Page 1

INSTALLATION AND SERVICE

MANUAL

FOR

ICE COOLED DISPENSER

1523

REV. 11/03/97

P.N. 28-0086/03

This manual supersedes Installation And Service Manual 28-0086/02, dated 12/02/96

FAX ENGINEERING: • 210-310-7096

"Lancer" is the registered trademark of Lancer • Copyright — 1997 by Lancer, all rights reserved.

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

6655 LANCER BLVD. • SAN ANTONIO, TEXAS 78219 USA • (210) 310-7000

FAX SALES

• NORTH AMERICA – 210-310-7245 • INTERNATIONAL SALES – 210-310-7242 • CUSTOMER SERVICE – 210-310-7242 •

• LATIN AMERICA – 210-310-7245 • EUROPE – 32-2-755-2399 • PACIFIC – 61-8-8268-1978 •

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS ......................................................................................................................................i

SPECIFICATIONS ...............................................................................................................................................i

1. INSTALLATION ...........................................................................................................................................1

1.1 RECEIVING........................................................................................................................................1

1.2 UNPACKING ......................................................................................................................................1

1.3 SELECTING A COUNTER LOCATION..............................................................................................1

1.4 WATER SUPPLY................................................................................................................................1

1.5 ELECTRICAL SUPPLY ......................................................................................................................1

1.6 SYRUP CONTAINERS.......................................................................................................................1

1.7 INSTALLATION OF THE UNIT...........................................................................................................2

1.8 CONNECTION OF THE UNIT ...........................................................................................................2

1.9 START UP..........................................................................................................................................3

1.10 ADJUSTING WATER FLOW ..............................................................................................................3

1.11 ADJUSTING WATER-TO-SYRUP RATIO (BRIX) ..............................................................................4

1.12 REPLENISHING SYRUP SUPPLY (5 GALLON TANKS) ..................................................................4

2. RECOMMENDED SERVICE AND MAINTENANCE...................................................................................4

2.1 SCHEDULED .....................................................................................................................................4

2.2 CLEANING AND SANITIZING SYSTEMS.........................................................................................4

2.3 CLEANING AND SANITIZING FIGAL SYSTEMS..............................................................................5

2.4 CLEANING AND SANITIZING BAG-IN-BOX (BIB) SYSTEMS .........................................................7

2.5 VALVES ..............................................................................................................................................7

2.6 ICE BIN COMPARTMENT ON ALL ICE CHESTS.............................................................................8

3. TROUBLESHOOTING.................................................................................................................................8

3.1 NO CARBONATION...........................................................................................................................8

3.2 NOISY CARBONATOR PUMP...........................................................................................................8

3.3 OFF TASTE IN SODA........................................................................................................................8

3.4 VALVES INOPERABLE ......................................................................................................................8

4. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS............................................................9

4.1 LANCER ICE COOLED DISPENSER - ACCESSORIES ..................................................................9

4.2 SERIES 1500 DROP-IN (PRE-MIX) ...........................................................................................10-11

4.3 SERIES 1500 DROP-IN..............................................................................................................12-13

4.4 SERIES 1500 PLUG-IN DROP-IN SABRE.................................................................................14-15

4.5 ICE COOLED UNIVERSAL WIRING DIAGRAM WITH BIN LID SWITCH ......................................16

4.6 ICE COOLED UNIVERSAL WIRING DIAGRAM WITHOUT BIN LID SWITCH...............................17

i

SPECIFICATIONS

DIMENSION

Drop-In Ice Chest

Width 15 inches (38.10 cm)

Depth 23 inches (58.42 cm)

Height 21 1/4 inches (53.98 cm)

Dispensing Tower

Width 18 3/8 inches (46.65 cm)

Height 18 1/4 inches (46.35 cm)

Height (with Valves) 19 1/2 inches (49.53 cm)

WEIGHT

Shipping 130 pounds (59.09 kg)

Empty 106 pounds (48.18 kg)

Operating 166 pounds (75.46 kg)

ICE BIN CAPACITY 60 pounds (27.28 kg)

Page 3

1. INSTALLATION OF LANCER ICE COOLED DISPENSER

1.1 RECEIVING

Each unit is completely tested under operating conditions and thoroughly inspected before

shipment. At the time of shipment, the carrier accepts the unit, and any claim for damage must be

made with the carrier. Upon receiving units from the delivering carrier, carefully inspect carton for

visible indication(s) of damage. If damage exists, have carrier note the same on the bill of lading

and file a claim with the carrier.

1.2 UNPACKING

A. The Lancer Ice Cooled Dispenser is shipped in a corrugated shipping carton.

B. Carefully remove the corrugated shipping carton from the unit.

C. Remove parts from the Ice Compartment.

D. Inspect unit for concealed damage(s). If evident, notify delivering carrier and file a claim against

same.

1.3 SELECTING A COUNTER LOCATION

A. Select a counter location which is close to a properly grounded electrical outlet, and a water

supply that meets the requirements specified in Section 1.4 below.

B. Counter location must be able to safely support a minimum of 225 pounds (102.3 kg) after

counter cutout is made.

1.4 WATER SUPPLY

CAUTION

FAILURE TO LIMIT WATER PRESSURE TO 50 PSI WILL RESULT IN IMPROPER

PERFORMANCE OF THE DISPENSER.

A. An adequate potable water supply must be provided. The water supply line must be at least a

3/8 inch pipe with a minimum of 20 PSI line pressure, but not exceeding a maximum of 50 PSI.

Water pressure exceeding 50 PSI must be reduced to 50 PSI with a pressure regulator.

CAUTION

A FILTER IN THE WATER LINE MUST BE USED IF THE WATER SUPPLY CONTAINS ANY

APPRECIABLE AMOUNT OF SILT, SAND, OR ANY OTHER DEBRIS. FAILURE TO DO SO CAN

RESULT IN EQUIPMENT DAMAGE.

B. The Carbonator Pump is equipped with a Strainer and a Tee on the outlet side for a plain water

Valve (if required), but a water supply containing any appreciable quantity of silt, fine sand, or

other debris requires a Filter ahead of the Unit. The Filter cartridge must be cleaned

periodically, depending upon the condition of the water. Failure to do so may starve the Pump

and cause it to burn out; thereby, voiding the equipment warranty

1.5 ELECTRICAL SUPPLY

W

ARNING

THE POWER SUPPLY MUST BE PROPERLY ELECTRICALLY GROUNDED TO AVOID

POSSIBLE ELECTRICAL SHOCK OR SERIOUS INJURY TO THE OPERATOR. THE POWER

CORD IS PROVIDED WITH A THREE PRONG GROUNDED PLUG. IF A THREE-HOLE

GROUNDED ELECTRICAL OUTLET IS NOT AVAILABLE, USE AN APPROVED METHOD TO

GROUND THE UNIT.

A. A standard 15 AMP, 110 VAC, 60 Hz, single phase electrical power outlet with a ground

connector should be provided for the operation of the unit

1.6 SYRUP CONTAINERS

A. When the unit is used in the Coca-Cola Company installations, the syrup containers are to be

attached as outlined in the appropriate Coca-Cola Company Service Manual.

B. For other installations, the syrup containers (sold as an accessory) are of stainless steel

construction with a capacity of five gallons. They are equipped with a CO

2 gas quick disconnect

1

Page 4

fitting and a syrup quick disconnect fitting. The standard syrup outlet is a 1/4 inch (6.35 mm)

male flare (MF). A low pressure regulator manifold (an accessory) may be mounted on the wall

above the syrup tanks.

C. The inlets on the unit, located on the right rear of the machine, are tagged (or coded) to the

proper valves. When making the connection to these inlets, provide a good, leak tight joint to

prevent twisting the tubing.

1.7 INSTALLATION OF THE UNIT

A Inspect the counter location where the unit is to be installed. Verify that the counter is strong

enough to safely support a 225 pound (102.3 kg) load, after the cutout for the unit is made.

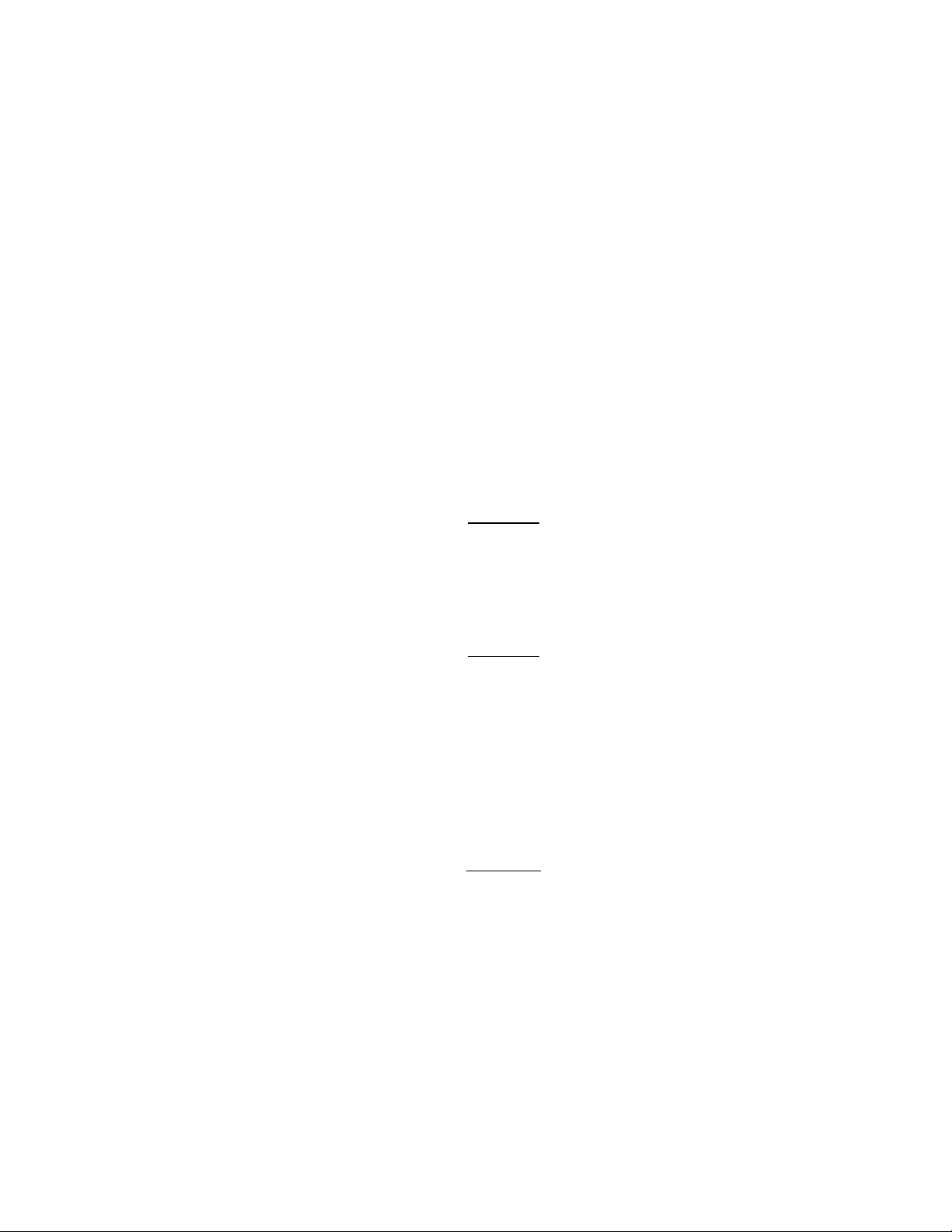

B. Verify that the unit will fit in the desired location. See Figure 1 for the footprint and counter cutout

for the unit.

NOTE

Remember that the unit can extend up to 23 inches (58.42 cm) below the counter, including the

shipping risers, which Lancer recommends be left attached to the unit. Should the dispenser

ever require removal, the shipping risers will protect the inlet tubes from being damaged.

C. After the counter cutout is complete, the unit may be lowered into the counter.

2

Counter Cutout for Dispenser

Figure 1

1.8 CONNECTION OF THE UNIT

A. Position the CO2 gas tank in the desired location. Assemble the high pressure regulator to the

CO2 gas tank and run jumper line to low pressure regulator.

B. Attach the CO2 gas line to the carbonator by attaching the line from the high pressure regulator

to the single check valve marked “gas” on top of the Carbonator Tank. The setting of the high

pressure CO

2 gas Regulator should be 90 PSI to 110 PSI.

CAUTION

DO NOT TURN ON THE CO

2 SUPPLY AT THIS TIME.

C. Position the syrup tanks in the desired location. Attach the CO

2 gas lines leading from the low

pressure regulator to these tanks.

D. Connect syrup lines from tanks to the appropriate inlets at the right front of the unit. The syrup

inlets are identified.

CAUTION

A FILTER IN THE WATER LINE MUST BE USED IF THE WATER SUPPLY CONTAINS ANY

APPRECIABLE AMOUNT OF SILT, SAND, OR ANY OTHER DEBRIS. FAILURE TO DO SO CAN

RESULT IN EQUIPMENT DAMAGE.

E. Mount the water filter assembly (if required) and water regulator (if required) in a convenient

location.

(CUTOUT)

23 1/4" (59.06 cm)

NOTES:

Solid lines

represent counter

cutout dimensions.

Dashed lines

represent the counter

footprint of the ice

bin flange.

FRONT

17"

(43.18 cm)

(CUTOUT)

15 1/4"

(38.74 cm)

25" (63.50 cm)

SIDE

(View Looking Down)

Page 5

CAUTION

FAILURE TO LIMIT WATER PRESSURE TO 50 PSI WILL RESULT IN IMPROPER

PERFORMANCE OF THE DISPENSER.

F. Connect the water inlet line to the water regulator (if required), water filter (if required), and then

to the water inlet of the carbonator pump on the carbonator.

G. Provide a suitable drain in the plumbing system and attach the one (1) inch (2.54 cm) diameter

schedule 40 PVC drains to the drain. The drip pan drainage outlet is located at the center rear

of the unit. The ice water drainage outlet is located at the right front of the unit

H. Be sure to place the ice trap in the drain outlet inside the ice bin before filling the cabinet with

ice. This device holds the ice away from the drain outlet, allowing the ice water to drain

properly.

W

ARNING

THE POWER SUPPLY MUST BE PROPERLY ELECTRICALLY GROUNDED TO AVOID

POSSIBLE ELECTRICAL SHOCK OR SERIOUS INJURY TO THE OPERATOR. THE POWER

CORD IS PROVIDED WITH A THREE PRONG GROUNDED PLUG. IF A THREE-HOLE

GROUNDED ELECTRICAL OUTLET IS NOT AVAILABLE, USE AN APPROVED METHOD TO

GROUND THE UNIT.

I. Plug in the transformer box to a standard 15 AMP, 110 VAC, single phase outlet. The unit will

internally convert 110 VAC electricity to 24 VAC.

1.9 START UP

A. After all connections to water, CO

2 gas, electrical power, and syrup containers are made, check

for leaks.

B. Check to insure that syrup tanks contain syrup.

CAUTION

DO NOT OPERATE CARBONATOR PUMP WITH WATER SUPPLY SHUT OFF.

C. Turn water ON. Open the pressure relief valve on the carbonator tank by lifting the wire ring,

and hold it open until water flows from the relief valve. Close the relief valve and turn on the

CO2 gas and electrical power in that order.

3

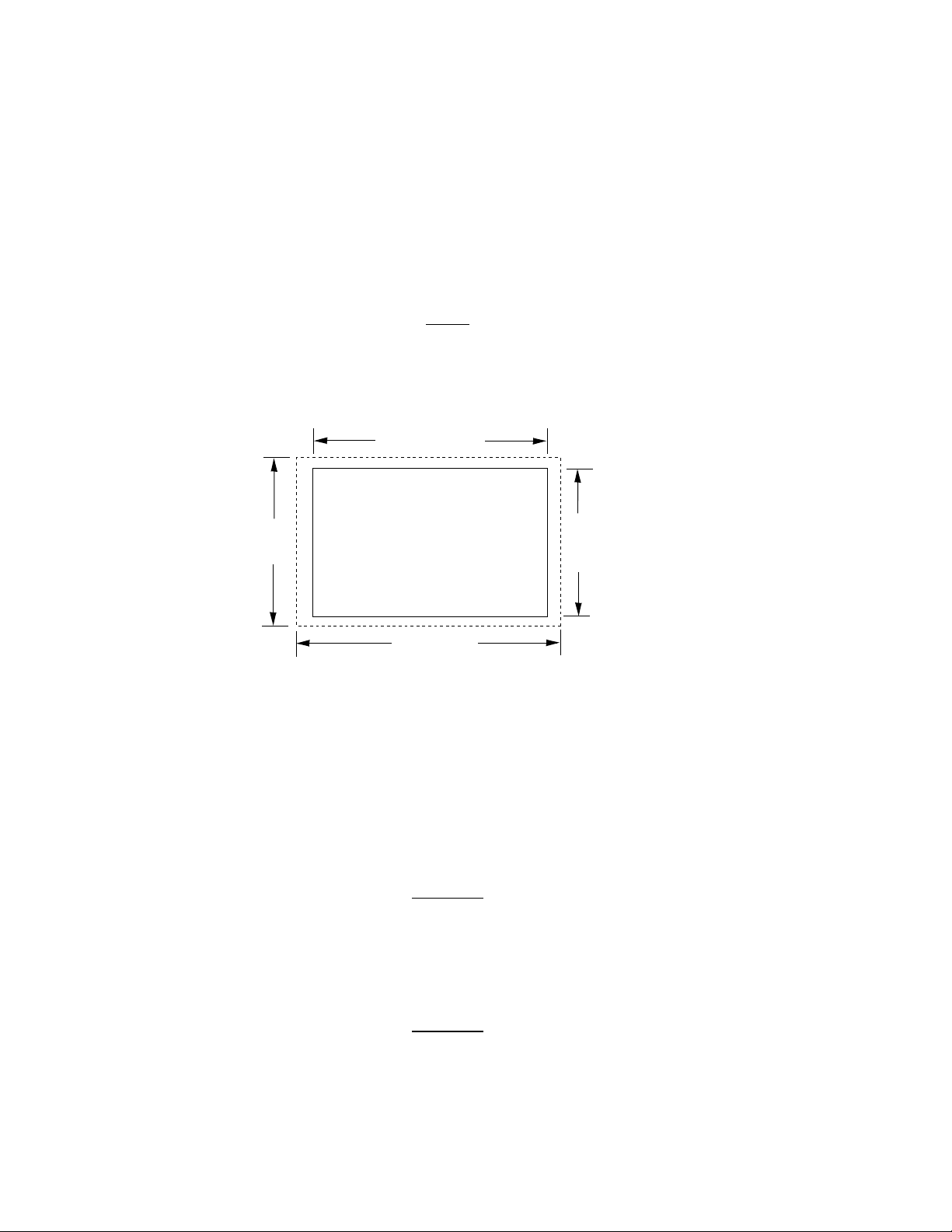

Valve Adjustments

Figure 2

D. To fill all lines with water, cycle the carbonator

several times by operating the dispersing

valves.

1. A low pressure gas regulator controls the

flow of syrup to each dispensing valve.

For proper operation of the valves, the

pressure regulator should be set so that

40 PSI is at the back block of the valve.

2. For diet type syrup, the tank pressures

should be set at 10 PSI, or as

recommended by the syrup supplier.

Additional pressure may be necessary,

depending on the distance from the syrup

tank to the unit.

E. Fill unit with ice cubes to the level of the door

opening at this time.

1.10 ADJUSTING WATER FLOW

A The water flow can be adjusted to either1.25

oz/sec (37 ml/sec) or 2.50 oz/sec(74 ml/sec)

on all dispensing valves by using the following

procedure.

B. The unit should have ice on the cold plate for

open position)

FLOW CONTROL

WATER

COVER SCREW

FLOW CONTROL

DecreaseIncrease

I.D. PANEL

(Shown in

SYRUP

DecreaseIncrease

NOZZLE (WITH

DIFFUSER INSIDE)

Page 6

at least one hour before attempting to BRIX the valves. The drink temperature should be no

higher than 40°F (4.4°C) when the ratio is set. This is done after the unit has ice in the ice bin.

C. Slide the ID panel UP until the flow controls are exposed (see Figure 2).

D. Remove the nozzle by turning the nozzle counter clockwise and pulling down.

E. Remove the diffuser by pulling the diffuser in a downward motion.

F. Install the Lancer (yellow) syrup separator (PN 54-0031) in place of the nozzle.

G. Activate dispensing valve to fill the separator syrup tube.

H. Hold a Lancer BRIX cup (PN 05-0090) under the syrup separator and dispense water and syrup

into the BRIX cup for four (4) seconds. Divide the number of ounces (ml) of water in the cup by

four (4) to determine the water flow rate per second.

I. To obtain the proper flow, use a screwdriver to adjust water flow control (see Figure 2).

J. Repeat this process for each valve.

1.11 ADJUSTING WATER-TO-SYRUP RATIO (BRIX)

A. Hold the Lancer ratio cup under the syrup separator and activate valve. Check ratio (BRIX).

B. To obtain the proper ratio, use screw-driver to adjust syrup flow control (see Figure 2).

C. Remove syrup separator.

D. Install diffuser and nozzle.

E. Slide ID panel DOWN.

F. Repeat this process for each valve.

NOTE

In all cases of re-assembly of valves involving o-rings, be sure the o-ring is lubricated with water

or an FDA approved lubricant to prevent leakage or damage to the o-ring.

1.12 REPLENISHING SYRUP SUPPLY (5 GALLON TANKS)

A. The following procedure should be used to add syrup to a tank after the system is in operation.

1 Shut off CO2 gas supply system to syrup tanks.

2. Snap off the self-sealing quick-coupler. Allow gas in the syrup tank to escape by pulling the

outer shell of the quick-coupler toward the flexible line and allowing the whole connection to

pull free.

W

ARNING

TO AVOID POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE, DO NOT ATTEMPT TO

REMOVE SYRUP TANK COVER UNTIL CO

2

PRESSURE HAS BEEN RELEASED FROM

TANK.

3. Remove the cover by pulling upward on the hinged locking bar.

4. Fill tank with appropriate syrup, leaving one (1) inch (2.54 cm) of space for CO

2 gas.

5. Replace locking cover insuring that the cover and cover gasket are properly aligned.

6. Snap on quick-coupler and lock it securely in place. Turn CO

2 gas pressure ON. When

properly connected, the gas will automatically enter the tank with an audible noise.

2. RECOMMENDED SERVICE AND MAINTENANCE

2.1 SCHEDULED

A. Daily – See Section 2.5 for daily cleaning.

B Monthly – See Section 2.6 for monthly cleaning.

C. Periodic Sanitizing - See sections 2.2, 2.3, and 2.4 for sanitizing requirements.

D. As Needed - Keep exterior surfaces (to include drip tray and cup rest) of dispenser cleaned with

damp, clean cloth.

2.2 CLEANING AND SANITIZING SYSTEMS

A. General Information

(1) Lancer equipment (new or reconditioned) is shipped from the factory cleaned and sanitized

in accordance with NSF guidelines. The operator of the equipment must provide continuous

maintenance as required by this manual and/or state and local health department guidelines

4

Page 7

to ensure proper operation and sanitation requirements are maintained.

NOTE

The cleaning and sanitizing procedures provided herein pertain to the Lancer equipment

identified by this manual. If other equipment is being cleaned, follow the guidelines

established for that equipment.

(2) Cleaning and sanitizing should be accomplished only by trained personnel. Sanitary gloves

are to be used during cleaning and sanitizing operations. Applicable safety precautions

must be observed. Instruction warnings on the product being used must be followed.

IMPORT

ANT

Water lines are not to be disconnected during the cleaning and sanitizing of syrup lines to

avoid contamination.

(3) Recommended Preparation of Cleaning Solutions.

(a) Cleaning solutions (for example, Ivory Liquid, Calgon, etc.) mixed with clean, potable

water at a temperature of 90 to 110 degrees Fahrenheit should be used to clean

equipment. The mixture ratio, using Ivory Liquid, is one (1) ounce of cleanser to two (2)

gallons of water. A minimum of four (4) gallons of cleaning mixture should be prepared.

NOTE

Extended lengths of product lines may require that an additional volume of solution be

prepared.

(b) Any equivalent cleanser may be used as long as it provides a caustic based,

non-perfumed, easily rinsed mixture containing at least two (2) percent sodium

hydroxide (NaOH).

(4) Recommended Preparation of Sanitizing Solutions.

(a) Sanitizing solutions should be prepared in accordance with the manufacturer’s written

recommendations and safety guidelines. For example, mix Diversol CX in clean,

potable water at a temperature of 90 to 110 degrees Fahrenheit so that the solution

provides 200 parts per million (PPM) available chlorine. A minimum of four (4) gallons

of sanitizing solution should be prepared.

NOTE

Extended lengths of product lines may require that an additional volume of solution be

prepared.

(b) Any equivalent sanitizing solution may be used as long as it is prepared in accordance

with the manufacturer’s written recommendations and safety guidelines, and provides

200 parts per million (PPM) available chlorine.

2.3 CLEANING AND SANITIZING FIGAL SYSTEMS

A. Remove all ice from ice bin by melting with hot water.

B. Remove quick disconnect from syrup tank.

CAUTION

DO NOT USE A WIRE BRUSH TO CLEAN VALVES.

C. Using a clean plastic bristle brush and a detergent soap solution prepared in accordance with

the instructions in Section 2.2, scrub both valves of the disconnect. Rinse with clean, potable

water.

D. Using a mechanical spray bottle and a sanitizing solution prepared in accordance with the

instructions in Section 2.2, spray both halves of the quick disconnects. Allow to air dry.

NOTE

Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only with the

end use product. This is an NSF requirement.

E. Connect syrup line to a syrup tank filled with clean, potable, room temperature water. Connect

CO

2 supply hose to tank and pressurize.

5

Page 8

F. Place waste container under applicable dispensing valve. Activate valve until water is

dispensed. Flush and rinse line and fittings for a minimum of 60 seconds to remove all traces

of residual product.

NOTE

Extended lengths of product lines may require additional time for flushing and rinsing lines.

WARNING

TO AVOID POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE, DO NOT ATTEMPT

TO REMOVE SYRUP TANK COVER UNTIL CO2 PRESSURE HAS BEEN RELEASED FROM

TANK.

G. Disconnect CO2 supply hose from the water filled syrup tank.

H. Prepare cleaning solution as described in Section 2.2 above. Fill a tank with cleaning solution.

Connect syrup line to the tank. Connect CO2 supply hose to tank and pressurize.

I. Place waste container under applicable dispensing valve. Activate valve and draw cleaning

solution through lines for a minimum of 60 seconds. This will ensure line is flushed and filled

with cleaning solution. Allow line to stand for at least 30 minutes.

NOTE

Extended lengths of product lines may require additional time for flushing and filling lines.

J. Disconnect CO2 supply hose from the tank.

K. Connect syrup line to a tank filled with clean, potable, water at a temperature of 90 to 110

o

F.

Connect CO

2 supply hose to tank and pressurize.

L. Place waste container under applicable dispensing valve. Activate valve to flush and rinse line

and fittings for a minimum of 60 seconds to remove all traces of cleaning solution. Continue

rinsing until testing with phenolpthalein shows that the rinse water is free of residual detergent.

M. Disconnect CO

2 supply hose from the tank.

N. Fill a tank with sanitizing solution. Connect syrup line to the tank. Connect CO

2 supply hose to

tank and pressurize.

O. Remove dispensing valve nozzle (twist and pull down) and pull out center mixing baffle. Using

a plastic bristle brush and detergent soap solution scrub the nozzle, mixing baffle, bottom of

dispensing valve, and cup lever. Rinse with clean water.

P. Reassemble mixing baffle and nozzle.

Q. Place waste container under applicable dispensing valve. Activate valve and draw sanitizing

solution through line for a minimum of 60 seconds. This will ensure line is flushed and filled with

sanitizing solution. Allow line to stand for at least 30 minutes.

R. Disconnect CO

2 supply hose from the tank.

S. Reconnect syrup lines to syrup containers (for example, quick disconnects, figal containers, etc.)

and ready unit for operation.

W

ARNING

FLUSH SANITIZING SOLUTION FROM SYRUP SYSTEMS AS INSTRUCTED. RESIDUAL

SANITIZING SOLUTION LEFT IN SYSTEM COULD CREATE HEALTH HAZARD.

T. Draw drinks and refill lines with end product to flush sanitizing solution from the dispenser.

NOTE

Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only with the

end use product. This is an NSF requirement.

U. Test dispenser in normal manner for proper operation. Taste dispensed product to ensure there

is no off-taste. If off-taste is found, additional flushing of syrup system may be required.

V. Repeat cleaning, rinsing, and sanitizing procedures for each valve/syrup circuit.

W. Clean exterior of unit as instructed in Section 2.6.

X. Using a spray bottle of sanitizing solution, spray the underside of all dispenser valves, valve

spouts and cup levers. Allow to air dry.

Y. Fill ice bin with ice. Install ice bin cover on unit.

NOTE

Thoroughly rinse inside and outside of syrup tank that was used for sanitizing solution with plain

6

Page 9

water to remove all solution residue.

2.4 CLEANING AND SANITIZING BAG-IN-BOX (BIB) SYSTEMS

A. Disconnect syrup quick disconnect coupling from syrup packages and connect coupling to a bag

valve removed from an empty Bag-in-Box package.

B. Place end of syrup inlet line, with bag valve attached, in a clean container filled with clean,

potable, room temperature water.

C. Place waste container under applicable dispensing valve. Activate valve until water is

dispensed. Flush and rinse line and fittings for a minimum of 60 seconds to remove all traces

of residual product.

NOTE

Extended lengths of product lines may require additional time for flushing and rinsing lines.

D. Prepare cleaning solution as described in Section 2.2 above. Place end of syrup inlet line in

container filled with cleaning solution.

E. Place waste container under applicable dispensing valve. Activate valve and draw cleaning

solution through lines for a minimum of 60 seconds. This will ensure line is flushed and filled

with cleaning solution. Allow line to stand for at least 30 minutes.

F. Place end of syrup inlet line in a clean container filled with clean, potable, water at a

temperature of 90 to 110°F.

G. Place waste container under applicable dispensing valve. Activate valve to flush and rinse line

and fittings for a minimum of 60 seconds to remove all traces of cleaning solution. Continue

rinsing until testing with phenolpthalein shows that the rinse water is free of residual detergent.

H. Prepare sanitizing solution as described in Section 2.2 above. Place end of syrup inlet line in

container filled with sanitizing solution which has been prepared.

I. Activate valve and draw sanitizing solution through line for a minimum of 60 seconds. This will

ensure line is flushed and filled with sanitizing solution. Allow line to stand for at least

30 minutes.

J. Remove bag valve from quick disconnect coupling and reconnect syrup inlet line to syrup

package. Ready unit for operation.

W

ARNING

FLUSH SANITIZING SOLUTION FROM SYRUP SYSTEMS AS INSTRUCTED. RESIDUAL

SANITIZING SOLUTION LEFT IN SYSTEM COULD CREATE HEALTH HAZARD.

K. Draw drinks and refill lines with end product to flush sanitizing solution from the dispenser.

NOTE

Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only with the

end use product. This is an NSF requirement.

L. Test dispenser in normal manner for proper operation. Taste dispensed product to ensure there

is no off-taste. If off-taste is found, additional flushing of syrup system may be required.

M. Repeat cleaning, rinsing, and sanitizing procedures for each valve circuit.

2.5 VALVES

A. Valves may be cleaned and sanitized (see preparation in Section 2.2) in the same manner.

1. Remove cover and disconnect power so the valve will not be activated during the cleaning

procedure. Remove nozzle and diffuser. Wash these parts in cleaning solution; then

immerse them in a bath of sanitizing solution for 15 minutes.

2. Visually inspect around nozzle area for syrup residue. This area may be cleaned with warm

water and cloth or with the nozzle brush supplied. Wipe off dispensing lever.

3. Wearing sanitary gloves, remove, drain and air dry the nozzle and diffuser.

4. Wearing sanitary gloves, replace diffuser, twist nozzle in place.

5. Connect power and replace cover. Valve is ready for operation.

2.6 ICE BIN COMPARTMENT ON ALL ICE CHESTS

A. The ice bin compartment of the dispenser should be thoroughly cleaned and sanitized at least

7

Page 10

once every month. Use. the following procedure.

B. Prepare cleaning solution and sanitizing solution in accordance with Section 2.2.

C. Using the cleaning solution and a clean soft cloth, wash down the sides of the ice bin and the

surface of the aluminum casting.

D. Using clean, potable water, thoroughly rinse away the cleaning solution from the sides and

surface of the casting.

E. Using plastic sanitary gloves, soak a white cotton gauze cleaning rag in the sanitizing solution

and wipe all surfaces in the ice compartment.

NOTE

Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only with the

end use product. This is an NSF requirement.

F. Sanitizing of the ice compartment is complete. Refill with ice.

3. TROUBLESHOOTING

TROUBLE

CAUSE REMEDY

3.1 No carbonation. A. Carbonator motor not A. Check power supply. Be sure

running. toggle switch is in ON position.

B. Absence of CO2 gas. B. Replace with full tank of CO2 gas.

C. Gas only from valves. C. Check for power failure. Check

fuses. Clean strainer on pump.

D. Carbonator tank air bound. D. Relieve gas pressure in tank by

pulling ring on safety relief valve

until water spurts out.

E. CO2 gas pressure below E. Reset high pressure CO2 gas

90 PSI. regulator to 90-110 PSI. Change

CO

2 tank if required.

F. Carbonator motor running F. Check switch on carbonator. Check

continuously. water in check valve for blockage.

Check carbonator control. Check

carbonator pump for efficiency.

3.2 Noisy Carbonator A. Insufficient water supply or A. Provide adequate water supply.

Pump. water leak, allowing air to be Check strainer for Cleanliness.

pulled into pump.

B. Loose pump coupling. B. Tighten set screw on pump

coupling.

3.3 Off taste in soda. A. Leaking water check valve, A. Dismantle and clean check valve.

allowing carbonated water to Replace O-Ring, if torn or distorted.

back into supply line.

3.4 Valves inoperable. A. Loss of power. A. Check power supply to see if

plugged in. Check transformer

circuit breaker. Check main power

circuit breaker, 110V.

8

Page 11

9

4. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS

4.1 LANCER ICE COOLED DISPENSER -- ACCESSORIES

Illuminated Merchandiser

PN 85-2304

Illuminated Marquee

PN 85-2301

Splash Guards Kit

PN 82-2479

Page 12

10

*

*

*

*

*

*

*

4.2 SERIES 1500 DROP-IN (PRE-MIX)

25

24

27

1

2

3

4

5

23

22

21

6

26

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Page 13

ITEM PART NO. DESCRIPTION

1 07-0360 Plug

2 30-5985 Tower Cap, with Holes

3 04-0148 Screw, 10 - 32 X 0.250

4 51-5538 Tower Body

5 C-15-0794-100 Yoke Fitting

6 01-0222 Fitting

7 07-0438 Clamp, Oetiker

8 08-0263 Tubing, Red Line

9 88-0118 Insulation

10 07-0405 Plug

11 06-0645-204 Name Plate

- 06-0645-205 Name Plate

- 06-0645-206 Name Plate

R 12 51-5605 Base

13 51-5503 Rim

14 42-0038 Tank Assy, Foamed

15 04-0072 Rivet

R 16 30-7070/02 Wrapper

17 23-0862 Wire Drain

18 30-0294 Riser

19 04-0510 Screw, 8 - 18 X 0.500

20 01-1612 Drain Fitting

R 21 30-7332 Lid, Universal, 1523

22 19-0002 Valve, Pre Mix

23 05-1512 Drip Tray

24 23-1214 Cup Rest

25 30-7093-01 Splash Plate

26 04-1028 Screw, 10 - 32 X 0.375, HH, SS

27 30-6005 Faucet Plate (4 Valve)

- 30-6004 Faucet Plate (5 Valve)

- 30-6003 Faucet Plate (6 Valve)

NOTE: R in margin indicates revision

4.2 SERIES 1500 DROP-IN (PRE-MIX) (CONTINUED)

11

Page 14

*

*

*

*

*

*

*

12

4.3 SERIES 1500 DROP-IN

21

22

24

25

26

27

23

28

30

COVER MUST BE COMPLETELY

CLOSED TO OPERATE VALVES

S

L

ID

IN

D

O

G

N

C

O

O

T

V

L

IF

T

29

1

2

3

4

5

6

31

7

8

9

10

E

R

11

19

20

12

13

14

15

16

17

18

Page 15

ITEM PART NO. DESCRIPTION

1 07-0360 Plug

2 30-5985 Tower Cap, with Holes

3 04-0148 Screw, 10 - 32 X 0.250

4 48-0810 Foamed Manifold (4 Valve, 3-1)

- 48-1108 Foamed Manifold (5 Valve, 3-1 - 1)

- 48-1054 Foamed Manifold (6 Valve, 3-2-1)

- 48-0894 Foamed Manifold (5 Valve, 2-1-2)

- 48-0895 Foamed Manifold (6 Valve, 3-1-2)

5 51-5538 Tower Body

6 12-0097 Key Lock

7 81-0126 Keys

8 06-0645-204 Name Plate (4 Valve)

- 06-0645-205 Name Plate (5 Valve)

- 06-0645-206 Name Plate (6 Valve)

R 9 51-5605 Base

10 51-5503 Rim

11 82-2112 Switch/Bracket Assy

12 42-0040 Foamed Tank Assy

13 04-0072 Rivet

R 14 30-7070/02 Wrapper

15 23-0862 Wire Drain

16 30-0294 Riser

17 04-0510 Screw, 8 - 18 X 0.500

18 01-1612 Drain Fitting

19 82-1103 Power Supply

20 05-1512 Drip Tray

21 23-1214 Cup Rest

22 30-7093 Splash Plate

R 23 30-7332 Lid, Universal, 1523

24 19-0117 LEV

®

- 19-0118 LEV® with Soda Lever

25 11-0015 Housing Socket

26 13-0005 Bushing

27 04-0558 Screw, 10 - 32 x 0.375

28 30-5746/01 Faucet Plate (5 Valve, SS)

- 30-5623/01 Faucet Plate (6 Valve, SS)

29 52-0828/03 Wire Harness (5 Valve)

- 52-0827/03 Wire Harness (6 Valve)

30 04-1028 Screw, 10 - 32 X 0.375, HH, SS

31 30-7259 Door stop

NOTE: R in margin indicates revision

4.3 SERIES 1500 DROP-IN (CONTINUED)

13

Page 16

*

*

*

*

*

*

*

14

4.4 SERIES 1500 PLUG-IN DROP-IN SABRE

29

28

30

31

1

2

21

22

23

24

25

26

27

32

3

4

DO NOT UNSCREW

TO REMOVE TOWER

5

6

33

7

8

9

C

OVER

CLOSED

M

UST BE COM

TO

OPER

ATE VALVES

PLETELY

SLIDING

DO NO

CO

T LIFT

VER

10

11

12

13

20

14

15

16

17

18

19

Page 17

ITEM PART NO. DESCRIPTION

1 06-0234 Coca Cola Sabre Sign

2 05-0332 Graphic Panel

3 51-5505 Sabre Tower

4 05-1516 Plug

5 48-1148 Manifold Assy (5 Valve, Sabre)

6 12-0097 Key Lock

7 81-0126 Keys

8 06-0645-255 Name Plate

R 9 51-5605 Base

10 51-5503 Rim

11 82-2112 Switch/Bracket Assy

12 02-0003 O-Ring

13 42-0051 Foamed Tank Assy

14 04-0072 Rivet

R 15 30-7070/02 Wrapper

16 23-0862 Wire Drain

17 30-0294 Riser

18 04-0510 Screw, 8 - 18 X 0.500

19 01-1612 Drain Fitting

20 82-1103 Power Supply

21 05-1512 Drip Tray

22 23-1214 Cup Rest

23 30-7093 Splash Plate

R 24 30-7332 Lid, Universal, 1523

25 19-0117 LEV

®

- 19-0118 LEV® with Soda Lever

26 11-0015 Housing Socket

27 13-0005 Bushing

28 07-0556 Plug

29 04-0558 Screw, 10 - 32 x 0.375

30 51-5504 Faucet Plate (5 Valve Sabre)

31 52-0828/03 Wire Harness (5 Valve)

32 04-1028 Screw, 10 - 32 X 0.375, HH, SS

33 30-7259 Door stop

NOTE: R in margin indicates revision

4.4 SERIES 1500 PLUG-IN DROP-IN SABRE (CONTINUED)

15

Page 18

16

4.5 ICE COOLED UNIVERSAL WIRING DIAGRAM WITH BIN LID SWITCH

BLACK

WHITE

3F

LIGHT KIT

3M

SYRUP OUT

CDA

SOLENOID

2M

BLACK

PCB

1

2

PRESSURE SWITCH

BLACK

2F

WHITE

BLACK

62F543

WHITE

2M

2F

F

WHITE

Y

WHITE

KEY

F

BLACK

WHITE

M

LOCK

F

BLACK

WHITE

F

BLACK

FY

WHITE

SOLENOID

WATER SPIGOT

2F

2M

2F

2M

F

BLACK

F

ORIGINAL

POWER SUPPLY

2F

2M

F

F

F

F

BUTTON

WATER SPIGOT

2F

2F

2F

2M

2F

ON SPRITE VALVE

REPLACES INTERNAL

CHERRY SWITCH HARNESS

F M

VALVE MANIFOLD HARNESS

F

F

WHITE

BIN

M

WHITE

F

SWITCH

F

Y

ALTERNATE

POWER SUPPLY

2F

IN CONJUNCTION WITH

THIS HARNESS IS NOT USED

ALTERNATE POWER SUPPLY

2F

2M

OR

MARQUEE

MERCHANDISER

: 2 PIN FEMALE CONNECTOR

: MALE BLADE

: FEMALE BLADE RECEPTACLE

F

M

2F

: "Y" CONNECTOR (2 MALES, 1 FEMALE)

: 2 PIN MALE CONNECTOR

: 3 PIN MALE CONNECTOR

: 3 PIN FEMALE CONNECTOR

Y

3F

2M

3M

Page 19

17

4.6 ICE COOLED UNIVERSAL WIRING DIAGRAM WITHOUT BIN LID SWITCH

BLACK

WHITE

3F

3M

LIGHT KIT

SYRUP OUT

CDA

SOLENOID

2F

2M

BLACK

WHITE

PCB

2

1

PRESSURE SWITCH

BLACK

543 6

BLACK

WHITE

2M

BLACK

F

F

ORIGINAL

BLACK

WHITE

SOLENOID

WATER SPIGOT

KEY

LOCK

F

Y

F

F

WHITE

WHITE

BLACK

2F

WHITE

M

F

BLACK

WHITE

F

Y

2F

2M

2F

2M

POWER SUPPLY

2F

2M

F

F

F

F

BUTTON

WATER SPIGOT

2M

2F 2F 2F 2F 2F

ON SPRITE VALVE

REPLACES INTERNAL

CHERRY SWITCH HARNESS

MF

VALVE MANIFOLD HARNESS

F

Y

ALTERNATE

POWER SUPPLY

2F

IN CONJUNCTION WITH

THIS HARNESS IS NOT USED

ALTERNATE POWER SUPPLY

2M

2F

OR

MARQUEE

MERCHANDISER

: 2 PIN FEMALE CONNECTOR

: FEMALE BLADE RECEPTACLE

: MALE BLADE

F

M

2F

: "Y" CONNECTOR (2 MALES, 1 FEMALE)

: 2 PIN MALE CONNECTOR

: 3 PIN MALE CONNECTOR

: 3 PIN FEMALE CONNECTOR

Y

3F

3M

2M

Page 20

18

NOTES

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

Loading...

Loading...