Page 1

BLENDPOINT SMOOTHIE DISPENSER

PN: 28-0938

Operation Manual

Lancer Corporation

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

“Lancer” is the registered trademark of Lancer © 2014 by Lancer, all rights reserved.

BID-1

Technical Support/Warranty

800-729-1550

custserv@lancercorp.com

lancercorp.com

Page 2

TABLE OF CONTENTS

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product and

should be handed over to the operator after the installation and

preserved for any further consultation that may be necessary.

Please read carefully the guidelines and warnings contained

herein as they are intended to provide the user with essential

information for the continued safe use and maintenance of the

product. In addition, it provides GUIDANCE ONLY to the user

on the correct services and site location of the unit.

The installation and relocation, if necessary, of this product must be carried out by qualied personnel with

up-to-date safety and hygiene knowledge and practical experience, in accordance with current regulations.

IMPORTANT SAFETY INSTRUCTIONS..........................3

Intended Use..............................................................3

Power Warning...........................................................3

Automatic Agitation.....................................................3

Water Notice...............................................................3

SPECIFICATIONS AND FEATURES...............................4

PRE-INSTALLATION CHECKLIST...................................5

INSTALLATION.................................................................6

Unpacking Dispenser..................................................6

Dispenser Installation..............................................6-7

START-UP AND CALIBRATION......................................7

Unit Start and Touch Screen Calibration....................7

Water Calibration........................................................8

Ice Calibration..........................................................8-9

Product Calibration.....................................................9

BASIC OPERATIONS.....................................................10

Loading Ice...............................................................10

Making Drinks...........................................................10

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly

inspected before shipment. At the time of shipment, the

carrier accepts responsibility for the unit. Upon receiving the

unit, carefully inspect the carton for visible damage. If

damage exists, have the carrier note the damage on the freight

bill and le a claim with carrier. Responsibility for damage to the

dispenser lies with the carrier.

Manual Controls...................................................10-11

Replace Empty Product.......................................11-12

CLEANING AND SANITIZING.......................................12

General Information..................................................12

Cleaning and Sanitizing Solutions............................13

After Every Use........................................................13

Daily Cleaning..........................................................13

Weekly Cleaning..................................................13-15

Every Six Months......................................................16

TROUBLESHOOTING...............................................16-17

ILLUSTRATIONS AND PART LISTINGS.......................18

Main Unit Assembly 1...............................................18

Main Unit Assembly 2...............................................19

Ice Hopper Assembly................................................20

Condensor Fan Assembly.........................................20

Pump Cube Assembly...............................................21

Wiring Diagram.........................................................22

DISPENSER DISPOSAL................................................23

READ ALL SAFETY INSTRUCTIONS BEFORE USING THIS UNIT.

This manual contains important safety information and all applicable safety precautions must be observed. To reduce

the risk of re, electric shock, damage to the equipment or personal injury when using this unit all instuctions/warnings

on the product being used must be followed:

! WARNING

Text following the Warning signal indicates a

hazardous situation, which if not avoided, will result

in death or serious injury. Be sure to read all Warning

statements before proceeding with the installation.

! CAUTION

Text following the Caution signal indicates a

hazardous situation, which if not avoided, could result

in death or serious injury. Be sure to read the Caution

statements before proceeding with the installation

2

SAFETY NOTICES

! ATTENTION

Text following the Attention signal addresses a

situation that if not followed could potentially damage

the equipment. Be sure to read the Attention

statements before proceeding

NOTE

Text following the Note signal provides you with

information that may help you more effectively perform

the installation procedures within this manual.

Disregarding information will not cause damage or

injury, however it may limit the performance of the

dispenser.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

! Intended Use F Power

• The dispenser is for indoor use only

• This appliance is intended to be used in commercial

applications such as restaurants or similar.

• This appliance should not be used by children or

inrm persons without supervision.

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.

• This appliance can be used by children aged from 8

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

• Cleaning and user maintenance shall not be

performed by children without supervision.

• This unit is not a toy and children should be advised

not to play with the appliance.

• The min/max ambient operating temperature for the

dispenser is 40°F to 75°F (4°C to 24°C).

• Do not operate unit below minimum ambient operation

conditions.

• Should freezing occur, cease operation of the unit and

contact authorized service technician.

• The maximum tilt for safe operation is 5°.

• This appliance must be installed and serviced by a

professional.

! Automatic Agitation

• Units equipped with an automatic agitation system and

will activate unexpectedly.

• Avoid contact with moving parts.

• WARNING: Keep ngers, hair, hands, and clothing away

from all moving parts. Keep utensils away from drive

socket, ice augers, and blender blades during operation.

• CAUTION: Metal utensils will damage blades and auger.

• WARNING: Never place a jar into the drive socket if the

blender motor is operating.

• WARNING: Do not rock the blender jar while it is

operating.

• Keep the blender jar straight up until the operation is

complete.

• Unplug the dispenser during servicing, cleaning, and

sanitizing.

• WARNING: To avoid personal injury, do not attempt

to lift the dispenser without assistance. For heavier

dispensers, use a mechanical lift.

• Follow all local electrical codes when making

connections.

• Check the dispenser serial number plate for

correct electrical requirements of unit. DO NOT plug

into a wall electrical outlet unless the current shown

on the serial number plate agrees with local current

available.

• Each dispenser must have a separate electrical

circuit.

• DO NOT use extension cords with this unit.

• DO NOT ‘gang’ together with other electrical devices

on the same outlet.

• WARNING: Always disconnect electrical power to the

unit to prevent personal injury before attempting any

internal maintenance.

• The resettable breaker switch should not be used as

a substitute for unplugging the dispenser from the

power source to service the unit.

• Only qualied personnel should service internal

components of electrical control housing.

• WARNING: Make sure that all water lines are tight and

units are dry before making any electrical connections

• If this dispenser is installed in an area that is

susceptible to ±10% variation of the nominal line

voltage, consider installing a surge protector or similar

protection device.

! Water Notice

• Provide an adequate, potable water supply. Water

pipe connections and xtures directly connected to

a potable water supply must be sized, installed, and

maintained according to federal, state, and local

codes.

• The water supply line must be at least a 3/8 inches

(9.525 mm) pipe with a minimym of 25 PSI (0.172

MPA) line pressure, but not exceeding a maximum of

50 PSI (0.345 MPA). Water pressure exceeding 50

PSI (0.345 MPA) must be reduced to 50 PSI (0.345

MPA).

• Use a lter in the water line to avoid equipment

damage and beverage off-taste. Check the water lter

periodically, as required by local conditions.

• CAUTION: The water supply must be protected by

means of an air gap, a backow prevention device

(located upstream of the CO2 injection system)

or another approved method to comply with NSF

standards. A leaking inlet water check valve will

allow carbonated water to ow back through the pump

when it is shut off and contaminate the water supply.

• CAUTION: Ensure the backow prevention device

complies with ASSE and local standards. It is the

responsibility of the installer to ensure compliance.

3

Page 4

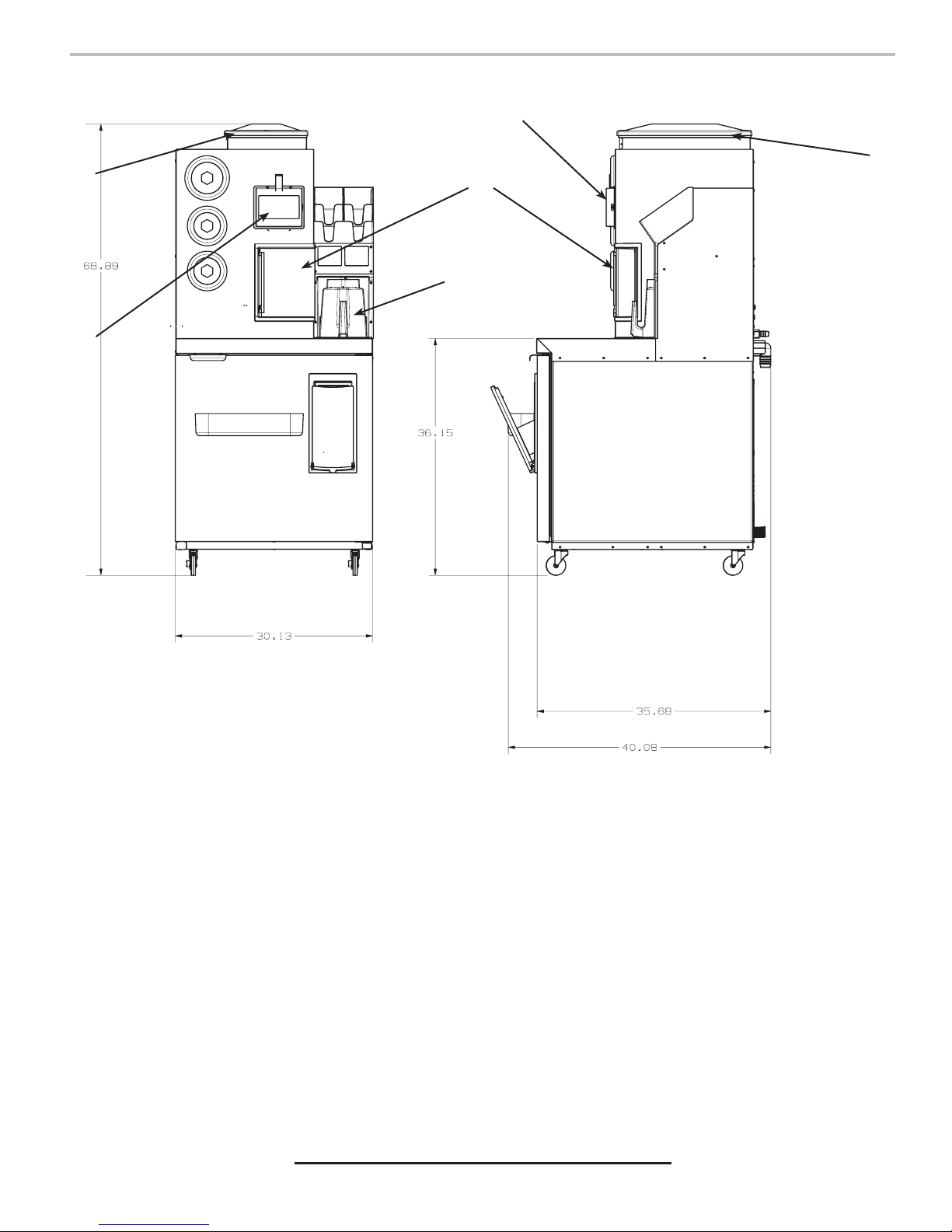

SPECIFICATIONS AND FEATURES

C

D

D

C

B

A

A. Blender Jar

B. Blend Station

C. Touch Screen

D. Ice Bin

DIMENSIONS

Width: 30 inches (762 mm)

Depth: 33-37 inches (838.2-939.8 mm)

Height: 66 inches (1,676 mm)

WEIGHT

Without Ice: 380 lbs (172.37 kg)

With Ice: 410 lbs (185.98 kg)

Shipping: 400 lbs (181.44 kg)

BLENDING

Capacity: 2 lbs (0.907 kg)

ELECTRICAL

115 VAC / 60 Hz / 20 Amps

This unit emits a sound pressure level below 70 dB

4

PLAIN WATER SUPPLY

Min Flowing Pressure: 30 PSIG (0.207 MPA)

Max Flowing Pressure: 90 PSIG (0.621 MPA)

FITTINGS

Water for Rinser: 3/8 inch barb

Plain Water Inlet: 3/8 inch barb

Brand Product Inlets: 3/8 inch barb

Drain: 1 inch (25.4 mm) PVC

PRODUCT

8 x 2 Gallon Bags

Page 5

PRE-INSTALLATION CHECKLIST

TOOLS REQUIRED:

Oetiker Pliers

Tubing Cutters

Wrench

Phillips Screwdriver

BEFORE INSTALLATION:

Do you have enough space to

install the dispenser?

Is dispenser located away from

direct sunlight or overhead

lighting?

Read This Manual

POST MIX ACCESSORIES:

Beverage Tubing

Oetiker Clamp Fittings

CONSIDER LOCATION OF THE

FOLLOWING BEFORE THE INSTALL:

Water Supply Lines

Drain

Electrical Outlet

Heating and Air Conditioning

Ducts

This manual was developed by Lancer Corporation as a reference guide for the owner/operator and

installer of this dispenser. Please read this manual before installation and operation of this

dispenser. Please see pages 16-17 for troubleshooting or service assistance. If the service cannot

be corrected please call your Service Agent or Lancer Customer Service. Always have your model

and serial number available when you call.

5

Page 6

Unpacking the Dispenser

INSTALLATION

1. Cut package banding strap and remove.

2. Open the box and remove the accessory kit and loose

parts.

3. Remove top board, corner inserts and lift outer carton to

remove, if included.

NOTE

Inspect unit for concealed damage. If evident, notify

deliveringcarrierandleaclaimagainstthesame.

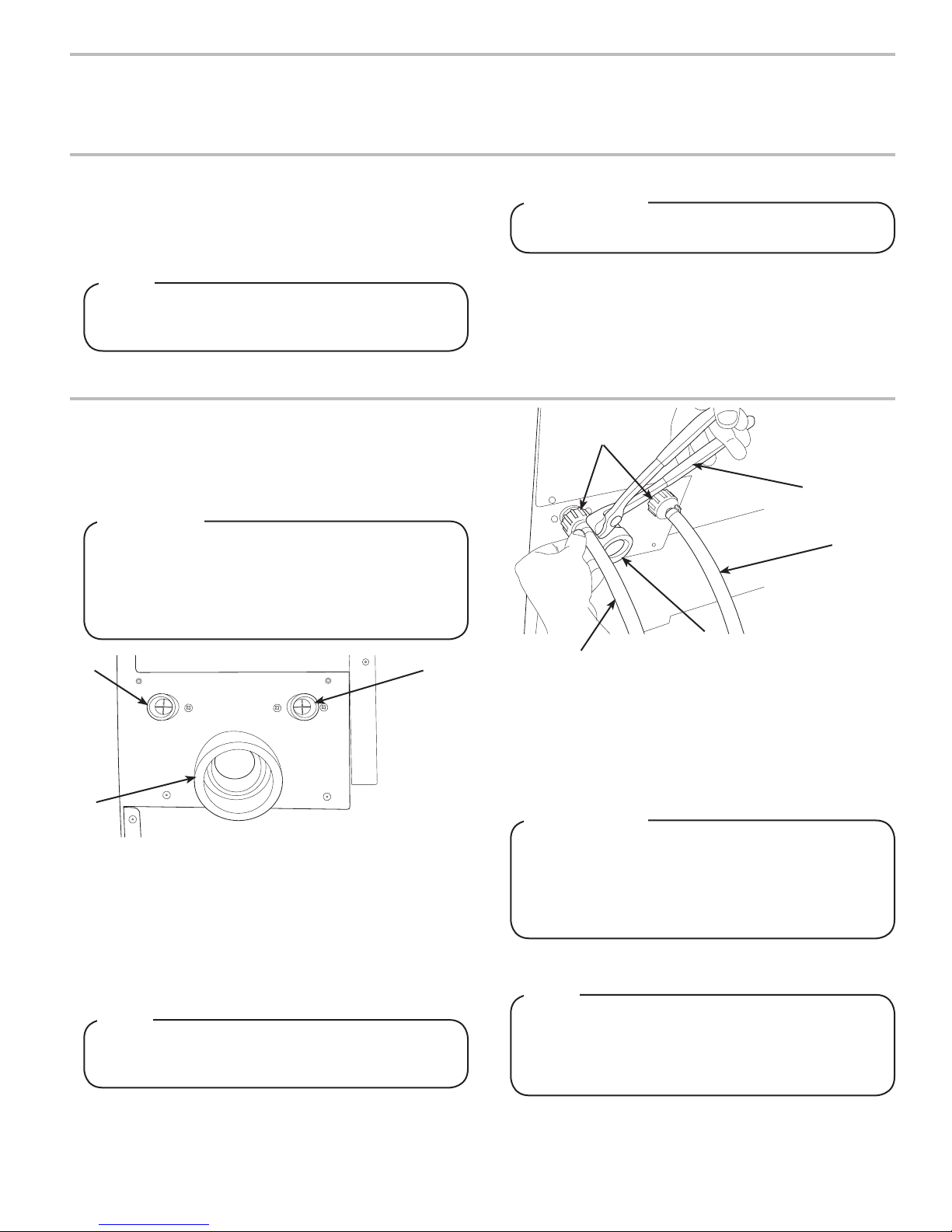

Dispenser Installation

1. Connect the two (2) 3/4 inch garden hose ttings supplied

with the unit to the cold/drink water inlet and the hot/rinse

water inlet.

2. Route appropriate tubing from the water source to the cold/

drink water inlet on the back of the unit.

! CAUTION

DO NOT reuse beverage tubing, installer should

provide new beverage tubing that meets IEC Standard

61770.Lancerbeveragetubingkitsareavailablefor

purchase. Contact your Sales Representative or

Lancer Customer Service for more information.

A

C

A. Hot/Rinse Water Inlet

B. Cold/Drink Water Inlet

C. Drain Inlet

3. Turn on water source and ush water supply line

thoroughly.

4. Using tubing Cutters, cut the cold drink water line and install

an in-line watet lter with a ow rate of at least 1 gallon

(3.78 liters) per minute.

5. Route appropriate tubing from the hot water rinse tting to

hot water source and connect tubing to inlet.

NOTE

Leave 12 inches (305 mm) of extra tubing below the

counter for servicing and moving the dispenser

B

4. If leg kit has been provided, assemble legs by tilting unit.

! ATTENTION

DO NOT LAY UNIT ON ITS SIDE OR BACK

E

D

B

A. Hot/Rinse Line

B. Cold/Drink Line

C

A

6. Turn on water supply and check for leaks.

7. Locate the 1 inch (25.4 mm) PVC bulkhead tting on the

rear of portion of the unit.

8. Loosen the nut on the drain tting and install the 1.0 inch

(25.4 mm) O.D. smooth wall tubing drain pipe and retighten

the nut to seal against the tube.

C. Drain Inlet

D. Oetiker Pliers

E. Garden Hose Fitting

! ATTENTION

Drainttingmustbeinstalledwithadequatebackow

protection and any other necessary equipment to

comply with federal, state or local codes. It is

recommended that rigid or reinforced tubing is used

for installation.

9. Locate the product line inlets in the refrigerated portion of

the unit.

NOTE

Eachlineislabeled“1-8”foridenticationpurposes.

These labels correspond to the pump numbers as

found on the front of the pump cube and as used

duringsystem/drinkprogramming.

6

Page 7

?

HOME

48°F

10. Connect the product bags to the corresponding, desired

pump/drink locations using the pre-installed quick connect

quarter turn fasteners.

! ATTENTION

Trays should be used with compatible products. The

use of other products can harm the pumps and other

components of the unit.

START-UP AND CALIBRATION

Unit Start and Touch Screen Calibration

11. Make sure product bags are fully inserted into their

protective tray and the front stopper is fully engaged with

the front of the tray.

1. Locate unit power cord.

! WARNING

DO NOT operate with a damaged power cord or plug.

If the power cord or plug is damaged they must be

replaced by the manufacturer or its authorized service

agent in order to prevent any hazard. DO NOT let the

powercordhangovertheedgeoftheworksurface.

2. Connect unit power cord to a grounded electrical outlet.

! WARNING

The dispenser must be properly electrically grounded

toavoidseriousinjuryorfatalelectricalshock.The

power cord has a three-prong grounded plug. If a

three-hole grounded electrical outlet is not available,

use an approved method to ground the unit. Follow

alllocalelectricalcodeswhenmakingconnections.

Each dispenser must have a separate electrical circuit.

Do not use extension cords. Do not connect multiple

electrical devices on the same outlet.

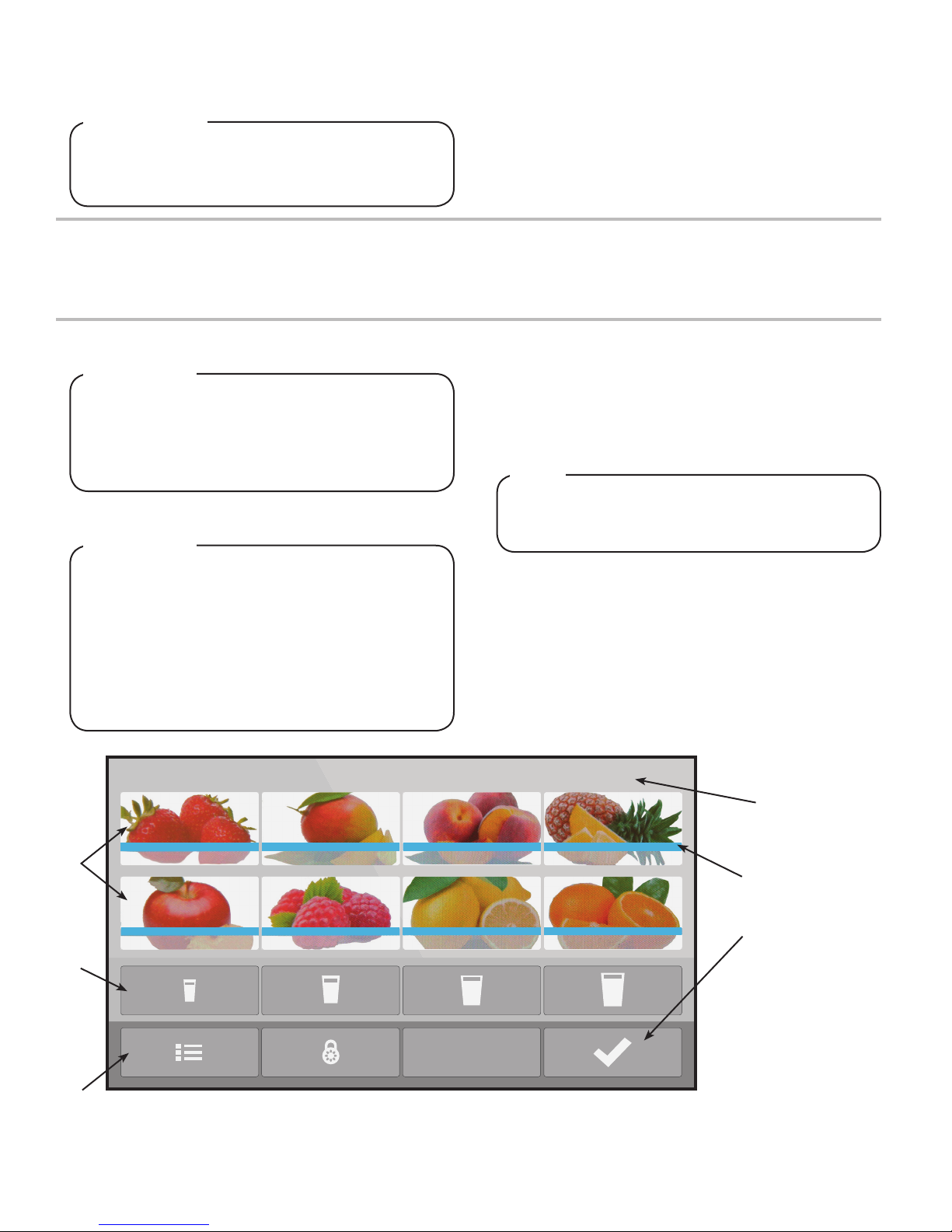

3. BlendPoint will begin to boot up and the touch screen will

show a countdown to initiate screen calibration. Press

and hold anywhere on thescreen before the countdown

commences to initiate the touch screen calibration.

4. Follow instruction on the screen to calibrate the touch

screen. Once Calibration is complete it will take you to the

home screen.

NOTE

Prior to loading product, allow unit to reach thermal

equillibrium by allowing unit to cycle for no less than

four (4) hours once start-up has commenced.

A

B

C

E

F

G

A. Flavors

B. Drink Sizes Bar

C. Main Menu

D. Secure Screen

E. Cabinet Temperature

F. Inventory Bar

G. Start Drink

7

Page 8

CALIBRATE ICE

Place empty jar in machine and press next to start calibration...

BackHome

Next

Main Menu

Water Calibration

MENU

Replace

Inventory

Fault History

Cleaning

About

BackHome

Calibrate

Product

Manual

Controls

Machine

Lockout

CALIBRATE

Calibrate

BackHome

Product

Calibrate

Water

Calibrate

Ice

Main Menu

CALIBRATE

Calibrate

BackHome

Product

Calibrate

Water

Calibrate

Ice

Main Menu

CALIBRATE WATER

Place empty jar in machine and press next to start calibration...

BackHome

Next

Main Menu

CALIBRATE WATER

Enter volume water in jar

Volume

0.0

1

4

7

0

89

56

23

ounces

BackHome

Main Menu

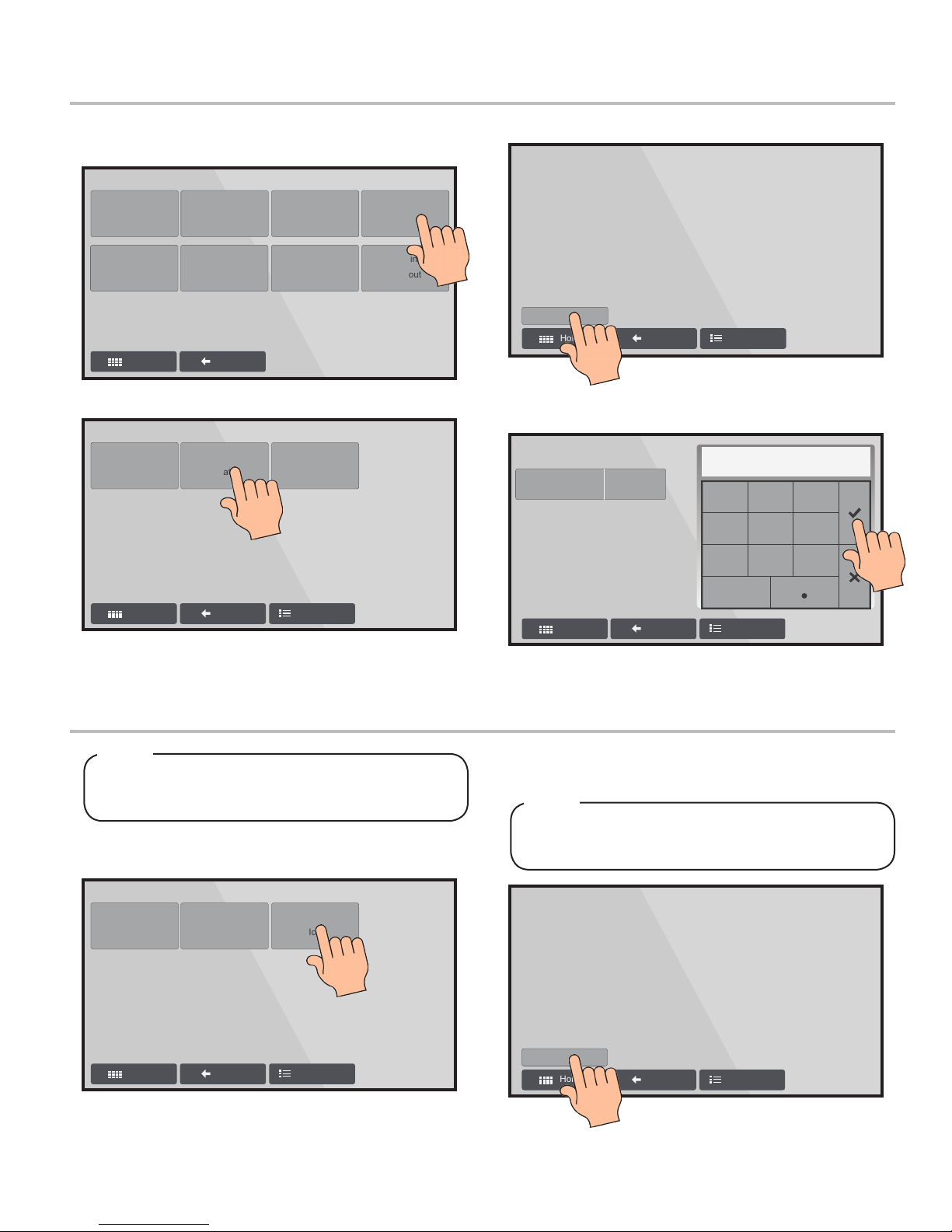

1. From the Home Screen, press the Main Menu button.

2. Press Calibrate.

3. Press Calibrate Water.

4. Place an empty Jar in the Blend Station and press Next.

5. Once completed record how many ounces of water were

dispensed by typing amount on keypad and pressing √.

Ice Calibration

NOTE

Water must be calibrated before calibration of the ice,

otherwise the unit will not calibrate the ice properly.

1. From the Calibrate Screen in the Main Menu, press

Calibrate Ice.

6. Empty Jar and replace in blend station.

2. Make sure there is an empty Jar in the Blend Station, then

press Next.

NOTE

Water and ice will be dispensed, this is necessary to

perform an accurate calibration.

8

Page 9

CALIBRATE PRODUCT 1

Enter volume product in jar

Volume

0.0

1

4

7

0

89

56

23

ounces

BackHome

Main Menu

CALIBRATE PRODUCT 1

Place empty jar in machine and press next to start calibration...

BackHome

Next

Main Menu

CALIBRATE PRODUCT

Product 2Product 1

Product 6Product 5

Product 3

Product 7 Product 8

BackHome

Product 4

Main Menu

CALIBRATE ICE

Enter volume water and ice in jar

Volume

0.0

1

4

7

0

89

56

23

ounces

BackHome

Main Menu

CALIBRATE

Calibrate

BackHome

Product

Calibrate

Water

Calibrate

Ice

Main Menu

3. Once completed, record how many ounces of ice and water

were dispensed by typing amount on the keypad and press

√.

Product Calibration

4. Empty Jar and replace in blend station.

1. From the Calibrate Screen in the Main Menu, press

Calibrate Product.

2. Make sure there is an empty jar in the Blend Station, then

press Product 1.

3. Press Next.

4. Once completed, record how many ounces of product was

dispensed by typing amount on keypad and press √.

5. Repeat Steps 2-4 with the remaining product numbers (2-8)

by pressing Calibrate Next Product.

NOTE

Empty jar before conducting calibration on the next

product line. If there is product remaining in the jar

from the ast calibration then the next product line

calibration will be inaccurate.

6. Empty Jar and replace in blend station.

9

Page 10

48°F

MANUAL CONTROLS

Product 2Product 1

Product 6Product 5

Product 3

Product 7Product 8

WaterIce Blender

BackHome

Product 4

Main Menu

Loading Ice

?

HOME

48°F

1

MENU

Replace

Inventory

Fault History

Cleaning

About

BackHome

Calibrate

Product

Manual

Controls

Machine

Lockout

BASIC OPERATIONS

1. Remove the black ice hopper lid from atop the unit

NOTE

Water and ice will be dispensed, this is necessary to

perform an accurate calibration.

2. Carefully pour up to 24 lbs (10.87 kg) of ice into the ice

hopper. Ensure that the ice covers both augers to provide

for the most consistent ice dispenser.

Making Drinks

1. Place an empty blender jar in the Blend Station with the

blender lid in place.

2. Select Flavor from the Home screen.

3. Select the size and Quantity.

3. Place the lid back on the top of the unit to re-enable the unit

to function.

4. If you are lling an empty ice hopper you should prime the

system by putting a blender jar in the blend station and

press the Ice button on the Manual Controls menu (See

Manual Controls Section below).

NOTE

You can dispense multiple quantities of the same size

orofdifferentsizesaslongasthenishedproduct

size does not exceed 36 ounces.

4. Press √.

5. The unit will automatically dispense ice, product, and water,

and then blend.

Manual Controls

1. From the Home screen, press the Main Menu button.

2. Press the “Manual Controls” button, from here you can

manually dispense ice, water, and product and blend as

desired.

10

Dispense Product Only:

• Press and hold the desired product number (1-8).

• The unit will dispense the product selected until you release

the button.

• The maximum time that the product number button will

dispense is 25 seconds. This feature allows you to prime

your product lines easily with little waste.

Page 11

MENU

Replace

Inventory

Fault History

Cleaning

About

BackHome

Calibrate

Product

Manual

Controls

Machine

Lockout

48°F

MANUAL CONTROLS

Product 2Product 1

Product 6Product 5

Product 3

Product 7Product 8

WaterIce Blender

BackHome

Product 4

Main Menu

48°F

MANUAL CONTROLS

Product 2Product 1

Product 6Product 5

Product 3

Product 7Product 8

WaterIce Blender

BackHome

Product 4

Main Menu

Dispense Ice Only:

INVENTORY

BackHome

Save

Product 1 2.0 gal.

Initial

Volume%Remaining

2.0 gal.

2.0 gal.

2.0 gal.

Reset

Reset

Reset

Reset

99%

100%

100%

100%

Product 2

Main Menu

Product 3

Product 4

Product 1 2.0 gal.

Initial

Volume%Remaining

2.0 gal.

2.0 gal.

2.0 gal.

Reset

Reset

Reset

Reset

99%

100%

100%

100%

Product 2

Product 3

Product 4

NOTE: % remaining is an estimation.

Actual volume remaining may vary.

Dispense Water Only:

• Place an empty jar in the blend station and press and hold

the Ice button to dispense the desired amount of ice.

• The ice will dispense as long as the Ice button is held down

or up to 25 seconds.

• Use this feature when you’re lling an empty ice hopper to

prime the system.

Replace Empty Product

NOTE

There are a couple different methods to determine

how much product is remaining in a product bag, so

before replacing an empty product follow these initial

steps.

1. From the Home Screen, locate the blue inventory bar

through each of the avor buttons. This inventory bar

deterines how much product of that particular avor

remains in their corresponding product bags.

• By pressing and holding the Water button you can dispense

cold water only as desired.

• The maximum amount of time the feature will run is 25

seconds.

Run Blender Only:

• Press and hold the Blender button to manually blend

product as desired.

• The unit will run until the Blender button is released or for

25 seconds.

3. From here, you can determine the remaining percentage of

each product in their corresponding product bags simply by

looking at the “% Remaining” bar for each product.

NOTE

When product bags are replaced “% Remaining”

numbers should automatically return to “100%”

NOTE

Inventory bar is an estimation of the remaining

product. Remaining volume may vary.

2. From the Main Menu press the Inventory button.

4. After determining product in need of replacement, open the

refrigerated portion of the unit.

5. Unhook the product line from the desired product bag.

6. Remove and replace the empty product bag with the new,

full product bag.

11

Page 12

7. Once new product bag is connected, go back to the Main

MENU

Replace

Inventory

Fault History

Cleaning

About

BackHome

Calibrate

Product

Manual

Controls

Machine

Lockout

REPLACE PRODUCT

Product 2Product 1

Product 6Product 5

Product 3

Product 7 Product 8

BackHome

Product 4

Main Menu

Replace bag then press product button.

Menu screen and press the Replace Product button.

CLEANING AND SANITIZING

8. From here you can prime the product pump line simply by

pressing the number of the product line that you have just

replaced.

NOTE

MakesurethereisanemptyJarintheBlendStation

before priming the product pump lines.

9. Repeat Steps 4-9 for any other empty product bags there

may be.

General Information

! ATTENTION

DO NOTattempttoperformrepairs.Neverremovethesideorbackpanelsontheunit.Theunitdoesnotcontain

adjustable or customer servicable parts. The manufacturer or an authorized agent must perform all interior service

and adjustments. Removing panels or attempting to perform repairs without authorization will void the warranty.

• Lancer equipment (new or reconditioned) is shipped from the factory cleaned and sanitized in accordance with NSF guidelines.

The operator of the equipment must provide continuous maintenance as required by this manual and/or state and local health

department guidelines to ensure proper operation and sanitation requirements are maintained.

NOTE

ThecleaningproceduresprovidedhereinpertaintotheLancerequipmentidentiedbythismanual.Ifother

equipment is being cleaned, follow the guidelines established by the manufacturer for that equipment.

• Cleaning should be accomplished only by trained personnel. Sanitary gloves are to be used during cleaning operations.

Applicable safety precautions must be observed. Instruction warnings on the product being used must be followed.

! ATTENTION

NOTE

• Use sanitary gloves when cleaning the unit and observe all applicable safety precautions.

• DO NOT use a water jet to clean or sanitize the unit.

• DO NOT disconnect water lines when cleaning and sanitizing syrup lines, to avoid contamination.

• DO NOT use strong bleaches or detergents; These can discolor and corrode various materials.

• DO NOT use metal scrapers, sharp objects, steel wool, scouring pads, abrasives, or solvents on the dispenser.

• DO NOT use hot water above 140° F (60° C). This can damage the dispenser.

• DO NOT spill sanitizing solution on any circuit boards. Insure all sanitizing solution is removed from the system.

12

Page 13

Cleaning and Sanitizing Solutions

Cleaning Solution

Mix a mild, non-abrasive detergent (e.g. Sodium Laureth

Sulfate, dish soap) with clean, potable water at a temperature

of 90°F to 110°F (32°C to 43°C). The mixture ratio is one

ounce of cleaner to two gallons of water. Prepare a minimum of

ve gallons of cleaning solution. Do not use abrasive

cleaners or solvents because they can cause permanent

damage to the unit. Ensure rinsing is thorough, using clean,

potable water at a temperature of 90°F to 110°F. Extended

lengths of product lines may require additional cleaning solution.

After Every Use

1. Rinse out the blender jar.

2. Make sure blender station has been wiped down if there is

any spillage.

3. Make sure blender door has been wiped down if there is

any spillage.

4. Remove rinse station grate.

5. Wipe down rinse station for any remaining product.

Daily Cleaning

Sanitizing Solution

Prepare sanitizing solutions in accordance with the

manufacturer’s written recommendations and safety guidelines.

The solution must provide 100 parts per million (PPM) chlorine

(e.g. Sodium Hypochlorite or bleach). A minimum of ve

gallons of sanitizing solution should be prepared. Any sanitizing

solution may be used as long as it is prepared in accordance

with the manufacturer’s written recommendations and safety

guidelines, and provides 100 parts per million (PPM) chlorine.

6. Wipe down counter around blend station and rinse station.

NOTE

Alwayskeepanemptyjaronblendermotorwhenthe

unit is not in use. This helps any melt water that is not

captured by the ice hopper drain from splashing onto

the blender motor itself.

1. Wash jars with smooth cloth or sponge using cleaning

solution.

! ATTENTION

DO NOT immerse the jars for longer than necessary in

any type of liquid.

2. Rinse the jar and sanitize using appropriate sanitizing

solution.

3. Hold the jar by the handle and give three (3) or more sharp

downward shakes to remove all liquid from around the shaft

area.

4. Place the jar upside down on the grate in the rinse station

to dry.

Weekly Cleaning

Blender Jar:

1. Remove jar from blend station.

2. Fill jar with hot water and sanitizing solution.

3. Stir and let stand for ve (5) minutes then empty.

5. Remove the splash guard from the blend station.

6. Wash the splash guard with a smooth cloth or sponge

using cleaning solution, rinse, and sanitize using

appropriate sanitizing solution.

7. Wipe down exterior of the unit including counter space,

interior of the blend station, door, and rinse station with a

damp rag.

8. Wash nozzle ports, located in the interior of the blend

station with a damp clean rag.

9. Run hot sanitizer solution through rinse station drain to

sanitize drain tube.

10. Replace splash guard.

4. Hold the jar by the handle and give three (3) or more sharp

downward shakes to remove all water from around the shaft

area.

5. Place the jar upside down on the grate in the rinse station

to dry.

13

Page 14

CLEAN PRODUCT LINES

Place cleaning jar on blender, disconnect hoses from

bags and place hoses in a bucket of warm water.

1/10

BackHome

Main Menu

Start

CLEANING

BackHome

Main Menu

Clean

Product Lines

Clean Ice

Hopper

Blend Station:

MENU

Replace

Inventory

Fault History

Cleaning

About

BackHome

Calibrate

Product

Manual

Controls

Machine

Lockout

Product Lines:

1. Remove blender jar and splash guard. Empty jar if needed.

2. Using cleaning solution, wipe down all surfaces of the blend

station, including the blend station door. Excess water will

drain through drain opening located at the back of the unit.

3. Use clear, hot water to rinse blend station. Avoid getting

excess water on the motor.

4. Using sanitizing solution, spray solution on all surfaces of

the blend station including the nozzle ports located on the

upper portion where splash guard is located and wipe with

a clean rag.

5. Using the brush provided, clean and sanitize ice chute

located on the upper surface of the blend station. Slide

brush all the way through the ice chute to the other side

making sure to cover all interior surfaces.

6. Clean and sanitize splash guard.

7. Replace splash guard, blender jar.

Ice Hopper:

1. Place empty jar in the blend station and turn OFF the

power.

2. Manually remove and discard as much ice as possible from

the ice hopper.

3. Turn ON the power.

4. In the Manual Controls section found on the Main Menu,

press and hold the Ice button to discharge all remaining ice

in the hopper (See Manual Controls Section, page 10).

5. Empty jar and replace in the blend station.

6. Turn OFF power

7. Fill another jar with cleaning solution and apply to ice

hopper.

8. Make sure to apply cleaning solution to all interior surfaces

of the ice hopper, both of the augers, the crusher plate, and

the three (3) plastic bushings. Empty jar in Blend Station

and replace.

9. Wipe down all surfaces of the ice hopper with a clean,

damp rag.

10. Fill another jar with warm water and run over all surfaces

of the ice hopper until there is no cleaning solution present,

watch the water level in the jar to ensure it does not

overow. Empty jar as needed.

11. F i l l a n o t h e r j a r w i t h s a n i t i z i n g s o l u t i o n a n d a p p l y t o a l l

interior surfaces of the ice hopper including both of the

augers, the crusher plate, and the three (3) plastic

bushings.

12. Wipe down all surfaces of the ice hopper with a clean,

damp rag soaked with sanitizing solution.

1. Disconnect all product lines from their corresponding

product bags.

2. Remove all product bags and trays.

3. From the “Home Screen” press the Main Menu button.

4. Press Cleaning.

5. Press Clean Product Lines.

6. Place an empty jar into the Blend Station.

7. Place ends of product hoses into a bucket of warm water

then press Start.

NOTE

For further Ice Hopper cleaning instructions see

Cleaning section found on the Main Menu

14

Page 15

CLEAN PRODUCT LINES

Remove hoses from bucket, then reconnect hoses to product bags.

Press next to prime hoses with product.

8/10

BackHome

Main Menu

Next

CLEAN PRODUCT LINES

Prepare bucket of sanitizer, place end of hoses in bucket,

press next when ready.

6/10

BackHome

Main Menu

Next

CLEAN PRODUCT LINES

Prepare bucket of cleaner, place end of hoses in bucket,

press next when ready.

4/10

BackHome

Main Menu

Next

CLEAN PRODUCT LINES

Once hoses are disconnected from product bag, use spray bottle

filled with sanitizer, to clean connections on product bag.

2/10

BackHome

Main Menu

Next

8. Using a soft cloth or sponge, clean the product line

connections on all of the product bags with sanitizing

solution, then press Next.

NOTE

Theunitwillbeginushingwarmwaterthroughthe

product lines. Each pump will run for one whole cycle

(approximately 25 seconds) to ensure lines are

completelyushedofanyremainingproduct.

9. Empty and replace jar in Blend Station, if needed.

10. Place ends of product hoses into a bucket of cleaning

solution then press Next.

13. Place ends of product hoses into a bucket of sanitizing

solution then press Next.

NOTE

Theunitwillbegintolltheproductlineswith

sanitizing solution. Each pump will run for one whole

cycle (approximately 25 seconds) to ensure lines are

completelylledwithsanitizingsolution.

14. Let sanitizing solution sit in lines for ten (10) minutes before

continuing.

15. Empty and replace jar in Blend Station, if needed.

16. Replace product bags and trays.

17. Reconnect product hoses to their corresponding product

bags then press Next.

NOTE

Theunitwillbegintolltheproductlineswith

cleaning solution. Each pump will run for one whole

cycle (approximately 25 seconds) to ensure lines are

completelyushedofanyremainingproduct.

11. Let cleaning solution sit in lines for ten (10) minutes before

continuing.

12. Empty and replace jar in Blend Station, if needed.

NOTE

Theunitwillbegintolltheproductlineswiththe

original product. Each pump will run for one whole

cycle (approximately 25 seconds) to ensure sanitizing

solutioniscompletelyushedfromthesystem.

! CAUTION

Following sanitization, rinse with end-use product

until there is no aftertaste. Do not use a fresh water

rinse. This is a nsf requirement. Residual sanitizing

solution left in the system creates a health hazard.

18. Taste each product to verify there is no off-taste.

19. If off-taste is found, ush the product system again by using

the Manual Controls option, (See Manual Controls Section,

page 10).

20. Press and hold each product number for one whole cycle

(approximately 25 seconds) to ensure off-taste does not

occur.

15

Page 16

Every Six Months

1. Remove the external drain hose from the back of the unit.

2. Slowly pour sanitizing solution down the tube. It is not

necessary to rinse the drain hose.

TROUBLESHOOTING

TROUBLE CAUSE REMEDY

Machine won’t run. • Power Cord not plugged in.

• Switch on back of unit is not ON.

• Circuit breaker button in rear has been

tripped.

Blender stopped working. • Circuit breaker button in rear has been

tripped.

Ice stopped dispensing or ice

auger not turning.

• No ice in the hopper.

• Obstructions present in the ice hopper or

ice chute.

• Ice hopper lid not properly closed.

• Check the power cord to be sure it is

plugged into a live, grounded circuit.

• Check that the switch on the back of the

unit is on.

• Press the breaker button back in to reset

it. (This unit utilizes a 13 AMP circuit

breaker).

• Press the breaker button back in to reset

it. (This unit utilizes a 13 AMP circuit

breaker).

• Ensure there is ice in the hopper, if not

rell hopper.

• Check for obstuctions (foriegn objects) and

blockage in the ice hopper and its chute

and remove

• Replace the ice hopper lid or make sure it

is rmly in place to activate the lid sensor

switch.

Ice dispenses when not in use. • Timed “ice buster” being activated. • If the machine dispenses ice by itself for

about two seconds every hour or so, this

is caused by our timed “ice buster” being

automatically activated. Your machine

is programmed to activate the ice auger

every 30 minutes and dispense ice for six

(6) seconds when the unit is on, but not in

use.

Drinks too runny. • No ice in the hopper.

• Ice hopper lid not properly closed.

Drinks too thick or cavitation in

blender.

• Product bags are empty.

• Water supply is OFF or blocked.

• Water, product, and ice amounts are not

programmed correctly.

• Cavitation is caused when the liquid and

ice mixture in the blender jar is too thick

and an air pocket is created around the

spinning blender blade.

• Ensure there is ice in the hopper, if not

rell hopper.

• Replace the ice hopper lid or make sure it

is rmly in place to activate the lid sensor

switch.

• Ensure product bags are not empty and if

so then replenish accordingly.

• Ensure water supply is ON if not then

switch on. If water line is blocked then

clear obstruction.

• See Section 4 above to reprogram your

ingredients correctly.

• Be sure to put in enough products to

produce a good avor then adjust the

• water to ice ratio until the blender does not

cavitate when you make your drink.

16

Page 17

TROUBLE CAUSE REMEDY

Little or no avor in drinks. • Product bags are empty.

• Product hoses are kinked.

Too much avor in drinks. • More than one pump is turning at one time.

• A pump is turning that was not requested.

• A single pump is turning as long as the ice

is dispensing.

Ice chunks in drinks. • Blend time in the program for that product

is off.

• Cavitation is caused when the liquid and

ice mixture in the blender jar is too thick

and an air pocket is created around the

spinning blender blade.

Water won’t dispense. • Water supply is OFF or blocked.

• Water supply line is kinked.

• Ensure product bags are not empty and if

so then replenish accordingly.

• Unkink product hoses

(Contact the manufacturer if pumps do not turn)

• Check the programming for any of these

conditions and if any are present then

contact the manufacturer.

• See Section 4 above to reprogram the

blend time correctly.

• Be sure to put in enough products to pro-

duce a good avor then adjust the water to

ice ratio until the blender does not cavitate

when you make your drink.

• Ensure water supply is ON if not then

switch on. If water line is blocked then

clear obstruction.

• Unkink water supply line.

(If neither problems exist contact manufacturer)

Product bag is leaking. • Product bag is torn or ripped. • Replace the bag.

Lid light in on. • Ice hopper lid is malfunctioning • Replace ice hopper lid.

(If replacing the lid does not clear the light

contact your manufacturer for further help)

Low ice indicator. • Ice level in ice hopper not high enough • Add ice to the ice hopper to a level above

the photo-electric eyes which are located

inside the ice hopper on each side.

• (If the light does not go off then contact

your manufacturer for further help)

17

Page 18

ILLUSTRATIONS AND PART LISTINGS

Main Unit Assembly 1

1

2

3

6

15

Item Part No. Description

1 05-3226 Lid, Ice Dispenser, Gemini

2 82-4715 Ice Hopper, BDI - 409, Gemini

3 82-4720 Splash Cover, Blend Station, Smoothie

4 82-4654 Product Jar, Blendtec, Smoothie

5 82-4747 Alcove Door Assy, Blend Station, Gemini

6 04-1032 SCR, 8 - 32 x .375”, Flathead

7 82-4656 Blender Motor, Blendtec, Smoothie

8 82-4677 Bezel Assy, Blend Station, Gemini

9 82-4733 Grate, Rinse Station, Gemini

10 05-3209 Door, Whipcrm Door, Front, Gemini

11 82-4739 Flow Sensor, Right, Blendtec, Gemini

12 91-0206 Fan, Axial, 115/60, Smoothie (x4)

13 05-3217 Cap, Vinyl, Black Caplug, 1Wx1H .06 gap

14 82-4651 Tray, Bagged Product, Smoothie (x8)

15 82-4711 Flow Sensor, Left, Blendtec, Gemini

18

4

5

7

8

9

10

11

12

13

14

Page 19

Main Unit Assembly 2

1

2

3

4

Item Part No. Description

1 82-4660 Board, Electronics, Smoothie

2 82-4723 Valve Water, Blend Station, Gemini

3 82-4724 Valve Water, Rinse Station, Gemini

4 04-0585 Filter, Air, LIV

19

Page 20

Ice Hopper Assembly

Item Part No. Description

1 82-4820 Motor, Ice Hopper, Gemini

Condenser Assembly

Item Part No. Description

1 91-0007 Motor, Fan, 115/60, 9W

2 07-0389 Fan Blade, OJ SL, 500

1

1

2

20

Page 21

Pump Cube Assembly

4

3

5

1

2

Item Part No. Description

1 05-3331 Elbow, .5 barb x .375 barb, 90 Deg., Gemini

2 05-3332 Elbow, .375 barb x .375 barb, 90 Deg., Pump Cube, Gemini

3 07-0438 Clamp, STPLS, Oetiker, 21/32 (17mm)

4 49-0344 Hose, Pump Cube, .375 ID x .137W, Gemini

5 01-2985 Cotton Pin, Pump Cube, Gemini

6 82-4818 Clutch, Pump Cube, Gemini

6

21

Page 22

WIRING DIAGRAM PN 06-3418/01

22

Page 23

Dispenser Disposal

To prevent possible harm to the environment from improper disposal, recycle the unit

by locating an authorized recycler or contact the retailer where the product was purchased.

Comply with local regulations regarding disposal of the refrigerant and insulation.

23

Page 24

Lancer Corp.

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Loading...

Loading...