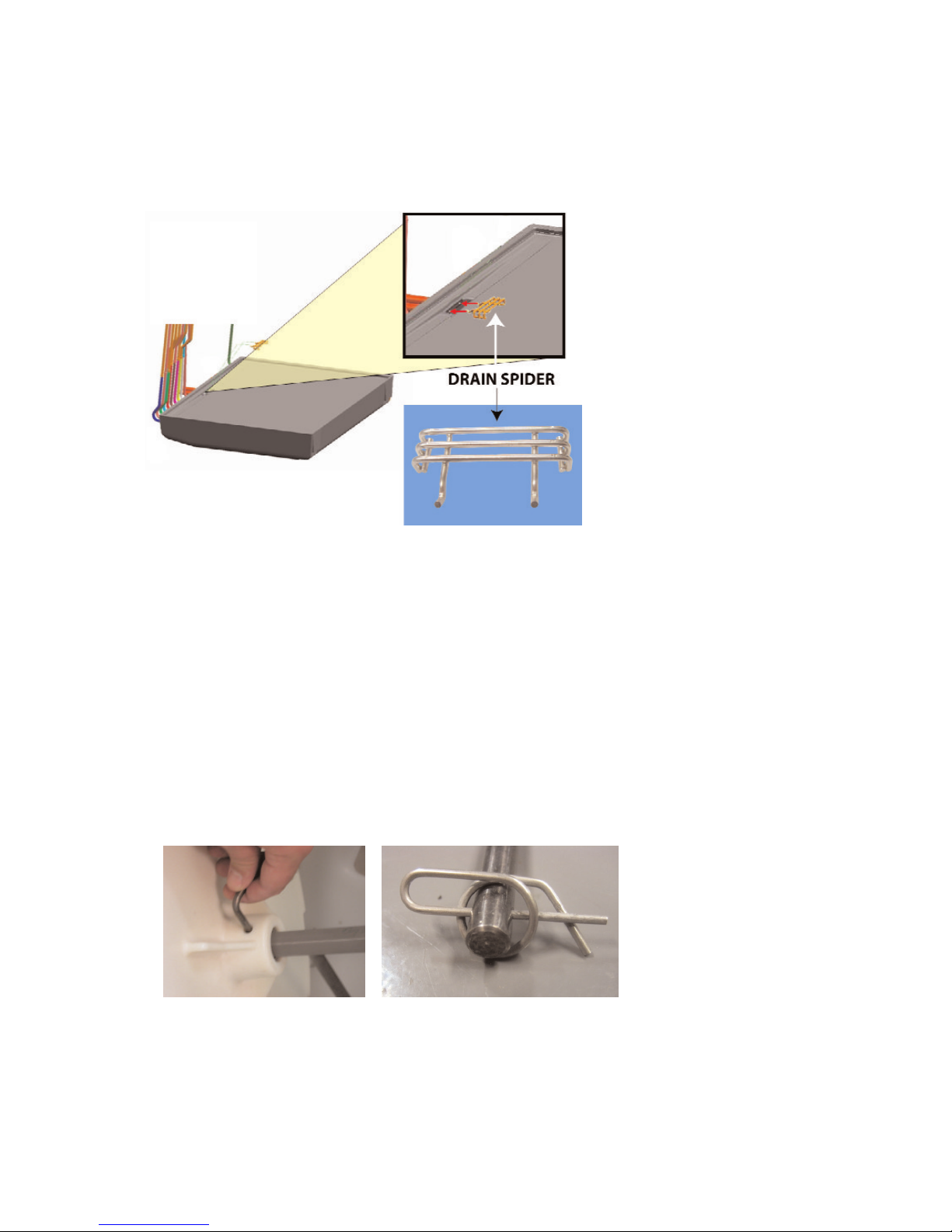

1.2 DRAIN SPIDER

The drain spider is located directly in the center of the bin under the ice shroud.

plate has a cavity designed to hold the drain spider

cold

lation, the drain spider may become dislodged from it

. During shipment or instal-

s original position.

The

Prior to installing the dispenser, ensure the drain spider is in the correct position.

This will prevent drain clog issues. Inspect the lower bin area and reach under the

shroud to ensure the drain spider is secure in the cold

plate cutout. If the spider is

not in place, proceed with the following steps:

A. Remove agitator clip and pin from agitator bar.

B. Remove agitator bar from paddle wheel.

C. Remove paddle wheel.

D. Remove ice shroud by lifting back then out of bin.

E. Locate drain spider and reinstall in the coldplate cavity where drain line exits

(see figure above).

. Reinstall all components. Ensure agitator clip is locked:

F

P.N. 28-0580/02

10

Page 11

1.3 FS22 INSTALLATION OVERVIEW - 1

11

P.N. 28-0580/02

Page 12

1.4 FS22 INSTALLATION OVERVIEW - 2

P.N. 28-0580/02

12

Page 13

1.5 CONNECTING TO WATER SUPPLY LINES

WAR NING!

WAR NING!

A. Use a filter in the water line to avoid equipment damage and beverage off-taste.

Check the water filter periodically, as required by local conditions.

Protect the water supply by means of an air gap, a backflow prevention device,

B.

or another approved method that complies with NSF standards. A leaking inlet

water check valve will allow carbonated water to flow back through the pump

when it is shut of

prevention device complies with ASSE and local standards. It is the

responsibility of the installer to ensure compliance.

Do not operate the carbonator pump with the water supply off.

Doing so can damage components and void the warranty.

C. Provide an adequate potable water supply. Water pipe connections and fixtures

directly connected to a potable water supply must be sized, installed, and

maintained according to federal, state, and local laws.

f and will contaminate the water supply. Ensure the backflow

For the plain water supply line, the inlet water flowing pressure should be at

D.

least 75 PSI. If the water pressure is lower than 75 PSI flowing, use a water

booster system.

If the water flowing pressure is lower than 75 PSI at the plain water inlet and a

water booster is not

water/syrup ratio. Flow conditions at the nozzle can also be af

installed, water products will not hold a proper flow rate or

fected, causing

poor nozzle coning and mixing.

NOTE: The Lancer Water Booster/Tank (PN MC-163172) is offered as a kit. The

water booster must be inst

alled as close as possible to the plain water circuit

inlet.

E. For the soda water supply line, do not exceed 50 PSI for the inlet water static

pressure going into the carbonator pump. If the static water pressure exceeds

50 PSI, install a water regulator before the carbonator water inlet.

NOTE: Install the water regulator (Lancer PN 18-0306) included with unit as

close as possible to the water carbonator pump inlet. The recommended water

pressure value feeding the carbonator is a minimum of 25 PSI. If the normal

water pressure does not exceed 50 PSI, but fluctuates over this value (for

example, when water usage on other equipment connected to the same water

supply causes pressure spikes), use a water regulator.

Do not connect to a hot water or soft water source. This causes

excessive foaming.

13

P.N. 28-0580/02

Page 14

1.6 CONNECTING CO

WAR NING!

A. Provide a regulated CO2 supply to the dispenser through a 3/8 inch supply line.

The maximum pressure is 80 PSI.

2

Excessive CO2 pressure can damage component

1.7 CONNECTING T

A. Check the dispenser serial number plate for correct electrical requirements of

unit. Do not plug into a wall electrical outlet unless the current shown on the

serial number plate agrees with local current available.

The dispenser must be electrically ground to avoid danger. The

power cord has a three-prong grounded plug. If a three-holed

grounded electrical outlet is not available, use an approved

method of ensuring a proper ground to the dispenser.

1.8 INST

ALLING THE FS22 DISPENSER

A. Remove the cup rest, drip tray, splash plate, and top cover from the unit.

O ELECTRICAL

s.

POWER

B. Remove the cover plate at the back of the unit (if not a through-the-counter

C.

P.N. 28-0580/02

allation).

inst

Connect the plain water supply line to the 3/8 inch barb fittings at the front of the

unit.

For the plain water supply line, the inlet water flowing pressure should be at

least 75 PSI. If the water pressure is lower than 75 PSI flowing, use a water

booster system.

If the water flowing pressure is lower than 75 PSI at the plain water inlet, and a

water booster is not installed, water products will not hold a proper flow rate or

water/syrup ratio. Flow conditions at the nozzle can also be affected, causing

poor nozzle coning and mixing.

NOTE: The Lancer Water Booster/Tank, PN MC-163172, is offered as a kit. The

Water Booster must be installed as close as possible to the plain water circuit

inlet.

For the soda water supply line, do not exceed 50 PSI for the inlet static water

pressure going into the carbonator pump. If the static water pressure exceeds

50 PSI, inst

all a water regulator in front of the carbonator water inlet.

14

Page 15

NOTE: Inst

all the water regulator (Lancer PN 18-0306) as close as possible to

the water carbonator pump inlet.

The recommended water pressure value feeding the carbonator is a minimum

of 25 PSI. If the normal water pressure does not exceed 50 PSI, but fluctuates

over this value (for example, when water usage on other equipment connected

to the same water supply causes pressure spikes), use a water regulator

.

Locate pump deck as close as possible to the unit.

all the water regulator to the inlet line of the pump deck and connect 3/8”

Inst

water supply line to the inlet of the pump.

Connect 3/8” outlet carbonated water supply line to the carbonated water inlet

of the unit.

Connect the harness into the pump deck and into the power supply on the unit.

D. Place the CO2cylinder with the CO2regulator in a serviceable location and

route the CO2supply line (75 PSI) to the 3/8 inch barb fitting at the front of the

unit.

Connect the syrup supply lines to the 3/8 inch barb inlet fittings at the front of

E.

the unit. Connect other end to BIB pumps.

F. Connect the flavor injection lines to the barb fittings at the front of the unit.

G. Install the drip tray and extend the hose to an open drain.

Insulate drain lines with a closed cell insulation. Ensure that the insulation

H.

o prevent

covers the entire length of the drain hose, including fittings.

T

condensation from forming, install the drain so that water does not collect in

sags or other low point

Install the cup rest and splash plate.

I.

Connect the power cord to a grounded electrical outlet.

J.

The bin agit

ation system will operate automatically. Do not place

s.

hands in the bin or the ice chute.

Test motor operation by pushing the ice chute.

K.

Clean and sanitize the dispenser (see section 2).

L.

Fill the dispenser half full with ice. Test ice delivery by pushing the ice chute.

M.

N. Fill the dispenser with ice.

O. Install the top cover.

P. Set the brix ratio for beverage dispensing valves according to the

manufacturer's instructions.

15

.N. 28-0580/02

P

Page 16

WAR NING!

When installing an icemaker on an IBD dispenser, use a bin

thermost

at to control the ice level. This will prevent damage to the

dispensing mechanism. the bracket for mounting a thermost

located in the ice bin.

at is

During the automatic agit

ensure there is adequate sp

ation cycle and while dispensing ice,

ace between the top of the ice level and

the bottom of the icemaker so the ice can move without

obstruction.

Contact your icemaker manufacturer for information on a suitable

bin thermost

at.

Disconnect the dispenser from the power source before removing

any parts from the bin. Automatic agitation can occur at any time.

P.N. 28-0580/02

16

Page 17

CLEANING AND SANITIZING

2.

2.1 GENERAL INFORMATION

Lancer equipment is shipped from the factory cleaned and sanitized in accordance

with NSF guidelines. The equipment must be cleaned and sanitized after

installation is complete. The operator of the equipment must provide

continuous maintenance as required by this manual and st

health department guidelines to ensure proper operation and sanitation

requirements are maintained.

NOTE: The cleaning and sanitizing procedures provided in this manual pertain to

the Lancer FS30 dispenser

guidelines established for that equipment.

Cleaning and sanitizing should be performed by trained personnel only. Use

ary gloves. Observe applicable safety precautions. Follow instruction warnings

sanit

on the product.

ate and local

. If other equipment is being cleaned, follow the

DO NOT:

Disconnect water lines when cleaning and sanitizing syrup lines,

to avoid cont

Use strong bleaches or detergent

corrode various materials.

Use met

al scrapers, sharp objects, steel wool, scouring pads,

abrasives, or solvent

Use hot water above 140 degrees F (60 degrees C). This can

damage the dispenser

amination.

s on the dispenser.

.

s; these can discolor and

17

.N. 28-0580/02

P

Page 18

2.2 CLEANING AND SANITIZING SOLUTIONS

WAR NING!

CLEANING SOLUTION: Mix a mild, non-abrasive detergent with clean, pot

water at a temperature of 90 to 1

cleaner to two gallons of water

10 degrees F

. Prepare a minimum of five gallons of cleaning

solution. Do not use abrasive cleaners or solvent

. The mixture ratio is one ounce of

s because they can cause

able

permanent damage to the dispenser. Ensure rinsing is thorough, using clean,

able water at a temperature of 90 to 110 degrees F. Extended lengths of product

pot

lines may require additional cleaning solution.

SANITIZING SOLUTION: Prepare a minimum of five gallons of sanitizing solution

according to the manufacturer’s recommendations and safety guidelines. Ensure

the solution provides 50 to 100 p

arts per million (PPM) chlorine. Any sanitizing

solution may be used as long as it is prepared as directed above. Extended lengths

of product lines may require additional sanitizing solution.

Following sanitization, rinse with end-use product until there is no

aftertaste. Do not use a fresh water rinse. This is an NSF

requirement. Residual sanitizing solution lef

t in the system creates

a health hazard.

For powder sanitizers, dissolve completely with water prior to

adding to the syrup system. Hot water will help dissolve powder

sanitizers.

Avoid getting sanitizing solution on circuit boards.

OTHER SUPPLIES NEEDED:

- Clean cloth towels

- Bucket

- Small brush (PN 22-0017) - included with installation kit.

- Extra nozzle

- Sanitary gloves

2.3 DAILY CLEANING

Carefully remove the nozzle housings by turning counterclockwise and pulling

A.

down from the nozzle body.

B. Wash the nozzle housings in cleaning solution and rinse with clean warm water.

et a clean cloth in cleaning solution.

W

C.

While the nozzle housing is removed, wipe down the perimeter and end of the

D.

nozzle body

.

P.N. 28-0580/02

18

Page 19

Fill a cup with clean warm water and rinse nozzle body.

E.

F. Make certain that the nozzle o-ring is not torn or otherwise damaged. If

necessary, replace damaged o-ring with Lancer PN 02-0231.

G. Wet the inner surface of the nozzle housing with water and reinstall the nozzle

housing by sliding it over the nozzle body and turning clockwise to lock in

position.

2.4 ICE BIN CLEANING - PERFORM AT STARTUP AND MONTHLY

Disconnect power to the dispenser

A.

.

B. Remove the top cover.

Melt out any remaining ice from the bin.

C.

D. Remove the splash plate, drip tray and front and rear bin covers.

E. Remove the agitator pin from the agitator shaft. Slide the agitator shaft rearward

out of the motor shaft and pull out of the rear bearing to remove.

. Remove the dispensing wheel from the motor shaft by sliding rearward.

F

CONTINUED ON NEXT P

AGE

19

.N. 28-0580/02

P

Page 20

. WHITE WHEEL

G

SHROUD (PELLET ICE)

. BLACK WHEEL SHROUD (CUBED ICE)

G

Remove the gasket which secures the

shroud by pulling it out.

Push the front section of the shroud back.

Pull the shroud up and out.

Remove the lower ice chute assembly

.

H. Using the cleaning solution described in the “Cleaning and Sanitizing Solutions”

section and a clean cloth or sof

ice chute and surface of aluminum casting.

I. Using hot water, thoroughly rinse away the cleaning solution.

J. Wearing sanitary gloves, soak a clean cloth towel in sanitizing solution, described

in the “Cleaning and Sanitizing Solutions” section above, and wash all surfaces of

removable parts, sides of ice bin, ice chute liner, and surface of aluminum casting.

K. Wearing sanitary gloves, reassemble all removable parts.

Fill the unit with ice and replace the top cover

L.

Reconnect the dispenser to the power source. Ensure agitator clip is locked:

M.

Remove the dispensing wheel shroud.

Remove the lower ice chute assembly.

t brush, clean all removable p

arts, sides of ice bin,

.

P.N. 28-0580/02

20

Page 21

2.5 CLEANING AND SANITIZING BEVERAGE COMPONENTS BAG-IN-BOX SYSTEMS

NOTE: Extended lengths of product lines may require more time for flushing and

rinsing lines than st

ated below

.

Disconnect the syrup quick disconnect coupling from the syrup p

A.

ackages and

connect the coupling to a bag valve removed from an empty Bag-in-Box (BIB)

ackage.

p

B. Place the syrup inlet line in a clean container filled with clean, potable, room

temperature water

. Activate the valve until water is dispensed. Flush and rinse

the line and fittings for a minimum of sixty seconds to remove all traces of

residual product.

Make the sanitizing solution. Place the syrup inlet line in a container filled with

C.

sanitizing solution.

D. Activate the valve and draw sanitizing solution through the line for a minimum of

sixty seconds.

This will ensure the line is flushed and filled with sanitizing

solution. Allow the line to stand for at least thirty minutes.

E. Remove the bag valve from the quick disconnect coupling and reconnect the

syrup inlet line to syrup package. Ready the unit for operation.

. Draw drinks to refill the lines and to flush the sanitizing solution from the

F

dispenser

.

NOTE: Do not follow the sanitization procedure with a fresh water rinse. Purge only

with end-use product until there is no aftertaste. This is an NSF requirement.

G. Test the dispenser for proper operation. Taste the dispensed product to ensure

there is no off-taste. If off-taste is found, flush the syrup system again.

Repeat cleaning, rinsing, and sanitizing procedures for each valve and circuit.

H.

2.6 ICE CHUTE CLEANING

It is recommended to perform this procedure monthly

the cleaning solution described above.

one p

A.

B. Remove merchandiser.

C. Unhook the spring from the upper ice chute by pulling up and out.

D.

E.

F

G

art vinegar may be used to remove water spots and calcium deposits.

Turn off power to the dispenser.

Remove the lower chute by carefully spreading ap

chute.

Mix the cleaning solution. Put a portion of the solution into a spray bottle. Soak

the lower chute in the remaining solution.

. Spray the upper chute with the cleaning solution.

. With a soft sponge, clean the inside of the upper and lower chutes.

, or more often if desired. Use

An alternate solution of one part water to

art the arms of the lower

21

.N. 28-0580/02

P

Page 22

Rinse the lower chute thoroughly

H.

I. Dry the lower chute thoroughly.

.

Empty the cleaning solution from the spray bottle, then refill with plain water

J.

Rinse the upper chute thoroughly

Dry the upper chute.

K.

.

L. Reinstall the lower ice chute onto the upper chute, then reinstall the spring.

Reinstall merchandiser.

M.

Reconnect power to the dispenser.

N.

HOW TO OPERATE AND ADJUST THE DISPENSER

3.

3.1 NORMAL OPERATION

A. Fill cup with desired amount of ice.

Place cup under nozzle below desired brand.

B.

Select up to two desired bonus flavors from those available on the keypad, by

C.

pressing against the flavor label once. Selection indicator light will illuminate,

acknowledging selection.

D. Press and hold brand label to fill cup.

E. Top off cup as desired.

.

3.2 PROGRAMMING AND SETUP SOFTWARE

Lancer reserves the right to make changes and updates as required. If

you have any questions regarding the latest versions of programs, please

contact your Lancer representative.

The Lancer FS22 has been factory preset to the settings necessary to comply with

the brand/flavor version of the unit requested by the customer

Adjustment

upgrades, an upgrade kit may be purchased.

s or upgrades should only be performed by trained personnel. For any

The kit includes all of the hardware

required for the upgrade, including bezels and valves.

CONTINUED ON NEXT PAGE

.

P.N. 28-0580/02

22

Page 23

INITIALIZATION SCREEN

(BOOT UP ONLY)

LANCER FS SERIES

VER. 0.xxxx

MAIN MENU

SUB-CATEGORY

FS-22 (NO PWB) C

MAJOR / MINOR

BRANDS PER SIDE

V:1 L:2 R:2

FS-22 (NO PWB) C

CONFIG BONUS KEY

BONUS KEY SETUP

V:1 T:F M:F B:F

FS-22 (NO PWB) C

CARB / WATER SETUP

CARB / WATER SETUP

V1 B1 SODA

FS-22 (NO PWB) C

NUMBER OF VALVES

1 2

Y Y

FS-22 (NO PWB) C

GLOBAL CONFIG

Scrolls through Main Menu

Press "Enter" to enter sub-category

Moves cursor to right or left

Changes value (number/letter)

Press "Enter" to save changes

Press "Cancel" to exit menu

CANCEL

ENTER

FS-22 (NO PWB) C

RELOAD DEFAULTS?

FS-22 (NO PWB) C

SOFTWARE VERSION

CONTROLLER X.XXX

V1 X.XXX

SET MAIN CONFIG

FS8 (PWB)

NO YES

RESET DEFAULTS

FS-22 (NO PWB) C

CONFIG ICE TYPE

CUBE PELLET

FS-22 (NO PWB) C

VW ICE STIR TMS

ICE STIR ON 2000

CONFIG ICE TYPE

ICE STIR OFF 60

NOTE:

C = CUBED ICE

P = PELLET ICE

O = OVERRIDDEN

Valves can be adjusted by scrolling through the menus (see figure above) using the

UP and DOWN arrows. By pressing the ENTER button, a submenu is revealed. In

the submenu, the individual valves can be adjusted to the desired configuration.

B. MENUS AND SUBMENUS

23

.N. 28-0580/02

P

Page 24

Bonus Flavors

1.

a. Decide if the bonus flavors will be set to add an injected flavor to the

brands or dispense carbonated water/plain water.

b. Choose the Valve number (1-2) by scrolling UP and DOWN arrows.

c. Use the LEFT and RIGHT arrows to shift to the Top, Middle, or Bottom

"bonus" flavors categories.

Press the

d.

it as an injected flavor

Press

e.

UP and DOWN arrows under Top, Middle, or Bottom to select

, carbonated

Soda water

ENTER to finalize settings. Panel light

, or plain

Water

.

s should confirm finalized

configurations.

Brands

2.

Decide how the brands will be setup.

a.

b. Choose the Valve number (1-2) by scrolling UP and DOWN arrows.

c. Use the LEFT and RIGHT arrows to shift to the Left or Right categories.

The Lef

t or Right categories are set with the assumption that you

are looking at them from the front.

d. Press UP and DOWN arrows under Left (1-2) or Right (1-2) to select the

brand per side as a single or double. For example, for bezel PN 05-2120,

V:1 L:1 R:2

3. Soda/Water

a. Decide which switch locations will be carbonated and/or non-carbonated

drinks.

Choose the

b.

Valve number (2-3) by scrolling the UP and DOWN arrows.

c. Use the LEFT and RIGHT arrows to shift to the number categories (1-4).

The number categories correspond to the brand location (per valve)

that is being configured.

Press the

d.

UP and DOWN arrows under the number to select if that brand

will be carbonated Soda or non-carbonated plain Water. If a single brand

per side, only number 1 and/or 3 need to be set.

Automatic

4.

Agitation

a. Each Series 14400 ice beverage dispenser is equipped with automatic

agitation for the ice bin. The unit is shipped with timing set at two seconds

(2000 milliseconds) ON every sixty minutes for cubed ice. The unit is

shipped with timing set at four seconds (4000 milliseconds) ON every

150 minutes for pellet ice.

3.3 PURGING THE CARBONATION SYSTEM

Purge the carbonator tank whenever carbonation issues occur.

urn off CO

A.

T

supply

2

.

B. Turn off power to the unit. Unplug the carbonator harness from the power

supply

Open the relief valve until water is coming out. Close the relief valve, checking

C.

.

for any remaining air in the t

Allow the carbonator tank to fill with plain water by way of the water booster.

D.

P.N. 28-0580/02

ank.

24

Page 25

Once the t

E.

dispensing a carbonated drink.

still of

. Turn on the CO

F

f. Dispense several times.

ank is full, turn the power back on and purge the system by

ou should only get plain water as the CO

supply

2

Y

is

2

G. Turn off the power in order to reconnect the pump harness. Turn power back on.

H. Dispense soda at valve until the carbonator pump comes on. Release the

button, allow the carbonator to fill and stop (usually a few seconds). Repeat this

process until the water is carbonated (about five cycles).

Place dispenser back into service.

I.

NOTE: T

the pressure to the system drop

o check for CO

leaks, close the valve on the CO2cylinder and observe if

2

s with the cylinder valve closed for five minutes.

Open the cylinder valve after check.

PURGING THE W

3.4

ATER AND SYRUP SYSTEMS

A. Open a dispensing valve until water and syrup are flowing steadily from the

valve. Repeat for each valve.

Check all of the dispenser's syrup and water connections for leaks and repair if

B.

necessary.

C. Replace the dispenser's splash plate and cup rest.

ADJUSTING W

3.5

ATER FLOW AND WATER TO SYRUP RATIO (BRIX)

The water flow can be adjusted between 3.25 oz/sec (96 ml/sec) and 4.50 oz/sec

(133 ml/sec) on all dispensing valves. Ensure ice is on the cold plate for at least one

hour before you brix the valves. The drink temperature should be no higher than 40

degrees F (4.4 degrees C) when the brix is set.

Remove merchandiser assembly.

A.

If necessary, rotate switches panel forward and down by releasing the two pin

B.

latches on its sides.

ate light panel, forward and up by releasing the two pin latches on its sides

Rot

C.

towards the top.

Remove nozzle by twisting counterclockwise and pulling down.

D.

E. Install Lancer syrup separator (PN 82-3458) in place of nozzle.

F. Activate dispensing valve to fill separator syrup tube.

G. Hold a Lancer brix cup under the syrup separator and dispense water and syrup

into cup for four seconds. Divide number of ounces of water in cup by four to

determine water flow rate per second.

o obtain the proper flow, remove protective cap, and use a screwdriver to

T

H.

adjust water flow control.

Repeat process for each water valve. There can be up to six gray water valves

I.

on this dispenser (up to four carbonated water valves and two plain water

25

.N. 28-0580/02

P

Page 26

valves).

J. Hold the Lancer brix cup under the syrup separator and activate valve. Check

brix.

ain the proper brix, use screwdriver to adjust syrup flow control.

o obt

T

K.

L. Once proper ratio is obtained, repeat to verify.

M. Repeat process for each valve.

Remove syrup separator.

N.

O. Install nozzle.

. Once all the valves have been brixed, restore switches panel and light panel to

P

their original positions.

3.6 CARBONATOR PUMP MODIFICATIONS

The electric, positive displacement rot

ary vane pump with 170 PSI byp

ass should

only be serviced by trained personnel. To achieve optimum carbonation, use

filtered water with the pump.

Turn off power to the dispenser.

A.

Remove drip tray and splash plate.

B.

urn off water.

T

C.

Turn the CO2 off, activate the relief valve.

D.

Once the pressure has been released, untighten the inlet/outlet nut

E.

s on the

pump.

F. Unscrew the mounting bracket.

G. Part should easily slide out for replacement or maintenance.

P.N. 28-0580/02

26

Page 27

4. TROUBLESHOOTING

TROUBLE CAUSE REMEDY

4.1 No product when switch is

activated. (Switch p

anel does not

light up when activated.)

4.2 No product when switch is

activated. (Switch p

anel does light

up when activated.)

4.3 Push chute and nothing

happens.

A. Keyswitch is of

f, or keyswitch

harness is disconnected.

B. 9-in valve harness is

disconnected.

C. Defective switch assembly.

D. No power to unit.

A. 25-pin valve harness is

disconnected.

B. Defective switch assembly.

A. Dispenser not connected to

power source.

B. Microswitch defective.

C. Wiring harness not plugged in.

D. PC board defective.

urn keyswitch on and/or

T

A.

reconnect keyswitch harness.

B. Turn off power, reconnect 9-pin

harness, and restore power.

C. Replace switch assembly.

D. Check internal breaker and

incoming power.

Turn off power, reconnect 25-

A.

pin harness, and restore power

.

B. Replace switch assembly.

A. Connect dispenser to power

source.

B. Replace microswitch.

C. Plug in wiring harness.

D. Replace PC board.

4.4 Push chute. Ice door opens

but motor does not run.

4.5 Push chute. Motor runs but

ice door does not open.

4.6 Push chute, ice door opens,

motor runs, but no ice dispenses,

or ice is of poor quality.

iring harness not plugged in.

A. W

B. PC board defective.

C. Motor defective.

A. Solenoid not connected to PC

board.

B. Solenoid defective.

C. PC board defective.

D. Solenoid bracket screwed too

low and not opening completely

A. Dispenser is out of ice.

B. Agitator pin is missing or

damaged.

C. Poor ice quality.

A. Plug in wiring harness.

B. Replace PC board.

C. Replace motor

.

A. Connect solenoid to PC

B. Replace solenoic.

C. Replace PC board.

D. Unscrew solenoid bracket,

raise solenoid and rescrew

.

bracket.

A. Fill unit with ice.

B. Replace agitator pin.

C. Install water

filtration/purification to icemaker

supply water.

board.

CONTINUED ON NEXT PAGE

27

.N. 28-0580/02

P

Page 28

TROUBLE CAUSE REMEDY

4.7 Valves do not operate. A. Keyswitch is off, or keyswitch

harness is disconnected.

B. Circuit breaker tripped.

C. Unit not plugged in.

ater in ice bin.

4.8 W

ater leakage around nozzle.

4.9 W

A. Cold

A. Damaged or improperly

inst

4.10 Miscellaneous leakage. A. Gap between p

plate drain is obstructed.

alled o-ring on nozzle.

arts.

B. Damaged or improperly

alled o-rings.

inst

4.11 Noisy/cavitating carbonator

pump.

A. Insufficient incoming water

supply pressure.

A. Turn keyswitch and/or make

sure keyswitch harness is

connected.

B. Reset circuit breaker

C. Plug in dispenser

A. Remove splash plate to obt

.

.

ain

access to drain tubes and clear

accordingly

.

A. If damaged, replace. If

improperly inst

Tighten appropriate retaining

A.

alled, adjust.

screws.

B. Replace or adjust appropriate

o-rings.

A. Verify incoming supply water

pressure to carbonator pump is a

minimum of 25 PSI (max 50 PSI).

4.12 Insufficient soda flow

(carbonated drinks).

4.13 Insuf

ficient water flow (plain

water).

A. Insufficient CO2 supply

pressure.

B. Shutoff on mounting block not

fully open.

C. Foreign debris in soda flow

control.

A. Insuf

ficient incoming supply

pressure.

B. Shutof

f on mounting block not

fully open.

C. Foreign debris in water flow

control.

ater filtration problem.

D. W

A. Verify incoming CO2 pressure

between 70-75 PSI.

B. Open shutoff fully.

C. Remove soda flow controlf

rom valve and clean out any

foreign material to ensure smooth

spool movement.

erify incoming supply water

A. V

pressure to plain water inlet is a

minimum of 70 PSI

(max 125

PSI).

B. Open shutof

f fully.

C. Remove water flow control

from valve and clean out any

foreign material to ensure smooth

spool movement.

D. Service water system as

required.

CONTINUED ON NEXT PAGE

.N. 28-0580/02

P

28

Page 29

TROUBLE CAUSE REMEDY

4.14 Insufficient syrup flow. A. Insufficient CO2 pressure to

BIB pumps.

B. Shutoff on mounting block not

fully open.

C. Foreign debris in syrup flow

control.

D. Defective BIB

pump.

4.15 Erratic ratio. A. Incoming water and/or syrup

supply not at minimum flowing

pressure.

B. Foreign debris in water and/or

syrup flow control.

C. CO2 regulator malfunction.

A. Adjust CO2 pressure to 80 PSI

(min 70 PSI) for BIB pumps.

B. Open shutoff fully.

C. Remove syrup flow control

from valve and clean out any

foreign material to ensure smooth

spool movement.

D. Replace pump.

A. Check pressure and adjust.

B. Remove flow control from

suspected valve and clean out

any foreign material to ensure

smooth spool movement.

C. Repair or replace CO2

regulator as required.

4.16 Water only dispensed, no

syrup. Or syrup only dispensed,

no water.

A. Syrup BIB empty.

B. Water or syrup shutoff on

mounting block not fully open.

C. Improper or inadequate water

or syrup supply.

D. CO2 pressure to syrup pump

too low.

E. Stalled or inoperative BIB

pump.

F. Kinked line.

G. CO2 regulator malfunction.

A. Replace syrup BIB as required.

B. Open shutoff fully.

C. Remove valve from mounting

block, open shutoff slightly and

check water and syrup supply. If

no supply, check dispenser for

other problems. Ensure BIB

connection is engaged.

D. Check the CO2 pressure to the

pump to ensure it is between 7080 PSI.

E. Check CO2 pressure and/or

replace pump.

F. Remove kink or replace line.

G. Repair or replace CO2

regulator as required.

CONTINUED ON NEXT P

29

AGE

.N. 28-0580/02

P

Page 30

TROUBLE

CAUSE

REMEDY

alve will not shut of

4.17 V

f.

A. Debris in solenoid seat.

B. Solenoid plunger sticking.

4.18 Syrup only dispensed. No

water, but CO2 gas dispensed

A. Improper water flow to

dispenser.

with syrup.

B. Carbonator pump motor has

timed out. (A message will be

displayed on the LCD screen.)

C. Liquid level probe not

connected properly to PCB.

D. Defective PCB assembly.

E. Defective liquid level probe.

4.19 Excessive foaming. A. No ice in bin.

Activate valve a few times to

A.

free debris. Remove the solenoid

coil and plunger and clean out

foreign material.

B. Replace solenoid coil.

A. Check for water flow to

dispenser.

B. Reset by turning the unit off

and then of by using the circuit

breaker on the power supply, or

momentarily unplugging unit.

C. Check connections of liquid

level probe to PCB assembly.

Replace PCB assembly.

D. Replace PCB assembly.

E. Replace liquid level probe.

A. Fill bin with ice and allow

plate to restabilize.

cold

B. Incoming water or syrup

temperature too high.

C. CO2 pressure too high.

ater flow rate too high.

D. W

fuser not clean.

4.20 W

ater continually leaking at

E. Nozzle and dif

. Air in BIB lines.

F

A. Loose water connections.

connections.

B. Flare seal washer leaks.

4.21 Water leaking from ice door. A. Securing screws loosened.

B. Ice door improperly seated.

CONTINUED ON NEXT P

B. Correct prior to dispenser

Adjust CO2 pressure

C.

downward, but not less than 70

PSI.

D. Readjust and reset ratio.

E. Remove and clean.

. Bleed air from BIB lines.

F

Tighten water connections.

A.

B. Replace flare seal washer

A. Tighten screws.

B. Reattach door assembly to

dispenser.

AGE

.

.

P.N. 28-0580/02

30

Page 31

TROUBLE

CAUSE

REMEDY

4.22 Circuit breaker tripping. A. V

to it

B. Controller PCB is bad.

C. Secondary wire harness is

shorted.

D. Power supply is bad.

alve wire harnesses shorted

self or faucet plate.

A. Detect short by disconnecting

valve harnesses from switch

anel (2 25-pin harnesses and 2

p

9-pin harnesses).

Restore power. If breaker does

not trip, then find and replace

shorted harness. If breaker still

trips, reinstall the eight harnesses

and proceed to Step B.

B. Detect by disconnecting the

white 5-pin harness from the controller PCB. Restore power. If

breaker does not trip, then

replace controller PCB. If breaker

still trip

s, reinst

harness and proceed to S

all the white 5-pin

tep C.

C. Locate short from a motor or

solenoid harness and replace as

necessary

.

D. Detect short by disconnecting

all harnesses connected to power

. Restore power

supply

still trip

s, replace power supply

. If breaker

.

4.23 BIB pump does not operate

when dispensing valve is opened.

4.24 BIB

flow

pump operating, but no

.

4.25 BIB pump continues to

operate when bag is empty.

A. Out of CO2, CO2 not turned

on, or low CO2 pressure.

B. Out of syrup.

C. BIB connector not tight.

D. Kinks in syrup or gas lines.

A. Leak in syrup inlet or outlet

line.

B. Defective BIB

pump check

valve.

A. Leak in suction line.

B. Leaking o-ring on pump inlet

fitting.

C. Defective syrup BIB pump.

A. Replace CO2 supply, turn on

CO2 supply, or adjust CO2 pressure to 70-80 PSI.

B. Replace syrup supply.

C. Fasten connector tightly.

D. Straighten or replace lines.

A. Replace line.

B. Replace BIB pump.

A. Replace line.

B. Replace o-ring.

C. Replace defective pump.

CONTINUED ON NEXT PAGE

31

.N. 28-0580/02

P

Page 32

ILLUSTRATIONS, PARTS LISTINGS AND WIRING DIAGRAMS

1

2

5

6

3

4

9

10

7

8

11

12

14

15

35

34

13

27

28

29

25

26

30

31

32

33

16

17

18

19

20

21

24

22

23

36

5.

5.1 FINAL ASSEMBLY

P.N. 28-0580/02

32

Page 33

5.1

E

A

B

C

D

F

H

I

G

J

FINAL ASSEMBLY - PARTS LIST

No.

Part

85-14408-06-2

Description

ACMB, 22”, 150#, 8/6, LFCV, Cubed

IBD,

85-14408N-06-2 IBD, ACMB, 22”, 150#, 8/6, LFCV, Pellet

Item Part No. Description

1 82-3441/01 Drip Tray Assy, IBD22

2 04-0236 Screw, 10-24 x 0.375, PHD,

PH, MS, SS

3 23-0969/01 Cup Rest, Wire, 22”, IBD

4 30-9194 Splash Plate, FS-8

5 17-0611. Check Valve, Vented,

5/8-18

6 82-3688/01 Motor Assy, Gear, 115V,

1/7HP, IBD

91-0165/01 Motor, Agitator, 562, 115V,

4RPM, IBD

7 82-3370 CO2 Assy, Inlet/P-Off, FS-16

54-0066 Relief Valve Assy, Plastic

8 54-0289 Nozzle Assy, Multi-Flavor

9 01-2214 Nut, Swivel, Probe, Carb,

FS-16

10

52-2751/02

Probe Cord Assy, Carb,

FS-16

82-3820 Valve Assy, LFCV, .2 Syrup

1

1

are

p

are with

p

12

13

82-3824

82-3823

Injection, Natural (S

Adapter)

with

Valve Assy, LFCV, 3.0 - 4.5,

, Gray (Spare

Soda/W

with

ater

Adapter)

Valve Assy, LFCV, 3.0 - 4.5,

Syrup, Black (S

Adapter)

14

15

82-2317/01

04-1089

Block Mounting Assy, SGL

Screw, 10-32 x 1.000, RH,

PH/SL

16 02-0406/01 Seal, Shaft, Motor, IBD

Item Part No. Description

17 23-1373 Agitator Assy, FS/IBD, HEX

18 54-0472 Bearing, Agitator, Rear, IBD

19 10-0762 Pin, Hex Design, FS-16

20 03-0368 Retainer, Pin, Agitator, IBD

21 82-3556 Dispensing Wheel Assy,

22 05-1467 Lid, Back, IBD22, RND

23 05-1476/01 Lid, Front, IBD, RND

24 05-1309/02-01 Shroud, Dispensing Wheel,

25 52-2985 Harness, Valve 25-pin,

26 52-2686 Harness, Control-To-Valve,

27 12-0146/01 Lamp, 18”, 5W, T8, Daylight

82-3771

28

06-2994-02

-

82-3664

29

52-2820/01

30

82-3538/01

31

05-2058

32

82-3630

33

12-0104

34

12-0188

35

36 82-3791 Pump Assy, Remote, FS22,

86-0084 Pump Assy

91-0008 Motor, Carb 1/3 HP

Hex

MOD, IBD

FS-16, Sealed

9-pin, M/F, FS-8

Merchandiser, Assy, FS-22

Graphic, FS-22,

ellow

Brilliant

Y

Assy, Power Supply, FS-8

PCB Assy, FS-IBD

Controller Board

Ice Chute Assy, IBD30,

Pellet

Bezel, M-Brand, 2L/2R

Switch Assy, FS, 2L/2R

Starter, with Condenser,

IBD

Ballast, Fluorescent Light,

LC-14-20-C

1/3 HP

ICE DOOR SOLENOID

A 03-0086 Ring, Retaining (5304-18)

B 04-0328 Washer, Rubber

C 04-0327 Washer, Flat

D 12-0195 Solenoid, D-90

E 30-5165 Bracket, Solenoid

F 23-1380 Plunger Assy

G 10-0496 Pin, Solenoid Assy

H 03-0110 Spring, Solenoid

I 03-0111 Ring, Retaining (5133-62)

J 30-8356 Linkage, Door, FS

ASSEMBLY (AT LEFT):

33

.N. 28-0580/02

P

Page 34

10

11

4

6

5

3

2

1

7 x2

9 x2

8

5.2

ICE CHUTE ASSEMBLY

Part No. Description

Item

1 05-2257/01 Chute, Upper, IC

2 54-0406 Chute, Printed, IBD

3 05-0999/01 Lever, Chute, IBD

4 04-0268 Scr, 6-19X.625 LG, PLSTI,HHSW/W

5 03-0241 Spring, Chute, IBD

6 12-0244 Switch, SPST, 5A, 250V, MDM

7 05-0359 Bushing, .123 ID x .187 OD, NYLN

8 05-0928/02 Trap Door, IBD

9 03-0113 Ring, Retaining

10 05-0546 Lever, Door

11 10-0732 Shaft, Ice Chute Door, IC

P.N. 28-0580/02

34

Page 35

PELLET ICE ASSEMBLY AND PARTS LISTING

5.3

Use the components listed on this page with pellet ice only.

35

ITEM

PART NO. DESCRIPTION

1 05-2325/01 Ice Shroud, IC

2 23-1401/01 Agitator Assy,

Helical, IC

3 10-0762 Pin, Hex Design,

FS-16

4 03-0368 Retainer, Pin,

Agitator, IBD

5 82-3651 Dispensing Wheel

Assy, Pellet Ice

6 30-9801/01 Shield, Nugget, IC

.N. 28-0580/02

P

Page 36

5.4

8

7

5

4

3

2

Spare Parts

Valve Assembly

1

6

LFCV V

LANCER FLOW CONTROL VALVE (LFCV)

VE ASSEMBLIES

AL

82-3820

82-3823

82-3824

LFCV SP

1 10-0430/05 PLUG NUT

2

ARE PARTS

02-0538 O-RING

3 12-0364/04-01COIL, LFCV

4 23-1301/01 CORE SEAL ASSY

5

03-0180/02 SPRING, CORE

6 02-0109 O-RING

7 05-1745/02 SEAT, LFCV

8 02-0133 O-RING

LFCV, BONUS INJECTOR

LFCV, 3.0 - 4.5, SYRUP

ASSY

LFCV, 3.0 - 4.5,

SODA/W

ATER ASSY

LFCV KIT

82-4020

P.N. 28-0580/02

LFCV REBUILD KIT

36

Page 37

5.5 WIRING DIAGRAM

WIRING DIAGRAM

FS22

AGITATO R

ICE DOOR

SOLENOID

REMOTE PUMP

KEY

SWITCH

LED COMMUNICATION LIGHTS

LED

NOTE:

FLASH WHEN COMMUNICATING

PROBE

ICE

SWITCH

NOZZLE

NOZZLE

V2

V1

BLACK

BLACK

WHITE

BLACK

WHITE

BLACK

POWER

SUPPLY

CONTROLLER

BOARD

DISPLAY

CARB/AGI

FOT

COMM

ICE OPTIC

ICE DOOR

ICE

SWITCH

KEY

SOLD OUT

JV1

JV2

JV3

JV4

CARB PROBE

POWER

CARBONATOR

BALLAST

ICE

AGITATOR

CARB/

AGI

CONTROLLER

POWER

LIGHTING

RESETABLE

SWITCH

POWER

CORD

BLK

WHT

GRN

TRANSFORMER

BLK

GROUND TO

ICE DOOR

SOLENOID

SCREW

37

P

.N. 28-0580/02

Page 38

S1-1

S1- 2

S1- 3

S1- 4

IS2- 3 IS2- 2

IS2- 1

IS1- 1

IS1- 2 IS1- 3

IS1-1

V1

S2-1

S2-2

S2- 3

S2- 4

V2

IS2-3

IS2-2

IS2-1

S2-4

S2-3

S2-1

SODA2

S2-2

WATER2

YEL

BLK

BRN

BLK

BLU

BLK

RED

BLK

BLU

WHT

V1

YEL

WHT

V1

RED

WHT

V1

YEL

BLK

RED

BLK

BRN

BLK

YEL

GRY

BLU

BLK

RED

GRY

S1-3 SODA1

WATER1

S1-4 S1-2 S1-1

IS1-1

IS1-2 IS1-3

VALVE HARNESS

DIAGRAM

PLUMBING

DIAGRAM

BLU

WHT

V2

YEL

WHT

V2

RED

WHT

V2

RED

GRY

YEL

GRY

IS1-2

IS1-3

IS2-1

IS2-2

IS2-3

RED

BLK

YEL

BLK

BLU

BLK

BRN

BLK

YEL

BLK

BRN

BLK

RED

BLK

BLU

BLK

PUMP

S2- 2

S2- 3

S2- 4

WATER

WATER

SUPPLY

CARB

S2- 1

S1- 4

S1- 1

S1- 2 S1- 3

5.6 PLUMBING DIAGRAM WITH V

ALVE WIRING

.N. 28-0580/02

P

38

Page 39

NOTES

39

.N. 28-0580/02

P

Page 40

LANCER

To order parts, call

Customer Service: 800-729-1500

arranty/Technical Support: 800-729-1550

W

Email: custserv@lancercorp.com

.lancercorp.com

www

Loading...

Loading...