Page 1

MXB-360

®

360,000 BTU BOILER

Installation and Operating Instructions

Lanair Waste Oil Heaters & Boilers

4109 Capital Circle

Janesville,Wisconsin 53546

608-752-1601

www.lanair.com

Page 2

®

BEFORE YOU BEGIN INSTALLATION...

Read and understand this manual completely before beginning installation.

Code Requirements

Installation must comply with all state, local and utility codes, laws, regulations and ordinances and CSA standard

B139. When required, installations must conform to A.S.M.E. safety code for controls and safety devices for

automatically fired boilers No. CSD-1.

All electrical wiring must be done by a licensed electrician in accordance with the National Electrical codes latest

edition and all state and local codes.

Rules for Safe Installation and Operation

1. This boiler is for commercial and industrial use only. This unit is not intended for residential use.

2. This boiler must be installed by a licensed HVAC/Hydronic contractor.Installer should be trained and thoroughly

familiar with the installation and operation of oil-fired boilers.

3. Read this owner's manual and the rules for safe operation carefully. Failure to follow the rules of safe operation

and the instructions could cause a malfunction of the boiler and result in death, serious bodily injury, and/or

property damage.

4. Locate the boiler as close to the chimney as practical. Observe the minimum clearances outlined in Fig. 1,

page 8. Remember to allow room for the boiler door to open with the burner mounted.

5. Make sure that the surface on which the boiler is to be installed is capable of supporting the weight of the boiler,burner, and all other equipment supported by that surface.

6. A boiler pad is strongly recommended . This pad is to be made of poured concrete.It should be at least 4 inches

thick and should cover the entire area underneath the boiler (not just the legs).

7. Make sure the location chosen for the boiler will provide adequate air for combustion and ventilation (see Fig.2,

page 9). Also make sure that fuel and electrical requirements can be satisfied at the boiler location chosen.

8. The heating system design shall not permit the boiler's return water temperature to be lower than 130˚F for a

significant period of time.This will prevent fire side corrosion and insure a long life expectancy for your boiler.

9. Check to make sure you have all the required components needed for proper installation and operation.

10. Check each component for visible damage. If you find a damaged component, contact a Lanair Service

Representative for a replacement. Do not install broken or damaged parts.

11. This boiler is designed to provide economically and environmentally friendly disposal of waste oil.Due to the

nature of the fuel used, this boiler should not be relied upon as the sole source of heat.

12. Read and understand the warranty.Fill out the enclosed warranty card and return within 10 days of purchase.

2

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 3

MXB 360

360,000 BTU BOILER

Installation and Operating Instructions

Table of Contents:

Code Requirements and Rules For Safe Installation and Operation . . . . . . . . . . . . . . . . page 2

Sec. 1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Sec. 2 Typical Boiler Room Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Sec. 3 Boiler Room Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Sec. 4 Chimney/Vent System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Sec. 5 Draft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Sec. 6 Fuel Supply Tank Piping Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Sec. 7 Fuel Supply Pump/Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Sec. 8 Typical Boiler Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Sec. 9 Boiler Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

Sec. 10 Boiler Controls and Accessory Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Sec. 11 Burner Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Sec. 12 Electrical Connections/Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Sec.13 Compressed Air Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 24

Sec.14 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Sec.15 Start Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

Sec.16 Priming Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

Sec.17 Flame Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Sec.18 Maintenance Schedule / Service Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

Sec.19 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 40

Sec.20 Warranty Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 42

Sec.21 Burner Reference Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 43

Visit our website at: www.lanair.com

Page 4

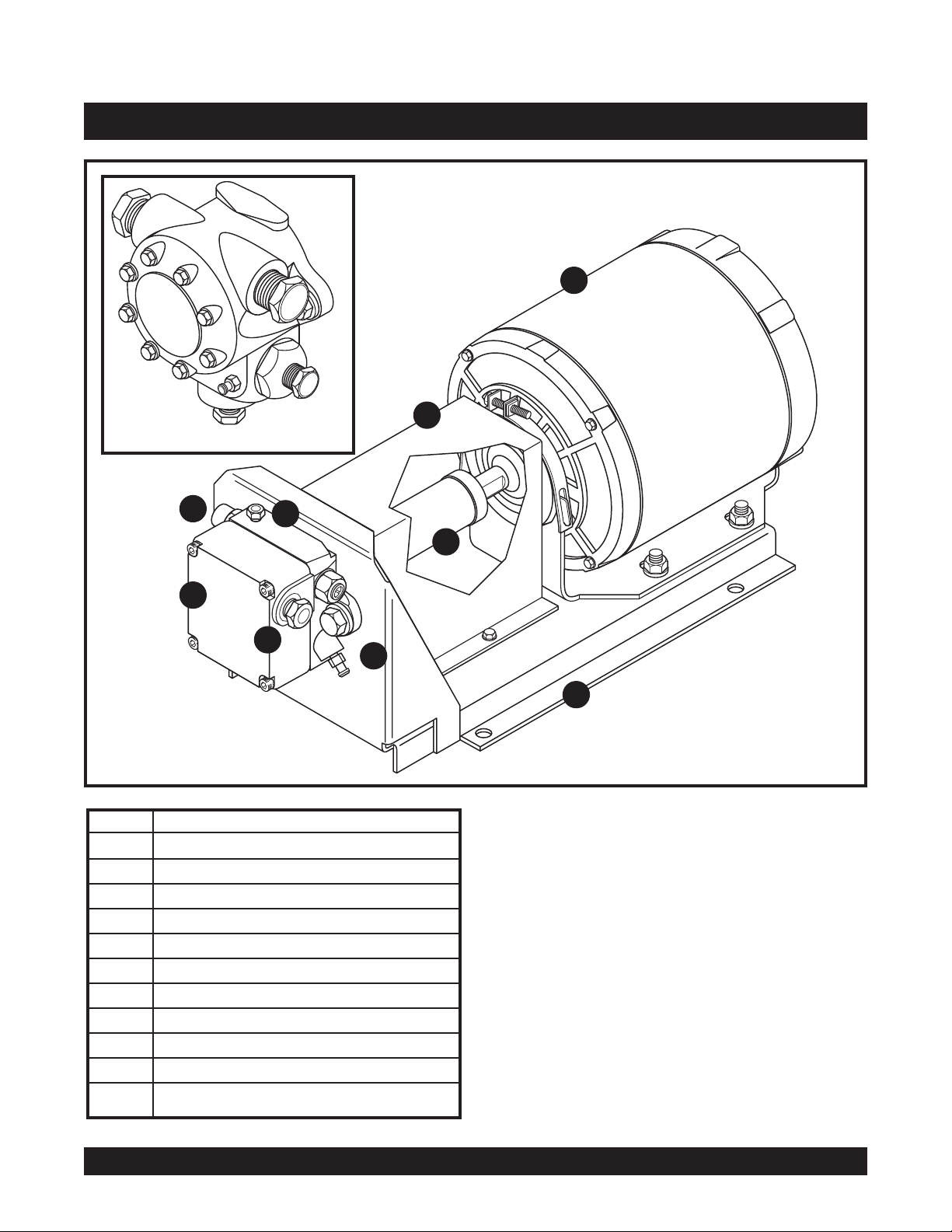

Section 1 - Burner Specifications

10

11

2

1

3

4

5

No. Description

1 Mounting Plate

2 Ignitor Transformer

3 Fuel Line Inlet

4 Fuel Pressure Gauge

5 Combustion Air Baffle

6 View Port

7 Oil Primary Safety Control

8 Waste Oil/Fuel Oil Switch

9 Quick Disconnect Receptacle

10 Air Supply Inlet

11 Combustion Blower Motor

6

7

8

9

10

11

Burner Assembly-Performance Ratings

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 vac

Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 hz

Total Operating Amperage . . . . . . . . . . . . . . . . . . 4.9

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 lbs

Oil Primary . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 amps

Pre-Heater Block . . . . . . . . . . . . . . . . . . . . . . .2.6 amps

Ignitor Transformer . . . . . . . . . . . . . . . . . . . 0.3 amps

4

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 5

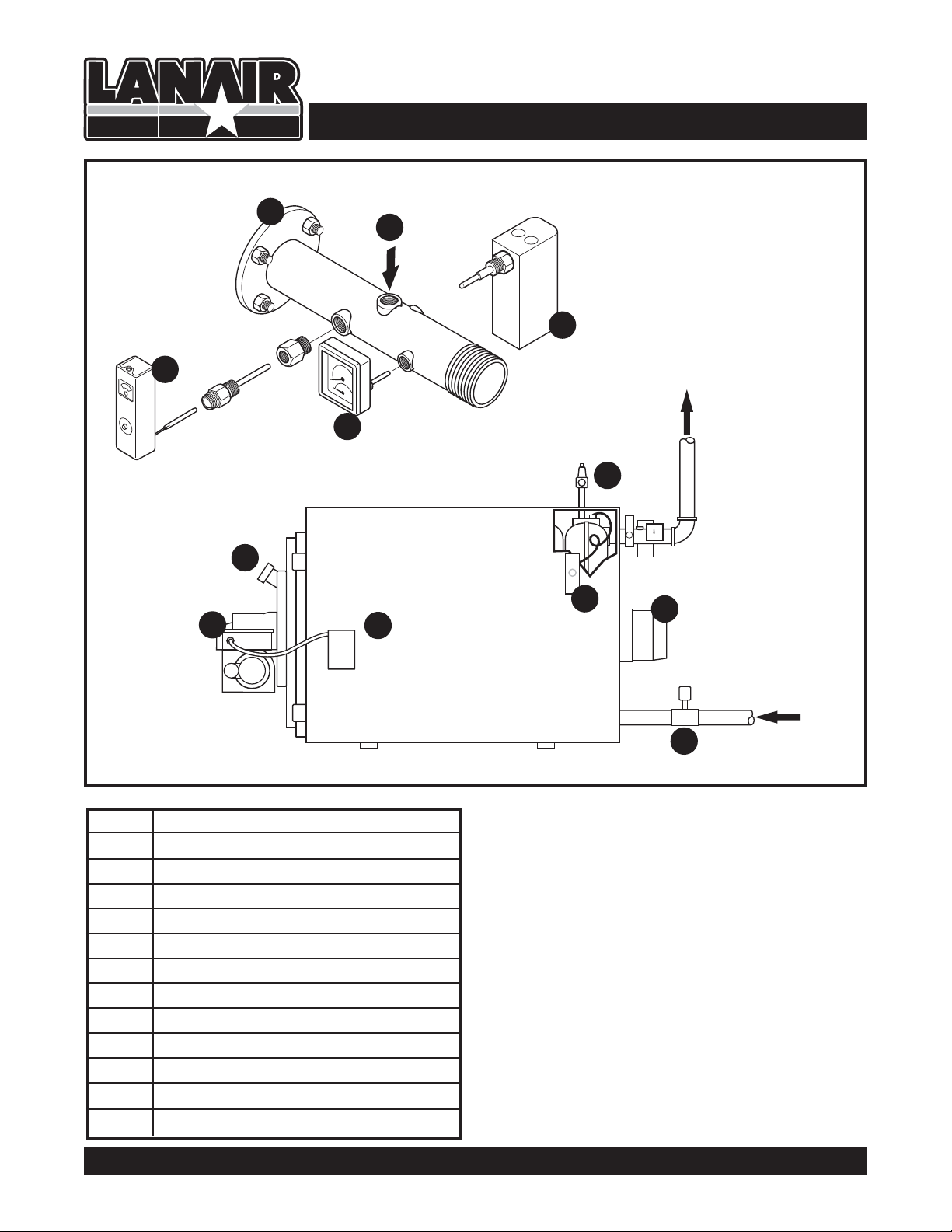

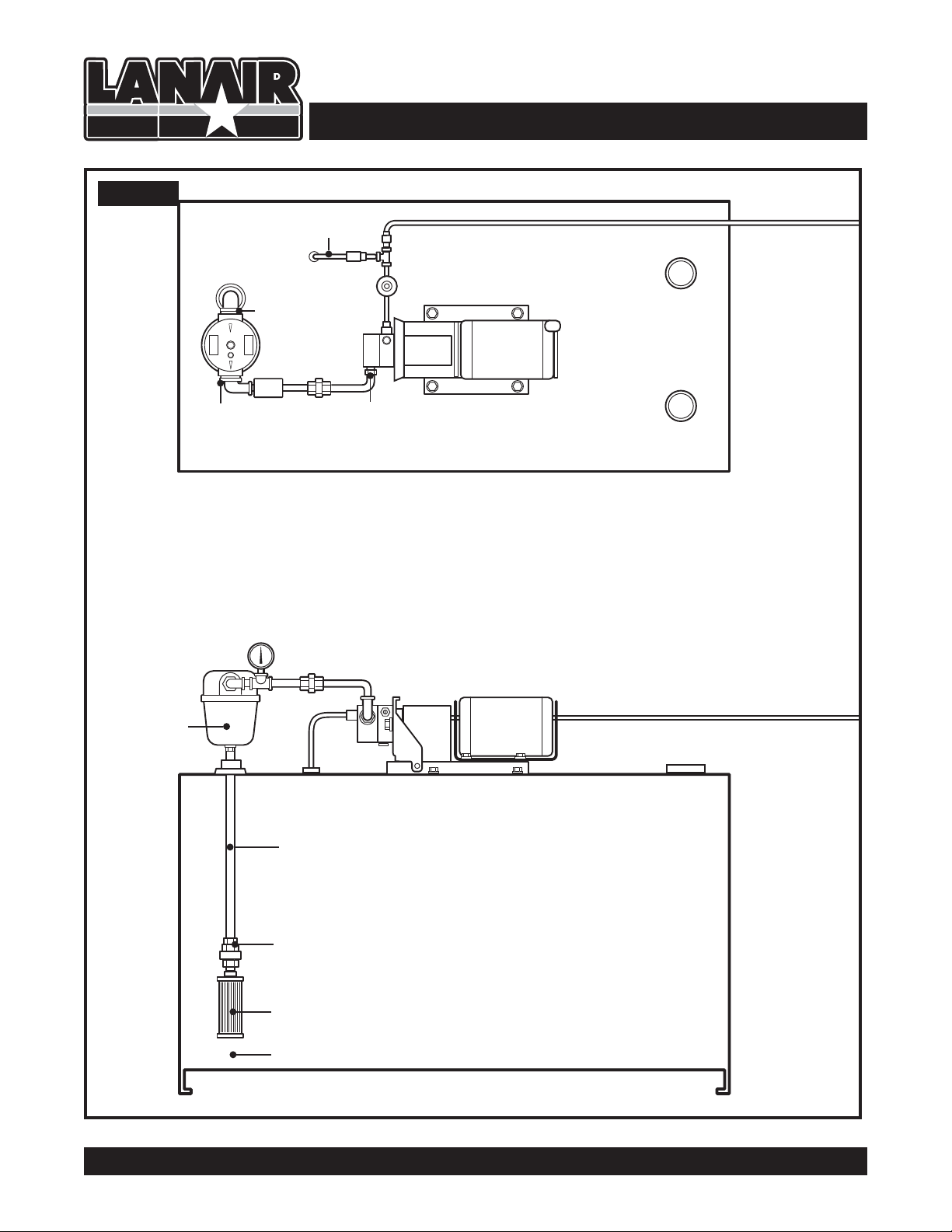

OPTIONAL J-PUMP

Section 1 - Pump Specifications

2

3

8

5

4

7

No. Description

1 Pump Platform

2 Pump Motor

3 Adapter Shaft Cover

4 Pump

5 Pressure Gauge port

6 Easy Flow Bleed Valve

7 1/4" NPT Inlet

8 1/8" NPT Outlet

9 Adapter Shaft

9

6

1

Pump Assembly-Performance Ratings

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 vac

Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 hz

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 lbs

Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 amps

Visit our website at: www.lanair.com

5

Page 6

Section 1 - Boiler Specifications

8

DETAIL A

9

12

11

10

MX BOILER

2

1

No. Description

1 Burner Assembly

2 View Port

3 Electrical Junction Box

4 HI-Limit Switch

5 Relief Valve

6 Chimney Outlet

7 Flow Switch (not included)

8 Supply Manifold

9 Hi-Limit Switch

10 Temperature/Pressure Gauge

11 Low Water Cut-off Switch

12 Optional Relief Valve Location

3

Electrical Junction Box

Supply

Relief Valve

5

Supply Manifold

(see Detail A)

4

6

Flow Switch (not included)

Return

7

Boiler-Performance Ratings

Burner Fuel Consumption . . . . . . . . . . . . . 2.57 GPH

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360,000 BTU

Output Capacity . . . . . . . . . . . . . . . . . . . 297,000 BTU

Net Rating - Water BTU/HR . . . . . . . . . . . . . 309,600

Approx. Dry Weight . . . . . . . . . . . . . . . . . . . 1,900 lbs.

Vent Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8" dia.

Water Content . . . . . . . . . . . . . . . . . . . . . . . . 28.5 gal.

Max Operating Water Pressure . . . . . . . . . . . 75 PSI

6

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 7

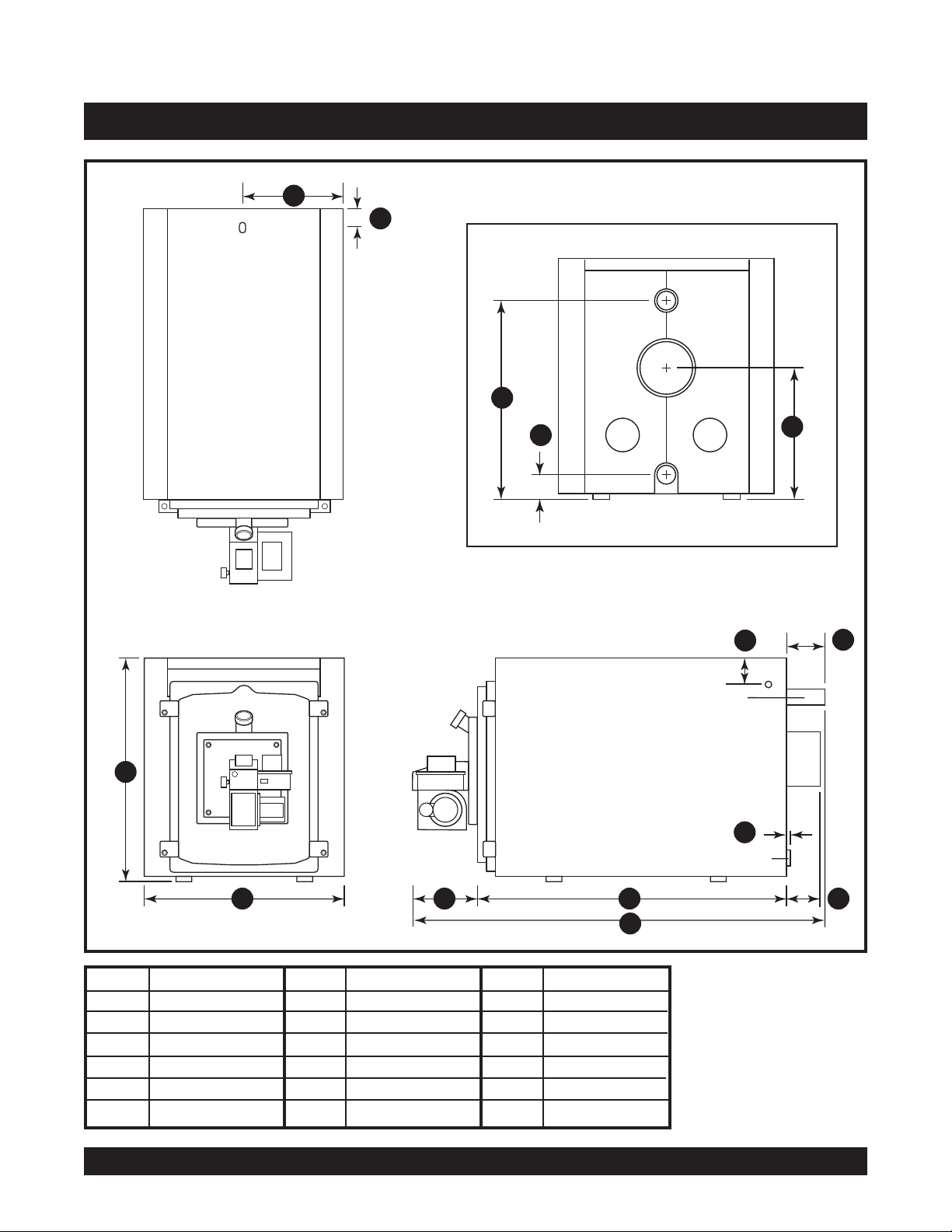

Section 1 - Boiler Specifications

TOP

FRONT

10

11

12

SIDE

13

REAR

Clean-Out

Port

Clean-Out

Port

14

9

8

1

2

No. Dimension

1 36"

2 33"

3 73-3/8"

4 12"

5 52"

68"

No. Dimension

73/4"

8 9-3/8"

9 7-3/4" oc

10 18" oc

11 5" oc

12 29-1/2" oc

2-1/2” MPT Supply

7

2-1/2” FPT Return

54 6

3

No. Dimension

13 4" oc

14 20" oc

Visit our website at: www.lanair.com

7

Page 8

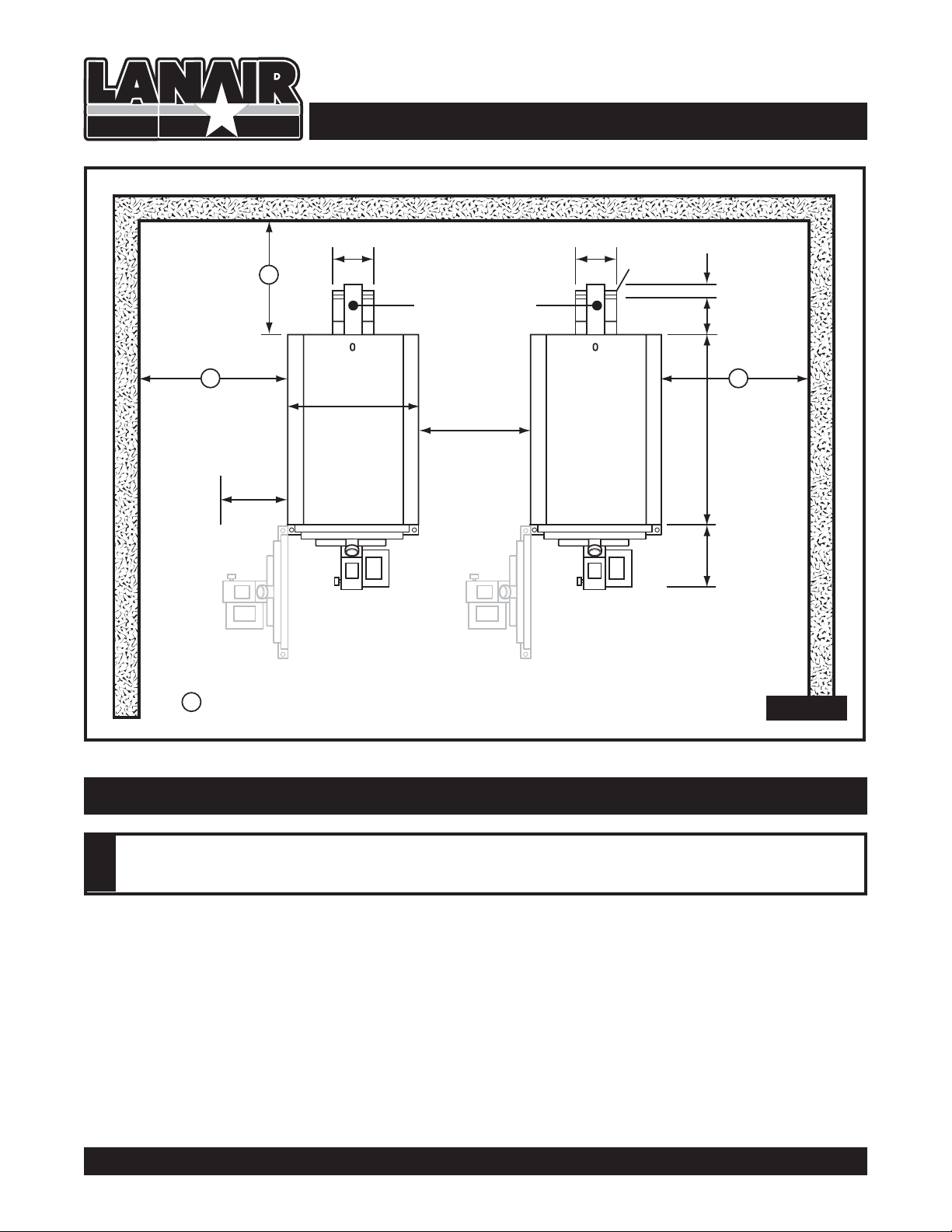

Section 2 - Typical Boiler Room Layout

16.5”

8”

CL

2-1/2” Boiler

Supply Connection

33”

16.5” min.

8”

Boiler Vent

Connections

2“

8“

CLCL

47.5”

16.5”

CL

Dimension as per job specifications and local codes

Figure 1

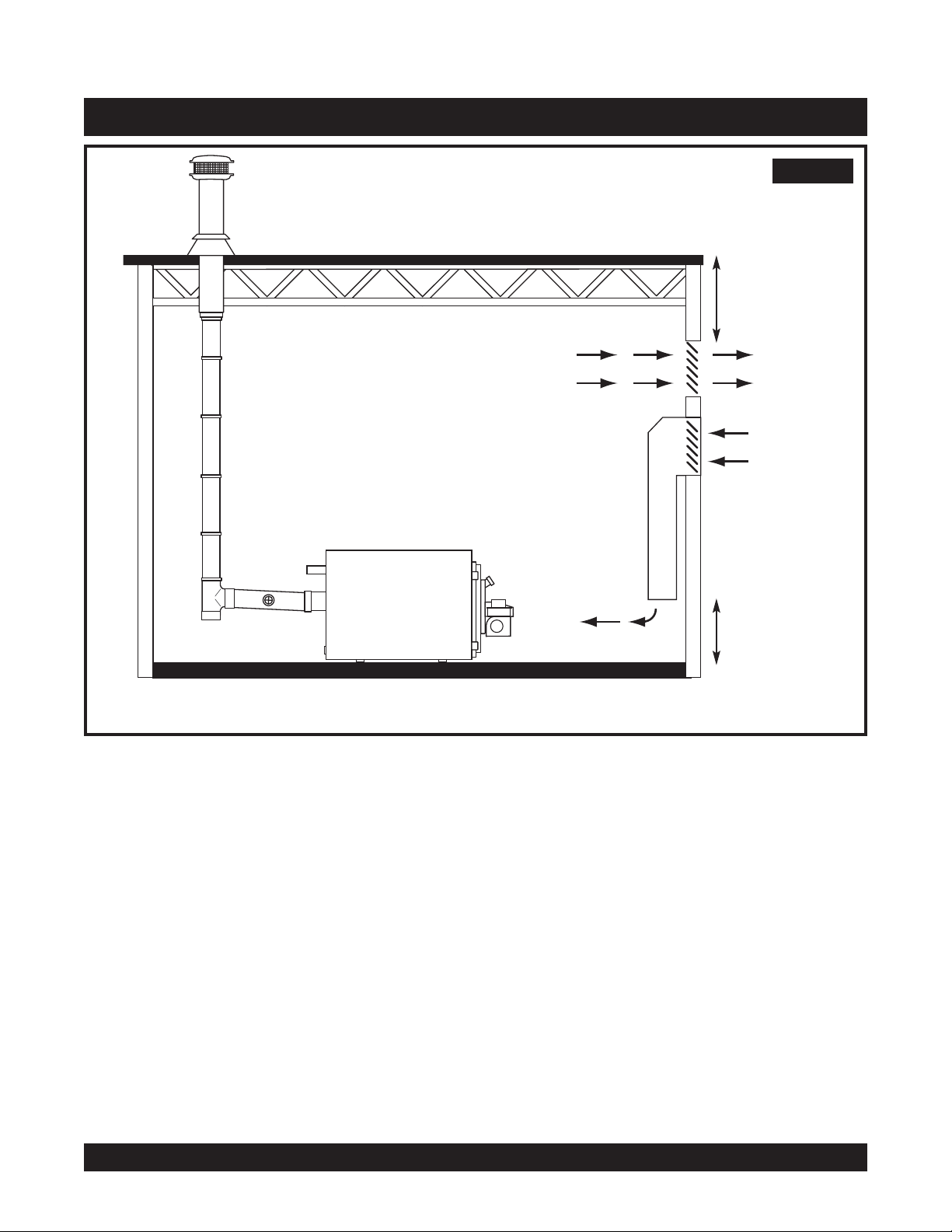

Section 3 - Boiler Room Air Requirements

WARNING: Failure to provide an adequate supply of fresh air for combustion will result

in hazardous operating conditions.Do not use an exhaust fan in the boiler room.

!

1. To ensure safe efficient operation, the boiler system must be supplied with sufficient air for combustion and ventilation (see Fig.2)

2. Unless properly controlled, avoid the use of forced ventilation, since it can create an undesirable pressure differential between the boiler room and air source.

3. All boilers located in confined rooms should have free access to ventilation and combustion air from two permanent openings. One opening should terminate within 12" of the ceiling, the other within 12" from the floor

(see Fig.2). Each opening shall have at least 1 sq. inch free area per 1,000 BTU/HR of burner input. Openings should

freely connect with areas having adequate infiltration of outside air

8

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 9

Section 3 - Boiler Room Air Requirements

Figure 2

12" Maximum

Louvered

openings for

ventilation &

combustion

12" Maximum

When air comes directly from outdoors, again use two openings as explained on page 8 and above except:

• Direct connection or vertical ducting allow 1 sq. inch per 4,000 BTU/HR.

• Direct connection through horizontal ducting allow 1 sq. inch per 2,000 BTU/HR

• All ducting shall be the same size as opening but no less than 3" x 3" or 9 square inches.

Remember to compensate for louver blockage when calculating free air. Refer to manufacturer's instructions or use this

general guide:

WOOD LOUVERS- Allow 20-25% free air

METAL LOUVERS OR GRILLES - Allow 60-70% free air

Any louver damper should lock open or interlock with the burner to open automatically when the boiler operates.

Visit our website at: www.lanair.com

9

Page 10

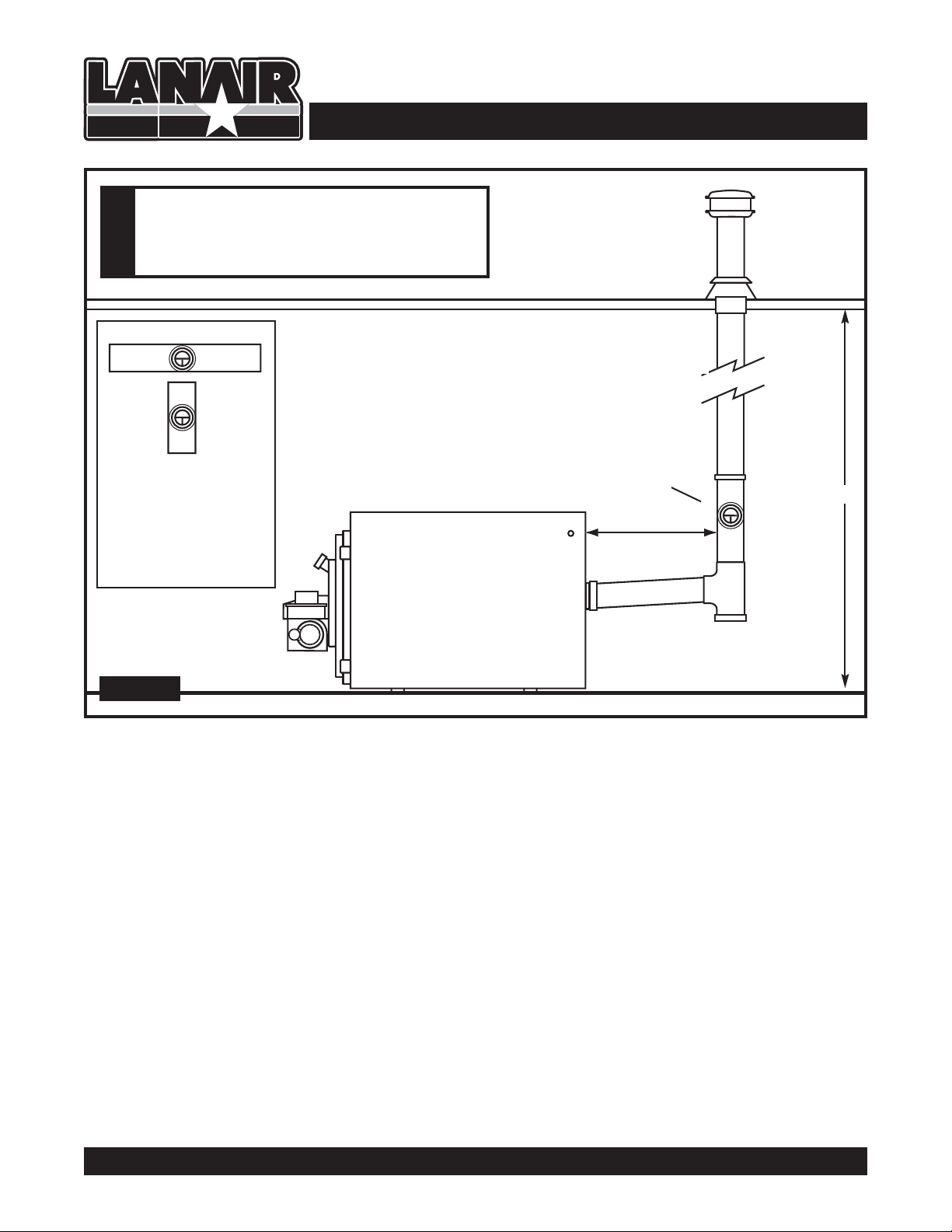

Section 4 - Chimney or Vent System

Failure to provide proper venting of the boiler

exhaust gases could result in death, serious

injury, and/or property damage. FOLLOW

!

CHIMNEY MANUFACTURERS INSTRUCTIONS.

HORIZONTAL

VERTICAL

NOTE: Barometric

Damper may be mounted horizontally or vertically. Angle gate pins

must be horizontal for

proper operation

NOTE: Class "A" components require a 2" clearance from combustible materials. All other chimney components require a

minimum 18" clearance from combustible materials

Figure 3

Class "A" Chimney Cap

8" Class "A" Chimney

Barometric Damper

(24"-36" from boiler)

NOTE: Chimney

adapter is included.

P/N 4799

3' taller than any

objects within 10'

15' Typical

Capped

Clean-out

Tee

NOTE: Horizontal pipe

must have a 1/4" rise

per foot of length

General Requirements

1. Chimney MUST be a 8” Class "A" chimney. Do Not Use chimney smaller than 8”.

2. INSTALLATION MUST BE DONE BY A LICENSED HVAC/HYDRONIC CONTRACTOR FAMILIAR WITH ALL STATE

AND LOCAL CODES.Safe operation of any gravity vented heating appliance requires a proper air make-up system

to prevent the heater exhaust gases from being drawn into the building. These gases could cause death, serious

injury, and/or property damage. Exhaust fans, paint booths may cause draft problems.

3. Never vent this boiler into another heating appliances chimney. Never vent into ‘Class B” chimney. Gas boilers use

“Class B” chimney,it is rated for a much lower temperature than is required for your waste oil boiler. This

boiler must have its own separate “Class A”chimney.

4. Inspect and maintain the chimney on an annual basis.

5. Install a U.L. listed barometric damper in the chimney. Do not reduce or enlarge the vent pipe.

6. Position the draft control as shown. Chimney angle gate pins must be horizontal for proper operation.

7. Keep the barometric draft control at least 24” from the boiler.

10

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 11

Section 4 - Chimney or Vent System

8. Do not use more than one 90° elbow. Each 90° elbow equals a 10’ run of chimney.The maximum run for the chimney

connector is 30’.

9. Secure all connections in the chimney connector with 3 screws per joint.

10. The chimney connector clearance to any combustible material is 18”. The Class "A”chimney clearance to any com-

bustible is 2”. FOLLOW THE CHIMNEY MANUFACTURER’S INSTRUCTIONS.

11. Do not install heat re-claimers, manual draft controls, or any other type of restrictive control in the chimney.

12. Install a 8” diameter clean out tee with a cap, at the transition of the chimney.

FOLLOW CHIMNEY MANUFACTURER’S INSTRUCTIONS.

13. Use a 8” inside diameter “Class A”insulated chimney pipe to vent exhaust gases through wall, ceilings, attics,roofs,

combustibles, etc..

14. Vent chimney at least 3 feet above the roof and at least 3 feet higher than any portion of the building, roof, or

obstruction within 10 feet of the chimney.

15. The chimney cap should be at least 3’ above the roof exit.

16. Do not use a rotating chimney cap. Use a non-restrictive “Class A”cap made for the type of “Class A” chimney you are

using. FOLLOW CHIMNEY MANUFACTURER’S INSTRUCTIONS.

17. The chimney must be capable of producing a negative -.02 W.C. draft when cold and -.06 W.C. draft when hot.Refer

to Section 5 Draft Instructions.

18. If you are unable to attain the proper draft, check for exhaust fans in the building.To test if there is a problem, open

an overhead door and see if you now have the proper draft. You may have to add one or more sections of “Class A”

chimney to the roof to get the proper draft.

19. The boiler and chimney must be installed in accordance with all state and local codes. The boiler must be

installed by a licensed HVAC/Hydronics contractor in accordance with the specifications listed in this manual.

The chimney must be installed per the chimney manufacturers instruction. Use “Class A”chimney only.

WARNING: FOLLOW THE CHIMNEY MANUFACTURER’S INSTALLATION INSTRUCTIONS AS

WELL AS STATE AND LOCAL FIRE CODES.

!

Section 5 - Draft

The boiler should have a (negative) -.02 draft reading when cold, and a (negative) -.06 when hot.Check the boiler when it

is running after 45 minutes. If the reading is not what it should be, adjust the barometric damper according to the

instructions provided with the damper.The draft reading should be taken with a manometer. Consult your heating contractor,or manometers can be purchased from the Lanair Customer Service Department 800-753-1601.

Visit our website at: www.lanair.com

11

Page 12

Figure 4

3/8” Copper

Tube P/N 9182

Section 6 - Fuel Supply Tank Installation

3/8” Fuel Line To Burner (not included)

Vacuum Gauge P/N 8398

1/2” x 1/4” x 1/4” Tee

P/N 9412

Primary Strainer

P/N 9807

1“ x 1/2” bushing

P/N 8904

TOP VIEW

1“ x 1/2” bushing

P/N 8904

Fuel Regulator Assembly

(see page 14)

1/4” Nipple P/N 8647

1/4” x 1/2” Coupling P/N 8558

ASSEMBLY

PUMP

ASSEMBLY

PUMP

Vent

Fill

STORAGE

TAN K

3/8” Fuel Line To Burner (not included)

12

STORAGE

TAN K

1/2” pick-up tube

(not included)

Check Valve P/N 8662

(inside tank)

Strainer Suction Line P/N 8748

6“ from bottom of tank

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 13

Section 7 - Fuel Supply Pump/ Piping

General Requirements - Fuel Tank

1. The fuel supply tank and supply lines must be installed in accordance with the National Fire Protection Association

requirements, as well as state and local ordinances.

2. Regulations require oil storage tanks located inside a building not exceed 275 gallons individually and are not to

exceed 550 gallons in one building. Check state and local codes.

3. Oil storage tank must be inside the building as close to the boiler as possible (max. 25 feet) to avoid flow problems.

4. Pitch the fuel supply 2º with the drain valve at the lowest end to drain off water and sludge. Sludge may have to

manually be removed.

5. Some ordinances may require the fuel supply tank to be vented to outside,and above the roofline.Check State and

Local codes. Keep the vent clear.

6. Install the fuel tank fill pipe at the end of the tank and above the drain.

7. Label the fuel tank for the recommended fuels.

8. Strain all fuel with a 50 X 50 mesh strainer before putting fuel into the tank.

9. When filling the fuel tank with a motorized pump, never leave unattended to prevent over filling and/or spillage.

10. Keep fill cap on the fuel tank when not filling.

General Requirements - Fuel Pump/Piping

1. Mount the fuel supply pump in a horizontal position (shaft horizontal) near the fuel supply tank.

2. The oil pump has a maximum suction lift of 14 feet. Suction lift is the length of pipe run from the bottom of the

pick up strainer to the fuel supply pump.

3. The fuel pump/motor are for indoor use only.

4. The fuel pump contains an internal strainer that periodically needs to be cleaned (see Section 18, page 33). This

internal strainer is mounted behind the pump cover. Before removing the pump cover make sure you have a new

gasket on hand. Contact the Lanair Customer Service Department for the proper gasket for your model of pump, at

800-753-1601.

5. Install the suction supply line from the inlet side of the fuel pump into the fuel tank opposite the drain.

6. Install a 1/2” inside diameter (.493) steel pipe, or 1/2” outside diameter copper throughout the suction supply line

and pick up tube.The use of smaller line,or rubber, plastic or hydraulic line is unsafe and will void your warranty.

7. Use thread sealing compound on all pipe thread connections. DO NOT USE TEFLON TAPE.

8. Install the suction line strainer in the suction line. Make sure the suction line strainer is 6”off the bottom of the tank.

The suction line strainer may be mounted horizontally or vertically.Consider accessibility.

9. Install a pipe union between the suction line strainer and the pick up tube to allow for service on the pick up tube.

Visit our website at: www.lanair.com

13

Page 14

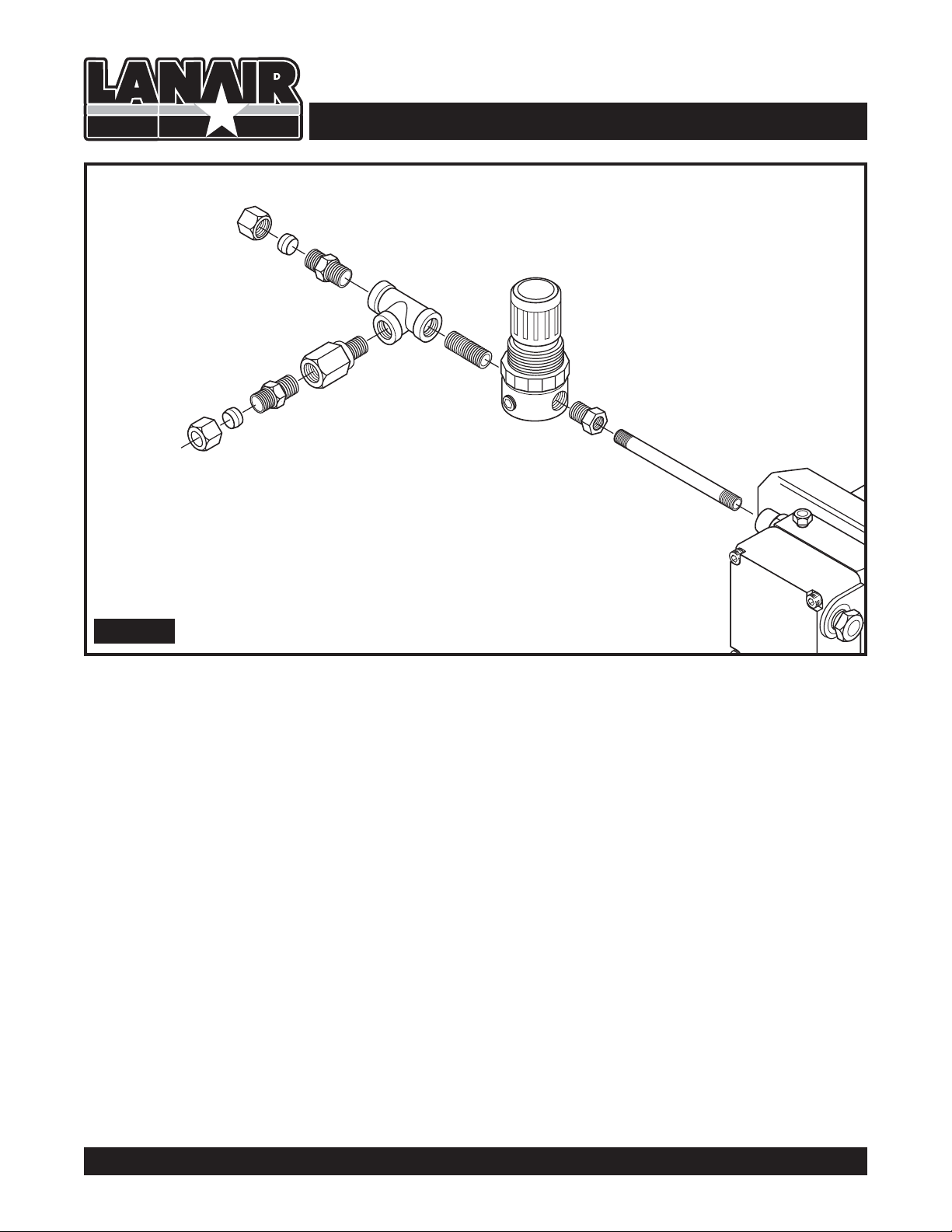

Section 7 - Fuel Supply Pump/ Piping

NOTE:This item comes pre-assembled from the factory.

RETURN LINE

TO TANK

Figure 5

FUEL LINE

TO BURNER

3/8” x 1/4’” NPT

P/N 8939

Fuel Relief Valve

P/N 8470

3/8” x 1/4’” NPT

P/N 8939

Tee

P/N 8909

Close Nipple

P/N 8647

Fuel Regulator

P/N 8460

Bushing P/N 8908

Nipple P/N 8915

10. Install the check valve (arrow facing towards the pump) on the bottom of the pick up tube.

11. Install a vacuum gauge (included, P/N 8398) in the suction line. This gauge will indicate when service is needed on

the strainer,pump,connections, or fuel level.

12. Install fuel regulator and fuel relief valve assembly (see Fig 5). NOTE:This item comes pre-assembled from the

factory.

13. Install the 3/8" diameter copper line from the fuel relief valve to the fuel supply tank. Do not allow this line to protrude into the tank more that 1”. This line should not be submerged in oil. Failure to install this line properly will

result in damage to your boiler, and will void your warranty.The use of smaller line,or rubber, plastic or hydraulic

line is unsafe and will void your warranty.

14. Install the fuel supply line from the fuel regulator/ relief valve assembly to the inlet port on the left side of the

burner using 3/8” outside diameter copper tubing. NOTE: THE MAXIMUM DISTANCE OF THIS LINE IS 25 FEET.

15. If using copper line on the suction side of the pump, use flare fittings.Compression fittings may be used on the

push side of the pump.

16. Keep the fuel supply lines 1” off any outside walls.

14

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 15

Section 8 - Typical Boiler Piping

Figure 6

Single Boiler Piping with Blend Pump

*16.3 GPM Blend Pump should be used

ATTENTION: Heating system design and burner operation must incorporate interlock to prevent burner

!

from firing when boiler has no system water flow.

Air Separator

Amtrol #720

Air Eliminator

or Equal

Blend

Pump

*

Check

Valve

Expansion

Tan k

System Supply

System Circulator

System

Return

Pressure Reduction Valve

Backflow Preventer

From City

Water Supply

Figure 6B

System Return

Single or Multiple Boiler Piping for Primary/Secondary Pumping

Air Separator

Amtrol #720

Blend

Pump

Check

Valve

12” M

Air Eliminator

Blend

Pump

Check

Valve

ax.

M

12”

x.

a

NOTES:

or Equal

Expansion

• Size secondary Pump GPM at gross boiler output

for a 20” drop.

• When calculating pump head,the maximum

boiler resistance for any boiler will not exceed

14” in W.C. of head

System Supply

Tank

System Circulator

Pressure Reduction Valve

Backflow Preventer

From Cit y

Water Supply

Visit our website at: www.lanair.com

15

Page 16

Section 9 - Boiler Installation

All MX Series boilers are shipped with the boiler sections assembled and hydrostatically

tested to A.S.M.E. at the factory. Inspect boiler for any visible damage before beginning

!

installation.

Inspect Shipment

Any claims for damage or shortage must be filed against carrier or consignee. No claims for variances from, or shortages

in orders, will be considered unless presented 7 days after receipt of goods.

Boiler shipment comes in two separate pallets.

1. Wood pallet with:

• Boiler block with insert installed

• Box of jacket parts

• Box marked #3 (Burner Assembly)

a) Complete Lanair MXB Burner assembly

b) Secondary Air Filter/Regulator

• Box marked #4 (Accessories Box)

a) Oil filter, oil pressure gauge, oil supply line relief valve, and regulator assembly, plumbing kit and Instruction

Manual/Warranty Card Packet

2. Boxes in the boiler chamber

• Box marked #1 (Manifold Box)

a) Supply and return manifold, gaskets, 3/4” x 6” pipe, mounting studs, washers and nuts

b) Return diffuser and gaskets

c) Two (2) 3/4" male x female extension couplings for optional controls

• Box marked #2 (Controls Box)

a) High Limit with 3/4" well and capillary clip

b) Temperature/Pressure Gauge

c) Relief Valve

d) Flame sight assembly

e) Four (4) spacers to secure back jacket panel

f) Burner mounting hardware

g) 1” to 3/4” reducer

• Box marked #5 (Low Water Cut Out)

• Chimney Adapter

Placement

1. Move the boiler (in the crate) as close as possible to its final location. Boiler must be positioned on a proper load

bearing concrete pad or floor. See Fig. 1, page 8 for typical boiler room layout.

2. Remove the lag screws (2) holding the rear feet to the skid.

3. Remove the front jacket panel. Cut the banding holding the front of the boiler to the skid.

4. Carefully move the boiler into its final position.

INSTALLATION MUST BE DONE BY A LICENSED HVAC/HYDRONIC CONTRACTOR

FAMILIAR WITH ALL STATE AND LOCAL CODES.

!

16

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 17

Section 9 - Boiler Installation

Note: Threads used on the studs is metric. Any attempt to use standard (English) threaded studs in place of those supplied will damage the boiler block.

!

Figure 7

(4) 12mm x 50mm studs

Gasket

(4) 12mm washers

TOP OF BOILER

Supply Manifold

(4) 12mm nut

Manifold and Diffuser Installation

1. Attach supply manifold as indicated in Fig. 7.Install return port diffuser and attach return flange as shown in Fig.8.

NOTE: Make sure diffuser slots face upward (see Fig. 8).

Figure 8

(4) 12mm x 50mm studs

Gasket

Diffuser

Gasket

(4) 12mm washers

(4) 12mm nut

BOTTOM OF BOILER

Visit our website at: www.lanair.com

Return Flange

17

Page 18

Figure 9

Section 9 - Boiler Installation

086

038

036

041

094

018

033

030

040

018

060

043

093

ATTENTION: DO NOT INSTALL THE BOILER JACKET WITHOUT FIRST ATTACHING THE

SUPPLY MANIFOLD AND DIFFUSER (SEE PAGE 17).

!

PARTS LIST

018 HINGE BRACKET (factory mounted to boiler)

030 ADDITIONAL INSULATION

033 CENTER PANEL

036 RIGHT REAR PANEL

038 LEFT REAR PANEL

040 INSULATING MAT FOR BOILER SHELL (FOIL OUT)

18

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

041 UPPER FRONT TRIM PANEL

043 SETSCREW AF-17 AND SPACER (4 required)

060 REAR INSULATING MAT (2 PIECES)

086 TOP PANEL

093 RIGHT SIDE PANEL

094 LEFT SIDE PANEL

Page 19

Section 9 - Boiler Installation

Boiler Jacket Installation

1. Screw the four (4) jacket extensions (043) into the the

four outer holes in the corners of the rear boiler section.

Securely tighten the jacket extensions. Check other

bolts on the rear panel and tighten if necessary.

2. Place the large wrap-around insulation blanket (040)

over the boiler block. NOTE:The aluminum foil side of

the blanket should be facing out.

3. Place smaller piece of insulation (030) on top of the

insulation blanket. This will provide extra insulation on

the top of the boiler block.

4. Remove flue collector clean-out covers (see illustration

on page 7 for location).

5. Place rear insulation (060) on the rear panel. The holes

of the insulation should align with the clean-out ports

and the jacket extensions (043). Compress insulation

until the jacket extensions (043) protrude. NOTE:The rear insulation is two separate pieces (right and left) Position

with the aluminum foil side of the insulation facing out.

ATTENTION: THIS BOILER REQUIRES A LINER

(INCLUDED) FOR OPERATION. DO NOT

!

OPERATE BOILER WITHOUT LINER IN PLACE.

6. Align the right rear jacket panel (036) to the jacket extensions (043) and attach using two (2) M6 x 10 pan head

screws provided. Align the left rear jacket panel (038) to the jacket extensions (043) and attach using two (2) M6 x

10 pan head screws provided. Align the corresponding holes of the right and left rear jacket panels and secure

using five (5) sheet metal screws provided.

7. Re-attach the flue collector clean-out covers. NOTE: Do not over tighten bolts of the clean-out covers. Over tightening may crack or break the covers.

8. Attach the right (093) and left (094) jacket panels. Each panel attaches to the unit using the hooks on the factoryinstalled hinge brackets (018) at the front of the unit and the holes in the previously mounted rear panels.

9. Place the center panel (033), with flange edge down,

between side panels.

10. Attach the upper front trim panel (041) between the

right (093) and left (094) side panels. The front panel has

hooks which are inserted into slots in the front of the

side panels.

11. Align the hooks of the top panel (086) with those of slots

on the top of the side panels. Place top panel between

side panels and slide forward to lock in position.

Cap

Gasket

Lens

Sight Glass Installation

1. Remove the sight glass plug on the door of the unit.

2. Install sight glass assembly. Hand tighten (Fig. 10).

Visit our website at: www.lanair.com

Figure 10

19

Page 20

MX BOILER

Section 10 - Boiler Controls and Accessory Location

Figure 11

pressure relief valve

Aquastat

Electrical Junction Box

Burner Service Switch

INSTALLATION MUST BE DONE BY A LICENSED HVAC/HYDRONIC CONTRACTOR

FAMILIAR WITH ALL STATE AND LOCAL CODES.

!

Boiler Controls and Accessory Location

1. Remove the top of the boiler jacket. Install

3/4" x 6" relief valve pipe to the top of the

unit as indicated in Fig.12. Pipe mounts to

the 3/4" hole at the top rear of the boiler

block.

2. Insert the sensor of the aquastat through the

side of the boiler jacket. Mount the aquastat

to the side of the boiler as indicated in Fig.

11.

3. Insert 1" to 3/4" reducer to boiler top and

tighten. Insert sensor housing into reducer

and tighten. Insert the sensor into the housing. NOTE: Sensor must be fully seated for

proper operation.

4. Replace the top of the boiler jacket.

Figure 12

aquastat sensor

sensor housing

1” to 3/4 reducer

pressure relief valve

NOTE: Install AFTER

boiler jacket has

been re-installed

3/4" x 6" pipe

5. Attach the pressure relief valve to the previously attached 3/4" x 6" pipe and tighten.

20

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 21

Section 10 - Boiler Controls and Accessory Location

Discharge piping from pressure relief valve must be piped to a drain or must terminate 6"

above floor to avoid damage to the structure or personal injury. It must NO

!

a point where freezing might occur.

T be piped to

Figure 13

supply manifold

3/4" pipe extension

hi limit switch

low water cut-out

3/4" plug (not included)

sensor

housing

temperature/pressure

gauge

6. Install discharge piping from pressure relief valve.

7. Install 3/4" pipe extension to supply manifold. Attach sensor housing to the extension. Insert hi-limit

sensor into housing and attach to

the sensor housing.

8. Attach temperature/pressure

gauge and low water cut-out to

the supply manifold (see Fig.13)

9. Insert 3/4" plug (not included) into

top of manifold and tighten

If a blend pump is not used, consult your licensed hydronic contractor regarding system

design.

!

Section 11 - Burner Installation

Figure 14

(4) washer

(4) bolt

Burner Installation

1. Unpack the burner and inspect for

2. Remove cardboard insert from

3. Position the burner to the door of

Visit our website at: www.lanair.com

any signs of damage.

door front.

the boiler and attach using four

(4) bolts and washers provided

(see Fig.14).

21

Page 22

Section 12 - Electrical Connections

CAUTION: HAZARD OF ELECTRICAL SHOCK!

!

Main Electrical Installation

1. All wiring must comply with the National Electrical Code. State and Local Ordinances, and be wired by a qualified

electrician.

2. Electrical service MUST be connected to a separate 20 AMP, 115 VAC, 60 HZ single phase circuit.

3. Electrical service connections are made in the electrical junction box on side of the boiler.

4. The boiler must have a safety equipment ground from the main electrical service, stranded 12 GA minimum.

5. The electrical conductors for electrical service to the heater MUST be stranded 12 GA minimum.

6. Install a manual service disconnect near the heater, and label its function.

7. The supply voltage must be maintained at a minimum 110 VAC.

8. The electrical conductors from the main electrical service must be within approved conduit.

9. Keep all electrical conductors and conduit away from the chimney connector as well as any other hot surfaces. Refer

to Figure 15, Wiring Diagram for color code, etc. Keep the power off until the heater is ready to be started. Refer to

Section 13 Start Up Procedure.

Fuel Supply Pump Electrical Installation

1. All wiring must comply with the National Electrical Code, State and Local Ordinances, and be wired by a qualified

electrician.

2. The electrical conductors to the fuel pump motor MUST be stranded 14 GA minimum.

3. The electrical service connections for the fuel pump motor are made in the electrical junction box on the side of the

boiler.

4. The pump motor MUST have a safety equipment ground from the main electrical service, stranded 12 GA minimum.

5. The electrical conductors from the electrical junction box to the pump motor must be within approved conduit.

6. Keep all electrical conductors and conduit away from the chimney connector as well as any other hot surfaces. Refer

to Figure 15 Wiring Diagram for color code, etc. Keep the power off until the boiler is ready to be started. Refer to

Section 13 Start Up Procedure.

Hi-Limit Switch and Manifold Controls Electrical Installation

ATTENTION! DUE TO VARYING SYSTEM DESIGNS,ONLY A CERTIFIED HVAC/HYDRONICS

!

INSTALLER CAN DETERMINE THE PROPER WIRING OF THESE COMPONENTS.

22

All wiring must comply with the National Electrical Code. State and Local Ordinances, and be wired by a qualified

electrician.

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 23

slot. Push tip all the way down and

push forward. Remove wire.

Remove wires from the block by insert-

ing a flat tip screwdriver into the top

Visit our website at: www.lanair.com

CAD

CELL

YELLOW

YELLOW

F2 F1 T2 T1

OIL PRIMARY

WHITE

ORANGE

BLUE (NOT USED)

SNAP

DISK

TO THERMOSTAT

OR JUMPER

(DEPENDING ON INSTALLATION)

WHITE

BLACK

PRE-HEATER

WHITE

AIR

COMBUSTION

BLOWER

ORANGE

WHITE

OIL

PRE-HEATER

WHITE

WHITE

TRANSFORMER

WHITE

BLUE

PRE-HEATER

SWITCH

RED

BLACK

WHITE

WHITE

PURPLE

ORANGE

WHITE

AIR

SOLENOID

PUMP

MOTOR

MAIN POWER IN

120 VOLT

ORANGE

RED

WHITE

TO HI-LIMIT

SWITCH AND

SUPPLY MANIFOLD

CONTROLS

Section 12 - Burner/Pump Electrical Connections

Figure 15

23

MANUAL

RESET

BLACK

RED

Page 24

Section 13 - Compressed Air Installation

Compressed Air Supply Installation

1. Install an air pressure supply line connection to the air filter/regulator.

2. The air supply source must be capable of producing 1.0 CFM @ 100 PSI.

3. Install a shut off valve in the air supply line for service.

4. Install a primary air filter/regulator with a gauge (capable of reading line pressure) in the air supply line prior to

the air filter/regulator mounted on the furnace. THE PRIMARY AIR FILTER/REGULATOR IS NOT SUPPLIED WITH

THE BOILER.

5. If the primary air regulator does not have a filter with a bowl, a condensate drain leg must be installed in the air sup-

ply line.

6. Install a quick disconnect at the air filter/regulator on the boiler for service.

7. For the ease of installation install a flexible air line (.250 I.D. minimum) from the quick disconnect to the primary air

regulator.

8. The air supply line must be pitched upward from the primary regulator to the boiler to prevent condensation from

entering your burner.

9. Open all air shut off valves, and set the primary air regulator at 30 PSI.

10. Set the secondary air filter/regulator to 15 PSI.

Figure 16

to air supply

24

secondary air filter/regulator (included)

primary air

filter/regulator

(not included)

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 25

Section 14 - Controls

Burner Controls and Operation

• Oil Primary Safety Control/Cad Cell:

The oil primary control is mounted on top of the burner’s electrical box.When the thermostat calls for heat the oil

primary control starts the burner by switching on the air solenoid valve, ignition transformer, combustion air blower,

and the fuel pump.The oil primary control works in conjunction with the cadmium sulfide cell (cad cell).The cad cell

is mounted inside the burner cover, and faces the flame. The cad cell monitors the light level inside the combustion

chamber to insure there is a flame present. If there is a loss of flame the primary control will go into its recycle

mode. After 1-2 minutes the primary control will restart the burner.When this happens if there is a flame present,

the burner will continue to function. If on start up no flame is established in 30 seconds the primary control will lock

out. CAUTION: Do not press the reset button more than twice. If the burner fails to start refer to Section 19, Trouble

Shooting.

• Barometric Draft Control:

The Barometric Draft Control automatically maintains a pre-set chimney draft, and is located in the chimney connector (see page 10, Fig. 3). NOTE: The draft must be set/checked using a manometer.

• Air Filter/Regulator:

The Air Filter/Regulator performs two functions: 1. It removes condensation and dirt from the air. 2. It controls the

amount of air pressure reaching the nozzle and air operated fuel valve. The Air/Filter Regulator is mounted on the

cabinet near the burner.

• Electric Air Solenoid Valve:

The Electric Air Solenoid Valve is controlled by the Oil Primary Control. It acts as a shut-off valve, (it’s open during

operation, and closed when the burner is off ). The Electric Air Solenoid Valve is located inside of the burner’s electrical box.

• Air Operated Fuel Valve:

The Air Operated Fuel Valve controls fuel flow to the nozzle. When the Electric Air Solenoid Valve opens and air pressure pushes on the fuel valve diaphragm, the plunger moves off the nozzle seat allowing fuel to enter the nozzle.

The Air Operated Fuel Valve is located on the back of the air pre-heater.

• Air/Oil Pre-heater:

The Air/Oil pre-heater is an assembly that preheats the atomizing air and fuel to a predetermined temperature to

properly combust used oil.The Air/Oil pre-heater is located in the burner.

• Snap Disc Assembly:

The Snap Disc accurately controls the temperature of the air/oil pre-heater assembly with two resistance type cartridge-heating elements.The Snap Disc is mounted on the oil pre-heater inside the burner.

• Nozzle:

The Nozzle uses air pressure to help pull fuel through its small orifice, and to atomize the fuel for proper combustion. The Nozzle is located on the end of the air pre-heater opposite the fuel valve. Replace the Nozzle annually, as

they are prone to wear by contaminants in waste oil/used oil.

Fuel Pump Controls and Operation

• Fuel Supply Pump:

The Fuel Supply Pump pumps fuel from your oil storage tank to the burner.The Fuel Supply Pump should be located as close to the fuel supply tank as possible.The Fuel Supply Pump must be mounted horizontally (Shaft). See

page 12, Fig. 4.

Visit our website at: www.lanair.com

25

Page 26

Section 14 - Controls

Fuel Pump Controls and Operation

• Fuel Regulator:

A Fuel regulator is used to adjust the fuel pressure of waste oil to the burner.

• Fuel Relief Valve:

The fuel relief valve prevents excess pressure build-up in the fuel line upon burner shut-down.

Boiler Controls and Operation

• Hi-Limit Switch:

Hi-limit switches are immersion type devices for regulating the temperature of liquids in a boiler where temperature

control is required.The Hi-limit switch is mounted to the supply manifold at the rear of the boiler (see page 21 for

details).

• Low Water Cut-Out:

The low water cut-out switch is located on the supply manifold at the rear of the boiler.This device will turn the system off if it senses low water levels or pressure.The low water cut-out switch is mounted to the manifold at the rear

of the boiler (see page 21 for details).

• Aquastat

The aquastat is an immersion type device for limiting the temperature of liquids in a boiler. The aquastat is mounted

to the cabinet and the sensor is installed at the rear of the boiler next to the pressure relief valve (see page 20)

• Pressure Relief Valve:

The Pressure Relief Valve is mounted to the top of the boiler near the rear.This valve is used to automatically or

manually release excess pressure which may be present in the boiler. See page 20.

• Temperature/Pressure Gauge:

This dual purpose gauge monitors supply temperature and pressure.The temperature/pressure gauge is mounted

to the supply manifold at the rear of the boiler (see page 21).

Section 15 - Start-Up Procedures

Boiler Start-Up - Fill System

1. Fill boiler and system according to job specifications. System pressure should be set to have 5 PSI pressure at the

highest point in the heating system. Boiler pressure gauge will indicate pressure relative to the height of water column from the boiler to the highest point, plus the additional 5 PSI.

Example: To calculate cold fill pressure: Highest point in system is 40’; 40 ÷ 2.31 = 17.32 (1 PSI = 2.31 ft w.c.)

Add 5 PSI to 17.32 = 22.32 PSI; boiler pressure gauge will indicate 22.32 PSI (cold fill pressure)

2. Purge air from boiler and system . WARNING: Never purge system while boiler is in operation or fill a hot/empty

boiler with cold water

26

The expansion tank must be properly sized to system requirements. An undersized expansion tank will

cause system water to be lost through the relief valve and make-up water to be introduced through the fill

!

valve eventually causing mineral build-up in the boiler sections which could lead to eventual section failure.

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 27

Section 15 - Start-Up Procedures

Waste Oil Burner Start-Up

1. Make sure the main electrical service for the heater is turned off, and locked out.

2. Fill the oil supply tank with an approved fuel to a level that is above the pick-up tube check valve.

3. Check for proper draft in the chimney.The draft must read -.02 W.C.cold.

4. Make sure there is air pressure at the heaters air filter/regulator, set it at 12 PSI.Set the primary regulator on the air

supply line to 30 PSI.

5. Set the fan/limit control slide switch to automatic.

6. Check the combustion air adjustment baffle for proper setting. Refer to Section 17, Flame Adjustment.

7. Set the room thermostat below room temperature (if applicable).

8. Turn the main electrical service ON.

9. Push the reset button on the oil primary control for 3 seconds.

10. Flip the lighted rocker switch for preheating on the burner electrical box to the ON position (pre-heater OFF the

light is off, pre-heater ON the light is on.).

11. Prime the fuel supply pump. Refer to Section 16, Priming the Fuel Supply Pump.

12. If using waste10W-50W oil or automatic transmission fluid for fuel, flip the pre-heater rocker switch on (light ON, and

wait 5-7 minutes for the pre-heater assembly to reach operating temperature. Leave the pre-heater switch OFF if

using No. 1 or No. 2 fuel oil.

13. Turn the room thermostat up above the room temperature (if applicable). The burner will now fire, check the sight

glass on the rear of the burner also inspect the flame through the inspection port. Refer to section 17, Flame

Adjustment pages 29-30.

14. Adjust the burner air filter/regulator to 12 PSI, and the primary air regulator to 30 PSI. NOTE: 12 PSI on the air

filter/regulator is the starting point, you may need to adjust from there when setting the flame. See pages 29-30.

15. Adjust the fuel pressure gauge on the left side of the burner to read 7lbs.. NOTE: Adjust the knob on the fuel regulator clockwise to increase pressure, and counter clockwise to decrease pressure to the burner. The oil pressures listed

above are a starting point, you may need to adjust from there when setting the flame. Refer to section 17, Flame

Adjustment pages 29-30.

16. Adjust the barometric damper to obtain a draft of -.06 W.C. while the heater is hot and operating. NOTE: It is VERY

IMPORTANT that the barometric damper is set to the required settings to ensure the natural draft of exhaust gases.

See Section 5, Draft , page 11.

17. Depending on the type of fuel used, the elevation, temperature, and oil viscosity, the combustion air baffle will need

to be adjusted for optimum performance. Refer to section 17, Flame Adjustment pages 29-30.

The combustion air baffle is NOT factory set

!

Visit our website at: www.lanair.com

27

Page 28

Section 16 - Priming the Fuel Pump

1. The fuel level in the supply tank must be above the check valve

on the pick-up tube. Fill suction line with oil.

2. Remove the bowl of the suction line strainer,and fill with clean

fuel. Replace the strainer bowl.

3. Remove the two yellow wires from the F-F terminal on the oil primary control (Fig. 17). Install a jumper wire between the F-F terminals (Fig.18).

4. Adjust the air filter/regulator on the heater to –0- PSI.

5. Remove the fuel supply line from the burner and position a con-

tainer to catch the fuel.

6. Loosen the bleeder screw on the pump one turn, and attach a

piece of 3/16” ID clear plastic tubing.The tubing should be long

enough to allow the fuel to be returned to the tank.

Figure 17

Remove two yellow wires

7. Turn the room thermostat above room temperature, or to the

“ON” position.

8. Disconnect one end of the jumper wire at the F-F terminals on

the oil primary.The fuel pump will now start.

9. Observe the clear tubing attached to the bleeder screw on the

pump.When a steady stream of fuel (no air bubbles) flows close

the bleeder screw.Remove the tubing from the bleeder screw.

10. Observe the end of the fuel supply line that is disconnected from

the burner.Allow a steady stream (no air bubbles) of fuel to flow

into the container for several minutes.This will flush any debris

from the fuel line that could potentially plug the nozzle.The vacuum gauge reading should not exceed 5”HG of vacuum.

11. Turn the room thermostat below room temperature or “OFF”. The fuel supply pump will now stop.

12. Reconnect the fuel supply line to the burner.

13. Remove the jumper wire from the F-F terminals on the oil primary control, reattach the yellow cad cell wires.

14. Adjust the burner air filter/regulator to 12 PSI.

Figure 18

Install jumper wire

15. If the fuel supply pump prime, or fuel stream has air in it (spurting, fluctuating flow) there is likely a leak in the suction side of the plumbing. Refer to section 19, Trouble Shooting. The burner should now be ready to fire.

28

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 29

Section 17 - Flame Adjustment

Flame Adjustment

1. Start boiler, let it run for at least 45 minutes to reach operating temperature before proceeding.

2. Check chimney draft, set the barometric damper to -.06 WC when hot and running.

3. Check the atomizing air pressure, set the air filter/regulator on the heater to 15 PSI as a starting point.

4. Check the fuel pressure gauge on the burner,set to: 7 LBS.

Adjust the screw on the fuel regulator. Lock into position. The flame should extend no more than 3/4 of the way into

the chamber.

NOTE: The above pressure is a starting point, depending on your installation you may need further adjustment.

5. Loosen the combustion air adjustment baffle, slowly close the baffle in 1/16” increments until the heater (flame)

starts to rumble. Then slowly open the baffle in 1/16”increments until the rumbling stops, (wait 2 minutes between

adjustments) finally open the baffle an additional 1/8” to provide excess oxygen.Secure the baffle, (See Fig 19).

NOTE: Mechanical equipment like gauges and regulators are not always 100 percent accurate,

6. Drill a hole in the smoke outlet transition piece and the damper and run combustion tests using combustion testing

equipment.

Figure 19

7. Adjust flame to achieve the following

readings:

CO2; 12-15%

Smoke; 1-2 on the Bacharach

Scale Oil Burner Smoke Scale with

a maximum of 4.

8. Adjust the damper to have negative -.06

W.C.pressure (after 45 min. of operation) at

the smoke outlet. Secure damper.

9. Seal combustion sample hole and smoke

outlet connections using a high

temperature silicone sealant. Also seal all

breeching smoke pipe joints, seams and

connections to the chimney.

10.After burner has been adjusted and while

it is operating, check the front door for

leakage of flue gas. Should leakage occur,

tighten the door closure bolts. Also adjust

door hinge bolts.

combustion air

baffle

The combustion air baffle is NOT factory set

!

Visit our website at: www.lanair.com

29

Page 30

Flame Adjustment - Visual

Flame is over-fired (Fig. 20).

• Dark yellow,to orange in color.

• The flame is hitting the walls,filling the chamber with a smokey

flame. Correct immediately or chamber may be damaged.

• Decrease fuel pressure, and adjust combustion air baffle. Air pressure

may also need to be adjusted.

Problem: Too large of a flame, dark yellow in color.

1. Too much fuel pressure.

2. Not enough combustion air.

3. Not enough atomizing air pressure.

4. Ash inside the chamber is dark brown to sooty black in color.

Flame is under-fired (Fig. 21).

• The flame is like a blow torch.

• Light yellow,to white in color.

• Flame is too short.

• Check to see if pre-heater block is hot.

• Check air PSI, it may be too high. Adjust in 1 LB. increments.

• Oil pressure and the combustion air baffle may need adjustment.

Section 17 - Flame Adjustment

Figure 20

BAD FLAME

The flame is too big, creating an over-fire

condition

Problem: Too small a flame, similar to a blowtorch.

1. Too much atomizing air pressure.

2. Too much combustion air pressure.

3. Not enough fuel pressure.

Solutions:

1. Correct fuel pressure setting.

2. Flame tips reach 3/4 of the way into the chamber.

3. Flame has slightly yellow/orange tips.

4. No black smoke coming from the chimney.

5. Ash inside the chamber is white to off white in color.

Flame is full (Fig.22).

• Bright yellow in color.

• Flame extends 3/4 into the chamber.

• Flame is not impinging on the chamber walls.

If you need assistance with flame adjustment, please call Lanair's

Parts and Service Department.

BAD FLAME

The flame is too short

GOOD FLAME

The flame length is approximately 3/4 of

the chamber

DO NOT OVER FIRE YOUR BOILER. IMMEDIATELY ADJUST THE BURNER TO THE PROPER

FLAME LENGTH TO PREVENT DAMAGE TO YOUR BOILER.

!

Figure 21

Figure 22

30

CHECK FLAME DAILY (see page 31). ADJUST ACCORDINGLY

!

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 31

Section 18 - Service / Maintenance

MX SERIES BOILER SERVICE / MAINTENANCE SCHEDULE

DAILY

• Check fuel supply tank

level.

• Check vacuum gauge

reading on suction line.

See Section 19.

• Check atomizing air pressure at the air filter/ regulator.Set to 12 psi. Drain

water from the bowl if

necessary

• Check the fuel pressure

gauge on the burner.set

to the correct pressure

for the fuel being used.

• Visually inspect flame.

Adjust accordingly.

• Check draft using a

manometer.Set draft to .02 cold, -.06 hot.

WEEKLY

• Drain water/ anti-freeze

from the fuel supply

tank.

• Check the air pressure

setting on the primary air

regulator.Set to 30 psi.

• Drain water from the air

pressure supply line

drain leg and primary

regulator.

MONTHLY

• Check the combustion

chamber flue passages.

Clean if needed (see

page 32).

• Clean the chimney, chimney connector and barometric damper.

• Clean pump strainer, suction line strainer and

pick-up tube strainer (pp

33). NOTE: Always prime

pump after cleaning

strainers.

• Check for dirt build-up

on the combustion

blower wheel. Keep

wheel clean.

• Inspect the combustion

chamber,ash build-up,

and flame.

ANNUALLY

(Season Shut Down)

• Shut off main power supply to boiler.

• Perform monthly service/maintenance.

• Flip air/fuel pre-heater

switch off.

• Shut off air supply.

• Remove air/fuel preheater assembly.

Disassemble and clean.

Replace all o-rings (pp.

34, 35).

• Remove air turbulator

and clean (pp. 34, 35).

• Replace nozzle and quad

ring (pp. 34, 35 ,39)

• Replace Ignitor (pp 38).

• If boiler is not to be used

for an extended period

of time, flip the preheater rocker switch off

(light off).

• Adjust turbulator (pp 38).

• Lubricate all motors following specifications on

the motor rating plate.

• Clean fuel pump

strainer (see pp 33).

• Drain and clean fuel supply tank.

• Clean combustion blower,axial fan blades and

fan cage

NOTE: ALWAYS WEAR EYE, FACE AND BREATHING PROTECTION AND PROTECTIVE CLOTH-

!

ING WHEN INSPECTING OR CLEANING CHAMBER OR ADJUSTING FLAME.

Visit our website at: www.lanair.com

31

Page 32

Section 18 - Service / Maintenance

NOTE: ALWAYS WEAR EYE, FACE AND BREATHING PROTECTION AND PROTECTIVE CLOTH-

!

ING WHEN INSPECTING OR CLEANING CHAMBER.

WARNING: DISCONNECT ALL ELECTRICAL POWER TO BOILER BEFORE SERVICING!

!

Flue/Combustion Chamber Cleaning

1. The boiler core must be completely cool to the touch before attempting to clean.

2. Turn off all power to the boiler (120 VAC) at the main disconnect.

3. Turn off air pressure supply

4. Disconnect power line from burner (Quick Disconnect-Heavy yellow cable from service box to burner).

5. Disconnect air line from burner.

6. Remove bolts from the boiler door. Carefully swing the boiler door open.

7. Remove smoke pipe and clean out port covers at rear of the boiler.

8. Using a cleaning brush, scrub all fire side surfaces in combustion chamber, flue passages and flue collector areas.

9. Use an industrial type canister vacuum cleaner with a high efficiency filter to remove any ash from the chamber or

flue passages. Failure to clean flue passages will impair draft.

10. Inspect the combustion chamber and flue passages.

11. Re-connect smoke pipe and reinstall clean out port covers at rear of the boiler.NOTE:Do not over tighten bolts of

the clean-out port covers. Over tightening may crack or break the covers.

12. Check the front door and flue collector rope seals. Replace as required.

13. Re-assemble boiler door and burner connections.

IMPORTANT: When boiler is to be layed-up at the end of the heating season or out of service for a

prolonged period of time:

A) Make sure all boiler surfaces are clean and dry.

B) Open boiler front door and place a tray of calcium chloride in the center of the furnace.This will absorb

moisture and keep the heat transfer surfaces dry.When calcium chloride becomes mushy, replace with new.

C) Block the door approximately 1/4 open.

32

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 33

Section 18 - Service / Maintenance

Cleaning Suction Line Strainer

inlet 1” NPT

o-ring

bolt

washer

gasket

spring

outlet 1” NPT

strainer

o-ring

The suction line strainer should be cleaned every 30

days of operation.The element is a washable metal

element. If your waste oil is extremely dirty, this strainer

may need to be cleaned more frequently. Your vacuum

gauge will help you determine when the filter needs

cleaning.The vacuum gauge reading should not exceed

5" HG of vacuum. If it does, the strainer needs cleaning.

1. Disconnect power to the boiler.

2. While holding the lower housing, unscrew the cen-

ter bolt on the top of the suction line strainer.

3. Rinse the filter and lower housing in solvent.

4. Air dry the strainer and lower housing.

5. Re-assemble the strainer, ensuring the rubber gas-

kets, spring and o-rings are in place.

6. Fill the lower housing with waste oil or fuel oil.

7. Position the lower housing to the top making sure

the o-ring is properly seated. Secure the top and

bottom together using the bolt, washer and gasket removed earlier.

water drain

strainer

hex cap screws

bowl

8. Prime the fuel pump (see page 28).

Cleaning/Replacing Fuel Pump Strainer

1. Disconnect power to the boiler.

2. Remove four hex head screws from pump cover.

Carefully remove cover, strainer and gasket.

3. Clean housing, strainer and pump surface. Check

for excess wear.

4. Install a new gasket (P/N 9817).

gasket

5. Install strainer and pump housing.

6. Prime the fuel pump (see page 28).

Visit our website at: www.lanair.com

33

Page 34

34

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

1

6

Air Pre-Heater Tune -Up

Kits (PN# 9870 & 9871) Required.

Annual Maintenance - Air Pre-Heater

3

4

2

Ref. Part

No. No. Qty. Description

1 9853 1 turbulator

2 7004 1 set screw

3 9758 1 nozzle Boiler 100L/140I

4 9870 1 quad ring (K)

5 9814 1 air pre-heater block

6 3730 1 ignitor assembly

7 9870 2 hex cap screw *

8 7418 2 flat washer

9 3726 1 connector

10 9870 1 1/4" o-ring *

11 9870 1 11/16" o-ring *

12 9856 1 air cartridge heater

13 9870 1 spring *

14 9870 1 Viton insert *

15 9835 1 plunger

16 9838 1 Adapter block assembly

17 9870 2 hex head cap screw *

18 9871 1 1/2" o-ring (K)

19 9871 1 diaphragm assembly **

20 9871 2 hex head cap screw **

22 oil pre-heater block

7

8

5

22

* contained in tune up kit 9870

** contained in tune-up kit 9871

9

11

10

See pages 36-37 for required

annual oil block maintenance

13

14

16

19

18

17

12

15

20

Section 18 - Service / Maintenance

Page 35

Section 18 - Service / Maintenance

1. Remove Pre-Heater Assembly

• Disconnect the air line from the brass fitting on the air pre-heater and then from

the air solenoid and remove.

• Disconnect wiring from the oil pre-heater cartridge, air pre-heater cartridge and

snap disc assembly in the wiring junction box.

• Disconnect fuel line and fitting (6) from the oil block (5).

• Disconnect fuel pressure gauge (8) and fitting from the oil block (5).

• Remove button hex screw (14) and washer (11).

• Lift pre-heater assembly and carefully pull straight back. Remove entire assembly

from the burner.

• Remove ignitor assembly (6).

2. Remove Diaphragm Assembly from Air Pre-Heater

• Carefully place pre-heater assembly in a vice.NOTE: Do not damage pre-heater.

• Unscrew diaphragm assembly (19) from air pre-heater and set aside. Remove o-ring

and discard.

3. Remove Adapter Assembly

• Remove hex cap screws (17) and set adapter assembly aside.

4. Remove Plunger , Spring and Cartridge Heater

• Remove spring (13) from plunger (15) and discard.

• Using a hook or screwdriver, carefully remove Viton insert (14) and discard.

• Remove and discard 1/4" o-ring (10) and 11/16" o-ring (11).

• Loosen and remove cartridge heater and set aside.

5. Remove Nozzle Assembly and Quad Ring

• Remove nozzle assembly (3) using a 9/16" wrench.

• If quad ring (4) does not come out with nozzle, carefully remove it and discard.

6. Clean all parts using a parts washer

• All passages must be thoroughly cleaned with a brush.

7. Replace Nozzle Assembly and Quad Ring

• After cleaning air pre-heater assembly, blow dry.

• Install new quad ring (4). Before inserting quad ring in air pre-heater block, a light coat of oil should be

applied. NOTE: Make sure quad ring is properly seated in block before proceeding (see page 39 for clarification).

• Apply a light coat of oil to the shaft of the new nozzle assembly (3). Carefully insert new nozzle assembly (3)

through the quad ring and into the block. Hand tighten until snug.

• Check alignment of ignitors and adjust if necessary (see page 38).

Remove wires from the block by

inserting a flat tip screwdriver

into the top slot. Push tip all the

way down and push forward.

Remove wire.

8. Replace O-rings and Plunger

• Insert a new 1/4" o-ring (10) and a new 11/16" o-ring (11) into the air pre-heater block (5).

• Insert new Viton insert (14) into the end of the plunger (15) and place new spring (13) on the end of the

plunger.Insert plunger into air pre-heater block spring end first.

9. Replace Cartridge Heater

• Apply pipe dope to cartridge heater threads.Insert cartridge heater into air pre-heater block and tighten.

10. Replace Adapter Assembly

• Align the holes of the adapter assembly (16) with those on the air pre-heater block (5). NOTE: Make

sure the small end of the adapter pin is facing toward the air pre-heater block.

• Attach the Adapter assembly (16) to the block using two hex cap screws (17).Tighten screws.

11. Replace Diaphragm

• Replace diaphragm, o-ring and spring (see page 39) Re-attach diaphragm assembly and hand tighten.

NOTE: Do not over tighten.

12. Replace Ignitor Assembly (see page 39)

13. Service Oil Pre-Heater (see pages 36-37 for Annual Maintenance Instructions)

Visit our website at: www.lanair.com

35

Page 36

Annual Maintenance - Oil Pre-Heater

Oil Pre-Heater Tune -Up

Kit (PN# 9869) Required.

Section 18 - Service / Maintenance

13

12

12

5

9

7

6

14

8

11

6

Ref. Part

No. No. Qty. Description

1 8992 1 cartridge heater

2 9813 1 pre-heater face plate

3 9869 6 hex cap screw *

4 9869 4 o-ring 13/16" OD *

5 2901 1 oil block

6 9029 2 fitting

7 9869 2 o-ring 5/16" OD *

8 8498 1 oil gauge

9 7242 1 hex cap screw

10 9869 1 o-ring 1/2" OD *

11 7418 1 washer

12 7109 3 plug

13 9366 1 snap disc assembly

14 7242 1 button hex screw

10

12

4

7

2

3

1

36

* contained in tune up kit 9869

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 37

Section 18 - Service / Maintenance

1. Separate Air Pre-Heater from Oil Pre-Heater

• Remove o-ring and discard(10).

2. Disassemble Oil Pre-Heater

• Remove o-ring and discard(10).

• Remove six hex cap screws (3) from face plate (2) and discard.

• Remove oil cartridge heater (1).

• Remove four 13/16"OD o-rings and discard(4).

• Remove three plugs (12) from oil block (5)

• Remove hex cap screw (9) from inside oil pre-heater block and clean.NOTE: Do not discard (5).

3. Clean Oil Pre-Heater Block

• Clean oil pre-heater block using a parts washer and brush. NOTE: Make sure all passages are clean.

• Blow dry the oil pre-heater block. inspect ALL passages making sure they are clear and clean.

4. Reassemble Oil Pre-Heater

• Replace four 13/16" OD o-rings (4) with new.

• Replace cartridge heater. NOTE: Do not over-tighten.

• Re-attach face plate (2) using six new hex cap screws (3) provided with tune-up kit (P/N 7240).

• Apply loc-tite to three block plugs (12) and replace.

• Replace hex cap screw (9) inside oil pre-heater block (5).

• Replace o-ring (10) with new.

5. Attach Air Pre-Heater Assembly

• Align the holes of the ignitor assembly and air pre-heater with those of the oil pre-heater (see page 34).

• Attach air pre-heater assembly to the oil pre-heater block (5) using two hex cap screws.Tighten securely.

6. Re-install Pre-Heater Assembly

• Place the air/oil pre-heater assembly into the burner body.

• Align the holes of the pre-heater assembly with those in the burner body.

• Secure the assembly to the body by re-installing the button hex screw (14) and washer (11). NOTE:Do not tighten

this screw at this time.

• Replace the o-rings (7) on the PSI gauge and the oil line fittings (6) with new.NOTE:Do not tighten these fittings at

this time.

• Adjust the pre-heater assembly for proper setting.The end of the turbulator should be recessed approximately 1/4"

into the burner tube (see page 38 for turbulator adjustment).

• Once adjusted tighten button hex screw (14) and fittings (6)securely.

7. Re-connect Electrical

• Re-connect all wires previously disconnected in the electrical junction box (refer to wiring diagram, page 23 and

the burner reference diagram, page 43).

8. Reconnect PSI Gauge, Fuel Line and Air Line

• Reconnect the PSI gauge (8) to the fitting (6) and tighten securely.

• Reconnect the fuel line to the fitting (6) and tighten securely.

• Reconnect the air line by connecting the one end of the air line to the air solenoid and the other end to the

air fitting (see page 34).

9. Test Operation

• Follow start-up procedure,page 26.

Visit our website at: www.lanair.com

37

Page 38

Section 18 - Service / Maintenance

Ignitor Replacement / Adjustment

3/8”

1/16”

1/8”

electrodes should extend approximately

1/8” beyond nozzle tip

Side View

Top View

1. Disconnect power to the boiler.

2. Remove the pre-heater assembly from

the burner housing. Disassemble and

clean all parts as instructed on pages

34-37.

3. Using a 7/16" wrench, carefully remove

the one-piece ignitor from the air preheater.

4. Install a new one piece ignitor

(P/N 3730) to the top of the air preheater.NOTE: The tips of the ignitor

should be 3/8" above the center of the

nozzle assembly and should extend

approximately 1/8" beyond the end of

the nozzle. The tips of the one piece

ignitor should be 1/8" apart. Adjust as

required and tighten nut on the top of

the ignitor (see illustrations for clarification of placement).

5. Re-assemble pre-heater assembly (see

pages 34-37) carefully re-install the preheater assembly into burner housing.

The turbulator should be approximately

1/4” from the end of the burner tube.

Adjust as required and secure the preheater assembly to the burner housing

by tightening the adjustment screw on

the side of the burner housing (see

illustration).

38

Pre-heater Assembly

adjustment screw

Turbulator 1/4” max. from

end of the tube

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 39

Section 18 - Service / Maintenance

Air Pre-Heater Diaphragm

Replacement

1. Remove the four hex cap screws from

the diaphragm assembly and discard.

2. Disassemble and discard diaphragm,

spring and o-ring .

3. Thoroughly clean remaining parts.

4. Re-assemble using new diaphragm,

o-ring, spring and hex cap screws.

Air Pre-Heater Nozzle Cleaning /

Replacement

1. Periodic cleaning of the nozzle assem-

bly may be required.

2. Carefully remove nozzle from the air

pre-heater block.

o-ring

diaphragm

piston

hex cap

screws

spring

Air Pre-Heater Diaphragm Assembly

body

fuel orifice

pin/seat

3. Disassemble the nozzle as shown and

clean thoroughly.Re-assemble nozzle.

4. Carefully remove the quad ring from

the block and inspect. Replace if necessary.

5. Insert clean/new quad ring into the air

pre-heater block. NOTE: The quad ring

must be properly seated. Failure to

properly seat the quad ring may result

in leakage and improper burner operation. DO NOT INSTALL QUAD RING ON

THE NOZZLE.

6. Lubricate pin/seat and re-install nozzle.

Tighten securely.

Failure to properly seat the

quad ring may result in leakage and improper burner

!

operation. DO NOT INSTALL

QUAD RING ON THE NOZZLE.

Air Pre-Heater Nozzle Assembly

nozzle assembly

quad ring

Proper Quad Ring Position

Visit our website at: www.lanair.com

39

Page 40

Section 19 - Troubleshooting

Symptom Possible Cause Corrective Action

A. Burner will not start 1. Main electrical power 1. Reset breaker

circuit breaker tripped

2. Service disconnect 2. Turn switch on or

switch off or fuse blown replace fuse

3. Thermostat turned down/ 3. Turn thermostat up,

improperly installed/ check wires/test

defective components/replace

4. Oil primary safety 4. Reset/test components,

tripped/defective replace if needed

5. Too much light showing 5. Eliminate light to cad cell

on cad cell/defective Test component

B. Burner attempts to fire, 1. Low oil in supply tank or 1. Fill tank, or drain and

but does not establish a flame contaminated fuel clean tank

2. Plugged or worn nozzle 2. Clean or replace

3. Fuel pressure gauge 3. See section 7, Page 12

fluctuating/pumping system

4. Pre-heater switch is turned off 4. Turn switch on or test

or defective, or defective switch and cartridge heater

cartridge heater

5. Transformer/electrodes not 5. Test transformer/look

sparking for shorts & repair

Replace electrodes/ transformer

6. No air pressure/defective 6. Turn compressor on/test

regulator/defective solenoid regulator/solenoid. Replace

defective components

7. Water in air system 7. Clean air pre-heater and drain

water from system

8. Combustion blower not 8. See flame adjustment

properly adjusted or pages 29-30.

defective Replace blower

9. Improper draft 9. Check draft see page 11.

Make sure chimney is properly

installed

40

10. Plugged heat exchanger, 10. Clean heater including manifold,

or chimney chimney

QUESTIONS?... Contact Customer Service at 1-800-753-1601 M-F 8:00 am- 4:30 pm CST

Page 41

Section 19 - Trouble-Shooting

Symptom Possible Cause Corrective Action

C. Burner fires, and then 1. Contaminated fuel supply 1. Drain and clean fuel

fails on oil primary safety (water/anti freeze/gear lube) supply tank. Clean fuel

or dirty fuel filter. filter (see page 33)

2. Improper draft 2. Check draft see page 10.

Make sure chimney is properly

installed

3. Plugged heat exchanger, 3. Clean heater including manifold,

manifold, or chimney and chimney

4. Wrong air pressure 4. See flame adjustment pages

29-30

5. Wrong fuel pressure or 5. See flame adjustment

pressure fluctuating pages 29-30. See fuel piping

page 12

6. Improper combustion blower 6. See flame adjustment

setting, or blower is defective pages 29-30. See fuel piping

page 12

7. Oil primary/cad cell defective. 7. Test components/adjust

Cad cell improperly adjusted. cad cell/ clean turbulator

Dirty flame turbulator.

8. Plugged nozzle or pre-heater 8. Clean nozzle and /or pre-heater

assembly assembly

D. Pre-heater assembly 1. Cartridge heaters defective 1. Test cartridge heaters

not heating or disconnected using an ohm meter.

Air heater 112 Ω ±10%.

Oil heater 37 Ω ±10%.

2. Snap disc defective 2. Test snap switch for continuity if

pre-heater is cold

3. Hi-Limit snap disc defective 3. Replace snap disc assembly

Visit our website at: www.lanair.com

41

Page 42

Section 20 - Warranty

LANAIR 1O YEAR WASTE OIL BOILER

LIMITED WARRANTY

Lenan Corp., MANUFACTURER, hereby warrants that manufacturer’s products shall be free from defect in

material and workmanship under normal use according to the provisions and limitations herein set forth.

MANUFACTURER warrants the heat exchanger/combustion chamber for three (3) years from the date of

purchase and pro rata thereafter according to the following schedule: If a defect occurs during the first three