lancer Blue Star CB Series, Renew Shots IBD CB Series, Renew IBD CB Series, Renew Shots CB Series, Blue Star IBD CB Series Operation Manual

Blue Star IBD CB Series 22”/25”/30”

Renew & Renew Shots IBD CB Series 25”/30”

- Blue Star CB Series 25” - Renew IBD CB Series 25”

- Blue Star CB Series 30” - Renew Shots CB Series 30”

Operation Manual

Lancer Corporation

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

“Lancer” is the registered trademark of Lancer © 2018 by Lancer, all rights reserved.

4500

Tech Support/Warranty: 800-729-1550

®

email: custserv@lancercorp.com

web: lancercorp.com

Lancer PN: 28-0946/03

Revision: January 2018

TABLE OF CONTENTS

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product.

Please carefully read the guidelines and warnings contained

herein as they are intended to provide the user with essential

information for the continued safe use and maintenance of the

product. In addition, it provides GUIDANCE ONLY to the user

on the correct services and site location of the unit.

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly

inspected before shipment. At the time of shipment, the

carrier accepts responsibility for the unit. Upon receiving the

unit, carefully inspect the carton for visible damage. If

damage exists, have the carrier note the damage on the freight

bill and le a claim with carrier. Responsibility for damage to the

dispenser lies with the carrier.

The installation and relocation, if necessary, of this product must be carried out by qualied personnel with

up-to-date safety and hygiene knowledge and practical experience, in accordance with current regulations.

IMPORTANT SAFETY INSTRUCTIONS....................................3

Intended Use.......................................................................3

Power Warning....................................................................3

CO2 Warning........................................................................3

Water Notice........................................................................3

Automatic Agitation...............................................................4

SPECIFICATIONS AND FEATURES..........................................4

Blue Star IBD CB Series 22”................................................4

Blue Star/Renew IBD CB Series 25”...................................5

Blue Star/Renew IBD CB Series 30”...................................6

Features of the Blue Star IBD CB Series 22”/25”/30”..........7

General Systems Overview - Remote Syrup Pumps...........7

PRE-INSTALLATION CHECKLIST.............................................8

INSTALLATION.....................................................................8-15

Unpacking the Dispenser.....................................................8

Selecting/Preparing a Counter Location..............................9

Installing an Icemaker.........................................................10

Dispenser Installation....................................................10-11

Remote Pump Installation...................................................11

Installing Remote Syrup Pumps - Bag in Box....................12

Installing CO2 Supply..........................................................13

Dispenser Setup.................................................................14

Adjust Water Flow Rate & Syrup/Water Ratio....................15

CLEANING AND SANITIZING............................................16-19

General Information...........................................................16

Cleaning and Sanitizing Solutions.....................................16

Daily Cleaning....................................................................16

Ice Bin Cleaning - Start-Up and Monthly............................17

Cleaning and Sanitizing Syrup Lines-Bag in Box...............17

Cleaning and Sanitizing Flavor Shot Lines........................17

Cleaning and Sanitizing Nozzles.......................................18

Cleaning and Sanitizing Flavor Shot Nozzle.....................18

Ice Chute Cleaning............................................................19

TROUBLESHOOTING.........................................................19-22

Valve/Flavor Shot Troubleshooting...............................19-21

Ice Bin/Ice Chute/Carbonator Pump Troubleshooting........21

Remote Syrup/Flavor Shot Pump Troubleshooting............22

ILLUSTRATIONS AND PART LISTINGS............................23-27

Main Unit Assembly - 22”/25”/30”......................................23

Flavor Shot Module Assembly............................................24

Plumbing Diagram - 22”.....................................................25

Plumbing Diagram - 25”.....................................................25

Plumbing Diagram - 30” 8 Valve........................................26

Plumbing Diagram - 30” 10 Valve......................................26

Wiring Diagram..................................................................27

DISPENSER DISPOSAL..........................................................27

READ ALL SAFETY INSTRUCTIONS BEFORE USING THIS UNIT.

This manual contains important safety information and all applicable safety precautions must be observed. To reduce

the risk of re, electric shock, damage to the equipment or personal injury when using this unit all instuctions/warnings

on the product being used must be followed:

! WARNING

Text following the Warning signal indicates a

hazardous situation, which if not avoided, will result

in death or serious injury. Be sure to read all Warning

statements before proceeding with the installation.

! CAUTION

Text following the Caution signal indicates a

hazardous situation, which if not avoided, could result

in death or serious injury. Be sure to read the Caution

statements before proceeding with the installation

2

! ATTENTION

Text following the Attention signal addresses a

situation that if not followed could potentially damage

the equipment. Be sure to read the Attention

statements before proceeding

NOTE

Text following the Note signal provides you with

informationthatmayhelpyoumoreeectivelyperform

the installation procedures within this manual.

Disregarding information will not cause damage or

injury, however it may limit the performance of the

dispenser.

IMPORTANT SAFETY INSTRUCTIONS

! Intended Use

• The dispenser is for indoor use only

• This appliance is intended to be used in commercial

applications such as restaurants or similar.

• This appliance should not be used by children or

inrm persons without supervision.

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.

• This appliance can be used by children aged from 8

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

• Cleaning and user maintenance shall not be

performed by children without supervision.

• This unit is not a toy and children should be advised

not to play with the appliance.

• The min/max ambient operating temperature for the

dispenser is 40°F to 105°F (4°C to 41°C).

• Do not operate unit below minimum ambient operation

conditions.

• Should freezing occur, cease operation of the unit and

contact authorized service technician.

• The maximum tilt for safe operation is 5°.

• This appliance must be installed and serviced by a

professional.

5 Carbon Dioxide (CO2)

• WARNING: Carbon Dioxide (CO2) is a colorless,

noncombustible gas with a light pungent odor. High

percentages of CO2 may displace oxygen in the

blood.

• WARNING: Prolonged exposure to CO

Personnel exposed to high concentrations of CO2 gas

will experience tremors which are followed by a loss

of consciousness and suocation.

• WARNING: If a CO

ventilate the contaminated area before attempting to

repair the leak.

gas leak is suspected, immediately

2

• WARNING: Strict attention must be observed in the

prevention of CO2 gas leaks in the entire CO2 and soft

drink system.

can be harmful.

2

F Power

• Follow all local electrical codes when making

connections.

• Check the dispenser name plate label, located behind

t h e s p l a s h p l a t e , f o r t h e c o r r e c t e l e c t r i c a l r e q u i r e m e n t s

of unit. DO NOT plug into a wall electrical outlet

unless the current shown on the serial number plate

agrees with local current available.

• Each dispenser must have a separate electrical

circuit.

• DO NOT use extension cords with this unit.

• DO NOT ‘gang’ together with other electrical devices

on the same outlet.

• WARNING: Always disconnect electrical power to the

unit to prevent personal injury before attempting any

internal maintenance.

• The resettable breaker switch should not be used as

a substitute for unplugging the dispenser from the

power source to service the unit.

• Only qualied personnel should service internal

components of electrical control housing.

• WARNING: Make sure that all water lines are tight and

units are dry before making any electrical connections

• If this dispenser is installed in an area that is

susceptible to ±10% variation of the nominal line

voltage, consider installing a surge protector or similar

protection device.

! Water Notice

• Provide an adequate, potable water supply. Water

pipe connections and xtures directly connected to

a potable water supply must be sized, installed, and

maintained according to federal, state, and local

codes.

• The water supply line must be at least a 3/8 inches

(9.525 mm) pipe with a minimym of 25 PSI (0.172

MPA) line pressure, but not exceeding a maximum of

65 PSI (0.448 MPA). Water pressure exceeding 65

PSI (0.448 MPA) must be reduced to 65 PSI (0.448

MPA).

• Use a lter in the water line to avoid equipment

damage and beverage o-taste. Check the water lter

periodically, as required by local conditions.

• CAUTION: The water supply must be protected by

means of an air gap, a backow prevention device

(located upstream of the CO2 injection system)

or another approved method to comply with NSF

standards. A leaking inlet water check valve will

allow carbonated water to ow back through the pump

when it is shut o and contaminate the water supply.

• CAUTION: Ensure the backow prevention device

complies with ASSE and local standards. It is the

responsibility of the installer to ensure compliance.

3

! Automatic Agitation

• Units are equipped with an automatic agitation system and will activate unexpectedly.

• CAUTION: Do not place hands or foreign objects in the ice bin tank. Unplug the dispenser during servicing, cleaning, and

sanitizing.

• CAUTION: To avoid personal injury, do not attempt to lift the dispenser without assistance. For heavier dispensers, use a

mechanical lift.

SPECIFICATIONS AND FEATURES

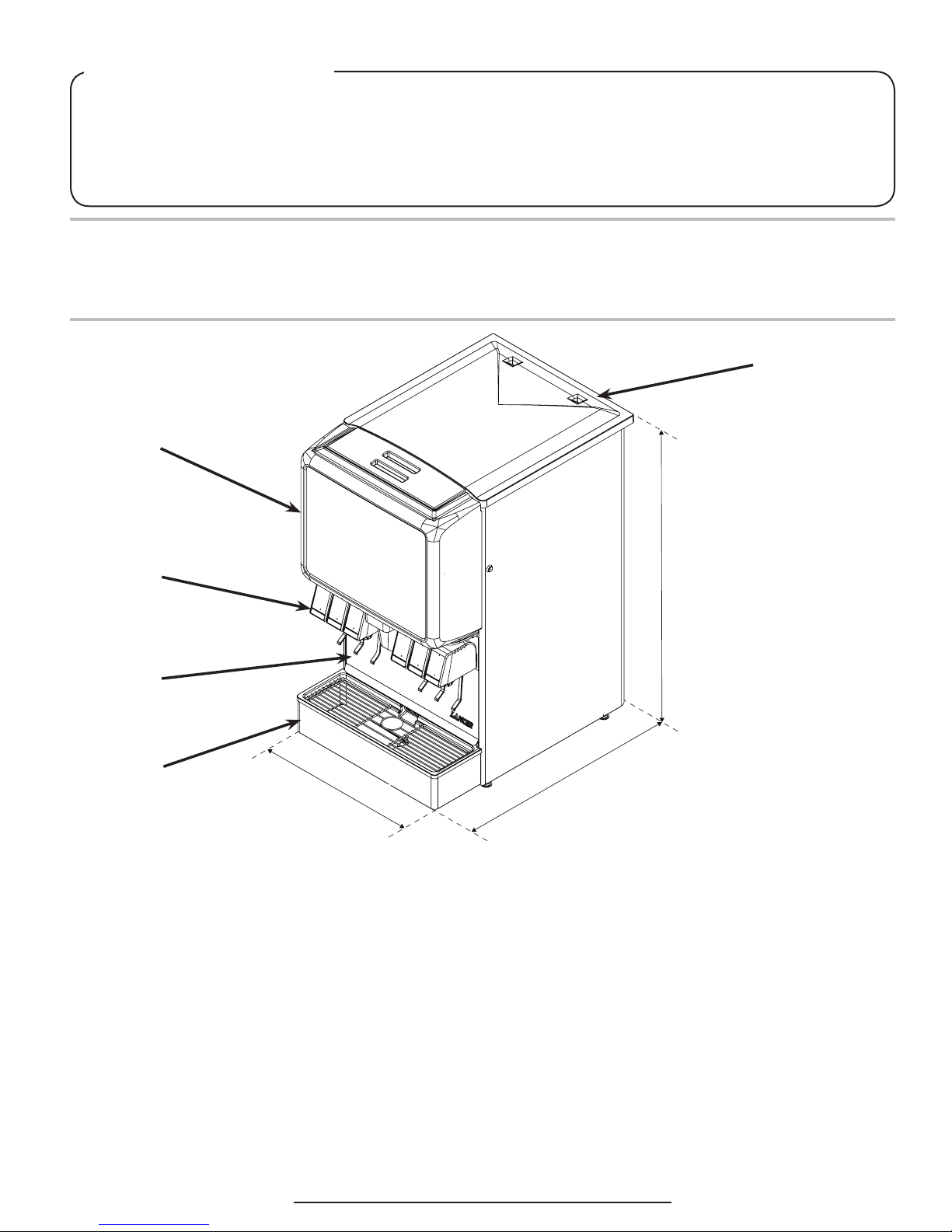

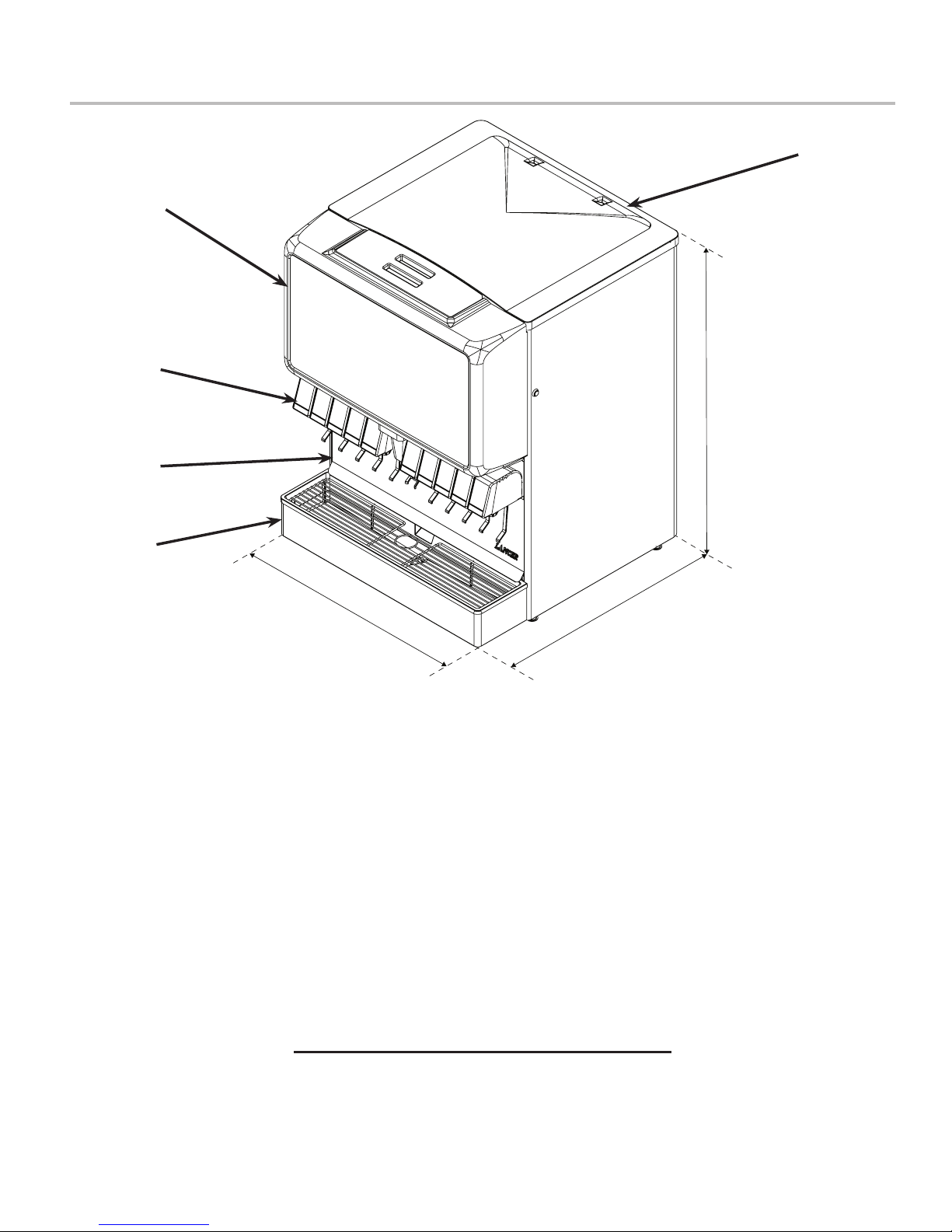

Blue Star IBD CB Series 22”

A

B

C

D

E

22.0 in.

DIMENSIONS

Width: 22.0 inches (559 mm)

Depth: 30.5 inches (775 mm)

Height: 40.25 inches (1022 mm)

WEIGHT

Shipping: 310 lbs (141 kg)

Empty (without Ice): 280 lbs (127 kg)

Ice Capacity: 200 lbs (91 kg)

ELECTRICAL

115 VAC / 60 Hz / 3.6 Amps

PLAIN WATER SUPPLY

40.25 in.

A. Top Cover

30.5 in.

B. Merchandiser

C. Valves

D. Splash Plate

E. Drip Tray

CARBONATED WATER SUPPLY

Min Flowing Pressure: 25 PSI (0.172 MPA)

Max Static Pressure: 65 PSI (0.448 MPA)

CARBON DIOXIDE (CO2) SUPPLY

Min Pressure: 70 PSIG (0.483 MPA)

Max Pressure: 80 PSIG (0.552 MPA)

FITTINGS

Carbonator Inlet: 3/8 inch barb

Plain Water Inlet: 3/8 inch barb

Brand Syrup Inlets: 3/8 inch barb

CO2 Inlet: 3/8 inch barb

Min Flowing Pressure: 75 PSIG (0.516 MPA)

4

This unit emits a sound pressure level below 70 dB

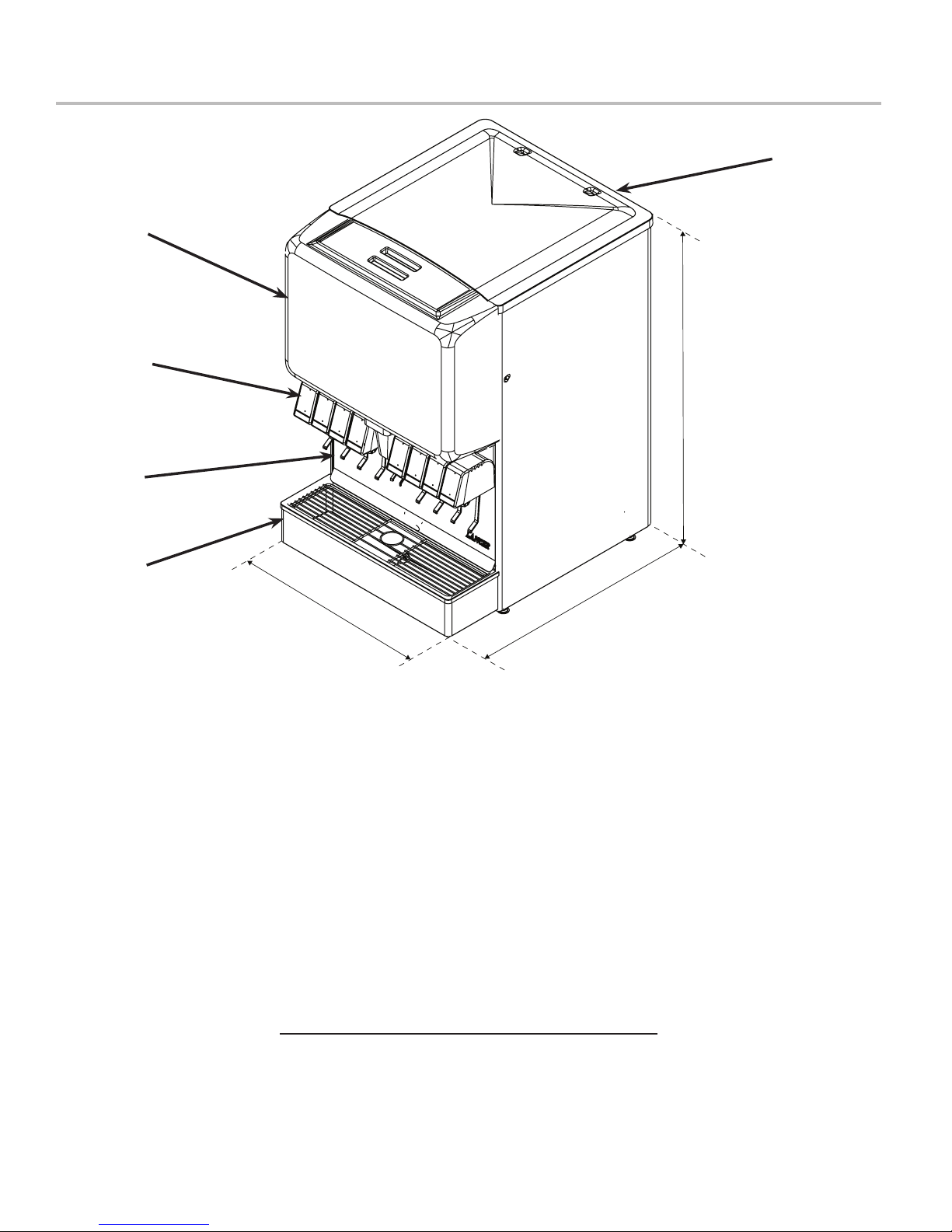

Blue Star IBD CB Series 25” & Renew IBD CB Series 25”

B

C

D

A

40.25 in.

E

25.0 in.

DIMENSIONS

Width: 25.0 inches (635 mm)

Depth: 30.5 inches (775 mm)

Height: 40.25 inches (1022 mm)

WEIGHT

Shipping: 331 lbs (150 kg)

Empty (without Ice): 295 lbs (134 kg)

Ice Capacity: 234 lbs (106 kg)

ELECTRICAL

115 VAC / 60 Hz / 3.6 Amps

PLAIN WATER SUPPLY

Min Flowing Pressure: 75 PSIG (0.516 MPA)

30.5 in.

A. Top Cover

B. Merchandiser

C. Valves

D. Splash Plate

E. Drip Tray

CARBONATED WATER SUPPLY

Min Flowing Pressure: 25 PSI (0.172 MPA)

Max Static Pressure: 65 PSI (0.448 MPA)

CARBON DIOXIDE (CO2) SUPPLY

Min Pressure: 70 PSIG (0.483 MPA)

Max Pressure: 80 PSIG (0.552 MPA)

FITTINGS

Carbonator Inlet: 3/8 inch barb

Plain Water Inlet: 3/8 inch barb

Brand Syrup Inlets: 3/8 inch barb

Flavor Shot Inlets: ““ inch barb

CO2 Inlet: 3/8 inch barb

This unit emits a sound pressure level below 70 dB

5

Blue Star IBD CB Series 30” & Renew IBD CB Series 30”

B

C

D

A

40.25 in.

E

30.0 in.

DIMENSIONS

Width: 30 inches (762 mm)

Depth: 30.5 inches (775 mm)

Height: 40.25 inches (1022 mm)

WEIGHT

Shipping: 365 lbs (161 kg)

Empty (without Ice): 320 lbs (145 kg)

Ice Capacity: 290 lbs (132 kg)

ELECTRICAL

115 VAC / 60 Hz / 3.6 Amps

PLAIN WATER SUPPLY

Min Flowing Pressure: 75 PSIG (0.516 MPA)

30.5 in.

A. Top Cover

B. Merchandiser

C. Valves

D. Splash Plate

E. Drip Tray

CARBONATED WATER SUPPLY

Min Flowing Pressure: 25 PSI (0.172 MPA)

Max Static Pressure: 65 PSI (0.448 MPA)

CARBON DIOXIDE (CO2) SUPPLY

Min Pressure: 70 PSIG (0.483 MPA)

Max Pressure: 80 PSIG (0.552 MPA)

FITTINGS

Carbonator Inlet: 3/8 inch barb

Plain Water Inlet: 3/8 inch barb

Brand Syrup Inlets: 3/8 inch barb

Flavor Shot Inlets: ““ inch barb

CO2 Inlet: 3/8 inch barb

This unit emits a sound pressure level below 70 dB

6

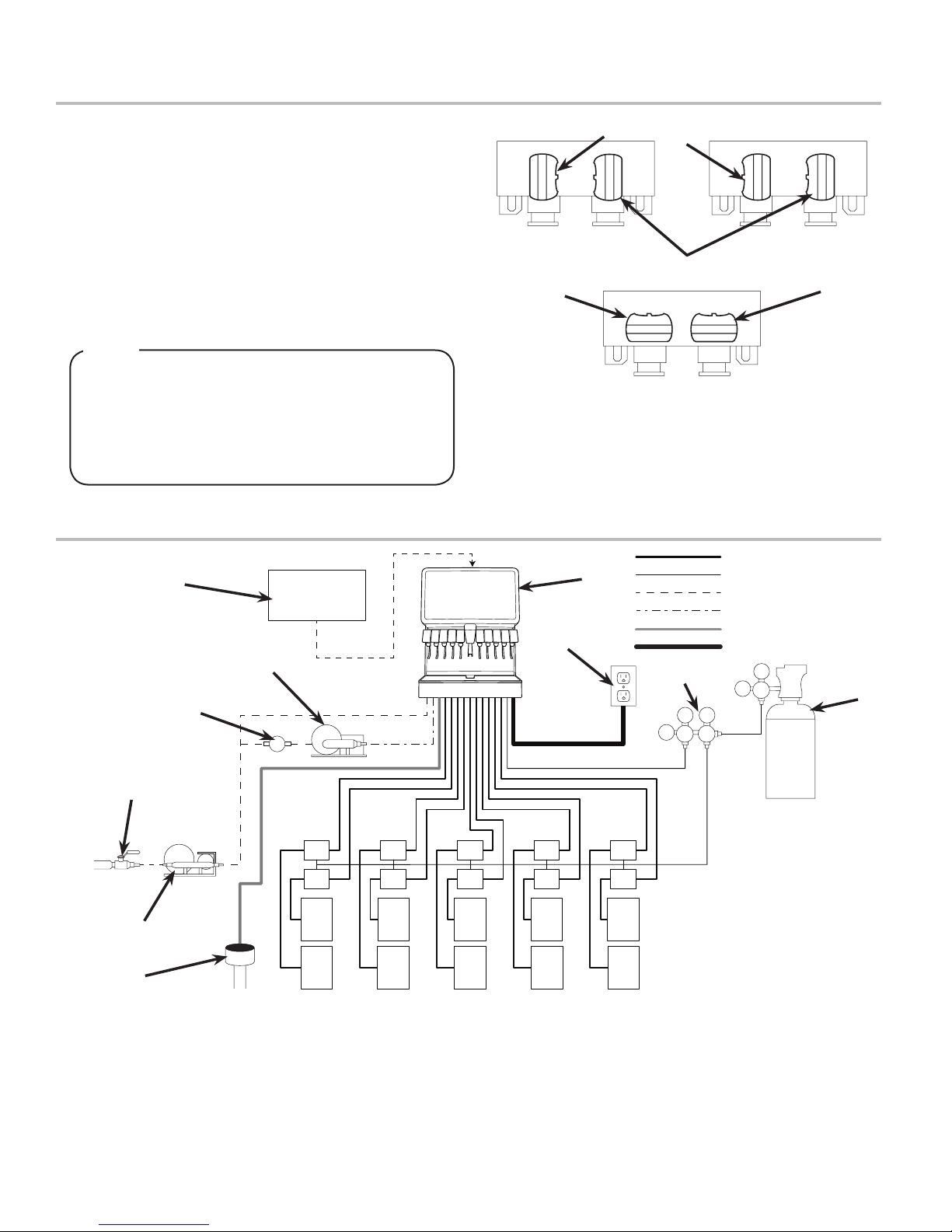

Features of the Blue Star IBD CB Series 22”/25”/30”

Cold Carbonation Capability

• Water is pre-chilled in the cold plate before entering the

carbonator tank.

• This allows it to absorb CO2 more eectively inside the

tank.

Three-Way Adjustable Back Blocks

• Allows for exibility between carbonated or plain water

drinks on the valves of your choice.

• To set adjustable back blocks, turn the shut-o stem to the

desired location, refer to the image below:

D

NOTE

Thereis100%exibilityonthe22”,6valveandthe30”

8 valve dispensers.

The30”,10valveandthe25”8valvedispensers

have space restrictions, so the two center valves are

plumbed only for carbonated watered drinks and are

non-adjustable.

General System Overview - Remote Syrup Pumps

I

E

D

A

H

J

B

C

E

A. Plain Water ON D. Water Closed

B. Carb Water ON E. Syrup Closed

C. Syrup ON

Syrup Line

CO2 Line

Plain Water Line

Carb Water Line

Drain Line

Electrical

K

110

L

75

75

A

F

F

B

C

G G G G G

G G G G G

A. Water Source

B. Water Booster

F

F

F F

F F

F

F

C. Floor Drain

D. Water Regulator

E. Remote Pump

F. Syrup Pump

G. BIB Syrup Containers

H. Dispenser

I. Icemaker (Optional)

J. Electrical Outlet

K. CO2 Regulator

L. CO2 Source

7

PRE-INSTALLATION CHECKLIST

TOOLS REQUIRED:

Oetiker Pliers

Tubing Cutters

Wrench

Slotted Screwdriver

Phillips Screwdriver

Drill

BIB SYSTEM:

BIB Rack

BIB Syrup Boxes

BIB Regulator Set

BIB Connectors

POST MIX ACCESSORIES:

High Pressure CO2 Regulator

Low Pressure CO2 Regulator

Manifold

CO2 Supply

Chain for CO2 Tank

Beverage Dispenser

Beverage Tubing

Oetiker Clamp Fittings

Water Booster (Lancer PN:

82-3401 or MC-163172

Water Regulator (supplied with

unit)

CONSIDER THE FOLLOWING

BEFORE INSTALLATION:

Location of Water Supply Lines

Location of Drain

Location of Electrical Outlet

Location of Heating and Air

Conditioning Ducts

Do you have enough space to

install the dispenser?

Is countertop level?

Can the countertop support the

weight of the dispenser? (Include

the weight of an ice machine plus

weight of ice, if necessary)

Is dispenser located away from

direct sunlight or overhead

lighting?

INSTALLATION

Read This Manual

This manual was developed by Lancer Corporation as a reference guide for the owner/operator and installer of this dispenser.

Please read this manual before installation and operation of this dispenser. See pages 20 - 23 for troubleshooting or service

assistance. If the service cannot be corrected please call your Service Agent or Lancer Customer Service. Always have your

model and serial number available when you call.

Unpacking the Dispenser

1. Set shipping carton upright on the oor then cut package

banding straps and remove.

2. Open top of carton and remove interior packaging.

3. Lift carton up and o of the unit.

4. Remove plywood shipping base from unit by moving unit so

that one side is o the counter top or table allowing access

to screws on the bottom of the plywood shipping base.

NOTE

If unit is to be transported, it is advisable to leave the

unit secured to the plywood shipping base.

5. Remove accessory kit and loose parts from ice

compartment.

NOTE

Inspect unit for concealed damage. If evident, notify

deliveringcarrierandleaclaimagainstthesame.

6. If leg kit has been provided, assemble legs by tilting unit.

! ATTENTION

DO NOT LAY UNIT ON ITS SIDE OR BACK

8

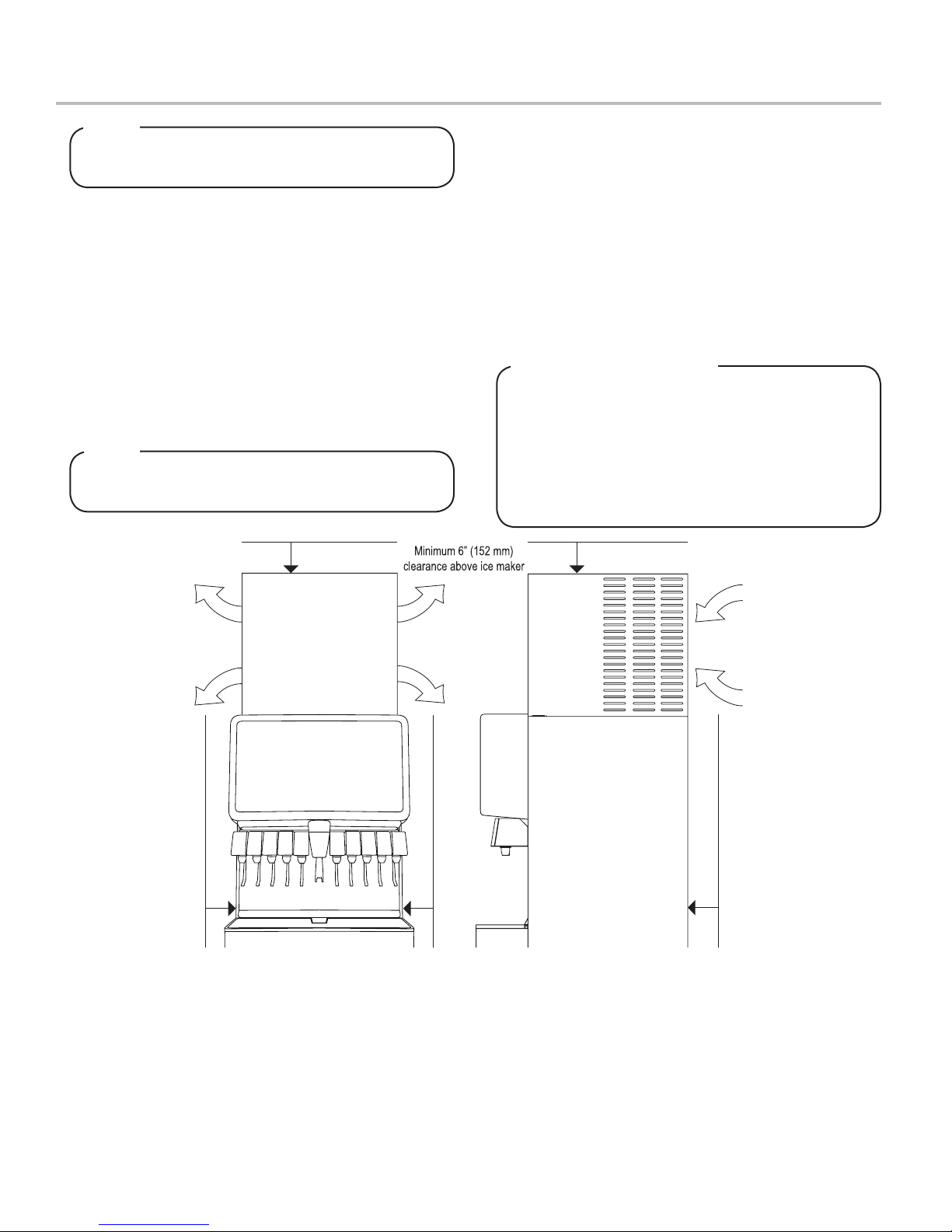

Selecting/Preparing a Counter Location

A

I

R

O

U

T

A

I

R

O

U

T

A

I

R

I

N

A

I

R

O

U

T

A

I

R

I

N

A

I

R

O

U

T

6” (152 mm) clearance

6” (152 mm) clearance

6” (152 mm) clearance

NOTE

The dispenser should only be installed in a location

where it can be overseen by trained personnel

1. Select a level, well ventilated location that is in close

proximity to a properly grounded electrical outlet, within ve

(5) feet (1.5 m) of a drain, a water supply that meets the

requirements shown in the Specications section found on

pages 4-6, away from direct sunlight or overhead lighting,

and has sucient clearance for air circulation.

2. Sucient clearance must be provided, if an ice maker is not

installed, to allow lling ice compartment from a ve gallon

bucket (a minimum of 16 inches is recommended).

3. The selected location should be able to support the weight

of the dispenser, ice and possibly an icemaker being

installed after counter cut out is made. Total weight (with

icemaker) for this unit could exceed 800 pounds (363.6kg).

NOTE

Lancer does NOT recommend the use of shaved or

akeiceinthedispenser.

4. Unit may be installed directly on countertop or on legs. If

installed directly on the counter, unit must be sealed to the

countertop with an FDA approved sealant. If an icemaker is

to be mounted on top of dispenser, do not install dispenser

on legs.

5. Select a location for the remote pump deck, remote syrup

pumps, remote avor shot syrup pumps (if necessary), CO2

t a n k , s y r u p c o n t a i n e r s , a n d w a t e r l t e r ( r e c o m m e n d e d ) .

Please see General System Overview on page 5 for

reference.

6. U s i n g C o u n t e r C u t o u t T e m p l a t e p r o v i d e d , c u t o u t r e q u i r e d

opening for the water, syrup, and CO2 lines in the

designated dispenser location.

Leveling the Dispenser:

In order to facilitate proper dispenser drainage,

ensure that the dispenser is level, front to back and

side to side. Place a level on the top of the rear edge

of the dispenser. The bubble must settle between the

level lines. Repeat this procedure for the remaining

three sides. Level unit if necessary. For optimum

performance place the unit at a 0° tilt. The maximum

tilt is 5°.

9

Loading...

Loading...