Lancer 85-1751 Service Manual

INSTALLATION AND SERVICE MANUAL

FOR

TWO LITER PREMIX

PUSH CART

(Part Number 85-1751)

This manual is an initial release

"Lancer" is the registered trademark of Lancer • Copyright — 1997 by Lancer, all rights reserved.

FAX ENGINEERING: • 210-310-7096

DATE: 01/27/97

P.N. 28–0325

6655 LANCER BLVD. • SAN ANTONIO, TEXAS 78219 USA • (210) 310-7000

FAX SALES

• NORTH AMERICA – 210-310-7245 • INTERNATIONAL SALES – 210-310-7242 • CUSTOMER SERVICE – 210-310-7242 •

• LATIN AMERICA – 210-524-9567 / 210-310-7245 • EUROPE – 32-2-755-2399 • PACIFIC – 61-8-8268-1978 •

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

TABLE OF CONTENTS

TABLE OF CONTENTS ......................................................................................................................................i

SPECIFICATIONS ...............................................................................................................................................i

1. PACKAGING AND INSPECTION................................................................................................................1

1.1 RECEIVING AND UNPACKING.........................................................................................................1

1.2 COMPONENTS..................................................................................................................................1

2. ASSEMBLY..................................................................................................................................................1

2.1 ASSEMBLY INSTRUCTIONS ............................................................................................................1

2.2 CO2REGULATOR ASSEMBLY .........................................................................................................3

2.3 CUTTING THE BOTTLE TUBES .......................................................................................................3

3. OPERATION ................................................................................................................................................4

3.1 CUP DISPENSER ..............................................................................................................................4

3.2 DISPENSING VALVE .........................................................................................................................4

3.3 CO2PRESSURE ASSEMBLY............................................................................................................4

3.4 CO2PRODUCT BOTTLES AND CO2CYLINDER EXCHANGE .......................................................4

3.5 CO2CYLINDER REFILL PROCEDURE............................................................................................5

3.6 UNLOADING 2 LITER PET BOTTLES FROM PUSH CART ICE CUBE COOLER..........................5

4. MAINTENANCE...........................................................................................................................................7

4.1 CUP DISPENSER ..............................................................................................................................7

4.2 CLEANING AND SANITIZING ...........................................................................................................7

4.3 REPLACEMENT OF BEVERAGE HOSE INSIDE DISPENSING VALVE ASSEMBLY......................7

4.4 CO2CYLINDER .................................................................................................................................7

4.5 CO2REGULATOR ASSEMBLY .........................................................................................................8

5. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS..........................................................10

5.1 COOLER AND HARDWARE .......................................................................................................10-11

5.2 CO2CYLINDER ASSEMBLY ...........................................................................................................11

5.3 REGULATOR ASSEMBLY ...............................................................................................................12

5.4 CONNECTOR VALVE ASSEMBLY ..................................................................................................12

5.5 DISPENSING VALVE ASSEMBLY ...................................................................................................13

5.6 CUP DISPENSER ASSEMBLY........................................................................................................13

5.7 REFILL ADAPTER ASSEMBLY .......................................................................................................14

5.8 PRESSURE GAUGE TESTING ASSEMBLY...................................................................................14

SPECIFICA

TIONS

CARBON DIOXIDE (CO2) REQUIREMENTS

Pressure Regulator Setting 22 PSI (Preset)

Relief Valve Setting 30 PSI (Preset)

CO

2

Cylinder Capacity 10 ounces of liquid CO2(Sufficient for 5 complete

discharges of each dispensing system)

CO

2

Cylinder Refill Use 50 pound CO2Bottle with a dip tube

DRINK CAPACITY

The system consists of two (2) independent banks of five (5) two (2) liter bottles. Each bank is capable of

providing 34 - 12 ounce cups or 24 - 16 ounce cups per one complete discharge using no ice in cup.

i

1. PACKAGING AND INSPECTION

1.1 RECEIVING AND UNPACKING

Open shipping case and carefully remove beverage dispenser components. Each unit has been

thoroughly inspected and tested prior to shipment. Inspect all items for damage. In the event of

shortage or damage, notify the delivering carrier (as well as Lancer) immediately. Merchandise

should be inspected for concealed damage no later than 15 days after receipt.

1.2 COMPONENTS

A. Installation and Service Manual

B. CO2 Cylinders

C. Dispensing Valve Assemblies - two (2)

D. CO2 Regulator Assemblies - two (2)

E. Eight (8) Bottle Connector/Valve

Assemblies

F. Cup Dispenser

G. Graphics Panel (Optional)

H. Refill Adapter (Optional)

I. Pressure Gauge Assembly (Optional)

2. ASSEMBLY

2.1 ASSEMBLY INSTRUCTIONS

A. Unpack the push cart and check the

items received against the parts list.

B. Assemble the push cart per the

Instruction Sheet included with cart.

NOTE

The riser is supplied mounted to the

Push Cart.

C. Install the cup rest bracket on the push

cart riser.

NOTE

The cup rest bracket sits on the riser,

with the angle flange of the bracket

inside the riser, the cube resting on the

bracket to hold it down.

D. Unpack the cup dispenser, and install

the two mounting brackets on the push

cart handle. The smaller tapered end of

the bracket should be facing down.

E. Unpack the cube, being careful to not

damage the dispensing valves while

unpacking. Place the cube on the riser,

and on the angle flange of the cup dis-

penser.

F. Place the drip tray in the cup rest

bracket. Place the wire cup rest in the

drip tray.

G. Place the cup dispenser on the two

mounting brackets. The black end of

the cup dispenser is up (i.e., the cups

are displaced up). Place cups in the cup

dispenser.

Fully Assembled Push Cart

Side View

Figure 1

1

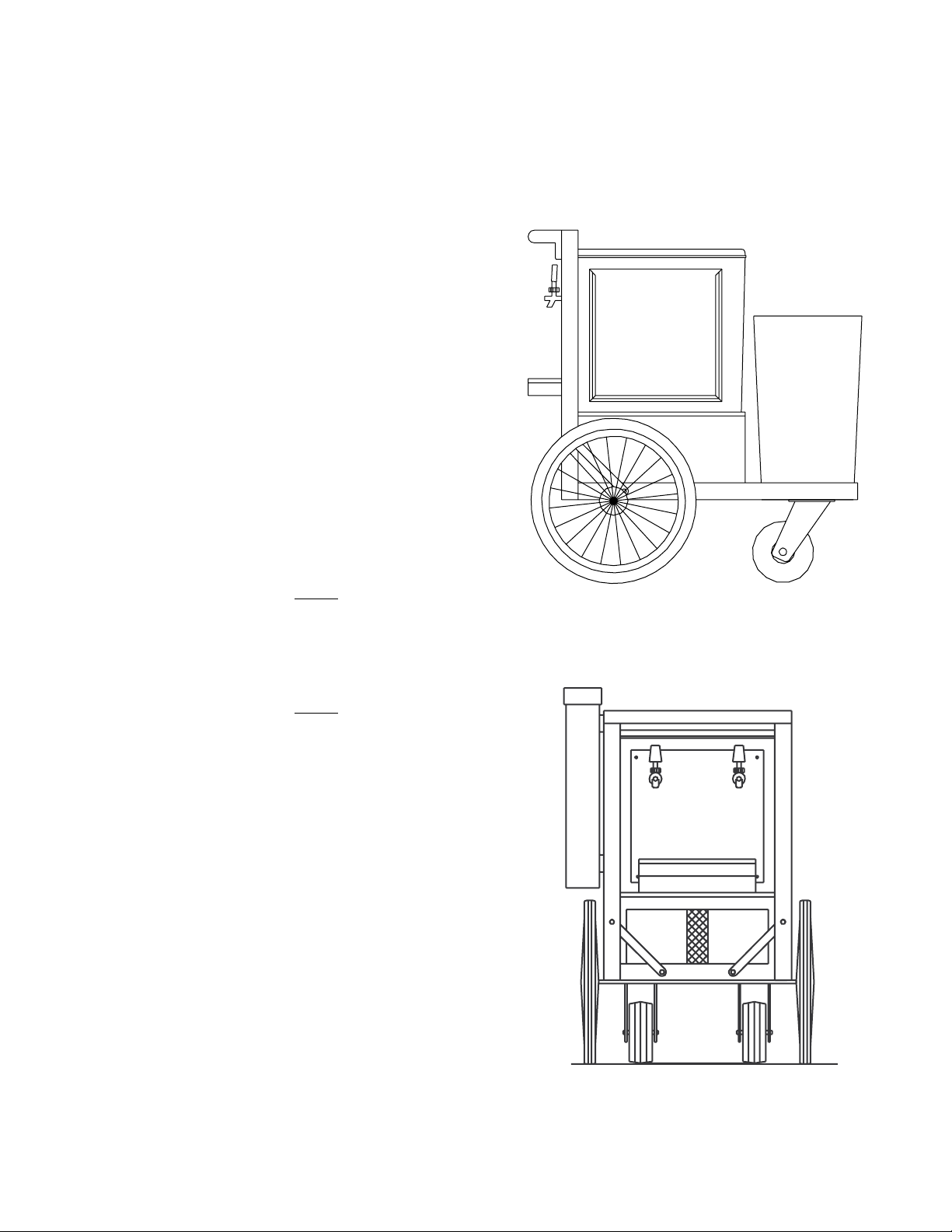

Fully Assembled Push Cart

Backside View

Figure 2

H. Place the trash bin on the front of the

cart as shown.

I. Install the (optional) umbrella in the

mounting bracket.

J. Remove the caps of eight (8) 2 liter

beverage products. Screw on the

eight connector valve bottle fitting

assemblies.

CAUTION

DO NOT OVER TIGHTEN THE FITTINGS.

OVER TIGHTENING CAN CAUSE

LEAKS! PLACE THESE BOTTLES IN

THE SPRING FRAME AS SHOWN.

K. Remove the caps of two (2) 2 liter

products. Screw the bottle onto the

connector valve bottle fittings inside

Quick Disconnect Cylinder Coupling

2

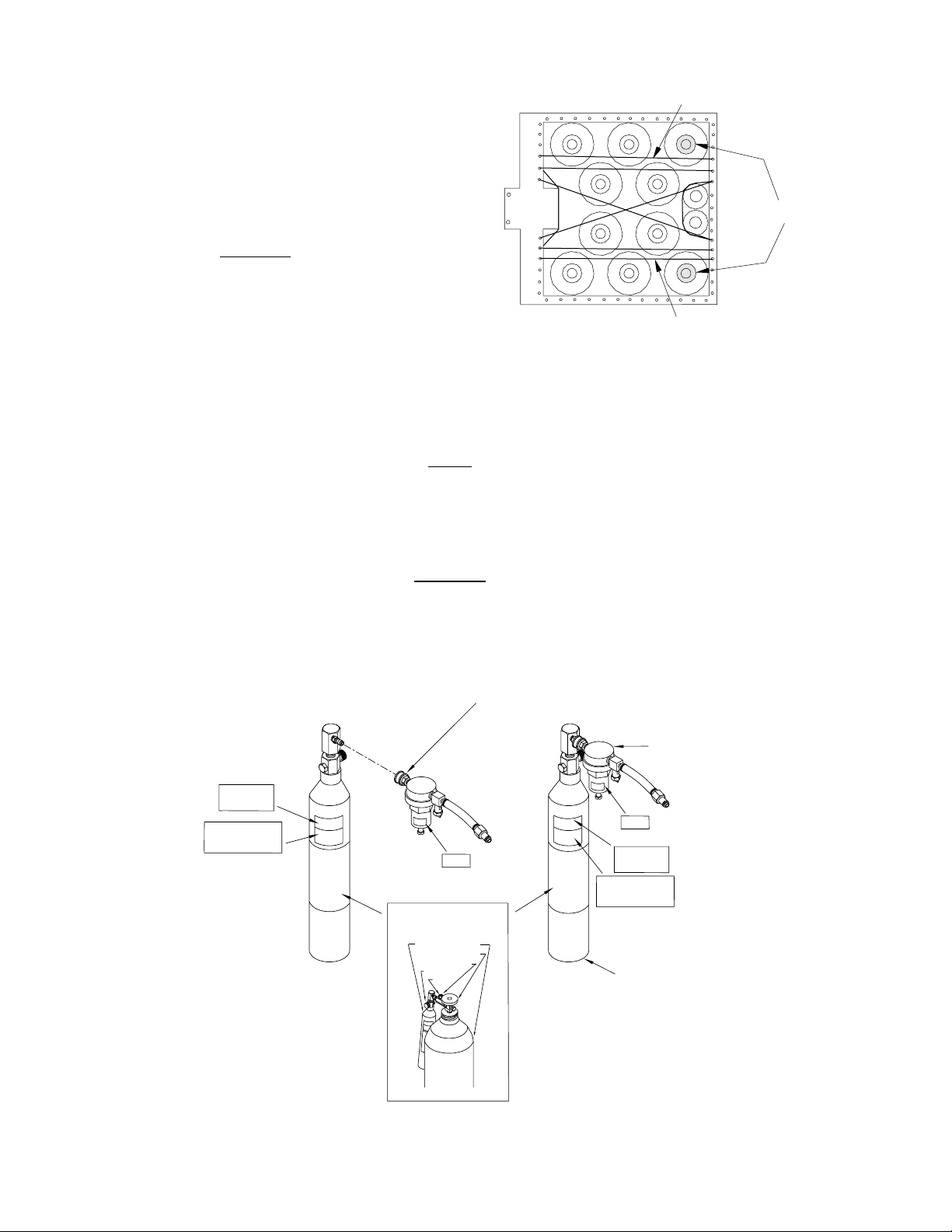

Bottle Hold Down Springs and

Bottle Placement

Figure 3

the cube that are connected to the dispensing valves. Place these two bottles in the spring

frame farthest away from the valves (see Figure 3).

NOTE

Place the four (4) corner bottles in first. Then put the bottles in between them. Then put the

four (4) center bottles in.

L. Reverse this order to remove the bottles.

M. Charge the two CO

2 cylinders following the instructions on the cylinders.

CAUTION

BE SURE TO WEIGH THE CYLINDERS AFTER CHARGING. THE FILLED WEIGHT MUST NOT

EXCEED 1.0 KG, OR 2 LB., 3 OZ. FAILURE TO KEEP THE WEIGHT BELOW THIS AMOUNT

COULD RESULT IN OVERPRESSURE OF THE CYLINDER, AND CAUSE THE SAFETY RELIEF

VALVE TO OPEN.

SPRINGS

ATTACH VALVES TO

THESE LOCATIONS

SPRINGS

WARNING

CONTENTS UNDER

PRESSURE

HANDLE WITH CARE

NOTE:

MAXIMUM CYLINDER WEIGHT

FULL, SHOULD NOT EXCEED

2 LB. 3 OZ.(1.0 KG.)

LANCER PN 06-1213

QUICK DISCONNECT CYLINDER COUPLING

I

S

T

P

O

2

2

T

P

E

R

S

E

RESET

TO 22 PSI

CO FILLING INSTRUCTIONS

2

NOTE:

CO BOTTLE MUST HAVE A DIP TUBE,

2

OR IT MUST BE INVERTED, TO INSURE

FILLING THE SMALL CO CYLINDER

WITH LIQUID.

TO FILL:

CO CYLINDER

SPEC

2

CO BOTTLE VALVE

CO CYLINDER VALVE

2

FILL

ADAPTER

WARNING

CONTENTS UNDER

PRESSURE

HANDLE WITH

CARE

NOTE:

MAXIMUM CYLINDER

FULL SHOULD NOT

2 LB. 3 OZ.

(1.0 KG.)

TO FILL:

1) CLOSE THE

THE REFI

2) CONNECT

TO THE

3) OPEN

CO

4) OPEN

VALVE

WITH

THE

5) OPE

THE

CO

CLO

6) OP

BOT

GA

7) CLO

CO

2

8) CLO

CO

2

9) OP

THE

10) DIS

CYL

AD

11) WE

THE

BE 2

IF IT

THE

AND

CO BOTTLE

2

WITH DIP TUBE

CO BOTTLE

2

2

FILL ADAPTER

VENT VALVE

2

IN

OUT

I

T

S

O

P

2

2

T

P

E

R

E

S

RESET

TO 22 PSI

WARNING

CONTENTS UNDER

PRESSURE

HANDLE WITH CARE

NOTE:

MAXIMUM CYLINDER WEIGHT

FULL, SHOULD NOT EXCEED

2 LB. 3 OZ.(1.0 KG.)

LANCER PN 06-1213

CO CYLINDER

2

ASSEMBLY

REGULATOR

ASSEMBLY

3

Connector Valve Assembly

Figure 6

N. Place the two cylinders in the spring

frame as shown. Connect a regulator

assembly to each of the cylinder

assemblies, by pulling back on the

quick disconnect body on the regulator,

and pushing it on the stem on the

cylinder assembly.

O. Connect the regulator assembly and

the bottles in series as follows: Plug

the hose end of the regulator assembly

into the fitting on the bottle fitting

assembly, on the center bottle farthest

away from the CO

2

cylinder. Plug the

hose end from that bottle into the

corner bottle next to the dispensing

valves. Plug the hose end from that

bottle into the center bottle along the

side. Plug the hose end from that

bottle into the center bottle next to the

CO

2 cylinder. Plug the hose end from

that bottle into the bottle with the hose

that connects to the valves. Make sure

the dispensing valves are closed.

P. Open the CO2

cylinder valve. Check

for leaks.

Q. Make sure the drain plug is in the drain

hole in the bottom of the cube. Cover

with ice as required.

NOTE

Do not allow water to rise above the

spring frame.

2.2 CO

2

REGULATOR ASSEMBLY

A. Attach CO

2 Regulator Assembly to CO2

Cylinder, utilizing Quick Disconnect

Cylinder Coupling (see Figure 4).

B. Pull back Socket Sleeve to connect or

disconnect coupling.

NOTE

Do not attempt to disconnect cylinder

coupling while under pressure.

Coupling will not disconnect.

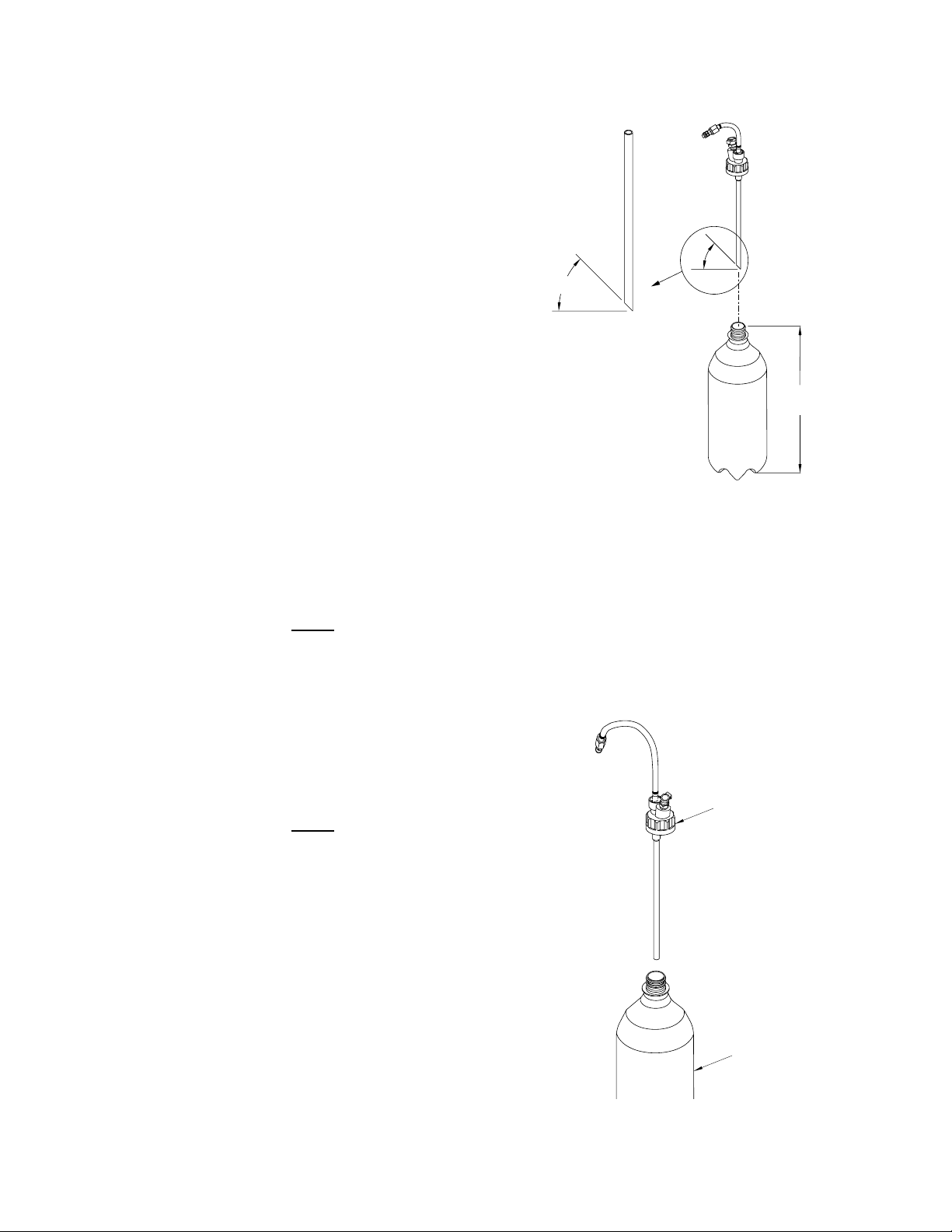

2.3 CUTTING THE BOTTLE TUBES

Cutting the bottle tubes to the correct

length is an important step. Bottle tubes

are supplied as loose items, to be cut by

the user to the correct length for the height

of the bottles being used. Use the following

procedure when cutting the bottle tubes

(see Figure 5):

A. Measure from the very bottom of an

empty bottle, to the top of the bottle.

Cutting the Bottle Tube

Figure 5

o

45

MEASUREMENT

DISTANCE

CONNECTOR VALVE

ASSEMBLY

PREMIX BOTTLE

(CUSTOMER SUPPLIED)

Loading...

Loading...