Page 1

DATE: 07/25/02

P.N. 28–0524

This manual is an initial issue.

INSTALLATION AND SERVICE MANUAL

FOR

VRTX

™

WATER TREATMENT SYSTEM

Part Number 85-1448-20A (20 GPM)

SPECIFICATIONS

ELECTRICAL:

230/460 VAC, 20A/10A (FACTORY WIRED 460)

NOTE:

230V REQUIRES CHANGING MOTOR OVERLOAD,

24 VOLT CONTROL TRANSFORMER JUMPER, AND

MOTOR ELECTRICAL CONNECTIONS

CONDUIT CONNECTION:

3/4”, LOCATED AT BOTTOM CORNER

WATER CONNECTION (SEE NOTES BELOW):

INLET: 1 1/4” NPT

OUTLET: 1 1/4” NPT

DIMENSIONS OVERALL:

WIDTH: 18 INCHES (45.72 CM)

DEPTH: 22 3/8 INCHES (56.83 CM)

HEIGHT: 29 1/2 INCHES (74.93 CM)

WEIGHT: 176.0 POUNDS (79.83 KG)

NOTES:

Inlet Pipe needs a minimum 15” straight pipe section to suction inlet, or a flow straightening (vane) device

must be installed. Inlet pipe must be 2” diameter or larger. Verify all valves on intake side are fully

opened.

VRTX™ Technologies

5807 Business Park

San Antonio, TX 78218

(210) 661-8800

ADVANCED FLUID TECHNOLOGY

For further Information:

e-mail: vrtx@vrtxtech.com

Or see our Web Site

www.vrtx-technologies.com

OUTLET

INLET

PRESSURE

VACUUM

RED

GREEN (POWER ON)

ON / OFF

SWITCH

POWER IN

Page 2

RECEIVING

CAUTION

INSPECT THE UNIT FOR DAMAGE! IF DAMAGE IS EVIDENT, NOTIFY THE FREIGHT

COMPANY IMMEDIATELY AND FILE A DAMAGE CLAIM REPORT.

Each unit is tested and inspected before shipment. At the time of shipment, the carrier accepts the

unit and any claim for damage must be made with the carrier. Upon receiving units from the

delivering carrier, carefully inspect the carton for visible indication of damage. If damage exists,

have the carrier note same on the bill of lading and file a claim with the carrier.

W

ARNING

THIS UNIT MUST BE PROPERLY ELECTRICALLY GROUNDED TO AVOID POSSIBLE FATAL

ELECTRICAL SHOCK OR SERIOUS INJURY TO THE OPERATOR.

CAUTION

BE SURE TO FOLLOW LOCAL ELECTRICAL CODES WHEN MAKING ALL CONNECTIONS.

CAUTION

BE SURE TO FOLLOW LOCAL PLUMBING CODES WHEN MAKING ALL CONNECTIONS.

TABLE OF CONTENTS

SPECIFICATIONS ...................................................................................................................................COVER

TABLE OF CONTENTS .....................................................................................................................................1

RECEIVING........................................................................................................................................................1

FIELD SERVICE TROUBLESHOOTING TIPS..................................................................................................2

VRTX PANEL INDICATOR LIGHTS - STATUS .................................................................................................2

ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS ..................................................................3

VRTX, 20GPM - ASSEMBLY, EXPLODED VIEW ....................................................................................3-4

VRTX, 20GPM - CONTROL PANEL ASSEMBLY ........................................................................................5

VRTX, 20GPM - VRTX ASSEMBLY.............................................................................................................6

VRTX, 20GPM - CONTROL BOX ASSEMBLY ............................................................................................7

VRTX, 20GPM - CONTROL BOX ASSEMBLY, DETAIL..............................................................................8

RIGHT SIDE VIEW.............................................................................................................................................9

FRONT VIEW .....................................................................................................................................................9

TOP VIEW ..........................................................................................................................................................9

VRTX ELECTRICAL DIAGRAM, LABEL, PN 06-2405/02 .............................................................................10

1

Page 3

2

FIELD SERVICE TROUBLESHOOTING TIPS

VRTX UNIT

1. Pressure gauge reads low.

• Clean strainer.

• If low on start-up, check pump rotation.

•• If running backwards, have electrician change two of the three electrical supply wires.

2. Vacuum gauge reads low.

• See pressure gauge.

• Make sure liquid filled pressure gauges are vented (see installation instructions).

• Check vacuum gauge line to make sure it is not plugged.

3. Gauges fluctuating.

• Check suction for leaks - starved for water.

• Check for pump cavitation (minimum submergence).

• Check for air bubbles at pump suction inlet.

NOTE: On older units, the vacuum gauge was not rated for any pressure. On units with 0-30 in Hg

(inches of mercury), disconnect

the vacuum gauge before

building up back pressure.

5. If there is still a problem, shut down the VRTX unit. Wait for two-three (2-3) minutes and re-start.

NOTE: If air leaks into the suction piping, the VRTX will not work (i.e., cavitate). The suction piping

must be air-tight.

VRTX PANEL INDICATOR LIGHTS - STATUS

GREEN OFF

RED OFF

GREEN ON INDICATES POWER “ON” TO VRTX AND VRTX OPERATING

RED OFF

GREEN OFF INDICATES POWER “ON” TO VRTX AND MOTOR THERMAL

RED ON OVERLOAD TRIPPED

Page 4

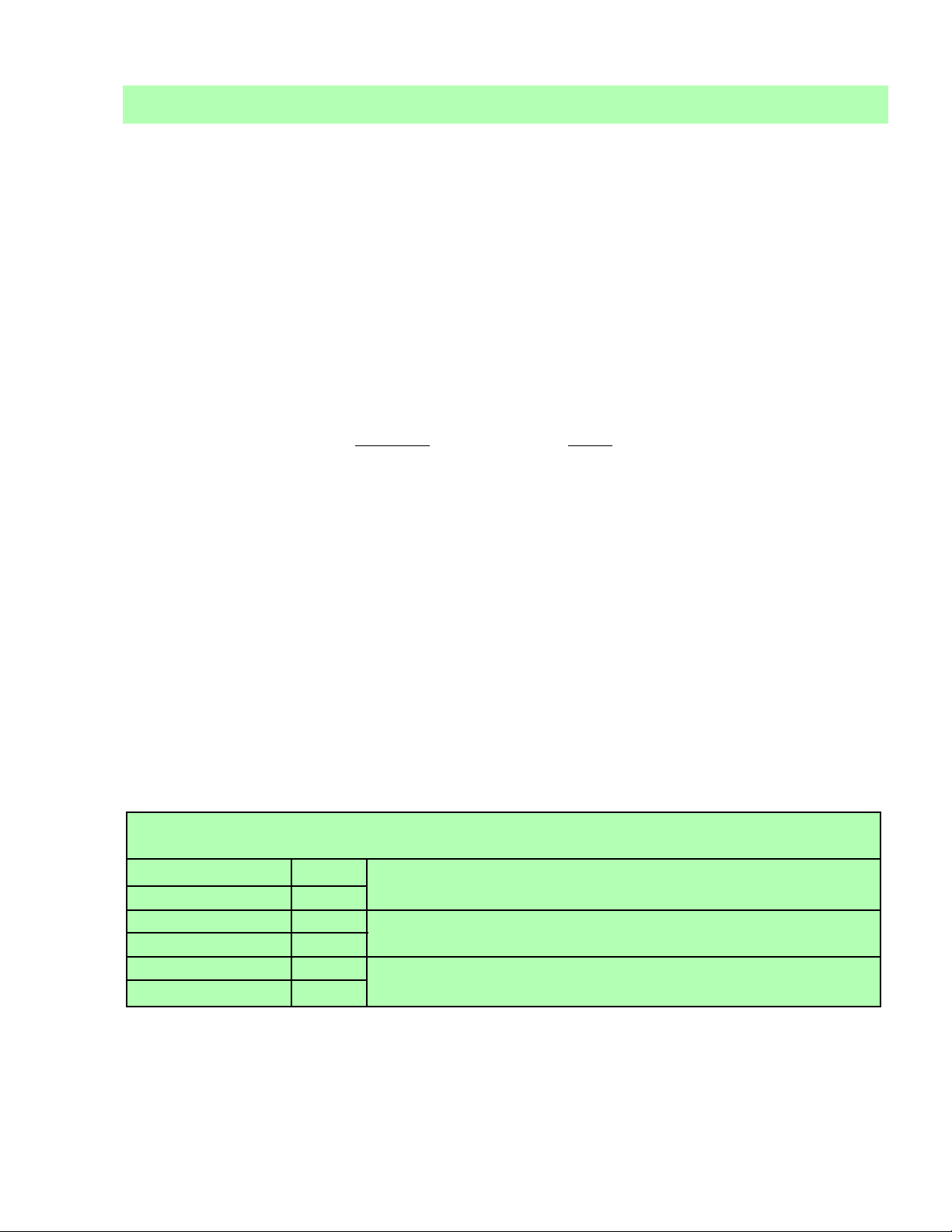

ILLUSTRATIONS, PARTS LISTINGS AND WIRING DIAGRAMS

VRTX, 20GPM - ASSEMBLY, EXPLODED VIEW

3

18

25

22

2

21

20

23

24

26

2

19

17

16

15

14

7

8

9

13

5

2

10

11

12

5

4

1

2

3

9

8

7

6

2

Page 5

ITEM PART NO. DESCRIPTION

1 30-7832 Cover, Top

2 04-1375 Screw, 8 - 32 x 3/8, Hex

Washer

3 82-2954 Control Panel Assy

4 51-5954 Panel Assy, Pump

5 07-0571 Plug Hole, 1 1/4”

6 30-7834 Cover, Floor, Right

7 04-1233 Screw, Hex Head, 1/4 - 20 x

7/8, SS

8 04-1170 Washer, Split, 1/4, SS

9 04-0279 Nut, Hex, 1/4 - 20, SS

10 04-0551 Screw, 5/16 - 18 x 0.750

11 04-1179 Washer, 5/16, Split, SS

12 04-0279 Nut, Hex, 5/16 - 18, Hex, SS

13 30-7835 Mount, Pump

14 01-1999 Fitting, 90 Degree Elbow,

Connector

15 30-7833 Cover, Floor, Left

16 86-0110 Pump, 20GPM, VRTX

™

17 30-7877 Plate, Base, Fluid End

18 30-7820 Panel, Back

19 01-2109 Fitting, Nipple, 1.250 x 3.00,

SS

20 30-7822 Panel, Right

21 04-1320 Screw, 1/4 - 20 x 0.625, SS

22 30-8490 Plate, Mounting, Chamber

23 01-1984 Fitting, Elbow, 1/8 NPT to 1/4

Tube

24 04-1319 Nut, lock, 1/4 - 20, SS, Nylock

25 08-0372 Tubing, Nylon, 1/4ODX-035W,

250 WP

26 51-5692 Weldment, Frame

VRTX, 20GPM - ASSEMBLY, EXPLODED VIEW (CONTINUED)

4

Page 6

VRTX, 20GPM - CONTROL PANEL ASSEMBLY

5

ITEM PART NO. DESCRIPTION

1 30-7819 Panel, Front

2 04-0901 Screw, 6 - 32 x 0.625, PH, SS

3 04-0124 Washer, Lock, INT, #6, SS

4 04-0370 Nut, Hex, 6 - 32, SS

5 16-0035 Gauge, Pressure

6 16-0046 Gauge, Vacuum

7 12-0459 Switch, Rotary, 3-Position

8 12-0460 Legend Plate

9 12-0326 Lens, Indicator, Red

10 12-0327 Lens, Indicator, Green

11 12-0452 Lamp, LED, Green

12 12-0355 Contact

13 12-0357 Socket, Pilot

14 12-0450 Lamp, LED, Red

15 52-2602-02 Lead, Black, Control

16 52-2602-01 Lead, White, Control

17 52-2430/02 Harness Assy

12

11

13

10

14

8

7

6

9

5

2

3

4

15

SW13

S9

SW23

BLK

L1 - X2 (GREEN)

16

L2 - X2 (RED)

WHT

1

17

S3

WHITE

BROWN

S5

YELLOW

S1

BLACK

S6

SW14

GREEN

S8

L2 - X1 (RED)

L1 - X1 (GREEN)

RED

SW24

Page 7

VRTX, 20GPM - VRTX™ASSEMBLY

6

ITEM PART NO. DESCRIPTION

1 03-0363 Clamp, Rigidlite, 7400, 2 1/2”

2 04-1273 Plug, 1/8 NPT, Parker,

#X218P-2

3 08-0372 Tubing, Nylon, 1/4ODX-035W,

250WP

4 51-5854 Weldment, End

5 03-0349 Clamp, Rigidlite, 7400, SS, 1”

6 01-2107 Fitting, Union Tee, 1/4 JG

7 51-5855 Weldment, Tree

8 01-2215 Elbow, Reducing, 3/8 x 1/4,

JG

9 48-2083 Tube Assy, Vacuum

10 10-0488 Nut, Vacuum Well, VRTX

™

11 02-0539 Seal, Compression, 3/8 Tube

12 02-0089 O-Ring, 2-012

13 01-1984 Fitting, Elbow, 1/8 NPT to 1/4

Tube

2

1

13

12

11

10

9

8

3

4

5

3

2

6

7

3

Page 8

VRTX, 20GPM - CONTROL BOX ASSEMBLY

ITEM PART NO. DESCRIPTION

1 51-5694 Weldment, Control Box,

VRTX

™

2 04-0279 Nut, Hex, 1/4 - 20, SS

3 04-1179 Washer, 5/16, Split, SS

4 06-2405 Label. Electrical Diagram

5 30-7875 Cover, Control Box

6 04-1375 Screw, 8 - 32 x 3/8, Hex

Washer

7 06-0986 Label, WARNING,

HIGH VOLTAGE

8 12-0424 Overload, Thermal, B2T-K,

4-6A

9 82-3110/01 Base Plate Assy, Control Box

10 06-2174 Nameplate, Water VRTX

™

,

Chesterton

11 01-2066 Fitting, Straight, 1/2 Conduit

12 04-1233 Screw, Hex Head, 1/4 - 20 x

7/8, SS

7

2

1

3

2

5

4

12

9

10

11

6

7

8

Page 9

CONTROL BOX ASSEMBLY, DETAIL

8

ITEM PART NO. DESCRIPTION

1 30-7853 Base Plate, Control Box

2 25-0080 Transformer, 220V/440-

24V, 50VA

3 04-0237 Screw, 8 - 32 x 0.250,

PH, MS, SS, PL

4 12-0352 Fuse (TRM-3-2/10), 250V

5 12-0425 Cover, Transformer

(See Item 2)

6 12-0350 Starter (LS7.10E-G),

24V/60Hz, Coil

7 04-0372 Screw, 8 - 32 x 0.500,

PH, MS, SS, PL

ITEM PART NO. DESCRIPTION

8 81-0549 Rail, Carrier, 4.900 LG

9 12-0461 Terminal, 4 CIR, GIO/4,

2716129

10 04-1361 Screw, 8 - 32 x 0.750,

PH, MS, SS, PL

11 12-0467 Contact, Auxilliary

12 12-0393 End Stop, Terminal Block

13 12-0391 Terminal, Block 2, Cond

14 12-0392 Terminal Block, 4 Cond,

Blue

15 12-0389 Terminal Block, 4 Cond,

Ta n

16 12-0395 End Plate, 4 Cond

12

16

15

14

13

13

13

13

12

11

7

6

8

3

10

9

1

2

4

3

5

Page 10

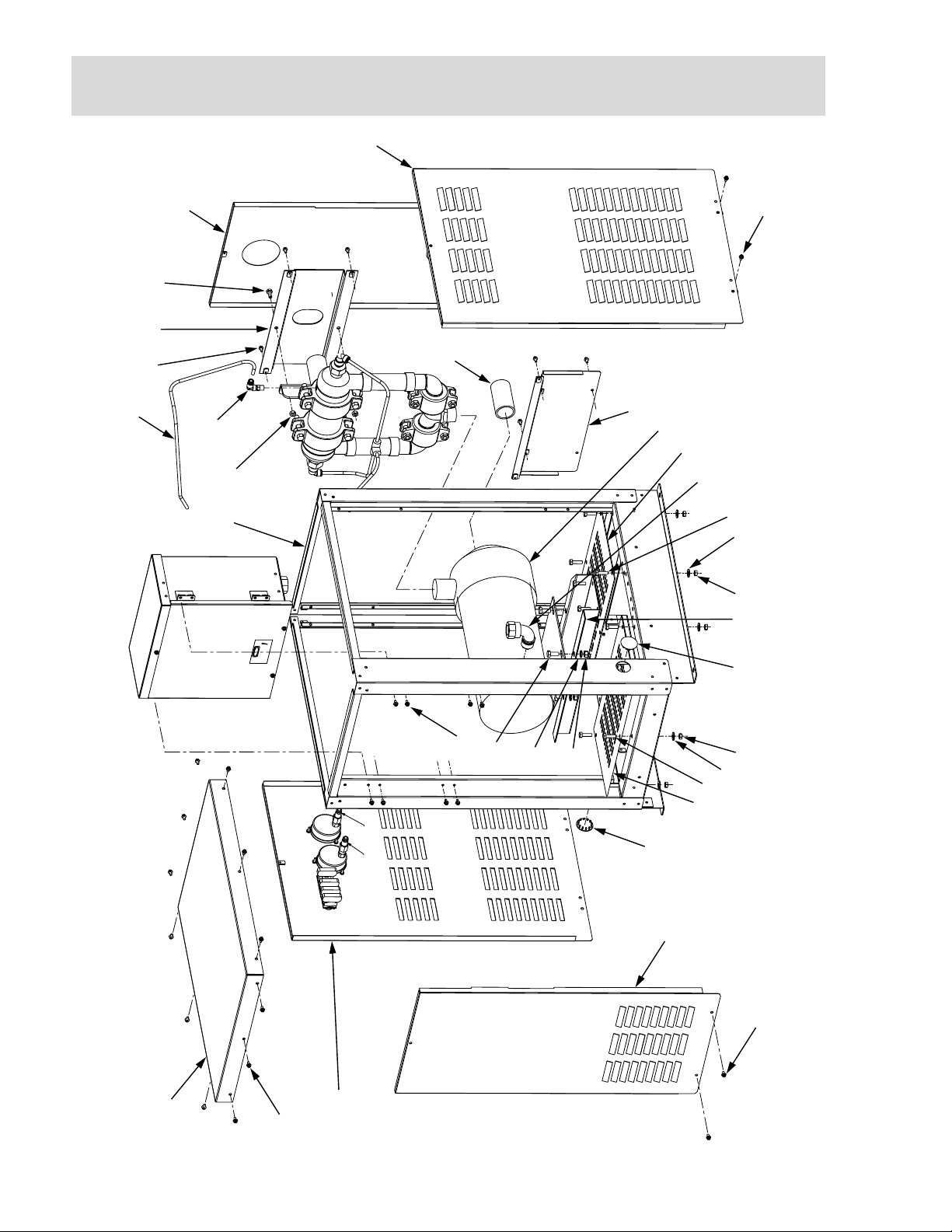

TOP VIEW

25.258

9

RIGHT SIDE VIEW

FRONT VIEW

15.632

9.625

22.379

16.313

29.625

29.582

POWER IN

(EITHER SIDE

CAN BE USED)

2.047

1.090

18.156

CONTROL PANEL

(MAY BE MOVED TO

OPPOSITE SIDE)

FRONT

20.000

0.406 MOUNTING

HOLES (4 PLACES)

0.500

17.000

1.000

Page 11

VRTX ELECTRICAL DIAGRAM, LABEL, PN 06-2405/02

10

TO

SWITCH S1-3

CONTROL PANEL SIDE

OPEN

J-1

J-2

SWITCH S1-4

OPEN

J-4

J-3

SWITCH S2-4

GREEN L1-X1

J-6

J-5

OPEN

J-7

RED L3-X1

WHITE L2-X2

J-8

J-9

OPEN

J-10

OPEN

J-11

OPEN

J-12

OPEN

OPEN

ELECTRICAL BOX INTERCONNECT

TO

CONTROL BOX SIDE

WIRE COLOR

THERMAL

OVERLOAD

MOTOR

TB1-4

BLACK

MOTOR

3 PHASE

(SEE NOTE 4)

STARTER

OL-96

BROWN

TB3-2

YELLOW

OL-95

GREEN

OL1

M1

OPEN

AUX B

TB2-4

WHITE

RED

24VAC

TB2

H2 H4

H3

(SEE NOTE 2)

H1

OPEN

TB2-1

WHITE

OPEN

X2

XFMR1

OPEN

TB2-2

WHITE

A1

A2

BLACK

96 95

SYSTEM OFF = ON

TB2-4

TB2-3

NORMAL OPERATION = 'ON'

WHITE

J-9

WHITE

2

M1

OL1

L1

GRN

1

J-6

GRN 2

RED

1

RED

51

52

L2

J-8

M1 AUX NC

8

7

56

L1

460VAC INPUT

J-3

BROWN

BLACK

OFF

HAND

23

J-1

OFF

24

BLK

TB1-4

13

14

AUTOMATIC

YELLOW

TB1-3

J-5

BLACK

TB1-2

F1

AUTOMATIC

XF

BLACK

L2

L3

GND

TB1-1

TB1

24VAC

RETURN

4

3

2

1

TERMINAL BLOCK TB 3

AUXILARY NORMALLY OPEN CONTACTS 13 & 14

TO SEPARATOR PUMP CONTROL BOX

NOTE 1: 230VAC INPUT OPTIONAL

NOTE 2: FOR 230VAC, CONNECT H1-H3 AND H2-H4

NOTE 4: FOR 230VAC, REPLACE THERMAL OVERLOAD

NOTE 3: FOR 230VAC, WIRE MOTOR PER MOTOR DATA PLATE

Page 12

NOTES

11

For further Information:

e-mail: vrtx@vrtxtech.com

Or see our Web Site

www.vrtx-technologies.com

Loading...

Loading...