Page 1

®

MX SERIES 250

MX SERIES 300

WASTE OIL HEATER

Installation and Operating

Instructions

Lanair Products LLC

4109 Capital Circle

Janesville,Wisconsin 53546

1-888-370-6531

www.lanair.com

Page 2

®

BEFORE YOU BEGIN INSTALLATION...

IMPORTANT

Read and understand this manual completely before beginning installation.

s This heater is for commercial and industrial use only. This unit is not intended for residential

use.

s This heater must be installed and/or inspected by a licensed heating contractor before

operation. Installer should be trained and thoroughly familiar with the installation and

operation of oil-fired heaters.

s Installation of this unit must be made in accordance with state and local codes or authori-

ties having jurisdiction over environmental control, fuel, fire and electrical safety.

s N.F.P.A. (National Fire Protection Association Publications for Heater Installation)

NFPA No. 30 Flammable and Combustible Liquids Code

NFPA No. 31 Standard for the Installation of Oil Burning Equipment

NFPA No. 70 National Electric Code

NFPA No. 80 A&B Repair Garages and Parking Structures

NFPA No. 211 Standard for Chimneys, Fireplaces,Vents, and

Solid Fuel Burning Appliances

The above standards are available from

Park, Quincey,MA 02269

the National Fire Protection Assn., Battery March

s Read and familiarize yourself with these instructions and associated photos, diagrams and

illustrations before beginning installation or operation.These instructions should be followed closely, to achieve the best possible results.

If you have questions or concerns at any time during the installation, stop the installation

and contact a Lanair Service Representative.

s Check to make sure you have all the required components needed for proper installation

and operation.

s Check each component for visible damage. If you find a damaged component, contact a

Lanair Service Representative for a replacement. D

s This heater is designed to provide economically and environmentally friendly disposal of

waste oil. Due to the nature of the fuel used, this heater should not be relied upon as the

sole source of heat.

s Read and understand the warranty. Fill out the enclosed warranty card and return within

10 days of purchase.

o not install broken or damaged parts.

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

2

Page 3

MX SERIES 250 WASTE OIL HEATER

MX SERIES 300 WASTE OIL HEATER

Installation and Operating Instructions

Table of Contents:

Rules For Safe Installation and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Sec. 1 General Specifications and Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Sec. 2 Heater Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Sec. 3 Chimney /Vent System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Sec. 4 Draft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Sec. 5 Fuel Supply Tank /Piping Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Sec. 6 Fuel Supply Pump/Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Sec. 7 Compressed Air Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

Sec. 8 Electrical Connections/Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Sec. 9 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Sec.10 Priming Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Sec.11 Burner Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Sec.12 Flame Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Sec.13 Maintenance Schedule / Service Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

Sec.14 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 44

Sec.15 Warranty Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 49

Sec.16 Burner Reference Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 51

Visit our website at: www.lanair.com

3

Page 4

Section 1 - General Specifications & Hazards

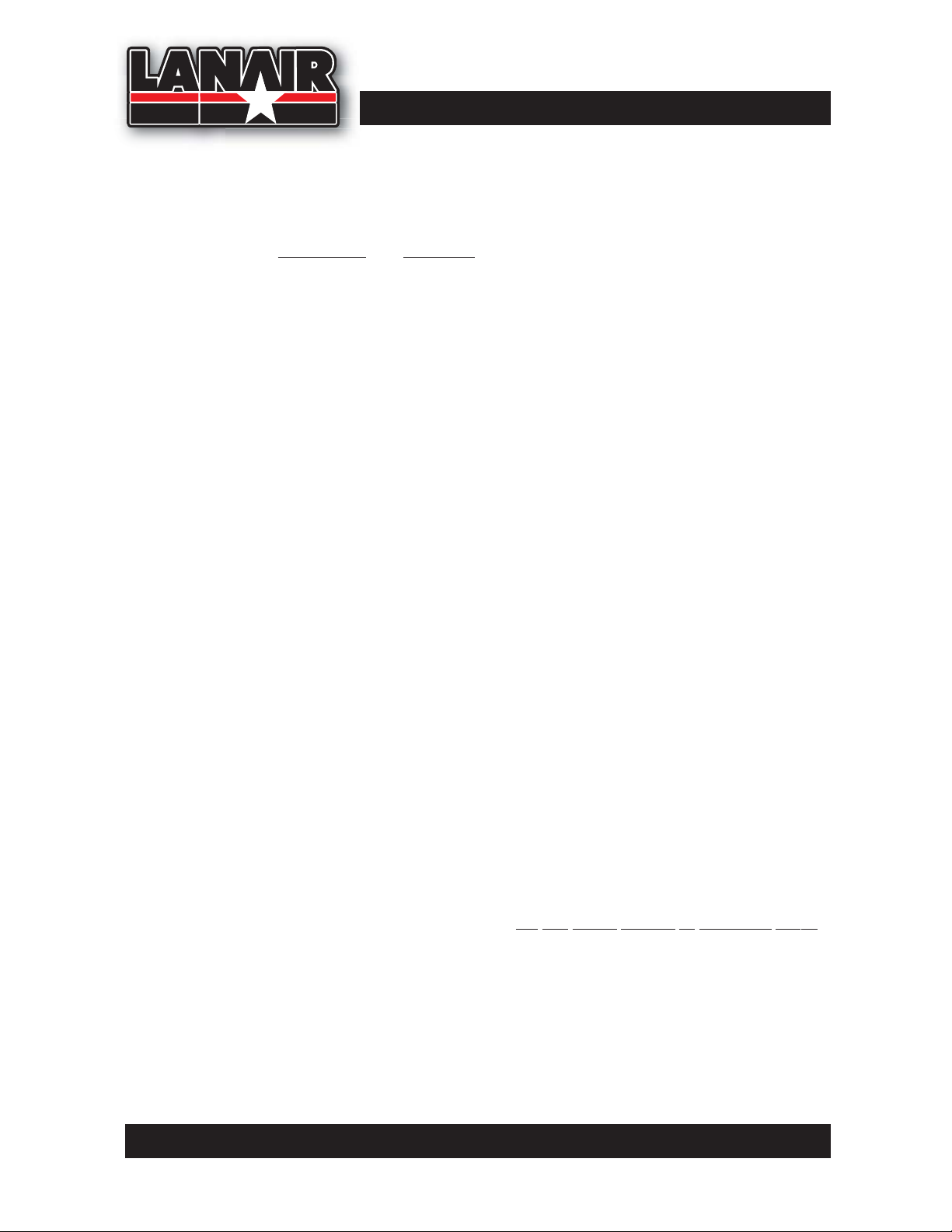

2

1

3

6

4

5

8

7

MX 250-300 Series Burner

NOTE: This burner intended for use

with MX Series Lanair Waste Oil-Fired

Heaters Only

No. Description

1 Mounting Plate

2 Ignitor Transformer

3 Fuel Line Inlet

4 Fuel Pressure Gauge

5 Combustion Air Baffle

6 View Port

7 Oil Primary Safety Control

8 Waste Oil/Fuel Oil Switch

9 Quick Disconnect Receptacle

10 Air Supply Inlet

11 Combustion Blower Motor

9

10

8

11

Burner AssemblyPerformance Ratings

Voltage . . . . . . . . . . . . . . . . . . . . . . 115 vac

Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . 60 hz

Total Operating Amperage . . . . . . . . 5.8

Weight . . . . . . . . . . . . . . . . . . . . . . . . .31 lbs

Oil Primary . . . . . . . . . . . . . . . . . . 0.2 amps

Pre-Heater Block . . . . . . . . . . . . .2.6 amps

Ignitor Transformer . . . . . . . . . . 0.3 amps

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

4

Page 5

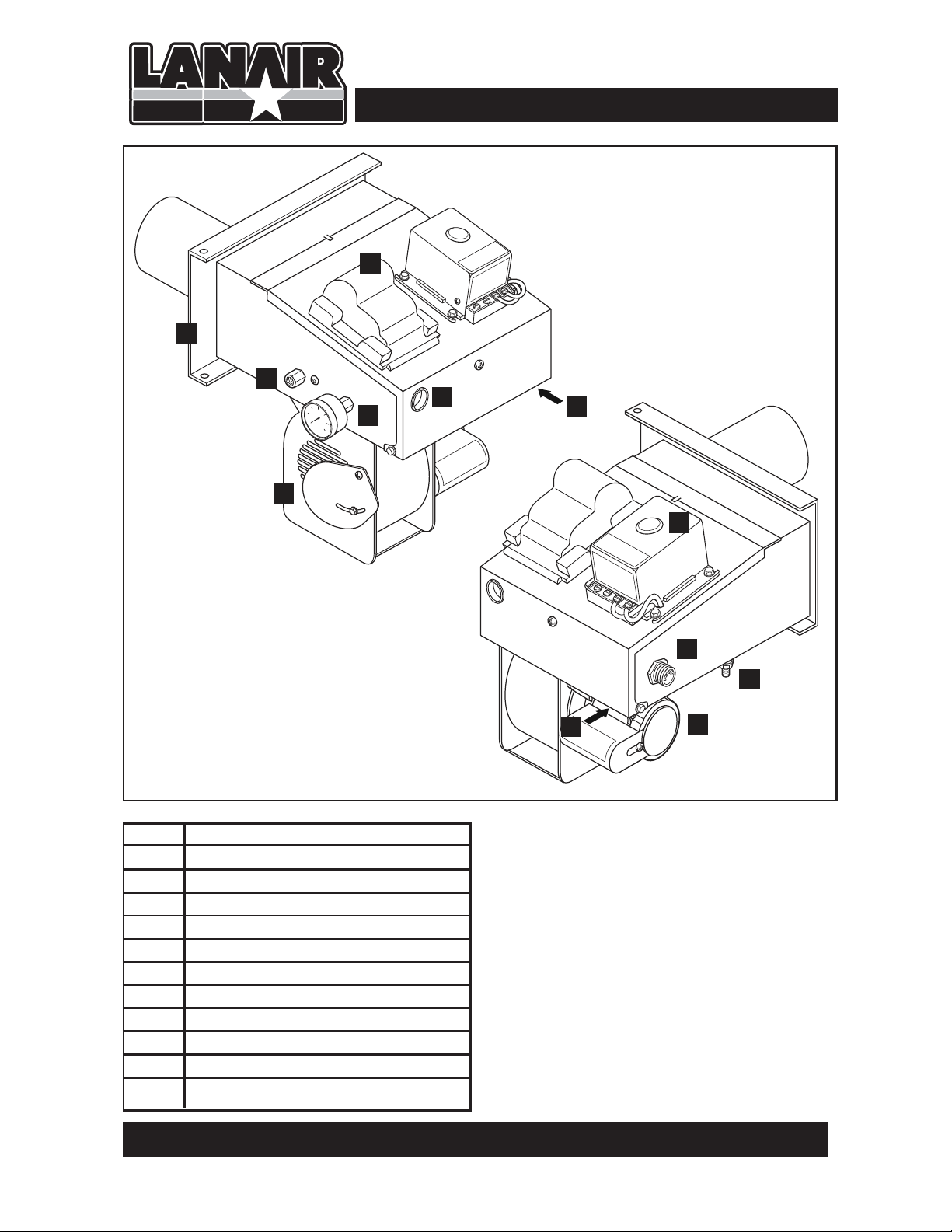

Section 1 - General Specifications & Hazards

9

4

2

1

3

2

2

7

2

5

6

8

No. Description

1 Adjustable Air Flow Louvers

2 Mounting Holes

3 Fan Limit Switch

4 8" Exhaust Flue

5 Flame View Port

6 Burner Assembly

7 Electrical Connections Cover

8 Secondary Air Filter/Regulator Location

9 Fan Assembly (Internal)

Visit our website at: www.lanair.com

5

Page 6

Section 1 - General Specifications & Hazards

MX-250/300 FRONT

DIMENSIONS:

MX-250 Height: 36” Width: 46” Depth: 48” Weight: 630 LBS

MX-300 Height: 36” Width: 46” Depth: 48” Weight: 630 LBS

FIRING CAPACITIES:

MX-250 Nozzle @ 1.79 gallons/hour, No. 2 fuel oil/used crankcase oil

MX-300 Nozzle @ 2.14 gallons/hour, No. 2 fuel oil/used crankcase oil

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

6

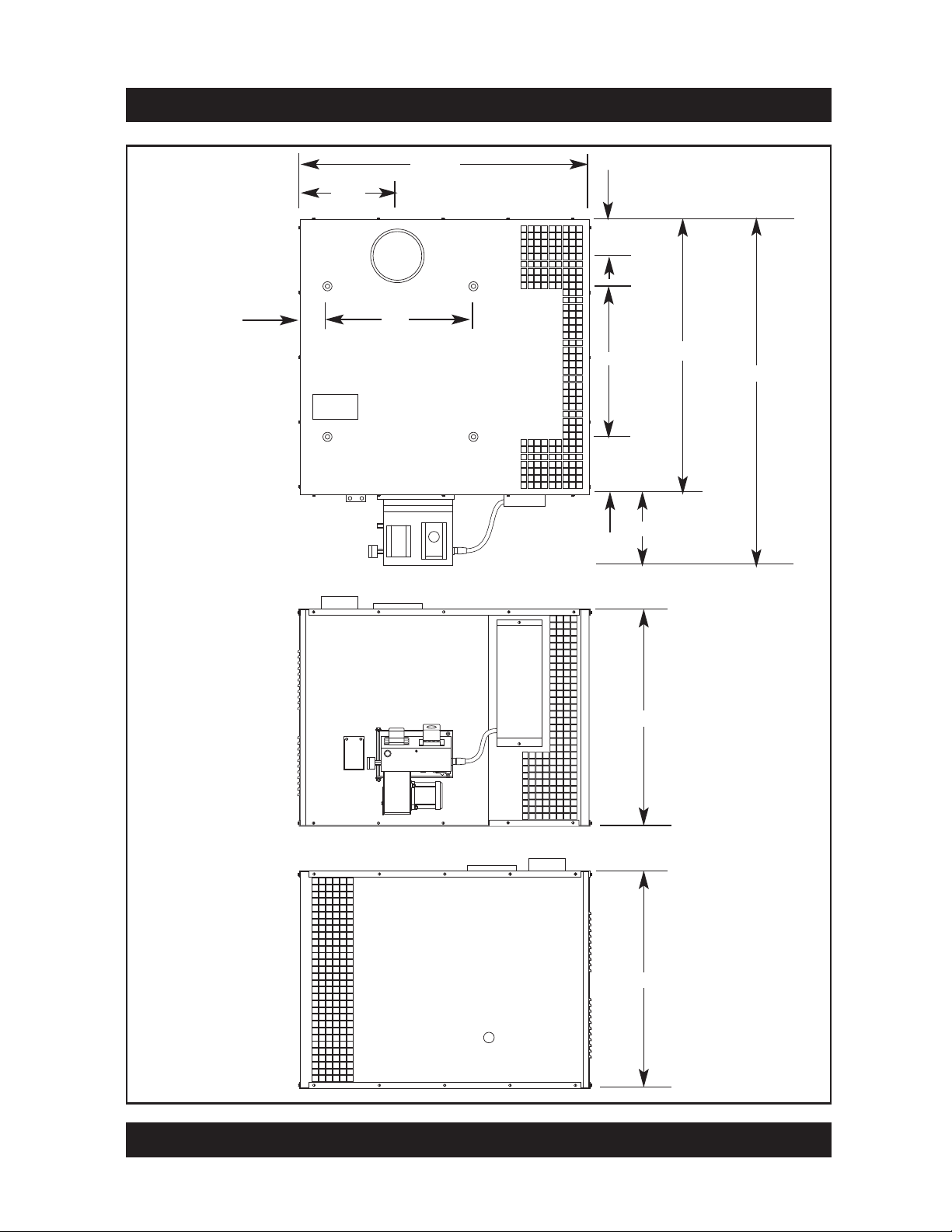

Page 7

16”

Section 1 - General Specifications & Hazards

48”

TOP VIEW

MX 250-300

RIGHT SIDE

MX 250-300

5.5”

25”

8” dia. flue

6"

24"

9.5"

46”

59.5"

13.5"

LEFT SIDE

MX 250-300

36"

36"

Visit our website at: www.lanair.com

7

Page 8

Section 1 - General Specifications & Hazards

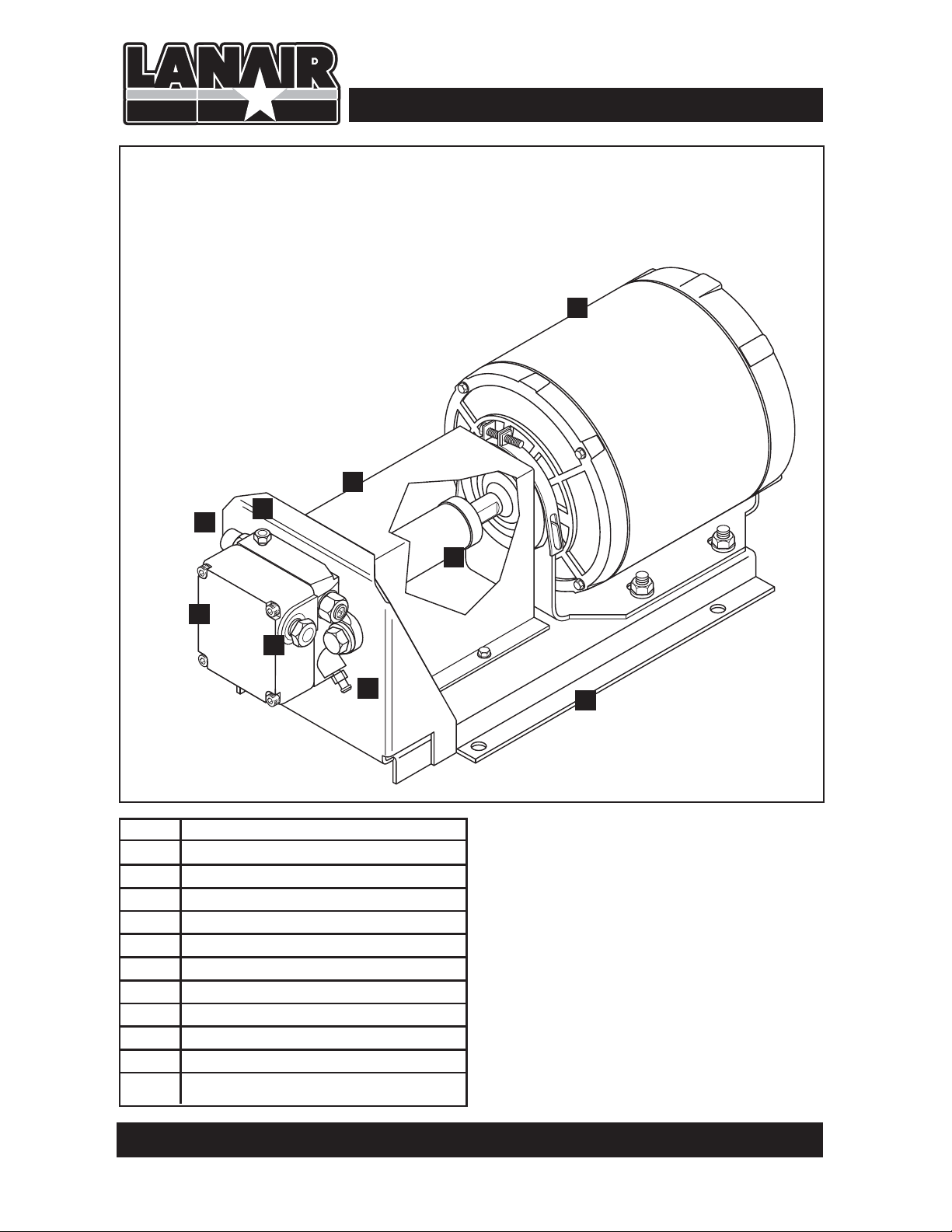

Pump Assembly for use with By-pass Regulator

3

2

8

5

4

7

No. Description

1 Pump Platform

2 Pump Motor

3 Pump Guard

4 Pump

5 Pressure Gauge port

6 Easy Flow Bleed Valve

7 1/4" NPT Inlet

8 1/8" NPT Outlet

9 Pump coupler

9

6

1

Pump AssemblyPerformance Ratings

Voltage . . . . . . . . . . . . . . . . . . . . . . 115 vac

Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . 60 hz

Weight . . . . . . . . . . . . . . . . . . . . . . . . . 24 lbs

Pump Motor . . . . . . . . . . . . . . . . . . 5 amps

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

8a

Page 9

Section 1 - General Specifications & Hazards

Optional Metering Pump Assembly

10

8

4

No. Description

1 Pump Platform

2 Pump Motor

3 Pump Guard

4 Pump

5 Pressure Gauge port

6 Easy Flow Bleed Valve

7 1/4" NPT Inlet

8 1/8" NPT Outlet

9 Pump coupler

10 Line to Burner

11 Line to Tank

11

5

7

2

3

9

6

1

Pump AssemblyPerformance Ratings

Voltage . . . . . . . . . . . . . . . . . . . . . . 115 vac

Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . 60 hz

Weight . . . . . . . . . . . . . . . . . . . . . . . . . 16 lbs

Pump Motor . . . . . . . . . . . . . . . 0.59 amps

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

8b

Page 10

Section 1 - General Specifications & Hazards

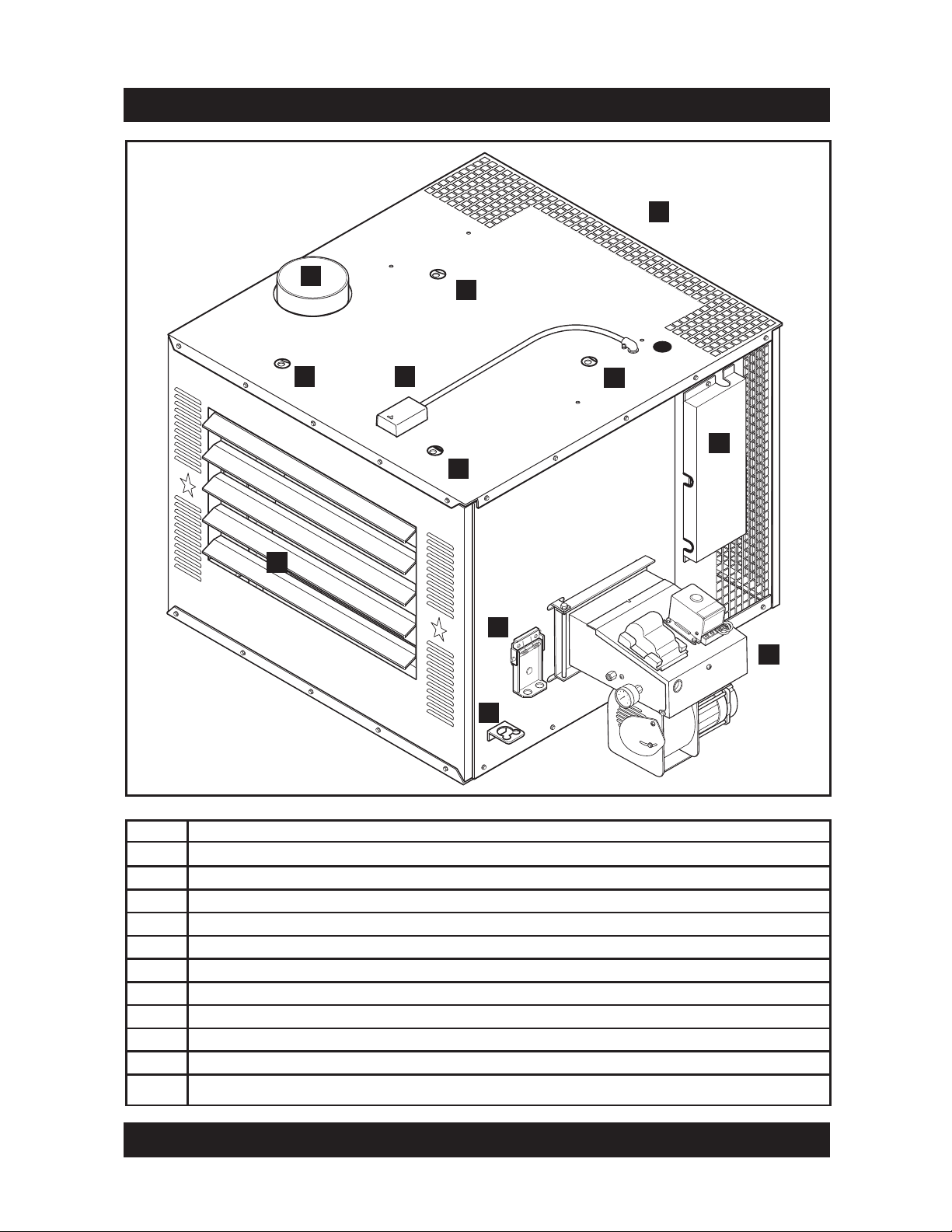

DIMENSIONS:

MX-250 Height: 36” Width: 46” Depth: 48” Weight: 630 LBS

MX-300 Height: 36” Width: 46” Depth: 48” Weight: 630 LBS

FIRING CAPACITIES:

MX-250 Nozzle @ 1.79 gallons/hour, No. 2 fuel oil/used crankcase oil

MX-300 Nozzle @ 2.14 gallons/hour, No. 2 fuel oil/used crankcase oil

MINIMUM CLEARANCE TO COMBUSTIBLES:

Top . . . . . . . . . . . . . . . . . . . . . . . . 6” Chimney Connector . . . . .18”

Sides . . . . . . . . . . . . . . . . . . . . . 18” Rear . . . . . . . . . . . . . . . . . . . . . 6”

Burner Side . . . . . . . . . . . . . . . 38”

Front . . . . . . . . . . . . . . . . . . . . . 60” Bottom . . . . . . . . . . . . . . . . 24”

THIS HEATER IS DESIGNED TO BURN THE FOLLOWING APPROVED FUELS:

Used 5W through 50W Crankcase Oils

No. 1 and No. 2 Fuel Oils

s4HE,ANAIR(EATERPROVIDESTHEOWNERWITHADEPENDABLEVERSATILEANDSIMPLEMEANSOF

BURNING.OAND.OFUELOILSAND7THROUGH7USEDCRANKCASEOILS-AINTAINED

CORRECTLYTHEHEATERWILLGIVEYOUYEARSOFSERVICE0LEASECAREFULLYREADTHISOWNERS

MANUAL)FINANYCASEYOUHAVEAPROBLEMWITHYOURHEATERORITSINSTALLATIONYOUSHOULD

CONTACTTHE,ANAIR#USTOMER3ERVICE$EPARTMENTAT

s This heater is not designed for attachment or use with ductwork.

s Do not attempt to start the burner when excess oil, oil vapor, or fumes have

accumulated! Never press the red button on the oil primary control more than

twice! This could cause excess vapor, or fuel to ignite causing damage to the

heater and/or chimney.

s Do not store or use gasoline, or any other FLAMMABLE liquid and/or Vapors near this

heater.

s This heater is not designed for use in hazardous atmospheres such as: 0aint Shops, Feed

Mills, installations WHEre explosiVe or FLAMMABLE conditions are present or could occur.

WARNING! Lanair heaters rely on natural draft. DoWN drafts (positiVe pressures)

in the heaters chimney WILL occur in BUILDINGS WHEre negatiVe pressures are created

By exhaust fans, (car exhaust, paint BOOTHs, etc). Do not try t

!

oVercome a doWN draft (positiVe pressure). An adequate make-up air system is

required WHEN exhaust fans are used (consult your heating contractor).

o use a poWer Vent to

Visit our website at: www.lanair.com

9

Page 11

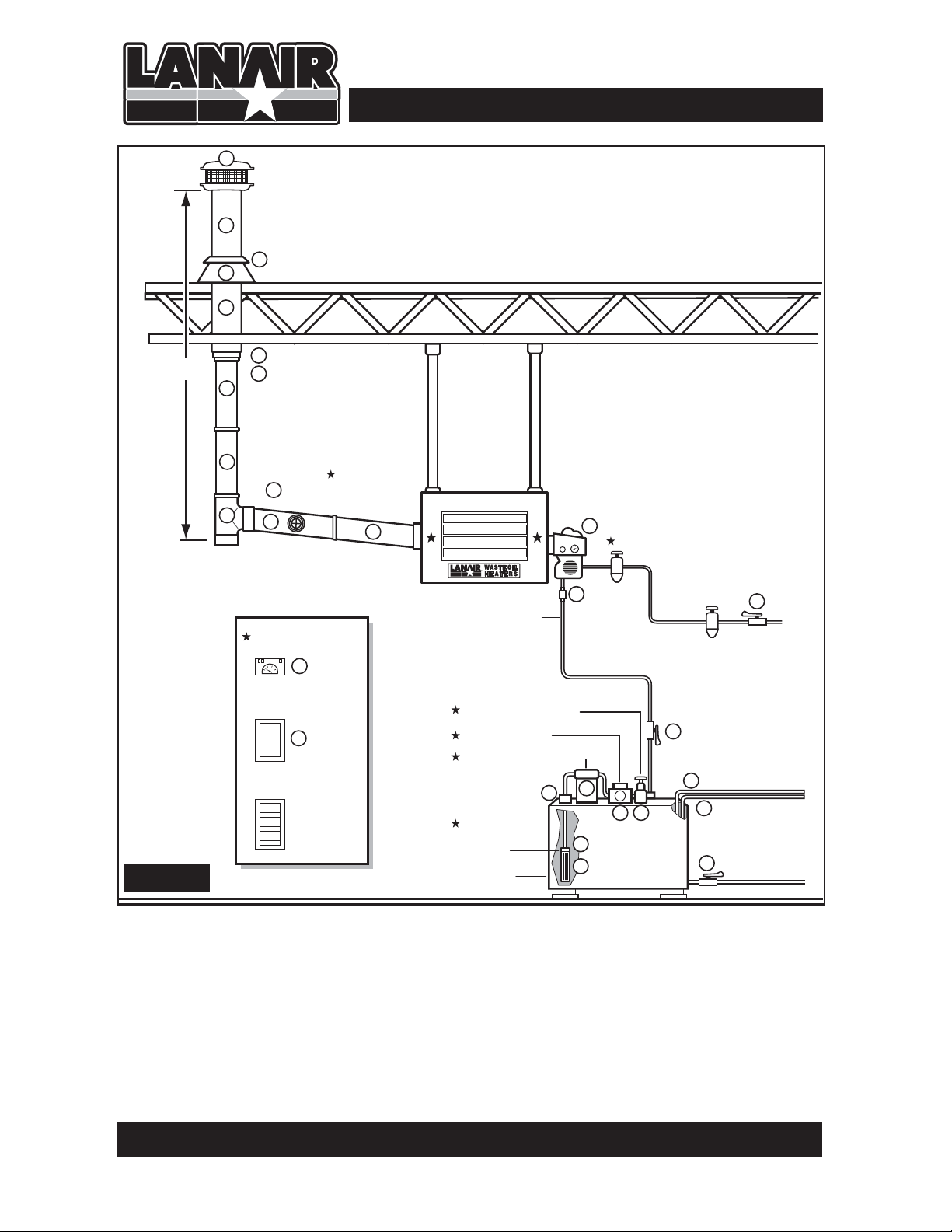

Section 2 - Heater Install w/ Bypass Regulator

10 ft.

min.

1

any object within 10 ft.

2

3

4

5

6

7

8

8

10

9

11

Room

Thermostat

Chimney Cap

3 ft. taller than

Class “A” Chimney

Barometric Damper

2-3 ft. away from heater

Chimney Connector

10 foot max. length

1/4” rise per foot of length

21

TYPICAL INSTALLATION:

HEATER/CHIMNEY PACKAGE

Through the roof installation

Ceiling Hung

8 ft. min.

10 ft. max.

11

Fuel Line - 1/2” O.D.

Soft Copper

12

Secondary Air Regulator

13

Primary Air Regulator (not supplied)

15

Set to 30 lbs.

Service

Disconnect

Main Power

120v - 60 hz 20 amp

Figure 1

1. Chimney Cap

2. Chimney Pipe (36”)

3. Storm Collar

4. Roof Flashing

5. Chimney Pipe (36")

6. Finishing Collar

7. Slip Connector (14")

8. Black Pipe (24")

9. Black Tee w/cap

22

10. Barometric Damper

11. Black Pipe (24")

12. Burner

13. Union

14.

Tank Vent

15. Shut-off Valve

16. Shut-off Valve

17. Suction Line Strainer

18. Fuel Pump

Oil Bypass Regulator

Pump Assembly

Primary Strainer

1/2” Checkvalve

and Oil

Strainer

Supply Tank

16

17

13

18 25

19

20

14

24

23

19. Check Valve

20. Pick-up Tube Strainer

21. Thermostat

22. Service Disconnect

23. Tank Drain

24. Fill Pipe

25. Oil Bypass Pressure Reg.

★ Included with Heater

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

10a

Page 12

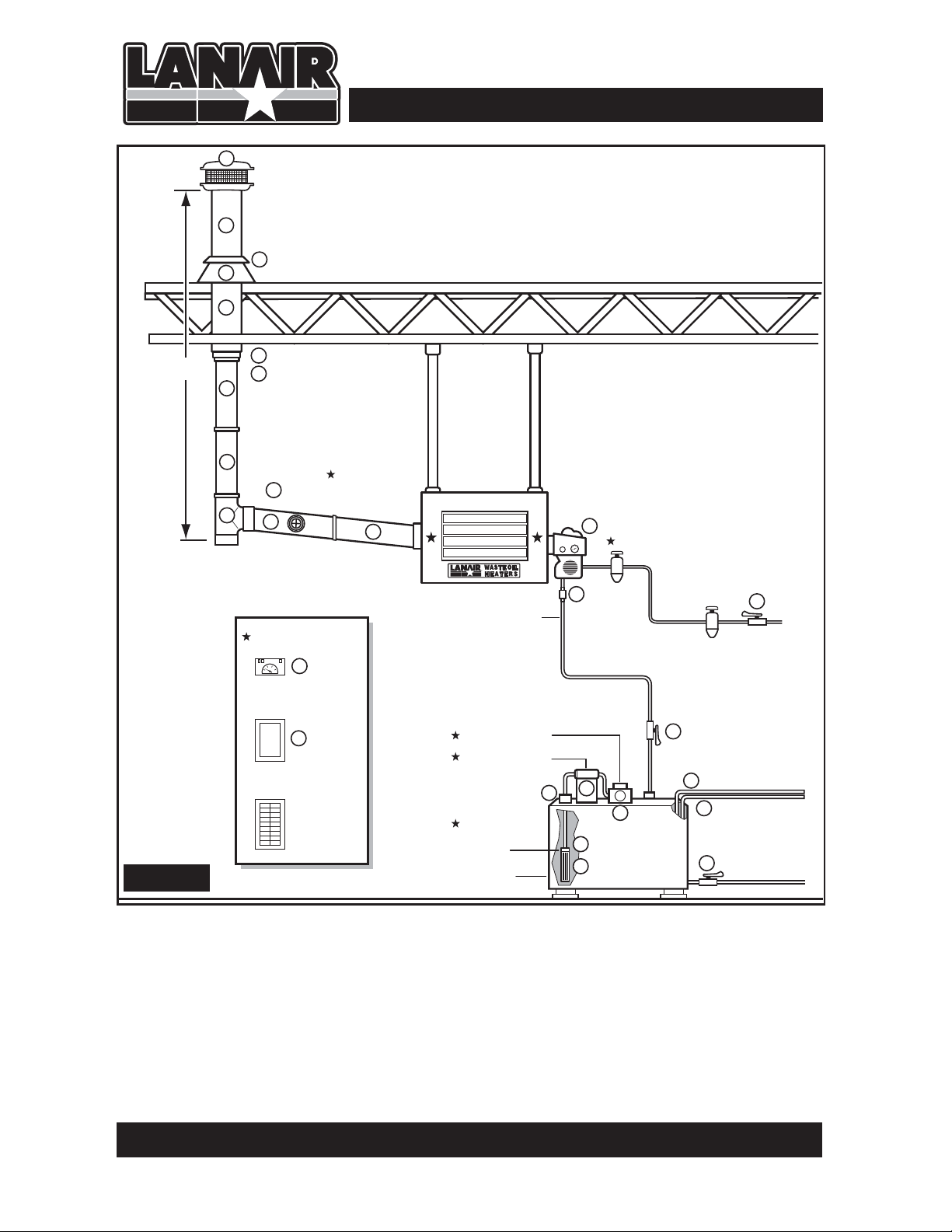

Section 2 - Heater Install w/ Metering Pump

10 ft.

min.

1

any object within 10 ft.

2

3

4

5

6

7

8

8

10

9

11

Room

Thermostat

Chimney Cap

3 ft. taller than

Class “A” Chimney

Barometric Damper

2-3 ft. away from heater

Chimney Connector

10 foot max. length

1/4” rise per foot of length

21

TYPICAL INSTALLATION:

HEATER/CHIMNEY PACKAGE

Through the roof installation

Ceiling Hung

8 ft. min.

10 ft. max.

11

Fuel Line - 1/2” O.D.

Soft Copper

12

Secondary Air Regulator

13

Primary Air Regulator (not supplied)

15

Set to 30 lbs.

Service

Disconnect

16

14

24

23

Main Power

120v - 60 hz 20 amp

Figure 1

1. Chimney Cap

2. Chimney Pipe (36”)

3. Storm Collar

4. Roof Flashing

5. Chimney Pipe (36")

6. Finishing Collar

7. Slip Connector (14")

8. Black Pipe (24")

9. Black Tee w/cap

22

10. Barometric Damper

11. Black Pipe (24")

12. Burner

13. Union

14.

Tank Vent

15. Shut-off Valve

Metering Pump

Primary Strainer

1/2” Checkvalve

and Oil

Strainer

Supply Tank

17

13

18

19

20

19. Check Valve

20. Pick-up Tube Strainer

21. Thermostat

22. Service Disconnect

23. Tank Drain

24. Fill Pipe

16. Shut-off Valve

17. Suction Line Strainer

18. Fuel Pump

★ Included with Heater

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

10b

Page 13

Section 2 - Heater Installation

General Requirements

1. Do not install the heater on a combustible surface of any kind. For minimum clearance to

combustible material (see Page 9)

2. Install the heater in a location to utilize total heat throw.

3. Install the heater in a location to permit a correct outdoor chimney exit to eliminate

down drafts, and provide easy chimney installation and maintenance. Class A chimney

MUST be used when passing through any wall or ceiling. See Section 3 Chimney

Installation

4. Install the heater in a location to permit the fuel supply to be as close as possible.

5. Do not install the heater more than 10 feet above the top of the fuel supply tank.

6. Before suspending the heater check the supporting structure and reinforce if necessary

to support the weight of the heater/system.

7. Use 3/8” steel threaded rod to suspend the heater from a capable load carrying ceiling

structure when not using the Lanair Waste Oil Storage Tank.

8. The heater must be suspended level for proper operation.A heater that is not level could

cause a hazardous situation in which personal injury or property damage may result.

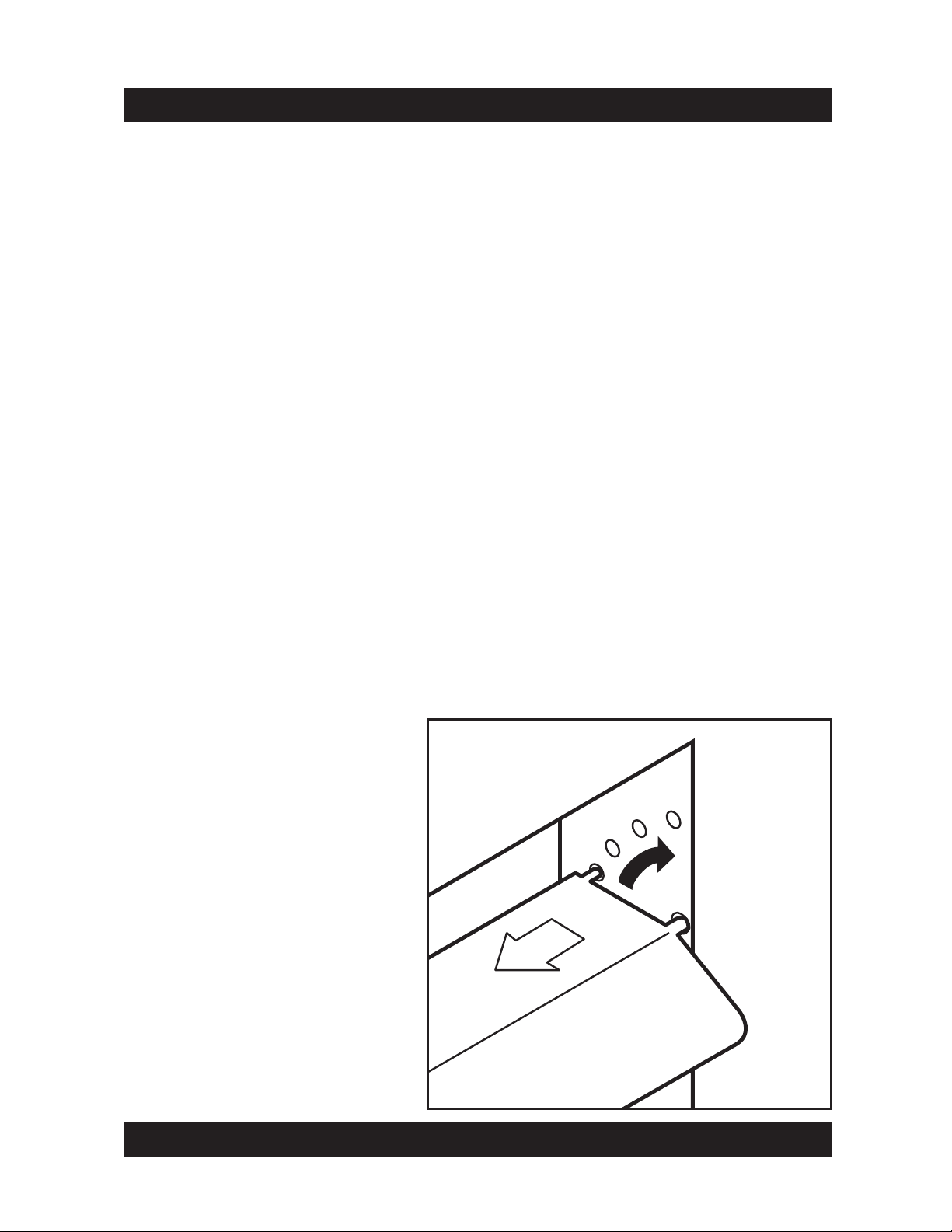

Adjustable Locking Louvers

The MX Series heaters feature spring

loaded locking louvers.To adjust:

s Slowly push the louver to the left

until the locking pin disengages.

NOTE: Do not allow the pivot pin

to come out of the hole.

s Tilt the louver forward/backward

until desired position is obtained.

s Release louver so locking seats

into the hole.

Pivot Pin.

NOTE: Do not

allow pin to

disengage while

adjusting

Visit our website at: www.lanair.com

11

Page 14

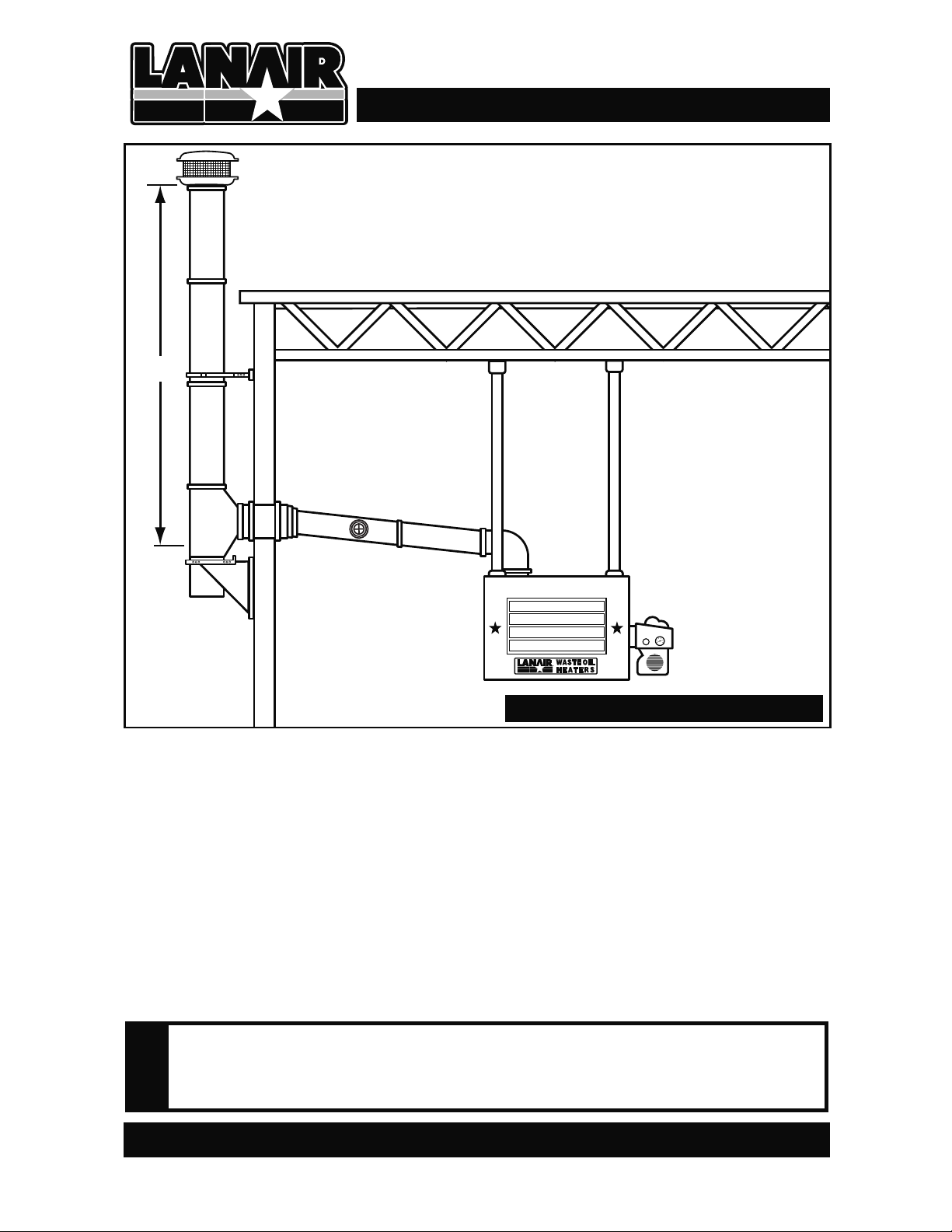

Section 3 - Chimney/Vent System

10 ft.

min.

Chimney Cap

3 ft. taller than

any object within 10 ft.

Class “A” Chimney

Barometric Damper

2-3 ft. away from heater

Chimney Connector

10 foot max. length

1/4” rise per foot of length

NOTE: Class "A" components require a 2" clearance

from combustible materials. All other chimney components require a minimum 18" clearance from combustible materials

(NOT TO SCALE)

Ceiling Hung

8 ft. min.

10 ft. max.

Figure 2 - Typical Chimney Installation

General Requirements

1. Safe operation of any gravity vented heating appliance requires a proper air make-up

system to prevent the heater exhaust gases from being drawn into the building.These

gases could cause death, serious injury, and/or property damage. Exhaust fans, paint

booths may cause draft problems.

2. Never vent this heater into another heating appliances chimney. Never vent into “Class B”

chimney.Gas heaters use “Class B”chimney, it is rated for a much lower temperature than

is required for your waste oil furnace.This heater must have its own separate “Class A”

chimney.

3. Inspect and maintain the chimney on an annual basis.

Failure to provide proper venting of the heater exhaust gases could

result in death, serious injury, and/or property damage. FOLLOW

!

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

CHIMNEY MANUFACTURERS INSTRUCTIONS.

12

Page 15

Section 3 - Chimney/Vent System

General Requirements (cont.)

4. Install a U.L. listed barometric damper in the chim-

ney. Do not reduce or enlarge the vent pipe.

5. Do not use more than one 90° elbow. Each 90°

elbow equals a 10’ run of chimney.The maximum

run for the chimney connector is 30’.

6. To prevent the drawing of exhaust gases into the

building, keep the barometric draft control at least

24” from the heater, exhaust fan etc..

7. Position the draft control as shown. Barometric

Damper gate pins must be horizontal (Parallel to

the floor) for proper operation.

8. Secure all connections in the chimney connector with 3 screws per joint.

9. The chimney connector clearance to any combustible material is 18”. The “Class A”

chimney clearance to any combustible is 2”. Follow the chimney

instructions.

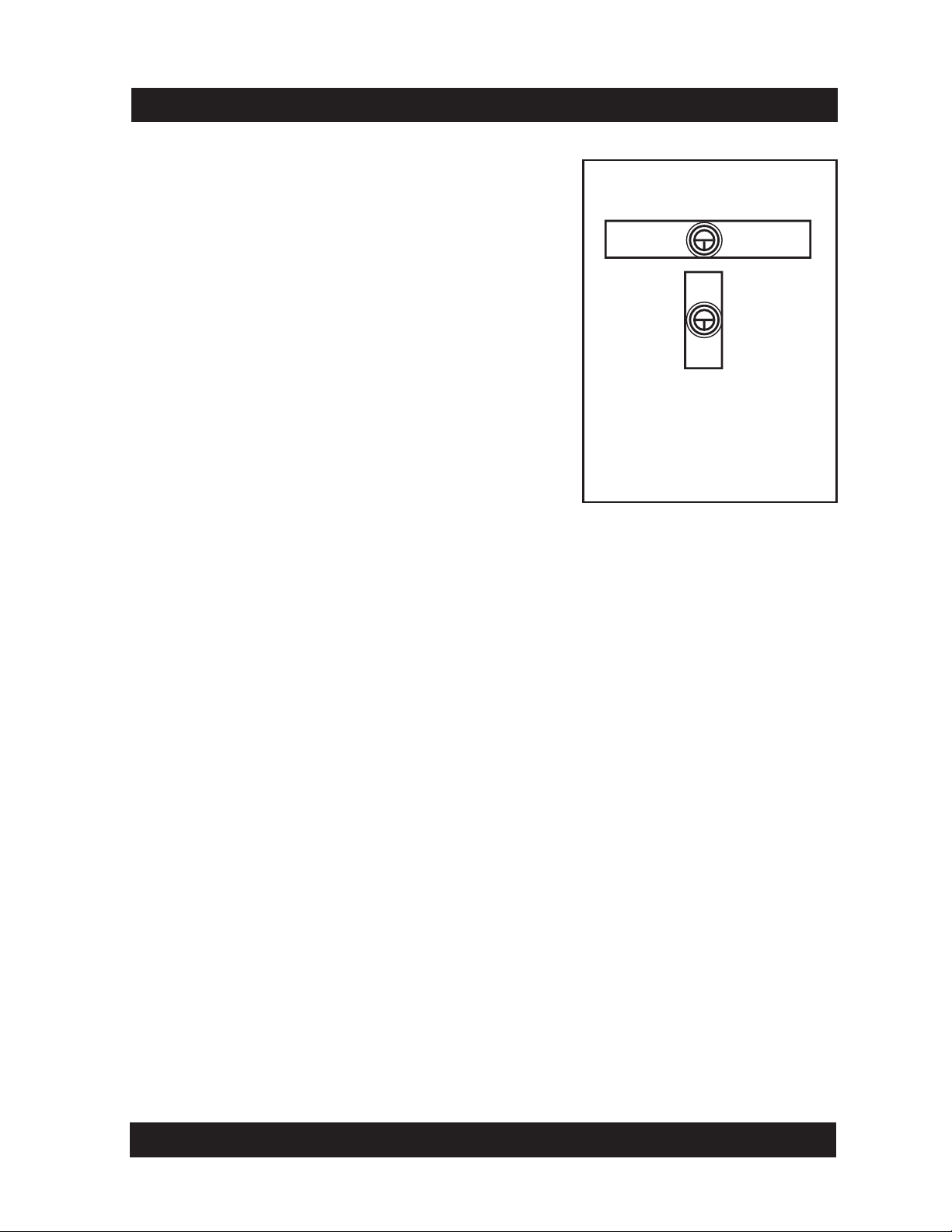

Barometric Damper Position

HORIZONTAL

VERTICAL

NOTE: Barometric Damper may

be mounted horizontally or

vertically. Angle gate pins

must be horizontal for proper

operation

manufacturer’s

10. Do not install heat re-claimers, manual draft controls, or any other type of restrictive

control in the chimney.

11. Install clean out tee with a cap, at the transition of the chimney. FOLLOW CHIMNEY

MANUFACTURERS INSTRUCTIONS.

12. Use “Class A”insulated chimney pipe to vent exhaust gases through wall, ceilings, attics,

roofs, combustibles, etc. Class A chimney must be used for the entire run once passing

through a wall of ceiling.

13. Vent chimney at least 3 feet above the roof and at least 3 feet higher than any portion

of the building, roof, or obstruction within 10 feet of the chimney.

14. The chimney cap should be at least 3’ above the chimney exit through the roof.

15. Do not use a rotating chimney cap. Use a non-restrictive “Class A” cap made for the type

“Class A”chimney you are using. Follow chimney manufactu

16. The chimney must be capable of producing a negative -.02 W.C. draft when cold and .06 W.C. draft when hot.Refer to Section 4 Draft Instructions. Refer to Section 3.10 for

typical Chimney Installation.

NOTE: Do not install chimney in front of the heater (in air stream of fan)

rer’s instruction.

Visit our website at: www.lanair.com

13

Page 16

Section 3 - Chimney/Vent System

17. If you are unable to attain the proper draft, check for exhaust fans in the building.To test

if there is a problem, open an overhead door and see if you now have the proper draft.

You may have to add one or more sections of “Class A”chimney to the roof to get the

proper draft.

18. The heater and chimney must be installed in accordance with all state and local

codes.The heater must be installed in accordance with the specifications listed in

this manual. The chimney must be installed per the chimney manufacturer’s

instruction. Use “Class A” chimney only.

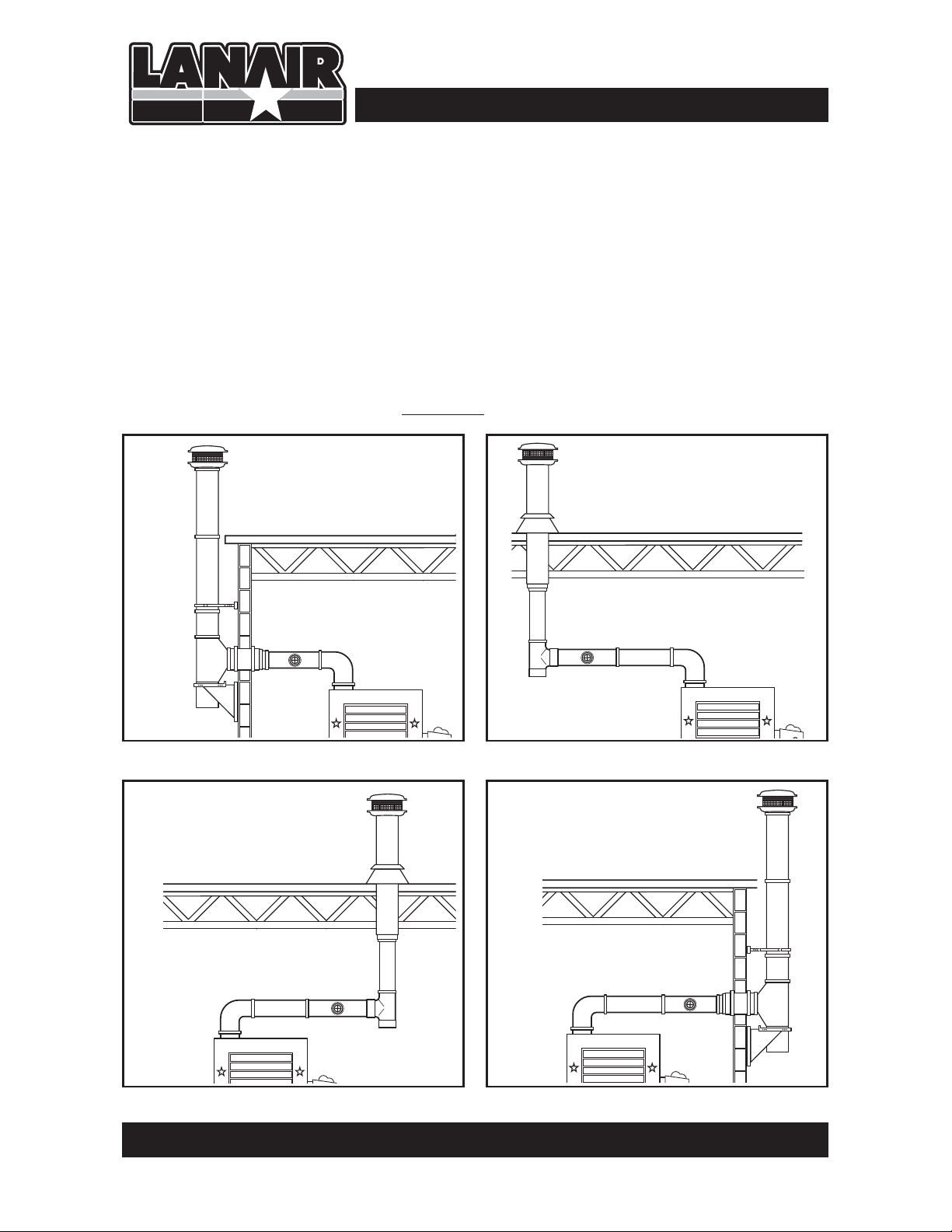

Chimney Configurations Using Top Vent ( not to scale )

Left Exhaust

Install Cap

On Vent

Right Exhaust

Through Roof

Left Exhaust

Through Roof

Install Cap

On Vent

Right Exhaust

Through Wall

Install Cap

On Vent

Install Cap

On Vent

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

14

Page 17

Section 4 - Draft

The Lanair heater should have a (negative) -.02 draft reading when cold,and a (negative) -.06

when hot. Check the heater when it is running after 45 minutes. If the reading is not what it

should be, adjust the barometric damper according to the instructions provided with the

damper.The draft reading should be taken with a manometer.Consult your heating contractor, or a manometer can be purchased from the Lanair Customer Service Department .

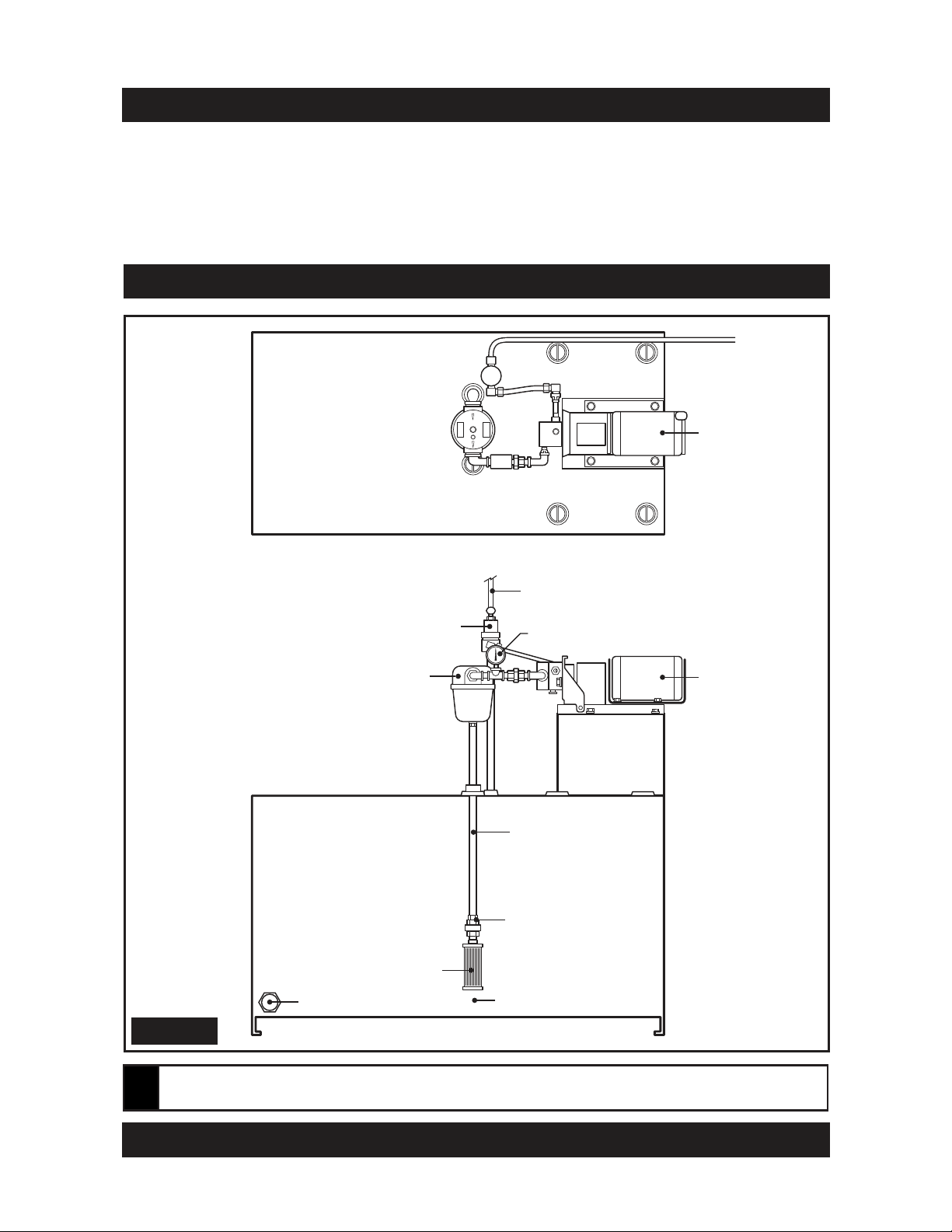

Section 5 - Fuel Supply Tank Install w/ Bypass Regulator

1/2” Copper Tube

(to Burner - not included)

PUMP

ASSEMBLY

(included)

TOP VIEW

Figure 3

9570 By-Pass

Regulator

(included)

9807 Primary Strainer

(included)

8748 Strainer Suction Line

(included)

Tank Drain Plug

1/2” Copper Tube

(to Burner - not included)

8398 Vacuum Guage (included)

1/2” Pick-up Tube

(not included)

8662 Check Valve

(included)

Bottom of strainer must be 6”

from the bottom of the tank

PUMP

ASSEMBLY

(included)

If using a Lanair supply tank follow instructions included with the tank.

!

Visit our website at: www.lanair.com

15a

Page 18

Section 4 - Draft

The Lanair heater should have a (negative) -.02 draft reading when cold,and a (negative) -.06

when hot. Check the heater when it is running after 45 minutes. If the reading is not what it

should be, adjust the barometric damper according to the instructions provided with the

damper.The draft reading should be taken with a manometer.Consult your heating contractor, or a manometer can be purchased from the Lanair Customer Service Department .

Section 5 - Fuel Supply Tank Install w/ Optional Metering Pump

3/8” Copper Tube

(to Burner - not included)

METERING PUMP

ASSEMBLY

(included)

3/8” Copper Tube

(return to tank - not included)

TOP VIEW

Figure 3

8398 Vacuum Guage (included)

9807 Primary Strainer

(included)

3/8” Copper Tube

(return to tank - not included)

8748 Strainer Suction Line

(included)

Tank Drain Plug

3/8” Copper Tube

(to Burner - not included)

1/2” Pick-up Tube

(not included)

8662 Check Valve

(included)

Bottom of strainer must be 6”

from the bottom of the tank

METERING PUMP

ASSEMBLY

(included)

If using a Lanair supply tank follow instructions included with the tank.

!

Visit our website at: www.lanair.com

15b

Page 19

Section 5 - Fuel Supply Tank Installation

If using a Lanair supply tank follow instructions included with the tank.

!

General Requirements

1. The fuel supply tank and supply lines must be installed in accordance with the National

Fire Protection Association requirements,as well as State and Local ordinances.

2. Regulations require oil storage tanks located inside not too exceed 275 gallons individu-

ally,and are not to exceed a total capacity of 550 gallons in one building. Check State

and Local codes.

3. Locate the fuel supply tank inside the building as close to the heater as possible. It

should be no further than 25 feet from the heater to avoid oil flow problems.

4. The fuel supply tank must be mounted below the burner and the by-pass regulator (or

supply pump assembly when using the optional metering pump). Mounting the fuel

supply tank above the burner will create head pressure and over-fire the burner voiding

the warranty.

5. Pitch the fuel supply 2º with the drain valve at the lowest end to drain off water and

sludge. Sludge may have to manually be removed.

6. Some ordinances may require the fuel supply tank to be vented to outside

and

above the roofline.Check State and Local codes. Keep the vent clear.

7. Install the fuel tank fill pipe at the end of the tank and above the drain.

8. Label the fuel tank for the recommended fuels.

9. Strain all fuel with a 50 X 50 mesh strainer before putting fuel into the tank.

10. When filling the fuel tank with a motorized pump, never leave unattended to prevent

over filling and/or spillage.

11. Keep cap on the fuel tank when not filling.

For optimum performance, the waste oil pump manufacturer recommends that multi-weight oils such as 5W-30W be maintained at 32˚ F

!

minimum and straight weight oils such as 40W and 50W be maintained

at 50˚ F minimum.

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

16

Page 20

Section 6 - Fuel Supply Pump/Piping

General Requirements

1. Mount the fuel supply pump in a horizontal position (shaft horizontal) near the fuel sup-

ply tank.

2. The oil pump has a maximum suction lift of 14 feet. Suction lift is the length of pipe run

from the bottom of the pick-up strainer to the fuel supply pump.

3. The fuel pump/motor are intended for indoor use only.

4. The fuel pump contains an internal strainer that periodically needs to be cleaned.This

internal strainer is mounted behind the pump cover. Before removing the pump cover

make sure you have a new gasket on hand. Contact the Lanair Customer Service

Department for the proper gasket for your model of pump, at 1-888-370-6531.

5. Install the suction supply line from the inlet side of the fuel pump into the fuel tank

opposite the drain.

6. Install a 1/2” inside diame

out the suction supply line and pick up tube. The use of smaller line, or rubber, plastic or

hydraulic line is unsafe and will void your warranty.

7. Use thread sealing compound on all pipe thread connections. Do Not Use Teflon Tape.

8. Install the suction line strainer in the suction line. Make sure the suction line strainer is 6”

off the bottom of the tank. The suction line strainer may be mounted horizontally or vertically.Consider accessibility.

9. Install a 1/2” NPT pipe union between the suction line strainer and the pick up tube to

allow for service on the pick up tube.

10. Install the check valve (arrow facing towards the pump) on the bottom of the pick up

tube.

11. Install a vacuum gauge in the suction line.This gauge will indicate when service

ed on the strainer, pump or connections.

12.

When using a by-pass regulator install a 1/2” inside diameter (.493) steel pipe, or 1/2”

outside diameter copper from the fuel by-pass regulator (port marked “T”) to the fuel

supply tank. Do not allow this line to protrude into the tank more than 1”. The use of

smaller line, or rubber, plastic or hydraulic line is unsafe and will void your

warranty.

ter (.493) steel pipe, or 1/2” outside diameter copper through-

is need-

When using the optional Metering Pump install a 3/8” copper line from the tee on the

metering pump assembly to the fuel supply tank do not allow this line to protrude

below the level of the oil. The use of smaller line, or rubber, plastic or hydraulic line is

unsafe and will void your warranty.

13. Do not allow the fuel level in the tank to cover the return line.

Visit our website at: www.lanair.com

17

Page 21

Section 6 - Fuel Supply Pump/Piping

14.

When using a by-pass regulator install the fuel supply line from the fuel by-pass regulator

(port B) to the inlet port on the left side of the burner using 1/2” inside diameter (.493)

steel pipe, or 1/2” outside diameter copper tubing. The maximum distance of this line is 25

feet. The fuel supply line must be run below the burner at all times. If the fuel supply line

runs above the burner it will create head pressure. This head pressure will over-fire the

burner voiding the warranty.

When using the optional metering pump install the fuel supply line from the pump

assembly to the burner (see diagram on page 10b).

15.

Install a union in the supply line close to the burner for service.

16.

install a shut-off valve in the fuel supply line for service.

17.

If using copper line on the suction side of the pump use 37º flare fittings on all copper

tubing connections. Do not use compression fittings.

18.

Keep the fuel supply lines 1” off any outside walls.

19.

The fuel supply line must gradually rise to the burner. It should not be higher than

the burner.

20.

Clean all lines, fittings, and parts internally before assembly. A small burr or piece of

rust could plug the nozzle. See Section 2 for an illustration of a typical pump and piping

installation.

When using the optional metering pump skip to Section 7

B.

Port to the oil inlet on the burner assembly.

Install 1/2” O.D. min. copper tubing, or 1/2”

schedule 40 pipe. Failure to install this line

properly will result in damage to your heater,

and will void your warranty.

T.

Port to the oil supply tank for the overflow

return line. Install 1/2” O.D. min. copper

tubing. or1/2“ schedule 40 pipe. This line

MUST run straight into the tank, and

should not be sub-merged in oil. No

elbows should be used. Failure to install

this line properly will result in damage to

your heater, and will void your warranty.

P.

Port from the outlet side of your fuel supply

pump. Install 1/2” O.D. min. copper tubing, or

1/2 schedule 40 pipe. Failure to install this

line properly will result in damage to your

heater, and will void your warranty.

Bottom View of the Aluminum Oil

By-Pass Regulator

Figure 4

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

18

Page 22

Section 7 - Air Supply Installation

General Requirements

1. Install an air pressure supply line connection to the air filter/regulator on the rear of the

heater.

2. The air supply source must be capable of producing 2.0 CFM @ 60 PSI.

3. Install a shut off valve in the air supply line for service.

4. Install a primary air filter/regulator with a gauge (capable of reading line pressure) in the

air supply line prior to the air filter/regulator mounted on the furnace.The primary air filter/regulator is not supplied with the furnace.

5. If the primary air regulator does not have a filter with a bowl, a condensate drain leg

must be installed in the air supply line.

6. Install a quick disconnect at the air filter/regulator on the furnace for service.

7. For the ease of installation install a flexible airline (.250 I.D.minimum) from the quick

disconnect to the primary air regulator.

8. The air supply line must be pitched uphill from the primary regulator to the furnace to

prevent condensation from entering your burner.

9. Open all air shut off valves, and set the primary air regulator at 30 PSI.

10. Set the air filter/regulator on the front of the furnace to 18 LBS. See illustration below

(Fig.5) for a typical air pressure supply installation.

Figure 5

secondary air filter/

regulator (included)

15

10

5

20

25

air inlet

bottom of burner

to primary air filter/regulator (not included)

and air supply

Visit our website at: www.lanair.com

19

Page 23

Section 8 - Electrical Connections

CAUTION: HAZARD OF ELECTRICAL SHOCK!

!

Main Electrical Installation

1. All wiring must comply with the National Electrical Code. State and Local Ordinances,

and be wired by a qualified electrician.

2. Electrical service MUST be connected to a separate 20 AMP, 115 VAC, 60 HZ

single phase circuit.

3. Electrical service connections are made in the electrical junction box on the side of the

heater.

4. The heater must have a safety equipment ground from the main electrical service,

stranded 12 GA minimum.

5. The electrical conductors for electrical service to the heater MUST be stranded 12 GA

minimum.

6. Install a manual service disconnect near the heater, and label its function.

7. The supply voltage must be maintained at a minimum 110 VAC.

8. The electrical conductors from the main electri-

cal service must be within approved conduit.

9. Keep all electrical conductors and conduit away

from the chimney connector as well as any

other hot surfaces. Refer to Figure 7, Wiring

Diagram for color code, etc. Keep the power off

until the heater is ready to be started. Refer to

Section 12 Start Up Procedure.

Remove wires from the block by inserting a small flat tip screwdriver into the

top slot. Push tip all the way down and

push forward. Remove wire.

Figure 6

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

20

Page 24

Lanair Pump Motor Electrical Connections

Provided by Installer

Figure 7

NAF

ETIHW

NEERG

EGNARO

DER

ETIHW

LINE IN +

LINE IN -

PUMP

MOTOR

WHITE

ETIHW

DIONELOS

RIA

ETIHW

KCALB

RED

KCALB/ETIHW

BLACK

sregdoR etihW

llewyenoH

TIMIL / NAF

LORTNOC

YELLOW

EGNARO

ELPRUP

TIMIL

NAF

RED

NAF

TIMIL / NAF

LORTNOC

TIMIL

WHITE/YELLOW

DER

RED

RETAEH-ERP

WHITE

WHITE

BLACK

HCTIWS

RETAEH-ERP

LIO

RETAEH-ERP

RIA

LAUNAM

PANS

KSID

TESER

KCALB

ETIHW

EULB

ETIHW

ETIHW

REMROFSNART

NOITSUBMOC

REWOLB

BLACK

TATSOMREHT

LLAW

LLEC

DAC

YELLOW

YELLOW

2F 1F 2T 1T

KCALB

YRAMIRP LIO

ETIHW

BLUE (NOT USED)

WHITE

ORANGE

Visit our website at: www.lanair.com

21a

Page 25

Lanair Metering Pump Electrical Connections

Provided by Installer

Figure 7

BLACK

RED

GEAR

LINE IN +

LINE IN -

CAPACITOR

MOTOR

BLACK

BLACK

BLUE

GREEN

GREEN

NAF

ETIHW

NEERG

EGNARO

DER

ETIHW

DIONELOS

RIA

WHITE

ETIHW

ETIHW

KCALB

RED

KCALB/ETIHW

BLACK

sregdoR etihW

llewyenoH

TIMIL / NAF

LORTNOC

YELLOW

EGNARO

ELPRUP

TIMIL

NAF

RED

NAF

TIMIL / NAF

LORTNOC

TIMIL

WHITE/YELLOW

DER

RED

RETAEH-ERP

WHITE

WHITE

BLACK

HCTIWS

RETAEH-ERP

LIO

RETAEH-ERP

RIA

LAUNAM

PANS

KSID

TESER

KCALB

ETIHW

EULB

ETIHW

ETIHW

REMROFSNART

NOITSUBMOC

REWOLB

BLACK

TATSOMREHT

LLAW

LLEC

DAC

YELLOW

YELLOW

2F 1F 2T 1T

KCALB

YRAMIRP LIO

ETIHW

BLUE (NOT USED)

WHITE

ORANGE

Visit our website at: www.lanair.com

21b

Page 26

Section 8 - Electrical Connections

CAUTION: HAZARD OF ELECTRICAL SHOCK!

!

Fuel Supply Pump Electrical Installation

1. All wiring must comply with the National Electrical Code, State and Local Ordinances,

and be wired by a qualified electrician.

2. The electrical conductors to the fuel pump motor MUST be stranded 14 GA minimum.

3. The electrical service connections for the fuel pump motor are made in the electrical

junction box on the side of the heater.

4. The pump motor MUST have a safety equipment ground from the main electrical service, stranded 14 GA minimum.

5. The electrical conductors from the electrical junction box to the pump motor must be

within approved conduit.

6. Keep all electrical conductors and conduit away from the chimney connector as well as

any other hot surfaces. Refer to Figure 7 Wiring Diagram for color code, etc. Keep the

power off until the heater is ready to be started. Refer to Section 11 Start Up Procedure.

Room Thermostat Installation

1. All wiring must comply with the National Electrical Code, State and Local Ordinances,

and be wired by a qualified electrician.

2. Install the room thermostat in accordance with the directions furnished with the ther-

mostat.

3. Use two conductor thermostat wire for the connection of the thermostat to the T.T. ter-

minals of the oil primary control that is mounted on top of the burners electrical box.

4. Mount the thermostat 5 feet above the floor on an inside wall away from the heater’s

warm air path.

5. The electrical current for thermostat is 24 V, and is provided by the oil primary control.

6. Keep the thermostat wire away from the chimney connector, or any other hot surfaces.

Refer to Section 2 for a typical thermostat installation.

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

22

Page 27

Section 9 - Controls

s Room Thermostat:

The room thermostat automatically controls the on/off operation of the heater according

to the setting of the desired room temperature.The thermostat works in conjunction with

the oil primary safety control.

s Oil Primary Safety Control/Cad Cell:

The oil primary control is mounted on top of the burner’s electrical box.When the thermostat calls for heat the oil primary control starts the burner by switching on the air solenoid

valve, ignition transformer, combustion air blower, and the fuel pump.The oil primary control works in conjunction with the cadmium sulfide cell (cad cell). The cad cell is mounted

inside the burner cover, and faces the flame.The cad cell monitors the light level inside the

combustion chamber to insure there is a flame present. If there is a loss of flame the primary control will go into its recycle mode. After 1-2 minutes the primary control will restart

the burner.When this happens if there is a flame present, the burner will continue to function. If on start-up no flame is established in 30 seconds the primary control will lock out.

CAUTION: Do not press the reset button more than twice. If the burner fails to start refer to

Section 14 - Trouble Shooting. Burner has a (2) minute automatic restart feature.

s Fan/Limit Control

The fan/limit control performs 3 functions. The fan/limit control monitors the temperature

of the air inside the cabinet. When the air reaches a set point (usually 120º F) it will switch

on the heater fan.When the temperature in the cabinet drops below 90º F the fan/limit

control will turn the fan off.The Fan/Limit Control contains

the axial fan on manual by-passing its automatic function.

The Fan/Limit Control monitors the temperature of the air inside the cabinet. When the

temperature exceeds a fixed set point it switches the burner (Oil Primary Control) off until

the temperature drops to a safe level.The burner will then restart.

“CAUTION”This means the heater has reached its “High Limit”, the cause must be determined and corrected before further use (over firing the unit is normally what causes this

condition). The Fan/Limit Control is located on the top on the front of the cabinet.

an external slide switch to turn

s Barometric Draft Control

The Barometric Draft Control automatically maintains a pre-set chimney draft, and is located in the chimney connector.

s Air Filter/Regulator

The Air Filter/Regulator performs two functions: It removes condensation and dirt from the

air.and it controls the amount of air pressure reaching the nozzle and air operated fuel

valve.The Air/Filter Regulator is mounted on the cabinet near the burner.

Visit our website at: www.lanair.com

23

Page 28

Section 9 - Controls

s Electric Air Solenoid Valve

The Electric Air Solenoid Valve is controlled by the Oil Primary Control. It acts as a shut-off

valve, (it’s open during operation, and closed when the burner is off). The Electric Air

Solenoid Valve is located inside of the burner’s electrical box. (See Page 51).

s Air Operated Fuel Valve

The Air Operated Fuel Valve controls fuel flow out the nozzle.When the Electric Air

Solenoid Valve opens and air pressure pushes on the fuel valve diaphragm, the plunger

moves off the nozzle seat allowing fuel to enter the nozzle. The Air Operated Fuel Valve is

located on the back of the air pre-heater. (See Page 51).

s Air/Oil pre-heater

The Air/Oil pre-heater is an assembly that preheats the atomizing air and fuel to a predetermined temperatu

burner (See Page 51).

s Snap Disc

The Snap Disc accurately controls the temperature of the air/oil pre-heater assembly with

two resistance type cartridge-heating elements. The Snap Disc is mounted on the oil preheater inside the burner. (See Page 51).

re to properly combust used oil. The Air/Oil pre-heater is located in the

s Nozzle

The Nozzle uses air pressure to help pull fuel through its small orifice, and to atomize the

fuel for proper combustion.The Nozzle is located on the end of the air pre-heater opposite

the fuel valve. Replace the Nozzle annually, as they are prone to wear by contaminants in

waste oil (See Page 47).

s Fuel By-Pass Regulator (This is not used with the Optional metering pump)

The Fuel By-Pass regulator controls the pressure of the fuel to the nozzle. The Fuel By-Pass

regulator is located in the line between the outlet side of the pump and the burner.

s Fuel Supply Pump

The Fuel Supply Pump pumps fuel from your oil storage tank to the burner. The Fuel Supply

Pump should be located as close to the fuel supply tank as possible. The Fuel Supply Pump

must be mounted horizontally (Shaft).

s Optional Metering Pump Assembly

The metering pump pumps fuel from your oil storage tank to the burner. It also controls the

volume of fuel, and no regulator is required. The metering pump should be mounted on

your fuel supply pump with the shaft in the horizontal position.

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

24

Page 29

Section 10 - Priming The Fuel Pump

Priming The Fuel Pump

1.

The fuel level in the supply tank must be

above the check valve on the pick-up tube.

2.

Remove the bowl of the suction line strainer,

and fill with clean fuel. Replace the strainer

bowl.

3.

Remove the two yellow wires from the F-F

terminal on the oil primary control. Install a

jumper wire between the F-F terminals (see

Figs. 8 & 9).

4.

Adjust the air filter/regulator on the heater to

18 PSI.

5.

Remove the fuel supply line from the burner,

and position a container to catch the fuel.

6.

Back the thumb screw out (CCW) on the

by-pass regulator until it is free, the turn (CW)

two turns to seat the diaphragm.

7.

Loosen the bleeder screw on the pump one

turn, and attach a piece of 3/16” ID clear plastic

tubing. The tubing should be long enough to

allow the fuel to be returned to the tank.

Figure 8

Remove two yellow wires

Figure 9

8.

Turn the room thermostat above room

temperature, or to the “ON” position.

9.

Momentarily disconnect one end of the

jumper wire at the F-F terminals on the oil

primary. The fuel pump will now start.

10.

Observe the clear tubing attached to the bleeder screw on the pump. When a steady

stream of fuel (no air bubbles) flows close the bleeder screw. Remove the tubing from the

bleeder screw.

11.

Observe the end of the fuel supply line that is disconnected from the burner. Allow a

steady stream (no air bubbles) of fuel to flow into the container for several minutes. This

will flush any debris from the fuel line that could potentially plug the nozzle. The vacuum

gauge reading should not exceed 5” HG of vacuum.

12.

Turn the room thermostat below room temperature or “OFF”. The fuel supply pump will

now stop.

13.

Reconnect the fuel supply line to the burner.

14.

Remove the jumper wire from the F-F terminals on the oil primary control, reattach the

yellow cad cell wires.

Visit our website at: www.lanair.com

Install jumper wire

25

Page 30

Section 10 - Priming The Fuel Pump

12. Turn the room thermostat below room temperature or “OFF”. The fuel supply pump will

now stop.

13. Reconnect the fuel supply line to the burner.

14. Remove the jumper wire from the F-F terminals on the oil primary control, reattach the

yellow cad cell wires.

15. Adjust the burner air filter/regulator to 18 PSI.

16. If the fuel supply pump prime, or fuel stream has air in it (spurting, fluctuating flow) there

is likely a leak in the suction side of the plumbing. Refer to section 14, trouble-shooting,

flow chart #2. The burner should now be ready to fire.

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

26

Page 31

Section 11 - Burner Start-Up Procedure

Waste Oil Burner Start-Up

1. Make sure the main electrical service for the heater is turned off, and locked out.

2. Fill the oil supply tank with an approved fuel to a level that is above the pick-up tube

check valve.

3. Check for proper draft in the chimney.The draft must read -.02 W.C. cold.

4. Make sure there is air pressure at the heaters air filter/regulator, set at 18 PSI. Set the pri-

mary regulator on the air supply line to 30 PSI.

5. Set the fan/limit control slide switch to automatic.

6. Check the combustion air adjustment baffle for proper setting. Refer to Section 15 Flame

adjustment.

7. Set the room thermostat below room temperature (OFF).

8. Push the reset button on the oil primary control for 3 seconds.

9. Turn the main electrical service ON.

10. Flip the lighted rocker switch for preheating on the burner electrical box to the ON posi-

tion (pre-heater OFF the

11. Prime the fuel supply pump. Refer to Section 10, Priming the Fuel Supply Pump.

If using waste 5W-50W oil, flip the pre-heater rocker switch on (light ON, and wait 5-7

12.

minutes for the pre-heater assembly to reach operating temperature; leave the

pre-heater switch OFF if using No. 1 or No. 2 fuel oil).

Turn the room thermostat up above the room temperature. The burner will now fire,

13.

check the sight glass on the rear of the burner also inspect the flame through the

inspection port. (See page 29-31, flame adjustment).

14. Adjust the burner air filter/regulator to 18 PSI, and the primary air regulator to 30 PSI.

NOTE: 18 PSI on the air filter/regulator is the starting point, you may need to adjust from

there when VISUALLY SETTING THE FLAME (See page 29-31, flame adjustment).

light is off, pre-heater ON the light is on.).

Visit our website at: www.lanair.com

27

Page 32

Section 11 - Burner Start-Up Procedure

15. When using the by-pass regulator adjust the fuel pressure gauge on the left side of the

burner to read.

No. 1 & No. 2 Fuel Oil Approved Waste Oil

Model MX-250

Model MX-300 3 - 3.25 (3-1/4) LBS. 3.5 (3-1/2) - 3.75 (3-3/4) LBS.

NOTE:

and counter clockwise to decrease pressure to the burner.The oil pressures listed above are a

starting point, you may need to adjust from there when VISUALLY SETTING THE FLAME

(See page 29-31, flame adjustment).

NOTE: When using the metering pump the fuel flow is determined by the pump. Pressures

may not be the same as shown above.

16. Adjust the barometric damper to obtain a draft of -.06 W.C. while the heater is hot and

NOTE: It is VERY IMPORTANT that the barometric damper is set to the required settings to

ensure the natural draft of exhaust gases (see section 4).

17. Depending on the type of fuel used,the elevation, temperature,and oil viscosity, the

18. When the room thermostat setting is met

Adjust the thumb screw on the fuel bypass regulator clockwise to increase pressure,

operating.

combustion air baffle will need to be adjusted for optimum performance (S

31, flame adjustment).

the burner will shut off, but the fan will continue to operate until the cabinet temperature drops to 90º F.

2.25 (2-1/4) - 2.5 (2-1/2)LBS. 2.5 (2-1/2) - 2.75 (2-3/4) LBS.

ee page 29-

Clockwise:

Increase fuel

pressure

Counter

Clockwise:

Decrease fuel

pressure

Thumb Screw

Fuel By-Pass Regulator

Not used with the optional Metering Pump

The combustion air baffle is NOT factory set

!

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

28

Page 33

Section 12 - Flame Adjustment

Flame Adjustment

1. Start the heater, let it run for at least 15 minutes to reach operating temperature before

proceeding.

2. Check the chimney draft, set the barometric damper to -.06 WC when hot and running.

3. Check the atomizing air pressure, set the air filter/regulator on the heater to 18 PSI as a

starting point.

4. When using the by-pass regulator check the fuel pressure gauge on the burner, set to:

Model MX-250 Model MX-300

No. 1 and No. 2 Fuel Oil

Used Crankcase Oil 10W-50W 2.5 (2-1/2) - 2.75 (2-3/4)LBS. 3.5 (3-1/2) - 3.75 (3-3/4)LBS.

When using the by-pass regulator adjust the thumb screw on the fuel by-pass regulator.

5.

Lock into position. The flame should extend no more than 3/4 of the way into the

chamber. When using the optional metering pump the flow is determined by the

metering pump. Pressures may vary from those listed above.

NOTE: The above pressure is a staring point, depending on your installation you may

need further adjustment. Always VISUALLY SET THE FLAME. See page 30.

6. Loosen the combustion air adjustment

baffle, slowly close the baffle in 1/16”

increments until the heater (flame) starts

to rumble.Then slowly open the baffle in

1/16” increments until the rumbling stops,

(wait 2 minutes between adjustments)

finally open the baffle an additional 1/8”

to provide excess oxygen

fle, (See Fig.10).

. Secure the baf-

2.25 (2-1/4) - 2.5 (2-1/2)LBS. 3 - 3.25 (3-1/4)LBS.

Figure 10

NOTE: Mechanical equipment like gauges

and regulators are not always 100 percent

accurate, VISUAL INSPECTION OF THE

FLAME IS REQUIRED in order to properly

dial in the flame settings, see page 30.

The combustion air baffle is NOT

factory set

!

Visit our website at: www.lanair.com

combustion

air baffle

29

Page 34

Section 12 - Flame Adjustment

NOTE: ALWAYS WEAR EYE, FACE AND BREATHING PROTECTION AND

PROTECTIVE CLOTHING WHEN INSPECTING OR ADJUSTING FLAME.

!

Lift the inspection port cover on the front of the combustion chamber to observe the flame.

The flame tips should extend 3/4 of the way into the combustion chamber. When the unit is

adjusted properly the ash inside the chamber will be white to off white.

Flame tips touching the target brick (end of the chamber) will cause combustion chamber

damage.This condition may be caused by a worn nozzle, or excess burner fuel pressure.

When this condition exists, the ash in the chamber will

be brown to black.

Flame Adjustment - Visual

Flame is over-red (Fig. 11).

t%BSLZFMMPXUPPSBOHFJODPMPS

t5IFøBNFJTIJUUJOHUIFXBMMTöMMJOHUIFDIBNCFS

XJUIBTNPLFZøBNF$PSSFDUJNNFEJBUFMZPSDIBNCFS

NBZCFEBNBHFE

t%FDSFBTFGVFMQSFTTVSFXIFOVTJOHBCZQBTT

SFHVMBUPSBOEBEKVTUDPNCVTUJPOBJS0QFOUIF

DPNCVTUJPOBJSCBõFPOUIFTJEFPGUIFCVSOFS"JS

QSFTTVSFNBZBMTPOFFEUPCFBEKVTUFE

BAD FLAME

The flame is too big, creating an overfire condition

Figure 11

Problem:5PPMBSHFPGBøBNFEBSLZFMMPXJODPMPS

1. 5PPNVDIGVFMQSFTTVSFPOMZXIFOVTJOHBCZQBTT

SFHVMBUPS

2. /PUFOPVHIDPNCVTUJPOBJS

3. /PUFOPVHIBUPNJ[JOHBJSQSFTTVSF

4. 0QFODPNCVTUJPOBJSCBõFPOUIFTJEFPGUIF

CVSOFS

5. "TIJOTJEFUIFDIBNCFSJTEBSLCSPXOUPTPPUZ

CMBDLJODPMPS

Flame is under-red (Fig. 12)

t5IFøBNFJTMJLFBCMPXUPSDI

t-JHIUZFMMPXUPXIJUFJODPMPS

t$IFDLUPTFFJGQSFIFBUFSCMPDLJTIPU

t$IFDLBJS14*JUNBZCFUPPIJHI"EKVTUJO-#

JODSFNFOUT

t0JMQSFTTVSFPOMZXIFOVTJOHBCZQBTTSFHVMBUPS

5IFDPNCVTUJPOBJSCBõFNBZOFFEBEKVTUNFOU

Figure 12

BAD FLAME

The flame is too short

Figure 13

GOOD FLAME

The flame length is approximately 3/4

of the chamber

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

30

Page 35

Section 12 - Flame Adjustment

Problem: Too small a ame, similar to a blowtorch.

1. Too much atomizing air pressure.

2. Too much combustion air pressure.

3. Not enough fuel pressure when using a by-pass regulator.

Solutions:

1. Correct fuel pressure setting when using a by-pass regulator.

2. Flame tips reach 3/4 of the way into the chamber.

3. Flame has slightly yellow/orange tips.

4. No black smoke coming from the chimney.

5. Ash inside the chamber is white to o white in color.

6. Open combustion air bae on the side of the burner.

Flame is full (Fig. 13).

Bright yellow in color.

Flame extends 3/4 into the chamber.

Flame is not impinging on the chamber walls.

If you need assistance with ame adjustment, please call Lanair's Parts and Service

Department.

DO NOT OVER FIRE YOUR HEATER. IMMEDIATELY ADJUST

THE BURNER TO THE PROPER FLAME LENGTH TO PREVENT

!

DAMAGE TO YOUR HEATER.

CHECK FLAME DAILY (see page 30). ADJUST ACCORDINGLY

!

Visit our website at: www.lanair.com

31

Page 36

Section 13 - Service / Maintenance

MX SERIES HEATER SERVICE / MAINTENANCE SCHEDULE

DAILY

s Check fuel supply

tank level (pre-strain

all fuels).

s Check vacuum gauge

reading on suction

line. See Section 19.

s Check atomizing air

pressure at the air filter/ regulator.Set to

18 psi. Drain water

from the bowl if necessary

s Check the fuel pres-

sure gauge on the

burner.Set to the

correct pressure for

the fuel being used.

s Visually inspect

flame. Adjust accordingly.NOTE: Wear

adequate eye,face

and breathing protection.

s Check draft using a

manometer.Set draft

to -.02 cold, -.06 hot.

s If heater is not to be

used for more than

48 hours (overnight)

flip the pre-heater

rocker switch off

(light off ).

WEEKLY

s Drain water/ anti-

freeze from the fuel

supply tank.

s Check the air pres-

sure setting on the

primary air regulator.

Set to 30 psi.

s Drain water from the

air pressure supply

line drain leg and primary regulator.

s Inspect the combus-

tion, ash build-up

and flame.

NOTE: Wear adequate eye,face and

breathing protection.

MONTHLY

s Check combustion

chamber and heat

exchanger. Clean if

neccessary. Inspect

fire brick.

NOTE: Wear protective clothing,adequate eye,face and

breathing protection. Do not breathe

dust from the combustion chamber.

Wash thoroughly

with soap and

water after cleaning

chamber.

s Clean the chimney,

chimney connector

and barometric

damper.

s Clean pump strainer,

suction line strainer

and pick-up tube

strainer (pp 38).

NOTE: Always prime

pump after cleaning

strainers.

s Check for dirt build-

up on the combustion blower wheel.

Keep wheel clean.

ANNUALLY

(Season Shut Down)

s Shut off main power

supply to heater.

s Perform monthly

service/maintenance.

s Flip air/fuel pre-

heater switch off.

s Shut off air supply.

s Remove air/fuel pre-

heater assembly.

Disassemble and

clean (pp. 34, 35).

s Remove air turbula-

tor and clean (pp. 33)

s Replace nozzle and

quad ring (pp. 34, 35,

39)

s Replace Ignitor (pp

39).

s Adjust turbulator (pp

39).

s Lubricate all

following specifications on the motor

rating plate.

s Clean fuel pump

strainer (see pp 38).

s Drain and clean fuel

supply tank.

motors

s Clean combustion

blower, axial fan

blades and fan cage

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

32

Page 37

Air Pre-Heater Breakdown

Section 13 - Service / Maintenance

02

51

91

81

41

31

9

7

8

5

6

71

61

11

01

32

21

See pages 36-37 for required

annual oil block maintenance

22

4

3

2

1

This entire pre-heater assembly is available.

Part# 9812

(For a Tune-Up)

Visit our website at: www.lanair.com

33

Page 38

Maintenance - Air Pre-Heater

Section 13 - Service / Maintenance

1. Remove Pre-Heater Assembly

s Disconnect the air line from the

brass fitting on the air pre-heater

and then from

the air solenoid and remove.

s Disconnect wiring from the oil pre-

heater cartridge, air pre-heater

cartridge and snap disc assembly in

the wiring junction box.

s Disconnect fuel line and fitting (6)

from the oil block (5).

s Disconnect fuel pressure gauge (8)

and fitting from the oil block (5).

s Remove button hex screw (14) and

washer (11).

s Lift pre-heater assembly and care

fully pull straight back. Remove

entire assembly from the burner.

s Remove ignitor assembly (6).

2. Remove Diaphragm Assembly

from Air Pre-Heater

s Carefully place pre-heater assembly

in a vice. NOTE: Do not damage

pre-heater.

s Unscrew diaphragm assembly (19)

from air pre-heater and set aside.

Remove o-ring.

Ref. Part

No. No. Qty. Description

1 9853 1 turbulator

2 - 1 set screw

3 9899 1 nozzle Heater

4 - 1 quad ring

5 9814 1 air pre-heater block

6 3728 1 ignitor assembly

7 - 1 hex cap screw

8 - 1 flat washer

9 - 1 connector

10 - 1 1/4" o-ring

11 - 1 11/16" o-ring

12 9549 1 air cartridge heater

13 - 1 spring

14 - 1 viton insert

15 - 1 plunger

16 - 1 adapter block assembly

17 - 1 hex head cap screw

18 - 1 1/2" o-ring

19 - 1 diaphragm assembly

20 - 1 hex head cap screw

21 - 1 oil pre-heater block

3. Remove Adapter Assembly

s Remove hex cap screws (17) and set adapter

assembly aside.

4. Remove Plunger , Spring and Cartridge Heater

s Remove spring (13) from plunger (15) and clean

both pieces.

s Remov

s Loosen and remove cartridge heater and set aside.

5. Remove Nozzle Assembly and Quad Ring

s Remove nozzle assembly (3) using a 5/8" wrench.

s If quad ring (4) does not come out with nozzle, care

fully remove it.

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

e 1/4" o-ring (10) and 11/16" o-ring (11).

Remove wires from the block by

inserting a flat tip screwdriver into the

top slot. Push tip all the way down

and push forward. Remove wire.

34

Page 39

Section 13 - Service / Maintenance

Maintenance - Air Pre-Heater

6. Clean all parts using a parts washer

s All passages must be thoroughly cleaned with a brush.

7. Replace Nozzle Assembly and Quad Ring

s After cleaning air pre-heater assembly, blow dry.

s Install new quad ring (4). Before inserting quad ring in air pre-heater block, a light coat

of oil should be applied. NOTE: Make sure quad ring is properly seated in block before

proceeding (see page 40 for clarification).

s Apply a light coat of oil to the shaft of the new nozzle assembly (3). Carefully insert new

nozzle assembly (3) through the quad ring and into the block. Hand tighten gently.

s Check alignment of ignitors and adjust if necessary (see page 39).

8. Re-install O-rings and Plunger

s Insert 1/4" o-ring (10) and 11/16" o-ring (11) into the air pre-heater block (5).

s Insert plunger

9. Re-install Cartridge Heater

s Apply pipe dope to cartridge heater threads. Insert cartridge heater into air pre-heater

block and tighten.

10. Re-install Adapter Assembly

s Align the holes of the adapter assembly (16) with those on the air pre-heater block (5).

NOTE: Make sure the small end of the adapter pin is facing toward the air pre-heater

block.

s Attach the Adapter assembly (16) to the block using two hex cap screws (17).Tighten

screws.

into air pre-heater block spring end first.

(cont.)

11. Re-install Diaphragm

s Re-attach diaphragm assembly and hand tighten. NOTE: Do not over tighten.

12. Replace Ignitor Assembly (see page 39)

13. Service Oil Pre-Heater (see pages 33-37 for Annual Maintenance Instructions)

THE ENTIRE PRE-HEATER ASSEMBLY IS AVAILABLE

PART# 9812

Visit our website at: www.lanair.com

35

Page 40

Oil Pre-Heater

Breakdown

Section 13 - Service / Maintenance

13

12

12

5

9

7

6

8

11

14

6

Maintenance - Oil Pre-Heater

1. Separate Air Pre-Heater from Oil

Pre-Heater (10)

s Remove o-ring

2. Disassemble Oil Pre-Heater

s Remove six hex cap screws (3)

from face plate (2).

s Remove oil cartridge heater (1).

s Remove four 13/16"OD o-rings (4).

s Remove three plugs (12) from oil

block (5)

s Remove hex cap screw (9) from

inside oil pre-heater block and

clean. NOTE: Do not discard (9).

NOTE: Do not discard.

10

7

2

3

12

4

1

Ref. Part

No. No. Qty. Description

1 8992 1 cartridge heater

2 - 1 pre-heater face plate

3 - 6 hex cap screw

4 - 4 o-ring 13/16" OD

5 2902 1 oil block

6 9029 2 fitting

7 - 2 o-ring 5/16" OD

8 8430 1 oil gauge

9 - 1 hex cap screw

10 - 1 o-ring 1/2" OD

11 - 1 washer

12 - 3 plug

13 9533 1 snap disc assembly

14 - 1 button hex screw

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

36

Page 41

Section 13 - Service / Maintenance

Maintenance - Oil Pre-Heater

3. Clean Oil Pre-Heater Block

s Clean oil pre-heater block using a parts washer and brush. NOTE: Make sure all

passages are clean.

s Blow dry the oil pre-heater block. inspect ALL passages making sure they are clear and

clean.

4. Reassemble Oil Pre-Heater

s Re-install four 13/16" OD o-rings (4).

s Re-install cartridge heater. NOTE: Do not over-tighten.

s Re-attach face plate (2) using six hex cap screws (3).

s Apply loc-tite to three block plugs (12) and replace.

s Re-install hex cap screw (9) inside oil pre-heater block (5).

s Re-install o-ring (10).

5. Attach Air Pre-Heater Assembly

s Align the holes of the ignitor assembly and air pre-heater with those of the oil pre-

heater (see page 33).

s Attach air pre-heater assembly to the oil pre-heater block (5) using two hex cap screws.

Tighten securely.

6. Re-install Pre-Heater Assembly

s Place the air/oil pre-heater assembly into the burner body.

s Align the holes of the pre-heater assembly with those in

s Secure the assembly to the body by re-installing the button hex screw (14) and washer

(11). NOTE:Do not tighten this screw at this time.

s Re-install oil gauge and oil fitting.

NOTE: Do not tighten these fittings at this time.

s Adjust the pre-heater assembly for proper setting.The end of the turbulator should b

recessed approximately 1/4” into the burner tube (see page 39 for turbulator

adjustment).

s Once adjusted tighten button hex screw (14) and fittings (6) securely.

(cont.)

the burner body.

7. Re-connect Electrical

s Re-connect all wires previously disconnected in the electrical junction box (refer to

wiring diagram, page 21 and the burner reference diagram, page 51).

8. Reconnect PSI Gauge, Fuel Line and Air Line

s Reconnect the PSI gauge (8) to the fitting (6) and tighten (Do Not Over Tighten)

s Reconnect the fuel line to the fitting (6) and tighten securely.

s Reconnect the air line by connecting the one end of the air line to the air solenoid and

the other end to the air fitting (see page 51).

9. Test Operation

s

Follow start-up procedure, page 27.

Visit our website at: www.lanair.com

37

Page 42

Section 13 - Service / Maintenance

Cleaning Suction Line Strainer

inlet 1” NPT

water drain

o-ring

bolt

washer

gasket

spring

outlet 1” NPT

strainer

o-ring

bowl

The suction line strainer should be cleaned

every 30 days of operation.The element is

a washable metal element. If your waste oil

is extremely dirty, this strainer may need to

be cleaned more frequently. Your vacuum

gauge will help you determine when the

filter needs cleaning.The vacuum gauge

reading should not exceed 5" HG of

vacuum. If it does, the strainer needs

cleaning.

1. Disconnect power to the heater.

2. While holding the lower housing,

unscrew the center bolt on the top of

the suction line strainer.

3. Rinse the filter and lower housing in

solvent.

4. Air dry the strainer and lower housing.

5. Re-assemble the strainer, ensuring the

rubber gaskets, spring and o-rings are

in place.

6. Fill the lower housing with waste oil or

fuel oil.

7. Position the lower housing to the top

making sure the o-ring is properly seated. Secure the top and bottom together using the bolt, washer and gasket

removed earlier.

8. Prime the fuel pump (see page 25).

Cleaning/Replacing Fuel Pump

Strainer

strainer

gasket

hex cap screws

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

1. Disconnect power to the heater.

2. Remove four hex head screws from

pump cover. Carefully remove cover,

strainer and gasket.

3. Clean housing, strainer and pump sur-

face. Check for excess wear.

4. Install a new gasket (P/N 9817).

5. Install strainer and pump housing.

6. Prime the fuel pump (see page 25).

38

Page 43

Ignitor Replacement /

Adjustment

Section 13 - Service / Maintenance

1. Disconnect power to the heater.

2. Remove the pre-heater assembly

from the burner housing.

Disassemble and clean all parts

as instructed on pages

33-37.

3. Using a 1/4" Allen wrench,

carefully remove the one-piece

ignitor from the air pre-heater.

4. Install a new one piece ignitor

(P/N 3728) to the top of the air

pre-heater.NOTE: The tips of the

ignitor should be 3/8" above the

center of the nozzle assembly

and should extend approximately 1/8" beyond the end of the

nozzle. The tips of the one piece

ignitor should be 1/8" apart.

Adjust as required and tighten

nut on the top of the ignitor (see

illustrations for clarification of

placement).

electrodes should extend approximately

1/8” beyond nozzle tip

3/8”

1/16”

Side View

1/8”

Top View

5. Re-assemble pre-heater assembly

(see pages 33-37) carefully reinstall the pre-heater assembly

into burner housing.The turbulator should be approximately 1/4”

from the end of the burner tube.

Adjust as required and secure the

pre-heater assembly to the burner housing by tightening the

adjustment screw on the side of

the burner housing (see illustration).

Visit our website at: www.lanair.com

39

Turbulator 1/4” max. from

end of the tube

Pre-heater Assembly

adjustment screw

Page 44

Air Pre-Heater Diaphragm Breakdown

1. Remove the four hex cap screws

from the diaphragm assembly

Section 13 - Service / Maintenance

o-ring

2. Disassemble and inspect diaphragm,

spring and o-ring .

3. Thoroughly clean remaining parts.

4. Re-assemble the diaphragm,

o-ring, spring and hex cap screws.

Air Pre-Heater Nozzle Cleaning /

Replacement

1. Periodic cleaning of the nozzle

assembly may be required.

2. Carefully remove nozzle from the air

pre-heater block.

3. Disassemble the nozzle as shown

and clean thoroughly.Re-assemble

nozzle.

4. Carefully remove the quad ring from

the block and inspect. Replace if necessary.

5. Insert clean/new quad ring into the

air pre-heater block. NOTE: The quad

ring must be properly seated.

Failure to properly seat the quad

ring may result in leakage and

improper burner operation. DO NOT

INSTALL QUAD RING ON THE NOZZLE.

6. Lubricate pin/seat and re-install noz-

zle. Tighten gently.

diaphragm

piston

spring

Air Pre-Heater Diaphragm Assembly

body

fuel orifice

pin/seat

Air Pre-Heater Nozzle Assembly

nozzle assembly

hex cap

screws

quad ring

Failure to properly seat the quad

ring may result in leakage and

improper burner operation. DO

!

NOT INSTALL QUAD RING ON

THE NOZZLE.

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

Proper Quad Ring Position

40

Page 45

Section 13 - Service / Maintenance

NOTE: ALWAYS WEAR EYE,FACE AND BREATHING PROTECTION AND PROTECTIVE

CLOTHING WHEN INSPECTING OR CLEANING CHAMBER OR HEAT EXCHANGER.

!

WARNING: DISCONNECT ALL ELECTRICAL POWER TO HEATER BEFORE

SERVICING

!

!

Cleaning Combustion Chamber/ Heat Exchanger

1. Turn thermostat to the

lowest setting; the

heater must be completely cool to the

touch before attempting to clean the heater

(place the fan/limit on

the manual position to

start the fan and shorten the cooling time if

the unit is hot).

FAN LIMIT SWITCH

2. Turn off all power to

the heater (120 VAC) at

the main disconnect.

Place the fan/limit

switch lever back into

the auto position so

the fan is off upon

restarting.

3. Remove the burner

and flame view port

from the heater.

Remove the galvanized panel covering

the clean-out cover

(remove four (4) #10

screws from the top

and four (4) #10 screws

from the bottom of the

panel and remove).

Spray all of the screws with penetrating oil to prevent breakage before removing

4.

any of the nuts that secure the combustion chamber access door. Let set for five

minutes to allow the oil to penetrate

REMOVE

SCREWS

REMOVE 16 NUTS & WASHERS

.

5.

Remove the clean out cover from the heater by removing (16) 1/2 hex head nuts &

washers. If more than 1/4” of ash is present clean the heat exchanger tubes.

Visit our website at: www.lanair.com

41

Page 46

Section 13 - Service / Maintenance

CAUTION:THE CLEAN OUT PANEL MUST HAVE AN AIR TIGHT SEAL TO

PREVENT EXTREME DAMAGE TO THE COMBUSTION CHAMBER

!

CAUTION:TO AVOID BOLT BREAKAGE,DO NOT OVER-TIGHTEN

!

6. Use an industrial type canister vacuum cleaner with a high efficiency filter, or suitable

tool. Failure to clean heat exchanger tubes annually will impair draft. Reaching

through the burner opening, vacuum or shovel the ash from the combustion chamber.

Inspect the combustion chamber and target brick. Use care when cleaning the combustion chamber area so the target brick is not disturbed. Insufficient or irregular cleaning

intervals will cause inefficiency, random shutdowns, and extreme damage to the combustion chamber.

7. Before replacing the combustion chamber access doors, replace the white gasket seal on

the door (contact the Lanair Service Department).When replacing the gaskets apply a

light film of gasket adhesive to adhere the new gasket to the door. Lube the threads of

the screws with a high temperature lubricant. Re-install the heat exchanger access panel.

If any nuts are stripped, replace (use brass).

8. Replace the inspection port with the two (2) #8 hex head sheet metal screws (if

removed). Re-install the clean out cover. Replace burner.

9. Remove the front panel of the unit by removing (10) #10” sheet metal screws. Slide the

front panel of the unit to the right side of the heater far enough to expose the manifold

clean out port.

10. On the left side facing the front of the unit remove the (4) #10 sheet metal

the manifold clean out ports. Using an industrial type canister vacuum cleaner with a

high efficiency filter, remove all ash accumulation.

11. The chimney connector can also be removed to allow access to the manifold for clean-

ing. Clean and inspect the chimney connector if necessary. Replace the four (4) #10

screws in the clean out ports on the heater. Replace the front of the cabinet replacing

the ten (10) #10 sheet metal screws. Check your draft reading to make sure your barometric damper is properly set (See Section 4).

12. Reconnect all power at the main breaker box, wait ten minutes before turning the ther-

mostat up. Your heater is now ready for normal operation.

NOTE: When changing the target brick, call the Lanair Service Department for assistance.

WARNING: DO NOT OPERATE YOUR FURNACE WITH CLEAN OUT PANELS

OR PORTS REMOVED

!

screws from

QUESTIONS?... Contact Customer Service at 1-888-370-6531 M-F 8:00 am- 4:15 pm CST

42

Page 47