Page 1

INSTALLATION AND SERVICE MANUAL

LANCER SERIES 100 AND 145

POST - MIX VALVE, LEV® AND LMV®

This Manual supersedes Installation and Service Manual, 28-0027/03, dated 09/30/98

MODEL 100 3.0 LMV®

MODEL 100L 3.0 LEV®

MODEL 100SSL 3.0 LEV® WITH

SELF-SERVE LEVER

MODEL 100P 3.0 LEV® PUSHBUTTON

MODEL 100SF 3.0 LEV

® SUREFILL

MODEL 100PC 3.0 LEV®

PORTION CONTROL

MODEL 145L 4.5 LEV®

MODEL 145SSL 4.5 LEV® WITH

SELF-SERVE LEVER

MODEL 145P 4.5 LEV®PUSHBUTTON

MODEL 145SF 4.5 LEV

® SUREFILL

MODEL 145PC 4.5 LEV

®

PORTION CONTROL

DATE: 07/16/01

P.N.: 28-0027/04

FAX ENGINEERING: • 210-310-7096

"Lancer" is the registered trademark of Lancer • Copyright — 2001 by Lancer, all rights reserved.

SPECIFICA

TIONS

FLOW RATE:

• All Model 100 (3.0 Valve) valves are adjustable from 1.5 ounces/second (44.4 ml/sec) to

3.0 ounces/second (88.8 ml/sec) of finished drink.

• All Model 145 (4.5 Valve) valves are adjustable from 2.5 ounces/second (74.0 ml/sec) to

5.0 ounces/second (148.0 ml/sec) of finished drink.

• Restricted flow adjustment plug, maximum flow 2.0 ounces/second (59.2 ml/sec) in the Model 100

valves and 3.3 ounces/second (97.7 ml/sec) in the Model 145 valves .

FLOW CONTROLS:

Water and syrup flow controls are individually adjustable without removing valve cover. Syrup flow

control operates with both sugar and diet syrups.

MOUNTING:

Mounts on the same hole center as the following valves with the same mounting screws.

Dole SEV Cornelius SF1

Dole FFV McCann Coca-Cola Valve

Smart Valve

SODA/WATER LEVER:

Manually operated and field convertible.

(SPECIFICATIONS continued inside cover)

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

6655 LANCER BLVD. • SAN ANTONIO, TEXAS 78219 USA • (210) 310-7000

FAX SALES

• NORTH AMERICA – 210-310-7245 • INTERNATIONAL SALES – 210-310-7242 • CUSTOMER SERVICE – 210-310-7242 •

• LATIN AMERICA – 210-310-7245 • EUROPE – 32-2-755-2399 • PACIFIC – 61-8-8268-1978 •

Page 2

i

(SPECIFICATIONS continued)

OPERATION:

Non-electric (LMV

®

) or electric (LEV®) operation.

WATER AND SYRUP REQUIREMENTS:

MODEL 100 (3.0 Valves) Flowing Pressures at Valve

Minimum Maximum

Water/Soda 40 PSIG (2.8 kg/cm

2

) 110 PSIG (7.73 kg/cm2)

Syrup (Sugar) 20 PSIG (1.4 kg/cm2) 70 PSIG (4.92 kg/cm2)

Syrup (Diet) 10 PSIG (0.7 kg/cm

2

) 70 PSIG (4.92 kg/cm2)

MODEL 145 (4.5 Valves) Flowing Pressures at Valve

Minimum Maximum

Water/Soda 30 PSIG (2.11 kg/cm

2

) 110 PSIG (7.73 kg/cm2)

Syrup (Sugar) 15 PSIG (1.1 kg/cm2) 80 PSIG (5.62 kg/cm2)

Syrup (Diet) 10 PSIG (0.7 kg/cm

2

) 80 PSIG (5.62 kg/cm2)

ELECTRICAL REQUIREMENT:

24 VAC, 50/60 Hz for LEV

® only

TABLE OF CONTENTS

SPECIFICATIONS......................................................................................................................................Cover

TABLE OF CONTENTS ......................................................................................................................................i

1. INSTALLATION ...........................................................................................................................................1

1.1 RECEIVING........................................................................................................................................1

1.2 REMOVAL OF EXISTING VALVE ......................................................................................................1

1.3 INSTALLATION OF VALVE (LMV® OR LEV®) ..................................................................................1

1.4 ADJUSTING WATER FLOW..............................................................................................................1

1.5 ADJUSTING WATER TO SYRUPoBRIX...........................................................................................2

1.6 INSTALLATION OF SODA LEVER ....................................................................................................2

1.7 REMOVAL AND INSTALLATION OF FRONT SODA WATER LEVER (KIT # 82-1458) ....................3

1.8 REMOVAL AND INSTALLATION OF FLOW CONTROLS.................................................................4

2. CLEANING ..................................................................................................................................................4

2.1 WEEKLY CLEANING .........................................................................................................................4

2.2 BI-WEEKLY SANITIZING ...................................................................................................................5

3. SYRUP BRIX CUP ......................................................................................................................................5

4. TROUBLESHOOTING.................................................................................................................................5

4.1 WATER LEAKAGE AROUND NOZZLE .............................................................................................5

4.2 LEAKAGE BETWEEN UPPER AND LOWER BODIES.....................................................................5

4.3 MISCELLANEOUS LEAKAGE ...........................................................................................................5

4.4 INSUFFICIENT WATER FLOW..........................................................................................................5

4.5 INSUFFICIENT SYRUP FLOW..........................................................................................................5

4.6 ERRATIC RATIO (OBRIX) .................................................................................................................6

4.7 NO PRODUCT DISPENSED .............................................................................................................6

4.8 WATER ONLY DISPENSED, NO SYRUP; OR SYRUP ONLY DISPENSED; NO WATER...............6

4.9 VALVE WILL NOT SHUT OFF ...........................................................................................................6

4.10 EXCESSIVE FOAMING .....................................................................................................................6

4.11 NO SYRUP-OUT LIGHT ....................................................................................................................6

5. ILLUSTRATIONS AND PARTS LISTINGS .................................................................................................8

5.1 LMV

® (MODEL 100, 3.0 OZ/SEC)..................................................................................................8-9

5.2 LEV

® (MODEL 100L, 3.0 OZ/SEC AND MODEL 145L, 4.5 OZ/SEC)........................................10-11

5.3 LEV® WITH SELF-SERVE LEVER (MODEL 100SSL, 3.0 OZ/SEC

AND MODEL 145SSL, 4.5 OZ/SEC) ..........................................................................................12-13

5.4 LEV

® PUSHBUTTON (MODEL 100P, 3.0 OZ/SEC AND

MODEL 145P, 4.5 OZ/SEC)........................................................................................................14-15

5.5 LEV® SUREFILL (MODEL 100SF, 3.0 OZ/SEC AND

MODEL 145SF, 4.5 OZ/SEC)......................................................................................................16-17

5.6 LEV

® PORTION CONTROL (MODEL 100PC, 3.0 OZ/SEC

AND MODEL 145PC, 4.5 OZ/SEC)............................................................................................18-19

Page 3

1. INSTALLATION

1.1 RECEIVING

Each unit is completely tested under operating conditions and thoroughly inspected before

shipment. At time of shipment, the carrier accepts the unit and any claim for damage must be made

with the carrier. Upon receiving units from the delivering carrier, carefully inspect carton for visible

indication(s) of damage. If damage exists, have carrier note same on bill of lading and file a claim

with the carrier.

1.2 REMOVAL OF EXISTING VALVE

A. Turn OFF carbonated water supply to dispenser to depressurize the system.

B. Turn OFF all syrup supplies to dispenser.

C. Operate each valve to ensure complete depressurization of water and syrup in the system.

D. Remove existing valve and mounting block. Reuse the mounting block screws.

1.3 INSTALLATION OF VALVE (LMV

® OR LEV

®)

WARNING

IF DISPENSER IS CONNECTED TO ELECTRICAL POWER, THE UNIT MUST BE PROPERLY

GROUNDED TO AVOID POSSIBLE FATAL ELECTRICAL SHOCK OR SERIOUS BODILY

INJURIES.

A. Slide I.D. panel up to expose cover mounting screw (see Figure 1).

B. Loosen cover mounting screw (DO NOT REMOVE) and remove cover.

C. Turn both stems on mounting block to the CLOSED position (see Figure 2).

D. Lift up wire retainer and remove mounting block from valve.

E. Replace the inlet water and syrup o-rings on dispenser valve fittings.

F. Lubricate o-rings on the fittings and mounting block with water or an FDA-approved lubricant.

G. If syrup-out light is furnished with valve, run light wires through mounting block and valve plate.

Connect wiring to pressure switch in product line (24 VAC power supply required).

H. Install mounting block to valve plate using four (4) mounting screws removed from existing

mounting block.

I. Install valve on mounting block. Push wire retainer down. This will lock valve to mounting block.

(White stems must be in closed position. See Figure 2.)

J. Turn on carbonator water supply and syrup supply to dispenser.

K. Turn both white stems on mounting block to the OPEN position (see Figure 3). Top of stem will

lock wire retainer in position.

L. If electric version, reconnect to 24 VAC power supply.

M. Operate the valve momentarily to ensure flow of carbonated water and syrup.

NOTE

Model 100 valves are factory preset for a flow rate of 3.0 ounces per second; an adjustment may

be required.

Model 145 valves are factory preset for a flow rate of 4.5 ounces per second; an adjustment may

be required.

N. Adjust water flow to correct flow rate (see following instructions).

O. Adjust ratio (

o

Brix) to correct setting (see following instructions).

P. Install cover on valve and tighten cover mounting screw.

Q. Slide down I.D. panel.

1.4 ADJUSTING WATER FLOW

The water flow for the Model 100 may be adjusted from 1.25 oz/sec (37 ml/sec) to 2.50 oz/sec

(74 ml/sec). The water flow for the Model 145 may be adjusted from 2.0 oz/sec (59.2 ml/sec) to

4.50 oz/sec (133.2 ml/sec). The restricted flow adjustment plug (Model 100) adjusts to a maximum

flow of 2.0 oz/sec (59.2 ml/sec). The restricted flow adjustment plug (Model 145) adjusts to a

maximum flow of 3.3 oz/sec (97.7 ml/sec).

A. Slide up I.D. panel until flow control adjustments are exposed (see Figure 1).

B. Remove nozzle by twisting counter clockwise and pulling down.

1

Page 4

Figure 5

2

C. Remove diffuser by pulling down.

D. Install Lancer syrup separator (yellow) (PN 54-

0031 for Model 100 valves) or Lancer syrup separator (smoke)

(PN 54-0201 for Model 145 valves) in place of the

nozzle.

E. Activate valve to fill separator syrup tube.

F. Hold a Lancer

o

Brix cup under syrup separator.

Dispense water and syrup into cup for two (2) seconds. Divide number of ounces (ml) of water in

cup by two (2) to determine water flow rate per

second.

G. To obtain desired water flow rate, use a screwdriv-

er to adjust water flow control (see Figure 1).

1.5 ADJUSTING WATER TO SYRUP

o

BRIX

For the Model 100, the syrup flow may be adjusted

from 0.25 oz/sec (7.4 ml/sec) to 0.50 oz/sec

Typical Valve

Figure 1

Mounting Block Stems in OPEN Position

Figure 3

Mounting Block Stems in CLOSED Position

Figure 2

Figure 4

STEMS

STEMS

(14.8 ml/sec). For the Model 145, the syrup flow may be adjusted from 0.50 oz/sec (14.8 ml/sec) to

0.90 oz/sec (26.6 ml/sec).

A. Hold the Lancer

o

Brix cup under the syrup separator and activate valve. Check oBrix.

B. To obtain desired

o

Brix, use screwdriver to adjust syrup flow control (see Figure 1).

C. Remove syrup separator.

D. Install diffuser and nozzle.

E. Slide down I.D. panel.

1.6 INSTALLATION OF SODA LEVER

The soda lever may be field installed on any LMV®

or LEV®.

A. Remove valve cover.

B. Turn both stems on mounting block to CLOSED position (see Figure 2).

C. If LEV

®, disconnect electric wiring harness.

D. Remove valve from mounting block.

E. Locate bottom plate plug in bottom plate on left side of nozzle (if necessary).

I.D. PANEL

(Shown in

open position)

FLOW CONTROL

WATER

DecreaseIncrease

COVER SCREW

FLOW CONTROL

SYRUP

DecreaseIncrease

NOZZLE (WITH

DIFFUSER INSIDE)

A

B

C

Page 5

F. Pull out stainless steel pin and remove bottom plate plug (see Figure 4).

NOTE

If valve does not have pin, push bottom of plug to snap it out of position.

G. Remove nozzle by twisting counter clockwise and pulling down.

H. Remove diffuser by pulling down.

I. Hold cup lever back and lay soda lever across bottom of valve with small leg extending through

hole. Twist soda lever slightly and bring to upright position. Soda lever will slide between the

vertical supports.

J. Release cup lever.

K. Line up holes in supports and soda lever and install stainless steel pin.

L. Install diffuser and nozzle.

M. Install valve on mounting block and latch wire retainer.

N. If LEV

®, reconnect electric wire harness.

O. Turn both stems on mounting block to OPEN position (see Figure 3).

P. Push soda lever back and check for soda/water flow.

Q. Install cover and tighten cover screw.

R. Slide down I.D. panel.

1.7 REMOVAL AND INSTALLATION OF FRONT SODA/WATER LEVER (KIT # 82-1458)

A. Slide I.D. panel up to expose cover mounting screw (see Figure 1).

B. Loosen cover mounting screw (DO NOT REMOVE) and remove cover.

C. Close stems on mounting block (see Figure 2).

D. Operate valve to check for complete shutoff of water and syrup.

E. Lift up wire retainer and carefully remove valve from mounting block. If LEV

®, disconnect wire

harness.

F. Locate bottom plate plug or soda lever in bottom plate on left side of valve. For removal of either

item, remove pin and retain for reinstallation (see Figure 4).

NOTE

If valve does not have pin, push bottom of plug to snap it out of position.

G. To remove existing soda lever, slide lever behind vertical supports (see Figure 5). Carefully pull

lever down, rotating it towards the back right corner of the bottom plate. Then slide lever out of

the slot.

H. To install the front soda/water lever, first position the lever so that the contact pad faces towards

the rear of the valve (see Figure 6).

(1) Insert the front soda/water lever through the bottom plate and rotate the lever to the left until

the contact pad is facing forward and the extension is positioned over the paddle arm on the

left.

(2) To install spring (see Figure 7), press stud pin into hole on upper body and fit one end of

spring into outer groove of stud pin. Fit other end of spring into hole on top of front

soda/water lever. Install pin.

I. Install diffuser and nozzle.

J. Install valve on mounting block and latch wire retainer.

3

Figure 6

FRONT

Figure 7

SODA/WATER

LEVER

SPRING

STUD PIN

PIN

FRONT

SODA/WATER

LEVER

Page 6

K. If LEV®, reconnect electric wire harness.

L. Turn both stems on mounting block to OPEN position (see Figure 3).

M. Push soda lever back and check for soda/water flow.

N. Attach appropriate label to push pad on front soda/water lever.

O. Install cover and tighten cover screw.

P. Slide down I.D. panel.

1.8 REMOVAL AND INSTALLATION OF FLOW CONTROLS

A. Slide I.D. panel up to expose cover mounting screw (see Figure 1).

B. Loosen cover mounting screw (DO NOT REMOVE) and remove cover.

C. Close stems on mounting block (see Figure 2).

D. Operate valve to check for complete shutoff of water and syrup.

E. Remove top screw and loosen bottom screw. Remove retainer.

F. Remove plug adjustment assembly by threading extractor tool (PN 52-1950) into the bonnet and

pulling it out. This will expose the flow control.

G. Lift up wire retainer and carefully remove valve from mounting block. If electric, disconnect wire

harness.

H. Tilt valve forward to remove spring and piston.

NOTE

If piston is going to be reused, use caution when handling.

4

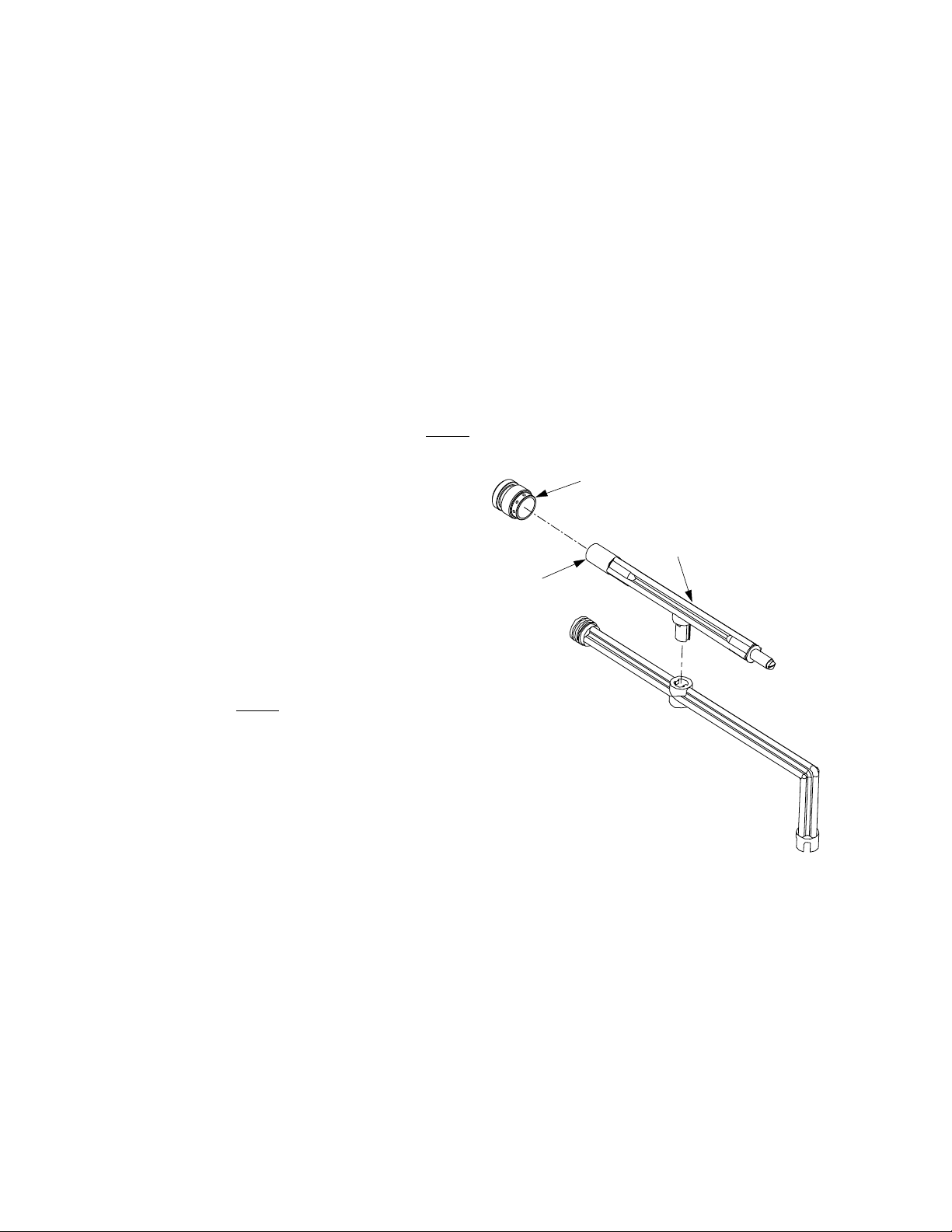

Flow Control Extractor Tool

Figure 8

L. Lubricate o-ring with water (or any FDA approved lubricant) and push sleeve to bottom.

M. Reassemble spool, spring, plug adjustment assembly, retainer and screws

N. Turn both shut offs on mounting block to the OPEN position (see Figure 3).

O. Replace cover and tighten mounting screw.

P. Adjust water flow to correct flow rate (refer to Section 1.4).

Q. Adjust

o

Brix to correct setting (refer to Section 1.5).

R. Slide down I.D. panel.

2. CLEANING

2.1 DAILY CLEANING

A. Nozzle and diffuser must be cleaned daily.

1. Remove nozzle by twisting counter clockwise and pulling down.

I. Replace valve to mounting block and

push wire retainer down. This will

provide a stable working condition.

J. To remove sleeve, use flow control

extractor tool (PN 52-1950) (see

Figure 8).

(1) Ensure rubber bushing is loose on

handle.

(2) Push rubber bushing into sleeve.

(3) Turn clockwise to tighten bushing

inside sleeve.

NOTE

This will allow sleeve to be removed

or installed.

(4) Turn counterclockwise to loosen

bushing inside sleeve. This will

allow tool to be removed from

sleeve.

K. To replace sleeve, place sleeve on flow

control extractor tool (see Figure 8) and

insert in upper body.

RUBBER BUSHING

SLEEVE

FLOW EXTRACTOR TOOL

Page 7

2. Remove diffuser by pulling down.

3. Wash nozzle and diffuser with warm water. Ensure that cleaning solution is thoroughly

rinsed from nozzle and diffuser. Residual solution will cause foaming and off taste in

finished product.

4. Reinstall diffuser and nozzle.

NOTE:

Ensure compliance with the instructions of the dispenser manufacturer to properly clean and

sanitize the nozzle and diffuser, and ensure no off-taste is present.

2.2 BI-WEEKLY SANITIZING

A. Nozzle and diffuser must be sanitized bi-weekly. Comply with the instructions of the dispenser

manufacturer to properly sanitize the nozzle and diffuser, and insure no off-taste is present.

3. SYRUP BRIX CUP

05-0081 Soda Brix Cup 05-0170 Syrup Brix Cup 5.00 to 1

05-0083 Syrup Brix Cup 4.00 to 1 05-0086 Syrup Brix Cup 5.2 to 1

05-0084 Syrup Brix Cup 4.20 to 1 05-0087 Syrup Brix Cup 5.30 to 1

05-0085 Syrup Brix Cup 4.40 to 1 05-0088 Syrup Brix Cup 5.40 to 1

05-0171 Syrup Brix Cup 4.50 to 1 05-0089 Syrup Brix Cup 5.50 to 1

05-0169 Syrup Brix Cup 4.75 to 1 05-0090 Universal Split Cup

4. TROUBLESHOOTING

TROUBLE

CAUSE REMEDY

4.1 Water leakage around A. O-ring is not properly installed A. Install or replace o-ring correctly.

nozzle. above diffuser.

B. O-ring is damaged or missing. B. Replace o-ring.

4.2 Leakage between A. One or more retaining screws A. Tighten all six (6) retaining screws.

upper and lower loose.

bodies. B. Paddle arm assemblies are B. Replace paddle arm assemblies.

worn or damaged.

4.3 Miscellaneous leakage. A. Gap between parts. A. Tighten appropriate retaining

screws.

B. Damaged, missing, or B. Replace appropriate o-rings.

improperly installed o-rings.

4.4 Insufficient water flow. A. Water flowing pressure is A. 1. Check incoming water from

too low, or restricted. carbonator to ensure minimum

flowing pressure. See

SPECIFICATIONS.

2. Check stems on mounting

block to ensure it is in fully

OPEN position.

B. Foreign debris in water flow B. Remove water flow control from

controls. upper body and clean out any

foreign materials to ensure smooth

free piston movement.

4.5 Insufficient syrup flow. A. Syrup flowing pressure is A. 1. Check incoming syrup to

too low, or restricted. ensure minimum flowing

pressure. See

SPECIFICATIONS.

2. Check shutoff on mounting

block to ensure it is in fully

OPEN position.

B. Foreign debris in syrup B. Remove syrup flow control from

flow controls. upper body and clean out any

foreign materials to ensure

smooth free piston movement.

(Continued on next page)

5

Page 8

6

(Continued from previous page)

4.6 Erratic Ratio oBrix. A. Incoming water and/or syrup A. Check incoming water and

supply not at sufficient syrup supply to ensure sufficient

flowing pressure. flowing pressure.

B. Foreign debris in water and/or B. Remove flow controls and clean

syrup flow controls. out any foreign materials to ensure

smooth free piston movement.

4.7 No product dispensed. A. Water and syrup shutoffs are A. Check stems on mounting block

not fully OPEN. to ensure they are in fully OPEN

position.

B. If LEV®, ensure cup lever B. If not, repair or replace.

arm, or I.D. Panel actuator is

actuating switch.

C. If LEV®, electric current not C. Check electric current supplied to

reaching valve. valve. See SPECIFICATIONS. If

current is adequate, check

solenoid coil and switch. Replace

if necessary.

D. Improper or inadequate water D. Remove valve from mounting block

or syrup supply. and open stems slightly and

check to ensure proper water and

syrup supply. If no supply, check

dispenser for freeze-up or other

problems.

E. If LMV®, valve is not E. Check manual operation of valve to

functioning correctly. ensure proper function.

4.8 Water only dispensed, A. Water or syrup stem on A. Check stems on mounting

no syrup; or syrup only mounting block not fully OPEN. block to ensure they are in full

dispensed, no water. OPEN position.

B. Improper or inadequate water B. Remove valve from mounting block

or syrup supply. and open stem slightly to check

for proper syrup and water supply.

If no supply, check dispenser for

freeze-up or other problems.

4.9 Valve will not shut off. A. Cup Lever may be sticking A. Correct or replace lever.

or binding.

B. If LEV®, switch not B. Check switch for free actuation.

actuating properly.

C. If LEV®, solenoid armature C. Replace defective solenoid

not returning to bottom armature or spring.

position.

D. Debris or damage to Paddle D. Remove debris and/or replace

arms. damaged paddle arms.

4.10 Excessive foaming. A. Incoming water or syrup A. Correct at dispenser.

temperature too high.

B. Water flow rate too high. B. Readjust and reset

o

Brix. See

Section 1.5.

C. Nozzle and diffuser not clean. C. Remove and clean.

D. Nozzle and diffuser not D. Remove and install properly.

properly installed.

E. CO2 pressure too high. E. Check for proper pressure setting.

4.11 No syrup-out light. A. Burned out or defective lamp. A. Replace harness.

(If equipped.) B. Faulty wiring and/or pressure B. Repair or replace.

switch in product line.

PROBLEM

CAUSE CORRECTIVE ACTION

Page 9

NOTES

Please refer to the Lancer web site (www.lancercorp.com) for information relating to Lancer

Installation and Service Manuals, Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

7

Page 10

8

5. ILLUSTRATIONS AND PARTS LISTINGS

5.1 LMV® (MODEL 100, 3.0 OZ/SEC)

3

1

4

6

2

7

5

9

11

8

Flow Control, 3.0, Syrup, Kit, PN 82-1027

13

14

15

Flow Control, 3.0, Soda, Kit,

PN 82-1026

18

16

20

21

22

23

21

26

12

16

29

30

25

28

Front Soda/Water Lever Kit,

PN 82-1458

39

40

38

36

25

27

33

10

41

35

29

34

16

31

42

37

14

11

32

17

19

16

20

21

22

23

24

Page 11

ITEM PART NO. DESCRIPTION

1 05-0287 I.D. Panel

2 54-0029 Cover Sub Assy

– 54-0030 Cover Assy (Item No. 1-2)

3 05-0266 Stem, Valve, Mounting Block

4 05-0267 Washer

5 02-0047 O-Ring

6 04-0269 Screw

7 03-0087 Retainer, Stem, Valve, Mounting

Block

8 05-0265 Mounting Block

– 82-0274 Block Mounting Assy

(Item No. 3-8, 21)

9 03-0233 Retainer, Valve, 1-Piece

10 03-0143 Spring, Pin, LEV

®

11 04-0270 Screw

R 12 54-0045 Body Assy, Upper, 3.0, LMV®

13 04-0302 Screw

14 81-0274 Sleeve, Syrup/Water, 3.0

15 81-0273 Piston, Syrup, 3.0

16 02-0132 O-Ring

17 81-0275 Piston, Soda, 3.0

18 03-0169 Spring, Syrup, Flow Control, LEV

®

19 03-0171 Spring, Soda, Flow Control, LEV®

20 05-0262 Bonnet, Flow Control

21 02-0126 O-Ring

R 22 05-1919 Plug, Adjustment, Flow Control, White

R – 82-0527/01 Plug, Adjustment Assy, White

(Item No. 16, 20-22)

23 03-0088 Retainer, Flow Control

24 04-0267 Screw

25 03-0095 Spring

26 03-0094 Spring (Center)

27 05-0222 Yoke, Mechanical

28 05-0248 Lever, Mechanical

– 82-0526 Lever Assy, Mechanical (Item No.

26-28)

R 29 82-2929 Arm, Paddle, Assy

30 54-0046 Body Assy, Lower, 3.0

31 02-0408 O-Ring, Nozzle, Red, 3.0

(Used in Valves produced

through September 1998)

32 05-0232 Plate, Bottom, 3.0

33 04-0310 Screw

34 02-0133 O-Ring (Used in Valves

produced through

September 1998)

35 05-0281 Plug, Bottom Plate

36 04-0775 Pin, Lever, Soda

37 05-0233 Nozzle, 3.0 (Used in Valves

produced through

September 1998)

- 05-1463 Nozzle, 3.0 (Used

in Valves produced in

September 1998 and later)

37 09-0120 Lever, Front Soda/Water

38 04-0724 Pin, Stud

9

5.1 LMV® (MODEL 100, 3.0 OZ/SEC) (CONTINUED)

39 03-0238 Spring, Front Soda/Water Lever

41 05-0274 Lever, Soda, 3.0

42 54-0028 Diffuser Assy, 3.0 (Used

in Valves produced

through September 1998)

- 05-1593 Diffuser Assy, 3.0 (Used

in Valves produced in

September 1998 and later)

R in margin indicates revision or data change

ITEM PART

NO.

DESCRIPTION

Page 12

10

5.2 LEV® (MODEL 100L, 3.0 OZ/SEC AND MODEL 145L, 4.5 OZ/SEC)

1

2

3

4

6

1a

7

8

Front Soda/Water

Lever Kit,

PN 82-1458

44

45

48

22

36

33

38

17

5

39

40

41

9

42

12

26

35

16

27

28

10

16

14

18

13

11

14

43

Flow Control, 3.0, Syrup, Kit,

PN 82-1027

Flow Control, 4.5, Syrup, Kit,

PN 82-2226

Flow Control, 3.0, Soda, Kit,

PN 82-1026

Flow Control, 4.5, Soda, Kit,

15

PN 82-2227

19

16

21

22

23

24

25

20

16

21

22

37

30

17a

11

29

47

46

Syrup-Out Light

Kit Option

PN 82-0783

23

24

25

51

52

32

31

50

34

53

Nozzle Assembly, 4.5,

Kit PN 82-2014

49

Page 13

11

ITEM PART NO. DESCRIPTION

1 05-0287 I.D. Panel

1a 54-0057 I.D. Panel (Syrup-Out)

2 54-0029 Cover Sub Assy

– 54-0030 Cover Assy (Item No. 1-2)

– 54-0059 Cover Assy (Item No. 1a-2)

3 05-0266 Stem, Valve, Mounting Block

4 05-0267 Washer

5 02-0047 O-Ring

6 04-0269 Screw

7 03-0087 Retainer, Stem, Valve,

Mounting Block

8 05-0265 Mounting Block

– 82-0274 Block Assy, Mounting

(Item No. 3-8, 22)

9 03-0233 Retainer, Valve, 1-Piece

10 03-0143 Spring, Pin, LEV

®

11 04-0270 Screw

12 54-0189 Body Assy, Upper

13 04-0302 Screw

14 81-0274 Sleeve, Syrup/Water, 3.0

- 81-0382 Sleeve, Syrup/Soda, 4.5

15 81-0273 Piston, Syrup, 3.0

- 81-0383 Piston, Syrup, 4.5

16 02-0132 O-Ring

17 52-0622 Wire Harness

17a 52-0902 Wire Harness (Syrup-Out)

18 81-0275 Piston, Soda, 3.0

- 81-0384 Piston, Soda, 4.5

19 03-0169 Spring, Syrup, Flow Control, LEV

®

20 03-0171 Spring, Soda, Flow Control, LEV®

21 05-0262 Bonnet, Flow Control

22 02-0126 O-Ring

R 23 05-1919 Plug, Adjustment,

Flow Control, White

R – 82-0527/01 Plug, Adjustment Assy, White

(Item No. 16, 21-23)

24 03-0088 Retainer, Flow Control

25 04-0267 Screw

R 26 82-2929 Arm, Paddle, Assy

27 54-0046 Body Assy, Lower, 3.0

- 54-0188 Body Assy, Lower, 4.5

28 02-0408 O-Ring, Nozzle, Red, 3.0

(Used in Valves produced

through September 1998)

29 05-0232 Plate, Bottom, 3.0

- 05-1108 Plate, Bottom, 4.5

30 04-0310 Screw

31 02-0133 O-Ring (Used in Valves

produced through

September 1998)

32 05-0281 Plug, Bottom Plate

33 04-0775 Pin, Lever, Soda

5.2 LEV® (MODEL 100L, 3.0 OZ/SEC AND MODEL 145L, 4.5 OZ/SEC) (CONTINUED)

34 05-0233 Nozzle, 3.0 (Used in Valves

produced through

September 1998)

- 05-1463 Nozzle, 3.0 (Used

in Valves produced in

September 1998 and later)

35 03-0081 Lever, Spring, Electric

36 05-0231 Lever, Electric

37 05-0238 Yoke, Electric

38 52-0288 Coil Assy,LEV

®

39 03-0125 Spring, Solenoid, LEV®

40 10-0117 Armature, LEV®

41 05-0935 Plug, Retainer, Micro-Switch

42 26-0265 Micro-Switch

43 04-0486 Screw

44 04-0724 Pin, Stud

45 03-0238 Spring, Front Soda/Water Lever

46 05-0490 Holder

47 04-0470 Screw

48 09-0120 Lever, Front, Soda/Water

49 05-0274 Lever, Soda, 3.0

50 54-0028 Diffuser Assy, 3.0 (Used

in Valves produced

through September 1998)

- 05-1593 Diffuser Assy, 3.0 (Used

in Valves produced in

September 1998 and later)

51 02-0133 O-Ring

52 02-0421 Seal, Nozzle, 4.5

53 54-0183 Nozzle Assy, 4.5

R in margin indicates revision or data change

ITEM PART NO. DESCRIPTION

Page 14

12

5.3 LEV® WITH SELF-SERVE LEVER (MODEL 100SSL, 3.0 OZ/SEC AND

MODEL 145SSL, 4.5 OZ/SEC)

1

2

3

4

6

38

5

1a

7

8

Front Soda/Water

Lever Kit, PN 82-1458

45

46

42

16

41

17

12

13

14

43

Flow Control, 3.0, Syrup,

Kit, PN 82-1027

Flow Control, 4.5, Syrup,

11

Kit, PN 82-2226

15

19

16

Flow Control, 3.0, Soda,

Kit, PN 82-1026

Flow Control, 4.5, Soda,

Kit, PN 82-2227

39

40

9

22

35

26

21

22

23

24

10

27

28

26

16

14

18

36

P

U

S

H

20

16

37

29

33

30

11

21

22

47

48

17a

Syrup-Out Light

Kit Option

23

24

25

PN 82-0783

31

50

51

52

44

49

32

34

Nozzle Assembly, 4.5,

Kit PN 82-2014

53

Page 15

ITEM PART NO. DESCRIPTION

1 05-0287 I.D. Panel

1a 54-0057 I.D. Panel (Syrup-Out)

2 54-0029 Cover Sub Assy

– 54-0030 Cover Assy (Item No. 1-2)

– 54-0059 Cover Assy (Item No. 1a-2)

3 05-0266 Stem, Valve, Mounting Block

4 05-0267 Washer

5 02-0047 O-Ring

6 04-0269 Screw

7 03-0087 Retainer, Stem, Valve,

Mounting Block

8 05-0265 Mounting Block

– 82-0274 Block Assy, Mounting

(Item No. 3-8, 22)

9 03-0233 Retainer, Valve, 1-Piece

10 03-0143 Spring, Pin,LEV

®

11 04-0270 Screw

12 54-0189 Body, Upper, Assy

13 04-0302 Screw

14 81-0274 Sleeve, Syrup/Water, 3.0

- 81-0382 Sleeve, Syrup/Soda, 4.5

15 81-0273 Piston, Syrup, 3.0

- 81-0383 Piston, Syrup, 4.5

16 02-0132 O-Ring

17 52-0622 Wire Harness

17a 52-0902 Wire Harness (Syrup-Out)

18 81-0275 Piston, Soda, 3.0

- 81-0384 Piston, Soda, 4.5

19 03-0169 Spring, Syrup, Flow

Control, LEV

®

20 03-0171 Spring, Soda, Flow

Control, LEV

®

21 05-0262 Bonnet, Flow Control

22 02-0126 O-Ring

R 23 05-1919 Plug, Adjustment,

Flow Control, White

R – 82-0527/01 Plug, Adjustment Assy, White

(Item No. 16, 21-23)

24 03-0088 Retainer, Flow Control

25 04-0267 Screw

R 26 82-2929 Arm, Paddle, Assy

27 54-0046 Body Assy, Lower, 3.0

- 54-0188 Body Assy, Lower, 4.5

28 02-0408 O-Ring, Nozzle, Red, 3.0

(Used in Valves produced

through September 1998)

29 05-0232 Plate, Bottom, 3.0

- 05-1108 Plate, Bottom, 4.5

30 04-0310 Screw

31 02-0133 O-Ring (Used in Valves

produced through

September 1998)

32 05-0281 Plug, Bottom Plate

33 04-0775 Pin, Lever, Soda

13

5.3 LEV® WITH SELF-SERVE LEVER (MODEL 100SSL, 3.0 OZ/SEC AND

MODEL 145SSL, 4.5 OZ/SEC) (CONTINUED)

34 05-0233 Nozzle, 3.0 (Used in Valves

produced through

September 1998)

- 05-1463 Nozzle, 3.0 (Used

in Valves produced in

September 1998 and later)

35 03-0081 Lever, Spring, Electric

36 54-0165 Lever, Self-Serve

37 05-0238 Yoke, Electric

38 52-0288 Coil Assy

39 03-0125 Spring, Solenoid

40 10-0117 Armature

41 05-0935 Plug, Retainer, Micro-Switch

42 26-0265 Micro-Switch

43 04-0486 Screw

44 09-0120 Lever, Front Soda/Water

45 04-0724 Pin, Stud

46 03-0238 Spring, Front Soda/Water Lever

47 04-0470 Screw

48 05-0490 Holder

49 05-0274 Lever, Soda, 3.0

50 54-0028 Diffuser Assy, 3.0 (Used

in Valves produced

through September 1998)

- 05-1593 Diffuser Assy, 3.0 (Used

in Valves produced in

September 1998 and later)

51 02-0133 O-Ring

52 05-0421 Seal, Nozzle, 4.5

53 54-0183 Nozzle Assy, 4.5

R in margin indicates revision or data change

ITEM PART NO. DESCRIPTION

Page 16

14

5.4 LEV® PUSHBUTTON (MODEL 100P, 3.0 OZ/SEC AND MODEL 145P, 4.5 OZ/SEC)

1

6

7

8

Front Soda/Water Lever

Kit, PN 82-1458

45

22

35

33

PUSH

2

3

4

36

5

12

16

40

13

14

39

Flow Control, 3.0, Syrup,

11

Kit, PN 82-1027

Flow Control, 4.5, Syrup,

Kit, PN 82-2226

Flow Control, 3.0, Soda,

Kit, PN 82-1026

Flow Control, 4.5, Soda,

Kit, PN 82-2227

37

9

38

15

19

26

16

21

22

23

24

27

28

10

26

16

14

18

20

16

21

17

30

29

43

40a

41

42

22

23

Syrup-Out Light

Kit, Option, PN 82-0783

24

25

11

46

44

47

32

31

48

34

49

50

Nozzle Assembly Kit, 4.5

PN 82-2014

51

Page 17

ITEM PART NO.

DESCRIPTION

1 54-0140 I.D. Panel, Large Pushbutton

2 54-0029 Cover Sub Assy

– 54-0139 Cover Assy, Large (Pushbutton,

Item No. 1-2)

3 05-0266 Stem, Valve, Mounting Block

4 05-0267 Washer

5 02-0047 O-Ring

6 04-0269 Screw

7 03-0087 Retainer, Stem, Valve,

Mounting Block

8 05-0265 Mounting Block

– 82-0274 Block Assy, Mounting

(Item No. 3-8, 22)

9 03-0233 Retainer, Valve, 1-Piece

10 03-0143 Spring, Pin

11 04-0270 Screw

12 54-0189 Body Assy, Upper

13 04-0302 Screw

14 81-0274 Sleeve, Syrup/Water, 3.0

- 81-0382 Sleeve, Syrup/Soda, 4.5

15 81-0273 Piston, Syrup, 3.0

- 81-0383 Piston, Syrup, 4.5

16 02-0132 O-Ring

17 05-0491 Filler

18 81-0275 Piston, Soda, 3.0

- 81-0384 Piston, Soda, 4.5

19 03-0169 Spring, Syrup,

Flow Control, LEV

®

20 03-0171 Spring, Soda,

Flow Control, LEV

®

21 05-0262 Bonnet, Flow Control

22 02-0126 O-Ring

R 23 05-1919 Plug, Adjustment,

Flow Control, White

R – 82-0527/01 Plug, Adjustment Assy, White

24 03-0088 Retainer, Flow Control

25 04-0267 Screw

R 26 82-2929 Arm, Paddle, Assy

27 54-0046 Body Assy, Lower, 3.0

- 54-0188 Body Assy, Lower, 4.5

28 02-0408 O-Ring, Nozzle, Red, 3.0

(Used in Valves produced

through September 1998)

29 05-0232 Plate, Bottom, 3.0

- 05-1108 Plate, Bottom, 4.5

30 04-0310 Screw

31 02-0133 O-Ring (Used in Valves

produced through

September 1998)

32 05-0281 Plug, Bottom Plate

33 04-0775 Pin, Lever, Soda

34 05-0233 Nozzle, 3.0 (Used in Valves

produced through

September 1998)

- 05-1463 Nozzle, 3.0 (Used

in Valves produced in

September 1998 and later)

35 05-0238 Yoke, Electric

36 52-0288 Coil Assy, LEV

®

5.4 LEV® PUSHBUTTON (MODEL 100P, 3.0 OZ/SEC AND MODEL 145P, 4.5 OZ/SEC)

(CONTINUED)

15

37 03-0125 Spring, Solenoid, LEV®

38 10-0117 Armature, LEV®

39 04-0486 Screw

40 52-0622 Wire Harness

40a 52-0902 Wire Harness (Syrup-Out)

41 04-0470 Screw

42 05-0490 Holder

43 26-0265 Micro-Switch

44 09-0120 Lever, Front

Soda/Water

45 04-0724 Pin, Stud

46 03-0238 Spring, Front

Soda/Water Lever

47 05-0274 Lever, Soda

48 54-0028 Diffuser Assy, 3.0 (Used

in Valves produced

through September 1998)

- 05-1593 Diffuser Assy, 3.0 (Used

in Valves produced in

September 1998 and later)

49 02-0133 O-Ring

50 02-0421 Seal, Nozzle, 4.5

51 54-0183 Nozzle Assy, 4.5

R in margin indicates revision or data change

ITEM P

ART NO. DESCRIPTION

Page 18

16

5.5 LEV® SUREFILL (MODEL 100SF, 3.0 OZ/SEC AND MODEL 145SF, 4.5 OZ/SEC)

10

1

21

20

11

3

12

2

13

4

6

14

5

15

36

33

48

36

37

49

37

38

47

39

40

Flow Control, 3.0, Syrup, Kit,

PN 82-1027

Flow Control, 4.5, Syrup, Kit,

PN 82-2226

Flow Control, 3.0, Soda, Kit,

PN 82-1026

Flow Control, 4.5, Soda, Kit,

PN 82-2227

41

42

56

44

57

45

46

7

18

16

17

8

9

22

35

34

35

32

42

23

19

31

24

30

25

43

44

57

45

46

26

27

53

28

29

50

51

54

55

Nozzle Assembly, 4.5,

Kit PN 82-2014

52

Front Soda/Water Lever Kit, PN 82-1458

Page 19

ITEM PART NO. DESCRIPTION

1 05-0287 I.D. Panel

2 54-0029 Cover Sub Assy

– 54-0030 Cover Assy (Item No. 1-2)

3 05-0266 Stem, Valve, Mounting Block

4 05-0267 Washer

5 02-0047 O-Ring

6 04-0269 Screw

7 03-0087 Retainer, Stem, Valve,

Mounting Block

8 05-0265 Mounting Block

– 82-0274 Block Assy, Mounting

(Item No. 3-9)

9 02-0126 O-Ring

10 04-0478 Screw

11 30-7245 Strap

12 82-1982 Module, Surefill

13 04-0270 Screw

R 14 05-0788 Module Bracket (Used in Valves

produced through September 2000)

R - 05-1928 Bracket, PCB, White (Used in Valves

produced in October 2000 and later)

15 52-0288 Coil Assy, LEV

®

16 03-0125 Spring, Solenoid, LEV®

17 10-0117 Armature, LEV®

18 03-0233 Retainer, Valve, 1-Piece

19 04-0724 Pin, Stud

20 05-0777 Bushing, Lever

21 30-5416 Lever

22 04-0642 Screw, 6 - 32 x 0.250

23 05-0238 Yoke, Electric

24 04-0775 Pin, Lever, Soda

25 04-0310 Screw

26 03-0238 Spring, Front

Soda/Water Lever

27 09-0120 Lever, Front

Soda/Water

28 05-0274 Lever, Soda

29 05-0281 Plug, Bottom Plate

30 04-0270 Screw

31 05-0801 Plate, Bottom, 3.0

- 05-1544 Plate, Bottom, 4.5

32 03-0143 Spring, Pin

33 02-0408 O-Ring, Nozzle, Red, 3.0

(Used in Valves produced

through September 1998)

34 54-0046 Body Assy, Lower, 3.0

- 54-0188 Body Assy, Lower, 4.5

R 35 82-2929 Arm, Paddle, Assy

36 02-0132 O-Ring

37 81-0274 Sleeve, Syrup/Soda, 3.0

- 81-0382 Sleeve, Syrup/Soda, 4.5

38 81-0275 Piston, Soda, 3.0

- 81-0384 Piston, Soda, 4.5

39 81-0273 Piston, Syrup, 3.0

- 81-0383 Piston, Syrup, 4.5

40 03-0171 Spring, Soda,

Flow Control, LEV

®

5.5 LEV® SUREFILL (MODEL 100SF, 3.0 OZ/SEC AND MODEL 145SF, 4.5 OZ/SEC) (CONTINUED)

17

41 03-0169 Spring, Syrup,

Flow Control, LEV

®

42 02-0132 O-Ring

43 05-0796 Bonnet, Surefill

44 02-0126 O-Ring

R - 82-2992 Plug, Adjustment Assy, SF, White

R 45 03-0088 Retainer

R 46 04-0267 Screw

R 47 04-0302 Screw

R 48 54-0189 Body Assy, Upper

R 49 04-0486 Screw

R 50 02-0133 O-Ring (Used in Valves

produced through

September 1998)

R 51 54-0028 Diffuser Assy, 3.0 (Used

in Valves produced

through September 1998)

- 05-1593 Diffuser Assy, 3.0 (Used

in Valves produced in

September 1998 and later)

R 52 05-0233 Nozzle, 3.0 (Used in

Valves produced through

September 1998)

- 05-1463 Nozzle, 3.0 (Used

in Valves produced in

September 1998 and later)

R 53 02-0133 O-Ring

R 54 02-0421 Seal, Nozzle, 4.5

R 55 54-0183 Nozzle Assy, 4.5

R 56 05-0262 Bonnet, Flow Control

R 57 05-1919 Plug Adjust, Flow Control, White

- 82-0527/01 Plug Adjust Assy, White (Items

42, 44, 57, and 58)

R in margin indicates revision or data change

ITEM PART NO. DESCRIPTION

Page 20

18

5.6 LEV® PORTION CONTROL (MODEL 100PC, 3.0 OZ/SEC AND MODEL 145PC, 4.5 OZ/SEC)

1

2

3

4

6

36

7

8

Front Soda/Water Lever

Kit, PN 82-1458

44

22

35

33

17

5

39

37

9

Flow Control, 3.0, Syrup,

11

Kit, PN 82-1027

Flow Control, 4.5, Syrup,

38

12

16

13

14

Kit, PN 82-2226

Flow Control, 3.0, Soda,

Kit, PN 82-1026

Flow Control, 4.5, Soda,

Kit, PN 82-2227

15

19

26

16

21

22

23

24

27

28

10

26

16

14

18

20

16

21

30

29

41

42

40

Syrup-Out Light Kit,

Option, PN 82-2131

22

23

24

25

11

45

43

46

32

31

47

34

48

49

Nozzle Assembly Kit, 4.5

PN 82-2014

50

Page 21

ITEM

PART NO. DESCRIPTION

R 1 52-1581 I.D. Panel (Used in Valves produced

through May 2000)

R - 52-2296 I.D. Panel, PC, Parylene (Used in

Valves produced through June 2000

and later)

2 54-0029 Cover Sub Assy

– 54-0181 Cover Assy, Large

(Items No. 1-2)

3 05-0266 Stem, Valve, Mounting Block

4 05-0267 Washer

5 02-0047 O-Ring

6 04-0269 Screw

7 03-0087 Retainer, Stem, Valve,

Mounting Block

8 05-0265 Mounting Block

– 82-0274 Block Assy, Mounting

(Item No. 3-8, 22)

9 03-0233 Retainer, Valve, 1-Piece

10 03-0143 Spring, Pin

11 04-0270 Screw

12 54-0189 Body Assy, Upper

13 04-0302 Screw

14 81-0274 Sleeve, Syrup/Water, 3.0

- 81-0382 Sleeve, Syrup/Soda, 4.5

15 81-0273 Piston, Syrup, 3.0

- 81-0383 Piston, Syrup, 4.5

16 02-0132 O-Ring

17 05-0491 Filler

18 81-0275 Piston, Soda, 3.0

- 81-0384 Piston, Soda, 4.5

19 03-0169 Spring, Syrup,

Flow Control, LEV

®

20 03-0171 Spring, Soda,

Flow Control, LEV®

21 05-0262 Bonnet, Flow Control

22 02-0126 O-Ring

R 23 05-1919 Plug, Adjustment, Flow Control, White

R – 82-0527/01 Plug, Adjustment Assy, White

24 03-0088 Retainer, Flow Control

25 04-0267 Screw

R 26 82-2929 Arm, Paddle, Assy

27 54-0046 Body Assy, Lower, 3.0

- 54-0188 Body Assy, Lower, 4.5

28 02-0408 O-Ring, Nozzle, Red, 3.0 (Used in

Valves produced through September

1998)

29 05-0232 Plate, Bottom, 3.0

- 05-1108 Plate, Bottom, 4.5

30 04-0310 Screw

31 02-0133 O-Ring (Used in Valves produced

through September 1998)

32 05-0281 Plug, Bottom Plate

33 04-0775 Pin, Lever, Soda

19

5.6 LEV® PORTION CONTROL (MODEL 100PC, 3.0 OZ/SEC AND MODEL 145PC, 4.5 OZ/SEC

(CONTINUED)

34 05-0233 Nozzle, 3.0 (Used in Valves

produced through

September 1998)

- 05-1463 Nozzle, 3.0 (Used in Valves produced

in September 1998 and later)

35 05-0238 Yoke, Electric

36 52-0288 Coil Assy, LEV

®

37 03-0125 Spring, Solenoid, LEV®

38 10-0117 Armature, LEV®

39 04-0486 Screw

40 52-2069 Wire Harness (Syrup-Out)

41 04-0470 Screw

42 05-0490 Holder

43 09-0120 Lever, Front

Soda/Water

44 04-0724 Pin, Stud

45 03-0238 Spring, Front

Soda/Water Lever

46 05-0274 Lever, Soda

47 54-0028 Diffuser Assy, 3.0 (Used in Valves

produced through September 1998)

- 05-1593 Diffuser Assy, 3.0 (Used in Valves

produced in September 1998 and

later)

48 02-0133 O-Ring

49 02-0421 Seal, Nozzle, 4.5

50 54-0183 Nozzle Assy, 4.5

R in margin indicates revision or data change

ITEM

PART NO. DESCRIPTION

Page 22

20

NOTES

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

Page 23

(Continued from previous page)

EcuaLancer S.A. - Ecuador

Lancer Sales Company

Contact: Luciano Lopez

Sector Las Acacias

Luis De Beethoven #958

Y Capitan Rafael Ramos

Quito, Ecuador

Phone: 593-22-401-598, 400-937, 406-418

FAX: 593-22-400-535

e-mail: Llopez@ecnet.ec

Lancer Authorized Distributors

Eximport & Barter Co. - Caribbean

2101 S.W. 56th Terrace

Hollywood, FL 33023 USA

Phone: (954) 967-9999

FAX: (954) 967-9900

e-mail: edbrandao@aol.com

PromoVen, S.A. - Argentina

Contact: Rafael Mendoza

Juncal 858 - Piso 3 Depto. “L”

(1062) Buenos Aires

Argentina

Phone: (54.11)4394.7654

FAX: (54.11)4394.1193

e-mail: promoven@customw.com.ar

Bras Sulamericana LTDA. - Brasil

Contact: Fabio Queiroz

Rua. Dr. Ladislau Retti, 1400

Parque Alexandre

Cotia Sao Paulo - Brasil

CEP: 06714-150

Phone: 55-11-4612-1122

FAX: 55-11-4612-2219

e-mail: fabio.queiroz@bras.com.br

Lancer Chile Ltda. - Chile

Contact: Heriberto Concha

Vicuna Mackenna 3019, San Joaquin

Santiago, Chile

Phone: 56-2-552-1657

FAX: 56-2-552-1961

e-mail: hconcha@lancer-intl.com

Lancer Pacific

International Sales

6655 Lancer Blvd.

San Antonio, TX 78219

Phone: (210) 310-7000

FAX: (210) 310-7242

1-800-729-1500

e-mail: asia@lancercorp.com

Australia

Lancer Pacific Pty Ltd

5 Toogood Avenue

Beverley 5009

South Australia

Phone: 61-8-8268-1388

FAX: 61-8-8268-1978

e-mail: ian-lunniss@lancer-pacific.com.au

steve-sotiriou@lancer-pacific.com.au

(for Fountain)

fiore-alvaro@lancer-pacific.com.au

(for Beer)

rob-burdock@lancer-pacific.com.au

(Senior Director - Asia)

Lancer Pacific Pty Ltd

7 Slough Avenue

Silverwater 2128

New South Wales

Australia

Phone: 61-2-9648-6840

FAX: 61-2-9648-6850

e-mail: richard-abraham@lancer-

pacific.com.au

R.B.P. Industrial Sales Inc - Philippines

Unit 20, Facilities Centre Bldg.

548 Shaw Blvd

Mandaluyong City, Philippines

Phone: 632-531-1215/1221/1289

FAX: 632-531-1271

e-mail: rbpsales@info.com.ph

Freser (S) Pte Ltd - Singapore

Blk 998 Toa Payoh North

#04-12/14

Singapore 318993

Phone: 65-6352-0943

FAX: 65-6352-8594

e-mail: fresersin@pacific.net.sg

Freser International Corporation - Taiwan

No. 76, Gui-Sui Street

Taipei 103, Taiwan R.O.C.

Phone: 886-2-2553-1555

FAX: 886-2-2553-2742

e-mail: allen@intl.freser.com.tw

Freser (Thailand) Co Ltd - Thailand

3/15 Moo 3, Soi Ruammitr

Tivanont Road, Banmai

Pakkred, Nonthaburi, 11120

Thailand

Phone: 662-961-9543

FAX: 662-961-9550

e-mail: prachat@asianet.co.th

Lancer - Indian Sub-Continent

India

Shabbir Shafiqui - Area Manager

India and Sub-Continent

B-7, Pannalal Silk Mill Compounds

78, LBS Marg, Bhandup (W)

Mumbai 400-078, India

Phone: 91-22-2561-6665

Cel No.: 91-98-2029-5252

FAX: 91-22-5637-4018

e-mail: shafiquis@vsnl.com

Lancer Authorized Distributors

Western Refrigeration Ltd - India

B-7, Pannalal Silk Mill Compounds

78 L.B.S. Marg, Bhandup (W)

Mumbai 400-078, India

Phone: 91-22-2561-6665

FAX: 91-22-2562-2257

e-mail: western@bom5.vsnl.net.in

Bengal Marketing Company - Bangladesh

Skylark Point (6th Floor)

Room #G-2

24/A Bijoy Nagar,

Dhaka-1000, Bangladesh

Phone: 880-2-934-2987

FAX: 880-2-935-0127

e-mail: bmc@dhaka.agni.com

Dynamic Equipment - Pakistan

Dynamic Equipment and Controls (Pvt.) Ltd.

F-1/23, Canal Cottages, Block-D.

New Muslim Town.

Lahore. Pakistan.

Phone: 0092-42-583-6737

0092-42-583-6787

FAX: 0092-42-586-7924

e-mail: info@dynamic-eqpt.com.pk

Lancer Pacific Pty Ltd

55 Keele Street

Collingwood 3066

Victoria

Australia

Phone: 03 8415 1920

FAX: 03 8415 1929

e-mail: glenn-blakiston@lancer-pacific.com.au

Lancer Pacific Pty Ltd

Unit 31, 284 Musgrave Drive

Coopers Plains 4108

Queensland

Australia

Phone: 61-7-3274-5700

FAX: 61-7-3875-1805

e-mail: brett-thomson@lancer-pacific.com.au

New Zealand

Lancer Pacific Ltd

9 O’Rorke Street

Onehunga, Auckland

New Zealand

Phone: 64-9-634-3612

FAX: 64-9-634-1472

e-mail: phil-mason@lancer-pacific.com.au

Hong Kong

Patrick Co - Area Manager - Asia

Phone: 852-29670900

FAX: 852-30105882

e-mail: patrickco@lancer-asia.com

Lancer Authorized Distributors

Shanghai Freser International Co Ltd. China

1856, Hu Tai Road

Shanghai, 200436, China

Phone: 86-21-5650-3555

FAX: 86-21-5650-2666

e-mail: daniel@freser.com.cn

Freser (HK) Company Ltd - Hong Kong

Flat A, 24/F., Houston Industrial Bldg.

32-40 Wang Lung Street

Tsuen Wan, N. T., Hong Kong

Phone: 852-2408-2595

FAX: 852-2408-2605

e-mail: freserhk@netvigator.com

P.T. Ciptapratama Sentosamakmur Indonesia

JI. Anggrek Nelly Murni, Blok A - 39, Slipi

Jakarta 11480, Indonesia

Phone: 62-21-532-3737

FAX: 62-21-532-3666

e-mail: ciptasm@indosat.net.id

Hayakawa Sanki - Japan

Hayakawa Sanki, Inc.

1-13-13, Kayaba-cho

Nihonbashi, Chuo-ku

Tokyo, 103-0025

Japan

Phone: 03-5651-1481

FAX: 03-5651-1445

e-mail: SANKI10217@aol.com

Tahoe Corporation - Korea

Tahoe Corporation

2FL, 835-66 Yocksam-dong

Kangnam-Ku

Seoul, Korea

Phone: 82-2-557-5612, -5614

FAX: 82-2-557-5615

e-mail: tahoepark@netsgo.com

Freser (MALAYSIA) SDN. BHD. - Malaysia

No. 31, Jalan TPP 5/13, Taman

Perindustrian Puchong, Seksyen 5,

47100 Puchong, Selangor, Malaysia

Phone: 60-3-8061-6666

FAX: 60-3-8062-1007

e-mail: freser@tm.net.my

21

Directory of USA - Canada Offices,

International Offices, and Authorized Distributors

(Continued)

Page 24

Lancer USA

Manufacturing Locations

Foster Road Facilities

6655 Lancer Blvd

San Antonio, TX 78219

Phone: (210) 310-7000

MFG FAX: (210) 310-7088

ENG FAX: (210) 310-7096

ACCT FAX: (210) 310-7091

PURCH FAX: (210) 310-7094

Lancer FBD

5620 Business Park

San Antonio, TX 78218

Phone: (210) 666-0544

FAX: (210) 666-2044

Lancer Ice Link

6655 Lancer Blvd

San Antonio, TX 78219

Phone: (210) 310-7174

FAX: (210) 310-7245

Remanufacturing

6655 Lancer Blvd

San Antonio, TX 78219

Phone: (210) 310-7356

FAX: (210) 310-7261

1-800-729-1550

Lancer North America

USA - Canada Sales

6655 Lancer Blvd.

San Antonio, TX 78219

Phone: (210) 310-7000

SALES FAX: (210) 310-7245

CUSTOMER SERVICE FAX: (210) 310-7250

1-800-729-1500

Georgia Office

1125 Northmeadow Parkway, Suite 116

Roswell, GA 30076

Phone: (770) 343-8828

FAX: (770) 475-8646

1-800-729-1750

Lancer Authorized Distributors

Advanced Beverage Solutions (ABS)

100 N. Gary Avenue, Suite C

Roselle, IL 60172

Phone: (847) 524-1707

(877) 814-2271

FAX: (847) 524-1710

www.absone.com

Bevco

6900 Camille Avenue

Oklahoma City, OK 73149

Phone: (405) 672-7770

FAX: (405) 672-7443

e-mail: info@bevcoinc.com

Joe Kirwan Company

119 White Oak Lane

Old Bridge, NJ 08857

Phone: (732) 679-1900

FAX: (732) 679-9236

e-mail: sales@jkirwan.com

L & M Beverage Equipment Co. Inc.

12510 Santa Fe Trail Drive

Lenexa, KS 66215

Phone: (913) 888-8988

FAX: (913) 888-9137

e-mail: L7mco@aol.com

(Update #44 - as of May 01, 2003)

Lancer Russia

Lancer Sales Company

Vyatskaya Street 27

Building 15, 4th Floor

125015 Moscow, Russia

Phone: 7-095-745-7108

FAX: 7-095-745-7109

Mobile Phone: 7-095-991-7778

7-095-139-0335

e-mail: lancer@online.ru

vdemkin@ktv.ru

Lancer Middle East / Africa

Elsayed Moniem - Technical Manager

Lancer Middle East/Africa

7 Mubarak Street

East Ain Shams 11311

Cairo, Egypt

Phone/FAX: 2-02-49-35-395

Mobile Phone (GSM): 2-010-500-4007

e-mail: elsayed_lancer@msn.com

Lancer Authorized Distributor

DispenseTech - South Africa

P.O. Box 17495

Sunward Park, 1470

South Africa

Phone: 27-11-397-7455

FAX: 27-11-397-7648

e-mail: david@dispensetech.co.za

Lancer Latin America

Latin America Sales

6655 Lancer Blvd.

San Antonio, TX 78219

Phone: (210) 310-7000

FAX: (210) 310-7245

1-800-729-1500

e-mail: latinamerica@lancercorp.com

Lancer de México, S.A. de C.V.

Contact: Gerardo Canales

Calle Lerdo De Tejada #544 PTE.

Col. Las Villas

San Nicolas De Los Garza, N.L.

Monterrey, N. L., México C.P. 66422

Phone: (52)-81-83-52-85-32

Phone: (52)-81-83-52-85-34

Phone: (52)-81-83-52-53-60

FAX: (52)-81-83-32-54-10

e-mail: direccion@lancer.com.mx

Lancer de México, S.A. de C.V.

Branch Office, Mexico City

Contact: Carlos Lopez

Lancer de Mexico S.A. de C.V.

Sucursal Mexico D.F.

Calle: Centeotl No. 112

Colonia: La Preciosa

Delegacion: Azcapotzalco

Mexico D.F. C.P. 02460

Phone: (52)-55-53-53-89-28

Phone: (52)-55-53-53-89-26

Phone: (52)-55-53-53-88-60

Phone: (52)-55-53-53-88-21

FAX: (52)-55-53-52-46-30

e-mail: lancer@prodigy.net.mx

Lancer de México, Branch Office, Cd.

Juarez

Contact: Yolanda Puga

Lancer de Mexico

Camino de la Lomas # 4380

Col. Partido Iglesias

Cd. Juarez, CHIH, C.P. 32617

México

Phone and FAX: 521-605-00-86

Phone: 521-605-00-87

e-mail: cdjuarez@lancer.com.mx

(Continued on reverse)

Ernest F. Mariani Company

614 West 600 South

Salt Lake City, UT 84104

Phone: (801) 359-3744

FAX: (801) 531-9615

e-mail: febell@efmco.com, or

clay@efmco.com

Mark Powers & Company, Inc.

P.O. Box 72

1821 Henry Street

Guntersville, AL 35976

Phone: (256) 582-6620

FAX: (256) 582-8533

e-mail: sales@markpowers-and-company.com

Maurer Supply, Inc.

843 Rainier Avenue South

Seattle, WA 98144

Phone: (206) 323-8640

FAX: (206) 323-9286

e-mail: maurersupply@qwest.net

Simgo Ltd.

5122 Timberlea Blvd.

Mississauga, Ontario L4W 2S5

Canada

Phone: 905-602-5800

FAX: 905-602-5804

e-mail: simgo@simgo.com

Simgo (B.C.) Ltd.

16-8125 - 130th Street

Surrey, B.C. V3W 7X4

Canada

Phone: 604-590-4022

FAX: 604-590-1601

Lancer Europe

Belgium - European Central Office

Lancer Europe, S.A.

Mechelsesteenweg 592

B-1930 Zaventem

Belgium

Phone: 32-2-755-2390

FAX: 32-2-755-2399

e-mail: lancer.europe@glo.be

England

17 Bembridge Gardens

Ruislip, Middlesex

HA4 7ER, England

Phone: 44-1895672667

FAX: 44-1895637537

e-mail: court4lancer@msn.com

Hungary

H-2100 Gödöllõ

Isaszegi út 67

Hungary

Phone: 36-28-417-179

FAX: 36-28416-881

e-mail: bodolai@compuserve.com

Lancer Authorized Distributors

Complete Beverage Services, Ltd.

Republic of Ireland and Northern Ireland

Gortrush Industrial Estate

Omagh County Tyrone

Northern Ireland

Office: 44-1662 250 008

FAX: 44-1662-252-991

Intercom - Spain

Intercom

Avda. Concha Espina 8

28036 Madrid Spain

Phone: 34-91-564 6900

FAX: 34-91-564 3065

e-mail: jmorales@bevserv.com

22

Directory of USA - Canada Offices,

International Offices, and Authorized Distributors

Corporate Office

6655 Lancer Blvd. • San Antonio, Texas 78219 • 210-310-7000 • 1-800-729-1500 • FAX 210-310-7250

Loading...

Loading...