Page 1

INSTALLATION AND SERVICE MANUAL

FOR

DELTA II PRE-MIX

COUNTER ELECTRIC DISPENSER

REV. 05/01/98

P.N. 28-0364

RADEMARKS

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

FAX ENGINEERING: • 210-310-7096

"Lancer" is the registered trademark of Lancer • Copyright — 1998 by Lancer, all rights reserved.

6655 LANCER BLVD. • SAN ANTONIO, TEXAS 78219 USA • (210) 310-7000

FAX SALES

• NORTH AMERICA – 210-310-7245 • INTERNATIONAL SALES – 210-310-7242 • CUSTOMER SERVICE – 210-310-7242 •

• LATIN AMERICA – 210-310-7245 • EUROPE – 32-2-755-2399 • PACIFIC – 61-8-8268-1978 •

This is an initial manual.

R

S

K

R

A

M

E

D

A

R

T

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS ......................................................................................................................................i

SPECIFICATIONS DELTA PRE-MIX .................................................................................................................ii

1. INSTALLATION ...........................................................................................................................................1

1.1 RECEIVING........................................................................................................................................1

1.2 UNPACKING ......................................................................................................................................1

1.3 SELECTING A COUNTER LOCATION..............................................................................................1

1.4 CONNECTING THE DRAIN...............................................................................................................1

1.5 FILLING UNIT WITH WATER ............................................................................................................1

1.6 CONNECTING TO ELECTRICAL POWER .......................................................................................2

1.7 CONNECTING TO PRODUCT SUPPLY ...........................................................................................2

2. SCHEDULED MAINTENANCE ...................................................................................................................3

2.1 DAILY .................................................................................................................................................3

2.2 WEEKLY .............................................................................................................................................3

2.3 MONTHLY ..........................................................................................................................................3

2.4 EVERY SIX MONTHS........................................................................................................................3

2.5 YEARLY..............................................................................................................................................3

3. DISPENSER CLEANING AND SANITIZING ..............................................................................................3

3.1 AMBIENT PROCESS.........................................................................................................................3

3.2 VALVES ..............................................................................................................................................4

4. TROUBLESHOOTING.................................................................................................................................4

4.1 MISCELLANEOUS LEAKAGE ...........................................................................................................4

4.2 INSUFFICIENT FLOW .......................................................................................................................4

4.3 EXCESSIVE FOAMING .....................................................................................................................4

4.4 COMPRESSOR DOES NOT START (NO HUM), BUT

CONDENSER FAN MOTOR RUNS...................................................................................................4

4.5 COMPRESSOR STARTS AND CONTINUES TO RUN UNTIL FREEZE UP

AND WILL NOT CUT OFF .................................................................................................................4

4.6 COMPRESSOR DOES NOT START BUT HUMS .............................................................................4

4.7 COMPRESSOR STARTS BUT DOES NOT SWITCH OFF START WINDING .................................4

4.8 COMPRESSOR STARTS AND RUNS A SHORT TIME BUT

SHUTS OFF ON OVERLOAD ...........................................................................................................5

4.9 WARM DRINKS..................................................................................................................................5

5. ILLUSTRATIONS, PARTS LIST, AND WIRING DIAGRAMS .....................................................................7

5.1 COMPRESSOR DECK ASSEMBLY ..................................................................................................7

5.2 DECK ASSEMBLY .............................................................................................................................9

5.3 CABINET ASSEMBLY ......................................................................................................................11

5.4 TUBING ASSEMBLY ........................................................................................................................13

5.5 CONTROL HOUSING ......................................................................................................................15

5.6 WIRING DIAGRAM ..........................................................................................................................17

i

Page 3

ii

RADEMARKS

SPECIFICATIONS

DIMENSIONS

Width 16 7/8 inches (42.86 cm)

Depth 24 3/4 inches (62.87 cm)

Height (without legs) 25 1/2 inches (64.77 cm)

WEIGHT

Shipping 170 pounds (77.1 kg)

Empty 146 pounds (66.2 kg)

Operating 220 pounds (99.8 kg)

ICE BANK WEIGHT 27 pounds (12.25 kg)

WATER BATH CAPACITY 10.87 gallons (41.15 liters)

COMPRESSOR 1/3 HP Tecumseh, 115V/60Hz

AGITATOR MOTOR 25W, 115V

CONDENSER MOTOR 9W, 115V

ICE BANK CONTROL Lancer Electronic Ice Bank Control (EIBC)

TRANSFORMER 120V (Primary)/24V (Secondary)

Optional 220V/50Hz and 220V/60Hz systems available.

490 - 12 ounce drinks under 40°F (4.4°C) at two (2) drinks per minute with 75°F (23.9°C) ambient inlet

product (pre-mix) using a 1/3 HP, 115V/60Hz refrigeration system.

R

S

K

R

A

M

E

D

A

R

T

Page 4

1. INSTALLATION

1.1 RECEIVING

Each unit is completed tested under operating conditions and thoroughly inspected before shipment.

At the time of shipment, the carrier accepts the unit and any claim for damages must be made with

the carrier. Upon receiving unit from the delivering carrier, carefully inspect carton for visible

indication of damage. If damage exists, have carrier note same on bill of lading and file a claim with

the carrier.

1.2 UNPACKING

A. Cut band and remove.

B. Remove top portion of carton by lifting up.

C. Remove top inner carton pad and corners.

D. Remove accessory kit of loose parts from drip tray.

E. Lift Unit up by plywood shipping base and remove lower portion of carton.

F. Inspect unit for concealed damage. If evident, notify delivering carrier. File claim against same.

G. Remove splash plate, located under unit on shipping base.

H. Remove plywood shipping base from unit by moving unit so that one side is off the counter top

or table allowing access to screws on the bottom of the plywood shipping base.

NOTE

If unit is to be transported, it is advisable to leave unit secured to plywood shipping base.

I. If Unit is to be installed with optional legs, assemble legs to unit by tilting unit. DO NOT LAY

UNIT ON ITS SIDE OR BACK.

J. Remove accessory kit of loose parts from drip tray.

1.3 SELECTING A COUNTER LOCATION

The dispenser is designed to sit on a flat supported surface capable of supporting a minimum weight

of 250 pounds (113.6 kg). It may be either counter or leg mounted. When the dispenser is to be

permanently bolted to the counter top, use Lancer Sealant Kit (PN 15-0010) to seal dispenser base

to counter top.

NOTE

NSF listed units must be sealed to the counter or have four (4) inch legs installed.

CAUTION

FAILURE TO MAINTAIN PROPER AIR CLEARANCE WILL CAUSE THE COMPRESSOR TO

OVERHEAT AND WILL RESULT IN COMPRESSOR FAILURE.

Locate dispenser to allow approximately eight (8) inches of unobstructed space above the unit for

proper air circulation. Air is drawn in through the front grill and exhausted out of the top grill. The

bonnet may be removed by lifting bonnet upward.

1.4 CONNECTING THE DRAIN

A. Remove cup rest. Lift splash plate up and pull out and down on the bottom to remove.

B. Remove the drip tray from the unit and connect the drain tube to the drain fitting located on the

bottom. Secure drain tube with clamp provided in accessory kit.

C. Route the drain tube to a suitable drain and replace the unit’s drip tray.

1.5 FILLING UNIT WITH WATER

A. Remove the bonnet from the unit.

B. Remove the yellow plastic plug from the unit’s fill hole.

CAUTION

THE WATER BATH COMPARTMENT MUST BE FILLED WITH WATER BEFORE PLUGGING

IN THE UNIT, OTHERWISE THE COMPRESSOR DECK AND CONDENSER FAN MAY NOT

OPERATE PROPERLY.

C. Fill the water bath compartment with water until it flows out of the overflow tube into the drip tray.

Use bottled drinking water where hard water problems exist. Do not use distilled water in units

1

Page 5

which are equipped with electronic ice bank controls (EIBC).

D. Replace the yellow plug.

1.6 CONNECTING TO ELECTRICAL POWER

WARNING

THIS UNIT MUST BE PROPERLY ELECTRICALLY GROUNDED TO AVOID POSSIBLE FATAL

ELECTRICAL SHOCK OR SERIOUS INJURY TO THE OPERATOR. THE POWER CORD IS

PROVIDED WITH A THREE PRONG GROUNDED PLUG. IF A THREE-HOLE GROUNDED

ELECTRICAL OUTLET IS NOT AVAILABLE, USE AN APPROVED METHOD TO GROUND THE

UNIT.

CAUTION

FAILURE TO DISCONNECT THE MOTOR POWER SUPPLY WILL DAMAGE THE CARBONATOR

MOTOR AND PUMP AND VOID THE WARRANTY.

A. Check the dispenser serial number plate for unit’s correct electrical requirements. Do not plug

into electrical outlet unless serial number plate electrical specifications are compatible with local

electric utility.

B. Route the power supply cord to a grounded electrical outlet of the proper voltage and amperage

rating, and plug the unit in. All USA/domestic models are equipped with a power kill switch

located on the left side of the condenser, in the bonnet. Kill switch must be on before the unit

will operate. Allow unit to run and start cooling while completing remainder of the installation.

NOTE

Units equipped with an electronic ice bank control contain a five (5) minute delay. Compressor

will not begin running until five (5) minutes after unit is energized.

1.7 CONNECTING TO PRODUCT SUPPLY

A. Using proper beverage tubing and fittings, connect to syrup inlet with flare seal washer

(PN 05-0011).

B. Mark syrup tube assemblies with product ID tape.

2

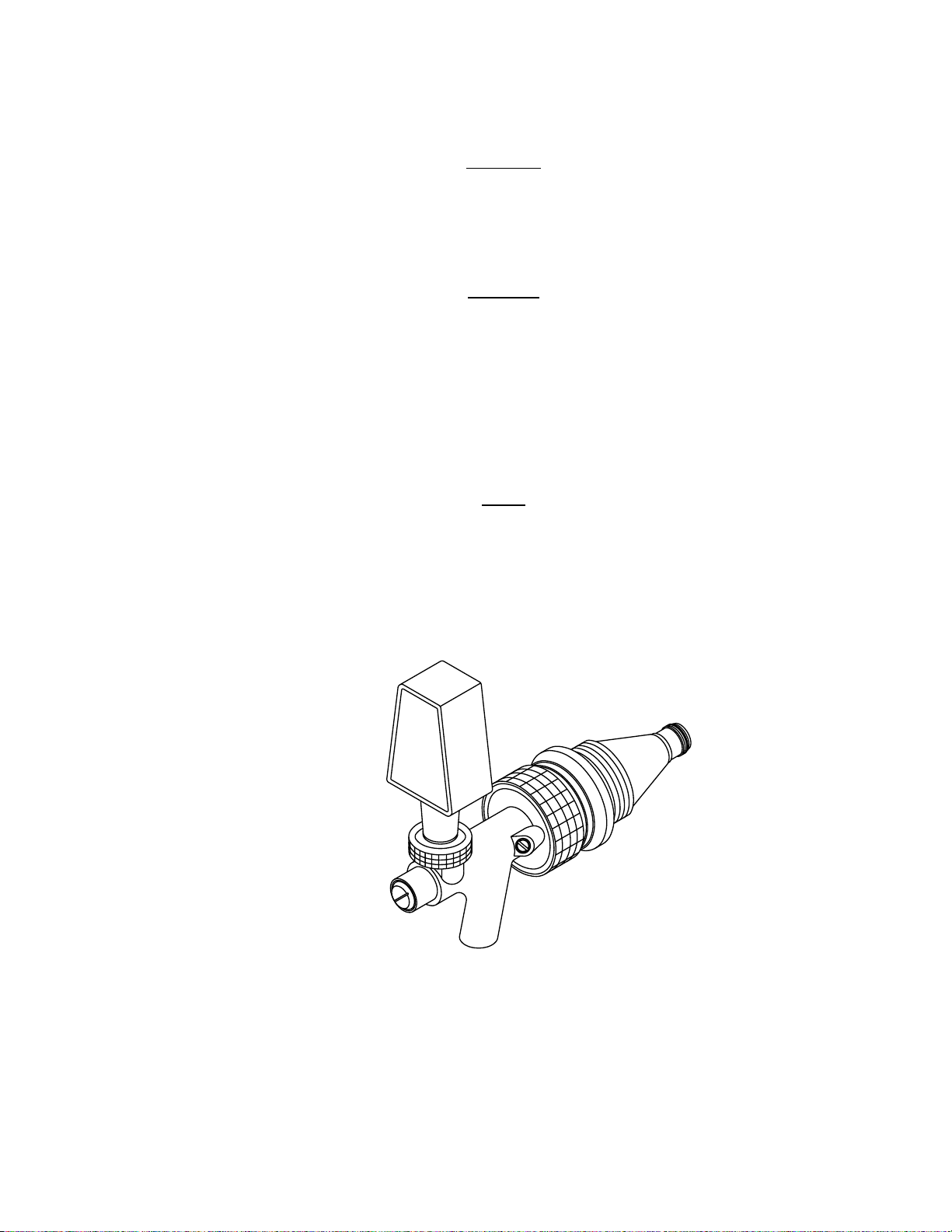

Premix Valve

Figure 1

C. Route through cutout in counter or through access hole in back of unit.

D. Leave approximately 12 inches (30 cm) of extra tubing length below the counter for servicing

and moving the dispenser.

E. Connect to appropriate figal pre-mix tanks.

F. Pressurize system.

G. Activate each valve until product is observed.

H. Check for leaks.

Page 6

2. SCHEDULED MAINTENANCE

2.1 DAILY

A. Remove the cup rest and wash in warm soapy water.

B. Pour warm soapy water into the drip tray and wipe with a clean cloth.

C. With a clean cloth and warm water, wipe off all of the unit’s exterior surfaces. DO NOT USE

ABRASIVE SOAPS OR STRONG DETERGENTS.

D. Replace the cup rest.

2.2 WEEKLY

A. Taste each product for off tastes.

B. Remove the bonnet and check the level of water in the water bath. Replenish as required, and

replace the bonnet.

NOTE

Use bottled drinking water where hard water problems exist. Do not use distilled water in units

which are equipped with electronic ice bank controls (EIBC).

2.3 MONTHLY

A. Unplug the dispenser from power source.

B. Remove the bonnet and clean the dirt from the condenser using a soft brush.

C. Replace the bonnet and reconnect power.

2.4 EVERY SIX MONTHS

A. Clean and sanitize the unit using the appropriate procedures outlined in Section 3 of this

manual.

2.5 YEARLY

A. Clean water bath interior, including evaporator coils and refrigeration components.

B. Clean the entire exterior of the unit.

C. Sanitize syrup lines using the appropriate procedures outlined in Section 3 of this manual.

3. DISPENSER CLEANING AND SANITIZING

3.1 AMBIENT PROCESS

A. The ambient process is the most common method for cleaning and sanitizing dispenser

equipment. The detergent should be caustic-based and the sanitizer should be low pH (7.0)

chloride solution.

B. Disconnect syrup containers and remove product from tubing by purging with carbon dioxide.

C. Rinse the lines and fittings with clean room temperature water to remove all traces of residual

product.

D. Fill lines with a caustic-based (low-sudsing, non-perfumed, and easily rinsed) detergent solution.

The solution should be prepared in accordance with the manufacturers recommendations, but

should be at least two (2) percent sodium hydroxide. Make sure the lines are completely filled

and allow to stand for at least 10 minutes.

E. Flush the detergent solution from the lines with clean water. Continue rinsing until

phenolphthalein test indicates the rinse water is free of residual detergent.

F. Fill the lines with a low pH (7.0) chlorine solution containing at least 50 PPM (50 mg/L) chlorine.

Make sure that lines are completely filled and allow to stand for ten (10) minutes.

G. Reconnect syrup containers and ready Unit for operation.

H. Draw drinks to refill lines and flush the chlorine solution from the dispenser.

NOTE

Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only with the

end use product. This is an NSF requirement.

I. Taste the beverage to verify that there is no off taste.

3

Page 7

3.2 VALVES

A. Valves may be cleaned and sanitized in the same manner.

1. Disconnect Unit from power source. Depressurize unit, disconnect syrup containers, and

remove product from tubing by purging with carbon dioxide.

2. Carefully remove valves from dispenser.

3. Wash valves in cleaning solution, then immerse them in a bath of sanitizing solution for

15 minutes.

4. Visually inspect dispenser for syrup residue. Clean with warm water and cloth or with the

nozzle brush supplied.

5. Install valves to dispenser. Pressurize and ready Unit for operation.

6. Connect Unit to power source.

7. Reconnect syrup containers and ready Unit for operation.

8. Draw drinks to refill lines and flush the chlorine solution from the dispenser.

NOTE

Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only with

the end use product. This is an NSF requirement.

9. Taste the beverage to verify that there is no off taste.

10. Valve is ready for operation.

4. TROUBLESHOOTING

TROUBLE

CAUSE

REMEDY

4.1 Miscellaneous leakage. A. Gap between parts. A. Tighten appropriately.

B. Damaged or improperly B. Replace or adjust appropriate

installed o-rings. o-rings.

4.2 Insufficient flow. A. Insufficient incoming supply A. Verify incoming supply pressure

pressure. is correct.

4.3 Excessive foaming. A. Incoming water or syrup A. Correct prior to dispenser.

temperature too high. Consider larger dispenser or

pre-cooler.

B. Flow rate too high. B. Readjust.

C. Air in lines. C. Bleed air from lines.

D. Poor quality ice. D. Check quality of ice used in drink.

E. High beverage temperature. E. Check refrigeration system.

4.4 Compressor does not A. Compressor relay or overload A. Replace compressor relay or

start (no hum), but malfunctioning. overload.

condenser fan motor B. Inadequate voltage. B. Measure voltage across common

runs. and run terminal on compressor.

Voltage must not drop below 90%

of rated voltage.

C. Incorrect wiring. C. Refer to wiring diagram and correct.

D. Compressor malfunctioning. D. Replace compressor.

4.5 Compressor starts and A. Ice bank control failure. A. Replace ice bank control.

continues to run until B. Incorrect wiring. B. Refer to wiring diagram and correct.

freeze up and will not

cut off.

4.6 Compressor does not A. Inadequate voltage. A. Measure voltage across common

start but hums. and run terminal on compressor.

Voltage must not drop below 90%

of rated voltage.

B. Incorrect wiring. B. Refer to wiring diagram and correct.

C. Starting relay malfunctioning. C. Replace starting relay. Be sure to

use correct relay. Failure to use

correct relay will cause compressor

failure.

D. Compressor malfunctioning. D. Replace compressor.

4

Page 8

5

4.7 Compressor starts but A. Inadequate voltage. A. Measure voltage across common

does not switch off start and run terminal on compressor.

winding (will run for only B. Incorrect wiring. B. Refer to wiring diagram and correct.

a few seconds before C. Starting relay malfunctioning. C. Replace starting relay. Be sure to

internal overload use correct relay. Failure to use

switches compressor correct relay will cause compressor

off). failure.

4.8 Compressor starts and A. Dirty condenser. A. Clean the condenser.

runs a short time but B. Insufficient or blocked air flow. B. Remove all obstructions and allow

shuts off on overload. for minimum clearance of

15 inches (38.1 cm) over top.

C. Inadequate voltage. C. Measure voltage across common

and run terminal on compressor.

Voltage must not drop below 90%

of rated voltage.

D. Incorrect wiring. D. Refer to wiring diagram and correct.

E. Defective condenser fan motor. E. Replace condenser fan motor.

F. Refrigerant leak. F. Repair and recharge.

G. Compressor malfunctioning. G. Replace compressor.

4.9 Warm drinks. A. Restricted airflow. A. Check clearances around sides,

top, and inlet of unit. Remove

objects blocking airflow through

grill.

B. Refrigeration system not B. Refer to Sections 4.11 - 4.15.

running.

C. Refrigerant leak. C. Repair and recharge.

D. Condenser fan motor not D. Replace condenser fan motor.

working.

E. Dirty condenser. E. Clean condenser.

F. Dispenser capacity exceeded. F. Add pre-cooler or replace with

larger dispenser.

NOTES

TROUBLE CAUSE REMEDY

Page 9

6

NOTES

Page 10

5. ILLUSTRATIONS, PARTS LISTS, AND WIRING DIAGRAMS

5.1 REFRIGERATION DECK ASSEMBLY

7

10

14

14

11

14

58

16

17

18

5

62

62

40

37

41

34

19

33

32

38

31

30

39

29

28

22

20

59

21

59

13

55

23

60

25

26

2

62

7

4

6

3

56

54

49

52

14

8

24

23

25

26

50

14

1

9

14

53

51

27

35

36

15

48

43

44

42

45

45

43

44

47

45

Page 11

5.1 REFRIGERATION DECK ASSEMBLY (CONTINUED)

ITEM PART NO. DESCRIPTION

- 82-1248/02 Deck Assy Refrig, R-134a,

220V/50Hz, Export

- 82-1372/02 Deck Assy Refrig, R-134a

115V/60Hz, Domestic

- 82-1428/02 Deck Assy Refrig. R-134a

115V/60HZ, Export

1 51-5107/01 Sub-Assy, Compressor Deck

2 50-0200/01 Insulation, Compressor Deck

3 04-0063 Washer, Flat

4 89-0014 Cover, Hole

5 REF Evaporator Coil Assy

- 82-1268 Evaporator Coil, R134a, Export

- 82-1373 Evaporator Coil, R134a,

Domestic

6 54-0137 Probe Assy, IBC

7 04-0470 Screw, 6 - 19 x 0.438

8 51-0068 Handle

9 04-0574 Washer

10 REF Control Housing Assy

- 52-0900 Control Housing Assy, with

"ON-OFF" Switch

- 52-0903 Control Housing Assy, without

"ON-OFF" Switch

11 REF Cover, Control Housing

- 30-5108 Cover, Control Housing, with

"ON-OFF" Switch

- 30-5118 Cover, Control Housing, without

"ON-OFF" Switch

12 06-0576/03 Label, Wiring Diagram

13 02-0032 Washer

14 04-0504 Screw, 8 - 18 x 0.375

15 06-0080-01 Label, Nameplate

16 52-1209 Lead Assy, Ground

17 02-0041 Seal

18 REF Capacitor, Carbonator

- 26-0374 Capacitor, Carbonator,

115V/60Hz

- 26-0377 Capacitor, Carbonator,

220V/50Hz and 60 Hz

19 REF Transformer

- 25-0047 Transformer, 115V/60Hz

- 25-0048 Transformer, 220V/50Hz and

60Hz

20 REF Motor, Assy

- 52-1262 Motor, Assy, 220V/50Hz and

60Hz

- 52-1261 Motor, Assy, 115V/60Hz

21 30-5113 Bracket, Agitator

22 05-0495 Propeller, 2.062 DIA

23 05-0502 Propeller, 2.250 DIA

24 02-0040 Seal, Extrusion

25 04-0032 Nut, Nylok, 1/4 - 20

26 04-0033 Washer, Flat (.281 ID)

27 REF Compressor

- 83-0033 Compressor, R-134a,

115V/60Hz, Domestic

- 83-0034 Compressor, R-134a,

220V/50Hz, Export

28 02-0114 Grommet

29 04-0537 Washer, Flat (0.467 ID)

30 03-0150 Retainer, Clip

31 REF Relay

- 12-0005 Relay, R-12 & R-134a,

115V/60Hz

- 12-0031 Relay, R-12 & R-134a,

220V/50Hz and 60Hz

ITEM P

ART NO. DESCRIPTION

8

32 REF Overload

- 12-0004 Overload, R-12 & R-134a,

115V/60Hz

- 12-0032 Overload, R-12 & R-134a,

220V/50Hz and 60Hz

33 13-0006 Cover Terminal

34 03-0040 Bale Strap

35 47-0344 Tube, Process

36 REF Tube, Compressor

- 47-0718 Tube, Compressor (Hi Side)

- 47-0347-01 Tube, Compressor R-12,

220V/60Hz (Hi Side)

37 REF Tube, Return

- 47-0724 Tube, Return (Lo Side)

- 47-0346 Tube,Return R-12, 220V/60Hz

(Lo Side)

38 51-0061 Accumulator

39 50-0211 Boot

40 50-0205 Insulation, Tube

41 50-0159 Insulation, Tube

42 23-0764/01 Condenser

43 50-0201 Baffle, Condenser

44 30-5112 Plate, Retainer

45 04-0518 Rivet, 0.1250 x 0.328

46 30-5867 Shield, Air,Left

47 30-5865 Shroud, Fan Top

48 50-0249 Barrier, long

49 30-5866 Shroud, Fan, Bottom

50 REF Motor, Fan

- 91-0007 Motor, Fan, 115V/60Hz

- 91-0009 Motor, Fan, 220V/50Hz and 60

Hz

51 07-0354 Fan Blade

52 04-0060 Nut

53 02-0413 Silencer

54 30-5864 Bracket, Fan Motor

55 REF Dryer Cap Assy

- 23-0982 Dryer Cap Ass,y R-134a,

115V/60Hz

- 23-0932 Dryer Cap Assy, R-134a,

220V/50Hz

56 47-0698 Tube, Condenser Out

57 REF Freon

- 95-0177 Freon, R-134a

58 52-1213 Harness Assy, XFM12

59 04-0110 Nut, 8 - 32

60 04-0576 Washer, Int., Tooth

61 06-0877 Label, Ground

62 REF Bracket Assy Guide

- 51-5147 Bracket Assy Guide, R-134a,

115V/60Hz

Page 12

5.2 DECK ASSEMBLY

9

5

3

4

1

W

A

TE

FILL W

R

-IM

W

B

AT

A

T

PO

TH

AN

A

ER

TE

R

FILL H

K

T

F

O

R

AN

LO

B

VE

T

AT

W

-

R

O

S FR

H

FLO

LE

U

N

W

O

TIL

M

T

U

BE

.

2

6

Page 13

ITEM PART NO. DESCRIPTION

1 04-0711 Caplug

2 06-0856 Label, Water Fill

3 04-0334 Screw, 1/4 - 20 x 1.000,

Round Head

4 04-0033 Washer, 1/4

5 30-5891 Plate, Carbonator

(No Carbonator)

6 50-0254 Insulation, Carbonator Deck

(No Carbonator)

5.2 DECK ASSEMBLY (CONTINUED)

10

Page 14

RADEMARKS

R

ADEMARKS

5.3 CABINET ASSEMBLY

11

34

29

35

36

23

28

32

R

RADEMARKS

T

15

T

R

A

D

E

M

A

R

K

S

R

11

12

REF

26

25

18

29

5

1

3

REF

4

17

9

6

8

6

22

14

21

2

37

33

19

7

16

20

24

13

27

6

30

10

6

31

6

Page 15

ITEM PART NO. DESCRIPTION

1 51-0675/01 Wrapper Assy

2 12-0097 Key Switch

3 07-0347 Cover Plate

4 04-0068 Screw, 10 - 24 x 0.375 FH, Machine

5 82-1311 Tank Assy, Foamed

6 04-0504 Screw, 8 - 18 x 0.375 AB

7 30-0587 Bracket, Right

8 30-0588 Bracket, Left

9 30-5114/01 Front Plate

10 05-0462 Drip Tray

11 30-0319 Splash Plate

12 23-0483 Cup Rest

13 30-5850 Plate, Bottom

14 06-0075-01 Nameplate, Serial Number

15 23-0782 Bonnet Assy, (Graphics ordered by

Country)

16 03-0062 Clip, Retaining

17 04-0074 Nut, Clip

18 50-0150 Insulation

19 04-0072 Rivet

20 04-0077 Screw, 4 - 20, 0.250, AB

21 04-0545 Screw, 8 - 16, 0.78, Plastite

22 06-0881 Label, Key Switch

23 06-0632 Label, CAUTION, Delta II Bonnet

24 06-0851 Label, Overflow

25 50-0248 Insulation, Front

26 50-0209 Insulation, Comb, Delta II

27 82-1312 Drain Assy

28 13-0050 Plug, 5/8 Inch

29 50-0151 Insulation, Side

30 30-5221 Leg Bracket Assy

31 81-0112 Legs

32 05-0786 Plug, Bonnet

33 06-0075-94 Nameplate, 9004

- 06-0075-95 Nameplate, 9005

- 06-0075-96 Nameplate, 9006

34 51-0715 Merchandiser Plate Assy

35 10-0229 Stand Off

36 04-0069 Screw, Merchandiser

37 07-0405 Plug, Key Lock

5.3 CABINET ASSEMBLY (CONTINUED)

12

Page 16

5.4 TUBING ASSEMBLY

13

10

9

8

7

6

5

REF

3

4

REF

2

1

Page 17

ITEM PART NO. DESCRIPTION

1 19-0138 Valve Assy, Pre-Mix, Becker

2 30-5514 Faucet Plate, 4 Valve

- 30-5486 Faucet Plate, 5 Valve

- 30-5488 Faucet Plate, 6 Valve

3 30-5515 Support, Faucet Plate, 4 Valve

- 30-5487 Support, Faucet Plate, 5 Valve

- 30-5489 Support, Faucet Plate, 6 Valve

4 04-0508 Plug, Pull, Delta

5 48-0760 Tube Assy, Prod #4/3, 6V/5V

6 48-0759 Tube Assy, Prod #5/4/3, 6V/5V/4V

7 48-0761 Tube Assy, Prod #3, 6V

8 48-0762 Tube Assy, Prod #2, Pre-Delta

9 30-5490/01 Bracket, Product Tube, Pre-Delta

10 23-0911 Tube Assy, Product, Cage, Pre-Delta

5.4 TUBING ASSEMBLY (CONTINUED)

14

Page 18

5.5 CONTROL HOUSING

15

4

9

20

23

2

3

5

16

17

19

1

21

14

15

7

6

8

18

22

10

13

11

12

Page 19

ITEM PART NO. DESCRIPTION

- 52-0900 Control Housing with ON/OFF Switch

(uses Items 20 & 21)

- 52-0903 Control Housing without ON/OFF

Switch, Delta II

1 30-5109 Control Housing

2 05-0570 Guide, Right

3 05-0571 Guide, Left

4 11-0185 Terminal Block

5 04-0566 Screw

6 13-0059 Bushing

7 13-0028 Strain Relief

8 52-1219 Power Cord Assy

- 52-1218 Power Cord Assy without ON/OFF

Switch

9 52-0952/01 PCB Assy

10 52-0904 Lead Assy, Transformer, PRI #1

11 52-0905 Lead Assy, Transformer, PRI #2

12 52-0906 Lead Assy, Compressor #1

13 52-0907 Lead Assy, Compressor #2

14 52-1210 Harness Assy, Recirc

15 52-0908 Harness Assy, Carbonator

16 11-0187 Jumper, 2 Position

17 11-0186 Jumper, 4 Position

18 11-0008 Tie Wrap

19 - Capacitor (See appropriate Compres-

sor Deck Assy)

20 52-0868 Lead Assy, ON/OFF Switch

21 12-0089 Switch, ON/OFF

22 REF Extension, Power Cord (Order by

Country)

23 04-0504 Screw

5.5 CONTROL HOUSING (CONTINUED)

16

Page 20

17

5.6 WIRING DIAGRAM

NOTE

1. WHEN STARTING UNIT OR IF CURRENT IS INTERRUPTED, THERE IS A (FIVE) 5

MINUTE DELAY BEFORE THE COMPRESSOR/FAN STARTS.

2. THERE IS A (THREE) 3 MINUTE PROTECTION TIMER ON THE CARBONATOR

PUMP MOTOR. IF THE MOTOR HAS TIMED OUT, CHECK WATER SUPPLY AND

RESET BY MOMENTARILY DISCONNECTING POWER.

KEY

SWITCH

WHT OR RED

BLK

J2

PCB,IBC

BLK/WHT

GRN

BLK

WHT

BLK

1234

12345678

B

L

K

1

GRN

3

BIBBED BLK

PLAIN BLK

BLK

GRN

WHT

B

L

BLK

S1

BLK

S2

V

A

L

V

E

S

BLK

S3

BLK

S4

BLK

S5

BLK

S6

POWER

CORD

K

W

H

T

W

H

T

W

H

T

W

H

T

W

H

T

G

R

N

/

B

E

LYR

U

L

WHT

BRN

ONLY

B

N

LINE

24 V

KILL

SWITCH

USA

SYM.

BLK/WHT

BLK

WHT

BLK

RIBBED

BLK

AGITATOR

MOTOR

BLK

WHT

J1

J4

TB1

PLAIN

BLK

COMPRESSOR

BLK/WHT

DESCRIPTION

ICE

PROBE

OPTIONAL

RECIRC

MOTOR, OR

MERCHANDISER

FAN

MOTOR

DELTA II

CHASSIS GROUND

CONTROL BOX

CHAMFER PIN 1

®

LABEL,

WIRING DIAGRAM

06-1813

Loading...

Loading...