Page 1

Turbo Carbonator

Operation Manual

PN: 28-0315/09

85-1923-00 Carbonator, 115V, VCV, Diagnostic

85-1923-01 Carbonator, 115V, VCV, Diagnostic, Insulated

85-1923-02 Carbonator, 115V, VCV, Diagnostic, Tee

85-1923-07 Carbonator, 115V, VCV, Diagnostic, Polished

85-1924-00 Carbonator, 230V, VCV, Diagnostic

85-1924-01 Carbonator, 230V, VCV, Diagnostic, Insulated

85-1924-06 Carbonator, 230V, VCV, Diagnostic, Reset

Certied

< 0.25 weighted

average percent lead

“Lancer” is the registered trademark of Lancer © 2014 by Lancer, all rights reserved.

Lancer Corp.

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Manual PN: 28-0315/09

11/26/13

FOR QUALIFIED INSTALLER ONLY

Page 2

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product and should be handed over to the operator after the

installation and preserved for any further consultation that may be necessary. Please read carefully the guidelines and

warnings contained herein as they are intended to provide the user with essential information for the continued safe

use and maintenance of the product. In addition, it provides GUIDANCE ONLY to the user on the correct services and

site location of the unit.

The installation and relocation, if necessary, of this product must be carried out by qualied personnel with up-to-date

safety and hygiene knowledge and practical experience, in accordance with current regulations.

TABLE OF CONTENTS

SPECIFICATIONS...............................................................................................................................................2

WARNINGS/CAUTIONS......................................................................................................................................3

THEORY OF OPERATION..................................................................................................................................4

1. INSTALLATION INSTRUCTIONS.................................................................................................................4

2. ELECTRICAL REQUIREMENTS..................................................................................................................4

2.1 IMPORTANT SAFETY INSTRUCTIONS.............................................................................................4

2.2 GROUNDING INSTRUCTIONS..........................................................................................................5

3. OPERATING INSTUCTIONS........................................................................................................................6

4. USER MAINTENANCE INSTRUCTIONS.....................................................................................................7

4.1 INSPECTIONS.....................................................................................................................................7

5. CLEANING AND REPLACEMENT...............................................................................................................7

5.1 CO2 CHECH VALVE...........................................................................................................................7

5.2 BACKFLOW PREVENTER.................................................................................................................7

5.3 PUMP STRAINER SCREEN...............................................................................................................7

5.4 REPLACING PROBE..........................................................................................................................8

5.5 REPLACING PC BOARD....................................................................................................................8

6. CONFIGURATION........................................................................................................................................9

7. TROUBLESHOOTING...........................................................................................................................10-11

8. ILUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS..............................................................11

8.1 CHECK VALVE ASSEMBLY...............................................................................................................11

8.2 WIRING DIAGRAM............................................................................................................................11

8.3 CARBONATOR TANK.......................................................................................................................12

9. APPLIANCE DISPOSAL............................................................................................................................13

TURBO CARBONATOR SPECIFICATIONS

DIMENSIONS

Width: 12 1/4 inches (311 mm)

Depth: 15 1/4 inches (387 mm)

Height: 11 1/2 inches (292 mm)

ELECTRICAL

115 VAC / 60 Hz / 6.3 Amps

230 VAC / 56-60 Hz/ 3.5/3 Amps

TIMEOUT FEATURE: The carbonator is designed with a Timeout feature for self-protection. If the

carbonator runs for longer than three minutes without the demand for water being met, the carbonator will

shut down. On newer units, an automatic retry feature can be enabled to allow self-recovery within 3 hours.

Refer to Troubleshooting section.

WEIGHT

Shipping: 33.5 lbs (15.2 kg)

Empty: 31.1 lbs (14.1 kg)

Operating: 45.3 lbs (20.5 kg)

MOTOR

1/3 Horsepower (HP)

FITTINGS

Water for carbonator inlet:

3/8” s.a.e. Male Flare

CO2 inlet: 1/4” s.a.e. Male Flare

2

BACKFLOW PREVENTER:

Max 130° F (54° C)

Max 200 PSIG (0.138 MPA)

ASSE 1022 Compliant

TANK OPERATING CAPACITY:

215 Ounces (6.4 L)

PUMP

125 Gallons Per Hour (GPH)

(473 Liters Per Hour (LPH))

Page 3

ELECTRICAL WARNING/ADVERTENCIA ELÉCTRICA/

F F

AVERTISSEMENT ÉLECTRIQUE

F Check the dispenser serial number plate for correct electrical requirements of unit. Do not plug into a wall

electrical outlet unless the current shown on the serial number plate agrees with local current available. Follow

all local electrical codes when making connections. Each dispenser must have a separate electrical circuit. Do not

use extension cords with this unit. Do not ‘gang’ together with other electrical devices on the same outlet. The

keyswitch does not disable the line voltage to the transformer primary. Always disconnect electrical power to the unit

to prevent personal injury before attempting any internal maintenance. The resettable breaker switch should not

be used as a substitute for unplugging the dispenser from the power source to service the unit. Only qualied

personnel should service internal components of electrical control housing. Make sure that all water lines are

tight and units are dry before making any electrical connections!

F Verique la placa con el número de serie del dispensador, donde encontrará los requisitos eléctricos correctos

de la unidad. No enchufe la unidad en un tomacorriente de pared a menos que la corriente indicada en la placa con

el número de serie concuerde con la corriente local disponible. Al hacer las conexiones, respete todos los códigos

eléctricos locales. Cada dispensador debe tener un circuito eléctrico independiente. No use extensiones con esta

unidad. No la conecte junto con otros dispositivos eléctricos al mismo tomacorriente. El interruptor de llave no corta

el voltaje de línea al transformador primario desconecte siempre la alimentación eléctrica a la unidad para evitar

lesiones personales antes de tratar de realizar tareas de mantenimiento. El disyuntor de sobrecarga

reseteable no se debe usar como sustituto para desenchufar el dispensador de la fuente de alimentación para

realizar tareas de servicio de la unidad. El servicio de los componentes internos de la caja de control eléctrico debe

conarse exclusivamente a personal calicado. Asegúrese de que todas las líneas de agua estén ajustadas y las

unidades estén secas antes de hacer conexiones eléctricas.

F Examinez la plaque de numéro de série du distributeur pour connaître les bonnes exigences en matière

d’électricité pour l’appareil. Ne le branchez pas à une prise électrique murale à moins que le courant indiqué sur la

plaque de numéro de série corresponde au courant local disponible. Respectez tous les codes électriques locaux

lorsque vous faites des connexions. Chaque distributrice doit avoir un circuit électrique séparé. N’utilisez pas

de cordons prolongateurs avec cet appareil. Ne pas le brancher avec d’autres appareils électriques sur la même

prise. L’interrupteur à clé ne coupe pas la tension secteur au transformateur primaire. Débranchez toujours le courant

électrique à l’appareil, an de prévenir des blessures, avant de faire un entretien interne quelconque. Le disjoncteur

réarmable ne devrait pas être utilisé au lieu de débrancher le distributeur de la source d’alimentation en électricité

pour faire de l’entretien/une réparation de l’appareil. Seul le personnel qualié devrait faire l’entretien/la réparation

des composants internes dans le logement des commandes électriques. Assurez-vous que toutes les conduites

d’eau sont étanches et que les appareils sont secs avant de faire des connexions électriques!

CO2/CARBON DIOXIDE /El ANHÍDRIDO CARBÓNICO/

5 5

DIOXYDE DE CARBONE

5 Carbon Dioxide (CO2) is a colorless, noncombustible gas with a light pungent odor. High percentages of CO2 may

displace oxygen in the blood. Prolonged exposure to CO2 can be harmful. Personnel exposed to high concentrations

of CO2 gas will experience tremors which are followed by a loss of consciousness and suffocation. If a CO2 gas leak

is suspected, immediately ventilate the contaminated area before attempting to repair the leak. Strict attention must

be observed in the prevention of CO2 gas leaks in the entire CO2 and soft drink system.

5 El anhídrido carbónico (CO2) es un gas incoloro, no combustible, con un olor pungente ligero. Altos porcentajes

de CO2 en la sangre pueden desplazar el oxígeno en la sangre. La exposición prolongada al CO2 puede ser nociva.

El personal expuesto a concentraciones altas de CO2 sufre temblores seguidos de la pérdida de la consciencia y

sofocación. Si se sospecha que existe una pérdida de CO2, ventile el área contaminada antes de tratar de reparar

la pérdida. Hay que prestar suma atención para evitar pérdidas de CO2 en todo el sistema de CO2 y de bebidas

gaseosas.

5 Le dioxyde de carbone (CO2) est plus lourd que l’air et déplace l'oxygène. Le CO2 est un gaz incolore et

incombustible, ayant une odeur un peu âcre. Des concentrations fortes de CO2 peuvent déplacer l'oxygène dans le

sang. Une exposition prolongée au CO2 peut être nocive. Le personnel exposé à de fortes concentrations de CO2

gazeux éprouvera des tremblements, suivis rapidement d'une perte de conscience et de suffocation. On doit faire très

attention de prévenir les fuites de CO2 gazeux dans le système entier de CO2 et de boisson gazeuse. Si on suspecte

qu'il y a une fuite de CO2 gazeux, aérez le secteur contaminé immédiatement avant d'essayer de réparer la fuite.

3

Page 4

THEORY OF OPERATION

A carbonator is a device designed to dissolve carbon dioxide gas (CO2) in water, producing carbonated water.

CO2 gas is delivered through a regulator to the carbonator tank. Simultaneously, plain water is pumped into

the tank. The CO2 gas, under pressure, dissolves in the water and the result is carbonated water. When the

level of carbonated water reaches a pre-determined point, the liquid level sensing device (inside the tank)

signals the liquid level control module which, in turn, shuts off the pump motor. As carbonated water is drawn

from the tank, the level of carbonated water will drop. At a certain point, the liquid level sensing device

recognizes the drop in the level and turns on the pump motor which replenishes the amount of carbonated

water that has been taken out of the tank.

WARNING CARBON DIOXIDE (CO2) DISPLACES OXYGEN. STRICT ATTENTION MUST BE OBSERVED IN THE

PREVENTION OF CO2 GAS LEAKS IN THE ENTIRE CO2 AND SOFT DRINK SYSTEM. IF A CO2 GAS LEAK IS

SUSPECTED, IMMEDIATELY VENTILATE THE CONTAMINATED AREA BEFORE ATTEMPTING TO REPAIR THE

LEAK. CO2 IS HEAVIER THAN AIR. IT IS A COLORLESS, NON-COMBUSTIBLE GAS WITH A FAINTLY PUNGENT

ODOR. HIGH PERCENTAGES OF CO2 MAY DISPLACE OXYGEN IN THE BLOOD; PROLONGED EXPOSURE TO

CO2 MAY BE HARMFUL. PERSONNEL EXPOSED TO HIGH CONCENTRATIONS OF CO2 GAS WILL EXPERIENCE

TREMORS WHICH ARE FOLLOWED RAPIDLY BY LOSS OF CONSCIOUSNESS AND SUFFOCATION.

ADVERTENCIA DIOXYDE DE CARBONE (CO2) DÉPLACE L’OXYGÈNE. ATTENTION STRICTE DOIT ÊTRE

OBSERVÉE DANS LA PRÉVENTION DES FUITES DE GAZ DE CO2 DANS LE SYSTÈME DE CO2 ET DE

BOISSONS GAZEUSES ENTIER. SI UNE FUITE DE GAZ DE CO2 EST SOUPÇONNÉ, AÉREZ IMMÉDIATEMENT LA

ZONE CONTAMINÉE AVANT DE TENTER DE RÉPARER LA FUITE. CO2 EST PLUS LOURD QUE L’AIR. IL EST UN

GAZ NON INFLAMMABLE INCOLORE AVEC UNE ODEUR LÉGÈREMENT ÂCRE. DES POURCENTAGES ÉLEVÉS DE

5

1. INSTALLATION INSTRUCTIONS

Select a level, well-ventilated, accessible location convenient to water and electrical supply, which can

support a weight of 100 lbs (45.3 kg).

CO2 PEUVENT DÉPLACER L’OXYGÈNE DANS LE SANG; EXPOSITION PROLONGÉE AU CO2 PEUT ÊTRE NOCIF.

LE PERSONNEL EXPOSÉ À DES CONCENTRATIONS ÉLEVÉES DE GAZ DE CO2 FERONT L’EXPÉRIENCE DES

TREMBLEMENTS QUI SONT SUIVIS RAPIDEMENT PAR LA PERTE DE CONSCIENCE ET LA SUFFOCATION.

AVERTISSEMENT LE DIOXYDE DE CARBONE (CO2) DÉPLACE L’OXYGÈNE. IL FAUT PORTER UNE ATTENTION

TRÈS STRICTE À LA PRÉVENTION DES FUITES DE GAZ DE CO2 DANS L’ENSEMBLE DU SYSTÈME DE CO2 ET

DE BOISSONS GAZEUSES. SI VOUS SOUPÇONNEZ UNE FUITE DE GAZ DE CO2, VENTILER IMMÉDIATEMENT

L’ENDROIT CONTAMINÉ AVANT DE TENTER DE RÉPARER LA FUITE. LE CO2 EST PLUS LOURD QUE L’AIR. C’EST

UN GAZ INCOLORE INCOMBUSTIBLE AYANT UNE LÉGÈRE ODEUR ÂCRE. DE FORTS POURCENTAGES DE CO2

PEUVENT DÉPLACER L’OXYGÈNE DANS LE SANG; UNE EXPOSITION PROLONGÉE AU CO2 PEUT ÊTRE NOCIVE.

LE PERSONNEL EXPOSÉ À DE FORTES CONCENTRATIONS DE CO2 PEUT RESSENTIR DES TREMBLEMENTS,

SUIVIS RAPIDEMENT DE LA PERTE DE CONNAISSANCE ET DE LA SUFFOCATION.

2. ELECTRICAL REQUIREMENTS

2.1 IMPORTANT SAFETY INSTRUCTIONS

WARNING WHEN USING ELECTRIC APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED,

INCLUDING THE FOLLOWING:

A. READ ALL THE INSTRUCTIONS BEFORE USING THE APPLIANCE.

B. DO NOT USE OUTDOORS.

C. DO NOT UNPLUG BY PULLING ON THE CORD.

D. FOR A GROUNDED APPLIANCE, CONNECT TO PROPERLY GROUNDED OUTLET ONLY. SEE GROUNDING

INSTRUCTIONS.

E. UNPLUG FROM OUTLET BEFORE SERVICING OR CLEANING.

ADVERTENCIA CUANDO SE UTILIZAN APARATOS ELÉCTRICOS, LAS PRECAUCIONES BÁSICAS SIEMPRE SE

DEBEN SEGUIR, INCLUYENDO LAS SIGUIENTES:

A. LEA TODAS LAS INSTRUCCIONES ANTES DE USAR EL APARATO.

B. NO USAR EN EXTERIORES.

C. NO DESENCHUFE TIRANDO DEL CORDÓN.

F

D. PARA UN APARATO CON CONEXIÓN A TIERRA, CONEXIÓN A TIERRA ADECUADA TOMA SOLAMENTE. VEA

CONEXIÓN A TIERRA INSTRUCCIONES.

E. DESCONECTE DEL TOMACORRIENTE ANTES DE REPARAR O LIMPIAR.

AVERTISSEMENT DES PRÉCAUTIONS DE BASE DOIVENT TOUJOURS ÊTRE SUIVIES LORSQUE DES

APPAREILS MÉNAGERS ÉLECTRIQUES SONT UTILISÉS, NOTAMMENT :

A. LIRE TOUTES LES INSTRUCTIONS AVANT D’UTILISER L’APPAREIL.

B. NE PAS UTILISER À L’EXTÉRIEUR.

C. NE JAMAIS TIRER SUR LE CORDON POUR DÉBRANCHER L’APPAREIL.

D. BRANCHER TOUT APPAREIL DEVANT ÊTRE MIS À LA TERRE UNIQUEMENT SUR UNE PRISE AVEC MISE À LA

TERRE. VOIR LES INSTRUCTIONS DE MISE À LA TERRE.

E. DÉBRANCHER L’APPAREIL DE LA PRISE AVANT DE LE RÉPARER OU DE LE NETTOYER.

4

Page 5

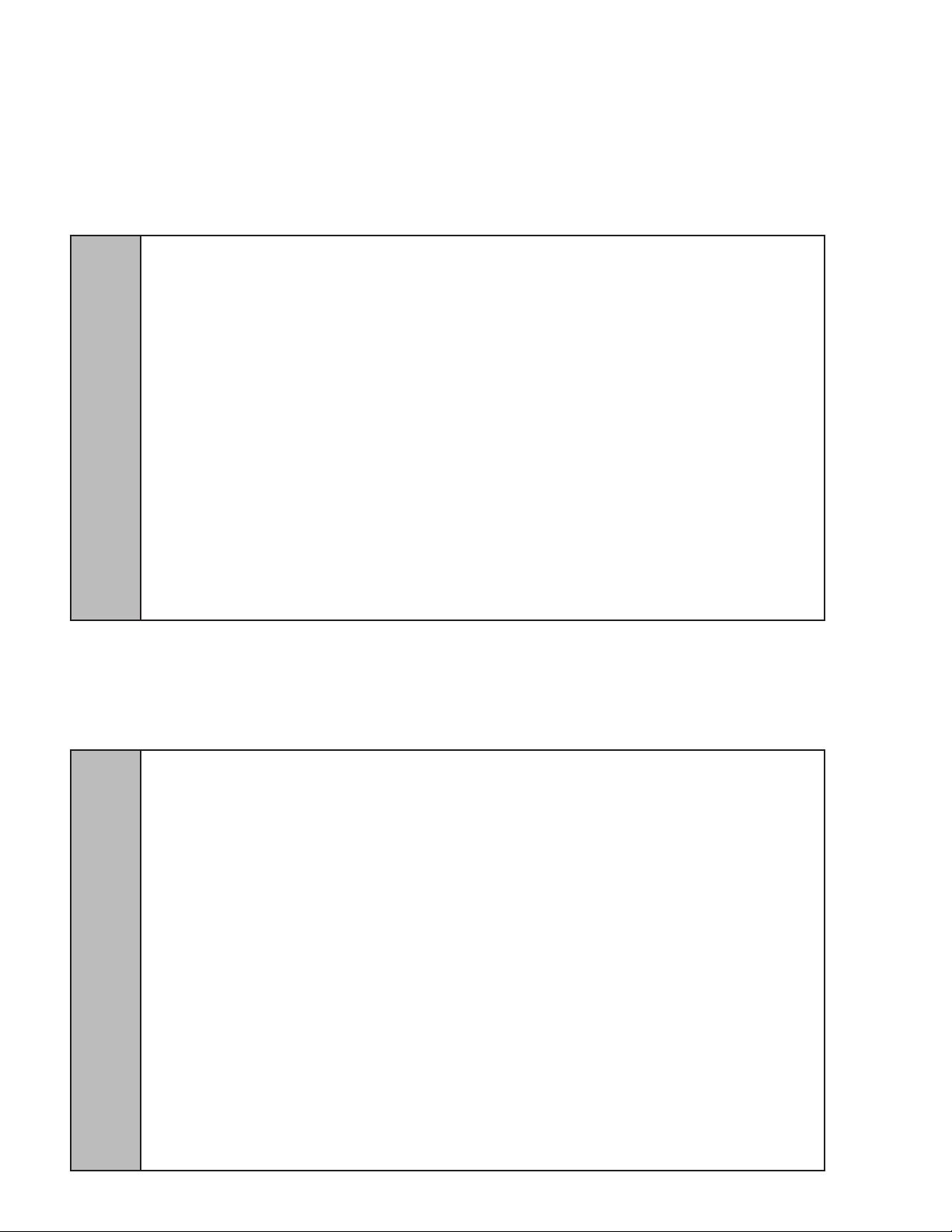

2.2 GROUNDING INSTRUCTIONS

GROUNDING WARNING THIS APPLIANCE MUST BE PROPERLY GROUNDED TO AVOID POSSIBLE FATAL

ELECTRICAL SHOCK OR SERIOUS INJURY TO THE OPERATOR. THE POWER CORD IS PROVIDED WITH A THREE

PRONG GROUNDED PLUG. IF A THREE HOLE GROUNDED ELECTRICAL OUTLET IS NOT AVAILABLE, USE AN

APPROVED METHOD TO GROUND THE UNIT. IN THE EVENT OF MALFUNCTION OR BREAKDOWN,

GROUNDING PROVIDES A PATH OF LEAST RESISTANCE FOR ELECTRIC CURRENT TO REDUCE THE RISK OF

ELECTRIC SHOCK. THIS APPLIANCE IS EQUIPPED WITH A CORD HAVING AN EQUIPMENT-GROUNDING PLUG.

THE PLUG MUST BE PLUGGED INTO AN APPROPRIATE OUTLET THAT IS PROPERLY INSTALLED AND GROUNDED IN ACCORDANCE WITH ALL LOCAL CODES AND ORDINANCES.

THIS APPLIANCE IS FOR USE ON A NOMINAL 120V (OR 230V, AS APPLICABLE) CIRCUIT, AND

HAS A GROUNDING PLUG THAT LOOKS LIKE THE PLUG ILLUSTRATED BELOW.

ADVERTENCIA, PUESTA A TIERRA ESTE APARATO DEBE ESTAR CORRECTAMENTE CONECTADO A TIERRA

PARA EVITAR POSIBLES DESCARGAS ELÉCTRICAS MORTALES O LESIONES GRAVES AL OPERADOR. EL CABLE

DE ALIMENTACIÓN ESTÁ DOTADO DE UN TRES PUNTAS TOMA DE TIERRA. SI UN AGUJERO DE TOMA DE

CORRIENTE CON CONEXIÓN A TIERRA DE TRES NO ESTÁ DISPONIBLE, UTILICE UN MÉTODO APROBADO PARA

LA UNIDAD. EN CASO DE MAL FUNCIONAMIENTO O AVERÍA, CONEXIÓN A TIERRA PROPORCIONA UNA VÍA DE

MENOR RESISTENCIA PARA LA CORRIENTE ELÉCTRICA PARA REDUCIR EL RIESGO DE DESCARGA

ELÉCTRICA. ESTE APARATO ESTÁ EQUIPADO CON UN CABLE QUE TIENE UN TIERRA DEL EQUIPO DE

F

ENCHUFE. EL ENCHUFE DEBE CONECTARSE A UN TOMACORRIENTE ADECUADO QUE ESTÁ INSTALADO Y

CONECTADO A TIERRA DE ACUERDO CON TODOS LOS CÓDIGOS LOCALES Y ORDENANZAS.

ESTE APARATO ES PARA USO EN UN NOMINAL DE 120V (O 230V, SEGÚN EL CASO) DE CIRCUITO, Y

TIENE UN ENCHUFE DE CONEXIÓN A TIERRA QUE SE PARECE AL ENCHUFE ILUSTRADO A CONTINUACIÓN.

EXIGENCES DE MISE À LA TERRE CET APPAREIL DOIT ÊTRE MIS À LA TERRE DE LA MANIÈRE

APPROPRIÉE AFIN D’ÉVITER DES CHOCS ÉLECTRIQUES MORTELS OU DES BLESSURES GRAVES À

L’OPÉRATEUR. LE CORDON D’ALIMENTATION EST FOURNI AVEC UNE FICHE À TROIS BROCHES POUR LA

MISE À LA TERRE. UTILISER UNE AUTRE MÉTHODE APPROUVÉE POUR METTRE L’APPAREIL À LA TERRE

LORSQU’UNE PRISE DE COURANT DE MISE À LA TERRE (TROIS TROUS) N’EST PAS DISPONIBLE. ADVENANT

UNE DÉFAILLANCE OU UN BRIS, LA MISE À LA TERRE FOURNIT UN TRAJET DE MOINDRE RÉSISTANCE POUR

LE COURANT ÉLECTRIQUE AFIN DE RÉDUIRE LE RISQUE DE CHOC ÉLECTRIQUE. CET APPAREIL EST ÉQUIPÉ

D’UN CORDON AYANT UNE FICHE DE MISE À LA TERRE. LA FICHE DOIT ÊTRE BRANCHÉE SUR UNE PRISE

APPROPRIÉE CORRECTEMENT INSTALLÉE ET MISE À LA TERRE CONFORMÉMENT AUX CODES AUX

RÈGLEMENTS LOCAUX.

CET APPAREIL DOIT ÊTRE UTI LISÉ SUR UN C IRCUIT DE 120 V (O U 230V EST D”APPLICATION) NOMINAL ET

COMPORTE UNE FICHE QUI RESSEMBLE À LA FICHE ILLUSTRÉE CI-DESSOUS.

GROUNDING

PIN

BROCHE DE MISE

A LA TERRE

METAL SCREW

COVER OF GROUNDED

OUTLET BOX

VIS METALLIQUE

COUVERCLE DU COFFRET

DE PRISE DE

COURANT MIS

A LA TERRE

5

Page 6

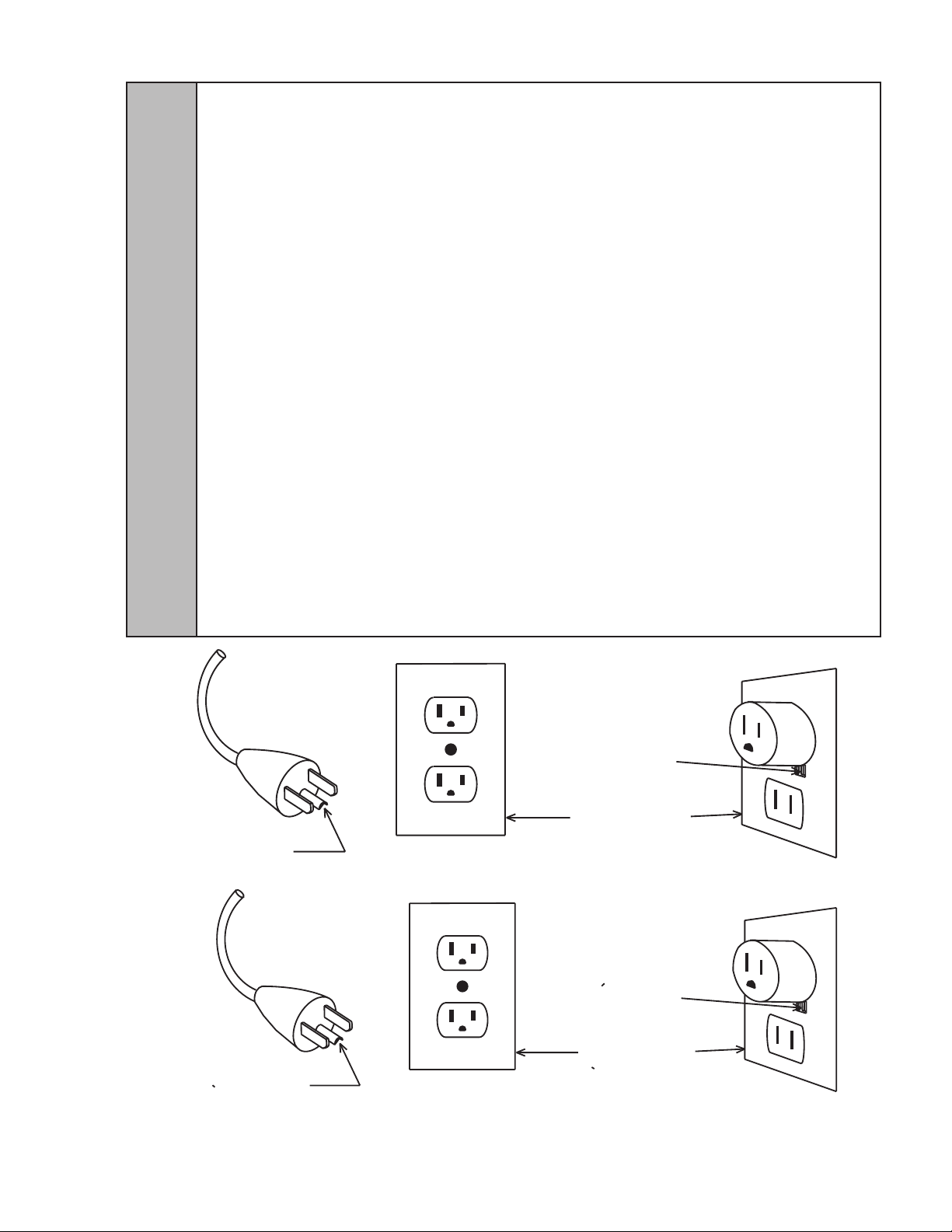

GROUNDING WARNING IMPROPER CONNECTION OF THE EQUIPMENT-GROUNDING CONDUCTOR CAN RE-

SULT IN A RISK OF ELECTRIC SHOCK. THE CONDUCTOR WITH INSULATION HAVING AN OUTER SURFACE THAT

IS GREEN, WITH OR WITHOUT YELLOW STRIPS, IS THE EQUIPMENT-GROUNDING CONDUCTOR. IF REPAIR OR

REPLACEMENT OF THE CORD OR PLUG IS NECESSARY, DO NOT CONNECT THE EQUIPMENT GROUNDING

CONDUCTOR TO A LIVE TERMINAL. CHECK WITH A QUALIFIED ELECTRICIAN OR SERVICEMAN IF THE GROUNDING INSTRUCTIONS ARE NOT COMPLETELY UNDERSTOOD, OR IF IN DOUBT WHETHER THE APPLIANCE IS

PROPERLY GROUNDED. DO NOT MODIFY THE PLUG PROVIDED WITH THE APPLIANCE. IF IT WILL NOT FIT THE

OUTLET, HAVE A PROPER OUTLET INSTALLED BY A QUALIFIED ELECTRICIAN.

ADVERTENCIA, PUESTA A TIERRA LA CONEXIÓN INCORRECTA DEL CONDUCTOR DE TIERRA DEL EQUIPO

PUEDE OCASIONAR UN RIESGO DE DESCARGA ELÉCTRICA. EL CONDUCTOR CON AISLAMIENTO QUE TIENE

UNA SUPERFICIE EXTERIOR VERDE, CON O SIN FRANJAS AMARILLAS, ES EL CONDUCTOR DE PUESTA A

TIERRA. SI LA REPARACIÓN O REEMPLAZAR EL CABLE O EL ENCHUFE ES NECESARIO, NO CONECTE EL

EQUIPO CONDUCTOR A TIERRA A UN TERMINAL CON CORRIENTE. CONSULTE A UN ELECTRICISTA CALIFICADO

O TÉCNICO DE SERVICIO SI LAS INSTRUCCIONES DE CONEXIÓN A TIERRA NO SE ENTIENDEN

F

COMPLETAMENTE, O SI EN DUDAN DE SI EL APARATO ESTÁ CORRECTAMENTE CONECTADO A TIERRA. NO

MODIFIQUE EL ENCHUFE QUE SE PROPORCIONA CON EL APARATO. SI NO ENTRA EN LA TOMA, PIDA A UN

ELECTRICISTA QUE INSTALE UNA ELECTRICISTA CALIFICADO.

EXIGENCES DE MISE À LA TERRE UN BRANCHEMENT INAPPROPRIÉ DU CONDUCTEUR DE MISE À LA

TERRE PEUT CAUSER UN RISQUE DE CHOC ÉLECTRIQUE. LE CONDUCTEUR DE MISE À LA TERRE EST CELUI

DONT L’ISOLANT A UNE SURFACE EXTÉRIEURE VERTE (AVEC OU SANS BARRES JAUNES). S’IL EST

NÉCESSAIRE DE RÉPARER OU DE REMPLACER LE CORDON OU LA FICHE, NE PAS BRANCHER LE

CONDUCTEUR DE MISE À LA TERRE SUR UN TERMINAL SOUS TENSION. FAIRE APPEL À UN ÉLECTRICIEN OU

UN RÉPARATEURQUALIFIÉ SI LES INSTRUCTIONS DE MISE À LA TERRE NE SONT PAS COMPLÈTEMENT

COMPRISES OU SI L’APPAREIL NE SEMBLE PAS ÊTRE MIS À LA TERRE DE LA MANIÈRE APPROPRIÉE. NE

JAMAIS MODIFIER LA FICHE FOURNIE AVEC L’APPAREIL. SI ELLE NE S’INSÈRE PAS DANS LA PRISE,

DEMANDER À UN ÉLECTRICIEN QUALIFIÉ D’INSTALLER UNE PRISE APPROPRIÉE.

A. Check the serial number plate for correct electrical requirements of the unit. Do not plug into the

electrical outlet unless the current shown in the serial number plate agrees with local current

available.

B. A separate electrical circuit must be supplied for each carbonator.

C. Do not use extension cords or “gang” together with other electrical devices on the same outlet.

3. OPERATING INSTRUCTIONS

A. Before installing, make any desired conguration changes. Refer to conguration section.

B. Connect 3/8” exible pressure tubing, or larger, from water supply to pump inlet. Do not connect

to a hot water or soft water source. A shutoff valve and screen (minimum 100 mesh), should be

installed in water supply line to carbonator. A water lter may also be necessary in water supply

line to carbonator, depending on local conditions. Water pressure entering the pump should be at

a minimum of 25 PSIG (0.172 MPA); recommended water pressure is 50 PSIG (0.345 MPA), and

should never exceed CO2 pressure. If necessary, install a regulator.

C. Connect CO2 pressure supply to CO2 inlet on carbonator tank, with normal operating pressure at

105 PSIG (0.720 MPA). Do not exceed 120 PSIG (0.830 MPA). If excessive foam in drink is

present, reduce CO2 pressure to approximately 90 PSIG (0.620 MPA).

D. Connect carbonator water outlet to dispensing system. If only one tank outlet is used, cap remain-

ing with stainless steel cap and are washer, PNs 01-0212 and 05-0017. To avoid contamination of

potable liquids, do not connect copper tubing or tting between the discharge tting of carbonator

tank and dispenser.

E. Open pressure relief valve by moving yellow lever to vertical position.

F. To remove air, turn water supply on and ll tank until water can be seen coming out of pressure

relief valve.

G. Close pressure relief valve by moving yellow lever to horizontal position.

H. Turn on CO2 supply and adjust to correct pressure.

I. If electrical requirements have been met, plug in carbonator.

J. Check for CO2 and water leaks.

K. Open a dispensing valve. Allow carbonator to cycle several times, turning motor OFF and ON to

ush system.

6

Page 7

4. USER MAINTENANCE INSTRUCTIONS

4.1 INSPECTIONS

A. Periodically inspect for CO2 or water leaks. Perform maintenance as necessary.

B. Inspect and clean pump strainer.

5. CLEANING AND REPLACEMENT

5.1 CO2 CHECK VALVE

A. Unplug power cord.

B. Shut water supply OFF to pump.

C. Turn CO2 supply OFF and set CO2 pressure regulator at 0 PSIG.

D. Disconnect CO2 supply line from CO2 check valve.

WARNING DO NOT PROBE VALVE WITH ANY OBJECT.

ADVERTENCIA NO HAGA PRUEBAS VÁLVULA CON UN OBJETO.

!

E. Cover end of check valve with soap suds. If check valve is defective, gas bubbles will appear. If

F. Release pressure in tank, using relief valve.

G. Disassemble check valve body and components. Inspect spring and o-rings. Re place as

required.

H. Reassemble and reinstall check valve.

I. Reconnect CO2 supply line to CO2 check valve.

J. Follow start up procedure to put carbonator back into operation.

5.2 BACKFLOW PREVENTER

!

A. Unplug power cord.

B. Shut water supply OFF to pump.

C. Set CO2 pressure at 100 to 125 PSIG (0.690 to 0.860 MPA).

D. Disconnect stainless steel water line from water inlet check valve. Do not loosen check valve

E. Cover end of check valve with soap suds. If check valve is defective, gas bubbles will appear.

F. Turn CO2 pressure OFF. Release pressure in tank, using relief valve.

G. Replace the backow preventer.

H. Reconnect stainless steel line to water inlet check valve.

I. Follow start up procedure to put carbonator back into operation.

5.3 PUMP STRAINER SCREEN

A. Unplug power cord.

B. Shut water supply OFF to pump.

C. Unscrew brass plug on pump, and remove strainer from pump.

D. Inspect and clean, or replace, strainer screen.

E. Reinstall strainer, and tighten brass plug.

F. Turn water supply ON.

G. Check for leaks. If a leak is detected, carefully tighten brass plug.

H. Plug power cord into electrical outlet.

AVERTISSEMENT NE JAMAIS SONDER LE CLAPET AVEC UN OBJET QUELCONQUE.

a leak is detected, continue with the following steps.

WARNING IF THE FIRST CHECK ON THE BACKFLOW PREVENTER FAILS, CARBONATED WATER WILL LEAK

FROM THE VENT ON THE VALVE. DO NOT DISASSEMBLE THE BACKFLOW PREVENTER. REPLACE BY

ORDERING PART NUMBER 17-0611. DO NOT DISABLE THE BACKFLOW PREVENTER.

ADVERTENCIA SI LA PRIMERA COMPROBACIÓN DE LA VÁLVULA ANTIRRETORNO FALLA, AGUA CON GAS SE

ESCAPARÁ DE LA REJILLA DE VENTILACIÓN DE LA VÁLVULA. NO DESARME LA VÁLVULA ANTIRRETORNO.

REEMPLAZAR POR PEDIR EL NÚMERO DE PIEZA 17-0611. NO DESACTIVE LA VÁLVULA ANTIRRETORNO.

AVERTISSEMENT SI LE PREMIER CONTRÔLE DU DISCONNECTEUR HYDRAULIQUE ÉCHOUE, DE L’EAU

CARBONÉE FUIRA PAR L’ÉVENT DU CLAPET. NE JAMAIS DÉSASSEMBLER LE DISCONNECTEUR HYDRAULIQUE.

COMMANDER UN NOUVEAU DISCONNECTEUR HYDRAULIQUE, Nº DE PIÈCE 17-0611. NE JAMAIS METTRE LE

DISCONNECTEUR HYDRAULIQUE HORS FONCTION.

assembly.

If a leak is detected, continue with the following steps. If no leak is detected, proceed to Step I

below.

7

Page 8

5.4 REPLACING PROBE

A. Unplug power cord.

B. Shut water and CO2 gas supplies OFF.

C. Relieve pressure in tank using relief valve.

D. Remove cover and unplug probe leads from PC board.

E. Unscrew probe from top of tank.

F. Screw new probe into top of tank. Be sure to install white plastic washer as a water tight seal

will not be obtained without the washer.

G. Connect probe leads to PC board as follows:

Green G

Black LO

White HI

H. Slide probe strain relief into slot and replace cover.

I. Follow start-up procedure for putting carbonator back into operation.

5.5 REPLACING PC BOARD

A. Unplug power cord.

B. Remove cover from PC board enclosure.

C. Unplug probe, power cord and motor cord leads from PC board.

D. Remove PC board assembly.

E. Congure new board, refer to conguration section.

F. Install new PC board and secure with screws.

G. Connect push leads and secure to PC board as follows:

Probe Power Cord Motor Cord

Green G Black 1 Black 3

Black LO White 2 White 4

White HI

H. Replace cover.

I. Plug in power cord.

J. Test diagnostic switch connector.

8

Page 9

6. CONFIGURATION

The new carbonator PCB assemblies 64-5076 (230V) and 64-5081 (115V) have two conguration

switches, located between the Power and Timeout LEDs:

On Off

These switches can be switched with a small screwdriver or a ballpoint pen. Toward the edge of the board

is ON, toward the center is OFF.

Pos 1 — Enable

Diagnostic/Reset Switch

Pos 2 — Enable

Timeout Auto-Retry

ON OFF

Switch must be connected to J9

Pressing and holding the switch

connected to J9 will test the motor.

Releasing the switch will reset any

timeout.

If the tank fails to ll within 3

minutes, the carbonator times

out and will attempt to ll itself

every 15 minutes for 3 hours. If it

succeeds, normal operation will

resume. The timeout LED will blink

slowly within the 3 hours, then

quickly after.

J9 may be empty (no jumpers

required). Any connected switch is

ignored.

If the tank fails to ll within 3

minutes, the carbonator times out

and never retries. The

timeout LED will turn on

continuously when the carbonator

times out.

9

Page 10

7. TROUBLESHOOTING

PC Board Self-Diagnostics

Follow instruction label on enclosure cover to help determine if probe, motor or board is faulty.

TROUBLE CAUSE REMEDY

7.1 Motor does not start. (Motor hums.) A. Pump binding.

A. Rotate pump slightly to free binding. If

this fails, replace pump.

B. Open winding ineld

7.2 Motor does not start. (Motor does not

hum.)

7.3 Motor runs continuously. A. Restriction in inlet water check valve.

A. Overload by pump binding.

B. Fuse or circuit breaker.

C. Faulty motor.

D. Faulty PC board.

E. Faulty probe.

F. Timeout feature has activated. This

happens when the carbonator runs longer

than three minutes without the demand

for water being met.

B. Restriction in pump.

C. Faulty board or probe.

B. Replace motor.

A. Let motor cool and free pump binding.

B. Replace fuse or reset circuit breaker.

C. Replace motor.

D. Replace PC board.

E. Replace probe.

F. Reset power to the carbonator or press

and release reset switch.

A. Disassemble inlet water check valve

and clean.

B. Clean strainer or replace pump.

C. Replace board or probe.

7.4 Pressure relief valve releases water. A. Faulty relief valve. A. Replace relief valve.

7.5 Low Carbonation. A. Low CO2 pressure.

B. Leaking CO2 supply line.

7.6 Foamy product. A. Over carbonation. A. Reduce CO2 pressure.

A. Increase CO2 pressure or replace

CO2 tank.

B. Locate leak and repair.

10

Page 11

Basic Go/No Go Carbonator Control Test

Part Number 06-1236/01 (shown below) is found on the cover of the carbonator assembly. It provides a

basic troubleshooting procedure to determine if the liquid level control is operating properly. The

procedure will help isolate problems to the probe, motor or PC Board.

8. ILUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS

8.1 CHECK VALVE ASSEMBLY

1

2 3

Item Part No. Description

1 17-0342 CO2 Check Valve Assy

2 01-0669 Body

3 02-0005 O-Ring

4 01-0689 Sleeve

8.2 WIRING DIAGRAM (PN 06-0266/02)

4

5

6

Item Part No. Description

5 01-0674 Ball

6 03-0021 Spring

7 02-0003 O-Ring

GREEN

BLACK

WHITE

J4

J3

L2

7

PROBE

LOW VOLTAGE

WHITE

BLACK

GREEN

HI LO

PC BOARD

G

11

L1

MOTOR

115 VAC

115 V or 220 V

WHITE

BLACK

GREEN

Page 12

8.3 CARBONATOR TANK

2

1

3

13

16

14

11

12

15

11

17

18

33

19

4

6

34

5

7

9

10

9

8

2

32

31

30

29

28

27

26

25

24

21

9

22

23

20

18

Item Part No. Description

1 05-0528-01 Cover, Carb LLC

2 04-0470 Screw, 6-19X0.500, PHD

3 12-0241 Boot, U-1403-APEM

4 06-1289 Label, Test Switch, Carb

06-3400 Label, Test/Reset Switch

5 06-1236/01 Label, Troubleshoot

7 04-0836/01 Washer, Lock, Internal Tooth

8 04-0049 Nut, Hex, 8-32, SS

9 04-0297 Nut, Hex, 8-32, KEPS, SS

10 06-0266/02 Label, Wiring Diagram

11 05-0017 Washer, Seal, Flare, Nylon, 3/8

12 87-0026 Tank Assy, Carb, 3/8, Flare

13 48-2386 Tubing Assy, Water, 3/8

14 17-0611 Check Valve, Vented, BR,

ABCO

17-0611-01 Check Valve, SS

15 01-0111 Adapter, BR, 3/8 x 3/8

16 86-0085 Pump Assy, Water,

Replaceable

17 07-0017/01 Clamp with Screw, ZP

18 04-0032/01 Nut, Nylock, 1/4-20, SS

19 06-0075-01 Nameplate, Vinyl, PN/SN/ ELEC

20 07-0199/01 Plate, Base Probe, Carb

Item Part No. Description

21 04-1361 Screw, 8-32 x 0.75, PH, SS

22 04-0247 Isolator, 1/4-20 Single Stud

23 52-0588 Power Cord Assy

52-1898 Cord Assy, Carb, 220V

24 04-0033/01 Washer, Flat, 4 x 0.065 x

0.281 ID

25 04-0520/01 Screw, 1/4-20 x 0.500, HHD, SS

26 91-0008 Motor, Carb, 1/3HP, 115V/60A

91-0011/01 Motor, Carb, 1/3HP, 220V/50Hz

27 52-0585 Cord Assy, Motor

28 13-0028 Relief, Strain, 7/8 DIA

29 13-0008 Bushing Relief, HEYCO, 1200

30 13-0026 Strain Relief, Small

31 05-0529-01 Enclosure, Carb, Control, Self

32 64-5000 PCB Assy

64-2962 PCB Assy, 220V

64-2962-01 PCB Assy, 220V w/Reset

64-5076 PCB Assy, 220V w/Auto reset

64-5081 PCB Assy, w/Auto reset

33 54-0066 Relief Valve Assy, Plastic

34 06-2590 Label, “Reset Button”

35 52-0590/01 Probe Assy

12

Page 13

NOTES

9. APPLIANCE DISPOSAL

To prevent possible harm to the environment from improper disposal, recycle the unit

by locating an authorized recycler or contact the retailer where the product was pur

chased. Comply with local regulations regarding disposal of the refrigerant and

insulation.

13

Page 14

Lancer Corp.

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Loading...

Loading...